North Star MHOTPWR User Manual

MHOTPWR

g

_____________

ITEM NUMBER: 157321,322,325,326

SERIAL NUMBER:

HP:______ Volts:______ Amp:______ Ph:_____

Proven Performance

K-BAR Industries, Faribault, MN, 55021

Installation, Operation, and Maintenance Manual

HOT WATER PRESSURE WASHER: Cleans dirty surfaces with high

To the Owner:

Thank you for purchasing a Northstar hot water pressure washer. Your machine is designed for long life,

dependability, and the top performance you demand! Take time now to read through this manual so you better

understand the machine’s operation, maintenance and safety precautions. Everyone who operates this machine

must read and understand this manual. The time you take now will prolong your machine’s life and prepare you

for its safe operation. Enjoy the exceptional performance of your Northstar hot water pressure washer, the

industry leader! The manufacturer reserves the right to make improvements in design and/or changes in

specifications at any time without incurring any obligation to install them on units previously sold.

RPM:____ PSI:____ GPM:____ Nozzle Size:_____

Pump:___________ Hose:______ Lance:_______

Max. Dischar

eTemperature:

pressure hot water.

Quick Facts

Pump Oil Pump is shipped with oil. Change oil plug and check pump oil level before starting.

Use SAE 30 Non-detergent pump oil (item# 4043) or Cat Pump oil (item# 22158) for oil

changes.

Water Make sure your water flow is 20% higher than the pressure washer’s flow rate.

Make sure your water is clean and particle free.

Storage Do not allow water to freeze in the pump, hose, coil, or spray gun.

Spraying

Chemicals

Maintenance

Schedule

Hours: Monday - Friday 7:00 AM to 5:30 PM Unit 2, Keel Close,

Saturday 7:30 AM-11:30 AM Central Time Portsmouth, Hants PO3 5QD, England

Use any North Star brand or equivalent pressure washer chemicals.

Adjust soap adjustment knob to regulate cleaning power.

Pump: Oil: change after first 50 hours, then every 3 months or 500 hours.

Read and understand all manuals before operating.

Any Questions, Comments, Problems or Parts Orders

In the United States In the United Kingdom

Northstar Customer Service

Call 1-800-270-0810 Northern Tool and Equipment Co. (UK) Ltd.

Call 02392639752

Table of Contents

Important Safety Instructions 2 Safety Features 12

Grounding Instructions 3 Maintenance Instructions 13-16

Extension Cords 3 Moving and Handling Instructi ons 17

Specifications 4 Long Term Storage 17

Machine Component

Identification

Installation Instructions 6-9 Parts Breakdowns 20-26

Operation Instructions 10-12 Wiring Diagram 27-28

5 Troubleshooting 18-19

Important Safety Instructions

WARNING -Risk of Injection or Injury to Persons - Do Not Direct Discharge Stream at Persons. - Do not use a

hose if exterior damage is evident.

-Risk of explosion. - Do not spray flammable liquids. - Do not operate in a flammable environment.

CAUTION -Risk of Asphyxiation - Exhaust fumes are deadly, for outdoor use only. Avoid inhaling exhaust

fumes.

-Risk of fire. Do not add fuel when the product is operating or hot.

-Gun kicks back. Hold with both hands.

-To reduce the risk of injury, read operating instructions carefully before use.

WARNING - When using this product basic precautions should always be followed, including the following:

1.) Read all the instructions before using the product.

2.) To reduce the risk of injury, close supervision is necessary when the product is used near children. Do

not allow irresponsible use by children. Always stop the product and bleed pressures before leaving

unattended, disconnecting hoses, or servicing the pump.

3.) Know how to stop the product and bleed pressures quickly. Be thoroughly familiar with the controls.

4.) Stay alert - watch what you are doing.

5.) Do not operate the product when fatigued or under the influence of alcohol or drugs. Never smoke while

operating or fueling this machine.

6.) Keep operating area clear of all persons.

7.) Do not overreach or stand on unstable support. Keep good footing and balance at all times. Wear

footwear capable of maintaining a good grip on wet surfaces - Do not place the machine on soft or

unstable ground.

8.) Follow the maintenance instructions specified in all manuals. Do not run machine without sufficient

lubrication or sufficient water to cool the pump.

9.) Wear safety glasses, gloves, face protection and appropriate clothing when operating the machine.

10.)Do not operate this machine with broken or missing parts. - Never alter the manufacturer’s original

design or deactivate any safety device on the machine.

11.)Risk of exposure to dangerous chemicals. Wear protective gloves when handling and cleaning with

chemicals. Follow the chemical manufacturer’s directions. Understand all safety hazards and first aid for

all chemicals being used. Check whether dangerous chemicals have been used and take any

precautions that may have been recommended by the supplier of these chemicals when cleaning filters.

Do not pump highly abrasive fluids or use with incompatible chemicals or solvents.

12.) Know the pressure and temperature limits of your machine. Be sure all high pressure accessories meet

or exceed your machine’s limits. Do not set the pressure relief valve above the machine’s limit.

13.)Do not move this machine by pulling on the hose. Do not use the pump to support other items of

equipment that impose unacceptable loads on the pump. Do not attempt to use this machine as a prop.

14.)To reduce risk of injury, do not secure the spray gun open. Your spray gun is equipped with a built-in

trigger safety latch to guard against accidental trigger release and potentially dangerous high pressure

spray. Rotate the safety latch to the locked position when not spraying.

15.) Do not clean this machine with its own spray. Cleaning should be done with a damp sponge with the

motor OFF.

16.) NEVER attempt to immediately run or re-light the burner if it doesn’t ignite the first time. Unburned oil or

gas may have accumulated causing potential explosion or fire hazard.

