Nissan Procedures Service Manual

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 1 Printed on: April 8, 2005

A Word to NISSAN FORKLIFT

Operators

This booklet describes operating procedures, daily cares and simple

maintenance for safe usage of your NISSAN FORKLIFT. We urge you

to read this booklet carefully before operating the lift truck to familiarize

yourself with safety instructions. These instructions will not only reduce

mechanical troubles of your lift truck, but may also save your life.

If you encounter any problems with your NISSAN FORKLIFT truck,

contact the authorized NISSAN FORKLIFT dealer in your area and

request a complete check-up. The dealership will insure that your Lift

Truck is serviced in accordance with the latest factory approved

methods.

All information, specifications and illustrations in this manual are

on a basis of the latest data obtainable at the time of the publication. Nissan reserves the right to make changes or improvements

at any time without notice.

Throughout this manual we have used the symbol

the word WARNING. This is used to indicate the presence of a hazard

which may cause the possibility of a personal injury or other damage

and must be followed precisely.

CAUTION. This is also used throughout the manual to indicate the

presence of a hazard that could cause possible minor injury to yourself

or components and the procedures must be followed carefully.

followed by

Contents

Name of Components ......................................................................... 2

Safety Rules ........................................................................................ 3

Positioning of Warning, Caution and Instruction Labels................... 13

Instruments and Controls .................................................................. 20

Starting and Operating ...................................................................... 27

Loading and Unloading ..................................................................... 35

Other Handling and Operations ........................................................ 35

Daily Care.......................................................................................... 43

Maintenance...................................................................................... 55

Putting Forklift in Storage.................................................................. 68

Load Chart......................................................................................... 70

Identification Numbers....................................................................... 71

Specifications .................................................................................... 72

Side shift (Optional attachment)........................................................ 84

Cabin (Option) ................................................................................... 94

Index................................................................................................ 100

© 2005 NISSAN MOTOR CO., LTD.

TOKYO, JAPAN

This Operator’s Manual has been prepared on the assumption that your

truck is fully equipped (including all optional equipment). Thus if you

have any questions regarding equipment, please contact your authorized NISSAN FORKLIFT dealer.

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 2 Printed on: April 8, 2005

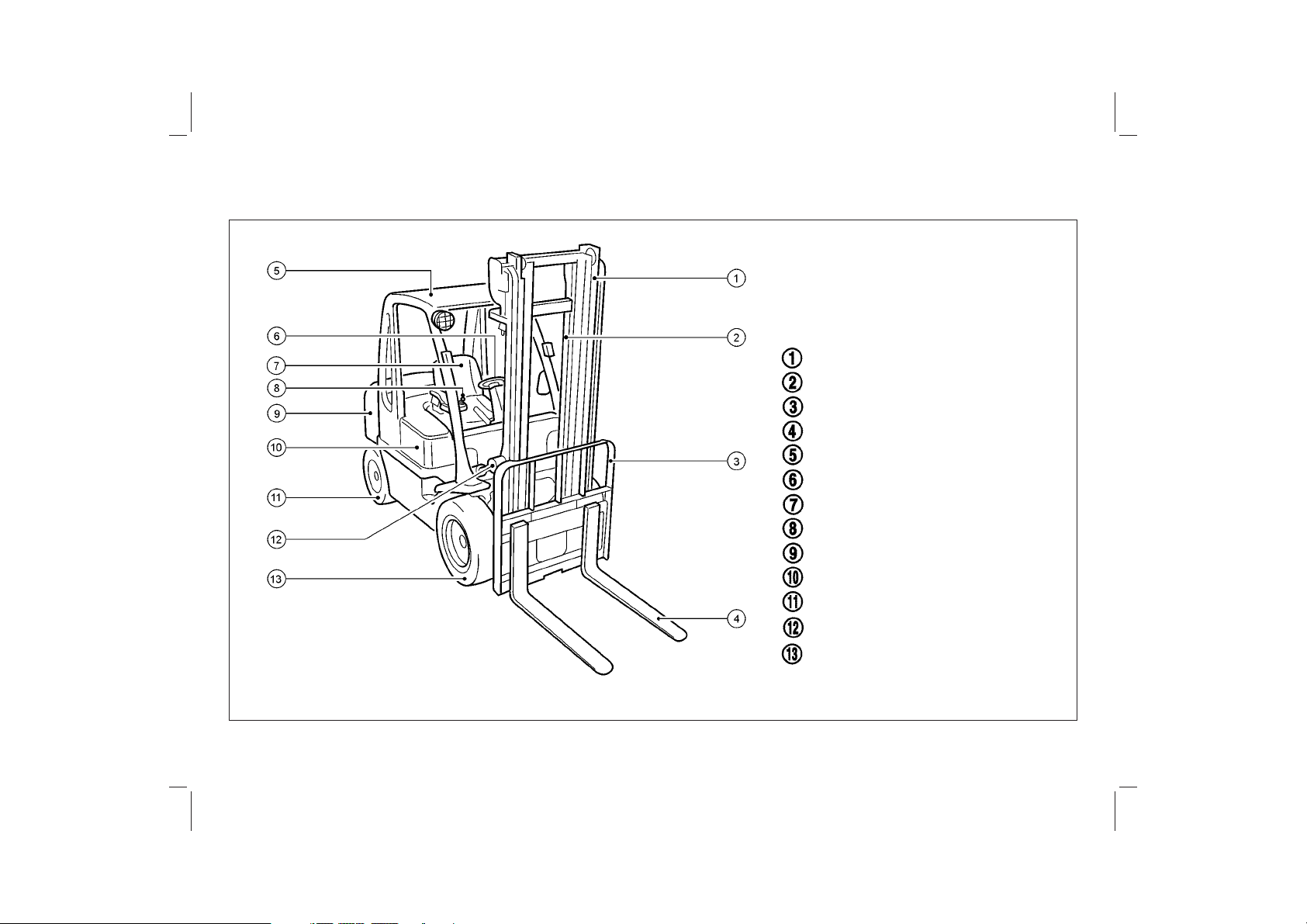

NAME OF COMPONENTS

Mast

Lift cylinder

Backrest

Fork

Overhead guard

Steering wheel

Operator’s seat

Joystick lever

Counterweight

Top panel

Rear tire

Tilt cylinder

Front tire

MOM1826

2

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 3 Printed on: April 8, 2005

SAFETY RULES

The forklift shall be operated in

accordance with the conditions of

the operator’s license, and the applicable provisions of the laws and

regulations of your country.

Operator must be trained and authorized to drive the lift truck, and

must understand safety technics

and rules for lift truck operation.

Before installing hook-on attachments, be sure to read the installation manual issued by the attachment manufacturer to assure

correct and proper installation.

Contact your NISSAN FORKLIFT

dealer for the revised load capacity

figures.

When warning and caution labels

are damaged so they cannot be

read or have peeled off, they

should be immediately replaced

with new labels to ensure that they

are constantly maintained in a legible condition. The warning and

caution labels are available at your

nearest NISSAN FORKLIFT dealer.

Inspect the lift truck before operating. Do not operate lift truck if it is

in need of repair. If it is in need of

repair, tag the lift truck, remove the

key, and report the condition to the

proper authority. Do not attempt

repair unless you are trained and

authorized for repairing.

MOM0015

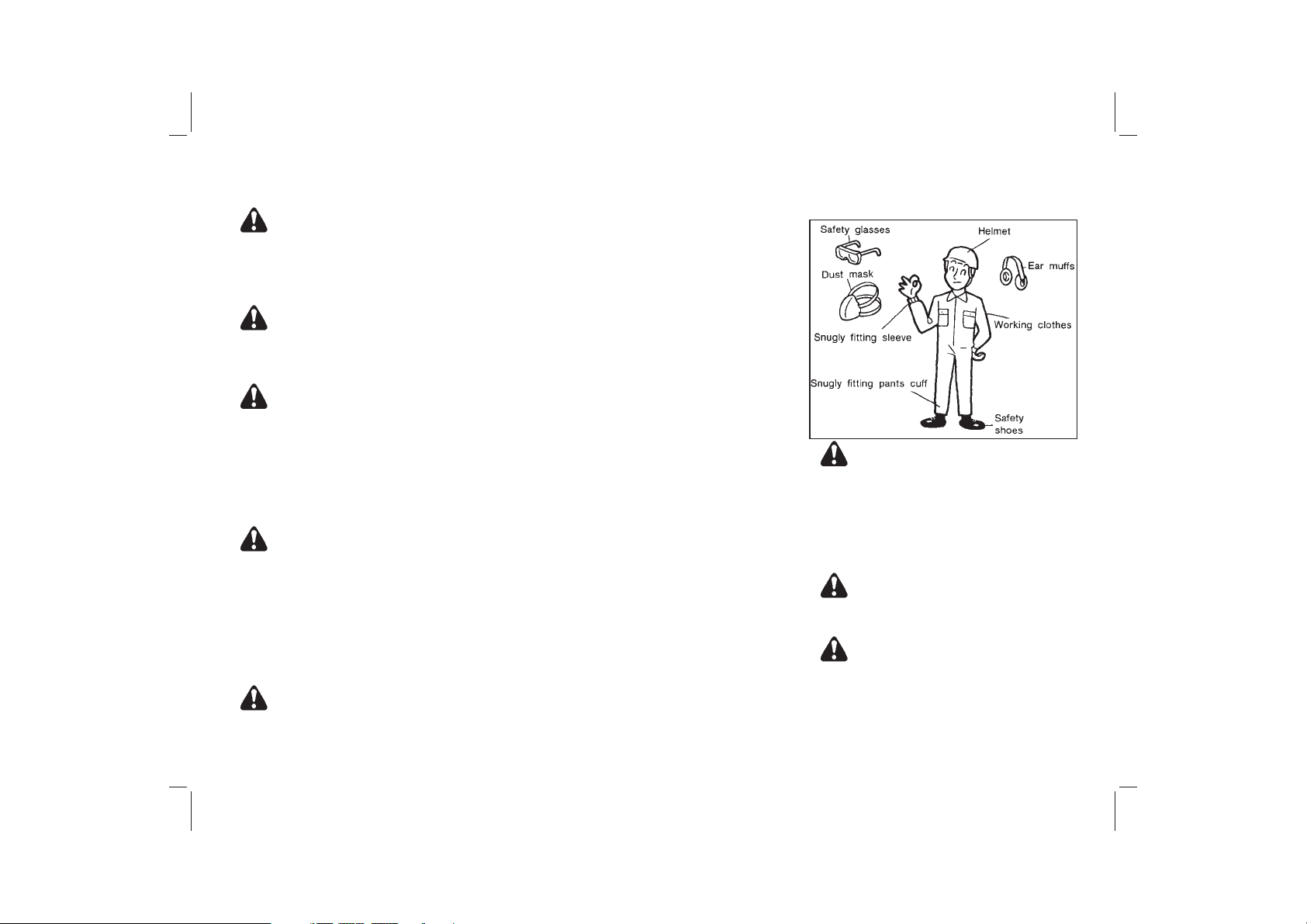

The working clothes worn by the

operator shall be such that sleeves

and cuffs fit snugly so as to prevent

them from getting caught on forklift

levers, etc., and safety glasses, ear

muffs, dust mask and safety shoes

should also be worn.

Do not remove overhead guard or

backrest unless specifically authorized.

Make sure that forward-reverse lever is set in neutral and hand brake

is applied before starting the engine. Do not start or operate the lift

truck if you are not in designated

3

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 4 Printed on: April 8, 2005

operator’s position.

Before starting the engine, make

sure that the seat belt is secure.

D01/D02 models do not have creeping phenomena.

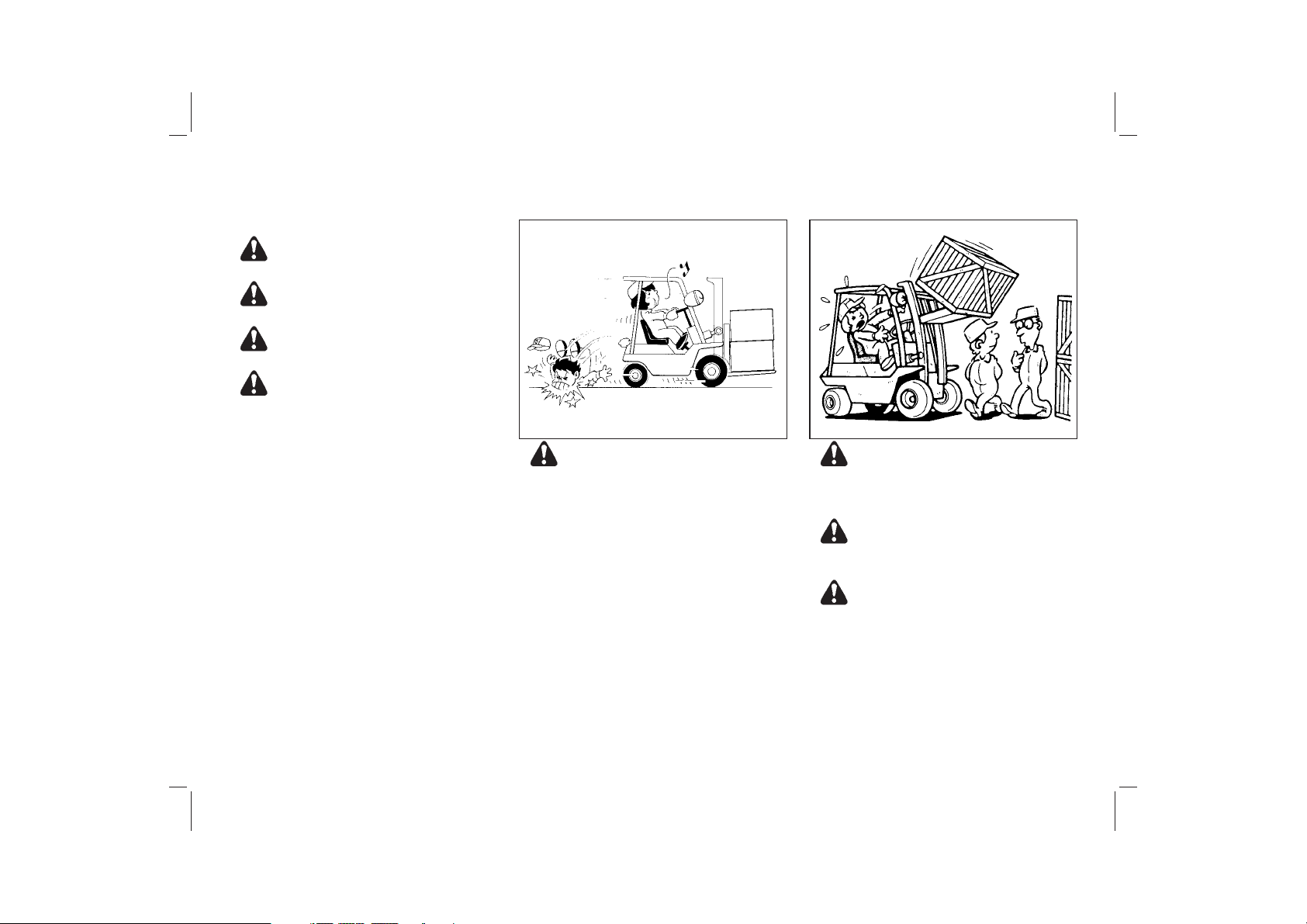

Do not allow anyone on any part of

the lift truck while moving or lifting.

