NEC UPD9611GT Datasheet

PRELIMINARY DATA SHEET

MOS INTEGRATED CIRCUIT

µ

PD9611

FOUR-CHANNEL PCM CODEC

The µPD9611 incorporates 4-channel A-law/µ-law PCM CODECs compliant with ITU-T Recommendation G.711/

G.714 and is suitable for applications such as PBX analog subscriber line circuits.

Its gain setting circuit allows transmit/receive gain to be set for 4 channels independently by externally inputting

digital signals.

FEATURES

Single-chip CMOS monolithic LSI

•

ITU-T Recommendation G.711/G.714 compliant

•

Four-channel PCM CODECs integrated on a single chip

•

Compatible with A-law and µ-law

•

Digital gain setting for each channel

•

• Transmit : +7.5 to –8.0 dB (0.5 dB step)

• Receive : 0 to –15.5 dB (0.5 dB step)

Data transfer system: Transmit/receive synchronization

•

Data rate: 2048 kHz

•

+5 V single power supply

•

Power down function for each channel

•

Low power consumption

•

ORDERING INFORMATION

Part Number Package

µ

PD9611GT 48-pin shrink SOP (375 mil)

The information in this document is subject to change without notice.

Document No. S11018EJ2V0DS00 (2nd edition)

Date Published October 1996 P

Printed in Japan

©

1996

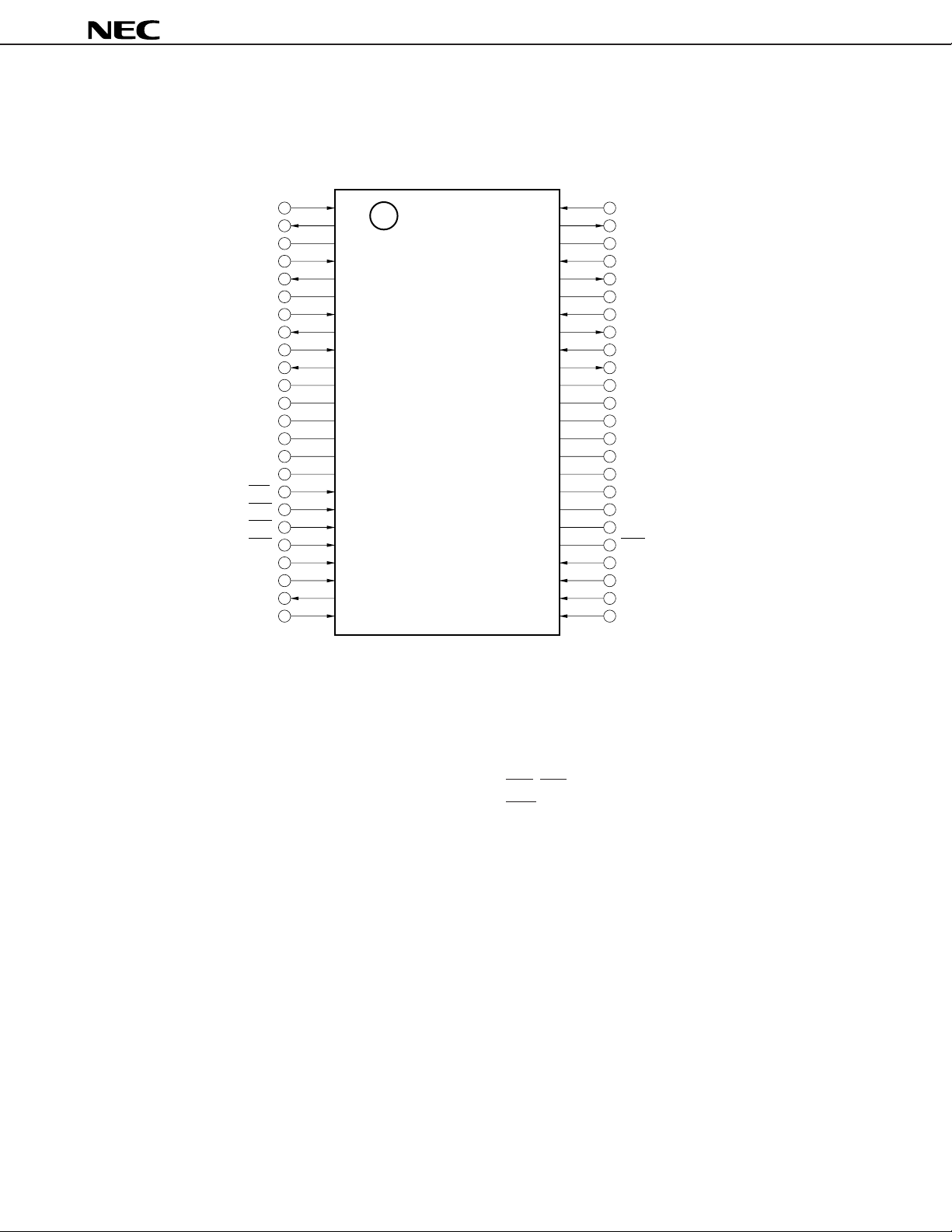

PIN CONFIGURATION (Top View)

48-pin shrink SOP (375 mil)

