Oliver 1808-CE Installation Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 1808-CE

AUTOMATED PACKAGING SYSTEM

1808S20015CV

1808-CE

INDEX

Section Description

Document No. Page No.

INTRODUCTION -------------------------------------------------- 1808S20004 --------------------------- 1-1

SAFETY INSTRUCTIONS -------------------------------------- 1808S20017 --------------------------- 2-1

Labels -------------------------------------------------------------------------------------------------------- 2-3

DESCRIPTION/SPECIFICATIONS --------------------------- 1808S20018 --------------------------- 3-1

Description -------------------------------------------------------------------------------------------------- 3-1

Specifications----------------------------------------------------------------------------------------------- 3-1

INSTALLATION INSTRUCTIONS ---------------------------- 1808S20007 -------------------------- 4-1

Inspection -------------------------------------------------------------------------------------------------- 4-1

Uncrating --------------------------------------------------------------------------------------------------- 4-1

OPERATING INSTRUCTIONS -------------------------------- 1808S20019 --------------------------- 5-1

CLEANING INSTRUCTIONS ---------------------------------- 1808S20009 --------------------------- 6-1

TRAY CARRIER (CUTOFF) CHANGE ---------------------- 1808S20035 --------------------------- 7-1

Changing to a tray carrier set with same cutoff as previous set ------------------------------ 7-2

Changing to a tray carrier set with a different cutoff length than the previous set -------- 7-3

MAINTENANCE --------------------------------------------------- 1808S20011 --------------------------- 8-1

RECOMMENDED SPARE PARTS -------------------------- 1808S20021 --------------------------- 9-1

TROUBLESHOOTING ------------------------------------------- 1808S20022 -------------------------- 10-1

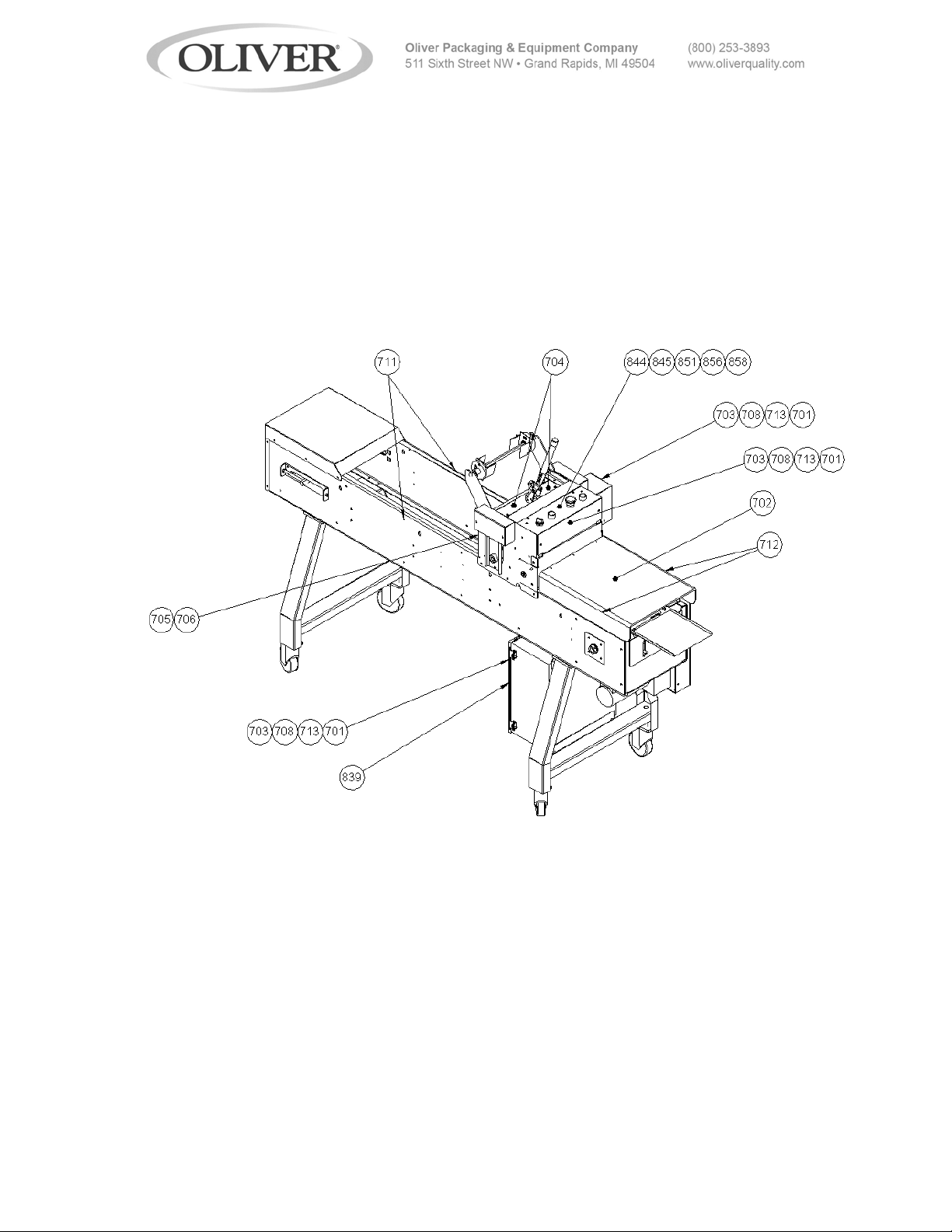

FRAME AND DRIVE ASSEMBLY ---------------------------- 1808S20023 -------------------------- 11-1

Parts list ---------------------------------------------------------------------------------------------------- 11-2

LEG ASSEMBLY -------------------------------------------------- 1808S20024 ------------------------- 12-1

Parts list ---------------------------------------------------------------------------------------------------- 12-2

