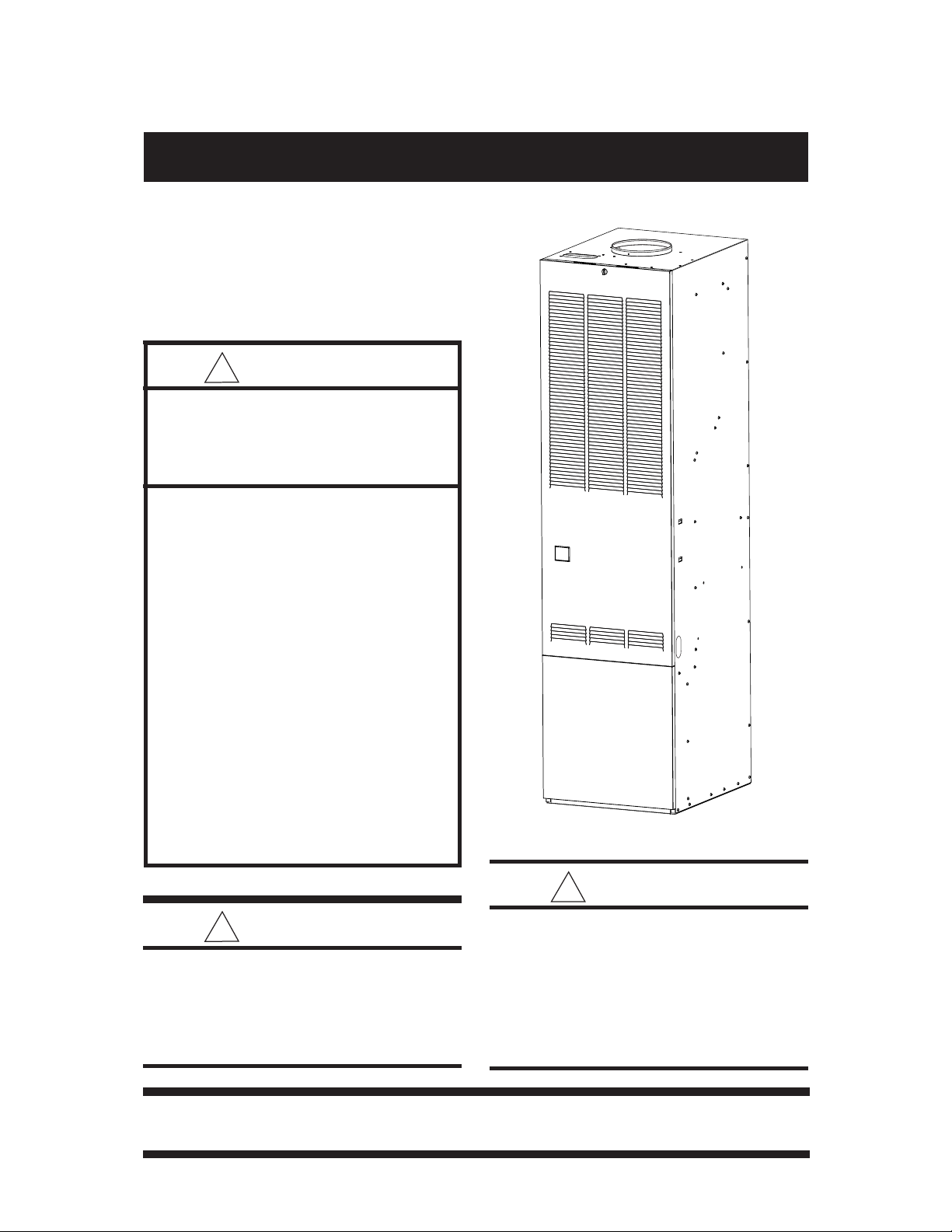

Nordyne M1M, M1G, M1B, M1S User Manual 2

Downflow, Direct Vent (Sealed Combustion)

Forced Air Gas and Oil Furnaces

Owners Manual/Installation Instructions

Series M1B, M1G, M1M and M1S

For installation in:

1. Manufactured Homes

2. Recreational Vehicles, Park Models,

Manufactured Buildings

3. Modular Homes/Buildings

!

WARNING:

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

– Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

– Installation and service must be per-

formed by a qualified installer, service agency or the gas supplier.

!

WARNING:

!

WARNING:

Should overheating occur, or the gas

supply fail to shut off, shut off the

manual gas valve to the appliance

before shutting off the electrical supply.

Improper installation, adjustment, alteration, service or maintenance can

cause injury or property damage. Refer to this manual. For assistance or

additional information consult a qualified installer, service agency or the

gas supplier.

LEAVE THESE INSTRUCTIONS WITH THE HOMEOWNER.

TABLE OF CONTENTS

1. SPECIFICATIONS ...................................................................................3

2. OWNERS INFORMATION ....................................................................... 3

3. MANUFACTURER WARRANTY, OWNER RESPONSIBILITY .................3

4. INSTALLATION STANDARDS ................................................................. 5

5. UNIT LOCATION .....................................................................................6

6. MINIMUM CLEARANCES ........................................................................ 6

7. RETURN AIR PROVISIONS .................................................................... 6

8. AIR DISTRIBUTION SYSTEMS .............................................................. 8

9. ROOF JACK SELECTION ....................................................................... 8

10. DUCT CONNECTOR SELECTION ........................................................... 9

11. INSTALLATION ..................................................................................... 11

12. INSTALLATION OF TRANSIT-MODE VENTING SYSTEM ................... 14

13. ELECTRICAL WIRING ........................................................................... 15

14. FUEL PIPING ........................................................................................ 16

15. FLUE GAS SAMPLING.......................................................................... 19

16. LIGHTING AND FURNACE SHUT DOWN .............................................. 20

17. SERVICE GUIDE ................................................................................... 25

18. MAINTENANCE ..................................................................................... 30

19. OPTIONAL ACCESSORIES .................................................................. 31

20. WIRING DIAGRAMS ......................................................................... 34-39

21. EQUIVALENT ORIFICE SIZES AT HIGH ALTITUDES .......................... 40

M 1 M B - 056 A - B W

Application

M-Manufactured Home

Furnace Series

Fuel, Type of Combustion

G-Gas, Direct Vent, Pilot Burner

Natural or Forced Draft

M-Gas, Direct Vent, HSI,

Forced Draft

B-Gas, Direct Vent, Gun Burner

S-Oil, Direct Vent, Gun Burner

Comfort Model

H - Heating

A - Heating, A/C Ready

B - A/C Ready, 3 Ton

C - A/C Ready, 4 Ton

D - A/C Ready, 5 Ton

2

Door Color

W - White

G - Gray

Cabinet Dimensions

A - 56" x 19-3/4" x 23-3/4”

B - w/Coil Cavity,

76" x 19-3/4" x 23-3/4"

Electrical Code

A - 1PH, 60 Hz, 120 VAC

Heating Capacity

Input, BTUH (000’)

Table 1. Model Identification

!

WARNING:

Do not use this appliance if any part

has been submerged under water.

Immediately call a qualified service

technician to inspect the appliance

and to replace any part of the control

system and any gas control that has

been submerged underwater.

NOTICE TO INSTALLER

Installer is advised to follow carefully all instructions and warnings in this manual to insure

maximum performance, safety, and operating

efficiency of these appliances. Improper installation may create hazardous conditions, and

will void the appliance warranty.

1.SPECIFICATIONS

General Description

M1 Series gas and oil furnaces are listed direct

vent (sealed combustion), downflow heating

appliances for manufactured (mobile) homes,

recreational vehicles, and for use in residential/

modular/commercial construction. The furnace

must be located so that venting can be properly

achieved.

Air conditioning may be added to structures with

M1 series furnaces using Platinum series air

conditioning or conventional units. This Installation Instruction manual includes special requirements for incorporation of air conditioning

equipment to the M1 series of furnaces.

Multi-speed blower assemblies as shown in

Table 3 have been certified for field installation

in M1 Series furnaces. An air conditioner can be

easily field installed with M1GH Series furnaces

if used in conjunction with certified 2-wire relay

box, p/n 903092A or 4/5 wire relay box 902898A.

2. OWNER INFORMATION

ABOUT YOUR CENTRAL

FURNACE SYSTEM

NORDYNE has been involved in the design of

products for the manufactured home industry

since the first manufactured home or trailer was

built.

NORDYNE originated the sealed combustion

system, which separates the furnace combustion system from the living area of the home,

now a standard for the manufactured home

industry.

NORDYNE engineers developed the first central heating system and the first central air

conditioner for manufactured homes.

NORDYNE is dedicated to bringing to its customers the finest heating and cooling comfort

possible. NORDYNE constantly seeks to further refine its products to continuously provide

exceptional comfort.

Follow the instructions in this booklet carefully

and this appliance will provide many years of

superior performance.

If you wish to cool your home automatically with

a central air conditioning system investigate the

excellent NORDYNE cooling systems available from your heating and cooling contractor.

