491 E

CHO

S

OUNDER

I

NSTALLATION

Part Number GM495

Northstar

a unit of Brunswick New Technologies Marine Electronics

30 Sudbury Road

Acton, Massachusetts 01720

Rev A

M

ANUAL

www.NorthstarNav.com

Service: 978/897-6600

Sales: 800/628-4487

Table of Contents

SECTION ONE — Introduction

Welcome to the Northstar 491

Who should read this manual

Scope of this manual

Installation considerations

- - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - 2

SECTION TWO — Installing the transducer

Safety considerations

Selecting a transducer

Installation considerations

Choosing a mounting location

Installing the transducer

Maintaining the transducer

SECTION THREE — Installing the 491

Safety considerations

System components

Choosing a mounting location

Mounting the 491

Wiring the 491

Initial checkout

Installation test checklist

- - - - - - - - - - - - - - - - - - - - - 3

- - - - - - - - - - - - - - - - - - - - - 4

- - - - - - - - - - - - - - - - - - - 5

- - - - - - - - - - - - - - - - - 5

- - - - - - - - - - - - - - - - - - - - 7

- - - - - - - - - - - - - - - - - - 8

- - - - - - - - - - - - - - - 11

- - - - - - - - - - - - - - - - - - - - 11

- - - - - - - - - - - - - - - - - - - - - 13

- - - - - - - - - - - - - - - - 14

- - - - - - - - - - - - - - - - - - - - - - 14

- - - - - - - - - - - - - - - - - - - - - - - 15

- - - - - - - - - - - - - - - - - - - - - - - 19

- - - - - - - - - - - - - - - - - - 20

- - - - - - - - - - - - - - 3

SECTION FOUR — Troubleshooting and servicing the 491

Common 491 installation problems

The status LED

Getting technical support

Ordering replacement parts

Servicing the 491

Returning a 491 for service

- - - - - - - - - - - - - - - - - - - - - - - 21

- - - - - - - - - - - - - - - - - - 24

- - - - - - - - - - - - - - - - - 25

- - - - - - - - - - - - - - - - - - - - - - 25

- - - - - - - - - - - - - - - - - 26

APPENDIX A — Technical specifications

Glossary

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

- - - - - - - - - - - - - - 21

- - - - - - - - - - - - - - 27

- - - - - - 21

SECTION ONE — Introduction

Welcome to the Northstar 491

An echo sounder is a device that provides information about the water

directly beneath a vessel. The Northstar echo sounder system consists of:

•

the Northstar 491 echo sounder sensor

•

a Northstar navigation system such as the 962, 958 or 6000i

•

a transducer

The 491 can be used with either a single-element transducer or a

dual-element transducer. The 491 automatically pings both transmitters

at power-up to determine the number of transducer elements connected.

If a single element is detected, the 491 operates in single-frequency or

dual-frequency interleaved mode (as determined by the operator) at 600

Watts. If two elements are detected, the 491 uses both elements at 1000

Watts.

Installation and setup procedures are different for the two basic types of

Northstar navigators. The following terminology should be carefully followed:

•

the term 961/962 indicates instructions that apply to the Northstar

961 and the 962 navigators

•

the term 957/958/6000i is used for these units

•

the term navigator by itself identifies information that applies to all

units

Who should

read this

This manual is for marine technicians who are installing the Northstar

491 and connecting it to a Northstar navigator and a transducer.

manual

Scope of this manual

491 INSTALLATION MANUAL Revision A PAGE 1

In this manual, you’ll find information about the following:

•

mounting and wiring the 491

•

connecting the 491 to the Northstar navigator

•

installing a transducer (an overview is provided, but for such details

as wiring, see the documentation provided by the transducer’s manufacturer)

SECTION ONE — Introduction

Installation

•

connecting the 491 to a transducer (see also the Transducer Connec-

tor Instructions —GM492)

•

troubleshooting and testing the system

•

technical specifications for the 491

For information about obtaining technical support and returning the 491

for factory service, “SECTION FOUR — Troubleshooting and servicing the

491” beginning on page 21.

For details about operating the 491, see the Northstar 491 Echo Sounder

Operations Manual (GM494) or Northstar 6000i’s Reference Manual, for

that product.

considerations

CAUTION!