HEAT SEAL FRAME ASSEMBLY ---------------------------- 1808S20025 ------------------------- 13-1

Parts list ---------------------------------------------------------------------------------------------------- 13-2

HEAT SEAL ROLL ASSEMBLY ------------------------------- 18

Parts list ---------------------------------------------------------------------------------------------------- 14-2

DISCHARGE ASSEMBLY -------------------------------------- 1808S20027 ------------------------- 15-1

Parts list ---------------------------------------------------------------------------------------------------- 15-2

FILM MANDREL ASSEMBLY ---------------------------------- 1808S20028 ------------------------- 16-1

Parts list ---------------------------------------------------------------------------------------------------- 16-2

08S20026 ------------------------- 14-1

Continued

1808S20016 0-1

1808-CE

ELECTRICAL ASSEMBLY -------------------------------------- 1808S20029 ------------------------- 17-1

Parts list ---------------------------------------------------------------------------------------------------- 17-2

WIRING DIAGRAM 2/50-60/208-240 ------------------------ 1808S20030 ---------------------------18-1

WARRANTY ---------------------------------------------------- --- GEN 040225

WARRANTY PROCEDURE------------------------------------ GEN 040226

RETURNED PARTS POLICY --------------------------------- GEN 040227

1808S20016 0-2

1808-CE

INTRODUCTION

Thank you for purchasing your new line of packaging machinery from Oliver Products

Company. Your new equipment was specifically designed and manufactured to meet

your individual requirements and represents the quality, innovation and attention to detail

that Oliver provides as a continuing process of improving and expanding our products.

Please let us know if there is any way we can better serve you or if there is an

adaptation to our product that would make it more useful or convenient for your purpose.

1808S20004 1-1

1808-CE

SAFETY INSTRUCTIONS

VARIOUS SAFETY DEVICES AND METHODS OF GUARDING HAVE BEEN

PROVIDED ON THIS MACHINE. IT IS ESSENTIAL HOWEVER THAT THE MACHINE

OPERATORS AND MAINTENANCE PERSONNEL OBSERVE THE FOLLOWING

SAFETY PRECAUTIONS. IMPROPER INSTALLATION, MAINTENANCE, OR

OPERATION OF THIS EQUIPMENT COULD CAUSE SERIOUS INJURY OR DEATH.

1. Read this manual before attempting to operate your machine. Never allow an

untrained person to operate or service this machine.

2. Connect the machine to a properly grounded electrical supply that matches the

requirements shown on the electrical specification plate and follow all specifications

of local electrical codes.

3. Disconnect and lockout the machine from the power supply before cleaning or

servicing.

4. Check and secure all guards before starting the machine.

5. Observe all caution and warning labels affixed to the machine.

6. Use only proper replacement parts.

7. Do not wear loose fitting clothing or loose hair when working near this machine.

Shirt tails should be tucked in.

8. Wear proper personal protective safety equipment.

9. Keep Hands away form the moving parts of this machine while it is in operation.

10. In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the machine operating instruction manual.

11. Hazardous energy source: Electricity.

DO NOT USE FOR OTHER THAN ORIGINALLY INTENDED PURPOSE.

1808S20017 2-1

1808-CE

DO NOT USE FOR OTHER THAN ORIGINALLY

INTENDED PURPOSE.

Electrics-Theory of Operation

Power supply to machine is: 2line, 1 ground.

Both lines are protected by a 2 pole circuit breaker.

Various electrical control items are protected by fuses in the electrical enclosure.

Heater roll will only heat when all

Correct power is supplied to machine

Machine is in Reset condition

Emergency stop pushbutton released

Circuit breaker is in reset condition

Heater roll selector is in the “I” on position

Temperature control output contact is closed.

Conveyor is started only when all

Correct power is supplied to machine

Machine is in Reset condition

Emergency stop pushbutton released

Circuit breaker is in reset condition

Fuses are intact and in place

Roll in lowered position (operating handle in sealing position)

*Safety limit switch is activated – In-feed gate in place

*Start pushbutton is momentarily depressed

In the event of a power failure conveyor will only operate after all the above conditions

are met. Conveyor will not automatically restart when power is restored.

the conditions are met;

these conditions are met;

Continued

1808S20017 2-2

Heater roll will heat until any

Power supply interrupted

*Heater roll selector is in the “O” off position

*Emergency stop pushbutton depressed

Circuit breaker is in tripped (open) condition

Fuses opened due to short circuit and/or over-current

*Safety limit switch de-activated – In-feed gate displaced

*Interlock (Reset) circuit activated

Conveyor will operate until any

Power supply interrupted

Roll in raised position (operating handle in idle position)

*Emergency stop pushbutton depressed

Circuit breaker is in tripped (open) condition

Fuses opened due to short circuit and/or over-current

*Safety limit switch de-activated – In-feed gate displaced

*Interlock (Reset) circuit activated

* = requires operator action

of the following conditions are met.

1808-CE

of the following conditions are met.

DECOMMISIONING STATEMENT

Please dispose of all materials as suggested in the appropriate MSDS reports at the end

of this manual, and as required by your state and local regulations.

Remember to always recycle when possible

RECYCLE

.

