Page 1

Nokia Customer Care

SERVICE

MANUAL

[NMP Part No. 9231858]

3125 (RH-61)

Series Mobile Phones

Issue 1

COMPANY CONFIDENTIAL

ISSUE 1 08/2004

Copyright © 2004 Nokia. All Rights Reserved.

Page 2

Nokia Customer Care

Amendment Record Sheet

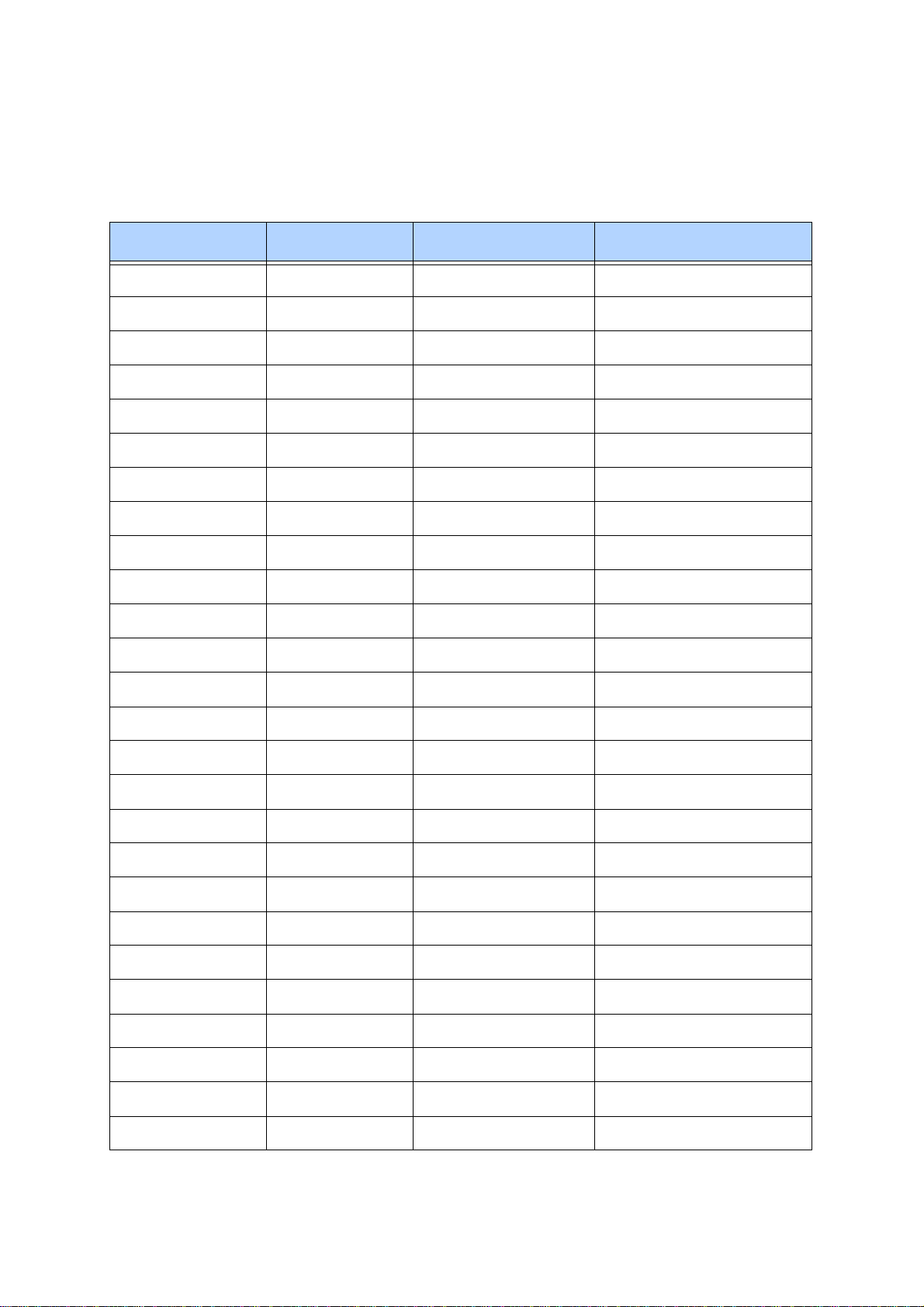

Amendment No Date Inserted By Comments

08/2004 N. Cheshier Issue 1

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 2

Copyright © 2004 Nokia. All Rights Reserved.

Page 3

Nokia Customer Care

Copyright © 2004 Nokia. All rights reserved.

Reproduction, transfer, dist ribut io n or st orage of par t o r all of t he con tents i n

this document in any form withou t the prior written permis sion of Nokia is prohibited.

Nokia, Nokia Connecting People, X and Y are trademarks or reg istered trademarks of Nokia Corporation. Other product and company names mentioned

herein may be trademarks or tradenames of their respective owners.

Nokia operates a policy of continuous development. Noki a reserves the right

to make changes and improvements t o any of the pro duct s descri bed in thi s

document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or income or any special, inc idental, consequenti al or indirect d amages howsoever caused.

The contents of this doc ument are provided "as is". Except as required by applicable law, no warranties of any kind, either express or implied, including,

but not limited to, the implied warr anties of merchantability and fitness for a

particular purpose, ar e made in relation to the accura cy, reliability or conten ts

of this document. Nokia reserves the right to revise this document or withdraw it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personne l

only.

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 3

Copyright © 2004 Nokia. All Rights Reserved.

Page 4

Please refer to the product’s user guide for instructions re l ating

to operation, care and maintenance including important safety

information. Note also the following:

Warnings:

1. IF THE DEVICE CAN BE INSTALLED IN A VEHICLE, CARE

MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED

WITH ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND

ANTI-SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT

CONDITIONS, EMITTED RF ENERGY CAN AFFECT THEIR

OPERATION. IF NECESS ARY, CONSULT THE VE HICLE

DEALER/MANUFACTURER TO DETERMINE THE IMMUNITY

OF VEHICLE ELECTRONIC SYSTEMS TO RF ENERGY.

Nokia Customer Care

Warnings and Cautions

2. THE product MUST NOT BE OPERATED IN AREAS LIKE LY TO

CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES EG

PETROL STATIONS (SERVICE STATIONS), BLASTING

AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT,

INCLUDING CELLULAR TELEPHONES, MAY INTERFERE

WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR

THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU

HA VE AN Y QUESTIONS. OTHER ELECTRONIC EQU IPMENT

MAY ALSO BE SUBJEC T TO INTERFERENCE.

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and

that an anti-static wrist strap is worn.

3. Ensure solder, wire, or foreign matter does not enter the telephone as damage may result.

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are correctly re-fitted after s ervicing and alignmen t. Ensure all cables

and wires are repositioned correctly.

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 4

Copyright © 2004 Nokia. All Rights Reserved.

Page 5

Nokia Customer Care

For your safety

QUALIFIED SERVICE

Only qualified personnel may install or repair phone equipment.

ACCESSORIES AND BATTERIES

Use only approved accessories and batteries. Do not connect incompatible

products.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read its user’ s guide for detailed safety

instructions. Do not connect incompatible products.

ESD protection

Nokia requires that product ser v ice points have sufficient

ESD protection (against static electricity) when servicing

products.

Any product of which the covers are removed must be han dled with ESD protection. The SIM card can be replaced

without ESD protection if the product is otherwise ready for

use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD.

Resistors, too, can be damaged by static electricity discharge.

All ESD sensitive parts must be packed in metallized protective bags during ship ping and handl ing out side any ESD

Protected Area (EPA).

Every repair action involving opening the product or handling the product components must be done under ESD

protection.

ESD protected spare part packages MUST NOT be

opened/closed out of an ESD Protected Area.

For more information and local requirements about ESD

protection and ESD Protected Area, contact your local

Nokia After Market Services representative.

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 5

Copyright © 2004 Nokia. All Rights Reserved.

Page 6

Nokia Customer Care

Battery information

Note that a new battery's full performance is achieved only aft er two or three

complete charge and discharge cycles!

The battery can be charged and discharged hundreds of times but it will

eventually wear out. When th e operatin g ti me (talk- time and s tandby time) i s

noticeably shorter than normal, it is time to buy a new battery.

Use only batteries approved by the phone manufacturer and recharge the

battery only with the chargers approved by the manufacturer. Unplug the

charger when not in use. Do not leave the batte ry connected to a charger for

longer than a week, since overchargi ng may shorten its lifetime. If l eft unused

a fully charged battery will discharge itself over time.

Temperature extremes can affect the ability of your battery to charge.

For good operation times with Ni-Cd/NiMh batteries, discharge the battery

from time to time by leaving the produc t switched on unt il it t urns itsel f off (or

by using the battery discharge facility of any approved accessory available

for the product). Do not atte mpt to discharge t he batt ery by any othe r means.

Use the battery only for its intended purpose.

Never use any charger or battery which is damaged.

Do not short-circuit the ba ttery. Acc idental short-ci rcuiting can occur when a

metallic object (coin, clip or pen) ca uses direct connection of t he + and - terminals of the battery ( metal strips on the battery) fo r example when you c arry

a spare battery in your pocket or purse. Short- circuiting the terminals may

damage the battery or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer

or winter conditions, will reduce the capacity and lifetime of the battery. Always try to keep the battery between 15°C and 25°C (59°F and 77°F). A

phone with a hot or c old battery may temporari ly not work, even when th e battery is fully charged. Batt eries' per formance is par ticular ly limit ed in temperatures well below freezing.

Do not dispose of batteries in a fire!

Dispose of batteries according to l ocal regulations (e.g. recycling). Do not dis-

pose as household waste.

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 6

Copyright © 2004 Nokia. All Rights Reserved.

Page 7

Nokia Customer Care

Care and Maintenance

The product is a product of superior design and cr aftsmanship and should be

treated with care. The suggestions belo w will help you to fulfil any warranty

obligations and to enjoy this product for many years.

Keep the phone and all its parts and accessories out of the reach of small

children.

Keep the phone dry. Precipitation, humidity and all types of liquids or moisture can contain minerals that will corrode electronic circuits.

Do not use or store the phone in dusty, dirty areas. Its moving parts can be

damaged.

Do not store the phone in hot areas. High temperatur es can shorten t he lif e

of electronic devices, damage batteries, and warp or melt certain plastics.

Do not store the phone in cold areas. When it warms up (to its normal temperature), moisture can form inside, which may damage electronic circuit

boards.

Do not drop, knock or shake the phone. Rough handling can break internal

circuit boards.

Do not use harsh chemicals, cl eaning solvents, or strong detergents to clean

the phone.

Do not paint the phone. Paint can clog the moving parts and prevent proper

operation.

Use only the supplied or an approved replacement antenna. Unauthorised

antennas, modifications or att achments could damage the phone and may violate regulations governing radio devices.

All of the above sug gestions apply equal ly to the produc t, battery, ch arger or

any accessory.

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 7

Copyright © 2004 Nokia. All Rights Reserved.

Page 8

Nokia Customer Care

Company Policy

Our policy is of continuous devel opment; details of all technical modifications

will be included with service bulletins.

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If any errors are found by the reader, NOKIA

MOBILE PHONES Business Group should be notified in writing.

Please state:

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicabl e)

Page(s) and/or Figure(s) in error

Please se nd to :

NOKIA CORPORATION

Nokia Mobile Phones Business Group

Nokia Customer Care

PO Box 86

FIN-24101 SALO

Finland

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 8

Copyright © 2004 Nokia. All Rights Reserved.

Page 9

Nokia Customer Care

Table of Contents

1- General Information

2- Parts Lists and Exploded View

3- Service So ftware Instru ctions

4- Service Tools

5- Disassembly/Reassembly Instr uctions

6- BB Description and Troubleshooting

7- RF Description and Troubleshooting

8- Schematics

ISSUE 1 08/2004 COMPANY CONFIDENTIAL 9

Copyright © 2004 Nokia. All Rights Reserved.

Page 10

Nokia Customer Care

3125 (RH-61) Series Transceivers

General Information

Issue 1 08/2004 Company Confidential ©2004 Nokia Corporation

Page 11

3125 (RH-61)

General Information

Contents Page

Introduction ..................................................................................................................................................... 3

Module List .................................................................................................................................................... 4

Technical Specifications ............................................................................................................................ 5

Supported Accessories ...............................................................................................................................5

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 12

3125 (RH-61)

Nokia Customer Care General Information

Introduction

The 3125 is an 800 MHz CDMA DCT4 transceiver and supports the CDMA IS-95 and

IS-2000 interfaces. Features include the following:

• High-resolution 4,096 color display (128 x 128)

• Keymat support for the visually impaired

• Internal antenna

• Voice tagging

• Internal vibra

• 16 polyphonic ring tones (MIDI)

• Costomizeable covers, ring tones, screensavers, etc.

• Optional, network-dependent features:

• Video and multimedia messaging

• Java and application downloading

• High-speed data (HSD)

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 13

3125 (RH-61)

General Information

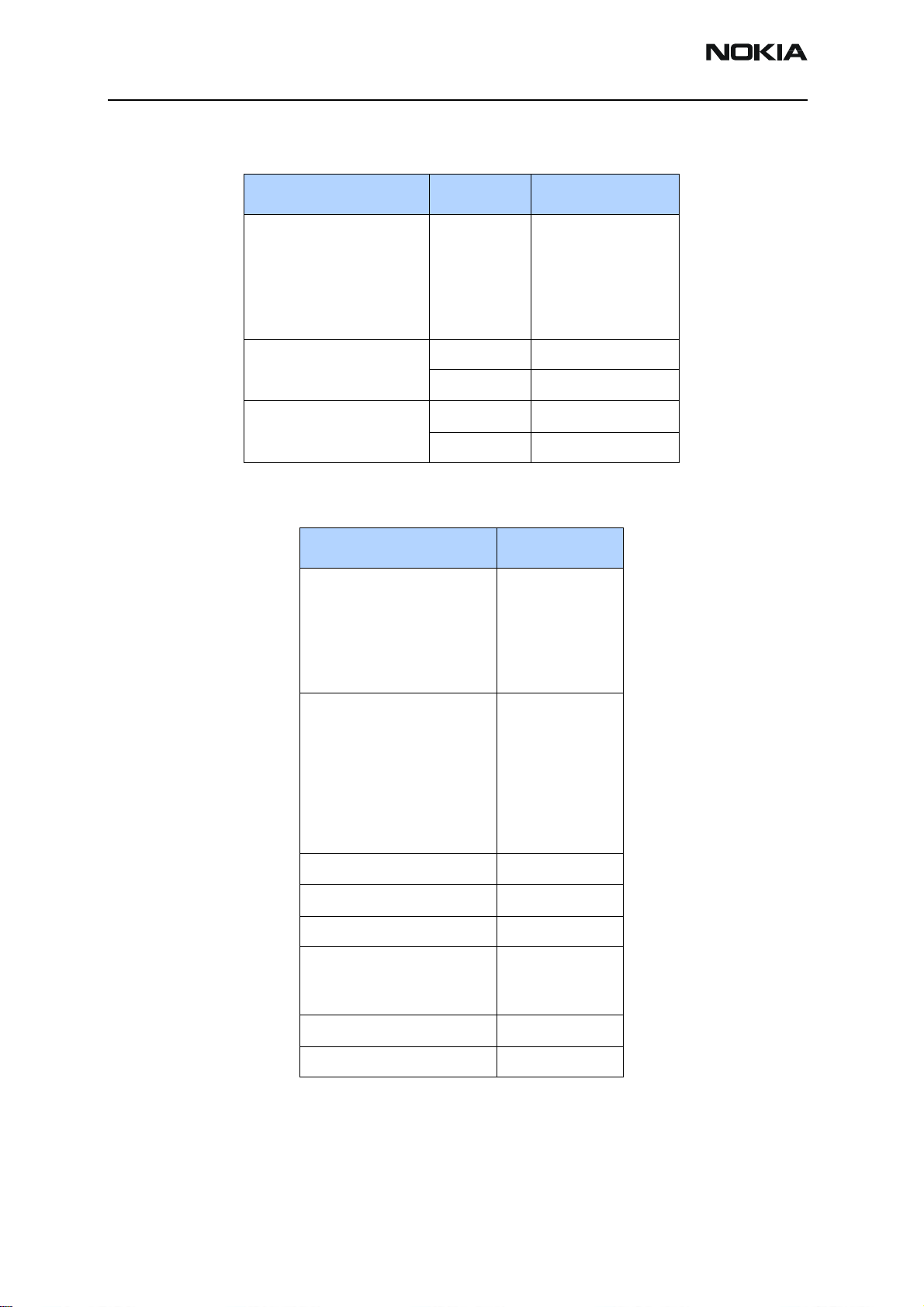

Parameter Mode Value and Unit

Dimensions:

Volume

Length

Width

Thickness

Weight

74 cc

102 mm

43 mm

16-22 mm

85 g

Module List

Talk time

Standby time

Description Code

A-cover assembly:

Metallic Blue

Dune Beige

Camellia

Aluminum

Clay Red

Keypad:

Blank

Latin

BoPoMoFo

Hindi (without “i”)

Stroke (China)

Thai (Generic)

Thai (Hutch)

IS-95 up to 4.0 hours

IS-2000 up to 3.0 hours

IS-95 up to 168 hours

IS-2000 up to 312 hours

0266032

0266031

0266030

0266029

0266028

9791414

9791415

9791416

9797092

9797093

9797112

9797111

Screws 9380209

LCD assembly 0211425

PWB module 0202397

B-cover assembly:

Metallic Blue

Dune Beige

Domesheet frame assembly 9481160

Battery (BL-5C) 0670400

0264009

0264008

Page 4 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 14

3125 (RH-61)

Nokia Customer Care General Information

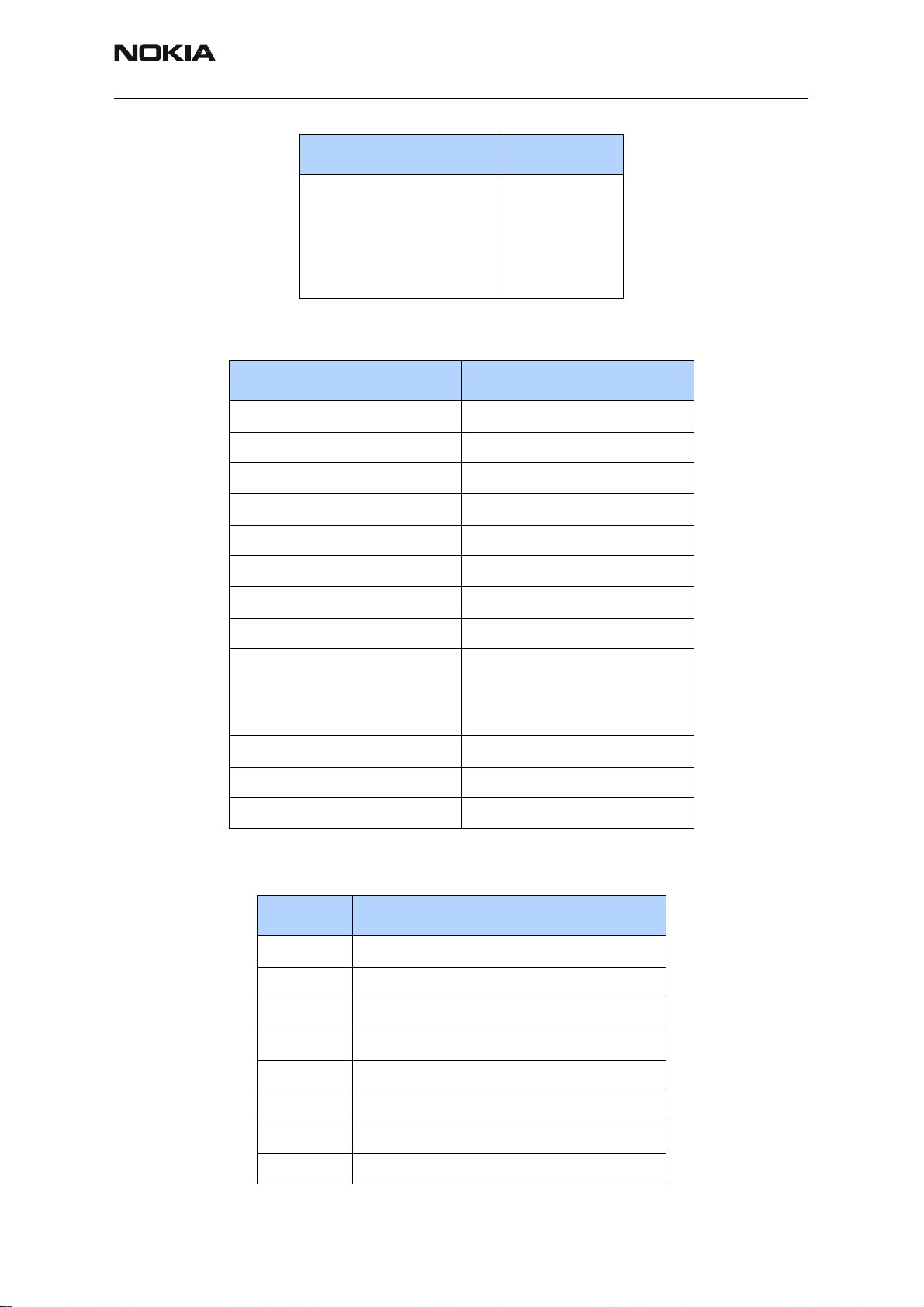

Description Code

C-cover

Metallic Blue

Dune Beige

Camellia

Aluminum

Clay Red

9453963

9453961

9453959

9453957

9453955

Technical Specifications

Parameter Unit

Cellular system CDMA, IS2000

RX frequency band 869.04 ... 893.91 MHz

TX frequency band 824.04 ... 848.97 MHz

Output power 23 dBm

Duplex spacing 45 MHz

Number of RF channels 832

Channel spacing 30 kHz

Power levels -50 to +25.3 dBm CDMA

Method of frequency synthesis Three digital phase locked loops:

Frequency control 19.2 MHz VCTCXO: AFC used

Receiver type Linear, one IF for CDMA

Modulator type OQPSK

Supported Accessories

Type Name

AC-1 Retractable charger

VHF RX 367.2 MHz

VHF TX 457.2 MHz

UHF 1052.61 - 1077.57 MHz

ACP-7 Standard charger

ACP-12 Travel charger

AD-5B Wireless audio adapter

BHF-1 Headrest handsfree

BHF-3 Headrest handsfree

CARK-126 Car kit (for APAC)

DCV-14 Desk stand with 1-button synchronization

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 5

Page 15

3125 (RH-61)

General Information

Type Name

DKU-5 USB data cable

HDA-10 TTY adapter (US)

HDB-4 Boom headset

HDW-2 Bluetooth wireless headset

HS-1C Camera headset (US)

HS-2R FM stereo headset (US)

HS-3W Wireless clip-on headset

HS-4W Wireless boom headset

HS-5 Standard earbud headset

HS-10 Retractable headset

LCH-12 Mobile charger

LPS-4 Inductive loopset

MBC-15S Mobile holder

PT-3 Fun camera (US)

SU-5 Image viewer

Page 6 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 16

Nokia Customer Care

3125 (RH-61) Series Transceivers

Parts Lists and Exploded View

Issue 1 08/2004 Company Confidential ©2004 Nokia Corporation

Page 17

3125 (RH-61)

Parts Lists and Exploded View

Contents Page

Exploded View ................................................................................................................................................. 3

Assembly Parts ............................................................................................................................................. 3

Parts List............................................................................................................................................................ 5

3125 (RH-61) — Build 004 — Engine Code 0202397 ....................................................................... 5

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 18

3125 (RH-61)

Nokia Customer Care Parts Lists and Exploded View

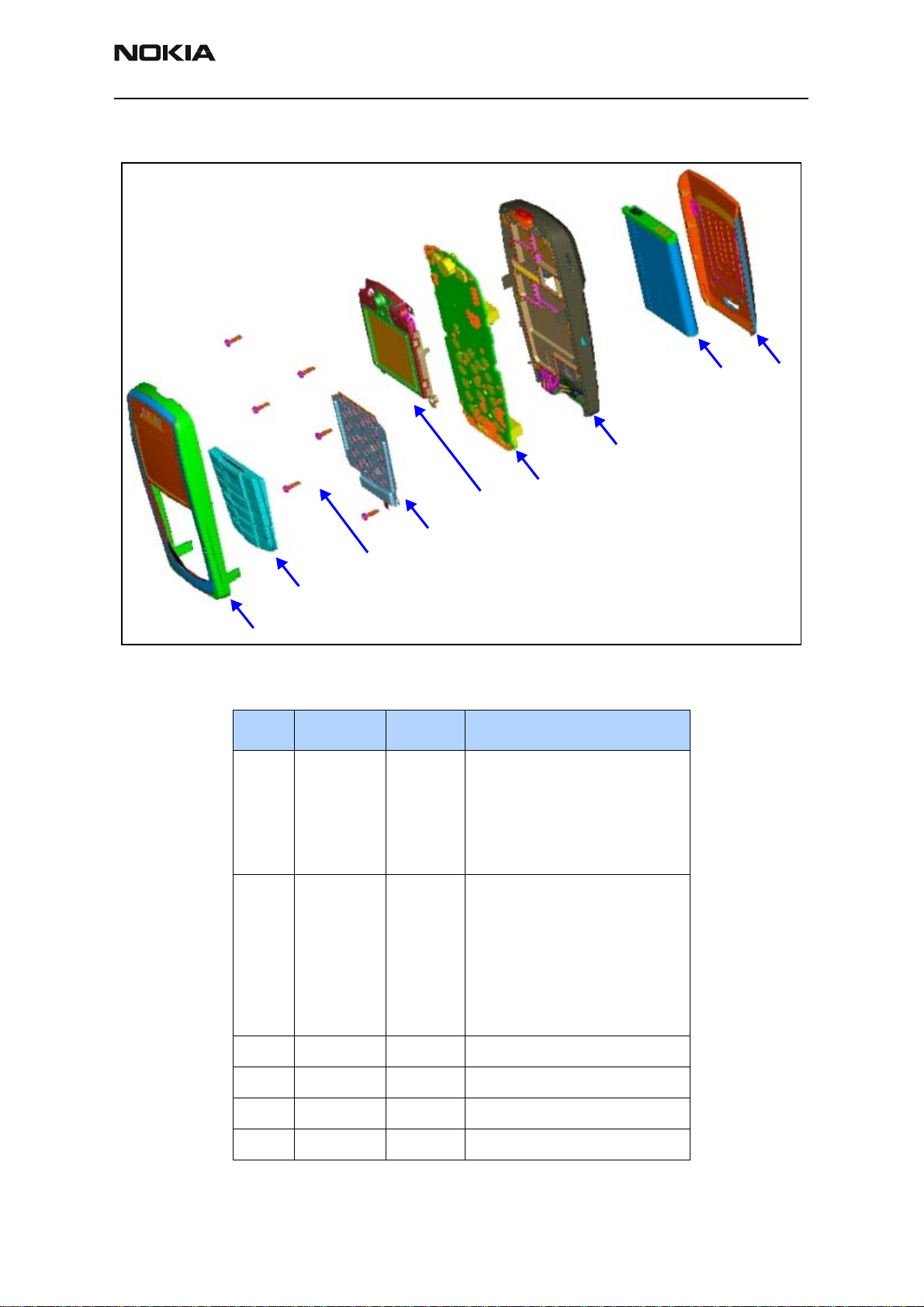

Exploded View

Assembly Parts

5

4

3

2

1

6

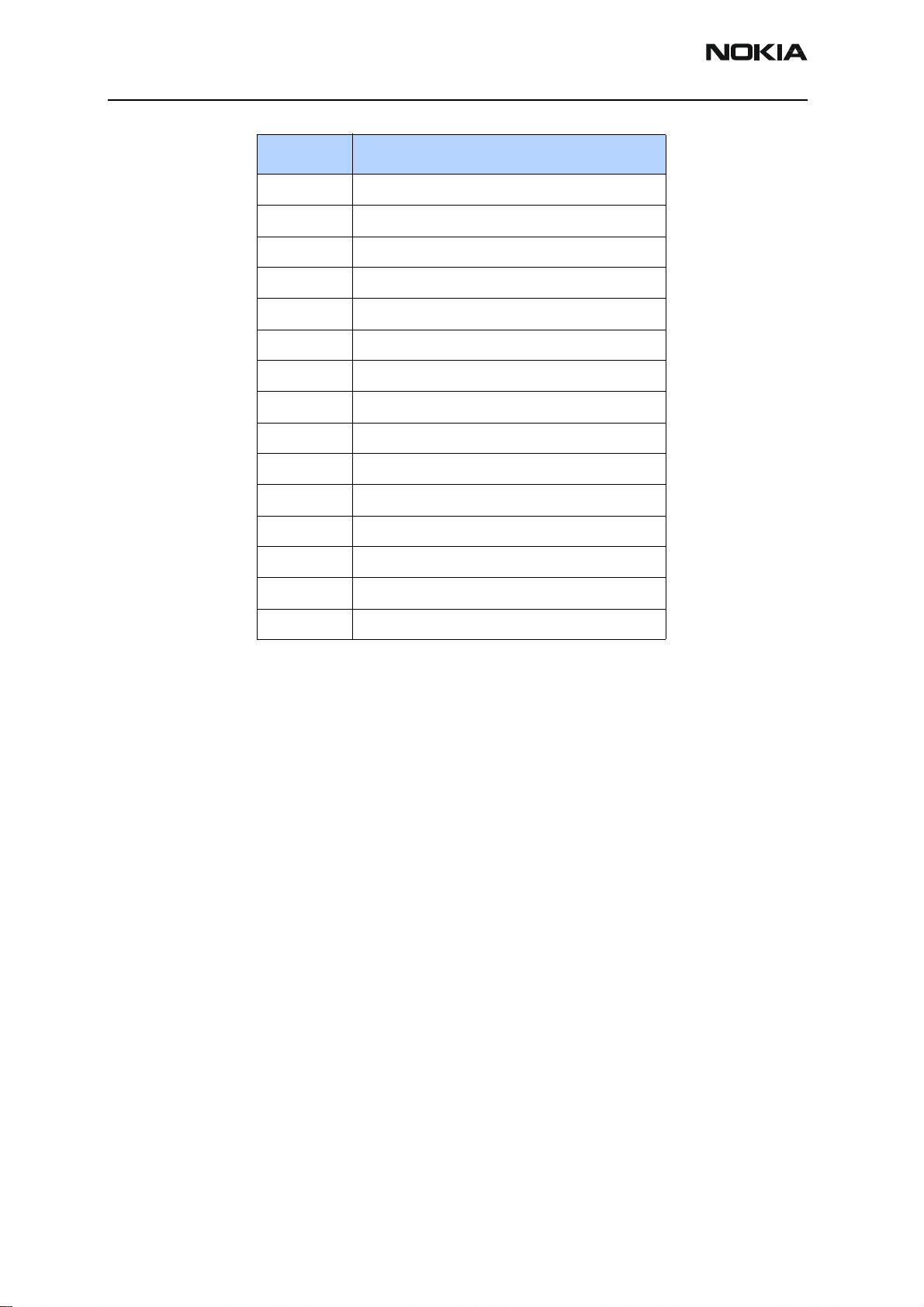

Item Quantity Code Description

11

0266032

0266031

0266030

0266029

0266028

A-cover assembly:

Metallic Blue

Dune Beige

Camellia

Aluminum

Clay Red

8

7

9

21

9791414

9791415

9791416

9797092

9797093

9797112

9797111

3 6 9380209 Screws 1.8X6 RF T6+BLK

4 1 9481160 Dome sheet frame assembly

5 1 0211425 LCD module assembly

6 1 0202397 PWB

Keymat assembly

Blank

Latin

BoPoMoFo

Hindi (without “i”)

Stroke (China)

Thai (Generic)

Thai (Hutch)

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 19

3125 (RH-61)

Parts Lists and Exploded View

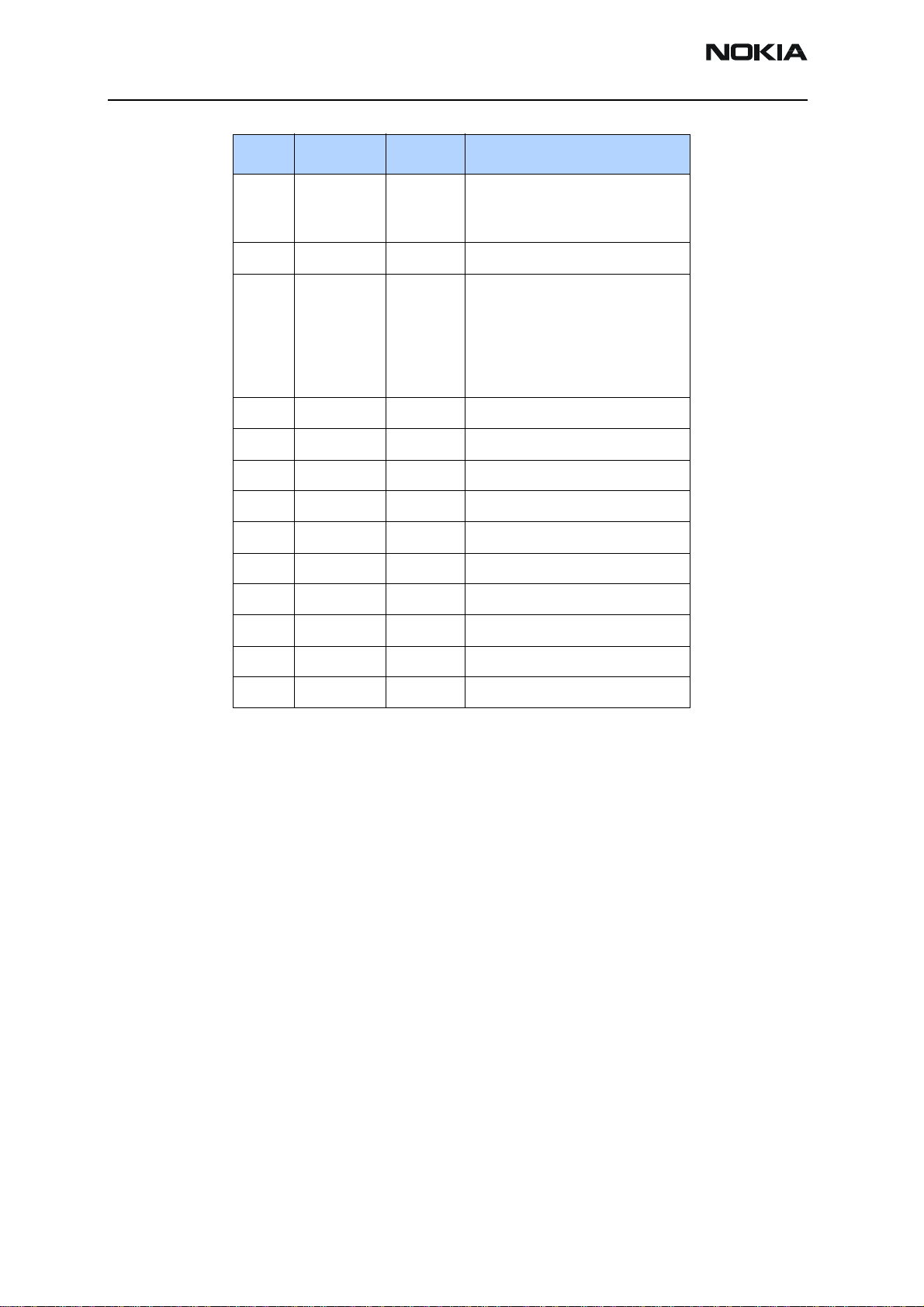

Item Quantity Code Description

71

0264009

0264008

8 1 0670400 Battery (BL-5C)

91

9453963

9453961

9453959

9453957

9453955

1 9453272 C-cover release button

1 9510935 C-cover release spring

1 5140265 Microphone assembly

1 5400243 DC-Jack 3.5mm 3POL SPR 90DEG

1 6800057 Vibra 1.3V 80MA

1 9453374 Power button

1 0660303 Antenna assembly

1 9517328 Shield assembly

B-cover assembly:

Metallic Blue

Dune Beige

C-cover assembly:

Metallic Blue

Dune Beige

Camellia

Aluminum

Clay Red

1 9560199 SIM flap

1 9511259 LCD frame assembly

Page 4 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 20

3125 (RH-61)

