Page 1

OKI C7000 Series and OKI C9000 Series

Colour Guide

Page 2

Preface

EEC compatibility

Every effort has been made to ensure that the

information in this document is complete, accurate, and

up-to-date. Oki assumes no responsibility for the results

of errors beyond its control. Oki also cannot guarantee

that changes in software and equipment made by other

manufacturers and referred to in this guide will not

affect the applicability of the information in it. Mention

of software products manufactured by other companies

does not necessarily constitute endorsement by Oki.

Copyright 2000 by Oki. All rights reserved.

Oki is a registered trademark of Oki Electric Industry

Company Ltd.

Energy Star is a trademark of the United States

Environmental Protection Agency.

Microsoft, MS-DOS and Windows are registered

trademarks of Microsoft Corporation.

This product complies with the

requirements of the Council

Directives 89/336/EEC (EMC) and

73/23/EEC (LVD), as amended

where applicable, on the

approximation of the laws of the

member states relating to

Electromagnetic Compatibility and

Low Voltage.

Energy Star

As an Energy Star Partner, Oki

has determined that this product

meets the Energy Star guidelines

for energy efficiency.

Universal Serial Bus

This printer is fitted with an

industry standard universal

serial bus (USB) data interface.

ii Colour Guide

Page 3

Table of contents

English

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

EEC compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . ii

Energy Star . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Universal Serial Bus . . . . . . . . . . . . . . . . . . . . . . . . ii

Table of contents. . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Colour Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Use of colour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Colour perception . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Electromagnetic spectrum. . . . . . . . . . . . . . . . . . . . .5

Primary and secondary colours. . . . . . . . . . . . . . . . .6

Additive and subtractive primaries . . . . . . . . . . . . . .7

Additive primaries. . . . . . . . . . . . . . . . . . . . . . . .7

Subtractive primaries . . . . . . . . . . . . . . . . . . . . .8

Neutral colours . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Colour complements. . . . . . . . . . . . . . . . . . . . . . . .10

Colour wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Problems using colour . . . . . . . . . . . . . . . . . . . . . .12

Colour management systems . . . . . . . . . . . . . . . . .13

Specifying colour . . . . . . . . . . . . . . . . . . . . . . . . . .14

Printing colour . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Colour registration . . . . . . . . . . . . . . . . . . . . . . . . .17

Colour adjustments . . . . . . . . . . . . . . . . . . . . . . . . .18

OKI C7000/C9000 Printer Drivers . . . . . . . . . . . . . 19

Colour management. . . . . . . . . . . . . . . . . . . . . . . . 20

Windows and Macintosh PostScript driver . . . . . . 21

Windows colour matching . . . . . . . . . . . . . . . . 21

Image colour matching. . . . . . . . . . . . . . . . 21

Black finish. . . . . . . . . . . . . . . . . . . . . . . . . 21

Colour halftone. . . . . . . . . . . . . . . . . . . . . . 22

Image colour rendering style . . . . . . . . . . . 22

Macintosh colour matching . . . . . . . . . . . . . . . 22

Colour/greyscale. . . . . . . . . . . . . . . . . . . . . 22

Black and white . . . . . . . . . . . . . . . . . . . . . 22

ColorSync colour matching . . . . . . . . . . . . 23

PostScript colour matching. . . . . . . . . . . . . 23

Windows ICM . . . . . . . . . . . . . . . . . . . . . . . . . 23

No colour matching . . . . . . . . . . . . . . . . . . . . . 24

Print in greyscale . . . . . . . . . . . . . . . . . . . . . . . 24

Print colour separations . . . . . . . . . . . . . . . . . . 24

Windows PCL driver . . . . . . . . . . . . . . . . . . . . . . . 25

Auto colour. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Manual colour . . . . . . . . . . . . . . . . . . . . . . . . . 25

Halftone type . . . . . . . . . . . . . . . . . . . . . . . 25

Colour setting . . . . . . . . . . . . . . . . . . . . . . . 26

Manual adjustment . . . . . . . . . . . . . . . . . . . 26

Print colour swatch . . . . . . . . . . . . . . . . . . . 26

Preface iii

Page 4

Monochrome . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Black finishing in photo printing . . . . . . . . 27

Monochrome dithering . . . . . . . . . . . . . . . . 27

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

iv Colour Guide

Page 5

Colour Printing

Introduction

This Colour Guide has been conceived to provide you

with a broad overview of issues related to colour

printing, in order that the best use of colour be made in

the software applications used. The text is designed to

describe the technical issues in a manner that can be

understood by anyone involved in the preparation of

colour documents.

Please familiarise yourself with the user documentation

provided, which describes operational details of the

OKI printer setup and configuration for specific

options.

OKI are sure that you will find this colour printer an

excellent part of printing solution. If you have any

comments with regard to the content of this document,

then please let us know through your local OKI

representative.

English

Colour Printing 1

Page 6

Use of colour

Recent advances have brought colour to the desktop in

a way that could not have been imagined a decade ago.

It has been shown that using colour in print can increase

memory retention by up to 65% and readership by as

much as 40%, not to mention the added impact that it

provides. As colour becomes more and more accessible

it is essential to understand the importance of colour

and how best to use it.

People use colour for different reasons; it has become a

very important tool and is used widely in marketing to

grab attention and communicate ideas and, when used

effectively, can alter the viewer’s perception.

Colour can be used in text documents as well as for

graphics. It can be used to emphasise headings or

particular words which would otherwise be lost in the

vast array of black and white. Colour adds impetus to a

company logo and can be as important as the design

itself. The use of colour also makes a document easier

to comprehend and can convey information at a glance.

For example, using red to highlight negative figures in

a spreadsheet.

The use of colour should be considered an integral part

of any presentation or document and not added at the

end as an afterthought.

