Nissan Quest 2007 Owner's Manual

J AIR CONDITIONER

A

B

SECTION MTC

MANUA L AIR COND ITIO NER

CONTENTS

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions for Working with HFC-134a (R-134a) ..... 5

Contamin at e d Refrigerant ............ ..................... ....... 5

General Refrigerant Precautions .............................. 6

Precautions for Leak Detection Dye ......................... 6

A/C Identification Label ............................................ 6

Precautions for Refrigerant Connection ................... 6

FEATUR ES OF NEW TY PE REFRIGERANT

CONNECTION ...................................................... 7

O-RING AND REFRIGERANT CONNECTION ..... 8

Precaution s fo r Se r vicing Compressor .................... 11

Precautions for Service Equipment ......................... 11

RECOVERY/RECYCLING EQUIPME NT ....... ......11

ELECTRONIC LEAK DETEC TOR ........ ....... ........ 11

V ACUUM PUMP ...... ...................... ..................... 12

MANIFOLD GAUGE SET .................................... 12

SERVICE HOSES ............................................... 12

SERVICE COUPLERS ........................................ 13

REFRIGERANT WEIGHT SCALE ............... ....... 13

CHARGING CYLINDER ...................................... 13

PREPARATION ......................................................... 14

Special Service Tools ............................................. 14

HFC-134a (R-134a) Service Tools and Equipment ... 14

Commercial Service Tools ...................................... 17

REFRIGERATION SYSTEM ..................................... 18

Refrigeran t Cycle ........... ............................ ............ 18

REFRIGERANT FLOW .......... ............................. 18

Refrigeran t System Protectio n .......... .............. ....... 18

REFRIGERANT PRESSURE SENSOR ............. 18

PRESSURE RELIEF VALVE .............................. 19

Component Layout ................................................. 20

FRONT REFRIGERATION SYSTEM .................. 20

REAR REFRIGERATION SYSTEM .................... 21

OIL ............................................................................ 22

Maintenance of Oil Quantity in Compressor .......... 22

OIL ...................................................................... 22

CHECKING AND ADJUSTING ........................... 22

AIR CONDITIONER CONTROL ...............................25

Description .............................................................. 25

Operation ................................................................ 25

AIR MIX DOOR CONTROL .................................25

BLOWER SPEED CONTROL .............................2 5

INTAKE DOORS CONTROL ............................... 25

MODE DOOR CONTROL ......... ..........................25

DEFROSTER DOOR CONTROL ...... ..................25

MAGNET CLUTCH CONTROL ........................... 26

SELF-DIAGNOSTIC SYSTEM ............................26

Description o f Control System ................................27

Control Operati o n ..................................... .............. 27

TEMPERATURE CONTROL DIAL (FRONT) ......28

TEMPERATURE CONTROL DIAL (REAR) .........28

RECIRCULATION () SWITCH .............................28

REAR WINDOW DEFOGGER SWITCH .............28

OFF SWITCH ......................................................28

A/C SWITCH ....................................................... 28

MODE SWITCHS (FRONT) ................................ 28

MODE DIAL (REAR) ...........................................28

FRONT BLOWER CONTROL DIAL .................... 28

REAR BLOWER CONTROL DIAL (FRONT) ....... 28

REAR BLOWER CONTROL DIAL (REAR) ......... 28

Discharge Air Flow ....... ..................... .....................2 9

FRONT ................................................................2 9

REAR ..................................................................29

System Description .................................................3 0

SWITCHES AND THEIR CONTROL FUNCTION ...30

CAN Communication System Description ..............31

TROUBLE DIAGNOSIS ............................................ 32

CONSULT-II Function (HVAC) ................................3 2

CONSULT-II START PROCEDURE ...... .............. 32

SELF-DIAGNOSIS .............................................. 32

DA TA MONITOR ............ ............................ .........3 3

CONSULT-II Function (BCM) .................................34

CONSULT-II START PROCEDURE ...... .............. 34

DA TA MONITOR ............ ............................ .........3 4

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ............................ ...................... ....35

WORK FLOW ......................................................3 5

C

D

E

F

G

H

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-1

SYMPTOM TABLE .............................................. 35

Component Parts and Harness Connector Location ... 37

ENGINE COMPARTMENT ............... ...................37

FRONT PASSENGER COMPARTMENT ............ 38

REAR PASSENGER COMPARTMENT ........ .......39

Schematic ...............................................................40

Wiring Diagram — A/C,M — ...................................41

Front Air Control T erminals and Reference Value ...49

FRONT AIR CONTROL HARNESS CONNEC-

TOR TERMINAL LAYOUT ...................................49

TERMINALS AND REFERENCE V ALUES FOR

FRONT AIR CONTROL .......................................49

A/C System Self-diagnosis Function ......................51

DESCRIPTION .................................................... 51

Operatio n al Check (Front) ................... ...................53

CHECKING BLOWER ............ ...................... .......53

CHECKING DISCHARGE AIR ........... ................. 53

CHECKING RECIRCULA TION ............................ 53

CHECKING TEMPERATURE DECREASE .........53

CHECKING TEMPERATURE INCREASE ..........53

CHECK A/C SWITCH ......... ..................... ............53

Operatio n al Check (Rear) ....................................... 55

CHECKING REAR BLOWER MOTOR ................55

CHECKING REAR DISCHARGE AIR ................. 55

CHECKING REAR TEMPERATURE

DECREASE ......................................................... 55

CHECKING REAR TEMPERA TURE INCREASE ...56

Power Supply and Ground Circuit for Front Air Con-

trol ...........................................................................57

INSPECTION FLOW ...........................................57

COMPONENT DESCRIPTION ............................58

DIAGNOSTIC PROCEDURE FOR A/C SYSTEM ...58

Mode Door Motor Circu it ........................................60

INSPECTION FLOW ...........................................60

SYSTEM DESCRIPTION ....................................61

COMPONENT DESCRIPTION ............................61

DIAGNOSTIC PROCEDURE FOR MODE

DOOR MOTOR ....................................... ............62

Air Mix Door Motor Cir cu it ..................... ................. 66

INSPECTION FLOW ...........................................66

SYSTEM DESCRIPTION ....................................68

.............................................................................68

COMPONENT DESCRIPTION ............................68

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (FRONT) ....................................69

