Page 1

SERVICE MANUAL

MODELS : T517C/T517CT SERVICE MANUAL

© NAD 2008

NAD ELECTRONICS INTERNATIONAL

TORONTO

SERVICE MANUAL

T517AH/T517AHT

T517C/T517CT/

DVD VIDEO PLAYER

T517C/T517CT/

T517C/T517CT

DVD VIDEO PLAYER

T517AH/T517AHT

DVD VIDEO PLAYER

Page 2

CONTENTS

SECTION 1.........SUMMARY

SECTION 2.........CABINET & MAIN CHASSIS

SECTION 3.........ELECTRICAL

SECTION 4.........MECHANISM (DP-12V)

SECTION 5.........REPLACEMENT PARTS LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD PRODUCTS..................................1-3

SERVICING PRECAUTIONS....................................................................................................................1-4

• GENERAL SERVICING PRECAUTIONS

• INSULATION CHECKING PRODEDURE

• ELECTROSTATICALLY SENSITIVE (ES) DEVICES

THE PROCESS OF DISC DOWNLOAD ...............................................................................................1-5

SPECIFICATIONS ........................................................................................................................................1-7

1-2

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original design be

modified or altered without permission from NAD. All components should be replaced

only with types identical to those in the original circuit and their physical location, wiring

and lead dress must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are allowed

without prior approval by NAD.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into the set

are not delayed until the new service literature is printed.

CAUTION

customized installations without manufacturer’s approval. Unauthorized modifications

will not only void the warranty, but may lead to property damage or user injury.

Service work should be performed only after you are thoroughly familiar with these

safety checks and servicing guidelines.

GRAPHIC SYMBOLS

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock. After the

original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

2. Verify that all protective devices such as insulators, barriers, covers, shields, strain

3. Soldering must be inspected to discover possible cold solder joints, solder splashes,

4. Check for physical evidence of damage or deterioration to parts and components,

5. No lead or component should touch a high current device or a resistor rated at 1 watt

6. After reassembly of the set, always perform an AC leakage test on all exposed

: Do not attempt to modify this product in any way. Never perform

The exclamation point within an equilateral triangle is intended to alert

the service personnel to important safety information in the service

literature.

The lightning flash with arrowhead symbol within an equilateral triangle

is intended to alert the service personnel to the presence of noninsulated

“dangerous voltage” that may be of sufficient magnitude to constitute a

risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral

triangle is intended to convey to the service personnel the following fuse

replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF

FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND RATING

AS MARKED NEAR EACH FUSE.

component shorts. This is especially important on items trans-ported to and from the

repair shop.

reliefs, power supply cords, and other hardware have been reinstalled per the

original design. Be sure that the safety purpose of the polarized line plug has not

been defeated.

or sharp solder points. Be certain to remove all loose foreign particles.

for frayed leads or damaged insulation (including the AC cord), and replace if

necessary.

or more. Lead tension around protruding metal surfaces must be avoided.

metallic parts of the cabinet (the channel selector knobs, antenna terminals, handle

and screws) to be sure that set is safe to operate without danger of electrical shock.

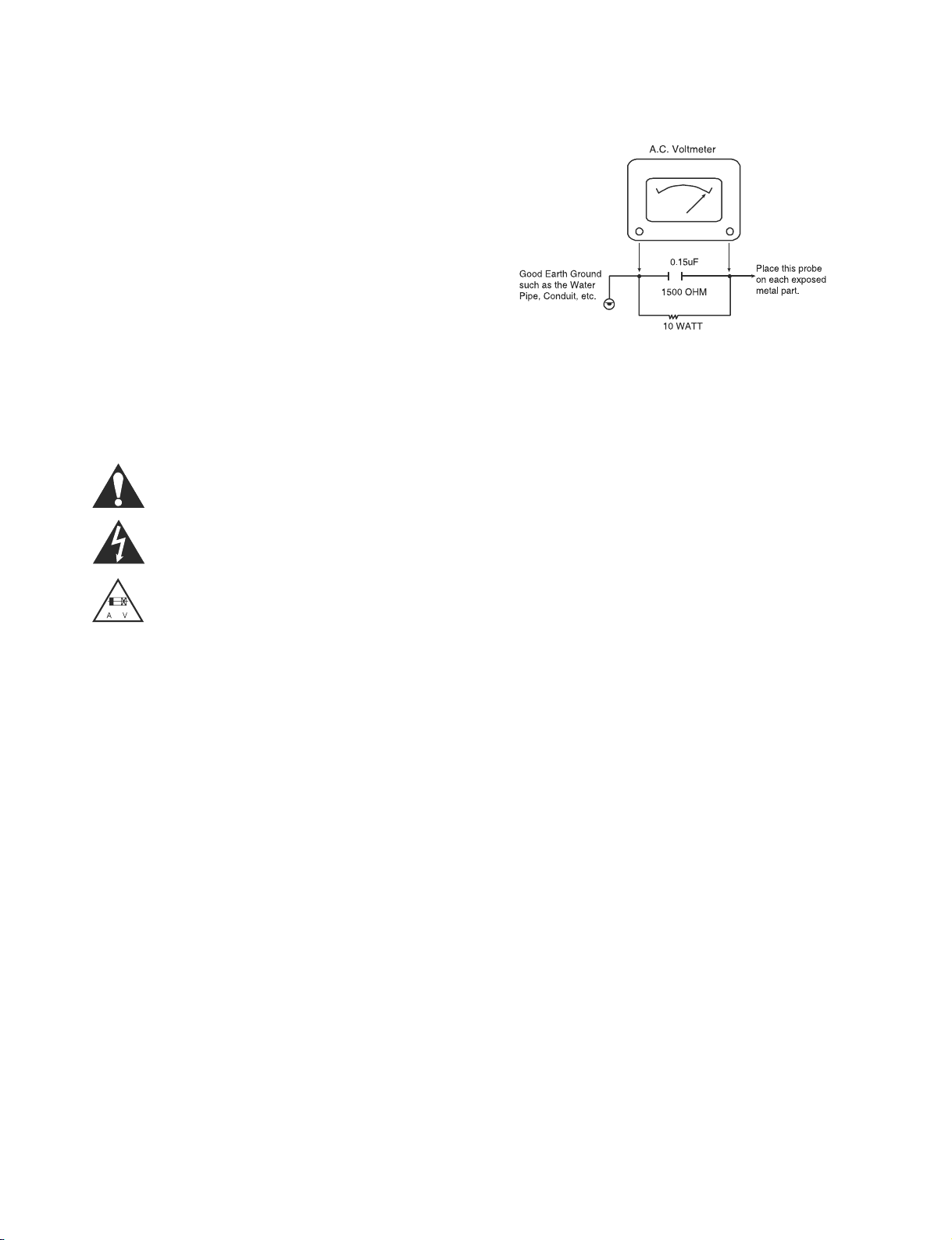

DO NOT USE ALINE ISOLATION TRANSFORMER DURING THIS TEST. Use an

AC voltmeter having 5000 ohms per volt or more sensitivity in the following manner:

Connect a 1500 ohm, 10 watt resistor, paralleled by a .15 mfd 150V AC type

capacitor between a known good earth ground water pipe, conduit, etc.) and the

exposed metallic parts, one at a time. Measure the AC voltage across the

combination of 1500 ohm resistor and .15 mfd capacitor. Reverse the AC plug by

using a non-polarized adaptor and repeat AC voltage measurements for each

exposed metallic part. Voltage measured must not exceed 0.75 volts RMS. This

corresponds to 0.5 milliamp AC. Any value exceeding this limit constitutes a potential

shock hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting shelf

space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where dew is a

factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer should also

avoid the use of decorative scarves or other coverings that might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must follow

the factory-approved mounting instructions. A product mounted to a shelf or platform

must retain its original feet (or the equivalent thickness in spacers) to provide

adequate air flow across the bottom. Bolts or screws used for fasteners must not

touch any parts or wiring. Perform leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters across

thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous consequences to

home and family.

1-3

Page 5

SERVICING PRECAUTIONS

CAUTION: Before servicing the DVD covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE: if unforeseen circumstances

create conflict between the following servicing precautions

and any of the safety precautions in this publication, always

follow the safety precautions.

Remember Safety First :

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC power

source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an

electrolytic capacitor.

Caution: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Do not spray chemicals on or near this DVD or any of its

assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner, cottontipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this DVD and / or any of its

electrical assemblies unless all solid state device heat sinks

are correctly installed.

6. Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1Mohm.

Note 1: Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power

to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

1-4

Page 6

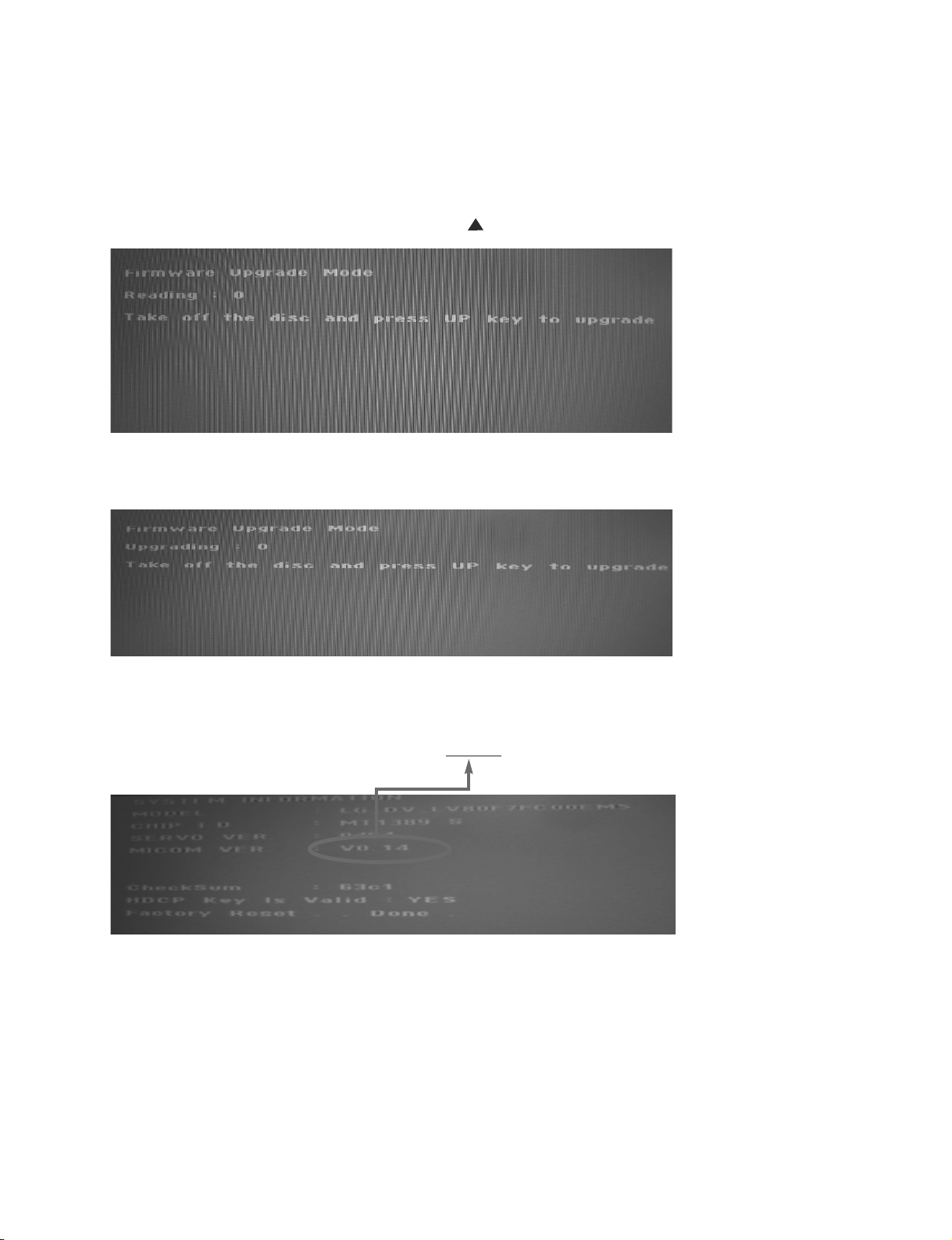

THE PROCESS OF DISC DOWNLOAD

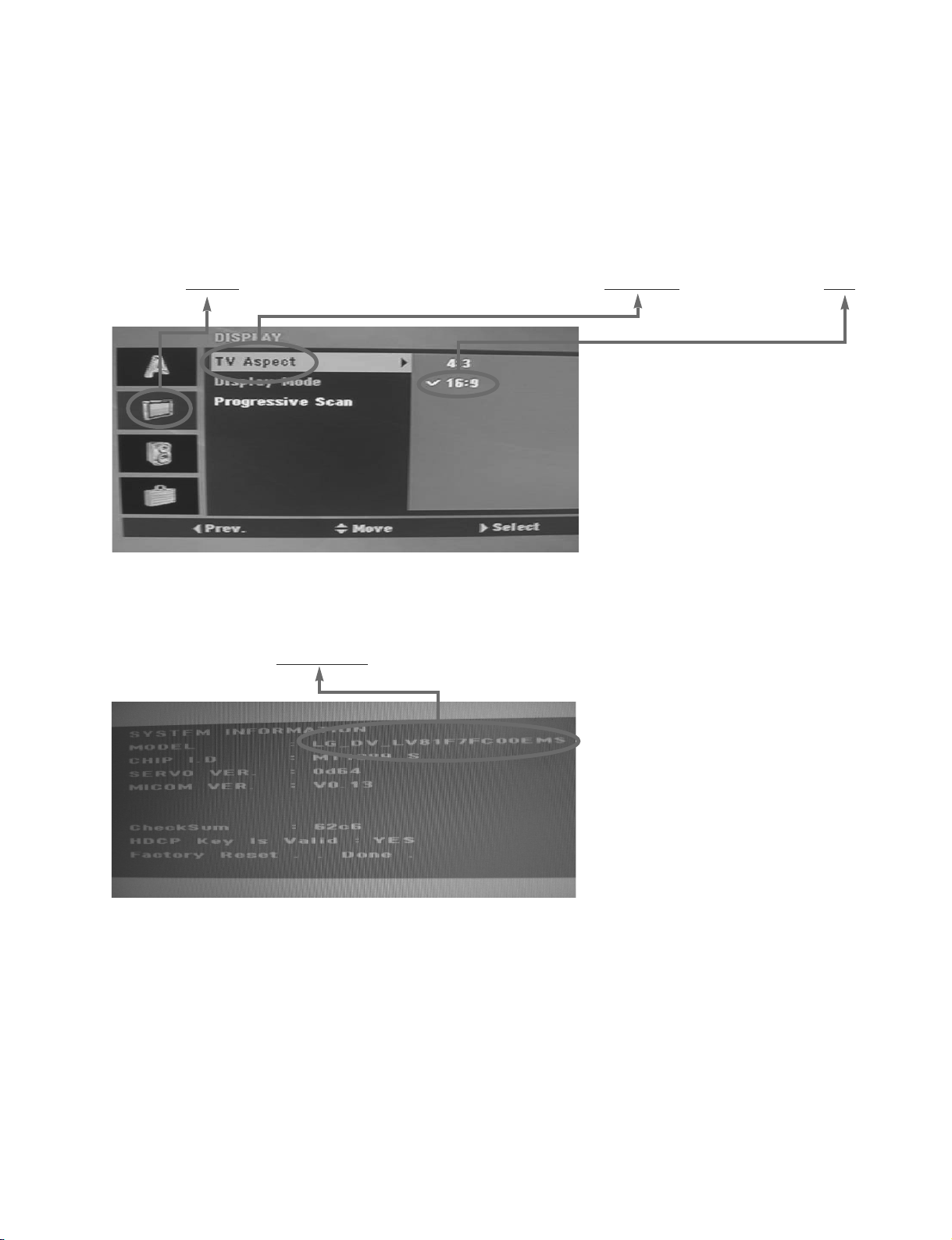

Please follow the below process to download a program with disc

1. Turn on the DVD-player.

(Note. Be sure that there is no disc in DVD-player)

2. Press “SETUP” button on Remote control.

3. Choose a “display” menu by using the cursor button and then choose a “TV Aspect” menu. And choose “16:9”

menu.

4. Press the 1 --> 3 --> 9 --> 7 --> 1 --> 3 --> 9(numerical button) --> Enter key on remote control to confirm the

system information.

5. Remember or write the model name.

6. Change the program file name of new version to the model name

Ex> New ver. program file->LG_DV_LV80F7FC10EMSMIS_V014.ROM

Model name -> LG_DV_LV81F7FC00EMS

Change New ver. program file like this --> LG_DV_LV81F7FC00EMSMIS.ROM

(NOTICE) You must add “MIS” at the end of model name

If you don”t change the file name like that, Disc download isn”t be worked.