These systems are designed to work best with

your NORDYNE furnace and have been carefully engineered to deliver optimum performance

when mated with NORDYNE manufactured

home furnaces.

NORDYNE also offers water heaters, fireplaces and ventilating systems specifically designed for manufactured housing applications.

Check with your manufactured home retailer,

your heating and cooling contractor or your

distributor for information. Write directly to the

factory (PO Box 46911, St. Louis, MO 63146)

if you are not able to locate a source for

NORDYNE manufactured housing products in

your area.

3. MANUFACTURER WARRANTY,

OWNER’S RESPONSIBILITIES

It is the sole responsibility of the homeowner to

make certain the gas furnace has been correctly set up and converted to the proper fuel

(L.P. gas or Natural gas) and adjusted to operate properly. All gas furnaces are manufactured for Natural gas and must be field converted when using L.P. gas.

A warranty certificate with full details is included

with these instructions. However, NORDYNE

will not be responsible for any costs found

3

necessary to correct problems due to improper

setup, improper installation, furnace adjustments, improper operating procedure on the

part of the user, etc.

5. Correcting problems due to improper gas

supply pressure to the furnace.

6. Providing instructional training on how to

light and operate the furnace.

7. Furnace problems caused by installation of

Some specific examples of service calls which

cannot be included in warranty payments are:

an air conditioner, heat pump or other air

comfort devices.

8. Adding a Roof Jack extension because of

1. Converting the furnace to use another type

of gas.

2. Repairing duct work in the home found to be

faulty.

3. Correcting wiring problems in the electrical

circuit supplying the furnace.

unusual wind and/or snow conditions.

9. Revising installation of the furnace flue assembly (Roof Jack).

10. Adjusting or calibrating of thermostat.

11. Any construction debris which falls into flue

system.

4. Resetting circuit breakers, blown fuses or

other switches.

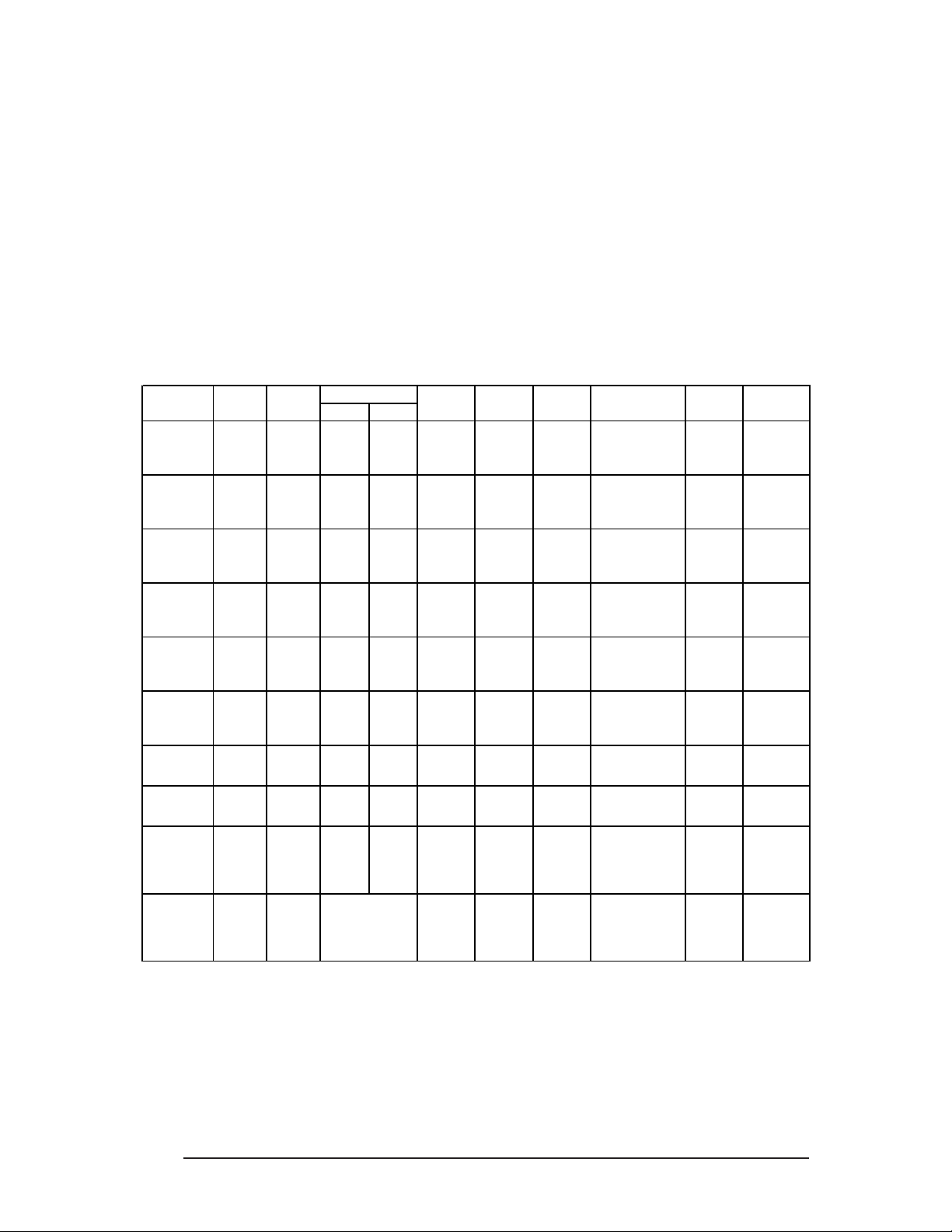

Furnace Input Output Orifice No E.S.P. Pilot Ignitor Comb. Motor A/C Ready

Model No MBtu/h MBtu/h Nat. LP In WC Burner Direct Blower Hp Tons

M1GH 056 56 45 29 45 0.3 x 1/8 2*

M1GB 056 56 45 29 45 0 .3 x 1/4 3

M1GC 056 56 45 29 45 0.3 x 1/2 4

M1GD 056 56 45 29 45 0.3 x 3/4 5

M1GH 070 70 57 24 42 0.3 x 1/5 2½*

M1GB 070 70 57 24 42 0 .3 x 1/4 3

M1GC 070 70 57 24 42 0 .3 x 1/2 4

M1GD 070 70 57 24 42 0 .3 x 3/4 5

M1GH 077 77 62 21 40 0 .3 x x 1/4 3*

M1GB 077 77 62 21 40 0.3 x x 1/4 3

M1GC 077 77 62 21 40 0 .3 x x 1/2 4

M1GD 077 77 62 21 40 0 .3 x x 3/4 5

M1GH 090 90 72 17 36 0 .3 x x 1/4 3*

M1GB 090 90 72 17 36 0.3 x x 1/4 3

M1GC 090 90 72 17 36 0 .3 x x 1/2 4

M1GD 090 90 72 17 36 0 .3 x x 3/4 5

M1MA 056 56 46 29 45 0.3 x x 1/8 2

M1MB 056 56 46 29 45 0.3 x x 1/4 3

M1MC 056 56 46 29 45 0.3 x x 1/2 4

M1MD 056 56 46 29 45 0.3 x x 3/4 5

M1MA 070 70 57 24 42 0.3 x x 1/5 2½

M1MB 070 70 57 24 42 0.3 x x 1/4 3

M1MC 070 70 57 24 42 0.3 x x 1/2 4

M1MD 070 70 57 24 42 0.3 x x 3/4 5

M1MB 077 77 62 21 40 0.3 x x 1/4 3

M1MC 077 77 62 21 40 0.3 x x 1/2 4

M1MD 077 77 62 21 40 0.3 x x 3/4 5

M1MB 090 90 72 17 36 0.3 x x 1/4 3

M1MC 090 90 72 17 36 0.3 x x 1/2 4

M1MD 090 90 72 17 36 0.3 x x 3/4 5

M1BA 066 66 53 26 43 0.3 x x 1/5 2½

M1BB 066 66 53 26 43 0.3 x x 1/4 3

M1BC 066 66 53 26 43 0.3 x x 1/2 4

M1BB 086 86 68 18 37 0.3 x x 1/4 3

M1BC 086 86 68 18 37 0.3 x x 1/2 4

M1SA 066 66 54

M1SB 066 66 54

M1SC 066 66 54

M1SB 086 86 71

M1SC 086 86 71

.50 Gph

.50 Gph

.50 Gph

.65 Gph

.65 Gph

0.3 x 1/5 2½

0.3 x 1/4 3

0.3 x 1/2 4

0.3 x 1/4 3

0.3 x 1/2 4

Burner Model

AF-10 Nozzle

Spray Angle

80° A

Electrical Supply - 120 volts, 60HZ, 1 Ph.

Fuse or Breaker - 15 amps

Temperature Rise - 45° to 75°F

High Altitude - See Table 11. For Canadian

High Altitude (2,000’ to 4,500’), reduce the

gas manifold pressure to 3.0” W.C. for

natural gas and to 8” W.C. for LP gas.

