Page 1

CC Technical Documentation

RM-11 Series Transceivers

System Module

Issue 1 02/2004 Confidential ©2004 Nokia Corporation

Page 2

RM-11

System Module CC Technical Document atio n

Contents Page

Introduction.................................................................................................................... 4

BB Hardware Characteristics ......................................................................................4

Technical Summary .....................................................................................................5

Functional Description .................................................................................................5

Modes of Operation................................................................................................... 5

RM-11 BB Functional Blocks .....................................................................................7

UEM and UPP........................................................................................................... 8

Battery....................................................................................................................... 9

Charger Detection ................................................................................................... 11

Charger Interface Protection ................................................................................... 12

LED Driver Circuit.................................................................................................. 12

LCD Display ........................................................................................................... 13

RF Interface Block .................................................................................................. 14

Combo Memory Module......................................................................................... 14

Combo Memory Interface....................................................................................... 14

SRAM Memory Description................................................................................... 14

Flash Memory Description...................................................................................... 15

Flash Architecture................................................................................................... 15

Keyboard (UI Module)............................................................................................ 15

Keyboard ESD Protection....................................................................................... 15

Internal Audio ......................................................................................................... 16

External Audio Connector....................................................................................... 17

External Microphone Connection ........................................................................... 18

External Earphone Connection................................................................................ 18

IrDa Interface .......................................................................................................... 19

Vibra........................................................................................................................ 19

FM Radio................................................................................................................. 19

Camera .................................................................................................................... 20

Flashlight................................................................................................................. 20

System Connector (Tomahawk).............................................................................. 21

PWB Strategy ............................................................................................................22

PWB Construction................................................................................................... 22

PWB Immunity ....................................................................................................... 22

Keyboard................................................................................................................. 23

Audio Lines............................................................................................................. 23

Microphone Lines ................................................................................................... 23

EAR Lines............................................................................................................... 23

Charger Lines.......................................................................................................... 23

HEADINT............................................................................................................... 23

Battery Supply Filtering.......................................................................................... 23

System Connector ................................................................................................... 24

Mechanical Shielding.............................................................................................. 24

EMC Strategy ............................................................................................................24

Test Interfaces ............................................................................................................25

Production / After Sales Interface........................................................................... 25

Flash Interface......................................................................................................... 25

FBUS Interface........................................................................................................ 25

Page 2 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 3

RM-11

CC Technical Documentation System Module

BB_RF Interface Connections ...................................................................................26

RF Functional Description .........................................................................................28

Circuit Diagrams and PWB Layout ........................................................................ 28

Receiver................................................................................................................... 28

Frequency Synthesizers........................................................................................... 29

Transmitter.............................................................................................................. 29

Antenna ................................................................................................................... 32

Software Compensations ...........................................................................................32

RF Frequency Plan.................................................................................................. 33

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 3

Page 4

RM-11

System Module CC Technical Document atio n

Introduction

This chapter describes the system module for the RM-11 transceiver.

The baseband module includes the baseband engine chipset, the UI components, and the

acoustic components. The RM-11 is a hand-portable, dual-band CDMA 800/1900 with

AMPS. It has been designed using a DCT4 generation baseband (UEM/UPP) and RF

module. RM-11 includes a template cutter and user-customizable template front and

back covers. Other features include an integrated VGA camera, an IR, and a built-in

flashlight.

The phone requires the BLD-3 battery with a nominal capacity of 780 mAh.

