Page 1

H. DESCRIPTION OF MECHANISM

C-8080Wide Zoom

H. DESCRIPTION OF MECHANISM

[1] CA1 CIRCUIT DESCRIPTION ................................................................................ H-2

[2] CP1 CIRCUIT DESCRIPTION ................................................................................ H-4

[3] PW1 POWER CIRCUIT DESCRIPTION ................................................................. H-5

[4] ST1 STROBE CIRCUIT DESCRIPTION................................................................. H-6

[5] SYA CIRCUIT DESCRIPTION................................................................................. H-7

H-1 Ver.1

Page 2

H. DESCRIPTION OF MECHANISM C-8080Wide Zoom

2

8

1

D

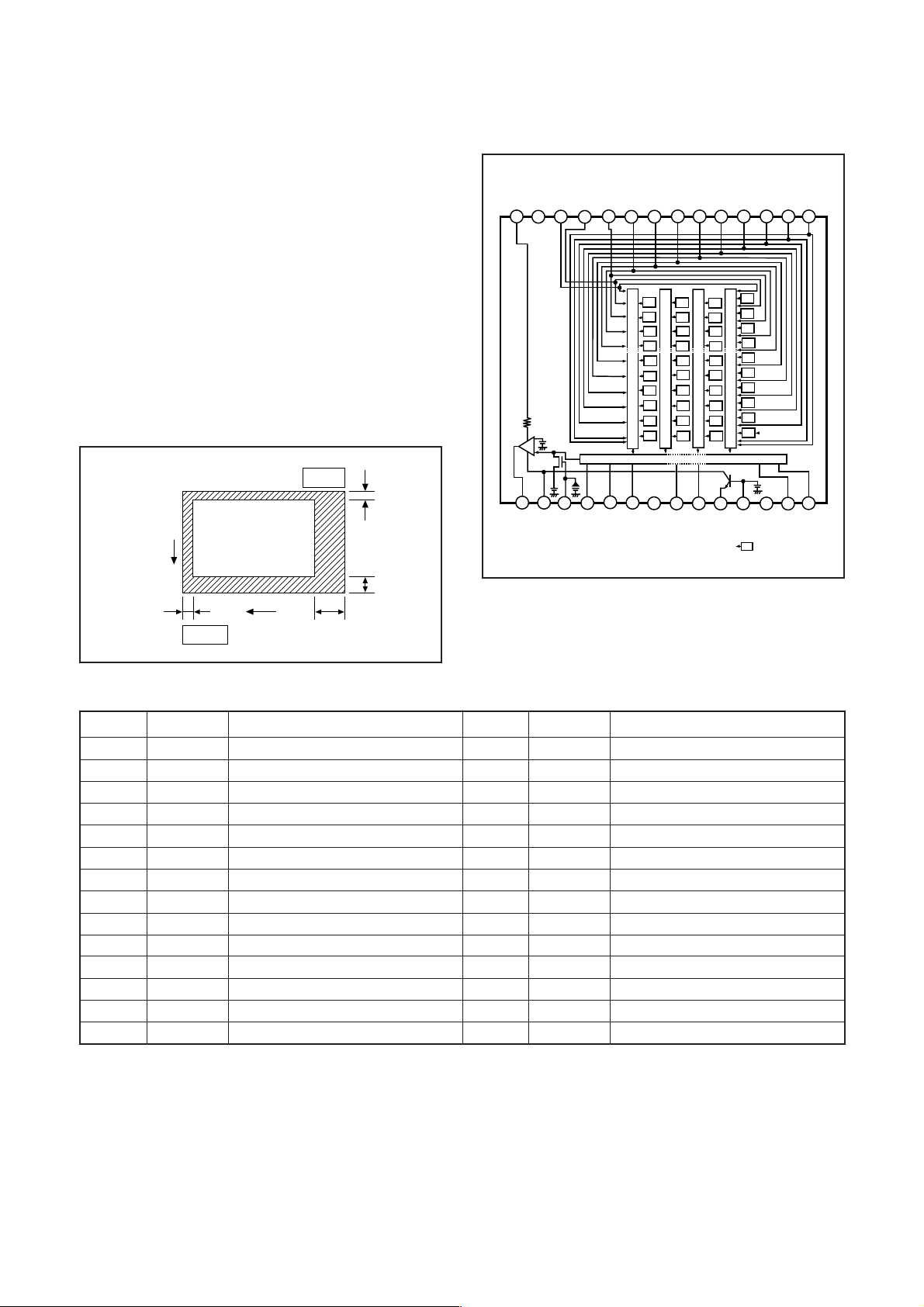

[1] CA1 CIRCUIT DESCRIPTION

1. IC Configuration

IC903 (ICX456AQ) CCD imager

IC904 (AD9945) CDS, AGC, A/D converter

IC905 (CXD3622GA) TG

2. IC903 (CCD)

[Structure]