Table 2. M1 Furnace Specifications

4

Thermostat Circuit - 24 volts, 60HZ, 30 vac

Normal Anticipator Setting - 0.4

Manifold Pressure - Natural Gas: 3.5” w.c.

LP Gas: 10” w.c.

*Blower capacity only - needs relay box for AC

Part No.

Blower / Motor Assembly

Blower Wheel Motor-Hp Ton

903773 10 x 8 1/4 2, 2½ & 3

903413 11 x 8 1/2 2, 2½, 3 & 4

903414 11 x 8 3/4 2, 2½, 3, 4 & 5

Table 3. Field Installation Blower Assemblies

Carefully review these responsibilities with your

manufactured housing dealer, service company or gas supplier so there will be no misunderstanding at a later time.

6" (152 mm)

Top Clearance

A/C Capacity

!

CAUTION:

• Never attempt to alter or modify this

furnace or any of its components.

• Never attempt to repair damaged or

inoperable components. Such action

could cause unsafe operation, explosion, fire and/or asphyxiation.

• If a malfunction has occurred, or if

you feel that the furnace is not operating as it should, contact a qualified

service agency or gas utility for assistance.

4. INSTALLATION STANDARDS

Installer shall be familiar with and comply with all

codes and regulations applicable to the installation of these heating appliances and related

equipment. In lieu of local codes, the installation

shall be in accordance with the current provisions of one or more of the following standards.

0" Side

Clearance

to Furnace

Cabinet

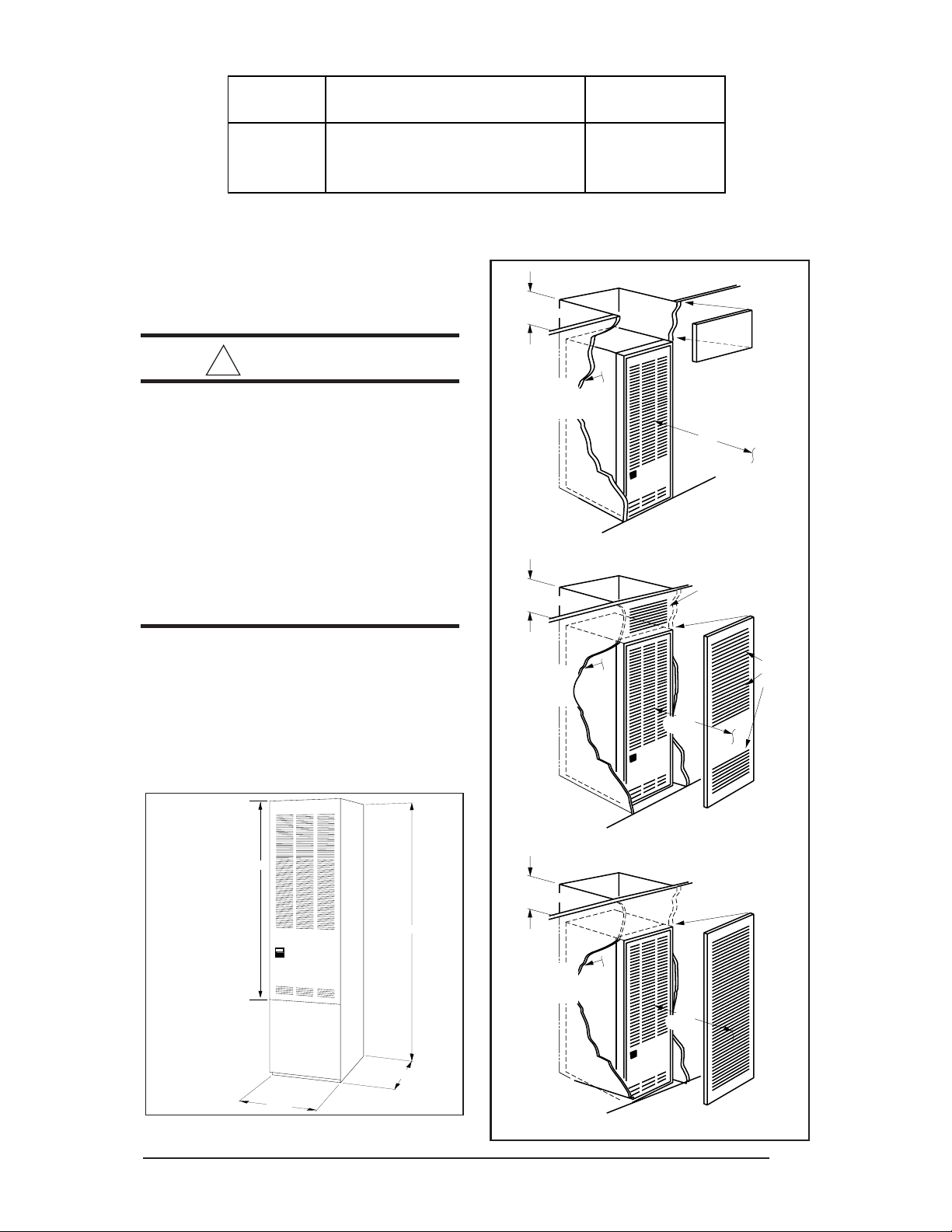

Figure 2. Alcove Installation

6" (152 mm)

Top Clearance

0" Side

Clearance

to Furnace

Cabinet

Removable access

panel should be

installed above

furnace door frame

to access roof jack

18"

(457 mm)

Provide min. 235

sq. in. (1516 cm )

open free area in

front or side wall

6"

(152 mm)

Nearest

Wall or

Partition

2

or

In closet

door

located

at top,

center

or bottom

CLOSET DOOR

“A”- 56"

“A” Modelw/o Coil Cabinet

“B” Modelw/Coil Cabinet

19 3/4"

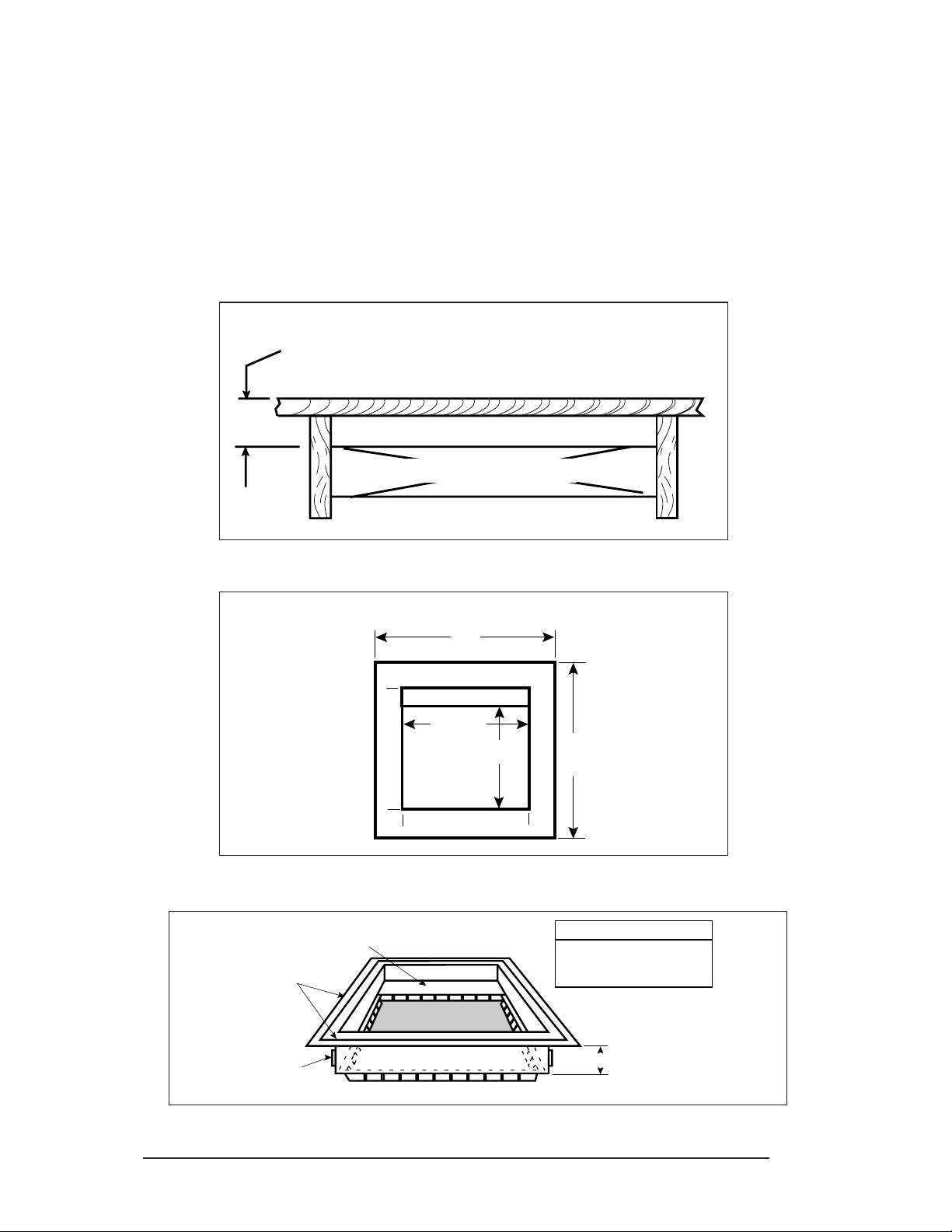

Figure 1. Overall Dimensions

“B”- 76"