DIAGNOSTIC PROCEDURE FOR AIR MIX

DOOR MOTOR (REAR) ....... .............. ................. 72

Intake Door Motor Circuit ........................................77

INSPECTION FLOW ...........................................77

SYSTEM DESCRIPTION ....................................78

COMPONENT DESCRIPTION ............................78

DIAGNOSTIC PROCEDURE FOR INTAKE

DOOR MOTOR (DRIVER) .... ............................... 78

DIAGNOSTIC PROCEDURE FOR INTAKE

DOOR MOTOR (PASSENGER) ......... ................. 80

Defroster Door Moto r Ci r cu it ................................... 82

SYMPTOM: ..........................................................82

INSPECTION FLOW ...........................................82

SYSTEM DESCRIPTION ....................................83

COMPONENT DESCRIPTION ............................83

DIAGNOSTIC PROCEDURE FOR

DEFROSTER DOOR MOTOR ............................. 83

Front Blower Motor Circuit ......................................85

INSPECTION FLOW ............................................ 85

SYSTEM DESCRIPT IO N ................... ..................86

COMPONENT DESCRIPTION ............................86

DIAGNOSTIC PR OCEDURE FOR BLOWER

MOTOR ................................................................87

COMPONENT INSPECTION ...............................92

Rear Blower Motor Circuit .......................................93

INSPECTION FLOW ............................................ 93

SYSTEM DESCRIPT IO N ................... ..................95

COMPONENT DESCRIPTION ............................95

TROUBLE DIAGNOSIS PROCEDURE 1 ............96

TROUBLE DIAGNOSIS PROCEDURE 2 ............97

TROUBLE DIAGNOSIS PROCEDURE 3 ............99

TROUBLE DIAGNOSIS PROCEDURE 4 ..........104

COMPONENT INSPECTION .............................106

Rear Temperature Control Circuit ......................... 107

INSPECTION FLOW ..........................................107

SYSTEM DESCRIPT IO N ................... ................109

DIAGNOSTIC PROCEDURE FOR REAR AIR

CONTROL (FRONT) ..........................................109

DIAGNOSTIC PROCEDURE FOR REAR AIR

CONTROL (REAR) ............................................112

Magnet Clutch Circuit ............................................114

INSPECTION FLOW ..........................................114

SYSTEM DESCRIPT IO N ................... ................115

DIAGNOSTIC PROCEDURE FOR MAGNET

CLUTCH ............................................................115

Insufficient Cooling ................................................120

INSPECTION FLOW ..........................................120

PERFORMANCE TEST DIAGNOSES .............. 122

PERFORMANCE CHART ..................................125

TROUBLE DIAGNOSES FOR UNUSUAL PRES-

SURE .................................................................126

Insufficient Heating ...............................................129

INSPECTION FLOW ..........................................129

Heater Pump Circuit ..............................................131

SYSTEM DESCRIPT IO N ................... ................131

DIAGNOSTIC PROCEDURE FOR HEATER

PUMP CIRCUIT .................................................132

COMPONENT INSPECTION .............................133

Noise .....................................................................134

INSPECTION FLOW ..........................................134

Self-diagnosis .......................................................135

INSPECTION FLOW ..........................................135

Ambient Senso r Circ u i t ............. ..................... .......137

COMPONENT DESCRIPTION ..........................137

AMBIENT TEMPER ATURE INPUT PROCESS . 137

DIAGNOSTIC PR OCEDURE FOR AMBIENT

SENSOR ............................................................137

COMPONENT INSPECTION .............................139

Intake Sensor Circuit .............................................139

COMPONENT DESCRIPTION ..........................139

DIAGNOSTIC PROCEDURE FOR INTAKE SEN-

SOR ...................................................................139

COMPONENT INSPECTION .............................141

Revision: March 2006 2007 Quest

MTC-2

CONTROL UNIT ..................................................... 142

Removal and Installation ...................................... 142

FRONT AIR CONTROL .......................... .......... 142

REAR AIR CONTROL (FRONT) ....................... 142

REAR AIR CONTROL (REAR) ......................... 142

AMBIENT SENSOR ................................................ 144

Removal and Installation ...................................... 144

REMOVAL ......................................................... 144

INSTALLATION ................................................. 144

INTAKE SENSOR ................................................... 145

Removal and Installation ...................................... 145

REMOVAL ......................................................... 145

INSTALLATION ................................................. 145

BLOWER MOTOR ................ ............................. ..... 146

Components ......................................................... 146

Removal and Installation ...................................... 147

FRONT BLOWER MOTOR ............................ ... 147

REAR BLOWER MOTOR ................................. 147

IN-CABIN MICROFILTER .......... ............................. 148

Removal and Installation ...................................... 148

FUNCTION ........................................................ 148

REPLACEMENT TIMING ............................. ..... 148

REPLACEMENT PROCEDURES ............. ........ 148

HEATER & COOLING UNIT ASSEMBLY .............. 149

Components ......................................................... 149

Removal and Installation ...................................... 150

FRONT HEA TER AND COOLING UNIT ASSEM-

BLY .................................................................... 150

REAR HEATER AND COOLING UNIT ASSEM-

BLY .................................................................... 151

HEATER CORE ........................... ........................... 152

Components ......................................................... 152

Removal and Installation ...................................... 153

FRONT HEA TER CORE ........ ........................... 153

REAR HEATER CORE ..................................... 154

HEATER PUMP ...... ..................... ...................... ..... 155

Removal and Installation ...................................... 155

REMOVAL ......................................................... 155

INSTALLATION ................................................. 155

DEFROSTER DOOR MOTOR ................................ 156

Removal and Installation ...................................... 156

REMOVAL ......................................................... 156

INSTALLATION ................................................. 156

INTAKE DOOR MOTOR ......................................... 157

Components ......................................................... 157

Removal and Installation ...................................... 158

DRIVER SIDE .......... ...................... ................... 158

PASSENGER SIDE ........................................... 159

MODE DOOR MOTOR ........................................... 160

Removal and Installation ...................................... 160

REMOVAL ......................................................... 160

INSTALLATION ................................................. 161

AIR MIX DOOR MOTOR ......................................... 162

Components ......................................................... 162

Removal and Installation ...................................... 162

AIR MIX DOOR MOTOR (FRONT) ................... 162

AIR MIX DOOR MOTOR (REAR) ..................... 163

VARIABLE BLOWER CONTROL .......................... 164

Components .........................................................164

Removal and Insta llation ............................. .........165

VARIABLE BLOWER CONTROL (FRONT) ......165

V ARIABLE BLOWER CONTROL (REAR) .........165

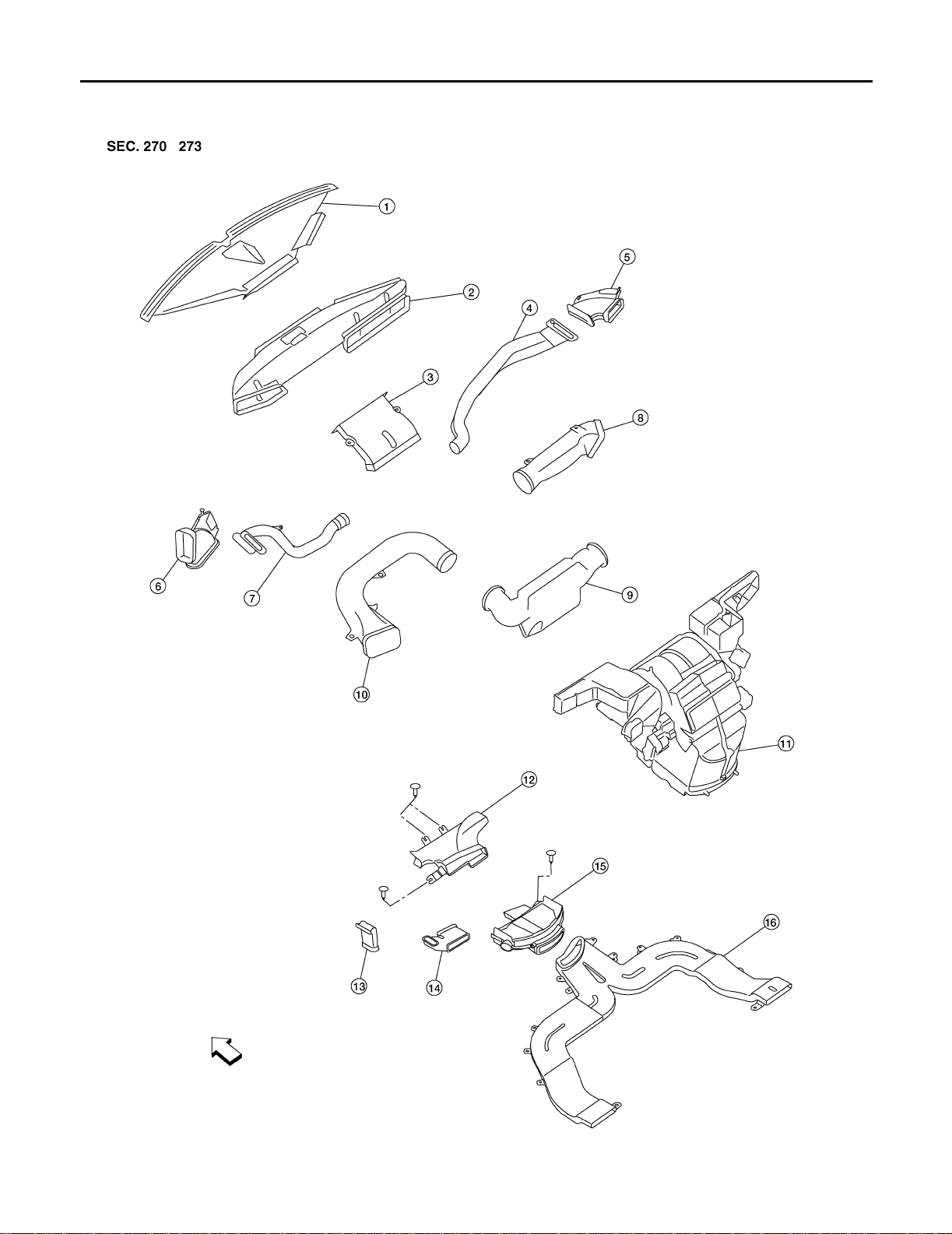

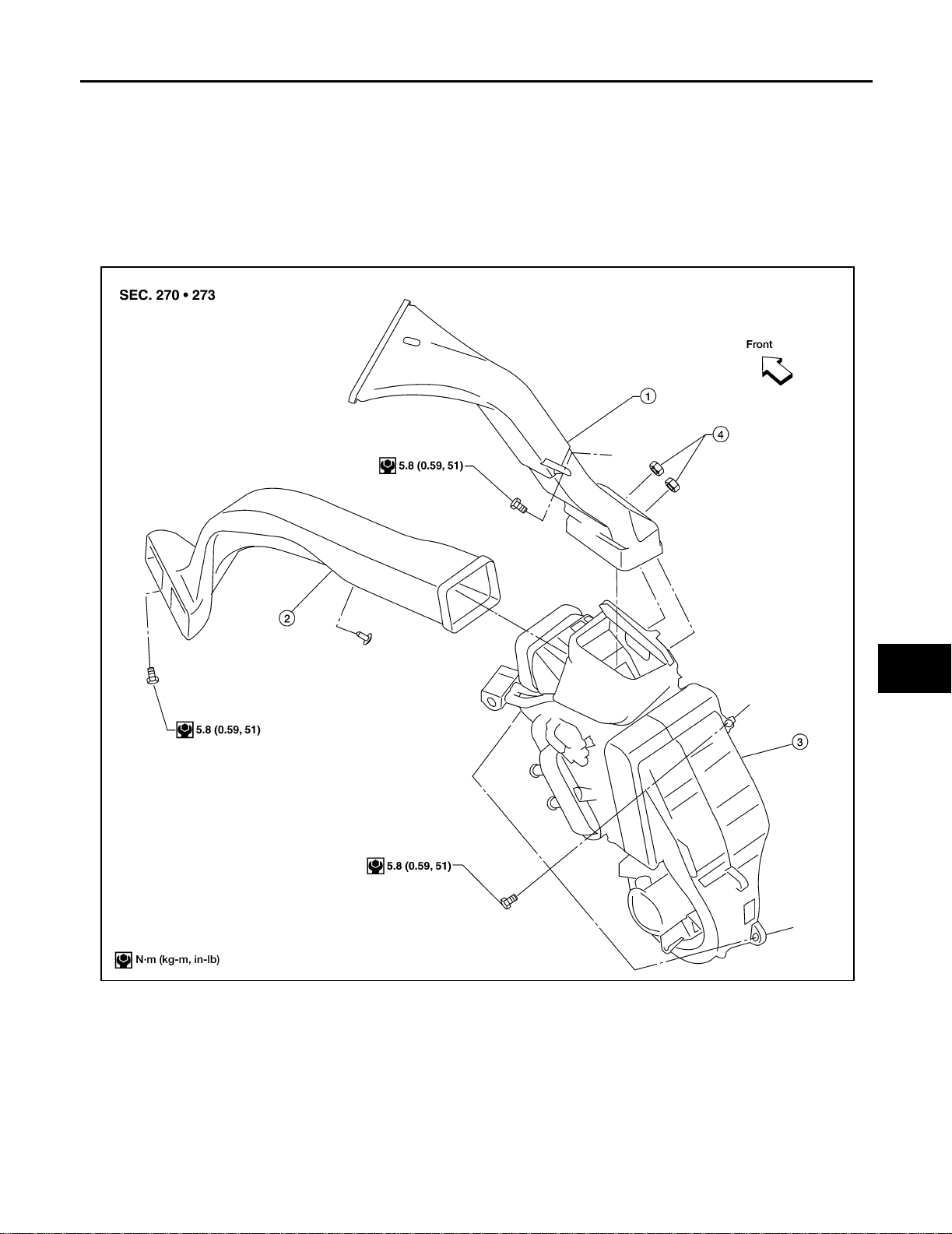

DUCTS AND GRILLES ...........................................166

Components .........................................................166

Removal and Insta llation ............................. .........169

DEFROSTER NOZZLE ..................... ................169

FRESH AIR DUCT ............................................169

DEFROSTER DUCT ........ ............................ .....169

RH AND LH SIDE DEMISTER DUCT ...............169

RH, LH, AND CENTER VENTILATOR DUCT ...169

FLOOR CONNECTOR DUCT ...........................169

FLOOR DISTRIBUTION DUCT .........................170

FLOOR JUNCTION DUCT ................................170

FLOOR JUNCTION DUCT EXTENSION ..........170

FLOOR DUCT ...................................................170

REAR OVERHEAD DUCT ........ ............... .........170

REAR FLOOR DUCT ........................................170

GRILLES ...........................................................170

REFRIGERANT LINES ..... .................................... ..172

HFC-134a (R-134a) Service Procedure ...............172

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................172

Components .........................................................174

Removal and Installation for Compressor .......... ..176

REMOVAL .........................................................176

INSTALLATION .................................................176

Removal and Installation for Compressor Clutch .177

REMOVAL .........................................................177

INSPECTION ....................................................178

INSTALLATION .................................................178

BREAK-IN OPERATION ....................................180

Removal and Installation for Low-pressure Flexible

Hose .....................................................................180

REMOVAL .........................................................180

INSTALLATION .................................................180

Removal and Installation for High-pressure Flexible

Hose .....................................................................180

REMOVAL .........................................................180

INSTALLATION .................................................180

Removal and Installation for High-pressure Pipe .180

REMOVAL .........................................................180

INSTALLATION .................................................180

Removal and Installation for High/Low-pressure

Pipe ......................................................................181

REMOVAL .........................................................181

INSTALLATION .................................................183

Removal and Installation for Refrigerant Pressure

Sensor ..................................................................184

REMOVAL .........................................................184

INSTALLATION .................................................185

Removal and Installation for Condenser ..............185

REMOVAL .........................................................185

INSTALLATION .................................................185

Removal and Installation for Front Evaporator .....186

REMOVAL .........................................................186

INSTALLATION .................................................187

Removal and Installation for Rear Evaporator ......188

A

B

C

D

E

F

G

H

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-3

REMOVAL .........................................................188

INSTALLATION ..................................................189

Removal and Installation for Front Expansion Valve .189

REMOVAL .........................................................189

INSTALLATION ..................................................189

Removal and Installation for Rear Expansion Valve .189

REMOVAL .........................................................189

INSTALLATION ..................................................189

Checking for Refrigerant Leaks ............................190

Checking Syste m for Leaks Using the Fluorescent

Dye Leak Detector ....... ............................. ............190

Dye Injection .........................................................190

Electronic Refrigerant Leak Detector ....................191

PRECAUTIO NS FOR HAND LI NG LEAK

DETECTOR .......................................................191

CHECKING PROCEDURE ................................192

SERVICE DATA AND SPECIFICATIONS (SDS) ....194

Service Data and Specifications (SDS) ................194

COMPRESSOR .................................................194

OIL .....................................................................194

REFRIGERANT .................................................194

ENGINE IDLING SPEED ...................................194

BELT TENSION ........... .............. ...................... .. 194

Revision: March 2006 2007 Quest

MTC-4

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions f or Supplemental Restraint Syst em (S RS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

EJS004LO

A

The Sup plemental Restraint Syste m such as “AIR BAG” and “SEAT BELT PRE-TENSIONER ”, used along

with a fron t seat be lt, hel ps to re duce th e risk or s everity of injur y to th e dr iver and fro nt pass enge r for cer tain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt sw itches to d etermine the fron t air bag dep loyment, and may on ly d eploy one fr ont

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB sectio n of this Service Manual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the eve nt of a collision whic h would result in air bag inflation, all mai ntenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper mai ntenance, includin g incorrect removal an d installation of the SRS , can lead to per-

sonal injury caus ed by unin te ntional activati on of th e system . For rem oval of Spiral Cab le an d Air

Bag Module, see the SR S section.

● Do not use electrica l test equipm ent on any circ uit related to the S RS unless in structed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harn esses or

harness connectors .

Precautions f or Working with HFC-134a (R-134a) EJS004LP

WARNING:

● CFC-12 (R-1 2) refrigeran t and H FC-1 34a (R-134 a) re frigeran t are n ot co mpatible. If the re frigeran ts

are mixed compressor failure is likely to occur. Refer MTC-5, "

determine the p urity o f HFC -134a ( R-134 a) in t he veh icle a nd reco ve ry tank, use refrig erant recovery/recycling equipment and refrigerant identif ier.

● Use only sp ecified oil f or t he HFC -13 4a (R- 13 4a) A/ C syst em an d H FC-1 34a (R-1 34a) c om ponen ts.

If oil other than that specified is used, compressor failure is l ikely to occur.

● The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

– When remo ving refr igerant c omponents from a veh icle, imm ediately c ap (seal) the co mponent t o

minimize the entry of moisture from the atmosphere.

– When installing re frigerant components to a vehicle, do not remove t he caps (unseal) until just

before conn ectin g th e com pon ents. Co nnec t all ref rig erant l oop comp one nts as quick ly a s p os sible to minim ize the entry of moisture into system.

– Only use the specified oil from a se aled container. Immediately reseal co ntainers of oil. Without

proper sealing, oil will become moisture saturated and should not be used.

– Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose a nd throat.

Remove HFC-134a (R-134a) from the A/C system using certified service equipment meeting

requirements of SAE J2210 [HFC-134a (R-134a) recycling equipment] or J2209 [HFC-134a ( R-134a)

recycling equip ment]. If accide ntal system dis charge occurs, ventila te work area b efore res umin g

service. Additional health and safety information may be obtained from refrigerant and oil manufacturers.

– Do not allow refrigerant oil to come in contact with styrofoam parts. Damage may result.

Contaminated Refrigerant" . To

B

C

D

E

F

G

H

I

MTC

K

L

M

Contaminated Refrigerant EJS004LQ

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

● Explain to the customer that environme ntal regulations prohibit the release of con taminated re frigerant

into the atmosphere.

● Explain that recover y of the c ontaminat ed r efriger ant coul d da mage your ser vice equ ipment and re friger-

ant supply.

● Suggest the c ustom er return the vehi cle to the l ocation o f pr evio us ser vice w her e th e contamina tio n ma y

have occurred.

● If you choose to perform the repair, recover the refrigerant using only dedicated equi p ment a n d c ontain-

ers. Do not re cover contaminated refrigerant into y our existing se rvice equipmen t. If you r facility

Revision: March 2006 2007 Quest

MTC-5

PRECAUTIONS

does not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available service. This refrigerant mu st be dispos ed of in accordanc e with all fe deral and local regulations . In

addition, replacement of all refrigerant system components on the vehicle is recommended.

● If the vehicle i s within the warranty period, the air conditioner war ranty is void. Please contact NISS AN

Customer Affairs for further ass istance.

General Refrig er ant Pre caut i ons EJS004LR

WARNING:

● Do not release ref rigerant into the air. Use approved recovery/rec ycling equ ipment to cap ture the

refrigerant every time an air conditioning system is discharged.

● Always w ear eye and hand prote ction (goggles and glov es) when wo rking with a ny refrigerant or

air conditioning system.

● Do not store or heat refrigerant containers above 52°C (125°F).

● Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a war m pail of water.

● Do not intentionally drop, puncture, or incinerate refrigerant containers.

● Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

● Refrigeran t will displace oxygen , therefore be certain to work in w ell ventilated areas to prev ent

suffocation.

● Do not pre ssure test or leak test HFC-134a (R-134a) service equipment an d/or vehicle air cond i-

tioning systems with compres sed air during repair. Some mixtures of air and HFC-134a (R-134a )

have been shown to be combust ible at elevat ed pressure s. These mix tures, if ignited , may cause

injury o r pro pe rty da mage . Addi t io nal he a lth a nd saf et y info r mati on ma y b e obtained from refri g erant manufacturers.

Precautions fo r Lea k Det ect ion Dye EJS004LS

● The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

● Always wear fluorescence enhancing UV safety glasses to protect your eyes and enhance the visibility of

the fluorescent dye.

● The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detec tor should be used in conjunction with an electronic refriger ant leak detector (J-

41995).

● For your safe ty and t he custom er's satisf action, read a nd follow al l manufac turer's operati ng instruc tions

and precautions prior to performing work.

● A compressor shaft seal sh ould not be repaired because of dye seepage. The compressor shaft seal

should only be repaired after confirming the leak with an electronic refrigerant l eak detector (J-41995).

● Always rem ove any dye from the leak area after repairs are complete to avoid a misdiagnosi s during a

future service.

● Do not a llow dye to come into contact with painted bo dy panels or interior c omponents. If dye is spilled,

clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period

of time cannot be removed .

● Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

● Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

● Leak detec tion dyes for HFC-134a (R13 4a) and CFC-12 (R-12) A/C s ystems are different. Do not use

HFC-134a (R134a) leak detection dye in CFC-12 (R-12) A/C systems or CFC-12 (R-12) leak detection

dye in HFC-134a (R134a) A/C systems or A/C system damage may result.

● The fluorescent properties of the dye will remain fo r over three (3) years unless a compressor failure

occurs.

A/C Identification Label EJS004LT

Vehicles with factory installed fluorescent dye have an identification label on the underside of hood.

Precautions fo r Refrigerant Connecti on EJS004LU

A new type refrigerant connection has been introduced to all refrigerant lines except the following locations.

Revision: March 2006 2007 Quest

MTC-6

PRECAUTIONS

● Expansion valve to cooling unit

● Evaporator pipes to evapor ator (inside cooling unit)

● Refrigerant pressure sensor

A

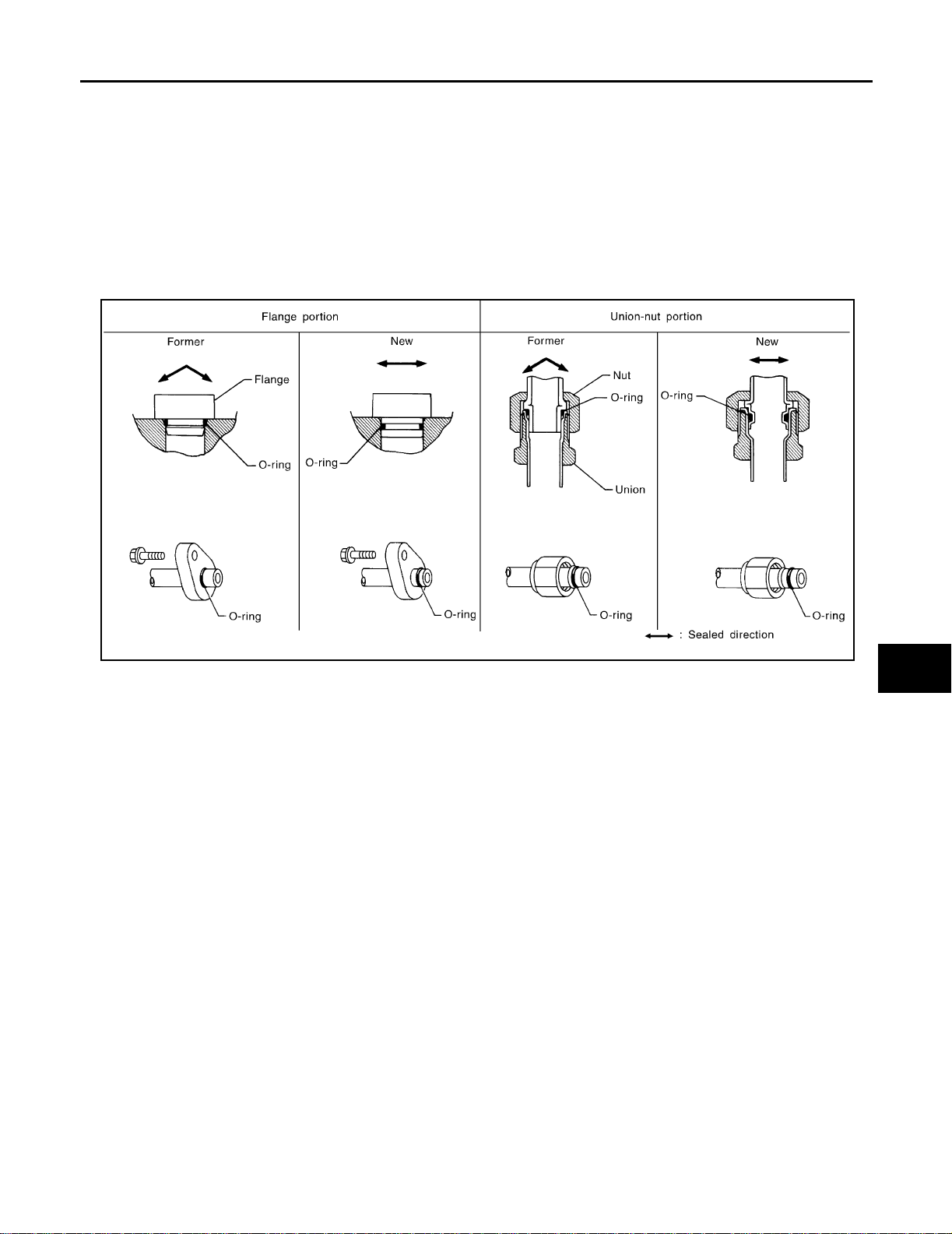

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

● The O-ring has been relocated. It has also been provided with a groove for proper installation. This

reduces the possibility of the O-ring being caught in, or damaged by, the mating part. The sealing direction

of the O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing

characteristics.

● The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby facil-

itating piping connections.

B

C

D

E

F

G

H

I

SHA815E

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-7

PRECAUTIONS

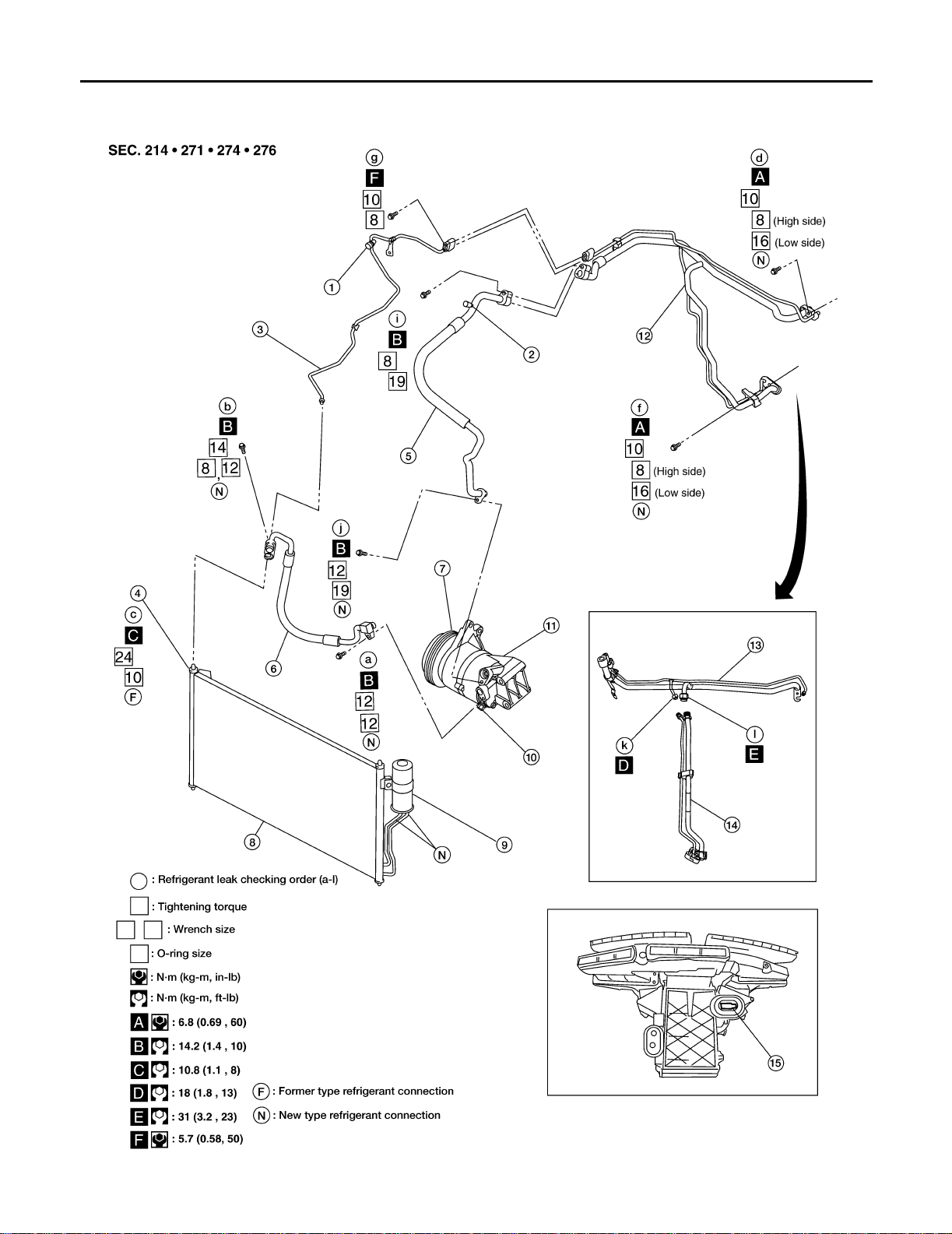

O-RING AND REFRIGERANT CONNECTION

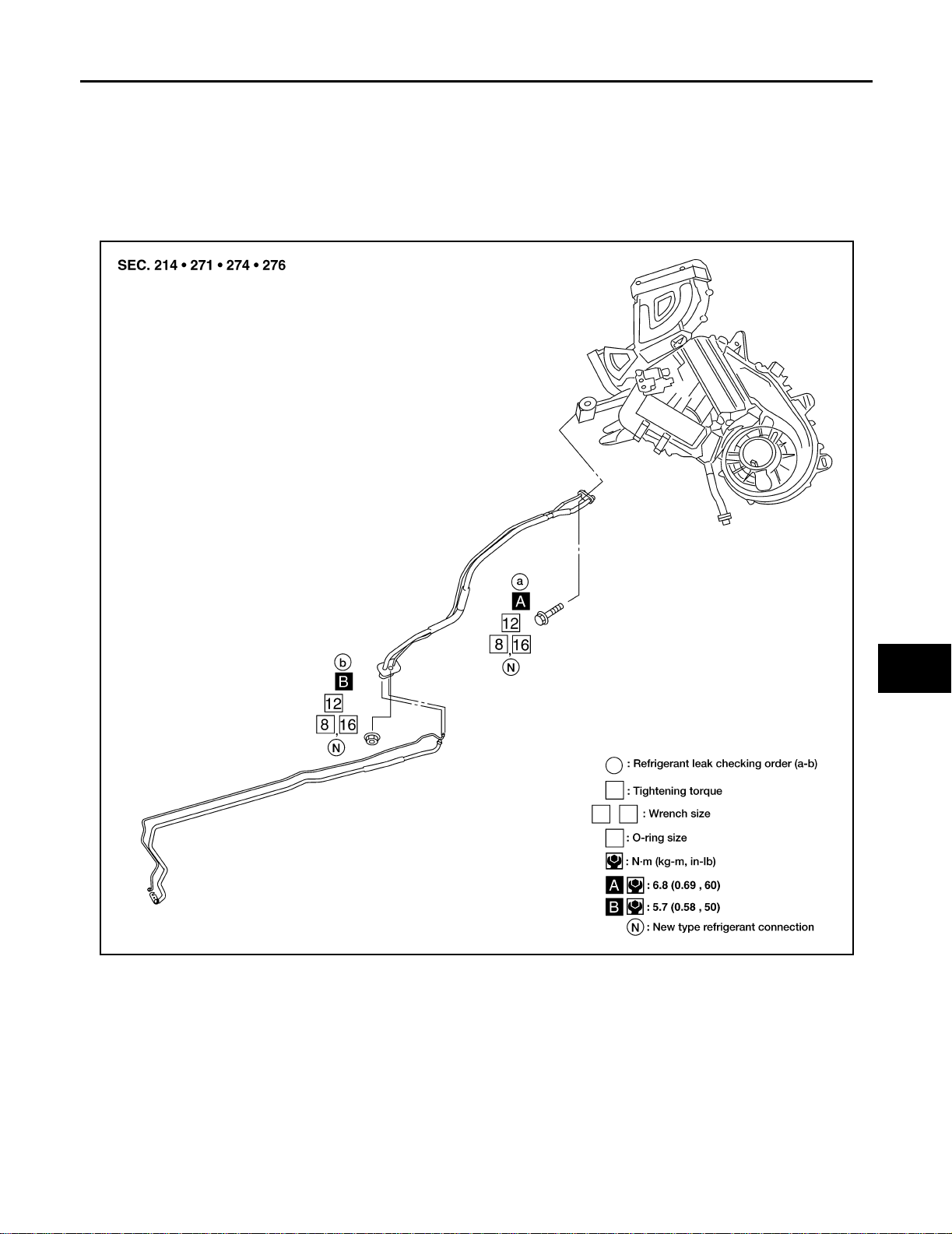

Front A/C Compressor and Condenser

WJIA1967E

Revision: March 2006 2007 Quest

MTC-8

PRECAUTIONS

1. High-pressure service valve 2. Low-pressure service valve 3. High-pressure pipe

4. Refrigerant pressure sensor 5. Low-pressure flexible hose 6. High-pressure flexible hose

7. Shaft seal 8. Condenser 9. Liquid t an k

10. Pressure relief valve 11. Compressor 12. High/low pressure pipe (production)

13. High/low pressure pipe - upper

(service)

14 High /low pressur e pipe - lower

(service)

15 Expansion valve (front)

Rear A/C

A

B

C

D

E

F

G

H

LJIA0016E

CAUTION:

The new an d former refrigerant connections u se different O-ring configurations. D o not confuse Orings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at or

around the connection.