1-5

Page 7

7. Copy the changed file to a disc.

8. Insert the copied disc to DVD-player.

9. If the below picture appears on the screen, Press “ ” key.

10.After the below picture appears on the screen, Disc will emerge from DVD-player automatically.

Take the disc out of the DVD-player.

11.After Disc download is completed, DVD-player turns off and then turns on automatically.

12.Do it again the process 1, 2, 3, 4 to confirm the version.

1-6

Page 8

SPECIFICATIONS

• GENERAL

Power requirements: AC 100 V ~ 240 V, 50 Hz / 60 Hz

Power consumption: 9 W

Dimensions (Approx.): 430 x 39 x 192 mm (17 x 1.5 x 7.6 inches) (W x H x D) without foot

Net weight (Approx.): 1.5 kg (3.3 lbs)

Operating temperature: 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity: 5 % to 90 %

• OUTPUTS

VIDEO OUTPUT: 1.0 V (p-p), 75 , sync negative, RCA jack x 1 / Scart (to TV)

S-VIDEO OUTPUT: (Y) 1.0 V (p-p), 75 , negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75

COMPONENT VIDEO OUTPUT: (Y) 1.0 V (p-p), 75 , negative sync, RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 , RCA jack x 2

HDMI OUTPUT (Video/Audio): 19 pin (HDMI standard, Type A)

AUDIO OUTPUT: 2.0 Vrms (1 kHz, 0 dB), 600 , RCA jack (L, R) x 1 / Scart (to TV)

DIGITAL AUDIO OUTPUT: COAXIAL: 0.5 V (p-p), 75 , RCA jack x 1

OPTICAL: 3 V (p-p), Optical jack x 1

• SYSTEM

Laser: Semiconductor laser, wavelength 650 nm

Signal system: PAL

Frequency response: DVD (PCM 96 kHz): 8 Hz to 44 kHz

DVD (PCM 48 kHz): 8 Hz to 22 kHz

CD: 8 Hz to 20 kHz

Signal-to-noise ratio: More than 90 dB (ANALOG OUT connectors only)

Harmonic distortion: Less than 0.02 %

Dynamic range: More than 95 dB (DVD/CD)

1-7

Page 9

MEMO

1-8

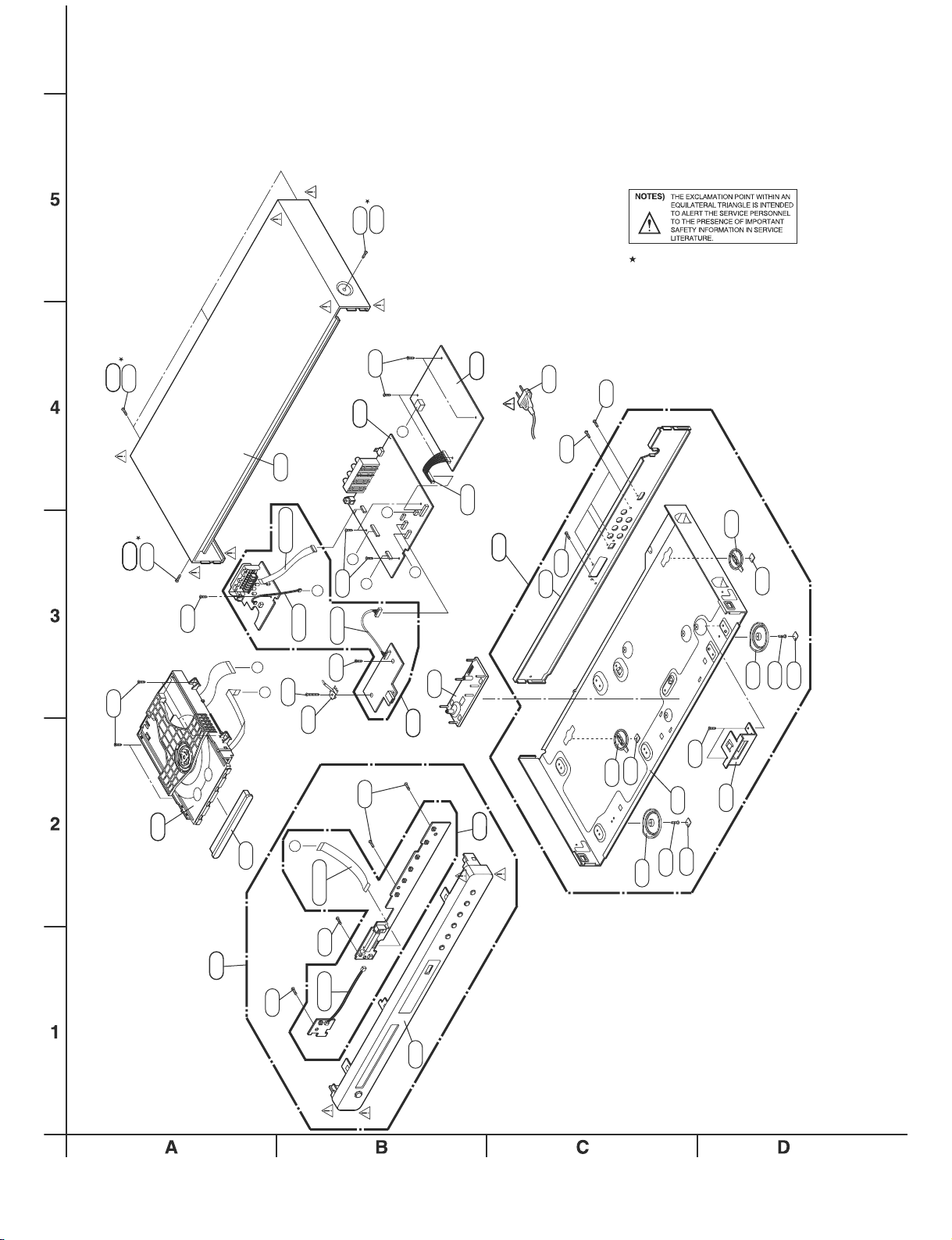

Page 10

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS .....................................................................................................................................2-2

1. CABINET AND MAIN FRAME SECTION ..................................................................................................2-2

2. DECK MECHANISM SECTION (DP-12V).................................................................................................2-3

3. PACKING ACCESSORY SECTION...........................................................................................................2-4

2-1

Page 11

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

60

463

4

OPTIONAL PART

3

46346346

462

460

3

3

46346346

46346

460

462

462

A46

A

250

MAIN

E

CABLE2

CART

P3702

S

B

C

461

B

62

C

4

E

N801

C

463

5

27

52

4

D

USB

A41

SMPS

276

A47

P101

100V~240V

POWER CORD

A44

20

3

300

467

465

470

261B

261

260

261B

261

62

4

261

261A

62

4

262

A26

A43

283

D

A50

62

261

4

261A

CABLE1

452

52

4

CN903

KEY

TIMER

80

2

2-2

Page 12

2. DECK MECHANISM SECTION (DP-12V)

A26

026

A02

017

013

015

435

439

015B

015A

001

A01

002

003

018

014

020

016

010

440

442

A03

012

442

012

442

037

012

019

2-3

Page 13

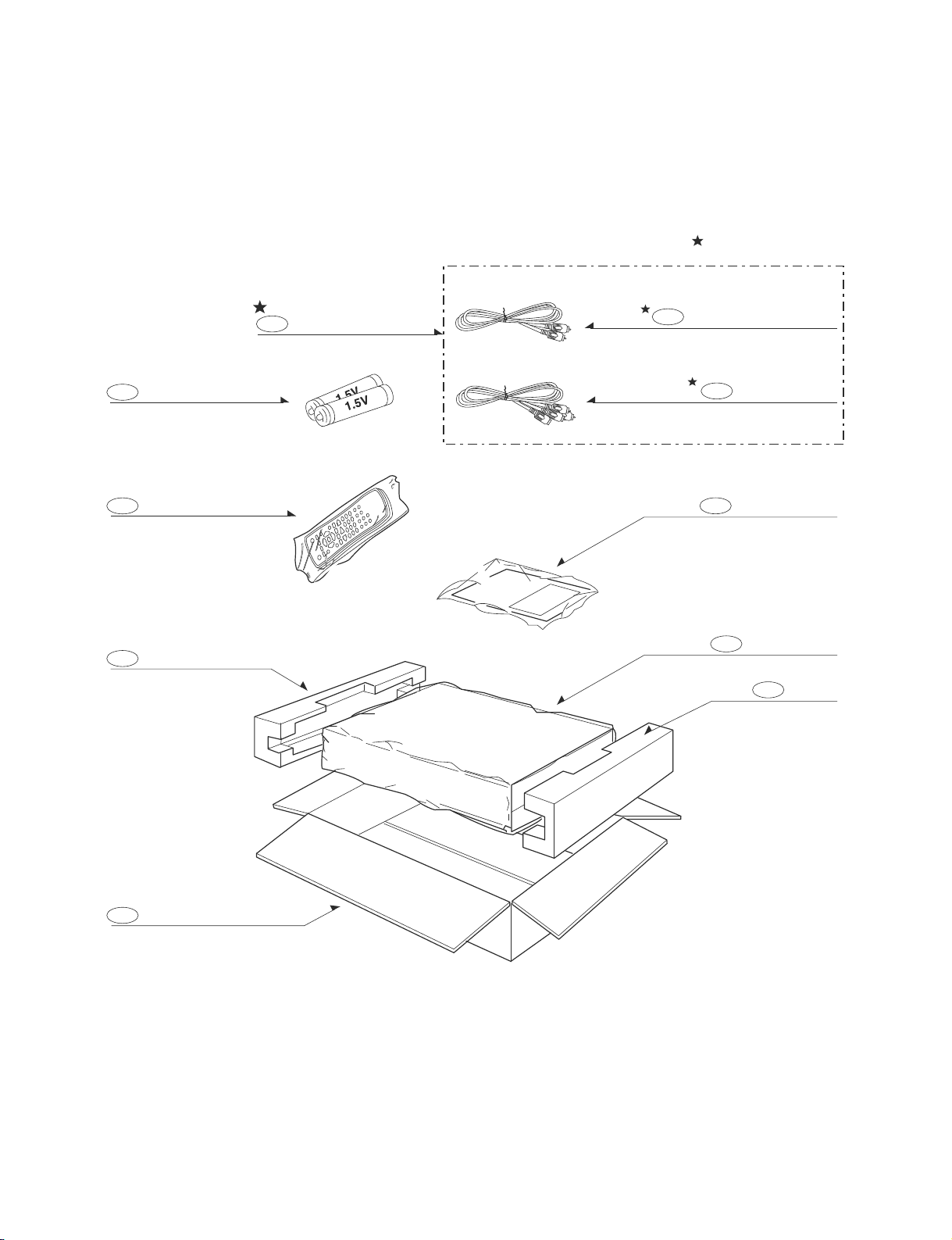

3. PACKING ACCESSORY SECTION

OPTIONAL PARTS

808 Battery

900 Remocon

803 Packing

810 Cable Set Ass'y

811 Plug Ass'y 1way(Yellow)

812 Plug Ass'y 2way

801 Owner's Manual

804

Packing Sheet

803 Packing

802

Box Carton

2-4

Page 14

SECTION 3

ELECTRICAL

CONTENTS

ELECTRICAL TROUBLESHOOTING GUIDE.....................................................................................3-2

1. SMPS TROUBLESHOOTING FLOW ......................................................................................................3-2

2. POWER CHECK FLOW ..........................................................................................................................3-4

3. SYSTEM OPERATION FLOW.................................................................................................................3-5

4. SYSTEM TEST FLOW ...........................................................................................................................3-6

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGIBG...................................3-12

1. SYSTEM 27MHZ CLOCK, RESET, FLASH R/W SIGNAL ....................................................................3-12

2. SDRAM CLOCK ...................................................................................................................................3-14

3. TRAY OPEN/CLOSE SIGNAL ...............................................................................................................3-14

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)............................................................3-15

5. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION) ..........................................................3-15

6. LASER POWER CONTROL RELATED SIGNAL (NO DISC CONDITION) ..........................................3-16

7. DISC TYPE JUDGEMENT WAVEFORM...............................................................................................3-16

8. FOCUS ON WAVEFORM ......................................................................................................................3-18

9. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION) ...............................................................3-19

10. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING) ....................................................3-20

11. MT1389S AUDIO OPTICAL AND COAXIAL OUTPUT (SPDIF) ............................................................3-21

12. MT1389S VIDEO OUTPUT WAVEFORM .............................................................................................3-21

13. AUDIO OUTPUT FROM MT1389S........................................................................................................3-22

CONNECTOR PICTURE ..........................................................................................................................3-23

1. ALL CONNECTOR PICTURE ................................................................................................................3-23

2. MAIN BOARD CONNECTOR PICTURE ...............................................................................................3-24

3. CN201 CONNECTOR PICTURE...........................................................................................................3-25

4. CN202 CONNECTOR PICTURE...........................................................................................................3-25

5. CN601 CONNECTOR PICTURE...........................................................................................................3-26

6. CN602 CONNECTOR PICTURE...........................................................................................................3-26

7. CN604 CONNECTOR PICTURE...........................................................................................................3-27

8. CN605 CONNECTOR PICTURE...........................................................................................................3-27

9. CN705 CONNECTOR PICTURE...........................................................................................................3-28

BLOCK DIAGRAMS ..................................................................................................................................3-29

1. OVERALL BLOCK DIAGRAM ...............................................................................................................3-29

2. POWER (SMPS) BLOCK DIAGRAM.....................................................................................................3-30

3. MPEG & MEMORY BLOCK DIAGRAM.................................................................................................3-31

4. SERVO BLOCK DIAGRAM ...................................................................................................................3-32

5. VIDEO & HDMI BLOCK DIAGRAM.......................................................................................................3-33

6. AUDIO BLOCK DIAGRAM.....................................................................................................................3-34

CIRCUIT DIAGRAMS................................................................................................................................3-35

1. POWER (SMPS) CIRCUIT DIAGRAM ..................................................................................................3-35

2. MPEG CIRCUIT DIAGRAM...................................................................................................................3-37

3. SERVO CIRCUIT DIAGRAM.................................................................................................................3-39

4. JACK CIRCUIT DIAGRAM ....................................................................................................................3-41

5. SCART CIRCUIT DIAGRAM (OPTION) ................................................................................................3-43

6. USB CIRCUIT DIAGRAM ......................................................................................................................3-45

7. KEY CIRCUIT DIAGRAM ......................................................................................................................3-46

8. TIMER CIRCUIT DIAGRAM ..................................................................................................................3-47

• CIRCUIT VOLTAGE CHART.........................................................................................................3-49

PRINTED CIRCUIT BOARD DIAGRAMS...........................................................................................3-53

1. MAIN P.C.BOARD..................................................................................................................................3-53

2. POWER (SMPS) P.C.BOARD ...............................................................................................................3-55

3. KEY P.C.BOARD ...................................................................................................................................3-55

4. TIMER P.C.BOARD ...............................................................................................................................3-55

5. SCART P.C.BOARD (OPTION) .............................................................................................................3-57

6. USB P.C.BOARD ...................................................................................................................................3-57

