Nikon AF-S DX Zoom-NIKKOR 18-70mm Repair manual

JAA79051-R.3624.A

INC

作成承認印

AF-S DX Zoom-Nikkor

ED 18-70mm f/3.5-4.5G IF

配布許可印

JAA79051

REPAIR MANUAL

NIKON CORPORATION

Tokyo, Japan

Recycled paper

Printed in Japan February 2004

Copyright c 2004 by Nikon Corporation.

All Rights Reserved.

SPECIFICATIONS

INC

This lens can be used for Nikon digital SLR camera only.

JAA79051-R.3624.A

Type of lens

Focal length

Maximum aperture

Lens construction

Picture angle

Focal length scale

Distance information

Zoom control

Focusing

Shooting distance scale

Closest focus distance

Diaphragm

Aperture range

Exposure measurement

Attachment size

Dimensions

G-type AF DX Zoom- Nikkor lens having built-in CPU and Nikon bayonet mount

18mm-70mm

f/3.5-4.5

15 elements in 13 groups (1 aspherical lens and 3 ED lens elements)

76°-22°50′with Nikon Digital Camera D1/D1H/D1X/D2H/D100)

18,24,35,50,70mm

Output to camera body

Manually via separate zoom ring

Nikon Internal Focusing (IF) system (utilizing an internal Silent Wave Motor);

manually via separate focus ring

Graduated in meters and feet from 0.38m (2ft.) to innity (∞)

0.38m (1.2ft.) at all zoom settings

Fully automatic

f/3.5 to f/22 (at 18mm), f/4.5 to f/29 (at 70mm)

Via full-aperture method with cameras having CPU interface system

67mm (P=0.75mm)

Approx. 73mm dia. ×75.5mm extension from the camera's lens mount ange

(min. length at 18mm focal length)

Weight

Approx.420g (14.8 oz)

- M1・AF-S DX18-70/3.5-4.5G -

DISASSEMBLY/ASSEMBLY/ADJUSTMENT

INC

DISASSEMBLY

1.

