Page 1

SERVICE MANUAL

SERVICE MANUAL

M3 C/

AH

MODEL : M3SERVICE MANUAL

©

NAD

2005

NAD

ELECTRONICS

INTERNA

TIONAL

T

ORONT

O

M3 C/AH

INTEGRATE AMPLIFLER

M3 C/AH

INTEGRATE AMPLIFIER

INTEGRATE AMPLIFIER

Page 2

CONTENTS

SECTION 1 . . . .SUMMARY

SECTION 2 . . . .CABINET & MAIN CHASSIS

SECTION 3 . . . .ELECTRICAL

SECTION 4 . . . .REPLACEMENT PARTS LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

............. 1-2

SERVICING PRECAUTIONS ........................................................................... 1-3

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

SPECIFICATIONS ........................................................................................... 1-6,7

1-1

ALIGNMENT PROCEDURE ............................................................................. 1-4,5

• POWER DRIVEN VOLTAGE

• IDLING CURRENT

• BALANCE INPUTS CMRR

Page 4

1-2

SUBJECT: GRAPHIC SYMBOLS

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

CAUTION : DO NOT ATTEMPT TO MODIFY THIS

PRODUCT IN ANY WAY, NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S

APPROVAL. UNAUTHORIZED MODIFICATIONS WILL

NOT ONLY VOID THE WARRANTY, BUT MAY LEAD TO

YOUR BEING LIABLE FOR ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY

AFTER YOU ARE THOROUGHLY FAMILIAR WITH ALL

OF THE FOLLOWING SAFETY CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,INCREASES

THE RISK OF POTENTIAL HAZARDS AND INJURY TO

THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINESHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS

BEEN CORRCTED. A CHECK SHOULD BE MADE OF

THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1.BE SURE THAT ALL COMPONENTS ARE POSI-

TIONED IN SUCH A WAY AS TO AVOID POSSIBILITY

OF ADJACENT COMPONENT SHORTS.THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH

ARE TRANSPORTED TO AND FROM THE REPAIR

SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS INSULATORS, BARRIERS,

COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVEBEEN REINSTALLED PER ORIGINAL DESIGN. BE

SURE THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER

POSSIBLE COLD SOLDER JOINTS, SOLDER

SPLASHES OR SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE

OR DETERIORATION TO PARTS AND COMPONENTS.

FOR FRAYED LEADS, DAMAGED INSULATION

(INCLUDING A.C. CORD). AND REPLACE IF NECES-

5. NO LEAD OR COMPONENT SHOULD TOUCH A

RECIVING TUBE OR A RESISTOR RATED AT 1 WATT

OR MORE. LEAD TENSION AROUND PROTRUNING

METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC.

MUST BE REPLACED WITH EXACT FACTORY TYPES,

DO NOT USE REPLACEMENT COMPONENTS OTHER

THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

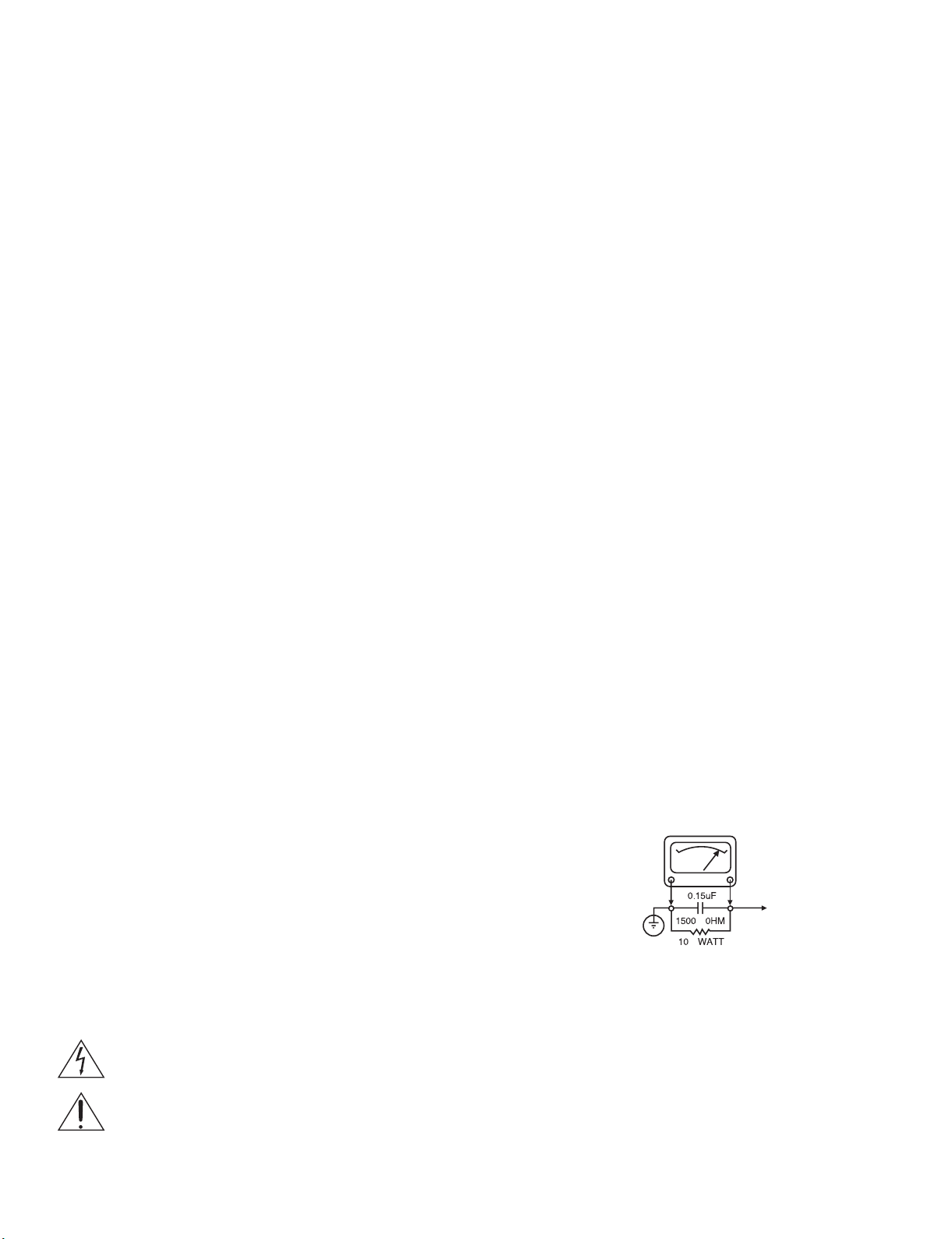

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C. LEAKAGE TEST ON ALL EXPOSED

METALLIC PARTS OF THE CABINET, (THE CHANNEL

SELECTOR KNOB, ANTENNA TERMINALS. HANDLE

AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER; CONNECT A

1500 OHM 10 WATT RESISTOR, PARALLELED BY A

.15 MFD. 150.V A.C TYPE CAPACITOR BETWEEN A

KNOWN GOOD EARTH GROUND (WATER PIPE,

CONDUIT,ETC.) AND THE EXPOSED METALLIC

PARTS, ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500OHM

RESISTOR AND .15 MFD CAPACITOR. REVERSE THE

A.C. PLUG AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75 VOLTS

R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C

ANY VALUE EXCEEDING THIS LIMIT CONSTITUTES A

POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED

TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE”

THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE LITERATURE.