3-1

Page 15

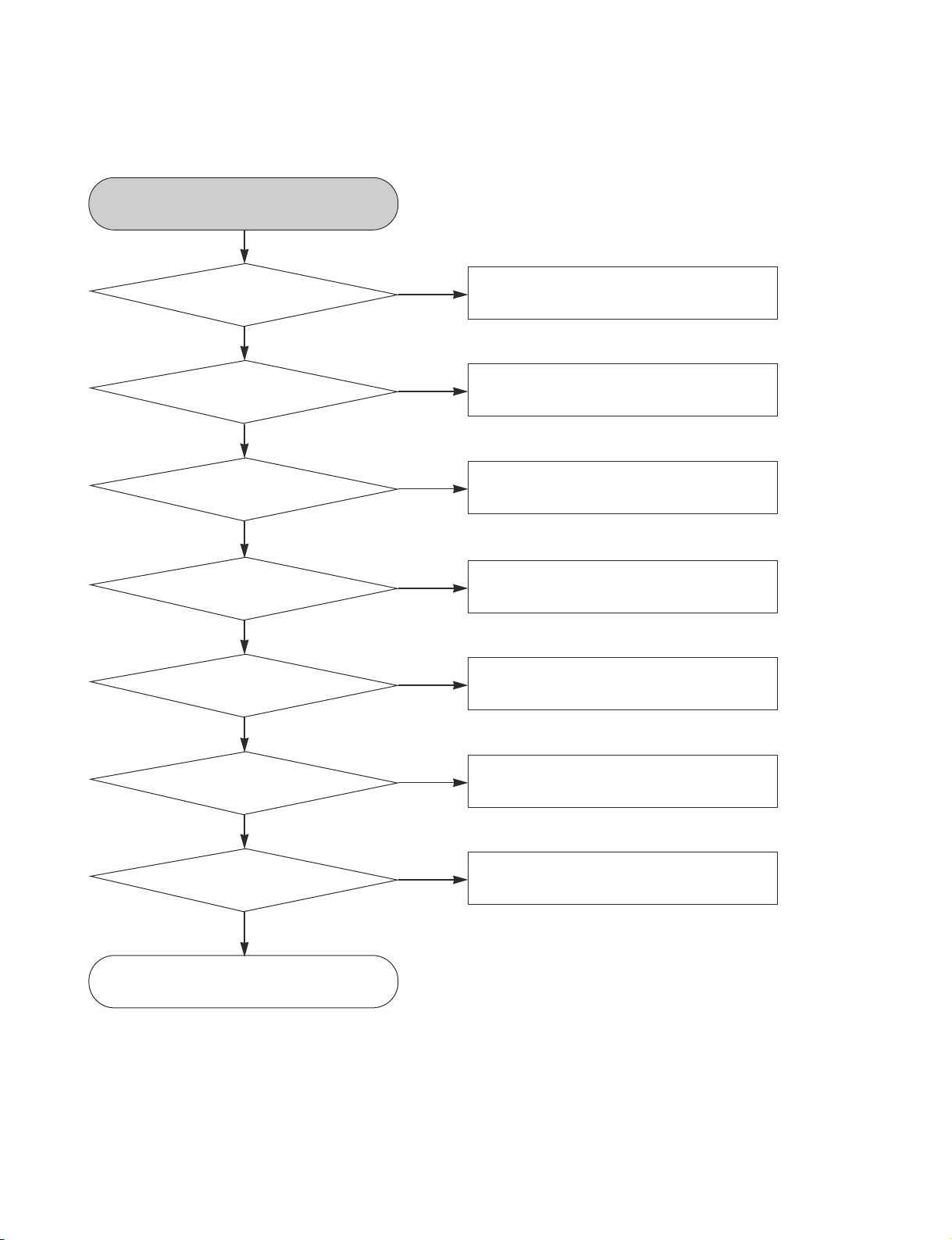

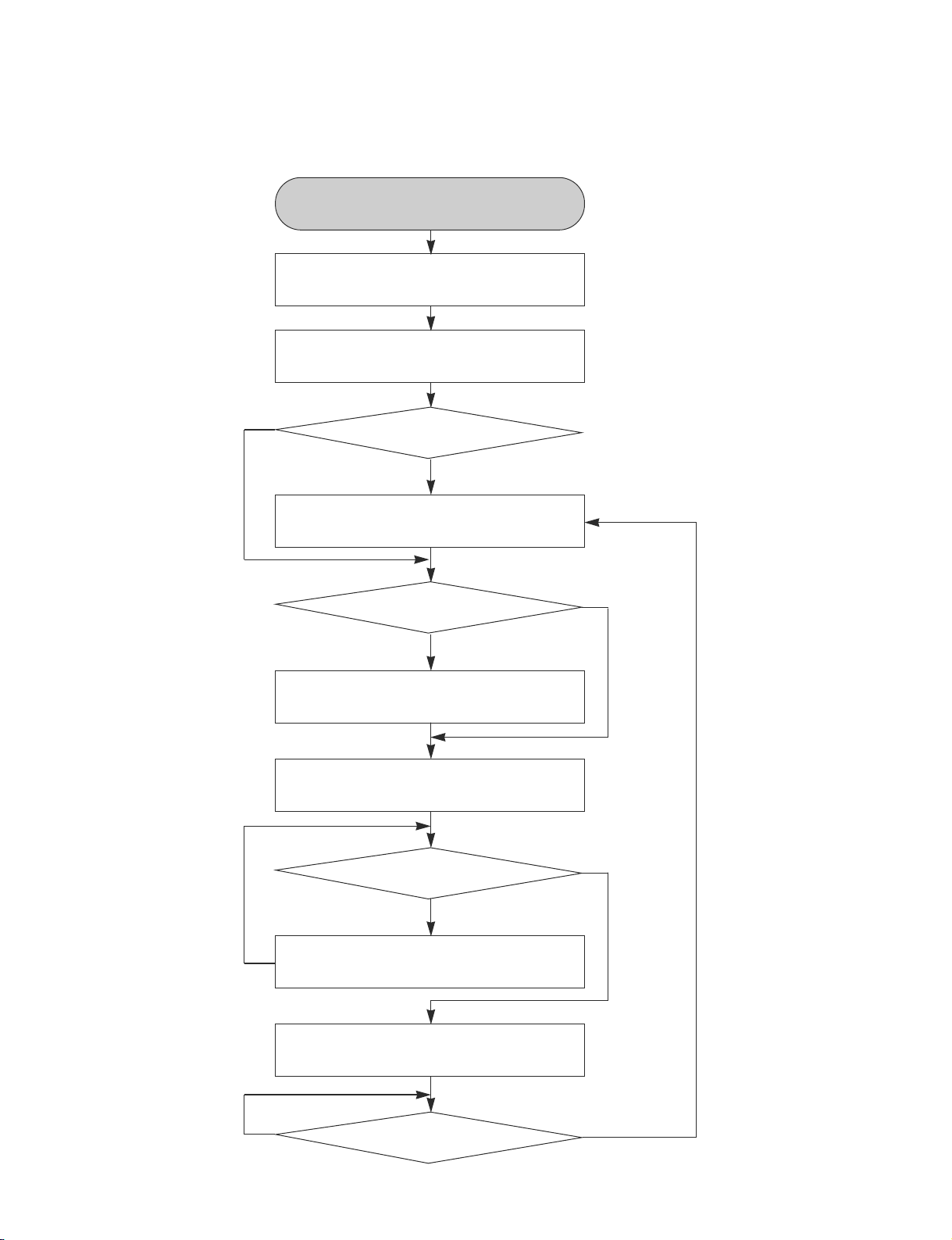

ELECTRICAL TROUBLESHOOTING GUIDE

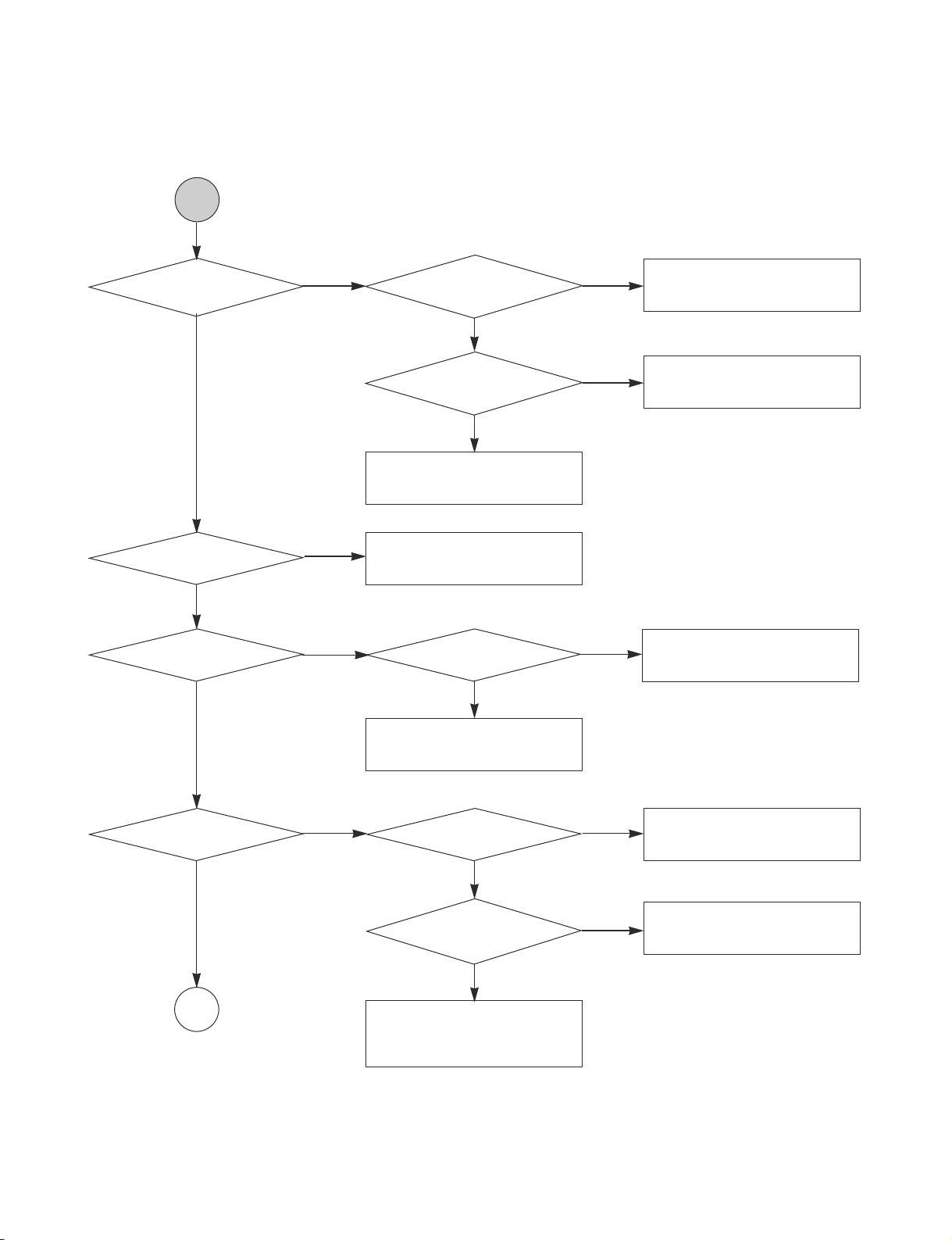

1. SMPS TROUBLESHOOTING FLOW

No 3.3VA

YES

Is the FR101 normal?

YES

Is the D105/D106/D107/

D108 normal?

YES

Is the Vcc (about 17V)

supplied to IC101 Pin2?

YES

Is the D121 normal?

YES

Is there about 2.5V at the

IC103 Pin1?

YES

NO

NO

NO

NO

NO

Replace the FR101

(Use the same ICW)

Replace the

D105/D106/D107/D108

Check or Replace the IC101

Replace the D121

Replace the IC103

Is the D123 normal?

YES

Is the D125 normal?

YES

Power Line of Main

PCB(DVD) is short

NO

NO

Replace the D123

Replace the D125

3-2

Page 16

ELECTRICAL TROUBLESHOOTING GUIDE

No REG 5.0V

YES

Is the Vcc(=5.6V)

•

•

supplied to Q126

Collector?

YES

Is the Vcc(=12V)

•

•

supplied to Q126

Base?

YES

Check or Replace the Q126

No 12V

YES

Is the Vcc(=14V)

•

•

supplied to Q123

Collector?

NO

NO

NO

Check or Replace the D123

Check the ‘PWR CTL “H”’

signal from μ-com

Check or Replace the D125

YES

Is the Vcc(=12V)

•

•

supplied to Q126

Base?

YES

Check or Replace the Q123

NO

Check the ‘PWR CTL “H”’