µ

PD9611

ACOM

ACOM

ACOM

ACOM

A

OUT

A

NC

AIN2

A

OUT

NC

OUT

OUT

AV

DD

AV

DD

AV

DD

AV

DD

DV

NC

PD1

PD2

PD3

PD4

FSC

DCLK

IN

1

1

2

IN

1

1

IN

2

2

1

2

3

4

DD

D

X

D

R

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

µ

PD9611GT

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

AIN4

OUT

4

A

NC

IN

3

A

A

OUT

3

NC

ACOM

IN

ACOM

OUT

ACOM

IN

ACOM

OUT

AGND1

AGND2

AGND3

AGND4

SUBGND

DGND

NC

NC

NC

RST

LAW

SP

DATA

SP

SYNC

SP

CLK

3

3

4

4

IN1-ACOMIN4 : Analog common voltage in

ACOM

ACOMOUT1-ACOMOUT4: Analog common voltage out

AGND1-AGND4 : Analog ground

IN1-AIN4 : Analog signal in

A

AOUT1-AOUT4 : Analog signal out

DD1-AVDD4 : Analog power supply

AV

DCLK : Data clock in

DGND : Digital ground

R : Receive PCM data in

D

DVDD : Digital power supply

D

X : Transmit PCM data out

FSC : Frame synchronous clock in

LAW : A-law/µ-law control in

NC : No connection

PD1-PD4 : Power down control

RST : Reset in

CLK : Serial port data clock in

SP

SPDATA : Serial port data in

SPSYNC : Serial port synchronous clock in

SUBGND : Sub ground

2

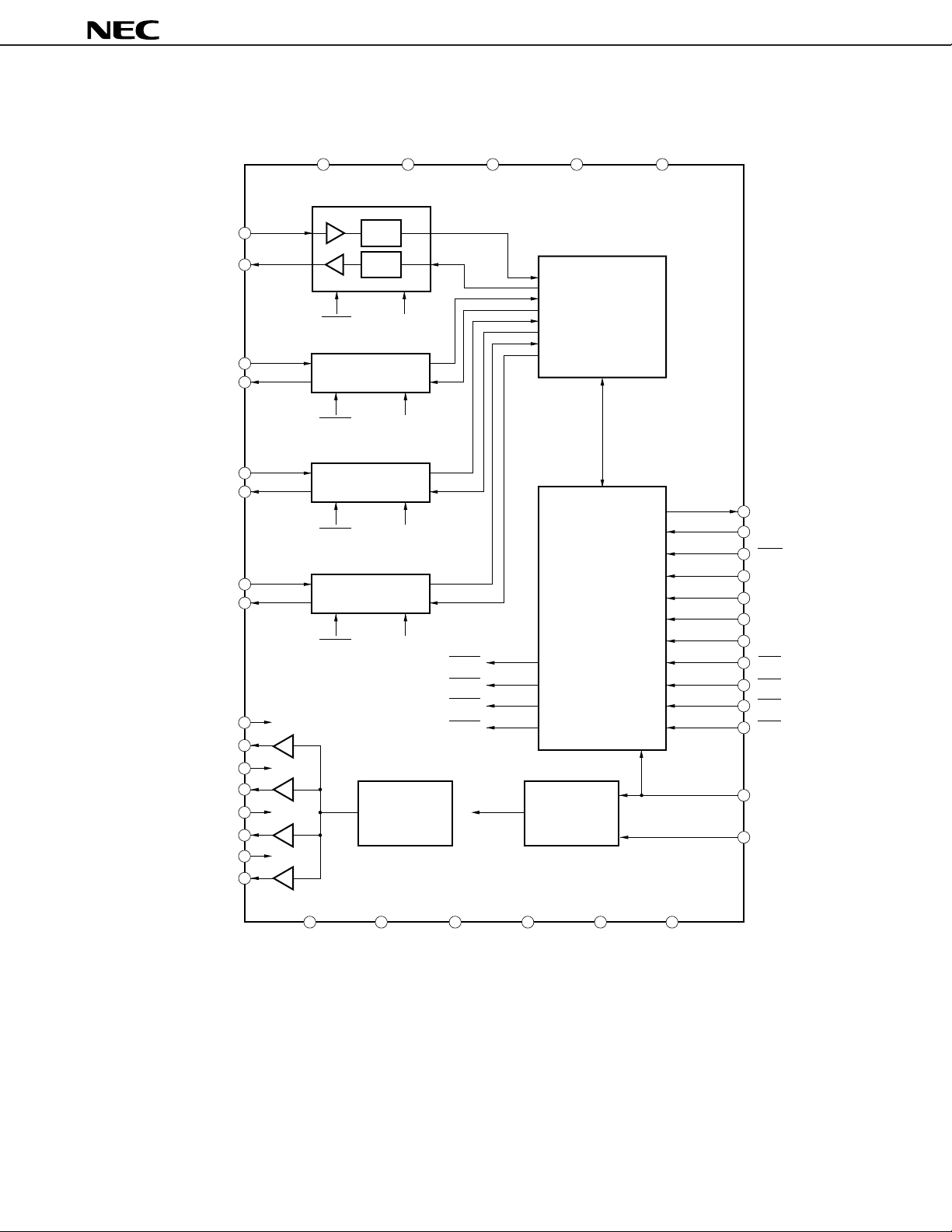

BLOCK DIAGRAM

µ

PD9611

A

A

A

A

ACOMIN1

ACOM

ACOM

ACOM

ACOM

ACOM

ACOM

ACOM

AIN1

OUT

IN

A

OUT

IN

A

OUT

IN

A

OUT

OUT

IN

OUT

IN

OUT

IN

OUT

AVDD1AV

DD

2AV

DD

3AV

DD

4DV

DD

CH1

A/D

1

D/A

DSP

APD1

2

ACOM

CH2

IN

1

Channel FiIter

2

IN

APD2

3

ACOM

CH3

2

3

D

X

D

ACOMIN3APD3

R

RST

SYNC

4

4

CH4

