Oliver 5015 Owner's Manual

5015 14” Cut Off Saw

Owner’s Manual

Oliver Machinery M-5015 5/2014

Seattle, WA Copyright 2003-2015

info@olivermachinery.net www.olivermachinery.net

TABLE OF CONTENTS

I. GENERAL DESCRIPTIONS ................................................................... 01

II. SPECIFICATIONS.................................................................................. 02

III. CUTTING CAPACITY DIAGRAM ........................................................... 02

IV. CAUTIONS BEFORE OPERATING ....................................................... 03

V. OPERATING PROCEDURES ................................................................ 04

VI. MAINTENANCE & SETVICE .................................................................. 04

VII. REMARKS ............................................................................................. 05

VIII. ADDITIONAL SAFETY RULES FOR THIS MACHINE (1) (2) ............ 06-07

IX. REPLACING THE SAWBLADE (1)(2) ............................................... 08-09

X. ADJUSTING V-BELT TENSION (1)(2) .............................................. 10-11

XI. DIAGRAMS AND PART LISTS ......................................................... 12-16

I. GENERAL DESCRIPTIONS

Much thanks for our honorable customers whom to select our

products, 14” Auto Hi-speed Cut-Off Saw. We deep believe your

intelligent selection which will make you feel easy and satisfactory.

In order to assist you realize the machinery character and how to

operate, maintain the machinery etc., affairs. Therefore, we compile

this manual for you to study and refer. Of course, the products which

before to deliver to the endorsers our company has made the

necessary testing, measuring & practical operations. But it is

essential to the machinery performance which is based on the

accurate maintenance and operations. Since we wish our honorable

customers must practiced operating method and maintenance

regularly. The manual is suggested to assist the user to understand

the operating method much better and maintenance note precisely;

moreover, to assure the supreme performance & long servicing life of

machinery.