Page 5

SERVICING PRECAUTIONS

1-3

CAUTION

this service data and its supplements and addends, read and

follow the SAFETY PRECAUTIONS. NOTE: if unforeseen

circumstances create conflict between the following servicing

precautions and any of the safety precautions in this publication,

always follow the safety precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the Stereo amplifier AC power cord from the

AC power source before:

(1) Removing or reinstalling any component, circuit board,

(2) Disconnecting or reconnecting any internal electrical

(3) Connecting a test substitute in parallel with an electrolytic

Caution: A wrong part substitute or incorrect polarity

2. Do not spray chemicals on or near this Stereo amplifier or

any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cot tont ipp e d swa b, or com par able s oft a ppl i cat or.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this Stereo amplifier and/or any

of its electrical assemblies unless all solid-state device heat

sinks are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground lead

last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter (500V) to the

blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1 M-ohm.

Note 1: Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

: Before servicing the Stereo amplifier covered by

module, or any other assembly.

plug or other electrical connection.

capacitor.

installation of electrolytic capacitors may result in an

explosion hazard.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical Es devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handing any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reason prior to applying power to

the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8.Minimize bodily motions when handing unpackaged

replacement ES devices. (Normally harmless motion such as

the brushing together of your clothes fabric or the lifting of

your foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

Page 6

ALIGNMENT PROCEDURE

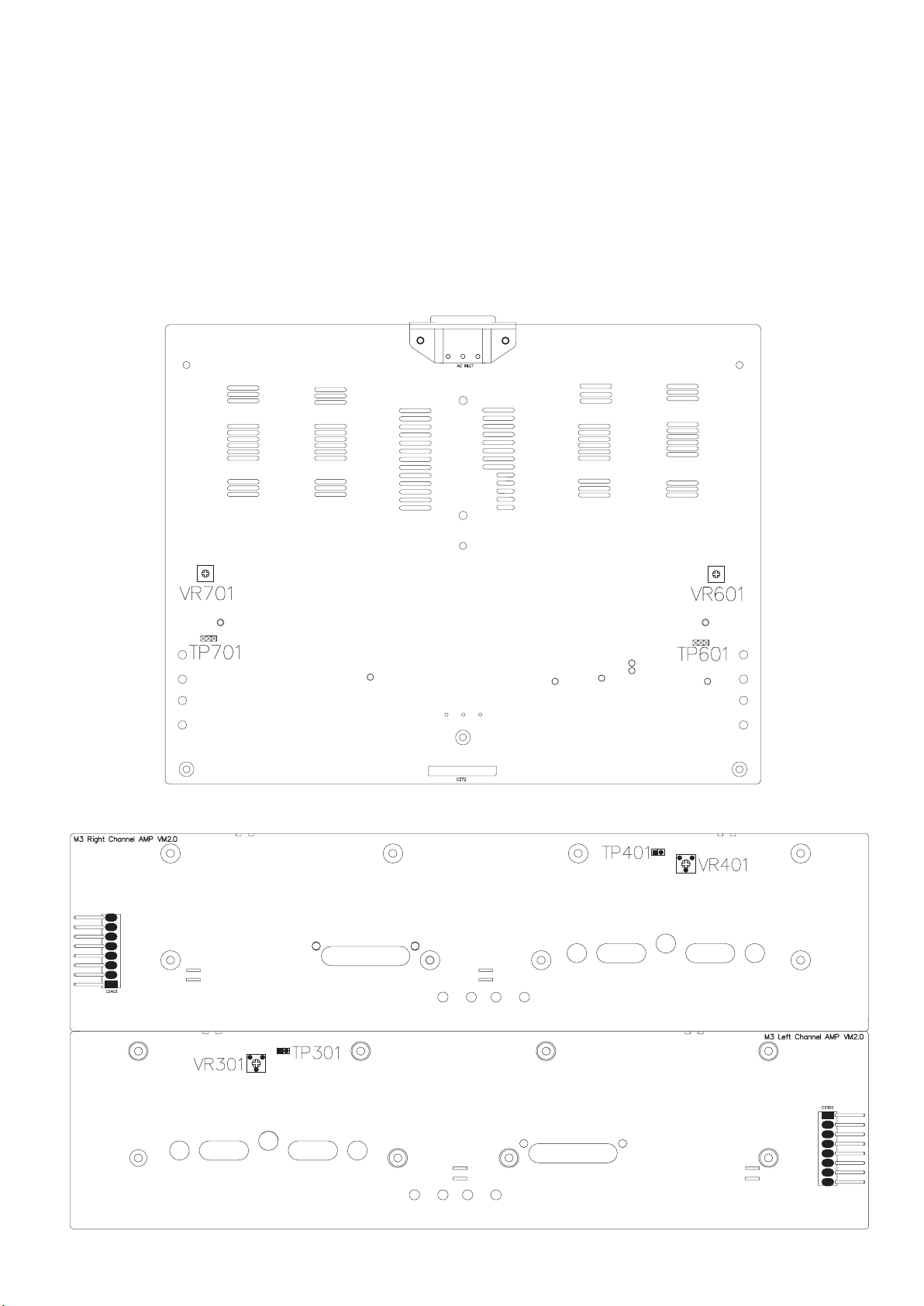

A. POWER DRIVEN VOLTAGE(PSU BOARD)

Connect a DC Millivoltmeter to TP601/TP701 1 and 2 pin, then adjust VR601/VR701(6.8kohms)

for 0V±0.1V.

B. IDLING CURRENT(AMP BOARD)

1.Connect a DC Millivoltmeter betweenTP301 2 pins, then adjust VR301 (200ohms) for 7-8mV

reading on meter.

2.Connect a DC Millivoltmeter between TP401 2 pins, then adjust VR401 (200ohms) for 7-8mV

reading on meter.

3. Watch for 10minutes, to make sure it is arround 7mV

PSU BOARD

AMP BOARD(L/R)

