Oliver 5370 Owner's Manual

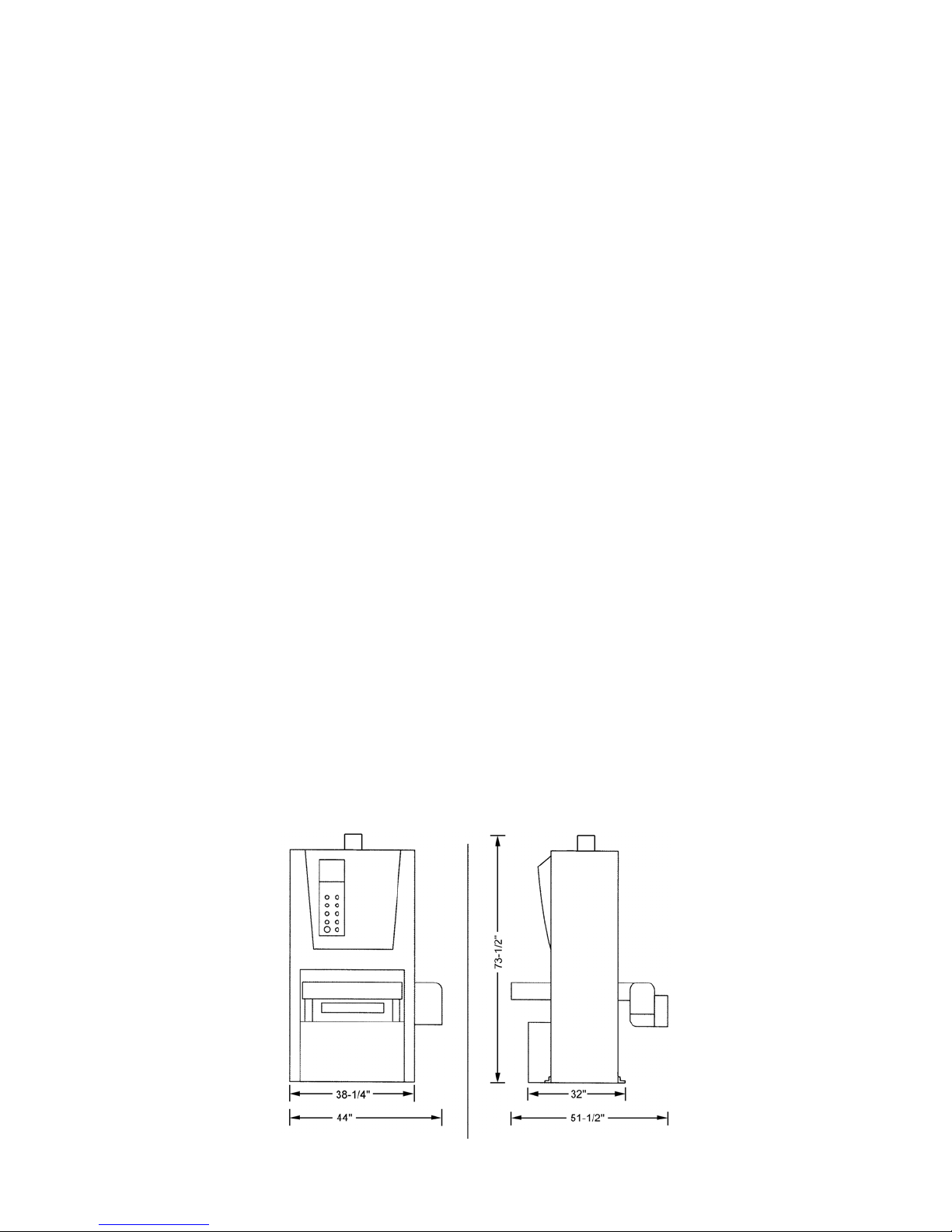

5370 25” Wide Belt Sander

Owners Manual

Oliver Machinery M-5370 4/2003

Seattle, WA Copyright 2003

info@olivermachinery.net www.olivermachinery.net

Warranty

Thank you for your purchase of a genuine Oliver woodworking machine. Oliver Machinery has made

every attempt to provide a machine that is safe and durable.

All Oliver products are guaranteed, to the ORIGINAL RETAIL CUSTOMER, to be free from defects for

TWO YEARS FROM THE DATE OF PURCHASE. Oliver Machinery will repair or replace, at its option,

any component that fails under normal use. Please note that the customer is responsible for returning the

failed component to Oliver Machinery prepaid for inspection.

This warranty does not cover damages caused by misuse, accident, unauthorized repair, alteration or

improper maintenance.

Warning

Read this manual thoroughly before operating the machine. Oliver Machinery disclaims any liability for

machines that have been altered or abused. Oliver Machinery reserves the right to effect at any time,

without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

For More Information

Oliver Machinery is always adding new Industrial Woodworking products to the line. For complete, up-todate product information, check with your local Oliver Machinery distributor, or visit

www.olivermachinery.net

2

WARNING!

Read this manual completely and observe all warning labels on the machine. Oliver Machinery has made

every attempt to provide a safe, reliable, easy-to-use piece of machinery. Safety, however, is ultimately

the responsibility of the individual machine operator. As with any piece of machinery, the operator must

exercise caution, patience, and common sense to safely run the machine. Before operating this product,

become familiar with the safety rules in the following sections.

• Always keep guards in place and in proper operating condition. Do not operate the machine

without the guards for any reason.

• This sander is intended to be used with wood and wood products only. Use of this sander

and a dust collector with metal products is a potential fire hazard.