The truck will not move if the select

lever is in the F (forward) or R

(reverse) position unless you depress the accelerator pedal. When

depressing the accelerator pedal,

be sure to visually confirm the position of the forward-reverse lever.

When starting on slopes, be sure to

apply the parking brake to hold the

truck and then start, even if the

slopes are gentle.

Avoid rapid acceleration (especially during high loading).

Do not allow anyone to stand or

ride on the forks, pallet, etc.

MOM1631 MOM1632

Do not allow anyone to stand or

walk under the elevated portion of

the forks whether it is empty or

loaded.

Keep hands, feet and other parts of

your body inside the operator’s

compartment all the times.

Never put any part of your body

into the mast structure or between

the mast and the truck.

4

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 5 Printed on: April 8, 2005

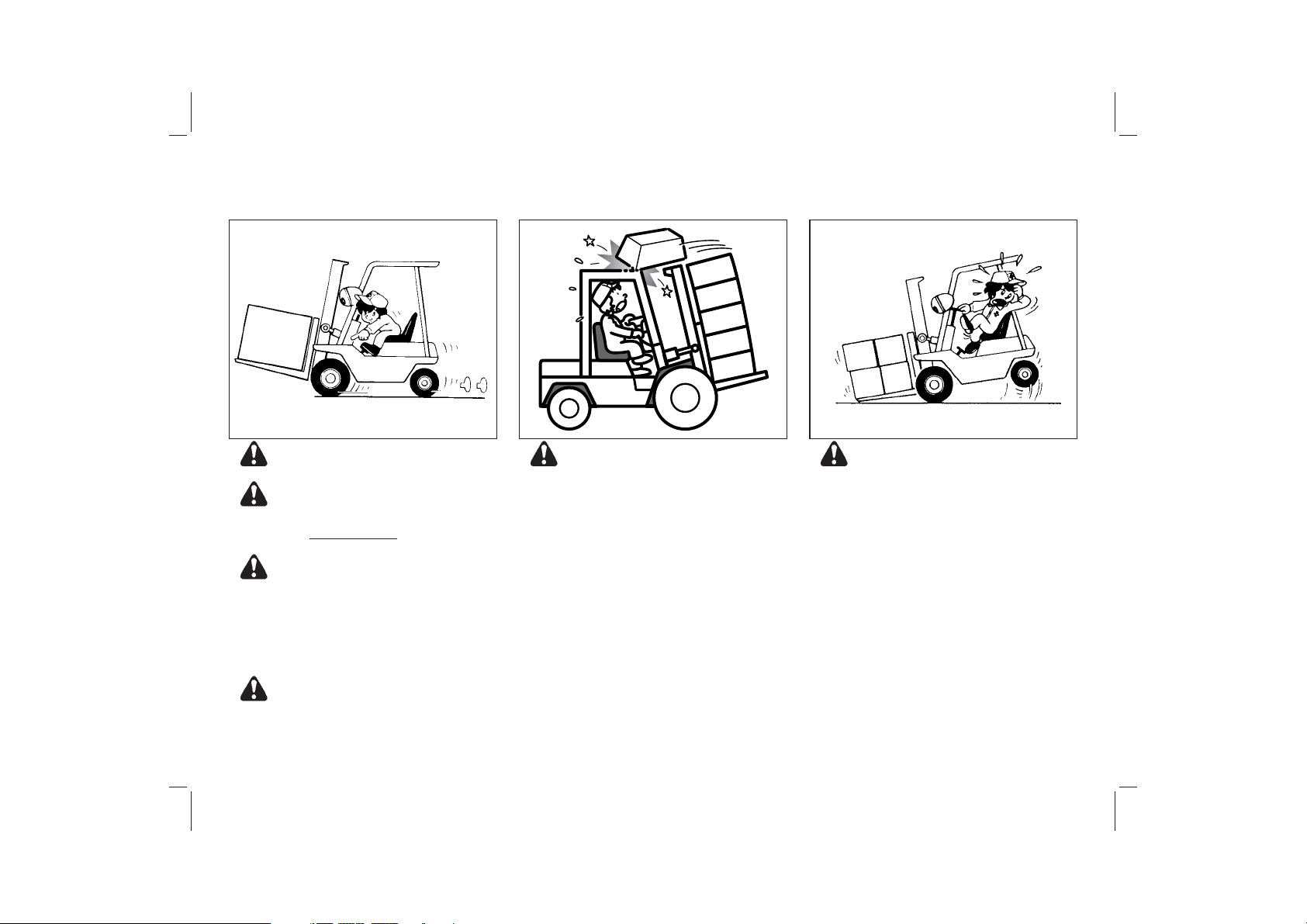

MOM1633 MOM1677 MOM1634

Space forks as far apart as the load

will permit.

Always carry loads low with the

mast tilted to the backmost position, never forward. Do not elevate

loads except during stacking.

Maintain a careful lookout for

people and obstructions, and

watch the path of travel. Watch

clearances, especially overhead

and tail swing. When visibility is

obstructed, use extreme caution.

Yield right of way to pedestrians.

If the load obstructs the front view,

drive the lift truck in reverse.

Do not place load higher than the

backrest of the lift truck. A load

placed higher than the backrest

may drop towards the operator and

is very dangerous. If such a load

must be handled, securely fasten

the load using suitable ropes or

holddown bands.

5

Do not overload lift truck. Check

the load chart for load weight and

load center information. Always

pick up loads as close to weight

center as possible to avoid offcenter loading.

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 6 Printed on: April 8, 2005

the tires so as prevent the forklift

from moving while it is parked in

the elevator.

Do not carry out work in the elevator.

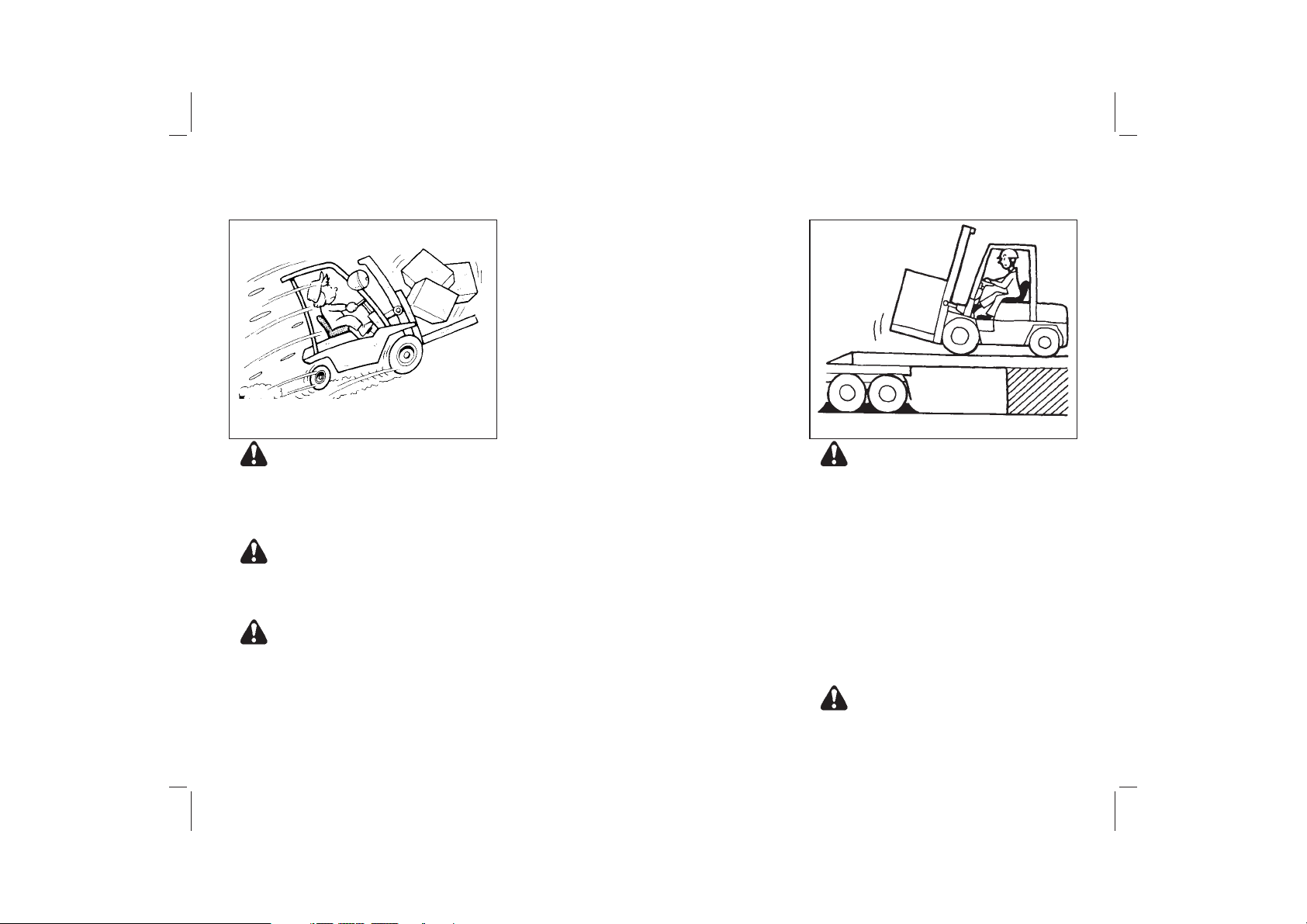

MOM1635 MOM0019

Avoid sudden starts, stops or

turns. Slow down for turns and on

uneven or slippery surfaces that

could cause lift truck to overturn or

slide.

Use special care when traveling

without load as risk of lateral overturn may be greater than when traveling with load.

When moving the forklift in elevators, check to make sure the elevator is capable of withstanding the

truck weight or the truck weight

plus load weight.

Be sure to apply stoppers under

Precautions relating to driving onto

freight cars and trailers

Check freight cars and trailers to

make sure they will not move.

The ramp for driving the forklift

onto a freight car or trailer shall

have sufficient strength to withstand the weight of forklift and its

load, and the forces exerted by the

bouncing of the truck.

The ramp shall be anchored so that

it is prevented from shifting.

Use the utmost care when driving

on and off a freight car or trailer.

Before entering trucks or trailers,

be certain the brakes on the truck

6

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 7 Printed on: April 8, 2005

or trailer are applied and the wheel

chocks are in place or trailer is

locked to the loading dock.

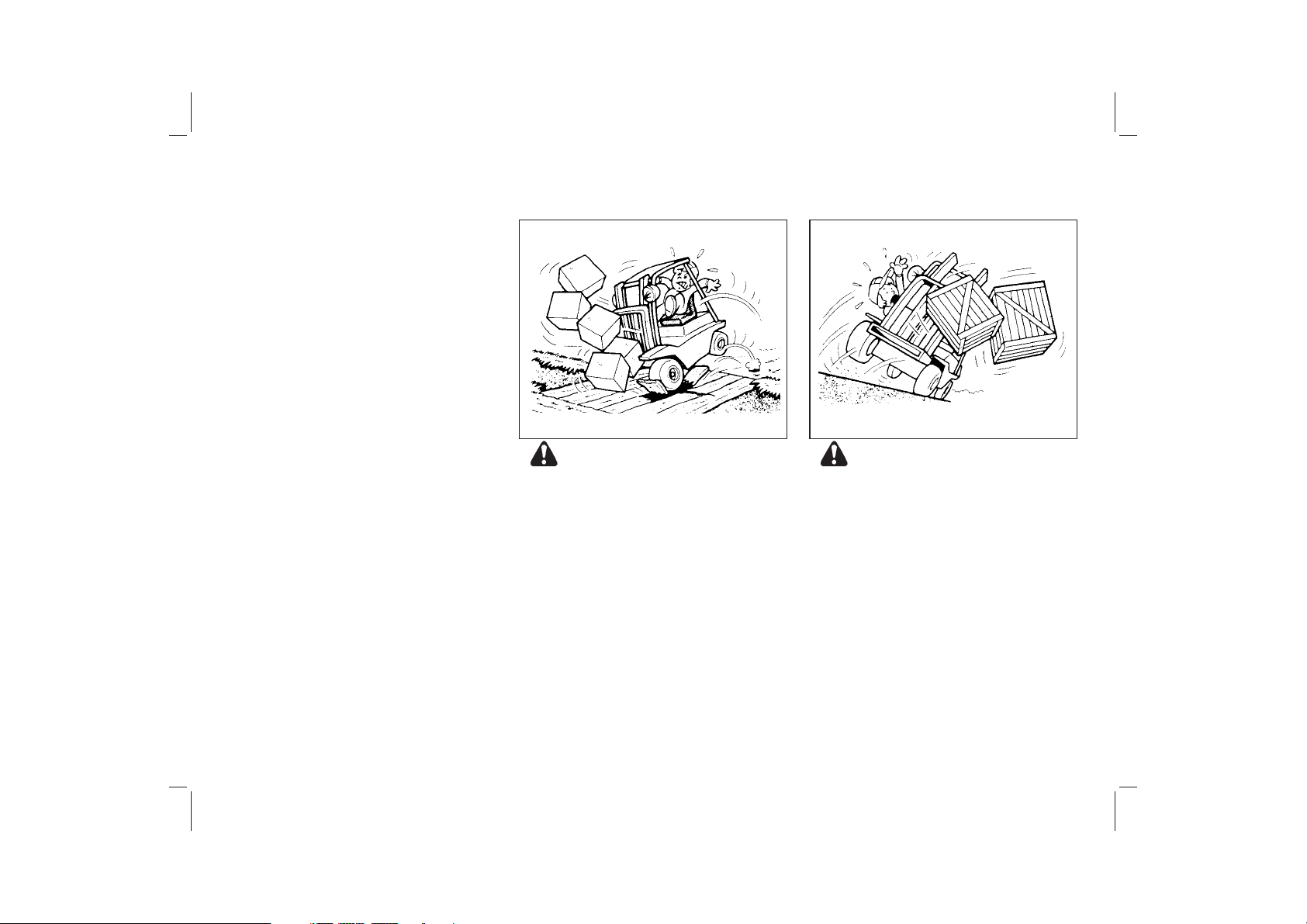

MOM1636 MOM1637

Before driving over a dockboard or

bridge plate, be certain that it is

properly secured. Drive carefully

and slowly across the dockboard

or bridge.