1808S20017 2-3

1808-CE

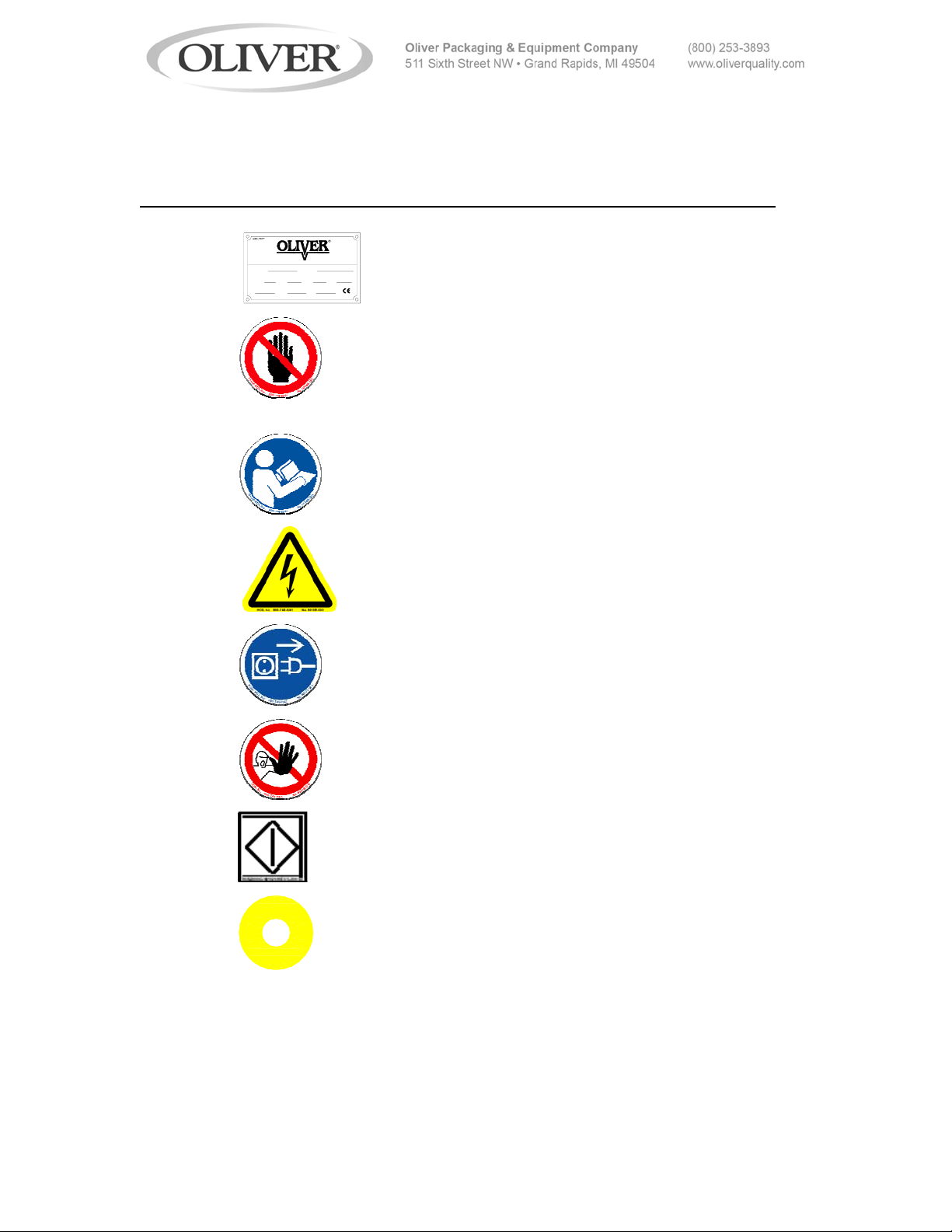

NAMEPLATES PART LIST

ITEM NO SYMBOL PART DESCRIPTION PART NUMBER

Spurkt 3

BAKERY

35804 AR Venray,

PRODUCTS BV

The Netherlands

“OLIVER” 6401-5076

709

MODEL NO. SERIAL NO.

VOLTAGE CYCLE PHASE AMPS

KW MFG’D MASS

711 “STAY CLEAR” 6401-9042

712 6401-9043

701 “CONSULT MANUAL” 6400-3029

703 “ELECTRICAL SHOCK” 6400-5009

713 “UNPLUG BEFORE OPENING” 6402-1028

708 “NO ACCESS FOR UNAUTH…” 6401-4020

858 “START (OF ACTION)” 6401-9041

856 “E-STOP (Yellow Background)” 6400-5011

Continued

1808S20017 2-4

1808-CE

NAMEPLATES PART LIST

ITEM NO SYMBOL PART DESCRIPTION PART NUMBER

844 “HEATED ROLL” 6400-8010

704 “HOT SURFACE” 6400-8020

705 6400-8021

706 6400-8022

851 “RESET” 6401-8002

839 “FEED” 6400-6025

1808S20017 2-5

1808-CE

NAMEPLATES DIAGRAM

1808S20017 2-6

1808-CE

Description

The OLIVER Model 1808-CE Tray Sealer has been designed and manufactured to

provide a machine of very high quality, yet with a cost effective approach to producing

film lidded trays. The Model 1808-CE Tray Sealer is designed to heat seal film to

paperboard and thermoplastic trays at speeds of up to 25 trays per minute. The

machine can be operated wherever an adequate power outlet is available (see power

requirements). The machine consists of a continuous motion conveyor system, a film

feed station, a heated sealing roll and a film cutter unit. The machine is supplied with

casters for ease of relocating. Its design will provide years of efficient, trouble-free

operation requiring a minimum of maintenance.

The Model1808-CE Tray Sealer is of stainless, plated, and painted steel construction for

easy cleaning and maintenance.

Oliver Products Company, who has a reputation of serving the Food Industry for over 70

years, backs this equipment.