321

123

1-4

Page 7

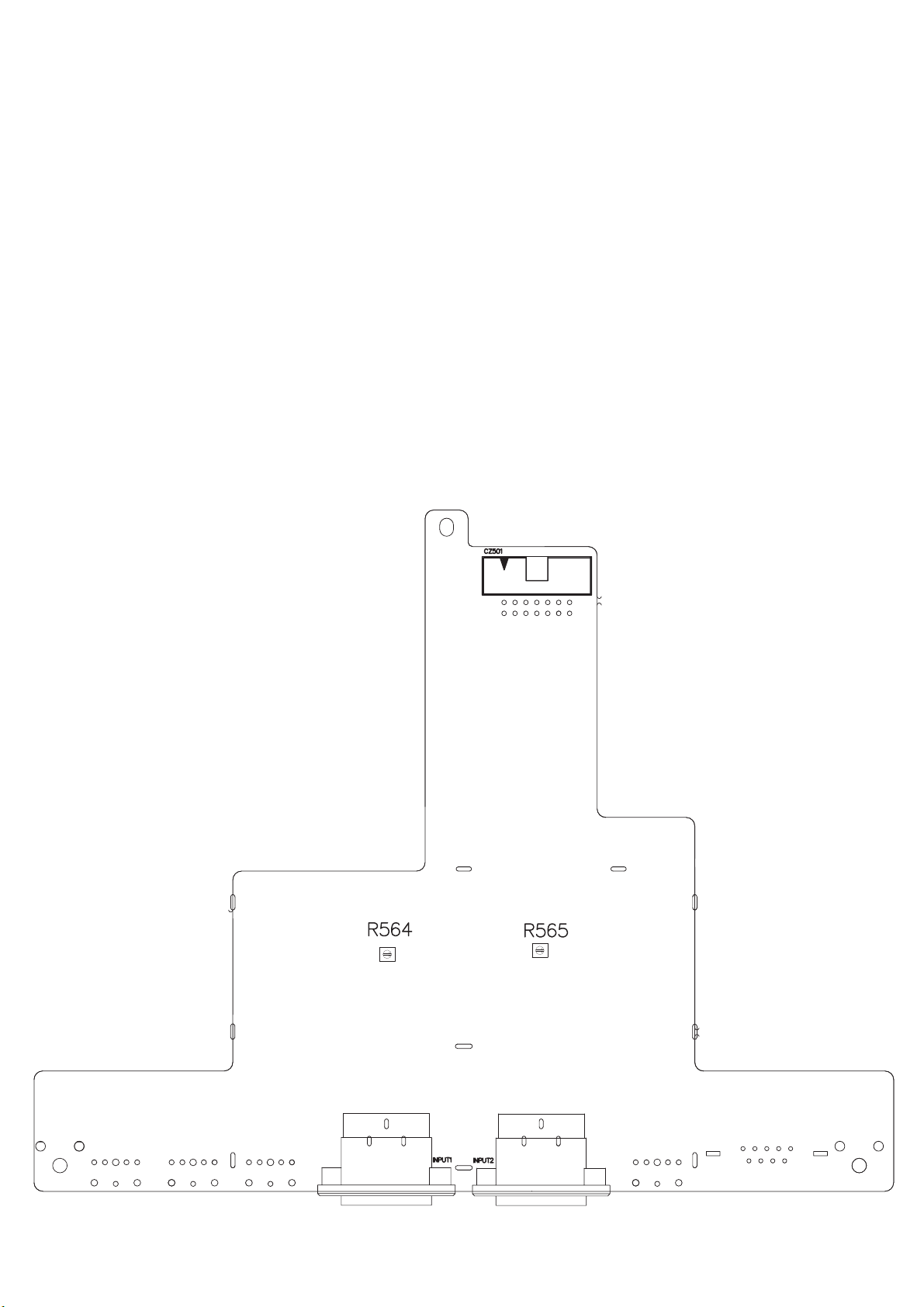

C. BALANCE INPUTS CMRR

1.Volum set 0dB, Input 2V/10KHZ common mode sinwave signal at L channel Balance input,Connect a AC

Millivoltmeter to preout1L then adjust R565 for lowest output level.

2. Volum set 0dB,Input 2V/10KHZ common mode sinwave signal at R channel Balance input,Connect a AC

Millivoltmeter to preout1R then adjust R564 for lowest output level.

1-5

Page 8

SPECIFICATIONS

1-6

NAD M3 INTEGRATE AMPLIFIER

Note: Specifications are measured in accordance with EIA

Standard RS-490 (IHF A-202) for amplifiers

Power Amplifier Section

Continuous output power into 4/8 ohms

(Minimum RMS power per channel, both channels

driven, With no more than the rated distortion)

Rated distortion (THD)(20Hz –20kHz) ≤0.004%

Channel Separation ≥100dB

(MAIN IN, 60W Out at 8Ω,1kΩ shorted, 1kHz)

Clipping power, 1kHz 220W

(Maximum continuous power per channel)

Dynamic Headroom at 8 ohms 4.2dB

Dynamic power

(Maximum short-term power per channel )

Damping factor ≥150

8ohms

4ohms

2ohms

180W (17dBw)

≥280W

≥480W

≥785W

Signal to noise ratio(refer 1W A-weighted) ≥≥100dB

Slew rate ≥≥20V/μsec

T.H.D and SMPTE I.M. ≤0.01%

(Distortion from 250mW to rated output)

IHF I.M. (CCIF IM) and T.I.M distortion ≤0.005%

(From 250mW to rated output))

Input impedance 20kΩ//680pF

Input sensitivity rate power into 8ohms) roF ( 1.38V

Power amp gain 29dB

Preamplifier Section

Input Impedance single-ended input 150k Ω //500pF

balanced input

120kΩ //100pF

Page 9

Signal-to-Noise ratio 110dB ref 500mV

1-7

(A-weighted, line In, Pre-Out)

Rated distortion (THD)(20Hz –21kHz) ≤0.005%

Channel Separation

(1kHz 2V Line/balanced IN, 2V Pre-Out)

Input Sensitivity 320mV for 2V out

Input Overload Line input

Balanced input

Frequency response(5Hz-70KHz)

THD (SUB OUT) ≤0.01%

(2V CD in, 2V SUB out; 50Hz, 80kHz LPF)

THD (ZONE 2 OUT)

(2V CD IN, 1kHz, 80kHz LPF) ≤0.01%

≥110dB

≥10V

≥9 V

< +/-0.3dB

Outputs

Preamp output impedance 100 Ω

Zone2 output impedance 600 Ω

Controls

Treble ±5dB at 10kHz

Bass ±5dB at 100Hz

Pre-in ,Power AMP out,input 2V

Signal-to-Noise ratio, A-weighted 107dB ref 1 W out

(500mV CD in, SPK out, 8Ω, A weighted)

Rated distortion (THD)(20Hz –20kHz) ≤0.008%

Input sensitivity 450mV

(CD in, SPK out, at rated power, volume max.)

Channel Separation ≥100dB

(CD in, 20W out at 8Ω, 1kΩ shorted, 1kHz)

Frequency response Bd3.0-/+

PHYSICAL SPECIFICATIONS

Dimensions(W x H x D)

Net 17.2x5.3x15.2”(435x135x386mm)

Gross 17.2x5.8x17.2”(435x147x435mm)

Net Weight 51.8lbs(23.5kg)

Shipping Weight 68.3lbs(31.0kg)

