Page 1

SERVICE MANUAL

MODELS : T512C/T532C/T512AH/T532AHSERVICE MANUAL

© NAD 2003

NAD ELECTRONICS INTERNATIONAL

TORONTO

T512AH/T532AH

T512C/T532C/

DVD PLAYER

SERVICE MANUAL

T512C/T532C/

T512AH/T532AH

DVD PLAYER

T512C/T532C/

T512AH/T532AH

DVD PLAYER

Page 2

CONTENTS

SECTION 1 . . . . SUMMARY

SECTION 2 . . . . CABINET & MAIN CHASSIS

SECTION 3 . . . . ELECTRICAL

SECTION 4 . . . . MECHANISM

SECTION 5 . . . . REPLACEMENT PART LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

........................... 1-3

SERVICING PRECAUTIONS .................................................................................................. 1-4

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

SPECIFICATIONS ...................................................................................................................... 1-5

Page 4

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 5

1-4

SERVICING PRECAUTIONS

CAUTION : Before servicing the DVD covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this DVD or any of

its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this DVD and/or any of its

electrical assemblies unless all solid-state device heat

sinks are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 6

1-5

SPECIFICATIONS

• GENERAL

Power requirements AC 120V, 60Hz(USA), AC 110~220V, 60Hz(EUROPE)

Power consumption 14W

Dimensions(approx.) 430 x 69 x 230mm (W/h/d)

Mass(approx.) 3.4kg

Operating temperature 5˚C to 35˚C (41˚F to 95˚F)

Operating humidity 5% to 9%

• SYSTEM

Laser Semiconductor laser, wavelength 650nm

Signal system NTSC(USA), NTSC/PAL(EUROPE)

Frequency response DVD (PCM 96kHz): 2Hz to 44kHz

DVD (PCM 48kHz): 2Hz to 22kHz

CD: 2Hz to 20kHz

Signal-to-noise ratio More than 100dB (ANALOG OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 95dB(DVD)

More than 95dB(CD)

Wow and flutter Less than detected value (±0.001% W PEAK)

• OUTPUTS

VIDEO OUTPUTS 1V p-p, 75 ohms, sync negative

S-V IDEO OUTPUTS (Y)1.0V(p-p), 75Ω, negative sync., Mini DIN 4-pin x 1

(C)0.286V(p-p), 75 ohms(USA),

(C)0.3V(p-p), 75 ohms(EUROPE)

Audio output(digital audio) 0.5V(p-p), 75Ω, RCA jack X 1 (TO TV)

Audio output(optical audio) Optical connector x 1

Audio output(analog audio) 2.0Vrms (1kHz, 0dB),

330Ω, RCA jack (L, R) x 1 (TO TV)

Page 7

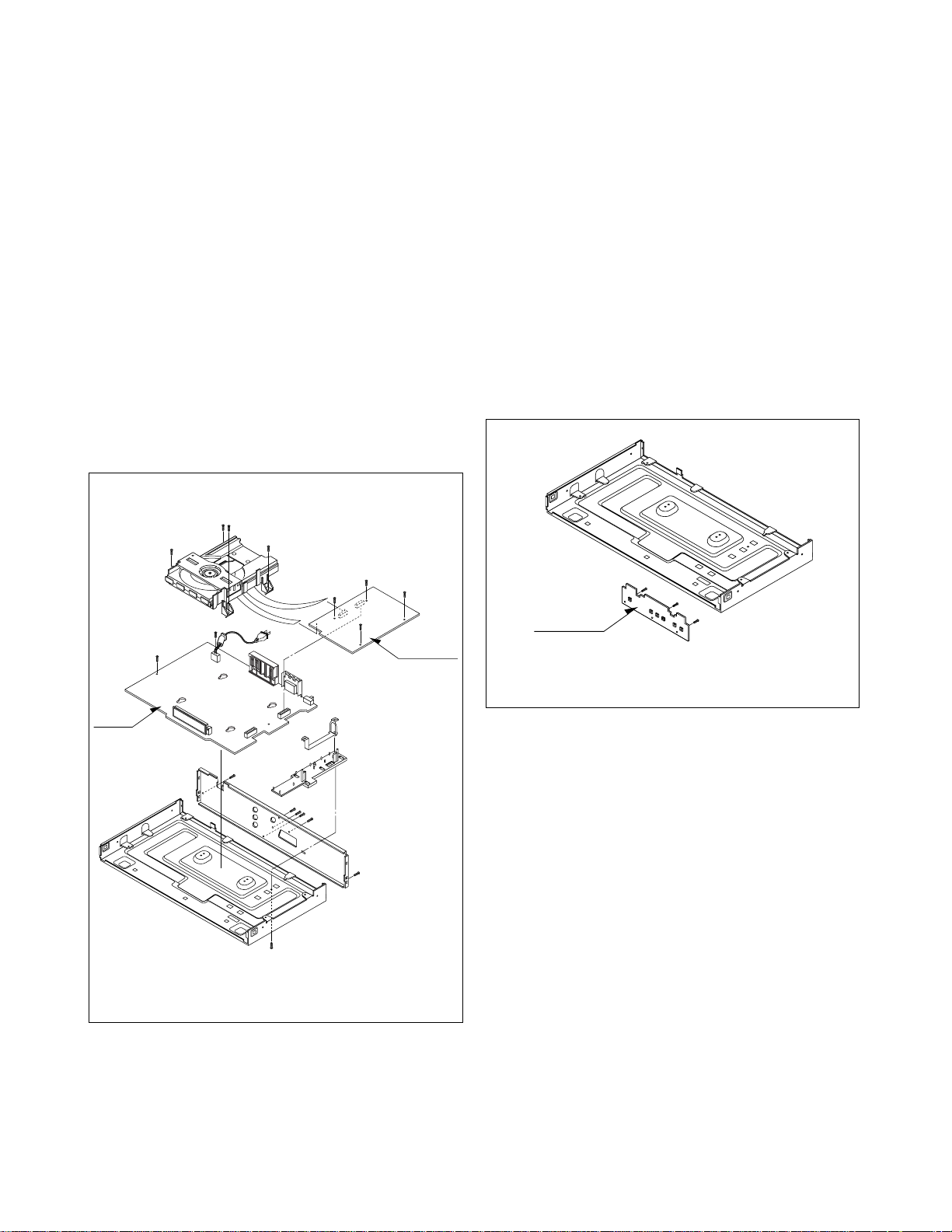

2-1

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

1. DISASSEMBLY.........................................................................................................................2-2

CABINET DISASSEMBLY ............................................................................................................2-2

CIRCUIT BOARD DISASSEMBLY ...............................................................................................2-3

2. EXPLODED VIEWS ................................................................................................................2-4

1. Cabinet and Main Frame Section ...........................................................................................2-4

2. Packing Accessory Section....................................................................................................2-5

Page 8

2-2

DISASSEMBLY

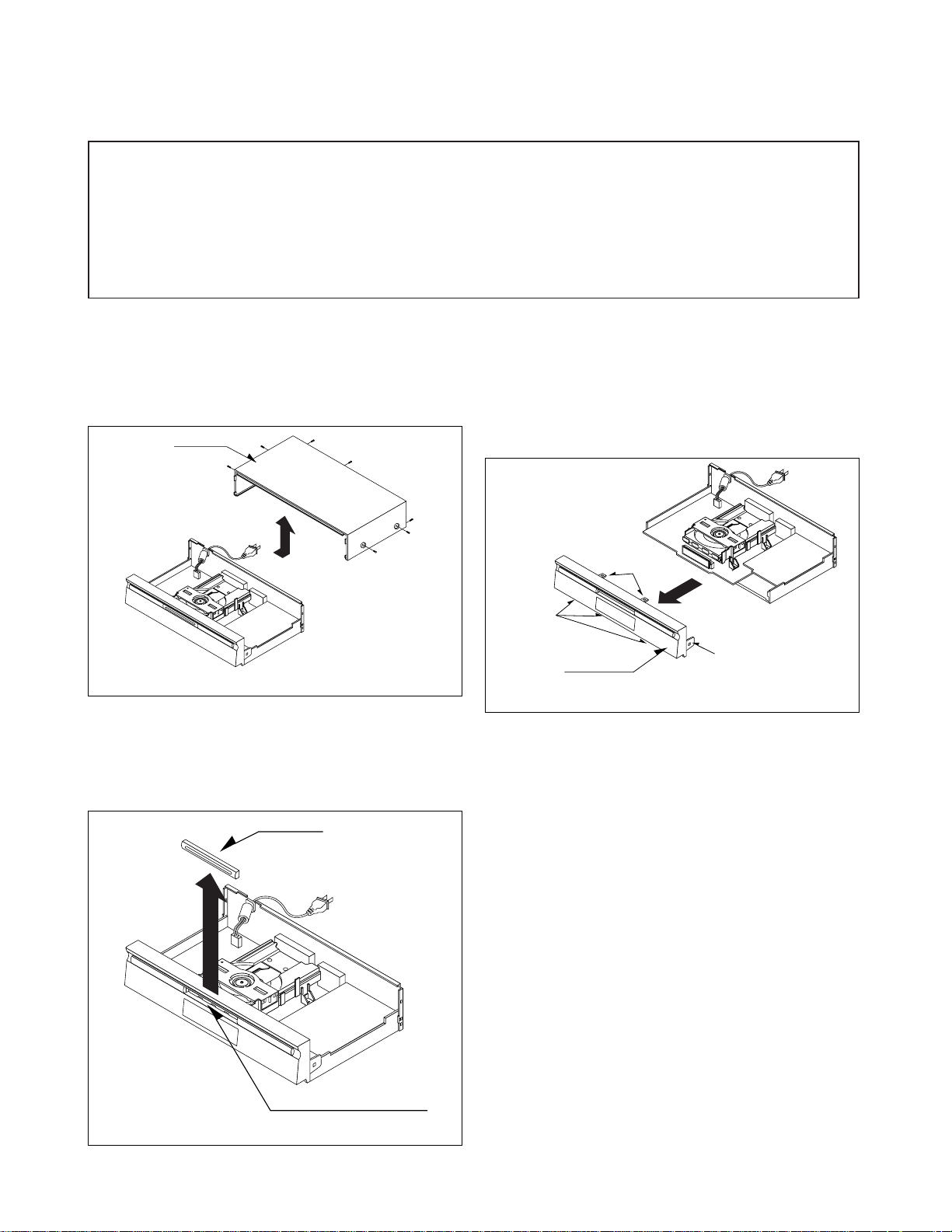

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily and damaged, so do not forget to take a

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to secure

metal parts. If they are used improperly, the screw holes will be easily damaged and the parts can not be fixed.

(A)

(A)

(A)

(A)

(A)

Top Case

(A)

(A)

Tray Door

Disc Tray

Stopper

Stopper

Stopper

Front Panel

CABINET DISASSEMBLY

1. Top Case

1. Release 7 screws (A). (See Fig. 2-1)

2. Lift the top case with holding the back of it,

and remove it in the direction of the arrow

Fig. 2-1

Fig. 2-2

Fig. 2-3

3. Front Panel

1. Eject the disc tray. (See Fig. 2-2)

2. Remove the tray door. (See Fig. 2-2)

3. Pull the front panel toward you while pressing

7 stoppers to disengage, and remove the front

panel. (See Fig. 2-3)

2.Tray Door

1.Eject the disc tray.

2.Lift up the tray door in the direction of the

arrow.

Page 9

2-3

Interface

Board

Main Circuit

Board

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(B)

(C)

Key

Circuit Board

(D)

(D)

(D)

Fig. 2-4

Fig. 2-5

1. Disassembling of Main Circuit Board

and Interface Board

1. Remove the top case.(See Fig. 2-1)

2. Remove 14 screw (B).

3. Remove the Deck from Main Circuit Board.

4. Remove Main Circuit Board from Interface Board.

5. Remove 2 screw (C).

6. Remove Interface Board from the chassis.

CIRCUIT BOARD DISASSEMBLY

Note: Before removing the main circuit board, be sure to shortcircuit the laserdiode output land.

After replacing the main circuit board, open the land after inserting the flexible connector.

(Refer to Mechanism Disassembly)

2. Digitron and Key Circuit Board

1. Remove the front panel.(See Fig. 2-3)

2. Release 3 screws (D), and remove the digitron

circuit board.