23 3/4"

Figure 3. Closet Installation

6" (152 mm)

Top Clearance

0" Side

Clearance

to Furnace

Cabinet

(25 mm)

Figure 4. Special 1” Clearance

Provide min. 250

sq. in. (1613 cm )

open free area in

front or side wall

1"

2

or

in closet

door

a fully

louvered

door may

be used

CLOSET DOOR

5

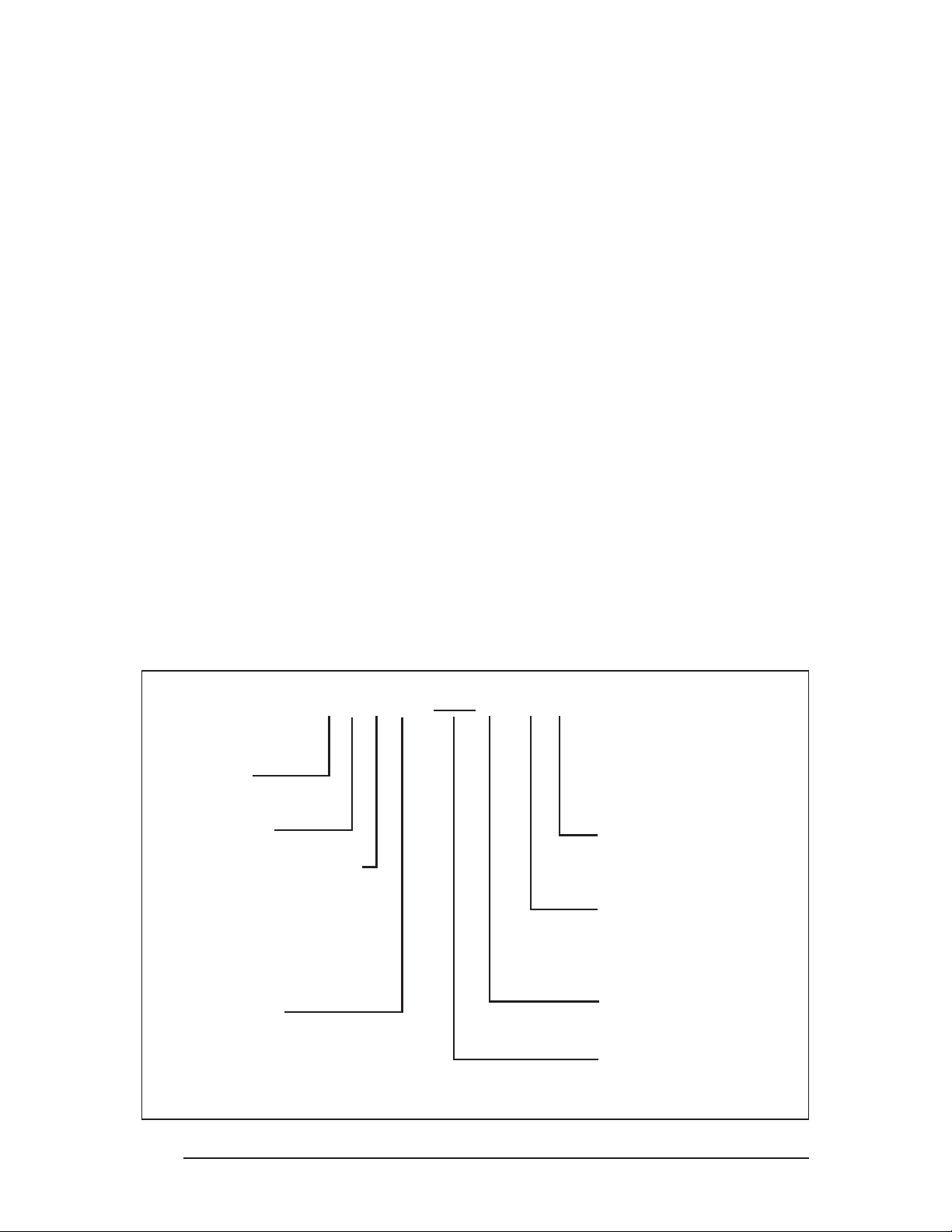

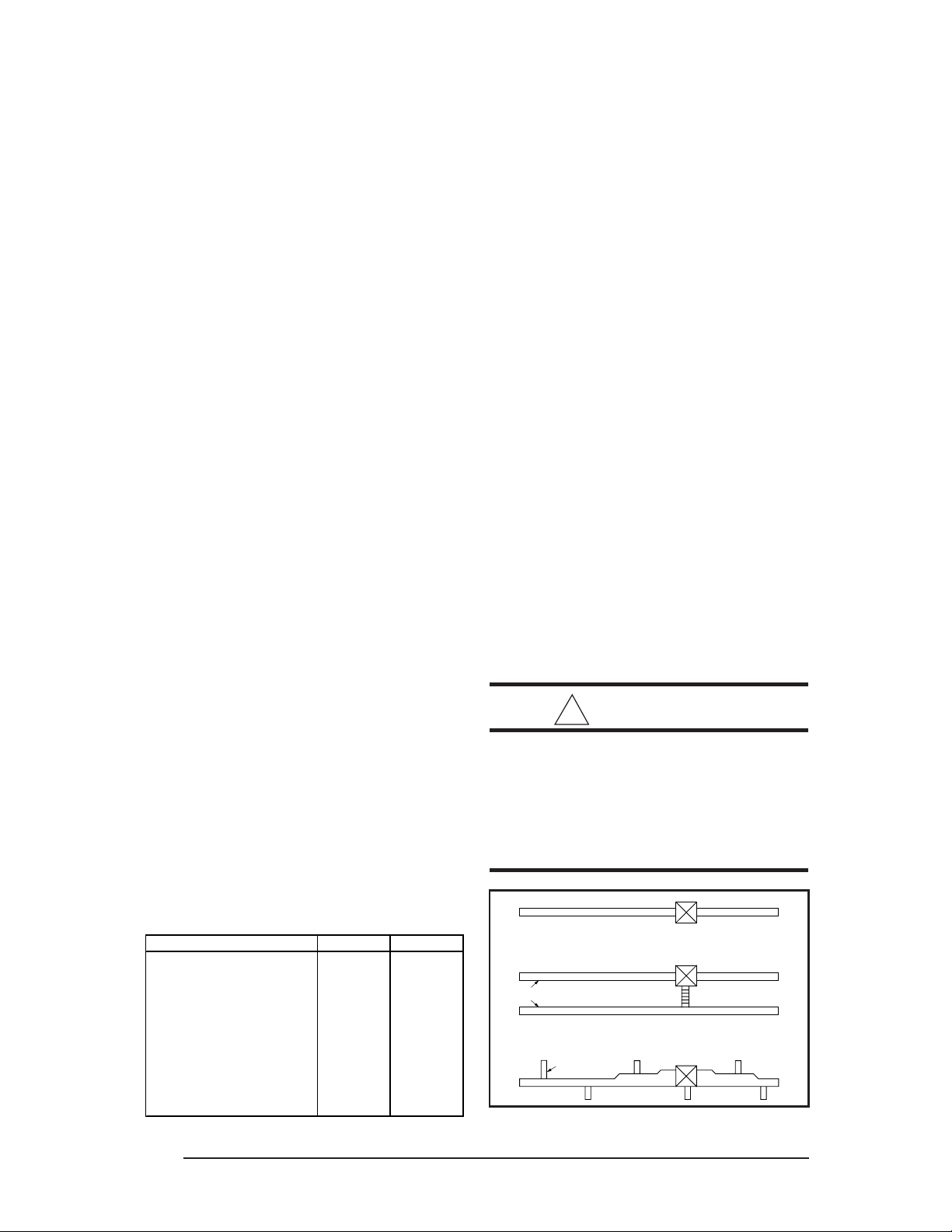

A Single trunk duct

B

Dual trunk duct

w/crossover connector

C

Transition duct

w/branches

a. Federal Manufactured Home Constructions

& Safety Standard (H.U.D. Title 24, Part

3280.707[a][2])

b. American National Standard (ANSI-119.2/

NFPA-501C) for all recreational vehicle installations.

c. American National Standard (ANSI-Z223.1/

NFPA-54) and/or CAN/CGA B149 for all gasfired furnace models.

d. American National Standard (ANSI-Z95.1/

NFPA-31) and/or CSA B139 for all oil-fired

furnace models.

e. American National Standard (ANSI-C1/

NFPA-70) and/or CSA 22.1 Canadian Electric Code Part 1 for all electrical field wiring.

f. Units have been investigated under stan-

dards UL 307A & B, UL727-1999, ANSI

21.47a - CAN/2.3a - 1995, and CSA B140.10.