RUBBER RING, SHEET

JAA79051-R.3624.A

# 35

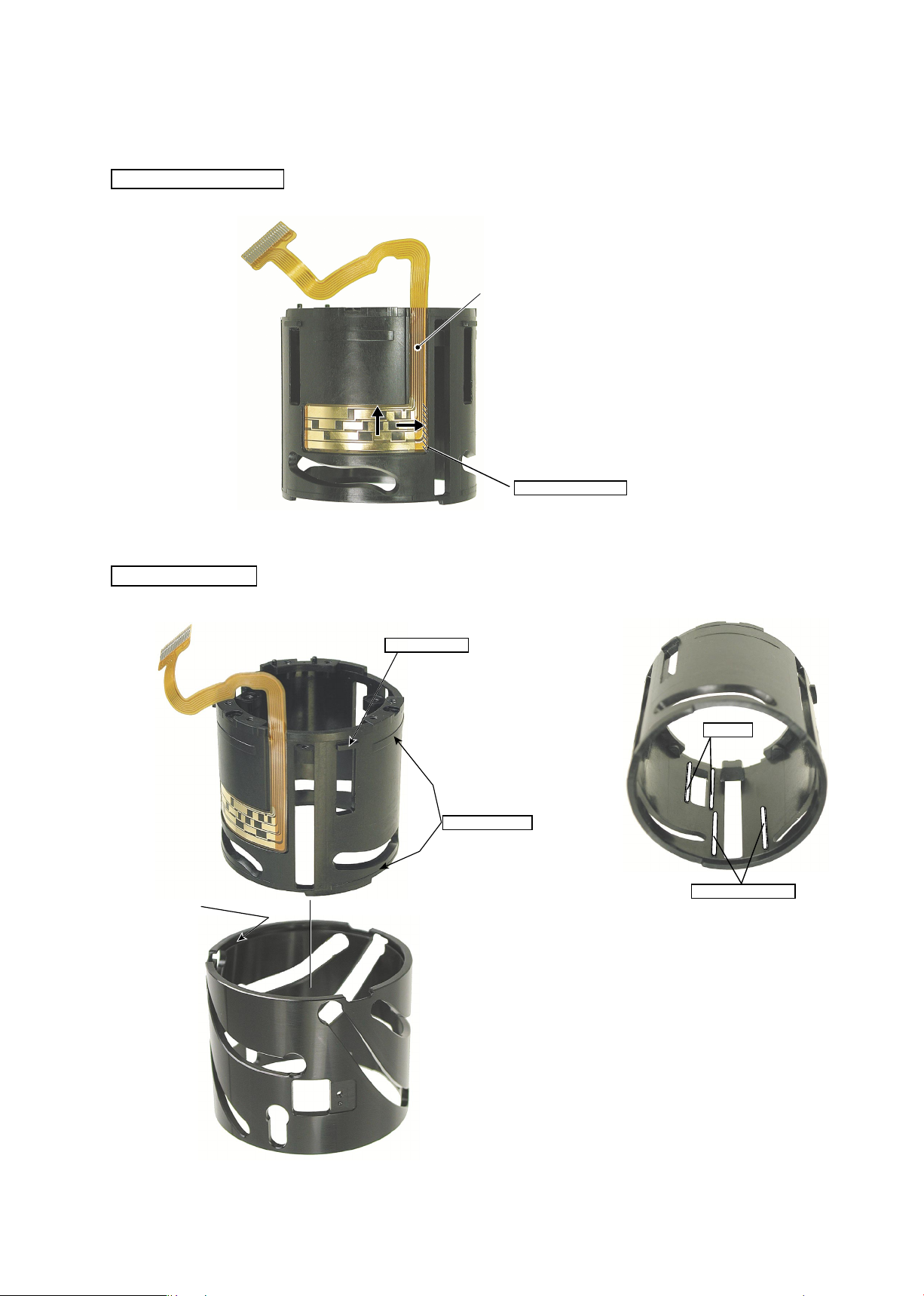

1st AND 2nd LENS GROUP

# 48

1st lens group unit

# 77

# 79

2nd lens group unit

- L1・ AF-S DX18-70/3.5-4.5G -

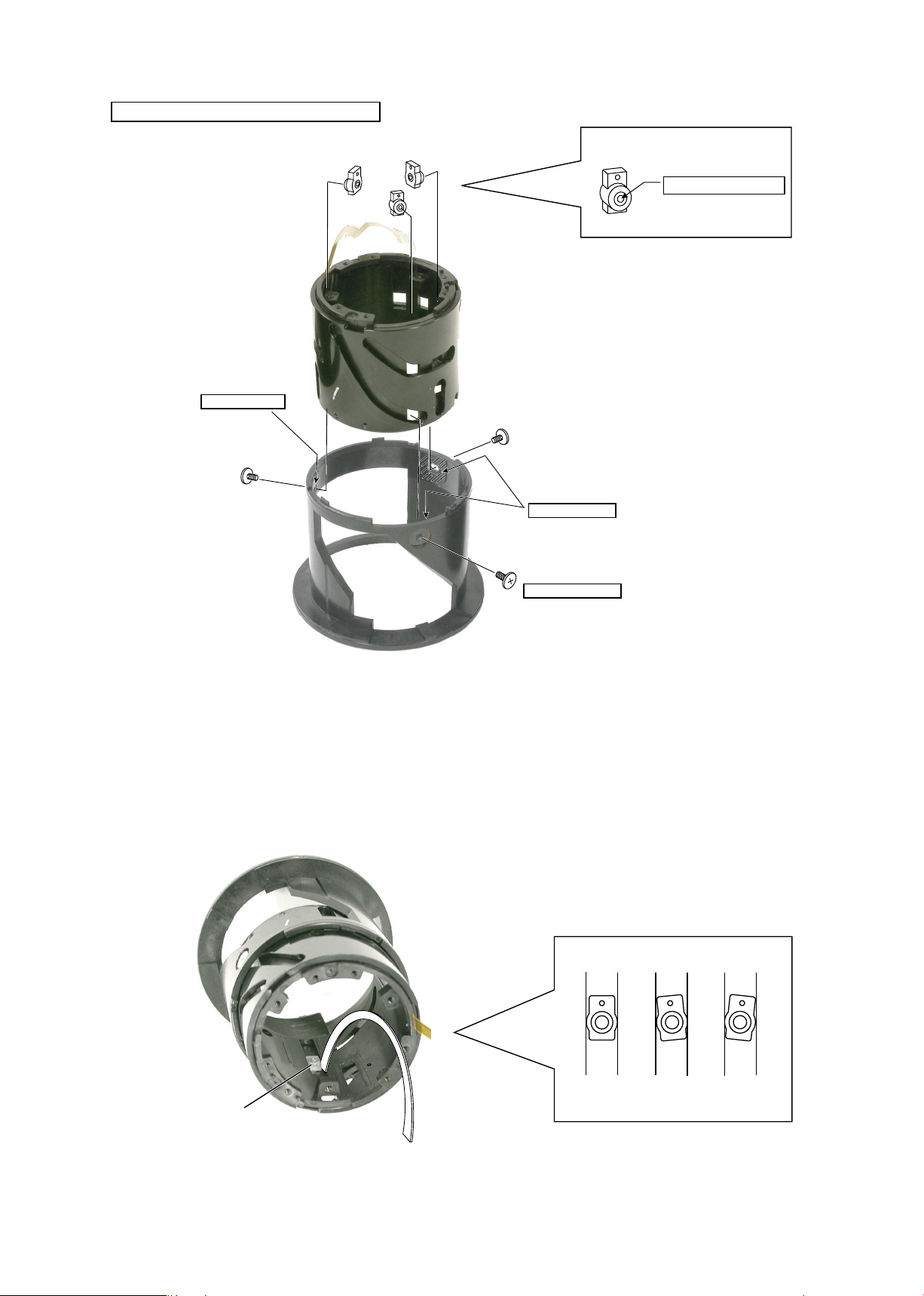

FILTER RING

INC

# 96 × 3

# 25

JAA79051-R.3624.A

Remove 3 screws (#96) and remove the lter

●

ring (#25) while rotating it in the arrow

direction.

ZOOM RING

# 61

① Remove the screw (#61).

- L2・ AF-S DX18-70/3.5-4.5G -

Convex section

INC

JAA79051-R.3624.A

Convex section

Groove

Zoom ring

Convex section

# 38

# 22

② Remove the zoom ring.

Note

:

The three convex sections on the inner

diameter of zoom ring are put into the

groove of #22.

When removing the zoom ring, rotate it

until the convex sections can be removed

from the groove and then remove it.