Interline type CCD image sensor

Optical size Diagonal 11 mm (2/3 type)

Effective pixels 3280 (H) x 2454 (V)

Pixels in total 3350 (H) x 2482 (V)

Optical black

Horizontal (H) direction: Front 12 pixels, Rear 50 pixels

Vertical (V) direction: Front 8 pixels, Rear 2 pixels

Pin 1

V

14

GND

OUT

V

13

GND

1615

Ø1B

V

Ø1

LH

V

10

19

Ø1C

H

Ø2

V

V

8

9

Gb

R

Gb

R

Gb

R

Gb

Vertical register

R

Gb

R

Horizontal register

20

21

Ø2C

GND

H

7

6

B

Gr

B

Gr

B

Gr

B

Gr

B

Gr

23

22

Ø1B

H

(Note) : Photo sensor

Ø1A

V

12

11

1817

DD

RG

V

Ø

V

Ø2B

H

Ø5B

Ø5A

V

V

3

4

5

B

Gb

Gr

R

B

Gb

Gr

R

B

Gb

Gr

R

B

Gb

Gr

R

B

Gb

Gr

R

(Note)

25

26

24

SUB

SUB

C

Ø

Ø4

Ø3AVØ3B

Ø1C

ØHL

Ø6

ØST

V

V

V

1

2

28

27

L

V

Ø2A

Ø1A

H

H

2

Pin 15

H

Fig. 1-1.Optical Black Location (Top View)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Symbol

Vφ

HLD

VφST

Vφ6

Vφ5B

Vφ5A

Vφ4

Vφ3B

Vφ3A

Vφ2

Vφ1C

Vφ

1B

1A

Vφ

GND

GND

Horizontal addition control clock

Horizontal addition control clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

GND

GND

Pin Description

50

Pin No.

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Fig. 1-2. CCD Block Diagram

Symbol

OUT

V

VDD

φRG

LHφ

1

Hφ1C

Hφ2C

GND

Hφ

1B Horizontal register transfer clock

2B

Hφ

φSUB

C

SUB

V

L

1A

Hφ

Hφ2A

Signal output

Circuit power

Reset gate clock

Horizontal register last step transfer clock

Horizontal register transfer clock

Horizontal register transfer clock

GND

Horizontal register transfer clock

Substrate clock

Substrate bias

Protection transistor bias

Horizontal register transfer clock

Horizontal register transfer clock

Pin Description

Table 1-1. CCD Pin Description

H-2 Ver. 1

Page 3

H. DESCRIPTION OF MECHANISMC-8080Wide Zoom

C

B

D

S

3. IC905 (TG)

IC905 is timing generator for image sensor. This is equipped

with H driver and V driver.

4. IC904 (CDS, AGC and A/D converter)

IC904 contains the functions of CDS, AGC and A/D converter.

The video signal which is output from the CCD is input to

pins (22) of IC904. There are sample hold blocks inside

IC904 generated from the SHP and SHD pulses, and it is

here that CDS (correlated double sampling) is carried out.

After passing through the CDS circuit, the signal passes

through the AGC amplifier (PGA: Programmable Gain Amplifier). It is A/D converted internally into a 12-bit signal,

and is then input to ASIC (IC102). The gain of the AGC

amplifier is controlled by pin (25)-(27) serial signal which is

output from ASIC (IC102).

PBLK

VRB

VRT

DRVD

DRVS

12

DOUT

CDIN

AD9945

CDS

6~40 dB

VGA

BANDGAP

REFERENCE

12-BIT

ADC

+

AVDD

AVSS

8

CLP

BLK LEVEL

OFFSET

INTERNAL

TIMING

SHP

SHD

10

CONTROL

REGISTERS

DIGITAL

INTERFACE

SL

SCK

SDATA

Fig. 1-3. IC904 Block Diagram

DATACLK

CLPO

DVDD

DVSS

H-3 Ver. 1

Page 4

H. DESCRIPTION OF MECHANISM C-8080Wide Zoom

[2] CP1 CIRCUIT DESCRIPTION

1. Circuit description

1-1. Signal processor

γγ

1.