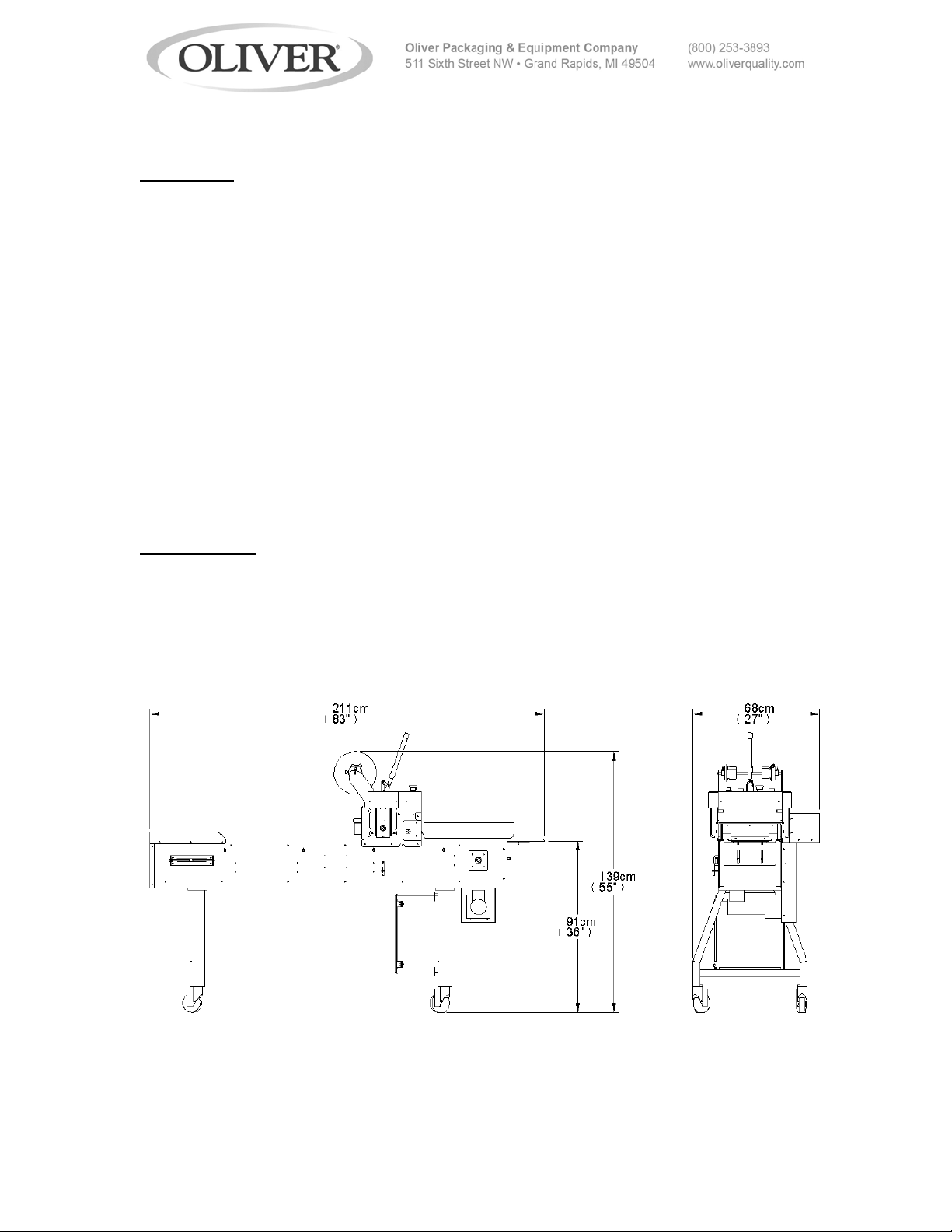

Specifications

Space Requirements:

Model 1808-CE (All Dimensions are Approximate)

Continued

1808S20018 3-1

1808-CE

Standard Electrical Options: (Others consult factory).

1 Phase, 50-60Hz, 208VAC, 10 Amps

Or

1 Phase, 50-60Hz, 220-240VAC, 10 Amps

Net Weight

154 kg (340 lbs.) (approximate)

Shipping Weight

181 kg (400 lbs.) (approximate)

1808S20018 3-2

1808-CE

INSTALLATION INSTRUCTIONS

INSPECTION

Upon receipt and prior to uncrating, inspect the exterior of the crate for damage. If

damage is noted, indicate damage on the Freight Bill and immediately contact the

Freight Carrier and notify them of the damage. Have a freight claim filed. This must be

done at the Recipients location and not at the Shipper’s location.

UNCRATING

Remove the corrugated carton from the skid by removing the nails that secure the carton

to the skid and carefully lift the carton up and over the machine. After removing the

carton from the machine, inspect for visible damage. If damage is noted, immediately

contact the freight company and file a concealed damage freight claim.

1808S20007 4-1

1808-CE

OPERATING INSTRUCTIONS

NOTE: Conveyor motion can be stopped at any time by lowering the operating

handle, or pushing the E-Stop Pushbutton (Emergency only). The E-Stop button

will also turn off power to heaters. Under normal operating conditions, conveyor

is stopped by Lowering Operating Handle.

Before operating the machine make sure it is plugged into a grounded 208-240V.A.C.

outlet rated for 10 AMPS. Once the machine is plugged in, the conveyor can be run

using the “Operating Handle” along with the “Start” pushbutton.