5. UNIT LOCATION

The furnace shall be appropriately located to

the supply and return air distribution system.

(See “AIR DISTRIBUTION”, Page 8) Sides and

back of the furnace may be enclosed by wall

framing. (See “Minimum Clearances,” Table 4,

and Figures 2 through 5.)

The furnace installation is only intended for free

air return through the furnace door louvers. DO

NOT connect a ducted return air system directly to the furnace. Improper installation may

create a hazard and damage equipment, as well

as void all warranties.

6. MINIMUM CLEARANCES

This heating appliance must be installed with

clearances not less than the minimums shown

in Table 4. This heating appliance must be

installed with ample clearance for easy access

to the air filter, blower assembly, burner assembly, controls, and vent connections.

a. Alcove installations (see Figure 2): minimum

18" clearance at front of furnace shall be

provided for future servicing. A removable

access panel should be installed between

top of the furnace door frame and the ceiling.

b. Closet installations must use a louvered door

having a minimum free area of 235 sq. in.

when located 6" from furnace (See Figure 3)

or 390 sq. in. for 5 ton ready M1 furnaces. For

special clearance between 1" and 6", requirements are a louvered door with a minimum of 250 sq. in. free area, with the openings in the closet door in line with the louvered

openings in the furnace door . A fully louvered

closet door may be used (See Figure 4 and

section 7.i. to evaluate compliance with this

requirement).

7.RETURN AIR PROVISIONS

U.S.A. home manufacturers shall comply with

all of the following conditions to have acceptable

return air systems for closet installed forced air

heating appliances:

Furnace may be installed on combustible flooring when using NORDYNE Duct Connectors

(see Section 10).

When installed in a residential garage, the furnace must be positioned so the burners and the

source of the ignition are located no less than

18 inches above the floor and protected from

physical damage by vehicles.

ALL MODELS CLOSET ALCOVE

Front 6" 18"

Back 0" 0"

Sides 0" 0"

Roof Jack 0" 0"

Top 6" 6"

Top and Sides of Duct 0" 0"

Bottom of Duct

B Cabinet 0" 0"

A Cabinet (w/ coil box) 0" 0"

A Cabinet (w/o coil box) 1/4" 1/4"

Table 4. Minimum Clearances

6

!

CAUTION:

HAZARD OF ASPHYXIATION: Negative pressure inside the closet, with

closet door closed and the furnace

blower operating on high speed, shall

be no more negative than minus 0.05

inch water column.

Figure 5. Non-Platinum

Supply Duct System

a. Regardless of the location, the return air

opening into the closet shall not be less than

specified in the appliance’s listing.

b. Means shall be provided to prevent inadvert-

ent closure by a flat object placed over the

return air opening when it is located in the floor

of the closet (versus the vertical front or side

wall).

c. The cross-sectional area of the return duct

system leading into the closet, when located

in the floor or ceiling shall not be less than 235

square inches (or 390 square inches for 5 ton

ready M1 Furnaces).

d. The total free area of openings in the floor or

ceiling registers serving the return air duct

system must be at least 235 sq. in. At least

one register should be located where it is not

likely to be covered by carpeting, boxes and

other objects.

e. Materials located in the return duct system

must have a flame spread classification of

200 or less. This includes a closet door if the

furnace is in a closet.

f. Noncombustible pans having 1" upturned

flanges are located beneath openings in a

floor duct system.

g. Wiring materials located in the return duct

system shall conform to Articles 300-22 of

the National Electrical Code (ANSI C1/NFPA-

70).