17.) Always make sure all switches and controls are in the OFF position prior to plugging in the electrical

cord. Do no stand in water while plugging and unplugging electrical cord.

18.) This product is provided with a ground fault circuit interrupter built into the power cord plug. If

replacement of the plug or cord is needed, use only identical replacement parts.

SAVE THESE INSTRUCTIONS

2

Grounding Instructions

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electrical shock. This product is equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

DANGER - Improper connection of the equipment - grounding conductor can result in a risk of electrocution. Check with a

qualified electrician or service personnel if you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the product - if it will not fit the outlet, have a proper outlet installed by a qualified electrician. Do not

use any type adapter with this product.

1. For a product rated 125 volts or less:

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

This pressure washer is provided with a ground fault circuit interrupter (GFCI) built into the plug of the power supply cord.

This device provides additional protection from the risk of electric shock. Should replacement of the plug or cord become

necessary, use only identical replacement parts that include GFCI protection.

2. For a product rated more than 125 volts:

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To comply with the National Electric Code (NFPA 70) and to provide additional protection from the risk of electric shock,

this pressure washer should only be connected to a receptacle that is protected by a ground fault circuit interrupter

(GFCI).

Extension Cords

Use only 3-wire extension cords that have 3 prong grounding-type plugs and 3-pole cord connectors that accept the plug

from the product. Use only extension cords that are intended for outdoor use. These extension cords are identified by a

marking “Acceptable for use with outdoor appliances; store indoors while not in use.” Use only extension cords having an

electrical rating not less than the rating of the product. Do not abuse extension cord and do not yank on any cord to

disconnect. Keep cord away from heat and sharp edges. Always disconnect the extension cord from the receptacle before

disconnecting the product from the extension cord.

Warning - To reduce the risk of electrocution, keep all connections dry and off the ground. do not touch plu g with wet

hands.

SAVE THESE INSTRUCTIONS

3

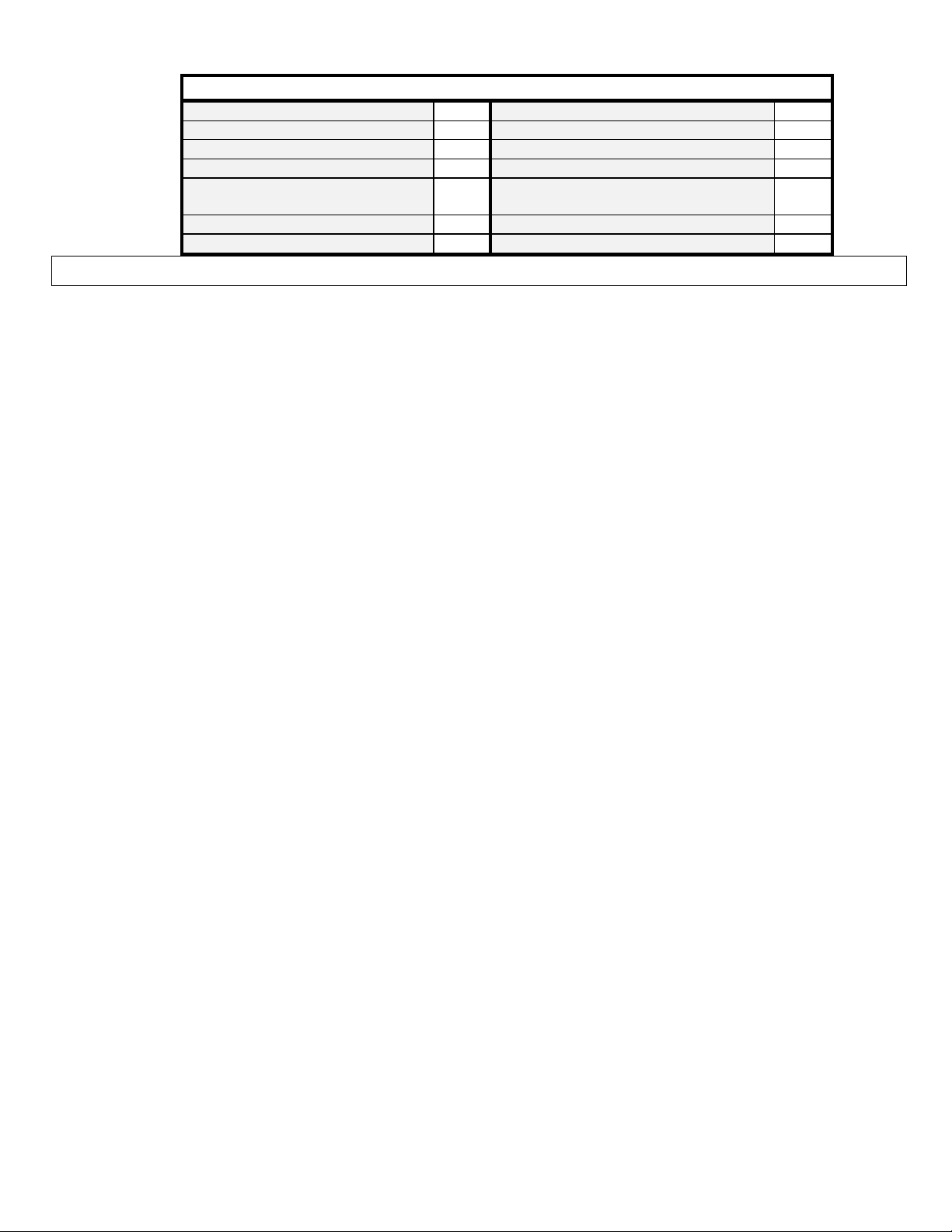

Specifications

Item Number

157321 157322 157325 157326

Pressure Rating 1000 psi 1000 psi 2000 psi 2000 psi

Flow Output 2 gpm 2 gpm 3.5 gpm 3.5 gpm

Pump Type Ceramic Triplex

Plunger

Water Supply Standard tap water

@ 20-100psi

Motor Horsepower 1.5 hp 1.5 hp 5 hp 5 hp

BTU Output 221,400 BTU 221,400 BTU 270,000 BTU 270,000 BTU

Temperature Rise 140 F

Maximum

Temperature

Approved Fuels #1 or 2 Diesel,

Fuel Capacity 8.25 gal. 8.25 gal. 8.25 gal. 8.25 gal.