Never exceed its rated capacity.

7

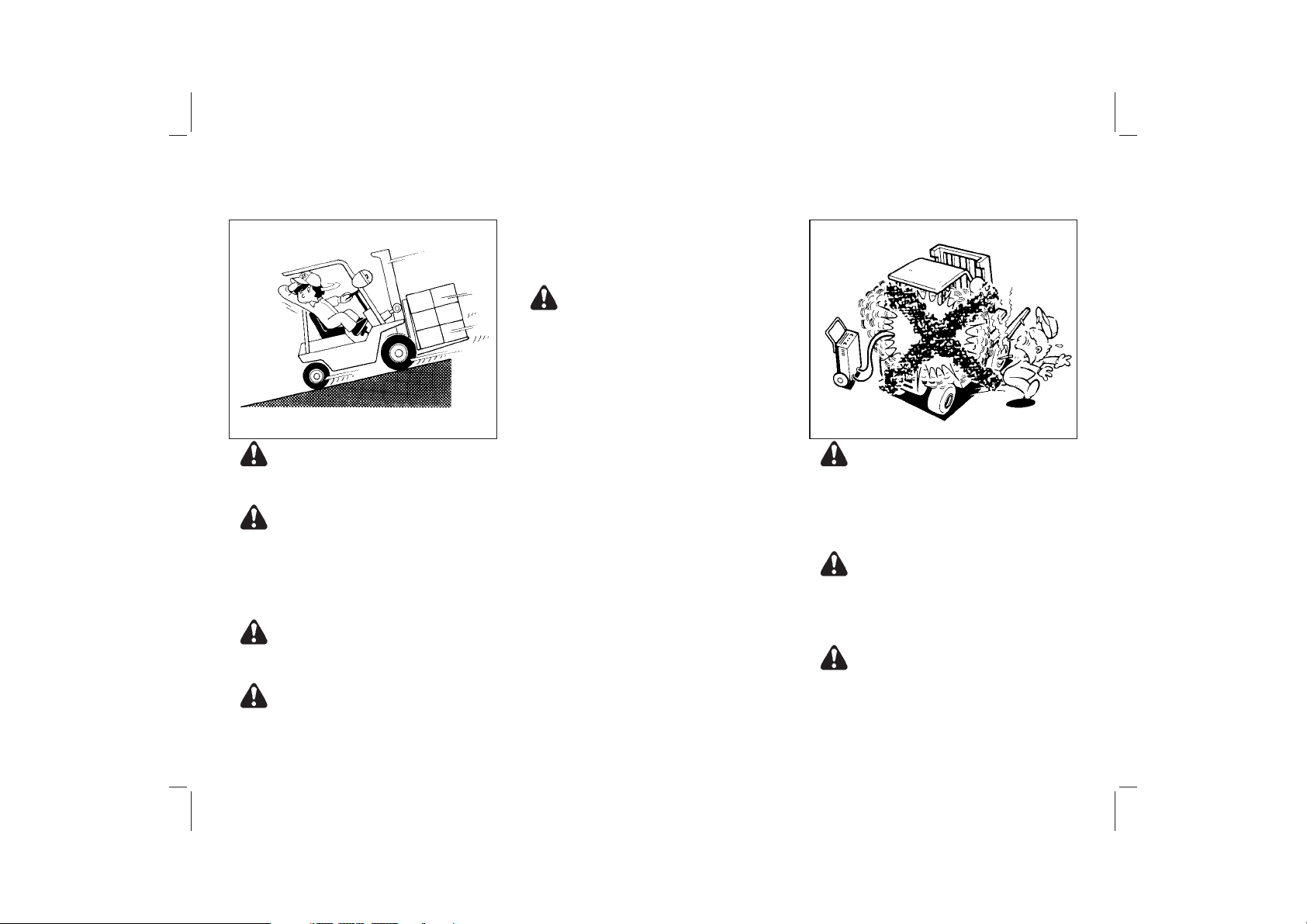

Use special care when operating on

slopes. Travel slowly and do not

angle across or turn.

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 8 Printed on: April 8, 2005

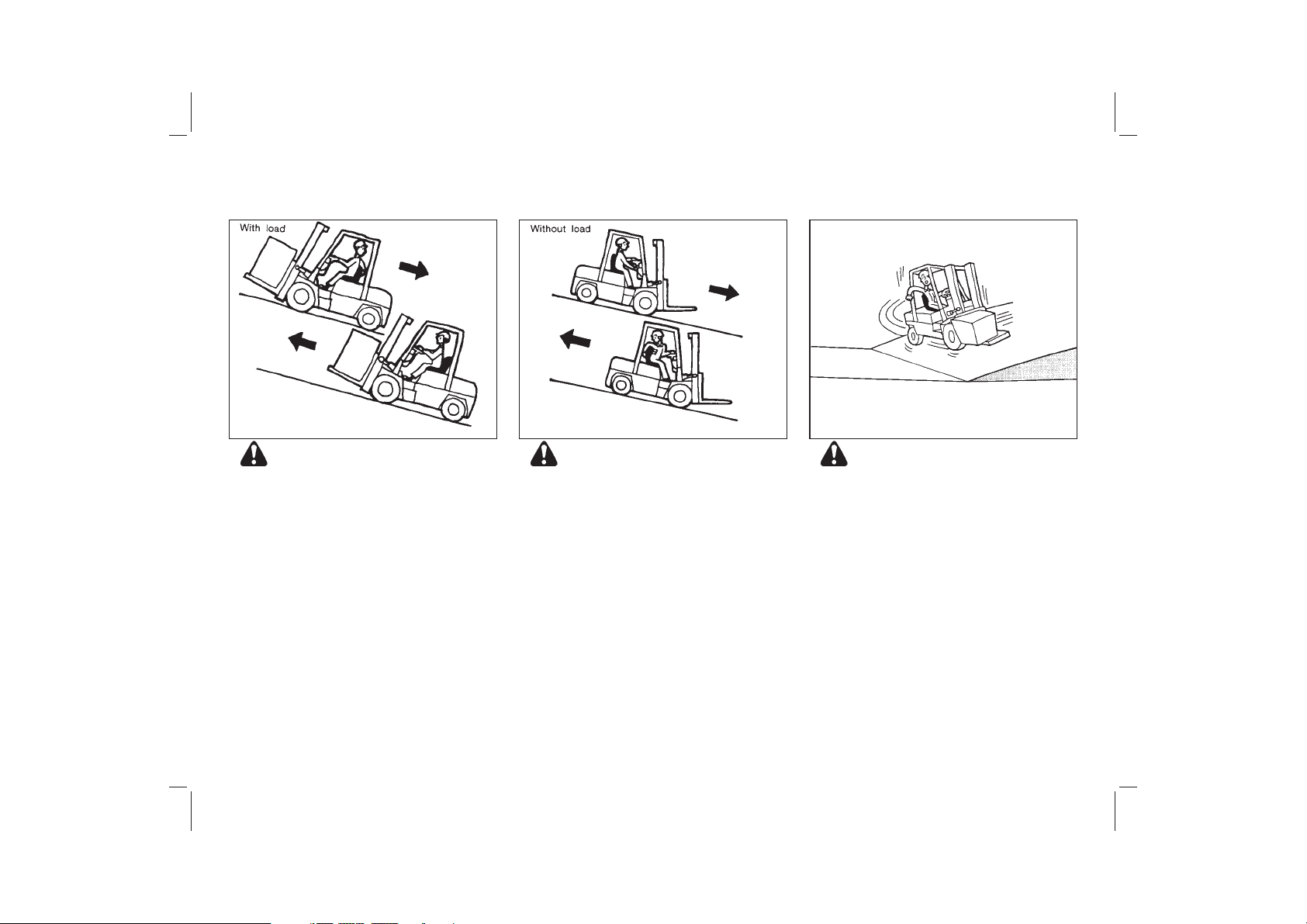

MOM0016 MOM0017 MOM0018

Use care when traveling on gradients.

When traveling on gradients with a

load, always drive forward on upward slopes and in reverse on

downward slopes.

Drive slowly on slopes. Drive in the

reverse direction on upward slopes

when without a load, and drive forward on downward slopes.

Use the brake pedal and engine

brake together when driving downhill so as to maximize the effectiveness of the engine brake.

8

Do not traverse and turn around on

slopes.

Since driving on slopes causes the

center of gravity to shift towards

the lowest point, the forklift is likely

to lose its balance.

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 9 Printed on: April 8, 2005

ered, forward-reverse lever is in

neutral, hand brake is applied and

key switch is turned off. Avoid

parking lift truck on a slope.

Fuel is highly flammable.

It must be handled with the utmost

care, in accordance with the safe

handling requirements of fuels and

the applicable safety provisions of

laws and regulations of your country.

MOM1638 MOM1639

When ascending or descending

slopes, drive the lift truck with the

load facing upgrade.

Do not handle unstable or loosely

stacked loads. When handling

long, high or wide loads, use special care to ensure stability and

carefully watch the surrounding

conditions.

When approaching cross aisles,

slow down, and sound horn if visibility is obstructed.

Before leaving the lift truck, be sure

that forks or attachments are low-

When filling the tank with fuel,

make sure the truck is properly

parked. Turn off the key switch and

remove it.

When fuel is spilled, wipe the area

clean with a cloth. The cloth shall

be disposed of in accordance with

the requirements of safe handling

of fuels, environmental requirements, and the applicable provisions of the laws and regulations of

your country.

When filling the tank with fuel or

recharging the battery, stop the engine and place the lift truck only in

designated area with good ventilation. Keep away from arcs, sparks,

flames or lit cigarettes.

Do not breathe exhaust gases: they

contain colorless and odorless carbon monoxide. Carbon monoxide

is a dangerous gas and can cause

unconsciousness or death.

Do not run the engine in closed

spaces or poorly ventilated rooms

such as a garage or refrigerator,

etc.

9

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 10 Printed on: April 8, 2005