γ correction circuit

γγ

This circuit performs (gamma) correction in order to maintain a linear relationship between the light input to the camera and the light output from the picture screen.

2. Color generation circuit

This circuit converts the CCD data into RGB signals.

3. Matrix circuit

This circuit generates the Y signals, R-Y signals and B-Y

signals from the RGB signals.

4. Horizontal and vertical aperture circuit

This circuit is used gemerate the aperture signal.

1-2. AE/AWB and AF computing circuit

The AE/AWB carries out computation based on a 64-segment screen, and the AF carries out computations based

on a 6-segment screen.

1-3. SDRAM controller

This circuit outputs address, RAS, CAS and AS data for

controlling the SDRAM. It also refreshes the SDRAM.

After AWB and

erated and aperture correction is carried out for the Y signal, and the data is then compressed by JPEG and is then

written to card memory (xD picture card).

When the data is to be output to an external device, it is

taken data from the memory. When played back on the LCD

and monitor, data is transferred from memery to the SDRAM,

and the image is then elongated so that it is displayed over

the SDRAM display area.

γγ

γ processing are carried out, a matrix is gen-

γγ

3. LCD Block

LCD Block is in the CP1 board, and it is constructed by

LCD driver (IC871) and around circuits.

The video signal from the ASIC are converted into RGB

signals by the LCD driver, and these RGB signals and the

control signal which is output by the LCD driver are used to

drive the LCD panel. The RGB signals are 1H transposed

so that no DC component is present in the LCD element,

and the two horizontal shift register clocks drive the horizontal shift registers inside the LCD panel so that the 1H

transposed RGB signals are applied to the LCD panel. Because the LCD closes more as the difference in potential

between the COM (common polar voltage: AC) and the R,

G and B signals becomes greater, the display becomes

darker; if the difference in potential is smaller, the element

opens and the LCD become brighter.

1-4. SIO

This is the interface for the 8-bit microprocessor.

1-5. PIO/PWM/SIO for LCD

8-bit parallel input and output makes it possible to switch

between individual input/output and PWM input/output.

1-6. TG/SG

Timing generated for 8 million pixel CCD control.

1-7. Digital encorder

It generates chroma signal from color difference signal.

2. Outline of Operation

When the shutter opens, the reset signals (ASIC and CPU)

and the serial signals (take a picture commands) from the

8-bit microprocessor are input and operation starts. When

the TG/SG drives the CCD, picture data passes through

the A/D and CDS, and is then input to the ASIC as 12-bit

data.

The AF, AE, AWB, shutter, and AGC value are computed

from this data, and three exposures are made to obtain the

optimum picture. The data which has already been

stored in the SDRAM is read by the CPU and color generation is carried out. At this time, correction of the lens distortion which is a characteristic of wide-angle lenses is carried

out.

4. Lens drive block

4-1. Shutter drive

The shutter drive signal (SIN1, SIN2) which is output from

the ASIC (IC101) is drived the shutter constant level driver,

and then shutter plunger is opened and closed.

4-2. Iris drive

The iris stepping motor drive signals (ACTRL1, ACTRL2,

ACTRL3 and ACTRL4) which are output from the ASIC

(IC101) are used to drive by the motor driver (IC956). Detection of the standard iris positions is carried out by means

of the standard switch (HSW) inside the lens block.

4-3. Focus drive

The focus stepping motor drive signals (FIN1, FIN2, FIN3

and FIN4) which are output from the ASIC (IC101) are used

to drive by the motor driver (IC956). Detection of the standard focusing positions is carried out by means of the

photointerruptor (PI) inside the lens block.

4-4. Zoom drive

The zoom DC motor drive signals (ZIN1, ZIN2) which are

output from the ASIC (IC101) are used to drive by the motor

driver (IC956). Detection of the zoom standard positions is

carried out by means of standard switch (WSW) inside the

lens block. Also counting of the zoom positions is carried out

by means of photointerruptor (ZPULSE) inside the lens block.