I/O

Linear ↔ A,

µ

DGS

ACOMIN4APD4

MUX, DEMUX

APD1

APD2

APD3

APD4

SP

SP

SP

LAW

PD1

PD2

PD3

PD4

CLK

DATA

1

2

2

3

Voltage

Reference

Clock

Generator

3

FSC

DCLK

4

4

AGND1

AGND2 AGND3 AGND4 DGND SUBGND

3

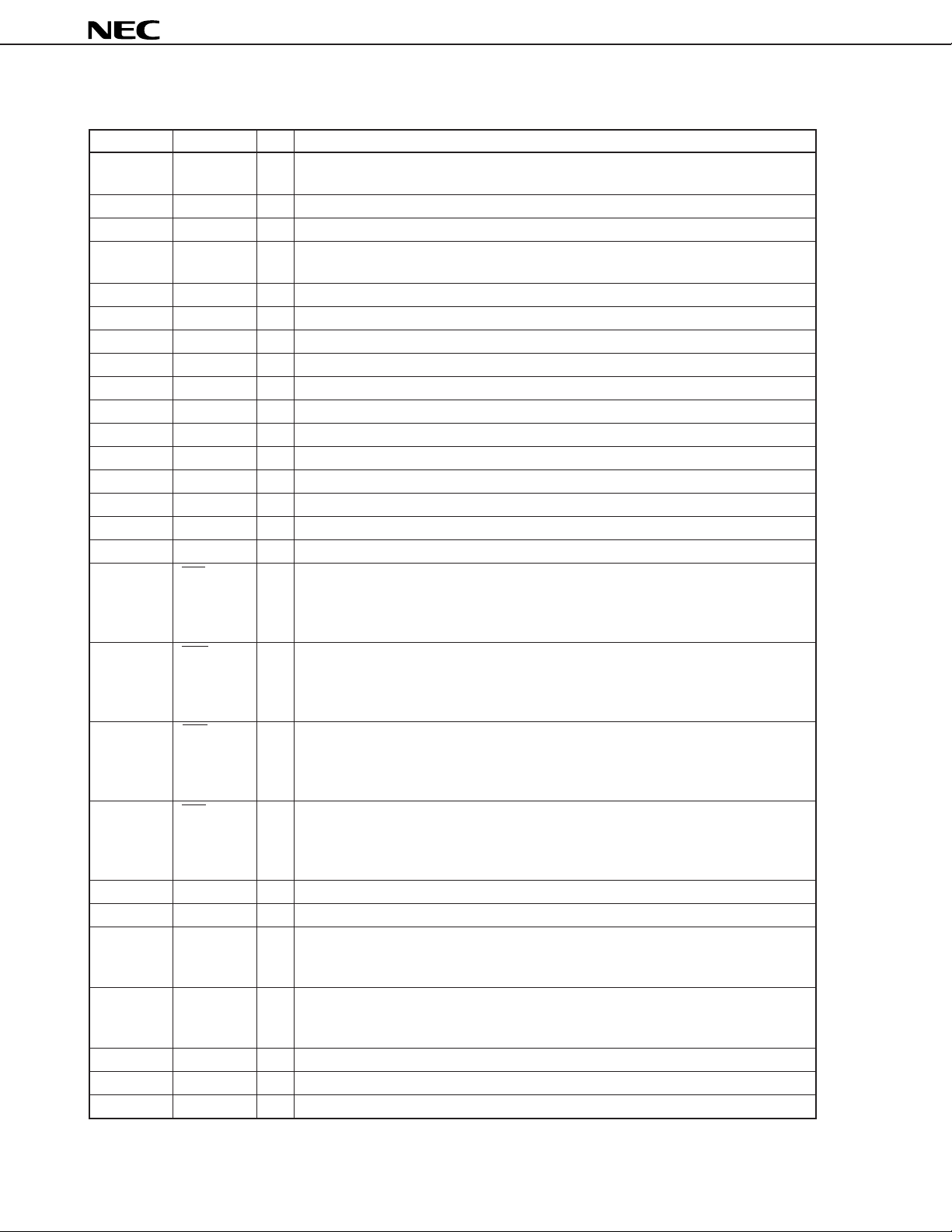

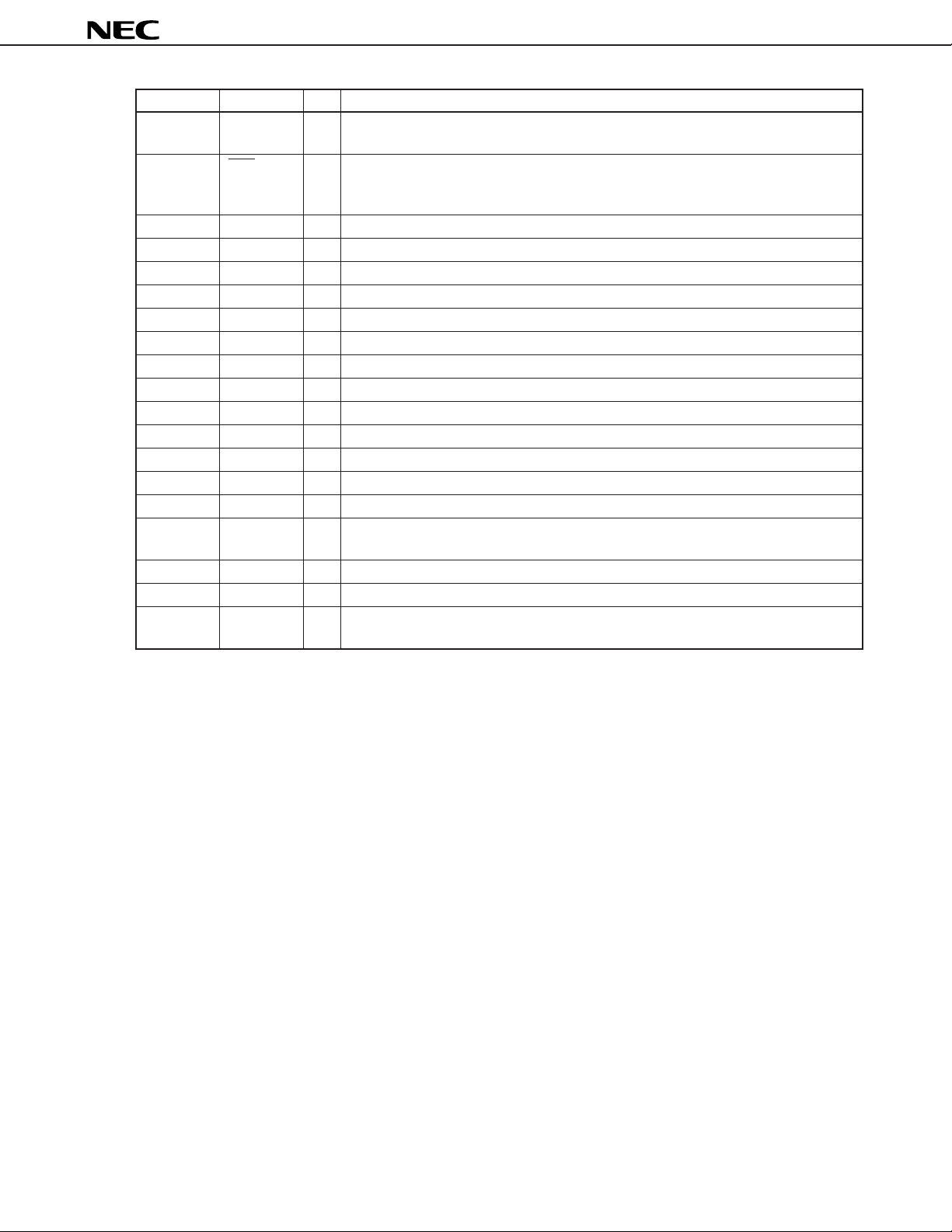

1. PIN DESCRIPTION

Pin No. Symbol I/O Name and Function

1AIN1 I Transmit analog input pin for channel 1

When not used, connect to ACOMOUT1 pin.

2AOUT1 O Receive analog output pin for channel 1

3 NC – Leave this pin open.

4AIN2 I Receive analog input pin for channel 2

When not used, connect to ACOMOUT1 pin.

5AOUT2 O Transmit analog output pin for channel 2

6 NC – Leave this pin open.

7 ACOMIN1 I Signal reference voltage input for channel 1

8 ACOMOUT1 O Signal reference voltage output for channel 1

9 ACOMIN2 I Signal reference voltage input for channel 2

10 ACOMOUT2 O Signal reference voltage output for channel 2

11 AVDD1 – Analog power supply pin for channel 1 +5 ± 0.25 V

12 AVDD2 – Analog power supply pin for channel 2 +5 ± 0.25 V

13 AVDD3 – Analog power supply pin for channel 3 +5 ± 0.25 V

14 AVDD4 – Analog power supply pin for channel 4 +5 ± 0.25 V

15 DVDD – Digital power supply pin +5 ± 0.25 V

16 NC – Leave this pin open.

17 PD1 I Power-down control input pin for channel 1

Channel 1 enters power-down mode when this signal is low level.

The output of DX pin for channel 1 becomes high-impedance and AOUT1 becomes

signal reference voltage in the power-down mode.

