Nissan Pathfinder 2000 Owner's Manual

EXIT

EXIT

GI

MANUAL TRANSMISSION

MA

EM

CONTENTS

PREPARATION ...............................................................2

Special Service Tools ..................................................2

Commercial Service Tool.............................................4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................5

NVH Troubleshooting Chart.........................................5

MANUAL TRANSMISSION

ON-VEHICLE SERVICE ..................................................6

Replacing Rear Oil Seal - 2WD Model .......................6

REMOVAL

INSTALLATION

Position Switch Check.................................................6

DESCRIPTION.................................................................7

Cross-sectional View - 2WD Model.............................7

Cross-sectional View - 4WD Model.............................8

REMOVAL AND INSTALLATION...................................9

Removal.......................................................................9

2WD MODEL

4WD MODEL

Installation..................................................................11

OVERHAUL ...................................................................12

Case Components.....................................................12

Gear Components .....................................................13

Shift Control Components .........................................15

DISASSEMBLY..............................................................16

Case Components.....................................................16

DISASSEMBLY

Shift Control Components .........................................17

DISASSEMBLY

Gear Components .....................................................18

.................................................................6

..........................................................6

.............................................................9

...........................................................10

........................................................16

........................................................17

..........................................5

SECTION

DISASSEMBLY

INSPECTION..................................................................22

Shift Control Components .........................................22

INSPECTION

Gear Components .....................................................22

INSPECTION

ASSEMBLY....................................................................24

Gear Components .....................................................24

ASSEMBLY

Shift Control Components .........................................32

ASSEMBLY

Case Components.....................................................33

ASSEMBLY

SERVICE DATA AND SPECIFICATIONS (SDS).........35

General Specifications...............................................35

Gear End Play...........................................................35

Clearance Between Baulk Ring and Gear................35

2ND AND 3RD BAULK RING

Distance Between Rear Surface of Reverse

Cone and Reverse Baulk Ring..................................36

Available Snap Ring..................................................36

MAIN DRIVE GEAR SNAP RING

MAINSHAFT FRONT SNAP RING

COUNTER GEAR REAR SNAP RING

Available C-ring .........................................................37

MAINSHAFT C-RING

Available Shim and Washer......................................37

TABLE FOR SELECTING PROPER COUNTER

GEAR FRONT BEARING THRUST WASHER

REVERSE IDLER REAR THRUST WASHER

........................................................18

...........................................................22

...........................................................22

.............................................................24

.............................................................32

.............................................................33

MT

....................................36

..............................36

.............................36

.......................37

...............................................37

............37

.............37

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

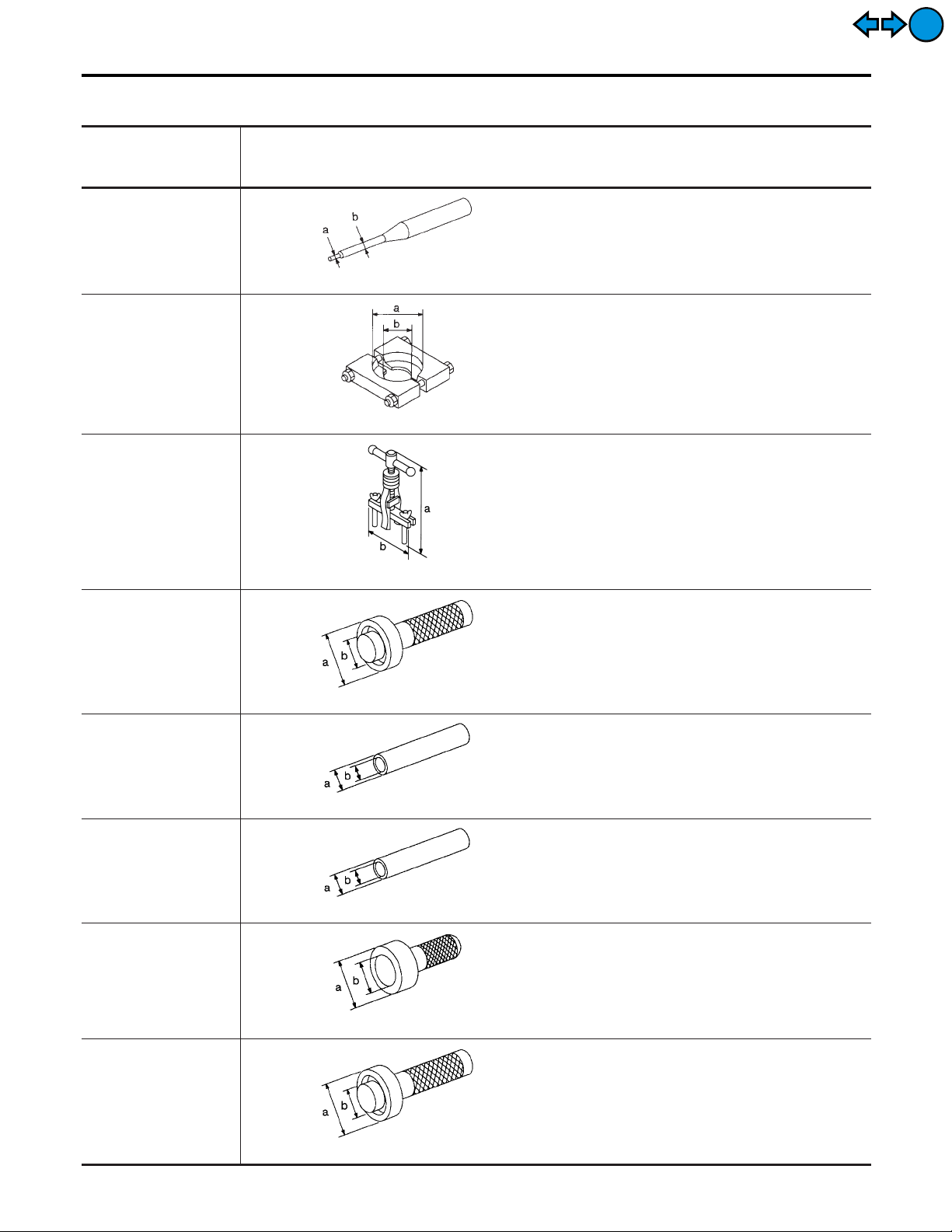

Special Service Tools

PREPARATION

EXIT

EXIT

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST23540000

(J25689-A)