2 Colour Guide

Page 7

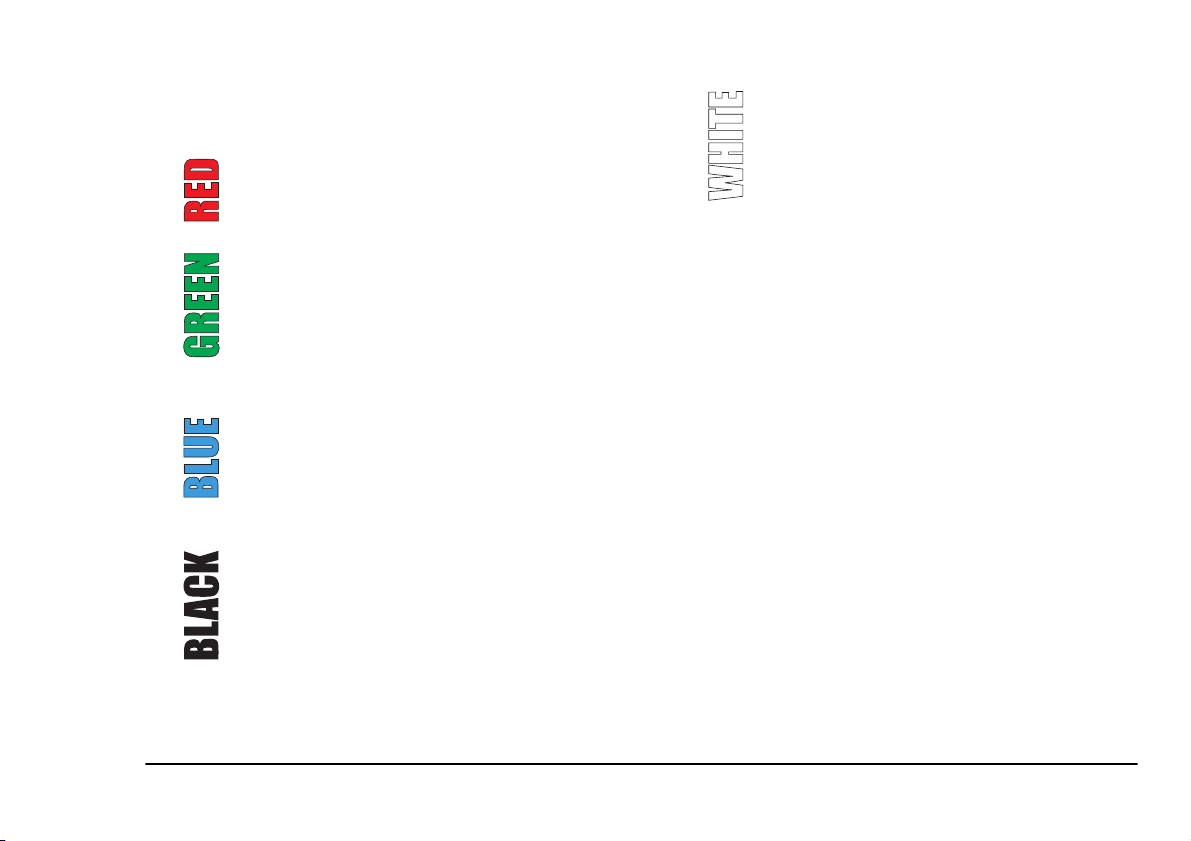

The following examples list some widely used colours

and their significance:

This is a very powerful and passionate colour.

The power and passion it portrays has made it

a favourite for many exotic sports cars.

Unlike red, green is a very calming and

‘natural’ colour. It signifies trees, grass and

plant life in general. It is soothing and perhaps

associated with a stroll in a field. As well as

the calming side of green, it is also the colour

of envy.

A cool and refreshing colour. It is the colour of

summer skies and a clear blue sea which

produces a calming effect. Dark blues are

associated with wealth and dignity and also

have names that suggest these virtues – Royal

blue, Navy blue, etc.

This is really an absence of colour and the

contrast that it provides with other colours has

made it one of the most widely used. Black is

usually associated with night and darkness

English

The colour of pure snow and in itself suggests

purity. It is used in hospitals to portray an air

of cleanliness and sterility. Like black, white

can be paired with most colours and is

therefore very popular.

In short, colours can be used effectively to send their

own message, regardless of the message that they are

supporting. The colours used within a message are seen

and automatically decoded before the message itself

has been read. This underlines the importance and

effectiveness of using colour.

Colour Printing 3

Page 8

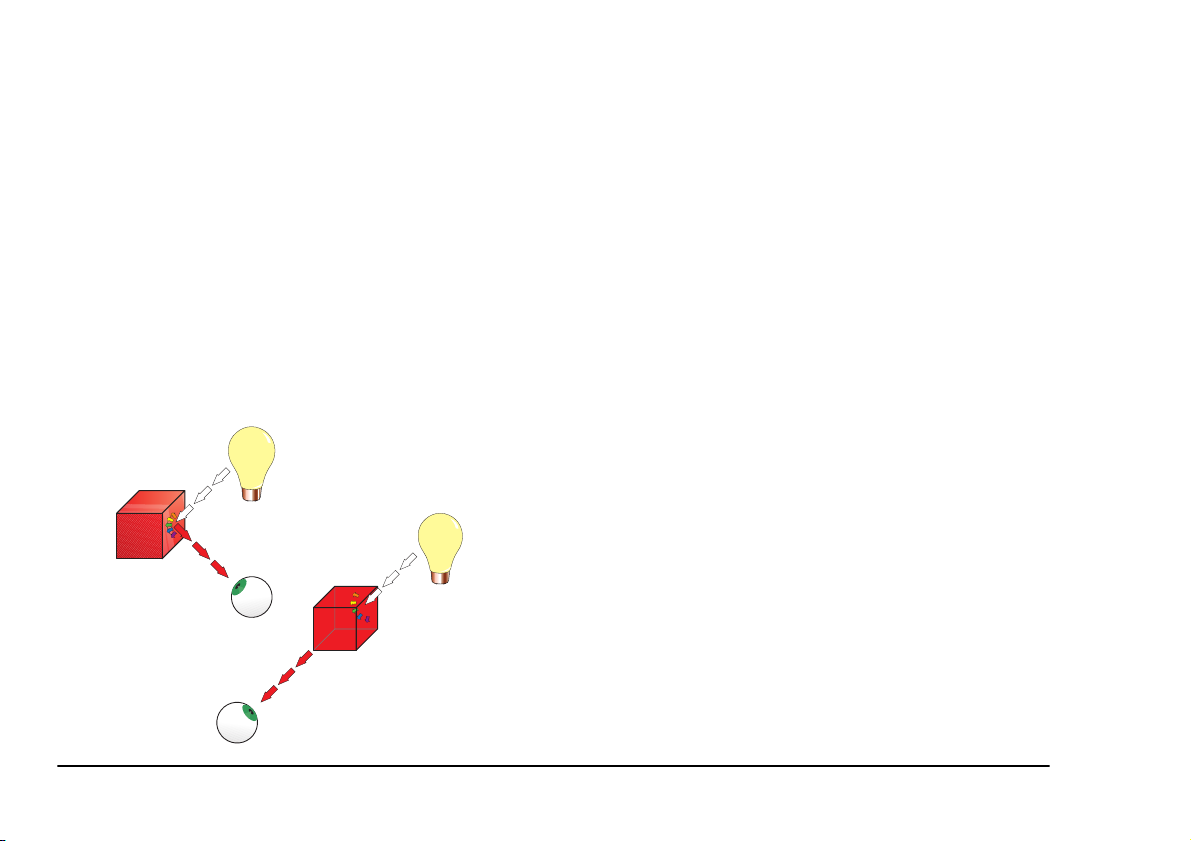

Colour perception

Colour does not exist by itself but is dependent on the

presence of:

• a light source

• an object

•an observer

Our perception of colour involves light from a source

being reflected off, or transmitted through, an object

and entering the eye.