signal from μ-com

3-3

Page 17

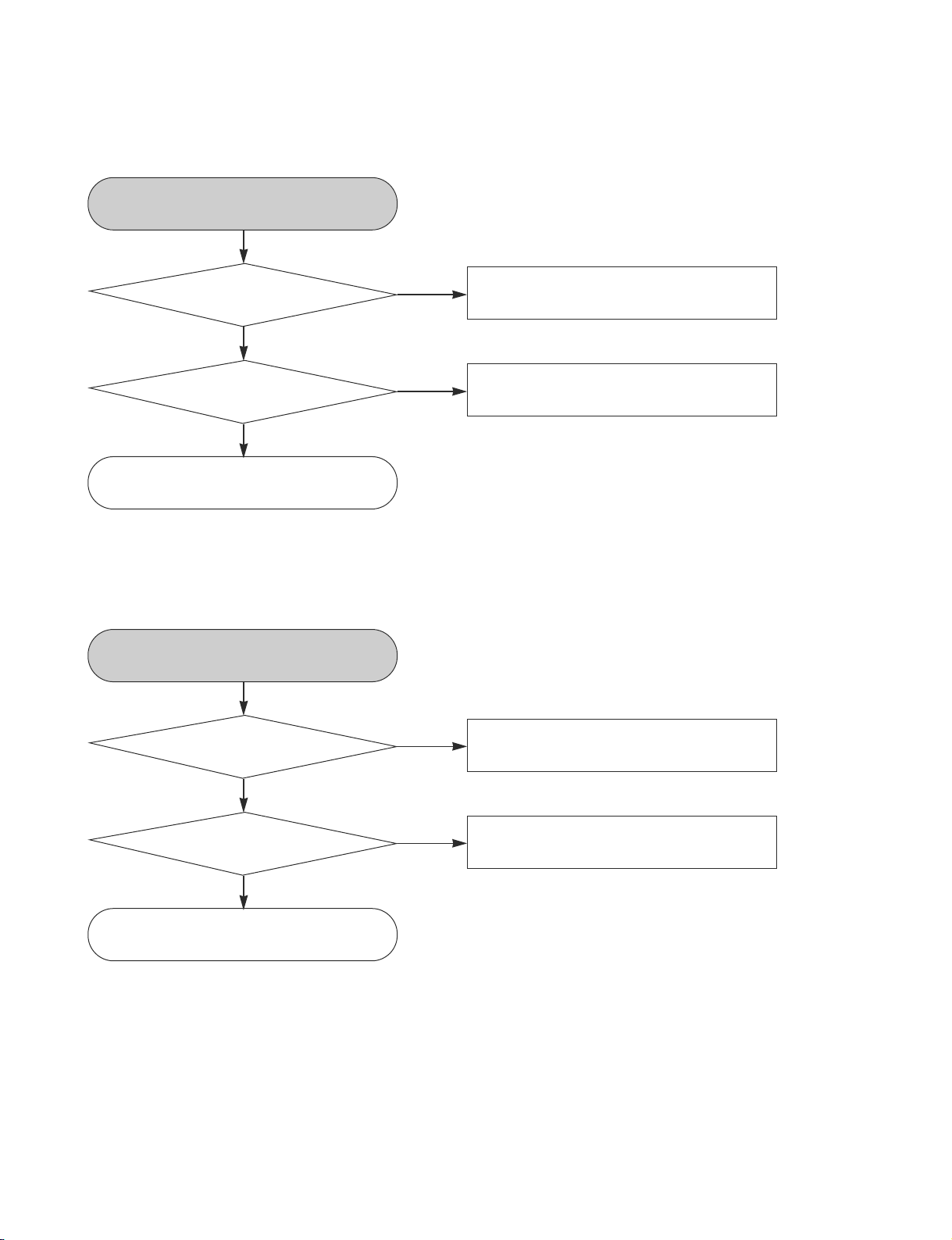

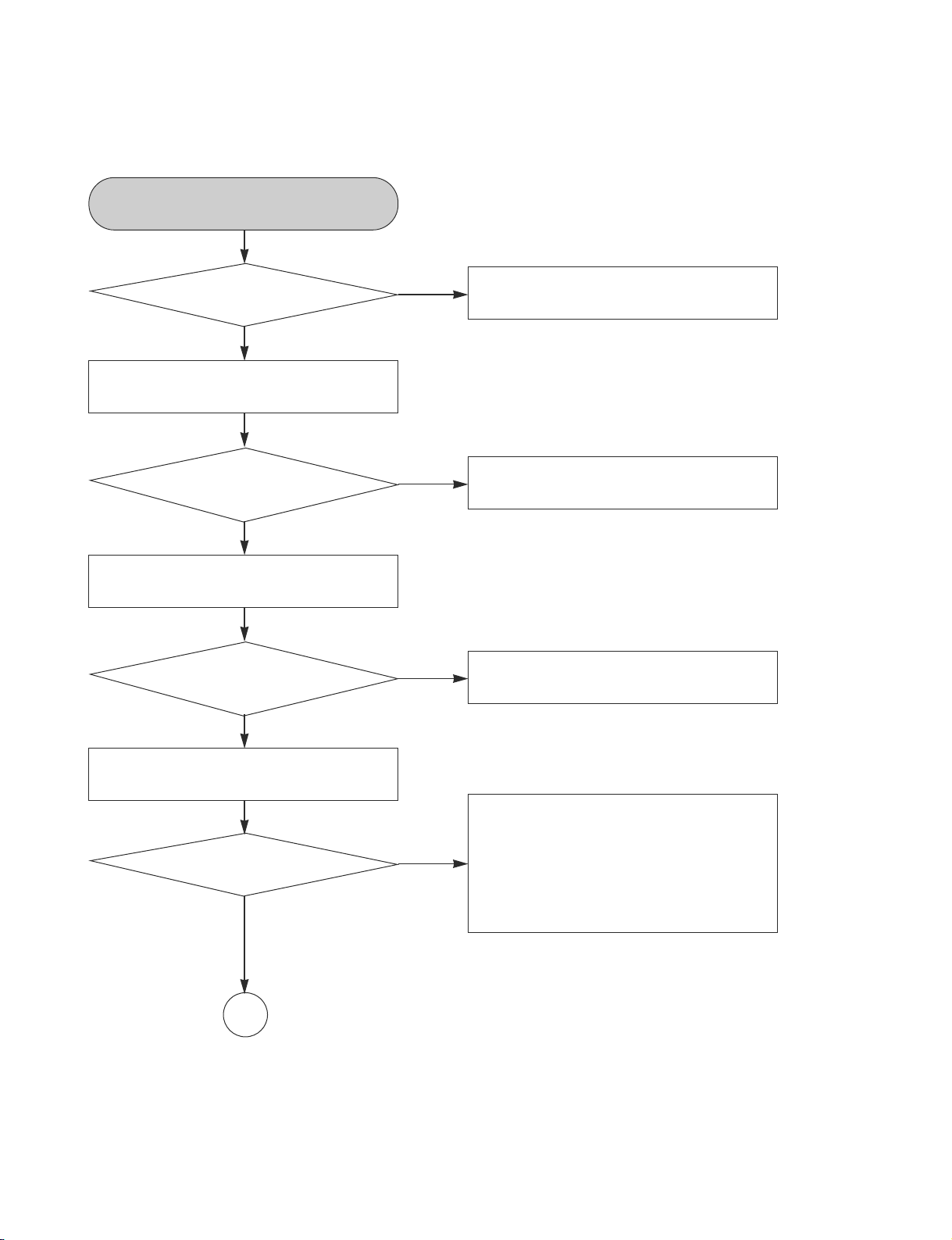

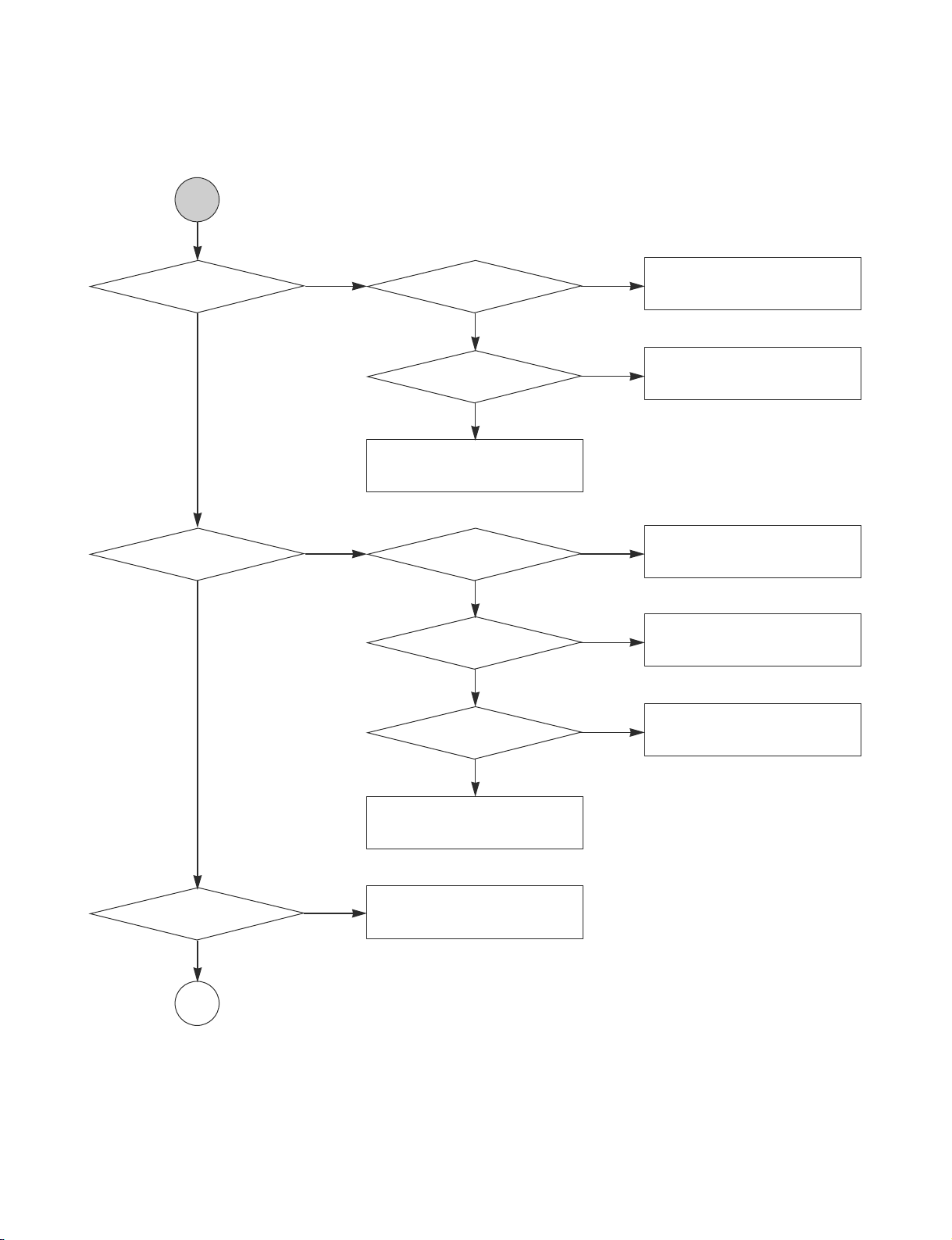

ELECTRICAL TROUBLESHOOTING GUIDE

2. POWER CHECK FLOW

A. B.

No 5V No 3.3VA.

Is 3.3VA

section working?

YES

Is 5.6V present at

collector of Q126?

YES

Replace Q126. Check FR101 Replace Q121.

NO

No 3.3VA

Is there a DC voltage at

cathode of D105 or D107?

NO

NO

NO

Is 3.3VA

section working?

YES

Is 3.3V

present at emitter

of Q121?

YES

YES

Check D105/D106/D107/

D108 and replace.

YES

Replace IC101.

3-4

Page 18

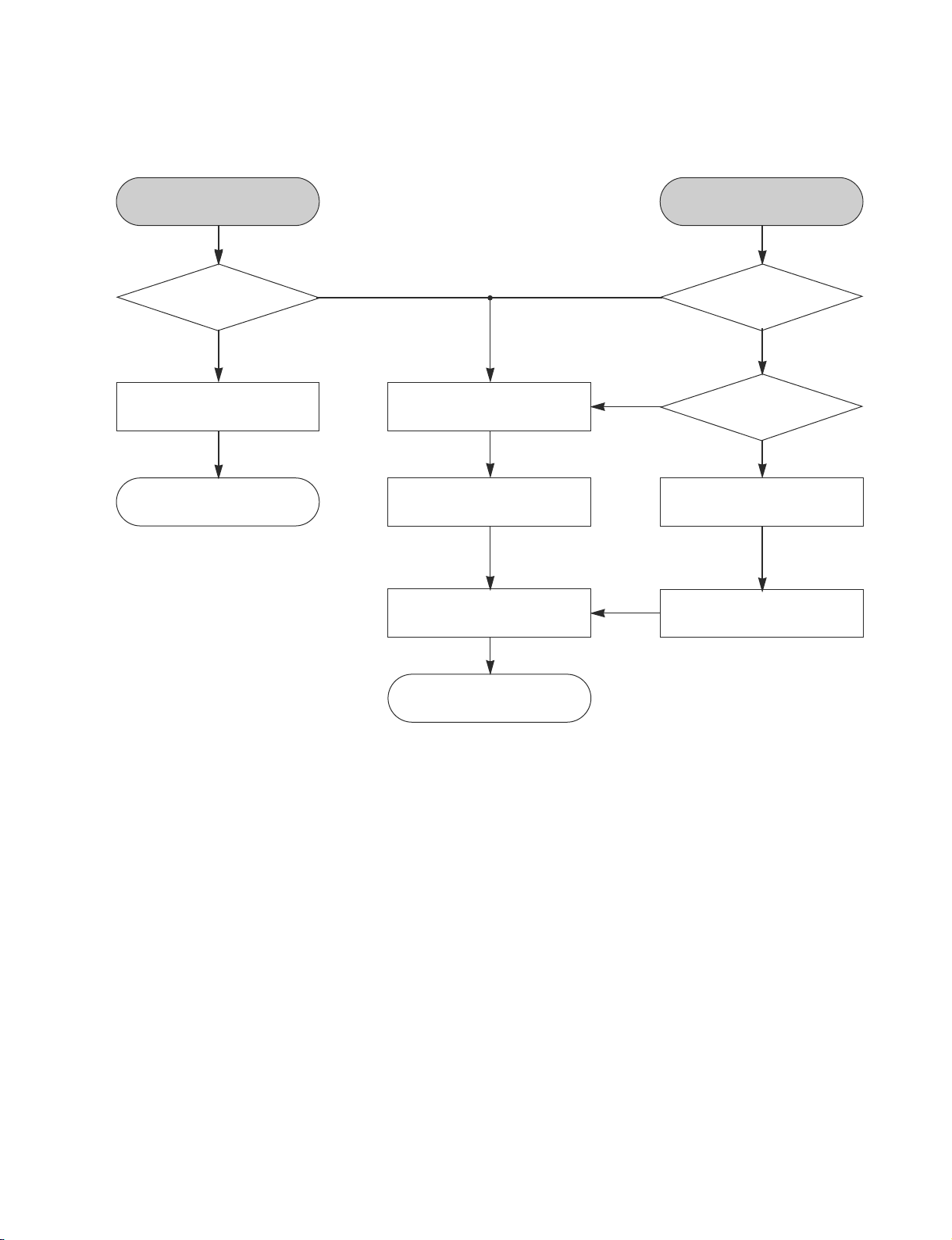

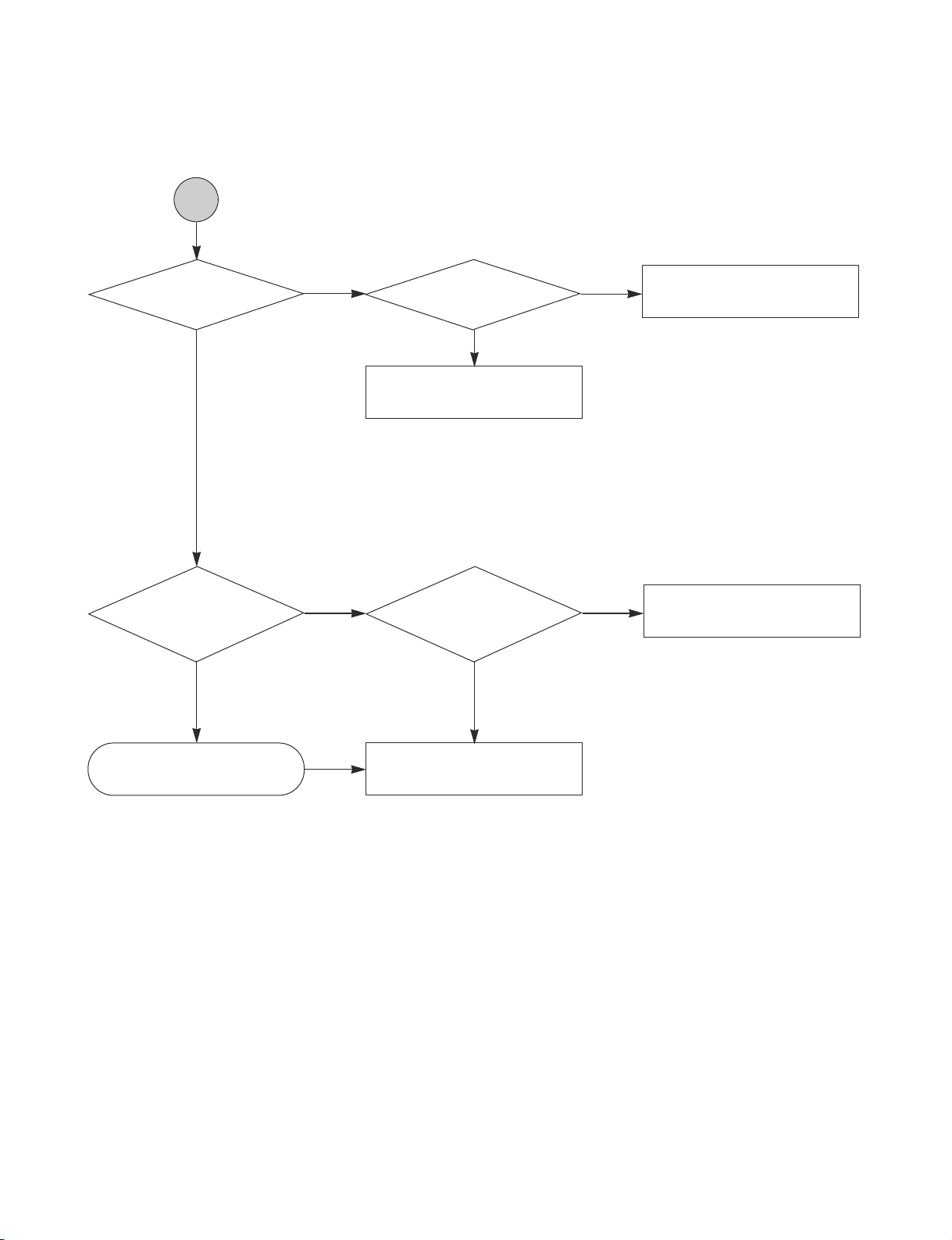

ELECTRICAL TROUBLESHOOTING GUIDE

3. SYSTEM OPERATION FLOW

Power on

1. 8032 initializes SERVO,DSP & RISC registers

2. Write RISC code to SDRAM

3. Reset RISC

Show LOGO

YES

Tray close to closed position

SLED moves to inner position

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

Recieve OPEN/CLOSE Key?

Tray closed?

NO

SLED at inner side?

NO

YES

YES

NO

1. Execute pressed Key & IR key

2. System operation routine loop

1. Stop playback & open Tray

2. Display tray open message & LOGO

NO

Receive CLOSE Key?

YES

3-5

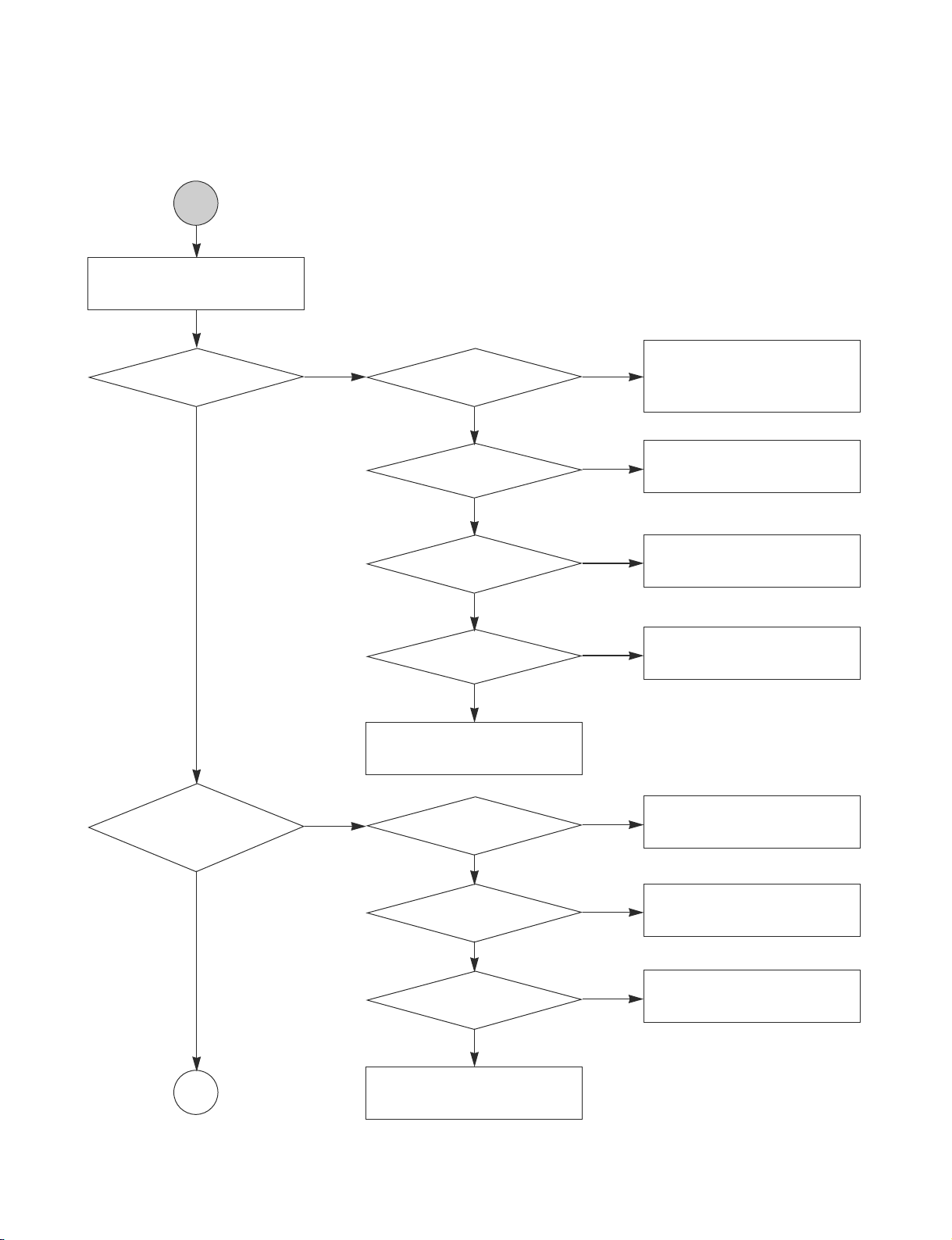

Page 19

ELECTRICAL TROUBLESHOOTING GUIDE

4. SYSTEM TEST FLOW

TEST

Check the AC

Voltage Power PCBA (110V

or 220V)

YES

Switch on the power PCBA

Is the DC

voltage outputs OK?

