Oliver 690-NC3 Service Manual

Walker, Michigan, U.S.A. 49534-7564

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 690-NC3

STEAM CONVECTION

OVEN

0690NC3-S20000-CV1

INDEX

Section Description Document No. Page No.

SAFETY INSTRUCTIONS ------------------------------- 0690S20067 --------------------- 1-1

DESCRIPTION/SPECIFICATIONS -------------------- 0690S20068---------------------- 2-1

Description -------------------------------------------------------------------------------------- 2-1

Physical Specifications----------------------------------------------------------------------- 2-1

INSTALLATION / SETUP -------------------------------- 0690S20069 --------------------- 3-1

Inspection --------------------------------------------------------------------------------------- 3-1

Location Selection ---------------------------------------------------------------------------- 3-1

Sealing Oven to Mounting Surface ------------------------------------------------------- 3-1

Oven Setup ------------------------------------------------------------------------------------- 3-2

Electrical Connection ------------------------------------------------------------------------- 3-2

Water Connection ----------------------------------------------------------------------------- 3-4

Venting ------------------------------------------------------------------------------------------- 3-4

OPERATING INSTRUCTIONS ------------------------- 0690S20070 --------------------- 4-1

Beginning Operation ------------------------------------------------------------------------- 4-1

Idle Mode --------------------------------------------------------------------------------------- 4-1

Running an Automatic Program ---------------------------------------------------------- 4-2

Running Two Automatic Programs at the Same Time ------------------------------ 4-2

Pre-Alarm -------------------------------------------------------------------------------------- 4-2

Running a Manual Program --------------------------------------------------------------- 4-3

Adding Steam --------------------------------------------------------------------------------- 4-3

Opening and Closing the Vent ------------------------------------------------------------ 4-3

Changing the Fan Setting ------------------------------------------------------------------ 4-3

PROGRAMMING ------------------------------------------- 0690S20071 --------------------- 5-1

TROUBLESHOOTING ------------------------------------ 0690S20072 --------------------- 6-1

Error Code Display --------------------------------------------------------------------------- 6-1

Solving Other Problems --------------------------------------------------------------------- 6-2

MAINTENANCE -------------------------------------------- 0690S20073 --------------------- 7-1

Cleaning ----------------------------------------------------------------------------------------- 7-1

Lubrication -------------------------------------------------------------------------------------- 7-1

Removal and Replacement Guide ------------------------------------------------------- 7-2

RECOMMENDED SPARE PARTS -------------------- 0690S20074 --------------------- 8-1

REV 8-27-15

0690S20066 0-1

INDEX (Continued)

Section Description Document No. Page No.

REPLACEMENT PARTS SECTION

ELECTRICAL SUB PANEL ------------------------------ 0690S20075 --------------------- 9-1

Drawing ----------------------------------------------------------------------------------------- 9-1

Parts List --------------------------------------------------------------------------------------- 9-2

FRONT PANEL & OTHER PANELS ------------------ 0690S20076 -------------------- 10-1

Drawing ---------------------------------------------------------------------------------------- 10-1

Parts List -------------------------------------------------------------------------------------- 10-2

DOOR ASSEMBLY ---------------------------------------- 0690S20077 -------------------- 11-1

Drawing ---------------------------------------------------------------------------------------- 11-1

Parts List -------------------------------------------------------------------------------------- 11-2

HOUSING / CHAMBER ASSEMBLY ----------------- 0690S20078 -------------------- 12-1

Drawing ---------------------------------------------------------------------------------------- 12-1

Parts List --------------------------------------------------------------------------------------- 12-2

WATER SYSTEM ASSEMBLY ------------------------- 0690S20079 -------------------- 13-1

Drawing ---------------------------------------------------------------------------------------- 13-1

Parts List -------------------------------------------------------------------------------------- 13-2

DAMPER CONTROL ASSEMBLY --------------------- 0690S20080 ------------------- 14-1

Drawing ---------------------------------------------------------------------------------------- 14-1

Parts List -------------------------------------------------------------------------------------- 14-2

ELECTRICAL DIAGRAMS ------------------------------ 0690S20081 -------------------- 15-1

Wiring Diagram 208 / 240 V -------------------------------------------------------------- 15-2

Wiring Diagram 375 / 480 V -------------------------------------------------------------- 15-3

Wiring Diagram 375 / 480 V con’t -------------------------------------------------------- 15-3

WARRANTY ------------------------------------------------ GEN 040225

WARRANTY PROCEDURE ---------------------------- GEN 040226

RETURNED PARTS POLICY -------------------------- GEN 040227

0690S20066 0-2

SAFETY INSTRUCTIONS

WARNING

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING HAVE BEEN

PROVIDED ON THIS OVEN. IT IS ESSENTIAL HOWEVER THAT THE OVEN

OPERATORS AND MAINTENANCE PERSONNEL OBSERVE THE FOLLOWING

SAFETY PRECAUTIONS. IMPROPER INSTALLATION, MAINTENANCE, OR

OPERATION COULD CAUSE SERIOUS INJURY OR DEATH.