Pin punch

ST30031000

(J22912-01)

Puller

ST33290001

(J25810-A)

Puller

Description

Removing and installing retaining pin

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

NT442

Removing 1st & 2nd synchronizer assembly

Removing counter gear rear thrust bearing

Removing main drive bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

NT411

Removing rear oil seal

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

NAMT0001

ST33230000

(—)

Drift

ST22350000

(J25678-01)

Drift

KV38100300

(J25523)

Drift

ST30720000

1 (J34286)

2 (J34331)

Drift

ST33210000

1 (J25523)

2 (J25803-01)

Drift

NT414

Removing mainshaft and counter gear

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

NT084

Removing counter gear front bearing (Use with

KV38100300)

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

NT065

Removing counter gear front bearing (Use with

ST22350000)

Installing counter gear rear bearing

a: 54 mm (2.13 in) dia.

b: 32 mm (1.26 in) dia.

NT065

1 Removing mainshaft front bearing

2 Installing mainshaft front bearing

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

NT115

1 Installing counter gear front bearing

2 Installing front cover oil seal

a: 44 mm (1.73 in) dia.

b: 24.5 mm (0.965 in) dia.

NT084

MT-2

PREPARATION

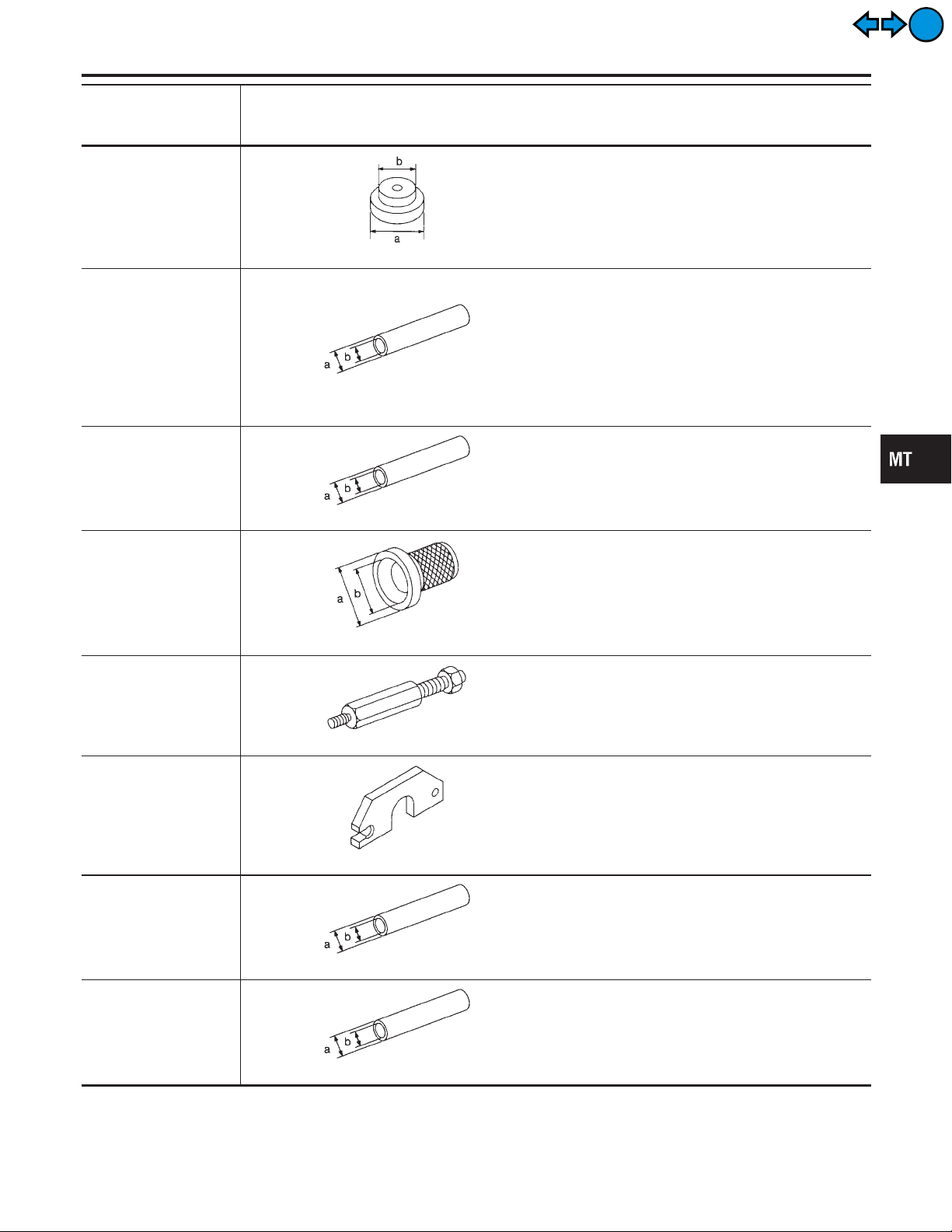

Special Service Tools (Cont’d)

EXIT

EXIT

Tool number

(Kent-Moore No.)