REAR COVER RING

# 105 × 2

Rear cover ring

# 107 × 3

- L3・ AF-S DX18-70/3.5-4.5G -

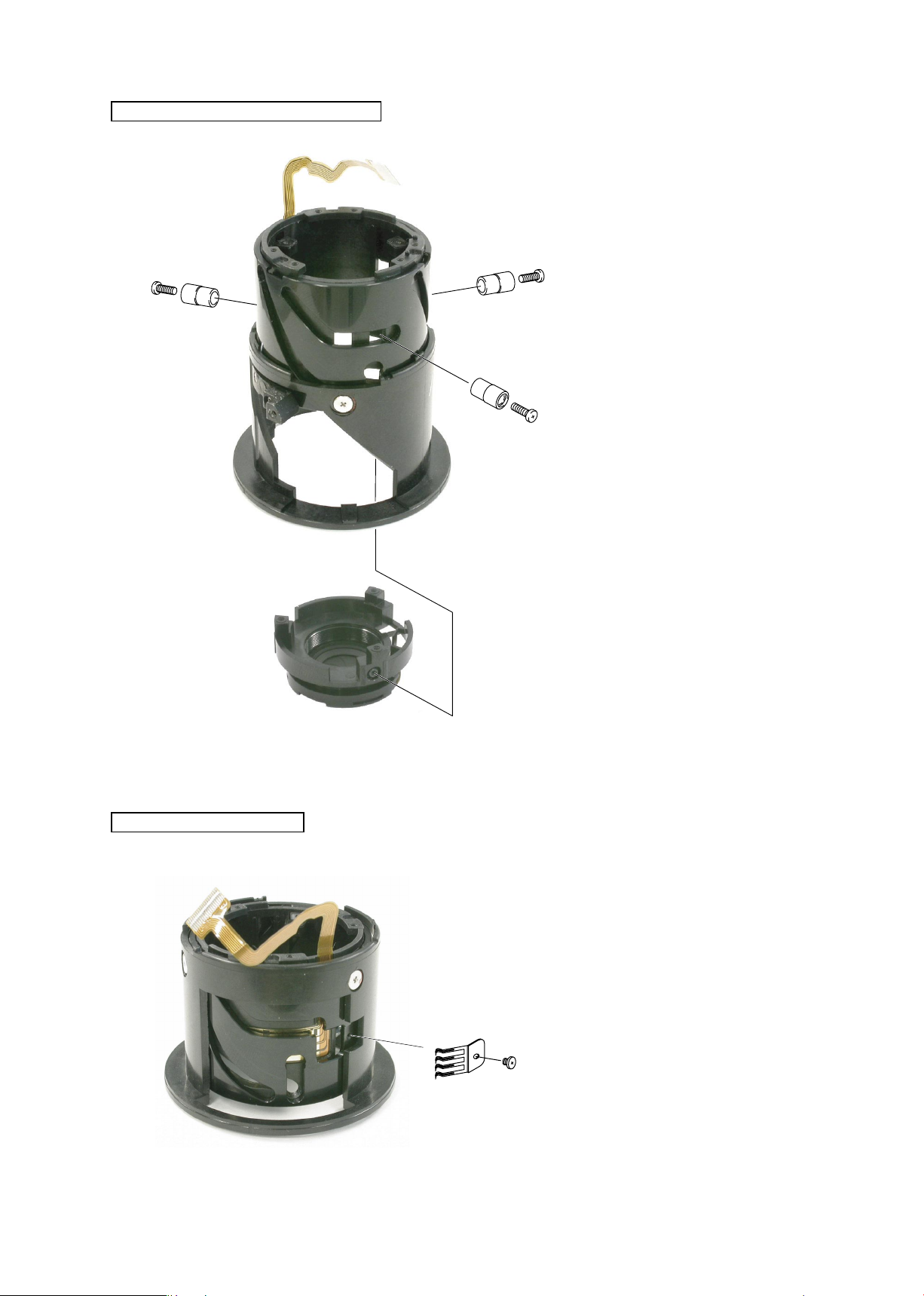

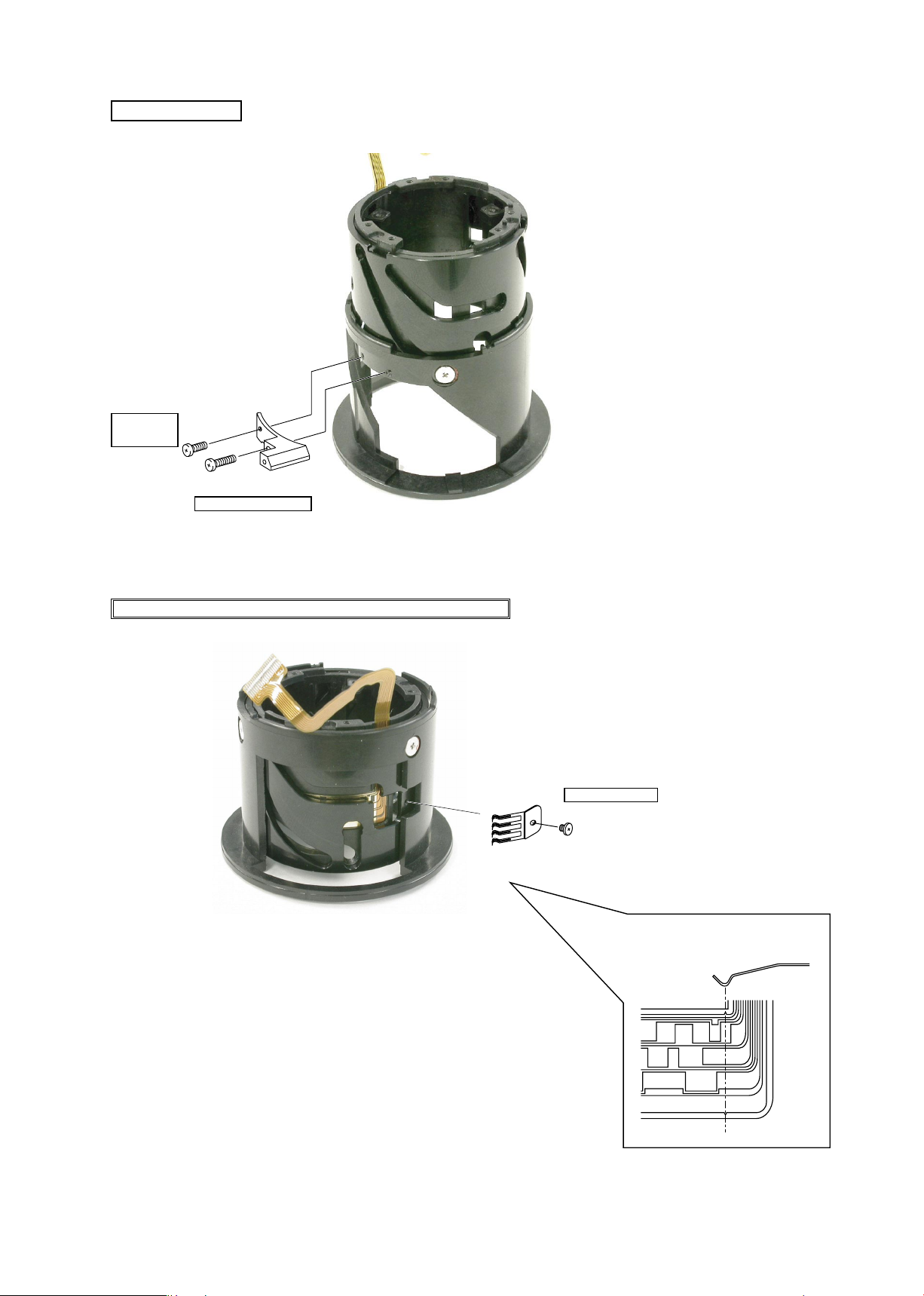

BAYONET MOUNT

INC

JAA79051-R.3624.A

# 116

# 98 × 3

# 78

Remove 3 screws (#98) and the screw (#116),

①

and detach the bayonet mount.

Remove the washers (#78).

②

INDEX RING, FOCUS RING

M/A selector switch

① Slide the M/A selector switch unit in the

arrow direction as shown in the left pic-

ture.

- L4・ AF-S DX18-70/3.5-4.5G -

Index ring

INC

Focus ring

M/A selector switch

JAA79051-R.3624.A

② Remove the index ring rst then the

focus ring.

As shown in the left picture, pass the

※

M/A selector switch unit through the

index ring.