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-9

PRECAUTIONS

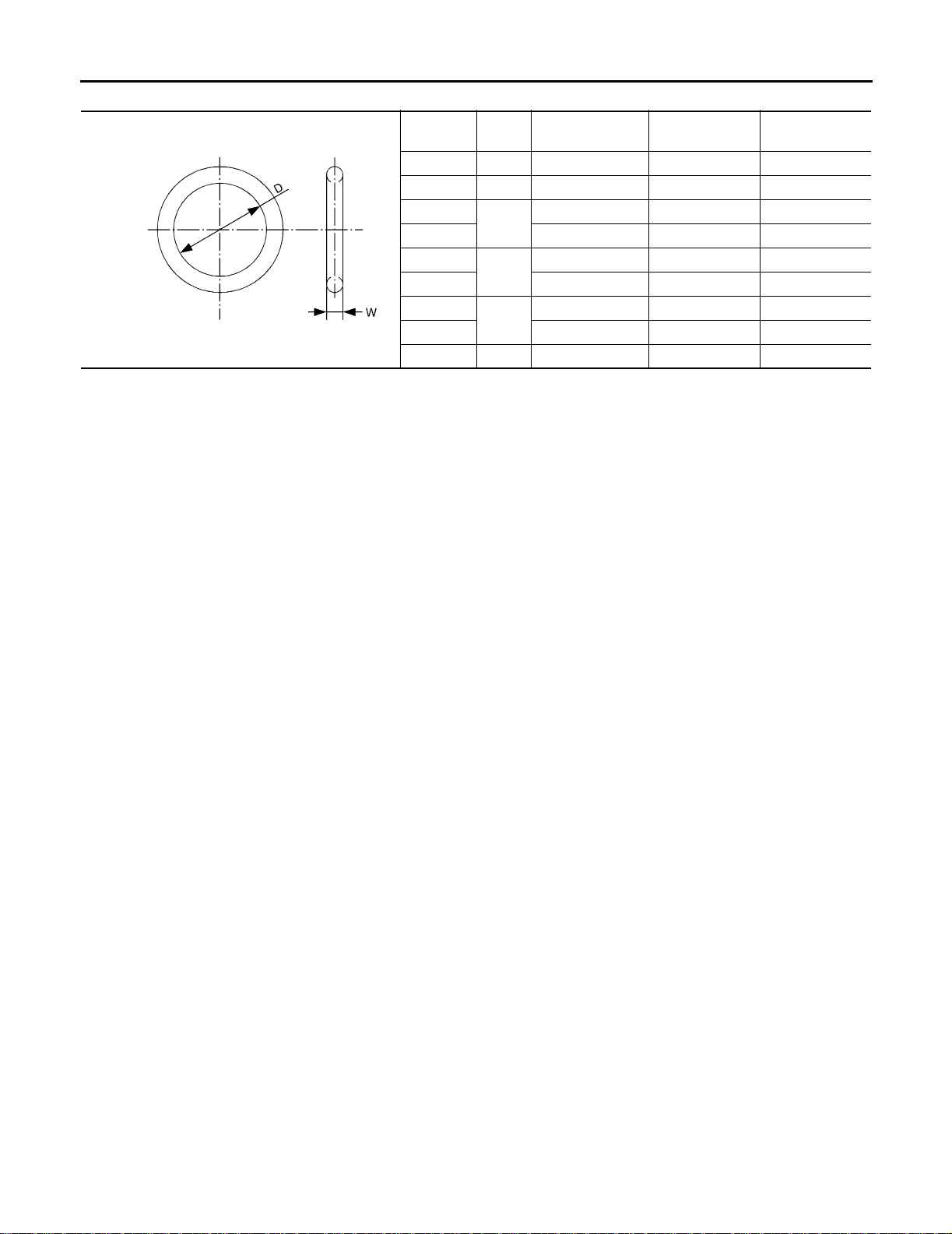

O-Ring Part Numbers and Specifications

Connection type

New 8 92471 N8210 6.8 (0.268) 1.85 (0.0728)

Former 10 J2476 89956 9.25 (0.3642) 1.78 (0.0701)

New

Former 92475 71L00 11.0 (0.433) 2.4 (0.094)

New

Former 92475 72L00 14.3 (0.563) 2.3 (0.091)

New

SHA814E

*: Always check with the Parts Department for the latest parts information.

Former 92477 N8200 17.12 (0.6740) 1.78 (0.0701)

New 24 92195 AH300 21.8 (0.858) 2.4 (0.094)

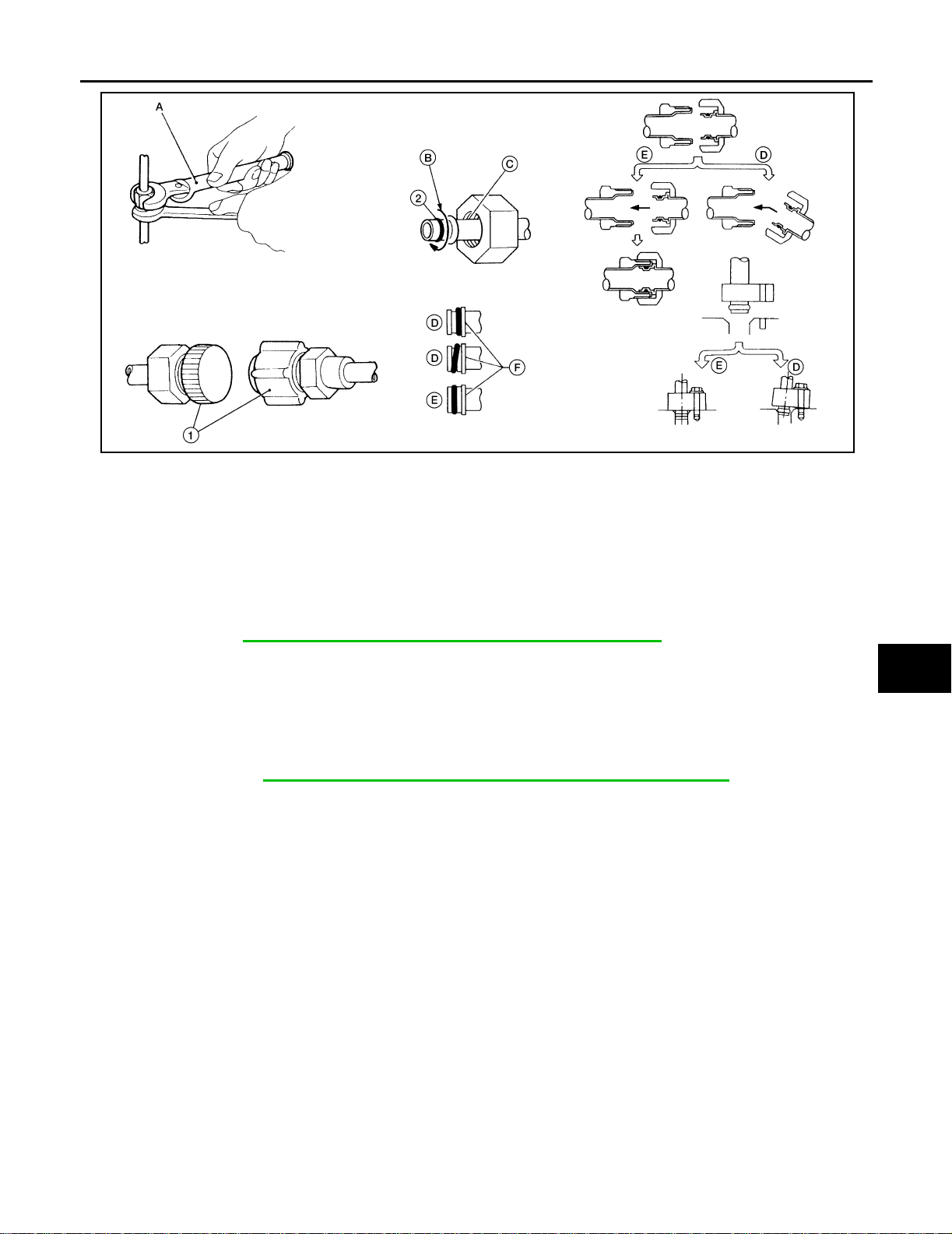

WARNING:

Make sure all refrigerant is discharged into the recycling equ ipment and the pressure in the syste m is

less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

● When t he co m presso r is rem oved , store it in t he sa me po siti on a s i t is w hen mou nted on the car.

Failure to do so will cause oil to enter the low pressure chamber.

● When connecting tubes, always use a torque wrench and a back-up wrench.

● After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

● When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other com ponents until just before required f or

connection.

● Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming in side A/C components.

● Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

● Always replace used O-rings.

● When con necting tube, apply oil to circle of the O-rings shown in illustration. Be careful n ot to

apply oil to threaded portion.

● O-ring must be closely attached to dented portion of tube.

● When replacing the O-ring, be careful not to damage O-ring and tube.

● Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correct ly.

● After conne cting line, cond uc t leak test and make su re that there is no leak ag e from con ne ctions.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten connections of seal seat to the specified torque.

O-ring

size

12

16

19

Part number* D m m (in) W mm (in)

92472 N8210 10.9 (0.429) 2.43 (0.0957)

92473 N8210 13.6 (0.535) 2.43 (0.0957)

92474 N8210 16.5 (0.650) 2.43 (0.0957)

Revision: March 2006 2007 Quest

MTC-10

PRECAUTIONS

1. Plug 2. O-ring A. Torque wrench

B. Apply oil C. Do not apply oil to threads D. NG (no good)

E. OK (okay) F. Inflated portion

A

B

C

D

E

F

WJIA1774E

G

Precautions for Servicing Compressor EJS004LV

● Plug all openings to prevent moisture and foreign matter from entering.

● When the compressor is removed, store it in the same position as it is when mounted on the car.

● When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to MTC-22, "

● Keep friction surfaces between clutch and pulley clean. If the surface is contaminated with oil,

Maintenance of Oil Quantity in Compressor" .

wipe it off by using a clean waste cloth moistened with thinner.

● After compressor serv ice opera tion , turn the compre ssor sha ft by hand m ore than 5 turn s in both

directions. Th is will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and operate the compressor for 1 hour.

● After replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation. Refer to MTC-177, "

Removal and Installation for Compressor Clutch"

Precautions for Service Equipment EJS004LW

RECOVERY/REC YCLING EQUIPMENT

Follow the manu fac turer's instruc tions for machi ne ope ration and mach ine mainten ance. N ev er introduc e an y

refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions for tester operati on and tester maintenance.

H

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-11

PRECAUTIONS

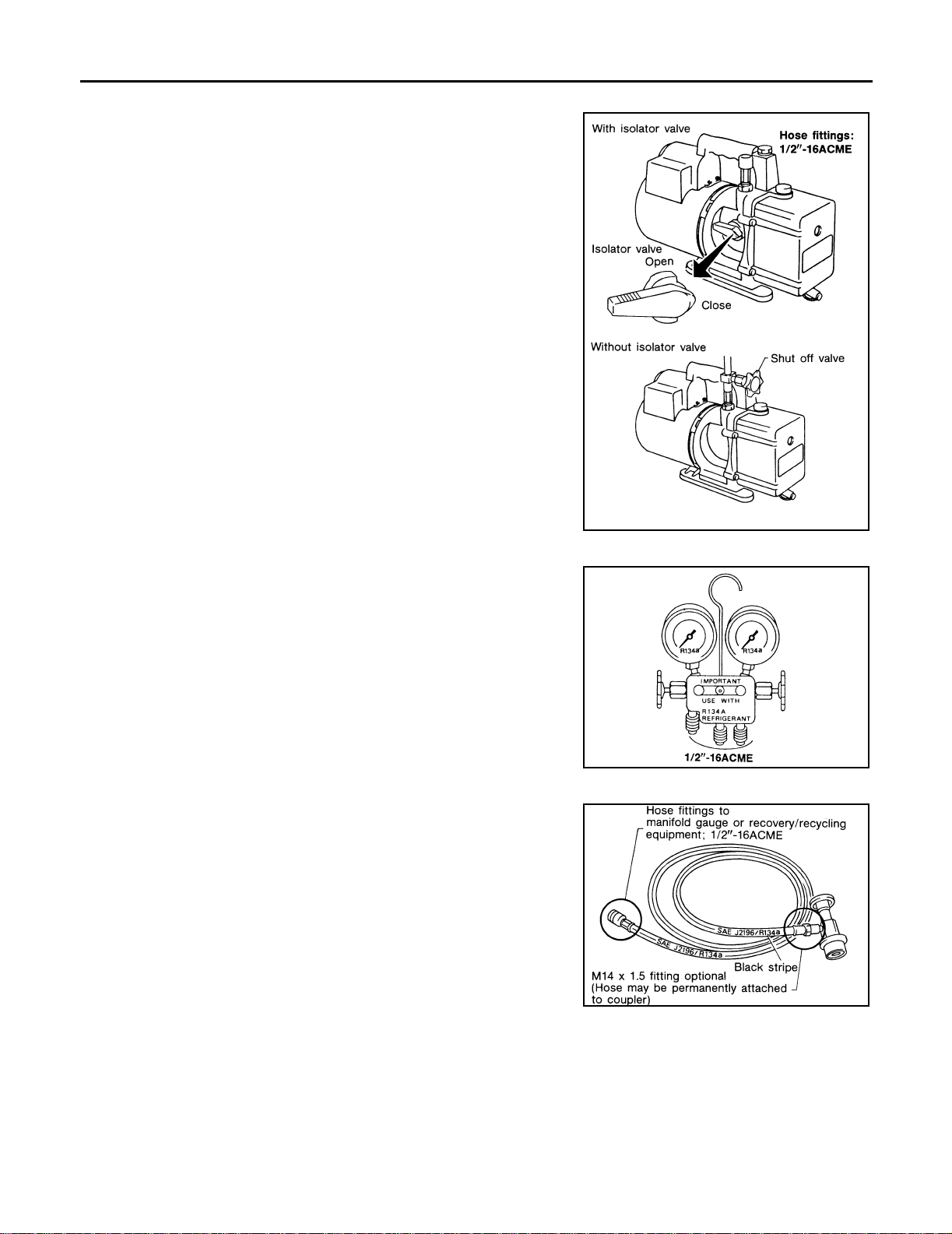

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC -134a (R-134a) A/C s ystems. The vent side of

the vacuum pump is exposed to atmospher ic pressure so the vacuum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve situated near the

hose-to-pump connection, as follows.

● Usually va cuum pumps have a manua l isolator valve as part of

the pump. C lose this valv e to isolate th e service hose fr om the

pump.

● For pumps without an isolator, use a hose equipped with a man-

ual shut-off valve near the pump end. Clos e the valve to isolate

the hose from the pump.

● If the hose has an automatic shu t off valve, disconnect the hose

from the pump : as long as the hose is conne cted, the valve is

open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum cond ition. Such valves may restric t the pump's

ability to pull a deep vacuum and are not rec ommended.

MANIFOLD GAUGE SET

Be certain that the g auge face indicate s HFC-134a (R-13 4a) Make

sure the gauge set has 1/2″-16 ACME threaded connections for service hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) along with specified oil.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shutoff devices (either manual or autom atic) near the end of the hoses

opposite the manifold gauge.