(5V, 3.3V, 12V, 5.6V

MOTOR)

YES

Make sure the main PCBA don't

short on VCCs and switch it on.

YES

Is 3.3V

and 1.8V DC outputs normal

on main PCBA?

YES

NO

NO

NO

Replace power PCBA or AC transformer.

Repair or Replace power PCBA

Check the regulators or related diodes.

Connect to PC RS232 cable and

update the FLASH memory code.

Update FLASH

successfully?

YES

A

NO

1. Check 27MHz system clock.

2. Check system reset circuit.

3. Check FLASH R/W enable signal PRD,

RWR.

4. Check RS232 SIGNALS.

5. Check FLASH Memory related circuit.

3-6

Page 20

ELECTRICAL TROUBLESHOOTING GUIDE

A

RESET or power on.

Show LOGO?

YES

Does

tray move inside

when it is not at closed

position?

NO NO

Flash

memory operates

properly?

YES

SDRAM

NO

works properly?

YES

MT1389S

VIDEO outputs

NO

properly?

YES

Have TV

NO

signal output?

YES

Check AV cable

connection to TV set.

NO

Normal

TROUT & TRIN

NO

signals?

YES

Check connection lines

between FLASH & MT1389S

and the FLASH access time

whether is suitable or not.

Check connection lines

between SDRAM & MT1389S

and the SDRAM is damaged.

Check the related

circuit of MT1389S.

Check the filtering and amp

circuit of TV signal.

Check the load

OPEN & CLOSE switch

B

YES

TRCLOSE & TROPEN

Normal

signal?

YES

Normal

LOAD+ & LOAD-

signal?

YES

Check the cable connection

between main PCBA and loader.

3-7

NO

NO

Check the tray control I/O

pins on MT1389S & AM5890.

Check the tray control

amplifying circuit on Motor driver.

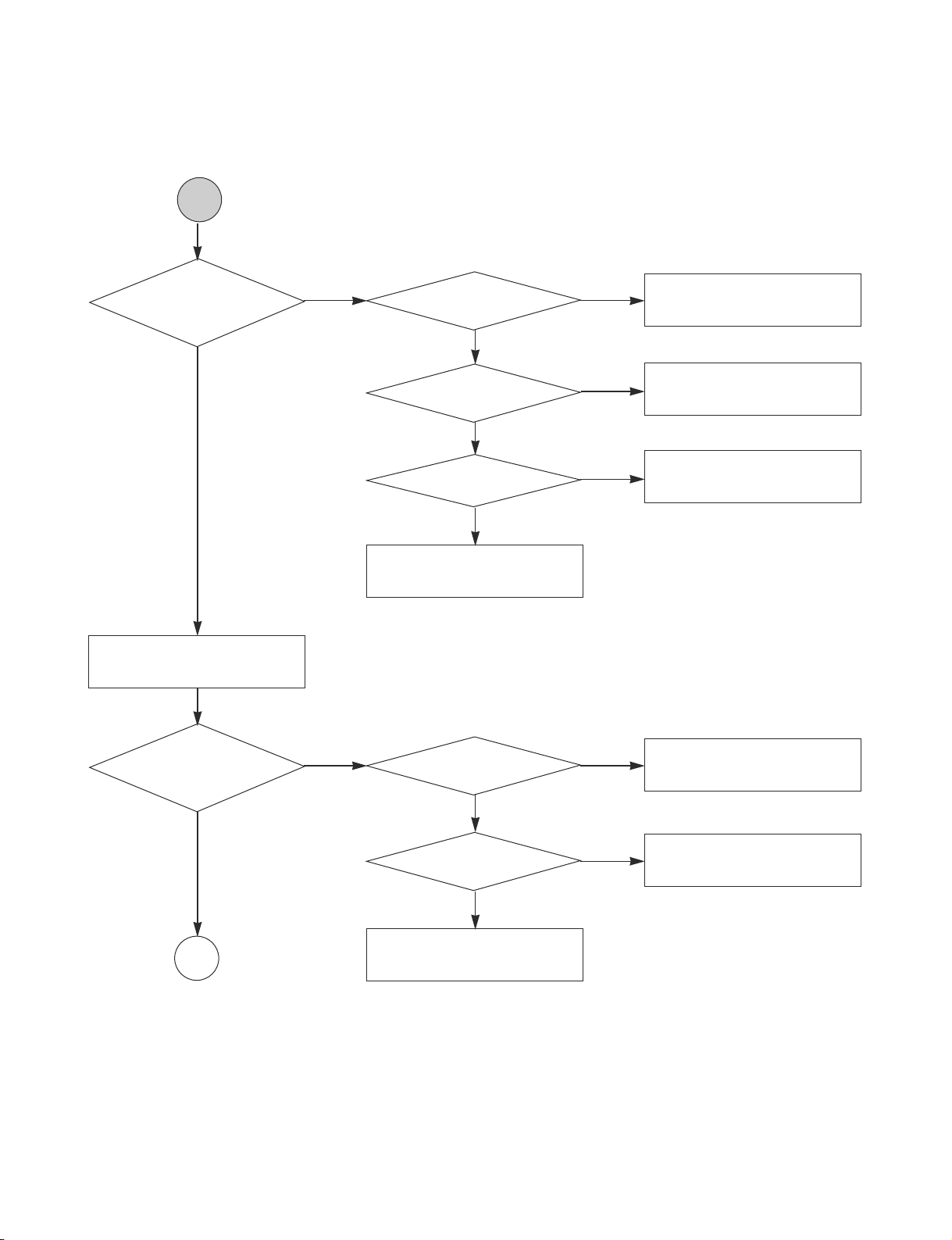

Page 21

ELECTRICAL TROUBLESHOOTING GUIDE

B

Does

the SLED move

to inner side when it is

at outter position?

YES

Do not put in

disc and tray close.

Motor

driver STBY pin

is high?

YES

Is FMSO

DC level higher

than 1.4V?

YES

SL+

and SL- output

properly?

YES

Check the cable

connection with MECHA.

NONO

NO

NO

Check the connection

line of STBY signal.

Check the related

circuit of FMSO.

Check the amp circuit

on motor driver.

Optical Lens

has movements for

searching

focus?

YES

C

Proper

FOSO outputs to

motor driver?

YES

Proper

F+ & F-

outputs?

YES

Check cable connect on

with pick-up head.

3-8

NONO

NO

Check FOSO connection on

MT1389S and motor dirver.

Check the amp circuit

on motor dirver.

Page 22

ELECTRICAL TROUBLESHOOTING GUIDE

C

Laser turns

on when reading

disc?

YES

Put disc in?

YES

Disc ID is

correct?

NO NO

LD01 or LD02

output properly?

YES

Collector

NO

voltage of power transistor

is OK?

YES

Check cable connection

between transistor ouput

and pick-up head.

NO

Laser off

NO

Proper

RFL signal on

NO

MT1389S?

YES

Check the laser power circuit

on MT1389S and connecting

to power transistor.

Check the related circuit on

laser power transistor.

Check the related circuit

on MT1389S RFL signal.

YES

Does

spindle rotate?

YES

D

Check LDO1 & LDO2 signal

NO NO

Proper

DMSO signal on

MT1389S.

YES

SP+ & SP-

NO

output properly?

YES

Check the cable

connection between spindle

and main PCBA.

3-9

Check DMSO related

circuit on MT1389S.

Check the spindle control

amp circuit of motor driver.

Page 23

ELECTRICAL TROUBLESHOOTING GUIDE

D

Focus on OK?

YES

Track on OK?

YES

NO NO

signals on A, B, C, D of

Proper

MT1389S

YES

Check FEO signal

NO

on MT1389S

YES

Check FOSO

signal on MT1389S

NO NO

Normal

TEO Signal on

MT1389S?

YES

Properly

TRSO signal on

NO

MT1389S?

YES

T+ & T- output

NO

properly?

YES

Check connections between

MT1389S and pick-up head.

Check the FOSO connection

on MT1389S and motor driver.

Check the related

circuit on MT1389S

Check the TRSO

connection on MT1389S

and motor dirver.

Check the tracking control

amp circuit on motor driver.

Disc is play?

YES

E

NO

Check cable connection

on pick-up head.

Check RFO & RFLVL

signal waveform.

3-10

Page 24

ELECTRICAL TROUBLESHOOTING GUIDE

E

Normal

Audio output when

disc playback?

YES

Normal

IR.VFD & Front pannel

key functions?

YES

NO

NO

Normal

audio DAC

out?

YES

Check audio filter,

amplify, mute circuit.

Commu-

nications between

IR.VFD Front pannel

key & MT1389S is

normally?

YES

NO

NO

Check the related

circuit of audio DAC.

Check communication

lines on MT1389S.

TEST END

NO

Check the cable

connection on Front pannel.

3-11

Page 25

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGIBG

1. SYSTEM 27MHz CLOCK, RESET, FLASH R/W SIGNAL

1) MT1389S main clock is at 27MHz (X601)

1

1

2) MT1389S reset is low active

2

3

4

RESET TIME

FIG 1-1

3.3V

PWR_CTL

2

3

4

IC601

FIG 1-2

3-12

Page 26

3) RS232 waveforn during procedure (Downloading)

5

TXD

6

RXC

FIG 1-3

4) Flash R/W enable signal during download (Downloading)

7

PRD

7

5

6

IC602

8

PWR

8

FIG 1-4

3-13

Page 27

2. SDRAM CLOCK

DCLK = 128MHz, Vp-p=2.2

IC603

9

9

FIG 2-1

3. TRAY OPEN/CLOSE SIGNAL

10

11

12

13

TRIN

TROUT

TRCLOSE

TROPEN

FIG 3-1

IC601

11

10

12

13

3-14

Page 28

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

15

14

15

16

17

FMSO(1.9V/1.4V/1.1V)

14

STBY(3.3V)

SL+(4.2V/2.8V/1.2V)

SL-(4.2V/2.8V/1.5V)

16

17

FIG 4-1

5. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION)

18

19

20

18

FOSO(1.5V/1.4V/1.3V)

F+(3.2V/2.7V/2.2V)

F-(3.2V/2.7V/2.2V)

20

19

FIG 5-1

3-15

Page 29

6. LASER POWER CONTROL RELATED SIGNAL (NO DISC CONDITION)

IC601

21

22

23

MDI1

(0V/180mV)

LD02

(3.3V/2.3V)

LD01

(3.3V/2.3V)

FIG 6-1

7. DISC TYPE JUDGEMENT WAVEFORM

21

22

23

CN201

24

24

25

26

F+

FE

RFL

FIG 7-1 (DVD)

3-16

IC601

25

26

Page 30

FIG 7-2 (DVD)

F+

FE

RFL

FIG 7-3 (CD)

3-17

F+

FE

RFL

Page 31

8. FOCUS ON WAVEFORM

F+

FE

RFL

FIG 7-4 (CD)

27

28

29

30

IC601

27

FE

28

FOSO

F+

F-

29

30

FIG 8-1 (DVD)

3-18

Page 32

FE

FOSO

F+

F-

FIG 8-2 (CD)

9. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

31

32

33

DMSO

(1.4V/1.8V)

SP(3.6V/2.4V)

31

32

SP+

(3.6V/4.8V)

33

FIG 9-1

3-19

Page 33

10. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING)

IC601

34

35

36

37

TE

TRSO

34

T+

T-

FIG 10-1 (DVD)

35

CN201

TE

TRSO

T+

T-

FIG 10-2 (CD)

3-20

36

37

Page 34

11. MT1389S AUDIO OPTICAL AND COAXIAL OUTPUT (SPDIF)

IC601

38

FIG 11-1

38

12. MT1389S VIDEO OUTPUT WAVEFORM

1) Full colorbar signal (CVBS)

FIG 12-1

JK701 2PIN

3-21

Page 35

13. AUDIO OUTPUT FROM MT1389S

FIG 13-1

3-22

Page 36

CONNECTOR PICTURE

1. ALL CONNECTOR PICTURE

3-23

Page 37

2. MAIN BOARD CONNECTOR PICTURE

3-24

Page 38

3. CN201 CONNECTOR PICTURE

CN201 (MD 23PIN)

4. CN202 CONNECTOR PICTURE

CN202 (MD 9PIN)

3-25

Page 39

5. CN601 CONNECTOR PICTURE

CN601 (Front 12PIN)

6. CN602 CONNECTOR PICTURE

3-26

CN602 (POWER 10PIN)

Page 40

7. CN604 CONNECTOR PICTURE

CN604 (USB 4PIN)

8. CN605 CONNECTOR PICTURE

CN605 (KARAOKE 4PIN)

3-27

Page 41

9. CN705 CONNECTOR PICTURE

CN705 (5.1ch 12PIN)

3-28

Page 42

BLOCK DIAGRAMS

JA

CK

1. OVERALL BLOCK DIAGRAM

JACK

3.3V

USB,Karaoke

P

IC604

KA741

OP-AM

A

ADC_DAT

ADC

IC607

CS6340

IC603

64M bit

SDRAM

IC604

3.3VA

FLASH ROM

6M)

(1

ACLK

ABCK

RAMCAS

ROMADD[0:11]

T

ALRCK

ADC_RS

[00:15]

RAMCS1

RAMCS0

RAMRAS

R

RAMBA

IC605

AT24C08A

3.3VA

K

I2CCL

I2CDAT

USBP,USBN

30MHz

ROMDAT

LK

PC

RAMWE

RAMCKE

ROMDATA[0:15]

MEMW

MEMRD

MEMADD[0:19]

3.3VA

1.8VA

EEPROM

L

R

12V

IC702

MC4580

OP-AMP

APWM_R +/=

APWM_L +/=

IC601

MT1389S

RCG_SEL

scart( 16:9)

5V

5V

IC701

S-Video YC

B/

Pb

G/Y

R/Pr

CVBS

SPDIF

27MHz

K

FP CL

FP STB

FP DATA

RF+DSP+5.1ch+karaoke+HDMI Tx + MPEG IC

FFER

VIDEO

BU

RESET

IR RCV

S-VIDEO OPTION

L

COAXIA

OPTICAL

H.H.P.P.D

CK

JA

HDMIHDMI

±

TXC TXC ±

TX[TX[ 0-2-2 ]

Circuit

IRIR

ReceReceiveiver

ToTo F Froront IC IC

DISC

DVD : A,B,C,D,RF

CD : A,B,C,D,E,F,RF

MDI

PICK

MOTOR

SPINDLE

1.8VA

RESET

SO

IC201IC201

A

3.3V

PWR_CTL_H

CDLD,DVDLD,VC20

UP

Pick-up

DP11DP11

M

M

SLED

MOTOR

(FEEDING)

M

MOTOR

LOADING

DECK MECHANISM

TRIN, TROUT

OP(+,-)

FMSO, DMSO,TRSO,FO

STBY, TROPEN, TRCLOSE

TRACK[+,-]

FOCUS[+,-]

SP[+,-]

SLED[+,-]

LOAD[+,-]

e

Voltage

IC201

Motor Driv

AM5890S(5Ch)

5.6VA(M)

5V

ction

dete

BOARD

POWER

50HZ/60Hz

AC 90V~240V

+12V

5.6VA(M)

3.3V

3-29

Page 43

2. POWER (SMPS) BLOCK DIAGRAM

A

12V

OP AMP

LPF

5V

Video Buffer

LPF

Motor Drive IC 1.8V

5.6VA(M)

MPEG

RemoconReceiver

Flash Memory

3.3V

LPF

3.3V

SDRAM

LED Clock,Driver

PWR CTL

RECTIFIER(14V)

RECTIFIER(5.6V)

TRANS

SWITCHING IC

3-30

RECTIFIER(3.3V)

FEED B.