Light interacts with an object and what we see is the

final result of that interaction. An object can reflect,

transmit or emit light. A reflective object absorbs some

sections of the visible spectrum and reflects the rest.

What we see is the reflected portion. An object

removing wavelengths at the ultra violet end for

example, will appear red in hue. A transmissive object

allows light to pass through it and may absorb a section.

The colour of the object in this case will depend upon

the wavelengths of light that are allowed to pass

through. An emissive object emits light and the

appearance of the light will depend on the wavelengths

emitted. In short, the composition of the light and its

interaction with the object will define the colour we see.

4 Colour Guide

Page 9

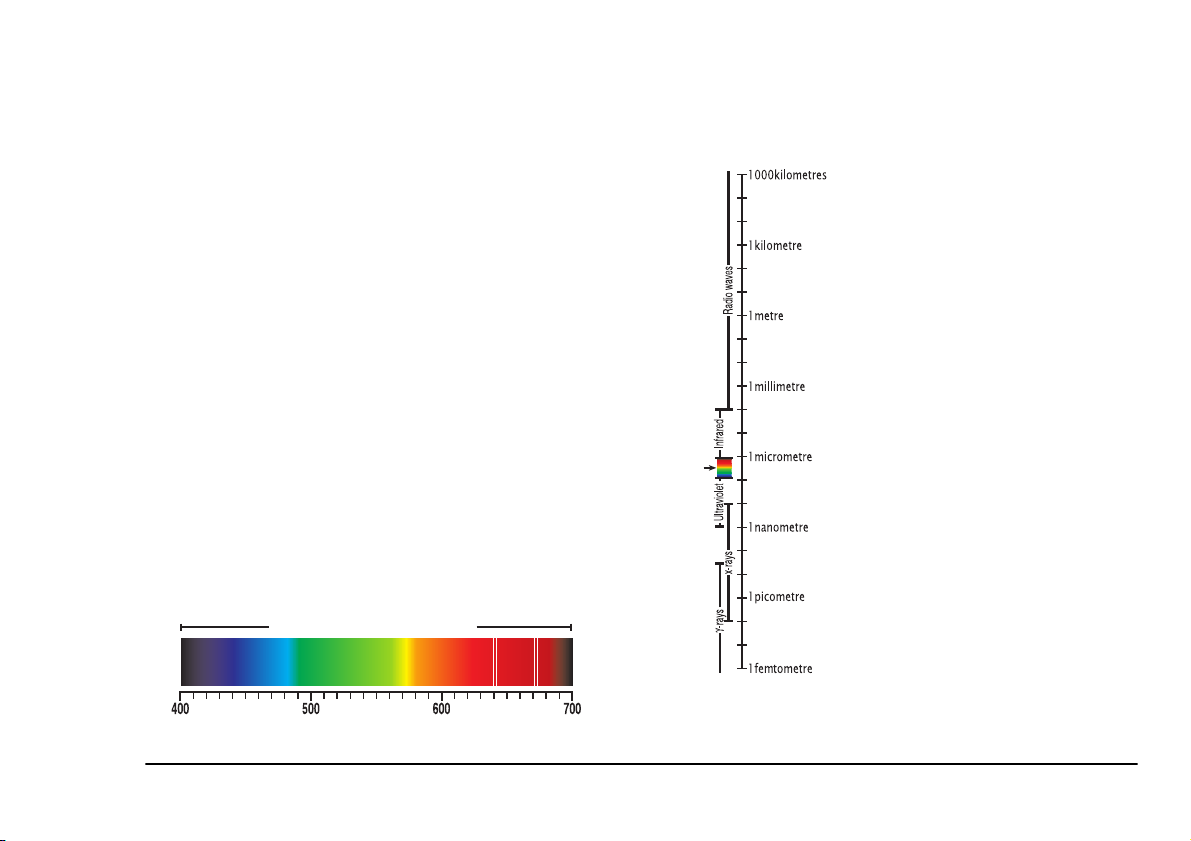

1 micrometre= 1×10-6 metre

(0·001 mm)

1 nanometre= 1×10

-9

metre

(0·000001 mm)

1 picometre= 1×10

-12

metre

(0·000000001 mm)

1 femtometre= 1×10

-15

metre

(0·000000000001 mm)

Visible light spectrum

Electromagnetic spectrum

All colours we can see fall into what is the visible part

of the electromagnetic (EM) spectrum. The visible

portion of the EM spectrum is minute and although we

are ‘blind’ to the rest, the part we can see has a

significant effect on our perception of everything

around us.

If light containing all visible wavelengths in balanced

quantities is detected, then white light is seen. If there

is an absence of all wavelengths then black is

perceived. The infinite combination of different

wavelengths give rise to what we perceive as colour. So

colour is light.

When our eyes receive information containing a strong

content of a particular wavelength then we interpret that

as a colour. A strong content around 700 nm (0.0007

mm wavelength) is interpreted as red and at the other

end of the scale, 400 nm is interpreted as violet.