Tool name

ST30613000

(J25742-3)

Drift

ST37750000

1 (J34286)

2 (J34332)

3 (J34334)

4 (J25679-01)

Drift

ST22452000

(J34337)

Drift

ST33400001

(J26082)

Drift

Description

NT073

NT065

NT065

Installing main drive gear bearing

a: 72 mm (2.83 in) dia.

b: 48 mm (1.89 in) dia.

1 Removing counter gear rear bearing

2 Installing OD gear bushing

2 Removing and installing mainshaft rear bearing

(4WD model)

2 Installing reverse cone

3 Installing reverse counter gear

4 Installing counter gear rear end bearing

a: 40 mm (1.57 in) dia.

b: 31 mm (1.22 in) dia.

Installing reverse hub

Installing mainshaft rear bearing (2WD model)

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

Installing rear oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

GI

MA

EM

LC

EC

FE

CL

AT

TF

(J26349-3)

Puller leg

(J34328)

Puller

(J26092)

Drift

(J34342)

Drift

NT086

NT078

NT079

NT065

Installing mainshaft and counter gear

(Use with J34328)

Installing mainshaft and counter gear

(Use with J26349-3)

Installing sub-gear snap ring

a: 44.5 mm (1.752 in) dia.

b: 38.5 mm (1.516 in) dia.

Installing OD main gear

Installing reverse gear bushing

a: 44.5 mm (1.752 in) dia.

b: 40.5 mm (1.594 in) dia.

PD

AX

SU

BR

ST

RS

BT

HA

SC

NT065

EL

IDX

MT-3

Special Service Tools (Cont’d)

Tool number

(Kent-Moore No.)

Tool name

Description

PREPARATION

EXIT

EXIT

ST33220000

(J25804-01)

Drift

NT084

Tool name Description

Puller

NT077

Installing mainshaft rear bearing

a: 37 mm (1.46 in) dia.

b: 22 mm (0.87 in) dia.

Commercial Service Tool

Removing counter gear rear end bearing

Removing mainshaft rear bearing (2WD model)

Removing reverse synchronizer hub

Removing reverse counter gear

NAMT0002

MT-4

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

NAMT0023

EXIT

EXIT

NVH Troubleshooting Chart

NAMT0023S01

Use the chart below to help you find the cause of the problem. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

MANUAL TRANSMISSION

Reference page

SUSPECTED PARTS

(Possible cause)

Refer to MA-23, “Checking M/T Oil”.

MT-12

MT-12

MT-15

MT-15

MT-15

MT-13

MT-13

NAMT0023S0101

MT-13

MT-13

GI

MA

EM

LC

EC

FE

CL

AT

TF

Symptom

OIL (Level low)

OIL (Wrong)

OIL (Level too high)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

CHECK PLUG RETURN SPRING AND

CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

Noise 1 2 3 3

Oil leakage 31222

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

PD

INSERT SPRING (Damaged)

