Page 1

Programmes After Market Services

NPC-1 Series Transceivers

A ssembly & Disassembly

Instructions

Issue 1 10/01 ãNokia Corporation

Page 2

NPC-1

Assembly & Disassembly Instructions PAMS Technical Documentation

Table of Contents

Page No

Disassembling the NPC-1 Basic Transceiver ................................................................ 3

Assembling the NPC-1 Basic Transceiver..................................................................... 8

Page 2 ãNokia Corporation Issue 1 10/01

Page 3

NPC-1

c

PAMS Technical Documentation Assembly & Disassembly Instructions

Disassembling the NPC-1 Basic Transceiver

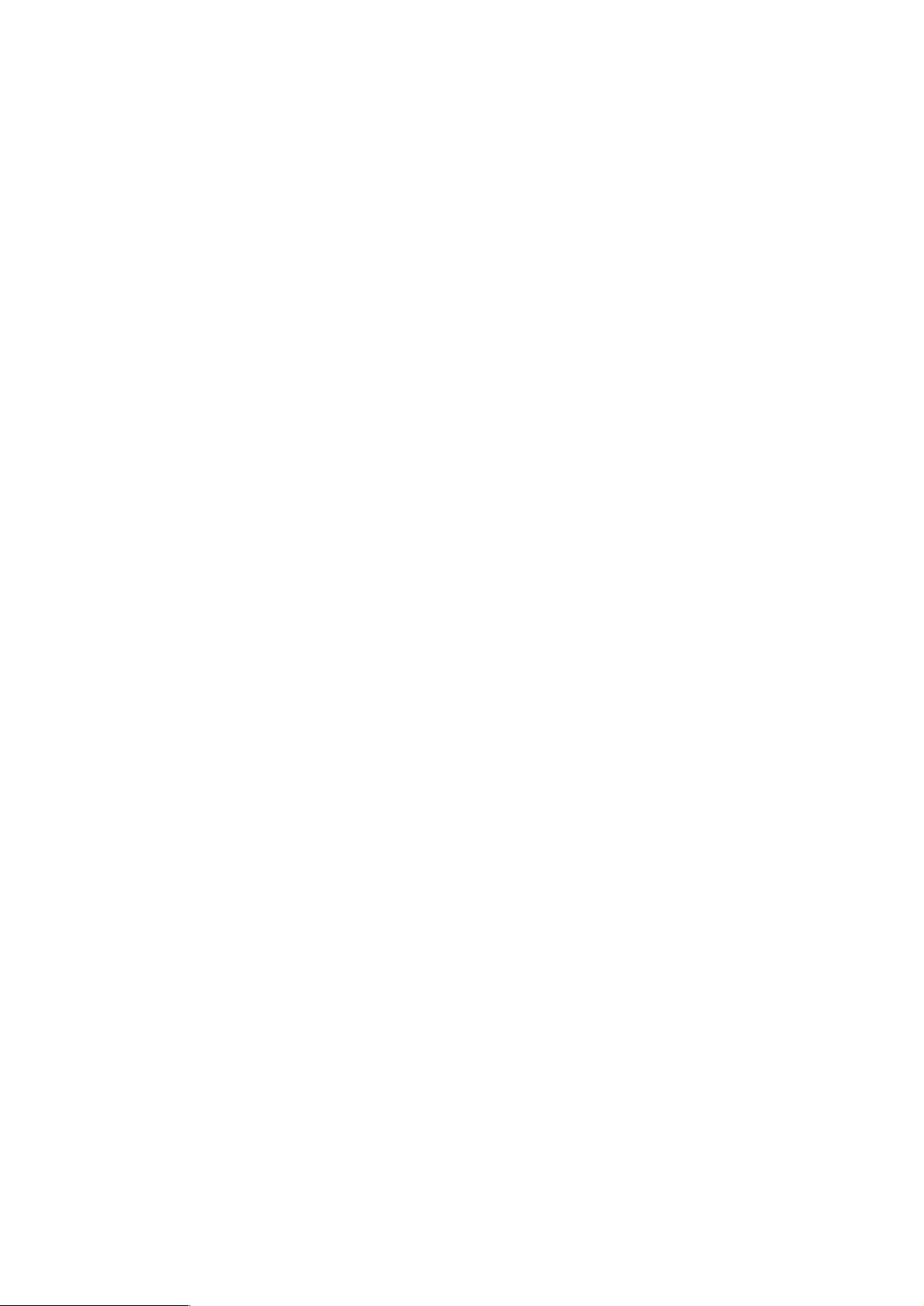

Remove the back cover.