H-4

Ver. 1

Page 5

H. DESCRIPTION OF MECHANISMC-8080Wide Zoom

[3] PW1 POWER CIRCUIT DESCRIPTION

1. Outline

This is the main power circuit, and is comprised of the following blocks.

Switching power controller (IC501)

Strobo system power output and analog system power output (T5001, Q5001)

Digital 1.7 V power supply output (Q5013, L5006)

Digital 3.25 V power supply output (Q5014, L5007)

LCD system power supply output (Q5015, L5008)

Backlight power supply output (Q5018, L5009)

AF LED power supply output (Q5033, L5016)

2. Switching Power Controller (IC501)

This is the basic circuit which is necessary for controlling

the power supply for a PWM-type switching regulator, and

is provided with six built-in channels, only CH1 (strobo system power output, analog system power output), CH2 (digital

1.7 V power supply output), CH3 (digital 3.25 V power supply output), CH4 (LCD system power supply output), CH5

(backlight power supply output) and CH6 (AF LED power

supply output) are used. Feedback from 15 V (A) (CH1),

1.7 V (D) (CH2), 3.25 V (D) (CH3), 12.0 V (L) (CH4) and AF

LED V (CH6) power supply outputs are received, and the

PWM duty is varied so that each one is maintained at the

correct voltage setting level.

Feedback for the LCD backlight power (CH5) is provided to

the both ends voltage of registance so that regular current

can be controlled to be current that was setting.

2-1. Short-circuit protection circuit

If output is short-circuited for the length of time determined

by the condenser which is connected to Pin (37) of IC501,

all output is turned off. The control signal (P ON) are recontrolled to restore output.

3. Strobo System 15 V and Analog System Power

Output

15 V (F), 15.0 V (A) and -7.6 V (A) are output. Feedback for

the 15 V (A) is provided to the switching controller (Pin (40)

of IC501) so that PWM control can be carried out.

4. Digital 1.7 V System Power Output

1.7 V (D) is output. Feedback for the 1.7 V (D) is provided to

the swiching controller (Pin (43) of IC501) so that PWM

control can be carried out.

5. Digital 3.25 V System Power Output

3.25 V (D) is output. Feedback for the 3.35 V (D) is pro-

vided to the swiching controller (Pin (45) of IC501) so that

PWM control can be carried out.

6. LCD System Power Output

12.0 V (L) is output. Feedback for the 12.0 V (L) is provided

to the switching power controller (Pin (47) of IC501) so that

PWM control can be carried out.

7. Backlight Power Output

Regular current (15 mA) is being transmitted to LED for

LCD backlight. Feedback for the both ends voltage of

registance that is being positioned to in series LED are provided to the switching controller (Pin (2) of IC501) so that

PWM control to be carried out.

8. AF LED Power Output

AF LED V (7V) is output. Feedback for the AF LED V is

provided to the switching power controller (Pin (4) of IC501)

so that PWM control can be carried out.

9. Analog System (3.45 V) Power Output

3.45 V (A) is output. Feedback for the 3.45 V (A) is provided

to the switching power controller (Pin (5) of IC502) so that

PWM control can be carried out.

H-5 Ver. 1

Page 6

H. DESCRIPTION OF MECHANISM C-8080Wide Zoom

[4] ST1 STROBE CIRCUIT DESCRIPTION

1. Charging Circuit

When UNREG power is supplied to the charge circuit and

the CHG signal from SYA circuit on the CP1 board becomes

High (3.3 V), the charging circuit starts operating and the

main electorolytic capacitor is charged with high-voltage

direct current.

However, when the CHG signal is Low (0 V), the charging

circuit does not operate.

1-1. Power supply filter

C5401 constitutes the power supply filter. They smooth out

ripples in the current which accompany the switching of the

oscillation transformer.

1-2. Oscillation circuit

This circuit generates an AC voltage (pulse) in order to increase the UNREG power supply voltage when drops in

current occur. This circuit generates a drive pulse with a

frequency of approximately 50-100 kHz. Because self-excited light omission is used, the oscillation frequency

changes according to the drive conditions.

1-3. Oscillation transformer

The low-voltage alternating current which is generated by

the oscillation control circuit is converted to a high-voltage

alternating current by the oscillation transformer.

2. Light Emission Circuit

When RDY and TRIG signals are input from the ASIC expansion port, the stroboscope emits light.