RHA270D

SHA533D

RHA272D

Revision: March 2006 2007 Quest

MTC-12

PRECAUTIONS

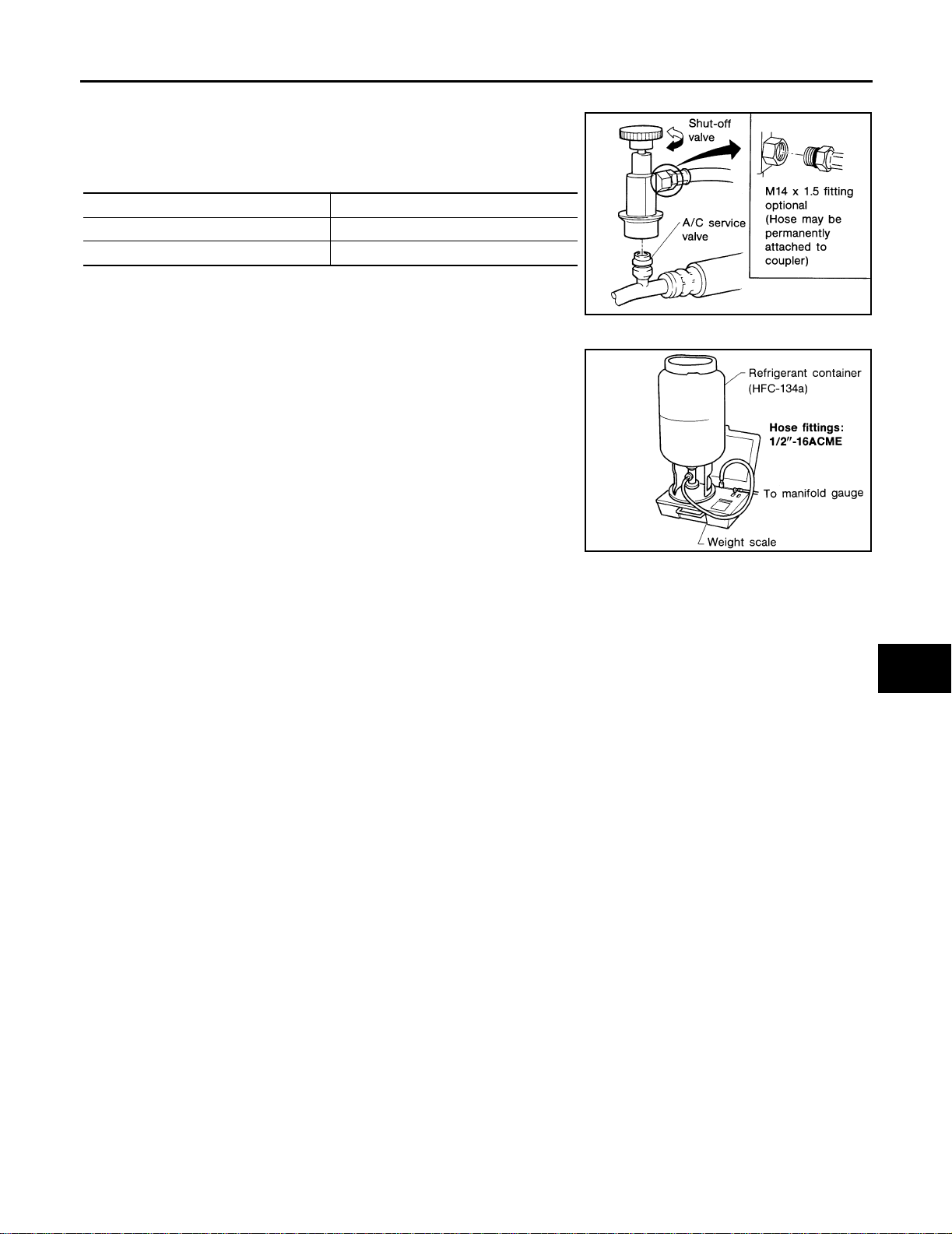

SERVICE COU PLE RS

Never attempt to connect HFC-134a (R-13 4a) service couplers to a

CFC-12 (R-12) A/C system . The HFC-134a (R-134a) cou plers will

not properly connect to the CFC-12 (R-12) system. If an improper

connection is attempted, discharging and contamination may occur.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

A

B

C

RHA273D

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC134a (R-134a) and specified

oils have been u sed with the scale . If the scale controls refrige rant

flow electronically, the hose fitting must be 1/2”-16 ACME.

RHA274D

CHARGING CYLINDER

Using a charging cylinde r is not recommended. Refrige rant may be vented into air from cylinder's top valve

when filling the cylinder w ith refrigerant. Also, the acc uracy of the cy linder is gener ally less than that of an

electronic scale or of quality recycle/recharge equipment.

D

E

F

G

H

I

MTC

K

Revision: March 2006 2007 Quest

MTC-13

L

M

PREPARATION

PREPARATION PFP:00002 Special Serv ice Tools EJS004LY

The actual shapes of Kent-Moore tools may differ from those of special servi ce tools illustrated here.

Tool number

(Ken t-Moore No.)

Tool name

—

(J-38873-A)

Pulley installer

LHA171

KV99233130

(J-29884)

Pulley puller

LHA172

Description

Installing pulley

Removing pulley

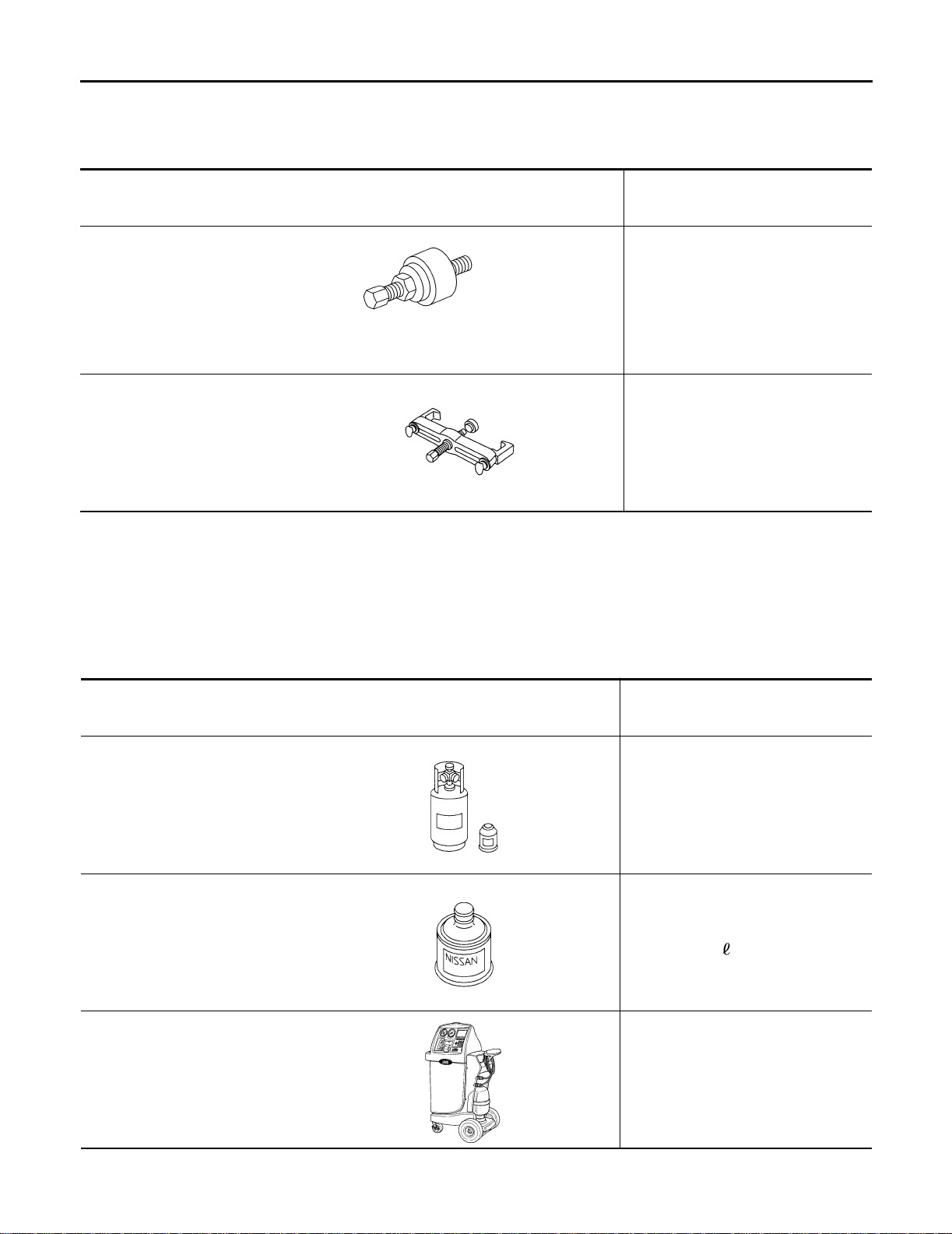

HFC-134a (R-134a) Service Tools and Equipment EJS004LZ

Never mix HFC-134a refrigerant and/or its specified oil with CFC-12 (R-12) refrigerant and/or its oil.

Separate and non-interchangeable service equipment must be used for ha ndling each type of refrigerant/oil.

Refrigerant c ontainer fittings, servi ce hose fittings a nd service equipment fittings (equipment which handles

refrigerant and /or oil) are different between C FC-12 (R-12) and H FC-134a (R-134a). Thi s is to avoid mixed

use of the refrigerants/oil.

Adapters that convert one size fitting to another must nev er be used refrigera nt/oil contamination wil l occur

and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool name

HFC-134a (R-134a)

(—)

Refrigerant

S-NT196

—

(—)

NISSAN A/C System Oil Typ e S

Description

Container color: Light blue

Container marking: HFC-134a (R134a)

Fitting size: Thread size

● large container 1/2”-16 ACME

Type: Poly alkylene glycol oil (PAG),

type S

Application: HFC-134a (R-134a) vane

rotary compressors (NISSAN only)

Lubricity: 40 m (1.4 US fl oz, 1.4 Imp

fl oz)

S-NT197

KV991J0130

(ACR2005-NI)

ACR5 A/C Service Center

WJIA0293E

Revision: March 2006 2007 Quest

MTC-14

Refrigerant recovery, recycling and recharging

PREPARATION

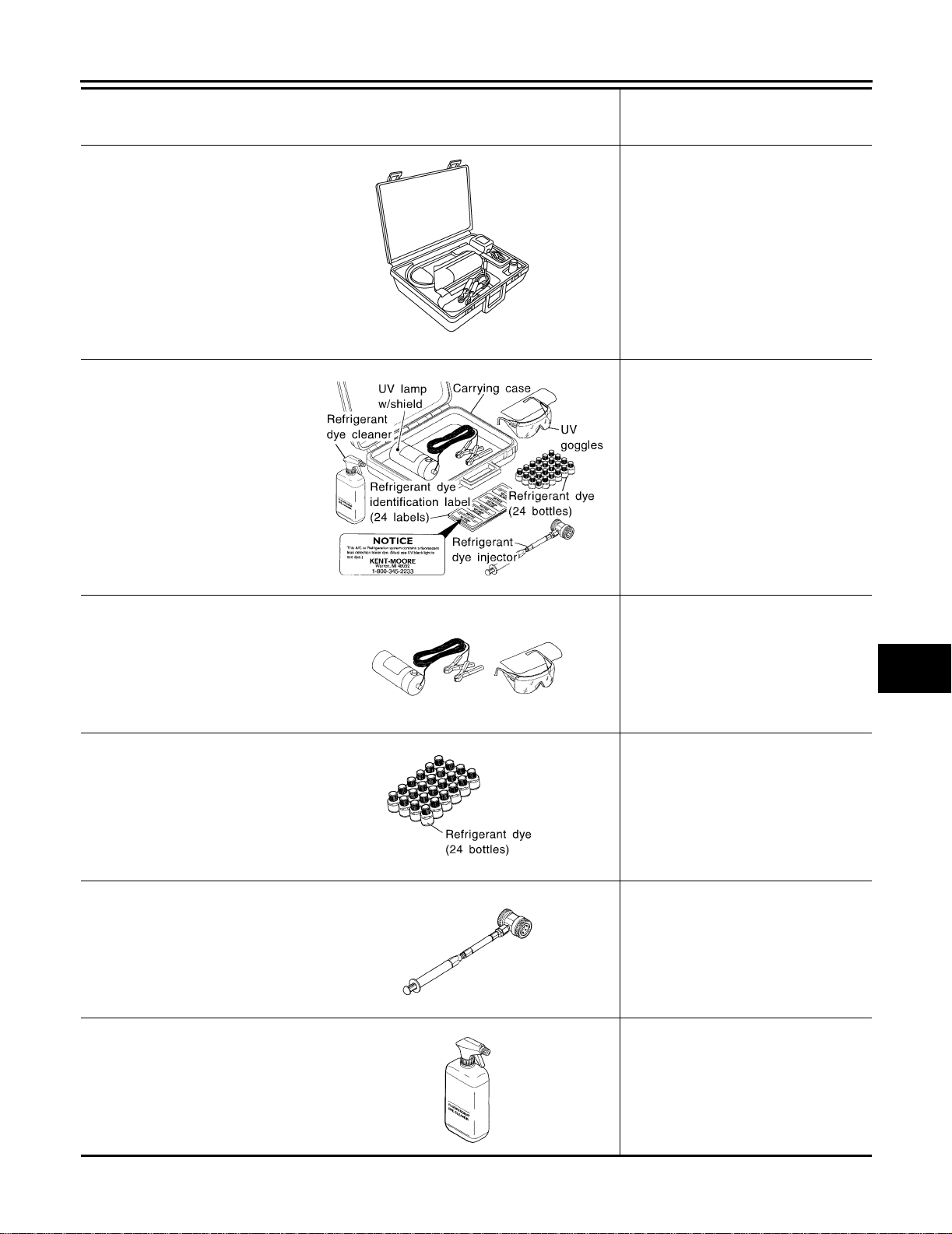

Tool number

(Ken t-Moore No.)

Tool name

—

(J-41995)

Electronic refrigerant leak detector

—

(J-43926)

Refrigerant dye leak de tecti on kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Quantity 24, 1/4 ounce bottles of

HFC-134a (R-134a) fluorescent

leak detection dye

(J-43872)

Refrigerant dye cleaner

—

(J-42220)

Fluorescent dye leak detector

AHA281A

ZHA200H

Description

Checking for ref r i ge rant leaks

(Power supply: DC 12V battery terminal)

Leak detection dye

(Power supply: DC 12V battery terminal)

Checking for refr igeran t le aks w hen f luorescent dy e is inst alled i n A/C syst em.

Includes: UV lamp and UV safety goggles

(Power supply: DC 12V battery terminal)

A

B

C

D

E

F

G

H

I

MTC

—

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/ 4 ounce bottl es)

—

(J-41459)

HFC-134a (R-134a) Dye injector

Use with (J-41447) 1/4 ounce bottles

—

(J-43872)

Refrigerant dye cleaner

SHA438F

SHA439F

SHA440F

SHA441F

Applicati on: For HFC-134a (R-134a)

PAG oil

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye identification labels for affixing to vehicle after

char ging system with dye.)