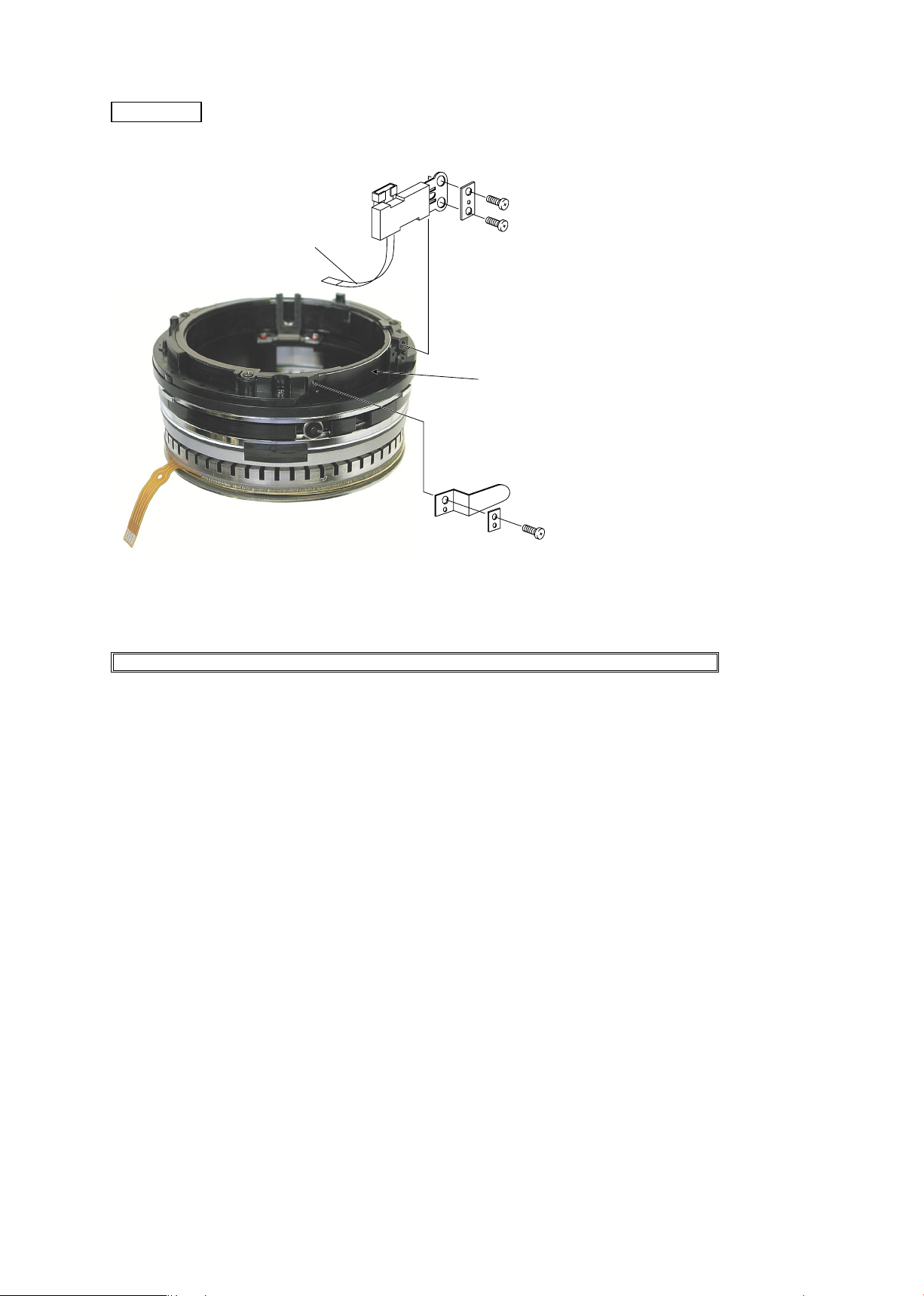

MAIN PCB

Zoom encoder FPC

MR sensor FPC

Distance encoder FPC

# 97

Main PCB

SWM-FPC

# 115

① Remove each FPC from the connectors as

shown in the left .

② Remove the screw (#115).

③ Remove the main PCB.