Page 10

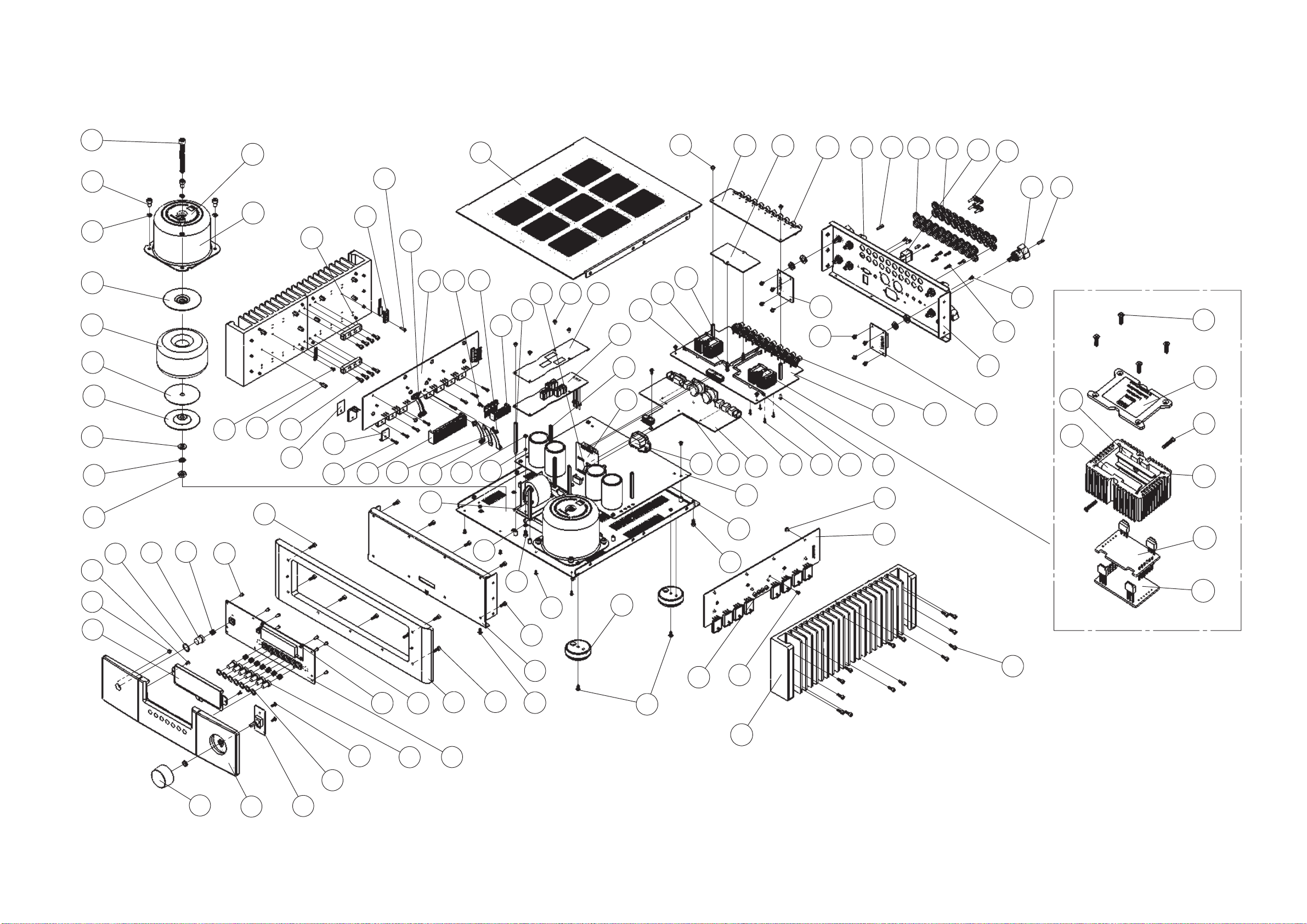

2-1

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS. ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. 2 -2

1. Cabinet and main frame section .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . . .. . ... . .. . . .. . 2 -2

2. Packing accessory section . .. ........... . . . . . . . .. ........... . . . . . . . ........... . . . . . . . ........... . . . . . . . 2-3

3. Exploded view parts list... . . . . . . . .. ........... . . . . . . . .. ........... . . . . . . . ........... . . . . . . . ........... . . 2- 4 , 5