Nokia Customer Care Parts Lists and Exploded View

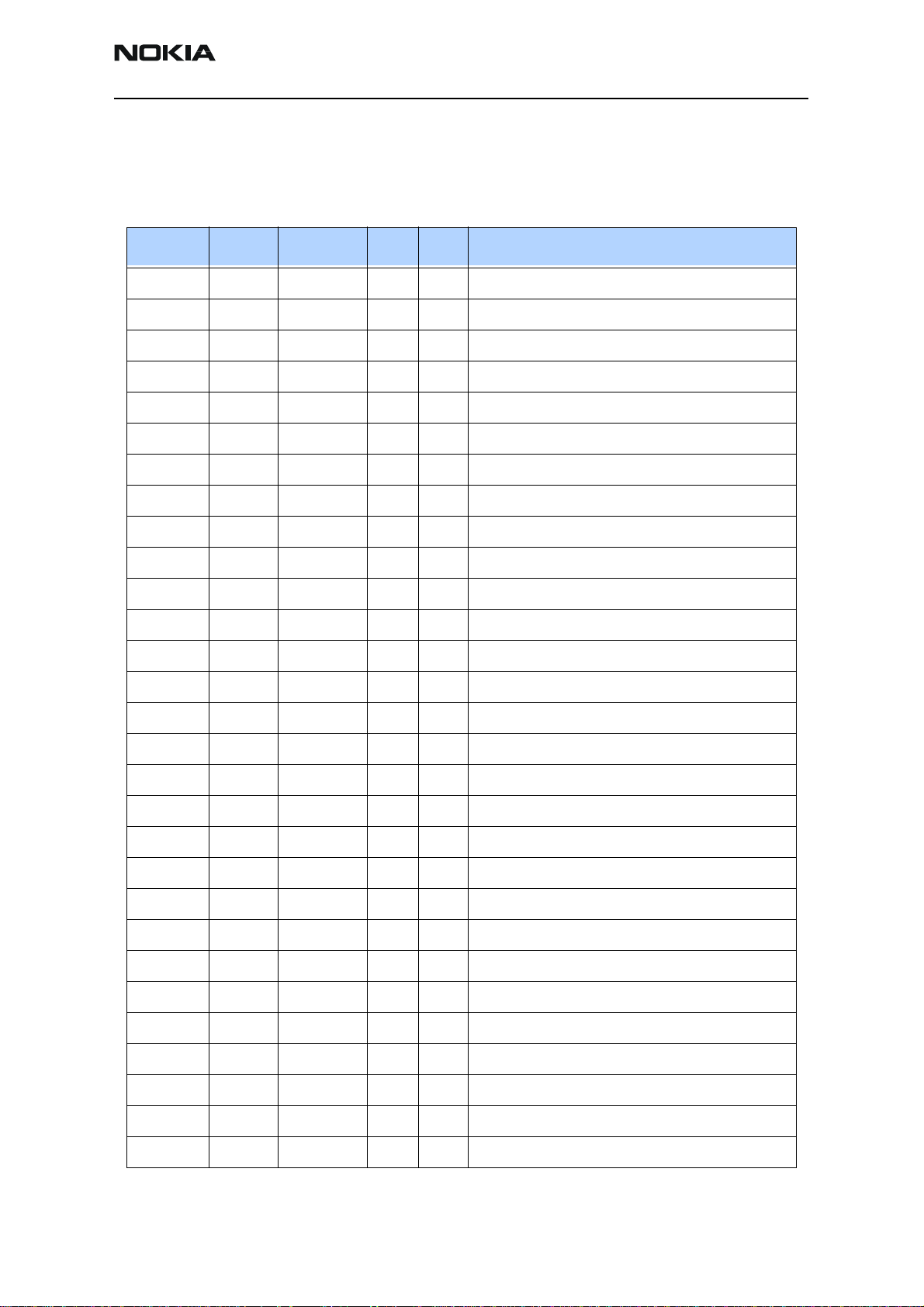

Parts List

3125 (RH-61) — Build 004 — Engine Code 0202397

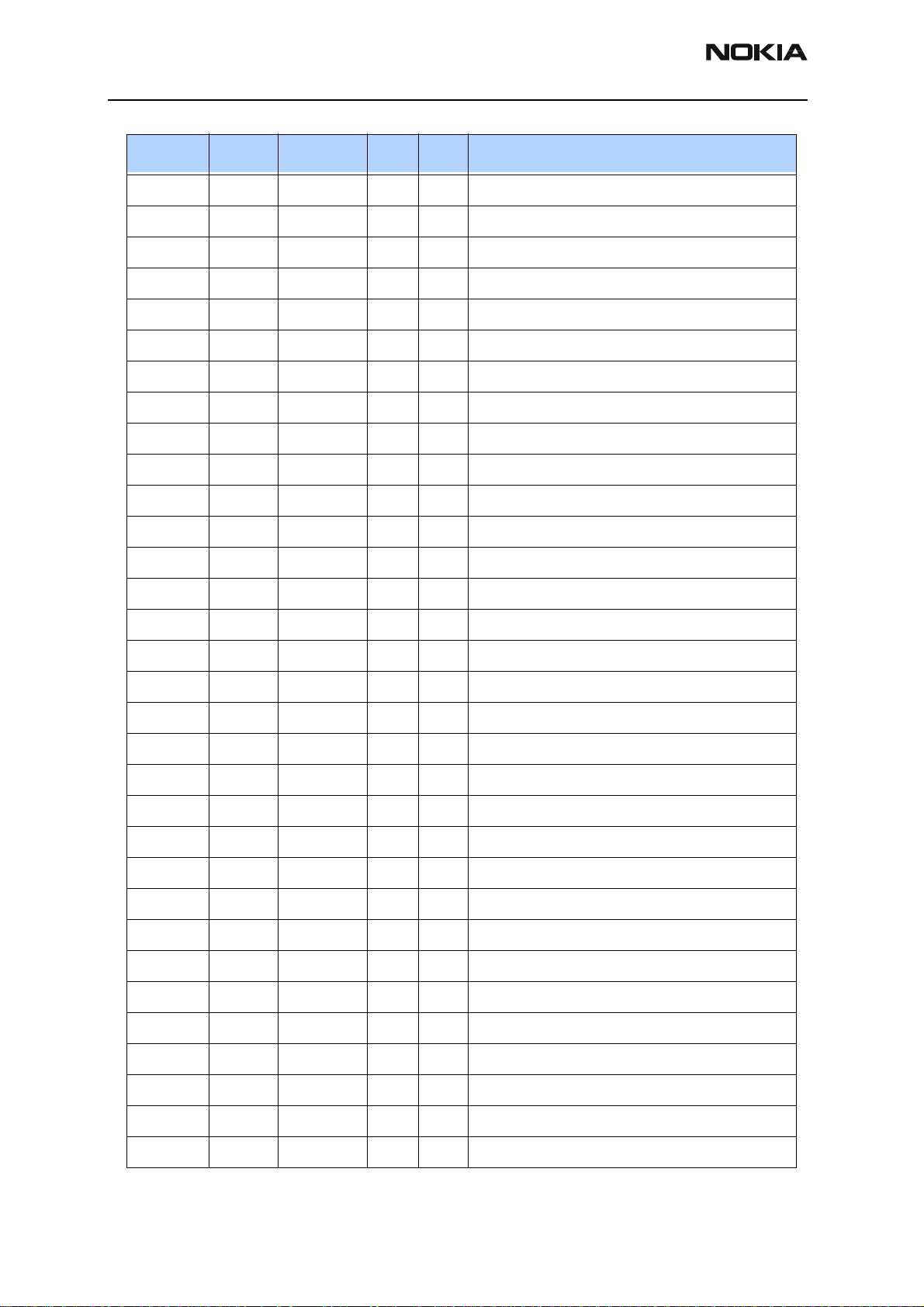

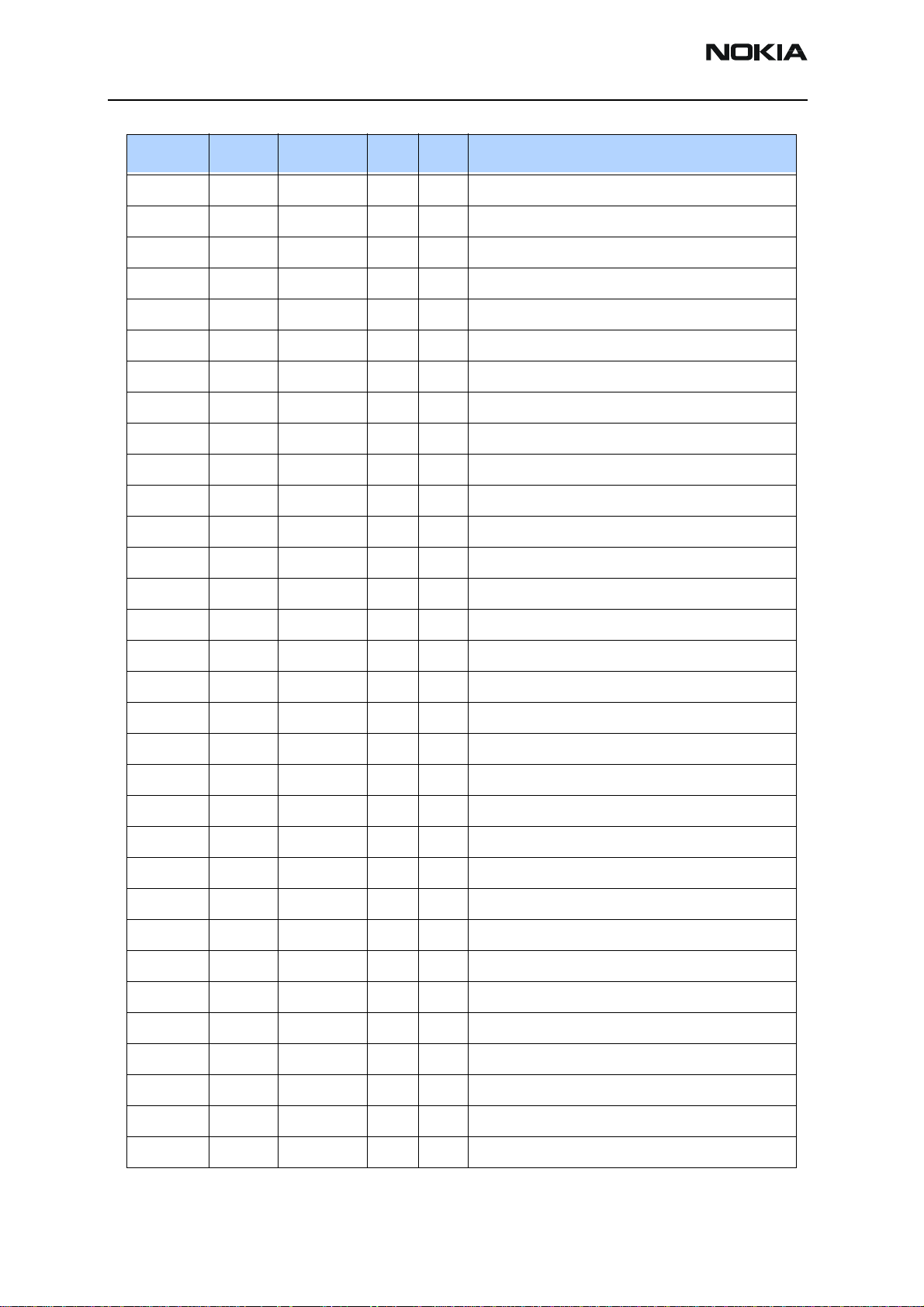

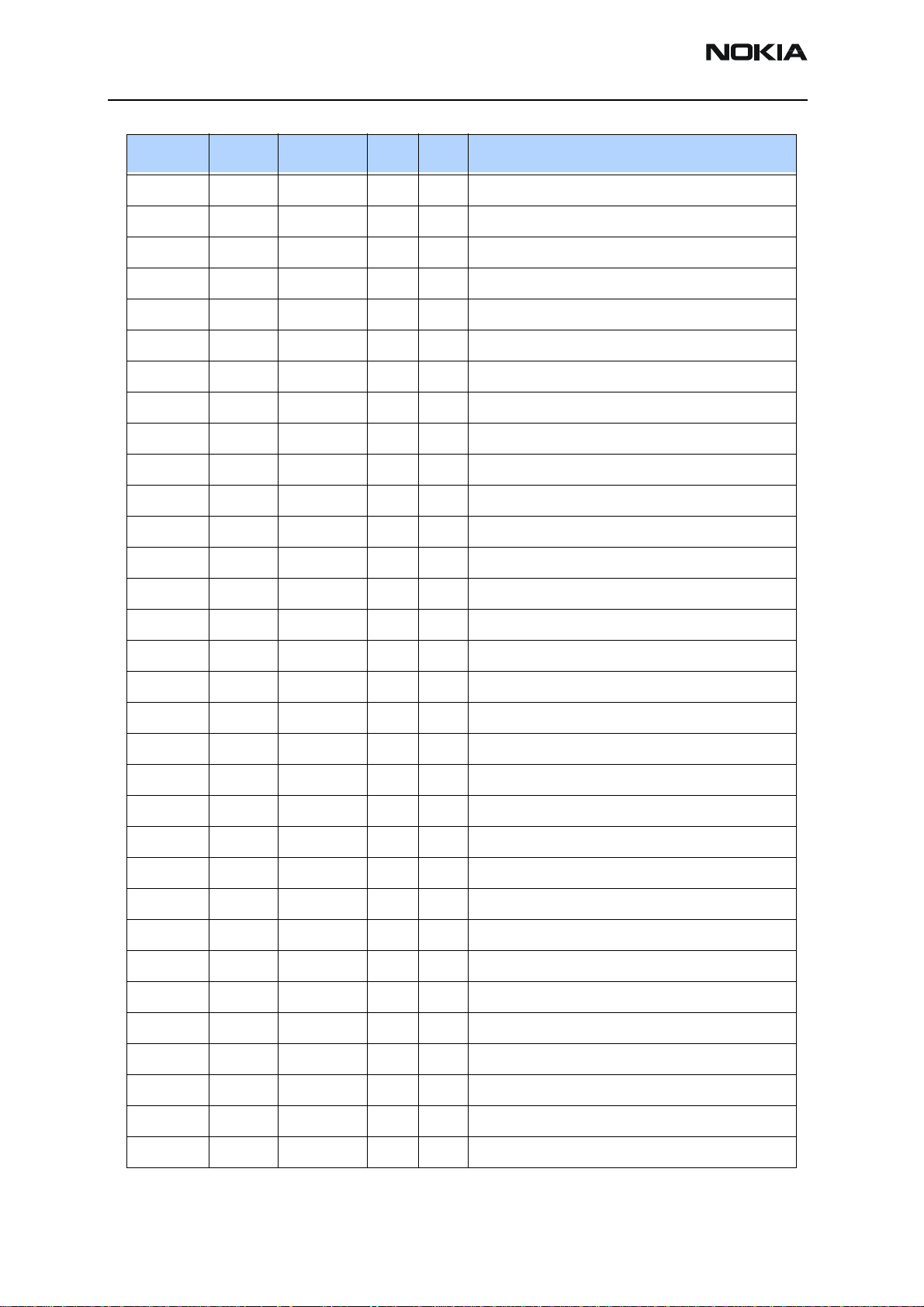

Code Item Side X Y Description

1419003 R200 BOTTOM L 7 CHIPRES 0W5 0R22 J 200PPM 1210

1430121 R302 BOTTOM O 9 CHIPRES 0W06 22K F 200PPM 0402

1430191 R156 BOTTOM O 7 CHIPRES 0W06 180K F 200PPM 0402

1430681 R607 BOTTOM G 6 CHIPRES 0W06 4R3 J 0402

1430681 R608 BOTTOM E 5 CHIPRES 0W06 4R3 J 0402

1430681 R617 BOTTOM G 6 CHIPRES 0W06 4R3 J 0402

1430681 R633 BOTTOM E 5 CHIPRES 0W06 4R3 J 0402

1430690 R270 BOTTOM P 6 CHIPRES JUMPER 0R0 0402

1430690 R914 BOTTOM C 5 CHIPRES JUMPER 0R0 0402

1430691 R632 BOTTOM E 7 CHIPRES 0W06 2R2 J 0402

1430693 R167 BOTTOM N 8 CHIPRES 0W06 5R6 J 0402

1430693 R168 BOTTOM N 8 CHIPRES 0W06 5R6 J 0402

1430693 R177 BOTTOM B 6 CHIPRES 0W06 5R6 J 0402

1430693 R178 BOTTOM A 6 CHIPRES 0W06 5R6 J 0402

1430693 R606 BOTTOM G 5 CHIPRES 0W06 5R6 J 0402

1430693 R609 BOTTOM G 5 CHIPRES 0W06 5R6 J 0402

1430693 R629 BOTTOM G 6 CHIPRES 0W06 5R6 J 0402

1430693 R910 BOTTOM D 6 CHIPRES 0W06 5R6 J 0402

1430700 R502 BOTTOM H 5 CHIPRES 0W06 10R J 0402

1430700 R516 BOTTOM J 5 CHIPRES 0W06 10R J 0402

1430700 R614 BOTTOM G 5 CHIPRES 0W06 10R J 0402

1430700 R618 BOTTOM H 7 CHIPRES 0W06 10R J 0402

1430700 R620 BOTTOM G 6 CHIPRES 0W06 10R J 0402

1430700 R701 BOTTOM J 9 CHIPRES 0W06 10R J 0402

1430700 R703 BOTTOM I 10 CHIPRES 0W06 10R J 0402

1430700 R715 BOTTOM J 10 CHIPRES 0W06 10R J 0402

1430708 R911 BOTTOM C 5 CHIPRES 0W06 18R J 0402

1430714 R315 BOTTOM P 4 CHIPRES 0W06 33R J 0402

1430718 R504 BOTTOM K 5 CHIPRES 0W06 47R J 0402

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 5

Page 21

3125 (RH-61)

Parts Lists and Exploded View

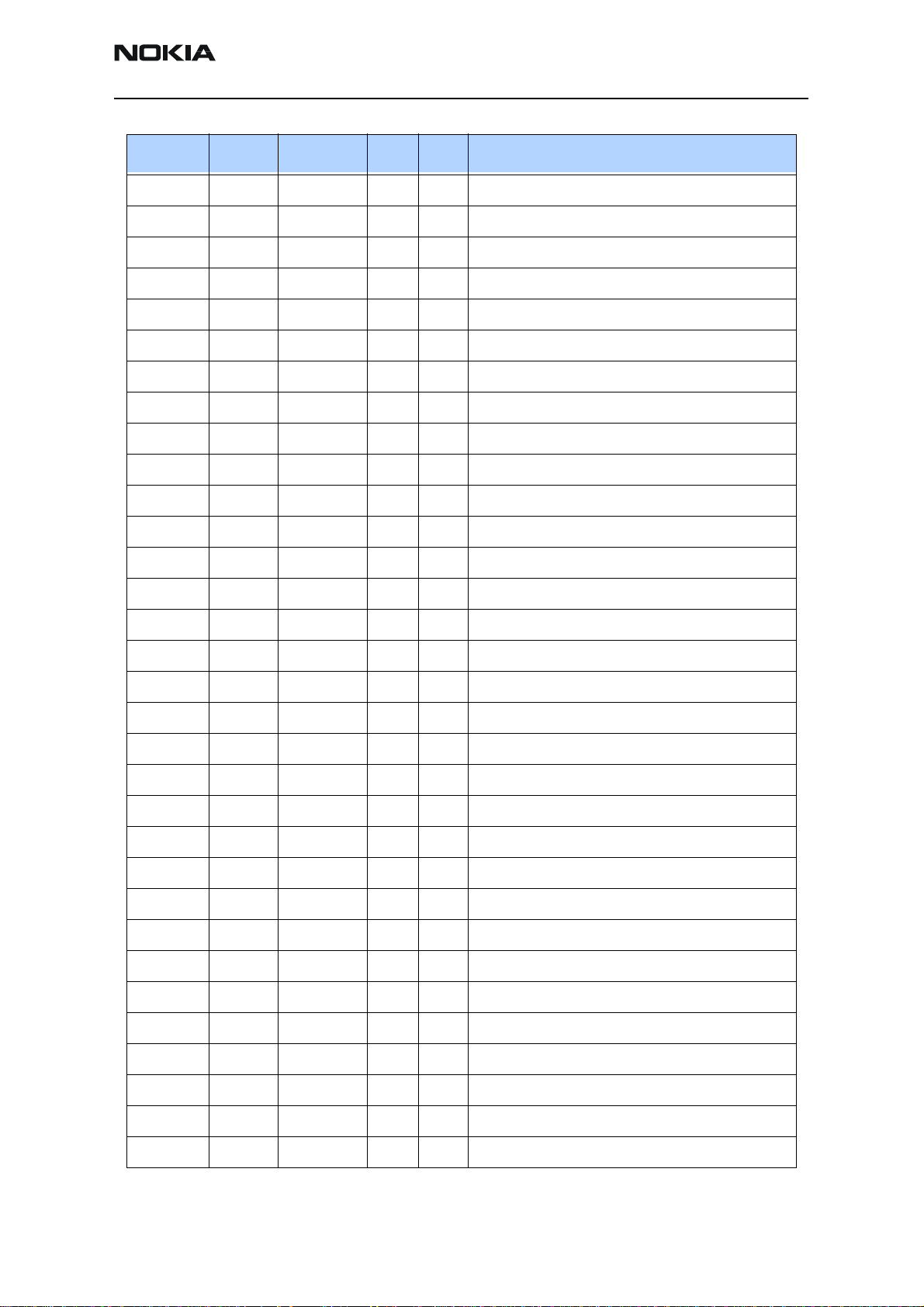

Code Item Side X Y Description

1430722 R301 BOTTOM R 4 CHIPRES 0W06 68R J 0402

1430722 R303 BOTTOM P 4 CHIPRES 0W06 68R J 0402

1430722 R308 BOTTOM F 8 CHIPRES 0W06 68R J 0402

1430722 R316 BOTTOM P 4 CHIPRES 0W06 68R J 0402

1430724 R905 BOTTOM C 5 CHIPRES 0W06 82R J 0402

1430726 R602 BOTTOM H 6 CHIPRES 0W06 100R J 0402

1430726 R603 BOTTOM M 7 CHIPRES 0W06 100R J 0402

1430726 R605 BOTTOM L 6 CHIPRES 0W06 100R J 0402

1430734 R309 BOTTOM F 8 CHIPRES 0W06 220R J 0402

1430734 R310 BOTTOM F 8 CHIPRES 0W06 220R J 0402

1430738 R912 BOTTOM D 5 CHIPRES 0W06 270R J 0402

1430738 R913 BOTTOM C 5 CHIPRES 0W06 270R J 0402

1430744 R154 BOTTOM N 8 CHIPRES 0W06 470R J 0402

1430754 R702 BOTTOM H 8 CHIPRES 0W06 1K0 J 0402

1430758 R616 BOTTOM F 7 CHIPRES 0W06 1K5 J 0402

1430762 R624 BOTTOM G 4 CHIPRES 0W06 2K2 J 0402

1430764 R321 BOTTOM Q 4 CHIPRES 0W06 3K3 J 0402

1430764 R427 BOTTOM M 6 CHIPRES 0W06 3K3 J 0402

1430764 R433 BOTTOM L 6 CHIPRES 0W06 3K3 J 0402

1430764 R435 BOTTOM K 4 CHIPRES 0W06 3K3 J 0402

1430764 R720 BOTTOM I 10 CHIPRES 0W06 3K3 J 0402

1430770 R306 BOTTOM B 7 CHIPRES 0W06 4K7 J 0402

1430770 R450 BOTTOM N 6 CHIPRES 0W06 4K7 J 0402

1430770 R508 BOTTOM H 4 CHIPRES 0W06 4K7 J 0402

1430770 R509 BOTTOM H 4 CHIPRES 0W06 4K7 J 0402

1430772 R157 BOTTOM O 7 CHIPRES 0W06 5K6 J 0402

1430772 R512 BOTTOM H 4 CHIPRES 0W06 5K6 J 0402

1430772 R626 BOTTOM G 5 CHIPRES 0W06 5K6 J 0402

1430772 R630 BOTTOM G 4 CHIPRES 0W06 5K6 J 0402

1430772 R631 BOTTOM G 4 CHIPRES 0W06 5K6 J 0402

1430772 R718 BOTTOM I 10 CHIPRES 0W06 5K6 J 0402

1430778 R207 BOTTOM O 10 CHIPRES 0W06 10K J 0402

Page 6 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 22

3125 (RH-61)