Step 1. Push down hard on the button.

Step 2. Slide the cover in the direction of the

arrow.

2.

Remove the battery.

Step 1. Place fingers on both ends of the battery lat

Step 2. Push the latch away from the battery.

The battery will “bounce off”.

Remove the front cover.

1.

3.

Step 1. Get a firm hold on the phone around the

accessory interfaces (in the D-cover).

Step 2. Hold the side of the front cover as indicated by

the arrow in the D-cover.

Step 3. Life the side up.

4.

Remove the PWB from the housing.

Remove 6 screws.

Note: The picture shows the assembly order.

Assembly is in the reverse order.

Issue 1 10/01 ãNokia Corporation Page 3

Page 4

NPC-1

Assembly & Disassembly Instructions PAMS Technical Documentation

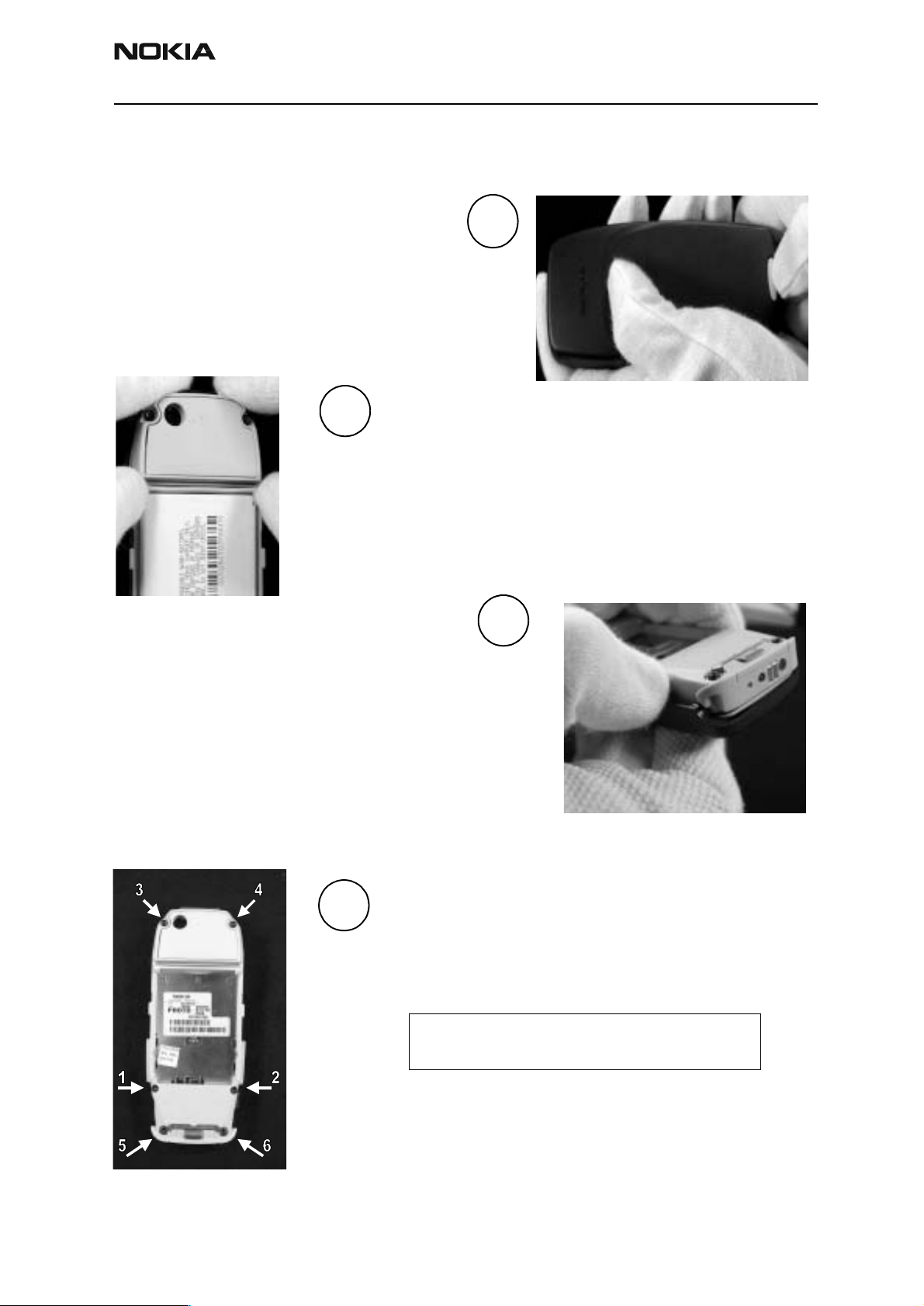

Disassemble C- and D-covers.

5.

Step 2. Lift the D-cover.

Step 1.

between the C- and D-covers’ snap feature.

Place a screwdriver with a chisel point

Note: The screwdriver must not hit the engine module’s

components during disassembly.

6.

Note: The use of gloves is mandatory while removing

the system connector, in order to prevent

fingerprints from appearing on the engine and

the springs. The springs may be damaged,

if touched.

Step 3. Remove the system connector.

The system connector assembly should

stay on the engine when the D-cover

is moved. It can be removed manually.

7.

Step 4. Remove the engine module.

Note: The use of gloves is mandatory while removing

the engine module, in order to prevent

fingerprints from appearing on the engine.

The engine module can be removed manually.

Note:

If the RF shield lid is removed, replace it with a new one as it is vital that the shield is

absolutely straight so that spurious radiation does not occur.

When removing the shield lid, please pay special attention to how it is done. The lid needs to

be removed extremely carefully, so as not to damage any other parts of the radio module.

Please use tweezers or a small screwdriver to remove the shield lid. Snap it open carefully.

Remove the LCD module.

8.

Note: If the LCD module is to be reused, the use of

gloves is mandatory to prevent fingerprints from