Visible light spectrum

English

Colour Printing 5

Page 10

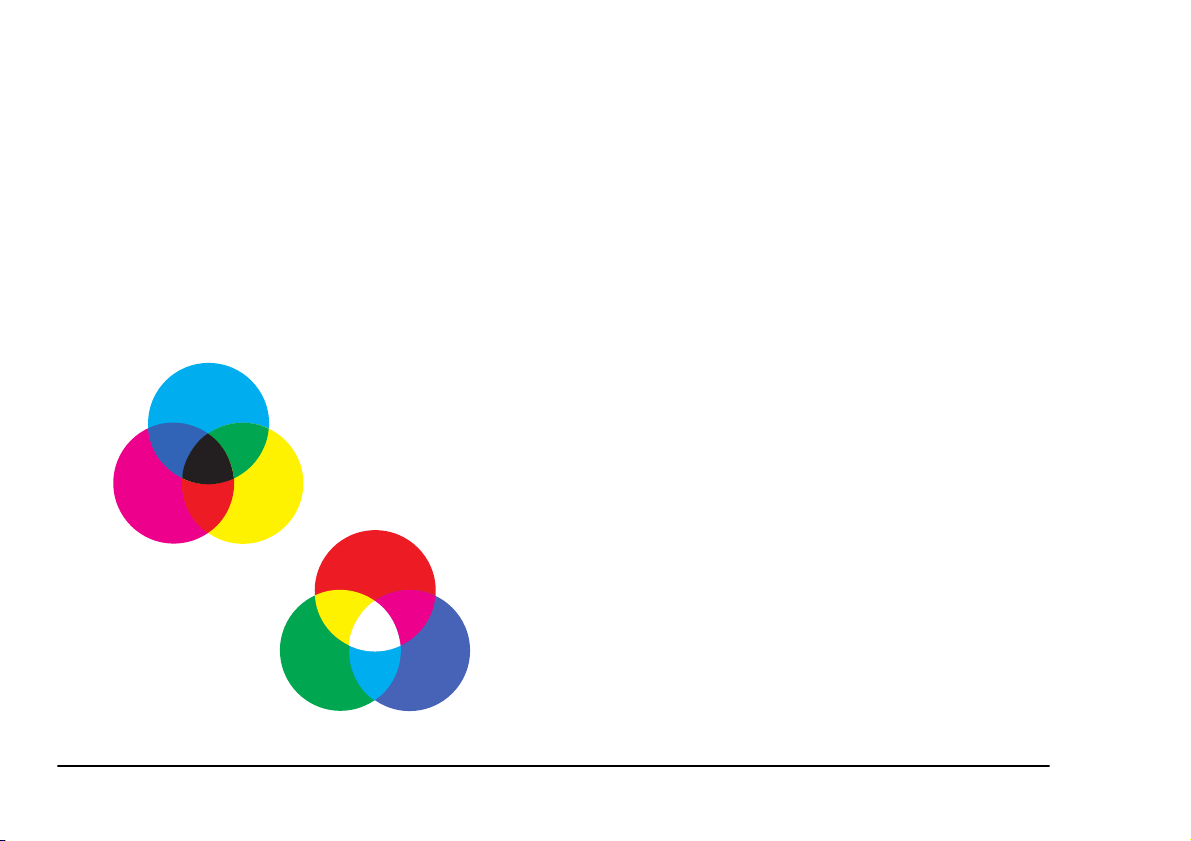

Primary and secondary colours

In theory, all colours can be made up from a very small

group of ‘colour elements’. There are three primary

colours, and all other colours can, in theory, be obtained

by mixing the primary colours in varying proportions.

Mixing two primary colours in equal proportions

produces what is known as a secondary colour.

PROCESS

DISPLAY

6 Colour Guide

Page 11

Additive and subtractive

standard dot display Trinitron™ display

primaries

Primary colours can be split into two categories which

are termed additive and subtractive. It is important to

note the difference between mixing additive primaries

and subtractive primaries. For example mixing red and

green inks will produce a ‘muddy’ brown, whilst red

and green light mixes to give yellow. So in which way

do the two models differ ?

GREEN YELLOW

CYAN

English

Additive primaries

Video technology such as computer monitors and

television screens use the additive model. The additive

primaries are Red, Green and Blue (RGB). Starting

from black (lack of colour) and adding red, green and

blue in equal quantities will generate shades of grey

with white being generated with full, balanced

intensities of all three. Mixing the three colours in

different quantities will generate intermediate colours.

RED

BLUE MAGENTA

Colour Printing 7

Page 12

Subtractive primaries

Cyan, Magenta and Yellow (CMY) are known as the

subtractive primaries and are commonly used in

printing processes. In this case we start with a white

background (usually paper) and add translucent inks of

cyan, magenta and yellow to subtract certain

wavelengths of light. For example, cyan ink on a page

appears to be this colour because the ink removes

components of red light and reflects green and blue,

which we perceive as cyan.

In theory, a combination of the three subtractive

primaries will produce black. In practice however,

pigments used in inks are not perfect and usually give

rise to a dark green/brown. For this reason, in many

colour output devices, a separate black ink is used to

produce greys and black (in shadows and black text for

example). This is the CMYK model and is the method

most widely used in the colour printing and printer

industry. The OKI C7000 Series and OKI C9000 Series

of printers use separate cartridges of cyan, magenta,

yellow and black toner to generate high definition

colour images for the workgroup or networked

environment.

Traditional CMYK print

8 Colour Guide

Page 13

Neutral colours

Although the term ‘colour’ is applied, neutral colours

do not have properties of hue or saturation. They are

described in terms of lightness only. The neutral

colours are black and white and all shades of grey in

between. A balanced mix of cyan, magenta and yellow

yields a neutral colour or black (in theory). The same

effect can be achieved with the additive primaries by

having an equal mix of red, green and blue light.

English

Colour Printing 9

Page 14

Colour complements

Complements are pairs of colours that combine to

produce a neutral colour. It can be seen from the above

that balanced quantities of all three primaries produce a

neutral. Mixing two primaries produces a secondary

colour. Mixing this secondary colour with the

remaining primary colour produces a neutral colour.

For example:

CYAN + MAGENTA + YELLOW = NEUTRAL

- red (magenta + yellow)+ cyan= NEUTRAL

- green (yellow + cyan)+ magenta= NEUTRAL

- blue (cyan + magenta)+ yellow= NEUTRAL

This relationship can be applied to all colours and is

shown in more detail in the following section.

10 Colour Guide

Page 15

Colour wheel

English

The relationship between colours can be best shown on

what is known as a colour wheel. The hue value of a

particular colour is expressed in degrees. Red for

example is at 0° and green and blue are located at 120°

and 240° respectively. The subtractive primaries,

yellow, cyan and magenta are located at mid points

between these.

The colour wheel shows the following relationships:

• the additive primaries are displaced by 120° from

each other.

• the subtractive primaries are displaced by 120°

from each other.

• each colour is a secondary colour of the two

colours either side of it. For example, mixing

equal quantities of yellow and magenta will

produce red.

• a colour is directly opposite its complement.

We can continue to mix neighbouring colours on the

colour wheel to produce further, intermediate colours.