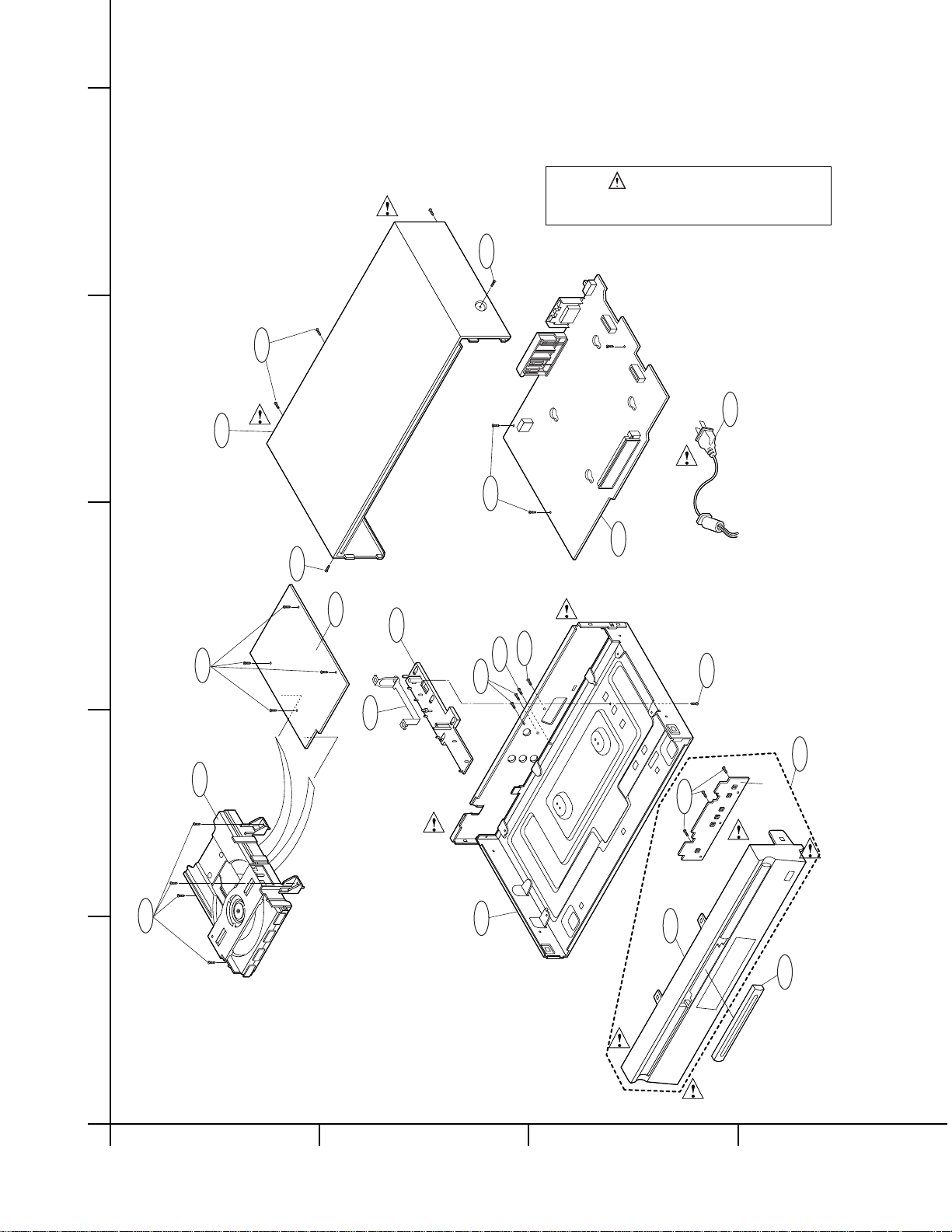

Page 10

2-4

EXPLODED VIEWS

1. Cabinet and Main Frame Section

463

463

A48

463

463

463

463

A46

250

300

A43

283

280

452

465

465

467

467

275

A00

332

260

PBT00

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

A

5

4

3

2

1

BCD

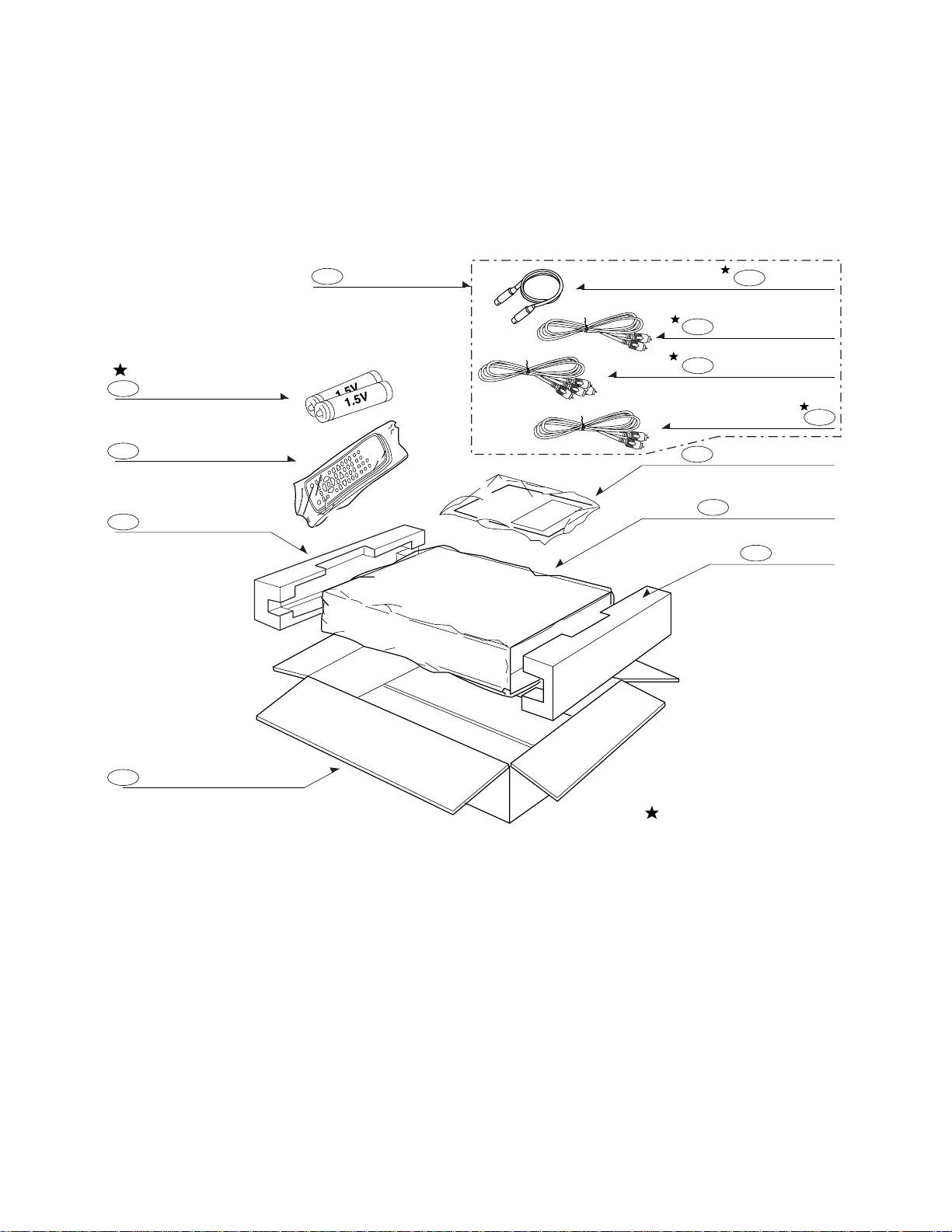

Page 11

2-5

2. Packing Accessory Section

BATTERY

808

PACKING SHEET

804

PACKING

OPTIONAL PARTS

803

806

813

OWNER'S MANUAL

RF CABLE

810

CABLE SET ASS'Y

801

REMOCON

900

BOX CARTON

802

PACKING

803

811

812

PLUG ASS'Y 1WAY

PLUG ASS'Y 2WAY

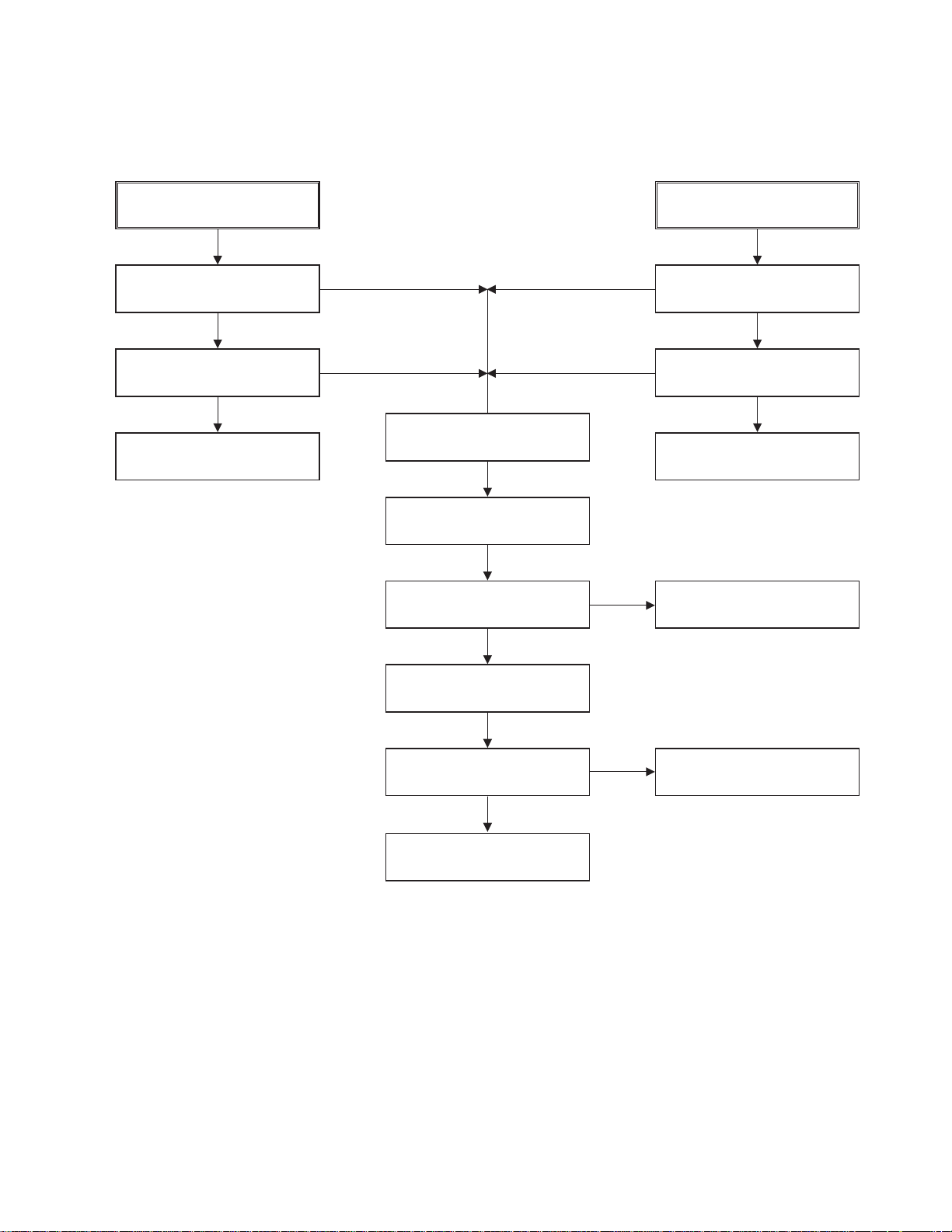

Page 12

3-1

SECTION 3

ELECTRICAL

CONTENTS

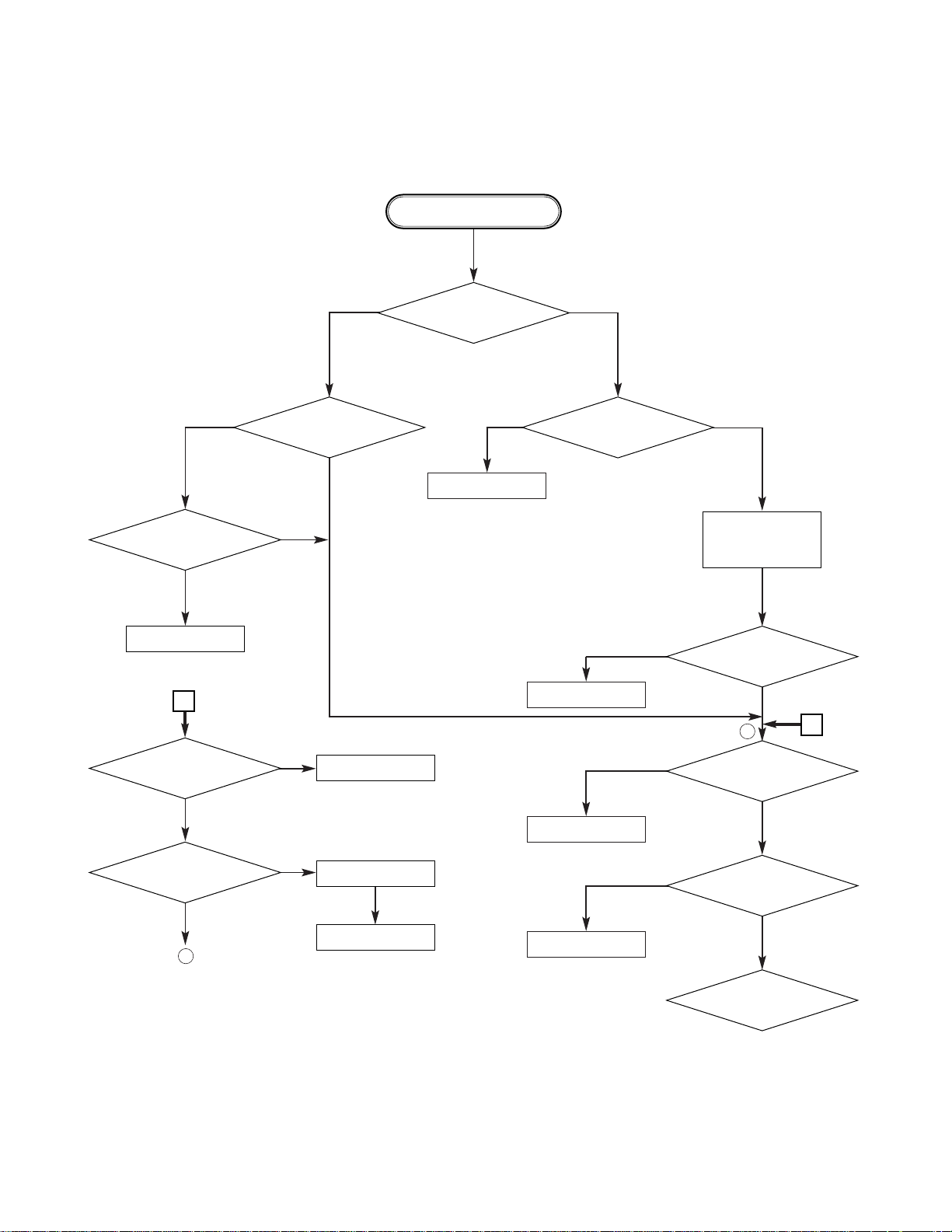

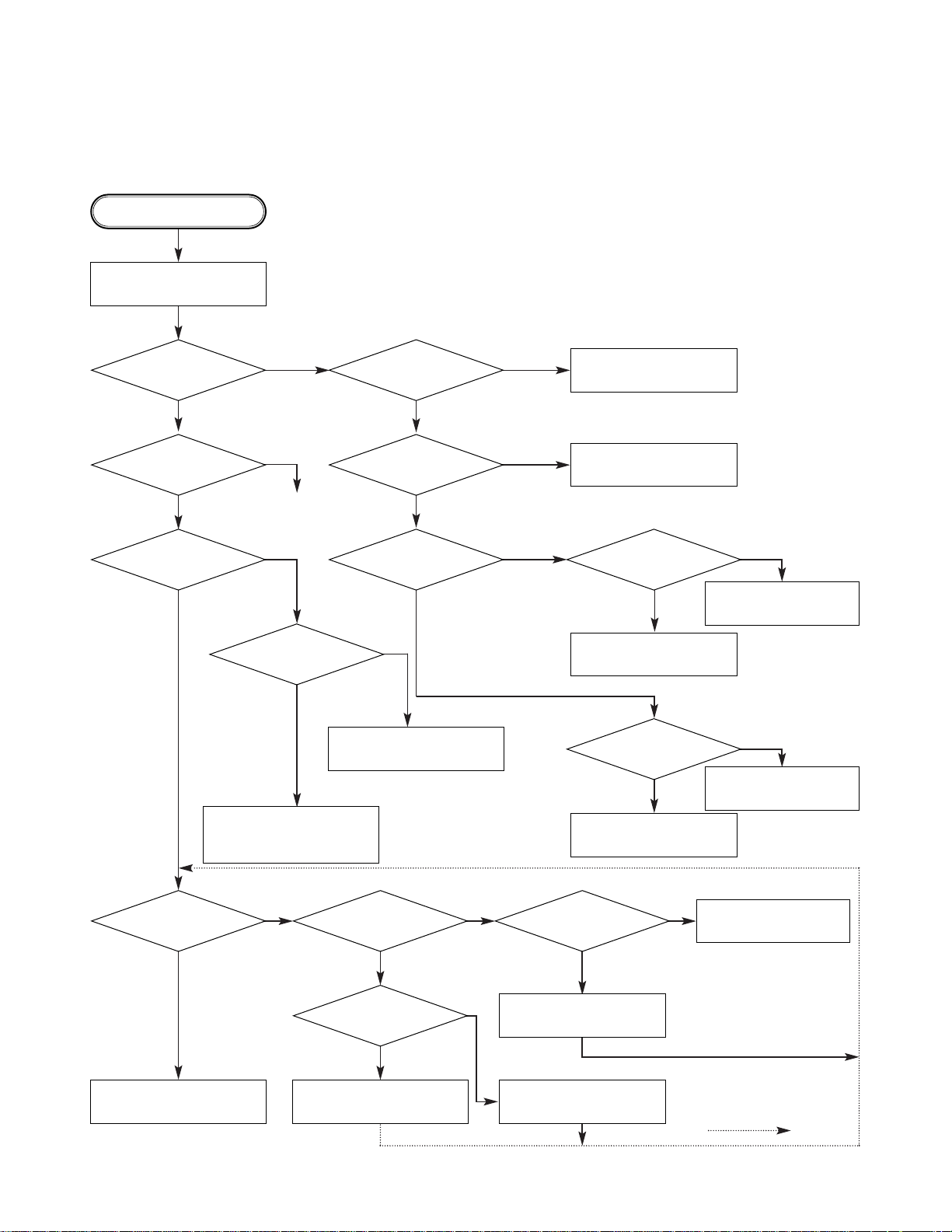

ELECTRICAL TROUBLESHOOTING GUIDE......................................................................3-2

1. Power(SMPS) Circuit ...............................................................................................................3-2

2. µ-com Circuit............................................................................................................................3-3

3. MPEG Circuit............................................................................................................................3-6

4. Front Circuit(Digitron & Key) ................................................................................................3-7

5. RF/Servo Circuit ......................................................................................................................3-8

BLOCK DIAGRAMS ..................................................................................................................3-12

1. Overall Block Diagram ..........................................................................................................3-13

2. Power (SMPS) Block Diagram ..............................................................................................3-14

3. RF/CD DSP/DVD DSP/DVD servo Block Diagram ..............................................................3-14

4. Audio Block Diagram ............................................................................................................3-15

5. MPEG & MEMORY Block Diagram .......................................................................................3-16

CIRCUIT DIAGRAMS................................................................................................................3-17

1. Power (SMPS) Circuit Diagram ............................................................................................3-17

2. DVD DSP Circuit Diagram.....................................................................................................3-19

3. Drive & RF Circuit Diagram ..................................................................................................3-21

4. MPEG Circuit Diagram ..........................................................................................................3-23

• WAVEFORMS ...........................................................................................................................3-25

5. Audio Circuit Diagram...........................................................................................................3-27

6. MEMORY Circuit Diagram.....................................................................................................3-29

7. FRONT Circuit Diagram.........................................................................................................3-31

8. A/V JACK Circuit Diagram ....................................................................................................3-33

• CIRCUIT VOLTAGE CHART ....................................................................................................3-35

PRINTED CIRCUIT DIAGRAMS ............................................................................................3-39

1. MAIN P.C.BOARD ...................................................................................................................3-39

2. POWER,A/V,FRONT P.C.BOARD ..........................................................................................3-41

3. KEY P.C.BOARD.....................................................................................................................3-43

Page 13

3-2

ELECTRICAL TROUBLESHOOTING GUIDE

No 5V_D

or 5V_A .

No 5.2VA.

Is 5.2VA section working?

Is oscillation present at the

Base of Q108?

Replace Q108.

Check L103.

Replace BD101.

(Bridge rectifier)

Check Fuse(F101).

Is 5.2V applied to IC102

Pin 1?

Is there a DC voltage at the

(+) terminal of BD101?

Replace IC101.

Check R127, 128.

(SHUTDOWN CKT)

1. Power(SMPS) Circuit

No VF+

Is 5.2VA section working?

Replace D109.

Is oscillation present at the

anode of D109?

NO

NO

NO

YES

YES

YES

YES

YES

YES

A. B.

NO

NO

NO

Page 14

3-3

Replace IC301.

Refer to Front Part

Check short

Reconnect it.

2. µ-COM Circuit

A. No Power

Does Logo appear

on the screen?

Is oscillation of

X501 normal?

Are IC503 Pins 193, 80

and 81 normal?

Does no DISC appear?

Does Hello

appear at FLD?

Is P5901

connected normally?

Is P5901 Pin 23 normal?

The waveform

on AD(00~21) of IC501

normal?

Are IC301 Pins 5, 26 normal?

Replace Main B/D.

Check the oscillation

Check short.

OK

Replace IC501

Check power.

(Refer to power)

If power is

normal

OK

POWER ON

1

1

YES

YES

YES

YES

YES

YES

YES

YES

A

NO

NO

NO

NO

NO

NO

NO

NONO

NO

A

Page 15

B. Audio abnormal

D. Open/Close abnormal

Check the

connection of P5901.

Check IC301 Pins 3, 4.

Check Audio jack.

YES (If OK)

YES

NO

NO

YES

YES

(If OK)

YES

YES

(If OK)

YES (If OK)

YES (If OK)

Check MPEG_CLK Signal

of MPEG part.

Refer to Audio part.

Refer to MPEG part.

Replace B/D.

Check Front.

Reconnect it.

Refer to SERVO part.

Check the connection of MD.

AUDIO ABNORMAL

OPEN/CLOSE ABNORMAL

C. Video abnormal

Check Video jack.

YES (If OK)

YES (If OK)

YES (If OK)

Refer to Video part.

Refer to MPEG part.

Replace B/D.

VIDEO ABNORMAL

3-4

Page 16

3-5

E. Picture abnormal

Check the disc.

If OK

YES (If OK)

YES (If OK)

Refer to Servo part

Check MPEG_CLK Signal

of MPEG part

Check DSP

Check MPEG

YES (If OK)

Replace B/D

PICTURE ABNORMAL

F. Disc Error

Check Disc

YES (If OK)

YES (If OK)

Refer to Servo part

Replace B/D

DISC ERROR

Page 17

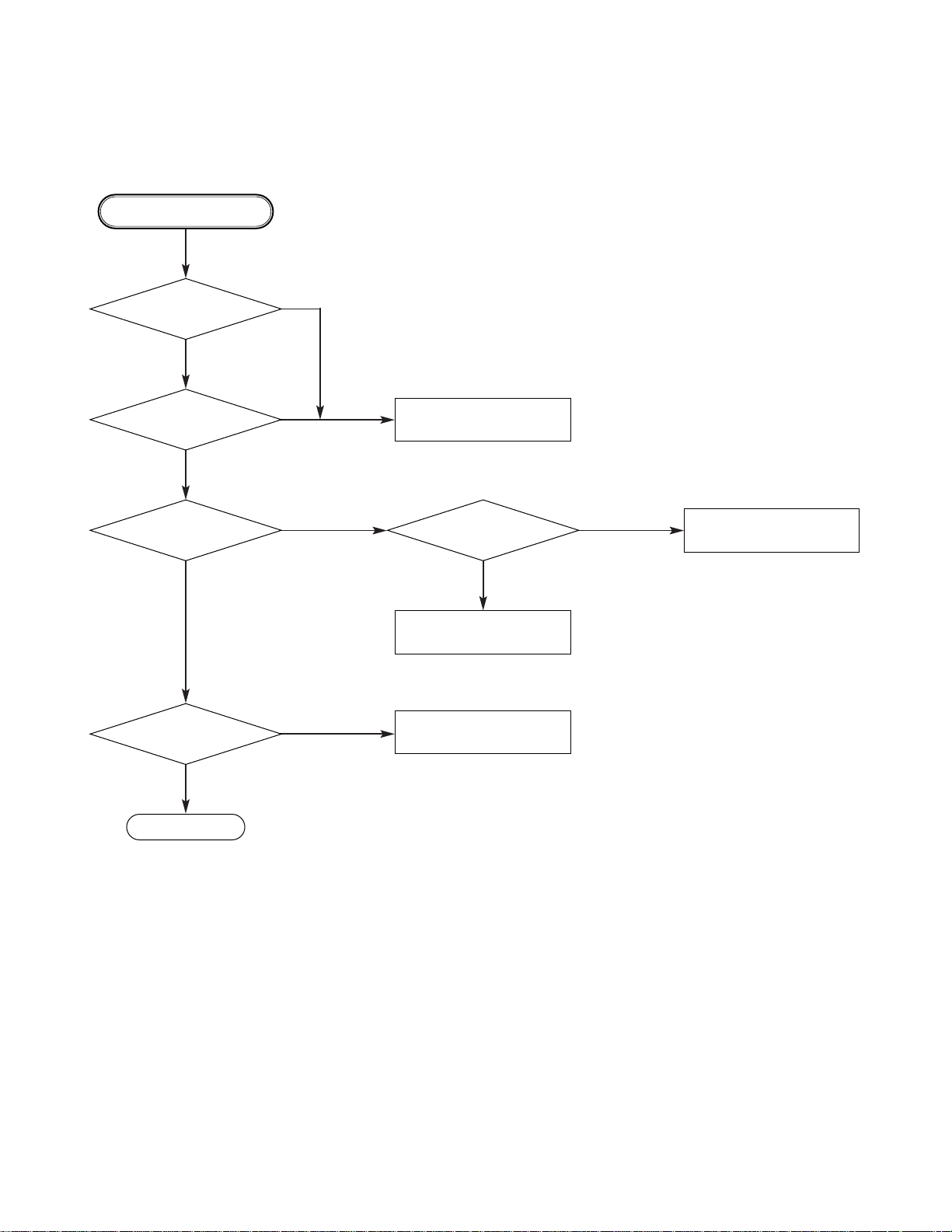

Power is on

Does Logo appear

on the screen?

Does the

moving picture of the DVD Disc

play on the screen

normally?

Is MPEG data signal normal?

Is error signal normal?

Is MPEG data signal normal?

Is Clock normal?

Does the audio

sound output from MPEG

decoder?

Does the

moving picture of the video

CD play on the screen

normally?

Does the audio sound

output normally?

END

Check power & clock.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check clock signal

Check clock signal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

OK

OK

OK

OK

NO

NO

NO

NO

NO

3. MPEG Circuit

_ OPTION

_ If included VCD function.

3-6

Page 18

3-7

NO

NO

NO

START

Does remote control

work normally?

Do all the

buttons work

normally?

Check waveform of

IC901 Pin 14.

Check waveform

of IC901 Pin 18, 19.

Is Digitron on normally?

LED ON?

Check waveform

of IC901 Pin 7.

Is oscillation of

X901 normal?

Is waveform of IC901

Pin 21 normal?

Check waveform

of IC901 Pin 14.

Does pulse

waveform of RC901 Pin 1

appear?

Is IC901

Pin 17 connected to

RC901 Pin 1 ?

Is RC901 Pin 2 5V?

Power on.

Check and replace

R903,R912, R904, R905,

R941, R906, R907.

Solder defective parts again.

Solder defective parts

Replace IC901.

Solder Key part.

Check Power.

Replace IC902.

Replace IC901.

Replace LED913.

Replace RC901.

Re-solder.

Recheck

Replace IC901.Complete repairing Front B/D.

NO

NO

NO

NO

NO

NONONO

NO

YES

YES YES

YES

YES YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

CD

4. Front Circuit (Digitron & key)

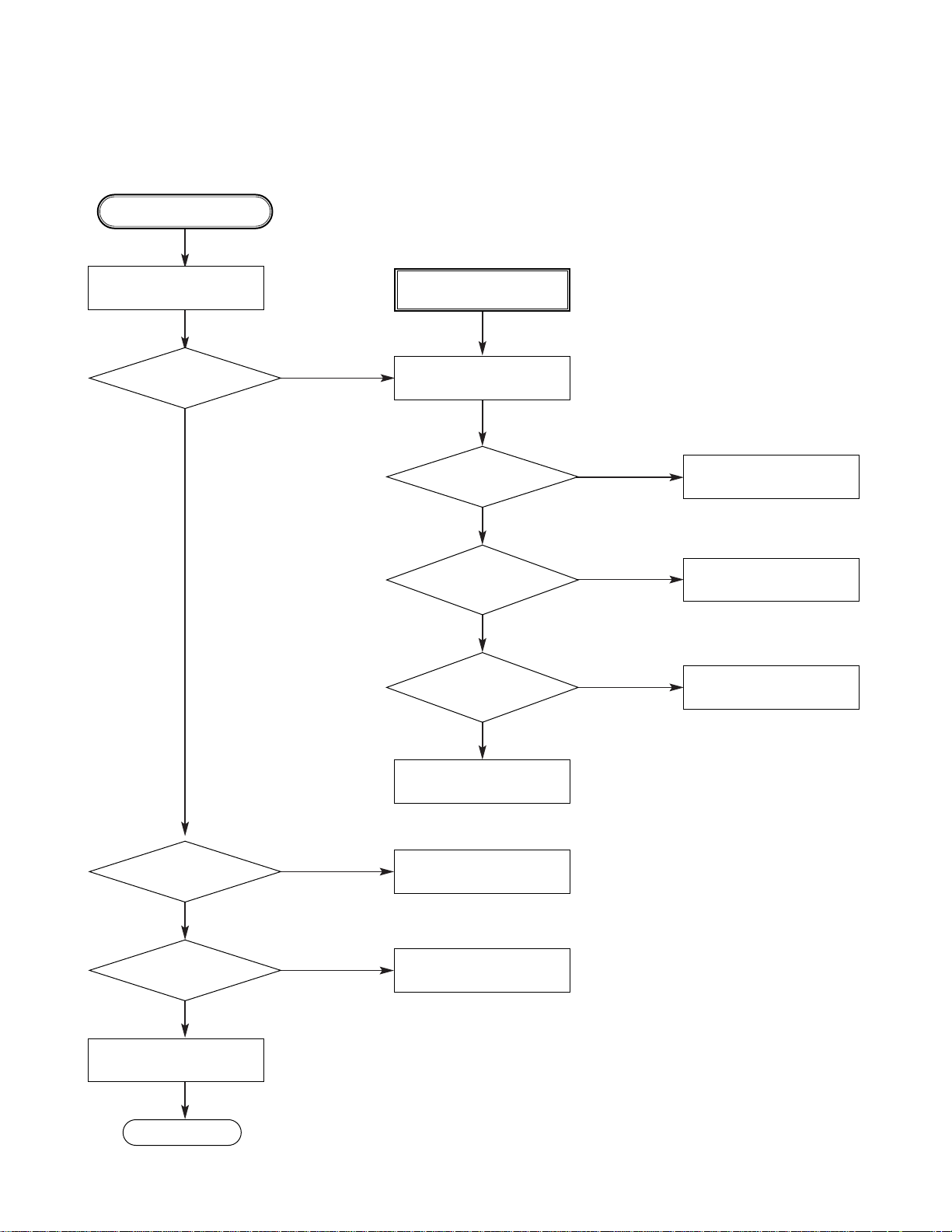

Page 19

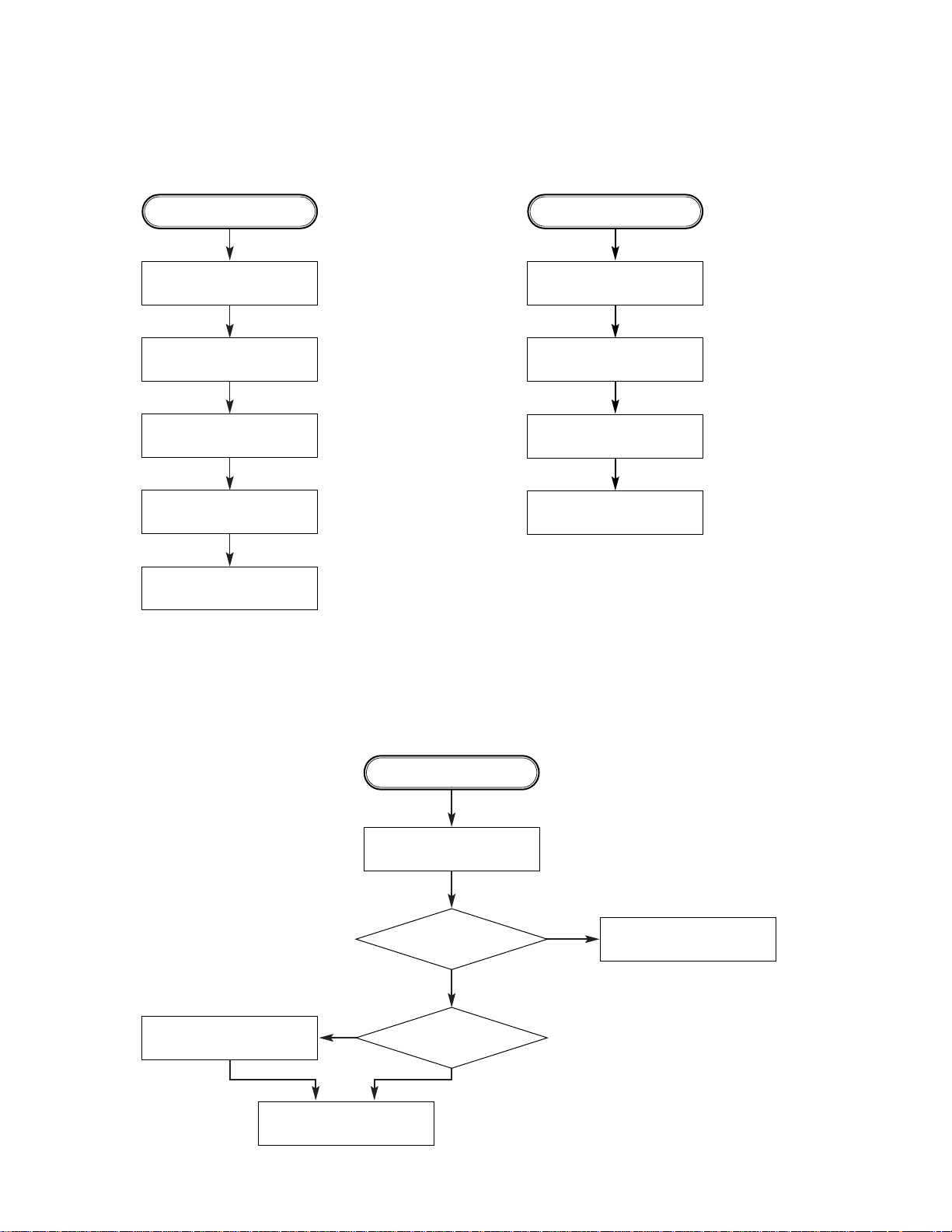

3-8

Does signal pulse

input to IC201 Pins 53, 54 when

the power is on?