Discharge Hose 3/8” x 30’ 3/8” x 50’ 3/8” x 30’ 3/8” x 50’

Power

Requirements

NEMA

Receptacles

Volts 115V 115V 230V 230V

Amps 20A 20A 30A 30A

Hertz 60Hz 60Hz 60Hz 60Hz

Phase single single single single

210°F 250°F 210°F 250°F

Kerosene, Fuel Oil

5-20R 5-20R 6-30R 6-30R

Ceramic Triplex

Plunger

Standard tap water

@ 20-100psi

140°F - (190°F steam

mode)

#1 or 2 Diesel,

Kerosene, Fuel Oil

Ceramic Triplex

Plunger

Standard tap water

@ 20-100psi

140°F 140°F - (190°F steam

#1 or 2 Diesel,

Kerosene, Fuel Oil

Ceramic Triplex

Standard tap water @

20-100psi

#1 or 2 Diesel,

Kerosene, Fuel Oil

Plunger

mode)

Dimensions

Length 38” 38” 38” 38”

Width 26” 26” 26” 26”

Height 43” 43” 43” 43”

Ship Weight 355 lb. 360 lb. 420 lb. 415 lb.

4

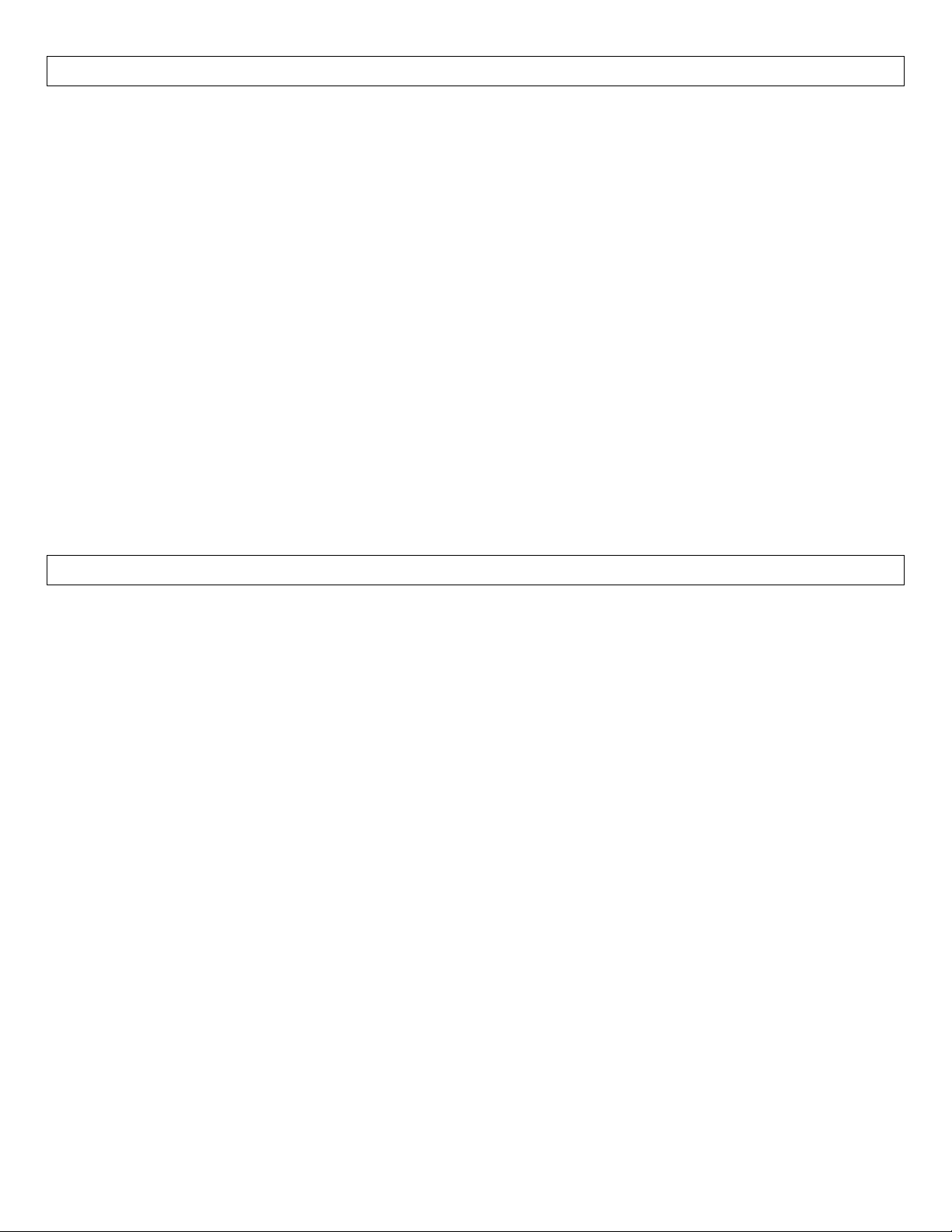

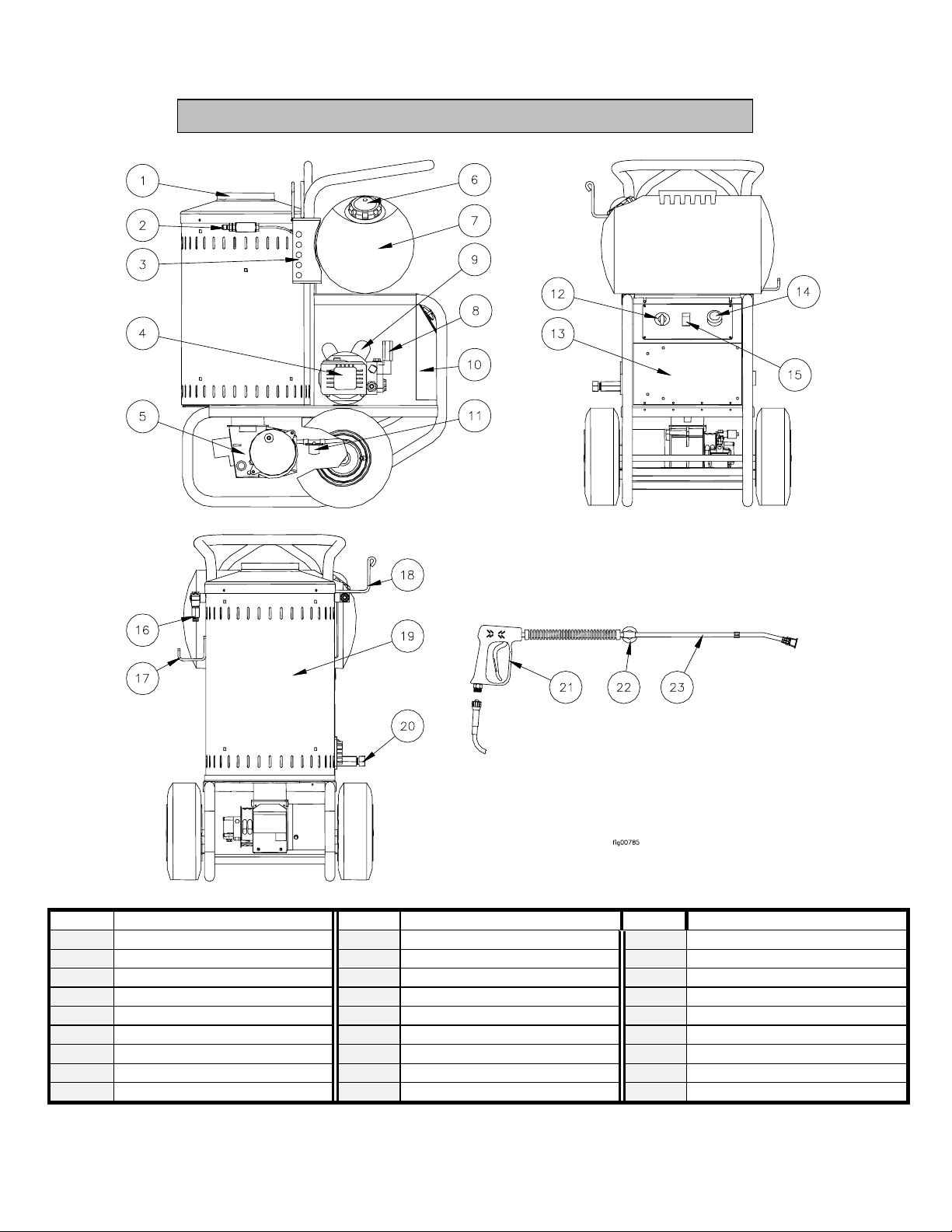

Machine Component Identification

157321, 157322, 157325, 157326

Description Ref # Description Ref # Description

1 Exhaust Vent 10 Control Box 19 Heating Coil

2 High Pressure Water Outlet 11 Fuel Filter 20 Garden Hose Water Inlet

3 Nozzle Holders 12 Main Power Switch 21 Spray Gun

4Pump 13 Service Panel 22 Grip

5 Burner 14 Thermostat (optional) 23 Dual Lance Wand

6 Fuel Fill Cap 15 Heat Switch

7 Fuel Tank 16 Safety Relief Valve

8 Unloader 17 Power Cord Hanger

9 Motor 18 Wand Holder

5

Installation Instructions

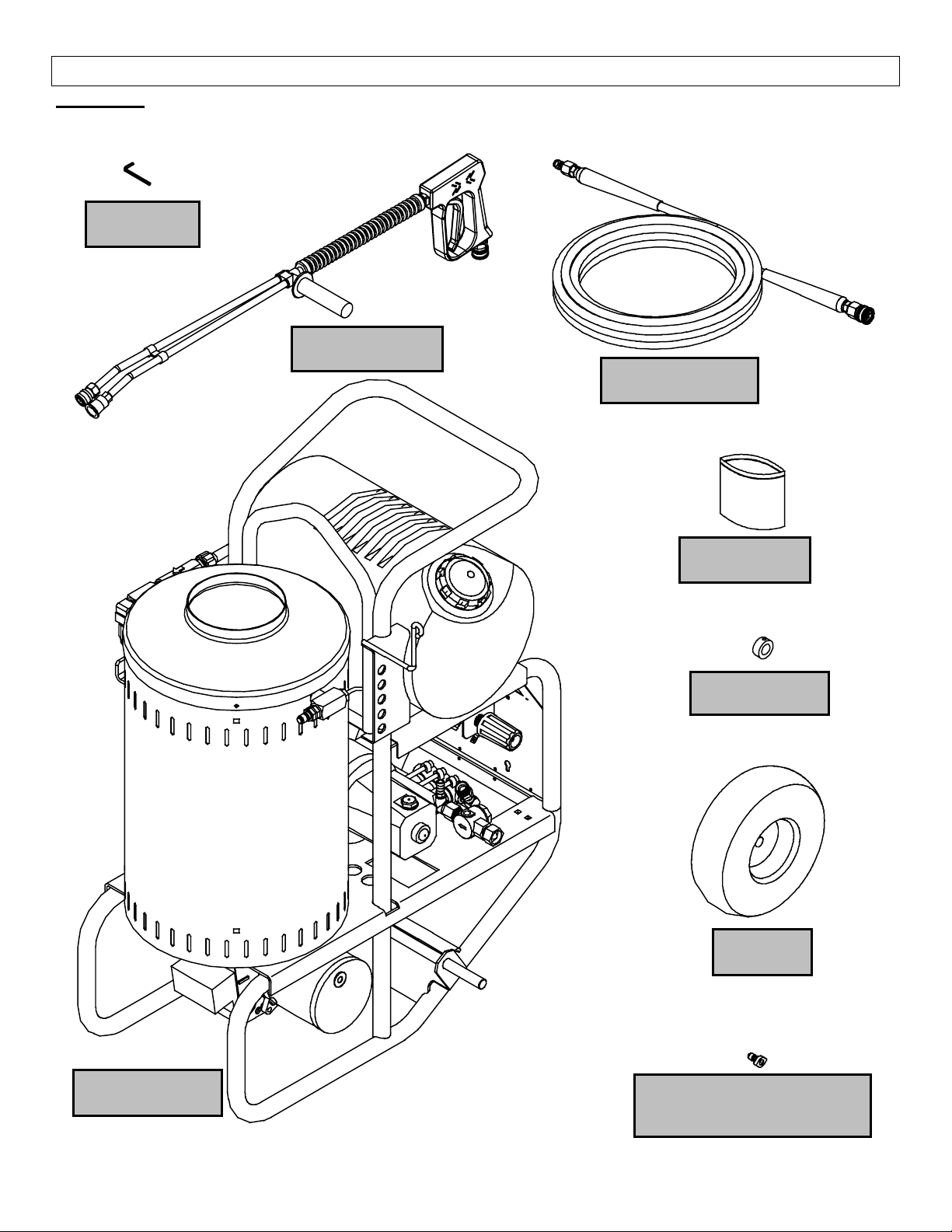

I.) Unpack

Separate and identify all components. Use the assembly instructions in this manual for assembly.