AX

SU

BR

ST

RS

BT

HA

SC

MT-5

EL

IDX

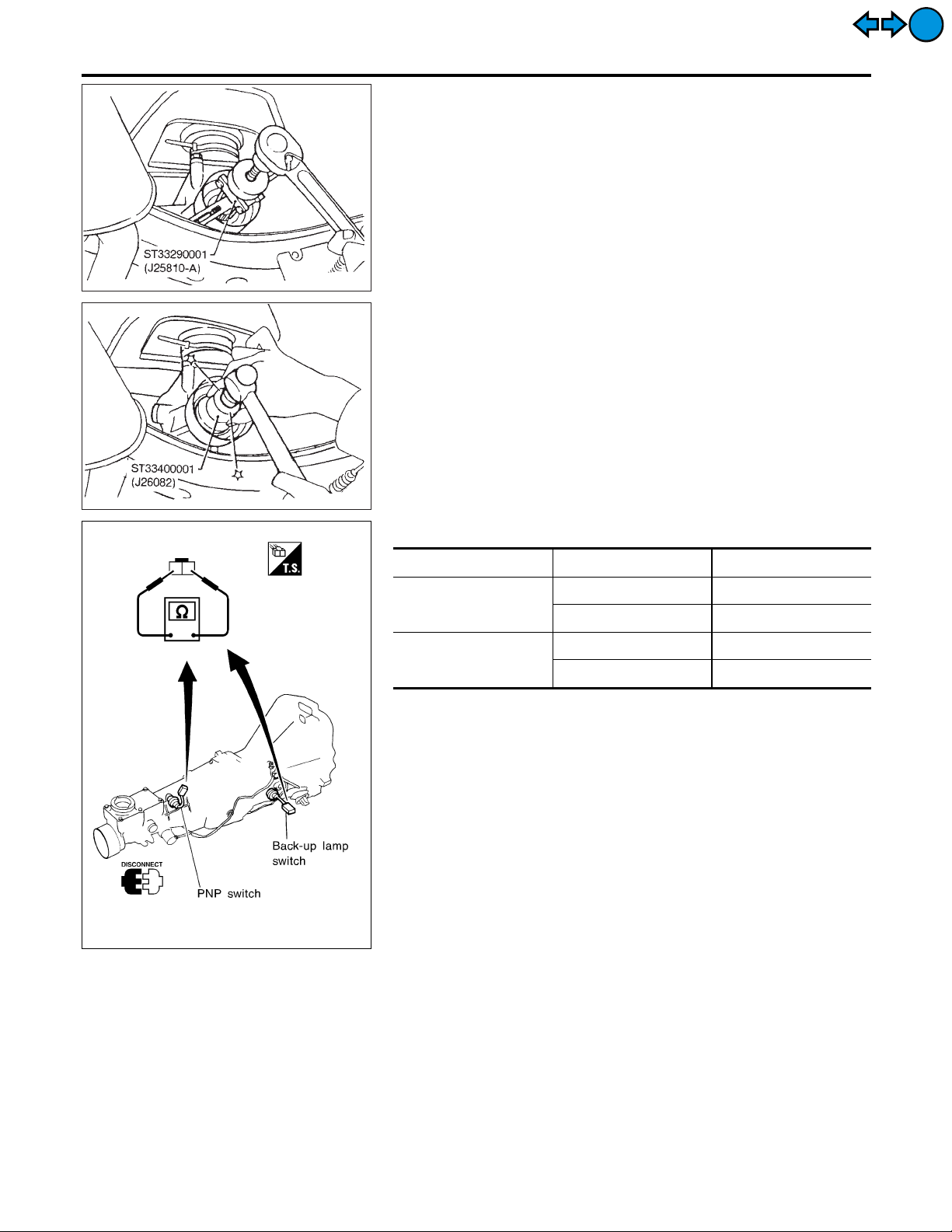

Replacing Rear Oil Seal — 2WD Model

ON-VEHICLE SERVICE

EXIT

EXIT

SMT479CA

SMT480CA

Replacing Rear Oil Seal — 2WD Model

REMOVAL

INSTALLATION

Position Switch Check

Switch Gear position Continuity

NAMT0003

NAMT0003S01

NAMT0003S02

NAMT0004

SMT451BE

Back-up lamp switch

Reverse Yes

Except reverse No

Neutral Yes

PNP switch

Except neutral No

MT-6

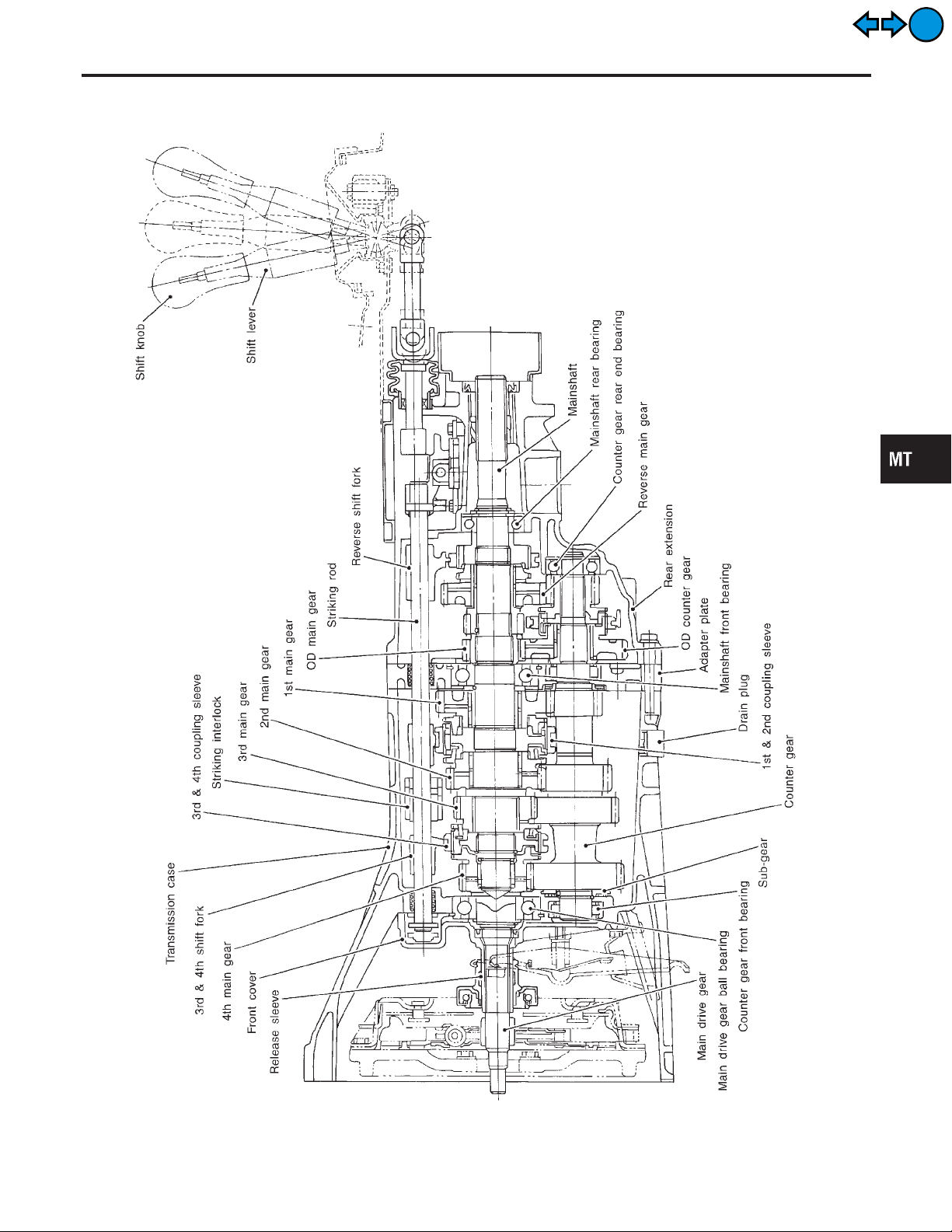

DESCRIPTION

NAMT0005

Cross-sectional View — 2WD Model

EXIT