VGA

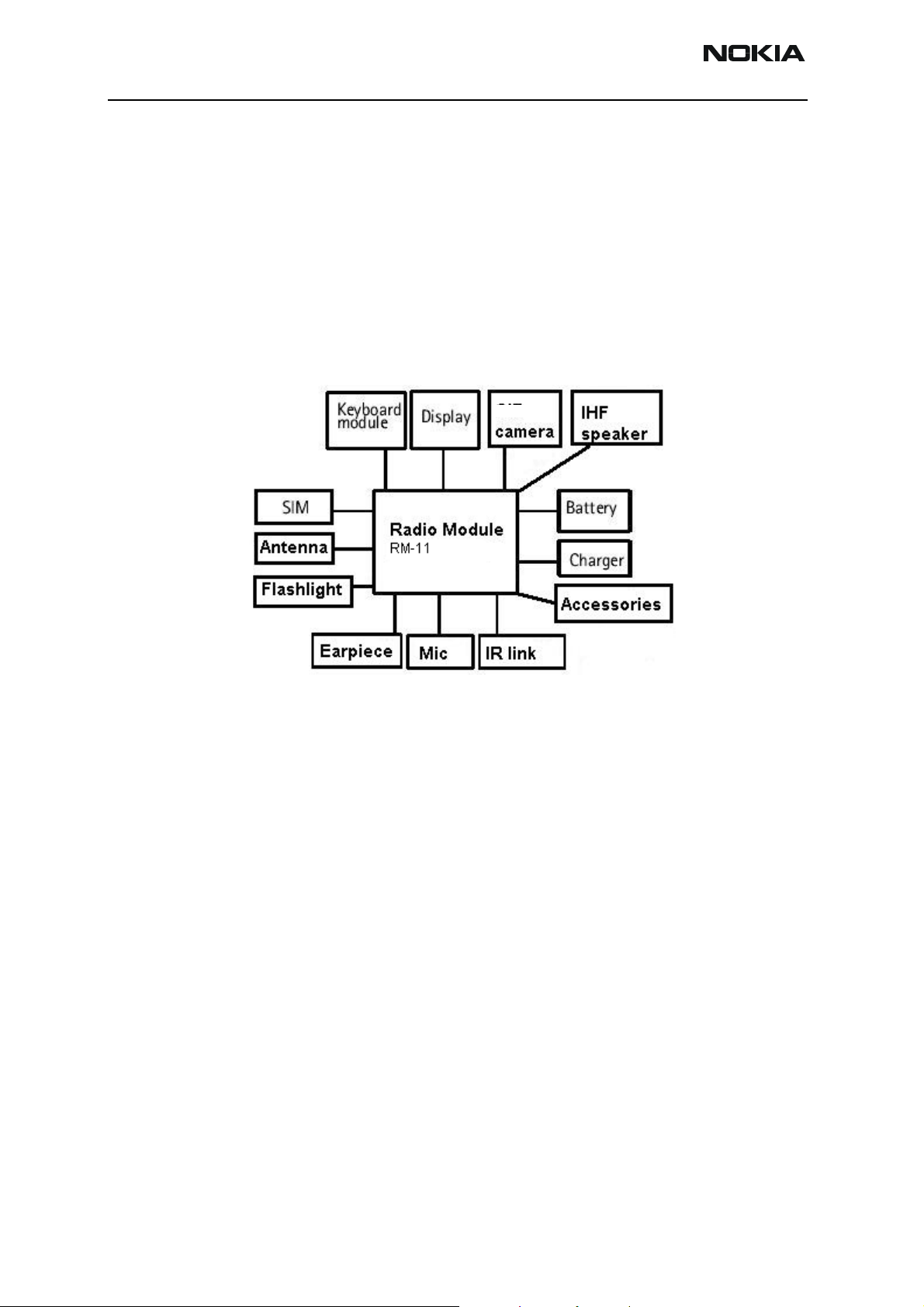

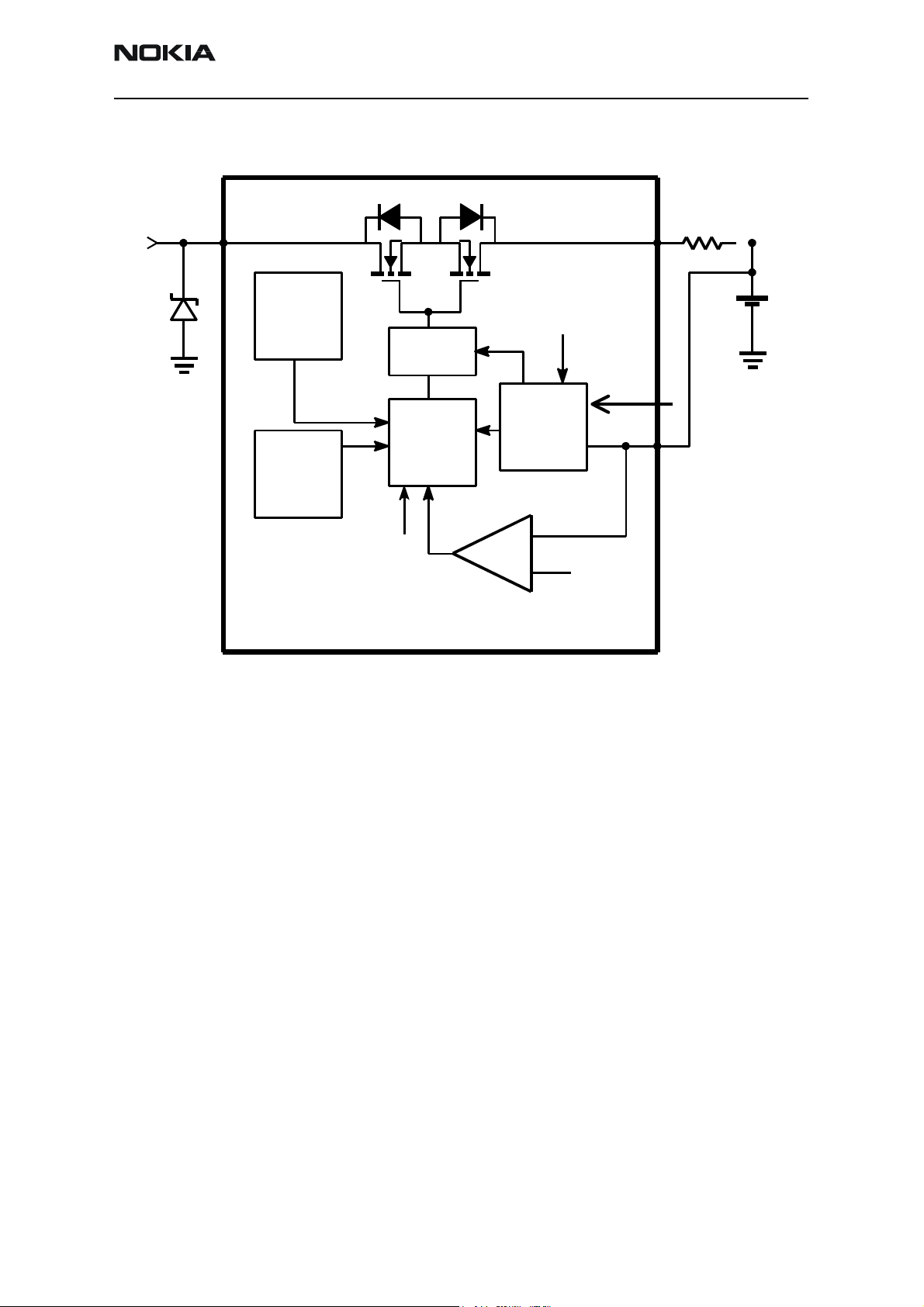

Figure 1: Interconnection diagram

BB Hardware Characteristics

Following are characteristics for the BB hardware:

• Hi-resolution (128x128 pixel) illuminated color display

• Active LCD pixel area: width 27.6mm X height 27.6mm

• ESD-proof keymat, with five individual keys for multiple key pressing

• Support for internal semi-fixed battery (Janette type BLD-3)

• Audio amplifier and SALT speaker for MIDI support

• Ringing volume 100dB @ 5cm (MIDI tones through SALT speaker)

• Stereo FM receiver as an accessory

• IrDa port/interface

• Internal vibra

• Supports voice dial activation via headset button

• Six white LEDs for the keymat on the UI board, and two for the LCD backlight in

the LCD module

• Six-layer PWB, SMD with components on both sides of the PWB

Page 4 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 5

RM-11

CC Technical Documentation System Module

Technical Summary

The baseband module is implemented using two main ASICs — the Universal Energy

Management (UEM) and the Universal Phone Processor (UPP). The baseband module also

contains an audio amplifier for MIDI support and a 128-Mbit Flash/ 8-Mbit SRAM

combo IC. EMC shielding is implemented using a metallized plastic frame. On the other

side, the engine is shielded with PWB ground openings. Heat generated by the circuitry is

conducted out via the PWB ground planes. The RM-11 transceiver module is implemented on a 6-layer, FR-4 material PWB.

Functional Description

Modes of Operation

The RM-11 baseband engine has five different operating modes:

• No supply

• Acting dead

•Active

•Sleep

• Charging

No Supply Mode

In NO_SUPPLY mode, the phone has no supply voltage. This mode is due to the disconnection of the main battery or a low battery voltage level. The phone exits from

NO_SUPPLY mode when a sufficient battery voltage level is detected. The battery voltage

can rise either by connecting a new battery with VBAT > VMSTR+, or by connecting a

charger and charging the battery voltage to above VMSTR+.

Acting Dead Mode

If the phone is powered off when the charger is connected, the phone is powered on and

enters a state called Acting Dead. In this mode, no RF circuitry is powered up. To the user,

the phone acts as if it is switched off. The phone issues a battery-charging alert and/or

shows a battery charging indication on the display to acknowledge to the user that the

battery is charging.

Active Mode

In active mode, the phone is in normal operation, scanning for channels, listening to a

base station, transmitting, and processing information. There are several sub-states in

the active mode depending on if the phone is in burst reception, burst transmission, etc.

SW controls the RF regulators by writing the correct values into the UEM control

registers. VR1A/B and VR2 can be enabled or disabled. VR4 - VR7 can be enabled,

disabled, or forced into low quiescent current mode. VR3 is always enabled in active

mode.

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 5

Page 6

RM-11

System Module CC Technical Document atio n

Sleep Mode

The phone enters Sleep mode when both the MCU and the DSP are in stand-by mode.

Both processors control sleep. When the SLEEPX low signal is detected, the UEM enters

Sleep mode. In this mode, the VCORE, VIO and VFLASH1 regulators are put into low

quiescent current mode. All RF regulators — with the exception of VR2 and VR3 — are

disabled in sleep mode. When the SLEEPX is set high and is detected by the UEM, the

phone enters Active mode and all functions are activated. Sleep mode is exited either by

the expiration of a sleep clock counter in the UEM, or by some external interrupt generated by a charger connection, key press, headset connection, etc. While in Sleep mode,

the main oscillator is shut down and the baseband section uses the 32 kHz sleep clock

oscillator as its reference.

Charging Mode

Charging can be performed in parallel with any other operating mode. The Battery Size

Indicator (BSI) resistor inside the battery pack indicates the battery type/size. The resistor

value corresponds to a specific battery capacity and technology. Under UPP software

control, the UEM's AD converters measure the battery voltage, temperature, size, and

current. The charging control circuitry (CHACON) inside the UEM controls the charging

current delivered from the charger to the battery. The battery voltage rise is limited by

turning the UEM switch off when the battery voltage has reached VBATLim

(programmable charging cut-off limits are 3.6V, 5.0V, 5.25V). Measuring the voltage

drop across a 0.22 Ohm resistor monitors the charging current.

Page 6 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 7

RM-11

CC Technical Documentation System Module

RM-11 BB Functional Blocks

Passive color STN

4096 colors

128/8 Mbit

UEMK

VGA

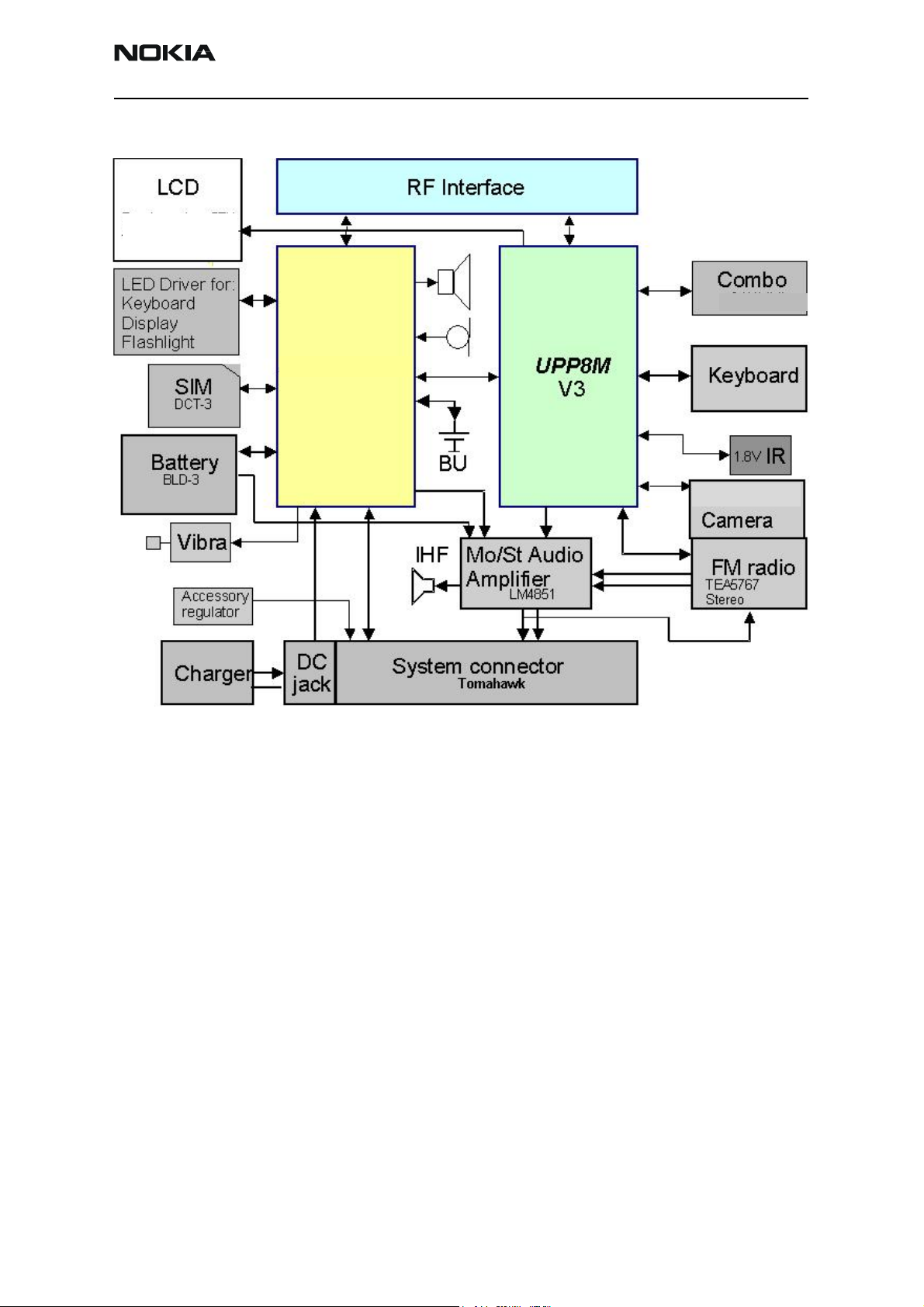

Figure 2: Baseband block assembly

RM-11 BB functional blocks are listed below:

• UEM and UPP

• Battery

•LED driver

•LCD display

• RF IF block

• Memory module

• Keyboard (UI module)

• External audio connector

•IrDa interface

•Vibra

•FM radio

• System connector (Tomahawk)

• PWB strategy

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 7

Page 8

RM-11

System Module CC Technical Documentation

•EMC strategy

• Test interface

UEM and UPP

The UEM contains a series of voltage regulators to supply both the baseband module and

the RF module. Both the RF and baseband modules are supplied with regulated voltages

of 2.78 V and 1.8 V. The UEM contains six linear LDO (low drop-out) regulators for the

baseband and seven regulators for RF circuitry. The RF regulator VR1 uses two LDOs and

a charge pump. The VR1 regulator is used by the RF module. The core of the UPP is supplied with a programmable voltage of 1.0 V, 1.3 V, 1.5 V, or 1.8 V. Note that with the

UEMK, VCORE supply voltage is set to 1.5 V.