18 PD2 I Power-down control input pin for channel 2

Channel 2 enters power-down mode when this signal is low level.

The output of DX pin for channel 2 becomes high-impedance and AOUT2 becomes

signal reference voltage in the power-down mode.

19 PD3 I Power-down control input pin for channel 3

Channel 3 enters power-down mode when this signal is low level.

The output of DX pin for channel 3 becomes high-impedance and AOUT3 becomes

signal reference voltage in the power-down mode.

20 PD4 I Power-down control input pin for channel 4

Channel 4 enters power-down mode when this signal is low level.

The output of DX pin for channel 4 becomes high-impedance and AOUT4 becomes

signal reference voltage in the power-down mode.

21 FSC I Frame synchronous clock input pin (8 kHz)

22 DCLK I Data clock input pin (2048 kHz)

23 DX O Transmit PCM data output pin

This pin outputs PCM data for channel 1 to 4 in synchronization with rising edges

of DCLK after rising edges of FSC. It becomes high-impedance for other timings.

24 DR I Receive PCM data input pin

This pin inputs PCM data for channel 1 to 4 in synchronization with falling edges of

DCLK after rising edges of FSC.

25 SPCLK I Setting data clock input pin

26 SPSYNC I Setting synchronous clock input pin

27 SPDATA I Setting data input pin

µ

PD9611

4

Pin No. Symbol I/O Name and Function

28 LAW I A-law/µ-law select pin in common to four channels

L: A-law, H: µ-law

29 RST – Reset input, power-on reset pin

H: normal operation

L: internal registers are in the default status.