1. Read this manual before attempting to operate your oven. Never allow an untrained

person operate or service this machine.

2. This oven must only be installed by qualified personnel. It also must be installed to

the specifications of local plumbing and electrical codes. See the installation section

of this manual for additional requirements.

3. Connect the oven to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow specifications of

local electrical codes.

4. Disconnect and lock-out the oven from the power supply before cleaning or

servicing.

5. Check and secure all guards before starting the oven.

6. Observe all caution and warning labels affixed to the oven.

7. Use only proper replacement parts.

8. Wear proper personal protective safety equipment.

9. Keep Hands away form the moving parts of this oven while it is in operation.

10. In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the oven in the operating instructions.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

0690S20067 1-1

DESCRIPTION/SPECIFICATIONS

Description

The Oven is a stainless steel, electric, forced air, (convection), oven with steam injection

capabilities. This oven offers consistent baking at all rack levels due to the careful

positioning of the heating and air circulation systems.

In addition to the above, this oven also offers many other features. It is well insulated

with a high quality asbestos free insulation. It is compact, attractive, quiet, and is

easily maintained. Should electrical servicing ever be required the electrical

components are readily accessible by removing the side or back panels.

The lighted, tempered glass door with its high temperature seal allows a full view of the

trays in the oven during baking.

The oven computer allows you to bake two items at once which makes the oven more

productive. It also has one of the fastest temperature recoveries on the market allowing

the oven to be turned off during non-peak hours, thus saving energy.

The oven has many protective features such as not allowing heating of the elements

when the door is open. Other features are resettable thermal overloads on the motors, a

high-limit thermostat, and a magnetic circuit breaker on the control circuit.

The computer allows easy selection of baking programs. The programs combine

precise control of the pre-heat temperature, baking temperature, time, pre-alarm, steam,

and damper control. This allows precise baking by even inexperienced individuals.

Physical Specifications

Electrical Options Available:

3 phase, 60 hz, 480VAC, 27 Amps.

3 phase, 60 hz, 208VAC, 47 Amps.

Product Capacities:

The Standard oven will hold (8) 18" X 26" pastry baking trays

these trays will be approximately 3-5/16 inches apart when in

the oven.

6, 12 and 16 tray ovens are also available.