The number of colours on the colour wheel now

doubles to twelve (as shown below). Repeating the

procedure a number of times produces a colour wheel

with subtle changes of hue from neighbour to

neighbour.

Colour Printing 11

Page 16

Problems using colour

As already explained, a computer monitor, where an

image is first viewed, and a printer, which produces the

final document, use different methods to generate

colours. Indeed they are based around a different set of

primaries (RGB for monitors, CMYK for printers).

Monitors do not generate a full range of perfect colours

and neither do printers. There is a limit on how many

colours a monitor or printer can generate. This is known

as a device’s colour gamut. Some colours can be

reproduced by both devices, while others can be

displayed on a monitor but cannot be printed or vice

versa. This in practice may lead to a colour print not

resembling the original on-screen image. So what has

happened?

Images (graphics and text) can be captured through

scans or digital photography, or input directly into the

PC via applications programs. However the original

image is obtained, it will be displayed and manipulated

in RGB colour space (on-screen) and finally converted

to CMYK for print. Each of these processes requires

data conversion/manipulation. An image seen on a

computer monitor relies on the monitor’s ability to

reproduce the image and represent colours within it.

Adjustments such as brightness, colour and contrast

also tailor the image to the preference of the viewer

rather than a display of true colour. The data sent to the

printer may not be adjusted to allow for imperfections

in the inks used.

12 Colour Guide

Page 17

Colour management systems

English

Colour management systems (CMS), such as those

found in the OKI C7000 Series and OKI C9000 Series

printer drivers, allow for any mismatches that may

occur between the RGB and CMYK conversion

process. Colour matching systems go a long way to

ensuring a better match between the input data and

printed result, but cannot always allow for monitor

adjustment or a variation in paper stock. Paper can

sometimes appear blue or cream in hue which will have

an effect on the light reflected from the page and

therefore change the appearance of some colours. The

texture of the paper used will affect the way that light is

scattered and may also result in patches of light or

dense colour. It is therefore best to find and adopt a

paper that provides you with the best results. This of

course may be a process of trial and error.

Although colour has its obvious benefits, it has also

created a whole new set of problems that need to be

dealt with:

• It is important not to go overboard and add dashes

of colour without thought as this will

undoubtedly have a negative effect on the whole

purpose of using colour.

• Using colours which are considered garish will

also affect the way in which your document or

presentation is perceived.

• The proximity of colours is also an important

factor and it is best to consider the result when

certain colours are paired.

To minimize any problems it is important to use colour

with pre-planning and a great deal of care. If specific

colours are of paramount importance (such as those in

a company logo) then it is best to print these colours

beforehand and note the composition that gives the

closest match to the required colour. Then use the

component amounts regardless of what is displayed on

the monitor.

Colour Printing 13

Page 18

Specifying colour

There are many different ways to specify colour and

there are many different models to cater for this. The

colour wheel, as already shown, is a two-dimensional

view of the HSL model which is based on Hue,

Saturation and Lightness as components for specifying

colour. The third dimension in this case is lightness and

describes the tendency towards black or white.

Commonly used models are:

•HSL

•HSB

•CMY(K)

•RGB

• CIE, CIELab, CIELuv

•YCC

Each of the models have their benefits and

disadvantages and are useful in particular situations.

Most applications will have support for the RGB model

which (along with CMYK) is perhaps the simplest to

use. This model is used to specify colours by varying

the proportions and levels of the red, green and blue

components.

The amount of red, green and blue present in a colour is

usually expressed as a number from 0 to 255. Less

HUE

commonly it may also be expressed as number between

0 and 65535 or as a percentage. Converting between the

systems is straight forward and a few examples are

given below:

Example:

To achieve a colour that is described as 100% red, 50%

Green and 40% blue…

255 Colour scale:

100/100× 255 = 255 red

50/100× 255 = 128 green

LIGHTNESS SATURATION

14 Colour Guide

40/100× 255 = 102 blue

Page 19

65535 Colour scale:

100/100× 65535 = 65535 red

50/100× 65535 = 32768 green

40/100× 65535 = 26214 blue

The printout from this set of numbers should produce a

colour close to the original. Due to the variation in

printer inks however, it may be necessary to make

minor adjustments until the right combination is found.

Once a colour match is obtained, the RGB components

should be entered regardless of the colours displayed

on-screen. To maintain colour consistency it is

recommended that OKI original consumables are used

as they are specifically manufactured for the OKI

C7000 Series and OKI C9000 Series of printers.

English

Colour Printing 15

Page 20

Printing colour

No matter how colours are specified, the printer is only

able to use a combination of three colours plus black to

generate an image on paper. To achieve this the printer

uses processes known as halftoning and dithering. Each

addressable picture element (pixel) on a monitor screen

or printed output contributes to what we see in the final

image. The pixels are placed in close proximity so the

eye is unable to resolve individual dots. Colours of

adjacent pixels appear to merge and produce a new

colour. Using dot patterns of a given set of colours to

generate new colours is known as dithering. Shades of

grey can be generated by using a similar technique of

black dot placement. This technique is known as

halftoning and gives rise to what we perceive as a

continuous tone image. Examples of dither and halftone

are shown below:

DITHER PATTERN

HALFTONE PATTERN

The entire printing area is split into sections known as

cells (much like a grid). The patterns within the cell are

then altered to obtain the required amount of greyscale.

An area of an image containing 50% grey will contain

cells that have half of the dots within the cell printed

with black and the other half left empty.

16 Colour Guide

Page 21

Colour registration

The CMYK printing process, as already stated, uses

overlapping inks of cyan, magenta and yellow. To

produce the best possible output, the colours must print

in specific positions so that overlaps and dithering are

accurate. If the colours are not aligned, the resulting

print will have colour shifts (colours produced where

incorrect colours overlap to produce an undesired

colour) or appear blurred. Using black to print grey and

also black in text eliminates the problem in these

instances but not when colour is constructed from two

or more of the process primaries. The illustration shows

how registration problems can cause undesired effects.

English

Colour Printing 17

Page 22

Colour adjustments

Certain images such as bitmaps, sometimes print with a

strong hint of a particular colour. Images that appear

fine when viewed on a monitor may not necessarily

print that way due to the reasons described previously.

The colour that appears to dominate the picture will

vary depending on factors such as the scanner (or other

input device) having a bias towards a particular colour,

or the monitor’s ability to represent certain colours onscreen. To compensate for this, OKI C7000 Series and

OKI C9000 Series of printers have a colour adjustment

system that can reduce the amount of any of the process

colours put on the page in relation to the others. The

printer drivers supplied with your printer provide these

adjustments, which are outlined in this manual and

explained in more detail in the driver’s on-line help.