30-32 NC – Leave this pin open.

33 DGND – Digital ground pin

34 SUBGND – Substrate ground pin

35 AGND4 – Analog ground pin for channel 4

36 AGND3 – Analog ground pin for channel 3

37 AGND2 – Analog ground pin for channel 2

38 AGND1 – Analog ground pin for channel 1

39 ACOMOUT4 O Signal reference voltage output for channel 4

40 ACOMIN4 I Signal reference voltage input for channel 4

41 ACOMOUT3 O Signal reference voltage output for channel 3

42 ACOMIN3 I Signal reference voltage input for channel 3

43 NC – Leave this pin open.

44 AOUT3 O Receive analog output pin for channel 3

45 AIN 3 I Transmit analog input pin for channel 3

When not used, connect to ACOMOUT1 pin.

46 NC – Leave this pin open.

47 AOUT4 O Receive analog output pin for channel 4

48 AIN 4 I Transmit analog input pin for channel 4

When not used, connect to ACOMOUT1 pin.

µ

PD9611

5

2. CAUTIONS ON USE

(1) Absolute maximum ratings

Application of voltage or current in excess of the absolute maximum ratings to the µPD9611 may result

in damage due to latch up, etc. Be especially cautions about power supply noise, etc.

(2) Wiring pattern

µ

The design of the ground pattern is extremely important for operating the

Connect the analog ground pins (AGND1 to AGND4), digital ground pin (DGND) and substrate ground

pin (SUBGND) close to the IC pins, and connect to a wide analog ground line on the board.

(3) Addition of bypass capacitors for power supply pins

µ

Because the

PD9611 uses many internal high-frequency operational amplifiers, high power supply

impedance can cause instability (such as oscillation) in these internal operational amplifiers. To

suppress such instability and eliminate power supply noise, connect all power supply pins (AV

AVDD4, DVDD) close to the IC pins, and put bypass capacitors (CVDD = approximately 0.1 µF) having

superior high-frequency characteristics very close to the pins.

PD9611 with high precision.

µ

PD9611

DD1 to

(4) Addition of bypass capacitors for ACOM pins

µ

PD9611 incorporates references voltages for signal sources. Superposing of noise on these

The

reference voltages may have adverse effects on transmission characteristics, etc. Therefore, connect

the ACOM

OUT pin and ACOMIN pin close to the IC pins, and put bypass capacitors (CACOM = approximately

0.1 µF) having superior high-frequency characteristics very close to the pins.