The UPP operates from a 19.2 MHz clock generated in the RF ASIC. The DSP and MCU

both contain phase locked loop (PLL) clock multipliers, which can multiply the system

frequency by factors from 0.25 to 31. The actual execution speed is limited by the

memory configuration and process size (Max. DSP speed for C035 is ~ 200MHz).

The UEM contains a real-time clock, sliced down from the 32768 Hz crystal oscillator.

The UPP uses the 32768 Hz clock as the sleep clock.

The communication between the UEM and the UPP is done via the bi-directional serial

busses, CBUS and DBUS. The CBUS is controlled by the MCU and operates at a speed of

1.08 MHz. The DBUS is controlled by the DSP and operates at a speed of 9.6 MHz. Both

processors are located in the UPP.

The interface between baseband and RF is implemented in the UEM and UPP ASIC. The

UEM provides A/D and D/A conversion of the in-phase and quadrature receive and transmit signal paths. It also provides A/D and D/A conversions of received and transmitted

audio signals to and from the user interface. The UEM supplies the analog signals to the

RF section according to the UPP DSP digital control. The RF ASIC is controlled via the UPP

RFBUS serial interface. There are also separate signals for PDM-coded audio. Digital

speech processing is handled by the DSP inside the UPP ASIC. The UEM is a dual voltage

circuit with the digital parts running from the baseband supply (1.8 V) and the analog

parts running from the analog supply of 2.78 V. The input battery voltage (VBAT) is also

used directly by some UEM blocks.

The baseband supports both internal and external microphone inputs as well as speaker

outputs. Input and output signal source selection and gain control are done by the UEM

according to control messages from the UPP. Keypad tones, DTMF, and other audio tones

are generated and encoded by the UPP and transmitted to the UEM for decoding. The

RM-11 has two external serial control interfaces: FBUS and MBUS provided by the UEM.

These busses can be accessed only through production test patterns. RM-11 also uses the

UPP8MV3 and UEMK.

Page 8 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 9

RM-11

CC Technical Documentation System Module

Battery

BLD-3 Li-ion (inbox battery) is used as the main power source. The BLD-3 has a capacity

of 780 mAh.

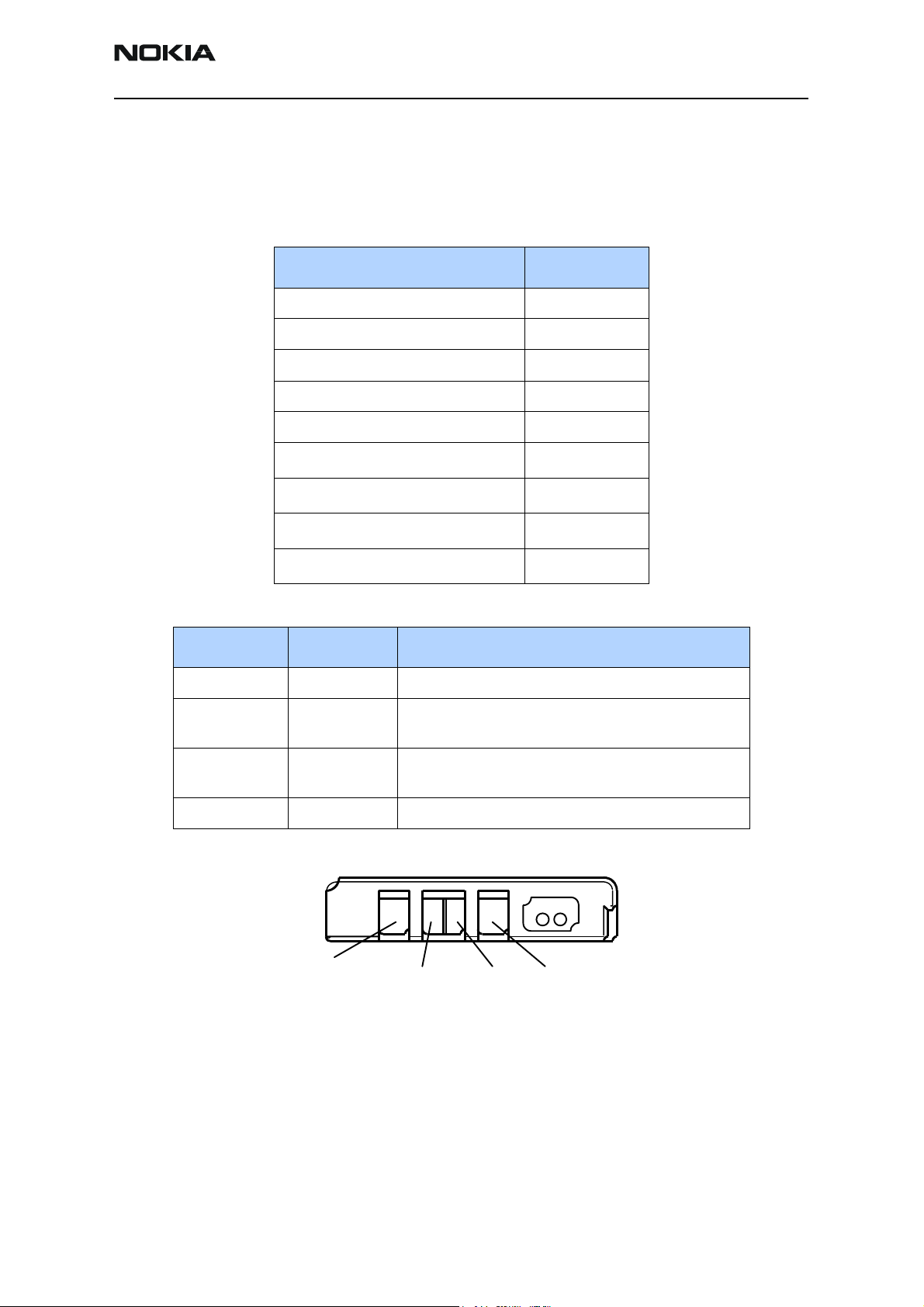

Table 1: BLD-3 characteristics

Description Value

Nominal discharge cut-off voltage 3.1V

Nominal battery voltage 3.7V

Nominal charging voltage 4.2V

Maximum charger output current 850mA

Minimum charger output current 200mA

Cell pack impedance -20 ... 0

Cell pack impedance 0 ... +20

Cell pack impedance +20 ...+60

Cell pack impedance +60 ...+80

Table 2: Pin numbering of battery pack

o

o

C

C

o

C

o

C

180mΩ max

150mΩ max

130mΩ max

250mΩ max

Signal name Pin number Function

VBAT 1 Positive battery terminal

BSI 2 Battery capacity measurement (fixed resistor inside the

battery pack)

BTEMP 3 Battery temperature measurement (measured by ntc

resistor inside pack)

GND 4 Negative/common battery terminal

2(BSI) 3(BTEMP) 4(GND)

Figure 3: Battery pack contacts

Charge

GND

The BSI fixed resistor value indicates the type and default capacity of a battery. The

NTC-resistor measures the battery temperature.

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 9

Page 10

RM-11

System Module CC Technical Documentation

Temperature and capacity information is needed for charge control. These resistors are

connected to the BSI and BTEMP pins of the battery connector. The phone has 100 kW

pull-up resistors for these lines so that they can be read by A/D inputs in the phone. For

safety reasons, the phone software will shut the phone off if it senses a temperature of

38oC or higher on the BTEMP line.