Page 11

EXPLODED VIEWS

1. Cabinet and main frame section

S010

S009

S008

C015

C016

C015

C017

S007

S006

S004

C013

C014

A005

S002

A004

C018

A003

S014

A006

A002

S011

C020

C019

C004

C022

S001

S018

T001

S013

A001

S017

C026

C024

S016

C023

C007

C025

C008

PR03

PR02

S016

PR01

C029

C028

C012

C009

C011

C027

PR06

R003

S013

S026

R006

PR04

R009

C010

S025

R007

PR05

R008

R010

R001

R002

R011

S001

R005

S015

R004

S023

PR10

PR12

S024

PR11

PR09

S005

S001

F006

F004

F013

F005

F007

F001

S001

F002

S002

F003

F008

S001

S021

S025

F009

C006

F011

F010

S020

S002

S003

S003

F012

S019

S004

C021

S019

S012

C001

S004

S004

C005

C002

S022

C003

PR08

PR07

S002

2-2

Page 12

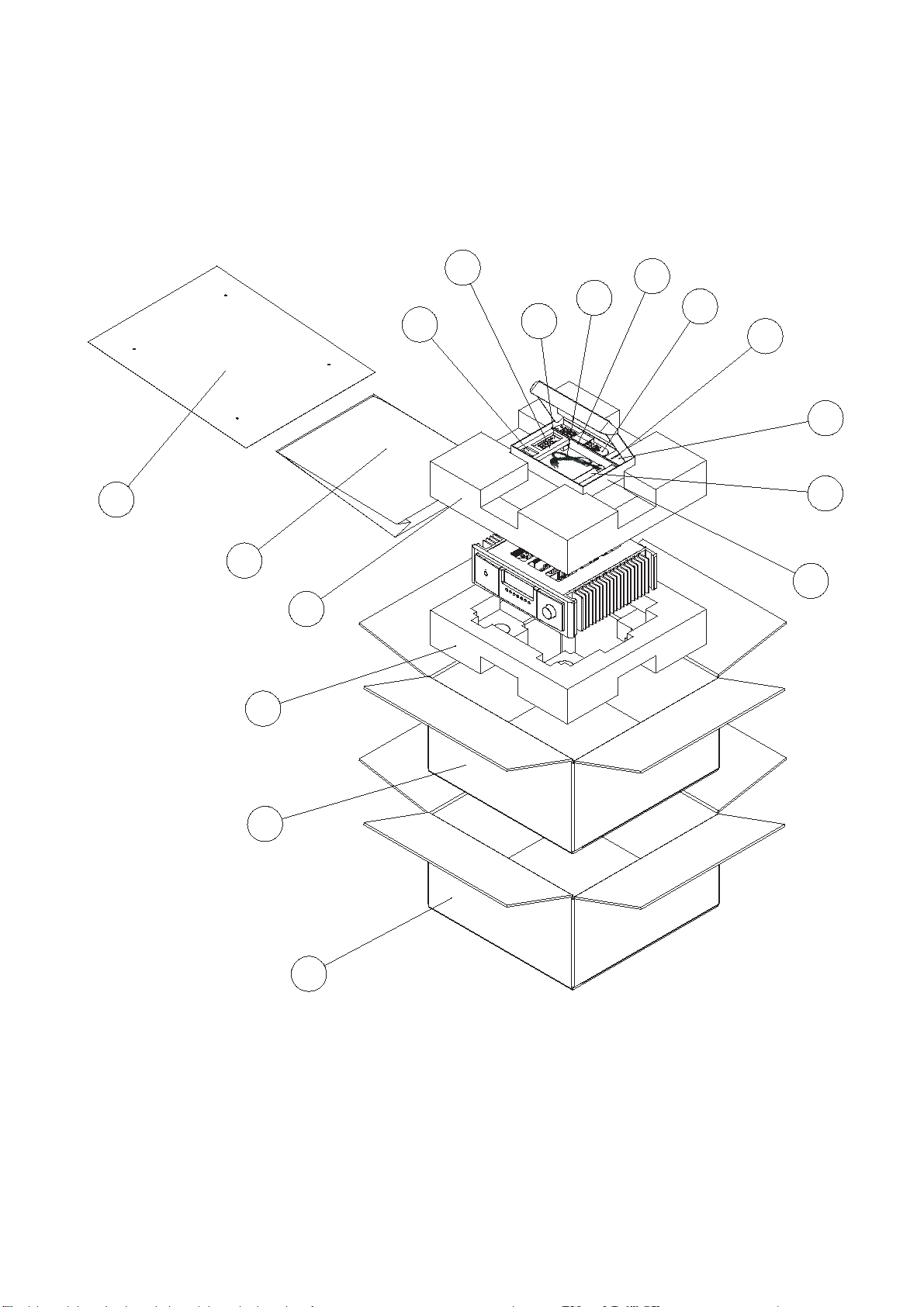

2. Packing accessory section

P006

P005

P003

P004

P016

P015

P014

P013

P012

P011

P010

P009

P008

P007

P002

P001

2-3

Page 13

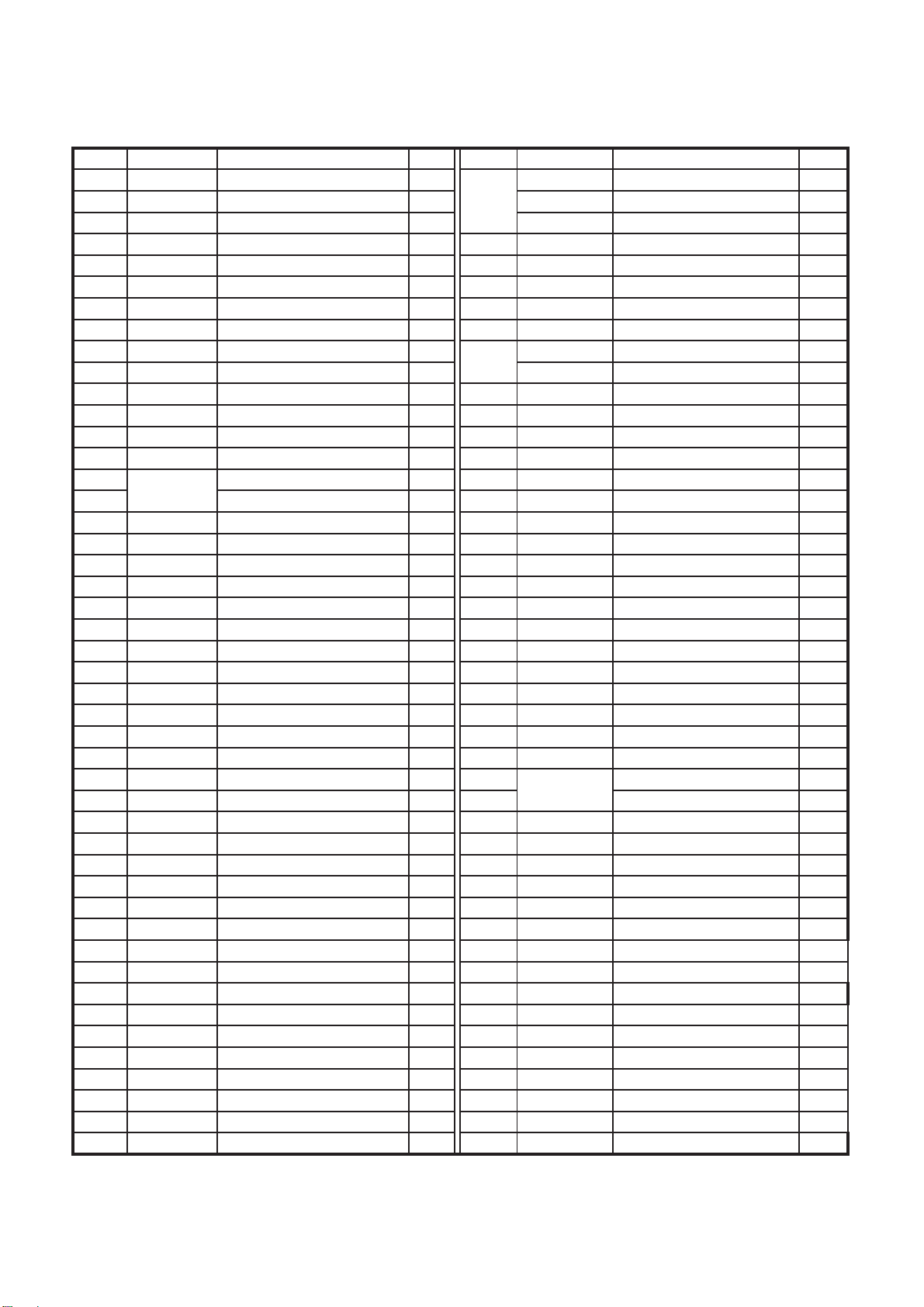

3. Exploded view parts list

REF.NO PART NO. DESCRIPTION Qty. REF.NO PART NO. DESCRIPTION Qty.