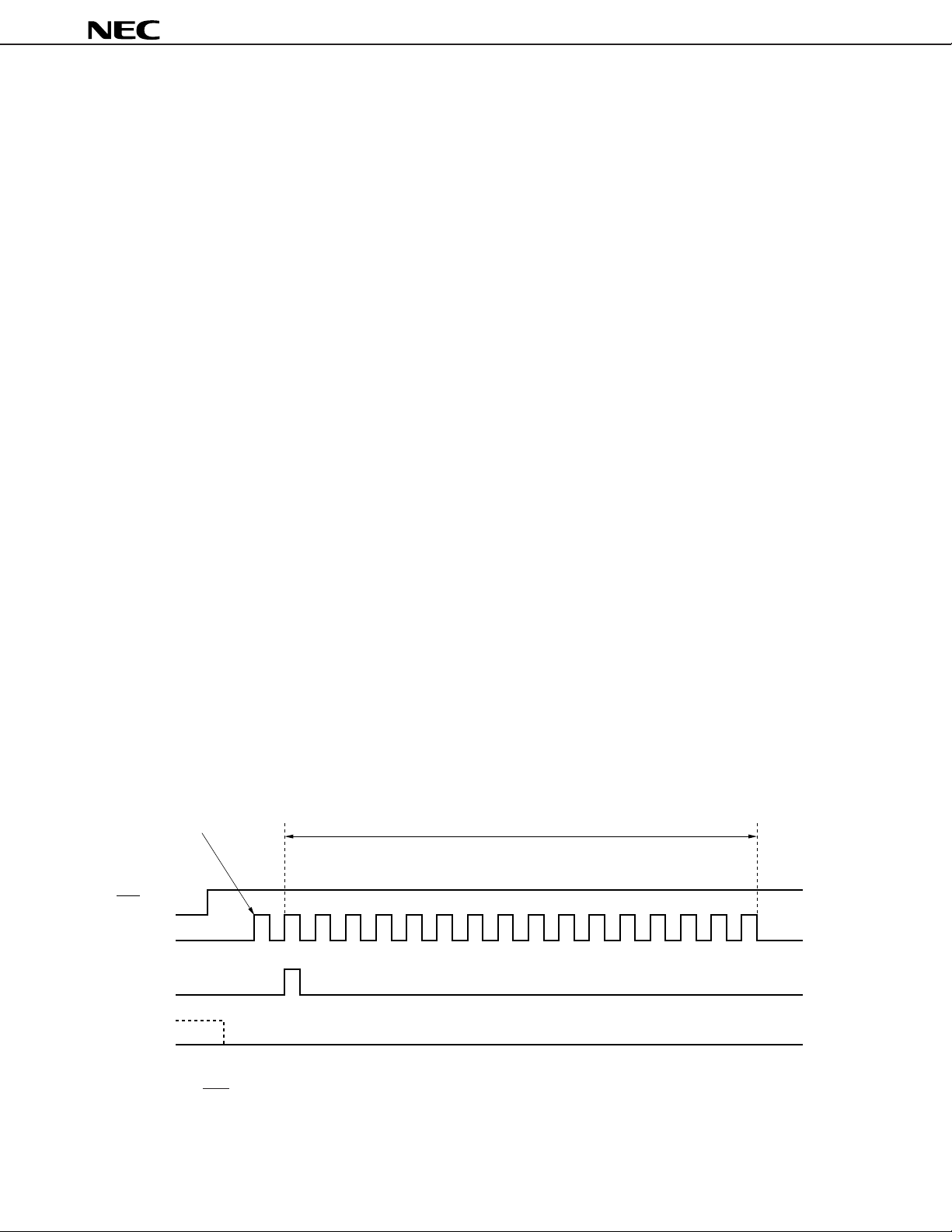

(5) Control or SP

DATA pin on reset

When inputting the setting data from the SPDATA pin after the µPD9611 is reset, first input the following

patterns to reset to 0 the couter used to fetch data from the SPDATA pin.

SP

SP

1 clocks or more

RST

CLK

SYNC

16 clocks or more

SP

DATA

After ther RST pin has been set to the high level, input 1 clock or more to the SPCLK pin, set the SPSYNC

pin to the high level and input 16 clocks more to the SPCLK pin.

During this operation, the SPDATA pin is held at the low level. Afterwards, input the setting data.

6

3. GENERAL OPERATION

(1) PCM data transfer

In the transmit section, if FSC pin is set to the high level in synchronization with the rising edge (↑) of

the data clock applied to the DCLK pin, the D

1 is output. The following data of 7 bits is clocked out in synchronization with the rising edge (↑) of each

data clock. Sign bit data (MSB) of channel 2 is output in synchronization with the rising edge (↑) of the

9th data clock. In the same manner, each data up to channel 4 is output and the rising edge (↑) of the

33rd data clock then sets the D

Similarly, in the receive section, if the FSC pin is set to the high level in synchronization with the rising

edge (↑) of the data clock applied to the DCLK pin, data of D

the data clock and consecutively clocked in.

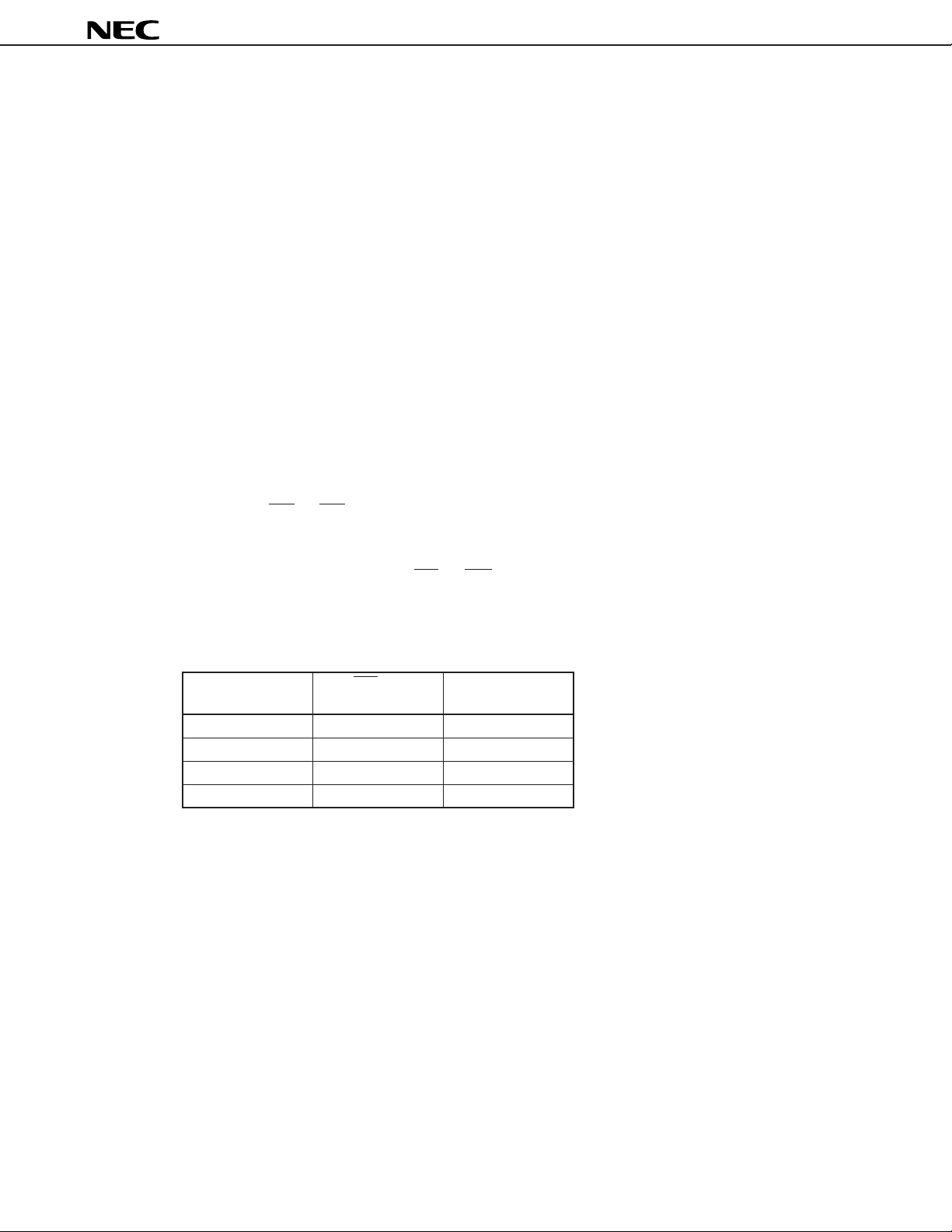

(2) Power down control

µ

PD9611 has the following two methods for power down control and is able to control power-down

The

independently for each channel.