Table 3: BSI resistor values

Parameter Min Typ Max Unit Notes

Battery size indicator resistor BSI 75 kΩ Battery size indicator (BLD-3)

Tolerance “1%

NTC thermistor BTEMP 47

VBATT

BSI

BTEMP

EMC

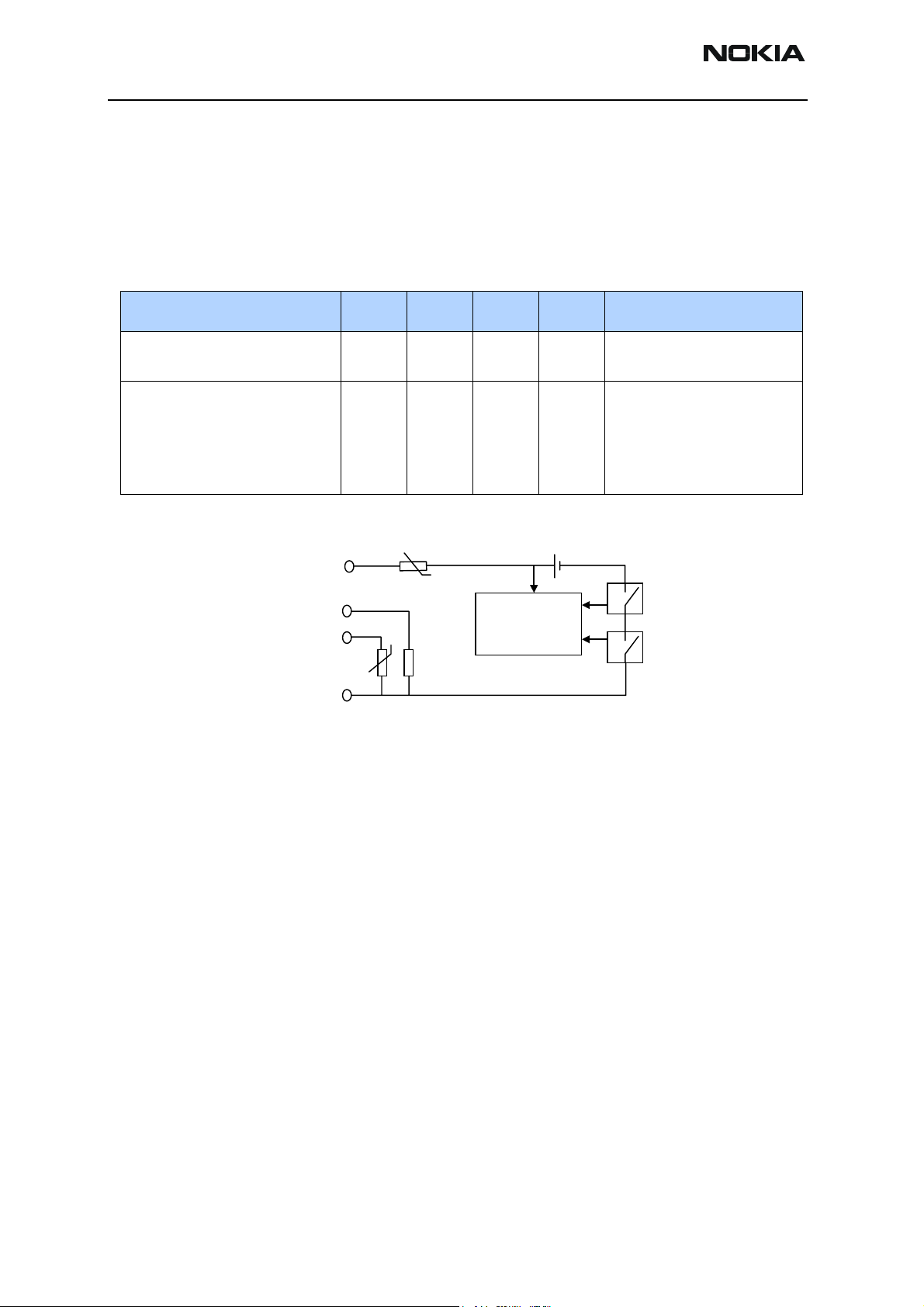

Figure 4: Interconnection diagram

Supply Voltage Regulation

The UEM ASIC controls supply voltage regulation. There are six separate regulators used

by the baseband block. For a more detailed description about the regulator parameters,

see the UEM ASIC Specification document.

4000

kΩ

K

Overcharge /

Overdischarge

protection

Battery temperature indicator (NTC pulldown) 47kΩ“5%

o

@ 25

C

Beta value (B).

Tolerance “5%, 25

Li-Ion

o

C / 85 oC

Charging

The RM-11 baseband supports the NMP charger interface specified in the Janette

Charger Interface document. SW control is specified in the EM SW Specification, ISA EM

Core SW Project document. The UEM ASIC controls charging, and external components

are used to provide EMC, reverse polarity, and transient protection of the charger input

to the baseband module. The charger connection is through the system connector interface. Both 2- and 3-wire type chargers are supported. The operation of the charging

circuit has been specified to limit the power dissipation across the charge switch and to

ensure safe operation in all modes.

Page 10 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 11

RM-11

V

CC Technical Documentation System Module

UEM

CHAR

VCHARin

Over

Temp.

Detection

WatchDog

Switch

Driver

Current

Ctrl

Logic

Figure 5: UEM charging circuitry

Sensing/

Limit

+

Comp

-

VCHARout

Vmstr

VBATT

VBATTlim

VBATT

Charger Detection

Connecting a charger creates voltage on the VCHAR input to the UEM. When the VCHAR

input voltage level rises above the VCHDET+ threshold, the UEM starts the charging

process. The VCHARDET signal is generated to indicate the presence of the charger for

the SW.

Energy Management (EM) SW controls the charger identification and acceptance. The

charger recognition is initiated when the EM SW receives a "charger connected" interrupt. The algorithm basically consists of the following three steps:

1. Check that the charger output (voltage and current) is within safety limits.

2. Identify the charger.

3. Check that the charger is within the charger window.

If the charger is identified and accepted, the appropriate charging algorithm is initiated.

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 11

Page 12

RM-11

System Module CC Technical Documentation

Charger Interface Protection

In order to ensure safe operation with all chargers and in misuse situations, the charger

interface is protected using a transient voltage suppressor (TVS) and a 1.5A fuse. The TVS

device used in RM-11 is rated for 16 V@175 W.

Figure 6: Charger interface diagram

Table 4 includes the values for the TVS.

Table 4: Charger interface TVS characteristics

Characteristic Value

Breakdown voltage (VBR) 17.8Vmin (at IT 1.0mA)

Reverse standoff voltage (VR) 6V

Max reverse leakage current at VR (IR) 5uA

Max peak impulse current (Ipp) 7A (at Ta=25*C, current waveform: 10/1000us)

Max clamping voltage at Ipp (Vc) 26V

LED Driver Circuit

In RM-11, white LEDs are used for LCD and keypad lighting. Two LEDs are used for LCD

lighting and six are used for the keyboard. A step-up DC-DC converter (TK11851) is used

as the white LED driver.

The display LEDs are driven in serial mode to achieve stable backlight quality. This means

that constant current flows through LCD LEDs. Serial resistance RLCD is used to define

the proper current. The feedback signal (FB) is used to control the current. The driver

increases or decreases the output voltage for LEDs to keep the current stable.

Keyboard LEDs are driven in 2-serial/3 parallel modes. Serial resistance R is used to limit

the current through LEDs. The feedback signal is not used to control the current. The

driver is controlled by the UEM via the DLIGHT output. This signal is connected to driver

EN-pin (on/off). It is possible to control the LED brightness by PWM to achieve smooth

on/off operation.

Page 12 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 13

RM-11

CC Technical Documentation System Module

VBAT

Cin

DLIGHT

Cosc

Figure 7: Shared LED driver circuit for LCD and keyboard backlight

LCD Backlight

The LCD backlight consists of two white LEDs, which are integrated with the

LCD module.

Keyboard Illumination

The keyboard light consists of six white LEDs on the UI board. They are placed under the

keyboard for proper illumination of the keypad.

V in

En

Cx

Coil

Is

Ext

LED Driver

Schottky

Vovp

FB

Gnd

Cout

Rlcd

LCD Illumination

R

Keyboard Illu mi na ti on

LCD Display

The LCD is a CSTN 130 x 130, full-dot matrix display with 12bit (4096 colors) color resolution and a single pixel border area around the content area, which makes the total

active area 128 x 128 pixels.

Table 5: LCD general specifications

LCD parameter Value

Glass size, width x height x thickness 33.98 mm x 37.95 mm x 1.71 mm

Glass thickness 0.50 mm

Viewing area (width x height) 30.29 mm x 30.29 mm

Active pixel area (width x height) 27.29 mm x 27.29 mm

Number of pixels 130 x 130 pixels

Technology CSTN (color super twisted nematic)

Operating temperature range

Main viewing direction 6 o’clock

Illumination mode transflective

-25

o

C to +70 oC

Color tone

Background: Neutral/Black

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 13

Page 14

RM-11

System Module CC Technical Documentation

C

Driver

Top View

Active area

128x128

C C

C 0 C 128

R 0

R 128

Figure 8: Color LCD module

RF Interface Block

The interface between the baseband and the RF module can be divided into two

categories: the digital interface and the analog interface. The digital interface is between

the UPP and the RF chip. The serial digital interface is used to control the operation of

the different blocks in the RF chip. The analog interface is between the UEM and the RF.

The entire BB-RF interface is discussed in the RF-BB Interface Specification RH-27

document.

Combo Memory Module

The RM-11 baseband memory module consists of a combo Flash/SRAM chip. It has

128 Mbit burst-type flash memory and 8Mbit of SRAM. In addition, the UPP has 8Mbits

of internal RAM. The UPP RAM is part of the UPP and is not discussed here.

Combo Memory Interface

The memory interface consists of a multiplexed address/data bus MEMADDA [23:0], the

MEMCONT[9:0] memory control bus, and the GENIO[23], which is used for memory

control. The purpose of the memory interface is to reduce the amount of

interconnections by multiplexing the address and data signals on the same bus. Because

the required Flash address space is more than 16bits, the MEMADDA[15:0] are multiplexed address/data lines and MEMADDA[22:16] are only address lines, which in total

allow for 8M addresses (MEMADDA[21:0]). The multiplexed data/address lines require

the memory to store the address during the first cycle in the read/write access. Data

access to the flash is performed as a 16-bit access (MEMADDA[15:0]) in order to improve

the data rate on the bus. The memory interface supports asynchronous read burst mode,

synchronous read, and simultaneous read-while-write/erase — all controlled by the UPP.

