Oliver 688-N Service Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 688-N

QUARTER-RACK ELECTRIC CONVECTION OVEN

0688S20000-CV

MODEL 688-N

INDEX

Section Description Document No. Page No.

SAFETY INSTRUCTIONS ------------------------------- 0688S20002 --------------------- 1-1

DESCRIPTION/SPECIFICATIONS -------------------- 0688S20003---------------------- 2-1

Description -------------------------------------------------------------------------------------- 2-1

Physical Specifications----------------------------------------------------------------------- 2-1

INSTALLATION / SETUP -------------------------------- 0688S20004 --------------------- 3-1

Inspection --------------------------------------------------------------------------------------- 3-1

Location Selection ---------------------------------------------------------------------------- 3-1

Sealing Oven to Mounting Surface ------------------------------------------------------- 3-1

Oven Setup ------------------------------------------------------------------------------------- 3-2

Electrical Connection ------------------------------------------------------------------------- 3-2

Venting ------------------------------------------------------------------------------------------- 3-3

Test Cycle --------------------------------------------------------------------------------------- 3-4

OPERATING INSTRUCTIONS ------------------------- 0688S20005 --------------------- 4-1

Beginning Operation ------------------------------------------------------------------------- 4-1

Adjusting the Temperature ----------------------------------------------------------------- 4-1

Turning Oven Off ----------------------------------------------------------------------------- 4-1

Adjusting the Moveable Shelves ---------------------------------------------------------- 4-1

TROUBLESHOOTING ------------------------------------ 0688S20006 --------------------- 5-1

Temperature Calibration (Re-calibration) ----------------------------------------------- 5-3

MAINTENANCE -------------------------------------------- 0688S20007 --------------------- 6-1

Cleaning ----------------------------------------------------------------------------------------- 6-1

Lubrication -------------------------------------------------------------------------------------- 6-1

Removal and Replacement Guide ------------------------------------------------------- 6-2

RECOMMENDED SPARE PARTS -------------------- 0688S20008 --------------------- 7-1

REPLACEMENT PARTS SECTION

HOUSING / CHAMBER ASSEMBLY ----------------- 0688S20009 -------------------- 8-1

Drawing ---------------------------------------------------------------------------------------- 8-1

Parts List --------------------------------------------------------------------------------------- 8-2

LINER ASSEMBLY ---------------------------------------- 0688S20010 -------------------- 9-1

Drawing ---------------------------------------------------------------------------------------- 9-1

Parts List --------------------------------------------------------------------------------------- 9-2

Continued

0688S20001 0-1

MODEL 688-N

INDEX (Continued)

Section Description

Document No. Page No.

DOOR ASSEMBLY --------------------------------------- 0688S20011 ------------------- 10-1

Drawing ---------------------------------------------------------------------------------------- 10-1

Parts List -------------------------------------------------------------------------------------- 10-2

FRONT CONTROL PANEL ASSEMBLY------------- 0688S20012 -------------------- 11-1

Drawing ---------------------------------------------------------------------------------------- 11-1

Parts List -------------------------------------------------------------------------------------- 11-2

ELECTRICAL SUB PANEL ------------------------------ 0688S20013 --------------------- 12-1

Drawing ----------------------------------------------------------------------------------------- 12-1

Parts List --------------------------------------------------------------------------------------- 12-2

REAR COVER ASSEMBLY ----------------------------- 0688S20014 -------------------- 13-1

Drawing ---------------------------------------------------------------------------------------- 13-1

Parts List -------------------------------------------------------------------------------------- 13-2

COVER ASSEMBLY -------------------------------------- 0688S20015 ------------------- 14-1

Drawing ---------------------------------------------------------------------------------------- 14-1

Parts List -------------------------------------------------------------------------------------- 14-2

ELECTRICAL DIAGRAM -------------------------------- 0688S20017 -------------------- 15-1

Three Phase Wiring Diagram 208 / 240 375 / 480 V -------------------------------- 15-1

WARRANTY ------------------------------------------------- GEN 050816

WARRANTY PROCEDURE ----------------------------- GEN 050817

RETURNED PARTS POLICY---------------------------- GEN 050818

0688S20001 0-2

MODEL 688-N

SAFETY INSTRUCTIONS

WARNING

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING HAVE BEEN

PROVIDED ON THIS OVEN. IT IS ESSENTIAL HOWEVER THAT THE OVEN

OPERATORS AND MAINTENANCE PERSONNEL OBSERVE THE FOLLOWING

SAFETY PRECAUTIONS. IMPROPER INSTALLATION, MAINTENANCE, OR

OPERATION COULD CAUSE SERIOUS INJURY OR DEATH.