appearing on the domes and elastomer connector.

The domes and the elastomer connector may be

damaged, if touched.

Page 4 ãNokia Corporation Issue 1 10/01

Step 5. Lift it off the C-cover.

Page 5

NPC-1

PAMS Technical Documentation Assembly & Disassembly Instructions

9.

Step 4. Remove the speaker

assembly from the

C-cover.

Note: Handle with care, as the speaker and the

springs may be damaged, if touched.

10.

11.

Remove the battery latch.

Step 5. Get a firm hold on the middle of the

latch.

Step 6. Bend the latch and push it away

from the antenna.

Remove the antenna.

Step 7. Place a screwdriver with a flat

head between the antenna and the

D-cover.

Step 8. Lift the antenna.

Note: The antenna’s snap feature may be damaged

during disassembly. The broken snap will not

prevent the reuse of the ante nna.

Step 9. Remove the IR-window.

12.

You can remove the IR-window once the

antenna has been removed.

Remove the battery connector.

Step 10. Push the battery connector

13.

Note: Do not reuse the battery connector after

disassembly.

from the battery side to

remove it.

Issue 1 10/01 ãNokia Corporation Page 5

Page 6

NPC-1

Assembly & Disassembly Instructions PAMS Technical Documentation

Remove the release spring.

14.

Note: The broken heat staking features will not prevent replacing a new release spring

or buzzer onto the cover.

15.

Step 11. Use a flat-headed screwdriver to remove

the release spring from the D-cover.

The heat staking features will break during

disassembly.

Remove the vibra assembly.

Step 12. Lift the vibra assembly from its slot.

Use a screwdriver or your finger.

Remove the buzzer assembly.

Step 13. Place a screwdriver with a chisel-point

between the buzzer assembly and the

D-cover.

16.

Step 14. Lift the buzzer assembly.

The heat staking features will break during

disassembly.

Note: The broken heat staking features will not prevent the use of the buzzer.

Remove the metal deck.

Step 15. Release the four side locks with a

screwdriver.

17.

Step 16. Push the metal deck from the engine’s side.

Note: Do not reuse the metal deck after disassembly.