SRAM Memory Description

The combo memory chip used in RM-11 has 8 Mbit of SRAM, 16-bits wide running at

1.8 V. It uses a multiplexed address and data bus to minimize the pin count of the device.

Control signals are used to allow byte access to the device.

Page 14 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 15

RM-11

CC Technical Documentation System Module

Flash Memory Description

The 128 Mbit density flash with 16-bit data access operates in both asynchronous

random access and synchronous burst access (with crossing partition boundaries) and

has various data protection features. Upon power up or reset, the device defaults to

asynchronous read configuration. Synchronous burst read is indicated to the device by

writing to the flash configuration register and can be terminated by deactivating the

device.

The device supports reads and in-system erase and program operations at Vcc=1.8 V

(Voltage range 1.7-1.9 V). Flashing at production is supported at Vpp=12 V (for limited

exposure length only).

Flash Architecture

The datasheet of RM-11 combo memory contains detailed information about Flash

architecture.

Keyboard (UI Module)

The RM-11 consists of a separate UI board and includes contacts for the keypad domes

and LEDs for keypad lighting. The UI board is connected to the main PWB through a

16-pole, board-to-board connector with springs. A 5x4 matrix keyboard is also used. Key

pressing is detected by a scanning procedure. Keypad signals are connected via the UPP

keyboard interface.

When no key is pressed, row inputs are high due to UPP internal pull-up resistors. The

columns are written zero. When a key is pressed, one row is pulled down and an interrupt

is generated to the MCU. After receiving the interrupt, the MCU starts the scanning

procedure. All columns are first written high and then one column at a time is written

down. All columns, except the column that is written down, are set as inputs. Rows are

read while a column at the time is written down. If a row is down, it indicates that key,

which is at the cross point of the selected column and row that was pressed. After

detecting the pressed key, all registers inside the UPP are reset and columns are written

back to zero.

Keyboard ESD Protection

The SMD chips LEDs on the UI board have 2kV ESD protection. In case the A-cover is

removed, there is a potential risk of damaging the LEDs with electrostatic discharge.

Ground openings are made around LEDs to catch ESD sparks. For additional protection,

the dome sheet is made of conductive metallized tape and grounded to the display

shield.

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 15

Page 16

RM-11

System Module CC Technical Documentation

Internal Audio

Internal Microphone

The internal microphone capsule is mounted to in the UI frame. The microphone is

omni-directional and is connected to the UEM microphone input (MIC1P/N). The microphone input is asymmetric and the UEM (MICB1) provides bias voltage. The microphone

input on the UEM is ESD protected. Spring contacts are used to connect the microphone

to the main PWB.

Charge

UEM

MIC1N

Internal Speaker

The internal earpiece is a dynamic earpiece with an impedance of 32 ohms. The earpiece

is low impedance because the sound pressure is to be generated using current and not

voltage as the supply voltage is restricted to 2.7 V. The earpiece is driven directly by the

UEM and the earpiece driver (EARP and EARN outputs) is a fully differential bridge

amplifier with 6 dB gain. In RM-11, an 8 mm leak tolerant PICO earpiece is used.

UEM

MIC1P

EARP

EARN

EMC

Microphone

Figure 9: Internal microphone connection

Common mode

choke

Figure 10: Speaker connection

IHF Speaker and Stereo Audio Amplifier

The Integrated Hands Free (IHF) speaker (16 mm MALT) is used to generate speech audio,

ringing and warning tones. The audio amplifier is controlled by the UPP. The speaker

capsule is mounted in the C-cover. Spring contacts are used to connect the IHF speaker

contacts to the main PWB.

Page 16 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 17

RM-11

CC Technical Documentation System Module

Phone

audio

By pass

UPP8M

GenIO(14)

GenIO(15)

GenIO(16)

Enable

Clock

Data

Figure 11: Digital interface of audio amplifier

VB AT

=

LM4855

Output

Mode

Select

SPI

Ri n

Li n

Bias

Amplifier

Amplifier

Amplifier

Digital

Volu me

Control

LM4855

EN

CLK

DATA

Amplifier

Amplifier

Amplifier

GN D

ou t +

ou t -

Rout +

Rout -

Lout +

Lout -

Stereo

IH F Speaker

Headset

The LM4855 features a 32-step, digital volume control and eight distinct output modes.

The digital volume control and output modes are accessed through a 3-wire interface

controlled by the UPP. Digital volume control is needed when the FM radio is activated;

there is no amplifier block in the FM radio module. Output modes are needed when

routing audio to different locations (i.e., headset, IHF).

External Audio Connector

The RM-11 is designed to support a fully differential external audio accessory connection

by using a Tomahawk system connector. The Tomahawk connector has a serial data bus

called Accessory Control Interface (ACI) for accessory insertion and removal detection,

identification, and authentication. The ACI line is used for accessory control purposes

and includes the following:

• 4-wire fully differential stereo audio (used also FM-radio antenna connection)

• 2-wire differential mic input

EN CL K DAT A

Figure 12: Block diagram of audio amplifier

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 17

Page 18

RM-11

Ct

A

System Module CC Technical Documentation

External Microphone Connection

The external microphone input is fully differential and lines are connected to the UEM

microphone input (MIC2P/N). The UEM (MICB2) provides bias voltage. The microphone

input lines are ESD protected.

Creating a short circuit between the headset microphone signals generates the hook

signal. When the accessory is not connected, the UEM resistor pulls up the HookInt

signal. When the accessory is inserted and the microphone path is biased the HookInt

signal decreases to 1.8 V due to the microphone bias current flowing through the

resistor. When the button is pressed, the microphone signals are connected together and

the HookInt input receives half of micbias DC value 1.1 V. This change in DC level causes

the HookInt comparator output to change states, in this case from 0 to 1. The button can

be used for answering incoming calls but not to initiate outgoing calls.

HookInt

MICB2

UEM

MIC2P

MIC2N

Figure 13: External microphone connection

External Earphone Connection

Headset implementation uses separate microphone and earpiece signals. The accessory is

detected by the HeadInt signal when the plug is inserted.

FM Radio

VAFR

VAFL

MIC3P

UEM

MIC3N

XEAR

udio Amplifier

Rin

Lin

PhoneIN (HS)

PhoneIN (IHF)

Rout+

RoutLout+

Lout-

SPKRout+

SPKRout-

XMICP

EMC/ESD

XMICN

EMC/ESD

IHF Speaker

Figure 14: External earphone and IHF connections

Page 18 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 19

RM-11

CC Technical Documentation System Module

IrDa Interface

When using transceiver with 1.8V I/O, the IrDa interface is designed into the UPP. The IR

link supports speeds from 9600 bit/s to 1.152 MBit/s up to a distance of 80 cm.

Transmission over the IR is half-duplex.

The length of the transmitted IR pulse depends on the speed of the transmission. When

230.4 kbit/s or less is used as a transmission speed, pulse length is a maximum of

1.63ms. If the transmission speed is set to 1.152Mbit/s, the pulse length is 154ns.

The IR transceiver can be set into SIR or MIR modes. In SIR mode the transceiver is

capable of transmission speeds up to 115.2kbit/s. In MIR mode faster transmission speeds

are used. The maximum speed is 1.152Mbit/s. The IR transceiver can be set into shutdown mode by setting the SD pin to logic '1' to save current.

Vibra

A vibra-alerting device is used to generate a vibration signal for an incoming call. Vibra

is located in the bottom end of the phone and a connection is done with spring contacts.

The vibra interface is the same as in other DCT4 projects. The vibra is controlled by a

PWM signal from the UEM. The frequency can be set to 64, 129, 258, or 520 Hz and the

duty cycle can vary between 3% - 97%. To ensure compatibility with different UEM

versions, the RM-11 uses 40.5% duty cycle of the vibra PWM signal.

FM Radio

FM radio circuitry is implemented by using a highly integrated radio IC (TEA5767).

TEA5767 is a single-chip, electronically tuned, FM stereo radio with fully integrated IF

selectivity and demodulation. The IF frequency is 225 kHz. The radio is completely

adjustment-free and only requires a minimum of small, low-cost, external components.

It has signal-dependent mono/stereo blend [Stereo Noise Cancelling (SNC)]. The radio

can tune the European, US, and Japan FM bands.

Channel tuning and other controls are controlled through a serial bus interface by the

MCUSW. The reference clock (32kHz) is generated by the UPP CTSI block (routed from the

sleep clock).

GenIO(3)

UPP8M

GenIO(12)

GenIO(11)

GenIO(8)

FMCtrlDa

FMCtrlClk

FMWrEn

FMClk

VIO

XTAL2

TEA5767

SDA

SCL

W/R

Figure 15: FM radio digital interface connections

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 19

Page 20

RM-11

A

System Module CC Technical Documentation

Camera

The VGA camera module is connected to the baseband (UPP) through an HW accelerator

IC. And external 1.8 V regulator is used as a power supply (VDIG) for the camera module

and HW accelerator, together with VFLASH2.

UPP

LCDUI(1)

LCDUI(0)

GenIO(27)

GenIO(28)

GenIO(26)

GenIO(3)

VDIG VFLASH2

LCDCamTxDa

LCDCamClk

CamRxDa

CamCSX

CamSDX

CamClk

Figure 16: Camera connections to baseband

HW

ccelerator

VDIG

CCISCL

CCIDA

CCPCLKN

CCPCLKP

CCPDATAN

CCPDATAP

VFLASH2

Camera

The VGA camera has a resolution of 640 x 480 with a pixel size of 5.6um x 5.6um. Both

the camera and the HW accelerator support sleep functionality in order to minimize the

current consumption.