1. Check the shipping carton for any damage, and immediately report

any damage to the carrier. Save all packing material in case you have

to return the 491 to the factory for repair or evaluation.

2. Unpack the carton, and check its contents. You should have

received:

•

the Northstar 491 Echo Sounder

•

10-foot (3-meter) data cable to connect the 491 to the navigator

•

10-foot (3-meter) power cable for the 491

•

491 parts kit (containing transducer cable end connector, backshell, heatshrink tubing, and the Transducer Connector Instruc-

tions —GM492)

•

Northstar 491 Echo Sounder Installation Manual (GM495)

•

Northstar 491 Echo Sounder Operations Manual (GM494)

•

owner registration card

3. Fill out the owner registration card and mail it to Northstar.

4. Review all of the installation requirements as outlined in Sections

Two and Three.

5. Install the transducer, then terminate the cable (see ”Connecting the

491 to a transducer” starting on page 18).

6. Mount the 491. For instructions, see ”Mounting the 491” beginning

on page 14.

7. Connect the 491 to ship’s power and to the navigator. Connection

information begins on page 15.

With the vessel in the water, turn on the system and verify proper operation.

The following list of installation considerations isn’t

a substitute for all the details in Section Three. To

ensure that you meet all critical installation parameters, be sure to read that entire section and follow

all of its recommendations.

PAGE 2 491 INSTALLATION MANUAL Revision A

SECTION TWO — Installing the transducer

Safety considerations

WARNING!

Be sure to turn the power off before starting the

installation. Further, it is highly recommended that

you keep power off while you’re performing the

installation. If power is left on or turned on during

the installation, fire, electrical shock, or other serious injury may occur.

Be sure to ground the equipment to prevent electrical shock and mutual interference.

WARNING!

CAUTION!

Be sure the transducer outputs are tied together

before handling to avoid electrical charge build-up.

Be sure to use a 3-amp fuse. Using the incorrect

fuse can result in fire or damage to the 491.

Mounting the transducer requires drilling holes

through the hull; make sure the installation does

not cause the vessel to leak. A thru-hull installation

should be performed by a professional installer. Do

not attempt this unless you are fully qualified.

Do not perform a thru-hull installation of the transducer when the vessel is actually in the water.

Immediately after installing the transducer, be sure

to check for leaks, and don’t leave the vessel in the

water for more than three hours before checking it

again.

Northstar assumes no responsibility for improper

installation of a transducer.

NOTE:

491 INSTALLATION MANUAL Revision A PAGE 3

Be sure that the transducer doesn’t interfere with

any of the on-board systems. Check all other systems to ensure that their performance doesn’t

degrade when the transducer is connected.