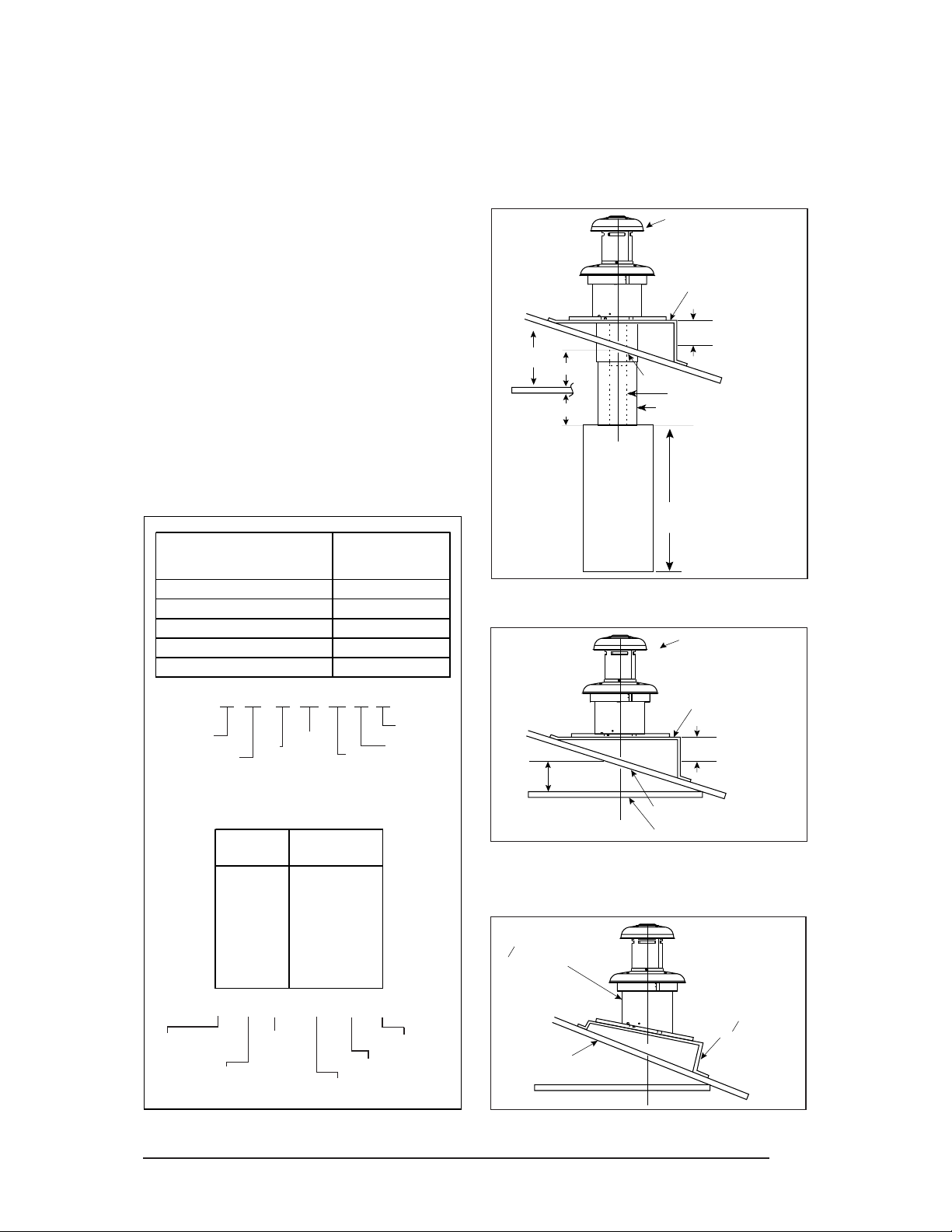

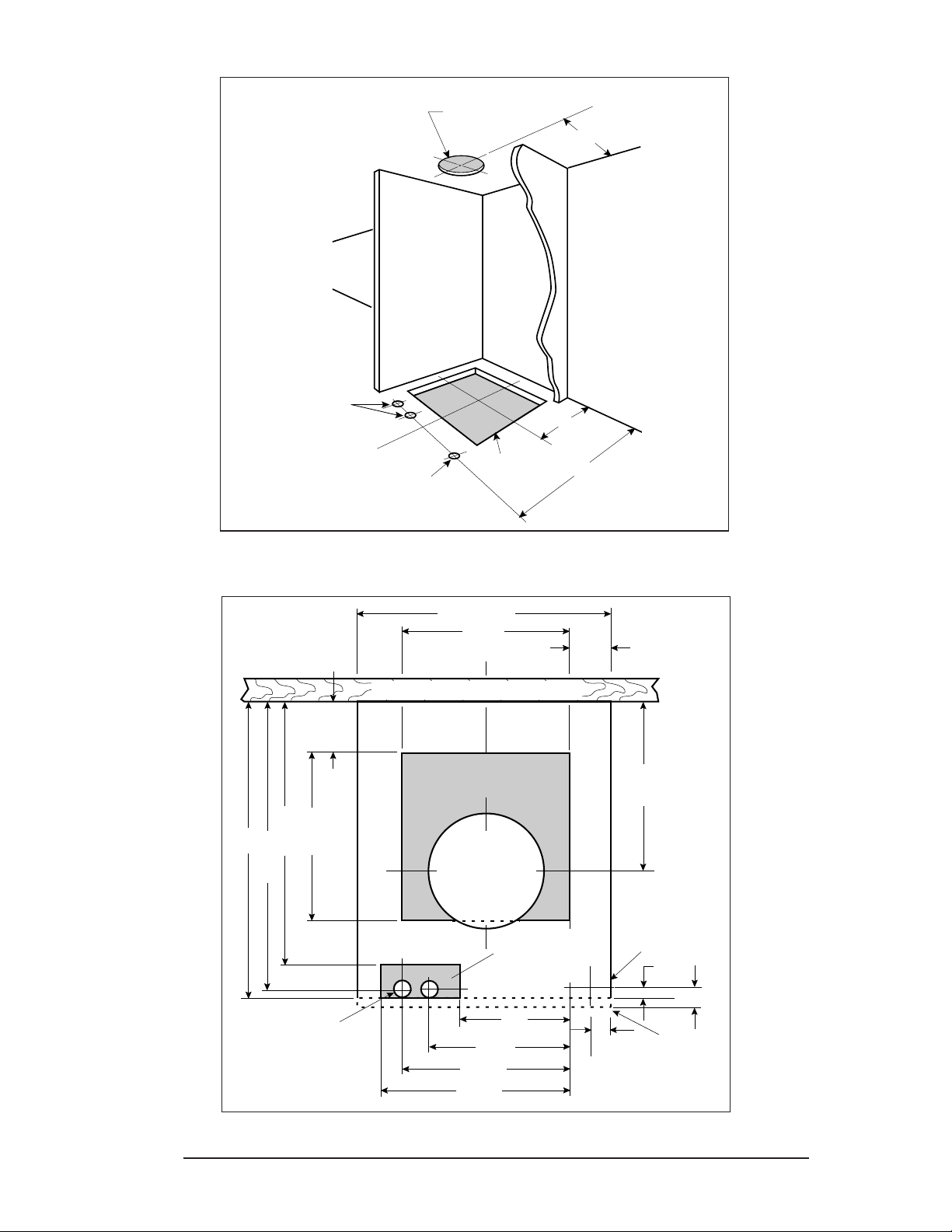

ROOF JACK

SLANT DECK

PITCHED

ROOF

CEILING

CAVITY

"A"

CEILING

"B"

Furnace

FLASHING

"X" (SEE TABLE 1)

ROOF

OPENING

Flue Pipe

Combustion

Air Pipe

56" or 76"

Approx. Length

Model Number Below Flashing

(F,S)AW(T)1523-(0,2,4)(A,S) 15" - 23"

(F,S)AW(T)2135-(0,2,4)(A,S) 21" - 35"

(F,S)AW(T)2747-(0,2,4)(A,S) 27" - 47"

(F,S)AW(T)3563-(0,2,4)(A,S) 35" - 63"

(F,S)AW(T)5195-(0,2,4)(A,S) 51" - 95"

F=S=FLAT FLASHING

SLANT FLASHING

AW= ALL WEATHER

SSAW

T

TYPE:

BLANK=NON-TRANSIT

T= TRANSIT MODE

27

MIN. ADJ.

LENGTH

47 - 2

MAX. ADJ.

LENGTH

All Weather Roof Jack Assemblies

MODEL APPROX . ADJ.

NUMBER LENGTHS*

FO1323 -5 13" - 23"

FO2343 -5 23" - 43"

SO1835 -5 18" - 35"

SO2447 -5 24" - 47"

SO3263 -5 32" -63"

SO4895 -5 48" - 95"

SOT2442 -5 24" - 42"

SOT2745 -5 27" - 45"

SOT4581 -5 45" - 81"

FOT2846 -5 28" - 46"

BELOW FLASHING

S O T 27 45 -5

S= SLAT FLASHING

F= FLAT FLASHING

O= TYPE; STANDARD

H= HIGH WIND

A= ARCTIC ROOF JACK

T= TRANSIT

MODE

TYPE

MAX. ADJ.LENGTH

MIN. ADJ.

LENGTH

FLUE STEEL TYPE

A= ALUMINIZED

S=STAINLESS

FLASHING

PITCH/12" RISE

0=FLAT

2=2.5/12

4=4/12

5 = 5" FLUE DIA.

Figure 6. Roof Jack Assemblies

ROOF JACK

SLANT DECK

PITCHED

ROOF

FLASHING

"X" (SEE TABLE 6)

CEILING CAVITY

CEILING

ROOF OPENING

CEILING OPENING

Figure 7. Example of Flat Jack

with Flashing

OOF JACK WITH

1

/12 SLANT

2

LASHING

5/12 ROOF SLOPE

1

/12

2

2

SLANT DECK

Table 5. Roof Jack Assemblies

Figure 8. Example of 2½/12 Slant Jack

with Flashing

7

h. Gas piping is not run in or through the return

(

duct system.

i. Test the negative pressure in the closet with

the air-circulating fan operating at high speed

and the closet closed. The negative

pressure is to be no more negative than

minus 0.05 inch water column.

j. Air conditioning systems may require more

duct register and open louver area to obtain necessary airflow. Use NORDYNE’s

certiduct program to determine proper duct

size for A/C.

8.AIR DISTRIBUTION SYSTEMS

For proper air distribution, the supply duct

system must be designed so that the static

pressure measured external to the furnace

does not exceed the listed static pressure

rating shown on the furnace rating plate.

b. F=Flat Flashing; flexes from 0/12 to 1/12 roof

slope.

c. S=Slant Flashing. 2.5/12 Slope flexes from 1/

12 to 4/12 roof slope, 4/12 flexes from 3/12

to 5/12.

d. Stainless steel roof jacks are available.

e. If the roof jack crown is covered or blocked

with snow, the furnace will not operate prop-

erly. If the home is located in regions where

snow accumulation exceeds 7” (HUD

snowload zones) use an external roof jack

extension p/n 901937.

f. M1 furnaces may be used with roof jacks as

tall as 170” (except M1M 056 & M1B 066

models, which are limited to 120”). An internal

roof jack extension (p/n 901935 - 10”, p/n

903107 - 18”) can be used to increase roof

jack height. All connections inside the home

must be made below the ceiling.

Location, size, and number of registers should

be selected on the basis of best air distribution

and floor plan of the home.

!

CAUTION:

HAZARD OF ASPHYXIATION: Do not

cover or restrict return air opening.

9.ROOF JACK SELECTION

Note: Install only Roof Jack Assemblies listed

in Table 5 on this heating appliance.

a. Determine depth of ceiling cavity from center

of roof opening to center of ceiling opening.

(See Dimension “A” in Figure 6.)

b. Determine ceiling height and subtract height

of furnace. (See Dimension “B” in Figure 6.)

c. Add dimensions A + B (and X from Table 6 and

Figure 7 if slant deck flashing is used). The

total length of (A + B + X) must be within the

minimum and maximum range of one of the

Roof Jacks listed in Table 5.

APPLICATION NOTES:

a. FAW, FAWT, SAW and SAWT Series Roof

Jacks with a 5" diameter inner vent pipe may

be used with all models of M1 Series gas and

oil furnaces.

These extensions are available as optional

accessories and may be purchased through

your NORDYNE distributor.

IF ROOF PITCH IS: FLASHING NO. "X" FACTOR IS:

2" in 12" 903893 (2.5/ 12) 2-1/8"

2-1/2" in 12" 903893 (2.5/12) 2-1/2"

3" in 12" 903894 (3/12) 2-7/8"

3-1/2" in 12" 903894 (3/12) 3-1/4"

4" in 12" 903895 (4/12) 3-5/8"

"S" Series Roof Jack (2. 5/12 Pi tch only)

4-1/2" in 12" 903895 (2.5/12) 2-1/8"

5" in 12" 903895 (2.5/ 12) 2-1/2"

5-1/2" in 12" 903894 (3/12) 2-7/8"

6" in 12" 903894 (3/12) 3-1/4"

6-1/2" in 12" 903895 (4/12) 3-5/8"

Optional Deck Flashings for Flat and 2.5/12 Pitch

(4/12 Pitch Roof Jacks not applicable.)

USE SLANT DECK

"F Series Roof Jack

Roof Jacks.