- L5・ AF-S DX18-70/3.5-4.5G -

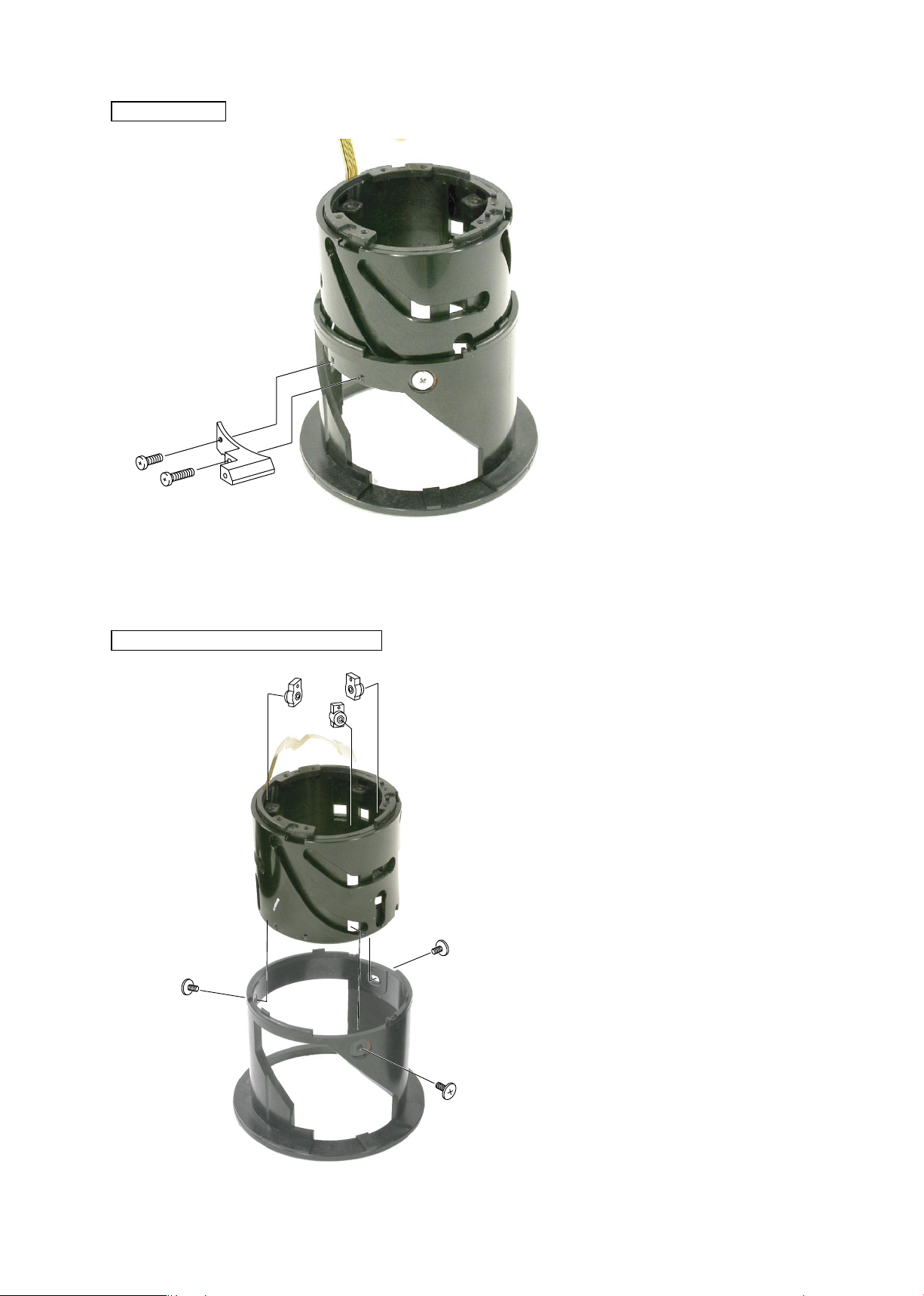

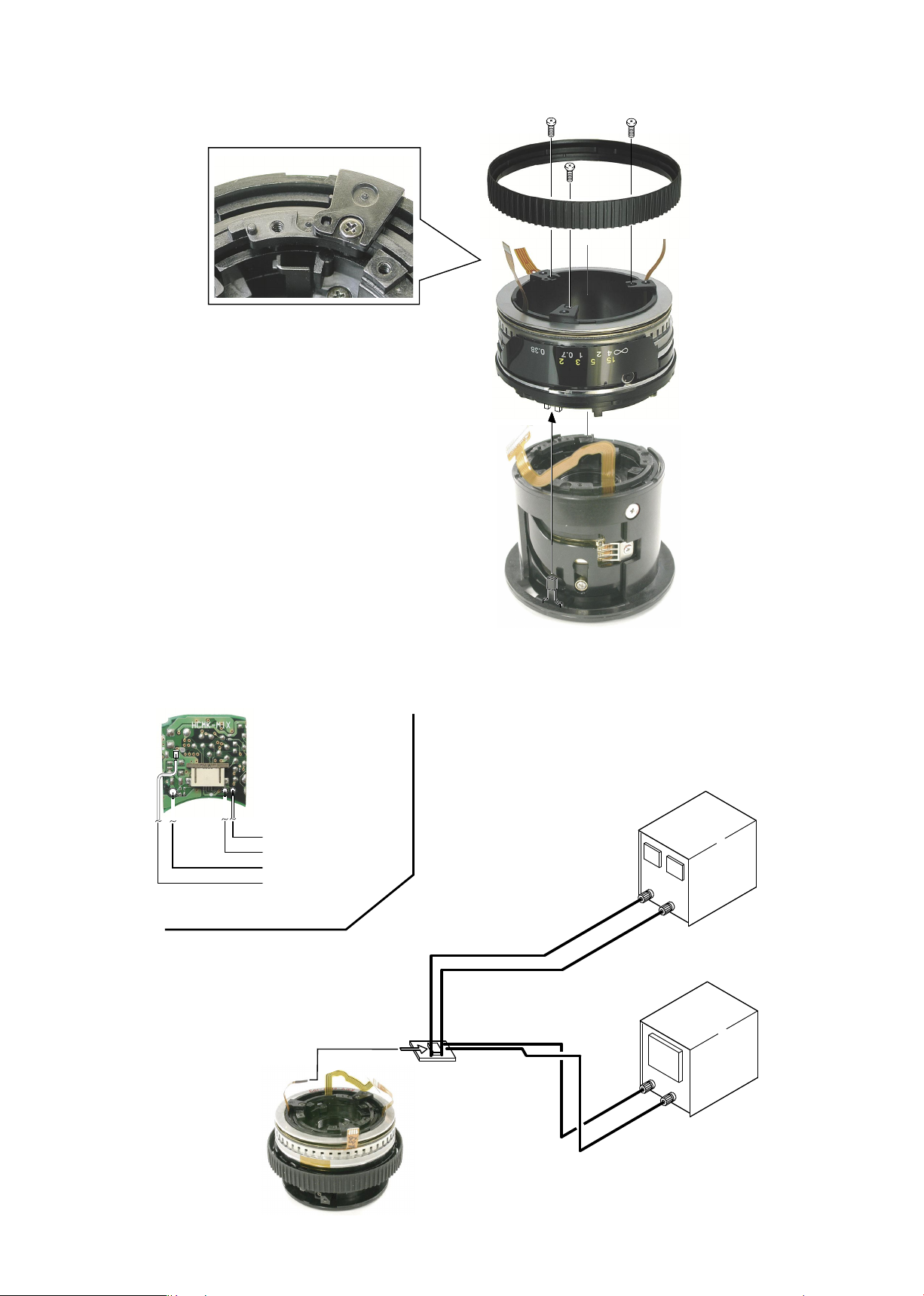

SWM UNIT

INC

# 96 × 3

# 29

JAA79051-R.3624.A

Remove 3 screws (#96), and detach the Rear

①

xed ring (#29).

# 96 × 3

SWM unit

Remove 3 screws (#96), and detach the SWM

②

unit.

- L6・ AF-S DX18-70/3.5-4.5G -

2nd LENS GROUP HOUSING UNIT

INC

# 85 × 3

# 86 × 3

# 84 × 3

JAA79051-R.3624.A

Remove 3 screws (#84), 3 springs (#86)and 3

②

rollers #(85).

2nd lens group housing unit

Note

:

After the above, the 5th and 4th lens groups should be removed.

When the 5th and 4th lens groups are removed, lens alignment should be

performed after assembly.

If the alignment is impossible in the service ofce, do not carry out

further disassembly work, but the zoom encoder brush and zoom key can

be replaced.

- L7・ AF-S DX18-70/3.5-4.5G -

4th AND 5th LENS GROUP

INC

JAA79051-R.3624.A

# 96 × 3

# 96 × 3

5th lens group

4th lens group

Remove 3 screws (#96) and detach the 5th lens

①

group.

Remove 3 screws (#96) and detach the 4th lens

②

group.

3rd LENS GROUP

3rd lens group

- L8・ AF-S DX18-70/3.5-4.5G -

APERTURE BLADE HOUSING UNIT

INC

# 83 × 3

# 80 × 3

JAA79051-R.3624.A

Remove 3 screws (#80), 3 rollers (#83), and

①

detach the Aperture blade housingunit.

Aperture blade housing unit

ZOOM ENCODER BRUSH

# 74

# 75

Remove 3 screws (#75) and detach the zoom

①

encoder brush (#74).

- L9・ AF-S DX18-70/3.5-4.5G -

ZOOM KEY

INC

# 60

# 62

# 59

JAA79051-R.3624.A

Remove the screws (#60 and#62) and detach

①

the zoom key (#59).

1st LENS GROUP SLIDING RING

B7 × 3

# 81 × 3

# 51

Remove 3 screws (#51), the three zoom keys

①

(B7) and detach the 1st lens group sliding ring

(#51).

Remove the 1st sliding ring (#51).