2-1. Emission control circuit

When the RDY signal is input to the emission control circuit, Q5409 switches on and preparation is made to let current flow to the light emitting element. Moreover, when a

STOP signal is input, the stroboscope stops emitting light.

2-2. Trigger circuit

When a TRIG signal is input to the trigger circuit, D5405

switches on, a high-voltage pulse of several kilovolts is generated inside the trigger circuit, and this pulse is then applied to the light emitting part.

2-3. Light emitting element

When the high-voltage pulse form the trigger circuit is applied to the light emitting part, currnet flows to the light emitting element and light is emitted.

Beware of electric shocks.

1-4. Rectifier circuit (T5401)

The high-voltage alternating current which is generated at

the secondary side of T5401 is rectified to produce a highvoltage direct current and is accumulated at electrolytic capacitor C5412 on the main circuit board.

1-5. Voltage monitoring circuit

This circuit is used to maintain the voltage accumulated at

C5412 at a constance level.

After the charging voltage is divided and converted to a

lower voltage by R5417 and R5419, it is output to the SYA

circuit on the CP1 board as the monitoring voltage VMONIT.

When this VMONIT voltage reaches a specified level at the

SYA circuit on the CP1 board, the CHG signal is switched

to Low and charging is interrupted.

H-6 Ver. 1

Page 7

H. DESCRIPTION OF MECHANISMC-8080Wide Zoom

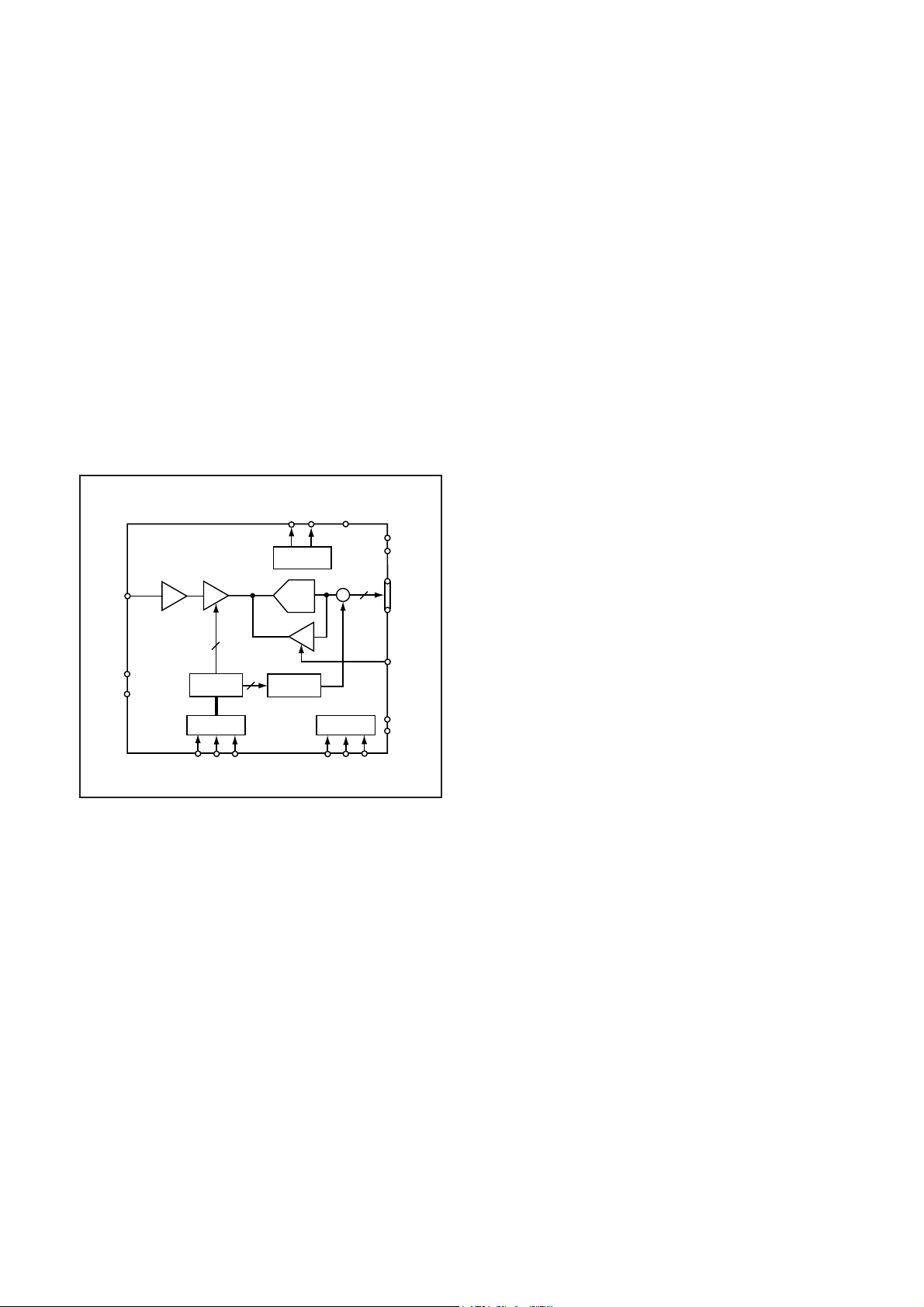

[5] SYA CIRCUIT DESCRIPTION

1. Configuration and Functions

For the overall configuration of the SYA block, refer to the block diagram. The configuration of the SYA block centers around

a 8-bit microprocessor (IC301).

The 8-bit microprocessor handles the following functions.

1. Operation key input, 2. Clock control, 3. Power ON/OFF, 4. Storobe charge control

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21 ZPULSE

22 LCD ON

23 EVF BL

24

25 SCAN IN3/PRG SO

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41~46

Signal

AVR EF

AVSS

IC (FLMD0)

VDD

REGC

VSS

XIN