1

II. SPECIFICATIONS

14” CUT-OFF SAW

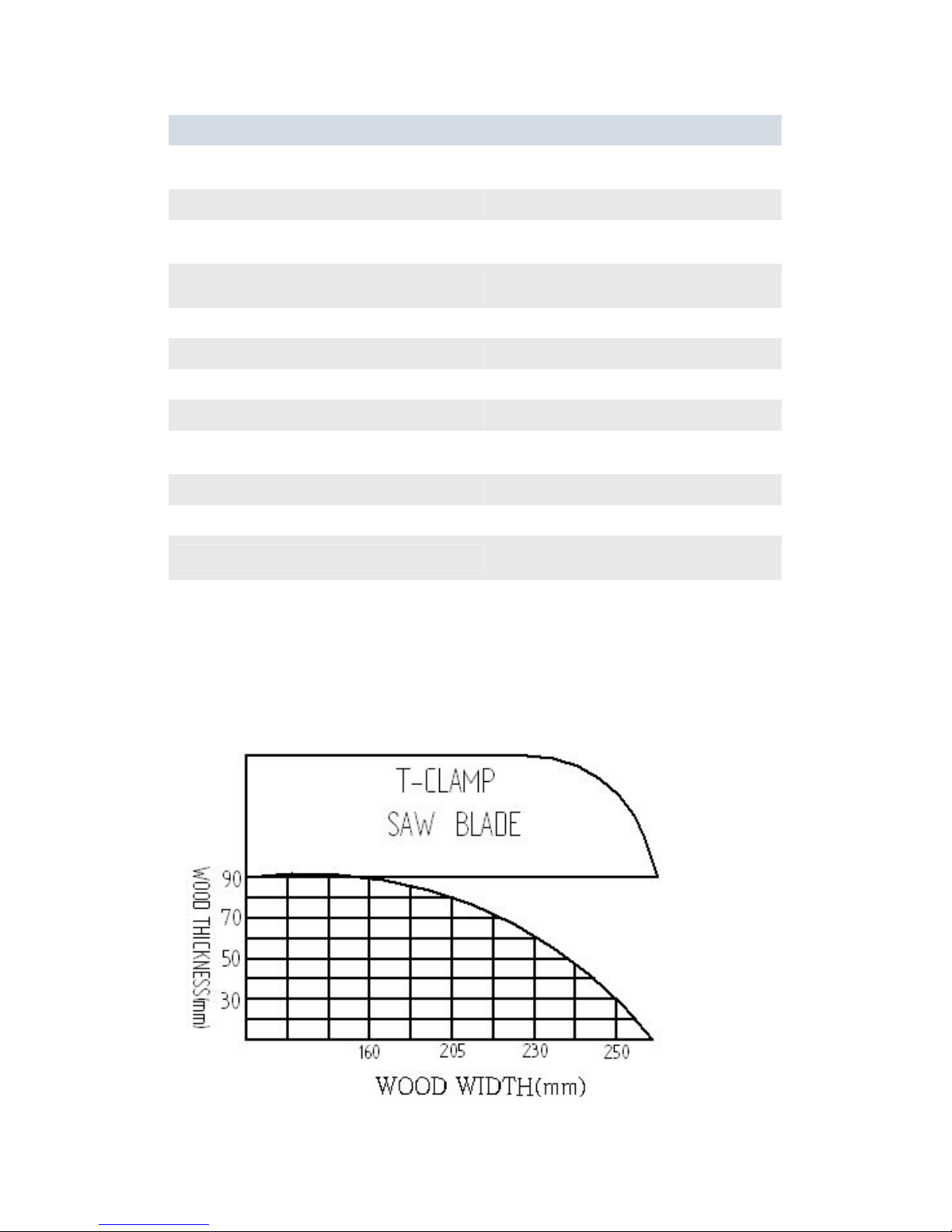

Cutting capacity (thickness x width) 1" x 10", 2" x 9", 3" x 8"

Cycle speed 95 strokes/min

Cycle operation Air

Saw blade size (optional) 14"

Saw arbor diameter 1"

Saw blade speed 4100 RPM

Dust exhaust diameter Ø4"

Motor 5 HP (7.5HP opt.)

Table size 630x 590 mm

Net weight 240 kgs

Gross weight 290 kgs

Packing dimensions (L x W x H) 770 x 760 x 1300 mm

*We reserve the right to modify design without prior notice.

III. CUTTING CAPACITY DIAGRAM

2

IV. CAUTIONS BEFORE OPERATING

1. After the machine is transported to the installed site which must be

cared to take off the exporting case and the install site must be

flatten and rugged. If there are not flatten which can be inserted

the shim at the bottom of the machine, so that there are not

swung.

2. After the installed process is completed and then, which can be

connected the power wire. Meanwhile, to inspect the rotating

direction of circular saw is same as indicated or not. Check if there

are not which must exchange the connecting terminal.

3. We can employed the kerosene to clean the anti-rust oil which

brushed on the sliding portion of machinery and then, to wipe new

lubricating oil or grease on the sliding way or transmitting portion.

4. Before operating, firstly inspecting safety appurtenance, guard of

saw blade- - - etc. and other safety device locked tightly or not.

5. To check and inspect if the air piping is connected with the R.F.L

unit, if the oil cup is poured oil, and if there is any leakage on the

piping system or not. Especially, to correct the error and then to

solve the problem. After that, to connect the dust chute with the

dust collector.

3

V. OPERATING PROCEDURES:

1. Adjust the angle between guide fence and circular saw which s

corresponded to the being cutting angle.

2. Turn selecting switch of air inlet to the ON position.

3. Start the electric power on.

4. Pedaling on the foot pedal switch and then, the cutting process

can be processed.

5. To inspect if the dimensions & profile of the first products meet the

requirement or not, therefore to adjust the assorted portion again.

VI. MAINTENANCE & SETVICE

1. Each week, the SPINDLE OIL NOZZLE must be lubricated with

grease on the circular saw shaft periodically. (Shell #3 or same

grade grease)

2. Poured the lubricating oil in the R.F.L unit periodically and

drained out the water which stored in the filtering cup.

3. Each day, after the work is over, clean the wood chips on the

machine sot that to assure the operation to be processed

continuously.

4

Loading...

Loading...