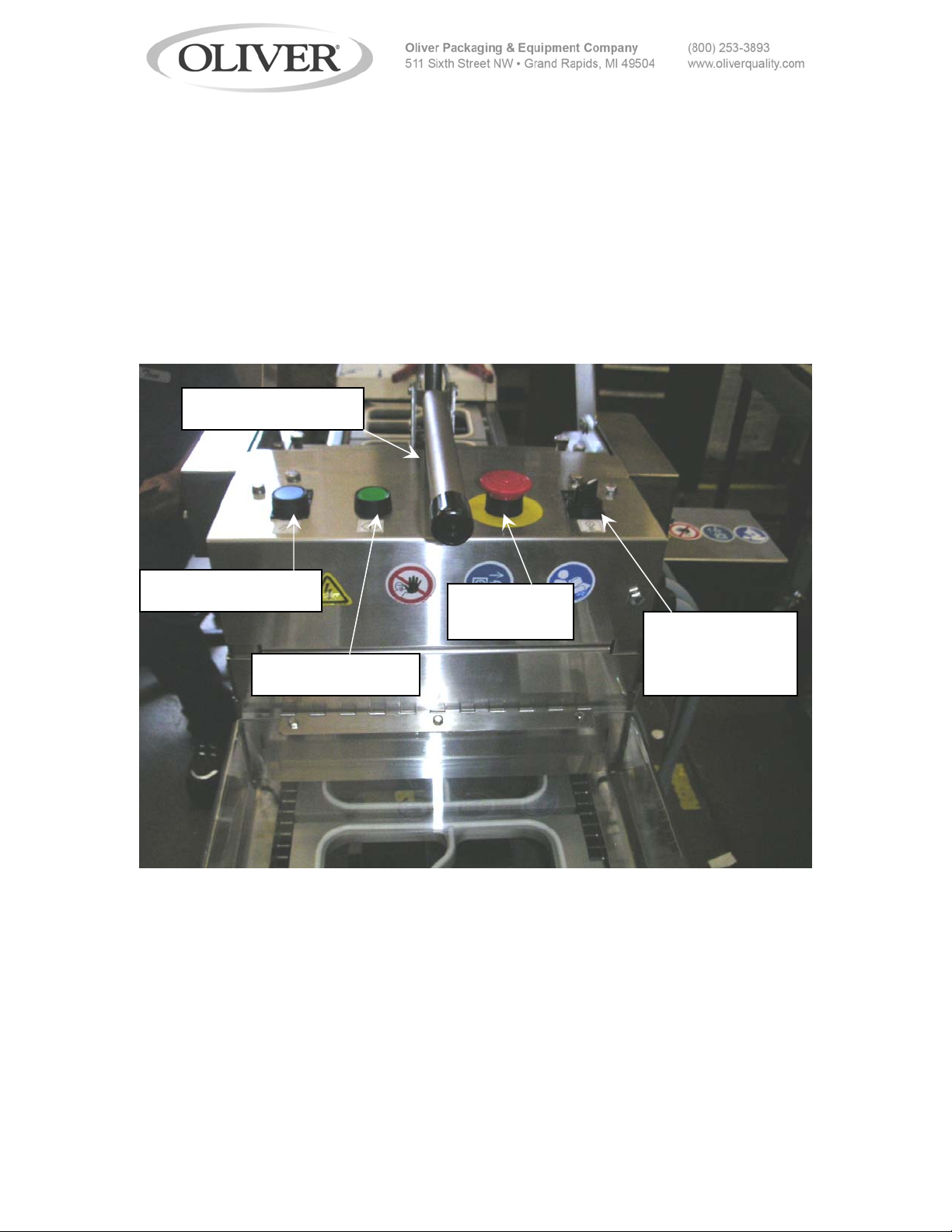

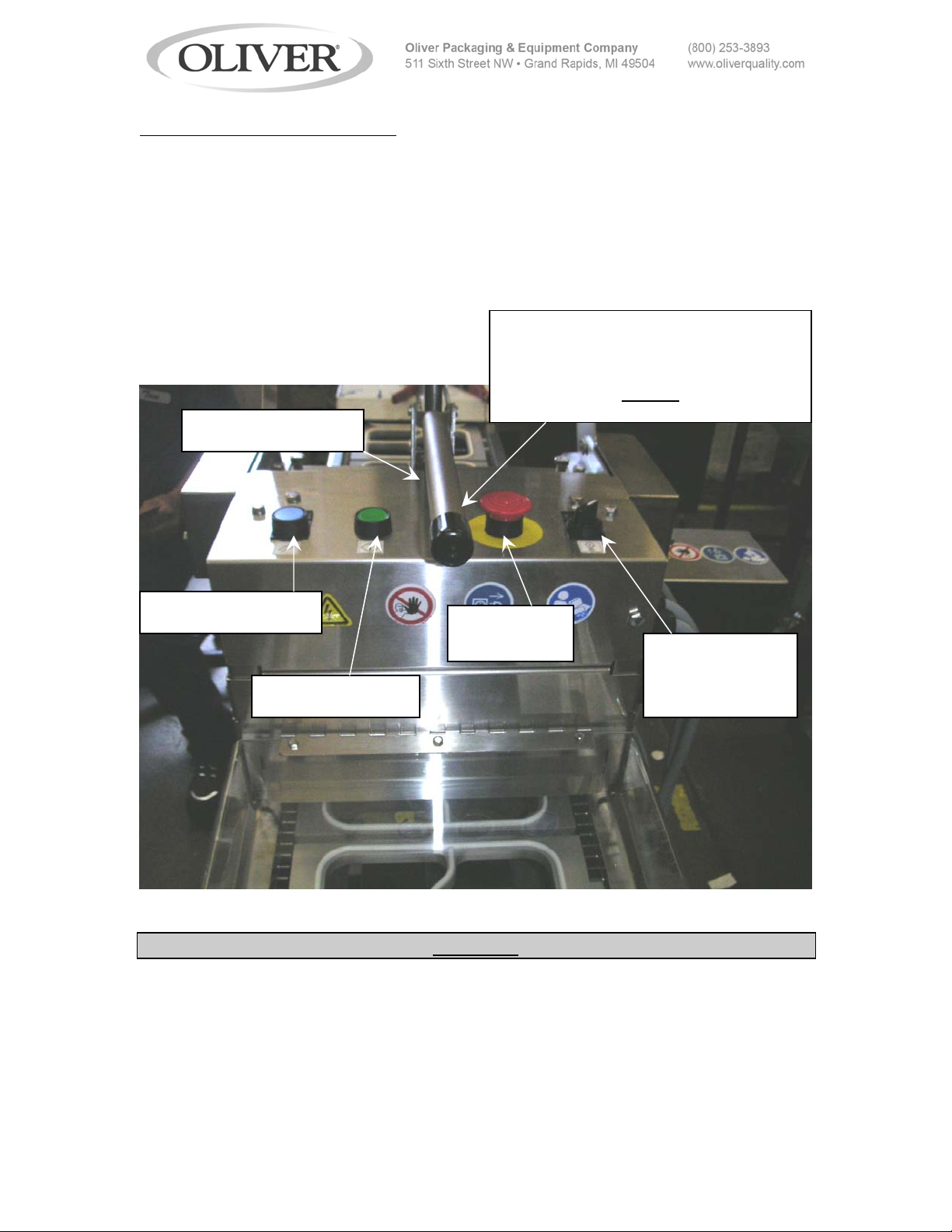

Operating Handle

Reset Pushbutton

Start Pushbutton

Continued

E-Stop

Pushbutton

Heated Roll

On/Off Selector

Switch

1808S20019 5-1

1808-CE

The speed control knob is used to adjust the machine speed by turning clockwise to a

higher number for higher speed and counter clockwise to a lower number for lower

speed.

Before you are ready to run production, turn the Heated Roll “ON/OFF” ( I/O) switch to

the “ON” ( I ) position. This will supply power to the heater elements in the heat seal roll

to bring it up to temperature. You should turn the power on approximately 20 minutes

prior to the time you want to begin production. This will give the heat seal roll ample

time to heat up. At the end of the day, turn the “ON/OFF” ( I/O ) switch to the “OFF” ( O )

position.

Continued

1808S20019 5-2

1808-CE

(“OPERATINTING THE MACHINE “ CONTINUED)

The conveyor can be run while the heated roll “ON/OFF” switch is in the “OFF” position.