Table 6. Slant Deck Flashings

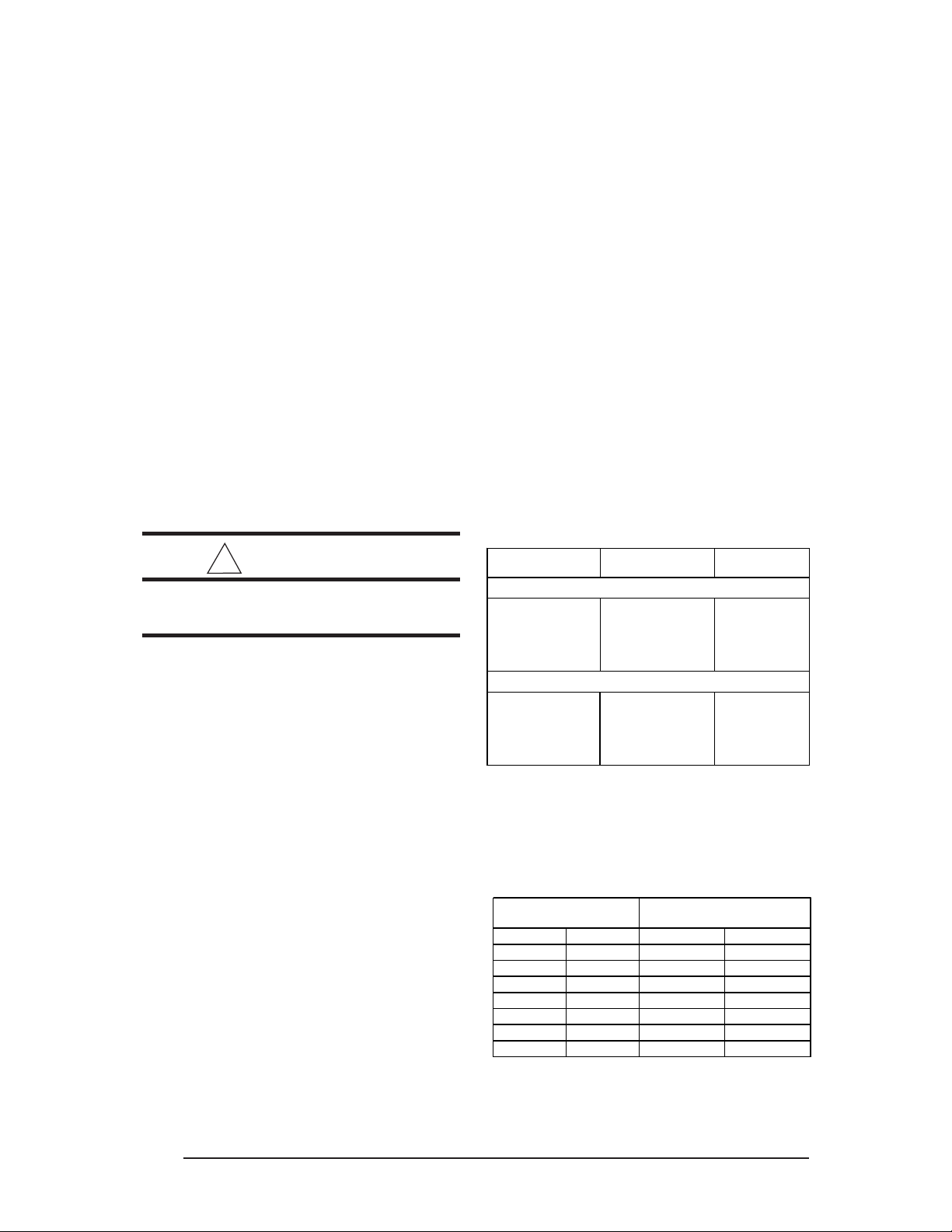

Use Duct Connector

If "X"

Floor Cavity) is:

English Metric (mm)

7/8" 22 901987 904008

2" 51 901988 904009

4-1/4" 108 901989 904010

6-1/4" 159 901990 904011

8-1/4" 210 901991 904012

10-1/4" 260 901992 904013

12-1/4" 311 901993 904014

Model Part Number:

Finger Tab Screw Down

Table 7. Floor Cavity Sizes

8

10. DUCT CONNECTOR SELECTION

PLATINUM SERIES

a. For Platinum ready construction use

the 14” round duct connector, p/n:

903896.

NON-PLATINUM SERIES

a. Determine depth of floor cavity from

surface of floor to top of supply air duct

(See Figure 9).

FLOOR CAVITY

(depth equal to "X" in Figure 11 and Table 7)

x

SUPPLY AIR DUCT

b. Select appropriate model from Table 7

which matches X-dimension of the floor

cavity. To maximize air delivery, remove reducer “C” (see Figure 11) to

obtain the largest open area that will fit

the duct/floor construction. Screw down

duct connector opening to duct without

reducer is 13” x 13”. With reducer it is

13” x 10-1/8”.

*FELT-SEAL

REDUCER

Figure 9.

19”

13 1/4"

10 1/4"

Figure 10.

C

Top View

of

Finger Tab

19"

Duct

Connector

*OPENING TO DUCT

WITH PLATE (C) REMOVED

OPENING BECOMES

13-1/4” x 13-1/4”

SPACERS

*INDICATES FINGER TAB DUCT CONNECTOR ONLY

Figure 11.

X

SEE

TABLE 7

9

LT. FUEL

INE HOLES

C

L

SIDE WALL

FUEL LINE

HOLE

CEILING AND ROOF

OPENINGS

C

L

REAR W

FLOOR

OPENING

ALL

10"

C

L

13-1/2"

23 -1/4"

C

L

24"

21-3/4"

23-1/4"

1-1/4" D.

ALT FUEL-LINE

14-1/2"

ENTRY

Figure 12. Closet or Alcove

20"

14-1/2"

C

L

REAR WALL OF CLOSET OR ALCOVE

FLOOR CUT-OUT

C

L

FOR DUCT CONN.

CEILING

CUT-OUT FOR

FLUE AND

ROOF JACK

(See Fig 12)

FLOOR CUT-OUT

FOR OPTIONAL

COOLING COIL

FOR NON-PLATINUM

SERIES UNITS

C

L

12-7/8"

14-3/4"

15-1/2"

2-1/4"

C

L

10"

2-3/4"

13-1/2"

FURNACE OUTLINE

FUEL-LINE

3/4"

1-3/4"

FURNACE

OUTER DOOR

2"

10

Figure 13. Cut-Out Locations

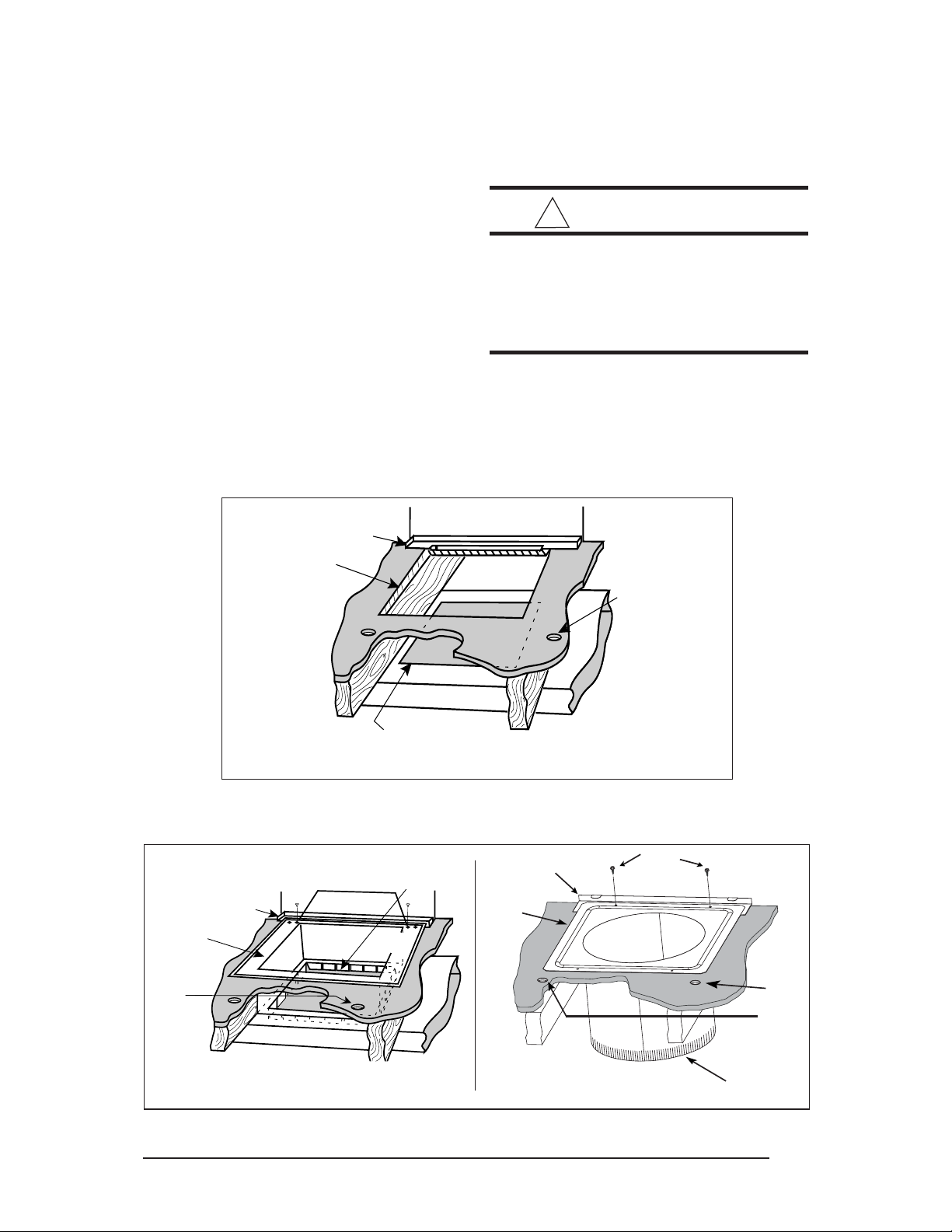

11. INSTALLATION

REAR WALL

MOUNTING

PLATE

FLOOR

OPENING

FUEL

LINE

HOLES

SUPPLY AIR DUCT

CUT DUCT OPENING

1/16TH. LARGER THAN

DUCT CONNECTOR

REAR WALL

SUPPLY AIR DUCT

FUEL

LINE

HOLES

M

OUNTING

PLATE

FLOOR

OPENING

UNDER DUCT OPENING

Required floor, ceiling, and roof cut-out openings must be carefully located to avoid misalignment of the furnace and Roof Jack (see Figures

12 & 13). Installation procedures are suggested

for typical furnace installations and need not be

followed in the exact listed sequence.