Nokia Customer Care Parts Lists and Exploded View

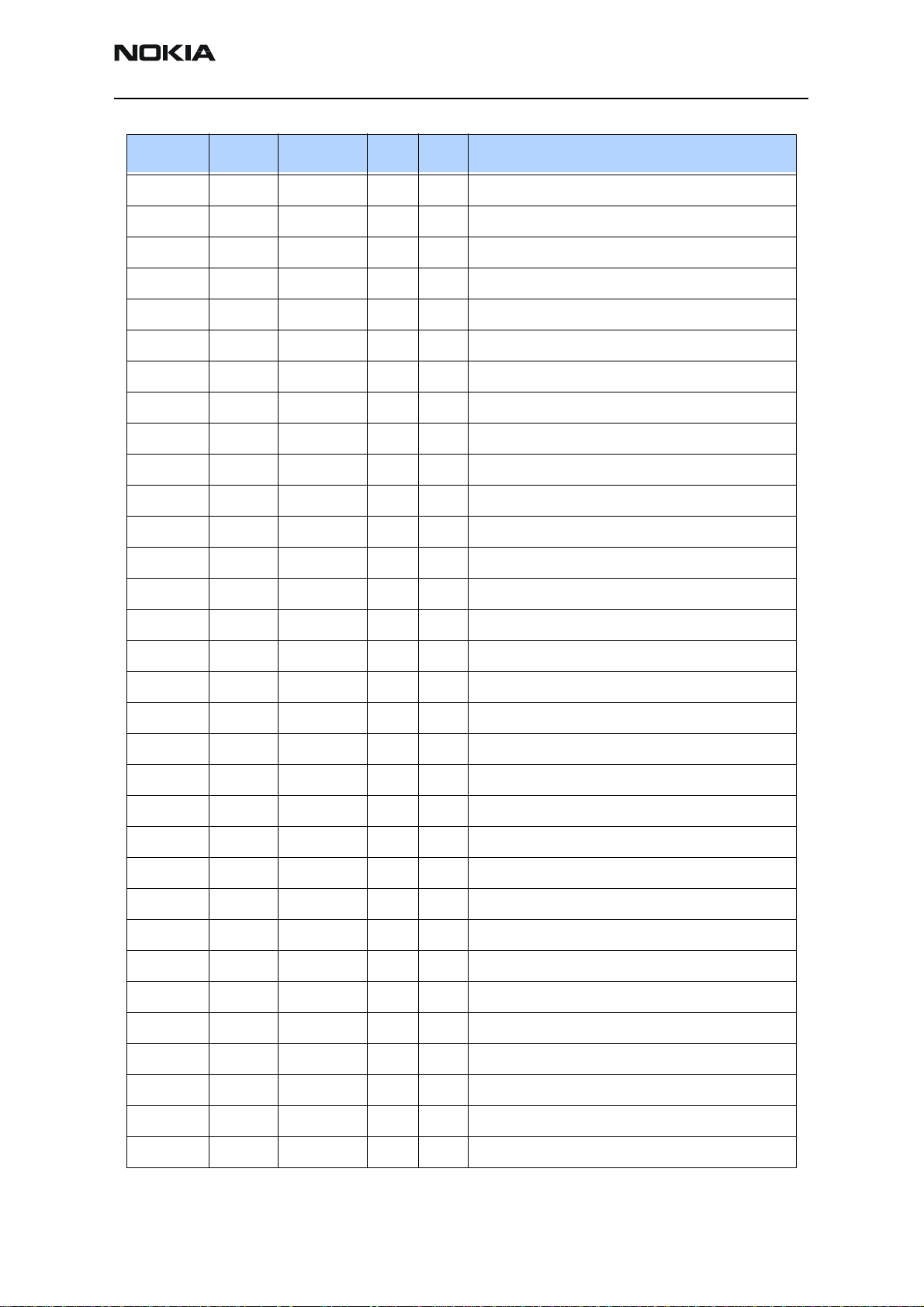

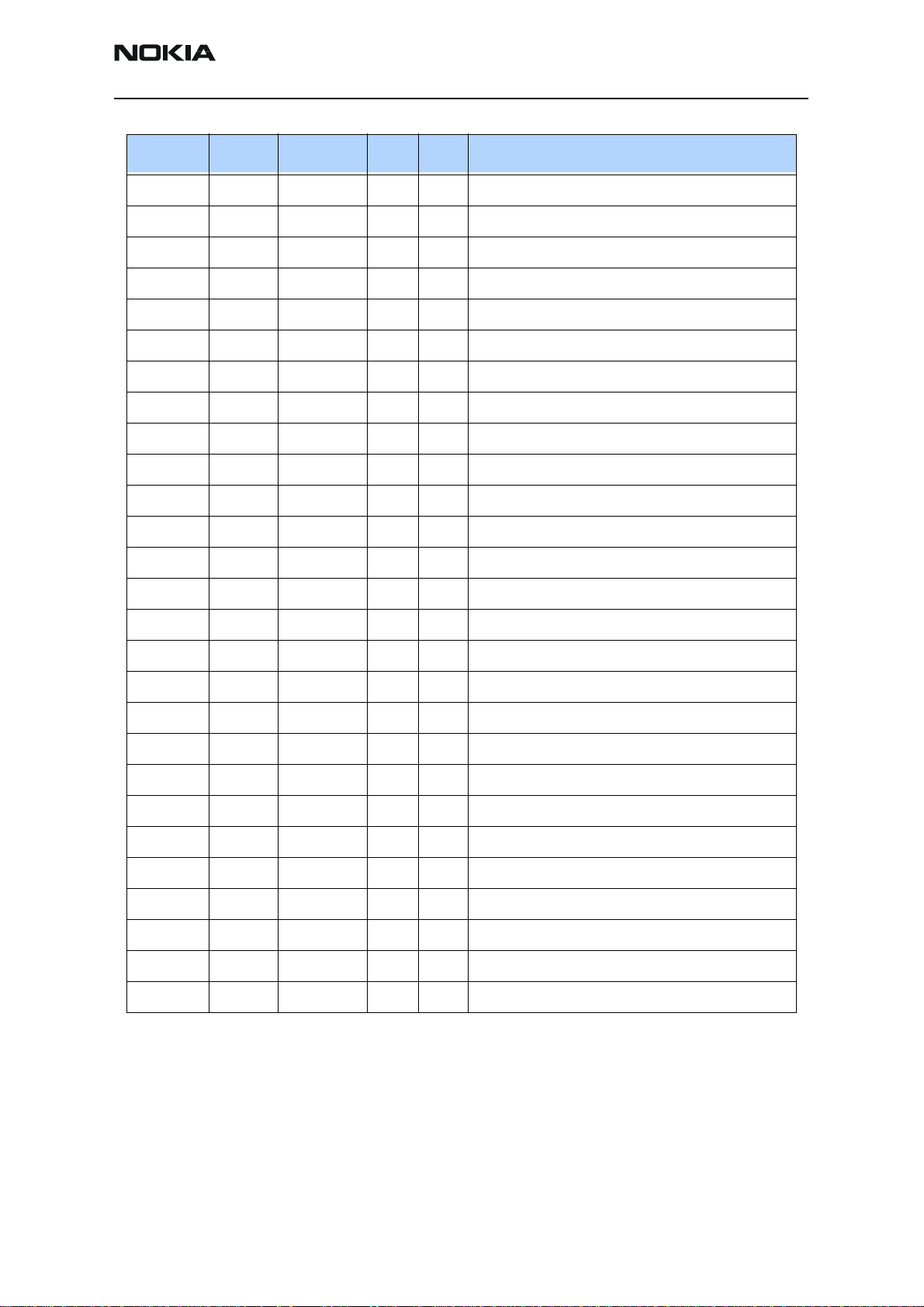

Code Item Side X Y Description

1430778 R517 BOTTOM J 5 CHIPRES 0W06 10K J 0402

1430796 R155 BOTTOM O 8 CHIPRES 0W06 47K J 0402

1430796 R173 BOTTOM O 8 CHIPRES 0W06 47K J 0402

1430796 R902 BOTTOM C 7 CHIPRES 0W06 47K J 0402

1430804 R107 BOTTOM O 6 CHIPRES 0W06 100K J 0402

1430804 R109 BOTTOM R 8 CHIPRES 0W06 100K J 0402

1430806 R706 BOTTOM I 8 CHIPRES 0W06 120K J 0402

1430812 R104 BOTTOM R 7 CHIPRES 0W06 220K J 0402

1430832 R814 BOTTOM D 9 CHIPRES 0W06 2K7 J 0402

1430915 R300 BOTTOM O 9 CHIPRES 0W06 1K3 F 250PPM 0402

1620027 R100 BOTTOM R 7 RES NETWORK 0W06 2X47R J 0404

1620027 R101 BOTTOM R 8 RES NETWORK 0W06 2X47R J 0404

1620027 R102 BOTTOM R 8 RES NETWORK 0W06 2X47R J 0404

1620029 R206 BOTTOM M 10 RES NETWORK 0W06 2X4K7 J 0404

1620031 R150 TOP T 8 RES NETWORK 0W06 2X1K0 J 0404

1620031 R151 BOTTOM O 8 RES NETWORK 0W06 2X1K0 J 0404

1620031 R152 TOP T 8 RES NETWORK 0W06 2X1K0 J 0404

1620031 R170 BOTTOM R 5 RES NETWORK 0W06 2X1K0 J 0404

1620031 R171 BOTTOM Q 5 RES NETWORK 0W06 2X1K0 J 0404

1620031 R172 BOTTOM O 8 RES NETWORK 0W06 2X1K0 J 0404

1620067 R202 BOTTOM M 10 RES NETWORK 0W06 4X100K J 0804

1820039 R106 BOTTOM N 7 NTC RES 0W1 47K J B 4050+-3% 0402

1820039 R821 BOTTOM D 9 NTC RES 0W1 47K J B 4050+-3% 0402

1825031 R105 TOP T 9 VARISTOR ARRAY 2XVWM16V VC50 0405

1825031 R110 TOP T 9 VARISTOR ARRAY 2XVWM16V VC50 0405

1825031 R179 BOTTOM B 6 VARISTOR ARRAY 2XVWM16V VC50 0405

2310037 C260 BOTTOM K 7 CHIPCAP X5R 10U M 6V3 0805

2310037 C805 BOTTOM C 9 CHIPCAP X5R 10U M 6V3 0805

2312243 C505 BOTTOM I 5 CHIPCAP X5R 4U7 K 6V3 0805

2312243 C655 BOTTOM E 5 CHIPCAP X5R 4U7 K 6V3 0805

2312255 C806 BOTTOM E 10 CHIPCAP X5R 10U K 10V 1206

2312255 C808 BOTTOM E 9 CHIPCAP X5R 10U K 10V 1206

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 7

Page 23

3125 (RH-61)

Parts Lists and Exploded View

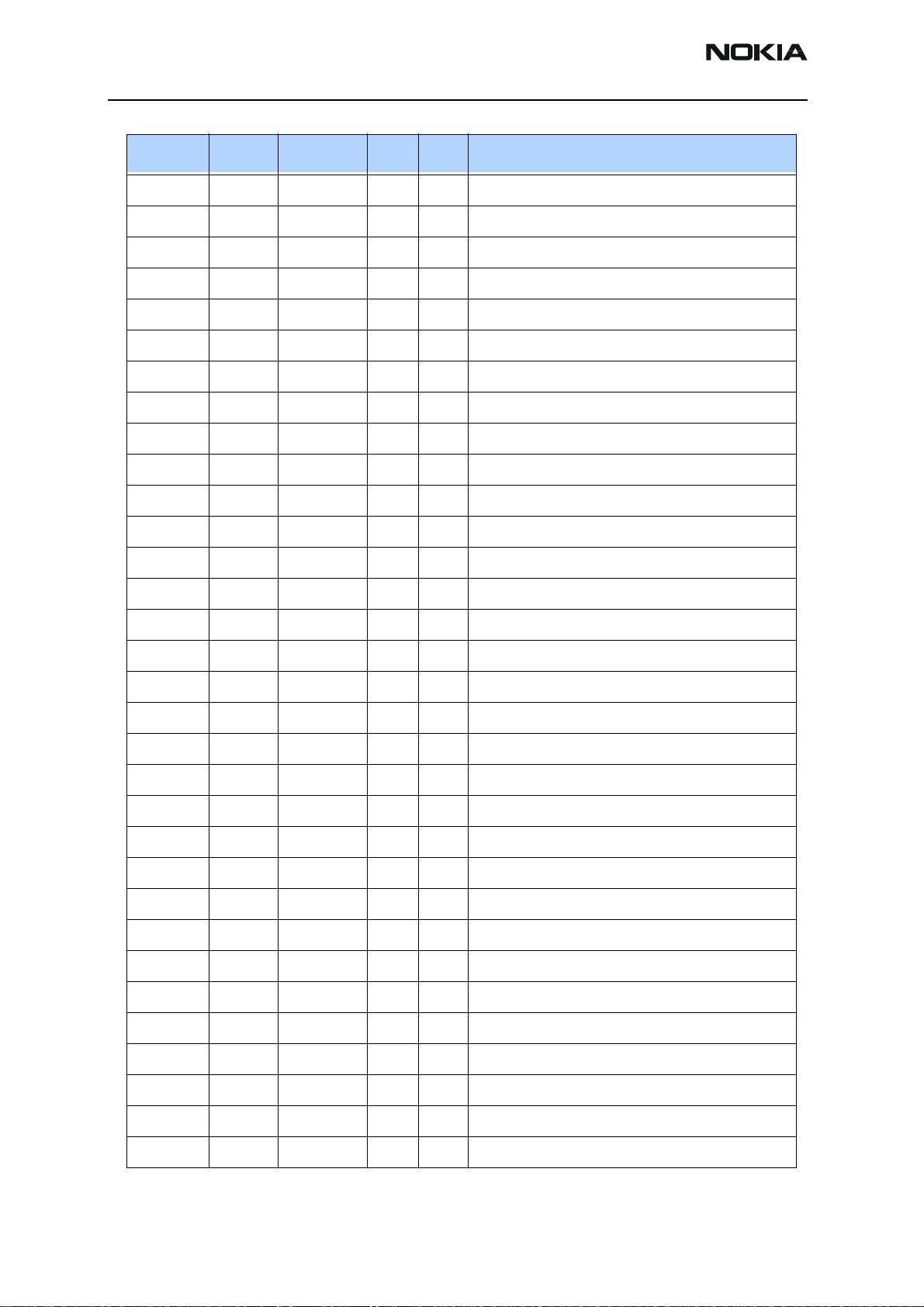

Code Item Side X Y Description

2312411 C304 BOTTOM N 10 CHIPCAP X5R 1U0 M 25V 1206

2320009 C754 BOTTOM I 9 CHIPCAP NP0 10P J 50V 0402

2320110 C111 BOTTOM F 9 CHIPCAP X7R 10N K 50V 0603

2320143 C238 BOTTOM L 7 CHIPCAP X5R 220N K 6.3V 0402

2320481 C101 BOTTOM O 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C102 BOTTOM O 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C167 BOTTOM O 7 CHIPCAP X5R 1U K 6V3 0603

2320481 C175 BOTTOM N 7 CHIPCAP X5R 1U K 6V3 0603

2320481 C201 BOTTOM L 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C203 BOTTOM N 10 CHIPCAP X5R 1U K 6V3 0603

2320481 C204 BOTTOM L 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C205 BOTTOM L 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C206 BOTTOM M 7 CHIPCAP X5R 1U K 6V3 0603

2320481 C207 BOTTOM M 10 CHIPCAP X5R 1U K 6V3 0603

2320481 C208 BOTTOM K 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C212 BOTTOM M 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C213 BOTTOM M 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C214 BOTTOM N 7 CHIPCAP X5R 1U K 6V3 0603

2320481 C215 BOTTOM N 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C219 BOTTOM K 7 CHIPCAP X5R 1U K 6V3 0603

2320481 C221 BOTTOM K 7 CHIPCAP X5R 1U K 6V3 0603

2320481 C222 BOTTOM K 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C223 BOTTOM K 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C224 BOTTOM K 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C225 BOTTOM K 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C226 BOTTOM K 9 CHIPCAP X5R 1U K 6V3 0603

2320481 C227 BOTTOM K 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C228 BOTTOM K 9 CHIPCAP X5R 1U K 6V3 0603

2320481 C229 BOTTOM K 9 CHIPCAP X5R 1U K 6V3 0603

2320481 C231 BOTTOM K 9 CHIPCAP X5R 1U K 6V3 0603

2320481 C232 BOTTOM K 8 CHIPCAP X5R 1U K 6V3 0603

2320481 C233 BOTTOM K 7 CHIPCAP X5R 1U K 6V3 0603

Page 8 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 24

3125 (RH-61)

Nokia Customer Care Parts Lists and Exploded View

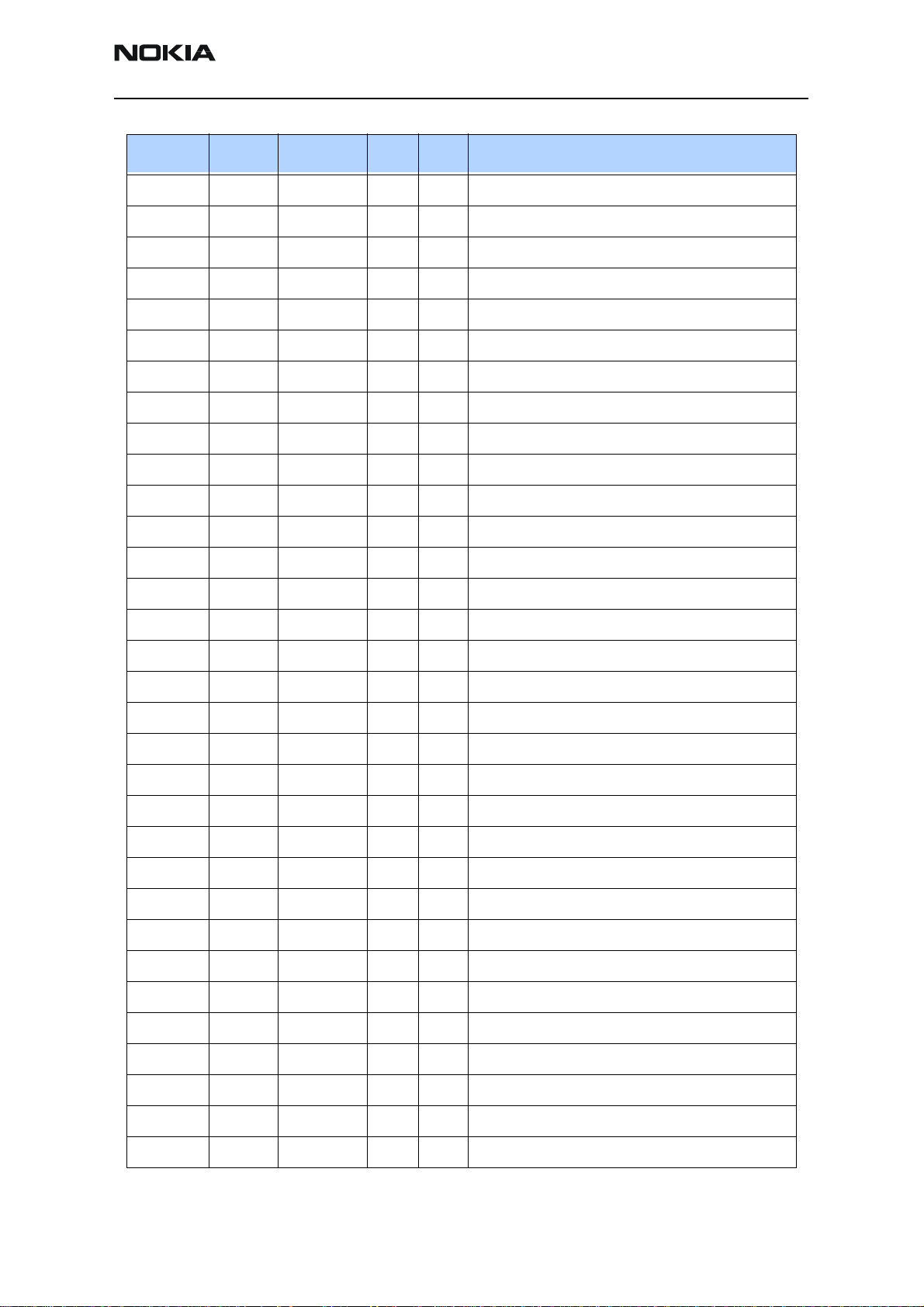

Code Item Side X Y Description

2320481 C234 BOTTOM K 9 CHIPCAP X5R 1U K 6V3 0603

2320481 C235 BOTTOM N 6 CHIPCAP X5R 1U K 6V3 0603

2320481 C243 BOTTOM N 9 CHIPCAP X5R 1U K 6V3 0603

2320481 C316 BOTTOM O 9 CHIPCAP X5R 1U K 6V3 0603

2320481 C663 BOTTOM E 6 CHIPCAP X5R 1U K 6V3 0603

2320505 C270 BOTTOM Q 6 CHIPCAP X5R 4U7 K 6.3V 0603

2320505 C271 BOTTOM Q 6 CHIPCAP X5R 4U7 K 6.3V 0603

2320505 C274 BOTTOM Q 5 CHIPCAP X5R 4U7 K 6.3V 0603

2320505 C275 BOTTOM Q 5 CHIPCAP X5R 4U7 K 6.3V 0603

2320508 C811 BOTTOM D 9 CHIPCAP NP0 1P0 C 50V 0402

2320516 C619 BOTTOM F 5 CHIPCAP NP0 1P5 C 50V 0402

2320518 C903 BOTTOM D 7 CHIPCAP NP0 1P8 C 50V 0402

2320520 C614 BOTTOM F 5 CHIPCAP NP0 2P2 C 50V 0402

2320520 C623 BOTTOM F 5 CHIPCAP NP0 2P2 C 50V 0402

2320524 C907 BOTTOM D 6 CHIPCAP NP0 3P3 C 50V 0402

2320526 C702 BOTTOM J 8 CHIPCAP NP0 3P9 C 50V 0402

2320526 C707 BOTTOM J 8 CHIPCAP NP0 3P9 C 50V 0402

2320534 C912 BOTTOM C 5 CHIPCAP NP0 8P2 C 50V 0402

2320538 C617 BOTTOM G 5 CHIPCAP NP0 12P J 50V 0402

2320538 C618 BOTTOM G 5 CHIPCAP NP0 12P J 50V 0402

2320538 C711 BOTTOM H 9 CHIPCAP NP0 12P J 50V 0402

2320540 C603 BOTTOM G 7 CHIPCAP NP0 15P J 50V 0402

2320544 C103 BOTTOM R 8 CHIPCAP NP0 22P J 50V 0402

2320544 C104 BOTTOM R 8 CHIPCAP NP0 22P J 50V 0402

2320544 C105 BOTTOM R 7 CHIPCAP NP0 22P J 50V 0402

2320544 C177 BOTTOM O 7 CHIPCAP NP0 22P J 50V 0402

2320544 C630 BOTTOM E 7 CHIPCAP NP0 22P J 50V 0402

2320546 C917 BOTTOM C 6 CHIPCAP NP0 27P J 50V 0402

2320548 C506 BOTTOM I 5 CHIPCAP NP0 33P J 50V 0402

2320550 C152 BOTTOM O 8 CHIPCAP NP0 39P J 50V 0402

2320550 C156 BOTTOM N 8 CHIPCAP NP0 39P J 50V 0402

2320550 C178 BOTTOM N 8 CHIPCAP NP0 39P J 50V 0402

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 9

Page 25

3125 (RH-61)