0690S20068 2-1

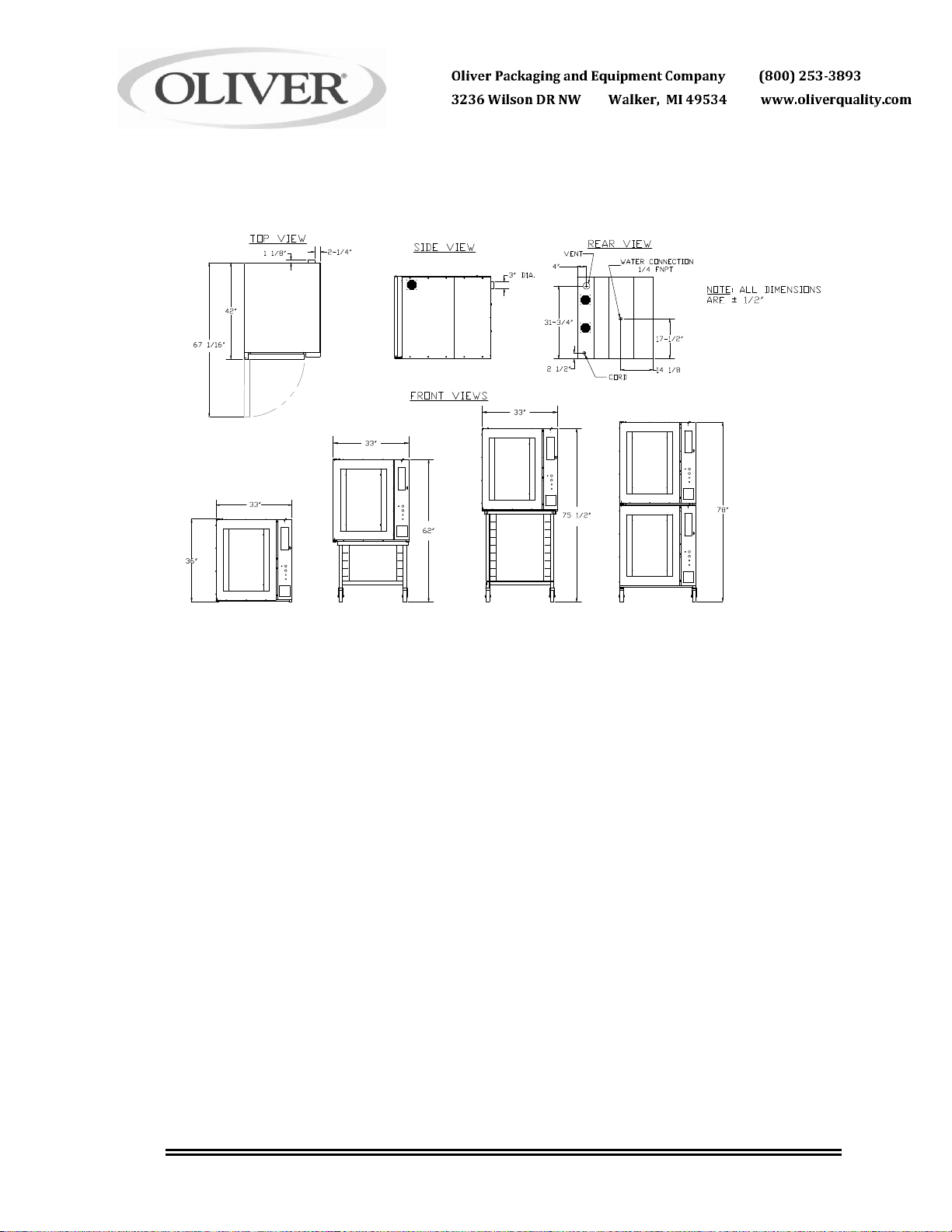

Space Requirements:

Figure 3.0

single: 42” Deep x 33” Wide x 35-3/4” high.

single with short stand and casters: 62” high.

single with tall stand and casters: 75-1/2”

stacked ovens with casters: 78”

Clearance:

Left side = 2”.

Right side = 12” without casters to have access to electrical components,

2” with casters.

Back side = 4” to allow for water connections and venting.

Net Weight: Approximately 500 pounds.

Shipping Weight: Approximately 675 pounds.

0690S20068 2-2

INSTALLATION / SETUP

CAUTION

TO QUALIFY FOR WARRANTY COVERAGE, INSTALLATION MUST BE COMPLETED BY

AN OLIVER PACKAGING & EQUIPMENT AUTHORIZED SERVICE DEALER.

Inspection

Before accepting delivery inspect the carton and machine for damage. Note any damage found

on the shipping documents. Remember shipping damage is not covered by your warranty, and

is the responsibility of the carrier. Also report the damage to the dealer from which the oven

was purchased for further direction and assistant in filing a claim with the carrier.

Location Selection

Select a location where the oven will be used. The oven must be set on a flat level surface. It

should have a grounded power supply of the same rating as shown on the nameplate located

on the rear of the oven and this power supply must be capable of carrying the load that the oven

will put on it (See “Electrical Connection” below). The oven must also be placed near both a

water supply and an area where the oven can be properly vented (See “Water Connection” and

“Venting” below).

Ovens with casters should be placed so that they have a minimum of two inches on each side

and a minimum of four inches in the rear of the oven to provide for proper venting, water, and

electrical connections.

Ovens without casters should be placed so that there is a minimum of two inches on all sides,

except for the side with the electrical panel, (right side), which should have a minimum of twelve

inches. The rear of an oven without casters should be a minimum of four inches away from

adjacent surfaces to allow room for the electrical, water and venting connections.

Sealing Oven to Mounting Surface

CAUTION

MAKE SURE THAT THE MOUNTING SURFACE IS ABLE TO SUPPORT THE WEIGHT OF

THE OVEN WHICH IS APPROXIMATELY 500 POUNDS PLUS AN ADEQUATE SAFETY

FACTOR BEFORE PLACING IT ON THE SURFACE.