②

- L10 ・ AF-S DX18-70/3.5-4.5G -

CAM RING

INC

JAA79051-R.3624.A

# 50

- L11 ・ AF-S DX18-70/3.5-4.5G -

2. ASSEMBLY/ADJUSTMENT

INC

ZOOM ENCODER FPC

JAA79051-R.3624.A

CAM RING GROUP

# 1002

# 24

3 convex places on outer diameter

Grease:I-40

・By aligning the edges as shown by the left

arrows,adhere the zoom encoder FPC

(#1002) to #24.

Adhesive: Aron alpha

# 24

# 24

Horizontal groove

3 sliding places on outer diameter

Grease:I-40

● Grease application:

# 50

Apply MZ-800S to 6 straight grooves of #24.

Apply I-40 to 3 cam grooves of #24.

Apply I-40 to 9 cam grooves and horizontal groove

of #50.

MZ-800S

Grease: MZ-800S

- L12 ・ AF-S DX18-70/3.5-4.5G -

1st LENS GROUP SLIDING RING

INC

JAA79051-R.3624.A

Grease: I-40

B7 × 3

(B7)

Adhesive: Lock END B

Grease: I-40

# 81 × 3

Adhesive: Screw Lock

# 51

《Reference》

Tighting the screws (#81) causes inclination of B7, and

it becomes heavy in operating the cam ring.

Therefore, as shown below, put a back washer, etc. in

between B7 and the straight groove and tighten the

screws (#81). This can prevent B7 from being inclined.

(B7)

B7

○ ×

Back washer (Thickness: 0.4mm)

- L13 ・ AF-S DX18-70/3.5-4.5G -

×

ZOOM KEY

INC

JAA79051-R.3624.A

Adhesive:

Lock End B

# 60

# 62

Adhesive: Lock End B

# 59

① Attach the

(#60 and #62).

zoom key #59 with the screws

ADJUSTMENT OF ZOOM ENCODER BRUSH POSITION

① Set the zoom encoder brush #74. Tighten the screw #75

temporarily.

Adhesive: Screw Lock

# 75

# 74

# 74

② Set the cam ring to the W side as shown in the above picture.

③ Adjust the brush position so that the edge of the brush are

positioned as shown right.

④ Tighten the screw (#75) securely and x it with the screw lock.

- L14 ・ AF-S DX18-70/3.5-4.5G -

APERTURE BLADE HOUSING UNIT

INC

JAA79051-R.3624.A

# 83 × 3

# 80 × 3

① Assemble the

unit with 3 screws (#80) and 3 rollers (#83).

zoom

Aperture blade housing

Aperture blade housing unit

Convex section

Check:When mounting the aperture

blade chamber unit, the aperture lever

Aperture lever

must be positioned as shown left.

- L15 ・ AF-S DX18-70/3.5-4.5G -

2nd LENS GROUP HOUSING UNIT

INC

JAA79051-R.3624.A

# 52

● Apply G92KA to the 3 cam grooves of #52.

# 56

Grease: G92KA

Apply to 2 convexties on outer diameter

# 85 × 3

① Assemble the 2nd lens group with 3 rollers

(#85), 3 springs #86 and 3 screws (#84).

# 86 × 3

# 84 × 3

2nd lens group housing unit

- L16 ・ AF-S DX18-70/3.5-4.5G -

MR HEAD

INC

JAA79051-R.3624.A

SWM unit

MR head

MR sensor FPC

# 534

# 541 × 2

Magnetic tape

# 533

# 536

① Set the MR head to be parallel with the

magnetic tape.

② Adhere the MR sensor FPC to the inside

of the SWM unit.

Note:Adhere the MR sensor FPC not to be

largely slack.

# 543

INSPECTION AND ADJUSTMENT FOR THE WAVEFORM OUTPUT FROM MR ENCODER

● In case of disassembling or replacing the MR head, be sure to conduct adjustment.

1.Equipment and tools required

・Single output rated voltage power supply: 1 unit With 5.0V and 100mA, applicable to the self-made tool

・Oscilloscope: 1 unit

・Self-made tool: 1 unit

Note:In case of any trouble in continuity between the self-made tool and the contacts of relay FPC, there may

be dust, corrosion or oxidation on the contact surface of relay FPC. Be sure to polish the contact surface prior to

getting connected with the self-made tool.

2.Preparation for measuring lens

・Assemble the SWM unit, on which the MR head is already attached, and the MF ring into the cam ring unit.

Then, connect to the measuring devices. (Refer to the next page.)