Parts Lists and Exploded View

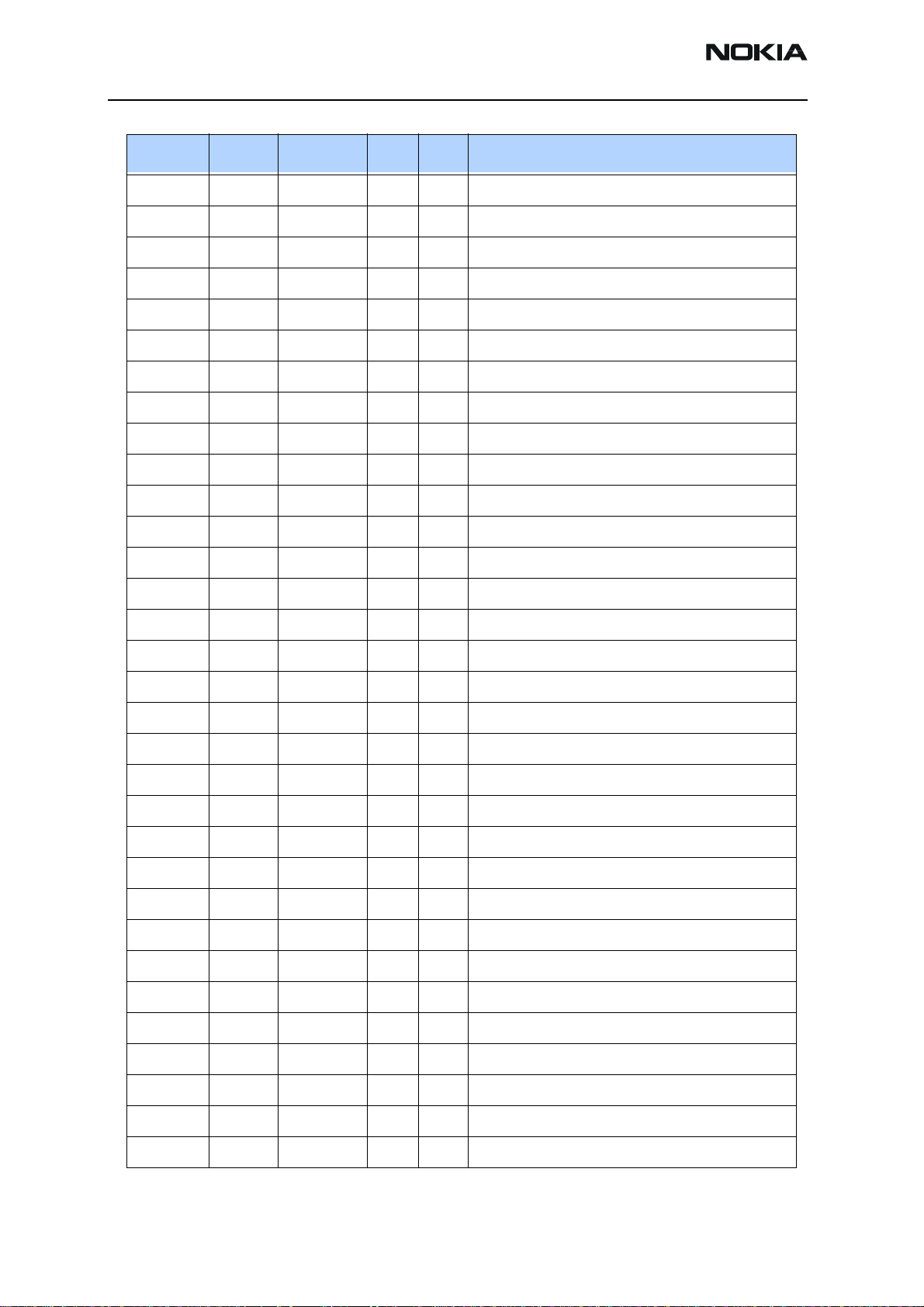

Code Item Side X Y Description

2320550 C179 BOTTOM N 8 CHIPCAP NP0 39P J 50V 0402

2320550 C624 BOTTOM E 6 CHIPCAP NP0 39P J 50V 0402

2320552 C100 BOTTOM F 9 CHIPCAP NP0 47P J 50V 0402

2320552 C115 BOTTOM F 9 CHIPCAP NP0 47P J 50V 0402

2320552 C153 TOP T 8 CHIPCAP NP0 47P J 50V 0402

2320552 C171 BOTTOM Q 5 CHIPCAP NP0 47P J 50V 0402

2320552 C306 TOP A 7 CHIPCAP NP0 47P J 50V 0402

2320552 C309 TOP C 7 CHIPCAP NP0 47P J 50V 0402

2320552 C656 BOTTOM F 5 CHIPCAP NP0 47P J 50V 0402

2320554 C901 BOTTOM D 5 CHIPCAP NP0 56P J 50V 0402

2320560 C644 BOTTOM G 6 CHIPCAP NP0 100P J 50V 0402

2320560 C659 BOTTOM G 7 CHIPCAP NP0 100P J 50V 0402

2320560 C906 BOTTOM D 6 CHIPCAP NP0 100P J 50V 0402

2320560 C909 BOTTOM C 7 CHIPCAP NP0 100P J 50V 0402

2320564 C802 BOTTOM E 9 CHIPCAP NP0 150P J 50V 0402

2320576 C813 BOTTOM E 8 CHIPCAP X7R 470P J 50V 0402

2320584 C106 TOP T 7 CHIPCAP X7R 1N0 J 50V 0402

2320584 C510 BOTTOM J 3 CHIPCAP X7R 1N0 J 50V 0402

2320584 C511 BOTTOM H 4 CHIPCAP X7R 1N0 J 50V 0402

2320584 C522 BOTTOM J 4 CHIPCAP X7R 1N0 J 50V 0402

2320584 C600 BOTTOM G 6 CHIPCAP X7R 1N0 J 50V 0402

2320584 C605 BOTTOM G 6 CHIPCAP X7R 1N0 J 50V 0402

2320584 C606 BOTTOM F 7 CHIPCAP X7R 1N0 J 50V 0402

2320584 C611 BOTTOM E 5 CHIPCAP X7R 1N0 J 50V 0402

2320584 C612 BOTTOM E 6 CHIPCAP X7R 1N0 J 50V 0402

2320584 C633 BOTTOM G 6 CHIPCAP X7R 1N0 J 50V 0402

2320584 C635 BOTTOM G 6 CHIPCAP X7R 1N0 J 50V 0402

2320584 C638 BOTTOM G 5 CHIPCAP X7R 1N0 J 50V 0402

2320584 C643 BOTTOM F 7 CHIPCAP X7R 1N0 J 50V 0402

2320584 C658 BOTTOM G 6 CHIPCAP X7R 1N0 J 50V 0402

2320584 C706 BOTTOM J 10 CHIPCAP X7R 1N0 J 50V 0402

2320584 C712 BOTTOM J 9 CHIPCAP X7R 1N0 J 50V 0402

Page 10 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 26

3125 (RH-61)

Nokia Customer Care Parts Lists and Exploded View

Code Item Side X Y Description

2320584 C735 BOTTOM H 8 CHIPCAP X7R 1N0 J 50V 0402

2320584 C736 BOTTOM H 8 CHIPCAP X7R 1N0 J 50V 0402

2320584 C814 BOTTOM D 8 CHIPCAP X7R 1N0 J 50V 0402

2320584 C919 BOTTOM C 5 CHIPCAP X7R 1N0 J 50V 0402

2320588 C516 BOTTOM H 4 CHIPCAP X7R 1N5 J 50V 0402

2320592 C164 BOTTOM O 7 CHIPCAP X7R 2N2 J 50V 0402

2320592 C646 BOTTOM G 4 CHIPCAP X7R 2N2 J 50V 0402

2320592 C647 BOTTOM F 5 CHIPCAP X7R 2N2 J 50V 0402

2320596 C601 BOTTOM F 7 CHIPCAP X7R 3N3 J 50V 0402

2320596 C913 BOTTOM C 5 CHIPCAP X7R 3N3 J 50V 0402

2320618 C519 BOTTOM H 4 CHIPCAP X7R 4N7 J 25V 0402

2320620 C713 BOTTOM J 10 CHIPCAP X7R 10N J 16V 0402

2320620 C744 BOTTOM J 9 CHIPCAP X7R 10N J 16V 0402

2320621 C641 BOTTOM F 7 USE 2320635 NP0 0P5 C 50V 0402

2320760 C728 BOTTOM I 9 CHIPCAP X7R 4N7 K 25V 0402

2320771 C648 BOTTOM G 5 CHIPCAP X5R 27N K 10V 0402

2320778 C113 BOTTOM O 7 CHIPCAP X7R 10N K 16V 0402

2320778 C202 BOTTOM K 7 CHIPCAP X7R 10N K 16V 0402

2320778 C220 BOTTOM M 10 CHIPCAP X7R 10N K 16V 0402

2320778 C240 BOTTOM M 10 CHIPCAP X7R 10N K 16V 0402

2320778 C241 BOTTOM L 10 CHIPCAP X7R 10N K 16V 0402

2320778 C310 BOTTOM B 6 CHIPCAP X7R 10N K 16V 0402

2320778 C422 BOTTOM M 6 CHIPCAP X7R 10N K 16V 0402

2320778 C426 BOTTOM L 6 CHIPCAP X7R 10N K 16V 0402

2320778 C428 BOTTOM K 4 CHIPCAP X7R 10N K 16V 0402

2320778 C450 BOTTOM O 6 CHIPCAP X7R 10N K 16V 0402

2320778 C454 BOTTOM O 6 CHIPCAP X7R 10N K 16V 0402

2320778 C650 BOTTOM H 5 CHIPCAP X7R 10N K 16V 0402

2320778 C652 BOTTOM G 5 CHIPCAP X7R 10N K 16V 0402

2320778 C703 BOTTOM I 8 CHIPCAP X7R 10N K 16V 0402

2320778 C704 BOTTOM I 9 CHIPCAP X7R 10N K 16V 0402

2320778 C810 BOTTOM D 9 CHIPCAP X7R 10N K 16V 0402

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 11

Page 27

3125 (RH-61)

Parts Lists and Exploded View

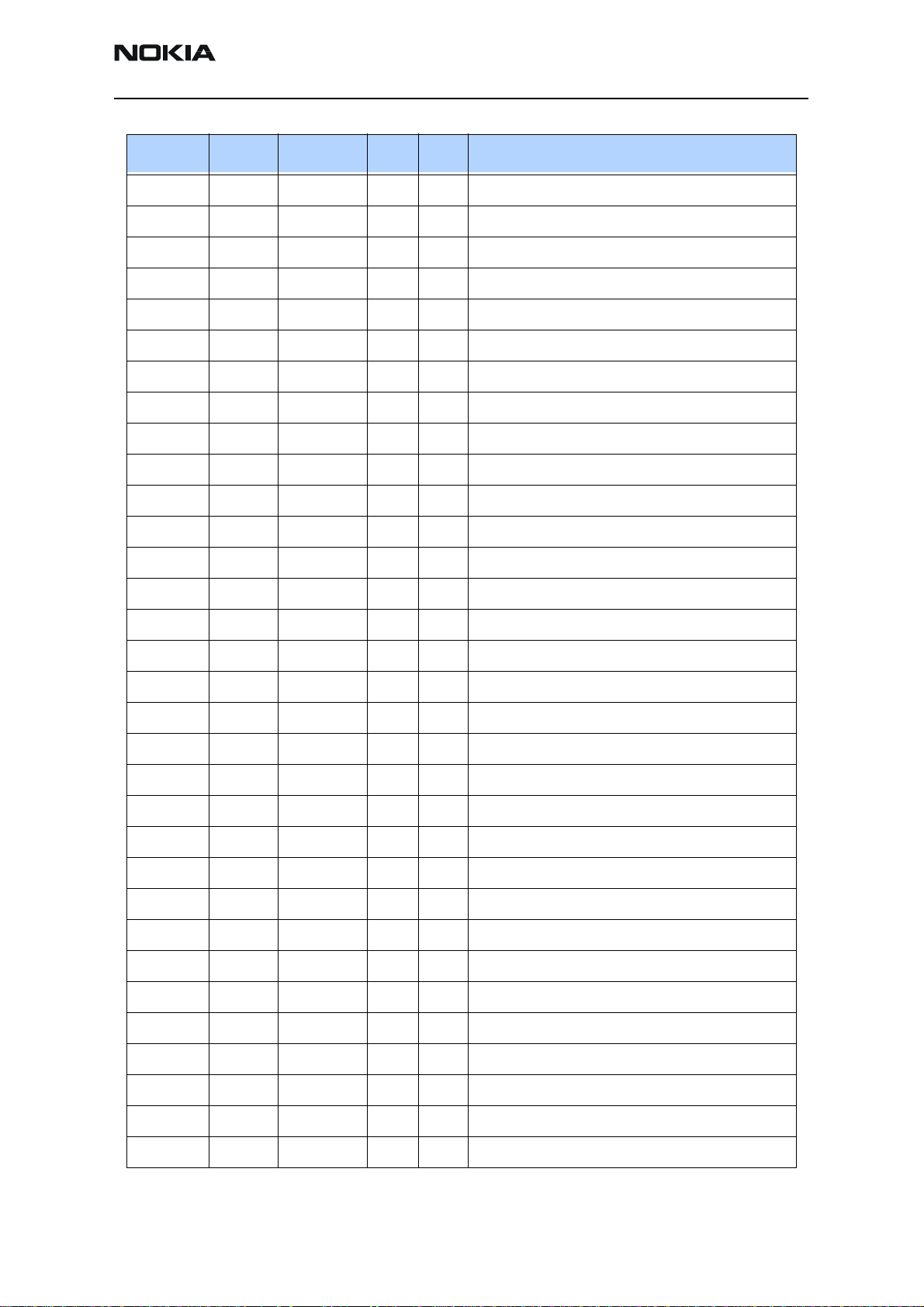

Code Item Side X Y Description

2320778 C816 BOTTOM E 8 CHIPCAP X7R 10N K 16V 0402

2320783 C807 BOTTOM E 5 CHIPCAP X7R 33N K 10V 0402

2320785 C918 BOTTOM D 7 CHIPCAP X7R 47N K 10V 0402

2320787 C756 BOTTOM I 9 CHIPCAP X7R 15N K 16V 0402

2320805 C151 BOTTOM O 8 CHIPCAP X5R 100N K 10V 0402

2320805 C154 BOTTOM O 8 CHIPCAP X5R 100N K 10V 0402

2320805 C169 BOTTOM O 8 CHIPCAP X5R 100N K 10V 0402

2320805 C172 BOTTOM O 8 CHIPCAP X5R 100N K 10V 0402

2320805 C174 BOTTOM O 7 CHIPCAP X5R 100N K 10V 0402

2320805 C180 BOTTOM R 5 CHIPCAP X5R 100N K 10V 0402

2320805 C181 TOP T 8 CHIPCAP X5R 100N K 10V 0402

2320805 C218 BOTTOM L 10 CHIPCAP X5R 100N K 10V 0402

2320805 C230 BOTTOM K 8 CHIPCAP X5R 100N K 10V 0402

2320805 C236 BOTTOM K 9 CHIPCAP X5R 100N K 10V 0402

2320805 C237 BOTTOM K 9 CHIPCAP X5R 100N K 10V 0402

2320805 C239 BOTTOM L 10 CHIPCAP X5R 100N K 10V 0402

2320805 C273 BOTTOM R 6 CHIPCAP X5R 100N K 10V 0402

2320805 C300 TOP B 7 CHIPCAP X5R 100N K 10V 0402

2320805 C301 TOP C 7 CHIPCAP X5R 100N K 10V 0402

2320805 C303 BOTTOM O 8 CHIPCAP X5R 100N K 10V 0402

2320805 C400 BOTTOM M 3 CHIPCAP X5R 100N K 10V 0402

2320805 C401 BOTTOM K 6 CHIPCAP X5R 100N K 10V 0402

2320805 C402 BOTTOM M 6 CHIPCAP X5R 100N K 10V 0402

2320805 C403 BOTTOM K 5 CHIPCAP X5R 100N K 10V 0402

2320805 C404 BOTTOM N 3 CHIPCAP X5R 100N K 10V 0402

2320805 C405 BOTTOM K 5 CHIPCAP X5R 100N K 10V 0402

2320805 C451 BOTTOM P 5 CHIPCAP X5R 100N K 10V 0402

2320805 C521 BOTTOM J 4 CHIPCAP X5R 100N K 10V 0402

2320805 C636 BOTTOM F 5 CHIPCAP X5R 100N K 10V 0402

2320805 C651 BOTTOM H 6 CHIPCAP X5R 100N K 10V 0402

2320805 C654 BOTTOM G 5 CHIPCAP X5R 100N K 10V 0402

2320805 C710 BOTTOM H 9 CHIPCAP X5R 100N K 10V 0402

Page 12 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 28

3125 (RH-61)