Does signal goes

"High" to IC201 Pin186 when the

power is on?

Does

TTL pulse output to

IC201 Pin 156?

Does

33.8688MHz clock input

to IC201 Pin 59?

Is IC201

Pins 79, 80, 84, 88 voltage

about 2.2V?

Replace IC201

(IC206 soldering or IC defect).

Check power circuit.

Check "2.µ-COM Part".

Replace X201 or IC206

(33MHz clock defect)

CHECK POINT(General)

5. RF/Servo Circuit

A.

END

NO

NO

NO NO

NO

YES

YES

YESYES

YES

Page 20

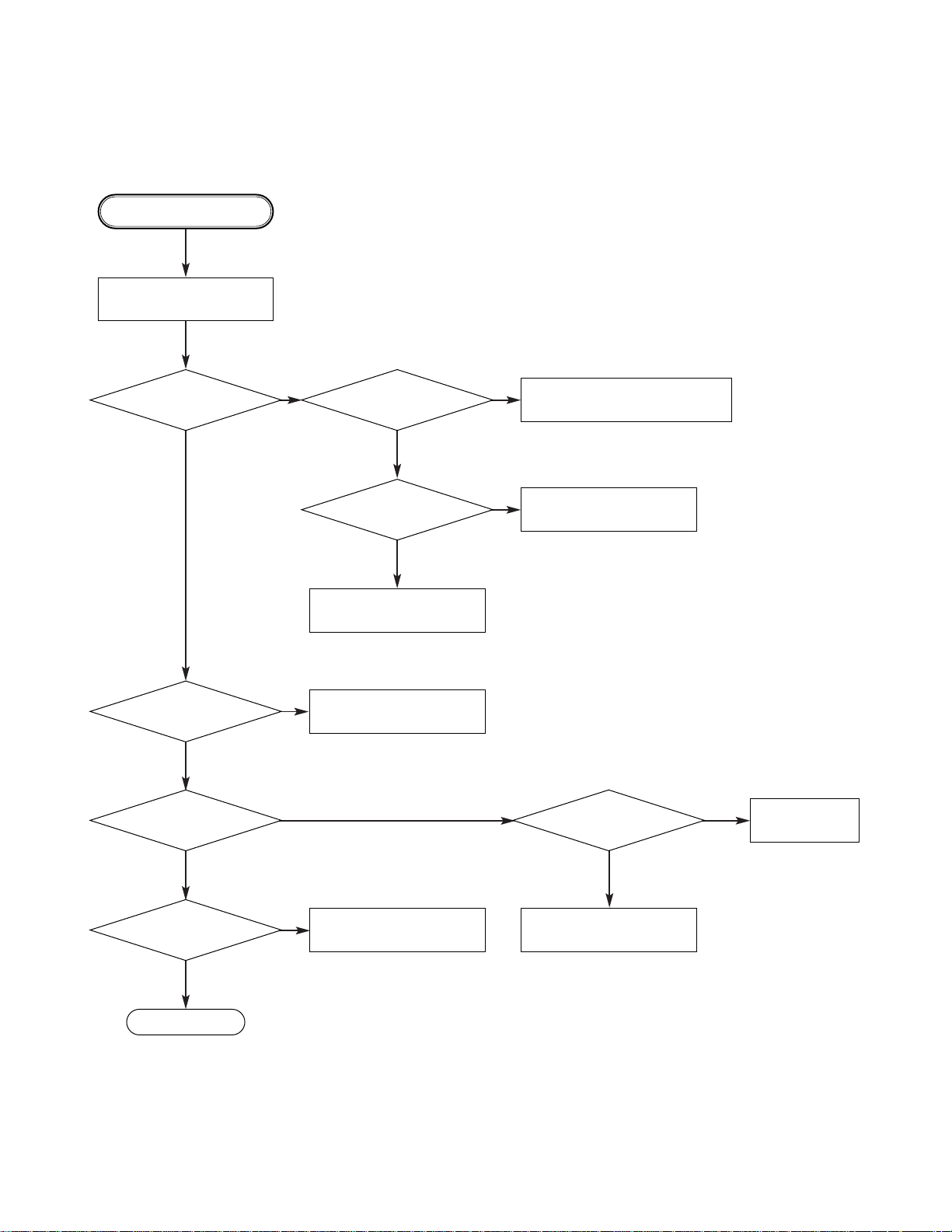

3-9

Does tray open or close?

Does the pick-up

slide inner or outer

track?

Fig.1. SLED Driver waveform

Fig.2. Focus Driver waveform

Does

the voltage change

at PMD03 Pins 7, 8 more than

2V on the basis of

3.8V?

Pressing

the open/close key

repeatedly, check the voltage of IC2M1

Pins 14, 15 change

0V to 5V

Does

PMD03 Pin 10 change

high to low?

Does

the pick-up lens move up

and down?

Check Focus Driver output.

(IC201 Pin 88, IC2M1 Pins 37, 38)

Check SLED Driver output.

IC201 Pin 80 IC2M1 Pins 28, 29.

IC201 Pin 80 no output : IC201 is defective

IC2M1 Pins 26, 27 no output : IC2M1 is defective

IC201 Pin 88 no output : IC201 is defective

IC2M1 Pins 37, 38 no output : IC2M1 is defective

DECK assembly is defective.

Slide the pick-up to

inner track.

.Power on

Check loading Part.

Push Pick-up to inner track to

the end by hand.

DECK assembly is defective.

(Limit sw)

check µ-COM Part.

Replace IC2M1.

No disc

B.

END

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Page 21

3-10

FOCUS ON?

Check

the focus error moving the

lens up and down.

(IC2A1 Pin 39)

Does the

TTL level change at IC201

Pin 121 and 152 moving

the lens?

Does the disc turn?

Is OK the track jump.

Does the signal

pulse appear at IC201

Pins 150, 151?

Does the screen appear?

OPEN/CLOSE

Replace µ-COM or IC201.

Replace IC201.

Check IC2A1 Pins 47,50,51,52

in DVD Mode

Fig.3. FOCUS ERROR waveform

IC201 no output : Pick-up is defective.

Check IC201 and IC2M1 when PMD03 Pin 6 is abnormal

Check IC2M1 Pin 21, PMD03

Pin 6 turn when the IC2M1

Pin 21 is less than 2.2V.

Video Part is defective.

Check "5.MPEG Circuit."

Check "7.OSD/Video Circuit."

Replace µ-COM part.

IC2A1 is defective.

DISC IN

C.

END

NO

NO

NO NO

NO

NO

NO

YES

YES

YES

YES

YES YES

YES

Page 22

3-11

Is the eye-pattern vivid?

Does the

sawtooth waveform emit

at IC2A1 Pin 36?

Does the 1.6V emit?

Check RF Eye-Pattern.

RF : 1.0~1.1V(TP2A0)

Fig.5. RF

waveform

Check IC2A1 Pin 3.

No signal: Pick-up is defective

Replace IC201.

Check IC201 Pin84.

No signal at IC201 : IC201 is defective

• Check IC201 Pin 165.

• Check the clock at the IC201 Pins 37, 59.

• Both are normal : IC201 is defective

Replace IC2A1.

CHECK A

D.

END

NO

NO NO NO

YES

YES YES YES

Page 23

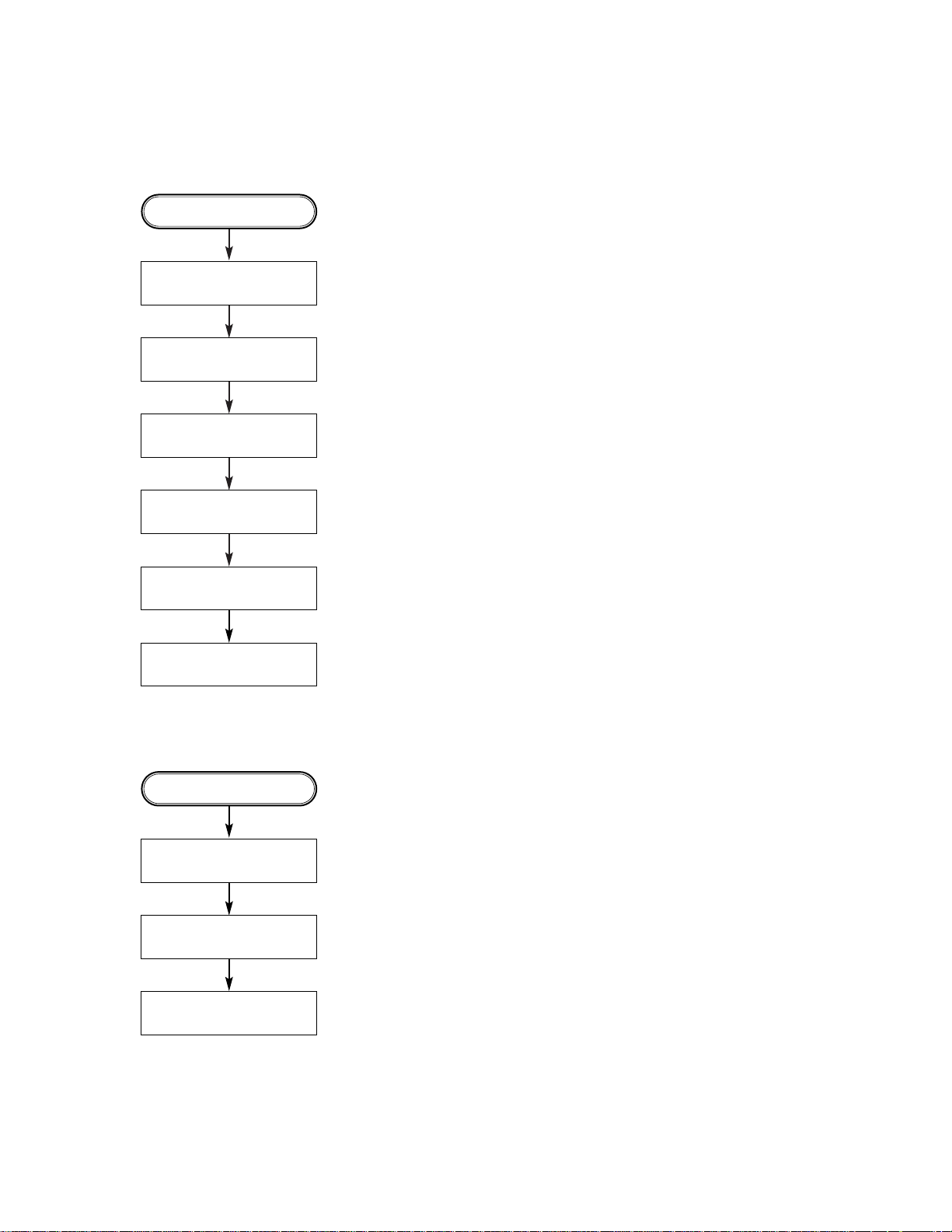

3-12

BLOCK DIAGRAMS

1. Overall Block Diagram

M

M

DISC

SPINDLE

MOTOR

LOAD ING

MOTOR

DECK M ECHANI SM

CD: A,B, E, F

DVD: A,B,C,D,

DVD; RF

PICK

UP

IC203

SDRAM

16bit

16M

IC201

HDC25D811

CD / DVD DSP

IC501

PANTERA

LE / PLUS

IC901

GMS1C2012

FROM

FL DI SPLA Y

KEY I nput

REMOCON

RECEI VER

6MHz

X-TA L

Pb

IC301

XC9572VL

CPLD

I/O PORT 72

IC304

SDRAM

16/32BIT

64M

IC502

93C56

EEPROM

IC2M 1

KA 3032

MOTOR

DRIVER

IC2A1

HD153702TF

RF

ICDATA

[00:15]

ICADD

[0:8]

LOADING

FOCUS,TRACKING,SLED

SPINDLE

MIRR,TZC,PI,TE

FE,DFECT_IN

RFO

SCLK,S DATA

;

SCOR,SQCK,SQSO

XLAT , E_STI , E_ENB , E_DR

RF_XLAT , LDO N

IC401/451

CS4391

PCM1603KY

XIO1,XIO

,XIO10

/SRST

F_CLK

F_OUT

PCMCLK

ALE

SPINDLE_FG

MSDATO

MDP1

FOK

DEFECT

DSP_SENSE

LOCK

E_SOUT

ZISENB

/XRST

DAC_RST

16

:9, PAL_SW , AUTO_SW , MI C_ON

Y_SEL

/A_MUTE

/DAC_CS1

/DAC_CS2

V_MUTE

DAC_CLK

DAC_OUT

ADCCLK

ACT_MUTE , LOAD_OPEN , LOAD_CLOSE

MIRR

AD[04:21]

PSENB

FLD

/FLD_CS

FLD_CLK

FLD_OUT

/FLD_CS

FLD_CLK

FLD_OUT

CPLD

EE_CS , EE_CLK , EE _OUT

F_IN

IC3F1

FLA SH

ROM

F_IN

/MRESET

/FLASH_CS , /RD

PWEO

LA0

LA1

LA2

LA3

LADD

[04:19]

MD[00:31]

MCLK2

CKE

MA[00:10]

MA12,13

/CS0

/RAS

/CAS

/WE

DQM0‘3

REQP

SDCLKI , PSYNC

DVD[1:7]

DSP_INT

SENSE

/DSP_CS

F_IN

DA_AIN

SPDIF

ACLK

LRCK

AOUT0~3

AM P

L/R

RR

RL

Composite

FIL TER

Y

Pr

SW602

S.OUT / COM P.OUT

SWICHI NG

FR

FL

WOOFER

CENTER

VIDEO SW

CVBS/Pr/R , C/Pb/ , Y/G

CVBS

Y

C

L/R

RR

RL

FR

FL

WOOFER

CENTER

-VF

AC 120V,

60Hz

POWER

BOARD

-VF

-24VA

+8V

+5.2VA

+5V_D

+5V_A

+12VA

+3.3V_M1

AD[0:7]

LADD4~5 , LA0~3

AD[00:15]

MDP,FDO,TDO,FMO,MON

OPEN_SW

CLOSE_SW

LIM IT_SW

CPLD

SBADD ,

27MHz

X-TAL

33.8688MHz

X-T AL

+3.3V/3.3V_M

POWER_CTL

MIC

IC206

INVE R

TER

DV5000’s

Page 24

2. Power(SMPS) Block Diagram

5V_D

5V_A

-24VA

F+

RECTIFIER

LINE FIL TER

SWITCHING TR

TRANS

FEED B.

REG(8V)

8V

5.2VA

F-

RECTIFIER(FLD )

RECTIFIER(9V)

RECTIFIER(5.2V)

LPF

LPF

RECTIFIER(14V)

LPF

12VA

AC90~240V

PWR ON/OFF

REG(3.3V)

REG(3.3V)

3.3V_M1

3.3V/3.3V_M

DV5000 s

3-13

Page 25

3-14

8

SENSE, FOK,

DEFECT,DSP_SENSE

IC2M1

KA3032

SpindleMotor, LoadingMotor,

Actuator Driver

CD: A,B,C,D / E, F

4

4

MIRR,TZC

8

4

3

6

XL AT , S_CLK, S_DATA

UCOM

I/F

focu

s, track

ing, l

oa

di ng,

sled

Spi ndle

M/D

PICK

UP

IC201

HDC25D811

CD / DVD DSP

DVD SERVO

IC2A1

HD153702TF

RF Signal

Process or

FDO,TDO,FMO

Load open/close(loading control)

UCOM

I/F

DVD: A,B,C,D,

FE,TE,PI,SBADD

4

DVD/CD RF

IC203

1M x 16bit

SDRAM

16

11

ICADDR[ 0:10 ]

ICDAT A[ 00:15]

DO[0:7]

AO[0 :3]

DVD_DATA[0:7]

MON,MDP

MPEG

I/F

2

DSP_CS, /W R, /RD

3

DV5000’s

3. RF/CD DSP/DVD DSP/DVD SERVO Block Diagram

Page 26

4. Audio Block Diagram

IC401

CS4391

Aud

i

o DAC

IC402

LPF & Bu ff

er

Buff

er

Buff

er

Buff

er

K

A

5532

OP AMP

DAC_RST

S_DAT A

S_CLK

DAC_L 0

DA_L RCK

DA_DAT A 0

DA_BCK

DA_X CK

FL

FR

RL

RR

WOOFER

CENTER

L

R

U-COM

I/F

IC452

LPF &

KA 5532

OP AMP

IC453

LPF &

KA 5532

OP AMP

IC454

LPF &

KA 5532

OP AMP

IC451

PCM1603K Y

Aud io DAC

(5.1CH)

FL

FR

RL

RR

WOOFER

CENTER

L

R

A/V

JACK

I/F

DAC_RST

S_DATA

S_CLK

DAC_L 1

DA_L RCK

DA_DAT A [1: 3]

DA_BCK

DA_X CK

MPEG

I/F

MPEG

I/F

U-COM

I/F

DV5000’s

3-15

Page 27

3-16

5. MPEG & MEMORY Block Diagram

IC501

PANTERA-2

LE/PLUS

IC301

XC9572VL

CPLD

I/O PORT 72

IC304

SDRAM

16/32BIT

64M

IC502

93C46

EEPROM

IC3F1

FL A SH

MEMORY

AD[0 :7]

8

DSP

I/F

DVD[0:7]

8

LA [0:3]

4

SCLK,SDATA

SQCK,SQS0

REQP

SDCL K1,PSYNC

DSP_INT

SENSE

/DSP_CS

AD[04:21]

RF &

MOTOR

I/F

MIRR

LDON

SCL K,SDAT A

EE_CS

F_IN

32

MD[ 00: 31]

MCLK2

CKE

MA [00:10]

MA 12,13

/CS0

/RAS/

/CAS

/WE

/DQM[0:3]

SPINDLE_FG

ALE

AD[04:19]

16

LADD[04:19]

16

LA [0:3]

4

AD[00:15]

16

AUDIO

I/F

DA_DAT A[0:3}

DA_BCK,DA_LRCK,DA_XCK

4

DAC_L 0,DAC_L1

DAC_RST

A/V

JACK

I/F

C/R(B)

CVBS/G(R)

Y/B (G)

CVBS

V_MUTE,16:9

ZISENB

/RD

/PWED

IC301

DV5000 s

Page 28

3-17 3-18

CIRCUIT DIAGRAM

1. POWER(SMPS) CIRCUIT DIAGRAM

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE NAD ELECTRONICS CORPORATION. ALL

COMPONENTS SHOULD BE REPLACED ONLY WITH

TYPES IDENTICAL TO THOSE IN THE ORIGINAL CIR-

CUIT. SPECIALCOMPONENTS ARE SHADED ON THE

SCHEMATIC FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTILTHE NEW SERVICE

LITERATURE IS PRINTED.

NOTE :

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

NOTES : Symbol denotes AC ground.

Symbol denotes DC chassis ground.

Page 29

3-19 3-20

TRACKING LOOP

FOCUS LOOP

SLED LOOP

SPINDLE LOOP

WAVEFORM

5

6

5

2. DVD DSP CIRCUIT DIAGRAM

Page 30

3-21 3-22

3. DRIVE & RF CIRCUIT DIAGRAM

TRACKING LOOP

FOCUS LOOP

SLED LOOP

SPINDLE LOOP

WAVEFORM

1

6

2

3

Page 31

3-23 3-24

4. MPEG CIRCUIT DIAGRAM

Optical/Coaxial out

CVBS

Y/Pb/Pr(Componet)

Y/C(S-VHS)

WAVEFORM

Page 32

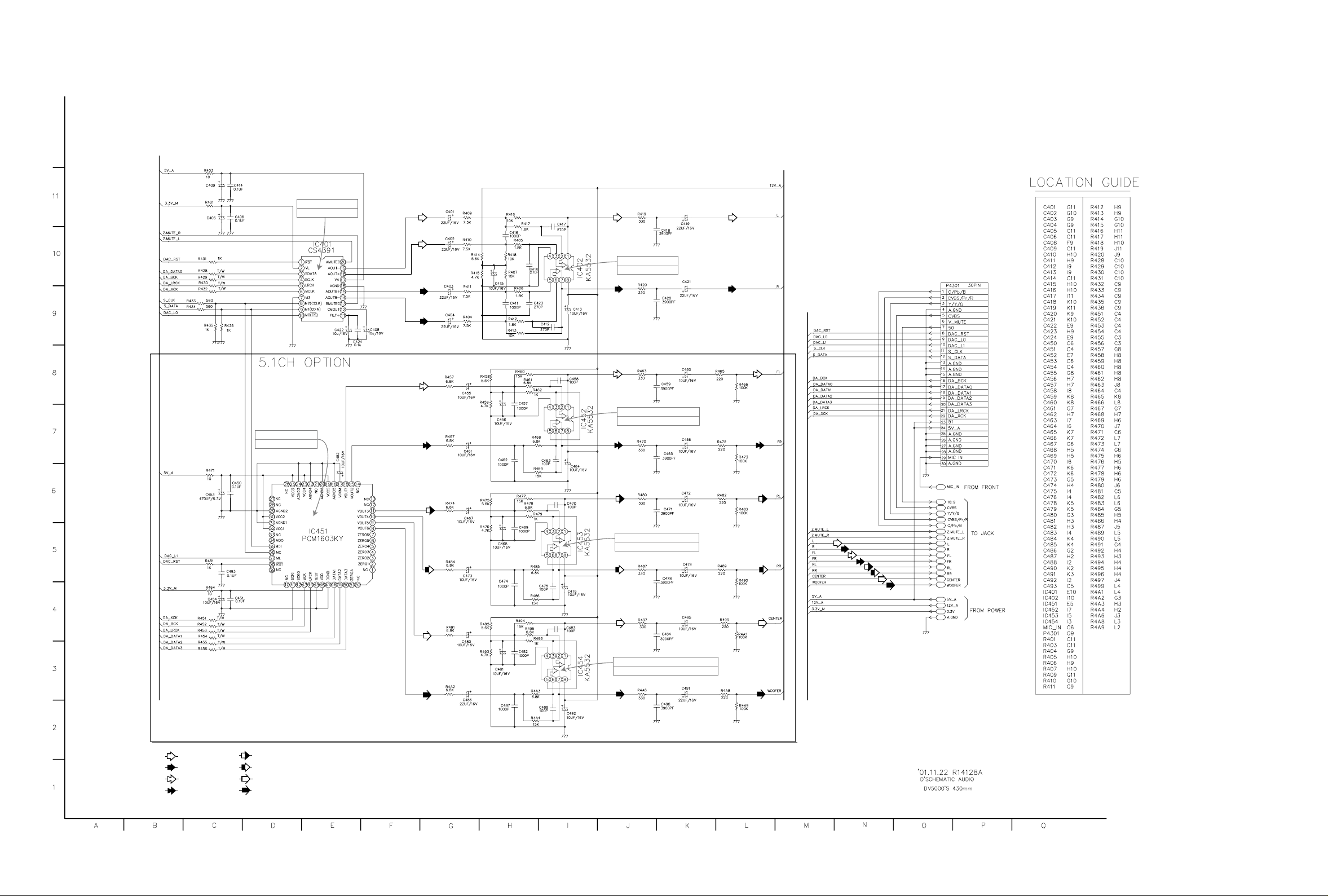

3-25 3-26

• WAVEFORMS

IC2A1 Pin 39, Focus Error

IC2A1 Pin 38, PE

IC2A1 Pin 36

Tracking Error

IC501 Pin 114

Component Y

IC2A1 Pin 36

VBR TRACKING Error

Q2A6 Collector output(TP2AO)