Page 6 ãNokia Corporation Issue 1 10/01

Page 7

NPC-1

PAMS Technical Documentation Assembly & Disassembly Instructions

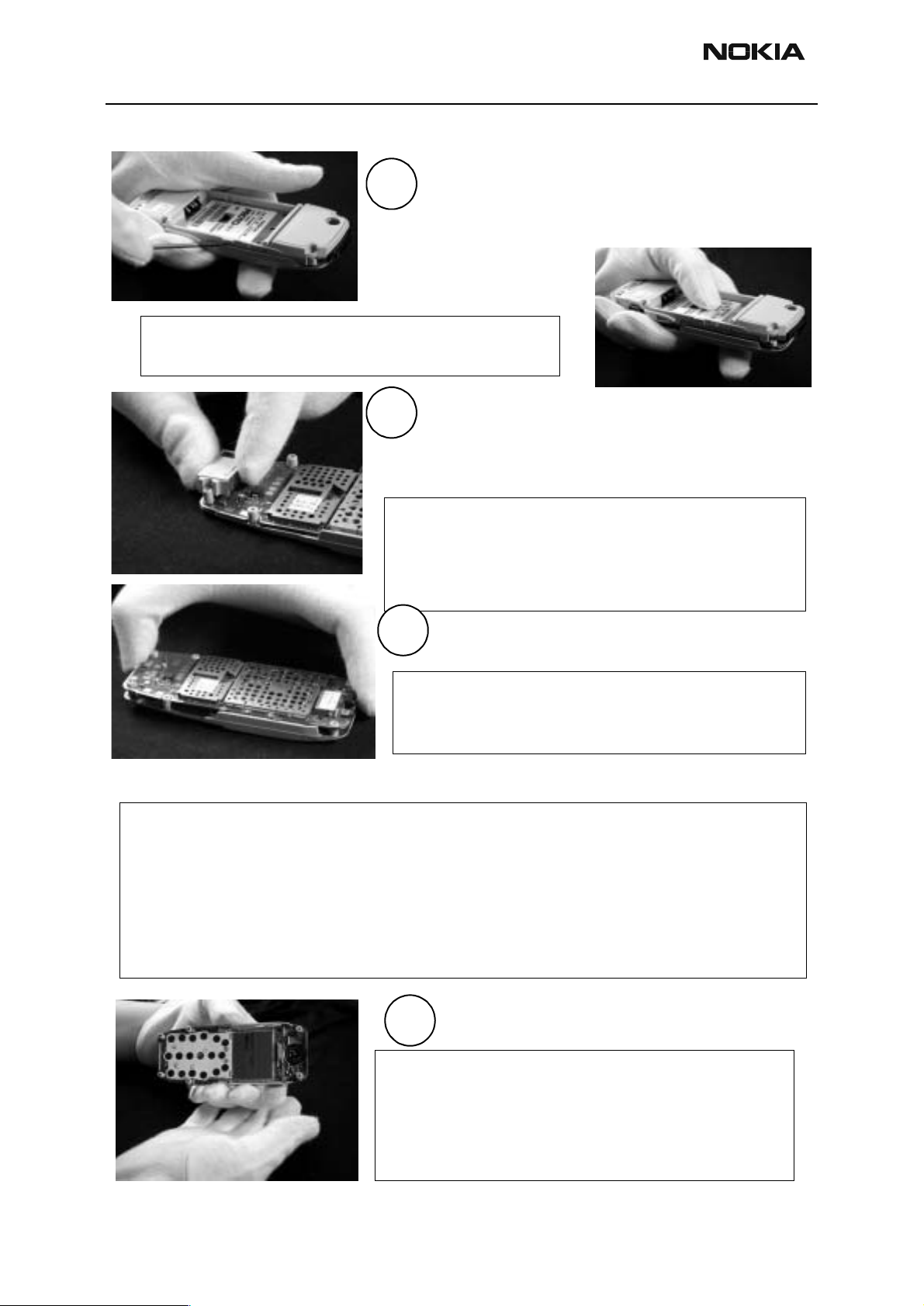

The main parts of the phone disassembled.

Issue 1 10/01 ãNokia Corporation Page 7

Page 8

NPC-1

Assembly & Disassembly Instructions PAMS Technical Documentation

Assembling the NPC-1 Basic Transceive r

Assemble the D-cover assembly.

1.

2.

Step 4. Press the antenna into its place.

Note: Make sure that the antenna springs do not

get damaged or touched during assembly.