EXIT

Cross-sectional View — 2WD Model

NAMT0005S01

GI

MA

EM

LC

EC

FE

CL

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

MT-7

SC

EL

SMT209D

IDX

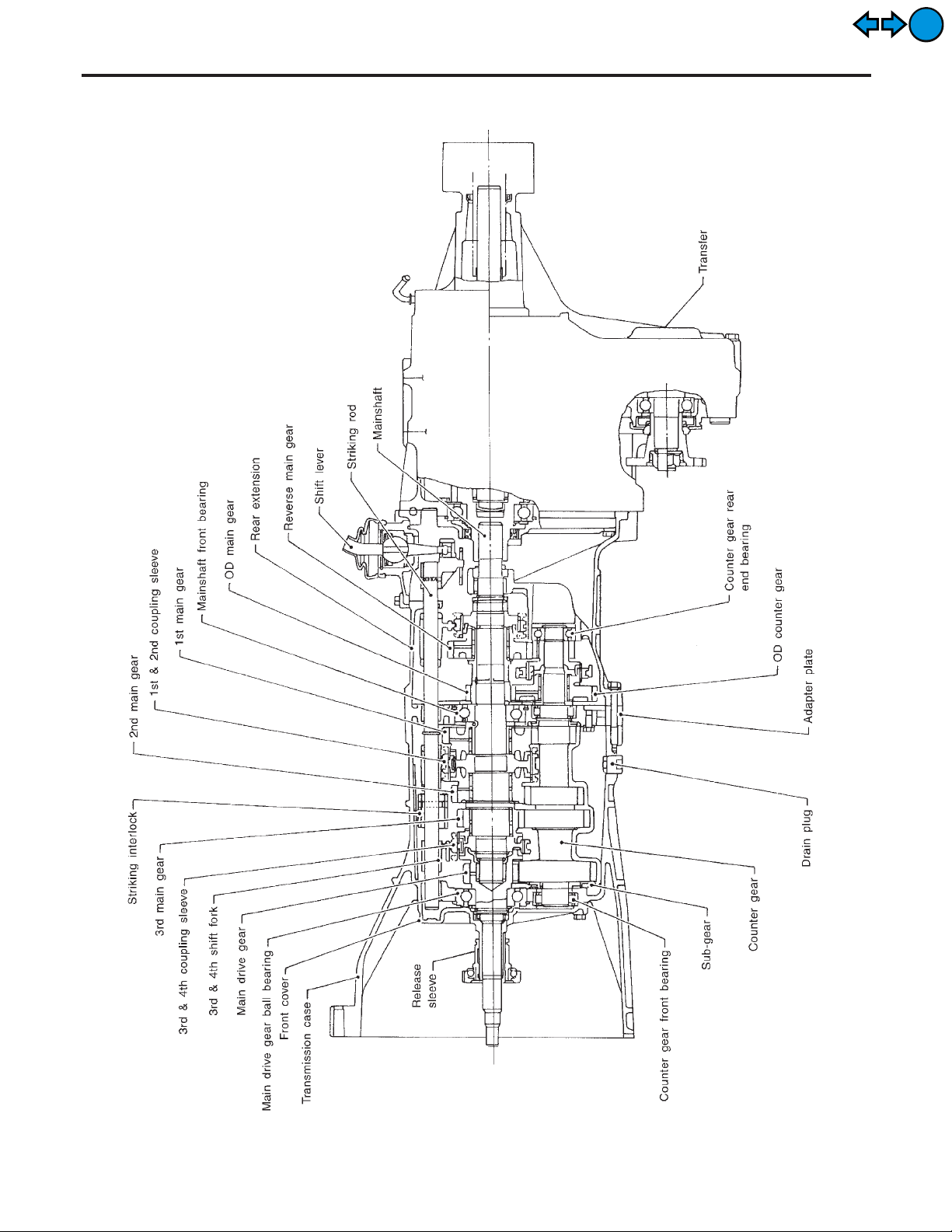

Cross-sectional View — 4WD Model

DESCRIPTION

EXIT

EXIT

Cross-sectional View — 4WD Model

NAMT0005S02

MT-8

SMT870CA

REMOVAL AND INSTALLATION

NAMT0006

Removal

EXIT

EXIT

Removal

CAUTION:

When removing the M/T assembly from engine, first remove

the crankshaft position sensor (OBD) from the M/T assembly.

Be careful not to damage sensor edge.