This allows for cleaning the conveyor without having the heat seal on. It is also a good

idea to unplug the machine when it will not be used for a lengthy period of time.

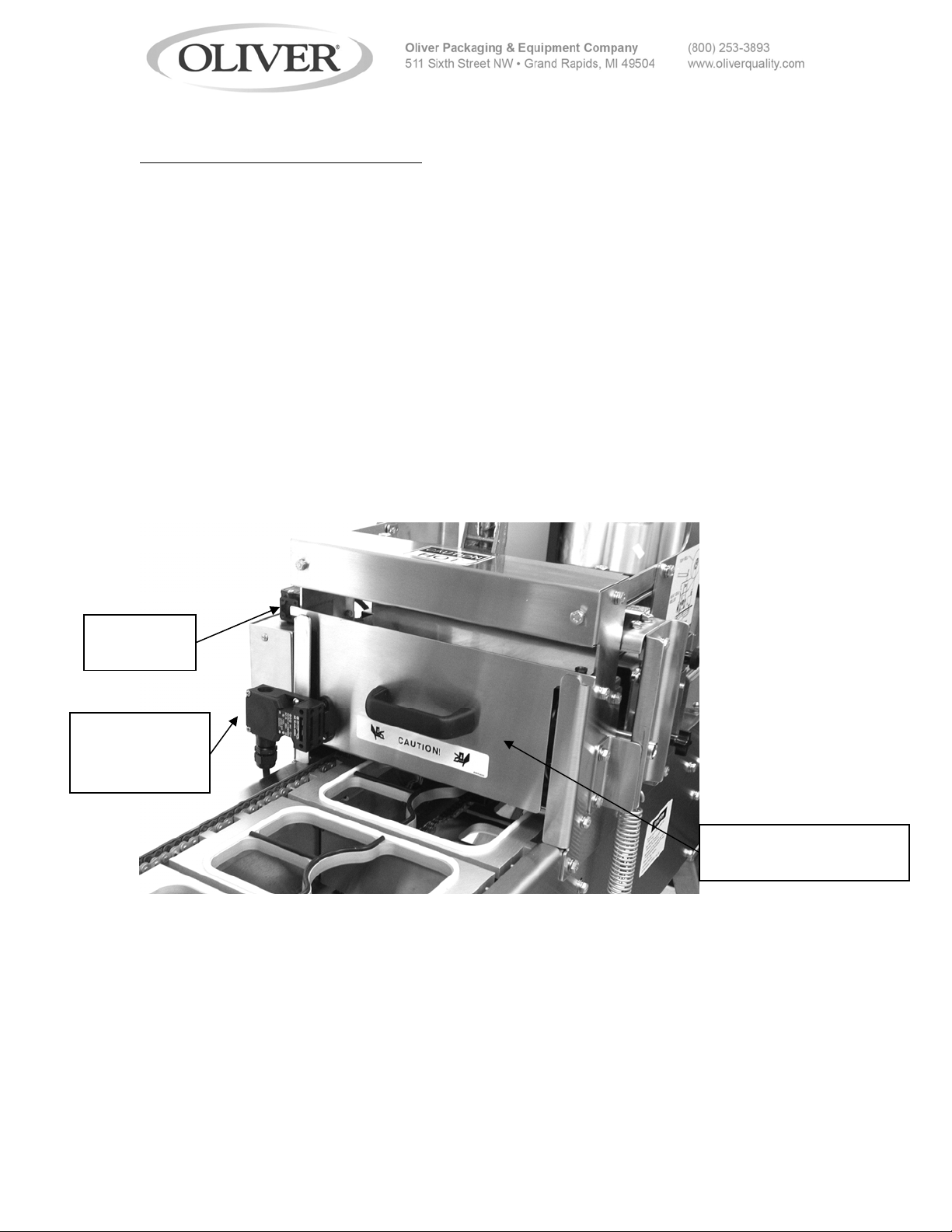

The “RESET” switch is used to reset the machine if the guard interlock switch has been

tripped or the E-Stop button is pressed. When this situation occurs, the “RESET” switch

lights up indicating that one of the switches has been has activated. Set the guard back

to its proper position, make sure E-Stop button is released (turn anti-clockwise), then

push the “RESET” switch to resume operation. If the guard has been repositioned

properly, and E-Stop button is released (turn anti-clockwise), then “RESET” switch is

pressed, the light on the switch will go out. The guard can be removed by pushing

forward on the handle and lifting up and out. To replace the guard, drop the guard

fingers into the notches and pull the handle so the interlock engages. See the photo

below for the location of the guard and interlock switch.