(Click on the Help button in any driver dialog box.).

This is useful if, for example, you find that all of your

graphics have a tendency to contain too much blue. To

compensate for this, you could reduce the amount of

cyan or magenta as it is these two colours that combine

to produce blue. Bear in mind that other colours

containing cyan or magenta will also be affected. An

alternative would be to increase the amount of yellow.

This has the advantage of increasing colour saturation

while balancing the image.

Another method of decreasing strong colours is to

increase the lightness setting in the printer driver. To

compensate for this, the saturation setting must be

stepped down accordingly. As a rule, the saturation

should be stepped down an equal number of steps to the

level that the lightness has been stepped up.

18 Colour Guide

Page 23

OKI C7000/C9000 Printer Drivers

There are various features designed to allow you to

achieve the best results with your OKI C7000 Series

and OKI C9000 Series of printers. The colour options

within the printer driver provides a list of colour

matching techniques and adjustments which can be

applied to your graphics and text to provide the

optimum balance of colour on your document. The

options and adjustments that can be made are described

below for each of the different printer drivers. Clicking

on the properties button after a print request has been

made allows you to carry out colour adjustments before

printing the document.

English

OKI C7000/C9000 Printer Drivers 19

Page 24

Colour management

Colour management ensures the best rendition of

colours when an image or page is displayed on your

monitor and printed by your printer. In most cases,

colour management works automatically using colour

profiles that are installed when a printer or monitor is

installed. These colour profiles are used every time

colours are displayed or printed.

Users with specialised needs, such as graphic artists and

desktop publishers, can manually specify which colour

profile a printer or monitor uses, or which colour

profile is used for images or pages with special colour

reproduction requirements.

There are two settings for colour management and these

are as follows:

Automatic

colour profile to use from the list of associated colour

profiles stored on your computer. This is the

recommended setting for colour management.

Manual

colour profile to use from the list of associated colour

profiles for all output from the printer if you have

specialised needs for colour printing.

20 Colour Guide

- Windows automatically selects the best

- This allows you to manually select which

Page 25

Windows and Macintosh PostScript driver

Windows colour matching

Clicking on the Options button allows you to select the

settings for colour matching system built into the

printer.

Image colour matching

English

OKI Colour Matching

colour matching process using ASIC installed in a

printer. The colour matching process is applied when

OKI C7000/C9000 Printer Drivers 21

- This option carries out a

print data with RGB colour space used in general

applications is converted into CMYK colour space of a

printer.

PostScript Colour Matching

a colour matching process using the colour rendering

dictionary of Adobe PostScript.

Black finish

- This option generates black in the most

Auto

appropriate method for the document to be printed. This

is the default setting and is recommended for most print

jobs.

- This option generates black only with black

Matte

toner and is the best setting for graphics and texts. If the

- This option carries out

Page 26

dark part of a photograph is printed with a blackish

tone, then please use Auto or Glossy setting.

- With this setting black is composed of cyan,

Glossy

magenta, yellow and black toner giving a brownish and

glossy black, which is best for printing photographs.

Colour halftone

Device Best Dither

that focuses on expression (resolution) and is best used

for printing graphics and text.

Cluster Ordered Dither

dithering to give smooth gradation between colours and

is best used for printing photographs.

Image colour rendering style

- This setting matches colours using the most

Auto

appropriate method for the document being printed.

This is the default setting and is recommended for most

print jobs.

Perceptual

contrast. All colours are equally converted into colours

within the colour range of the printer.

Vivid

brightness. Colours outside the colour range of the

printer are converted into colours with close saturation

in the colour range.

22 Colour Guide

- This setting gives colours with more

- This setting gives colours with mode

- This setting carries out dithering

- This setting carries out

Macintosh colour matching

Colour/greyscale

The Colour/Greyscale setting enables the Adobe

PostScrip to send colour data to colour printers or

equivalent greyscale data to monochrome printers. The

Colour/Greyscale setting produces better black-andwhite output than the Black and White option, even on

monochrome printers and is the default setting.

Black and white

The Black and White setting limits printing to

monochrome only. Use this option if you want your

printed output identical to the output you can obtain

using the Apple LaserWriter 7.x printer driver with

black-and-white printers.

Page 27

ColorSync colour matching

The ColorSync Color Matching setting enables a

Macintosh computer to convert from one colour

representation to another (for example, from monitor

colour to printer colour) using colour rendering

dictionaries that reside on the Macintosh computer.

This setting requires a printer profile, which contains

information defining the colours that the printer can

represent. This setting is available only if the Apple

ColorSync software is installed.

Choose this setting if your Macintosh processor is

faster and more powerful than your printer because it

will improve overall color-printing performance.

PostScript colour matching

The PostScript Color Matching setting enables your

printer to convert from one colour representation to

another (for example, from monitor color to printer

color) using colour rendering dictionaries that either

reside on the printer or have been downloaded from the

computer to your printer. Use this option if your printer

is not colour calibrated and uses PostScript Level 3.

Windows ICM

Clicking on the Options button allows you to select the

settings for Windows image colour matching.

Host Image Colour Matching

matching is carried out by the computer and gives a

better printer performance. This is the default setting.

Download Image Colour Matching

matching is carried out by the printer which results in

better computer performance. The printer driver creates

colour rendering dictionaries and downloads them to

the printer before printing.

Printer Image Colour Matching

matching is carried out by the printer using colour

- All image colour

- Image colour

- Image colour

English

This setting requires you to select a printer profile,

which contains information defining the colours that

the printer can represent.

OKI C7000/C9000 Printer Drivers 23

Page 28

rendering dictionaries that have been previously

downloaded to the printer or are resident in the printer.

This setting is recommended when printing to file.

No colour matching

This setting does not carry out colour matching.

Choose this setting when you use the colour matching

system of the software application being used.

Print in greyscale

Prints in greyscale using the colour information to

produce the various shades of grey that are required.

Print colour separations

This setting can be used if a software application does

not support printing colour separations of cyan,

magenta, yellow and black.

24 Colour Guide

Page 29

Windows PCL driver

Auto colour

Using Auto Colour, the printer automatically adjusts to

the colours specified in the document and prints. This is

the optimal printing mode for colour and is the default

setting. For normal printing, it is recommend to use this

setting.

Manual colour

With Manual Colour, you can adjust each item of the

colour setting. This setting is recommended for users

who have lot of experience using colour. When using

manual colour settings, the printed colours can differ

greatly from the colours on the monitor screen.