For injecti ng 1/ 4 oun ce of fluorescen t

leak detection dye into A/C system.

For cleaning dye spills.

K

L

M

Revision: March 2006 2007 Quest

MTC-15

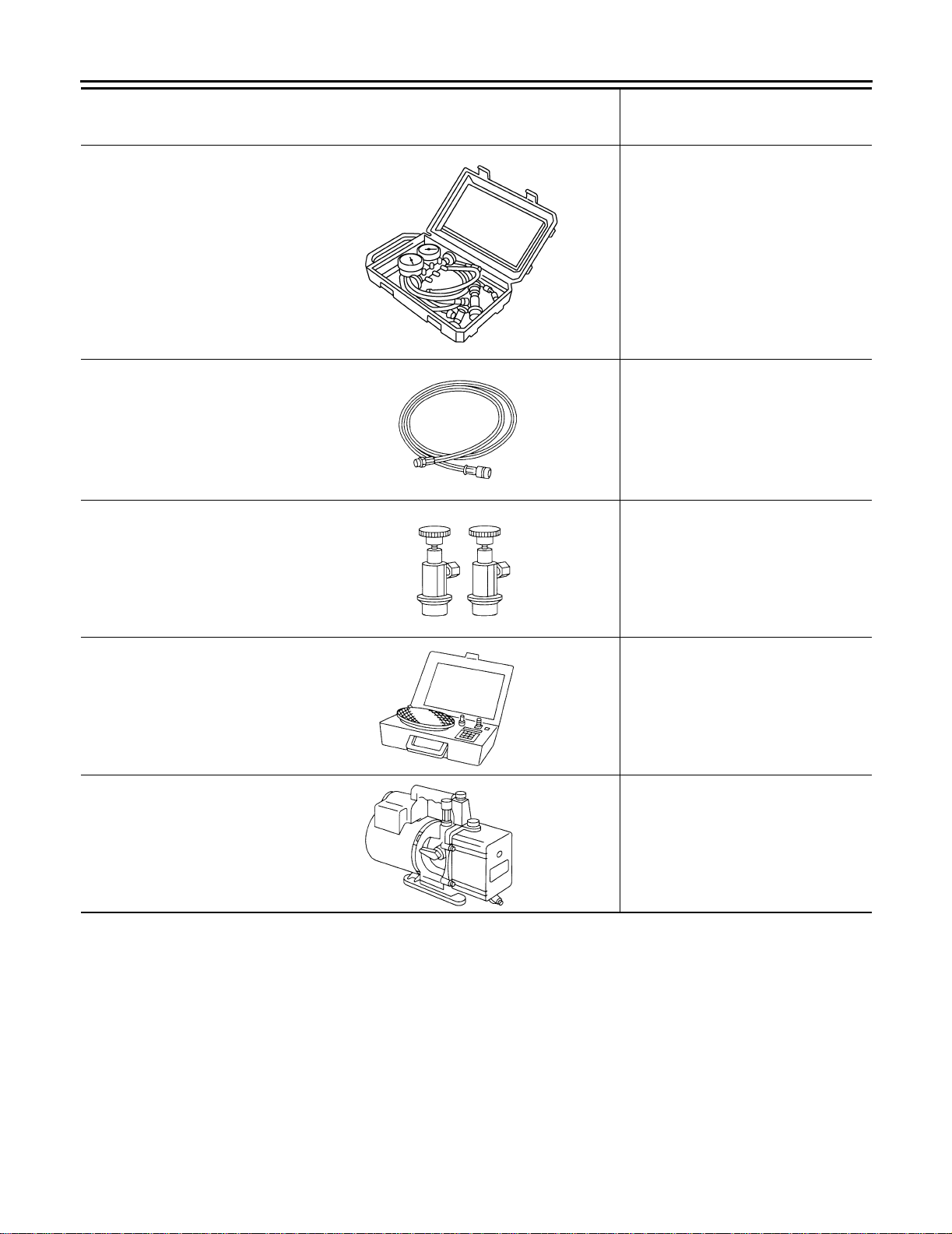

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

—

(J-39183-C)

Manifold gauge set (with hoses

and couplers)

Service hoses:

● (J-39500-72B)

High side hose

● (J-39500-72R)

Low si de hose

● (J-39500-72Y)

Utility hose

Service couplers:

● (J-39500-20A)

High side coupler

● (J-39500-24A)

Low si de coupler

S-NT201

Description

Identification:

● The gauge face indicates R-134a.

Fitting size: Thread size

● 1/2”-16 ACME

RJIA0196E

Hose colors:

● Low side hose: B lue w i th black s t ripe

● High side hose: Red with bla ck s tripe

● Utility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

● 1/2”-16 ACME

Hose fitting to service hose:

● M14 x 1.5 fitt ing i s opt ional or pe rma-

nently attached.

—

(J-39699)

Refrigerant weight scal e

—

(J-39649)

Vacuum pump

(Including the isolator valve)

S-NT202

For measuring of refrigerant

Fitting size - thread size:

● 1/2” - 16 ACME

S-NT200

Capacity:

● Air displacement: 4 CFM

● Micron rating: 20 microns

● Oil capacity: 482 g (17 oz)

Fitting size: Thread size

● 1/2”-16 ACME

S-NT203

Revision: March 2006 2007 Quest

MTC-16

PREPARATION

Commercial Service Tools EJS004M0

Tool number

Tool name

(J-41810-NI)

Refrige ran t id entif ier eq uip ment ( R134a)

Description

For checking refrigerant purity and

system contamination

A

B

C

D

RJIA0197E

Power tool Loosen ing bolts and nuts

PBIC0190E

(J-44614)

Clutch disc holding tool

WHA230

Clutch disc holding tool

E

F

G

H

I

MTC

K

L

Revision: March 2006 2007 Quest

MTC-17

M

REFRIG ERATION SYSTEM

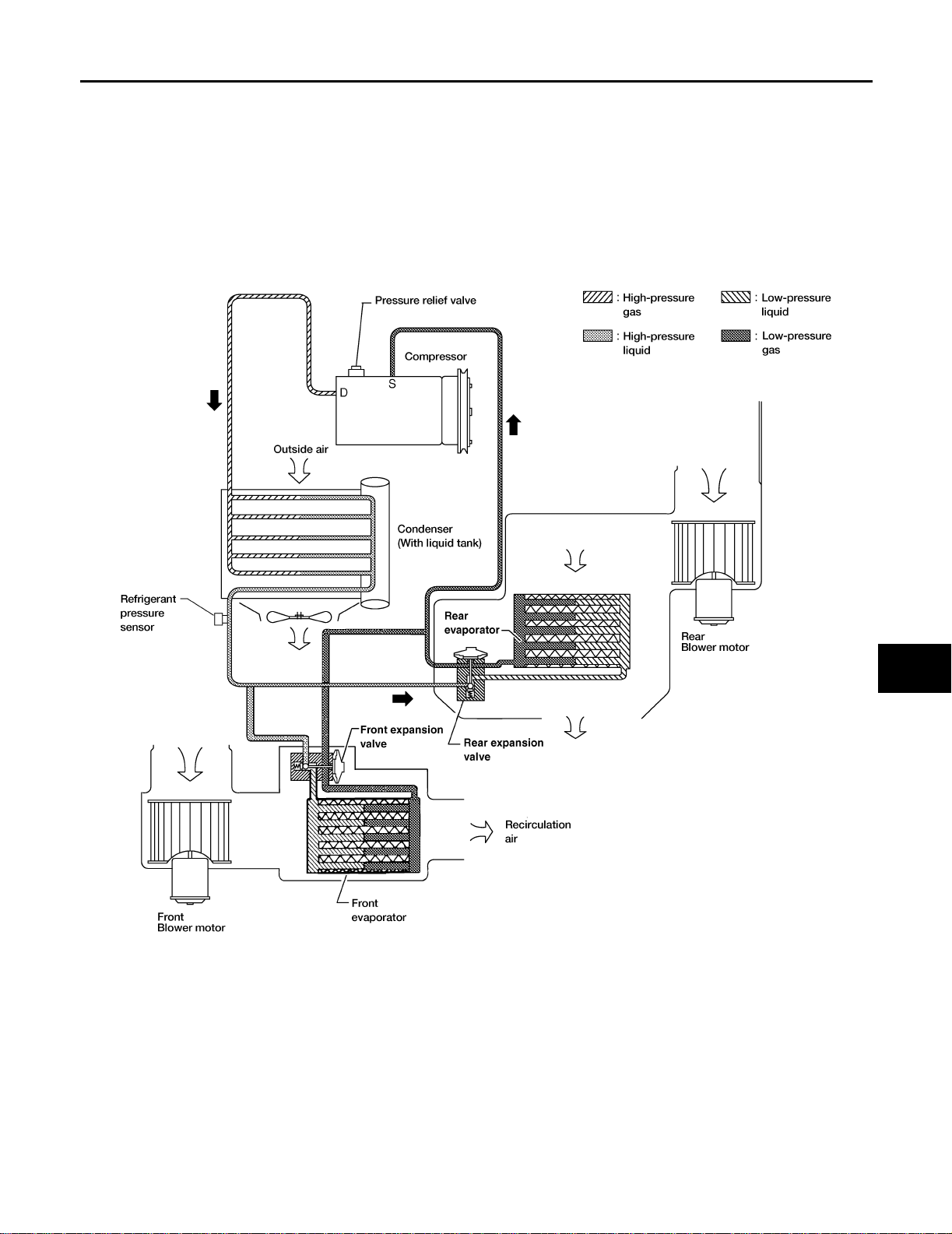

REFRIGERATION SYSTE M PFP:KA990 Refrigerant Cycle EJS004M1

REFRIGERANT FLOW

The refrigera nt flows in the standard pattern, that i s, through the compr essor, the condenser wi th liquid tank,

through the fr ont and r ear evaporat ors, and ba ck to the compress or. The refrigerant evapor ation thro ugh the

evaporator c oils are con trolled by a front and re ar externally eq ualized expansi on valves, l ocated inside the

front and rear evaporator cases.

Refrigerant System Protection EJS004M2

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sensor, located on the condenser. If the system pressure rises above or falls below the specifications, the refrigerant pressur e sensor dete cts the pressur e inside th e refrigerant line and sen ds a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

2

pressure side detected by refrigerant pr essure sensor is over about 2,746 kPa (28 kg/cm

2

about 120 kPa (1.22 kg/cm

, 17.4 psi).

, 398 psi), or below

Revision: March 2006 2007 Quest

MTC-18

REFR IGERATION SYSTEM

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an abnormal level [more than 2,990 kPa (30.5 kg/

2

, 433.6 psi)], the releas e port on the pressure reli ef valve automatically ope ns and releases refrigerant

cm

into the atmosphere.

A

B

C

D

E

F

G

WJIA1342E

H

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-19

REFRIG ERATION SYSTEM

Component Layout EJS004M3

FRONT REFRIGERATION SYSTEM

WJIA2219E

Revision: March 2006 2007 Quest

MTC-20

REFR IGERATION SYSTEM

1. Defroster nozzle (part of the

instrument panel)

4. RH side demister duct 5. RH side demister duct extension 6. LH side demister duct extension

7. LH side demister duct 8. RH ventilator duct 9. Center ventilator duct

10. LH ventilator duct 11. Front heater and cooling unit assembly 12. Floor connector duct

13. Floor junction duct extension 14. Floor junction duct 15. Floor distribution duct

16. Floor duct ⇐ Front

2. Fresh air duct 3. Defros t er duc t

REAR REFRIGERATION SYSTEM

A

B

C

D

E

F

G

H

LJIA0086E

1 Rear overhead duc t 2 Rear heat duct 3 Rear heater and cooling un i t assembly

4. Clips

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-21

OIL

OIL PFP:KLG00 Maintena n ce of Oil Qu a nt ity in Com pressor EJS004M4

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage has occurred. It is important to maintain the specified amount.

If oil quantity is not maintained properly, the following malfunctions may result:

● Lack of oil: May lead to a s eized compressor

● Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

Name: NISSAN A/C System Oil Type S or equivalent

CHECKING AND ADJUSTING

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

Start the engine and set the following conditions:

● Engine speed: Idling to 1,200 rpm

● A/C switch: On

● Blower fan speed: Maximum position

● Temperature control: Optional [set so that intake air temperature is 25° to 30° C (77° to 86°F).]

● Intake position: Recirculation ( )

● Perform oil return operation for about ten minutes

Adjust the oil quantity according to the following table.

Oil Adjusting Procedure for Components Replaceme nt Except Compressor

After replacing any of the following major components, add the correct amount of oil to the system.

Amount of Oil to be Added

Oil to be added to system

Part replaced

Front evaporator 75 (2.5, 2.6) —

Rear evaporator 75 (2.5, 2.6) —

Conden ser 75 (2.5 , 2.6) —

Liquid tank 5 (0.2, 0.2) Add if compressor is not replaced.

In case of refrigerant leak

*1: If refrigerant leak is small, no addition of oil is needed.