AC100~240V

RECTIFIER

Page 44

3. MPEG & MEMORY BLOCK DIAGRAM

O In

terf

ace

5.5.1C1CH

AL_R

AR_R

OptOption

CENTER

WOOFER

Y_G_OUT

CVBS

R_SY_OUT

B_SC_OUT

VIDVIDEO InO Interfterf aceace

AUDAUDIO

InInterfterface

)

ASPDIF(Optica l

ASPDIF(COAXIAL)

IC605

EEPROM

I2Cdata I2CLK

IC603

SDRAM

64M bit

IC604

: EXCEL, SST, MX

(16 M )

RAMADD[0:11]

RAMCAS -

RAMRAS -

RAMCS1 -

RAMCS0 -

RAMBA

RAMWE -

RAMCKE

RAMDAT[00:15]

PCLK

]

DA[0:15

AD[0:19 ]

RESE T,W R-, CS0 -

FLASH MEMORY

CK

USB

JA

ace

D_MUTE

USBP,US BN

MT1389S

terf

AUDIO In

AR

AL

IC601(M(MPEG + DPEG + DSP + RFSP + RF)

X60X601

27MH27MHz

5V

Y_G_OUT

CVBS

R_SY_OU

B_SC_OUT

IC701

VIDEO

BUFFER

H.P.D

T

TX [0-2 ] , TXC

RESET

IR

POWER,

DIN ,DOUT

IC(IC(IC901)C901)

LED D DRIDRIVE

VIDVIDEO InO Interfterf ace

er

HDMI

IC201

AM5890S(5Ch)

Motor Driv

3-31

Page 45

4. SERVO BLOCK DIAGRAM

L

X601

27MHz

X-TA

IC601

ALPC

MTK1389S

ONE CHIP

DVDPLAYER

P-

RESET

ction

Voltage

dete

OP+, OP-

Y

FMSO,DMSO

FOSO, TRSO

TROPEN,

TRCLOSE,

STB

IC201

,

IOA

MDI1

SEL1

CDLD(LD01),DVDLD(LD02),V20

DVD : A,B,C,D,RF

CD : A,B,C,D,E,F,RF

PICK

TRIN,TROUT

Motor Driver

AM5890S(5Ch)

-

PICK

UP

(IM)

3-32

F+, F-,

T+, T-

SL+, SL-

LOAD+,LOAD

M/D

SP+,S

(DP11)

Page 46

5. VIDEO & HDMI BLOCK DIAGRAM

Y

Pb

Y

RGB_H

16_9_H

V.OUT

B

G

R

CVBS

O

S-VIDE

Pb

Pr

HDMI JACK

Pr

SC

SY

±

±

H.P.D

TX[0- 2] , TXC

Y

Y

CVBS

C

Y_C MIX

Y

C

Y_G

Y(G)

Pb_B_SC

Pr_R_S

Pr(R)

Pb(B)

IC601

Mpeg IC

MT1389S

3-33

Page 47

6. AUDIO BLOCK DIAGRAM

A Out "L"

JACK

A out "R"

2

AMP

IC70

MC4580M

MUTE

S/W

AL_R

AR_R

CENTER

WOOFER

5.1ch

Connector

Option

A_L

A_R

IC601

MT1389S

MPEG

MUTEC

Audio

3-34

8DAC

DIF

COAXl _SP

Coaxial

Serial Stereo

Optical

PDIF

Optical _S

tal Out

Digi

Page 48

CIRCUIT DIAGRAMS

A B C D E F G H I J K L M N O P Q R ST

No Power

D105~D108 is Defective

14VA No Power

D125 is Defective

5.6VA No Power

D123 is Defective

3.3VA No Power

D121 or D122 are Defective

Switching Error

IC101is Defective

Switching Error

IC102,IC103 are Defective

No Power

FR101 is Defective

12V No Power

Q123 is Defective

5.0V No Power

Q126 is Defective

3.3V No Power

Q121 is Defective

1. POWER (SMPS) CIRCUIT DIAGRAM

IMPORTANT SAFETY NOTE :

WHEN SERVICING THIS CHASSIS, UNDER NO CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE NAD. ALL COMPONENTS SHOULD BE

REPLACED ONLY WITH TYPES IDENTICAL TO

THOSE IN THE ORIGINAL CIRCUIT. SPECIAL COMPONENTS ARE SHADED ON THE SCHEMATIC FOR

EASY IDENTIFICATION. THIS CIRCUIT DIAGRAM MAY

OCCASIONALLY DIFFER FROM THE ACTUAL CIRCUIT USED. THIS WAY, IMPLEMENTATION OF THE

LATEST SAFETY AND PERFORMANCE IMPROVEMENT CHANGES INTO THE SET IS NOT DELAYED

UNTIL THE NEW SERVICE LITERATURE IS PRINTED.

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter during Play mode.

3-35 3-36

Page 49

2. MPEG CIRCUIT DIAGRAM

3-37 3-38

Page 50

3. SERVO CIRCUIT DIAGRAM

3-39 3-40

Page 51

4. JACK CIRCUIT DIAGRAM

3-41 3-42

Page 52

5. SCART CIRCUIT DIAGRAM (OPTION)

3-43 3-44

Page 53

6. USB CIRCUIT DIAGRAM 7. KEY CIRCUIT DIAGRAM

3-45 3-46

Page 54

8. TIMER CIRCUIT DIAGRAM

3-47 3-48

Page 55

• CIRCUIT VOLTAGE CHART

MODE

PIN NO.

STOP PLAY

IC201(AM5869S)

1 1.392 1.397

2 1.705 1.637

3 1.375 1.436

4 1.393 1.396

5 1.243 1.238

6 0.01 0.01

7 0.02 0.02

8 5.589 5.53

9 0.001 0

10 0.001 0

11 2.729 2.771

12 2.729 2.687

13 2.733 2.686

14 2.733 2.757

15 2.739 2.701

16 2.739 2.725

17 2.734 3.725

18 2.734 1.656

19 5.598 5.55

20 3.277 3.253

21 5.598 5.54

22 0.001 0

23 1.395 1.734

24 3.275 3.251

25 5.574 5.51

26 1.392 1.391

27 1.392 1.391

28 0.019 3.197

29 0 0

30 0 0

IC601(MT1389S)

1 1.728 1.694

2 1.146 1.826

3 0.874 0.883

4 3.259 3.243

5 0.002 0.002

6 0.381 0.381

7 0.391 0.361

8 0.376 0.353

9 0.382 0.346

10 1.741 1.708

11 2.004 2.048

12 2.001 2.045

13 2.003 2.056

14 2.004 2.043

15 0.769 0.439

16 0.769 0.439

17 1.996 1.982

18 1.996 2.241

19 0 0.179

20 0 0.179

21 3.213 2.352

22 3.213 2.352

23 3.237 3.242

24 2.241 2.799

25 0.773 1.367

26 0.002 0.002

27 2.516 2.764

28 1.995 2.003

29 1.389 1.388

30 1.374 1.489

31 1.579 1.364

MODE

PIN NO.

STOP PLAY

32 1.578 1.359

33 2.431 1.824

34 2.593 1.828

35 2.196 1.684

36 1.391 1.834

37 1.391 1.466

38 0.008 0.009

39 1.391 1.391

40 1.388 1.382

41 1.387 1.422

42 0.002 0.001

43 1.859 1.856

44 0.011 0.008

45 0.011 0.008

46 3.281 3.272

47 0.002 0.002

48 0.819 0.794

49 1.859 1.854

50 0.002 0.002

51 0.971 0.864

52 0.971 0.717

53 3.261 0.017

54 3.241 0.022

55 1.848 1.851

56 1.954 2.257

57 1.884 2.054

58 1.947 2.239

59 1.694 1.604

60 1.785 1.783

61 1.816 2.346

62 1.997 1.652

63 0.127 0.125

64 0.012 0.015

65 3.285 3.277

66 3.285 3.276

67 1.393 1.093

68 1.759 1.806

69 1.251 3.043

70 2.245 3.006

71 1.249 3.131

72 0.305 0.712

73 2.466 1.706

74 2.759 1.332

75 0.011 0.013

76 0.011 0.013

77 2.079 1.895

78 0.011 0.012

79 1.369 1.523

80 1.705 1.803

81 0.002 0.002

82 0.585 0.854

83 0.971 0.956

84 1.561 1.616

85 1.547 1.469

86 1.683 0.974

87 0.021 0.024

88 1.171 1.127

89 1.368 1.117

90 0.002 0.002

91 0.025 0.024

92 1.998 1.846

93 1.876 1.828

94 3.254 3.257

MODE

PIN NO.

100 0.128 0.127

101 3.276 3.275

102 3.276 0

103 3.276 3.277

104 3.276 3.278

105 3.251 3.278

106 3.264 3.276

107 0.023 0.024

108 3.295 3.293

109 2.991 3.011

110 0.021 0.024

111 2.293 1.965

112 0.024 0.081

113 0.972 0.659

114 0.859 0.643

115 0.982 0.648

116 1.032 0.667

117 1.507 0.945

118 3.286 3.277

119 1.129 0.876

120 1.119 0.813

121 1.251 1.317

122 0.814 0.547

123 1.731 1.323

124 1.686 1.234

125 1.414 1.245

126 1.229 0.751

127 1.175 0.727

128 1.095 0.775

129 1.326 0.739

130 0.055 0.046

131 3.286 3.276

132 2.296 1.916

133 3.001 2.834

134 3.159 3.093

135 3.065 3.066

136 2.815 2.669

137 1.473 1.532

138 1.667 1.572

139 0.038 0.093

140 0.041 0.612

141 2.061 1.647

142 1.842 1.825

143 2.304 1.994

144 1.372 1.534

145 3.286 3.277

146 1.479 1.431

147 3.261 3.276

148 0.002 0.002

149 0.032 0.039

150 0.079 0.081

151 0.051 0.054

152 1.444 1.529

153 1.489 1.561

154 1.459 1.521

155 1.516 1.503

156 3.288 3.275

157 3.127 3.125

STOP PLAY

95 3.256 3.252

96 3.286 3.276

97 0.021 0.078

98 3.227 3.232

99 3.159 3.151

MODE

PIN NO.

158 3.266 3.258

159 4.82 4.82

160 1.842 1.829

161 4.84 4.84

162 0.021 0.017

163 0.002 0.002

164 1.331 1.33

165 3.099 3.086

166 3.099 3.086

167 0.345 0.208

168 0.001 0.001

169 0.001 0.001

170 0.001 0.001

171 0.003 0.004

172 1.842 1.831

173 0.002 0.001

174 0.002 0.002

175 0.001 0.001

176 0.002 0.003

177 0.002 0.002

178 1.845 1.832

179 0.002 0.002

180 0.002 0.002

181 0.002 0.002

182 0.637 0.032

183 0.701 0.034

184 0.003 0.003

185 0.496 0.127

186 3.251 3.237

187 2.614 2.567

188 0.003 0.002

189 0.676 0.659

190 3.251 3.238

191 0.498 0.281

192 0.002 0.002

193 1.212 1.207

194 1.289 1.203

195 3.251 3.239

196 0.016 0.018

197 0.016 0.018

198 0.024 0.022

199 0.024 0.022

200 0.024 0.023

201 0.128 3.248

202 0.027 0.023

203 0.024 1.523

204 0.023 1.608

205 0.023 1.635

206 2.915 1.321

207 3.266 3.256

208 0.023 0.024

209 0.023 0.024

210 0.018 0.021

211 0.019 3.218

212 1.831 1.829

213 0 0

214 2.945 2.936

215 1.539 1.533

216 3.241 3.251

217 1.892 1.698

218 0.002 0.002

219 0.002 0.002

220 0.002 0.002

STOP PLAY

MODE

PIN NO.

221 1.617 1.615

222 2.261 2.249

223 1.617 1.613

224 0 0

225 1.619 1.611

226 1.617 1.611

227 1.616 1.61

228 3.286 3.249

229 3.286 3.248

230 1.618 1.614

231 1.616 1.611

232 0.003 0.003

233 3.286 3.249

234 1.841 1.827

235 0.002 0.002

236 0.003 0.003

237 1.841 1.827

238 0.871 0.868

239 0.887 0.868

240 1.071 0.864

241 1.035 0.822

242 0.002 0.002

243 3.202 3.179

244 1.636 1.641

245 0.321 1.549

246 1.986 1.543

247 0.221 1.517

248 3.259 3.244

249 0.002 0.002

250 3.259 2.243

251 0.691 1.711

252 1.375 1.366

253 3.236 1.424

254 1.368 1.788

255 0.002 0.002

256 1.723 1.718

STOP PLAY

IC602(ES29LV160ET)

1 1.392 0.118

2 2.326 0.339

3 0.883 3.065

4 1.468 0.338

5 1.247 3.163

6 0.299 0.619

7 2.478 1.645

8 2.767 1.648

9 0.012 0.014

10 0.021 0.014

11 3.274 3.242

12 3.266 3.239

13 3.268 3.244

14 3.268 3.244

15 1.204 0.776

16 0.014 0.015

17 0.102 3.085

18 2.006 1.765

19 1.114 1.354

20 2.285 2.265

21 1.698 2.084

22 1.953 2.118

23 1.891 1.945

24 1.964 2.175

25 2.087 1.869

26 0.012 0.014

MODE

PIN NO.

27 0.002 0.001

28 0.012 0.013

29 1.376 1.561

30 0.528 0.202

31 1.706 1.766

32 0.436 0.775

33 0.961 1.188

34 0.441 0.587

35 0.588 1.134

36 0.365 0.729

37 3.267 3.241

38 1.383 1.442

39 0.432 1.291

40 1.505 1.536

41 0.413 0.847

42 1.637 1.527

43 0.447 1.028

44 1.339 1.142

45 2.012 1.846

46 0.001 0.001

47 0.001 0.001

48 0.014 0.026

STOP PLAY

IC603(HY57V64)

1 3.281 3.239

2 1.264 1.141

3 3.281 3.239

4 1.154 1.055

5 1.145 1.077

6 0.002 0

7 1.504 1.021

8 1.005 1.241

9 3.281 3.241

10 1.003 1.069

11 0.843 0.633

12 0.002 0

13 0.968 0.782

14 3.284 3.241

15 2.316 1.389

16 3.181 3.001

17 3.022 2.748

18 3.098 2.934

19 2.856 3.239

20 1.485 1.233

21 1.679 1.229

22 0.039 0.097

23 0.411 0.715

24 2.076 1.238

25 2.318 1.775

26 1.384 1.507

27 3.279 3.241

28 0.002 0.001

29 1.511 1.381

30 1.543 1.649

31 1.651 1.539

32 1.705 1.508

33 0.054 0.084

34 0.087 0.083

35 0.033 0.036

36 0 0

37 3.271 3.246

38 1.518 1.462

39 2.316 1.538

40 0 0

MODE

PIN NO.

41 0.002 0.001

42 1.339 0.796

43 3.278 3.267

44 1.117 0.885

45 1.217 1.009

46 0.002 0

47 1.231 1.144

48 1.473 0.745

49 3.279 3.267

50 1.742 1.127

51 1.786 1.281

52 0.002 0.001

53 0.828 1.051

54 0.002 0.001

STOP PLAY

IC606(S524C80D80-SCB1)

1 0.002 0

2 0.002 0

3 0.002 0

4 0.002 0

5 3.285 3.252

6 3.285 3.251

7 0.002 0

8 3.289 3.252

IC607(CS5340)

1 3.283 3.247

2 0.026 0.024

3 3.287 3.251

4 2.929 2.909

5 0.001 0.001

6 4.911 4.88

7 0.022 0.025

8 0.022 0.025

9 3.286 3.253

10 2.448 2.439

11 2.448 2.437

12 2.442 2.434

13 4.89 4.89

14 0.002 0

15 0.346 0.346

16 3.283 3.246

IC701(MM1692XVBE)

1 4.859 4.83

2 2.284 2.276

3 2.436 2.427

4 1.851 1.786

5 4.861 4.84

6 1.847 1.691

7 0.014 0.013

8 2.282 2.271

9 2.255 2.271

10 0.003 0.003

11 2.245 2.252

12 2.229 2.239

13 1.961 1.729

14 1.945 1.727

15 1.901 1.701

16 2.231 2.242

IC703(MC4580)

1 5.57 5.54

2 5.57 5.54

3 5.57 5.54

4 0.001 0.001

5 5.57 5.54

MODE

PIN NO.