C001

C002

C003

C004

C005

C006

C007

C008

C009

C010

C011 01-50312-00

C012 01-50311-00

C013 94-048001-2

C014

C015

C016

C017

C018

C019

C020

C021

C022

C023

C024

C025

C026

C027

C028

C029

01-50306-02 RAMP Board Assy 1 67-048024-0 Rear Panel(CCC) 1

01-50306-01 LAMP Board Assy 1

01-50305-00 Power Board Assy 1

01-50307-02 StandbyBoard(Buttom) Assy 1

01-50307-21 StandbyBoard(Top) Assy 1

01-50303-00 Connect Board Assy 1

01-50301-00 Balance Board Assy 1 77-048010-0

01-50309-00 PREM Board Assy 1 77-048011-0

Tone Board Assy 1

L Input Board Assy 1

Transformer label 2

68-048002-0 Shielding Box 2

Transformer rubber pad 4

Transformer 2

F001

F002

F003

F004

F005

F006

F007

F008

F009

F010

F011

F012

F013

18-53231-01

68-048001-1 HS Fixl Bar 4

75-048022-0 Bus Bar Washer 4

85-008001-1 Spacer Support 1

69-048013-0 Copper Spacer 2

69-048031-0 Copper Spacer-Screw 4

66-011011-0 Connectible Bracket 2

66-048004-0 Blance pcb Shielding 1

71-048010-0 Vol. Knob Assy 1

70-048011-0 M3 Fascia 2 1

01-50302-00 Encoder Board Assy 1

76-048010-0 Window lens 1

70-048013-0 Power Button 1

92-048001-0 Spring for Button 8

87-048002-0 Input Button Pad 7

70-048012-1 Input Button 7

01-50304-00 FPP Board Assy 1

70-048010-1 M3 Fascia 1 1

87-048003-0 Power Button Pad 1

R001

R002

R003

R004

R005

R006

R007

R008

R009

R010

R011

A01

2csiD lateM0-800100-66

4A raB suB1-010840-96

4B raB suB1-110840-96

4yssA tooF0-010840-38

1revoC CP0-210840-67

1telnI CA00-20170-71

1sneL DEL1-100800-67

1aicsafbuS1-300840-76

1revoC poT0-100840-76100T

A02

A03

A04

A05

A06

PR01

PR02

PR03

PR04

PR05

PR06

PR07

PR08

PR09

PR10

PR11

PR12

S001

S002

S003

S004

S005

S006

S007

S008

S009

S010

01-50308-02 SPK Board(R) 1

01-50308-01 SPK Board (L) 1

77-048001-0 Bindingpost Plug Red(C) 4

17-03001-03 HS Bindingpost Red Assy 4

17-03001-04 HS Bindingpost white Assy 4

Double step washer Red 10

Double step washer White 10

69-048016-0 Counternut 20

77-048002-0 Bindingpost Plug White(C) 4

11-01101-03 Power Switch 1

30-60480-00 RCA Shorting Plug 2

70-048005-0 Small Heatsink B 2

70-048004-0 Small Heatsink 2

66-005009-0 Tr. Clamping

78-005005-0 Insulated Cashion

69-048024-0 Copper Spacer-Screw 16

66-018005-0 Tem. SW. Clamper 2

69-048032-0 Copper Spacer 2

85-048001-0 Pcb Spacer 2

69-048027-0 PRE-BUSBAR L 1

69-048028-0 PRE-BUSBAR R 1

17-01001-16

17-01001-15

16-53013-00

70-048002-0 Module Base 2

70-048003-0 Module Cover 2

66-048001-0 Tr. Bracket 4

78-048004-0 Insulated Cashion 8

61-023208-0 Screws, BTB3×8 35

61-224512-1 Hex Screws 4×12 51

61-224508-1 Hex Screws 4×8 10

61-023206-0 Screws, BTB3×6 40

62-010802-0 Nut M8 2

63-020820-1

63-010816-0 Washers φ8 2

63-020616-0

61-226510-0 Hex Screws 6×10 8

64-208070-0 Bolts M8×70 2

HS RCA Red Assy 10

HS RCA White Assy 10

Pre. Module pcb Down 2

Pre. Module pcb Up 2

Spring Washers φ8

Spring Washers φ6

lenaP raeR1-400840-761sissahC2-200840-76 (C) 1

lenaP raeR2-410840-764knistaeH0-100840-07 (AH) 1

16

16

2

8

2-4

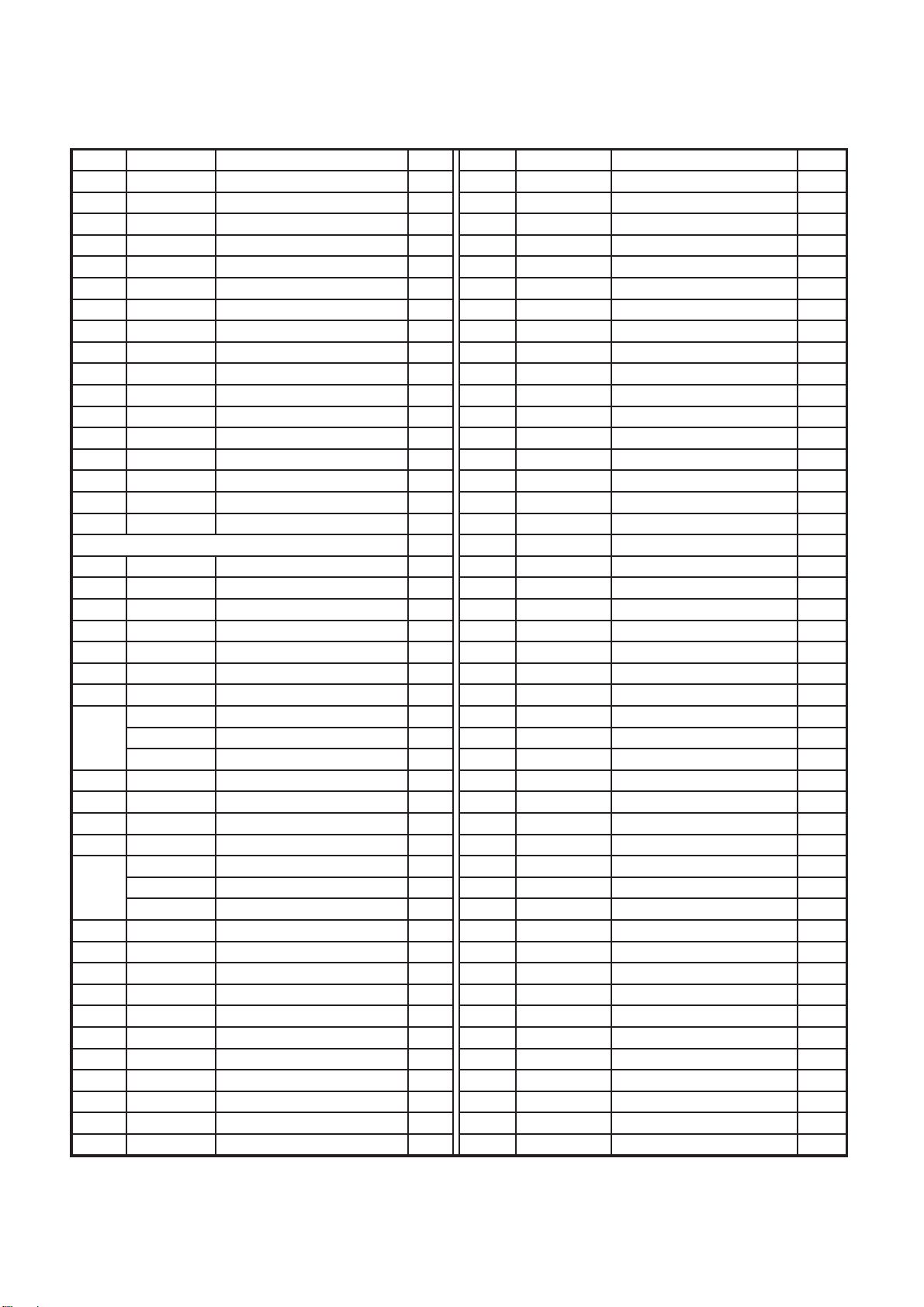

Page 14

REF.NO PART NO. DESCRIPTION Qty. REF.NO PART NO. DESCRIPTION Qty.