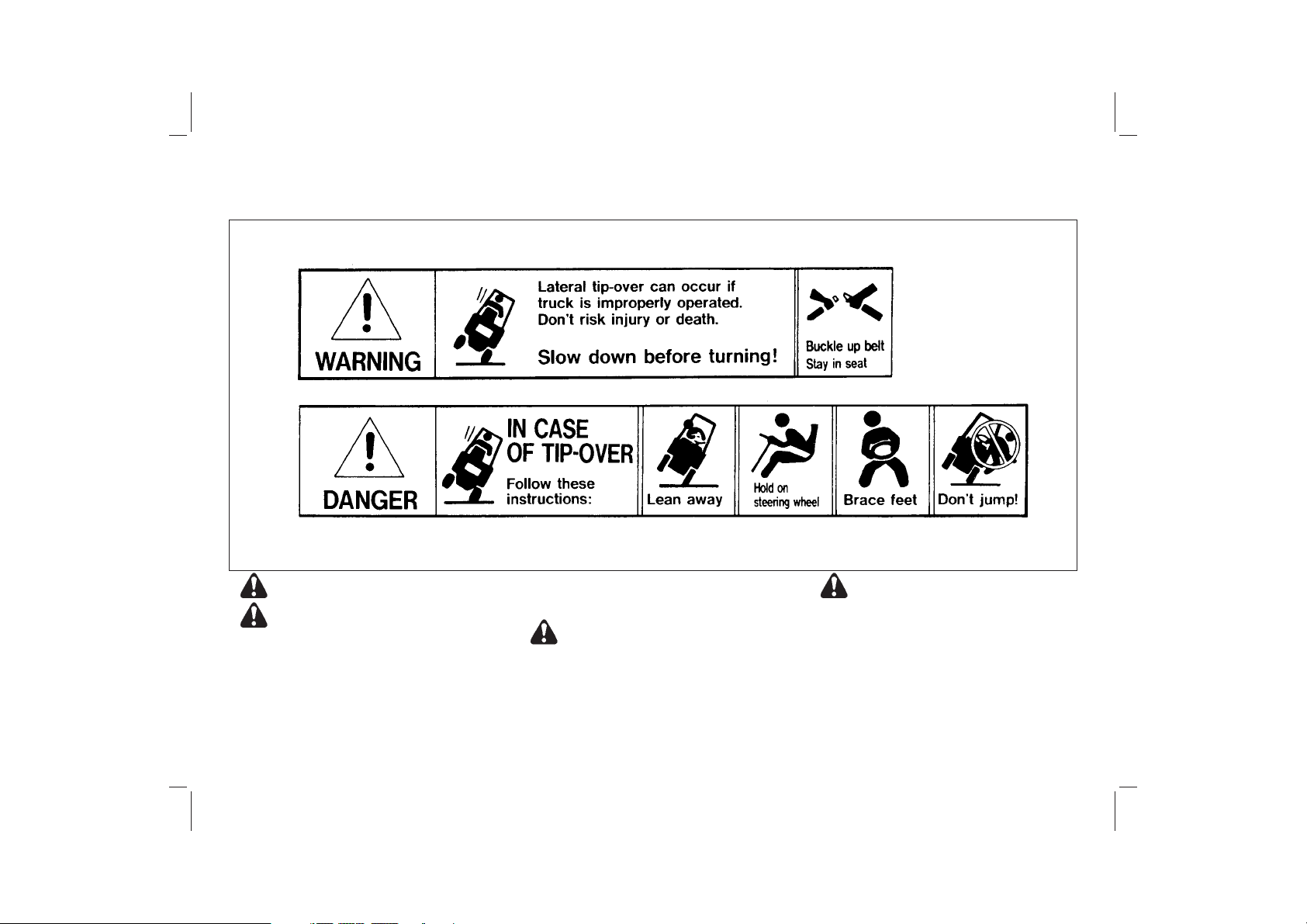

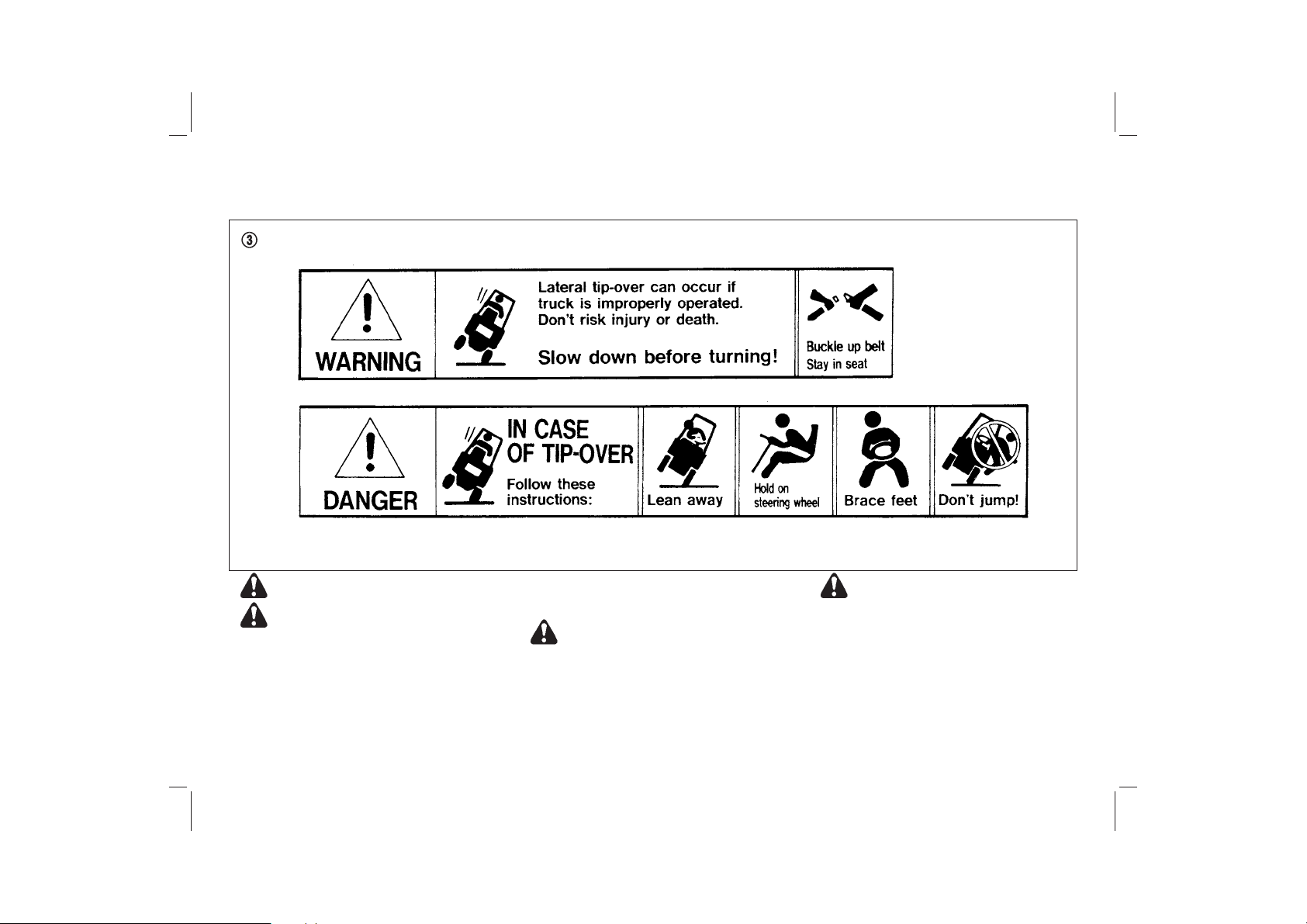

IN CASE OF TIP-OVER

Be extremely careful to prevent the

lift truck from tipping over during

operation. Slow down the lift truck

sufficiently when turning a corner

or tight curve.

The following precautions should

be closely observed to ensure safe

operation of the lift truck as well as

to protect personnel against injury.

If the forklift is equipped with a seat

belt, always make sure that your

seat belt is securely fastened and

the top panel latch is in the locked

position.

10

MOM0137C

If the lift truck begins to tip, DO

NOT ATTEMPT TO JUMP CLEAR.

The lift truck will fall faster than you

can jump.

Brace your feet and hold yourself

inside the operator compartment

by holding onto the steering wheel

with both hands.

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 11 Printed on: April 8, 2005

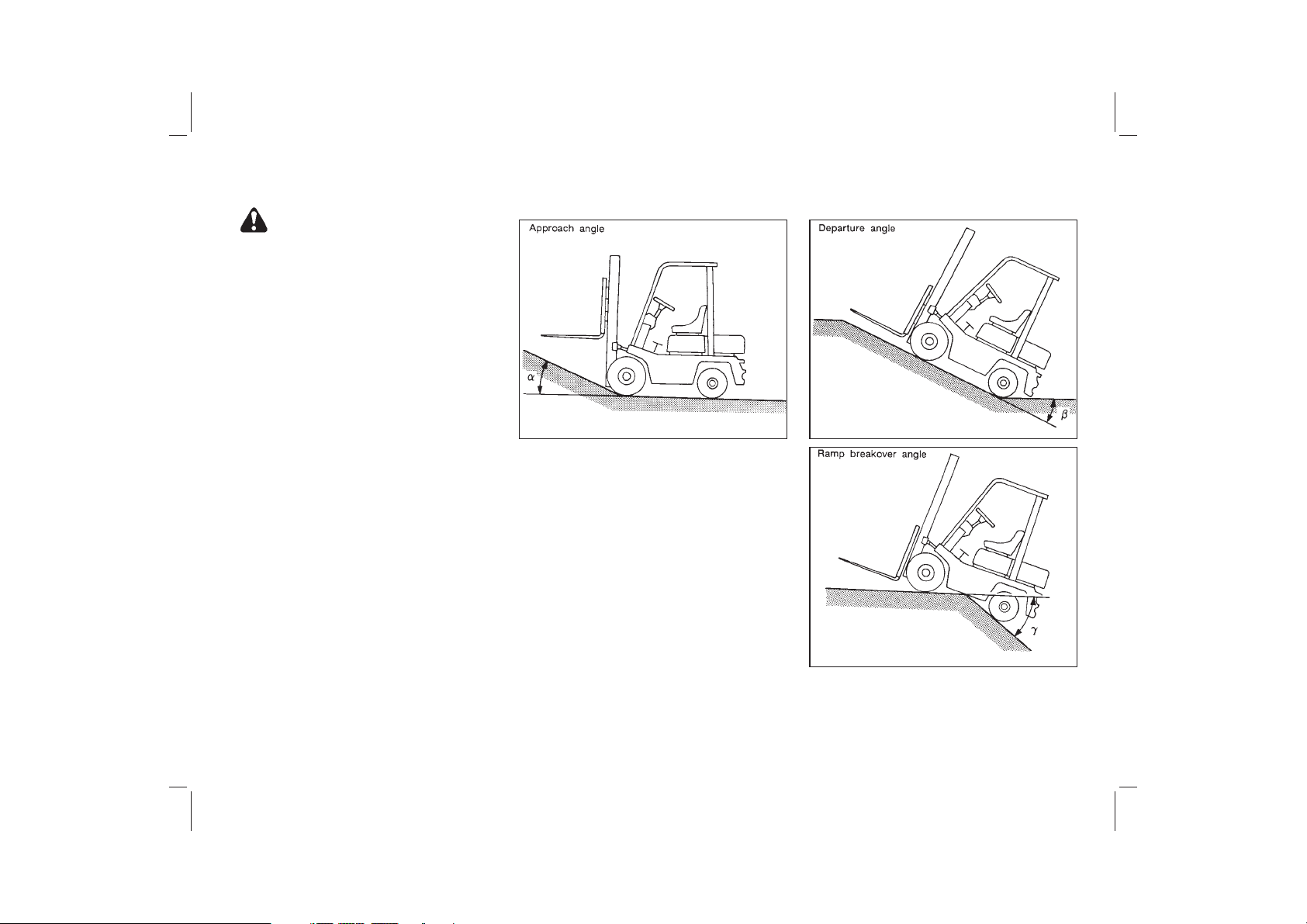

Tilt the mast back to the maximum

without load.

Check the approach angle, departure angle, and ramp breakover

angle to make sure the underside

of the forklift will not contact the

load carrying platform or the

ground.

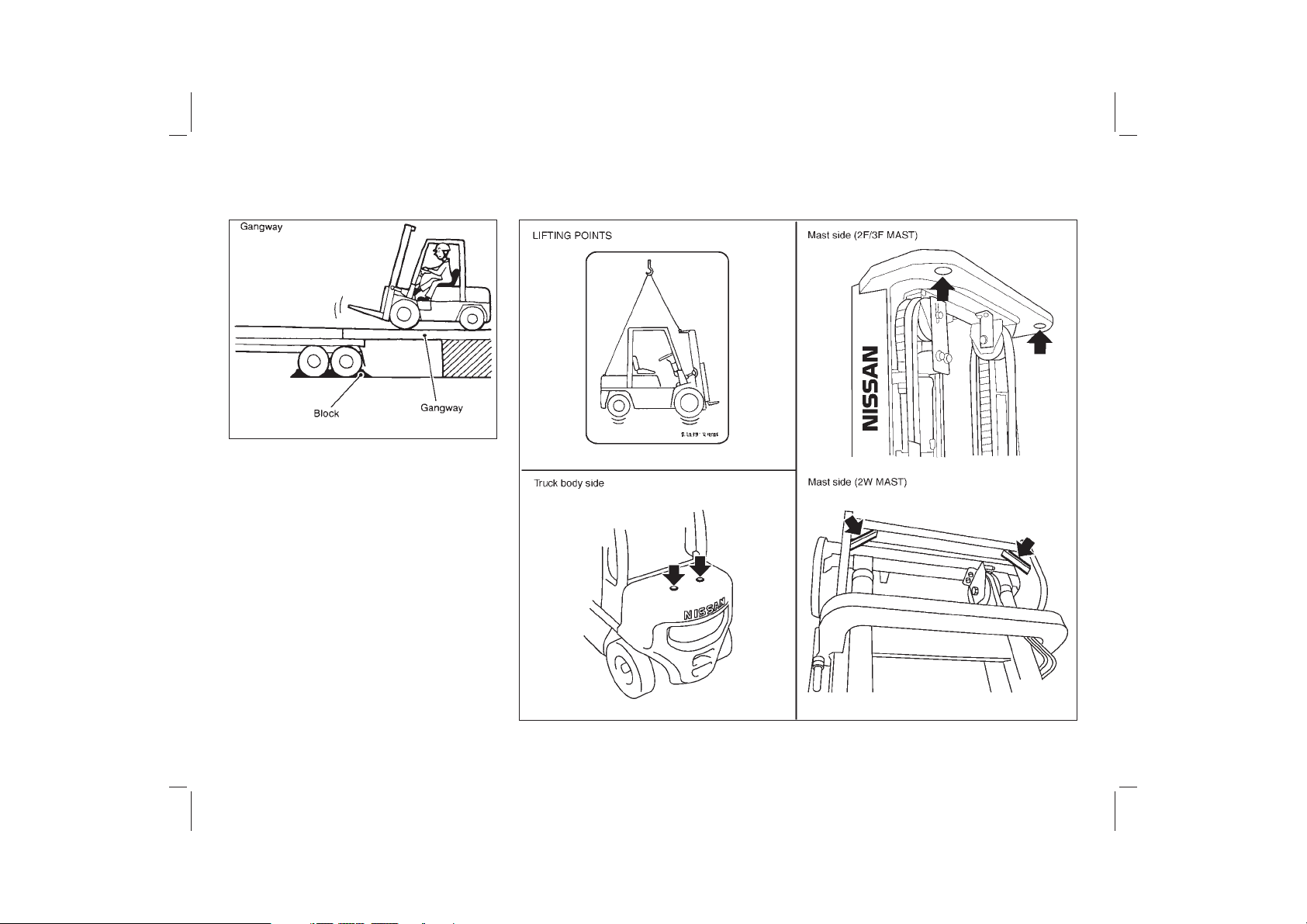

When using a gangway, make sure

the planks are capable of supporting the truck weight. Drive forklift

on and off the carrier slowly.

When winching the forklift onto a

load carrying platform, be sure to

attach the cable to the traction pin.

Do not ride on the forklift while it is

being winched.

Be sure to use lashing points and

firmly secure the truck to the load

carrying platform.

When hoisting the forklift, be sure

to use the lifting points.

Turn off the key switch and remove

it.

APPROACH ANGLE, DEPARTURE

ANGLE AND GANGWAY

MOM0020 MOM0021

11

MOM0022

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 12 Printed on: April 8, 2005

MOM0023

12

MOM1641

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 13 Printed on: April 8, 2005

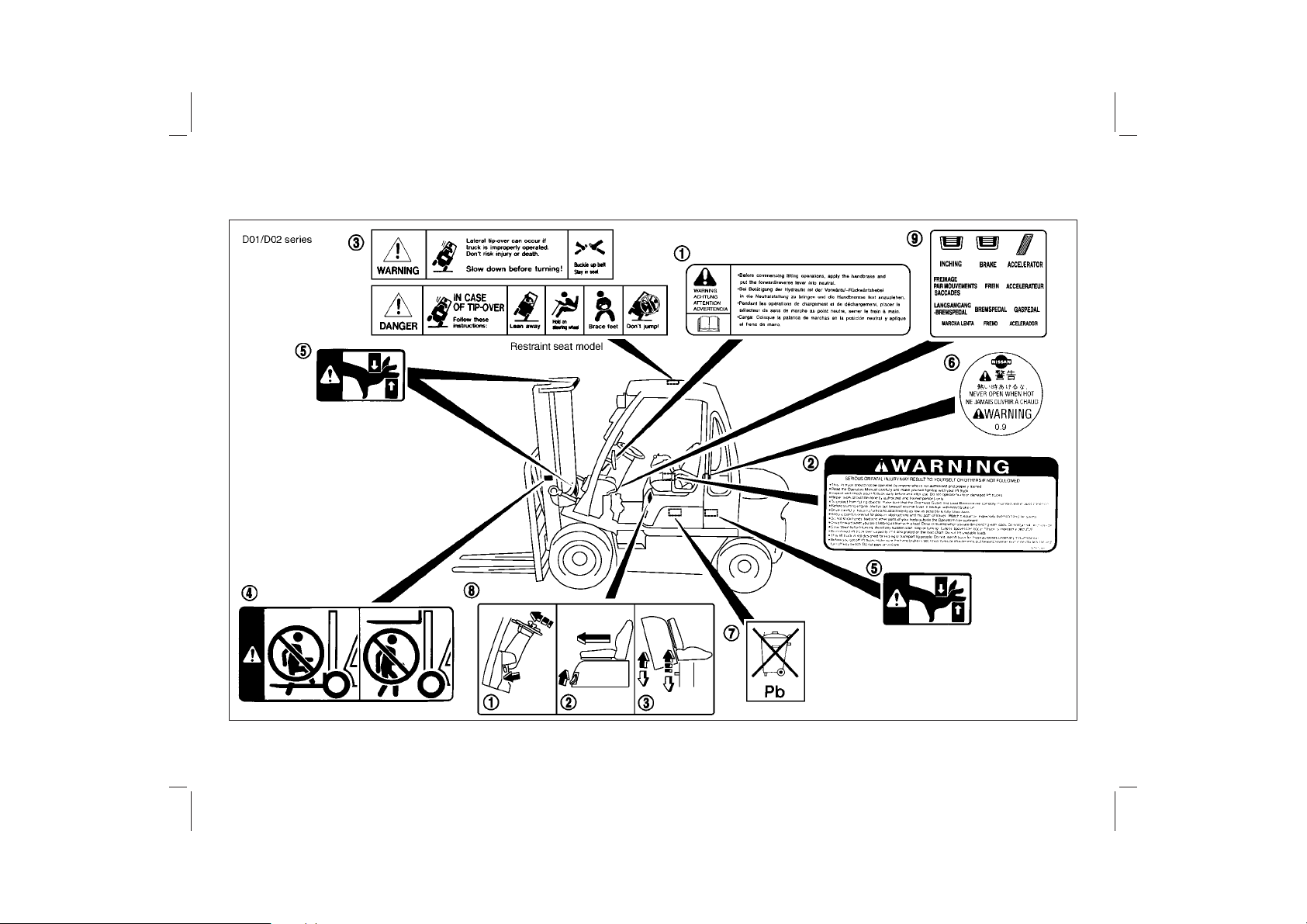

POSITIONING OF WARNING,

CAUTION AND INSTRUCTION

LABELS

Carry out the daily checks as per

“Daily care” on page 46, and the

applicable provisions of laws and

regulations of your country.