STOP PLAY

6 5.57 5.54

7 5.57 5.54

8 12.21 12.13

Q201

Emitter 3.297 3.266

Collector 0.384 0.034

Base 3.237 3.221

Q202

Emitter 3.301 3.039

Collector 0.385 2.328

Base 3.242 2.305

Q205

Emitter 0 0.002

Collector 0.008 4.887

Base 0.651 0.019

Q206

Emitter 0 0.001

Collector 0 0.179

Base 3.234 0.022

Q207

Emitter 0 0.001

Collector 0 0.001

Base 0.008 4.839

Q208

Emitter 1.751 1.705

Collector 1.885 1.886

Base 2.482 2.461

Q601

Drain 3.296 3.271

Gate 3.107 3.093

Source 4.912 4.912

Q702

Emitter 0.001 0.001

Collector 0.005 0.002

Base 0.716 0.667

Q703

Emitter 3.269 3.257

Collector 3.239 3.115

Base 2.558 3.247

Q705

Emitter 0.001 0.001

Collector 0.005 0.003

Base 0.726 0.671

Q706

Emitter 0.002 0.002

Collector 0.082 0.083

Base 0.729 0.727

Q707

Emitter 0.001 0.001

Collector 0.085 0.081

Base 0.728 0.728

Q708

Emitter 0.001 0.001

Collector 0.034 0.035

Base 0.728 0.727

Q709

Emitter 2.271 2.254

Collector 4.86 4.86

Base 2.921 2.902

3-49 3-50

Page 56

LOCATION SPEC

C642 33μ F/16V 1.858 0.002

C666 100μ F/6.3V 3.244 0.003

C6C1 10μ F/16V 12.251 0

C6C2 10μ F/16V 11.556 0

C6C6 10μ F/16V 3.257 0.001

C6C9 220μ F/16V 3.259 0.001

C6E0 47μ F/6.3V 2.758 0.001

C6E1 10μ F/16V 1.372 0.002

C6E2 47μ F/6.3V 1.396 0.002

C6E3 220μ F/6.3V 3.239 0.003

C6E4 220μ F/6.3V 3.268 0

C6E5 10μ F/16V 3.261 0.002

C6E6 100μ F/6.3V 3.165 0.003

C6E7 47μ F/6.3V 2.012 0.002

C6E8 10μ F/16V 1.852 0.002

C6E9 10μ F/16V 3.227 0.002

C202 220μ F/6.3V 3.257 0.001

C205 47μ F/6.3V 3.252 3.209

C206 47μ F/6.3V 3.252 2.254

C217 100μ F/6.3V 4.884 0.002

C220 220μ F/16V 5.515 0.016

C240 220μ F/6.3V 1.888 0.001

C242 10μ F/16V 3.266 0.002

C703 22μ F/16V 2.438 0.002

C704 47μ F/6.3V 4.859 0.002

C706 10μ F/16V 4.817 0.002

C728 47μ F/16V 12.256 0.145

C730 22μ F/16V 5.595 1.609

C731 47μ F/16V 5.599 0.002

C732 22μ F/16V 5.595 1.611

C734 22μ F/16V 5.595 0.006

C735 22μ F/16V 5.595 0.006

PLAY

+

-

3-51 3-52

Page 57

PRINTED CIRCUIT BOARD DIAGRAMS

1. MAIN P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3-53 3-54

Page 58

2. POWER (SMPS) P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3. KEY P.C.BOARD

(TOP VIEW)

(BOTTOM VIEW) (BOTTOM VIEW)

4. TIMER P.C.BOARD

(TOP VIEW)

3-55 3-56

Page 59

5. SCART P.C.BOARD (OPTION)

(TOP VIEW) (BOTTOM VIEW)

6. USB P.C.BOARD

(TOP VIEW) (BOTTOM VIEW)

3-57 3-58

Page 60

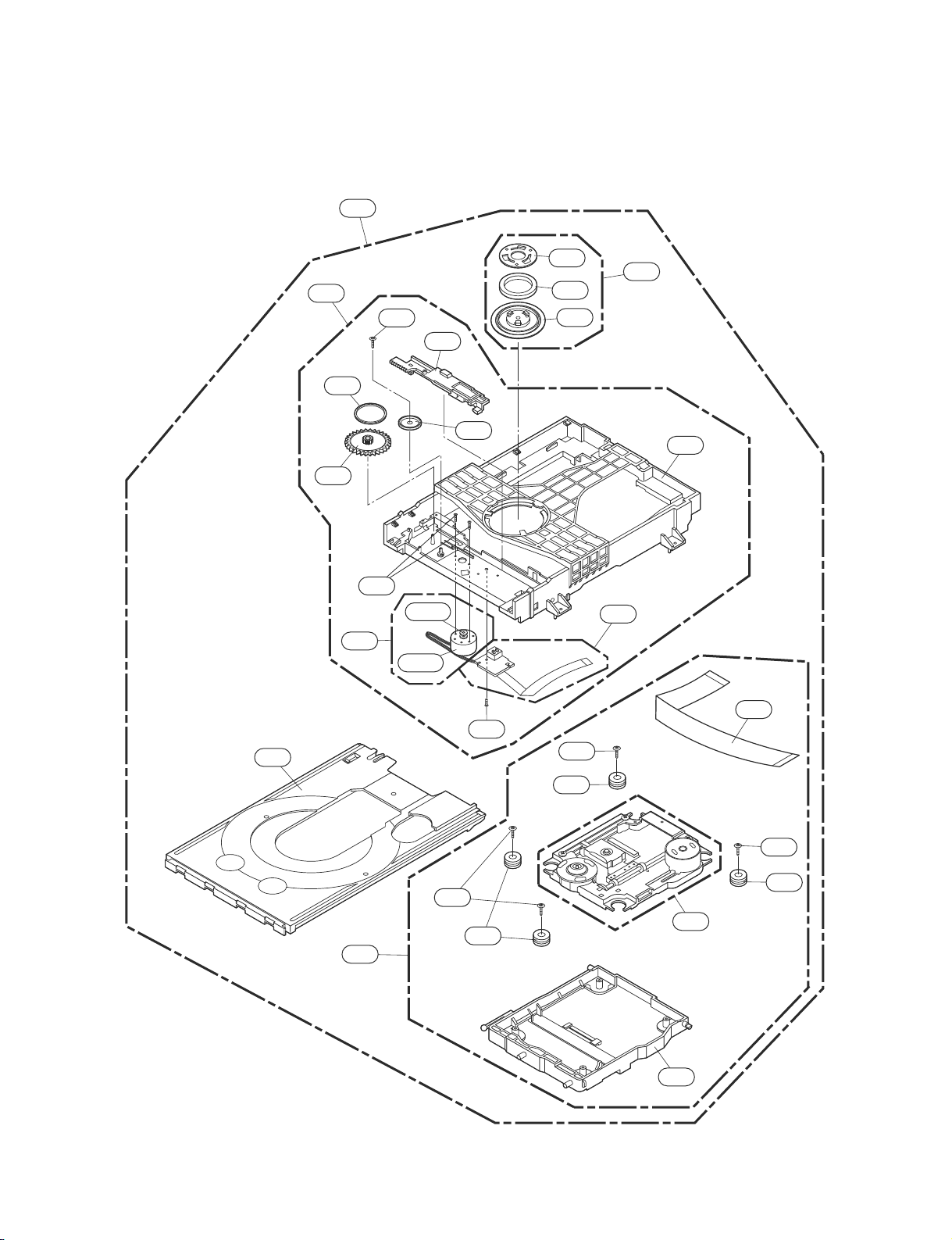

SECTION 4

MECHANISM (DP-12V)

CONTENTS

DECK MECHANISM PARTS LOCATIONS

• Top View......................................................................................................................................4-2

• Top View(without Tray Disc) .....................................................................................................4-2

• Bottom View ...............................................................................................................................4-2

DECK MECHANISM DISASSEMBLY

1. Main Base ....................................................................................................................4-3

1-1. Clamp Assembly Disc .........................................................................................................4-3

1-1-1. Plate Clamp ..............................................................................................................4-3

1-1-2. Magnet Clamp ..........................................................................................................4-3

1-1-3. Clamp Upper ............................................................................................................4-3

2. Tray Disc ......................................................................................................................4-3

3. Base Assembly Sled...................................................................................................4-4

3-1. Gear Feed...........................................................................................................................4-4

3-2. Gear Middle ........................................................................................................................4-4

3-3. Gear Rack...........................................................................................................................4-4

4. Rubber Rear.................................................................................................................4-4

5. Frame Assembly Up/Down.........................................................................................4-5

6. Belt Loading ................................................................................................................4-5

7. Gear Pulley ..................................................................................................................4-5

8. Gear Loading ...............................................................................................................4-5

9. Guide Up/Down ...........................................................................................................4-5

10. PWB Assembly Loading...........................................................................................4-5

11. Base Main...................................................................................................................4-5

EXPLODED VIEW

1. Deck Mechanism Exploded View ..............................................................................4-7

4-1

Page 61

DECK MECHANISM PARTS LOCATION

• TOP VIEW (WITHOUT TRAY)

• TOP VIEW (WITH TRAY)

Procedure

Starting No.

1 Main Base 4-1

12

1, 2 3 Plate Clamp 4-1

1, 2, 3 4 Magnet Clamp 4-1

1, 2, 3, 4 5 Clamp Upper 4-1

1 6 Tray Disc 4-2

1, 6 7 Base Assembly Sled 4-3

1, 2, 6 8 Gear Feed 1 Connector 4-3

1, 2, 6, 8 9 Gear Middle

1, 2, 6, 8,

9

1, 2, 7 11 Rubber Rear 4-3

1, 2, 7 12

1, 2 13 Belt Loading 1 Locking Tab 4-4

1, 2 ,13 14 Gear Pulley 4-4

1, 2, 13, 14 15 Gear Loading 1 Locking Tab 4-4

1, 2, 7, 12,

13, 14

1, 2, 13 17 PWB Assembly

1, 2, 7, 12,

13, 14, 15, 18 Base Main 2 Locking Tabs 4-4

16, 17

10 Gear Rack 1 Screw 4-3

16 Guide Up/Down 4-4

Parts Fixing Type

Clamp Assembly

Disc

Frame Assembly

Up/Down

Loading

4 Screws,

1 Locking Tabs

1 Screw Bottom 4-4

1 Locking Tab

1 Hook

2 Screw

Disass Fig-

embly ure

4-1

Bottom 4-4

• BOTTOM VIEW

Note

When reassembling, perform the procedure in

reverse order.

The “Bottom” on Disassembly column of above

Table indicates the part should be disassembled

at the Bottom side.

4-2

Page 62

DECK MECHANISM DISASSEMBLY

MAIN BASE

PLATE CLAMP

MAGNET CLAMP

CLAMP UPPER

HOLDER

BASE MAIN

(Fig. A)

DISC CLAMP ASSEMBLY

TRAY DISC

BASE MAIN

LEVER

FIG. 4-1 FIG. 4-2

1. MAIN BASE (FIG. 4-1)

1-1. Clamp Assembly Disc

1) Place the Clamp Assembly Disc as Fig. (A)

2) Lift up the Clamp Assembly Disc in direction of

arrow(A).

3) Separate the Clamp Assembly Disc from the

Holder Clamp.

1-1-1. Plate Clamp

1) Turn the Plate Clamp to counterclockwise

1-1-2. Magnet Clamp

1-1-3. Clamp Upper

direction and then lift up the Plate Clamp.

BASE MAIN

BOTTOM SIDE VIEW

2. TRAY DISC (FIG. 4-2)

1) Insert and push a Driver in the emergency eject

hole(A) at the right side, or put the Driver on the

Lever(B) of the Gear Emergency and pull the

Lever(B) in direction of arrow so that the Tray

Disc is ejected about 15~20mm.

2) Pull the Tray Disc until it is separated from the

Base Main completely.

4-3

Page 63

RUBBER DAMPER

(S2)

RUBBER D

Distinguish upper and

lower sides

(Assemble with care)

AMPER

(S2)

GENERAL PICK UP ASSEMBLY

GEAR RACK

SPINDLE MOTOR ASSEMBLY

(S2)

(S2)

BASE PU

RUBBER DAMPER

Distinguish upper and

lower sides

(Assemble with care)

FIG. 4-3

3. BASE ASSEMBLY SLED (FIG. 4-3)

1) Release 4 Screw (S2).

2) Disconnect the FFC Connector (C1)

3-1. Gear Feed

3-2. Gear Middle

3-3. Gear Rack

1) Release the Scerw (S3)

4. RUBBER REAR (FIG. 4-3)

4-4

Page 64

SCREW INSERTION

TORGUE CONTROL

(800gf DOWN)

GEAR PULLEY

(L4)

BELT LOADING

GEAR LOADING

PWB ASSEMBLY LOADING

BASE MAIN

GUIDE UP/DOWN

BASE MAIN

(H1)

(C2)

(S5)

(A)

(B)

GUIDE UP/DOWN

FIG. 4-4

GUIDE UP/DOWN

(A)

(L5)

FIG. (A)

(B)

(C)

FIG. (C)

5. FRAME ASSEMBLY UP/DOWN (FIG. 4-4)

Note

Put the Base Main face down (Bottom Side)

1) Release the screw (S4)

2) Unlock the Locking Tab (L3) in direction of arrow

and then lift up the Frame Assembly Up/Down to

separate it from the Base Main.

Note

• When reassembling move the Guide Up/Down in

direction of arrow(C) until it is positioned as

Fig.(C).

• When reassembling insert (A) portion of the

Frame Assembly Up/Down in the (B) portion of

the Guide Up/Down as Fig.(B)

6. BELT LOADING(FIG. 4-4)

Note

Put the Base Main on original position(Top Side)

7. GEAR PULLEY (FIG. 4-4)

1) Unlock the Locking Tab(L4) in direction of

arrow(B) and then separate the Gear Pulley from

the Base Main

(A)

(B)

GUIDE UP/DOWN

UP/DOWN FRAME ASSEMBLY

FIG. (B)

8. GEAR LOADING (FIG. 4-4)

9. GUIDE UP/DOWN (FIG. 4-4)

1) Move the Guide Up/Down in direction of

arrow(A) as Fig.(A)

2) Push the Locking Tab(L5) down and then lift up

the Guide Up/Down to separate it from the Base

Main.

Note

When reassembling place the Guide Up/Down as

Fig.(C) and move it in direction arrow(B) until it is

locked by the Locking Tab(L5). And confirm the Guide

Up/Down as Fig.(A)

10. PWB ASSEMBLY LOADING (FIG. 4-4)

Note

Put the Base Main face down(Bottom Side)

1) Release 1 Screws(S5)

2) Unlock the Loading Motor (C2) from the Hook

(H1) on the Base Main.

3) Unlock 2 Locking Tabs(L6) and separate the

PWB Assembly Loading from the Base Main.

11. BASE MAIN (FIG. 4-4)

4-5

Page 65

MEMO

4-6

Page 66

EXPLODED VIEW

1. DECK MECHANISM EXPLODED VIEW

DP-12V

A26

026

A02

017

013

015

435

439

015B

015A

001

A01

002

003

018

014

020

016

010

440

442

A03

012

442

012

442

037

012

019

4-7 4-8

Page 67

MEMO MEMO

4-9 4-10

Page 68

NOTES)

)

If you want to purchase

Flash memory, you must order

" IC602A "

NOTES)

Warning

Parts that are shaded are critical with

respect to risk of fire or electrical

shock.