Halftone type

Error Diffusion

spreads out any inaccuracies when representing a pixel

of colour with the surrounding pixels.

- A method of colour reduction that

English

OKI C7000/C9000 Printer Drivers 25

Page 30

- This setting carries out dithering to achieve

Photo

smooth tone that is required when printing photos.

Graphics/Text

an emphasis on form expression (resolution) that is

required when printing graphics and texts.

Colour setting

- Prints each photo, graphic and character in the

Auto

most suitable colours.

Natural

screen. Sometimes the printed colours do not match

those on the screen because colour characteristics

(brightness, saturation and contrast) of the monitor

cannot be recognized.

Natural Vivid

vividly as possible, i.e. colours are more saturated and

vibrant.

Unadjusted

data is sent directly to the printer. Printed colours may

not match those specified within the document.

Manual adjustment

Lightness

adjusted so that colours within it tend to appear closer

to black (negative adjustment or darker) or white

(positive adjustment or lighter).

- This setting carries out dithering with

- Makes the colours close to those seen on the

- Colours are printed as brightly and

- No colour adjustment is carried out and

- This allows the image brightness to be

Saturation

so that they appear dull (negative adjustment) or vivid

(positive adjustment).

Print colour swatch

Pressing this button allows the choice of printing out 4

pages or 12 pages of colour swatches from the printer.

These colour swatches are a range of colours and their

corresponding RGB (Red Green Blue) values. This

makes it possible to select a specific colour and see how

it will print from any application which allows you to

define colour using RGB values.

- This adjusts all colours within the image

Monochrome

All print data is sent as monochrome (black and white)

with colours being output as greyscale. Only the black

toner cartridge is used in this instance. The only manual

adjustments that can be made are as follows:

Lightness

adjusted so that greyscales within it tend to appear

closer to black (negative adjustment or darker) or white

(positive adjustment or lighter).

Contrast

within the image so that they appear dull (negative

adjustment) or vivid (positive adjustment).

- This allows the image brightness to be

- This adjusts the vividness of the greyscales

26 Colour Guide

Page 31

English

Quality

Two further options are available for colour printing

after clicking on the Quality tab in printer properties.

Composite black (CMYK)

composed of cyan, magenta, yellow and black toner

giving a brownish and glossy black. This setting is best

for printing the darker parts of photographs with a

- With this setting black is

slightly lighter tone.

Black finishing in photo printing

Monochrome dithering

True black

black toner (K) and is the best setting for graphics and

text. If the dark part of a photograph is printed with a

blackish tone, then please use composite black setting.

OKI C7000/C9000 Printer Drivers 27

- This option generates black only with

This option gives the choice of allowing the printer

driver or the software application to carry out dithering

when printing in monochrome.

Page 32

28 Colour Guide

Page 33

Glossary

English

Brightness

darkness of a colour and is usually measured as a

percentage from 0% (black) to 100% (white).

Cluster-dot screening

that uses multiple pixels that vary from small to larger

dots as the colour gets darker. It is characterized by a

polka-dot look.

Colour gamut

produce is known as its colour gamut. Devices are

unable to produce all colours that occur in nature so

their colour gamut is a subset of this.

Colour management system (CMS)

to communicate colour fidelity across devices such as

input, display and output to ensure that the best colour

rendition possible is given at all times.

Colour mapping

representation from one device (or system) to another.

Colour models

allows colours to be arranged or identified. There are

various models in existence, with some more suitable to

specific applications than others.

- Brightness is the relative lightness or

- This is a halftoning method

- The range of colours that a device can

- A system used

- This is the translation of colour

- A colour model is a system that

•

•

•

•

•

- Computer monitors for example, use red,

RGB

green and blue phosphors to display images and

colours are specified using the RGB model.

CMY(K)

the inks used in the four colour print process and

there is a model used to describe this. Due to the

imperfections in printing inks, black is added

rather than produced by mixing the other three

inks. Black is identified as ‘K’ to avoid confusion

with other colours such as blue.

HSL

lightness.

HSB

brightness. The dimensions are similar to the

HSL model but the HSB model is related to the

RGB system.

YCC

encoding colour images for display on video

monitors. RGB values are converted to a

luminance component (Y) and chromatic

components (C1) and (C2).

- Cyan, magenta, yellow and black are

- Colours are defined by hue, saturation and

- Colours are defined by hue, saturation and

- This system was developed by Kodak for

Glossary 29

Page 34

•

- In 1931 the Commission Internationale de

CIE

l’Eclairage (CIE) devised a colour system based

on the human visual system and is an accepted

standard. This system is not linear and difficult to

interpret. There have been modifications to the

system that have given rise to CIELab and

CIELuv.

Colour separations

- Each of the process colours are

printed separately and must therefore be specified

individually, as the colour is needed. Image data is

therefore split into the primary colours (plus spot

colours) before printing.

Colour space

- This is a method of describing colour.

Some systems are device-dependent such as RGB and

CMYK. The CIE system is a device independent colour

space. Note that all colour models are not colour spaces

in their own right.

Colourants

- These are the colours used by a device to

reproduce colour. A printing press uses the CMYK

colourants.

Density

- In this context, there is no relation to the mass

and volume of the object, but is the ability of the object

to absorb light. The more light absorbed, the higher the

object density.

Dithering

- A technique where pixels of different

colours are placed in close proximity to give the illusion

of another colour as perceived by the human visual

system.

Dot gain

- During the printing process, inks may spread

causing dots on a page to print larger than intended.

This results in darker tones and colours. The problem

can be compensated for by careful adjustment.

Error diffusion

- This is usually associated with

halftoning but can also be used with dither. The error

between a pixel and its intended value is propagated to

adjacent pixels to produce a balanced overall effect.

Results may sometimes appear grainy.

Greyscale

- Differing shades of grey ranging from

black to white. Eight bits of data will produce 256

shades of grey.

Halftoning

- A printed image is composed of dots (or

pixels). The spacing of these pixels can give the illusion

of shades or tone. Increasing the spacing of dots

lightens the shade so that it tends towards white (colour

of the page).

Highlight

- This is the lightest part of an image. In the

extreme, this would be white.

- Hue is the colour reflected from or transmitted

Hue

throough an object. It is measured as a location on the

30 Colour Guide

Page 35

standard colour wheel, expressed as a degree between

o

0

to 360o. In common use, hue is identified by the

name of the colour such as red, green, orange, etc.