RF

IC201 Pin 80, SLED FG

IC201 Pin 154, SLED FMO

IC2A1 Pin39, Focus Error(in Focus Search)

IC201 Pin 88, Focus Drive(FDO)

IC501 Pin 118, Composite IC501 Pin 112, Chrominance

(Super video out Mode)

Tek

Stop :

2.50MS/s

4 Acqs

M20.0µs

2 Apr 1999

14:47:27

Glitch

Ch1

Ch3

500mV

[T ]

T

3

IC501 Pin 114, Luminance

(Super video out Mode)

Tek

Stop :

1 00kS/s

3290 Acqs

M 500µs

CH1

280/mV

Edge Slope

Type

<Edge>

Source

Ch1

Coupling

DC

Level

280mV

Mode

&

Holdoff

3

Ch3

1.00V

[ T ][ T ]

Slope

T

IC501 Pin 98,

MPEG Clock(27MHz)

IC501 Pin 112

Component Pb

IC501 Pin 110

Component Pr

Page 33

3-27 3-28

5. AUDIO CIRCUIT DIAGRAM

2CH R SIGNAL

5.1CH RL SIGNAL

5.1CH RR SIGNAL

5.1CH CENTER SIGNAL

5.1CH FR SIGNAL

5.1CH FL SIGNAL

2CH L SIGNAL

5.1CH WOOFER SIGNAL

IC451 is defective

5.1CH Audio out bad

IC452 is defective

5.1CH FL/FR Audio out bad

IC402 is defective

2CH Audio out bad

IC401 is defective

2CH Audio out bad

IC453 is defective

5.1CH RL/RR Audio out bad

IC454 is defective

5.1CH Center/woofer Audio out bad

220µ/6.3V

47µ/16V

18

Page 34

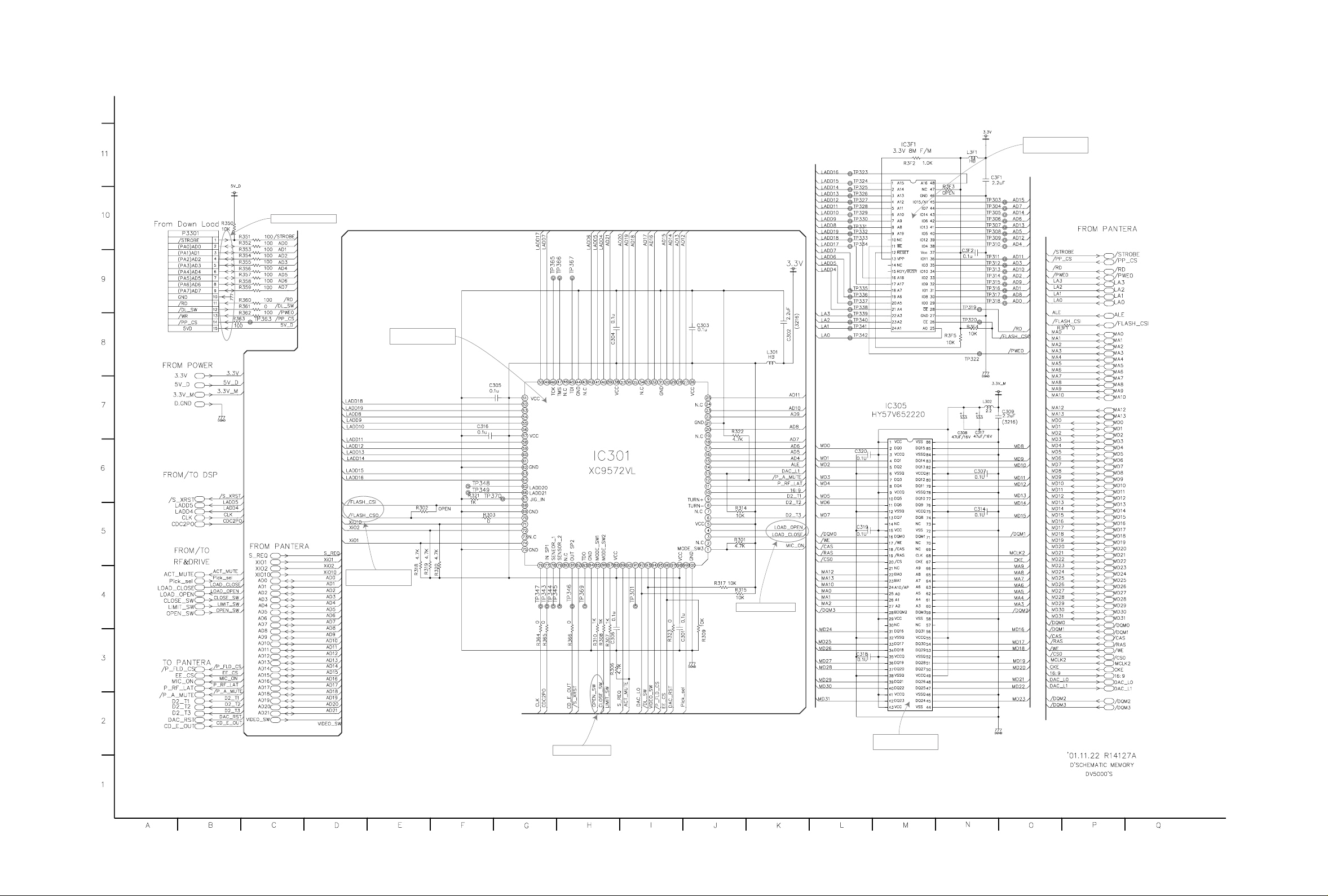

3-29 3-30

6. MEMORY CIRCUIT DIAGRAM

program download fail

Digitron all not display

system not workry

Tray not open/close

Digitron all not display

system not working

Tray not open/close

Digitron all not display

system not working

Digitron all not display

system not working

Page 35

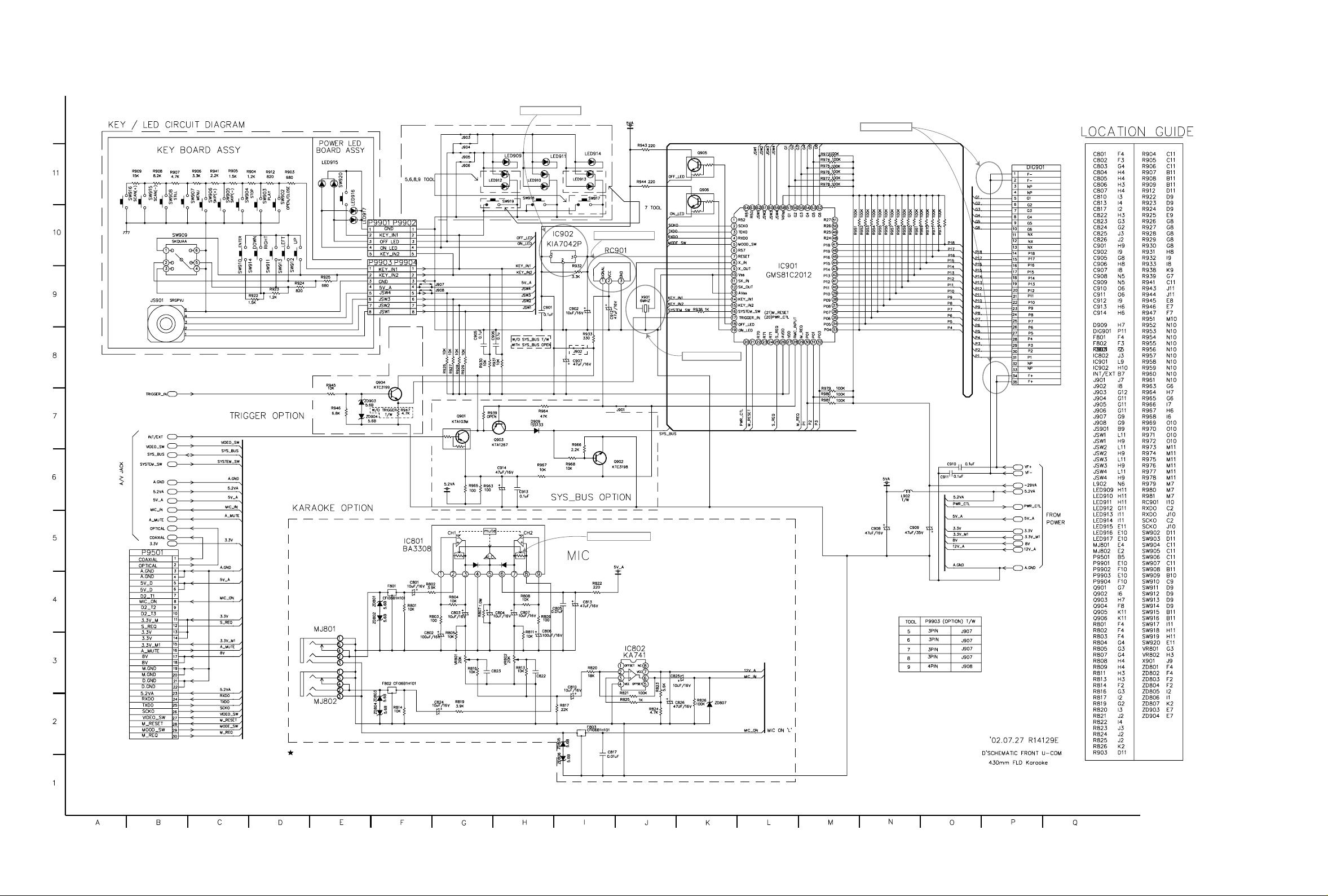

3-31 3-32

7. FRONT CIRCUIT DIAGRAM

Digitron abnormal

SYSTEM not operate

KARAOKE not operate

Remocon not operate

SYSTEM not operate

KARAOKE OPTION (WITH OUT)

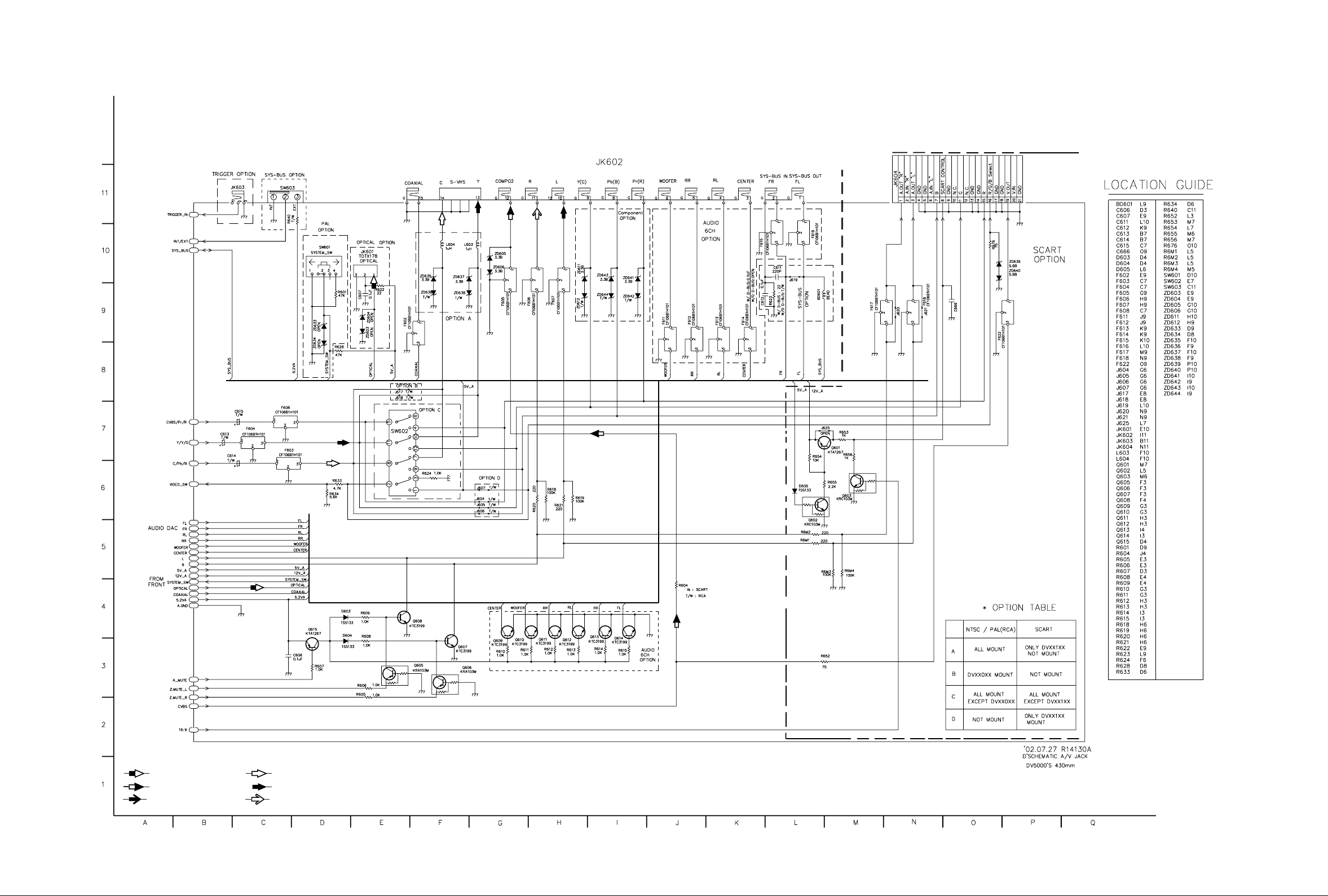

Page 36

3-33 3-34

8. A/V JACK CIRCUIT DIAGRAM

S VIDEO (C)

AUDIO (L)

AUDIO (R)

OPTICAL

COMP.VIDEO

S VIDEO (Y)