Hex Wrench

Qty-1

Spray Gun & Grip

Qty-1

High Pressure Hose

Qty-1

Fastener Bag

Qty-1

Wheel Retainer

Qty-2

Wheel

Qty-2

Pressure Washer

Qty-1

00786

Nozzle

157321, 157325 Qty-4

157322, 157326 Qty-5

6

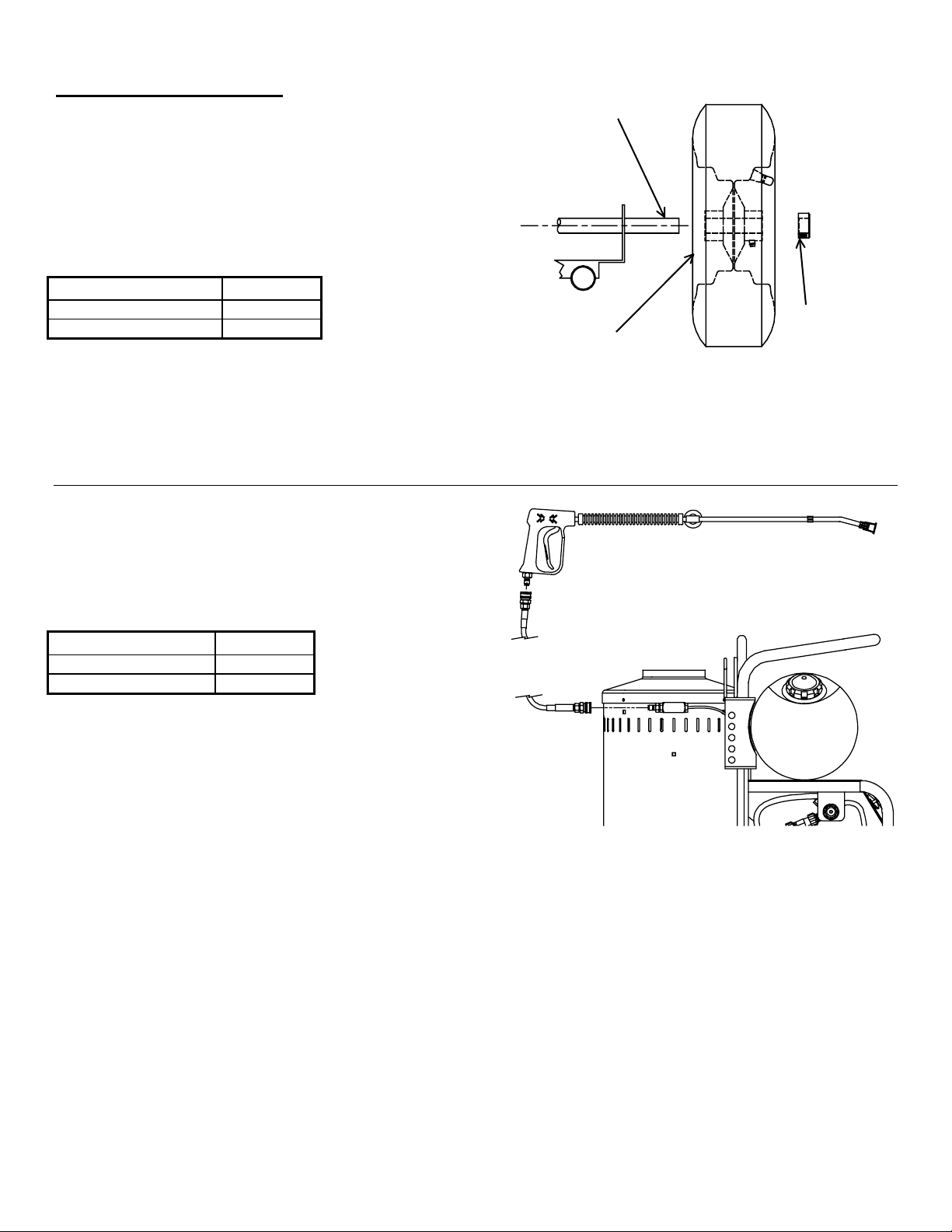

II.) Assembly Instructions

r

A

A. 1. Carefully raise the pressure washer off the floor by

using blocks or ramps. Make sure the pressure

washer is secure before proceeding.

2. Install the two wheels as shown with grease zerk

away from frame.

3. Slide the two wheel retainers onto the end of the

axle. Tighten the set screw with the hex wrench

provided in the parts bag .

Description Qty.

Wheel 2

Wheel Retainer 2

B. 1. Install the pressure hose onto the pressure washer

as shown.

2. Connect the other end of the pressure hose to the

spray gun as shown.

3. Make sure all plumbing connections are tight.

xle

Wheel Retaine

Wheel

Description Qty.