CUT OUT FLOOR OPENING & FUEL LINE

HOLE

a. Determine center of closet or alcove (Figure

13).

b. Locate center of the floor opening, measured

10" from the rear wall, and mark cut-out

measuring approximately 14-1/2" by 14-1/2"

(± 1”) for model duct connector used (refer

to Figures 10 & 11).

c. Locate center of fuel line hole, measured 23-

1/4" from the rear wall and 6-5/8" to the left of

center of the floor cut-out (See Figure 12) or

5-1/4" to the left of center of the floor cut-out,

or for entry through right-side of furnace

measured 9" to the right of center of the floor

cut-out.

d. Cut out floor opening and one fuel line hole.

!

IMPORTANT:

Refer to the installation instructions

provided with optional air conditioning

packages when installing furnaces with

optional cooling coil cabinet or with

optional C***-series indoor coils.

CUT OUT CEILING AND ROOF OPENINGS

a. Locate center of Roof Jack opening, mea-

sured 13 1/2" from the rear wall of closet or

alcove along the center line of furnace and

floor opening. (See Figure 13)

Non-Platinum Series

Figure 14. Mounting Plate

MOUNTING

PLATE

DUCT

CONNECTOR

Platinum Series

Figure 15. Duct Connector

SCREWS

FUEL

LINE

HOLES

14” SUPPLY

CONNECTION

11

b. Cut ceiling and roof holes as follows:

Ceiling Hole = 8-3/4" (222 mm) diameter

Roof Hole = 9-3/8" (238 mm) diameter

c. DO NOT ALLOW DEBRIS TO FALL INTO

THE FURNACE. THIS COULD CAUSE

UNSAFE OPERATION AND VOIDS THE

FURNACE WARRANTY. Use the top cap

that comes with the furnace packaging (or

alternate protector) to prevent debris from

falling into the furnace before the final roof

jack connection is made.

CUT DUCT OPENING (FINGER TABBED

ONLY)

a. Place duct connector through the floor open-

ing with bottom tabs resting on top of the

supply air duct.

b. Center duct connector and push back against

rear edge of floor opening.

c. Mark cut-out location (tab area) and remove

duct connector.

d. Cut out duct opening 1/4" larger than area

marked.

INSTALLING FINGER TABBED DUCT CONNECTORS

a. Place duct connector through the floor open-

ing with bottom tabs extending through the

duct opening. (See Figure 15)

b. Secure duct connector to floor.

c. Bend bottom tabs under and up tightly against

the supply air duct (See Figure 16).

NOTE: The duct connector is designed for use

on ducts 12" in width. When using the connector

on 12" wide ducts, there may be insufficient

clearance to bend the tabs on two sides of the

duct connector. In such cases the tabs may be

attached to the sides of the duct by using sheet

metal screws or other suitable fasteners. (See

Figure 17).

If sealant, mastic, or tape is used to provide a

better seal, it should be approved by applicable

national or local codes.

ALTERNATE ATTACHMENT METHODS

INSTALL FURNACE MOUNTING PLATE

a. Place mounting plate (supplied within duct

connector) at rear of the floor opening (See

Figure 15).

INSTALLING PLATINUM SERIES 14” ROUND

DUCT CONNECTOR

a. Place duct connector through the floor open-

ing. (See Figure 15).

b. Secure duct connector to floor.

INSTALLING SCREW DOWN DUCT CONNECTOR

a. Apply a bead of caulking, mastic, or other

approved sealant around bottom side of 1/2”

flange and restrictor plate, when applicable.

b. Locate the duct connector over duct and

carefully lower screw down duct connector

into place.

c. Once duct connector is located on duct,

temporarily hold in place while fastening duct

connector to the floor using flat head screws

or nails. Be sure flanges of duct connector

stay in contact with the duct.

d. Screw plenum to duct making sure a seal is

made between the duct and the duct connector. Additional screws may be added if required.

e. Cut away duct along edge of flange allowing

the center to drop into the duct. Remove

section of duct with caution, as edges will be

sharp.

This procedure may also be used to install a

furnace duct connector to narrow metal

ductwork where insufficient clearance prevents

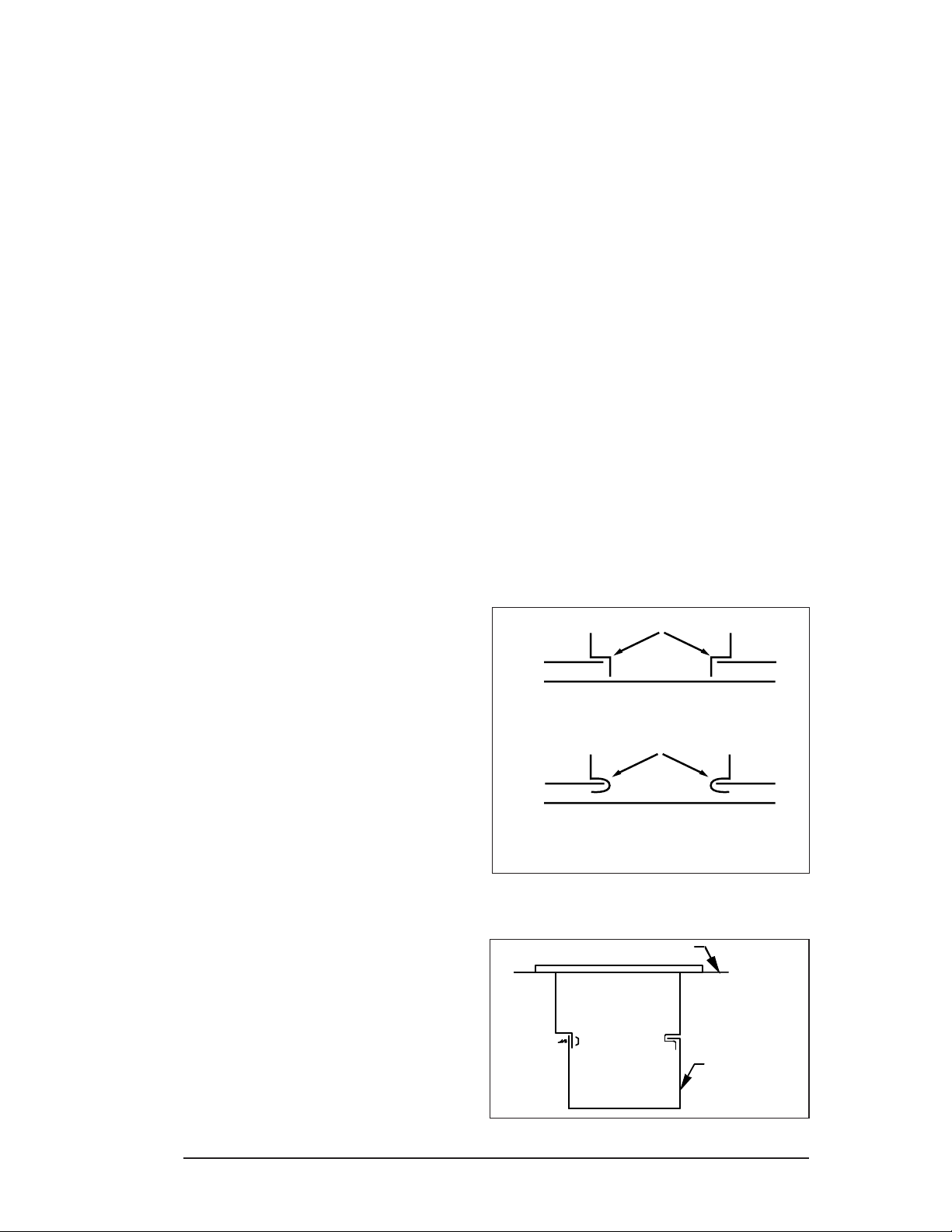

TABS

DUCT

1. INSERT DUCT CONNECTOR INTO

DUCT CUT-OUT.

TABS

DUCT

2. BEND BOTTOM TABS OVER

AND ONTO THE UNDERNEATH

DUCT SERVICE.

Figure 16. Installation of Duct Connector

Duct Connector

Narrow Duct

Duct

Figure 17.

12

Loading...

Loading...