Flashlight

The flashlight feature on C-Rio is driven by the white LED driver and is controlled by

the UEM. The circuit for the flashlight is driven by TK11851TL. In this situation, the driver

is used as a boost DC/DC. Vout is set using three precision resistors in R300, R316, and

R317. Vout = Vfb * (1+ (R316+R317)/ R300). The TK11851L is an active-high enable

device, whose enable signal is tied to Klight/Dlight signals from the UEM. When Klight

goes high it turns on the TK11851TL driver and the V301 transistor, which allows a path

to GND.

Page 20 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 21

RM-11

N

CC Technical Documentation System Module

System Connector (Tomahawk)

The 14-pin Tomahawk bottom connector consists of charging plug socket and Tomahawk

System Connector. The Tomahawk system connector includes signals for the following:

Table 6: Tomahawk system connector signals

Function Notes

Charging Pads for 2-wire charging in cradles

Audio 4-wire fully differential stereo audio output

2-wire differential microphone input

FM radio antenna connection

Power supply for accessories 2.78V/70mA output to accessories

ACI (Accessory Control Interface) Accessory detection/removal and controlling

FBUS Standard FBUS

DKU-5 (similar to USB) (optional) Power in 5V in from DKU-5 cable

ACI

Vout

Charge

Charge GND

Shielding GND

Figure 17: Tomahawk bottom connector (charger plug socket and Tomahawk system connector)

Fbus TX

Fbus RX

XMIC N

XMIC P

DATA GN D

HSEAR_L_P

HSEAR_L_N

Accessory Control Interface (ACI)

The ACI is a point-to-point, bi-directional serial bus. It has three main features:

• The insertion and removal detection of an accessory device

• Acting as a data bus, intended mainly for control purposes

• The identification and authentication of accessory type which is connected

The accessories are detected by the HeadInt signal when the plug is inserted. Normally

when an accessory is not present, the pull-up resistor 100k pulls up the HeadInt signal to

VFLASH1. If the accessory is inserted, the external resistor (located to accessory) works

as a voltage divider and decreases the voltage level below the threshold of Vhead. The

comparator output is then changed to a high state, which causes an interrupt.

If the accessory is removed, the voltage level of HeadInt increases again to VFLASH1. This

voltage level is higher than the threshold of the comparator and so its output is changed

to low, which leads to an interrupt. These HeadInt interrupts are initiated by the accessory detection or removal sequence.

HSEAR_R_N

HSEAR_R_P

Shielding GND

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 21

Page 22

RM-11

3985

System Module CC Technical Documentation

External Accessory Regulator

An external LDO Regulator is needed for accessory power supply purposes. All ACI accessories require this power supply. A regulator input is connected to the battery voltage

VBAT and output is connected to the Vout pin in the Tomahawk connector. The regulator

ON/OFF function is controlled via the UPP.

The pull-down resistor on the enable input of the regulator is needed because in the

switch-off mode of the phone, the output level of the Genio(0) is not defined. If the

Genio(0) is floating, the regulator may be enabled when it should not be.

UPP

GenIO(0)

PWB Strategy

PWB Construction

The PWB consists of a 6-layer board made up of FR4. Via types are through hole, laser,

buried, and blind vias. The PWB build up is shown in Figure 19:

110

Maximum thick ne ss with solder resist 1270um

Electromechanical Thickness with surface finish 1100um ±

VBAT

Voltage

En

regulator

LP

Figure 18: Accessory power supply diagram

Solder resist 20 µm ± 10 µm

Finished cop per 30 µm ± 10 µm

Dielectric Ar amid 100 µm ± 20 µm

Finished copper 17 µm +2/-5 µm

Dielectric 150 µm ± 25 µm

Finished copper 17 µm +2/-5 µm

Dielectric 150 µm ± 25 µm

Finished copper 17 µm +2/-5 µm

Dielectric 150 µm ± 25 µm

Finished copper 17 µm +2/-5 µm

Dielectric Ar amid 100 µm ± 20 µm

Finished cop per 30 µm ±10 µm

Solder resist 20 µm ± 10 µm

Tomahawk btm conn

VOUT

Figure 19: RM-11 PWB build up

PWB Immunity

The PWB has been designed to shield all lines susceptible for radiation. Sensitive PWB

tracks have been drawn with respect to shielding by having ground plane over tracks,

and ground close to the tracks at the same layer.

Page 22 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 23

RM-11

CC Technical Documentation System Module

All edges are grounded from both sides of the PWB and a solder mask is opened from

these areas. The purpose is for any ESD pulse to face a ground area when entering the

phone (i.e., between mechanics covers). All holes in the PWB are grounded and plated

through holes.

Keyboard

The keyboard PWB layout consists of a grounded outer ring and either a trefoil pattern

grid (matrix) or an inner pad. This construction makes the keys immune to ESD, as the

key dome has a low ohmic contact with the PWB ground.

Audio Lines

In order to obtain good signal-to-noise ratio and good EMC/ESD immunity, the audio

lines have been carefully routed with respect to obtaining low impedance in the signal

path and obtaining proper shielding.

Microphone Lines

Microphone signals are input lines and therefore very sensitive to radiated fields.

Immunity for radiated fields is done to obtain a low-impedance path and with respect to

a common noise point of view in the signal path. This applies for both internal and

external microphone lines.

EAR Lines

EAR lines are output signals, also routed on layer 2 and 7, to obtain immunity for

conducted emission from the UEM. Internal EAR lines are EMC/ESD protected by radiated

fields from the earpiece by the low-impedance signal path in the PWB.

The same PWB outline has been implemented for the SALT speaker. Low ohm coil

inductors are used in series with the speaker for immunity against incoming fields from

the speaker.

Charger Lines

The ground from the charger is connected directly to a common PWB ground for a low

impedance path to the battery. The positive charger line is ESD, EMC, and short-circuit

protected by appropriate circuits.

HEADINT

The HEADINT line is EMC/ESD protected by routing on shielded layer 2 and by placement

of resistor R154 close to the bottom connector.

Battery Supply Filtering

Battery supply lines to the UEM IC are filtered with LC filters. These filters provide

immunity against conducted RF noise.

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 23

Page 24

RM-11

System Module CC Technical Documentation

System Connector

The immunity strategy concerning the bottom connector lines is to shield all lines to this

part in order to prevent radiation in the phone itself when an external accessory is

connected, and to prevent radiated fields from disturbing the lines as well. Appropriate

discrete filters close to the bottom connector are implemented for EMC and ESD

protection.

Mechanical Shielding

The RM-11 has a metal shield over the RF and BB parts to provide immunity for internal

radiation and immunity for external fields.

EMC Strategy

The phone must comply with the given CE requirements concerning EMC and ESD. The

goal is to pass internal SPR requirements. Therefore attention has been paid to obtaining

immunity in the PWB layout itself, and the implementation of filters in the circuit

design.

The baseband EMC strategy is divided into electrical and mechanical items. All electrical

guidelines, clocks, and high-speed signals should be routed in inner layers and away from

the PWB edges. Clock signals distributed to other circuits should have series resistors

incorporated to reduce rise times and reflections. Slew rate-controlled buffers should be

used on custom components wherever possible to reduce the EMC produced by the

circuit. Separate power supplies for digital, analog, and RF-blocks should be used as

much as possible. Baseband and RF supply power rails should be isolated from each other

by means of inductors in the power supply rail to prevent high-frequency components

produced on the baseband power supply rail to spread out over the RF power supply

plane. This might be required to avoid interference from digital circuits to affect the

performance of the RF section.

All external connectors and connections must be filtered using RC or LC networks to

prevent the high-frequency components from entering connection cables that then will

act as antennas. The amount of this type of EMC component is in straight relation to the

amount of external connections. The type of network and amount of components to be

used is determined by the AC and DC impedance characteristic of that particular signal.

Low-impedance signals require LC networks while medium-impedance level signals

(input signals at moderate bandwidth) can use RC networks.

The EMC protection should also prevent external or internal signals to cause interference

to the baseband and, in particular, to audio signals. Internal interference is generated by

the transmitter burst frequency and the switchmode charging. The transmitter burst

frequency interference is likely to cause noise to both microphone and earphone signals.

The transmitter RF interference is likely to cause more problems in the microphone

circuitry than in the earphone circuitry because the earpiece is a low-impedance

dynamic type.

As mechanical guidelines, the baseband and RF sections should be isolated from each

other using EMC shielding, which suppresses radiated interference. The transmitter burst

frequency can also generate mechanical vibrations that can be picked up by the

Page 24 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 25

RM-11

CC Technical Documentation System Module

microphone if it is not properly isolated from the chassis using rubber or some other soft

material. Connection wires to the internal microphone and earphone should be as short

as possible to reduce the interference caused by internal signals.

ESD protection has to be implemented on each external connection that is accessible

during normal operation of the phone.

Test Interfaces

Using the Tomahawk connector’s FBUS connections, the phone HW can be tested by PC

software (i.e., Phoenix test software). In addition, RM-11 also supports a Flash programming interface via the service battery, JTAG, and Ostrich test interfaces. JTAG test interface may be removed from the final product for security reasons.

Production / After Sales Interface

Test pads are placed on the engine PWB for service and production purposes. The same

test pattern is used by the After Market Sales (AMS) group for product testing and software upgrades. The following figure shows the top view of the test pads. The FBUS_TX

and RX lines are used to transfer data in or out of the phone. VPP is the Flash programming voltage and the MBUS/CLK line is used as a Flash clock line during flashing.

Flash Interface

Flash programming in production is done through the test pads in Figure 20 on the PWB.

FBUS Interface

The FBUS is an asynchronous data bus that has separate TX and RX signals. The default

bit rate of the bus is 115.2 kbit/s. The FBUS is mainly used for controlling and programming the phone in production. This is the primary interface used in the RM-11.