SECTION TWO — Installing the transducer

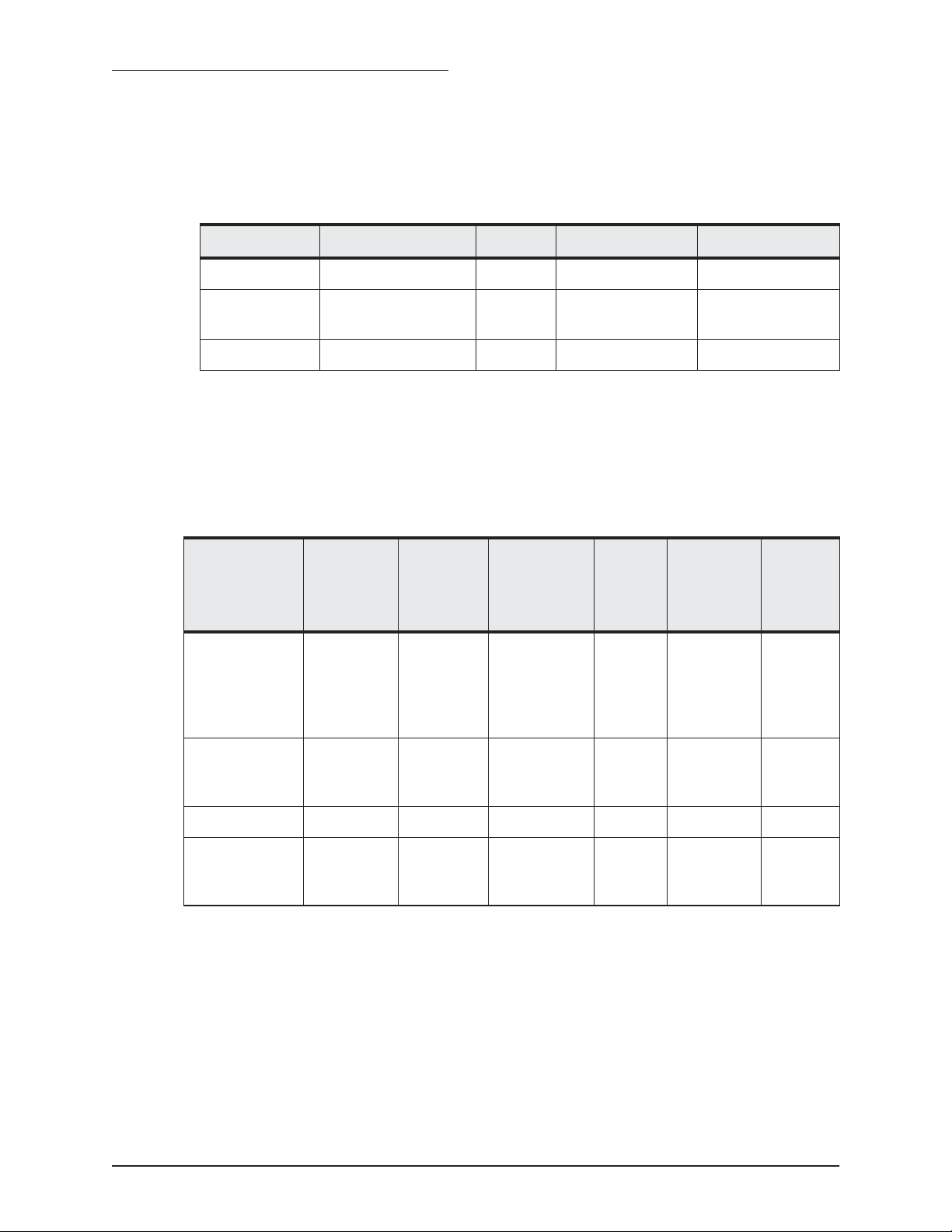

Selecting a transducer

Manufacturer Housing Power Frequency Northstar P/N

Airmar B260 1 kW 50/200 kHz TD1004

Airmar B744V/B44V (with

Airmar P66 600 W 50/200 kHz TD1006

Transducer

element

Northstar recommends using an Airmar transducer with the Northstar

491 echo sounder. The Airmar B260, B744 and P66 can be obtained from

Northstar as an installation kit with connectors installed.

Table 1: Northstar-recommended transducers

600 W 50/200 kHz TD1005

3-wire speed)

A table of Airmar transducer elements is given below to assist in evaluating characteristics of other Airmar transducers.

Table 2: Airmar transducer elements

Single

or Dual

element

Used in

Airmar

P/N

Acoustic

material

Beam

Width

(50

kHz)

Beam

Width

(200 kHz)

Rated

Power

50/200A Single B744V

B744VL

P319

B117

SS555

50/200A Single P66

P79

P74

50/200B Single B256 Urethane 23° 5° 1200W

50AE/200Riq Dual B45

B250-B

B260

Dealers can also purchase quantities of transducers directly from Airmar

Technology Corporation at:

Milford, New Hampshire 03055-4613

Urethane 45° 12° 600W

LPU 45° 11° 600W

Urethane 19° 6° 1000W

Airmar Technology Corporation

35 Meadowbrook Drive

Phone 603/673-9570

Fax 603/673-4624

(www.airmar.com)

PAGE 4 491 INSTALLATION MANUAL Revision A

SECTION TWO — Installing the transducer

Installation considerations

Choosing a mounting location

The following basic setup information isn’t a substitute for the installation instructions provided by the transducer’s manufacturer. To ensure

that you meet all critical installation parameters, be sure to read and follow all of the requirements in their instructions. Northstar assumes no

responsibility for improper installation.

CAUTION!

The two most common problems with echo sounder installations stem

from electrical noise and cavitation . Either of these situations can produce

poor performance.