Page 37

3-35 3-36

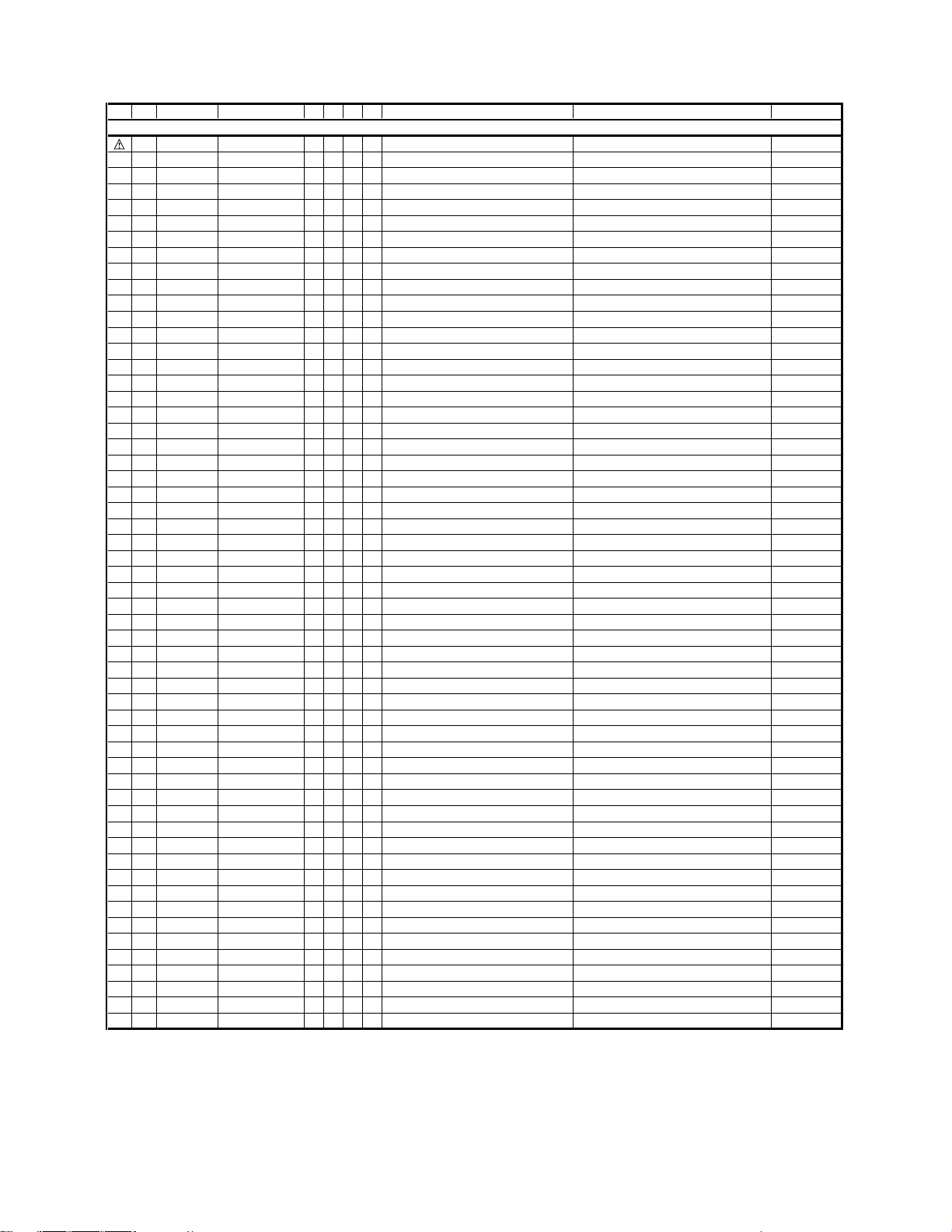

• CIRCUIT VOLTAGE CHART

IC203 IC201 IC301 IC3F1 IC501 IC305 IC2A1 IC2M1

PIN STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY

1 3.18 3.16 3.12 0 3.17 3.16 0 0 3.12 3.1 3.06 3.05 0 0 2.11 2.14

2 3.12 2.69 3.12 0 0 0 0 0 0 0.41 0.29 0.35 3.16 3.13 2.1 2.12

3 3.12 2.69 3.12 0 3.16 0 0 0 0 0.47 3.06 3.05 3.16 3.13 2.11 2.11

4 0 0 3.12 0 3.16 0 0 0 1.75 1.73 3.06 0.33 0.75 1.55 2.1 2.15

5 3.12 2.74 3.12 3.12 3.17 3.16 0 0 0 0.49 0 0 2.04 3.02 2.1 2.12

6 3.12 2.71 3.12 3.12 3.17 3.16 0 0 0 0 0 0 0 0 0 0

7 3.18 3.17 3.12 0 0 0 0 0 0 0.37 0 0.34 0 0 0 0

8 3.12 2.68 3.12 3.12 3.17 3.16 0 0 0 0.35 0.4 0 0 0.33 2.11 2.12

9 3.12 2.63 0 0 0 0 3.13 2.92 0 0.33 0 3.05 0 0 2.02 1.99

10 0 0 3.12 3.12 0 0 0 0 3.22 3.19 0.33 0 0.44 0 2.1 2.12

11 3.12 2.7 3.12 3.12 0 0 3.13 3.12 0 0 0.41 0 1.72 1.19 2.11 2.12

12 3.12 2.7 3.12 0 0 0 3.2 3.2 0 0 0 0 2.06 2.3 2.09 2.13

13 3.18 3.17 3.12 3.12 3.17 3.16 3.2 3.2 0 0 0 0.46 2.25 3.08 3.25 2.23

14 0 0 3.12 0 0 0 0 0 0 0 0 0 1.32 3.13 2.51 0

15 3.12 3.04 3.12 0 0 0 0 0 0 0.79 3.06 3.05 1.46 2.27 2.51 0

16 3.12 0 3.12 0 2.17 2.18 3.19 0 0 0.74 0 0 0 2.4 0 0

17 3.12 3.02 3.12 0 0.38 2.21 0 0 0 0 3.09 3.07 0 0 2.18 0

18 0 0 3.13 3.12 0.41 0.61 0 0 0 0.71 0 2.82 0 0 0 0

19 0 0 3.13 0 0 0 0 0 3.22 3.1 2.84 3.03 0 0 0 0

20 0 3.12 0 0 0 0 0 0 3.22 3.13 3.05 2.76 0 0 1.52 1.89

21 3.13 0 3.13 0 0 0 0 0 3.22 3.13 0 0 3.01 5.01 1.88 1.89

22 3.13 3.17 0 0 0 0 0 0 1.64 0 0 1.38 3.85 5.01 0 0

23 3.13 0 0 0 0 0 0 0 0 0 0.8 0.79 0 0 3.13 0

24 0 0 3.13 0 0 0 0 0 3.22 3.13 0 0 0 0 0 0

25 3.18 0 3.12 0 0 0 3.11 3.11 0 3.13 1.14 1.1 0 0 7.95 7.92

26 0 0 0 0 3.21 3.16 3.17 3.2 0 3.13 0.38 1.54 3.31 3.63 3.92 3.71

27 0 0 0 3.12 0 0 0 0 3.22 3.11 0 0 0 0 3.92 3.71

28 3.12 0 0 0 0 0 3.11 0 0 1.1 0 0 3.14 3.16 3.9 3.74

29 0 3.12 0 0 0 0 0.61 1.07 0 0 0 0.05 5.15 5.14 3.95 3.68

300 0000 0 00 0 0 00 00 00

31 0 3.17 0 3.12 0 0 0.6 0 0 0 0 0 0 0 0 0

32 0 0 0 0 0 0 0 0 3.22 1.39 0 0 0 0 1.18 4.2

33 3.1 0 3.12 0 0 0 0.59 0 3.22 0.8 0 0 0 0 1.18 3.43

34 3.18 0 3.12 0 0 0 0 0 1.75 1.52 0.34 0 5.03 4.99 0 0

35 1.5 0 3.12 0 0 0 0.61 0 3.22 2.76 3.03 3.05 2.29 2.34 3.92 3.75

36 0 3.12 0 0 0 0 0 0 3.22 3.11 0 0.34 2.2 2.3 3.93 3.73

37 0 0 1.51 0 0 0 3.18 0 3.22 3.03 0 0 2.2 2.2 3.92 3.73

38 3.18 0 0 0 3.17 3.16 0 0 3.22 2.83 0 0 2.29 2.26 3.92 3.68

39 3.12 3.12 0 0 0 0 0 0 3.22 3.08 0.56 0 2.24 2.24 7.95 7.94

40 3.12 3.12 0 0 0 0 2.17 0 0 0 0.56 0 0 0 7.91 7.87

41 0 3.17 0 0 0 0 0 0 0 0 0 3.05 5.03 5.01 0 0

42 3.12 0 0 0 0 0 0.38 2.28 0 0 3.03 0.45 0 0 0 0

43 3.12 0 0 0 0 0 0 0 0 0.34 3.03 3.05 0 0 0 0

44 3.18 0 0 0 0 0 0.41 0.65 3.22 3.11 0 0 5.03 1.59 0 0

45 3.12 3.12 0 0 3.17 3.15 0 0 0.45 0.33 0 0.44 2.3 2.3 7.95 7.94

46 2.76 3.12 1.56 0 0 0 0 0 0 0 0 0 2.3 2.3 2.11 2.12

47 0 0 0.91 0 3.17 3.15 0 0 0 0 0.38 0 1.74 2.3 2.1 2.12

48 3.12 1.65 0 2.19 0 0 0 0 0 0 0 0 0 2.11 2.12

49 3.12 3.14 0.53 0 0 0 0 3.03 0 0 0

50 0 0 0 0 0 0.43 0.39 0.36 3.05 2.3 2.3

51 0.64 0 3.17 0 0.42 0.45 0 0.34 2.3 2.3

52 0.43 0 3.17 3.19 0.43 0.35 0 0 2.3 2.3

53 0 0 3.11 2.91 3.12 3.11 0 0 2.3 2.3

54 2.58 0 0 0 0 0 0.41 0 2.3 2.3

55 0 0 0 0 0 0.33 3.03 3.05 2.3 2.3

56 3.11 0 0 0 0.39 0.36 0 0.34 2.3 2.3

57 0 0 3.17 3.19 0 0 0 0 2.3 2.3

58 1.65 0 0 0 0 0 0 0 2.3 2.3

59 1.79 0 0 0 0 0.42 0 0 2.29 2.3

60 0 0 0 0 0.44 0.4 0 0.79 2.29 2.3

61 3.13 0 0 0 0.44 0.47 0 0.79 0.36 0.56

62 0 0 0 0 3.12 3.11 0 2.26 0.37 0.62

63 3.13 0 0 0 0.45 0.35 0 0.74 5.03 5.02

64 0 0 0 0 0 0 0 0.78 0 0

65 0 0 0 0 0 0 0 0

66 3.12 0 0 0 0 0 0 0

67 0 0 0 0 0 0.31 3.11 3.1

68 3.13 3.12 3.11 3.1 1.51 0 1.6 1.59

69 4.08 0 0 0 0 1.5 0 0

70 3.13 0 0 3.16 1.47 0 0 0

71 0 0 3.11 3.1 0 0 0 0

72 3.13 3.13 0 0 0 0 0 0

73 0 0 0 0 0 0 0 0

74 0 0 3.11 3.1 0 0 0 0.45

75 0.78 0 0 0 3.12 3.11 3.04 3.05

76 1.41 0 0 0 1.48 1.26 0 0

77 0.77 0 0 0 1.74 1.74 0 0

78 0.77 0 0 0 1.54 1.54 0 0

79 2.1 2.11 3.17 0 1.56 1.55 0 0

80 2.12 2.11 0 0 3.11 3.1 0 0.34

81 3.18 0 3.17 0 3.01 3.01 1.69 0

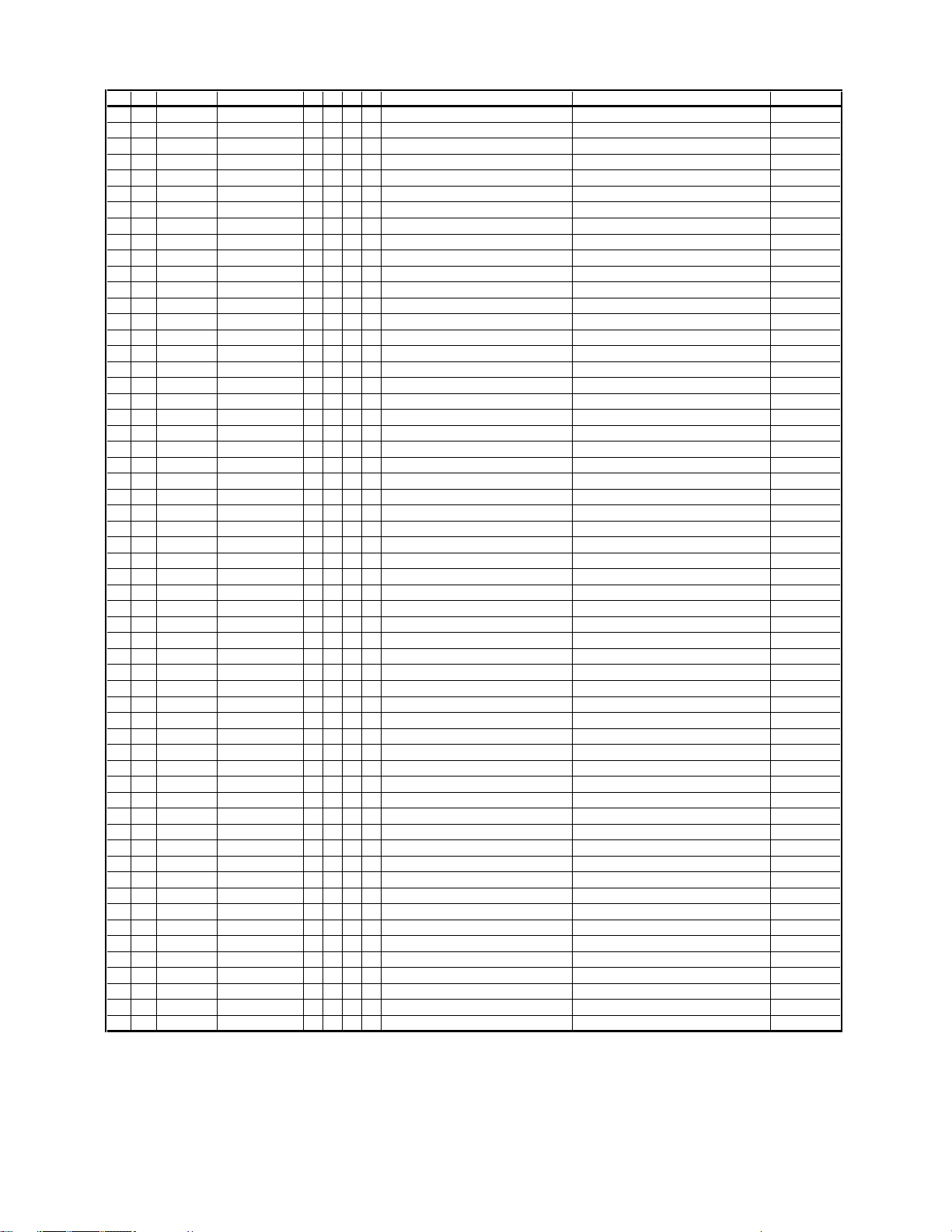

IC203 IC201 IC301 IC3F1 IC501 IC305 IC2A1 IC2M1

PIN STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY

82 3.18 0 3.17 3.19 0 0 0 0

83 1.93 1.93 2.12 2.27 0 0.33 0 0

84 2.11 2.11 0 0 1.74 5.12 0 0

85 0 0 4.41 4.41 0 0 0 0.33

86 0 0 0 0 0 0 0 0

87 1.93 0 0 0 1.42 3.11

88 2.1 0 3.17 3.19 1.87 3.11

89 1.93 1.92 2.66 0 1.67 1.74

90 1.59 0 0 3.17 0 0

91 0.8 0 3.19 0 3.11 3.11

92 2.36 2.36 3.19 3.19 0 3.11

93 2.24 1.6 3.19 3.19 3.11 3.11

94 1.58 1.56 0 0 0 0.34

95 1.64 1.62 3.13 3.13 0 0.34

96 1.58 1.62 0 0 2.82 3.11

97 1.58 1.56 3.19 3.19 0 0

98 0 0 3.19 3.19 0.85 0.92

99 0 0 0.36 0.36 0.89 0.93

100 1.58 0 0 0 0 0

101 3.18 0 1.79 1.74

102 3.18 0 3.23 3.1

103 2.01 2.01 0 0

104 2.01 2.01 0 0

105 0 0 0 0

106 3.12 0 0 0

107 2.07 3.12 3.23 3.09

108 0.41 0 1.74 1.74

109 0 0 0 0

110 2.15 0 1.75 1.3

111 0 0 0.34 0.74

112 0 0 0 1.39

113 0 0 3.2 3.1

114 0 0 0.49 0.64

115 0 0 0 0

116 0 0 1.17 1.29

117 0 0 1.79 1.74

118 0 0 0 0.74

119 0 0 1.17 1.28

120 3.12 0 2.04 1.82

121 0 0 0 0

122 3.12 3.12 0 0

123 3.12 3.12 0 0.36

124 0 0 0 0.36

125 3.12 3.12 3.16 3.1

126 3.12 0 0 0.36

127 2.42 0 0 0

128 0 0 0 0

129 2.41 0 0 0

130 3.18 3.17 0 0

131 3.12 3.12 0 0

132 3.12 0 0 0

133 0 0 3.13 0

134 3.12 3.12 0 0

135 3.12 3.12 1.74 1.74

136 2.45 2.33 0 0

137 1.68 1.65 0 0

138 1.77 1.87 0 0

139 2.45 2.33 0 0

140 2.61 0.32 3.13 3.1

141 2.54 0 0 0

142 3.12 0 0 0

143 0 0 0 0

144 0 0 0 0

145 0 0 3.13 3.09

146 2.54 0 0 0

147 2.54 0 0 0

148 2.54 0 0 0

149 2.54 0 0 0

150 4.76 0 0 0

151 4.13 0 0 0

152 0 0 0 0

153 0 0 0 0

154 0 0 3.13 3.1

155 3.12 0 0 0

156 3.12 0 3.13 3.09

157 3.12 0 0 0

158 0 0 0 1.73

159 0 0 1.74 1.73

160 0 0 1.12 1.83

161 2.64 2.62 3.13 0

162 3.18 3.16 0 0

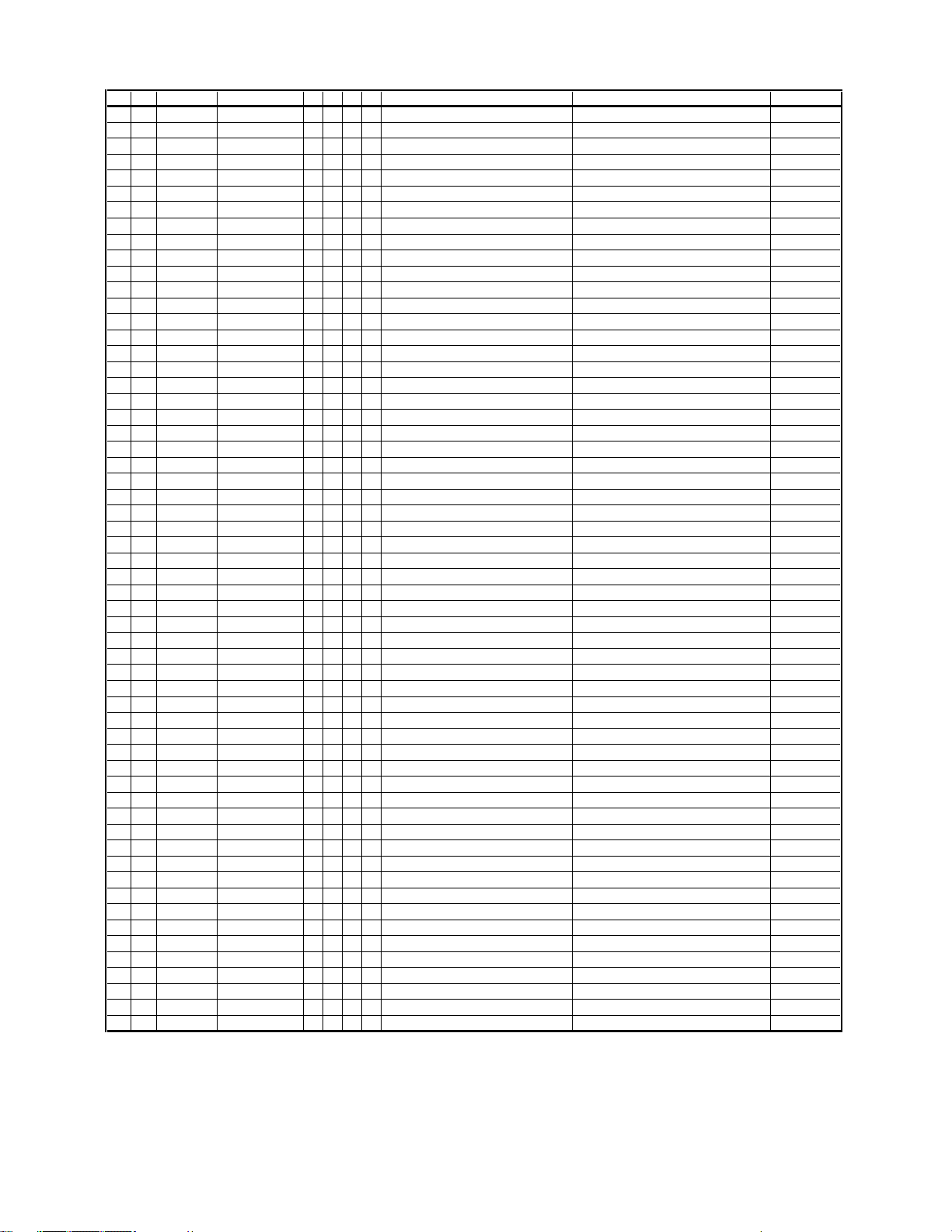

IC203 IC201 IC301 IC3F1 IC501 IC305 IC2A1 IC2M1

PIN STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY

163 3.18 3.15 0 0

164 2.02 0 0 0

165 2.08 0 0 0

166 2.09 0 0 0

167 1.57 0 0 0

168 2.51 0 0 0

169 1.6 1.57 3.13 3.1

170 3.13 3.01 3.13 0

171 2.53 0 0 0

172 0 0 0.44 0.6

173 3.11 0 0.4 2.15

174 3.11 0 2.2 2.15

175 3.11 3.1 0 0

176 0 0 0.66 0.8

177 3.12 0 0 0

178 3.12 2.59 0.65 0.83

179 3.11 3.03 0.65 0.79

180 0 0 0.67 0.79

181 0 0 0 3.1

182 0 0 3.13 3.1

183 0 0 0 0

184 0 0 3.13 3.1

185 0 0 0 0

186 3.17 0 0 0

187 0.69 0 0 0

188 3.18 3.12 0 0

189 0.66 0.77 0 3.1

190 0.65 0 0 0

191 0.67 0.87 0 0

192 0 0 0 1.75

193 2.21 2.17 3.13 3.09

194 0.41 0 3.13 3.16

195 0.45 0 0 0

196 0 0 3.13 3.1

197 0 0 0 0

198 0 0 3.13 0

199 0 3.12 3.13 3.1

200 0 0 0 3.1

201 0 0 0 0

202 0 1.22 3.18 0

203 0 1.22 3.18 3.1

204 0 0 0 0

205 3.11 3.11 0 0

206 1.53 3.11 0 3.1

207 3.12 0 0 0

208 3.12 3.12 0.37 0

209 0 0

210 3.13 3.1

211 0 0

212 0 0

213 0 0

214 0 0

215 0 0

216 0 0

217 0 0

218 0 0

219 0 0

220 0 3.12

221 0 0

222 0 0

223 0 0

224 0 0

225 3.13 0

226 0 0

227 0 0.41

228 0 0

229 0 0

230 0 0

231 0 0

232 0 0.43

233 3.24 0

234 0 0.45

235 0 0.34

236 0 0

237 0 0

238 0 0

239 0 0

240 0 0.36

241

242

243

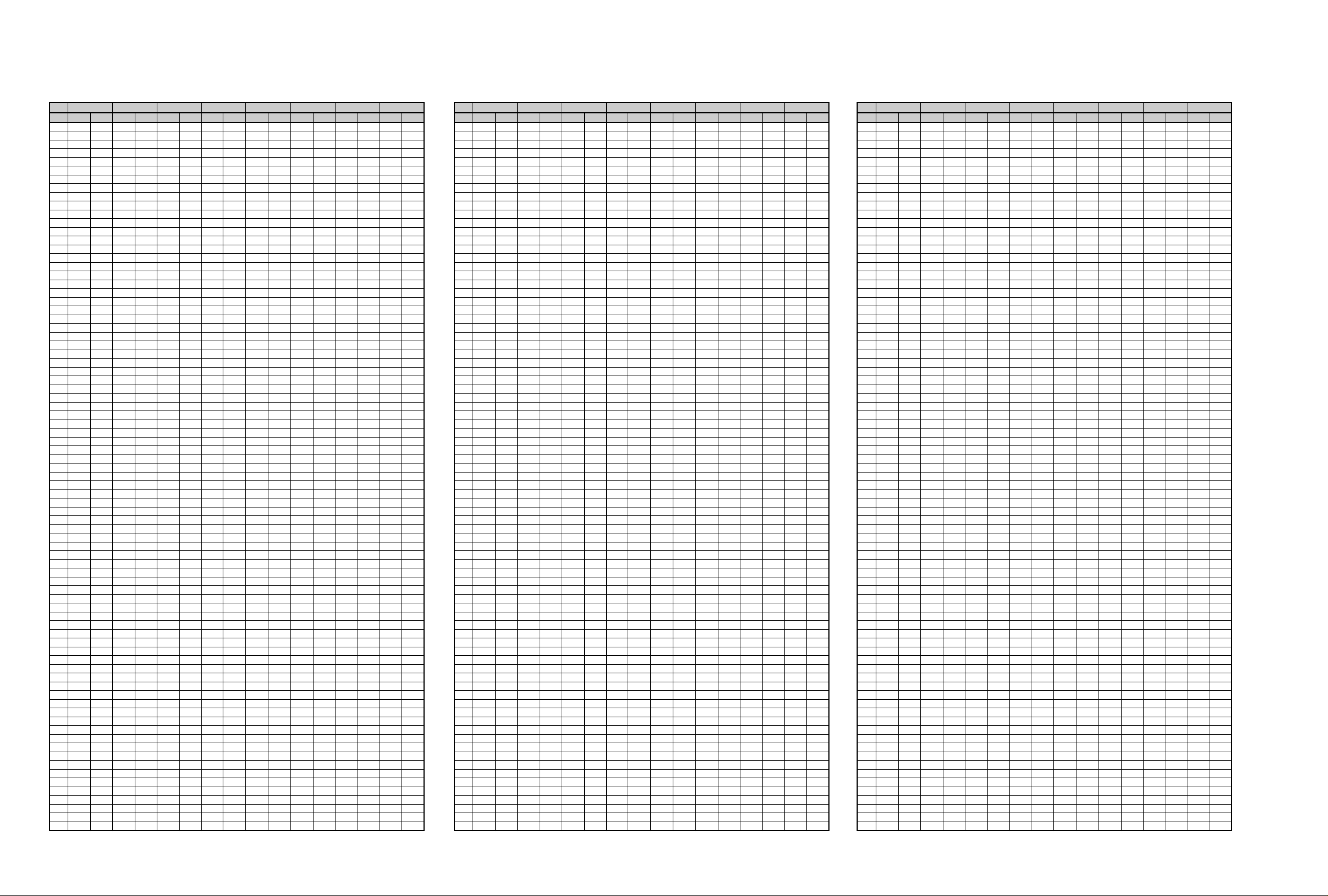

Page 38

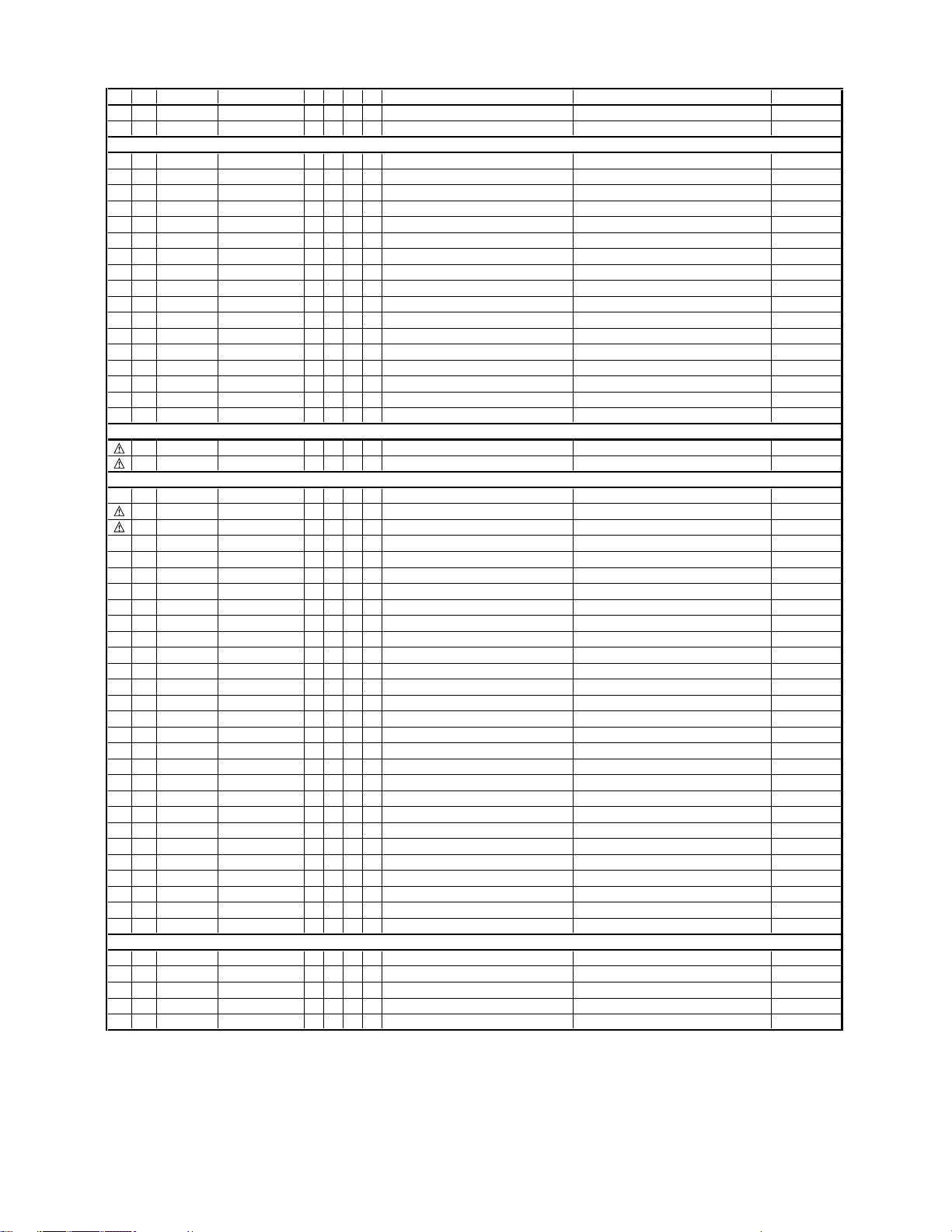

3-37 3-38

IC901 IC451 IC401 IC454 IC453 IC452 IC402 IC801

PIN STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY

1 0 0 0 0 2.98 2.98 5.51 5.51 5.41 5.42 5.49 0 5.47 5.47 1.83 1.81

2 5.1 5.05 3.15 3.15 3.26 3.26 5.51 5.51 5.41 5.42 5.49 5.51 5.47 5.47 0 0

3 0 0 3.15 3.15 0 0 5.51 5.51 5.41 5.41 5.49 5.51 5.47 5.47 1.83 1.81

4 5.14 5.14 3.15 3.14 1.57 0 0 0 0 0 0 0 0 0 0 0

5 0.48 0 3.15 3.15 1.58 1.58 5.51 5.51 5.41 5.41 5.49 5.51 5.47 5.47 0 0

6 0.48 0 3.15 3.15 1.3 0 5.51 5.51 5.41 5.42 5.49 5.51 5.47 5.47 4.59 4.57

7 5.17 5.17 3.15 3.15 0 0 5.51 5.51 5.41 5.41 5.49 0 5.47 5.47 1.84 1.82

8 2.22 2.21 2.43 2.42 3.24 3.24 11.95 11.95 11.95 11.95 11.95 11.95 11.95 11.95 0 0