Nokia Customer Care Parts Lists and Exploded View

Code Item Side X Y Description

2320805 C720 BOTTOM J 9 CHIPCAP X5R 100N K 10V 0402

2320805 C725 BOTTOM I 8 CHIPCAP X5R 100N K 10V 0402

2320805 C730 BOTTOM I 9 CHIPCAP X5R 100N K 10V 0402

2320805 C731 BOTTOM I 8 CHIPCAP X5R 100N K 10V 0402

2320805 C734 BOTTOM H 9 CHIPCAP X5R 100N K 10V 0402

2320805 C742 BOTTOM I 8 CHIPCAP X5R 100N K 10V 0402

2320805 C757 BOTTOM H 10 CHIPCAP X5R 100N K 10V 0402

2320805 C803 BOTTOM E 5 CHIPCAP X5R 100N K 10V 0402

2320805 C914 BOTTOM C 5 CHIPCAP X5R 100N K 10V 0402

2321007 C155 BOTTOM O 7 CHIPCAP X7R 22N K 16V 0402

2321007 C166 BOTTOM O 7 CHIPCAP X7R 22N K 16V 0402

2420029 C520 BOTTOM H 5 CHIPCAP PPS 39N G 16V 1206

3203705 L100 TOP T 6 FERRITE BEAD 0.015R 42R/100M 0805

3203741 L107 TOP T 7 FERRITE BEAD 0R5 600R/100MHZ 0603

3203743 L270 BOTTOM Q 6 FERR.BEAD 0R03 42R/100MHZ 3A 0805

3203743 L301 BOTTOM O 9 FERR.BEAD 0R03 42R/100MHZ 3A 0805

3203755 L106 TOP T 7 FERRITE BEAD 0.6R 600R/100MZ 0402

3203767 L150 BOTTOM E 3 FERR.BEAD 240R/100M 0.4A 0R3 0402

3203767 L151 BOTTOM E 3 FERR.BEAD 240R/100M 0.4A 0R3 0402

3203801 L102 TOP T 8 CHIP BEAD ARRAY 2X1000R 0405

3203801 L103 TOP T 9 CHIP BEAD ARRAY 2X1000R 0405

3640119 L300 BOTTOM N 9 CHOKE 22U M 1R4 0.33A 3.3X3.3X1.5

3640133 L800 BOTTOM D 10 CHIP COIL 2U7 K Q21/1MHZ 3.0X3.4

3640165 L271 BOTTOM P 6 CHOKE 10UH M 0.49A 3.0X2.8X1.2MM

3645011 L910 BOTTOM D 5 CHIP COIL 68NH J Q12/100MHZ 0603

3645161 L909 BOTTOM C 5 CHIP COIL 150N J Q14/100MHZ 0603

3645183 L701 BOTTOM J 8 CHIP COIL 56N J Q12/100MHZ 0603

3645189 L903 BOTTOM D 6 CHIP COIL 100N J Q12/100MHZ 0603

3645363 L708 BOTTOM J 9 CHIP COIL 22N J Q40/250MHZ 0603

3645375 L600 BOTTOM G 7 CHIP COIL 12N G Q35/250MHZ 0603

3645375 L601 BOTTOM G 7 CHIP COIL 12N G Q35/250MHZ 0603

3646047 L606 BOTTOM F 5 CHIP COIL 3N3 +-0N3 Q28/800M 0402

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 13

Page 29

3125 (RH-61)

Parts Lists and Exploded View

Code Item Side X Y Description

3646059 L607 BOTTOM F 7 CHIP COIL 5N6 +-0N3 Q28/800M 0402

3646059 L608 BOTTOM F 7 CHIP COIL 5N6 +-0N3 Q28/800M 0402

3646059 L609 BOTTOM F 7 CHIP COIL 5N6 +-0N3 Q28/800M 0402

3646061 L907 BOTTOM D 6 CHIP COIL 15N J Q30/800MHZ 0402

3646065 L615 BOTTOM G 5 CHIP COIL 12N J Q31/800MHZ 0402

3646065 L616 BOTTOM G 5 CHIP COIL 12N J Q31/800MHZ 0402

3646065 L901 BOTTOM C 7 CHIP COIL 12N J Q31/800MHZ 0402

3646069 L806 BOTTOM D 9 CHIP COIL 33N J Q23/800MHZ 0402

3646077 L702 BOTTOM I 6 CHIP COIL 82N J Q17/300MHZ 0402

3646081 L802 TOP B 5 CHIP COIL 68N J Q17/300MHZ 0402

3646099 L612 BOTTOM F 5 CHIP COIL 2N7 +-0N3 Q29/800M 0402

3646237 L908 BOTTOM C 6 CHIP COIL 18N J Q7/100MHZ 0402

3646425 L906 BOTTOM C 7 CHIP COIL 19N J Q25/250MHZ 0402

4110921 V701 BOTTOM I 10 CAP.DI BBY57-02W 1/4 16/4P SOD523

4110945 V601 BOTTOM G 4 CAP DIX2 BBY57-05W 4P7/17P SOT323

4113721 V100 TOP T 6 TVS DI 1PMT16AT3 16V 175W PWRMITE

4129011 R103 BOTTOM R 7 ASIP 4XESD *** PB-FREE *** BGA5

4129011 R317 BOTTOM R 9 ASIP 4XESD *** PB-FREE *** BGA5

4129031 Z300 BOTTOM K 6 ASIP KEYBOARD INTERFACE *PB-FREE*

4129071 R388 BOTTOM R 8 ASIP SIM INTERFACE ** PB-FREE **

4129091 N805 BOTTOM C 9 ASIP STPAC01F2 CDMA PWR DET BGA-8

4219935 N804 BOTTOM E 7 TRX2+4X10K PUMD3 N&P 50V SOT363

4219937 V317 BOTTOM Q 4 TRX2 UMT1/PUMT1 P40V100MA SOT363

4219937 V318 BOTTOM Q 4 TRX2 UMT1/PUMT1 P40V100MA SOT363

4219937 V319 BOTTOM Q 4 TRX2 UMT1/PUMT1 P40V100MA SOT363

4341703 N100 BOTTOM O 6 VREG LP3985ITLX-2.8 NOPB USMD5

4342303 N800 BOTTOM D 9 VREG CX20504 4.0X4.0X1.0MM

4342429 N150 BOTTOM O 7 AF AMP 0.4W LM4890/NCP2890 PBFREE

4342981 N302 BOTTOM O 9 DC/DC CONV TK65600 USMD8

4346047 N270 BOTTOM Q 6 DC/DC CONV LM2708H-1.35V/1.05V

4347043 D450 BOTTOM O 5 COMBO 128M NOR + 16M UTRAM FBGA44

4350429 G501 BOTTOM I 4 VCO 1051-1082MHZ 2.78V 10MA CDMA

Page 14 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 30

3125 (RH-61)

Nokia Customer Care Parts Lists and Exploded View

Code Item Side X Y Description

4359025 N803 BOTTOM E 8 PW AMP CX77145 CDMA800 ORCA

4375161 N901 BOTTOM C 6 LNA/MIXER/DOWNCNTR ALFRED VQFN-24

4377017 D400 BOTTOM M 5 UPP8M V4.1E F761806 C027 144UBGA

4377027 D200 BOTTOM M 8 UEMK LF WDOG ENA TO21 Phoenix TFBGA168

4380003 N601 BOTTOM F 6 JEDI TX RFIC CX74050 7X7 LGA

4380005 N700 BOTTOM I 9 Yoda Dig-V1 MD I.F IC 5x5LGA

4510329 Z802 BOTTOM D 8 ISOLATOR 824-849MHZ .65DB 5X5X2

4510405 B200 BOTTOM M 7 CRYSTAL 32.768KHZ+-20PPM 12.5PF

4510435 G500 BOTTOM J 4 VCTCXO 19.2MHZ +-2PPM 2.78V 2.2MA

4511365 Z601 BOTTOM E 6 SAW FILT 836.5+-12.5MHZ/3DB 2.5X2

4511379 Z901 BOTTOM D 6 SAW FILT 881.5+-12.5MHZ/2.5 2X2.5

4511425 Z701 BOTTOM I 7 SAW FILT 183.6+-0.63MHZ 7X5X1.3

4512179 Z803 BOTTOM B 8 DUPL 824-849/869-894MHZ 5X5X1.8

4550257 L501 BOTTOM J 5 DIR.COUPLER 1066+/-14MHZ 3.2X1.6

4860343 V313 TOP L 5 LED LWL883 WHITE 71MCD?10MA 0603

4860343 V314 TOP L 8 LED LWL883 WHITE 71MCD?10MA 0603

4865391 V307 TOP O 6 LED LBL893 SMARTLED BLUE 14-28mCd @ 10mA

4865391 V308 TOP O 8 LED LBL893 SMARTLED BLUE 14-28mCd @ 10mA

4865391 V309 TOP R 6 LED LBL893 SMARTLED BLUE 14-28mCd @ 10mA

4865391 V312 TOP R 8 LED LBL893 SMARTLED BLUE 14-28mCd @ 10mA

5119029 F100 TOP T 5 SM FUSE F 1.5A 32V ROHS-FREE 0603

5200025 S302 BOTTOM A 7 SM TACT SW SIDE TRAVEL 0.2 MM

5409219 X387 BOTTOM Q 8 SM SIM CONNECTOR 6POL P2.54

5409253 X103 BOTTOM G 9 SM BATTERY CONN 3POL SPR 12V 2A

5420047 X801 TOP B 5 SM COAX CONN+SW F 50R 250V 6GHZ

5460061 X101 BOTTOM T 7 SM SYSTEM CONNECTOR 14POL

5469175 X302 TOP B 8 SM CONN 2X5F P0.5 PWB/PWB

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 15

Page 31

3125 (RH-61)

Parts Lists and Exploded View Nokia Customer Care

This page intentionally left blank.

Page 16 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 32

Nokia Customer Care

3125 (RH-61) Series Transceivers

Service Software Instructions

Issue 1 08/2004 Company Confidential ©2004 Nokia Corporation

Page 33

3125 (RH-61)

Service Software Instructions

Contents Page

Phoenix User’s Guide ..................................................................................................................................... 3

Introduction .................................................................................................................................................. 3

General Setup Procedure ........................................................................................................................ 3

Hardware Requirements for Using Phoenix ...................................................................................... 4

Installing Phoenix ........................................................................................................................................4

Installation Instructions.......................................................................................................................... 5

Software Support Bundles ........................................................................................................................ 5

Starting a Phoenix Session ....................................................................................................................... 5

Initial Session with Phoenix .................................................................................................................. 6

Scanning for a Product ........................................................................................................................... 7

Using Components ................................................................................................................................... 7

Using Profiles ............................................................................................................................................. 8

Uninstalling Phoenix ..................................................................................................................................8

Uninstalling a Phoenix Version ............................................................................................................. 8

Diego User’s Guide ......................................................................................................................................... 9

Introduction .................................................................................................................................................. 9

General Setup Procedure ........................................................................................................................ 9

Hardware Requirements ...................................................................................................................... 10

Installing Diego ..........................................................................................................................................10

Installing................................................................................................................................................... 10

Software Support Bundles ......................................................................................................................11

Starting a Diego Session .........................................................................................................................11

Initial Session with Diego and FLS-4S Dongle .............................................................................. 11

Scanning for a Product ........................................................................................................................ 13

Using Components ................................................................................................................................ 13

Uninstalling Diego .....................................................................................................................................14

Uninstalling a Diego Version .............................................................................................................. 14

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 34

3125 (RH-61)

Nokia Customer Care Service Software Instructions

Phoenix User’s Guide

Figure 1: Phoenix introduction screen

Introduction

This section briefly describes how to install Phoenix and includes some basic information

on how to use the program. More detailed information can be found in the Phoenix Help

files. Each feature in Phoenix has its own Help file, which can be activated while running

Phoenix. To activate a Help file while Phoenix is running, press the F1 key or the specific

feature’s Help button.

General Setup Procedure

Initial installation of Phoenix requires the complete Phoenix installation package, which

is around 30 MB. Because of its large size, Phoenix is provided on a CD rather than on a

3.5" floppy or as a download. To install Phoenix, follow the steps as outlined in the

material that comes with the CD.

Note: You MUST have a Nokia dongle installed on the computer prior to beginning the software

installation.

The Phoenix software is packaged into an executable bundle that allows you to doubleclick the executable to access the automatic installation program. Standard installation

(i.e., selecting all of the default choices) is highly recommended. You may do a custom

installation and place Phoenix into a special location on your hard drive, but this is only

recommended for experienced users.

The installation process requires that you reboot the computer after installing the

software. Phoenix is not usable until a reboot is completed. After the reboot, the Phoenix

icon appears on the desktop. Double-click this icon to start the program.

Figure 2: Phoenix desktop icon

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 35

3125 (RH-61)

Service Software Instructions

Hardware Requirements for Using Phoenix

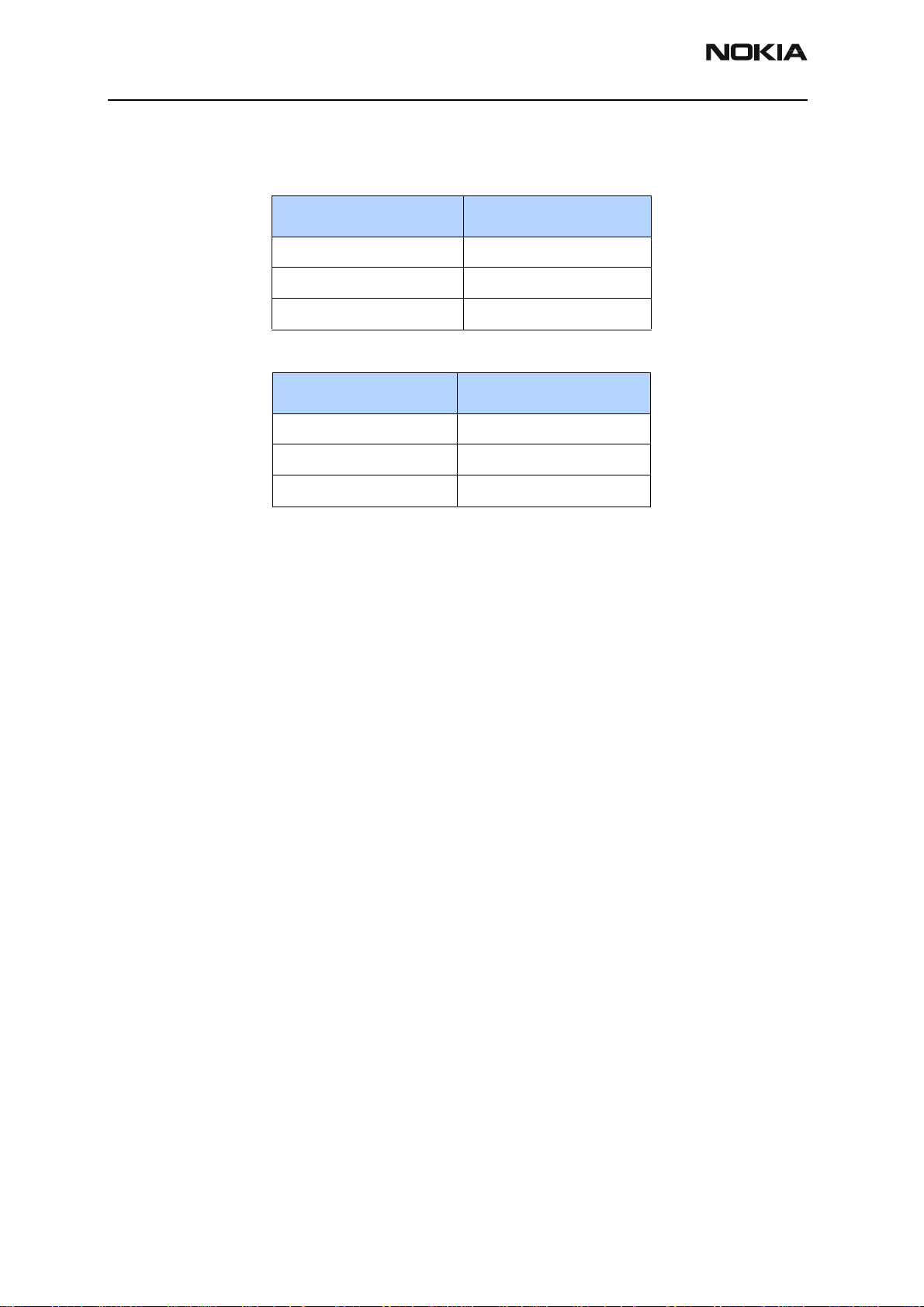

Table 1: Minimum Hardware Requirements

Hardware Minimum Value

Processor 233 MHz

RAM1 64 MB

Disk space needed 50-100 MB

Table 2: Supported Operating System Information

Operating System Notes

Windows 98 SE only

Windows NT 4.0 No USB support

Windows 2000 Professional version

Installing Phoenix

Before installing the software, verify the following:

• The dongle is attached to the parallel port for PKD version dongles, or an FLS-4

version dongle is attached on either the parallel port or the USB port (if the

computer supports USB).

• Ensure that if the computer supports administrator rights (typically on Windows

NT and Windows 2000 installations) that access is enabled for the user

performing the Phoenix installation.

• If a previous version of Phoenix has been installed, it may be necessary to first

properly remove that program prior to installing the new version. If installation is

performed, be sure to reboot the computer prior to continuing. See the

"Uninstalling Phoenix" section for instructions on how to uninstall.

Page 4 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 36

3125 (RH-61)

Nokia Customer Care Service Software Instructions

Installation Instructions

Use the following steps to install Phoenix:

1. Insert the CD into the computer.

2. Navigate to the CD-ROM drive, and double-click the Phoenix software package.

3. Follow the on-screen prompts.

4. Reboot the computer when the installation is complete.

Software Support Bundles

The Phoenix installation is auto-executable. You must obtain Software Support Bundles

to load software upgrade files to customer-specific phone models. These bundles are

created by Nokia Customer Care and made available by Nokia After Market Services

(AMS) on the Partners Web Page http://americas.partners.nokia.com. This web page is

password-controlled; if you have not registered as a user, contact Nokia Central Service

in Melbourne, Florida.

Similar to the Phoenix installation, these Software Support Bundles are InstallShield

executable packages. Double-click on the package and it will install automatically.

No rebooting of the computer is required.

Starting a Phoenix Session

When referring to Phoenix, Product is the cellular phone attached to the computer. More

specifically, it is the particular type of phone.

Connection is the type of cable used to attach the phone and the port on the computer

where it is attached. Refer to the Service Tools chapter for additional information.

The first time Phoenix is used, certain connection configurations must be made.

Subsequent uses will rely on these selections and they will not need to be made again.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 5

Page 37

3125 (RH-61)

Service Software Instructions

Initial Session with Phoenix

It is necessary to create a connection the first time you use Phoenix. Use the following

steps to create a connection:

1. Open the File menu, and select Manage Connections.

Figure 3: File Menu with the Manage Connections option

2. Click Add to create a new connection.

Figure 4: Manage Connections dialog box

Page 6 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 38

3125 (RH-61)

Nokia Customer Care Service Software Instructions

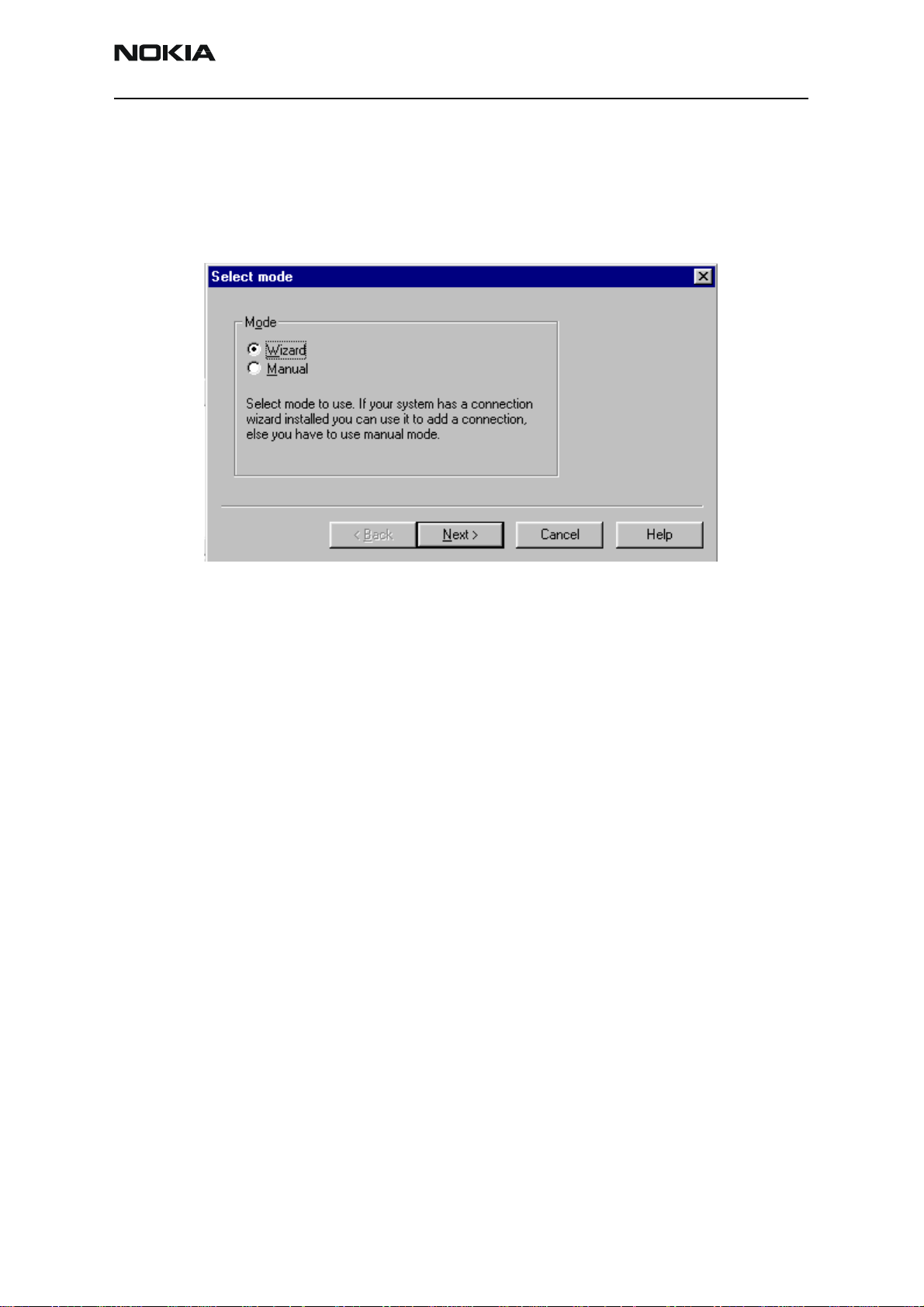

3. Choose one of the following on the Select mode dialog box:

• Select Wizard, which allows Phoenix to auto-detect your connection

configuration.