When replacing NISSAN FORKLIFT

truck parts (including lubricants),

be sure to use NISSAN FORKLIFT

genuine parts or the equivalents

guaranteed by Nissan Motor Co.,

Ltd.

Any irregularities arising from the

use of parts other than those specified above shall not be covered

under warranty.

MOM0062A

Used parts and materials such as

engine oil, long-life coolant, paint,

rag, battery fluid, and batteries

shall be disposed of as per the

applicable provisions of the laws

and regulations of your country.

Also consult with your nearest

NISSAN FORKLIFT dealer.

WARNING AND CAUTION LABELS

WARNING:

When warning and caution labels are damaged so they cannot be read or have peeled

off, they should be immediately replaced

with new labels to ensure that they are

constantly maintained in a legible condition. The warning and caution labels are

available at your nearest NISSAN FORKLIFT dealer.

+ The warning and caution labels are affixed

to the designated locations of the forklift as

shown in the figure below. Before operating

the truck, be sure to make note of the

details given in the labels so as to ensure

proper and safe operation.

13

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 14 Printed on: April 8, 2005

FIGURE INDICATING THE

POSITIONING OF WARNING AND

CAUTION LABELS

14

MOM1598

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 15 Printed on: April 8, 2005

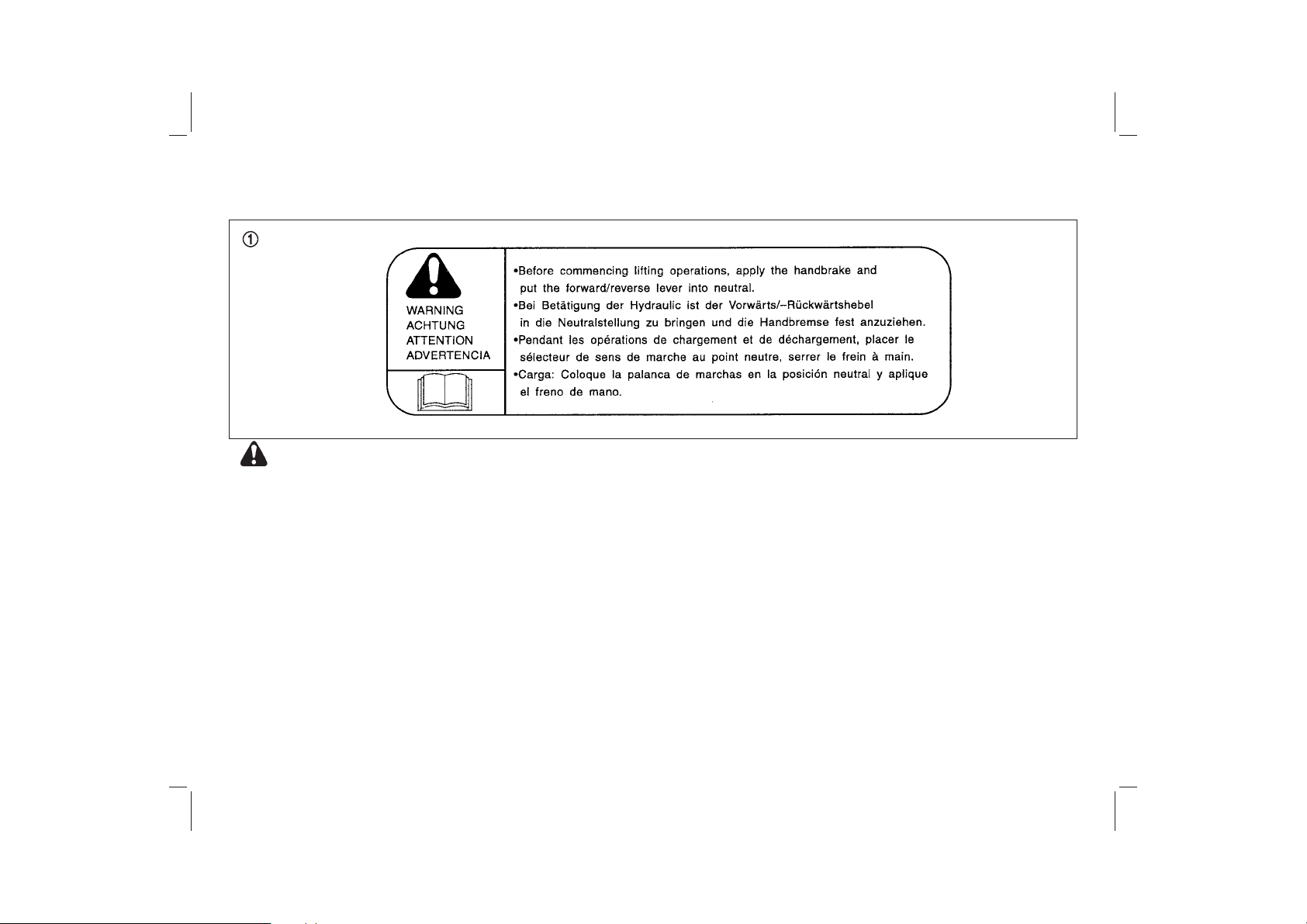

MOM1562A

WARNING:

+ This truck has no creeping phenomena.

+ The truck will not move if the forward-

reverse lever is in the F or R position

unless you depress the accelerator

pedal. When depressing the accelerator

pedal, be sure to visually confirm the

position of the forward-reverse lever.

+ When starting on slopes, be sure to

apply the parking brake to hold the truck

and then start, even if the slopes are

gentle.

+ Avoid rapid acceleration (especially dur-

ing high loading).

15

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 16 Printed on: April 8, 2005

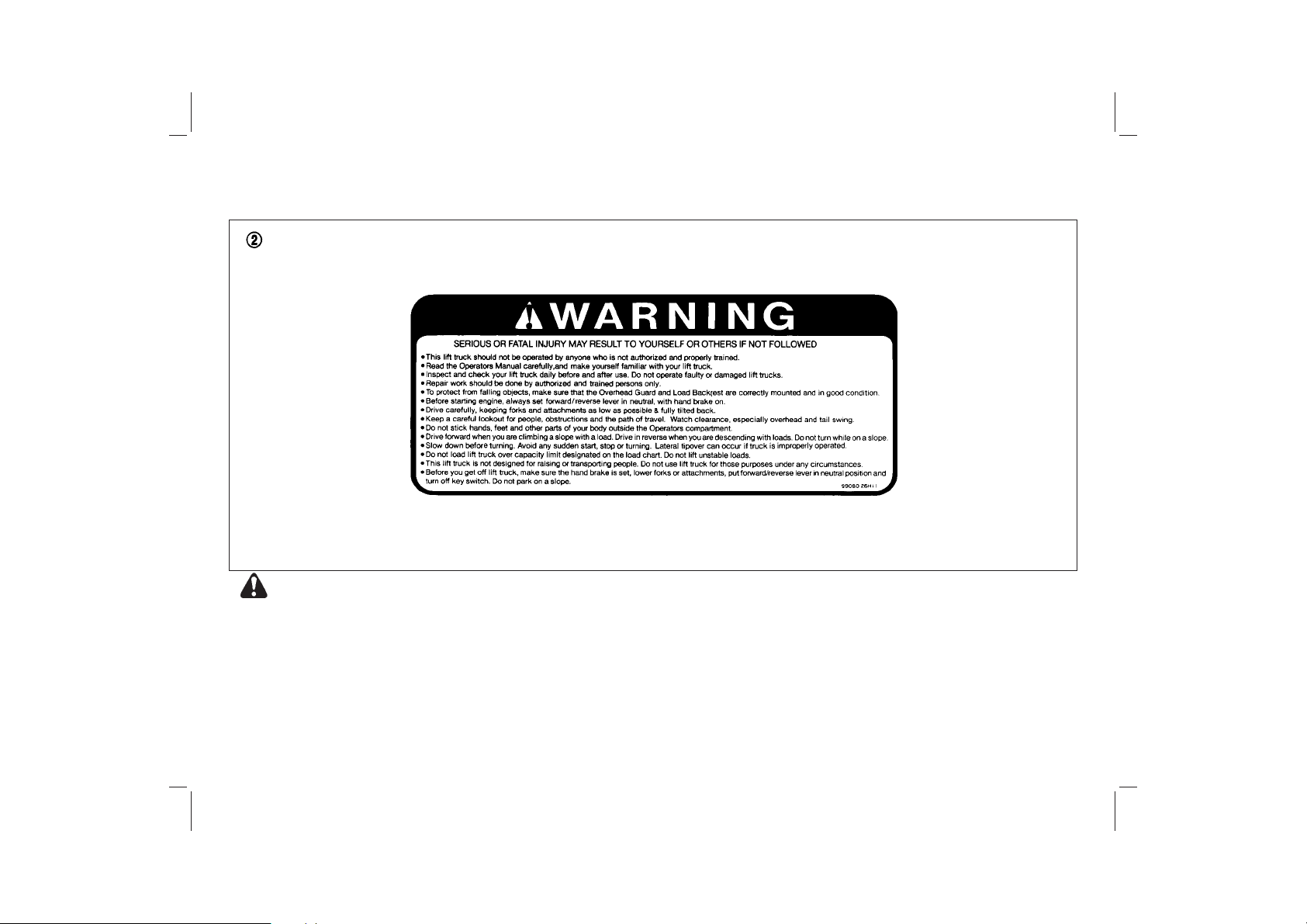

WARNING:

Operation precautions

+ This label contains instructions on how

to operate the forklift safely and avoid

accidents. Therefore, be sure to take

careful note of the instructions before

operating the forklift.

MOM1809

16

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 17 Printed on: April 8, 2005

IN CASE OF TIP-OVER

Be extremely careful to prevent the

lift truck from tipping over during

operation. Slow down the lift truck

sufficiently when turning a corner

or tight curve.

The following precautions should

be closely observed to ensure safe

operation of the lift truck as well as

to protect personnel against injury.

If the forklift is equipped with a seat

belt, always make sure that your

seat belt is securely fastened and

the top panel latch is in the locked

position.

17

MOM0137B

If the lift truck begins to tip, DO

NOT ATTEMPT TO JUMP CLEAR.

The lift truck will fall faster than you

can jump.

Brace your feet and hold yourself

inside the operator compartment

by holding onto the steering wheel

with both hands.

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 18 Printed on: April 8, 2005

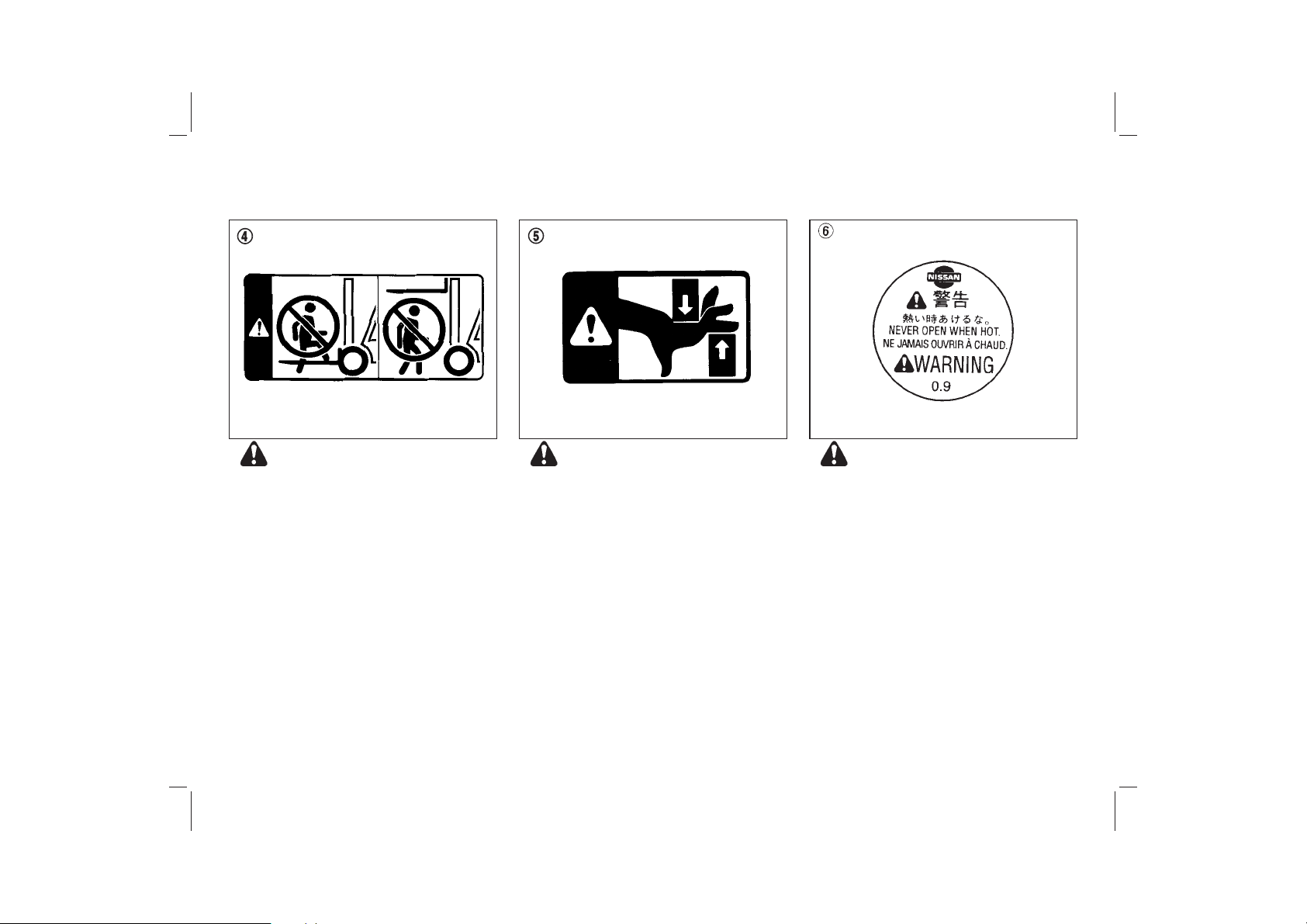

MOM0004A MOM0005C MOM0009

WARNING:

Do not stand on or below forks.