FBUS_RX FBUS_TX

VPP

MBUS/CLK

Figure 20: Production/test/after market interface

GND

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 25

Page 26

RM-11

System Module CC Technical Documentation

BB_RF Interface Connections

The BB and RF parts are connected together without a physical connector.

Rip

Signal

Name

#

DAMPS,

GSM1900

RFICCNTRL(2:0) RF IC Control Bus from UPP to RF IC (TACO)

RFBUSCLK UPP RFIC In Dig

0

RFBUSDA UPP/RFIC RFIC

1

RFBUSEN1X UPP RFIC In Dig

2

PUSL(2:0) Power Up Reset from UEM to RF IC (TACO)

PURX UEM RFIC Out Dig

0

GENIO(28:0) General I/O Bus connected to RF, see also separate collective GENI O(28:0)

TXP1 RFIC UPP Out Dig

5

Connected

from--- to

UPP

BB

I/O

Signal Properties

A/D--Levels---Freq./

Timing resolution

0/1.8V

I/O Dig

(0: <0.4V

9.72 MHz RF Control serial bus bit clock

Bi-directional RF Control serial bus data,

1: >1.4 V)

RFIC Chip Sel X

0/1.8V 10us Power Up Reset for RF IC

SLCLK & SLEEPX not used in RF

table. Control lines from UPP GENIOs to RF

0/1.8V

10 us Low Band Tx enabled

Description / Notes

TXP2 RFIC UPP Out Dig

6

11

BANDSEL

RFIC

UPP Out Dig

0/1.8V

0/1.8V

High Band Tx enabled

Rx Band select. Option for module LNA.

Not used in Stella.

Figure 21: BB_RF interface connections (1)

Page 26 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 27

RM-11

CC Technical Documentation System Module

Rip

Signal

Name

#

DAMPS,

GSM1900

RFCLK (not BUS -> no rip #) System Clock From RF To BB, original source VCTCXO, buffered (and

RFCLK

Connected

from--- to

VCTCXO >

RFIC

BB

I/O

Signal Properties

A/D--Levels---Freq./

Timing resolution

frequency shifted, WAM only) in RF IC (TACO)

UPP In Ana 800mVpp

typ (FET

probed)

Bias DC

blocked at

UPP input

Description / Notes

19.2 MHz

19.44 MHz System Clk from RF to BB,

RFClk

GND

RF UPP In Ana 0 System Clock slicer Ref GND, not

separated from pwb GND layer

SLOWAD(6:0) Slow Speed ADC Lines from RF block

5 PDMID

6 PATEMP

RF Power

detection

module

RF Power

detection

module

UEM In

UEM In

Ana

0/2.7V dig 0/VR2 Power detection module identification to

slow ADC (ch 5, previous VCTCXO Temp)

signal to UEM.

Ana

0.1-2.7V - Tx PA Temperature signal to UEM, NTC in

Power Detection Module

RFCONV(9:0) RF- BB differential Analog Signals: Tx I&Q, Rx I&Q and reference voltage

0

1

2

3

4

5

6

7

9

RXIP

RXIN

RXQP

RXQN

TXIP

TXIN

TXQP

TXQN

VREFRFO1

RFIC UEM In

UEM RFIC Out

UEM RFIC Out

Ana

Ana

Vref

1.4Vpp

max. diff.

Differential positive/negati ve in -p has e R x

Signal

0.5Vpp typ

bias

1.30V

2.2Vpp

max. diff.

Diff. Positive/negative quadrature phase Rx

Signal

Differential positive/negati ve in -p has e T x

Signal

0.6VppTyp

Bias

1.30V

Differential positive/negative quadrature

phase Tx Signal

1.35 V RF IC Reference voltage from UEM

Figure 22: BB_RF interface connections (2)

Rip

#

Signal

Name

DAMPS,

GSM1900

Connected

from--- to

BB

I/O

Signal Properties

A/D--Levels---Freq./

Timing resolution

Description / Notes

RFAUXCONV(2:0) RF_BB Analog Control Signals to/from UEM

TXPWRDET

1

AFC

2

TXP Det. UEM In Ana

UEM VCTCXO Out Ana

0.1-2.4 V 50 us Tx PWR Detector Signal to UEM

0.1-2.4 V Automatic Frequency Control for VCTCXO

Figure 23: BB_RF interface connections (3)

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 27

Page 28

RM-11

System Module CC Technical Documentation

VRF Globals instead of Bus Regulated RF Supply Voltages from UEM to RF. Current values are of the

VR1 A UEM RFIC

VR1 B UEM RFIC

VR2 UEM RFDiscr./

VR3 UEM VCTCXO

VR4 UEM RFIC

VR5 UEM RFIC

VR6 UEM RFIC

VR7 UEM RFIC,

IPA1 UEM RF PA

IPA2 UEM RFPA

VFLASH1 UEM RFIC

VBATT, Global

VBATTRF Batt

Conn

RFIC

UHF VCO

RFPA

regulator specifications, not the measured values of RF

Out Vreg

Out Vreg

Out Vreg

Out Vreg

Out Vreg

Out Vreg

Out Vreg

Out Vreg

Out Iout

Out Iout

Out Iout

Out Vbatt

4.75 V

+- 3 %

4.75 V

+- 3 %

2.78 V

+- 3 %

2.78 V

+- 3 %

--”-- 50 mA max. UEM linear regulat or. Power Supply for LNA

--”-- 50 mA max. UEM linear regulat or. P ower Supply for RF

--”-- 50 mA max. UEM linear regulat or. P ower supply for RF

--”-- 45mA UEM linear regulator. Power supply for RF

0-5 mA Settable Bias current for RF PA L-Band

0-5 mA Settable Bias current for RF PA H-band

2.78V ~2mA UEM linear regulator common for BB.

3…5V 0…1A

10 mA max. UEM, charge pump + linear regulator

output. Supply for UHF synth phase det ….

10 mA max. UEM, charge pump + linear regulator

output.

100 mA max. UE M linear regul ator. Supply voltage for Tx

IQ filter and IQ to Tx IF mixer.

20 mA max. UEM linear regulator. Supply for VCTCXO +

RFCLK Buffer in RF IC.

/ RFIC Rx chain.

low band PA driver section.

high band PA driver section.

Synths

RFIC digital parts and RF to BB digi IF.

Raw Vbatt for RF PA

2A peak

Figure 24: BB_RF interface connections (4)

RF Functional Description

Most of the RF functions are centered around the RF ASIC. Receiver IF stages, low-band

LNA, PLLs, RXVHF oscillator, TX VHF VCO active part and loop filter, high-band and lowband TX up-converters, TX IF stages, IQ modulator and demodulator and reference oscillator buffering are all integrated on single chip.

Circuit Diagrams and PWB Layout

Receiver

The receiver design and system partition is from the Snoopy AD project. The receiver

shows a superheterodyne structure with zero 2nd IF. Low-band and high-band receivers

have separate front ends from the diplexer to the first IF. Most of the receiver functions

are integrated in the RF ASIC. The only functions out of the chip are the high-band LNA,

duplexers, and SAW filters. Receiver characteristics are very similar on both bands.

An active first downconverter sets naturally high-gain requirements for preceding

stages. Losses in very selective front-end filters are minimized down to the limits set by

filter technologies used and component sizes. The LNA gain is set up to 16 dB, which is

close to the maximum available stable gain from a single-stage amplifier. LNAs are not

exactly noise matched in order to keep pass band gain ripple to a minimum. Filters have

relatively tight stop band requirements, which are not all set by the system requirements

Page 28 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 29

RM-11

CC Technical Documentation System Module

but the interference free operation in the field. In this receiver structure, linearity lies

heavily on the mixer design. The second order distortion requirements of the mixer are

set by the 'half IF' suppression. A fully balanced mixer topology is required. Additionally,

the receiver third order IIP tends to depend on active mixer IIP3 linearity due to high

LNA gain.

IF stages include a narrow-band SAW filter on the first IF and an integrated lowpass

filtering is on zero IF. The SAW filter guarantees 14 dBc attenuation at alternating

channels, which gives acceptable receiver IMD performance with only moderate VHF

local phase noise performance. The local signal's partition to receiver selectivity and IMD

depends mainly on the spectral purity of the first local. Zero 2nd IF stages include most

of the receiver’s signal gain, AGC control range, and channel filtering.

Receiver requirements and characteristics are presented in detail in the RX specification.

Frequency Synthesizers

The RM-11 synthesizer consists of three synthesizers: one UHF synthesizer and two VHF

synthesizers. The UHF synthesizer is based on an integrated PLL and external UHF VCO,

loop filter, and VCTCXO. Its main goal is to achieve the channel selection, thus for dualband operations associated with dual mode. Due to the RX and TX architecture, this UHF

synthesizer is used for down conversion of the received signal and for final

up-conversion in the transmitter. A common 2 GHz UHFVCO module is used for operation

on both low and high bands. The frequency divider by two is integrated in the RF ASIC.

The two VHF synthesizers consist of the RX VHF synthesizer and the TX VHF

synthesizer.The RX VHF synthesizer includes integrated PLL and VCO and loop filter and

resonator. The output of the RX-VHF PLL is used as a LO signal for the second mixer in

the receiver. The TX VHF Synthesizer and loop filter are integrated into the RF ASIC. See

the depicted block diagrams and synthesizer characteristics from the Synthesizer specification document.

Transmitter

The transmitter RF architecture is up-conversion type (desired RF spectrum is low side

injection) with (RF-) modulation and gain control at IF. The IF frequency is 180.54 MHz.