1. Read this manual before attempting to operate your oven. Never allow an untrained

person to operate or service this machine.

2. This oven must only be installed by qualified personnel. It also must be installed to

the specifications of local plumbing and electrical codes. See the installation section

of this manual for additional requirements.

3. Connect the oven to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow specifications of

local electrical codes.

4. Disconnect and lock-out the oven from the power supply before cleaning or servicing.

5. Check and secure all guards before starting the oven.

6. Observe all caution and warning labels affixed to the oven.

7. Use only proper replacement parts.

8. Wear proper personal protective safety equipment.

9. Keep Hands away form the moving parts of this oven while it is in operation.

10. In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the oven in the operating instructions.

WARNING

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

0688S20002 1-1

MODEL 688-N

DESCRIPTION/SPECIFICATIONS

Description

The Oven is a stainless steel, electric, forced air, (convection), oven. This oven offers

consistent baking at all rack levels due to the careful positioning of the heating and air

circulation systems.

In addition to the above, this oven also offers many other features. It is well insulated with

a high quality asbestos free insulation. It is compact, attractive, quiet, and is

easily maintained. Should electrical servicing ever be required the electrical components

are readily accessible by removing the side or back panels.

The tempered glass door allows a full view of the trays in the oven during baking.

The oven has one of the fastest temperature recoveries on the market allowing the oven

to be turned off during non-peak hours, thus saving energy.

The oven has many protective features such as not allowing heating of the elements when

the door is open. Other features are re-settable thermal overloads on the motor, and a

high-limit thermostat.

The temperature control allows precise control of the baking temperature.

The moveable shelves allow greater flexibility.

Physical Specifications

Electrical Options Available:

3 phase, 60 Hz, 208VAC, 24 Amps.

3 phase, 60 Hz, 240VAC, 27 Amps.

3 phase, 50 Hz, 375VAC, 11 Amps.

3 phase, 60 Hz, 480VAC, 14 Amps.

Product Capacities:

The Standard oven will hold (2 to 5) 18" X 26" pastry baking trays depending on the

placement of moveable shelves.

When using 2 trays – maximum distance between trays is 9-3/4"

When using 3 trays – maximum distance between trays is 4-3/4”

When using 4 trays – maximum distance between trays is 3"

When using 5 trays – maximum distance between trays is 2-1/4"