SECTION REPLACEMENT PARTS LIST

MODEL :5T517C/T517CT(NAD,SWEDEN

RUN DATE : 17-JUNE-08

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

*** INDIVIDUAL PARTS ***

250 MBN42830502 Case PRESS PCM 0.825 DV302H-NE PRES T517C

250 MBN42830501 Case PRESS PCM 0.825 DV302H-NE PRES T517CT

275 MGJ37320101 Plate,Ground PRESS STS 301 0.2mm MDD102 USB

276 MEG40359801 Holder MOLD HIPS 60HR DVD DV300 MOLD

283 3580R-T229C Door,Case MOLD ABS HF-380 DVD DVN156 (GR T517C

283 3580R-T229D Door,Case MOLD ABS HF-380 DVD DVN156 (TI T517CT

300 6410RCHP04A Power Cord Assembly HIT-101/H03VVH2-F/2X0.75MM2/70

460 1SZZR-0098H Screw,Customized - + 3MM 8MM MSWR FZW SIN JIN T517C

463 1SZZR-0098G Screw,Customized 1SZZR-0098G FH + 3MM 8MM MSWR T517CT

461 1SZZR-0098L Screw,Customized - + 3MM 16MM MSWR NI PLT SIN

462 1SZZR-0098J Screw,Customized 1SZZ0098J BH + 3MM 6.5MM MSWR

463 1SZZR-0098G Screw,Customized 1SZZR-0098G FH + 3MM 8MM MSWR

465 1SZZR-0097N Screw,Customized - + 3MM 8MM MSWR FZB SIN JIN

470 353-022S Screw,Customized BZN BK (CR +3) SPECIAL + 3MM 6

801 AFN52750438 Manual Assembly,Owners DVD DV302H-E.BSWENNK/T ASS'Y

802 MAY46749440 Box,Master BOX SW3 519 136 299 2 COLOR DV T517C

802 MAY46749442 Box,Master BOX SW3 519 136 299 2 COLOR DV T517CT

803 MFZ47272604 Packing CUTTING EPS DVD DV300-N_NAD 91

804 3880SCS001G Bag CUTTING HDPE 100 100 0.05 BAG NSP

808 534-008C Dry Cell Battery AAA(R03) 1PAIR 1.5V 50MAH AAA

900 6711R2N124D Remote Controller Assembly NAD DV302H-NE 08 DVD-P NAD

*** Accessory Assembly ***

810 6851R-0074B Accessory Assembly VCR LGEIN 1WAY YELLOW 1.2M + 2

811 6850R-PAA2F Cable,Assembly RCA PLUG RCA PLUG 1.2M 1P YELL

812 6850R-PBA2H Cable,Assembly RCA PLUG RCA PLUG 1.2M 2P RED/

*** Deck Assembly,DVD(MD) ***

A26 EAZ38311314 Deck Assembly,DVD DECK/MECHA DP-12V player (IN) NSP

A02 AAN34279702 Base Assembly DP-12 Loading 430mm

013 4400R-0010A Belt MOLD RUBBER DVD DP-9 OTHER LOA

014 4470R-0154A Gear COMPLEX DVD DECK/MECHA DP8 PUL

015 4681R-A015C Motor Assembly,DC DVD DP-9 loading

017 4470R-0176A Gear MOLD POM DVD DP-9 LOADING MO

435 1SZZR-0011A Screw,Customized MACHINE

439 1SZZR-0075A Screw,Customized - + 1.7MM 10MM SWRCH FZW SIN

440 1SZZH-1007B Screw,Customized + D2.0 6MM SWRCH16A/ZNBK 4MM 1

015A 4680R-E008A Motor,DC RF-300EA-1D390(80MM) 2V 90MA 2 NSP

015A EAU36590901 Motor,DC FC08I20TLG-1 2V 100MA 0A 1.37K NSP

015A EAU43506801 Motor,DC JQ24-35H390 2V 90A 28A 0RPM 0R NSP

015B 4560R-0008A Pulley MOLD POM DVD MD MOLD -

016 EBR34880104 PCB Assembly DP-12 FEEDING/LOADING -430mm

018 MEA32088501 Guide MOLD POM(LUCEL N109-LD) DVD PO

020 MAM38555601 Base MOLD ABS XR-401 DP-13 MOLD mai NSP

A03 AAN34281204 Base Assembly DP-12V Sled 430mm

010 EAD34861101 Cable,FFC AT10023270D01 270MM 1.00MM 23P

012 MCQ38556902 Damper EXTRUSION BUTYL RUBBER DECK/ME

019 MDQ38556002 Frame MOLD ABS XR-401 DP-12 MOLD up

037 EAZ40060202 Pick Up Assembly CMS-S77RFV(1) CMS-S77RFV(1) IM

Not Service Part

1-5

Page 69

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

r

(

442 FAB30124101 Screw,Taptite 1szzr-0064 PWH + B 2.6MM 7MM S

A01 ACA34280801 Clamp Assembly DECK/MECHA DP-12/13 ferrite ty

001 MGJ38556601 Plate PRESS SECC 0.8 dp-13 PRESS upp NSP

002 RAB30611501 Magnet,Ferrite FERRITE 50G NSP

003 MBU38556801 Clamp MOLD POM DECK/MECHA dp-13 MOLD NSP

026 MJS31956302 Tray MOLD ABS XR-401 DVD dp-12 MOLD

*** PCB Assembly,Powe

A47 EBR42200724 PCB Assembly,Power DV300'S SMPS IN WIDE NAD Total

BC101 636-004C Filter,Bead BFS3550R2FD8 70OHM 9X3.5X7.5MM

C101 624-088F Capacitor,Film,DIP PCX2 335 M9663 100nF 10% 275V

C101 624-088J Capacitor,Film,Box ECQU2A104ML 0.1uF 20% 250V MPE ALTERNATE

C101 624-088L Capacitor,Film,DIP 435D UL 250V/ VDE 275V 104 K 1 ALTERNATE

C101 624-088N Capacitor,Film,Box MPX104K2YL UL 250V/ VDE 275V 0 ALTERNATE

C103 0CZZR00011B Capacitor,Unclassified SAMYOUNG,SAMWHA,G-LUXON E-CAP

C104 0CZZR00011B Capacitor,Unclassified SAMYOUNG,SAMWHA,G-LUXON E-CAP

C105 0CQ1031Y519 Capacitor,Film,DIP 230S 2J 103 K 10nF 10% 630V MP

C106 624-087S Capacitor,Unclassified 47PF D 1KV 10% TR B(Y5P)

C108 0CN1040K948 Capacitor,Ceramic,Axial CH UP050 F104Z-A-B Z 100nF -20

C109 624-085D Capacitor,AL,Radial KME5.0TP50VB47M 47uF 20% 50V 1

C111 0CG2220U630 Capacitor,Ceramic,Radial SDE2G222M12BW1 2200pF 20% 400V

C113 0CQ1521N409 Capacitor,Film,DIP HPE 2A 152J TP 1.5nF 5% 100V P

C114 0CQ4721N409 Capacitor,Film,DIP 310M 2A 472 J 4.7nF 5% 100V PE

C121 0CE108BD630 Capacitor,AL,Radial RUS1A102MIS 1000uF 20% 10V 626

C122 0CE3376D638 Capacitor,AL,Radial SMS5.0TP10VB330M 330uF 20% 10V

C123 0CE108EF630 Capacitor,AL,Radial KMG5.0MC16VB1000M 1000uF 20% 1

C123 0CE108BF630 Capacitor,AL,Radial KME4.0CC16VB1000M 1000uF 20% 1 ALTERNATE

C124 0CE3376D638 Capacitor,AL,Radial SMS5.0TP10VB330M 330uF 20% 10V

C126 624-085D Capacitor,AL,Radial KME5.0TP50VB47M 47uF 20% 50V 1

C128 0CQ1042K409 Capacitor,Film,DIP 310M 1H 104 J 100nF 5% 50V PE

C153 0CE4754K638 Capacitor,AL,Radial ESS475M050T1A5B07G 4.7uF 20% 5

C154 0CE1054K638 Capacitor,AL,Radial ESS105M050T1A5B07G 1uF 20% 50V

C155 0CE1076F638 Capacitor,AL,Radial SMS5.0TP16VB100M 100uF 20% 16V

C156 0CN223AK948 Capacitor,Ceramic,Axial CH UP050 F223Z-A-B Z 22nF -20T

C157 0CN223AK948 Capacitor,Ceramic,Axial CH UP050 F223Z-A-B Z 22nF -20T

D101 0DRRE00163A Diode,Rectifier 1F7 1KV 1.3V 5UA 25A 500NSEC R

D101 0DD221009AA Diode,Rectifier ERA22-10 1KV 1.5V 10UA 10A 400 ALTERNATE

D101 0DR400709AA Diode,Rectifier 10SP07U(SUF4007SP) 1KV 1.7V 5U ALTERNATE

D104 0DR104009BA Diode,Rectifier RL104F 400V 1.3V 5UA 30A 150NS

D104 0DRGF00239A Diode,Rectifier FR104E 400V 1.3V 5UA 30A 150NS

D104 0DD010009AC Diode,Rectifier EU01W(R-FORM) 400V 2.5V 10UA 1

D105 0DRRE00203A Diode,Rectifier 1A7 600V 1.1V 5UA 25A - R1 TP

D105 0DRGF00309A Diode,Rectifier 1A5 600V 1.1V 1A 25A 1NSEC R1

D106 0DRRE00203A Diode,Rectifier 1A7 600V 1.1V 5UA 25A - R1 TP

D106 0DRGF00309A Diode,Rectifier 1A5 600V 1.1V 1A 25A 1NSEC R1

D107 0DRRE00203A Diode,Rectifier 1A7 600V 1.1V 5UA 25A - R1 TP

D107 0DRGF00309A Diode,Rectifier 1A5 600V 1.1V 1A 25A 1NSEC R1

D108 0DRRE00203A Diode,Rectifier 1A7 600V 1.1V 5UA 25A - R1 TP

D108 0DRGF00309A Diode,Rectifier 1A5 600V 1.1V 1A 25A 1NSEC R1

D121 0DR158220AA Diode,Schottky 1N5822 950MV 40V 3A 1NSEC 250p

D123 0DR202000AB Diode,Rectifier HER202 100V 1V 5UA 60A 50NSEC

D123 0DSTW00070A Diode,Rectifier HER202-TSC 100V 1V 5UA 60A 50N ALTERNATE

D125 0DR104009BA Diode,Rectifier RL104F 400V 1.3V 5UA 30A 150NS

D125 0DRGF00239A Diode,Rectifier FR104E 400V 1.3V 5UA 30A 150NS

D125 0DD010009AC Diode,Rectifier EU01W(R-FORM) 400V 2.5V 10UA 1

D151 0DS141489BB Diode,Switching 1N4148(26MM) 1V 100V 150MA 500

D151 0DD133009AA Diode,Switching 1SS133 1.2V 90V 400MA 600MA 4N ALTERNATE

FR101 0RM0221K634 Resistor,Cement ICW02M22R20J 2.2OHM 5% 2W 27X1

POWER) ***

2-5

Page 70

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

y

(

IC101 EAN34789801 IC,PWM Controller STR-A6259H 12.9V TO 15.7V 10V

IC102 6500RDB011B Sensor,Position K1010B 5V DIP BK 4P 4PIN PHOTO

IC102 657-063A Sensor,Position LTV-817B 5V DIP BK 2P PHOTO CO ALTERNATE

IC103 0IPMGUC004B IC,LDO Voltage Regulator TL431 MAX12V 3.3V 600MW TO92 T

IC103 0IKE431000A IC,Voltage Regulator KIA431 36V 36V 700MW TO92 TP 3 ALTERNATE

IC103 0ISS431000A IC,Voltage Regulator KA431AZ 2.495TO36V 36V 770MW T ALTERNATE

L101 EAM34728301 Filter,Line Noise LFU1116H2-01300 35MH 19X18X16M

L121 633-088G Coil,Choke 22KS 22uH - - 8X17MM LEAD - G

L121 6200J000147 Filter,Unclassified LPL0813T-220K ABCO TAPING

L121 6140R-C011A Coil,RF 6140R-C011A 22uH - - 8X17MM LE

L122 633-088G Coil,Choke 22KS 22uH - - 8X17MM LEAD - G

L122 6200J000147 Filter,Unclassified LPL0813T-220K ABCO TAPING

L122 6140R-C011A Coil,RF 6140R-C011A 22uH - - 8X17MM LE

P101 6631R-E078Q Harness,Single GIL-S10/9073 10ST 60mm GIL-S-1

PW101 6630V90108A Connector,Wafer JE202-2L-03 2P 3.96MM 1R ANGLE

Q121 0TR127109AA TR,Bipolar KTA1271Y PNP -5V -35V -30V -0.

Q122 0TR319809AC Transistor Assembly KTC3198 KTC3198 TP KEC - - -BL

Q122 0TR319909AF TR,Bipolar KTC3199-BL NPN 5V 50V 50V 150M ALTERNATE

Q122 0TR534309BA TR,Bipolar 2SC5343L NPN 5V 60V 50V 150MA ALTERNATE

Q123 0TR320309AA TR,Bipolar KTC3203 NPN 5V 35V 30V 800MA 1

Q123 0TR534409AA TR,Bipolar 2SC5344Y NPN 5V 35V 30V 800MA ALTERNATE

Q124 0TR220309AF TR,Bipolar SRA2203 PNP -40V - -50V -0.1A

Q124 0TR103009AF TR,Bipolar KRA103M(KRA2203) PNP -40V 0V - ALTERNATE

Q126 0TR320509AB Transistor Assembly KTC3205-Y(KTC2236A) KTC3205-Y(

Q126 0TR232809AB TR,Bipolar KSC2328A-Y NPN 5V 30V 30V 2A 1 ALTERNATE

Q126 0TR186209AB TR,Bipolar STD1862LY-AT NPN 5V 30V 30V 2A ALTERNATE

R102 0RS0101K619 Resistor,Metal Oxide Film RSD02R1J1R00 1OHM 5% 2W 12.0X4

R103 0RS5602K619 Resistor,Metal Oxide Film SML02R0J56K0 56KOHM 5% 2W 8.6X

R105 0RD0472F608 Resistor,Carbon Film RD-96S1J47R0 47OHM 5% 1/6W 3.2

R121 0RD1001F608 Resistor,Carbon Film RD-96S1J1K00 1KOHM 5% 1/6W 3.2

R122 0RD5600F608 Resistor,Carbon Film RD-96S1J560R 560OHM 5% 1/6W 3.

R123 0RD4702F608 Resistor,Carbon Film RD-96S1J47K0 47KOHM 5% 1/6W 3.

R124 0RD1800F608 Resistor,Carbon Film RD-96S1J180R 180OHM 5% 1/6W 3.

R125 0RD2201F608 Resistor,Carbon Film RD-96S1J2K20 2.2KOHM 5% 1/6W 3

R126 0RD1001F608 Resistor,Carbon Film RD-96S1J1K00 1KOHM 5% 1/6W 3.2

R127 0RN1001F408 Resistor,Metal Film RN-96S1F1K00 1KOHM 1% 1/6W 3.2

R128 0RN3001F408 Resistor,Metal Film RN-96S1F3K00 3KOHM 1% 1/6W 3.2

R130 0RD1002F608 Resistor,Carbon Film RD-96S1J10K0 10KOHM 5% 1/6W 3.

R140 0RD2200F608 Resistor,Carbon Film RD-96S1J220R 220OHM 5% 1/6W 3.

R143 0RD2200F608 Resistor,Carbon Film RD-96S1J220R 220OHM 5% 1/6W 3.

R144 0RD1001F608 Resistor,Carbon Film RD-96S1J1K00 1KOHM 5% 1/6W 3.2

R145 0RD1001F608 Resistor,Carbon Film RD-96S1J1K00 1KOHM 5% 1/6W 3.2

R151 0RD1003F608 Resistor,Carbon Film RD-96S1J100K 100KOHM 5% 1/6W 3

R152 0RD2202F608 Resistor,Carbon Film RD-96S1J22K0 22KOHM 5% 1/6W 3.

T101 6170RNGW05S Transformer,Switching 6170RNGW05S EE2532S 4OHM 2.5mH

V101 656-004C Varistor SVC681D-10A 680V 10% 250pF 10M

ZD101 0DZ330009CA Diode,Zener MTZJT-7733B 33V 30.32TO31.88V

ZD101 0DZ332609AA Diode,Zener GDZJ33B 33V 30.32TO31.88V 65OH ALTERNATE

ZD102 0DZ100009AA Diode,Zener MTZJT-7710B 10V 9.41TO9.9V 30O

ZD102 0DZ102609AB Diode,Zener GDZJ10B(26mm) 10V 9.41TO9.9V 3 ALTERNATE

ZD151 0DZ130009AA Diode,Zener MTZJT-7713A 13V 12.11TO12.75V

ZD151 0DZ132609BB Diode,Zener UZ-13BSA 13V 12.18TO12.71V 13O ALTERNATE

ZD152 0DZ560009CB Diode,Zener MTZJT-775.6C 5.6V 5.61TO5.91V

*** Board Assembl

A43 AAX65660901 Board Assembly DVD DV302H-NE BSWENNK Timer+Fr T517C

A43 AAX65660902 Board Assembly DVD DV302H-NE BSWENNT Timer+Fr T517CT

452 1SZZR-0098A Screw,Customized 1SZZR-0098A BH + 3MM 10MM MSWR

FRONT) ***

3-5

Page 71

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

y

(

280 AGL37044005 Panel Assembly,Front DVD DV302H-NE BSWENNK NAD play T517C