+ Riding on forks is strictly prohibited.

Furthermore, do not stand immediately

below the forks. Otherwise, serious accidents can occur if the forks should

move abruptly and the load placed on

the forks unexpectedly falls down. In the

worst cases, these accidents can be

fatal.

WARNING:

Be sure to keep your hands, feet, and body

away when operating the mast or closing

the top panel. Otherwise, parts of the body

are liable to become caught between the

moving and fixed sections of the masts or

top panel and injury may be incurred.

18

WARNING:

Handling of radiator cap

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 19 Printed on: April 8, 2005

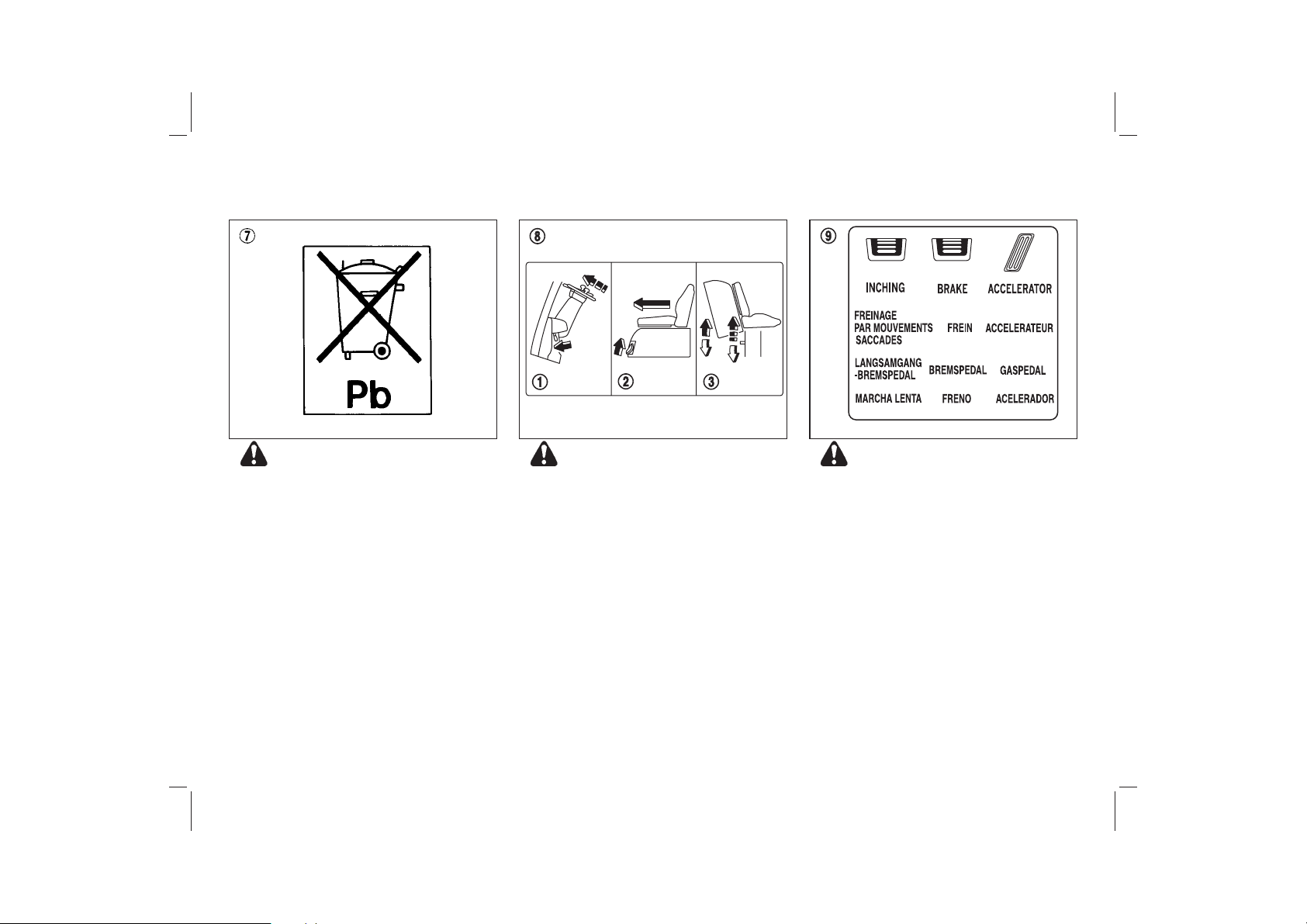

MOM0062B MOM1599 MOM1600

WARNING:

+ Diluted sulfuric acid and lead are used in

the battery.

+ Used battery fluid, and batteries shall be

disposed of as per the applicable provisions of the laws and regulations of your

country.

+ Also consult with your nearest NISSAN

FORKLIFT dealer.

WARNING:

+ As soon as the top panel is opened

while the engine is operating, the engine

will stop.

+ The engine cannot be started while the

top panel is open.

19

WARNING:

Pay attention to the position of the pedal.

+ The labels indicate the positions of ped-

als for the operation of forklift.

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 20 Printed on: April 8, 2005

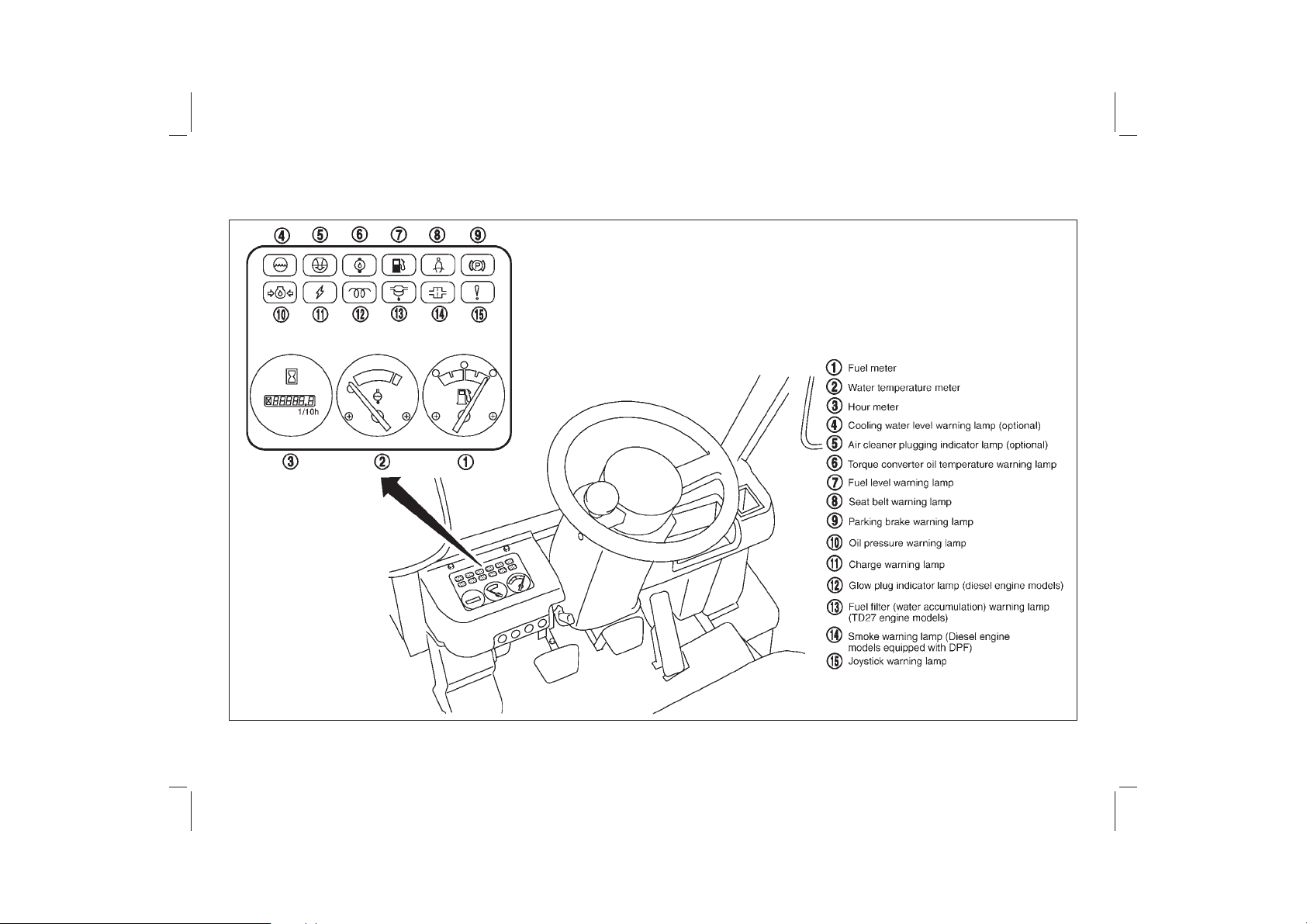

INSTRUMENTS AND CONTROLS

20

MOM1601C

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 21 Printed on: April 8, 2005

METERS, GAUGES, INDICATOR

AND WARNING LAMPS

Fuel meter

With the ignition switch ON, the fuel meter

indicates the approximate amount of fuel in the

tank. Always top up the fuel tank.

Water temperature meter

When the ignition switch is set at ON, the

water temperature meter operates and pointer

indicates coolant temperature. During ordinary

operation, the pointer will remain about the

center range of the gauge. If the pointer indicates “H” position and remains there for more

than a few minutes, stop the Lift Truck and

cool the engine at idling speed. After stopping

the engine, check the coolant level and fan belt

deflection.

Hour meter

The hour meter operates when the ignition

switch is in the ON position. The dial of the

hour meter advances one number when the

ignition switch remains in the ON position for

an hour. Consequently, the number of the hour

meter indicates total operating period of hour.

Cooling water level warning

lamp (Option)

This lamp comes on when the ignition switch is

turned to START. If the lamp comes on while

the forklift is in operation, it indicates that the

coolant in the radiator reservoir tank has

dropped below the MIN. level.

Add coolant to the MAX. level.

Air cleaner plugging indicator

lamp (Option)

This lamp comes on when the air cleaner is

clogged. If the lamp comes on while driving,

clean the air cleaner immediately.

Torque converter oil

temperature warning lamp

Under normal operating conditions, the warning lamp turns on when the key switch is

turned to the START position and turns off

when the engine starts. The lamp will turn on

during engine operation whenever the torque

converter oil temperature exceeds the normal

level.

NOTE:

Immediately stop the engine whenever the

warning lamp turns on during operation.

Check the oil level and replenish if required. If the lamp remains lit after oil

replenishment, contact your nearest

NISSAN FORKLIFT dealer to have the

torque converter inspected and serviced.

(Refer to “Automatic transmission oil

level” on Page 50 for the inspection and oil

replenishment procedure).

Fuel level warning lamp

If the remaining fuel drops below the specified

level when the key switch is turned ON, the

fuel warning lamp will come on.

When the fuel warning light illuminates,

add fuel up to the specified level as soon as

possible.

Emergency seat belt warning

lamp

The seat belt warning lamp comes on when

the seat belt is not fastened with the key switch

turned ON.

Fasten the seat belt.

Parking brake warning lamp

The parking brake warning lamp comes on

when the parking brake is applied with the key

switch turned ON.

+ Drive the vehicle with the parking brake

released.

21

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 22 Printed on: April 8, 2005

+ Make sure that the parking brake is

released during operation. Failure to do

this may cause premature wear of braking parts, overheat the brake system

and result in poor braking performance.

Oil pressure warning lamp

This lamp glows red when the ignition switch

turns ON and oil pressure is not built effectively in the engine lubricating system. If the

lamp glows under ordinary operating conditions, stop the engine immediately and check

the engine lubrication system.

Charge warning lamp

With the ignition switch ON, the warning lamp

glows red when the alternator is not supplying

current to the electrical system. After the engine starts, the lamp should go out, indicating

that the alternator is operating properly. If the

lamp glows or flickers occasionally during normal operating, the alternator and electrical

system should be checked.

Glow plug indicator lamp

(Diesel engine)

This lamp goes on when the ignition switch is

ON, and goes out when the glow plugs have

been preheated.

If the lamp remains lit after the glow plugs

are preheated, this indicates an abnormality in the glow system.

Have the system checked at your nearest

NISSAN FORKLIFT dealer or other competent service shop.

Fuel filter (water

accumulation) warning lamp

(Diesel engine)

Under normal operating conditions, the warning lamp turns on when the key switch is

moved to the START position and turns off

when the engine starts.

The lamp will turn on during engine operation

whenever the accumulated water in the fuel

filter exceeds the specified level.

When the lamp turns on during operation,

drain the water from the fuel filter as soon

as possible.

(Refer to the fuel filter draining procedure

on Page 57.)

Continued operation with the warning lamp

on can result in fuel pump seizure.

Joystick warning lamp

With the key switch turned ON, the joystick

warning lamp comes on when the electrically

controlled joystick system is malfunctioning.

WARNING:

If the warning lamp comes on, suspend

cargo handling operations and have thesystem checked and repaired by the nearest NISSAN FORKLIFT dealer.

22

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 23 Printed on: April 8, 2005

SWITCHES

Key (ignition) switch

Horn button

Lighting switch & tirn signal switch

Engine idling control knob

Backup operation lamp (OPT)

23

MOM1828

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 24 Printed on: April 8, 2005

the OFF position once, then turn it to the

START position.

Lighting switch &

turn signal switch

Horn button

ON

OFF

START

Pushing the button in the center of the steering

wheel will sound the horn, regardless of key

position.