0688S20003 2-1

MODEL 688-N

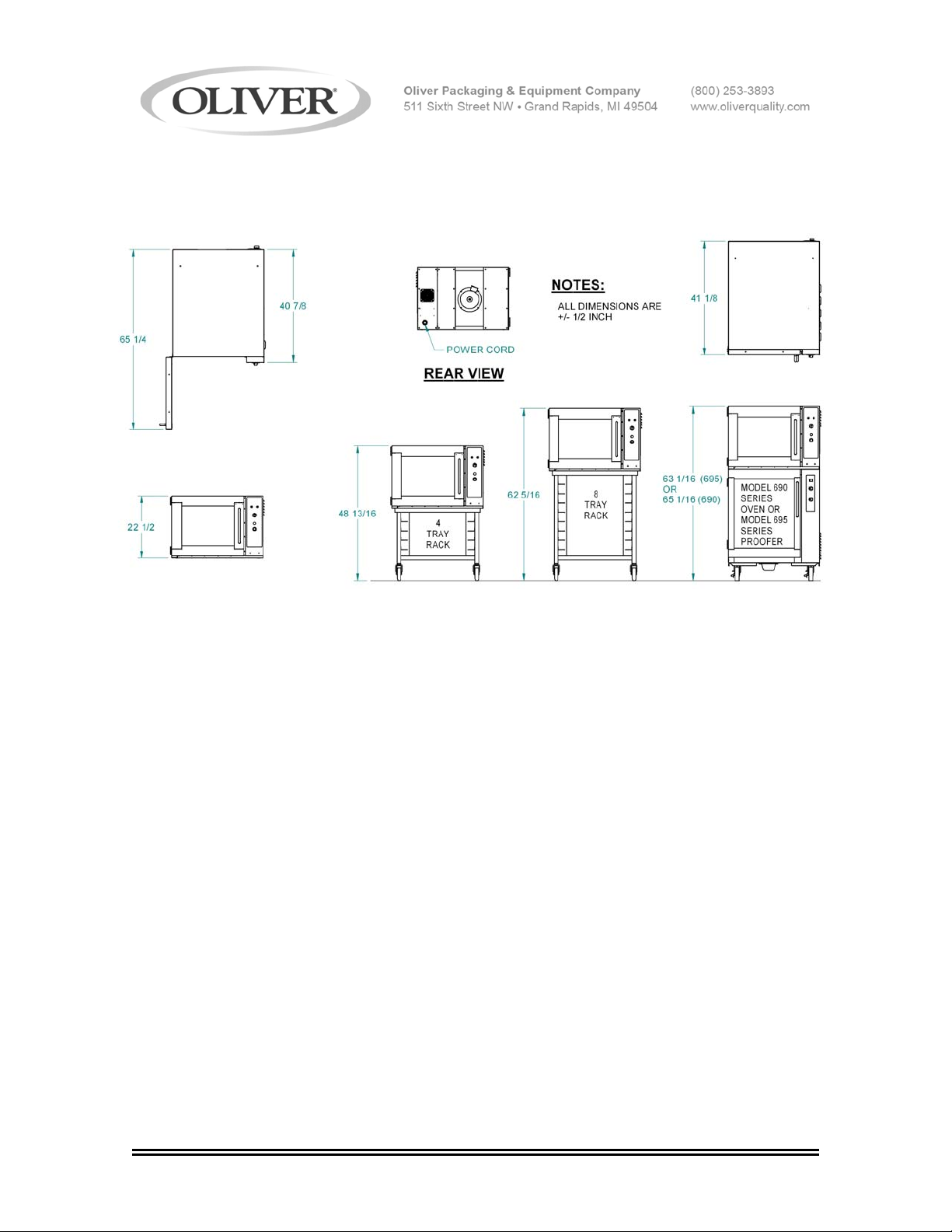

Space Requirements:

Single: 41-1/8” Deep x 33” Wide x 22-1/2” high.

Single with short stand and casters: 48-13/16” high.

Single with tall stand and casters: 62-5/16” high

Stacked 688 oven & 695 Proofer with casters: 63-1/16” high

Stacked 688 & 690 ovens with casters: 65-1/16” high

Clearance:

Left side = 2”.

Right side = 12” in a fixed location, (to have access to electrical components), or

2” when mounted on another unit which has casters.

Back side = 4” to allow for proper motor ventilation and electrical connection.

Net Weight: Approximately 300 pounds.

Shipping Weight: Approximately 350 pounds.

0688S20003 2-2

MODEL 688-N

INSTALLATION / SETUP

Inspection

Before accepting delivery inspect the carton and machine for damage. Note any damage

found on the shipping documents. Remember shipping damage is not

warranty, and is the responsibility of the carrier. Also report the damage to the dealer

from which the oven was purchased for further direction and assistant in filing a claim with

the carrier.

Location Selection

Select a location where the oven will be used. The oven must be set on a flat level

surface. It should have a grounded power supply of the same rating as shown on the

nameplate located on the rear of the oven and this power supply must be capable of

carrying the load that the oven will put on it (See “Electrical Connection” below).

Ovens mounted on other units with casters should be placed so that they have a minimum

of two inches on each side and a minimum of four inches in the rear of the oven to provide

for proper motor ventilation and electrical connection.