No fingerprints should get on the springs.

Step 1. Assemble the metal deck from the

back cover side by pressing it with your

fingers.

All six tabs should snap into the slots in the

D-cover.

Step 2. Place the IR-window onto the

D-cover before assembling the

antenna.

3.

The battery connector will be assembled onto the D-cover

with interference fixing.

Step 7. Place connector onto D-cover with tweezers.

Step 8. Push the connector into the D-cover slot with your fingers.

4.

Step 5. Place one end of the battery latch in to

the D-cover slot.

Step 6. Bend the latch and move the other

end into the D-cover slot.

Note: Make sure that the

battery connector is

below the D-cover edges after assembly. If the

buzzer- or vibra-assembly is in place, make

sure that the buzzer springs stay intact. The

may be damaged, if touched.

5.

Page 8 ãNokia Corporation Issue 1 10/01

Page 9

NPC-1

.

PAMS Technical Documentation Assembly & Disassembly Instructions

Step 9. Place the vibra assembly into its slot. Use

6.

Note: If the battery connector or the buzzer assembly is in

place, make sure that the battery connector springs

and the buzzer springs stay intact. the springs may be

damaged, if touched.

tweezers.

The vibra is assembled into the D-cover with

interference fixing.

Step 10. Place the buzzer assemble into its place.

Use tweezers.

The buzzer is assembled into the D-cover with

interference fixing.

Step 11. Place the release spring into the

8.

9.

D-cover slot.

The release spring is attached onto the

D-cover with screws that are used for

attaching the C- and D-covers. No heat

staking is needed.

Assemble the C-cover.

Step 1. Check the condition of the screw holes

If they are worn out, change the cover.

Step 2. Place the C-cover into a jig. Make sure

that the speaker with the speaker

gasket is in place.

7.

Note: Make sure that the speaker springs stay intact. They may be damaged, if touched.

Place the LCD-module onto the C-cover.

Note: the use of gloves or a vacuum picker

10.

Issue 1 10/01 ãNokia Corporation Page 9

is required, in order to prevent

fingerprints from appearing on the

LCD. Make sure that the elastomer

connector and domes stay intact

during assembly. Use compressed air

or a vacuum before assembling

the D-cover, in order to prevent

dust from getting onto the engine

layout.

Page 10

NPC-1

Assembly & Disassembly Instructions PAMS Technical Documentation

Note: The use of gloves is mandatory in

order to prevent fingerprints from

11.

Place the engine module on top of the

LCD-module.

appearing on the engine layout. Use

ionized air or a vacuum, before

assembling the D-cover, to remove

dust and other foreign particles

from the PWB assy.

Place the system connector on top of the

engine module.

12.

Note: The use of gloves is mandatory in orde r to

prevent fingerprints from appearing on

the engine layout and system connector

pads (charging pads). Make sure that the

system connector springs stay intact. The

springs may be damaged, if touched.

Assemble the D-cover assembly.

Step 1. Place the assembled D-cover on top of the

C-cover.

Step 2. Press the D-cover to snap the side locks.

14.

Assemble the keymat onto the front cover.

15.

Step 1. Place the keypad onto the front

cover before the cover is assembled

to the basic transceiver.

Step 2. Press the keypad into its place.

16.

13.

Assemble the screws.

Step 1. Fasten the 6 screws. The assembly

order is shown in the disassembly

section. The torque is 20 - 21 Ncm

350/RPM.

Assemble the front cover onto the basic

transceiver.

Step 1. First push the basic transceiver to the

front cover’s IR-window.

Step 2. Press the bottom part onto the front

part, so that it snaps onto the front

cover.

Page 10 ãNokia Corporation Issue 1 10/01

Page 11

NPC-1

PAMS Technical Documentation Assembly & Disassembly Instructions

Assemble the battery.

17.

Assemble the back cover.

Step 1. Place the back cover on the

phone.

Step 2. Slide the cover so that the spring snaps the

cover into place.

18.

Step 1. Push the battery connector interface.

Step 2. Press the battery down so that the

latch fits the battery in place.

Issue 1 10/01 ãNokia Corporation Page 11

Page 12

NPC-1

Assembly & Disassembly Instructions PAMS Technical Documentation

Page 12 ãNokia Corporation Issue 1 10/01

Loading...

Loading...