Spray Gun/ Lance 1

Spray Hose 1

00787

7

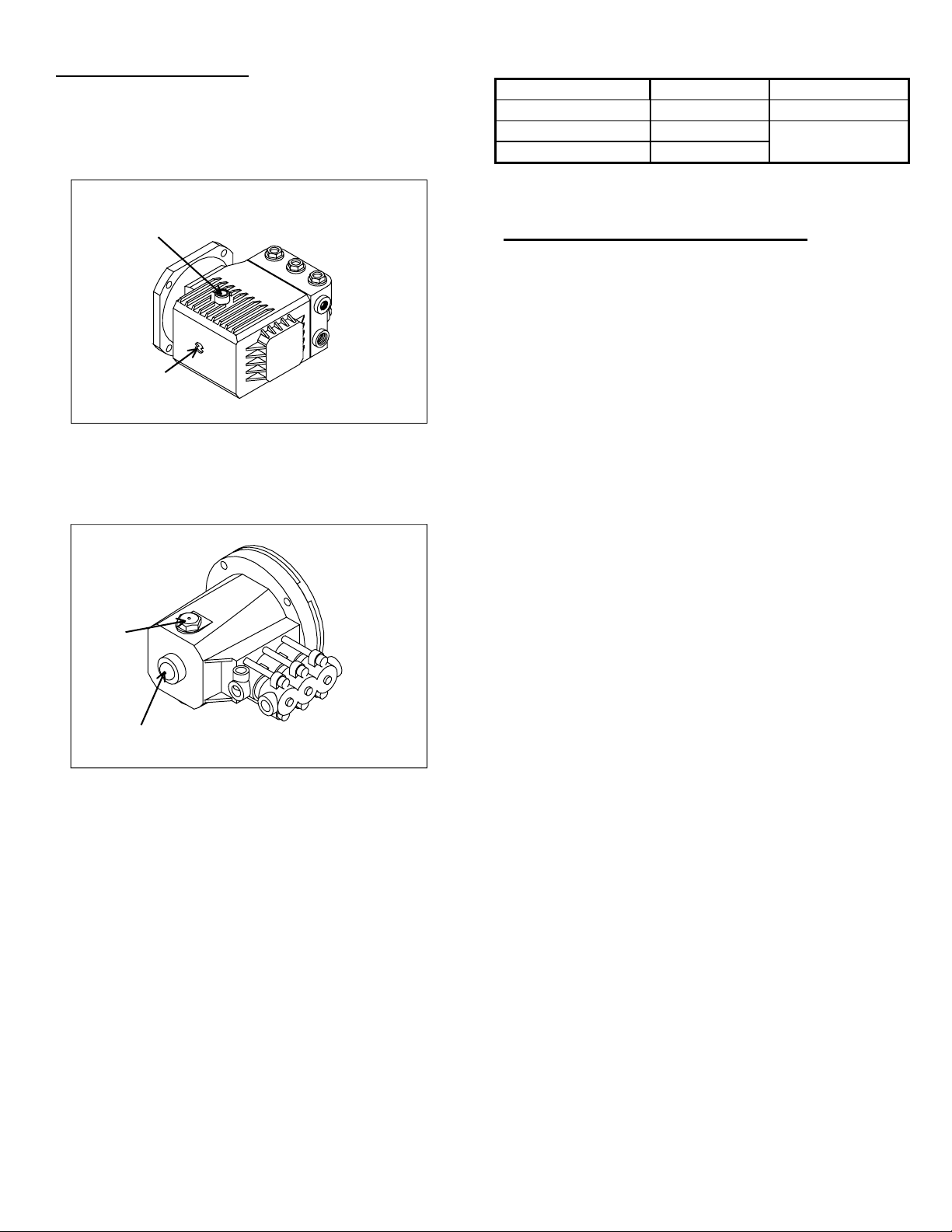

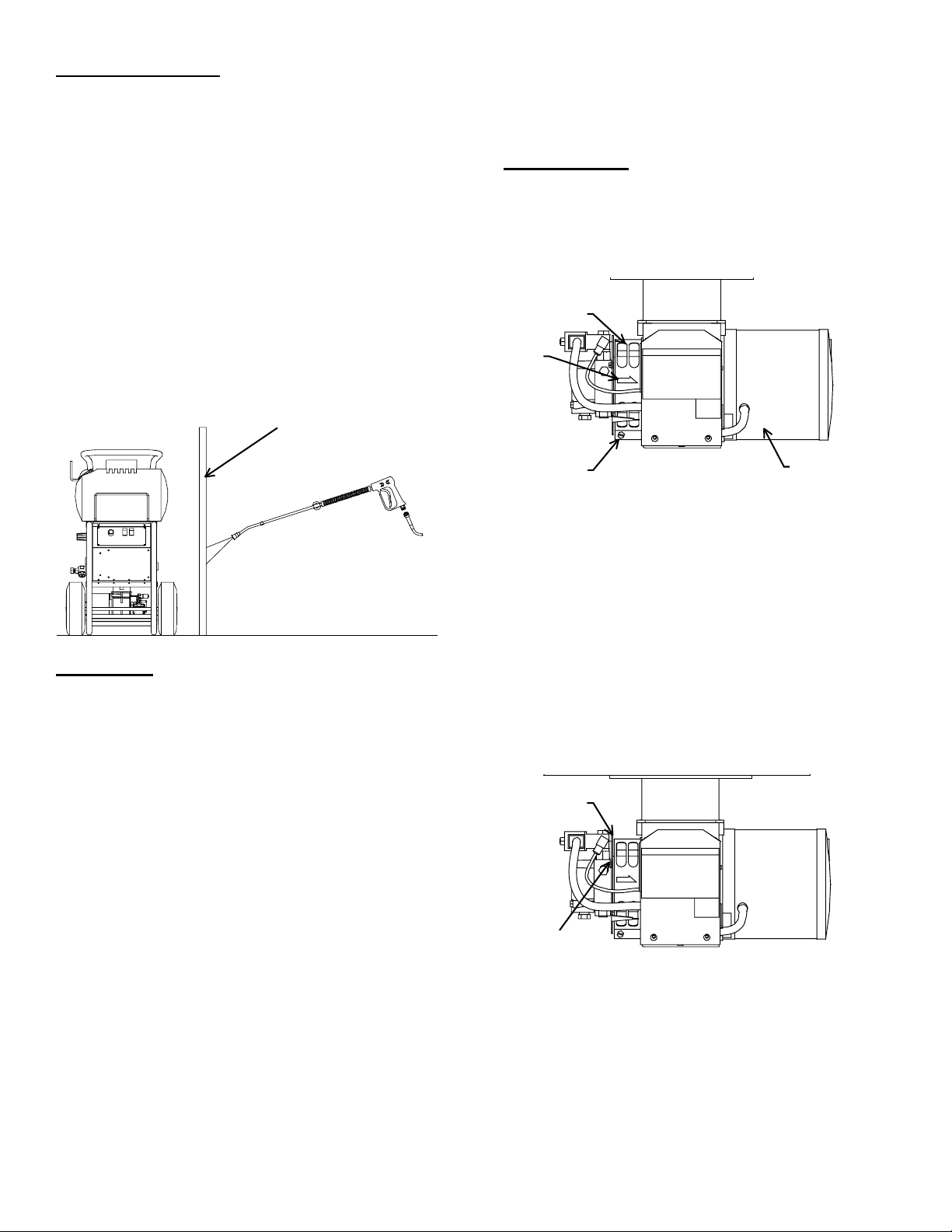

III.) Pump Preparation

*AR Pumps Only

A.) Remove the shipping plug from the oil fill hole.

B.) Screw the vented dipstick into oil fill hole.

C.) Check oil level in the pump. Make sure it is 1/2 way

up the sight glass .

AR PUMPS

Oil Fill Hole

Sight Glass

**Cat Pumps Only

A.)Remove shipping tape from oil fill cap

B.)Make sure the oil is 1/2 way up oil sight glass.