GUARD

FINGERS

GUARD

INTERLOCK

SWITCH

HEAT SEAL

ENTRANCE GUARD

`

1808S20019 5-3

(“OPERATING THE MACHINE” CONTINUED)

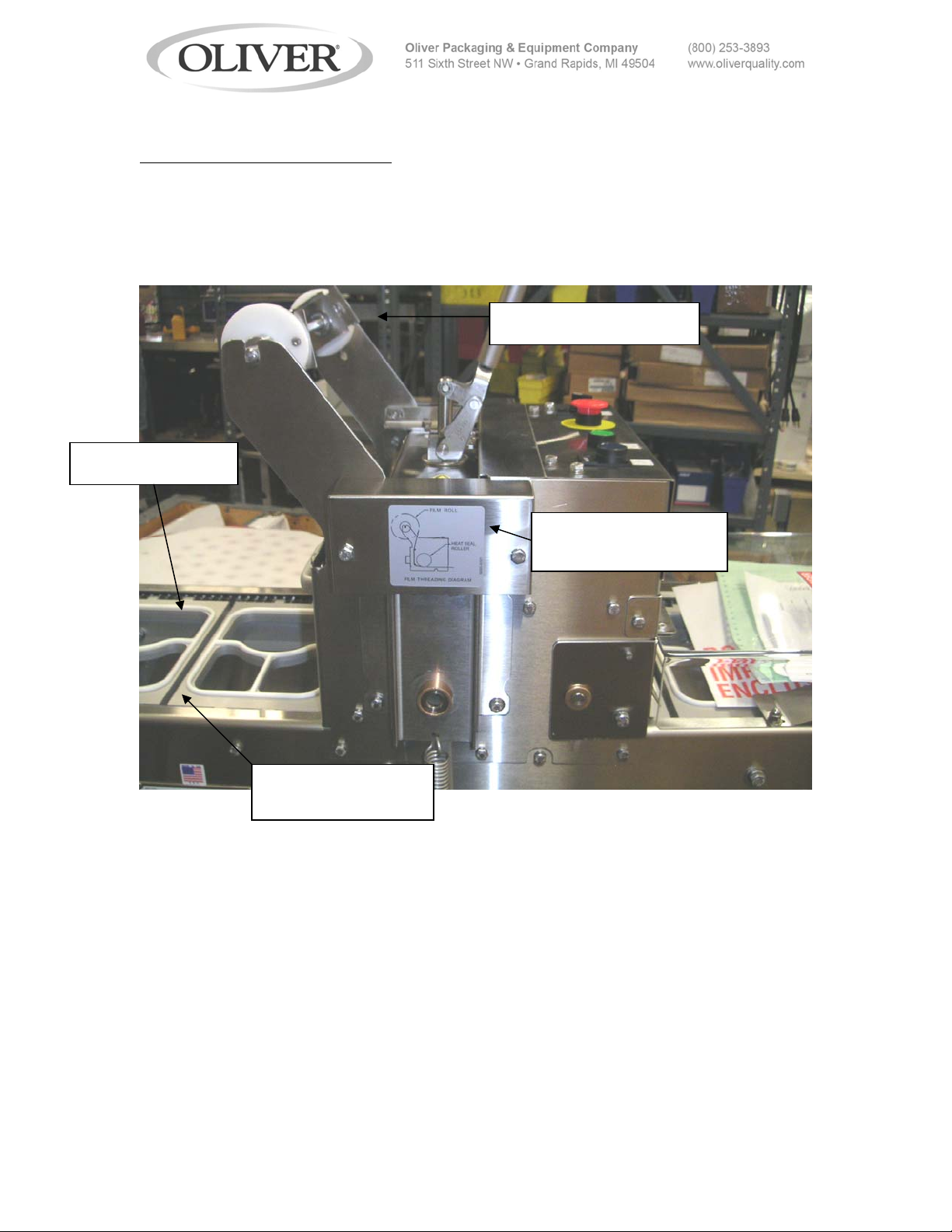

Filled trays are manually placed in the conveyor of the machine. Film is fed from the film

supply roll which must be threaded onto the machine as illustrated on the “Film

Threading Diagram” which is shown in the photo below. Pull enough film so the film can

be pushed down in the gap between the tray carriers. The film should hang down

through the carriers about 4 to 5 inches.

TRAY CARRIER

1808-CE

FILM SUPPLY ROLL

FILM THREADING

DIAGRAM

GAP BETWEEN

TRAY CARRIERS

1808S20019 5-4

1808-CE

(“OPERATING THE MACHINE” CONTINUED)

The machine is started by lifting the operating handle and pressing the START “I”

pushbutton. This should be done in a swift manner which allows the heat seal roll to

come into contact with tray and film quickly as the conveyor starts moving. This

procedure prevents voids in the seal area during and stopping. Also, when lowering the

handle to stop the machine, it should be done in swift manner as well.

LIFT HERE, THEN PRESS

“START” PUSHBUTTON TO

START CONVEYOR

NOTE:

Operating Handle

Reset Pushbutton

E-Stop

Pushbutton

Heated Roll

On/Off Selector

Start Pushbutton

Switch

CAUTION

Avoid leaving the heater roll in the lowered position with the conveyor not

moving. This will cause damage to the machine and any trays that are under the

heated roll.