9 2.35 2.35 2.48 2.46 0 0 1.84 1.82

10 0 0 2.43 2.42 3.2 3.19

11 2.26 2.24 2.48 0 4.85 4.84

12 2.46 2.45 0 0 2.31 0

13 0 0 0 0 2.35 0

14 5.17 5.16 0 0 2.35 0

15 5.17 5.16 2.43 2.43 0 0

16 5.1 5.06 2.47 3.14 0 0

17 0 0 2.45 0 4.91 0

18 0 0 0 0 2.34 2.34

19 5.16 5.16 4.91 4.88 2.34 2.33

20 5.14 5.14 0 0 0 0

21 5.01 5.02 0 0

22 0 0 0 0

23 0 0 4.91 0

24 0 0 0 0

25 2.68 2.68 4.9 4.88

26 5.17 5.17 0 0

27 5.17 5.17 0 0

28 4.77 4.87 0 0

29 5.07 5.06 0 0

30 21.58 18 4.91 4.88

31 23.58 18 0 0

32 23.6 23 4.91 4.88

33 27.54 21.21 0 0

34 23.6 17.18 0.36 0

35 23.6 22.91 0 0

36 21.6 19.14 3.24 3.23

37 21.61 25.01 3.19 3.19

38 23.65 23.06 2.93 3.92

39 23.65 23.09 0 0

40 23.57 23.08 0 0

41 25.6 23.07 1.3 1.31

42 25.6 25.03 1.48 1.47

43 25.6 25.03 1.57 0

44 25.6 23.07 1.58 1.58

45 27.6 25.07 0 0

46 27.6 21.16 3.15 3.15

47 27.5 25.11 0 0

48 27.5 24.76 0 0

49 27.5 27.86 0 0

50 27.5 26.88 0 0

51 6.73 6.69 3.15 3.14

52 25.7 25.13 0 0

53 25.6 25.08

54 25.6 25.16

55 25.6 25.15

56 25.6 25.08

57 25.6 25.13

58 27.7 27.08

59 5.16 5.15

60 5.16 5.16

61 5.16 5.16

62 5.16 5.16

63 0 0

64 0 0

IC503 IC502 IC2A4 IC2A2 IC206 IC504 IC506

PIN STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY

1 0 0 0 0 4.87 4.39 1.57 1.56 2.63 2.64 2.11 2.19 (IN)0 0

2 3.1 3.1 5.03 5.03 2.3 2.31 1.57 1.56 2.74 0 5.05 5.05

(OUT)1.80

0

3 5.03 5.03 0 0 2.29 2.29 1.57 0 2.74 2.76 2.37 2.44

4 0 0 5.1 5.1 0 0 0 0 0 0 0 0

5 0 0 0 0 2.29 2.29 1.62 1.62 1.92 1.88

6 0 0 5.04 5.04 2.3 2.31 1.62 1.62 2.28 0

7 5.05 5.05 0 0 2.51 2.45 1.62 1.62 2.28 0

8 0 3.15 5.03 5.04 5.02 5.02 5.04 4.99 5.04 0

90 0

10 0 0

11 0 0.46

12 0 0.15

13 3.11 3.1

14 0 0

15 0 0

16 0 0

17 3.09 3.09

18 5.15 5.14

19 0 0

20 5.15 5.15

Q2M1 Q2A1 Q2A6 Q2A5 Q2A2

STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY

E 0 0 5.02 0 0 2.41 2.34 2.35 5.02 4.95

B 0 0 0 0 3.62 3.72 3.82 0 0 0

C 0 3.14 0 0 0 3.1 0 0 5.01 4.94

Q610 Q611 Q609 Q613 Q614 Q612

PIN STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY STOP PLAY

Emitter 0 0 0 0 0 0 0 0 0 0 0 0

Collector 0 0 0 0 0 0 0 0 0 0 0

Base 0.77 0.78 0.77 0.77 0.76 0.77 0.76 0.77 0.77 0.77 0.76 0.79

Page 39

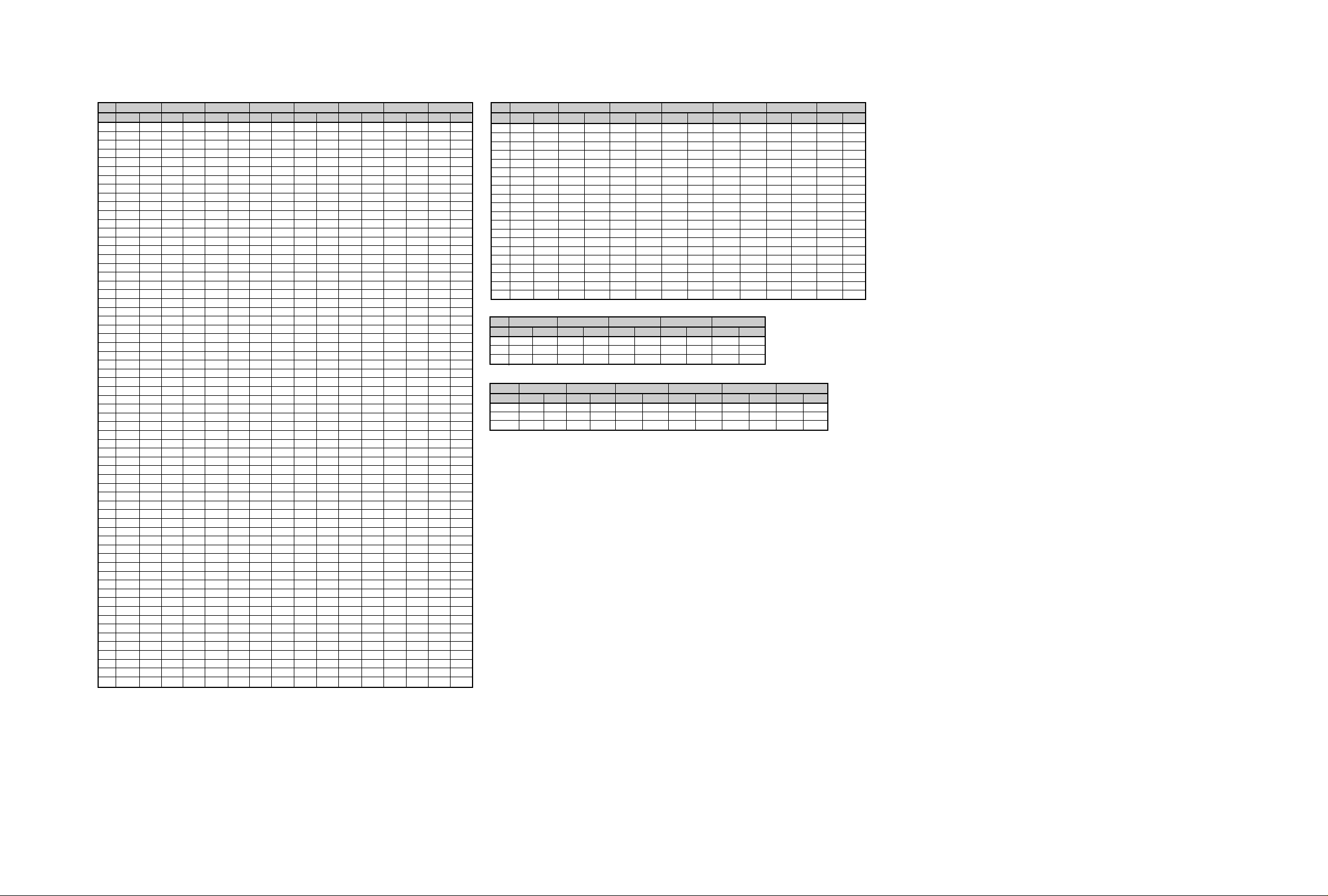

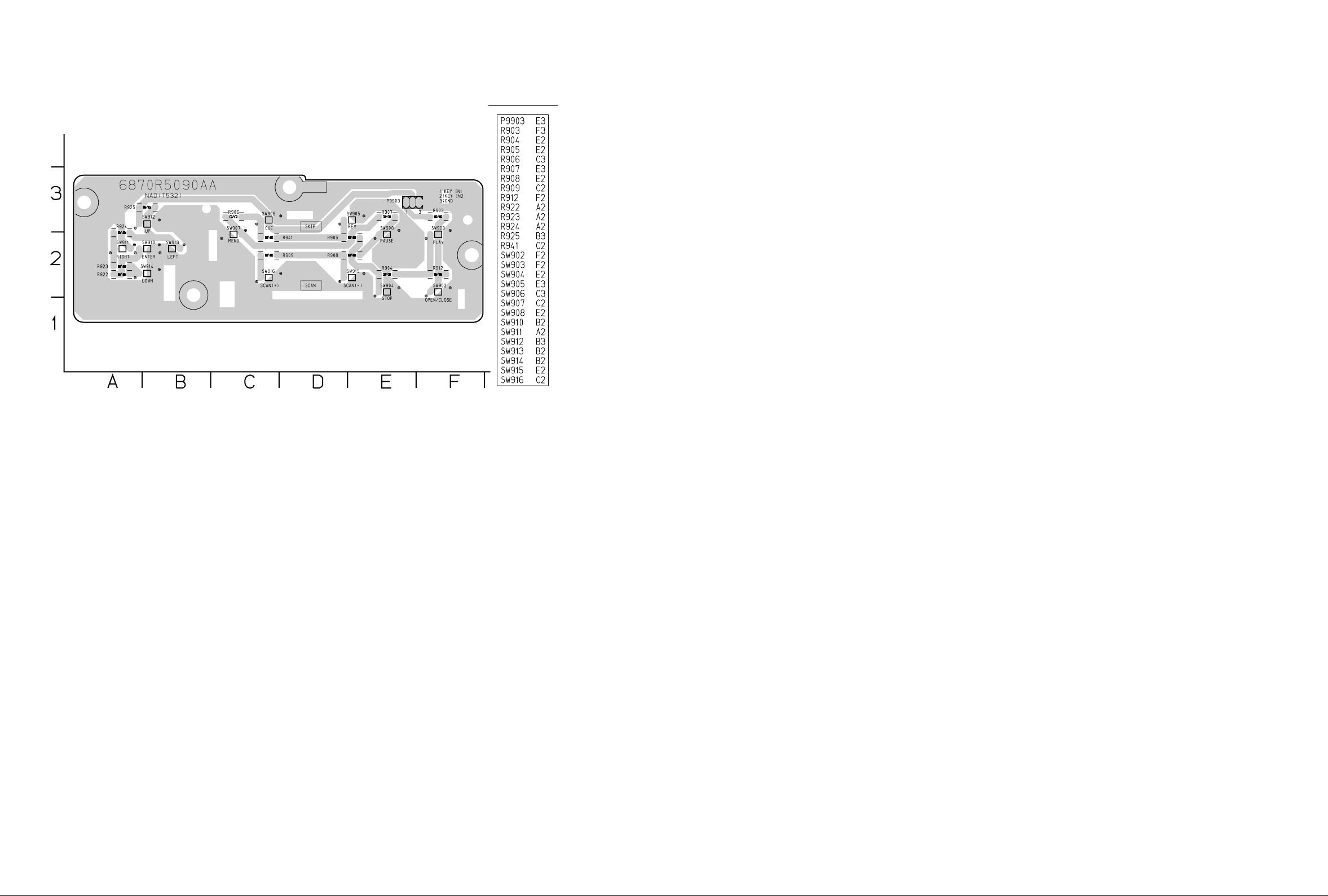

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C.BOARD

LOCATION GUIDE

3-39 3-40

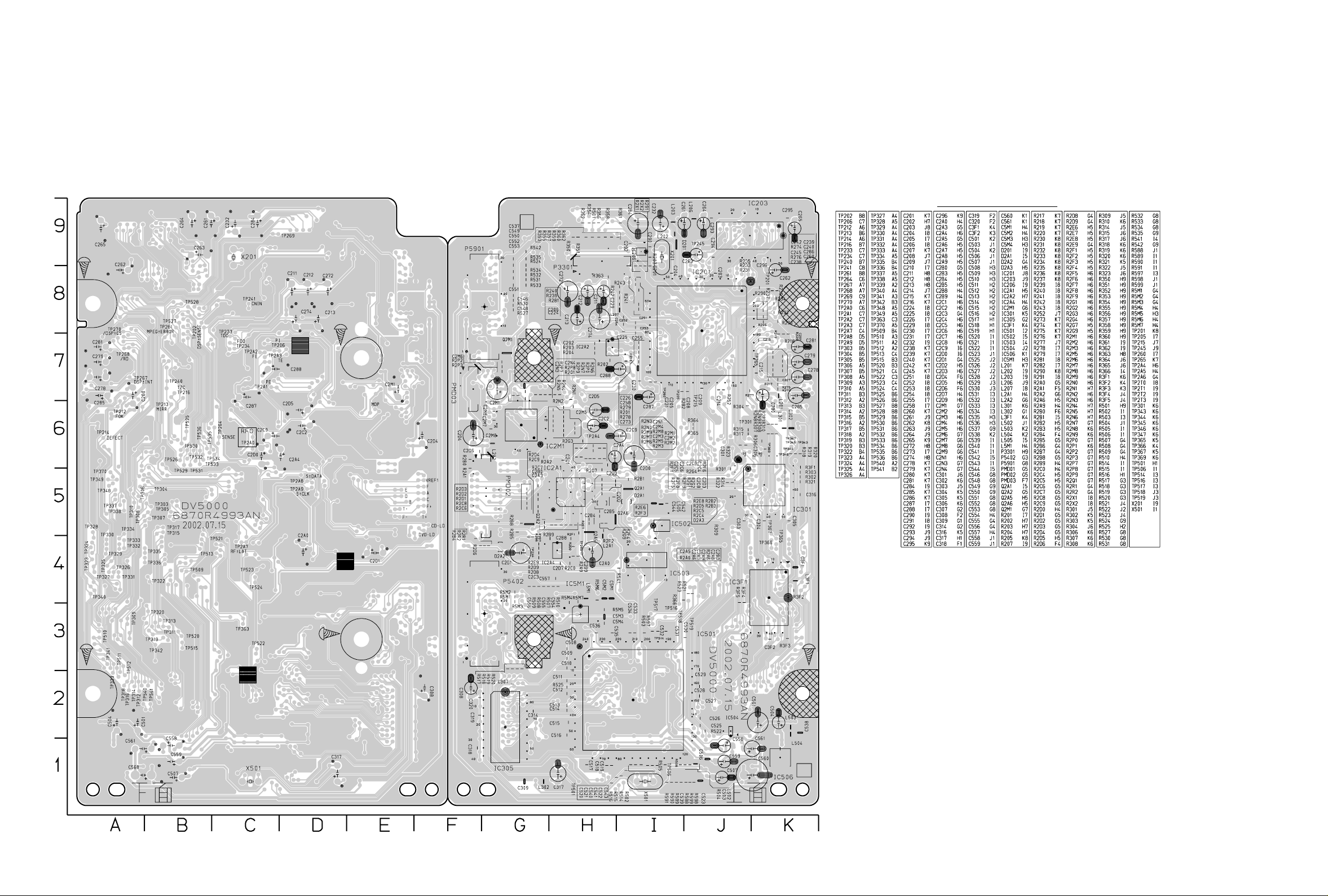

Page 40

3-41 3-42

2. POWER, A/V, FRONT P.C.BOARD

LOCATION GUIDE

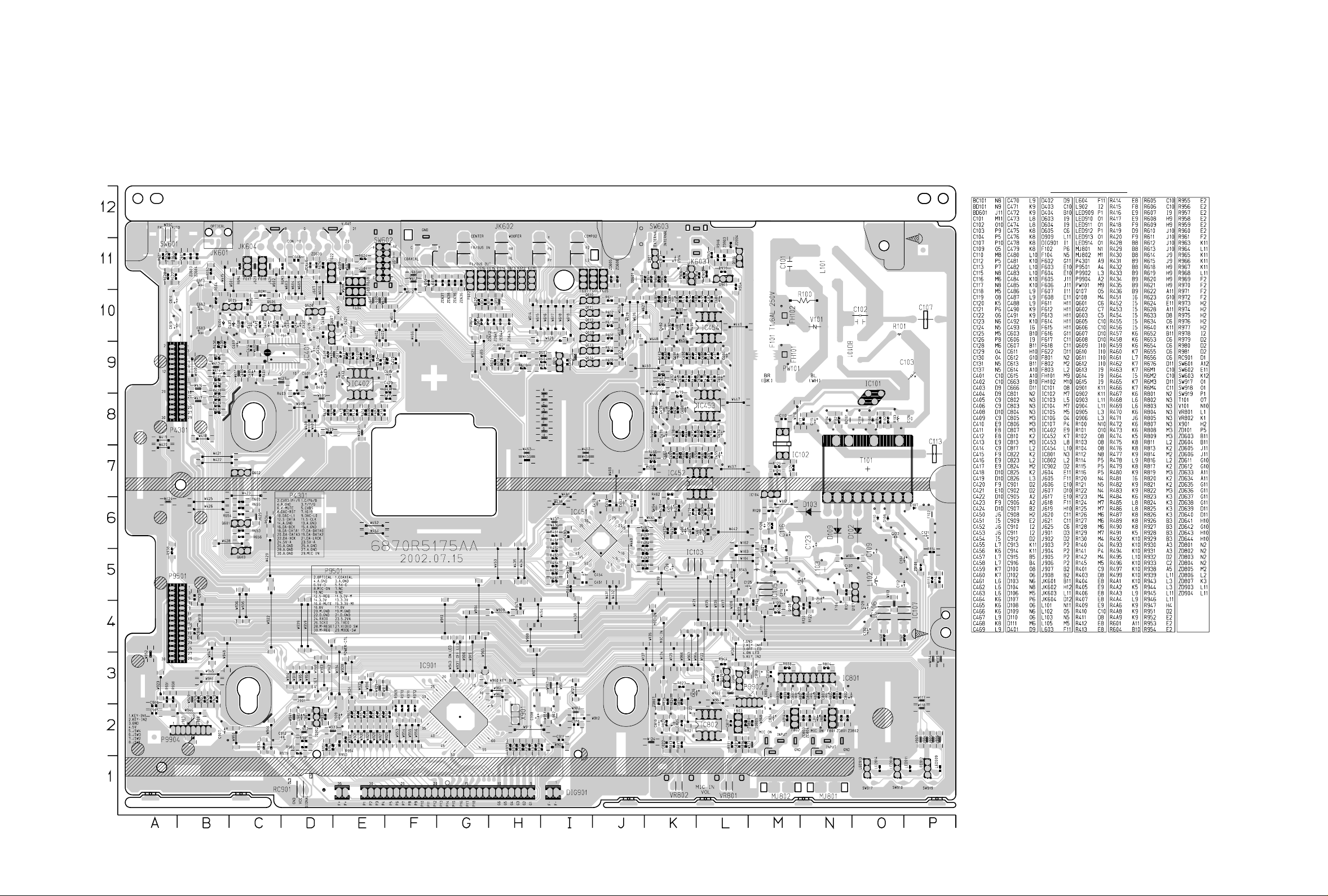

Page 41

3-43 3-44

3. KEY P.C.BOARD

LOCATION GUIDE

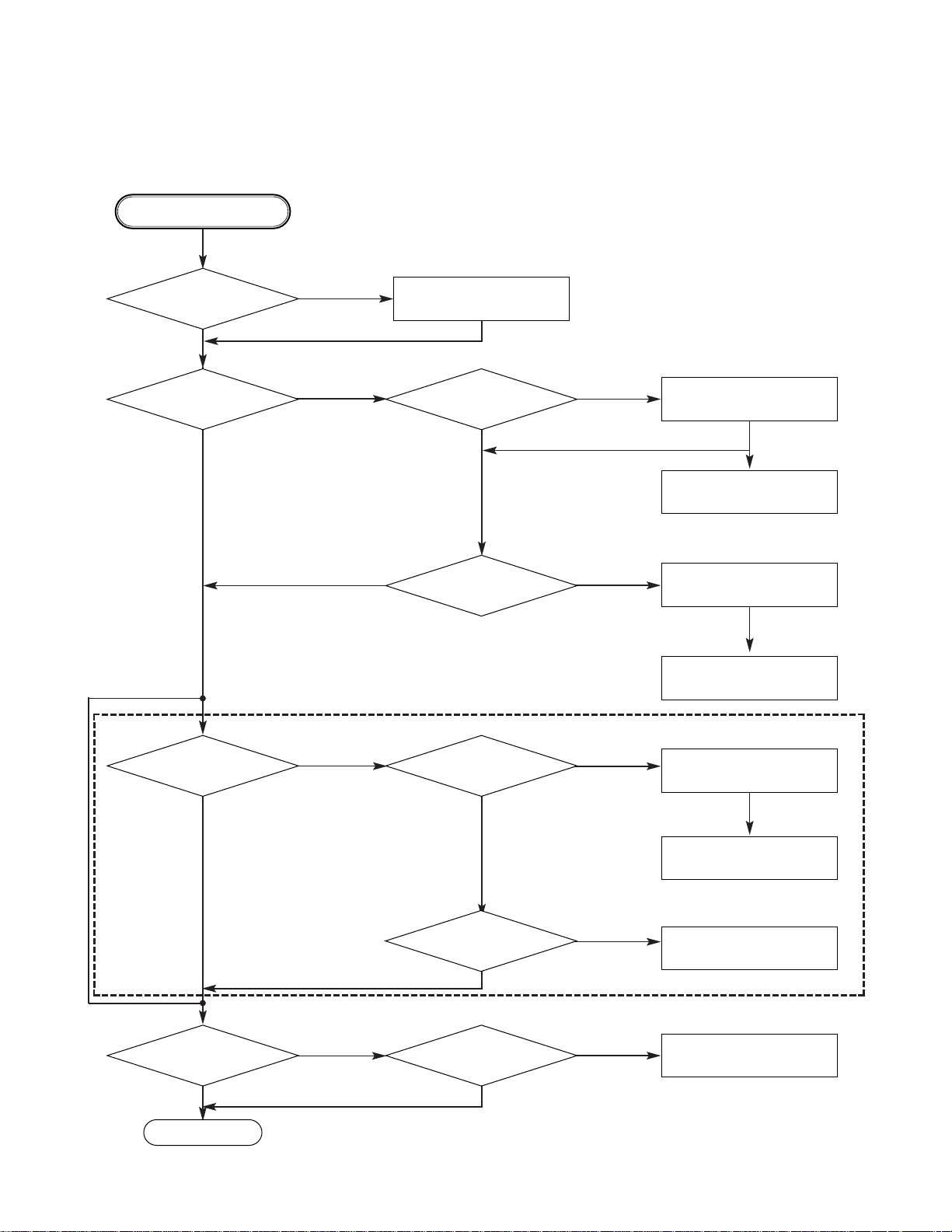

Page 42

• Top View..................................................4-1

• Top View(without Tray Disc) .................4-1

• Bottom View ...........................................4-1

1. Holder Clamp....................................4-2

1-1. Clamp Assembly Disc.......................4-2

1-1-1. Plate Clamp ..................................4-2

1-1-2. Magnet Clamp ..............................4-2

1-1-3. Clamp Upper.................................4-2

2. Tray Disc ...........................................4-2

3. Base Assembly Sled ........................4-3

3-1. Gear Assembly Feed........................4-3

3-2. Gear Assembly Middle......................4-3

3-3. Gear Assembly Rack........................4-3

4. Rubber Rear......................................4-3

5. Frame Assembly Up/Down..............4-4

6. Belt Loading......................................4-4

7. Gear Pulley .......................................4-4

8. Gear Loading ....................................4-4

9. Guide Up/Down.................................4-4

10. PWB Assembly Loading................4-4

11. Base Main........................................4-4

1. Deck Mechanism Exploded View....4-5

CONTENTS

SECTION 4 MECHANISM

DECK MECHANISM PARTS

LOCATIONS

EXPLODED VIEW

DECK MECHANISM

DISASSEMBLY

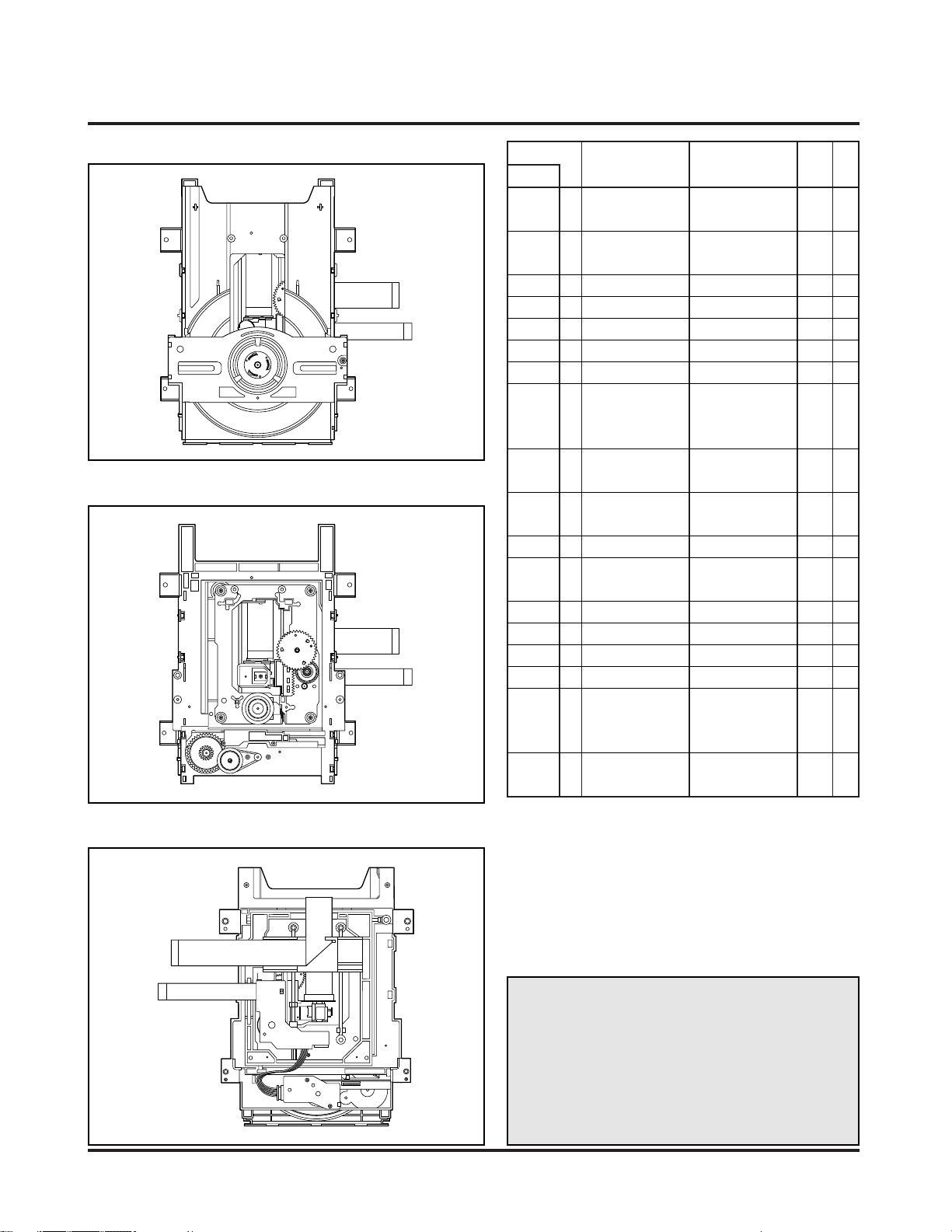

Page 43

4-1

DECK MECHANISM PARTS LOCATION

Starting No.

1

1, 2

1, 2, 3

1, 2, 3, 4

1

1, 6

1, 2, 6

1, 2, 6, 8

1, 2, 6, 8,

9

1, 2, 7

1, 2, 7

1, 2

1, 2 ,13

1, 2, 13, 14

1, 2, 7, 12, 13, 14

1, 2, 13

1, 2, 7, 12, 13,

14, 15, 16, 17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Holder

Clamp

Clamp Assembly

Disc

Plate Clamp

Magnet Clamp

Clamp Upper

Tray Disc

Base Assembly Sled

Gear Assembly

Feed

Gear

Middle

Gear Assembly

Rack

Rubber Rear

Frame Assembly

Up/Down

Belt Loading

Gear Pulley

Gear Loading

Guide Up/Down

PWB Assembly

Loading

Base Main

2 Screws,

2 Locking Tabs

4 Screws,

1 Connector

1 Locking Tabs

1 Screw

1 Screw

1 Locking Tab

1 Locking Tab

1 Locking Tab

1 Hook

2Screw

2 Locking Tabs

4-1

4-1

4-1

4-1

4-1

4-2

4-3

4-3

4-3

4-3

4-3

4-4

4-4

4-4

4-4

4-4

4-4

4-4

Bottom

Bottom

Procedure

Parts Fixing Type

Figure

Disass

embly

Note

When reassembling, perform the procedure in

reverse order.

The “Bottom” on Disassembly column of above

Table indicates the part should be disassembled