- L17 ・ AF-S DX18-70/3.5-4.5G -

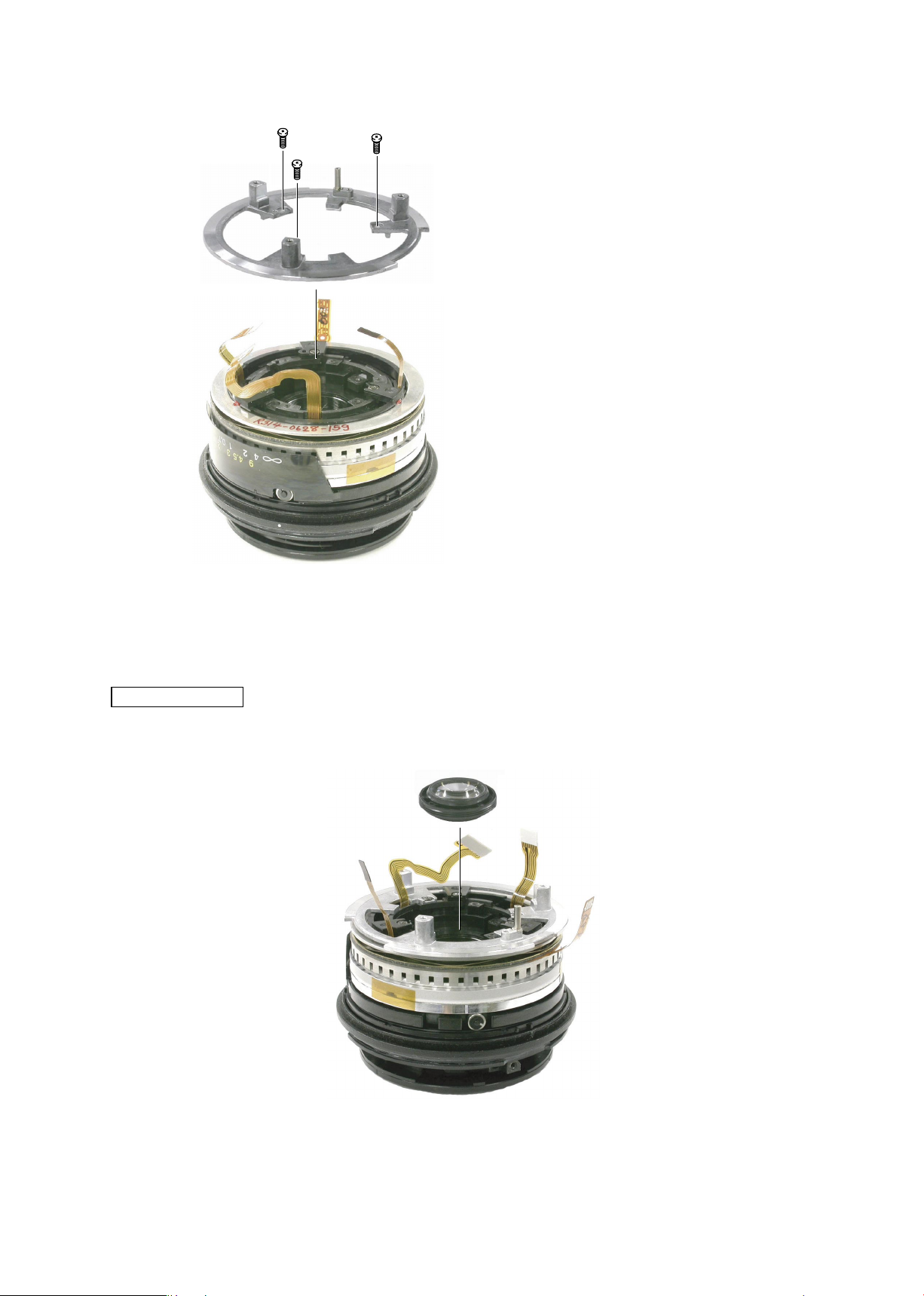

# 96 × 3

INC

JAA79051-R.3624.A

Focus ring

SWM unit

・Connection diagram

Oscilloscope

Oscilloscope

Power supply

Power supply

(2ch)

(1ch)

(+)

(-)

(GND)

Cam ring unit

(+)

Set values

5.0V

100mA

Power supply

Self-made tool

- L18 ・ AF-S DX18-70/3.5-4.5G -

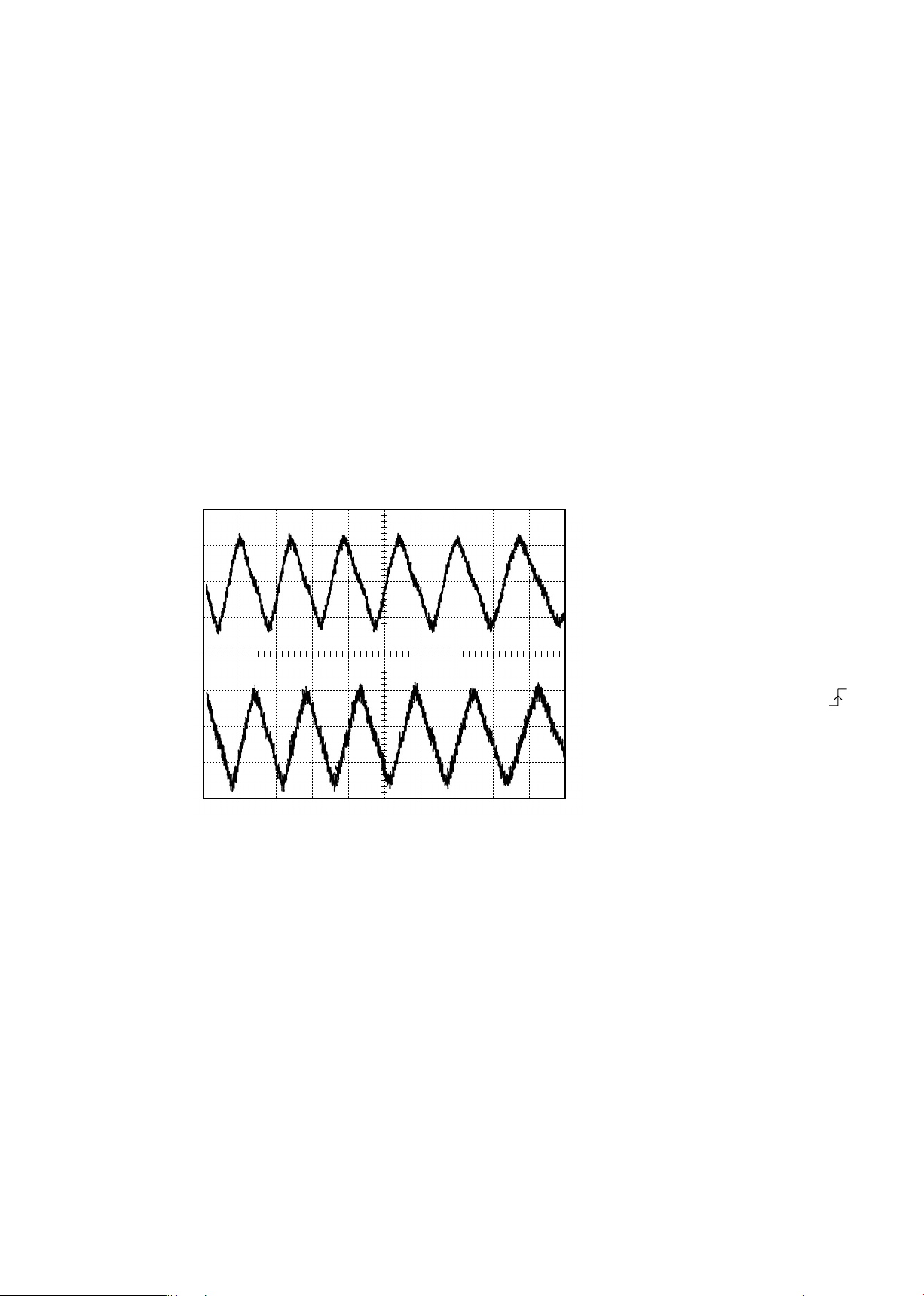

Oscilloscope

2ch

(

)

JAA79051-R.3624.A

C H 1 = 2 0 m V C H 2 = 2 0 m V 5 m s / d i v

AC 10 : 1 A C 10 : 1

NO RM 20 0K S/ s

INC

・How to conduct inspection and adjustment

Make sure that the current and voltage of the connected rated voltage power supply are set values.

①

Then, turn on the power.

② Set the oscilloscope and turn the focus ring by hand.

Note:Because the shape of waveform varies according to the driving speed of focus ring, set Time/Div accordingly.

In case of detecting any wide waveform noise, use the lter function.

③

How to set the ler function by Yokogawa-manufactured DL1540

1.Press the lter button.