NAMT0006S01

SMT795C

GI

MA

EM

LC

EC

FE

CL

AT

SMT099A

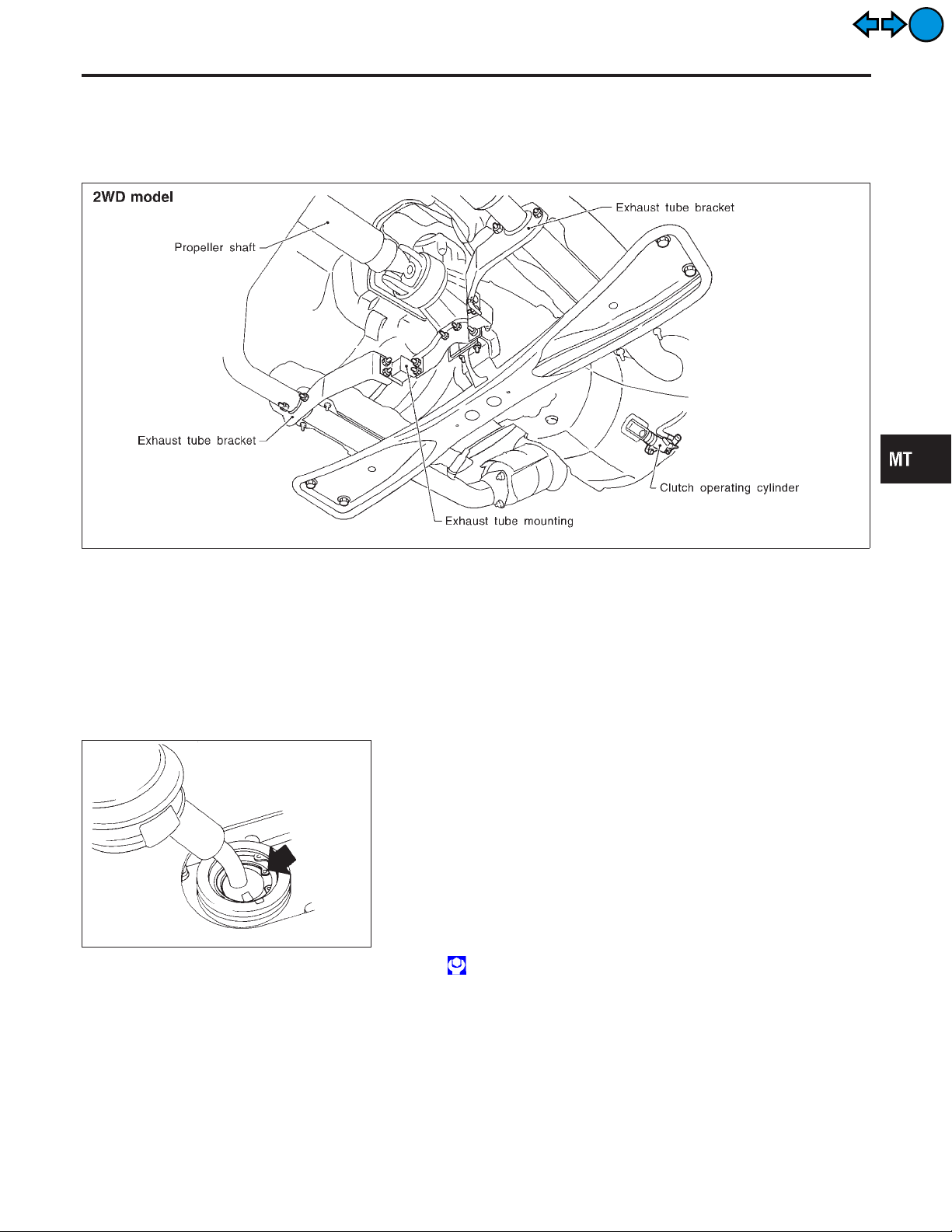

2WD MODEL

1. Remove battery negative terminal.

2. Remove shift lever with control housing from transmission.

3. Remove crankshaft position sensor (OBD) from upper side of

transmission case.

4. Remove clutch operating cylinder from transmission. Tighten

clutch operating cylinder to the specified torque. Refer to CL-5,

“CLUTCH SYSTEM”.

5. Disconnect speed sensor, back-up lamp switch, rear heated

oxygen sensor and PNP switch harness connectors.

6. Remove starter motor from transmission.

: 41 - 52 N·m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

7. Remove propeller shaft. Refer to PD-8, “Remova and Installation”.

I Insert plug into rear oil seal after removing propeller shaft.

I Be careful not to damage spline, sleeve yoke and rear oil

seal when removing propeller shaft.

8. Remove gussets from transmission or engine.

9. Remove exhaust tube mounting bracket from transmission.

Refer to FE-8, “EXHAUST SYSTEM”.

10. Support manual transmission with a jack.

NAMT0006S0101

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MT-9

Removal (Cont’d)

REMOVAL AND INSTALLATION

11. Remove rear mounting member. Tighten rear mounting member to the specified torque. Refer to EM-42, “Removal and

Installation”.

12. Lower manual transmission as much as possible.

WARNING:

Support manual transmission while removing it.