• Support the workpiece adequately at all times during operation; maintain control of the work

at all times.

• This sander is designed and intended for use by properly trained and experienced personnel

only. If you are not familiar with the proper and safe operation of a wide belt sander, do not

use until proper training and knowledge has been obtained.

1. REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit of checking to see that keys and

adjusting wrenches are removed from the machine before turning it on.

2. KEEP THE WORK AREA CLEAN. Cluttered areas and benches invite accidents.

3. DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t use machinery in damp or wet locations, or

expose them to rain. Keep work area well lighted.

4. KEEP CHILDREN AWAY. All visitors should be kept a safe distance from the work area.

5. MAKE THE WORKSHOP KIDPROOF with padlocks, master switches, or by removing starter keys.

6. DON’T FORCE THE MACHINE. It will do the job better and safer at the rate for which it was

designed.

7. USE THE RIGHT TOOL. Don’t force a machine or attachment to do a job for which it was not

designed.

8. DEDICATED CIRCUIT. Have an electrician hard wire the machine to a dedicated circuit that can

handle the load. Follow all local electrical codes.

9. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

10. ALWAYS USE SAFETY GLASSES. Also use face or dust masks. Everyday eye glasses only have

impact resistant lenses; they are not safety glasses.

11. DON’T OVERREACH. Keep proper footing and balance at all times.

12. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

13. ALWAYS DISCONNECT THE MACHINE FROM THE POWER SOURCE BEFORE SERVICING.

3

14. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is in the off position

before plugging in.

15. USE RECOMMENDED ACCESSORIES. The use of accessories and attachments not

recommended by Oliver Machinery may cause hazards or risk of injury to persons.

16. NEVER STAND ON A MACHINE. Serious injury could occur if the machine is tipped.

17. CHECK DAMAGED PARTS. Before further use of the machine, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform its

intended function - check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

18. NEVER LEAVE THE MACHINE RUNNING UNATTENDED. TURN POWER OFF. Don’t leave the

machine until it comes to a complete stop.

19. SOME DUST CREATED by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from those exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed to filter out microscopic particles

20. DO NOT operate machine while under the influence of drugs, alcohol or any medication.

21. AVOID kickback by sanding in accordance with directional arrows.

22. SAND with the grain of the wood.

23. DO NOT sand pieces of material that are too small to be safely supported.

24. WHEN sanding a large workpiece, provide additional support at table height.

25. MAKE CERTAIN the machine is electrically grounded and that all electrical connections are secure.

26. ATTACH SANDER to appropriately sized dust collection system.

27. MAKE CERTAIN the abrasive belt is free of defects (tears, holes, frayed edges, etc.)

28. DO NOT attempt to remove more than 1/32” of wood in one pass.

29. DO NOT open access doors while machine is running.

30. NEVER try to remove a workpiece from the machine after it has started feeding. Turn off the power,

lower the table, then remove the workpiece.

31. WHEN INSTALLING a new abrasive belt, be sure to install it with the directional arrows on the

backside of the sanding belt matching the drum rotation.

32. SAVE THESE INSTRUCTIONS refer to them often and use them to instruct others.

4

Table of Contents Page Number

Warranty........................................................................................................................................................ 2

Warnings ....................................................................................................................................................3-4

Table of Contents.......................................................................................................................................... 5

Specifications ................................................................................................................................................ 5

Contents of the Shipping Container .............................................................................................................. 6

Uncrating the Machine .................................................................................................................................. 6

Machine Preparation and Setup ................................................................................................................... 6

Connecting to a Dust Collector ..................................................................................................................... 7

Connecting to Air........................................................................................................................................... 7

Electrical Connections................................................................................................................................ 7-8

Control Panel ................................................................................................................................................ 8

Features and Controls................................................................................................................................... 9

Installing Sanding Belts............................................................................................................................... 10

Adjusting Platen Position ............................................................................................................................ 10

Setting Belt Tracking ................................................................................................................................... 11

Setting Belt Oscillation ................................................................................................................................ 12

Digital Controller.......................................................................................................................................... 12

Changing Units of Measure......................................................................................................................... 13

Sanding to a Specific Thickness ................................................................................................................. 13

Calibrating the PV (Present Value) ............................................................................................................. 13

Thickness Scale .......................................................................................................................................... 14

Conveyor Tracking ...................................................................................................................................... 14

Adjusting V-belt Tension ............................................................................................................................. 14

Replacing V-belts ........................................................................................................................................ 14

Maintenance................................................................................................................................................ 15

Troubleshooting .......................................................................................................................................... 15

Specifications

Main Motor ...............................................................................................................1 Ph, 10 HP, 220V Only

......................................................................................................... 3 Ph, 15 HP, 220/440V Prewired 220V

Conveyor Motor.......................................................................................................... 1 Ph, 1 HP, 220V Only

............................................................................................................ 3 Ph, 1 HP 220/440V Prewired 220V

Table Height Adjust Motor....................................................................................... 1 Ph, 1/4 HP, 220V Only

......................................................................................................... 3 Ph, 1/4 HP 220/440V Prewired 220V

Maximum Stock Width ...............................................................................................................................24”

Maximum Stock Thickness ..........................................................................................................................6”

Minimum Stock Thickness ........................................................................................................................1/8”

Air Requirements .................................................................................................................................. 70 psi

Dust Port Diameter....................................................................................................................................... 5”

Abrasive Belt Dimensions (W x L) ....................................................................................................25” x 75”

Feed Speed...................................................................................................................Variable 16 to 49 fpm

Gross Weight .................................................................................................................................. 2,000 lbs.

5

Loading...

Loading...