at the Bottom side.

• Top View (Without Tray)

• Bottom View

• Top View (With Tray)

Page 44

4-2

DECK MECHANISM DISASSEMBLY

1.Holder Clamp (Fig. 4-1)

1) Release 1 Screws(S1).

2) Unhook 2 Locking Tabs(L1).

3) Lift up the Holder Clamp and then separate it from the

Base Main.

1-1. Clamp Assembly Disc

1) Place the Clamp Assembly Disc as Fig. (A)

2) Lift up the Clamp Assembly Disc in direction of

arrow(A).

3) Separate the Clamp Assembly Disc from the Holder

Clamp.

1-1-1. Plate Clamp

1) Turn the Plate Clamp to counterclockwise direction and

then lift up the Plate Clamp.

1-1-2. Magnet Clamp

1-1-3. Clamp Upper

2. Tray Disc (Fig. 4-2)

1) Insert and push a Driver in the emergency eject

hole(A) at the right side, or put the Driver on the

Lever(B) of the Gear Emergency and pull the Lever(B)

in direction of arrow so that the Tray Disc is ejected

about 15~20mm.

2) Pull the Tray Disc until it is separated from the Base

Main completely.

HOLDER CLAMP

CLAMP ASSEMBLY DISC

PLATE CLAMP

MAGNET CLAMP

CLAMP UPPER

(S1)

(L1)

(L1)

HOLDER CLAMP

BASE MAIN

HOLDER CLAMP

(Fig. A)

(A)

TRAY DISC

EMERGENCY EJECT HOLE

LEVER

BASE MAIN

BASE MAIN

BOTTOM SIDE VIEW

(A)

(B)

Fig. 4-1 Fig. 4-2

Page 45

4-3

DECK MECHANISM DISASSEMBLY

3.Base Assembly Sled (Fig. 4-3)

1) Release 4 Screw(S2).

2) Disconnect the FFC Connector(C1)

3-1. Gear Assembly Feed

1) Unhook the Locking Tab(L2) in direction of arrow.

3-2. Gear Middle

3-3. Gear Assembly Rack

1) Release the Scerw(S3)

4. Rubber Rear (Fig. 4-3)

GEAR MIDDLE

GEAR ASSEMBLY RACK

PICK UP

ASSEMBLY

GENERAL

GEAR ASSEMBLY FEED

GEAR MIDDLE

GAER ASSEMBLY RACK

MOTOR ASSEMBLY SPINDLE

RUBBER REAR

MOTOR ASSEMBLY

SPINDLE

PICK UP ASSEMBLY GENERAL

BASE PU(OUTSERT)

GEAR ASSEMBLY FEED

(L2)

(S2)

(S2)

(C1)

(S2)

(S2)

(BLACK)

(GREEN)

(S3)

(BLACK)

(GREEN)

Fig. 4-3

Page 46

4-4

DECK MECHANISM DISASSEMBLY

5. Frame Assembly Up/Down

Put the Base Main face down(Bottom Side)

1) Release the Screw(S4)

2) Unlock the Locking Tab(L3) in direction of arrow and

then lift up the Frame Assembly Up/Down to separate

it from the Base Main.

• When reassembling move the Guide Up/Down in direction

of arrow(C) until it is positioned as Fig.(C).

• When reassembling insert (A) portion of the Frame

Assembly Up/Down in the (B) portion of the Guide

Up/Down as Fig.(B)

6. Belt Loading(Fig. 4-4)

Put the Base Assembly Main on original position(Top Side)

7. Gear pulley (Fig. 4-4)

1) Unlock the Locking Tab(L4) in direction of arrow(B) and

then separate the Gear Pulley from the Base Main.

8. Gear Loading (Fig. 4-4)

9. Guide Up/Down (Fig. 4-4)

1) Move the Guide Up/Down in direction of arrow(A) as

Fig.(A)

2) Push the Locking Tab(L5) down and then lift up the

Guide Up/Down to separate it from the Base Main.

When reassembling place the Guide Up/Down as Fig.(C)

and move it in direction arrow(B) until it is locked by the

Locking Tab(L5). And confirm the Guide Up/Down as Fig.(A)

10. PWB Assembly Loading

Put the Base Main face down(Bottom Side)

1) Release 2 Screws(S5)

2) Unkool the Loading Motor Connector (C2) from the

Hook (H1) on the Base Main.

3) Unlock 2 Locking Tabs(L6) and separate the PWB

Assembly Loading from the Base Main.

11. Base Main(Fig. 4-4)

Note

Note

Note

Note

Note

GEAR LOADING

GEAR PULLEY

(L4)

(L6)

(L5)

(A)

(B)

(B)

(A)

(A)

(B)

(C)

(S5)

(C2)

(S4)

PWB ASSEMBLY LOADING

BELT LOADING

BASE MAIN

GUIDE UP/DOWN

FIG. (A)

FIG. (C)

GUIDE UP/DOWN

GUIDE UP/DOWN

FIG. (B)

FRAME ASSEMBLY UP/DOWN

(H1)

BASE MAIN

(L6)

(L6)

(L3)

GUIDE UP/DOWN

Fig. 4-4

Page 47

EXPLODED VIEWS

4-5 4 -6

1. Deck Mechanism Exploded View

A0 1

2

0

0

1

0

0

3

0

0

4

0

0

9

2

4

01 3

01 4

A0 3

0

3

43 2

4

2

1

0

009

A0 2

0

6

2

0

00 8

0

3

4

2

1

0

0

3

4

2

1

0

8

1

0

01 6

0

3

4

2

1

0

01 0

0

2

A0 0

01 7

01 1A

01 5

43 1

01 1

43 1

Page 48

MEMO MEMO

Page 49

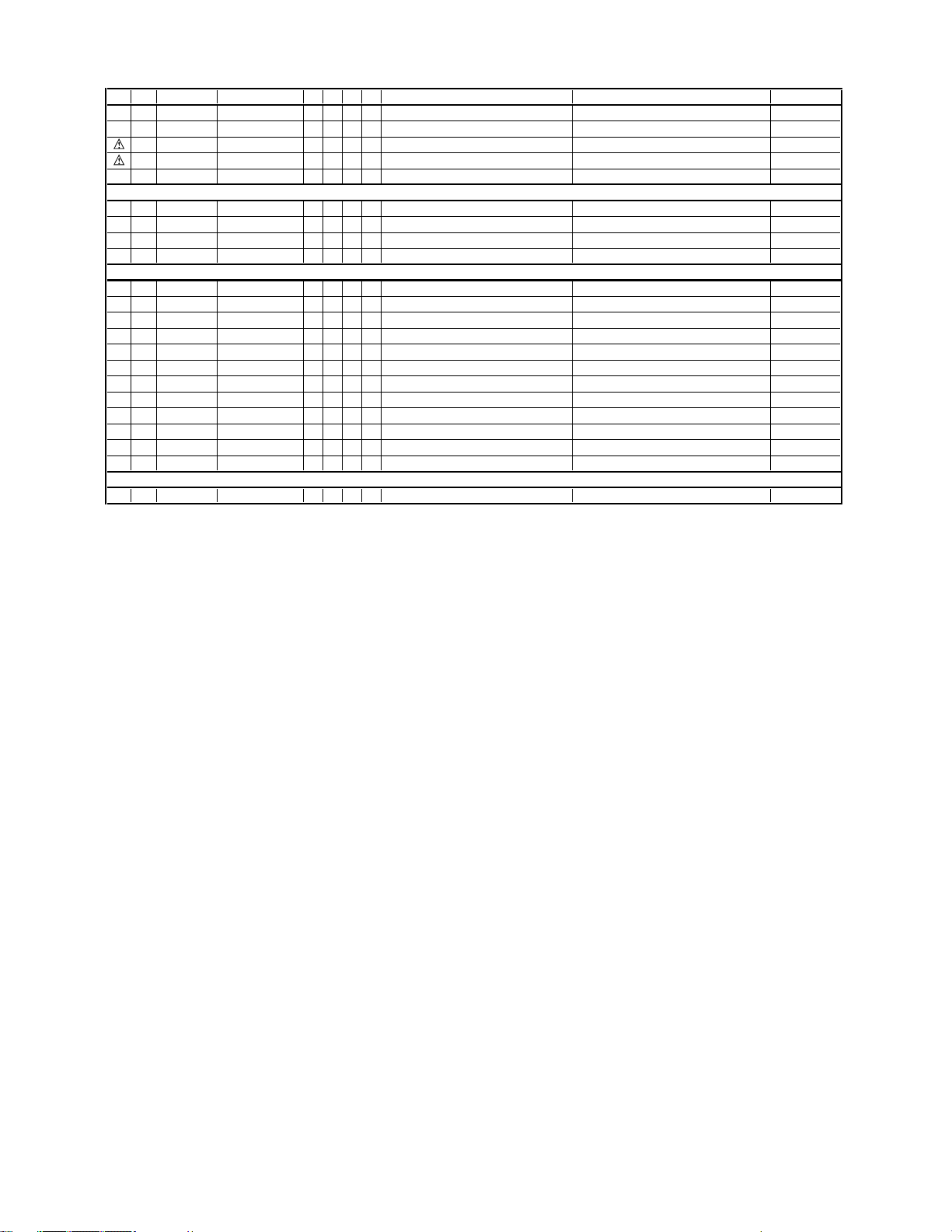

5-1

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

NOTES) If you want to purchase

Flash memory, you must order

"IC3F1A"

MODELS:(A)T512AH, (B)T512C, (C)T532AH, (D)T532C(NAD)

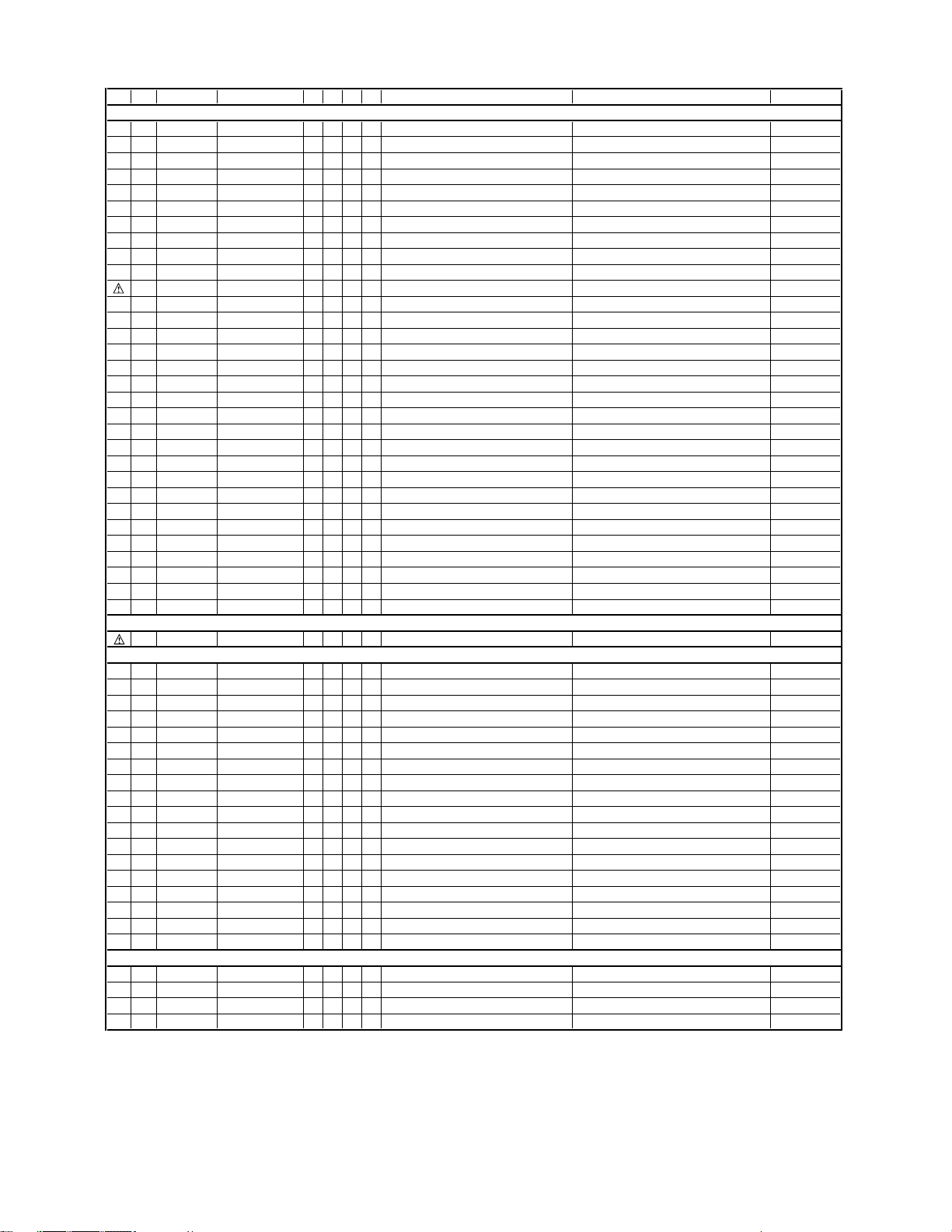

SECTION 5 REPLACEMENT PARTS LIST

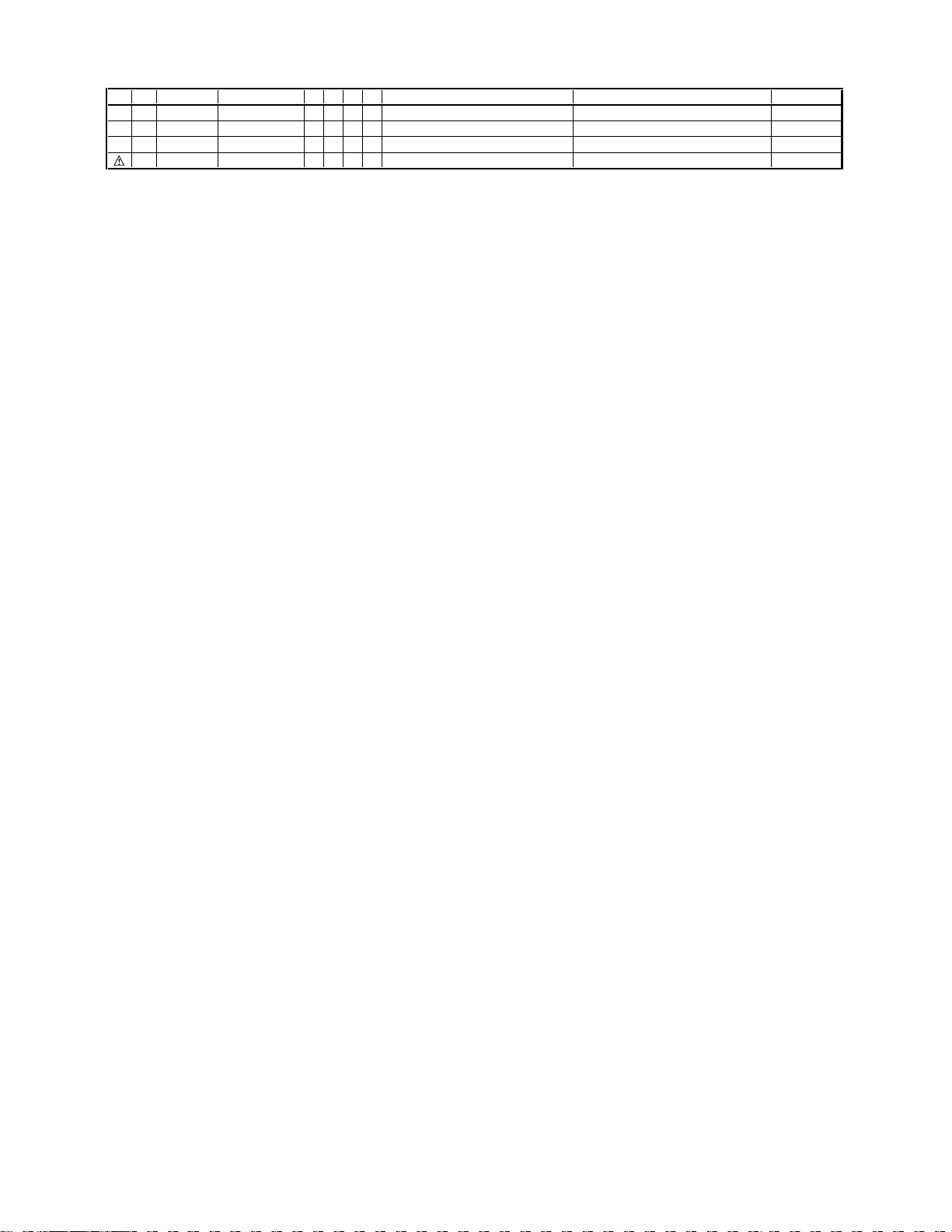

.MECHANICAL SECTION

S AL LOCA.NO PART NO(LG) ABCDDESCRIPTION SPECIFICATION REMARKS

ASSEMBLY PARTS SECTION

A00 6721RH0352A OOOODECK ASSEMBLY,VIDEO DP-5 R/RW -SH (MITSUMI 2LD 302

A01 4861R-0006B OOOOCLAMP ASSEMBLY DISC(DP2)-SH

A02 3041R-0053C OOOOBASE ASSEMBLY MAIN(DP-5RM, 2LD DC W/O SENSOR

A03 3041R-0054F OOOOBASE ASSEMBLY SLED (DP-5RM, 2LD 302T DC W/O

PARTS SECTION

001 3300R-0547A OOOOPLATE CLAMP NSP

002 5016H-1016B OOOOMAGNET CLAMP(LDM-R608,10*5,1*1.5T) NSP

003 4860R-0006A OOOOCLAMP UPPER NSP

004 4930R-0299A OOOOHOLDER,SHELF CLAMP(DP-5)

008 4470R-0047A OOOOGEAR ASSY RACK

009 4470R-0053A OOOOGEAR MIDDLE

010 6850R-GK12A OOOOCABLE,FLAT P=1.0 FFC UL2896(0.05X0.65) 11

011 3210R-0068A OOOOFRAME UP/DOWN(DP-5)