The cellular band is 824.01-848.97 MHz and the PCS band is 1850.01-1909.95 MHz.

Common IF

The RF modulator is integrated with a Programmable Gain Amplifier (PGA) and an IF output buffer inside the RFIC chip. I- and Q-signals, which are output signals from the

BB-side SW IQ-modulator, have some filtering inside the RF ASIC before RF modulation

is performed. The required LO-signal from TXVCO is buffered with phase shifting in the

RF ASIC. After modulation (p/4 DQPSK or FM), the modulated IF signal is amplified

in PGA.

Cellular Band

At operation in cellular band, the IF signal is buffered at the IF output stage that is

enabled by TXP1 TX control. The maximum linear (balanced) IF signal level to 50 W load

is about -8 dBm.

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 29

Page 30

RM-11

System Module CC Technical Documentation

For proper AMPS-mode receiver (duplex) sensitivity, the IF signal is filtered in a

strip-filter before up-conversion. The upconverter mixer is actually a mixer with a LO and

output driver that is able to deliver about +6dBm linear output power. The mixer is inside

the RF IC. Note that in this point, the term “linear” means -33dB ACP. The required LO

power is about -6dBm. The LO signal is fed from the RF IC.

Before power amplifier RF signal is filter in band filter. The typical insertion loss is about

-2.7dB, and the maximum is less than -3.0dB. The input and output return losses are

about -10dB.

The power amplifier is a 50W/50W module. It does not have its own enable/disable

control signal, but it can be enabled by bias voltage and reference bias current signals.

The gain window is +27 to +31dB and the linear output power is +30dBm (typical condition) with -28dB ACP. The nominal efficiency is 50%.

PCS Band

When operating in the PCS band, the IF signal is routed outside from RF IC to be filtered

in the TX IF strip filter, and after that back to the RF IC, then to the upconverter mixer.

The LO signal to the mixer is buffered and balanced inside the RF IC. The mixer output is

enabled by the TXP2 TX control signal. The maximum linear (balanced) RF signal level to

50 W load is about +7dBm.

Next, the RF IC-balanced RF signal is single-ended in 1:1 balun and then filtered in the

SAW filter. The typical insertion loss is about -4.0dB, and the maximum is less than

-5.0dB. This filter has a relatively high pass band ripple about 1.0-1.5dB with the largest

insertion being at the high end of the band. The input and return losses are about -10dB.

The power amplifier is a 50W/50W module. It does not have its own enable/disable

control signal, but it can be enabled by bias voltage and reference bias current signals.

The gain window is +31 to +36dB and linear output power is +30dBm (typical condition)

with -28dB ACP. The nominal efficiency is 40%.

Power Control

For power monitoring, there is a power detector module (PDM) build up from a dual

coupler, a biased diode detector, and an NTC resistor. RF signals from both bands are

routed via this PDM. The RF isolation between couplers is sufficient not to lose filtering

performance given by duplex filters.

The diode output and NTC voltages are routed to the BB A/D converters for power

control. The TX AGC SW takes samples from the diode output voltage and compares that

value to the target value, and then adjusts the BB I-and Q-signal amplitude and/or RF IC

PGA settings to keep power control in balance.

NTC voltage is used for diode temperature compensation and for thermal shut down

when the radio board's temperature exceeds +85°C.

A false TX indication is based on the detected power measurement when the carrier is

not on.

Page 30 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 31

RM-11

CC Technical Documentation System Module

The coupler’s insertion loss is -0.42dB (max) at the cellular band and -0.48dB (max) at

the PCS band. Typical values for insertion losses are about -0.2dB. The filtering performance of the diplexer is taken into account in system calculations.

Antenna Circuit

The antenna circuit stands for duplex filters and diplexer. The cellular band duplex filter

is a band pass type SAW filter with typical insertion loss at about -2.0dB. The PCS band

duplex filter is a band stop (for receiver band) ceramic filter and its typical insertion loss

is about -1.7dB. Insertion losses of the diplexer are -0.45dB and -0.55dB (at maximum)

for cellular and PCS band—typical values being about -0.30dB and -0.35dB.

RF Performance

The output power tuning target for power level 2 after diplexer (or after switch for

external RF) is +27.3dBm for p/4 DQPSK-type modulation and +24.5dBm for FM-type

modulation. Power levels downwards from PL2 are -4dB below next to the highest power

level, PL10 being -4.7dBm (and PL7 +6.5dBm with FM type of modulation). Modulation

accuracy and ACP are within the limits specified in IS-136/137.

Table 7: 800 MHz analog TX

Power

level

2 24.8 +/- 0.25 0.5/-0.5

3 22.0 +/-0.5 +/-2.0

4 18.5 +/-0.5 +/-2.0

5 14.5 +/-0.5 +/-2.0

6 10.5 +/-0.5 +/-2.0

7 6.5 +/-0.5 +/-2.0

Power

level

2 27.3 +/- 0.25 0.5/-0.5

RF power at

external Antenna

Pad (dBm)

Table 8: 800 MHz digital TX

RF power at

external Antenna

Pad (dBm)

Tuning target

tolerant (dB)

Tuning target

tolerant (dB)

Testing limits

(dB)

Testing limits

(dB)

3 23.3 +/-0.5 +/-2.0

4 19.3 +/-0.5 +/-2.0

5 15.3 +/-0.5 +/-2.0

6 11.3 +/-0.5 +/-2.0

7 7.3 +/-0.5 +/-2.0

8 3.3 +/-0.5 +/-2.0

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 31

Page 32

RM-11

System Module CC Technical Documentation

Table 8: 800 MHz digital TX (Continued)

Power

level

9 -0.7 +/-0.5 +/-2.0

10 -4.7 +/-0.5 +/-2.0

RF power at

external Antenna

Pad (dBm)

Table 9: CDMA 1900 TX

Tuning target

tolerant (dB)

Testing limits

(dB)

RF power at

Power level

external

Antenna Pad

Tuning target

tolerant (dB)

Testing limits (dB)

(dBm)

2 26.3*** +/- 0.25 0.5/-0.5

3 23.3 +/-0.5 +/-2.0

4 19.3 +/-0.5 +/-2.0

5 15.3 +/-0.5 +/-2.0

6 11.3 +/-0.5 +/-2.0

7 7.3 +/-0.5 +/-2.0

8 3.3 +/-0.5 +/-2.0

9 -0.7 +/-0.5 +/-2.0

10 -4.7 +/-0.5 +/-2.0

*** 26.3 dBm for channel 1000 and 1998; 27.0 dBm for channel 2.

Antenna

The RM-11 antenna solution is an internal dual resonance PIFA antenna. This antenna

has a common feeding point for both antenna radiators, which results in the need for a

diplexer. In a single band transciever, an SMD-compatible through chip can be used.

Software Compensations

The following software compensations are required:

• Power levels temperature compensation

• Power levels channel compensation

• Power level reduction due to low battery voltage

• TX power up/down ramps

• PA's bias reference currents vs. power, temp and operation mode

• RX IQ DC offsets

Page 32 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Page 33

RM-11

CC Technical Documentation System Module

• RSSI channel compensation

• RSSI temperature compensation

RF Frequency Plan

The RM-11 frequency plan is shown in Figure 25. A 19.44 MHz VCTCXO is used for the

UHF and VHF PLLs and as a baseband clock signal. All RF locals are generated in PLLs.

TX I

TX VHF LO

CELL 346.2 MHz

PCS 416.2 MHz

TX Q

RX I

RX VHF LO

CELL 256.2 MHz

PCS 256.2 MHz

RX Q

TX IF

CELL 173.6 MHz

PCS 208.1 MHz

°0

1

2

°90

UHF LO

CELL 997.14 - 1022.07 MHz, 30 kHz Step

PCS 2058.10 - 2118.05 MHz, 50 kHz Step

°0

1

2

°90

TX Block

RX Block

RX IF

CELL 128.1 MHz

PCS 128.1 MHz

Figure 25: RM-11 frequency plan

CELL

CELL

824.04 - 848.97 MHz

1850.00 - 1909.95 MHz

PCS

869.04 - 893.97 MHz

1930.00 - 1989.95 MHz

PCS

30 kHz Steps

50 kHz Steps

30 kHz Steps

50 kHz Steps

DC Characteristics

Regulators

The regulator circuit is UEM and the specifications are contained in Table 10:

Regulator

name

VR1 a/b 4.75 +/- 3% 10 4 4

VR2 2.78 +/-3% 100 100 76

VR3 2.78 +/-3% 20 2 2

VR4 2.78 +/-3% 50 23 24

VR5 2.78 +/-3% 50 5 0

VR6 2.78 +/-3% 50 tbd tbd

VR7 2.78 +/-3% 45 40 45

Table 10: Regulator circuit information

Output

voltage (V)

Regulator Max

current (mA)

RF total

1GHz

RF total

2GHz

Issue 1 02/2004 ©2004 Nokia Corporation Confidential Page 33

Page 34

RM-11

System Module CC Technical Documentation

Table 10: Regulator circuit information (Continued)

Regulator

name

IPA1, IPA2 2.7 max 1 +/- 10%

VREFRF01 1.35 +/- 0.5% 0.12 0.05 0.05

VFLASH1 2.78 +/- 3% 70 1 1

Output

voltage (V)

Regulator Max

current (mA)

3 +/- 4%

3.5 +/- 4%

5 +/- 3%

RF total

1GHz

1.3 - 5.0 1.3 - 3.7

RF total

2GHz

Page 34 ©2004 Nokia Corporation Confidential Issue 1 02/2004

Loading...

Loading...