0690S20069 3-1

The oven must be sealed to the mounting surface to comply with local sanitation codes. For

the purpose of sealing the unit a tube of NSF/FDA approved silicone sealant has been provided

with your unit. Apply, to the surface that the oven will rest on, a continuous bead of sealant

approximately 1/2 inch in from each of the four sides of the oven. After the oven has been

placed over this bead apply a second generous continuous bead at the joint where the oven

contacts the mounting surface thus totally sealing the bottom of the oven to that surface.

Oven Setup

Ovens may be mounted to a fixed surface, attached to an “Oliver” oven rack with casters or

stacked. For associated mounting heights for the above options see figure 3.0 on page 2-2.

CAUTION

USE CARE WHENEVER MOVING OVENS MOUNTED ON RACKS AS THEY ARE TOP

HEAVY AND PRESENT A TIPPING HAZARD.

Ovens attached to “Oliver” oven racks must be securely fixed to the rack with bolts. Stacked

ovens should be setup as shown on page 2-2 being sure that the alignment pins on the top of

the lower oven are securely positioned into the holes in the base of the upper oven.

After the Oven has been mounted to a surface, attached to a rack, or stacked, remove the

shipping bracket, which secures the door. To remove the shipping bracket, remove the two

screws from the top of the door with a screwdriver and open the door. Replace these screws

and tighten securely. To remove the shipping bracket from the front of the oven liner, remove

the two hex head screws with a wrench. The bracket and screws may be discarded. Replace

the removed hex head screws with the two screws provided in a bag taped to the floor of the

oven chamber and tighten securely.

Electrical Connection

WARNING

THE OVEN MUST BE CONNECTED TO A PROPERLY GROUNDED ELECTRICAL SOURCE

OF THE SAME RATING AS THE MACHINE. FAILURE COULD RESULT IN AN

ELECTRICAL SHOCK WHICH MAY CAUSE INJURY OR DEATH.

WARNING

ALL WIRING AND ELECTRICAL REPAIRS SHOULD BE DONE BY A QUALIFIED

ELECTRICIAN. FAILURE TO DO SO MAY CAUSE SERIOUS INJURY OR DEATH.

CAUTION

0690S20069 3-2

SPECIAL HEAVY DUTY ELECTRICAL SERVICES AND WALL DISCONNECTS MUST BE

PROVIDED FOR SAFE OPERATION OF THE OVEN.

Electrical Connection (continued)

The following service requirements are recommended, dependent on the voltage of the unit you

have purchased. Your oven’s requirements can be found on the nameplate attached to its rear

surface.

For voltages other than those shown below please contact the factory. Check the voltage at the

disconnect before proceeding to the next step.

480 Volts = 30 Amp service

208 Volts = 60 Amp service

The oven is shipped from the factory with a power cord, which does not include a plug. The

power cord should be wired to a disconnect enclosure which is accessible from the oven work

area, leave at least two feet of slack so that access can be gained to the ovens back and right

side. A plug may be used between the disconnect enclosure and the oven instead of hard

wiring as described above. This makes sliding the oven out for service more convenient.

Whatever method is used the oven should be wired in a manner which would conform to the

U.S. “National Electric Code”.

CAUTION

FANS MUST ROTATE IN THE CLOCKWISE DIRECTION FOR PROPER AIRFLOW. IMPROPER

DIRECTION MAY CAUSE UNEVEN BAKES AND LONGER BAKING TIMES.

Check fan rotation for clockwise direction. After the oven has been “Set Up” and connected to

the electrical service do the following to check the rotation of the fans. Use the following

sequence to start the oven to check fan rotation direction:

· Turn the main power switch on, (green button). The oven should start and fan rotation

can now be checked.

· Once complete, turn the main power switch off, (red button)

If the rotation is incorrect remove and interchange any two of the three incoming power leads

(red, white and black), at the plug or disconnect enclosure and retest.

REV. 8-27-15

0690S20069 3-3

Water Connection

All water connections must comply with the basic plumbing code of the Building Officials and

Code Service Sanitation Manual of the Food and Drug Administration (FDA)

CAUTION

WATER PRESSURES GREATER THEN RECOMMENDED CAN CAUSE EXCESS WATER

TO ENTER THE OVEN CAUSING WATER TO LEAK AT THE DOOR AND ALSO CAUSE

THE TEMPERATURE TO DROP SEVERELY AFFECTING THE BAKE. USE A PRESSURE

REGULATOR TO REGULATE THE PRESSURE.