S011

S012 62-050302-0 PEM NUT-PCB M3×0.5

S013

S014

S015

S016

S017

S018

S019

S020

S021

S022

S023

S024

S025

S026

P001

P002

P003

P004

P005

P006

P007

P008

P009

P010

P011

P012

P013

P014

P015

P016

61-023212-0 Screws, BTB3×12 2

16

61-223506-1 Hex Screws w/Tooth washer 24

61-223514-0 Hex Screws 3×14 16

61-023106-0 Screws, STB3×6 4

61-373506-0 Machine Screws M3×6 14

63-010408-0 Spring Washers φ4 2

62-010402-0 Nut M4 2

61-024108-0 Screws, STB4×8 4

63-020411-0 Washers φ4 2

62-010302-1 Nut M3 6

61-023506-1 Screws, MB3×6 16

61-062206-1 Screws, BTF2×6 8

61-062108-1 Screws, STF2×8 4

61-023508-0 Screws, MB3×8 10

61-022206-0 Screws, BTB2×6 8

Packing List

88-048001-0 Shipping Box 1

1xoB tfiG0-200840-88

89-048001-0 Polyfoam-Bottom 1

89-048002-0 Polyfoam-Cap 1

87-048004-0 Non-woven-cloth Bag 1

1gabyloP0-100500-09

88-043003-0 Accessories Box 1

30-45030-11 Instruction Nanual 1

30-45030-02 Instruction Nanual 1

30-45030-03 Instruction Nanual CCC 1

89-048003-0 Little Polyfoam A 1

30-28601-00 Batteries CR2025 1

30-10300-00 Remote Control 1

1teehS xoB0-400340-88

1C droC CA00-05201-51

15-10125-00 AC Cord AH

15-10250-03 AC Cord CCC 1

30-17200-01 Remote Control ZR3 1

89-048004-0 Little Polyfoam B 1

30-22100-00 Batteries AA 2

2-5

Page 15

SECTION 3

ELECTRICAL CONTENTS

ELECTRICALTROUBLESHOOTING GUIDE

1. Power check flow

2. Preamp operation flow

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 11MHz CLOCK

2. AT89C51 reset signal

3. Volume control DATA and CLOCK

4. REC(ZONE) select DATA and CLOCK

5. Input select DATA and CLOCK

BLOCK DIAGRAMS

1. POWER DISTRIBUTE DIAGRAM

2. PREAMP SIGNAL PATH

3. SYSTEM CONTROL PATH

CIRCUIT DIAGRAMS

1. POWER AMPLIFIER BOARD Circuit DIAGRAM

2. PREAMP BOARD Circuit DIAGRAM

3. STANDBY AND SPEAKER BOARD Circuit DIAGRAM

4. ENCODER AND CONNECT BOARD Circuit DIAGRAM

5. FRONT PANEL BOARD Circuit DIAGRAM

6. BALANCE INPUT BOARD Circuit DIAGRAM

7. POWER BOARD Circuit DIAGRAM

PRINTED CIRCUIT DIAGRAMS

1. Preamp Main board(PREM)

2. Preamp LCH input board(PREL)

3. Preamp tone control board(PRET)

4. Power supply board(PSU)

5. Balance amplifier board(BAL)

6. Connect board(CON)

7. Encoder board(ENC)

8. Speaker board(SPK)

9. Front pannel board(FPP)

10. Standby board Bottom(STBB)

11. Standby board top(STBT)

3-2

3-2,3

3-4,5

3-6

3-6

3-6

3-7

3-7

3-8

3-9

3-9

3-10

3-11

3-12

3-12

3-13

3-14

3-15

3-16

3-17

3-18

3-19

3-19

3-20

3-20

3-21

3-22

3-23

3-23

3-23

3-24

3-25

3-26

3-1

Page 16

ELECTRICAL TROUBLESHOOTING GUIDE

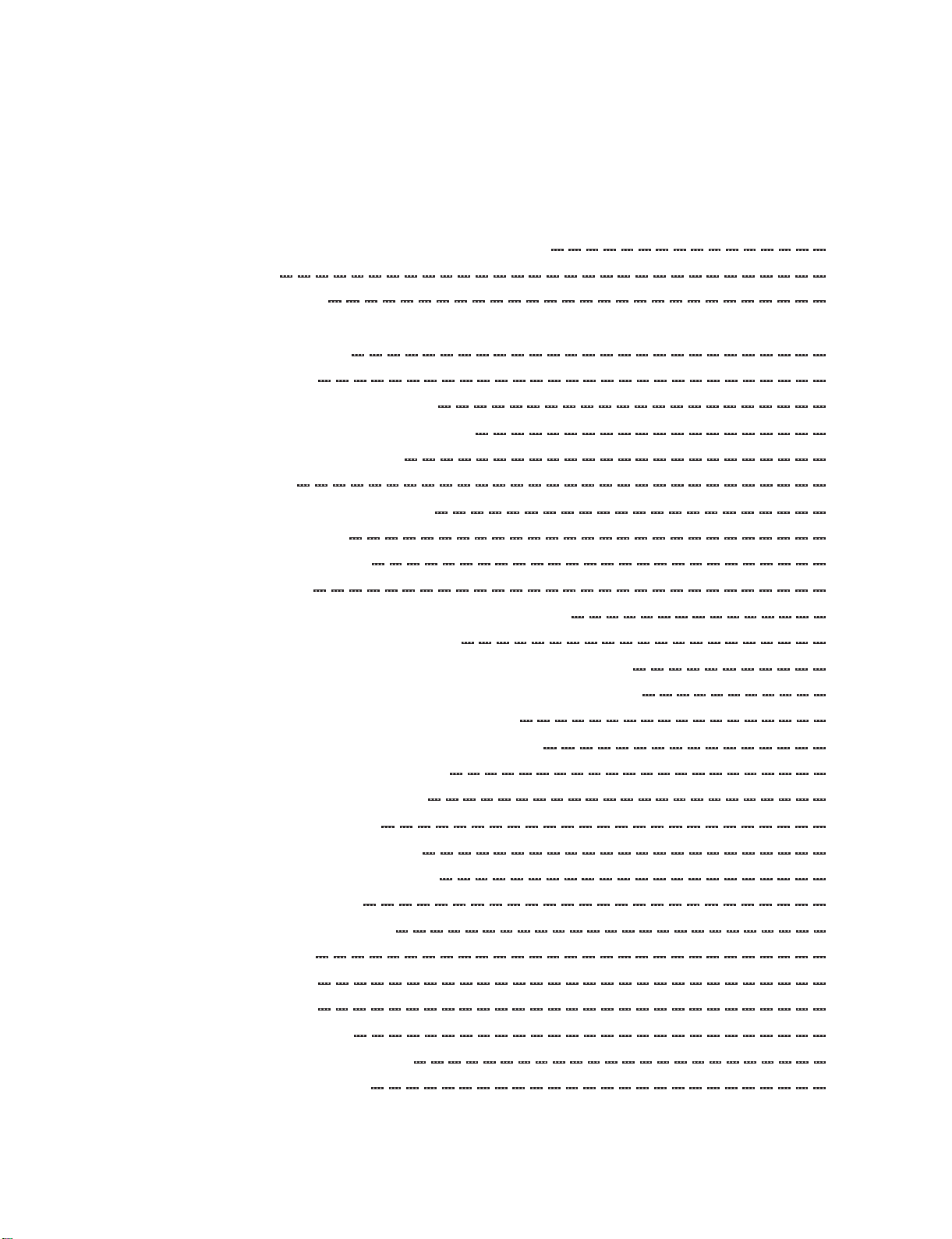

1.Power Check Flow

Power switch on

Amber LED ON?

NO

5V is Right ?

NO

Check S1 and its cable

Check F901

Check the standby Transformer

Check IC1 on the standby board

YES

Press the standby button

Hear the relay’s click?

YES

NO

YES

Check the MCU on the keyboard

Check U84 and Q82

Check the D81

Check the MCU on the keyboard

Check Q91 Q92 and OP91

Check if the main transformers

has been plugged in

+/-70V

un-regulated power supply

is correct?

YES

+/-20V

power supply is correct?

YES

+/-18V

power supply is correct?