MOM1603

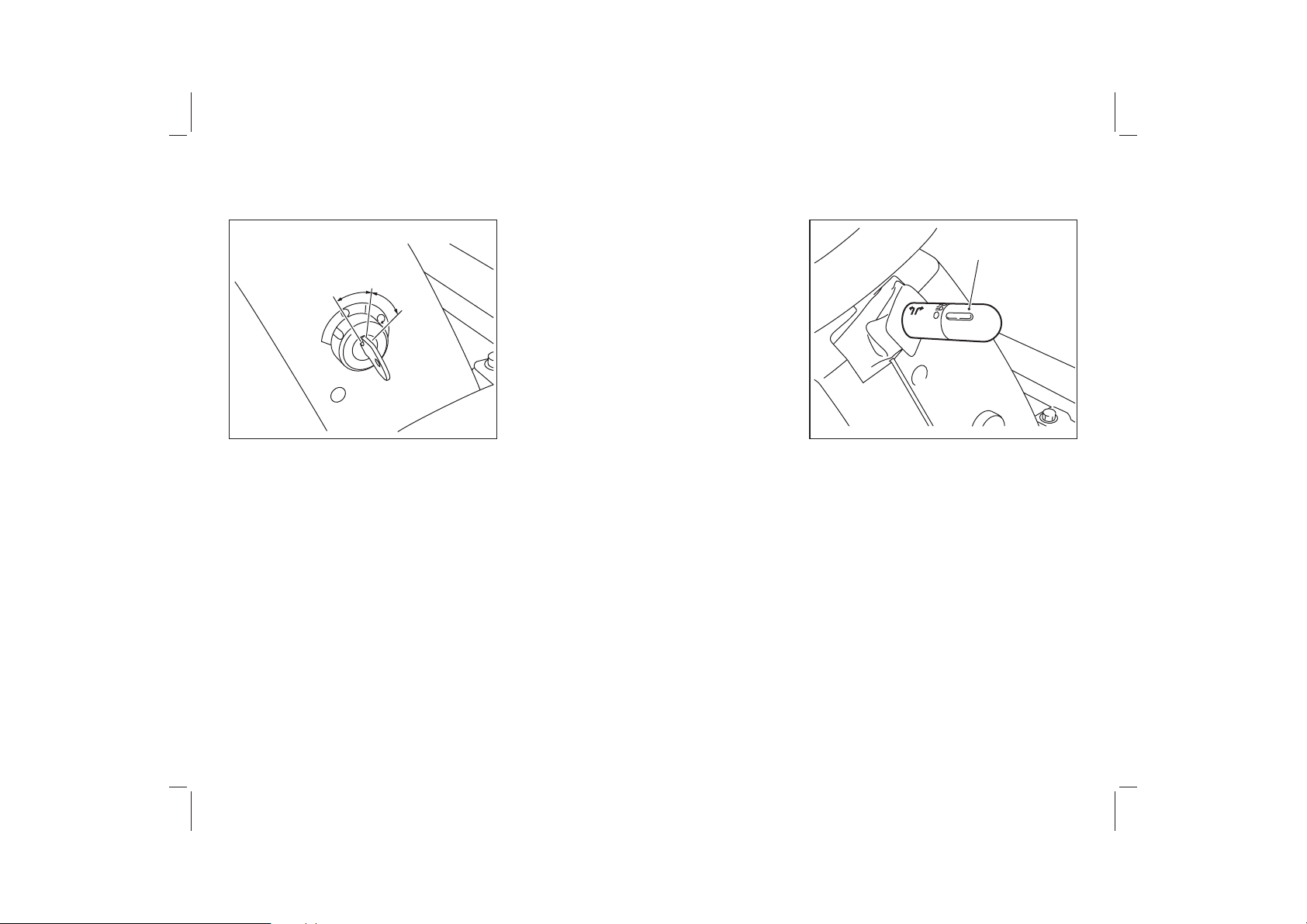

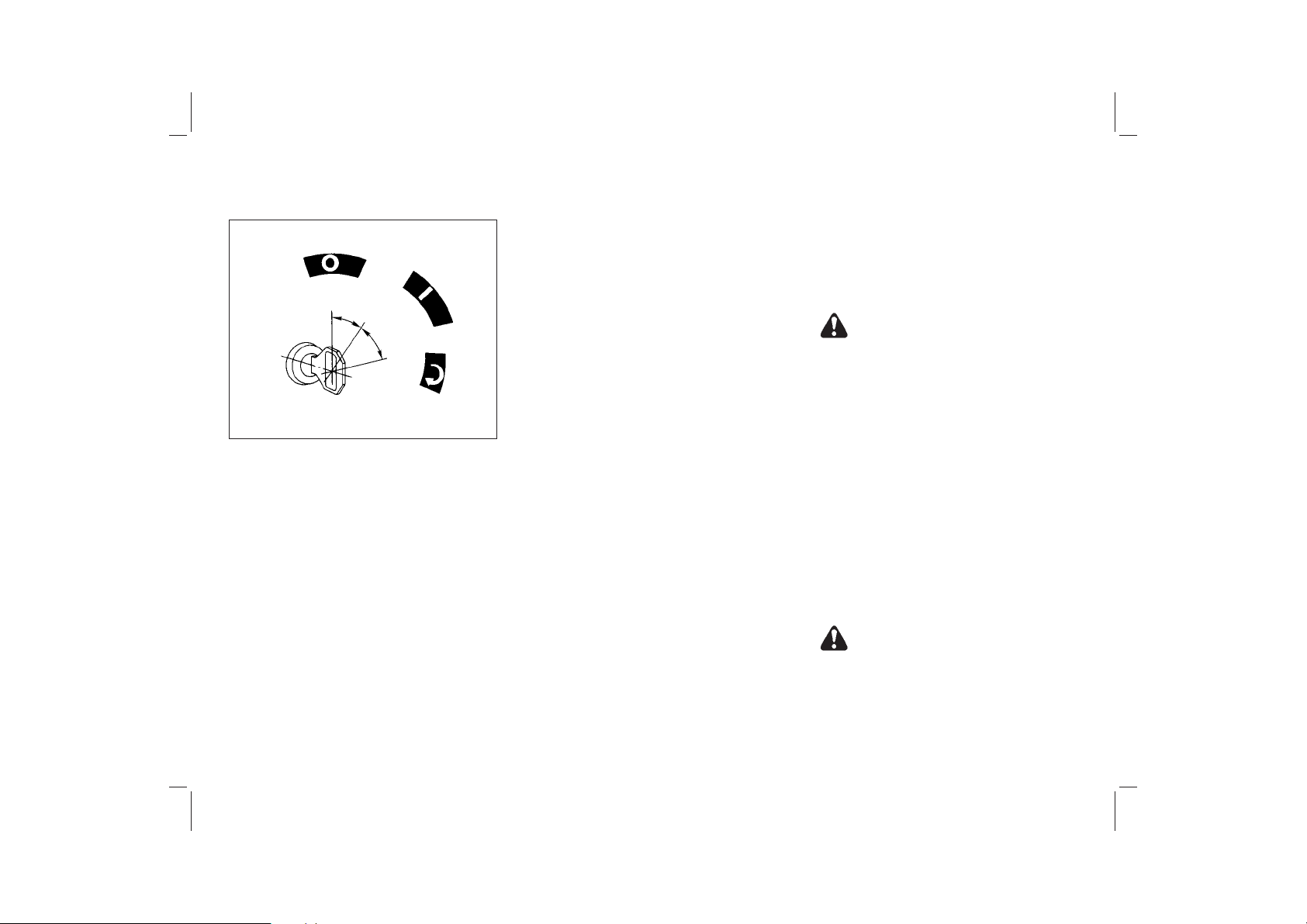

Key switch

The key switch controls the engine ignition

system and most of electrical equipments and

has three positions. The key can be inserted or

withdrawn only when the key is in the OFF

position.

To turn on the ignition system as well as other

electrical circuits, turn the key to ON position.

The start position allows to start engine. After

the engine has started, by releasing the key, it

will automatically spring back to the ON position.

This key switch incorporates an anti-restart

function. When restarting, return the key to

MOM1604

Lighting switch

The switch controls the headlamps and tail

lamps.

The lighting switch operates independently of

the key switch.

Turn the switch knob clockwise. The lamps

corresponding with the marked position will

come on. For details concerning lamp operation, refer to the table.

Turn signal switch

Push the switch lever forward when turning

left, and pull it backward when turning right.

The switch lever will automatically return to its

24

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 25 Printed on: April 8, 2005

original position after the lift truck has turned to

the left or right. If it does not, return it by hand.

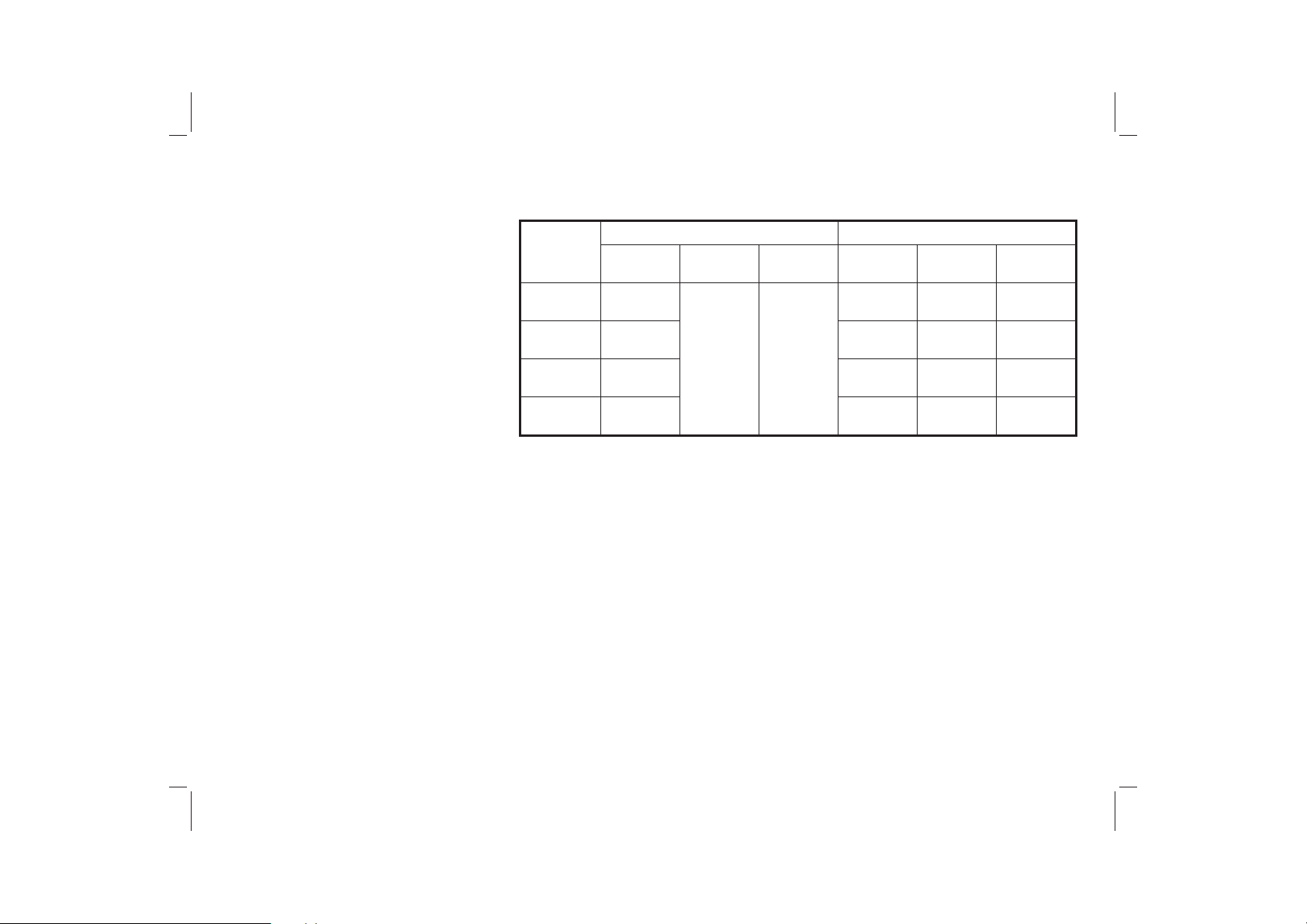

Switch lever

position

Passing

lamp

Turn to

1st step

Turn to

2nd step

Turn to the

right or left

Without combination lamp (Standard) With combination lamp (Optional)

Headlamp Tail lamp

Comes on

Comes on — Comes on —

——

Comes on Comes on Comes on —

— — — Comes on

Turn signal

The turn signal lever can be moved even in

vehicles not equipped with a combination

lamp.

lamp

Headlamp Tail lamp

Comes on Goes out —

Turn signal

lamp

25

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 26 Printed on: April 8, 2005

pended. Failure to do so can result in a

dead battery.

FAST

SLOW

MOM1605 MOM1606

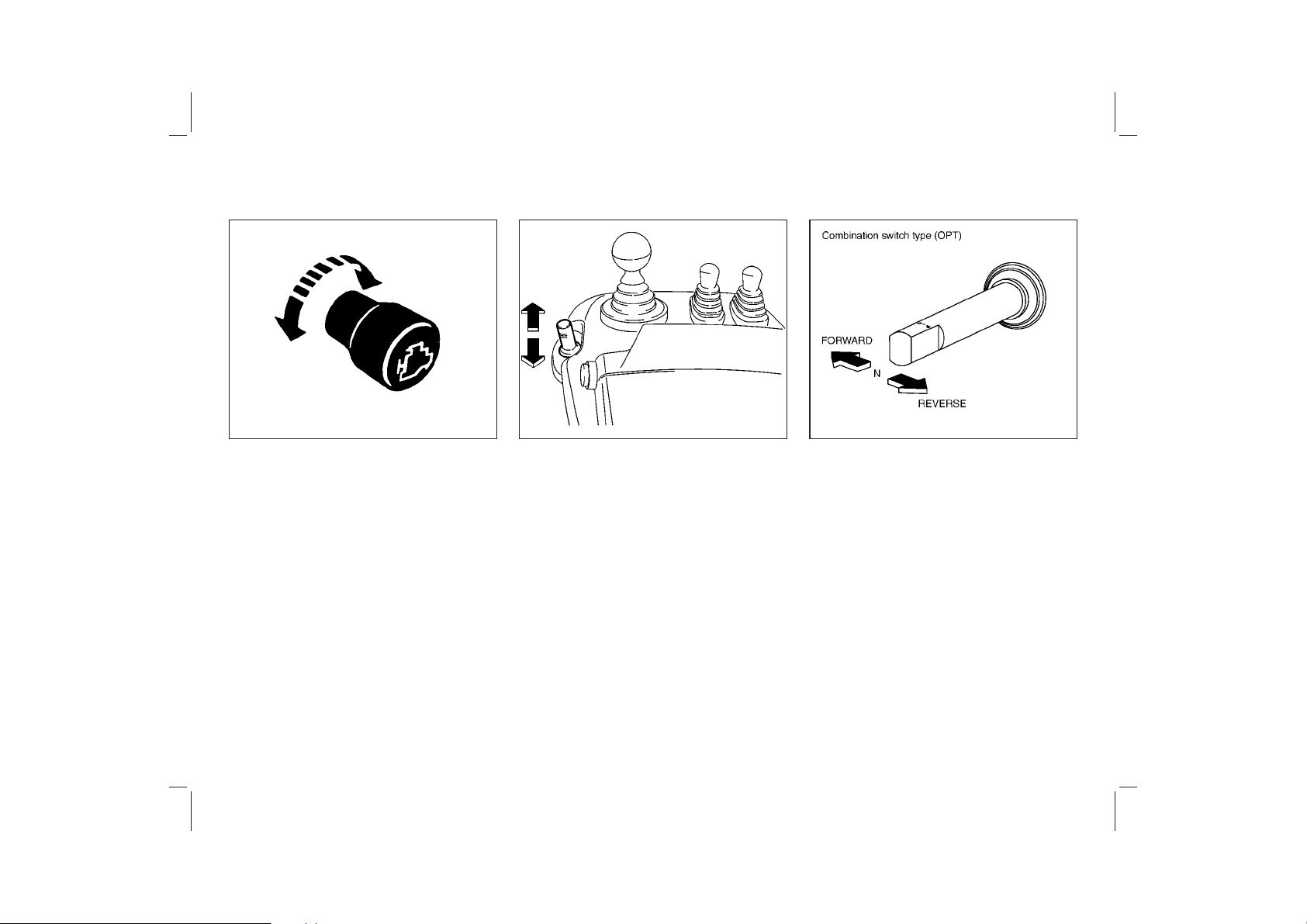

Engine idling control knob

(For diesel engines: cold climate

specifications are optional)

The control is located on the meter panel.