EXIT

EXIT

SMT815C

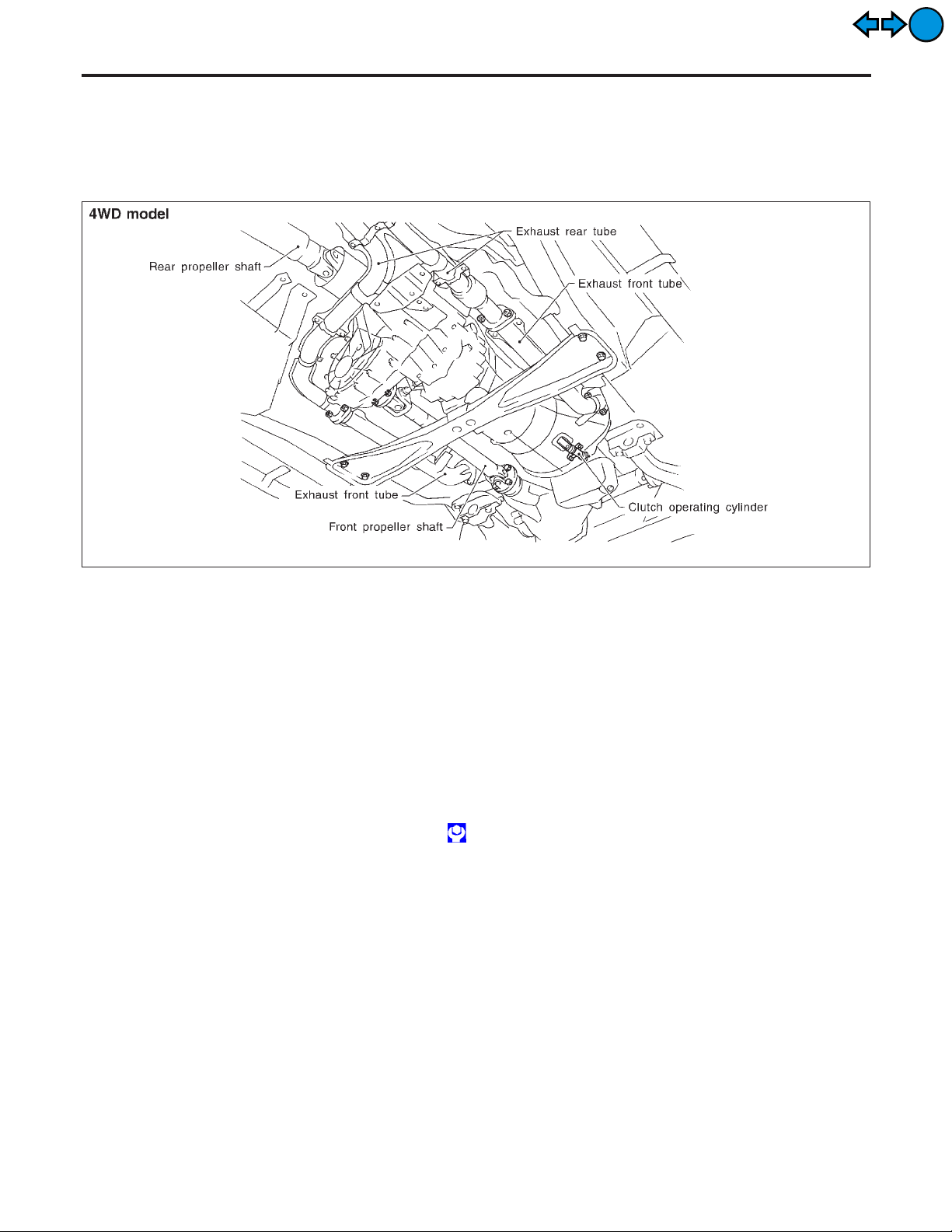

4WD MODEL

NAMT0006S0102

1. Remove battery negative terminal.

2. Remove shift lever from transmission and control lever from

transfer.

3. Remove crankshaft position sensor (OBD) from upper side of

transmission case.

4. Remove clutch operating cylinder from transmission. Tighten

clutch operating cylinder to the specified torque. Refer to CL-5,

“CLUTCH SYSTEM”.

5. Disconnect speed sensor, back-up lamp switch, rear heated

oxygen sensor and PNP switch harness connectors.

6. Remove starter motor from transmission.

: 41 - 52 N·m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

7. Remove front and rear propeller shafts. Refer to PD-8,

“Removal and Installation”.

I Insert plug into rear oil seal after removing propeller shaft.

I Be careful not to damage spline, sleeve yoke and rear oil

seal when removing propeller shaft.

8. Remove gussets from transmission or engine.

9. Remove exhaust tube mounting bracket from transmission.

Refer to FE-8, “EXHAUST SYSTEM”.

10. Support manual transmission with a jack.

11. Remove rear mounting member. Tighten rear mounting member to the specified torque. Refer to EM-42, “ENGINE

REMOVAL”.

12. Lower manual transmission as much as possible.

WARNING:

Support Manual Transmission together with transfer, while

removing it.