XOUT

RESET

XCIN

XCOUT

CLKSEL0

BAT_OFF

IR IN

USB CONNECT

EX STROBO

SREQ

COMREQ

JOG A

FLMD1

LCD BL

SCAN IN2/PRG SI

SCAN IN1/PRG SCK

MAIN RESET

SELF_LED

CARD LED

AVREF ON

VSS

VDD

P ON

PA ON

SCK

SI

SO

CHG ON

FLMD0_SY

SCAN OUT 3~0, 4, 5

I/O

O

O

O

O

O

O

I/O

I/O

O

O

O

O

O

O

O

O

O

O

O

Outline

I

-

I

I

-

-

I

I

I

I

I

I

I

I

I

I

I

I

I

-

I

I

Analog standard voltage input terminal

GND

Power for program writing

VDD

Regulator output stability capacity connection

GND

Main clock oscillation terminal (4MHz)

Main clock oscillation terminal

Reset input (L= RESET)

Clock oscillation terminal (32.768 kHz)

Clock oscillation terminal

PLL oscillation ON/OFF (H= ON)

Battery off detection signal input (L= detection)

Remote control detection signal

USB power detection terminal

External strobo connection detection (L= detection)

Serial communication requirement signal

ASIC serial communication requirement

Jog dial A detection

Power for program writing

Zoom motor drive pulse count

D/D converter (LCD system) ON/OFF signal

EVF backlight ON/OFF signal

LCD backlight ON/OFF signal

Key matrix input/Flash for serial data output

Key matrix input/Flash for serial data input

Key matrix input/Flash for serial clock output

System reset (MRST)

Self-timer LED (L = Lighting)

Card LED ON/OFF signal (L = LED lighting)

A/D standard voltage ON/OFF signal (L=ON)

GND

VDD

D/D converter (digital system) ON/OFF signal (H= ON)

D/D converter (analog system) ON/OFF signal (H= ON)

Serial clock output

Serial data input

Serial data output

Strobe charge control (H=ON)

Port for 8-bit rewriting

Key matrix output

H-7

Ver. 1

Page 8

H. DESCRIPTION OF MECHANISM C-8080Wide Zoom

47

48

49

50~53

54

55

56

57

58

59

60

61

62

63

64

PLLEN

ASIC TEST

EVF ON

SCAN IN 6~4, 0

TG RST

USB RST

BACKUP_CTL

CARD SW

JOG B

PAF THERM

xD CARD

CF CARD

SCAN IN 7

CHG VOL

BATTERY

O PLL oscillation ON/OFF (H= ON)

O

O

I

O

O

O

I

I

I

I

I

I

I

I

Table 5-1. 8-bit Microprocessor Port Specification

ASIC control signal (ZTEST)