X pin becomes active and sign bit data (MSB) of channel

X pin to high-impedance state.

µ

PD9611

R pin is latched by the falling edges (↓) of

• Sets pins PD1 to PD4 to high or low level.

• Inputs 8-bit setting data from SP

DATA pin (see (5) Control of SPDATA pin).

Internal data is the logical sum of PD1 to PD4 pin state and 8-bit setting data input.

If the internal data is 0, the channel enters the power-down state. If the internal data is 1, the channel

enters the power-up state. In the power down state, PCM data in the channel goes to high-impedance

state and analog output becomes the signal reference voltage level.

8-Bit Setting Data PD1 Pin Internal Data

(Channel 1)

000

101

011

111

Remarks 1. 0: Power down, 1: Power up

2. The settings are the same for channel 2 to channel 4.

7

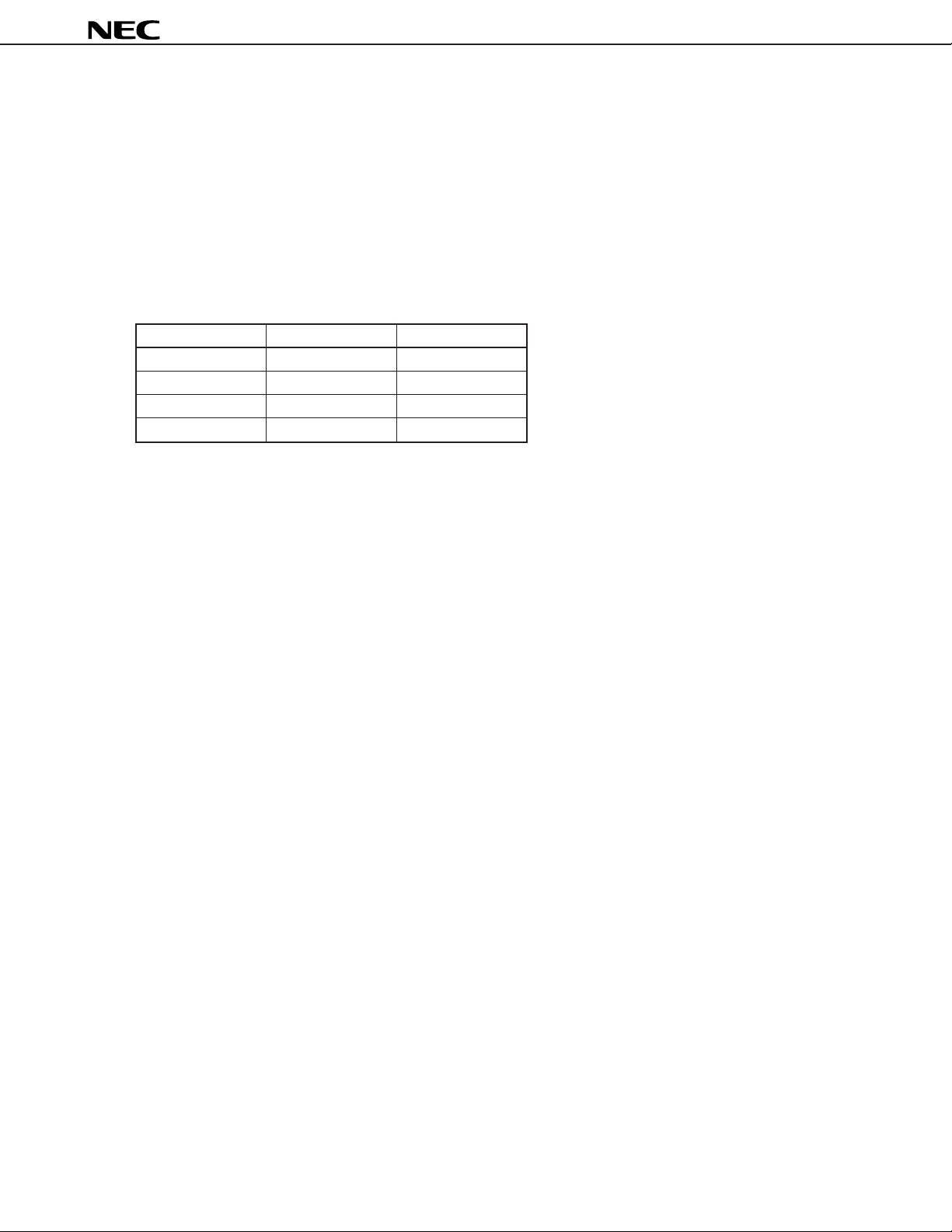

(3) A-law/µ-law control

µ

PD9611 has the following two methods for A-law/µ-law control.

The

• Sets LAW pin to high or low level.

• Inputs 8-bit setting data from SP

Internal data is the logical sum of LAW pin state and 8-bit setting data input.

If the internal data is 0, the

µ

-law mode.