Amount of oil

m (US fl oz, Imp fl oz)

30 (1.0, 1.1) Large leak

—Small leak *1

Remarks

Revision: March 2006 2007 Quest

MTC-22

OIL

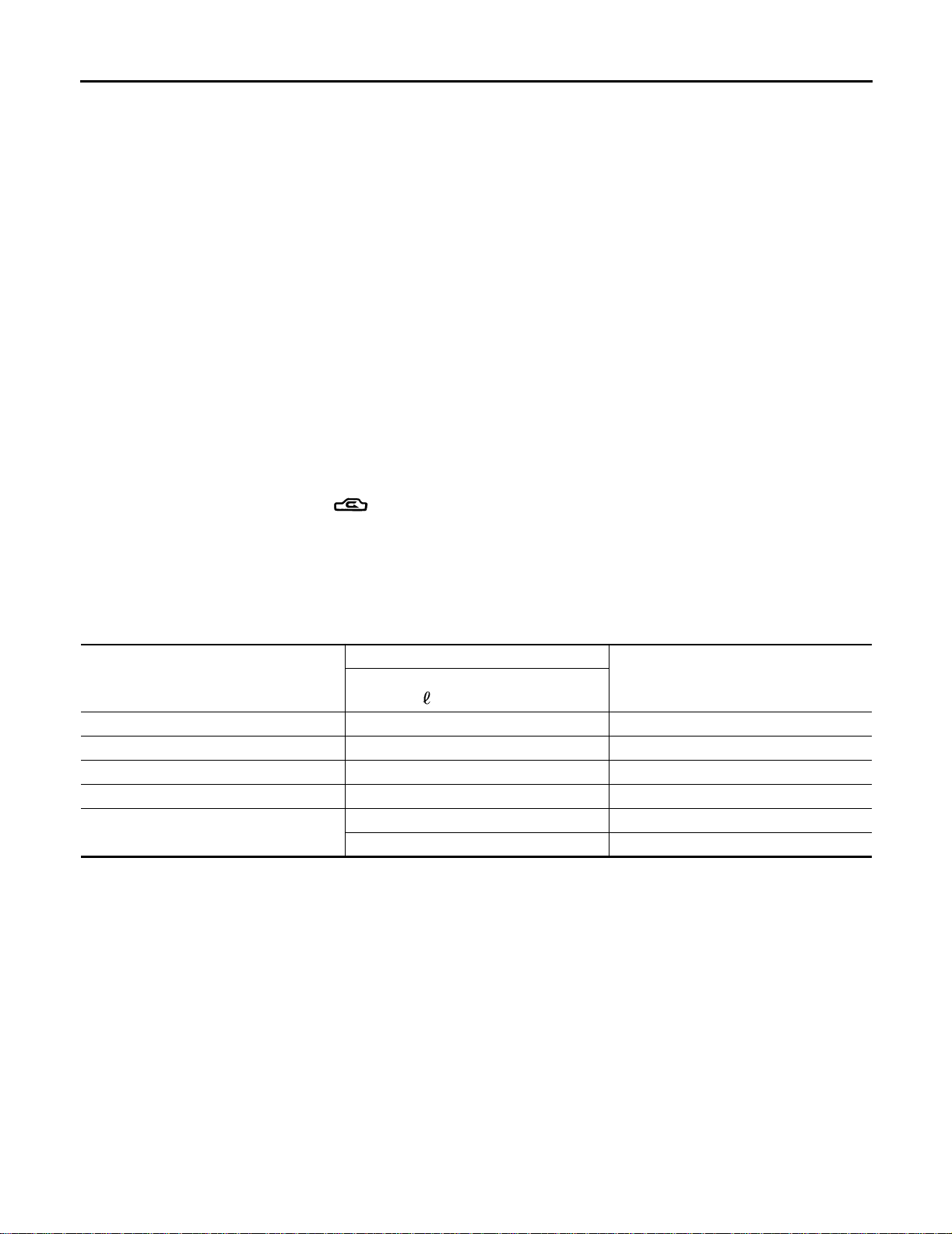

Oil Adjustment Procedure for Compressor Replacement

A

B

C

D

E

F

G

WJIA1716E

1. New compressor 2. Old compressor 3. Recovery/recycling equipment

4. Measuring cup X 5. Measuring cup Y 6. New oil

A. Drain oil from the new compressor

into clean container

D. Install new oil equal to recorded

amount s in m easur ing c ups X pl us Y

B. Record amount of oil recovered C.

Add an add iti o nal 5 m (0.2 US fl oz,

0.2 Imp fl oz) of new o il when repla cing liquid tank

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauge s.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycl ing equipment to vehicle. Confirm refrigerant purity in supply tank using recovery/

recycling equipment and refrigerant identifier. If NG, refer to MTC-5, "

Contaminated Refrigerant" .

3. Confirm refrigerant purity in vehicle A/C system using recovery/recycling equipment and refrigerant identifier. If NG, refer to MTC-5, "

Contaminated Refrigerant" .

4. Discharge refrigerant into the refrigerant recovery/r ecycling equipment. M easure oil discharg ed into the

recovery/recycling equipment.

5. Drain the o il from the “old” (remo ved) compr essor in to a graduate d container and rec over the am ount of

oil drained.

6. Drain the oi l from the “new” compressor into a separate, clean container.

7. Measure an a mount of new o il installed equal to amount dr ained from “old” com pressor. Add this oil to

“new” compressor through the suction port opening.

8. Measure an am ount of new oil equal to the a mount recovered during discharging. Add this oil to “new”

compressor through the suction port opening.

9. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 US fl oz, 0.2 Imp fl oz) of oil at this

time.

H

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-23

OIL

CAUTION:

Do not add this 5 m (0.2 US fl oz, 0.2 Imp fl oz) of oil if only replacing the compressor.

Revision: March 2006 2007 Quest

MTC-24

AIR COND ITIONER CONTROL

AIR CO NDITIONER CONT ROL PFP:27500

Description EJS004M5

The front air control provides regulation of the vehicle's interior temperature. The system is based on the position of the front air controls tempe rature switch selected by the driver. This is done by utilizing a micro computer, also referred to as the front air control, which receives input signals from the following three sensors:

● Ambient sensor

● Intake sensor

● PBR (position balanced resistor).

The front air control uses these signals (including the set position of the temperature switch) to control:

● Outlet air volume

● Air temperature

● Air distribution

The front air control also provides separate regulation of the vehicle's interior temperature for the rear passenger area. The system is based on th e temperature and rear blower setting s selected from rear air control

(front) control dials located in the overhead console, or from the rear temperature and blower settings from the

rear air contro l (rear) contr ol dials, when the REA R CTRL sw itch is pres sed (indica tor light is on) on the rear

air control (front).

The front air control is used to select:

● Outlet air volume

● Air temperature/dis tribution

A

B

C

D

E

F

G

Operation EJS004M6

AIR MIX DOOR CONTROL

The air mix door is controlled so that in-vehicle temperature changed based on the position of the temperature

switch.

BLOWER SPEED CONTROL

Blower speed is controlled based on front and rear blow er control dial settings.

When blower switch is turned, the blower motor starts and increases air flow volume each time the blower control dial is turned clockw ise, and decre ases air flow vol ume each time the bl ower control dial switch is turned

counterclockwise.

INTAKE DOORS CONTROL

The intake doors are controlled by the recirculation switch setting, and the mode (recirculation is not allowed in

floor, floor/defrost or defrost modes) switch setting.

MODE DOOR CONTROL

The mode door is controlled by the position of the mod e switch.

DEFROSTER DOOR CONTROL

The defroster door is controlled by pressing the defroster mode switch.

H

I

MTC

K

L

M

Revision: March 2006 2007 Quest

MTC-25

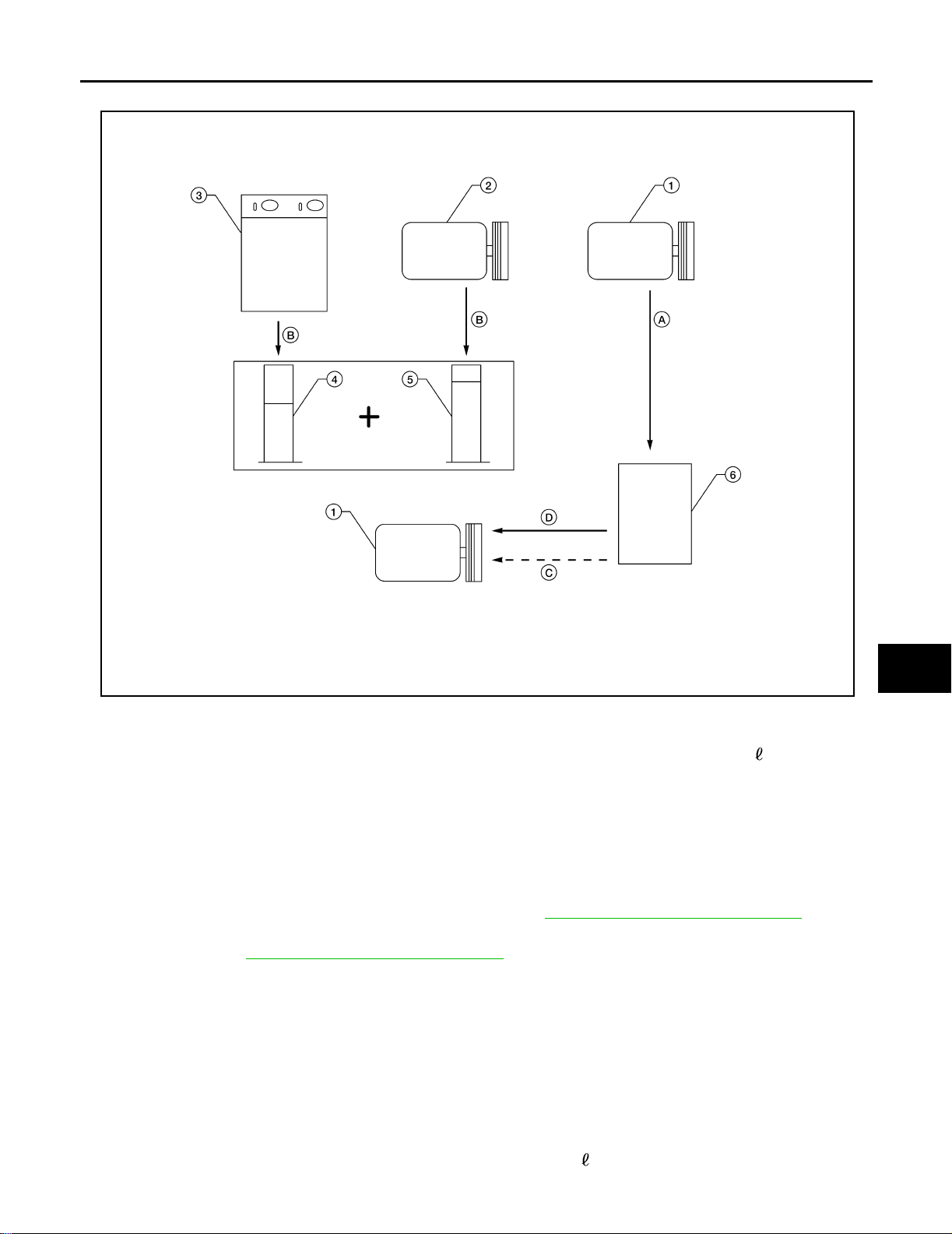

MAGNET CLUTCH CONTROL

AIR CONDITIONER CONTROL

WJIA2161E

When the A/C s witch is pres sed, or the defros ter mod e s witch is p ressed , the fro nt a ir contr ol ou tputs a com pressor ON signal to BCM.

The BCM then sends a compressor ON signal to ECM and front air control, via CAN communication line.

ECM judges wh ether compres sor can be turn ed ON, based on eac h sensor status (refr igerant pres sure sensor signal, throttle angle sensor, etc.). If it judges compressor can be turned ON, it sends compressor ON sig nal to IPDM E/R, via CAN communication line.

Upon receipt of com pressor ON si gnal from ECM, IP DM E/R turns air cond itioner relay O N to operate com pressor.

SELF-DIAGNOSTIC SYSTEM

The self-d iagnostic system is built into the fr ont air control to quickly locate the cause of certain symptoms .

Refer to ATC-53, "

A/C System Self-diagnosis Function" .

Revision: March 2006 2007 Quest

MTC-26

AIR COND ITIONER CONTROL

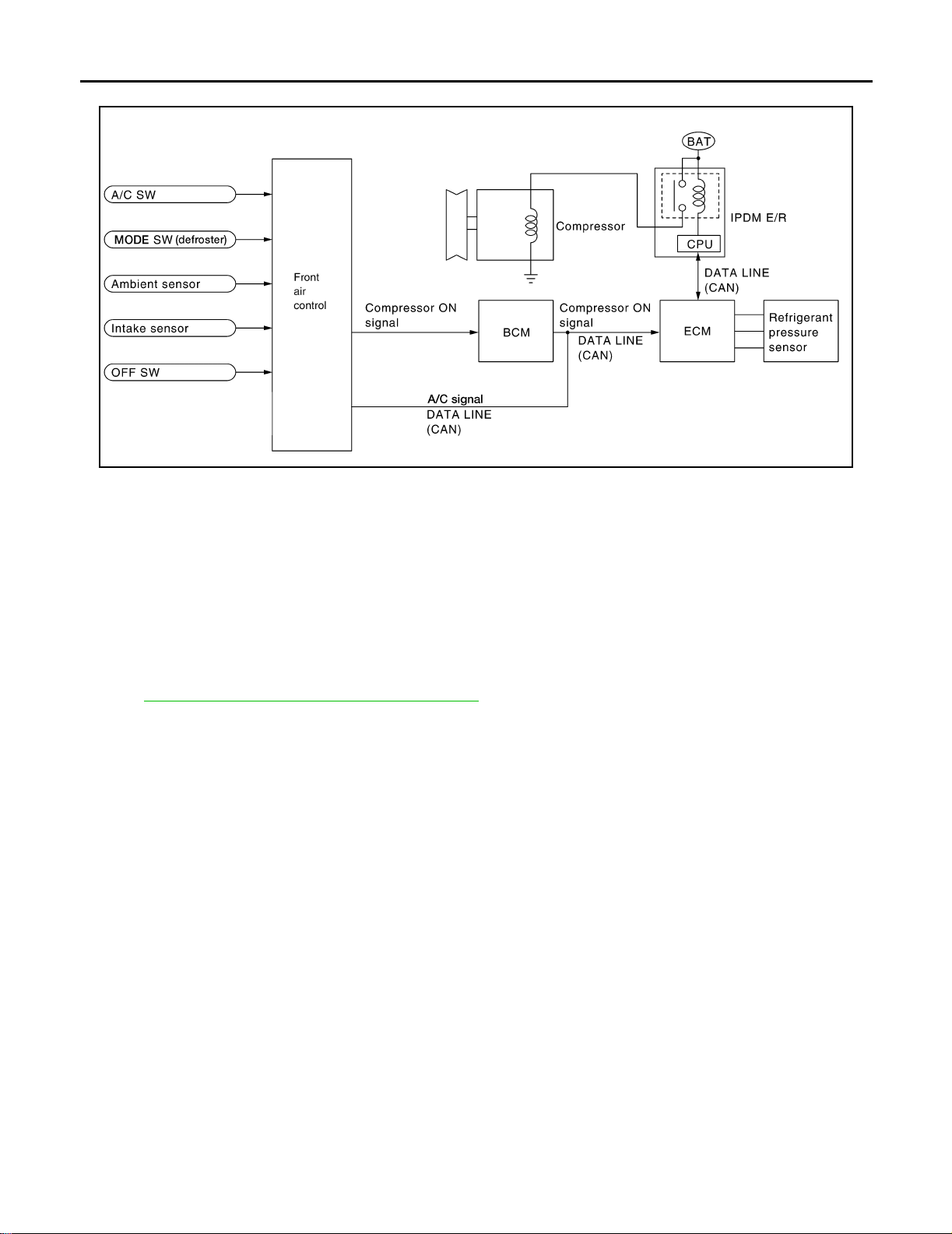

Description of Cont ro l System EJS004M7

The control system consists of input sensors, switches, the front air control (microcomputer) and outputs.