• Select Manual, which allows you to manually select options to create the

connection.

4. Once a connection is defined, make sure that the connection you want to use

appears at the top of the list. If it does not, use the up and down arrows on the

Manage Connections dialog box to move the connection to the top, and click

Apply.

5. Close the window when you are finished.

You can now proceed with the normal initiation of a session by selecting a

product or scanning for a product.

Scanning for a Product

Many features of this program are product-specific. Therefore it is necessary to configure

Phoenix for the product on which you will be working at the beginning of the session.

Choose Scan Product from the drop-down menu list and Phoenix automatically scans

for the product and selects the necessary configurations. The status bar at the bottom

indicates if the product was found and its type.

Using Components

When working with Phoenix, tasks are generally managed by specific software

components. From the menu, select the desired component or task to be performed.

Figure 5: Select Mode dialog box

“Opening a component” is defined as opening a tool window within Phoenix. When this

window is opened, Phoenix also opens a toolbar for it and adds component-specific

menu items in the Window menu.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 7

Page 39

3125 (RH-61)

Service Software Instructions

Using Profiles

Phoenix’s Profile feature allows product, connection, and currently open components to

be stored into permanent storage by creating a profile file with a name of your choice

followed by an .nmp file extension for later retrieval.

Saved profiles makes it easy to configure Phoenix into a desired configuration with

favorite windows already opened and ready to go.

Opening and saving profiles is done via the Open Profile and Save Profile options in the

File menu.

Profiles are stored into a disk file with user-defined names. As a result, there can be

multiple profiles for different repeated tasks or user preferences.

Uninstalling Phoenix

As mentioned in the "Installing Phoenix" section, it may be necessary or desirable to

remove Phoenix. Care must be taken to follow this procedure. Failure to remove the

program properly causes misconfiguration of the computer’s registry.

Uninstalling a Phoenix Version

Use the following steps to uninstall a version of Phoenix:

1. Navigate to the computer's Control Panel, which is accessible from the Start

button or by double-clicking the “My Computer” desktop icon.

2. Double-click the “Add/Remove Programs” icon.

3. Select the Phoenix version that you want to remove, and click Add/Remove.

4. Click OK to begin the removal process.

5. Follow the on-screen instructions.

6. When the removal is complete, reboot the computer.

Page 8 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 40

3125 (RH-61)

Nokia Customer Care Service Software Instructions

Diego User’s Guide

Figure 6: Diego introduction screen

Introduction

Diego was designed as an easy to use, minimal decision-making application for point of

sale locations. This section briefly describes how to install Diego and includes some basic

information about how to use the program. See the Diego Help files for more detailed

information. To activate a Help file while Diego is running, either press the F1 key or click

the specific feature's Help button.

General Setup Procedure

Initial installation of Diego requires the complete Diego installation package, which is

around 18 MB. Because of its large size, Diego is provided on a CD rather than on a 3.5"

floppy or as a download. To install Diego, follow the steps as outlined in the material that

comes with the CD.

Note: You MUST have a Nokia dongle installed on the computer prior to beginning the software

installation.

The Diego software is packaged into an executable bundle that allows you to doubleclick the executable to access the automatic installation program. Standard installation

(i.e., selecting all of the default choices) is highly recommended. You may do a custom

installation and place Diego into a special location on your hard drive, but this is only

recommended for experienced users.

The installation process requires that you reboot the computer after installing the

software. Diego is not usable until a reboot is completed. After the reboot, the Diego icon

appears on the desktop. Double-click this Icon to start the program.

Figure 7: Diego desktop icon

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 9

Page 41

3125 (RH-61)

Service Software Instructions

Hardware Requirements

Table 3: Minimum Hardware Requirements

Hardware Minimum Value

Processor 233 MHz

RAM1 64 MB

Disk space needed 50-100 MB

Table 4: Supported Operating System Information

Operating System Notes

Windows 98 SE only

Windows NT 4.0 No USB support

Windows 2000 Professional version

Installing Diego

Be sure to check the following items before installing Diego:

• An FLS-4 version dongle is attached to either the parallel port or the USB port

(if the computer supports USB). An FLS-2D may be used; however, the FLS-2D

does not support the new generation DCT-4 version phones.

• If the computer supports administrator rights (typically on NT and Windows 2000

installations), ensure that access is enabled for the user performing the

installation.

• If a previous version of Diego has been installed, remove that program prior to

installing the new version. Once removal is performed, be sure to reboot the

computer prior to continuing. (See the "Uninstalling Diego" section for

instructions on how to uninstall.)

Installing

Use the following steps to install Diego:

1. Insert the CD into the computer.

2. Navigate to the CD-ROM drive, and double-click the Diego software package.

3. Follow the on-screen prompts.

4. Reboot the computer when the installation is complete.

Page 10 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 42

3125 (RH-61)

Nokia Customer Care Service Software Instructions

Software Support Bundles

The Diego installation program is a generic software load. In order to support specific

custom transceivers (customer-specific phone models), it is necessary to also obtain

Software Support Bundles. These bundles are created by Nokia Customer Care and made

available by Nokia After Market Services (AMS) for the Americas region on the Partners

Web Page (http://americas.partners.nokia.com). This Web page is password-controlled.

Contact Nokia Central Service in Melbourne, Florida, if you have not registered as a user.

Similar to the Diego installation, these bundles are executables. Double-click the

executable file to automatically install the bundle. No re-booting of the computer is

necessary.

Starting a Diego Session

When referring to Diego, product is the cellular phone attached to the computer. More

specifically, product refers to the particular type of phone.

Connection is the type of cable used to attach the phone to the computer, and also

includes the port to which the cable is attached.

The first time Diego is used, certain connection configurations must be made.

Subsequent uses rely on these selections and do not need to be made again.

Initial Session with Diego and FLS-4S Dongle

You must configure the Virtual Port Connection in Diego the first time Diego is launched.

The FLS-4 dongle uses virtual port, which eliminates the need to use the serial port (as

the FLS-2D does). During the installation of the FLS-4 drivers (included in the Diego

installation package), a virtual COM port is set to the next available COM port number.

This port selection must be put into the Diego configuration.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 11

Page 43

3125 (RH-61)

Service Software Instructions

Use the following steps to select a port:

1. Select “My Computer” desktop icon, and click the “FLS Virtual Port” icon.

Figure 8: The FLS Virtual Port icon

2. Make note of the value in the Virtual Port Assignment field (COM 2 in this

example).

3. Click Add to create a new connection.

Figure 9: diego - Phone Settings dialog box

Note: COM port settings can only be entered or changed if the auto-connection feature of

Diego is disabled (as indicated in the grey Status box). To disable the auto-connect feature,

click on this icon in the toolbar.

Page 12 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 44

3125 (RH-61)

Nokia Customer Care Service Software Instructions

4. Select the Virtual COM port setting.

5. Click Apply.

6. Proceed with the normal initiation of a session.

Scanning for a Product

Many features of this program are product specific. Therefore, it is necessary to

configure Diego at the beginning of the session for the product on which you will be

working.

Scanning of the product can be done manually or automatically. The default setting is

automatic scanning. In automatic scan mode, Diego automatically scans for a product at

a periodic rate. The default rate is every 5 seconds, but you can change to a different

frequency in the setup menu.

You can change the scan setting to manual scanning on the General tab on the Settings

dialog box. To manually scan for a product, click the “Connect” icon.

Using Components

When working with Diego, tasks are generally managed by specific software

components. Select the desired component or "task" to be performed from the icons

displayed in the pane on the left side of the window.

Figure 10: Serial Port tab on the Settings dialog box

Opening a component refers to opening a tool window within Diego. When this window

is opened, Diego also opens a task box, which includes component-specific menu items.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 13

Page 45

3125 (RH-61)

Service Software Instructions

Uninstalling Diego

As mentioned in the "Installing Diego" section, it may be necessary to remove a previous

version of Diego. Follow the uninstall procedure with care.

Note: Failure to remove the program properly causes a misconfiguration of the computer's registry.

Uninstalling a Diego Version

Use the following steps to uninstall a previous version of Diego:

1. Navigate to the computer's Control Panel, which is accessible from the Start

button or by double-clicking the “My Computer” desktop icon.

2. Double-click the “Add/Remove Programs” icon.

3. Select the Diego version that you want to remove, and click Add/Remove.

4. Click OK to begin the removal process.

5. Follow the on-screen instructions.

6. When the removal is complete, reboot the computer.

Page 14 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 46

Nokia Customer Care

3125 (RH-61) Series Transceivers

Service Tools

Issue 1 08/2004 Company Confidential ©2004 Nokia Corporation

Page 47

3125 (RH-61)

Service Tools

Contents Page

Model 3125 Service Tools ............................................................................................................................ 3

Flashing, Testing, and Tuning ................................................................................................................... 7

High-volume Flashing and EM Calibration ....................................................................................... 7

Covers-Off Troubleshooting Using Service Jig (MJ-23)................................................................. 8

Automated Tuning and Alignment....................................................................................................... 9

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 48

3125 (RH-61)

Nokia Customer Care Service Tools

Model 3125 Service Tools

JBV-1 Docking Station MJF-17 Docking Station Adapter

0770298 0774282

The JBV-1 docking station connects flash prommers

and works in conjunction with the MJF-17 for flashing,

testing, an dan EM calibration. The docking station can

be powered by the FPS-8 or an external power supply.

Note: You must update your JBV-1s to the latest

firmware to properly operate Lynx handsets.

Note: Use the PCS-1 DC power and XRS-4 cables when

using the FPS-8 prommer box.

The MJF-17 works in conjunction with the JBV-1 docking station and the FPS-8 prommer to enable tuning,

testing, and flashing. The docking station adapter supports the LYNX batter interface, which does not require

BTEMP, and also has a built-in R-UIM card reader.

FPS-8 Flash Prommer RJ-32 Rework Jig

0080321 0770757

The FPS-8 flash prommer is used for high-volume

flashing at authorized service centers.

Note: You must register the FPS-8 in order to activate it.

(See the sales package for registration information.)

The rework jig is a PWB component that allows

de-soldering and soldering.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 49

3125 (RH-61)

Service Tools

XCS-4 Mbus/Fbus Cable CA-5S DC Service Cable

0730178 0730283

The XCS-4 Service Cable is a general purpose cable for

flashing and communicating with the phone. This is

used to connect the FPS-8 box to the docking station

adapter or the service jig.

CA-5S is used for EM calibration with the JBV-1. This

cable replaces the SCB-3 DC Cable (0730114).

Note: Required by the MJF-28 Docking Station Adapter.

PCS-1 Power Cable PKD-1 SW Security Device

0730012 0750018

The Power Cable PCS-1 is used to connect the service

tools (JBV-1, MJS-82) to an external power supply.

SW security device (PKD-1) is a hardware device that,

when connected to the parallel (LPT) port of the PC,

enables the use of service software. It is not possible to

use the service software without the dongle. Printers

or other peripheral devices can be connected to the PC

through the dongle, if needed.

Caution: Make sure that you have switched off the PC

and the printer before making connections. Also, do not

connect the PKD-1 to the serial port. You may damage

your PKD-1.

Note: PKD-1RD dongles are restricted to Nokai Product

Creation Centers only.

Page 4 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 50

3125 (RH-61)

Nokia Customer Care Service Tools

FLS-4S POS Flash Adapter DAU-9T MBUS Data Cable

0080543 0730267

The Point of Sale (POS) flash is a low-cost software

upgrade tool. (This requires the XCS-1 cable [0730218],

NOT included.)

FBUS cable DAU-9T provides a connection from the

serial port of the computer to the system connector of

the phone. This cable is used for diagnostic purposes.

Note: This cable does not support M-BUS.

DAU-9S (MBUS) Cable CA-25RS RF Test Cable

0730108 0730316

This is a general-purpose cable to support F / MBUS

communication between a Mod-10 device and a PC.

This cable is used for diagnostic purposes.

The CA-25RS test cable is used for CDMA RF engine

testing and tuning. This cable snaps directly on the

phone’s RF connector and converts the output to an

SMA connector. Removal of the A-cover is required.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 5

Page 51

3125 (RH-61)

Service Tools

CA-22DS Service Cable MJ-23 Module Test Jig

0730311 0770650

This cable is used for bottom connector flashing using

FLS-4S or FLC-20.

The MJ-23 secures and allows easy access to critical

areas of the handset’s PWB during troubleshooting. It

supports regulated and unregulated DC input voltages,

Local and Normal mode operations, a R-UIM card

reader, and a second DC input for VCHAR used in EM

tuning. The Jig also supports simultaneous RF connections to the CDMA engine. A completely functional UI

module is also provided on the right side.

Note: The MJ-23 is for use with the CA25RS RF cable.

SS-13 Tuning Docking Station (CDMA) XRS-6 RF Cable

0080852 0730231

SS-13 is used with the MJF-x/DA-x flashing adapters

(shown with MJF-17).

The XRS-6 cable is used to connect service tools to RF

measuring equipment.

Page 6 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 52

3125 (RH-61)

Nokia Customer Care Service Tools

Flashing, Testing, and Tuning

Tightened performance specifications require more precise equipment and methods for

testing and alignment. Manual tuning can not provide accurate results for the 3125,

which means that this test has to be automated.

These setups are intended to be with the Phoenix Service Software. Both manual testing

and automated tuning are permitted with Phoenix Service Software.

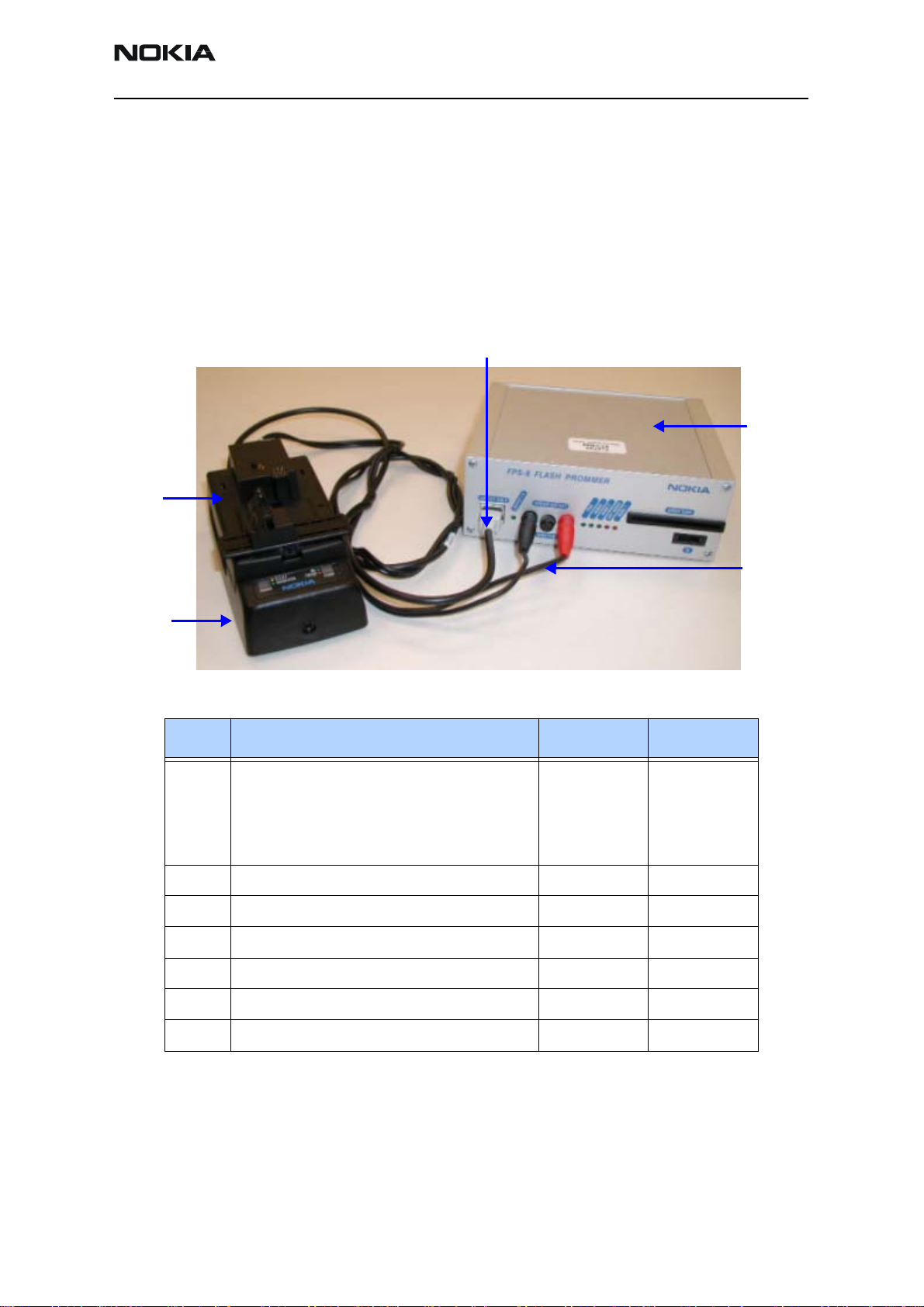

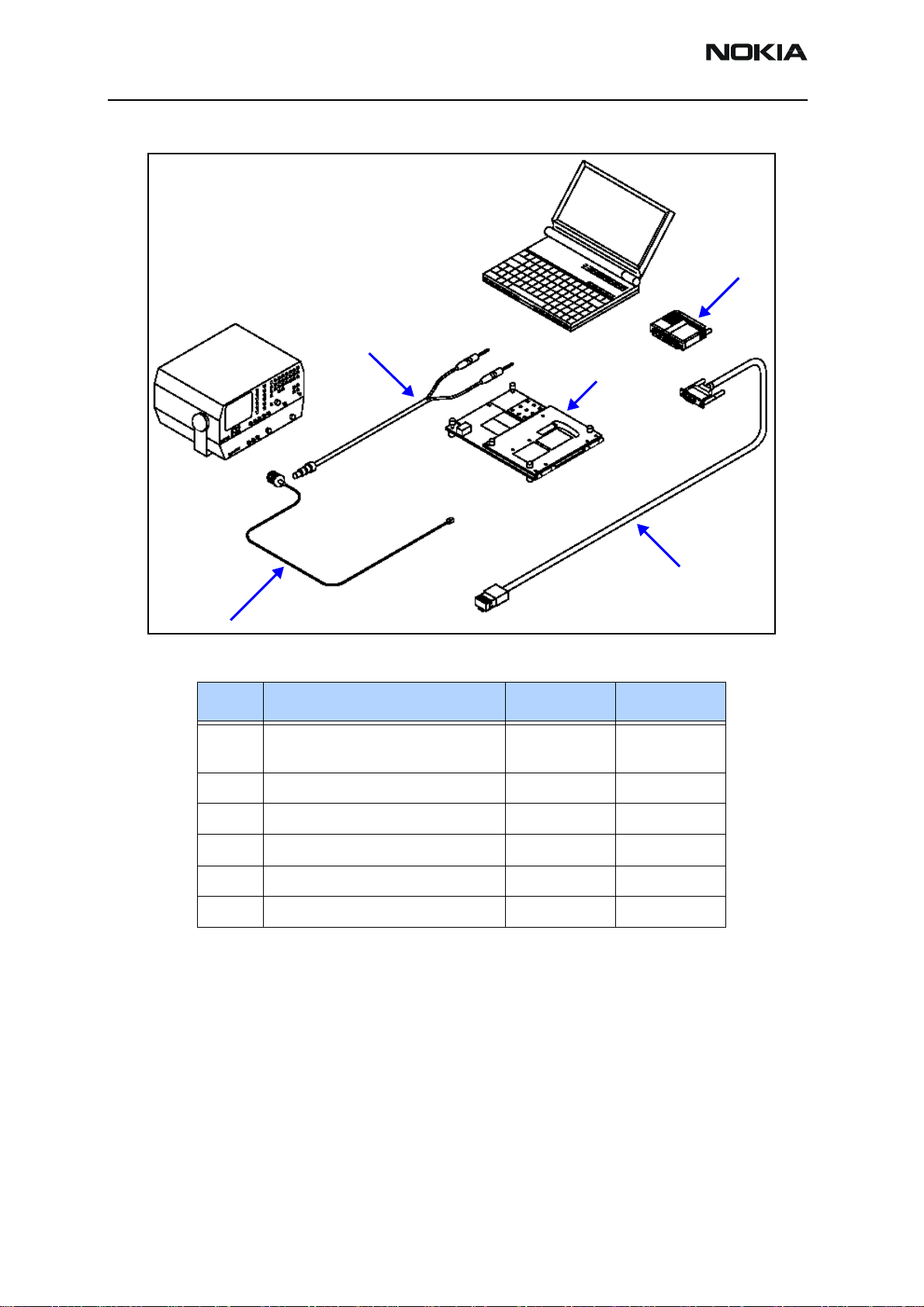

High-volume Flashing and EM Calibration

5

1

3

2

Item Name Type Code

1 Flash prommer box (sales pack)

Included in FPS-8 sales pack:

Service cable

Serial cable

Power supply

2 Docking station JBV-1 0770298

3 Docking adapter MJF-17 0774282

4 DC power cable PCS-1 0730012

5 Modular cable XCS-4 0730178

Software protection key (not shown) PKD-1 0750018

FPS-8

CA-10DS

AXS-4

ACF-8

0080321

0730298

0730090

0680032

4

Service software CDMA Phoenix 8407840

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 7

Page 53

3125 (RH-61)

Service Tools

Covers-Off Troubleshooting Using Service Jig (MJ-23)

2

5

1

3

Item Name Type Code

1 Module repair jig

includes RF test cable

2 DC power cable PCS-1 0730012

3 RF test cable XRS-6 0730231

4 Service MBUS/FBUS cable DAU-9S 0730108

5 Software protection key PKD-1 0750018

Service software (not shown) Phoenix 8407840

MJ-23

CA-25RS

0770650

0730316

4

Page 8 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 54

3125 (RH-61)

Nokia Customer Care Service Tools

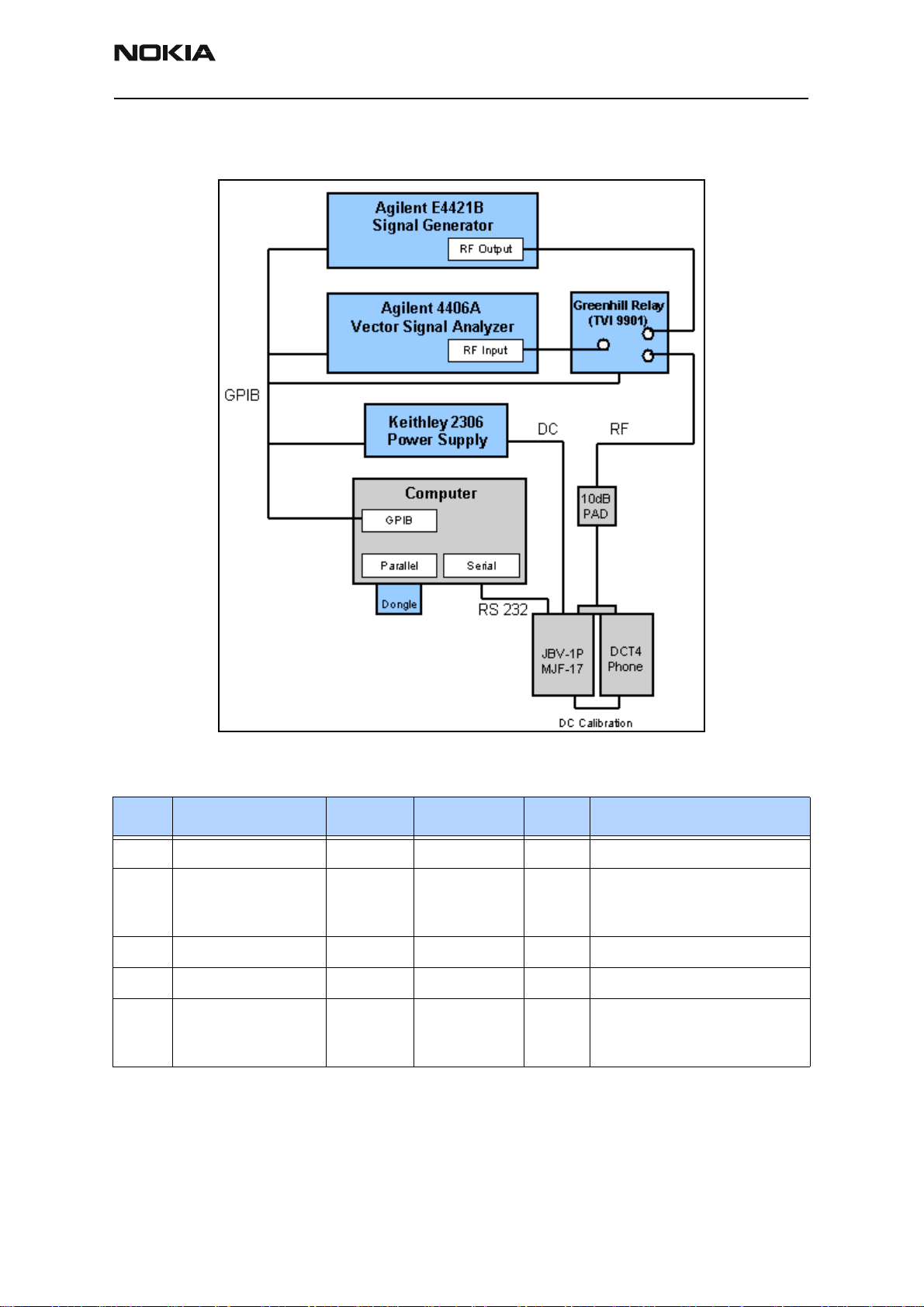

Automated Tuning and Alignment

This setup is used for tuning of the handset at Nokia Authorized Service Centers.

2

1

6

4

3

5

7

Following is the automated tuning and alignment equipment list.

Item Name MFR Model # QTY Comment

1 Vector Signal Analyzer Agilent E4406A 1

2 Signal Generator Agilent E4421B 1 Digital signal generator with

high-stability oscillator and

high-spectral purity

3 RF Series GreenHill TVi9901 1

4 Power Supply Keithly K2306 2 Programmable with sense wire

5 Win2000 PC Dell with Pentium III or above,

network card, 256M RAM, 20GB

HD, CD-ROM, etc.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 9

Page 55

3125 (RH-61)

Service Tools

Item Name MFR Model # QTY Comment

6 NI-GPIB Interface NI GPIB-USB-A 2 USB to GPIB adapter

(184983G-01)

7 Docking Station Nokia JBV-1P 1 For RF tuning, a modified JBV-1P

is used. The JBV-1P only supplies

power with sense lines to compensate voltage loss.

Page 10 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 56

Nokia Customer Care

3125 (RH-61) Series Transceivers

Disassembly/Reassembly

Instructions

Issue 1 08/2004 Company Confidential ©2004 Nokia Corporation

Page 57

3125 (RH-61)

Disassembly/Reassembly Instructions Nokia Customer Care

Introduction

Use the following procedures to disassemble and reassemble the phone.

Reassembly

To reassemble the phone, complete the following disassembly procedures in reverse

order.

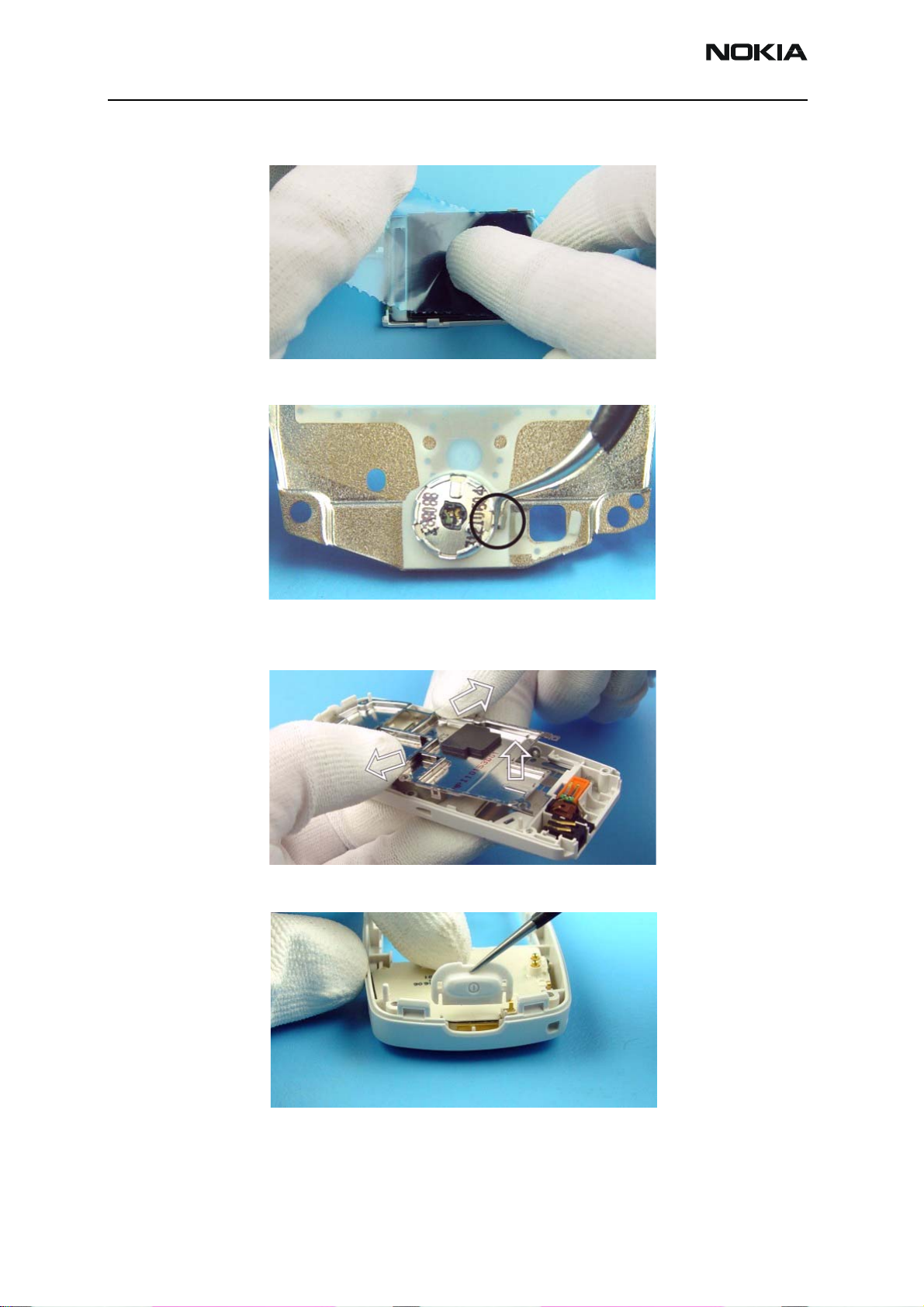

Disassembly

1. Press the release button before removing the C-cover.

2. Remove the A-cover.

3. Always protect the window with a protection film to avoid dust and scratches.

4. Unscrew the six T6 screws using the order shown. For assembly, you must use

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 58

3125 (RH-61)

Nokia Customer Care Disassembly/Reassembly Instructions

the reverse order and a Torx T6 PLUS with torque of 20Ncm.

Torque 20Ncm

for assembly

5. Separate the module from the B-cover and unplug the display connector

carefully by removing the UI shield from system module.

6. Separate the UI shield from the system module carefully. The key dome is

attached with adhesive tape, which must not be touched.

7. Separate the LCD from the UI shield by pressing out the LCD using a clean cloth.

Prevent the key dome tape from getting dirty.

8. Always protect the LCD window with a protection foil to avoid dust and

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 59

3125 (RH-61)

Disassembly/Reassembly Instructions Nokia Customer Care

scratches.

9. Remove the earpiece. Note the guiding pin when re-assembling.

10. The shielding is attached with hooks at its backside. To remove the shielding from

the B-cover, first expand the B-cover, then push the shielding upwards.

11. Remove the power button key.

Page 4 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 60

3125 (RH-61)

Nokia Customer Care Disassembly/Reassembly Instructions

12. Use the SRT-6 to lift up the antenna.

13. Remove the antenna.

14. Use tweezers to remove the vibra motor.

15. Use tweezers to pull up the microphone.

16. To remove the DC jack, place tweezers between the spring contacts and under

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 5

Page 61

3125 (RH-61)

Disassembly/Reassembly Instructions Nokia Customer Care

the jack. You need to use additional force to pull the jack upwards.

17. Use a flathead screwdriver as a lever to remove the release spring.

18. Turn the B-cover as shown to allow the release button to fall out.

19. Open the SIM flap and turn it as shown in the picture.

Page 6 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 62

3125 (RH-61)

Nokia Customer Care Disassembly/Reassembly Instructions

20. Expand the B-cover carefully and remove the SIM flap.

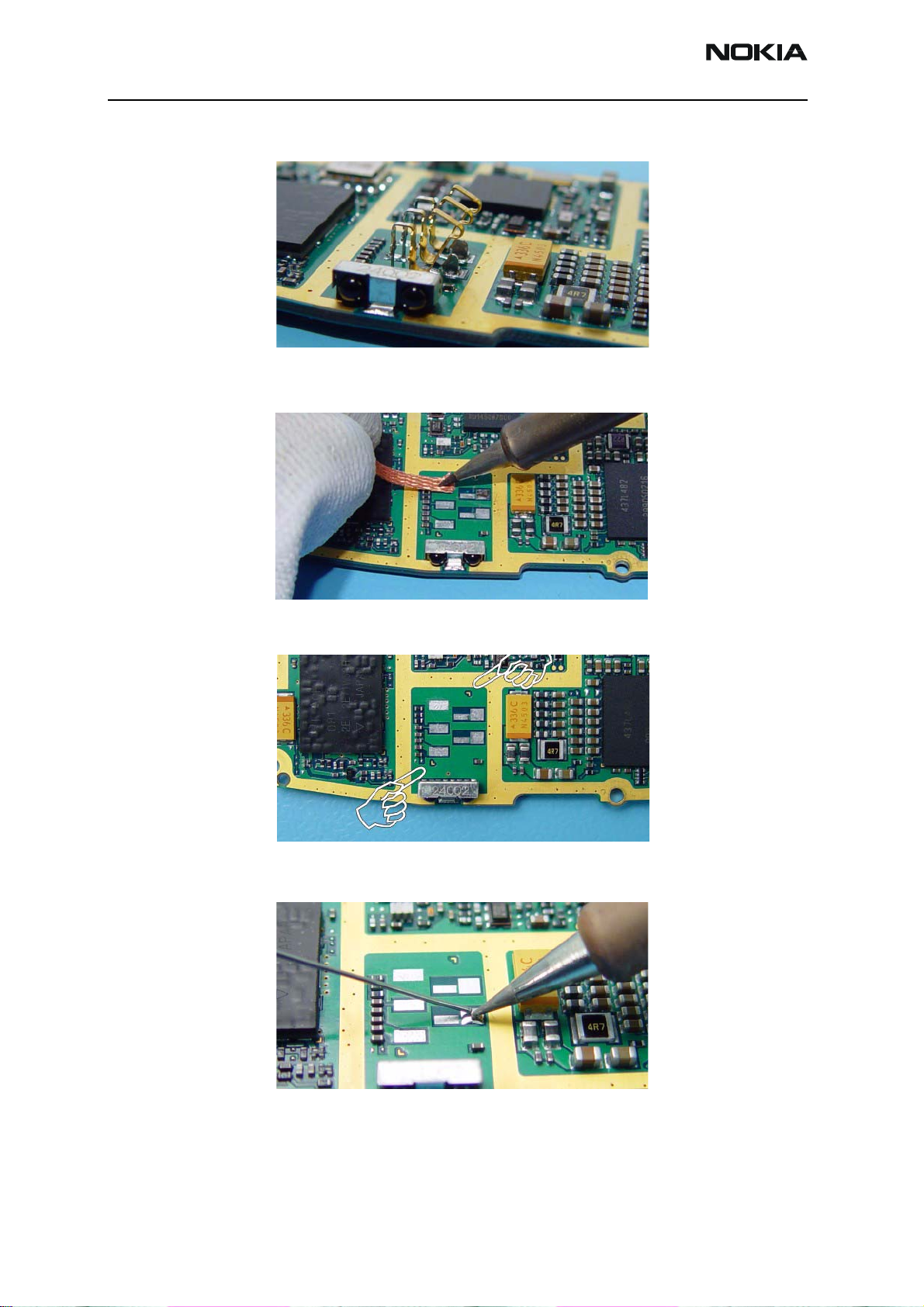

Exchange of Battery Connector X103

These are the two soldered support angles.

1. Use a side cutter to cut the support angles.

2. Push tweezers into the outside openings of the battery connector and lift up the

plastic cover.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 7

Page 63

3125 (RH-61)

Disassembly/Reassembly Instructions Nokia Customer Care

3. Desolder all pins and clean the pads.

You need a soldering iron with a higher temperature when cleaning or soldering

the ground pad.

Note the location markings to fit the connector precisely.

4. Tin one of the pads to fix the connector before soldering the following pins.

5. Place the connector between the markings and solder the first support angle. If

Page 8 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 64

3125 (RH-61)

Nokia Customer Care Disassembly/Reassembly Instructions

the position is exact, solder the other pins.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 9

Page 65

3125 (RH-61)

Disassembly/Reassembly Instructions Nokia Customer Care

Page 10 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 66

Nokia Customer Care

3125 (RH-61) Series Transceivers

Antenna Description and

Troubleshooting

Issue 1 08/2004 Company Confidential ©2004 Nokia Corporation

Page 67

3125 (RH-61)

Antenna Description and Troubleshooting Nokia Customer Care

Contents Page

Introduction ..................................................................................................................................................... 3

Internal Antenna Missing ..........................................................................................................................3

Damaged RF Feed Pin or Ground Pin .....................................................................................................4

Wrong Internal Antenna Installed .......................................................................................................... 4

Obstructed RF Feed or Ground Pads for Internal Antenna, or IHF Speaker Pads ...................... 5

Grounding of Display Frame ..................................................................................................................... 6

Grounding of RUIM Card Flap .................................................................................................................. 7

RF Connector Failure .................................................................................................................................. 7

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 08/2004

Page 68

3125 (RH-61)

Nokia Customer Care Antenna Description and Troubleshooting

Introduction

This troubleshooting guide addresses potential failures that can affect antenna

performance of the 3125 phone, and discusses methods for correction of these failures.

Internal Antenna Missing

IHF speaker

pins

If no internal antenna is installed, the antenna gain will degrade by more than 25 dB.

Figure 1: Front view of the 3125

RF feed

Figure 2: 3125 chassis assembly

Ground pin

RF shield

• If the internal antenna is missing, install a new one.

• If the radiator looks obviously damaged, replace the internal antenna.

Issue 1 08/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 69

3125 (RH-61)

Antenna Description and Troubleshooting Nokia Customer Care

Damaged RF Feed Pin or Ground Pin

RF pin Ground pin

Spacer

IHF speaker

pins

Figure 3: Bottom (left) and top (right) views of the 3125 internal antenna

If the RF feed does not touch the PWB, then the antenna gain will degrade by more than

25dB. If the ground pin does not touch the PWB, then the antenna gain may degrade

from 5—10 dB.

Replace the internal antenna if any of the following situations apply:

IHF speaker

port

Ground pin RF pin

Radiator

• Either the RF feed pin or ground pin are broken or bent such that either pin will

not touch the PWB

• The springs for the RF or ground pin appear damaged

• The slot in the radiator has a significantly different shape

• Obvious damage to the radiator (e.g., dents, corrosion)