Turning the knob clockwise will increase the

engine idling speed.

Turning the knob counterclockwise will slow

down the engine idling speed. It is used to

warm up the engine at starting.

Backup operation switch (Optional)

The rear operating lights are used for nighttime

operation and operation in poorly lit areas. The

rear operating light switch controls these

lights.

The light switch is a button type. When this

switch is pushed, the back operation lamp

comes on. When it is pushed again, the lamp

goes out.

+ The backup operation switch works in-

dependently of the key switch ON and

OFF positions.

+ Be sure to turn off the rear operating

lights by pushing the knob in whenever

the engine is stopped or operation sus-

26

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 27 Printed on: April 8, 2005

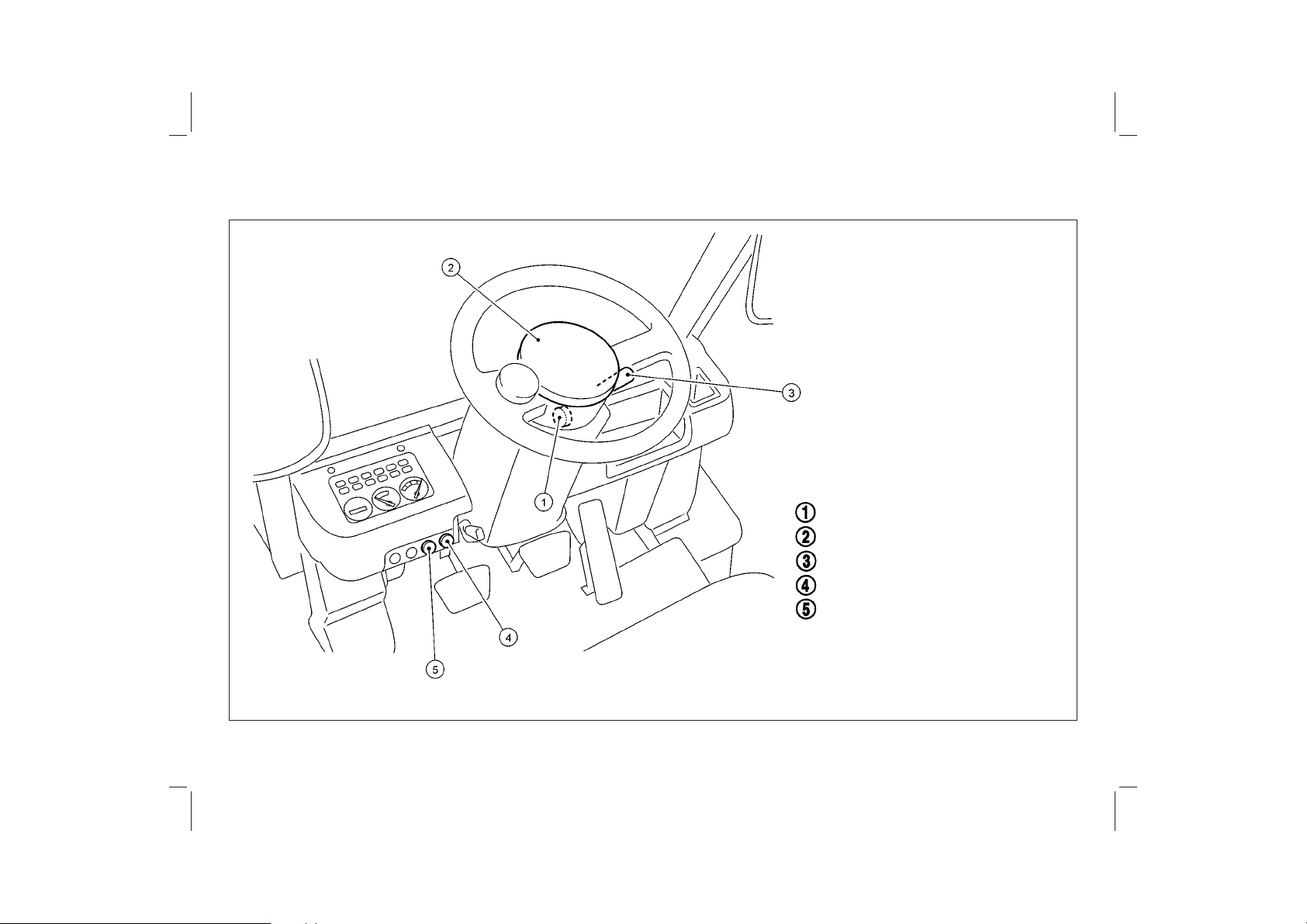

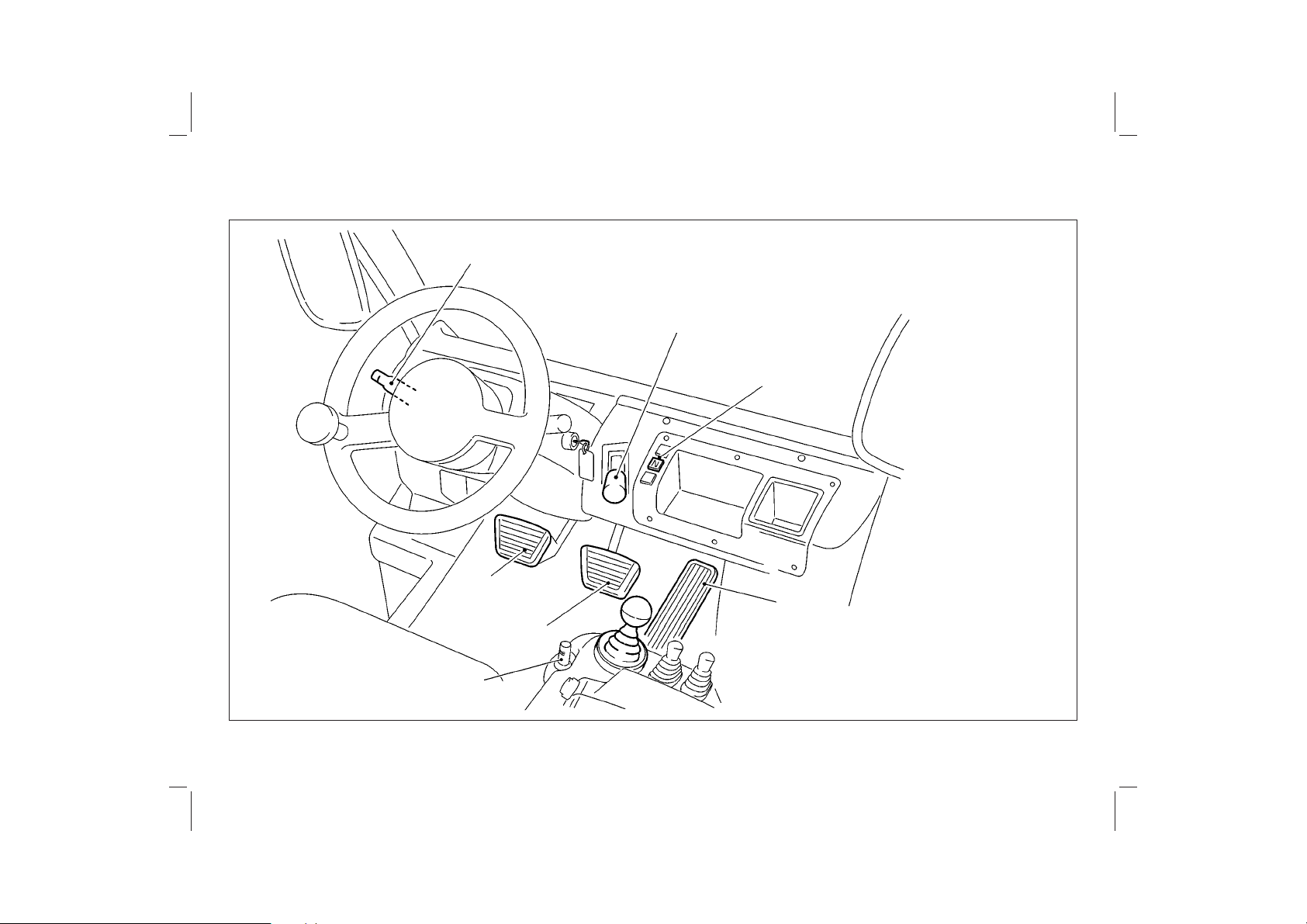

STARTING AND OPERATING

Forward-Reverse lever (OPT)

Hand brake

Neutral-position lamp

Inching brake pedal

Forward-Reverse lever

Accelerator pedal

Brake pedal

MOM1827

27

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 28 Printed on: April 8, 2005

OFF

ON

START

MOM1609

Gasoline engine starting (Including

LPG vehicles)

The engine is equipped with a fully automatic

choke. Follow the procedure outlined below to

start the engine.

On LPG models, open the discharge valve and

then start the engine.

1. Pull the hand brake lever up as far as

possible. Move the forward-reverse lever to

the neutral position.

NOTE:

When the forward-reverse lever is in the F

or R position, it is not possible to start the

engine.

2. Press the accelerator pedal fully to the floor

board (one-time only) and slowly release it.

If the engine is warm at starting, it is not

necessary to press the accelerator pedal.

3. Remove your foot from the accelerator

pedal. Turn the starter to start the engine.

NOTE:

Do not operate the starter for more than ten

seconds. If the engine fails to start within

ten seconds, release the starter and wait

for ten seconds before attempting to start

the engine again. This allows the battery

time to recover.

4. After starting the engine, allow it time to

warm up. Allow the engine to idle for one

minute after starting. Then, press the accelerator pedal lightly and release it. If the

surrounding temperature is high, lightly

pressing and releasing the accelerator

pedal will reduce engine speed and permit

quiet warming up. This also results in fuel

savings.

NOTE:

+ The engine is cold immediately after

starting. Do not intermittently race the

engine or run the engine at high speeds

immediately after starting.

+ Do not move the key to the START

position when the engine is running.

Damage to the starter motor will result.

+ Engine speed is high immediately after

starting. Exercise caution when moving

the vehicle or handling cargo.

WARNING:

+ Inspect the condition of LPG hose con-

nections and check for gas leaks from

LPG hoses and pipes before starting

engine.

+ In the event of LP gas leakage or some

other abnormal occurence, close the

discharge valve immediately. Have your

LP gas system checked at an authorized

service facility.

Stopping

Gasoline engine

To stop the engine, turn the ignition key to the

OFF position, then engine will stop.

LPG model

WARNING:

Carefully follow the below procedures

when turning the engine off after LPG operation:

28

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 29 Printed on: April 8, 2005

(1)Completely close the discharge valve

(red).

(2)Race the engine until it stops.

(3)Make sure that all of the remaining LPG

(in the piping and other receptacles) has

been used. After the engine stops, turn

the key switch to the OFF position.

+ After completion of operation and be-

fore storing the vehicle for an extended

period, check the engine for gas leakage. Refer to “LPG cylinder replacement” on Page 60.

+ In the event of gas leakage, an accident,

or some other abnormal occurrence, immediately and completely close the discharge valve (colored red). Have your LP

Gas system checked at an authorized

service facility.

OFF

ON

START

MOM1610

DIESEL ENGINE

Starting

1. Pull the hand brake lever up as far as

possible. Move the forward-reverse lever to

the neutral position.

NOTE:

When the forward-reverse lever is in the F

or R position, it is not possible to start the

engine.

2. When the key switch is set to the ON

position, the glow plug indicator lamp on the

combination meter goes on, indicating that

engine preheating has started.

Keep the key switch in the ON position till

the glow plug indicator lamp goes out (indicates completion of preheating).

Engine preheating is controlled automatically corresponding to the engine coolant

temperature, atmospheric air temperature

and so forth, and the glow plug indicator

lamp goes out when the engine is preheated to the specified temperature.

29

Maruboshi Europe B.V. NISSAN FORKLIFT - OWNER’S MANUAL

@dtp12/Archive/CLS_forklift/GRP_om/JOB_d01-u/DIV_u / PAGE 30 Printed on: April 8, 2005

FAST

SLOW

MOM1611 MOM1829

3. When the glow plug indicator lamp has

gone out, turn the key switch to the START

position while depressing fully the accelerator pedal, until the engine starts.

4. After the engine has started, release the

accelerator pedal gradually, and turn the

engine control knob clockwise until the engine runs smoothly.

When restarting, return the key to the OFF

position once, then turn it to the START

position.

Stopping

To stop the engine, turn the ignition key to the

OFF position, then engine will stop.

FORWARD

REVERSE

Forward-reverse lever

This lever is used to change the direction of

the lift truck, forward and reverse.

If the lever is pushed forward, the lift truck

moves forward; if pulled backward, the lift truck

moves backward. The midpoint between the

forward and reverse positions is the neutral

position. The engine must be started with the

lever set in the neutral position.

Lever in forward position:

When moving the lift truck forward.

Lever in reverse position:

When moving the lift truck backward.

MOM1812

Lever in neutral position:

When starting the engine and parking the

lift truck. (The neutral position lamp comes

on.)

CAUTION:

Before changing the direction of travel,

depress the brake pedal to stop the forklift

completely and place the change lever in

the Forward or Reverse position as desired.

30

Loading...

Loading...