D/D converter (EVF system) ON/OFF signal (H= ON)

Key matrix input

CCD TG RESET signal

USB RESET signal

Backup battery charge control (L= charge)

Card lid switch detection (L= detection)

Jog dial B detection

Passive sensor temperature detection

xD card detection signal (L= detection)

Expansion memory card (CF) attachement detection signal (L= detection)

Key matrix input

Main capacitor charge voltage detection

Battery voltage detection

2. Internal Communication Bus

The SYA block carries out overall control of camera operation by detecting the input from the keyboard and the condition of

the camera circuits. The 8-bit microprocessor reads the signals from each sensor element as input data and outputs this data

to the camera circuits (ASIC) or to the LCD display device as operation mode setting data. Fig. 5-1 shows the internal

communication between the 8-bit microprocessor and ASIC.

RESET

SREQ

PLL EN

8-bit

Microprocessor

Fig. 5-1 Internal Bus Communication System

ASIC SO

CLKSEL0

ASIC SI

ASIC SCK

ASIC

RESET

H-8

Ver. 1

Page 9

H. DESCRIPTION OF MECHANISMC-8080Wide Zoom

3. Key Operaiton

For details of the key operation, refer to the instruction manual.

SCAN

SCAN

OUT

IN

0

1

2

3

4

0

P

NIGHT

SCENE

1st

PICTURE

QUALITY

WIDE TELE

1

A

LAND-

SCAPE

2nd

WB

23

S

SPORTS

AEL

DC_IN

POP UP

M

PORTRAIT

SELF/REMOTE

CONTROL

EXTRA_

BAT

AV JACK

4

My MOVIE

SETUP

EXPOSURE

CONTROL

UP

CF/XD

5

PLAY

SPOT FLASH

DOWN

OK/MENU

LEFT

Quick View

6

7

AF/MF/

MACRO

RIGHT

5

PW ON

CUSTOM

Table 5-2. Key Operation

TEST

4. Power Supply Control

The 8-bit microprocessor controls the power supply for the overall system.

The following is a description of how the power supply is turned on and off. When the battery is attached, power voltage is

supplied to IC302, a regulated 3.2 V voltage is normally input to the 8-bit microprocessor (IC301) by IC302, clock counting

and key scanning is carried out even when the power switch is turned off, so that the camera can start up again.

When the power switch is off, the 8-bit microprocessor halts 4 MHz of the main clock, and operates 32.768 kHz of subclock.

When the battery is removed, the 8-bit microprocessor power switches the capacitor for memory backup by IC302, and

operates at low consumption. At this condition, the 8-bit microprocessor halts the main clock, and operates clock counting by

sub clock.

Also, the secondary battery for backup is charged 10 hours from it to be attached.

When the power switch is on, the 8-bit microprocessor starts processing. The 8-bit microprocessor first sets both the PON

signal at pin (34) and the PAON signal at pin (35) to High, and then turn on the power circuit. After PON signal is to High, sets

external port of ASIC after approximately 100 ms. According to setting of this external port, carry out setting of the operating

frequency and oscillation control in the ASIC. Also, it starts communication with ASIC, and confirms the system is operative.

When the through image is operating, set the PAON signal to High and then turn on the CCD. When playing, set the PAON

signal to Low and then turn off the CCD. When LCD panel turns on, set LCD ON signal at pin (22) to High, and then turn on

the power. Set LCD BL signal at pin (24) to High, and turn on the backlight power.

When the power switch is off, the lens will be stowed, and PON, PAON, LCDON and LCDBL signals to Low and the power

supply to the whole system is halted. The 8-bit microprocessor halts oscillation of the main clock, and set operation mode of

clock ocillation.

Power supply voltage

Power OFF

Playback mode

Shooting mode (LCD)

Shooting mode (EVF)

Shooting

USB connection

ASIC,

memory

1.7 V, 3.25 V

OFF

ON

ON

ON

ON

ON

Table 5-3. Power supply control

H-9

CCD

15 V, -7.5 V

3.45 V

OFF

OFF

OFF

OFF

ON

OFF

8bit

CPU

3.2 V

32KHz

4MHz

4MHz

4MHz

4MHz

4MHz

LCD

MONITOR

12 V, 3.0 V

OFF

ON

ON

OFF

ON

OFF

Ver. 1

Loading...

Loading...