The oven must be connected to a water supply to enable the oven to produce steam for baking.

As shipped from the factory the oven will have a solenoid valve at the back

center of the oven, (See figure 3.0 page 2-2). This valve has an internal 1/4” NPT thread for

connection. Water pressure should be a maximum of 60 to 70 PSI and the water must clean.

Use a pressure regulator and a water strainer/filter to meet these guidelines. Before making the

water connection flush all lines and install the regulator and filter. Remember solenoid failure

and related problems caused by dirt may not be covered by your warranty.

NOTE

HARD WATER LEAVES MINERAL DEPOSITS ON GLASS AND OTHER SURFACES WHICH

DETRACT FROM OVEN APPEARANCE.

While in IDLE mode, press “MANUAL” key. When prompted enter 400 degrees and 20:00

minutes. After preheat press “START/CANCEL” key, manual recipe should start. While running

manual recipe, test operation of steam by pressing “STEAM” key.

Venting

On the rear side of the oven near the top is a 3” diameter exhaust vent protruding approximately

3/4” from the oven. Vent the exhaust (hot air and steam) to the outside by connecting to this

vent.

WARNING

HOT STEAM CAN CAUSE SEVERE BURNS AND DAMAGE TO THE SENSITIVE

ELECTRONICS. VENT STEAM TO OUTSIDE TO AVOID INJURIES AND DAMAGE.