2.Select "Smooth" in the menu on the PC screen.

CH1

CH2

●Setting of oscilloscope

V/Div(CH1)

V/Div(CH2)

Coupling

Time/Div

Trigger Mode :NORMAL

Trigger Coupling

Trigger Source

Trigger Position

Trigger Type :EDGE

Trigger Level

:0V

Standard:The amplitude of every pulse/waveform should be 50mV or more.

:20mV

:20mV

:AC

m Sec

:5

:AC

:CH1

div

:+4

Note:Check the waveform by letting the focus ring to travel from the innity-end to the near

distance end and vice versa.

- L19 ・ AF-S DX18-70/3.5-4.5G -

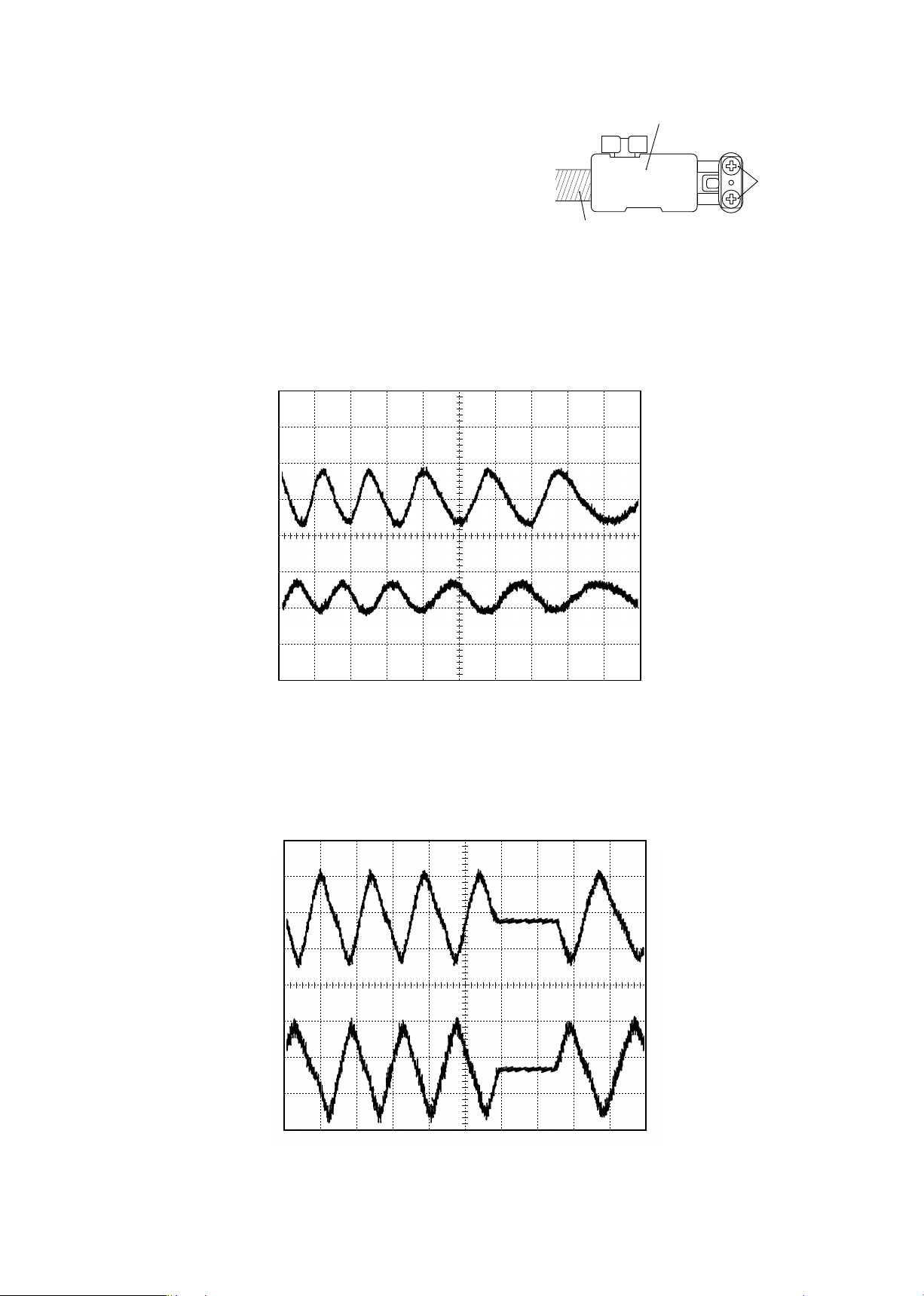

④ In the case of small amplitude, make an adjustment by

C H 1 = 2 0 m V C H 2 = 2 0 m V 5 m s / d i v

AC 10 : 1 A C 10 : 1

NO RM 20 0K S/ s

C H 1 = 2 0 m V C H 2 = 2 0 m V 5 m s / d i v

AC 10 : 1 A C 10 : 1

NO RM 20 0K S/ s

INC

JAA79051-R.3624.A

loosen 2 screws #541 to shift the MR head position as

MR head

shown right.

Note

:

During adjustment, prevent the magnetic tape and MR head

# 541 × 2

from touching the magnetized driver bit, or the magnetic data

may be damaged.

Magnetic tape

《Reference》

● In case the amplitude of either CH1 or CH2 is smaller, one of 2 screws #541 may be loosened, so check for it. But

if this is not the case, the MR head is regarded as malfunctioning. Be sure to replace the MR head unit (B15) and

adjust it again.

CH1

CH2

● In case there is a partial drop in the amplitude between the innity and the near distance, the magnetic data of

magnetic tape may be damaged. Then, replace the magnetic tape and adjust it again.

CH1

CH2

⑦ Turn off the rated voltage power supply and remove the SWM unit.

- L20 ・ AF-S DX18-70/3.5-4.5G -

ZOOM RING FIXING RING

INC

Note:When mounting #22, do NOT allow it to touch the MR head. If external pressure is applied to the

MR head, it causes misalignment and changes the accuracy.

# 22

# 96 × 4

JAA79051-R.3624.A

# 67

Adhere #67 to the zoom ring xing ring (#22)

●

and apply the oil barrier to the whole #67.

INSTALLATION OF THE SWM UNIT

# 96 × 3

Assemble the SWM unit

①

with 3 screws (#93).

- L21 ・ AF-S DX18-70/3.5-4.5G -

# 96 × 3

INC

# 29

JAA79051-R.3624.A

Set the rear xed ring (#29) with 3screws (#96).

①

3rd LENS GROUP

3rd lens group

- L22 ・ AF-S DX18-70/3.5-4.5G -

Loading...

Loading...