Ovens without casters should be placed so that there is a minimum of two inches on all

sides, except for the side with the electrical panel, (right side), which should have a

minimum of twelve inches. The rear of an oven without casters should be a minimum of

four inches away from adjacent surfaces to allow room for the electrical connection and

motor ventilation.

Sealing Oven to Mounting Surface

covered by your

CAUTION

MAKE SURE THAT THE MOUNTING SURFACE IS ABLE TO SUPPORT THE WEIGHT

OF THE OVEN WHICH IS APPROXIMATELY 300 POUNDS PLUS AN ADEQUATE

SAFETY FACTOR BEFORE PLACING IT ON THE SURFACE.

The oven must be

For the purpose of sealing the unit a tube of NSF/FDA approved silicone sealant has been

provided with your unit. Apply, to the surface that the oven will rest on, a continuous bead

of sealant approximately 1/2 inch in from each of the four sides of the oven. After the

oven has been placed over this bead apply a second generous continuous bead at the

joint where the oven contacts the mounting surface thus totally sealing the bottom of the

oven to that surface.

0688S20004 3-1

sealed to the mounting surface to comply with local sanitation codes.

MODEL 688-N

Oven Setup

Ovens may be mounted to a fixed surface, attached to an “Oliver” oven rack with casters

or stacked on either a Oliver Model 690 Oven or and Oliver Model 695 Proofer. For

associated mounting heights for the above options see page 2-2.

CAUTION

USE CARE WHENEVER MOVING OVENS MOUNTED ON RACKS AS THEY ARE TOP

HEAVY AND PRESENT A TIPPING HAZARD.

Ovens attached to “Oliver” oven racks must be

Stacked units should be setup as shown on page 2-2 being sure that the alignment pins

on the top of the lower unit are securely positioned into the holes in the base of the upper

oven.

Electrical Connection

securely fixed to the rack with bolts.

WARNING

THE OVEN MUST BE CONNECTED TO A PROPERLY GROUNDED ELECTRICAL

SOURCE OF THE SAME RATING AS THE MACHINE. FAILURE COULD RESUL T IN

AN ELECTRICAL SHOCK WHICH MAY CAUSE INJURY OR DEATH.

WARNING

ALL WIRING AND ELECTRICAL REPAIRS SHOULD BE DONE BY A QUALIFIED

ELECTRICIAN. FAILURE TO DO SO MAY CAUSE SERIOUS INJURY OR DEATH.

CAUTION

SPECIAL HEAVY DUTY ELECTRICAL SERVICES AND WALL DISCONNECTS MUST

BE PROVIDED FOR SAFE OPERATION OF THE OVEN.

The following service requirements are recommended, dependent on the voltage of the

unit you have purchased. Your oven’s requirements can be found on the nameplate

attached to its rear surface.

0688S20004 3-2

MODEL 688-N

Electrical Connection (continued)

For voltages other than those shown below please contact the factory. Check the voltage

at the electrical disconnect before proceeding to the next step.

480 Volts = 20 Amp service

375 Volts = 20 Amp service

240 Volts = 30 Amp service

208 Volts = 30 Amp service

The oven is shipped from the factory with a power cord, which does not include a plug.

The power cord should be wired to a disconnect enclosure which is accessible from the

oven work area, leave at least two feet of slack so that access can be gained to the ovens

back and right side. A plug may be used between the disconnect enclosure and the oven

instead of hard wiring as described above. This makes sliding the oven out for service

more convenient. Whatever method is used the oven should be wired in a manner which

would conform to the U.S. “National Electric Code”.

CAUTION

FANS MUST ROTATE IN THE CLOCKWISE DIRECTION FOR PROPER AIRFLOW.

IMPROPER DIRECTION MAY CAUSE UNEVEN BAKES AND LONGER BAKING TIMES.

Check fan rotation for clockwise direction. After the oven has been “Set Up” and

connected to the electrical service do the following to check the rotation of the fans. Use

the following sequence to start the oven to check fan rotation direction:

• Turn the main power switch on, (green button). The oven blower motor should

start. Once started the fan rotation can be checked.