MT-10

REMOVAL AND INSTALLATION

Installation

EXIT

EXIT

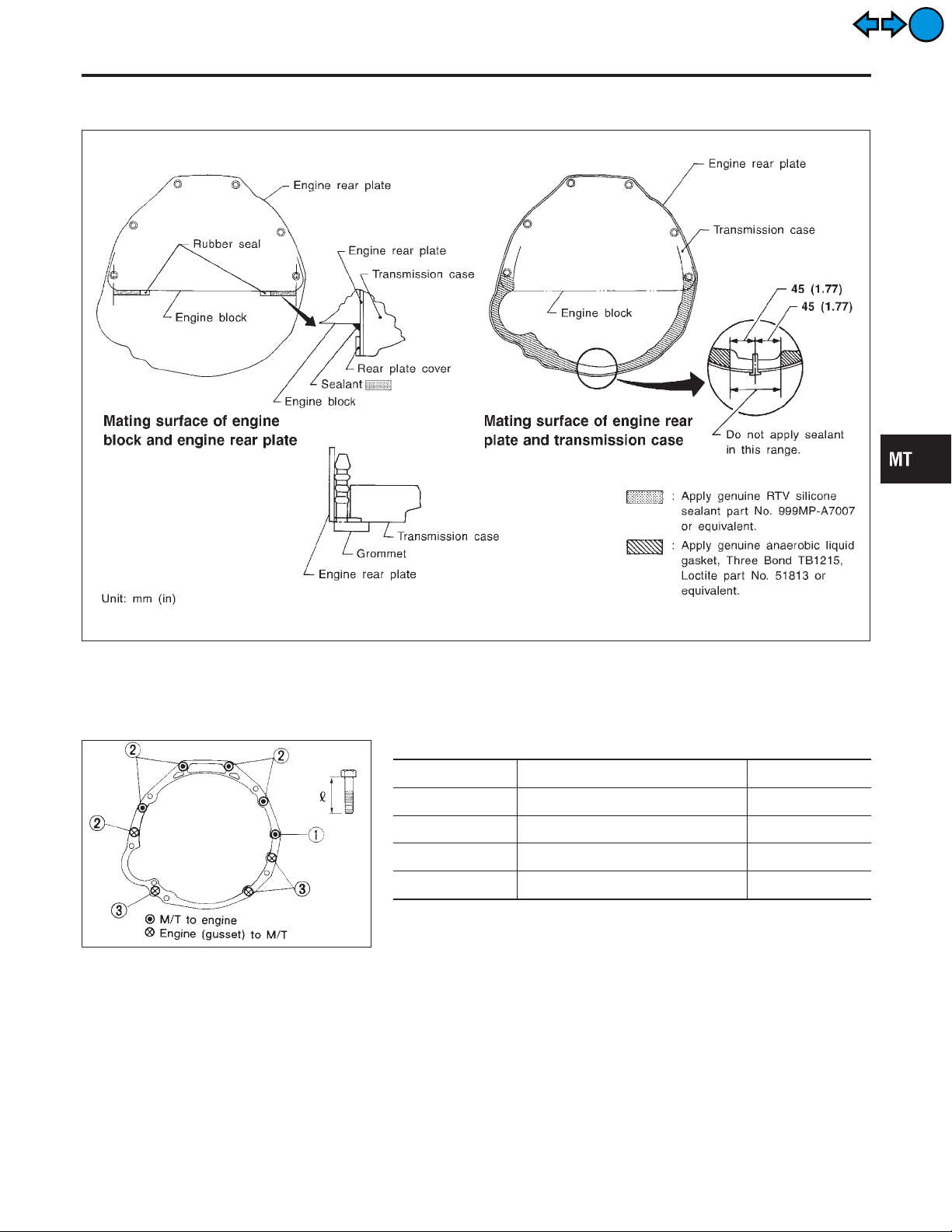

Installation

I Apply sealant as below: — 4WD model

NAMT0006S02

GI

MA

EM

LC

EC

FE

CL

AT

SMT573AB

I Tighten bolt securing transmission.

Bolt No. Tightening torque N·m (kg-m, ft-lb) mm (in)

1 39 - 49 (4.0 - 5.0, 29 - 36) 65 (2.56)

2 39 - 49 (4.0 - 5.0, 29 - 36) 58 (2.28)

3 29 - 39 (3.0 - 4.0, 22 - 29) 25 (0.98)

Gusset to engine 29 - 39 (3.0 - 4.0, 22 - 29) 20 (0.79)

SMT796CA

TF

PD

AX

SU

BR

ST

RS

BT

HA

MT-11

SC

EL

IDX

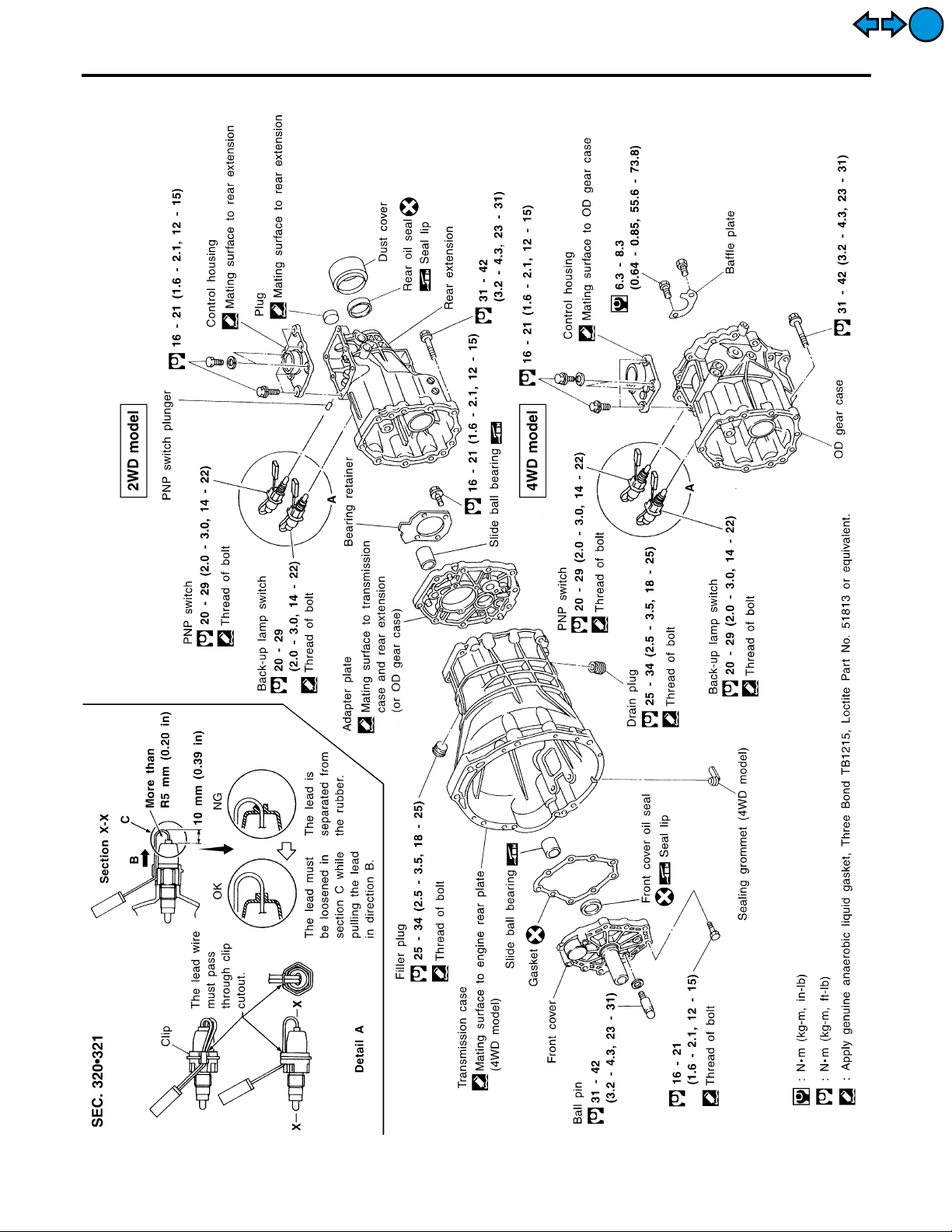

Case Components

OVERHAUL

NAMT0007

EXIT

EXIT

Case Components

NAMT0007S01

MT-12

SMT639DA

Loading...

Loading...