REV. 8-27-15

0690S20069 3-4

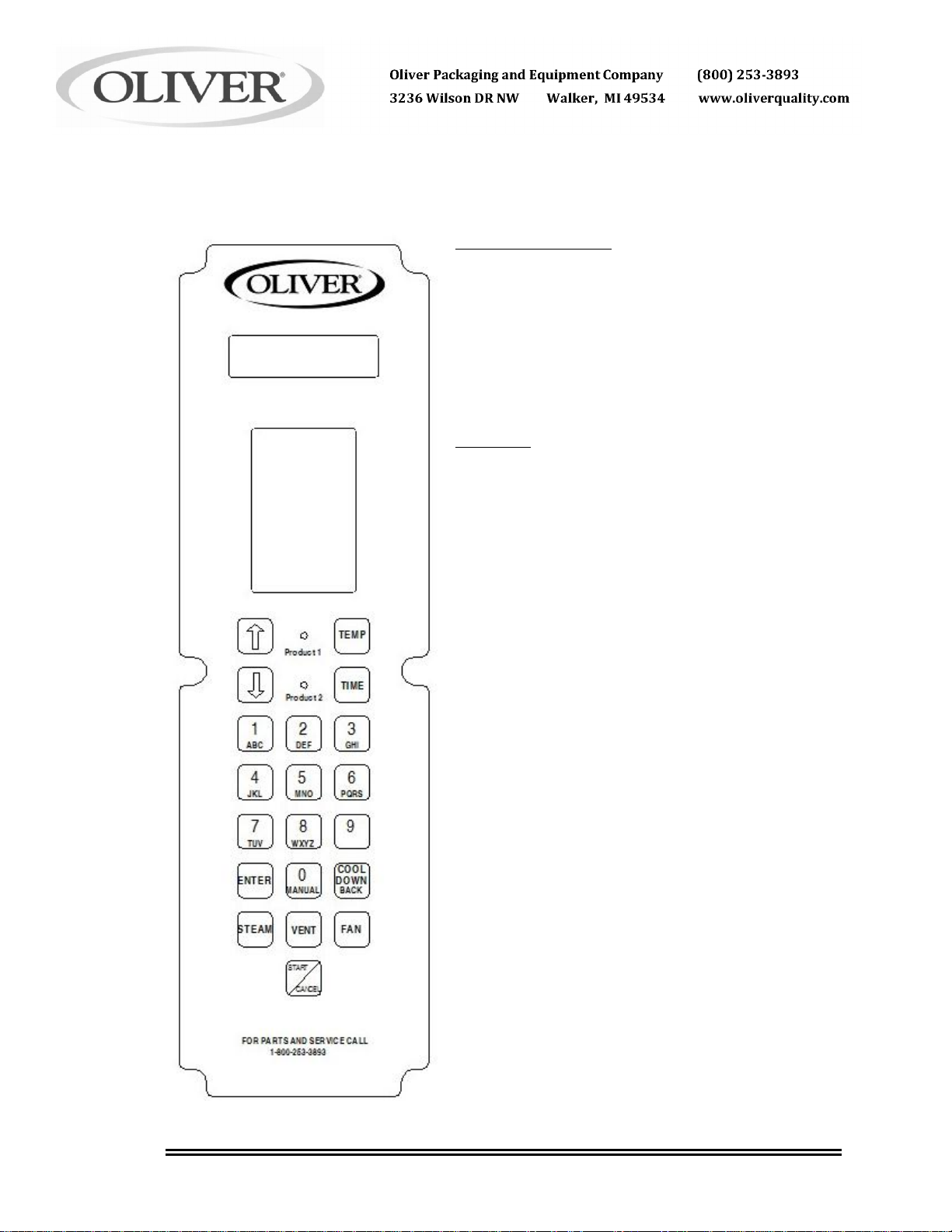

OPERATING INSTRUCTIONS

Beginning Operation

First turn the oven on by pressing the black ‘Start/

Reset’ button below the keyboard and display.

The computer will then check the oven and itself

for any faults. Then the small lcd screen will show

“IDLE”. in the current mode which is idle the

preset initial temperature is 250 °F.

Idle Mode (small LCD will display “IDLE”)

From Idle mode you can:

· Run an automatic program.

· Run a manual program.

0690S20070 4-1

Running an Automatic Program

1. From Idle mode enter the program number (01 - 40) using the keypad

2. Wait 3 seconds or press the START key to begin preheat stage.

3. Wait for oven to reach set temperature. When the set point is reached the buzzer

will sound and the display will show ready.

4. Put product into the oven.

5. Close door, bake begins.

6. Pre-Alarm #1 will sound, if programmed, press START/CANCEL to cancel the alarm.

For more details see the Pre-Alarm section.

7. Alarm will sound when bake is finished.

Open the door to end the program, this will hold the current bake temperature, add time

if required by pressing the up button. OR

Press CANCEL to end the bake and return the holding temperature to 250 °F.

Running two Automatic Programs at the Same Time

If two programs are compatible they may be run at the same time. They must both be

single stage menus with identical temperatures. While the program is running (Product

1 LED will be lit) enter the second program number (01-40) and hit start. Now both

product LED’s will be lit, the one with the shortest time will have a flashing LED and the

time remaining will be displayed.

Pre-Alarm

The pre-alarm will go off during the bake as programmed. The alarm will sound and the

display will show “Pre-Alarm 1” (the 1 is for product-1, product-2 pre-alarm displays “PreAlarm 2”. Press cancel or open the door to clear the alarm.

For advanced users: While the pre-alarm is displayed it is possible to add time to it. Do

this by pressing the up key. Press the up key once for each minute. Then wait three

seconds or press the start key. Example: by adding 2 minutes to the pre-alarm, another

pre-alarm will sound in two minutes. It is then possible to add time again and again.

If the alarm is cleared by opening the door it is still possible to add time. However if the

door is then shut and the up key isn’t pressed within three seconds, the pre-alarm will be

cleared and it will not be possible to add time.

0690S20070 4-2

Running a manual program

From idle mode press the 0 MANUAL key.

After a few seconds - display will prompt to enter temperature.

Now enter the desired temperature by using the numeric keypad or the arrow keys to

scroll.

Press the ENTER key to advance. Display will prompt to enter time.

Using the numeric keypad enter the time in minutes and seconds.

Press the ENTER key to start manual program. Oven should begin preheating.

Press CANCEL twice to cancel manual program.

Adding Steam

It is possible to inject steam at any time the door is closed by pressing and holding the

STEAM button.

Opening and Closing the Vent

It is possible to toggle the vent open and closed by pressing the VENT key. This will not

work when a program is running. Use this feature to vent some of the steam out of the

oven before opening the door. However, some hot steam will always remain.

CAUTION

SUPER HEATED STEAM IS INVISIBLE AND IS POSSIBLY PRESENT IN THE OVEN.

THIS STEAM MAY BURN SKIN. STAND AS FAR AS POSSIBLE AWAY FROM

OVEN WHEN OPENING THE DOOR. THEN PROCEED WITH CAUTION.

Changing the Fan Setting

The fan cannot be changed when a program is running.

In manual mode the fans can be set to high or low by pressing the FAN key.

Cool down allows the oven chamber to quickly cool down by keeping the blowers

running while the door is open.

The low fan setting is helpful for high sugar product.

0690S20070 4-3

Loading...

Loading...