8-Bit Setting Data LAW Pin Internal Data

000

101

011

111

Remark 0: A-law, 1: µ-law

µ

DATA pin (see (5) Control of SPDATA pin).

PD9611 enters A-law mode. If the internal data is 1, the µPD9611 enters

µ

PD9611

(4) Gain Setting control for transmit/receive

µ

PD9611 can control gain settings independently for the transmit/receive by inputting 8-bit setting

The

data (see (5) Control of SPDATA pin) from the SPDATA pin for four channels. Gain can be set from +7.5

to –8.0 dB for the transmit and +0.0 dB t o –15.5 dB for the receive in 0.5 dB steps.

8-bit setting data input from SP

of transmit/receive and gain setting in the second 8 bits.

DATA pin specifies the channel set in the first 8 bits, and performs selection

8

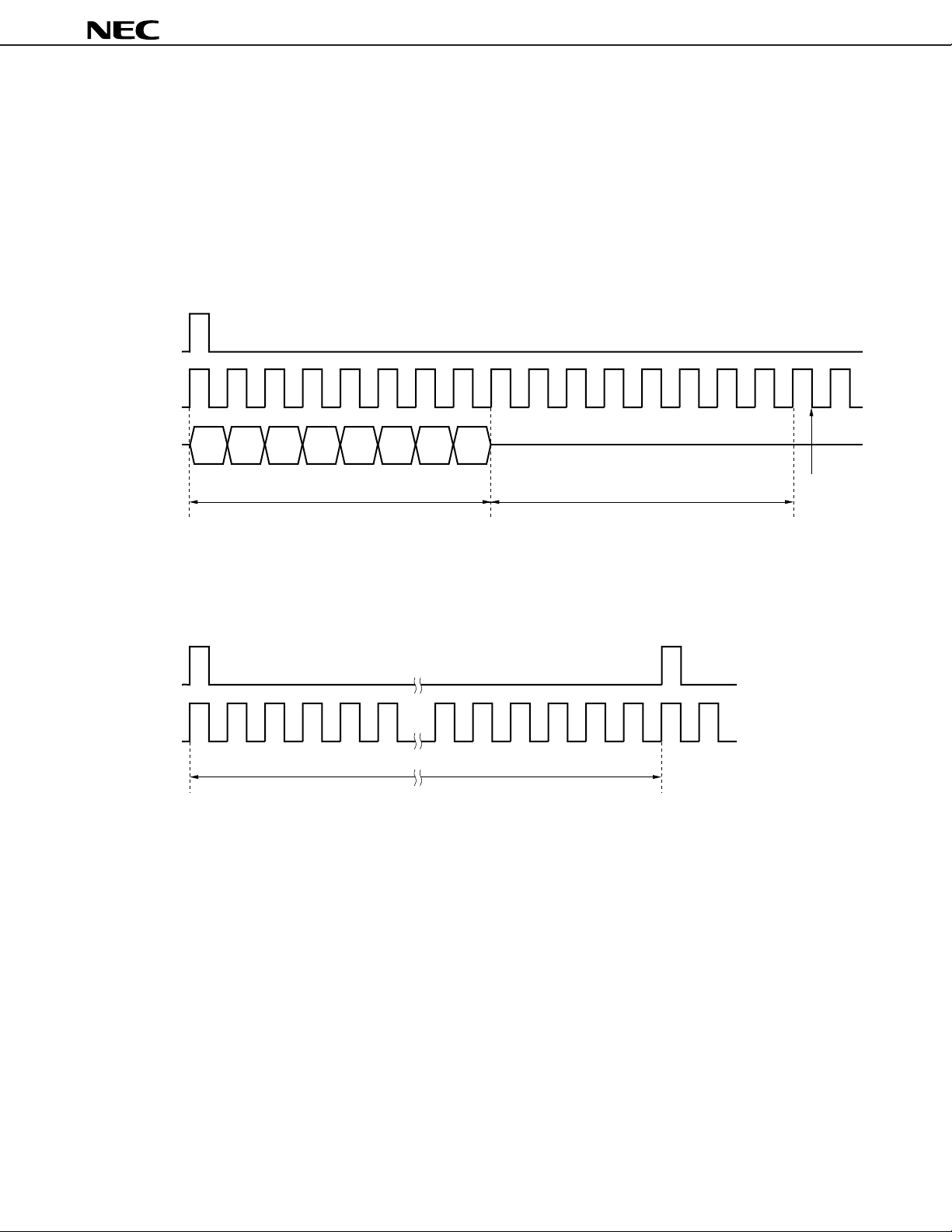

(5) Control of SPDATA pin

SYNC pin is set to the high level in synchronization with the rising edge (↑) of the data clock applied

If SP

to the SPCLK pin, data of the SPDATA pin is latched by the falling edge (↓) of the data clock and

consecutively fetched in.

After the 8-bit data has been fetched, the setting operation is performed according to the data.

This setting operation is performed during the 8 clocks after fetching the data and the next data is valid

at the 17th clock.

Therefore, when setting 1 word (8 bits) of data, input 17 clocks or more to the SP

SP

SYNC

CLK pin.

µ

PD9611

SP

SP

SP

123456789101112131415161718

CLK

DATA

Ensure that 17 clocks or more are input to the SP

SYNC.

17 clocks or more

SP

SYNC

CLK

the next SP

Don’t care

Setting operationData fetch

CLK pin between the rising of SPSYNC and the rising of

Setting

completed

(The next

data is valid.)

9

Loading...

Loading...