• Once complete, turn the main power switch off, (red button).

If the rotation is incorrect remove and interchange any two of the three incoming power

leads (red, white and black), at the plug or disconnect enclosure and retest.

Venting

The gap between the door and the housing of the model 688 oven is designed to be the

vent for the oven. SOME STEAM MAY ESCAPE THROUGH THE FRONT DOOR

GASKET.

0688S20004 3-3

MODEL 688-N

WARNING

HOT STEAM ESCAPING WHILE OPENING DOOR CAN CAUSE SEVERE BURNS.

STAND BACK WHILE OPENING DOOR TO AVOID INJURY.

Test Cycle

After completing the Set Up, and Electrical connections, you may wish to run the oven

through a test cycle to verify that everything is ready. Use the following sequence to test

the oven.

• Turn the main power switch on, (green button). The fan should start.

• Adjust temperature to 350 degrees F using thermostat. The heat light should

• Once the oven reaches the set temperature the heating elements should cycle on

• The gap between the door and the housing of the model 688 oven is designed to

• Once complete, turn the main power switch off, (red button).

illuminate, then extinguish when oven reaches temperature.

and off as indicated by the heat light.

be the vent for the oven. SOME STEAM MAY ESCAPE THROUGH THE FRONT

DOOR GASKET.

0688S20004 3-4

MODEL 688-N

OPERATING INSTRUCTIONS

Beginning Operation

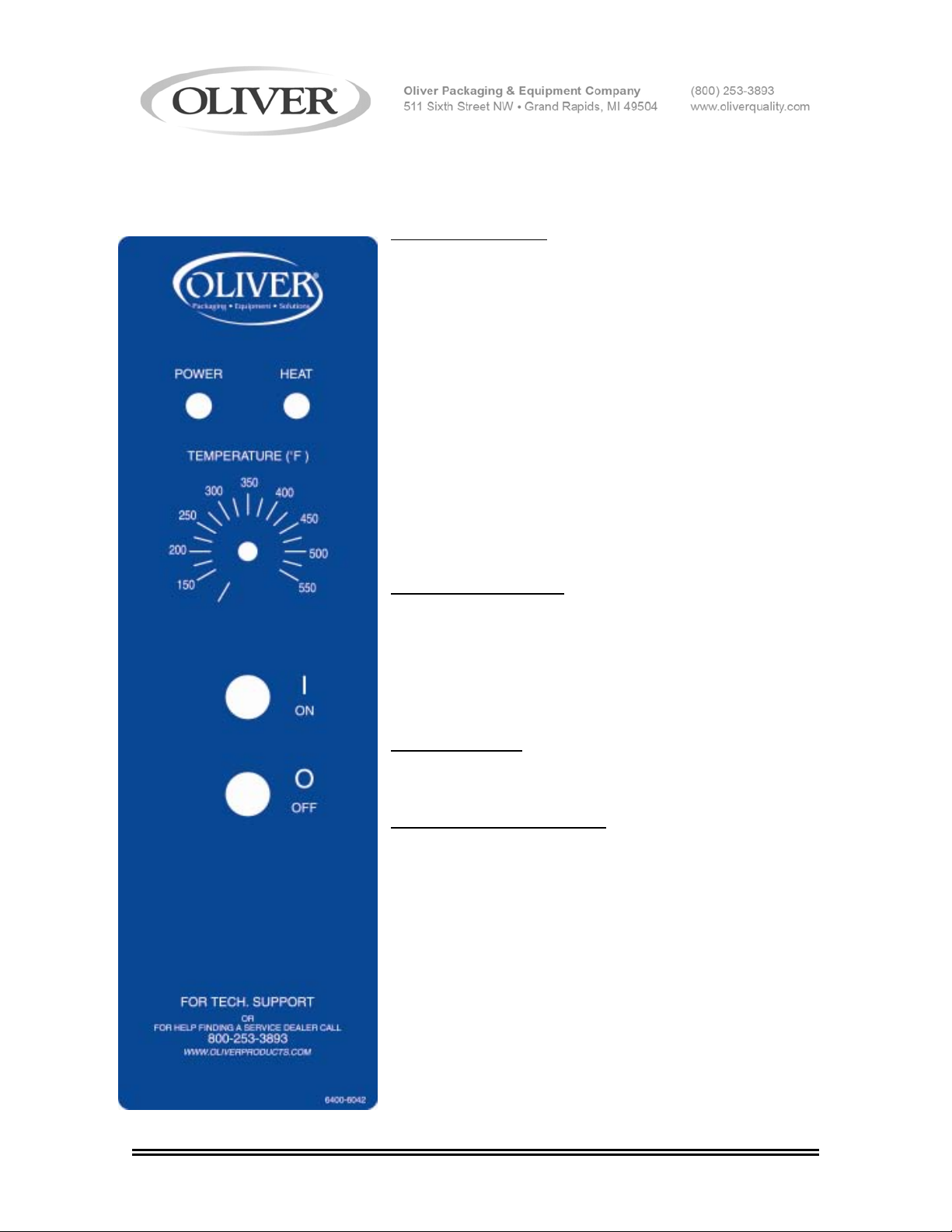

First turn the oven on by pressing the green “On”

button. The green “Power” lamp should be illuminated,

oven blower will start, and heater will be turned on if

temperature setting is higher than the temperature

inside of oven.

Green “Power” lamp is illuminated anytime units is on.

Red “Heat” lamp is illuminated anytime heater is on.

(When oven is up to temperature the lamp is off)

lamp will continue to cycle on/off with heaters.

Oven blower and heater will turn off anytime door is

opened regardless of temperature. Normal blower and

heater operation will resume after door is closed.

Adjusting Temperature

Adjust the temperature of the oven by turning dial to

correspond to the temperature desired. Allow oven to