011A 6850R-JW28Z OOOOCABLE,FLAT P=1.0 FFC UL2896(0.035X0.7) 23

012 5040R-0047B OOOORUBBER DAMPER(E2,5040H-1054A),CHUNPOO

013 4400R-0006A OOOOBELT LOADING

014 4470R-0055A OOOOGEAR PULLEY

015 6871R-4415D OOOOPWB(PCB) ASSEMBLY,TOTAL LOADING DP4 MITSUMI -SH

016 4470R-0050A OOOOGEAR ASSY FEED

017 4470R-0056A OOOOGEAR LOADING

018 4974R-0023A OOOOGUIDE UP/DOWN

020 3040R-0067A OOOOBASE MAIN NSP

026 3390R-0005A OOOOTRAY DISC

SCREW

430 1SZZH-1003A OOOOSCREW, + D2.0 6MM SWRCH16A/NIY 4.5MM

431 1SZZH-1007B OOOOSCREW,DRAWING + D2.0 6MM SWRCH16A/ZNBK 4MM 1

432 1SZZR-0011A OOOOSCREW, MACHINE

RUN DATE:AUG.06.2002

NSP:Not Service Part

.CABINET & MAIN FRAME SECTION

ASSEMBLY PARTS SECTION

A43 3501RF3003A O BOARD ASSEMBLY FRONT(T532_AH_)

A43 3501RF3003B O BOARD ASSEMBLY FRONT(T532_C_)

A43 3501RF3003C O BOARD ASSEMBLY FRONT(T512_AH_)

A43 3501RF3003D O BOARD ASSEMBLY FRONT(T512_C_)

A46 6885R-0509D O SUB PWB(PCB) ASSEMBLY DVN5022E HA2DNN T532 C

A46 6885R-0509E O SUB PWB(PCB) ASSEMBLY DVN5024N HA1UNN T532 AH

A46 6885R-0509F O SUB PWB(PCB) ASSEMBLY DVN5022N HA1UNNT T512 AH

A46 6885R-0509G O SUB PWB(PCB) ASSEMBLY DVN5022E HA2DNNT T512 C

A48 6871R-5175A O PWB(PCB) ASSEMBLY,TOTAL DVN5022E I/O SH

A48 6871R-5175B O PWB(PCB) ASSEMBLY,TOTAL DVN5024P I/O SH

A48 6871R-5175D O PWB(PCB) ASSEMBLY,TOTAL DVN5022N I/O SH

A48 6871R-5175E O PWB(PCB) ASSEMBLY,TOTAL DVN5022E I/O SH

PARTS SECTION

250 3110R-0311E O CASE DVD DV5000 TOP D-A288G (SILVER

250 3110R-0311F O O O CASE DVD DV5000 TOP NAD_D423G ( W/O

260 3141R-0066L O CHASSIS ASSEMBLY T532_AH #1 NSP

260 3141R-0066M O CHASSIS ASSEMBLY T532_#2 C NSP

260 3141R-0066P O CHASSIS ASSEMBLY T512#1 AH NSP

260 3141R-0066Q O CHASSIS ASSEMBLY T512#2 C NSP

275 4930R-0183A OOOOHOLDER MAIN PCB

280 3721R-F291A O PANEL ASSEMBLY,FRONT FRONT (T532_AH_)

280 3721R-F291B O PANEL ASSEMBLY,FRONT FRONT (T532_C_)

280 3721R-F291C O PANEL ASSEMBLY,FRONT FRONT (T512 _AH_)

280 3721R-F291D O PANEL ASSEMBLY,FRONT FRONT (T532 _AH_)

Page 50

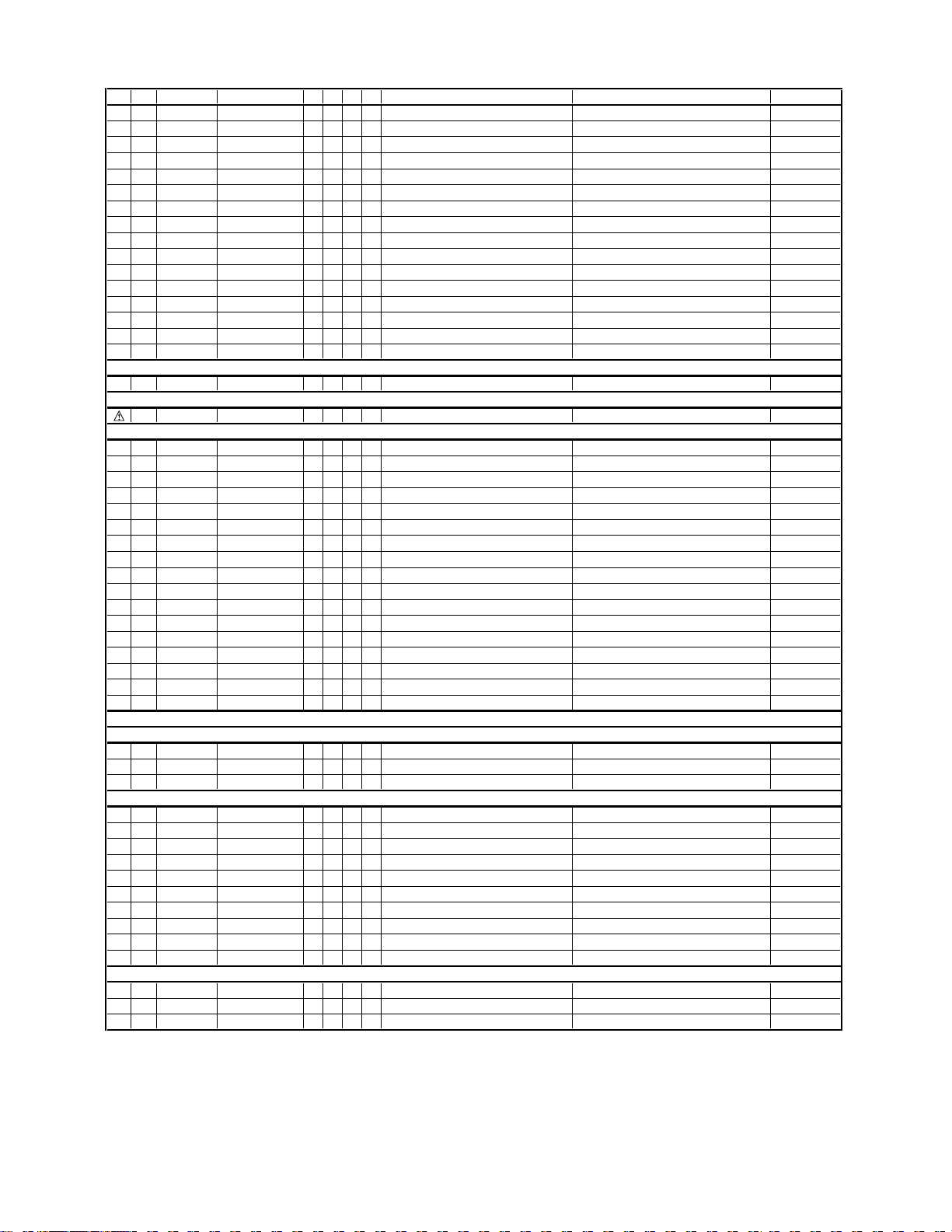

5-2

S AL LOCA.NO PART NO(LG) ABCDDESCRIPTION SPECIFICATION REMARKS

283 3580R-T042B O O O DOOR,CASE TRAY (T532)NAD

283 3580R-T042C O DOOR,CASE TRAY (T512)NAD

300 6410RAHJ02B O O POWER CORD JL001/NISPT-2(ST:HS=70MM) JIUL

300 6410RCHJ02B O O POWER CORD JL201B H03VVH2-F(S:H=70MM) JIU

332 3300R-M018A OOOOPLATE MAIN GND(DVD-3000 SUS-0.2T)

SCREW

452 353-051A OOOOSCREW SPECIAL

463 353-051G OOOOSCREW,DRAWING + 2 D3.0 L8.0 MSWR3/FN TB ROUN

465 353-046K OOOOSCREW SPECIAL (3X10 B.K)

467 353-046N OOOOSCREW, SPECIAL(3X8 BK.)

.PACKING & ACCESSORY SECTION

801 3835RS0043K O O INSTRUCTION ASSEMBLY DVN5022E_HA2DNN/HA2DNNT

801 3835RS0043L O O INSTRUCTION ASSEMBLY DVN5022N_HA1UNNT/DVN5024N_HA1U

802 3890R-H524P O BOX DVN5022E HA2DNNT SW3-A 0.955 1

802 3890R-H524Q O BOX DVN5022E HA2DNN SW3-A 0.955 1

802 3890R-H524R O BOX DVN5022N HA1UNNT SW3-A 0.955 1

802 3890R-H524S O BOX DVN5024N HA1UNN SW3-A 0.955 1

803 3920R-E061A OOOOPACKING,CASING NAD5000 0.02 80 EPS 5 935 1898

804 292-053B OOOOBAG SOFT(MIDI) NSP

808 841-0021 OOOOBATTERY,MN ER03X HI WATT 1.5V .MA/H AAA

810 6851RP0003N OOOOCABLE ASSY,RF DVD CABLE ASSY,RCA USING AREA

811 6611R1G001A OOOOPLUG ASSY 1WAY YELLOW GLOBAL

812 6611R2G001A OOOOPLUG ASSY 2WAY RED/WHITE GLOBAL

.REMOTE CONTROL SECTION

900 6711R2N010W OOOOREMOTE CONTROLLER ASSY D1 NOR DVN4021N NAD

Page 51

5-3

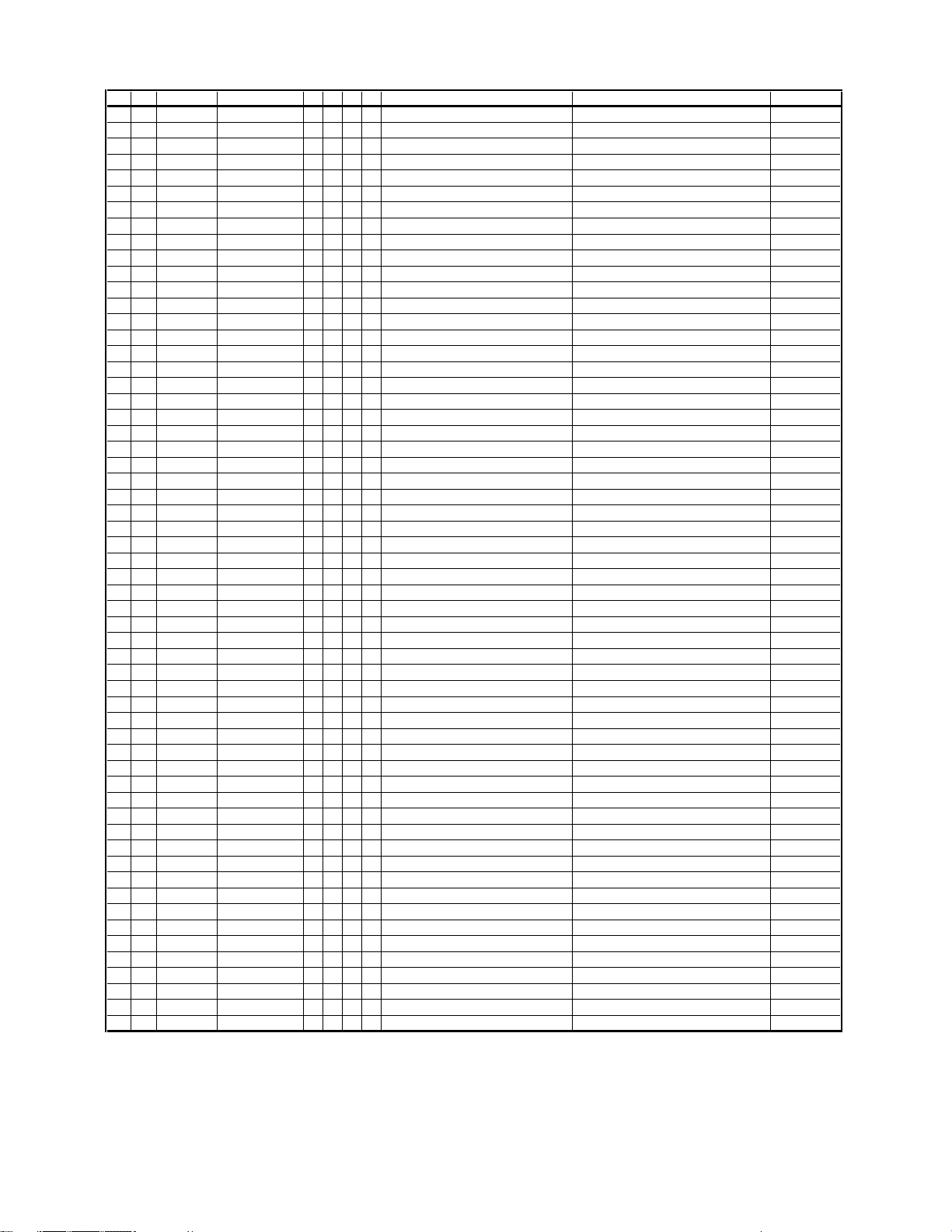

.ELECTRICAL SECTION

S AL LOCA.NO PART NO(LG) ABCDDESCRIPTION SPECIFICATION REMARKS

CAPACITOR

C101 624-088S OOOOCAPACITOR,DRAWING MPX104K ETR/EUROPTRONIC BULK

C102 0CG3320U632 OOOOCAPACITOR,FIXED CERAMIC(TEMP.C 3300PF D 400V 20% R Y ( N 800

C103 0CE1076Q600 O O CAPACITOR,ELECTROLYTIC 100UF SMS 200V M W BULK

C103 0CE686CU611 O O CAPACITOR,AL.ELECTROLYTIC 68UF SHL,SD 400V M FL BK7.5

C104 624-085D OOOOCAPACITOR CE 47UF/50V KME (SMPS)

C109 0CE108BF630 OOOOCAPACITOR,FIXED ELECTROLYTIC 1000UF KME 16V M FM5 BULK

C110 0CN4730K948 OOOOCAPACITOR,FIXED TUBULAR(High d 0.047UF D 50V 80%,-20% F(Y5V)

C112 0CE3376D638 OOOOCAPACITOR,ELECTROLYTIC 330UF SMS 10V M FM5 TP5

C113 0CG3320U632 OOOOCAPACITOR,FIXED CERAMIC(TEMP.C 3300PF D 400V 20% R Y ( N 800

C115 0CE1064K638 OOOOCAPACITOR,FIXED ELECTROLYTIC 10M SRA 50V M FM5 TP(5)

C116 0CE477BH630 OOOOCAPACITOR,AL.ELECTROLYTIC 470UF KME TYPE 25V M FM5 BULK

C117 0CN4730K948 OOOOCAPACITOR,FIXED TUBULAR(High d 0.047UF D 50V 80%,-20% F(Y5V)

C118 0CE1074F638 OOOOCAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C119 624-087B OOOOCAPACITOR HIGH-VOL 100P/1KV SMPS SAMHWA

C120 0CE1074F638 OOOOCAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C121 0CE2276F638 OOOOCAPACITOR,ELECTROLYTIC 220U SMS 16V M FM5 TP(5)

C122 624-085D OOOOCAPACITOR CE 47UF/50V KME (SMPS)

C123 0CE108BF630 OOOOCAPACITOR,FIXED ELECTROLYTIC 1000UF KME 16V M FM5 BULK

C124 0CE337CH618 OOOOCAPACITOR,FIXED ELECTROLYTIC 330UF SHL,SD 25V 20% FL TP 5

C125 0CE1054K638 OOOOCAPACITOR,ELECTROLYTIC 1.0M SRA/SS50V M FM5 TP(5)

C126 0CQ1031Y519 OOOOCAPACITOR,POLYESTER 0.01UF D 630V K PE NI TP

C128 0CQ1042K409 OOOOCAPACITOR,FIXED FILM 0.1UF S 50V J PE TP

C129 0CE1074F638 OOOOCAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C130 0CE1074F638 OOOOCAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C131 0CE1074F638 OOOOCAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C137 0CE3376D638 OOOOCAPACITOR,ELECTROLYTIC 330UF SMS 10V M FM5 TP5

C201 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C202 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C203 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C204 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C205 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C206 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C207 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C208 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C209 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C210 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C211 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C212 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C213 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C214 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C215 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C216 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C224 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C225 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C226 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C229 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C230 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C231 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C232 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C238 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C239 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C240 0CH1222K562 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 2200PF 50V K X7R(X) 1608 R/TP

C242 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C245 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C251 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C252 0CH4100K112 OOOOCHIP CAPA CERAMIC M/L T.C F/S 10P 50V D COG 1.6X0.8 R/TP

Page 52

5-4

S AL LOCA.NO PART NO(LG) ABCDDESCRIPTION SPECIFICATION REMARKS

C253 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C254 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C255 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C258 0CH1105D942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 1UF 10V Z Y5V(F) 1508 R/TP

C261 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C262 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C263 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C264 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C265 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C272 0CE4764F638 OOOOCAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C273 0CH1225F944 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 2.2UF 16V 80%,-20% Y5V(F) 3216

C274 0CE4764F638 OOOOCAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C278 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C279 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C280 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C281 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C284 0CE4764F638 OOOOCAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C285 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C286 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C287 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C288 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C290 0CH4180K412 OOOOCAPACITOR,CHIP[CERAMIC M/L TC 18P 50V J COG 1.6X0.8 R/TP

C291 0CH4180K412 OOOOCAPACITOR,CHIP[CERAMIC M/L TC 18P 50V J COG 1.6X0.8 R/TP

C292 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C293 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C294 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C295 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C296 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2A0 0CE4764F638 OOOOCAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C2A3 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2A4 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C2A5 0CH1683F942 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 0.068UF 16V 80%,-20% Y5V(F) 16

C2A6 0CH1102K562 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 1000PF 50V 10% X7R(X) 1608 R/T

C2A7 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2A8 0CH1152K562 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 1500PF 50V 10% X7R(X) 1608 R/T

C2A9 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2B3 0CH1392K562 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 3900PF 50V K Z5U(E) 1608 R/TP

C2B4 0CH1683F942 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 0.068UF 16V 80%,-20% Y5V(F) 16

C2B5 0CH1333K562 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.033UF 50V K X7R(X) 1508 R/TP

C2B9 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2C1 0CH1103K562 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 0.01UF 50V 10% X7R(X) 1608 R/T

C2C2 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C2C4 0CH1102K562 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 1000PF 50V 10% X7R(X) 1608 R/T

C2C5 0CH1332K562 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 3300P 50V K X7R 1.6X0.8 R/TP

C2C6 0CH1102K562 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 1000PF 50V 10% X7R(X) 1608 R/T

C2C8 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2C9 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C2D0 0CE4764F638 OOOOCAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C2D1 0CE4764F638 OOOOCAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C2D2 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2D3 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2D4 0CE4764F638 OOOOCAPACITOR,ELECTROLYTIC 47M SRA/SS 16V M FM5 TP(5)

C2D5 0CE1064F638 OOOOCAPACITOR,ELECTROLYTIC 10M SRA 16V M FM5 TP(5)

C2D6 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2D7 0CH1152K562 OOOOCAPACITOR,FIXED CERAMIC(Temp.c 1500PF 50V 10% X7R(X) 1608 R/T

C2D9 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2M1 0CE1074F638 OOOOCAPACITOR,ELECTROLYTIC 100U SRA 16V M FM5 TP(5)

C2M2 0CH1682K562 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 6800P 50V K X7R 1.6X0.8 R/TP

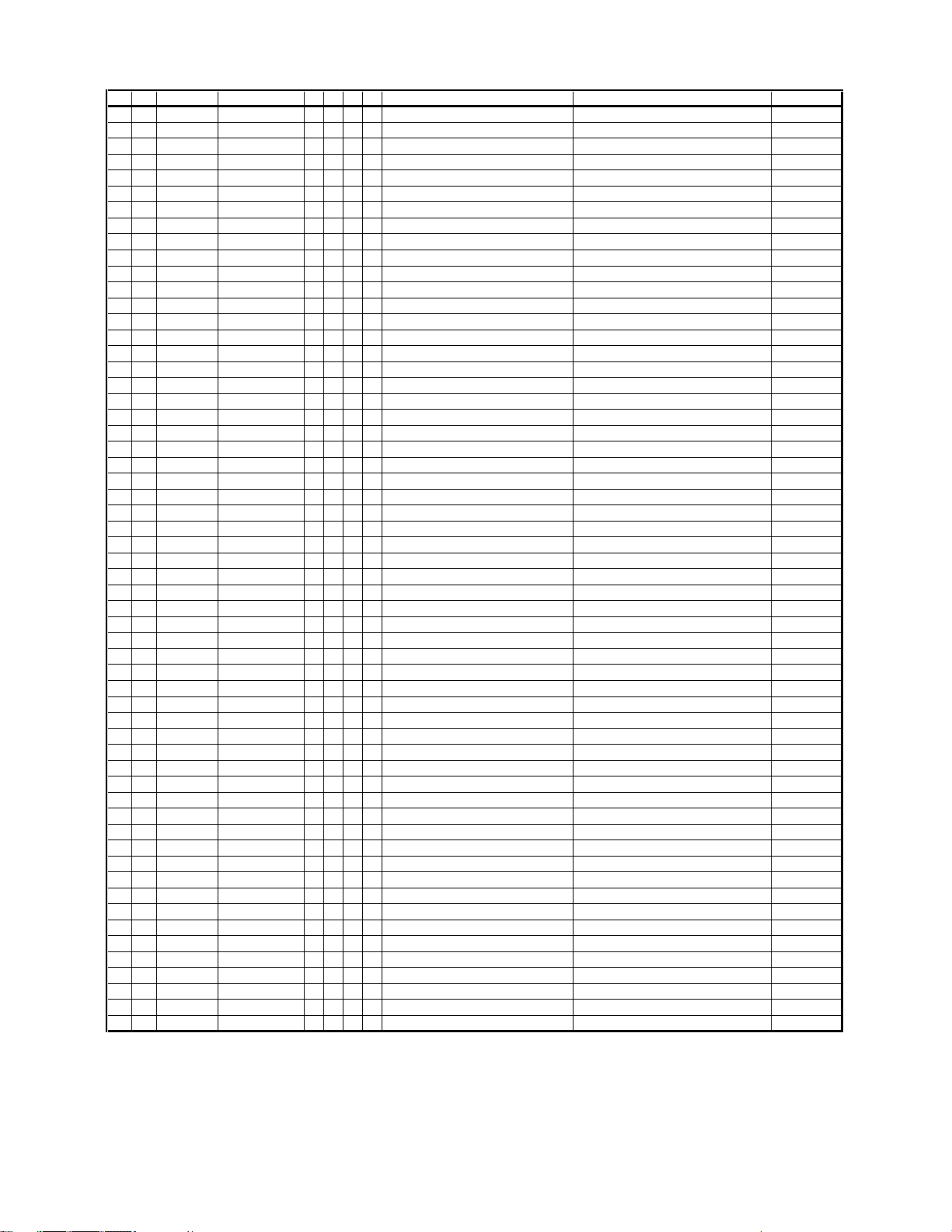

Page 53

5-5

S AL LOCA.NO PART NO(LG) ABCDDESCRIPTION SPECIFICATION REMARKS

C2M3 0CH1472K562 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 4700PF 50V K X7R(X) 1608 R/TP

C2M4 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2M5 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2M6 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2M7 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2M8 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2M9 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP

C2N1 0CH1104K942 OOOOCAPACITOR,CHIP[CERAMIC M/L HD 0.1UF 50V Z Y5V(F) 1508 R/TP