Do not mount the transducer:

behind strakes, fittings, or hull irregularities (mounting in those locations may increase turbulence, aeration, and cavitation) or near the keel

near openings for water intake or discharge

where it might be loosened by the vessel’s vibration

less than four feet away from the Northstar 961/962

processor or other similar equipment to minimize

interference

Choose the mounting

location to obtain the best

possible performance from

the transducer and the 491.

Take into account the

vessel’s maximum speed

when selecting a mounting

location, as turbulence can

affect echo sounding

capabilities.

Electrical noise occurs when the transducer cable is routed too closely to

noise-producing electronics, such as alternators, AC generators, radars,

etc. To avoid problems with noise, route the transducer cable by itself

(not in a bundle) and away from other wires or cables and the engine.

Cavitation can occur at high speeds. During cavitation, bubbles form

between the transducer and the water. When this happens, the transducer can’t get its energy into the water properly and won’t be able to

detect any echoes. To avoid cavitation, choose a mounting location with

good water flow all around it at all speeds.

Before any drilling or cutting takes place, carefully choose a mounting

location for the transducer that meets the following criteria (also see

Figure 1 on page 7), depending on the type of vessel:

•

the transducer is more than four feet away from the Northstar navigator and other similar equipment, to prevent mutual electrical and

magnetic interference

• the transducer and its cable are as far as possible from other electri-

cal cables

• there is space above the transducer for the transducer’s stem, hous-

ing, and cable

491 INSTALLATION MANUAL Revision A PAGE 5

SECTION TWO — Installing the transducer

• the path for running the transducer’s cable is reasonably direct—keep

in mind that the transducer cable is 33 feet long (10 meters). To prevent damage, coil any excess cable and secure it

• water turbulence and noise are minimal, decreasing the amount of

bubbles passing over the transducer face

• the transducer isn’t behind hull irregularities or near eroding paint;

both indicate areas subject to turbulence

• the transducer is as far as possible from the engine or propellers, and

inboard of the lifting strakes

• the transducer always remains submerged and parallel to the water

surface

• the transducer is easily accessible from inside the vessel for adjust-

ments and maintenance

• the transducer’s ultrasonic beams aren’t obstructed by the keel, pro-

peller shafts, or any other part of the vessel

• the hull thickness falls within the limits in Table 3 below (all dimen-

sions are perpendicular to the waterline):

Table 3: Hull thickness limits

Model Minimum Maximum

AirMar B44V/B744V with fairing 6 mm (1/4 inch) 19 mm (3/4 inch)

AirMar B44V/B744V without fairing 6 mm (1/4 inch) 65 mm (2 1/2 inches)

AirMar B260 with fairing —— 45 mm (1 3/4 inches)

AirMar B260 without fairing 19 mm (3/4 inch) 114 mm (4 1/2 inches)