1808S20019 5-5

1808-CE

(“OPERATING THE MACHINE” CONTINUED

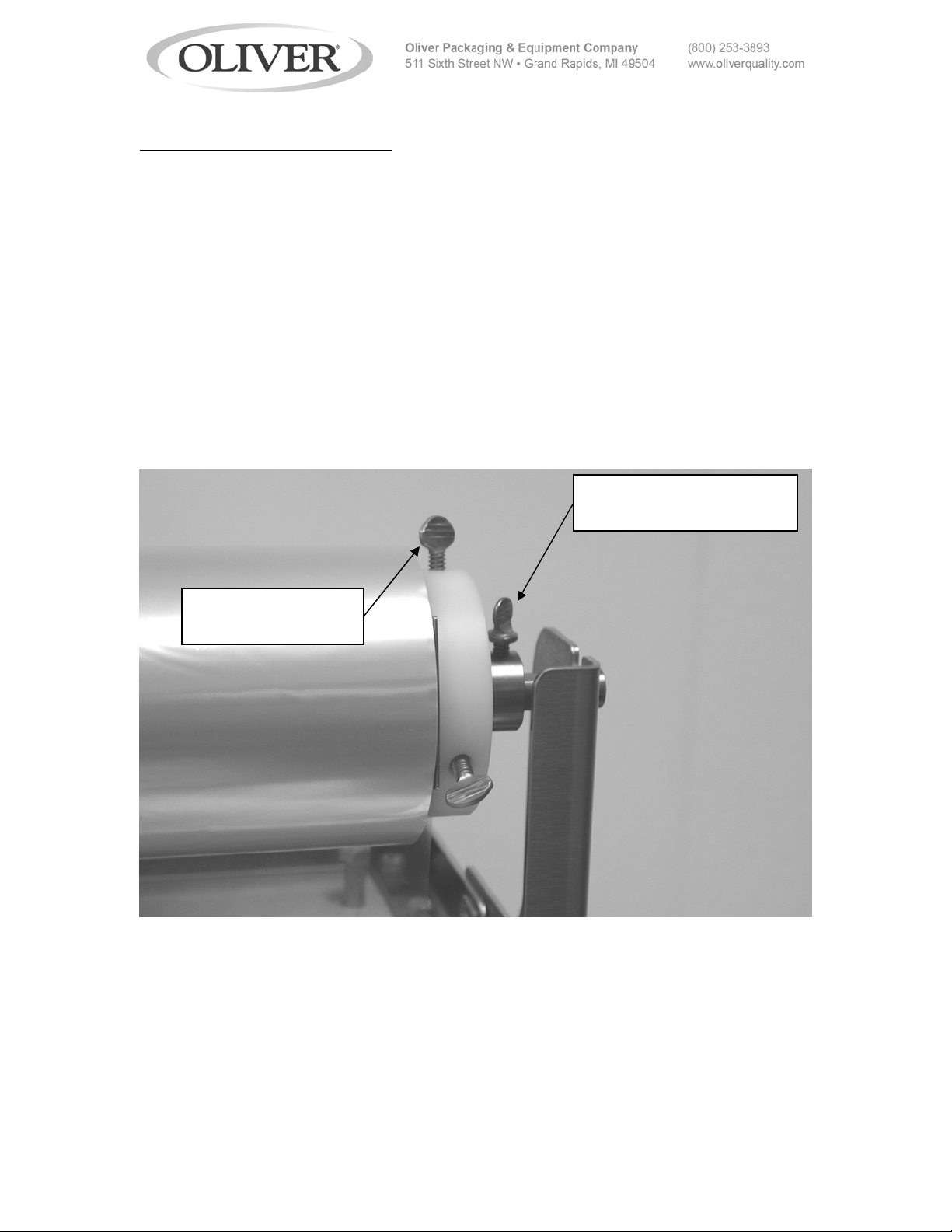

After a few sealed trays have come off the end of the machine, check to see if the film is

centered from side to side on the trays. If it is not, the film roll needs to be moved to one

side or the other on the film mandrel. There are thumb screws in the stainless steel

collars on each side of the film mandrel. First loosen the thumb screw on the side which

the film roll needs to move toward and move that collar about one half as far as you think

the film is off center and tighten the thumb screw. Then loosen the thumb screw on the

other collar and move the film roll holder up against the film roll core and tighten the

screw. After getting the film centered on the trays, check to see if the film is sealing to

the trays without excessive wrinkles. If there are excessive wrinkles, it might be that

there is not enough tension on the film roll. This can be adjusted with the three thumb

screws on the plastic film roll holder. Turning the screws clockwise will increase the film

tension. If the film tension is too tight and the film comes off of the roll too hard, back the

screws off by turning anti-clockwise.

SIDE TO SIDE FILM

ADJUSTMENT SCREW

FILM TENSION

SCREWS

1808S20019 5-6

1808-CE

(“OPERATING THE MACHINE”CONTINUED

)

As the trays come off the end of the machine, they are fed out of the tray carriers onto

the discharge table. This table can be adjusted in and out and, up and down. These

adjustments are shown in the photo below.

CAUTION

When making either of these adjustments, care must be taken to insure that the

discharge table does not get adjusted too close to the tray carriers. Doing so can cause

damage to the machine.

The purpose of this adjustment is to get the trays to smoothly exit the machine as they

make the transition from the tray carriers onto the table. After the trays are on the table,

each tray will be pushed off the table by the next tray.

IN AND OUT

ADJUSTMENT

UP AND DOWN

ADJUSTMENT

1808S20019 5-7

Loading...

Loading...