Indexed colour

- Colour pixels are represented by 8bits. This gives the possibility of 256 colours which are

contained in a lookup table.

Lightness

- This describes the intensity of a colour and

determines whether a colour is closer to black or white.

Moiré pattern

- This is an undesirable pattern that

occurs due to pixel (or) dot placement. The eye is able

to pick up repetitive patterns that exist within an image.

These can be eliminated during print by careful

selection of screen angles.

- This is the smallest addressable dot or PICture

Pixel

ELement. This has been abbreviated as PIXEL rather

than PICEL.

Primary colour

- All colours can be produced by

mixing a limited set of colours. There are two different

sets of primary colours associated with the video and

printing industries:

•

Additive primaries

- Red, Green and Blue

(RGB) are the additive primaries and the basis for

forming other colours in displays such as

computer monitors or television.

English

•

Subtractive primaries

- Cyan, Magenta and

Yellow (CMY) are the subtractive primaries and

are the basis for inks used in colour printing.

Colour is produced because inks are designed to

absorb certain wavelengths of light and transmit

others.

Registration

- This describes the alignment of the

various colours when printing. As each of the process

primaries are specified by their own plate and printed

individually, it is important that the ink is placed in

precise locations or colours will not align to produce the

desired result.

Saturation

- Saturation, sometimes called chroma, is

the strength or purity of the colour. It represents the

amount of grey in proportion to the hue and is measured

as a percentage from 0% (grey) to 100% (fully

saturated). On the standard colour wheel, saturation

increases from the centre to the edge.

Secondary colour

- Mixing two primary colours in

equal amounts will produce a secondary colour.

Spot colour

- These are additional colours used in

printing that are not a part of the process ink set and

specified individually. These colours are required when

the end result is of paramount importance (such as

within a corporate logo) as there is a substantial

increase in cost. A separate plate is also required.

Glossary 31

Page 36

32 Colour Guide

Page 37

Index

English

A

Additive primaries . . . . . . . . . . . . . . . . . . . . . . . . . 7, 31

Adjustments of colours. . . . . . . . . . . . . . . . . . . . . . . . .18

Auto colour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

B

Black and white . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Black finish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Brightness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

C

CIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14, 30

Cluster dot screening . . . . . . . . . . . . . . . . . . . . . . . . . .29

CMY(K) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ColorSync. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Colour gamut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Colour management . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Colour management systems . . . . . . . . . . . . . . . . 13

Colour mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Index 33

29

,

29

,

Colour matching

ColorSync. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Macintosh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PostScript . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Colour models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Colour separations . . . . . . . . . . . . . . . . . . . . . . . . .24

Colour setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Colour space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Colour swatch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Colour wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Colourants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Colours

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Complements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Perception. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Primary and secondary . . . . . . . . . . . . . . . . . . . . . . 6

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Problems using . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

30

,

Page 38

Significance and effectiveness . . . . . . . . . . . . . . . . 3

Specifying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Composite black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

D

Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dithering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dot gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

E

Electromagnetic spectrum . . . . . . . . . . . . . . . . . . . . . . . 5

Error diffusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

30

,

G

Greyscale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22, 30

H

Halftone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Halftoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Highlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

HSB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

HSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

29

,

29

,

I

Image colour matching. . . . . . . . . . . . . . . . . . . . . . . . .21

Image rendering styles . . . . . . . . . . . . . . . . . . . . . . . . .22

Indexed colour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

L

Lightness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26, 31

M

Macintosh colour matching . . . . . . . . . . . . . . . . . . . . .22

Manual adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Manual colour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Models of colour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Moiré pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Monochrome. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

N

Neutral colours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

P

Perception of colour . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Pixel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Primary colours. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Additive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Subtractive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

31

,

34 Colour Guide

Page 39

Printer drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Colour management . . . . . . . . . . . . . . . . . . . . . . .20

Colour matching . . . . . . . . . . . . . . . . . . . . . . . . . .22

Colour separations. . . . . . . . . . . . . . . . . . . . . . . . .24

Greyscale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Macintosh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

No colour matching. . . . . . . . . . . . . . . . . . . . . . . .24

Windows colour matching . . . . . . . . . . . . . . . . . .21

Windows PCL . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Windows PostScript . . . . . . . . . . . . . . . . . . . . . . .21

Printing colour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

R

Registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Registration of colours . . . . . . . . . . . . . . . . . . . . . . . . .17

RGB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

29

,

S

Saturation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Secondary colours . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifying colours . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Spot colour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Subtractive primaries . . . . . . . . . . . . . . . . . . . . . . . 8

31

,

31

,

English

T

True black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

W

Windows colour matching. . . . . . . . . . . . . . . . . . . . . . 21

Windows image color matching . . . . . . . . . . . . . . . . . 23

Y

YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14, 29

Index 35

Page 40

OKI SYSTEMS COMPANIES

Oki Systems (UK) Ltd

550 Dundee Road, Slough Trading Estate

Slough, Berkshire SL1 4LE

UNITED KINGDOM

Tel: +44 (0) 1753 819 819

Fax: +44 (0) 1753 819 899

http://www.oki.co.uk

Oki Systems (Ireland) Limited

The Square Industrial Complex

Tallaght, Dublin 24

EIRE

Tel: +353 (01) 459 8666

Fax: +353 (01) 459 8840

http://www.oki.ie

Hawthorn Business Centre

Adelaide Industrial Estate

Falcon Road, Belfast BT12 6HP

NORTHERN IRELAND

Tel: +44 (028) 9057 2355

Fax: +44 (028) 9057 2350

http://www.oki.ie

Oki Data Corporation

4-11-22, Shibaura, Minato-ku, Tokyo 108-8551

JAPAN

Tel: +81 (0) 3 5445 6111

Fax: +81 (0) 3 5445 6182

Oki Electronics (Hong Kong) Ltd

Suite 1901-9, Tower 3, China Hong Kong City

33 Canton Road, Tsim Sha Tsui, Kowloon

HONG KONG

Tel: +852 2736 2336

Fax: +852 2736 2395

Oki Electronics (Singapore) Pte Ltd

78 Shenton Way, #09-01

SINGAPORE 079120

Tel: +65 221 3722

Fax: +65 221 9282

Oki Systems (Thailand) Ltd

956 UdomVidhya Building 6th Floor, Rama IV Road

Silom, Bangrak, Bangkok 10500

THAILAND

Tel: +662 636 2535

Fax: +662 636 2536

36 Colour Guide

Loading...

Loading...