PAGE 6 491 INSTALLATION MANUAL Revision A

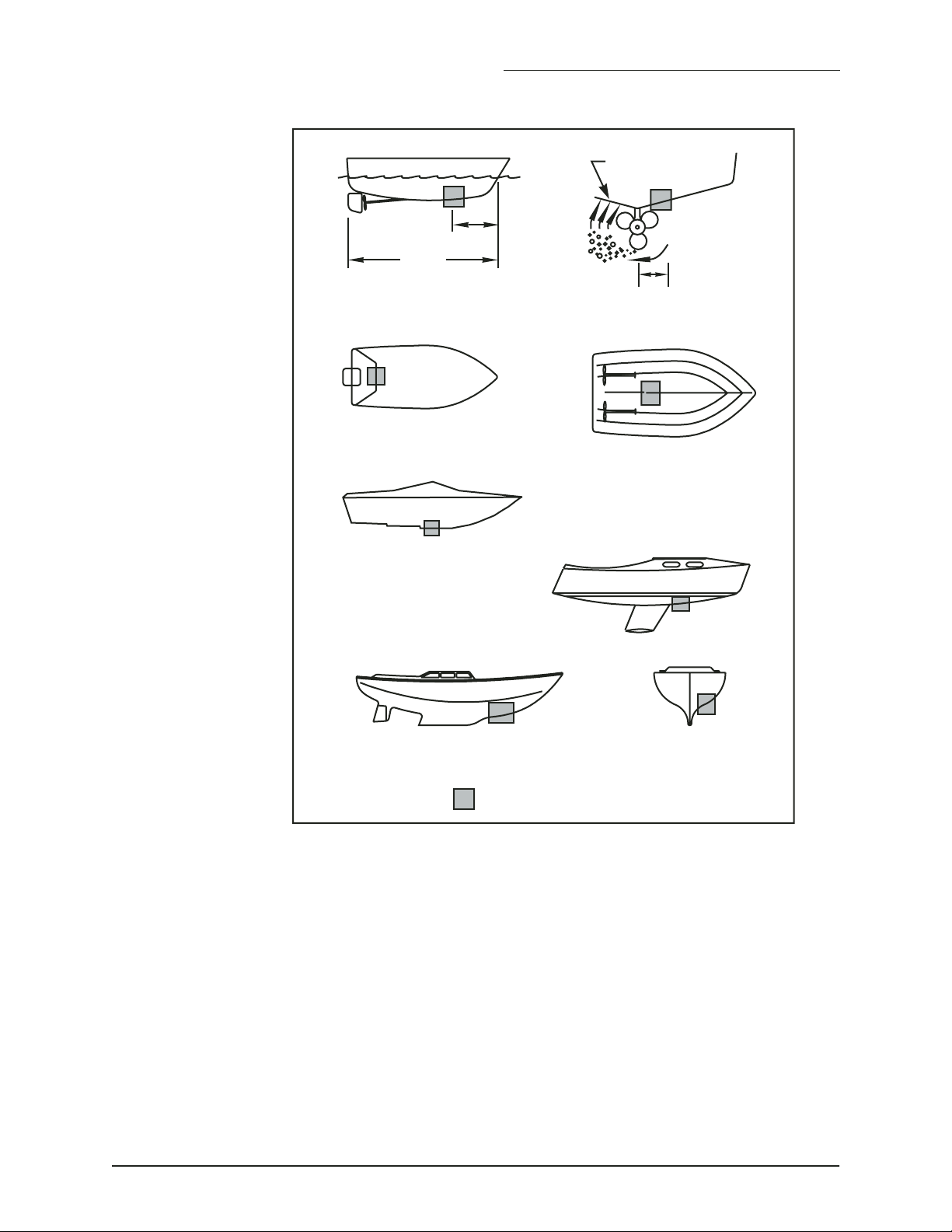

1/3 aft

LWL

(Load Waterline Length)

outboard and I/O

SECTION TWO — Installing the transducer

displacement hull

planning hulls

pressure waves

150-300mm

(6-12")

inboard

Installing the transducer

step-hull

fin keel sailboat

full keel sailboat

Best location for the transducer

FIGURE 1: Recommended installation locations for a transducer

A flat-bottom hull provides the best environment for mounting the transducer: It provides a horizontal surface and a constant water flow over the

transducer, with little turbulence (see Figure 2 for the recommended

transducer incline angle). If the vessel has a deadrise angle greater than 5

degrees, mount the transducer on a fairing block to create a horizontal

surface and keep the transducer perpendicular to the waterline (see

Figure 3). You must order the fairing block, if needed, from the transducer’s manufacturer.

491 INSTALLATION MANUAL Revision A PAGE 7

SECTION TWO — Installing the transducer

3˚ incline

angle

1/3 aft

LWL

(Load Waterline Length)

FIGURE 2: Recommended transducer incline angle

backing

block

hull

fairing thickness

at narrowest point

6– 12 mm (1/4–1/2")

slope of hull

parallel to

waterline

fairing

multisensor

deadrise

angle

Maintaining the transducer

Using anti-fouling

paint

Deadrise angle and fairing thickness (B44V shown)

FIGURE 3: Typical finished thru-hull installation with a fairing

block (Airmar B744V)

Do not expose the transducer’s face or plastic housing to gasoline or

strong solvents, such as acetone. These solvents can penetrate and

degrade many plastics and reduce their strength.

The transducer should be coated with water-based anti-fouling paint to

prevent aquatic growth.

PAGE 8 491 INSTALLATION MANUAL Revision A

Loading...

Loading...