reach temperature before baking. If adjusting to a lower

temperature, it may be necessary to allow oven to cool

by leaving door open for a few minutes.

Turning Oven Off

Turn oven off by pressing the red “Off” button.

Adjusting Moveable Shelves

6 moveable shelves are provided – 3 (RH) right hands,

3 (LH) left hands.

For 2 shelf operation – remove all moveable shelves.

For 3 shelf operation – install 1 RH and 1 LH moveable

shelves in center location.

For 4 shelf operation – install 2 RH and 2 LH moveable

shelves in locations closest, but not in, center.

For 5 shelf operation – install 3 RH and 3 LH moveable

shelves in center and the two outermost locations.

Shelves should be equally spaced for the best possible

bake.

0688S20005 4-1

MODEL 688-N

TROUBLESHOOTING

WARNING

TROUBLE SHOOTING OF ELECTRICAL EQUIPMENT SHOULD BE PERFORMED BY

QUALIFIED PERSONNEL ONLY. ELECTRICAL POTENTIAL IS GREAT ENOUGH TO

CAUSE INJURY OR DEATH.

CAUTION

BEFORE WORKING ON A OVEN WHICH HAS BEEN RECENTLY USED

ALLOW SUFFICIENT TIME FOR IT TO COOL TO PREVENT BURNS.

No Power – Oven Will Not Start.

• The machine is not plugged in.

• There is no power available at the outlet/disconnect

• A fuse has blown.

• The transformer has failed. (Control panel only)

• Oven temperature is too high. (Your oven comes with a high temperature limit switch

set at approx. 600 °F. This switch will reset when the oven has cooled.)

• Motor has overheated. (The blower motor is equipped with an internal thermal

switch). Turn the oven off and try to restart after the motor has cooled.

Possible causes:

1.) The motor bearing or winding has failed.

2.) Something is binding the motor or blower fan.

3.) The rear of the oven lacks sufficient clearance to allow proper air circulation.

No Heat or Oven Heats Slowly

A cooled dry empty oven can be heated from room temperature to 300 °F in four to six

minutes. If the oven is not meeting this specification, check the following.

• Check the fuses

• Check the two contactors.

• Check heater bank continuity.

(continued)

0688S20006 5-1

Loading...

Loading...