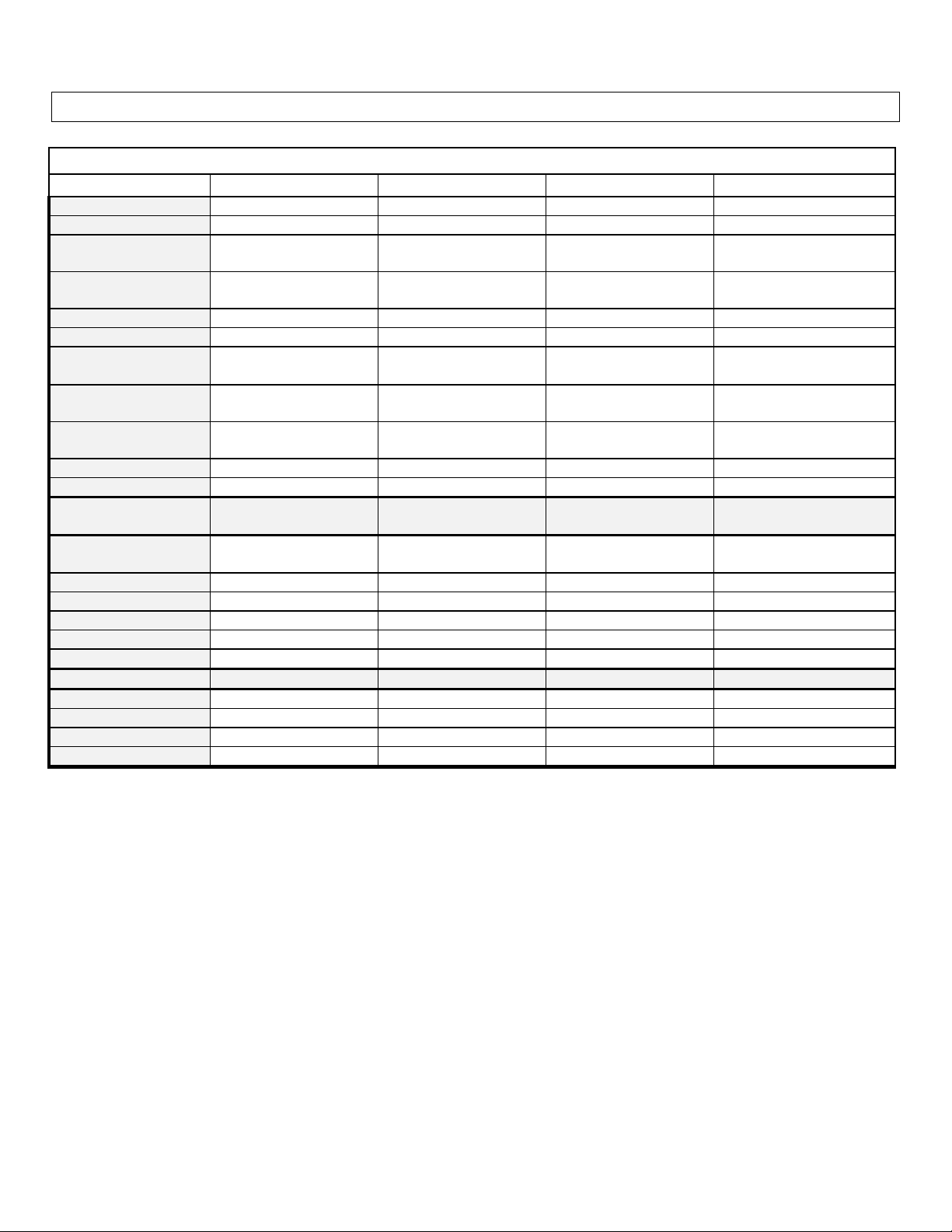

Quantities Of Fluid

Pump Type of Fluid QTY

AR XTV SAE 30* 8.0oz (0.24L)

AR XMV SAE 30* 14.0oz (0.41L)

Cat 2SFX SAE 30** 11.83oz (0.35L)

*SAE Non-Detergent Oil (order Pump Oil Item# 4043)

**SAE Non-Detergent (order Cat Pump Oil Item# 22158)

IV.) Chemical Injector Preparation

A.) Push clear hose onto chemical strainer.

B.) Push other end of clear hose onto chemical injector

CAT

PUMPS

Oil Fill

Hole

Sight

Glass

8

V.) Getting Started

A

r

r

IMPORTANT: Proper initial installation of equipment

will assure more satisfactory performance, longer

service life, and lower maintenance cost.

IMPORTANT: The use of a back flow preventer (Part

#222815 call 1-800-270-0810 to order) on the water

supply hose is recommended and may be required

by local code.

Make sure the pressure washer is on a level surface and

in a protected area where it is not readily influenced by

outside forces such as strong winds, freezing

temperatures, rain, etc. Locate the pressure washer for

easy access for filling fluids, adjustments, and

maintenance.

It is recommended that a partition be made between the

wash area and the pressure washer to prevent direct

nozzle spray from coming in contact with the pressure

washer. Moisture reaching the equipment will reduce

the pressure washer’s service life.

Partition

at a proper height and location to provide adequate draft.

This oil fired unit must have a draft controller installed in

the flue. A draft controller will permit proper upward air

flow of exhaust flue gases.

VI.) Oil Burner

Burner Air Adjustment: The oil burner is preset and

performance tested at the factory (elevation 1100 feet).

A one-time initial correction of the burner for your

location will pay off in economy, performance, and

extended service life.

ir Band

White

Arrow

V.) Venting

DANGER: Do not run machine indoors or in an

enclosed area without adequate ventilation, or in

areas where flammable vapors, (gasoline, solvents,

etc.) may be present. Do not vent exhaust gases into

a wall, a ceiling, or a concealed space.

CAUTION: All venting must be in accordance with

applicable federal and state laws, and local

ordinances. Consult local heating contractors.

If the pressure washer is to be used in an enclosed area,

a flue must be installed to vent burner exhaust to the

outside atmosphere. Be sure the flue is the same size

as the burner exhaust vent on the pressure washer lid.

Poor draft will cause the pressure washer to soot and

not operate properly. When selecting the location for

installation, beware of poorly ventilated locations or

areas where exhaust fans may cause an insufficient

supply of oxygen. Proper combustion can only be

obtained when there is a sufficient supply of oxygen

available for the amount of fuel being burned. If it is

necessary to install a unit in a poorly ventilated area,

outside fresh air may have to be piped to the burner and

a fan installed to bring sufficient air into the unit. Locate

the pressure washer in such a manner that the flue will

be as straight as possible and protrude through the roof

Locking

Burner

Screw

1.) Turn the pump and heat switches on (Refer to

“Operation” for details). Have someone operate the

spray gun so the burner fires.

2.) Loosen the locking screw and close the air band until

black smoke appears from the burner exhaust vent.

Note the position of the white arrow on the air band.

3.) Slowly open the air band until white smoke just starts

to appear.

4.) Turn the air band half way back to the black smoke

position previously noted. Tighten the locking

screw.

5.) Fine tune the burner air by loosening the shutter lock

screw and turning the shutter until the exhaust is

cleanest. Tighten the shutter lock screw.

Shutte

Shutte

CAUTION: If white smoke appears from the burner

exhaust vent during start-up or operation,

discontinue use and readjust air bands.

NOTE: If a flue is installed, have a professional

serviceman adjust your burner for a #1 or #2 smoke

spot on the Bacharach scale.

9

Loading...

Loading...