The relationship of these components is shown in the figure below:

A

B

C

D

E

F

G

WJIA2160E

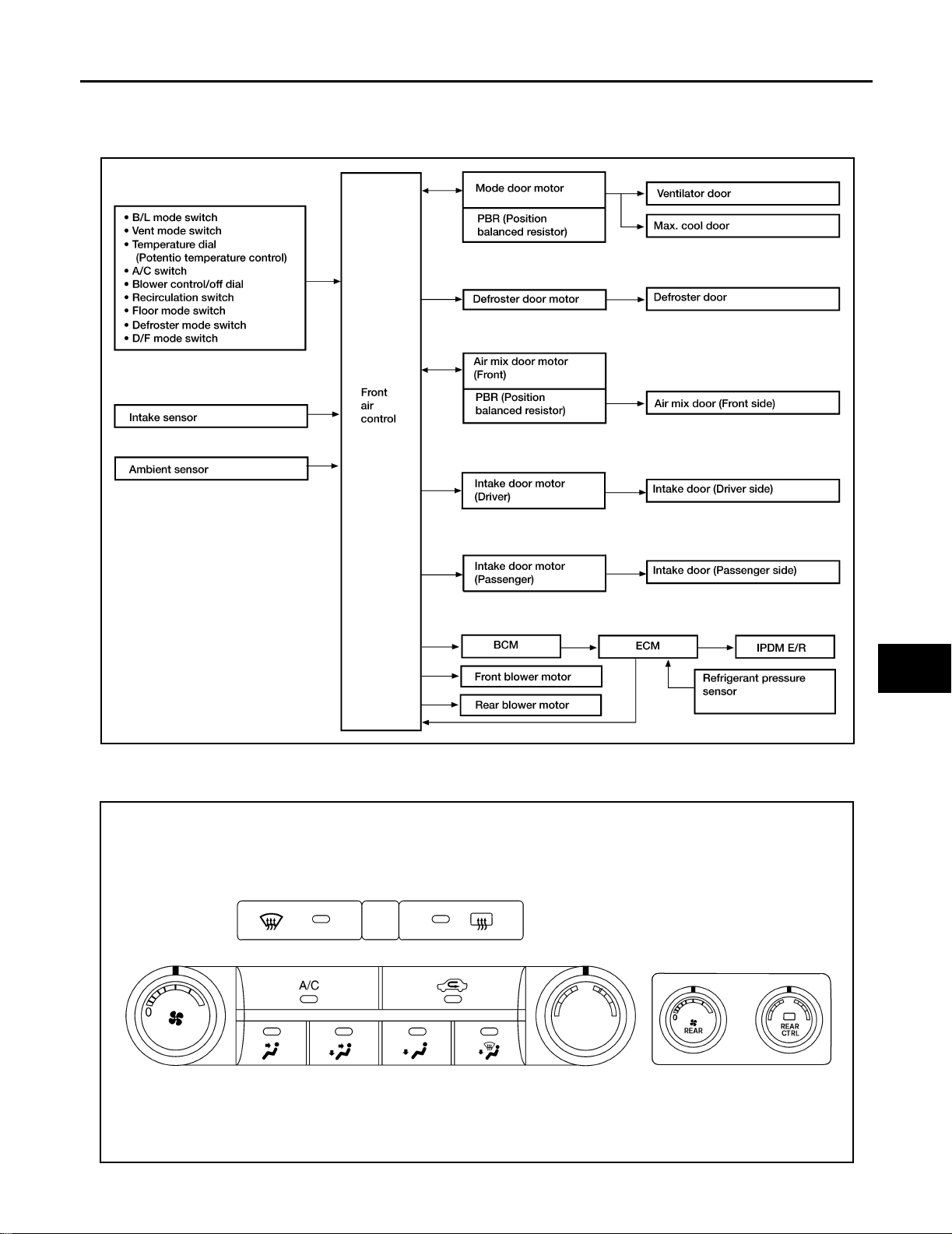

Control Ope ra tio n EJS004M8

Front air control

H

I

MTC

K

L

M

WJIA2162E

Revision: March 2006 2007 Quest

MTC-27

AIR CONDITIONER CONTROL

Rear air control (rear)

TEMPERATURE CONTROL DIAL (FRONT)

Increases or decreases the s et temperature.

TEMPERATURE CONTROL DIAL (REAR)

Increases or decreases the s et temperature.

WJIA2015E

RECIRCULATION () SWITCH

● When REC switch is ON, REC switch indicator turns ON, and air inlet is s e t to REC.

● When REC switch is turned OFF, or when compressor is turned fro m ON to OFF, REC switch is automati-

cally turned OFF. REC mode can be re-entered by pressing REC switch again.

● REC switch is not oper ated when D EF switch is turned ON, at t he D/F position, or in floor mode.

REAR WINDOW DEFOGGER SWITCH

When switch is ON, rear window is defogged.

OFF SWITCH

The compre ssor and blower are O FF, the intake doors are set to the o utside air position, and the ai r outlet

doors are set to the foot position.

A/C SWITCH

The compressor is ON or OFF.

MODE SWITCHS (FRONT)

Controls the air discharge outlets through control of the mode and defroster doors.

MODE DIAL (REAR)

Controls the air/temperature at discharge outlets.

FRONT BLOWER CONTROL DIAL

Manually control the blower speed. Fourteen speeds are available for manual control.

REAR BLO WER CONTROL DIAL (FRO NT)

When the R EAR CTRL swi tch is off (indicator off) the rear air cont rol (front) controls the rear blower moto r

speed regardless of the rear air control (rear) blower control dial (rear) position. The rear air control (front) controls the blo wer motor speed and the temperature/mode settings.

REAR BLO WER CONTROL DIAL (RE AR)

When the REAR C TRL switch is on (indicator on) the rea r air control (rear) controls the rear blo wer motor

speed regardl ess of the rear air contr ol (front) blower contr ol dial (front) position. The rear air control (rear)

controls the blower motor speed and the temperature/mode settings.

Revision: March 2006 2007 Quest

MTC-28

AIR COND ITIONER CONTROL

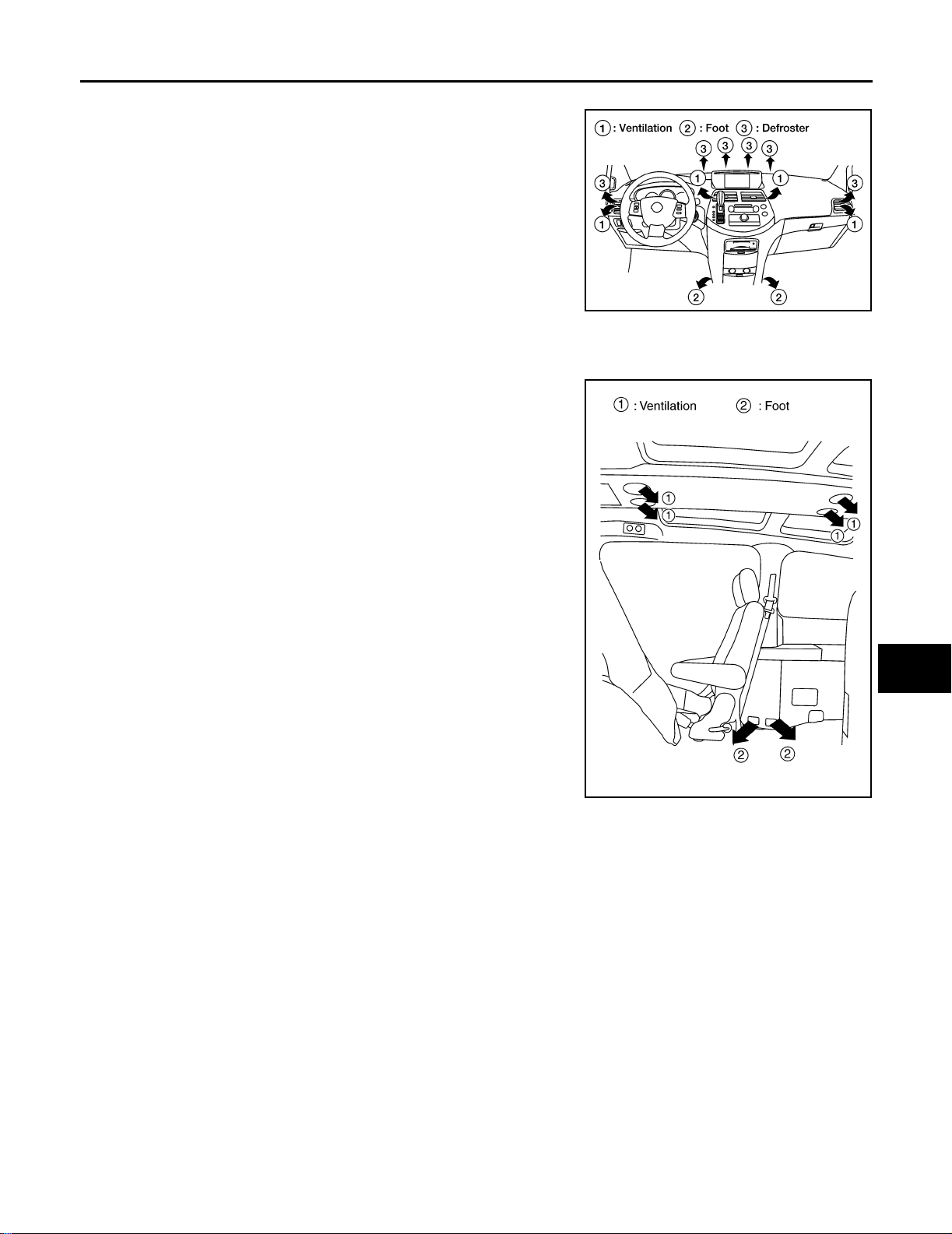

Discharge Air Flow EJS004M9

FRONT

A

B

C

REAR

NOTE:

Hot air comes from the floor vents, cold air comes from the roof

vents, and blended air comes from both vents.

WJIA2016E

D

E

F

G

H

I

MTC

K

LJIA0127E

Revision: March 2006 2007 Quest

MTC-29

L

M

AIR CONDITIONER CONTROL

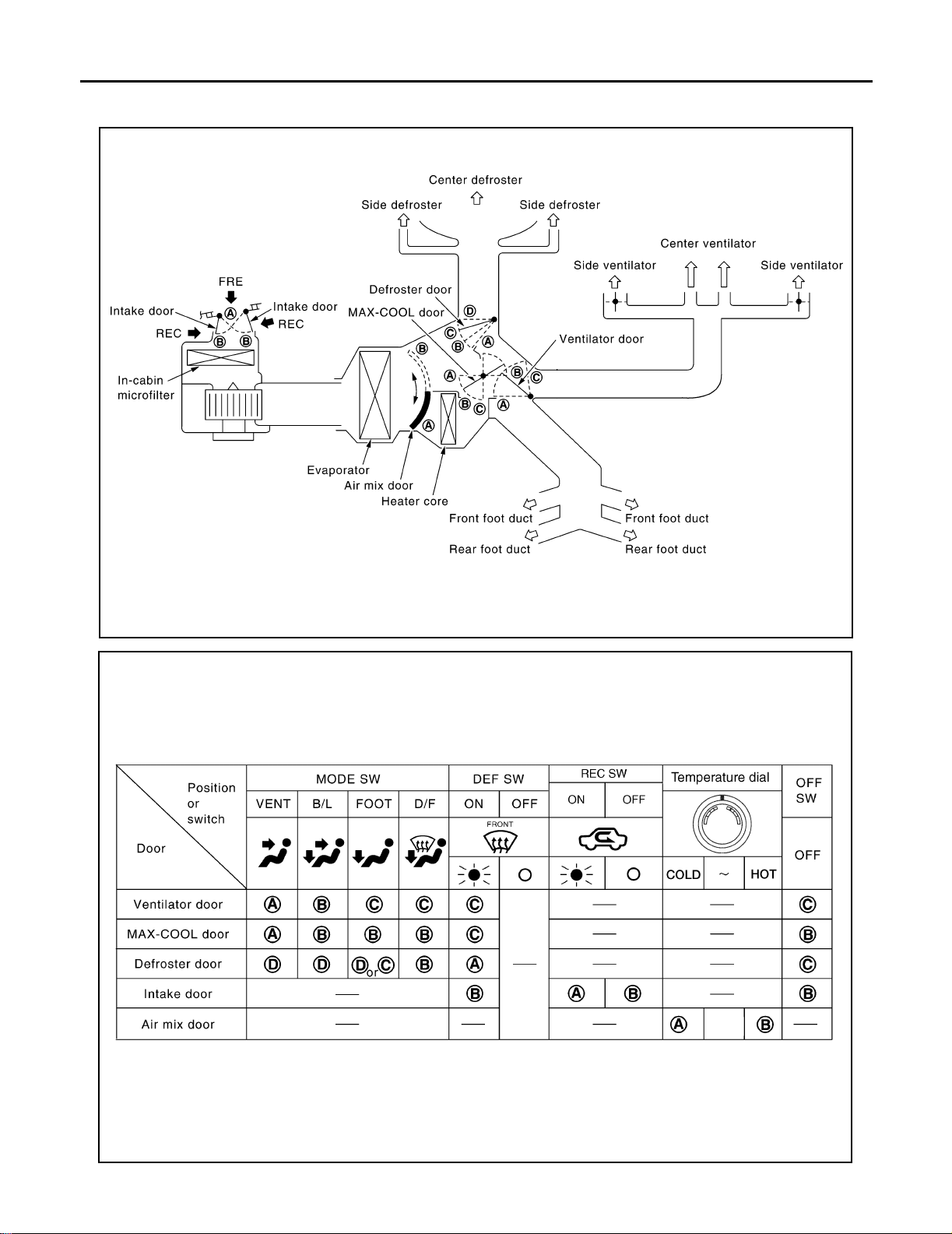

System Description EJS004MA

SWITCH E S AND THE I R CON TRO L FUNC TION

WJIA0531E

WJIA2163E

Revision: March 2006 2007 Quest

MTC-30

Loading...

Loading...