NO

NO

NO

Check F902 and F903

Check the main transformer

Check B603 B604 B703 B704

Check D602 D603 D702 D703

Check PSU PCB

Check R648 R649 R748 R749

Check B605 B705

Check IC603 IC604 IC703 IC704

Check the PCB track

Check the sockets and plugs

Check 1Q21 1Q22 2Q21 2Q22

A

YES

3-2

Page 17

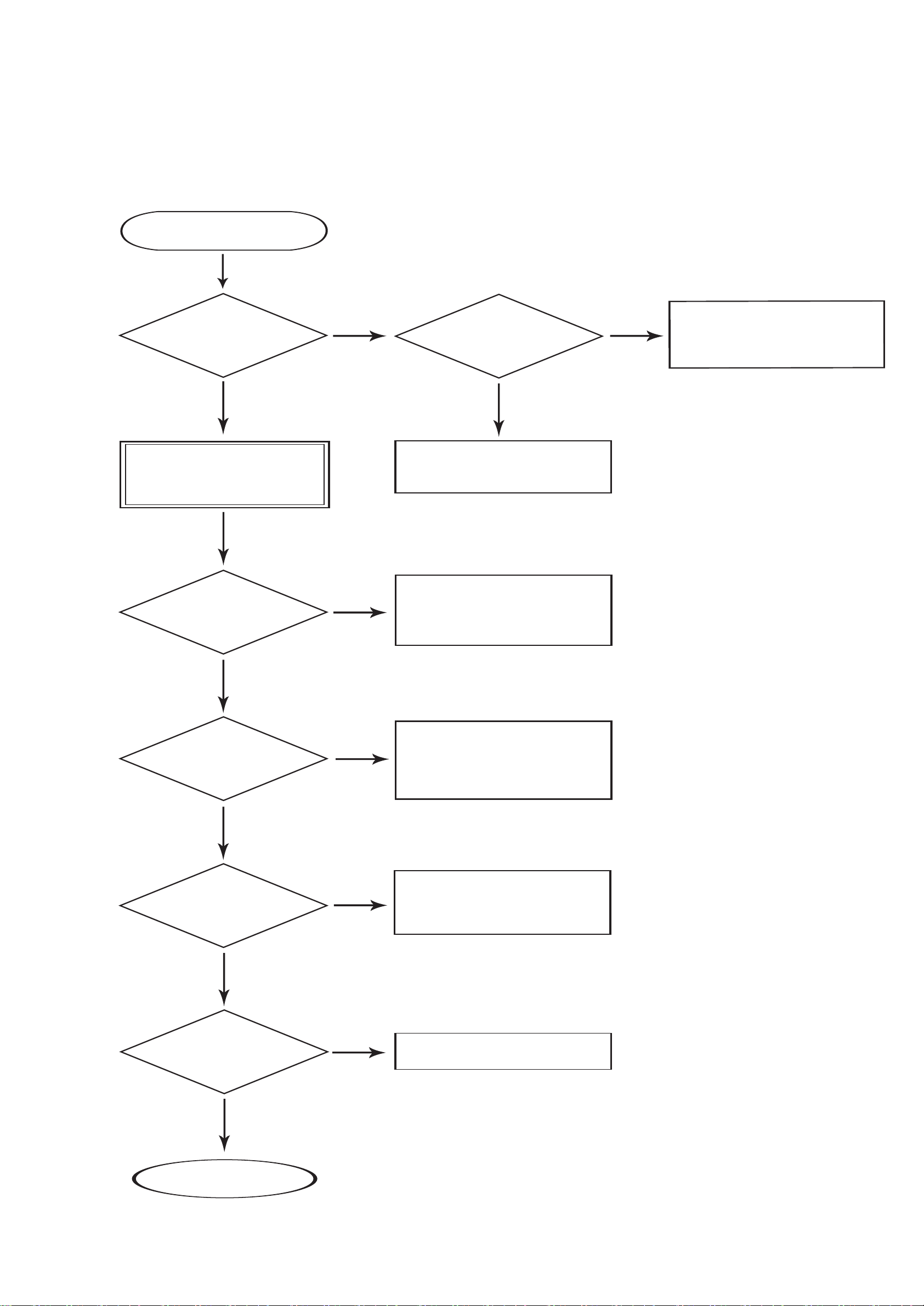

A

+72V

power supply is correct?

YES

-72V

power supply is correct?

YES

12V on the

preamp relayis correct?

NO

NO

NO

Check R646 R647 R746 R747 R622

Check B606 B706

Check Q609 Q610 Q611

Check the PCB track

Check R623

Check Q612 Q613

Check Q990 Q991

Check D990 D991

YES

THE END

3-3

Page 18

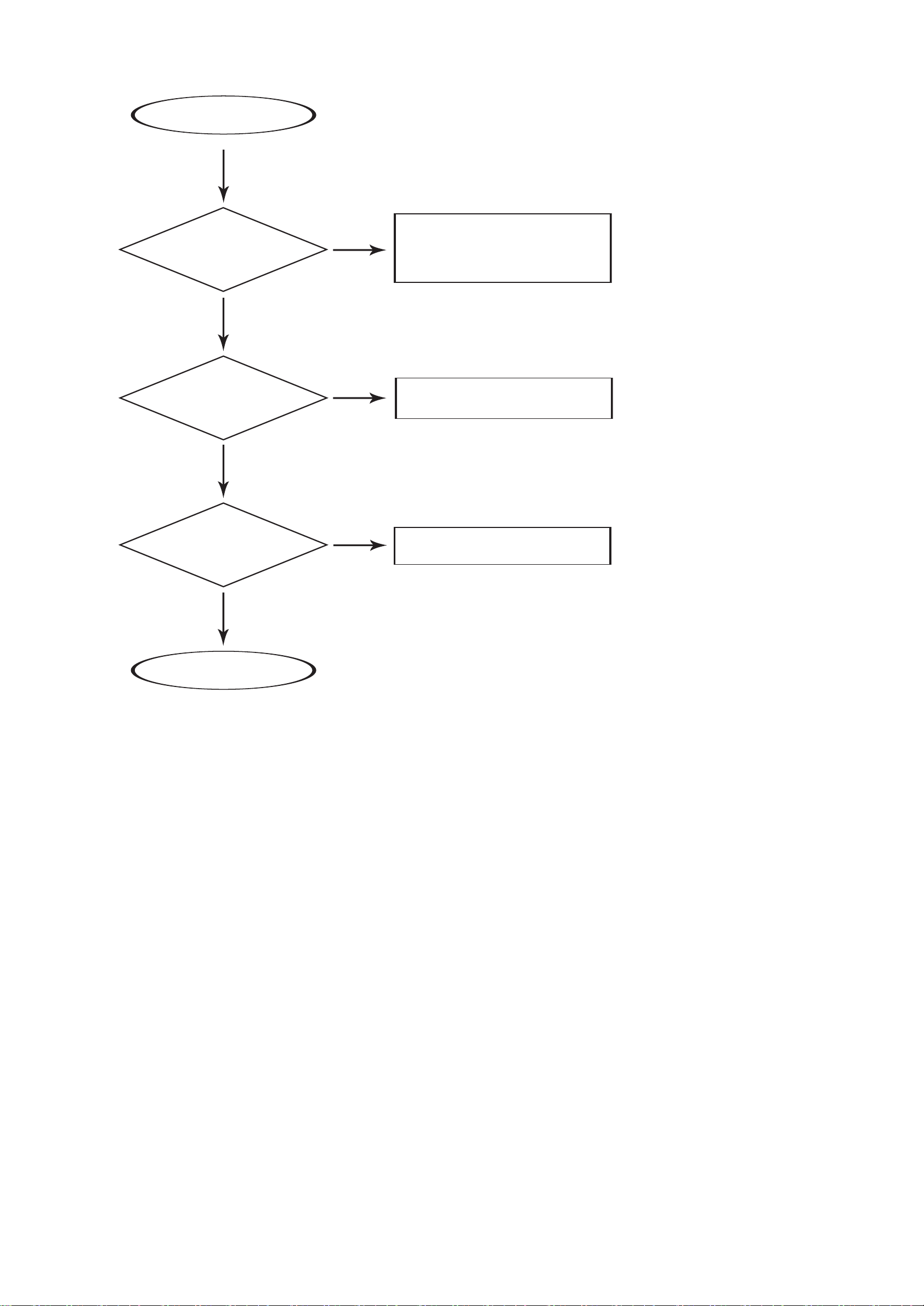

2.Preamp operation flow

Power on

Amber LED change to

blue?

YES

Wate for 10 second

Hear the relay’s click?

NO

NO

Check FPP board

Check 24V relay suply

Check U113,U108,U213,U208

Check HCLK,HDATA,FUNC signal

YES

Press listen,mode,biamp key

to change input and out put

mode

Relay respond properly?

YES

NO

Input 2V RMS 1K sinewave,turn

volume to 0dB,measure

preoutput level and THD

Level=2V±0.1V ?

YES

B

NO

THD>0.01%?

YES

Check U101,U201,U106,U206

NO

Check U105,U205,U104,U107,U204,U207

Check VOL_ CLK,STB,DATA(L/R) signal

Check VOLA signal and 1Q28

Check Q103,Q203,Q101,Q102,Q201,Q202

3-4

Page 19

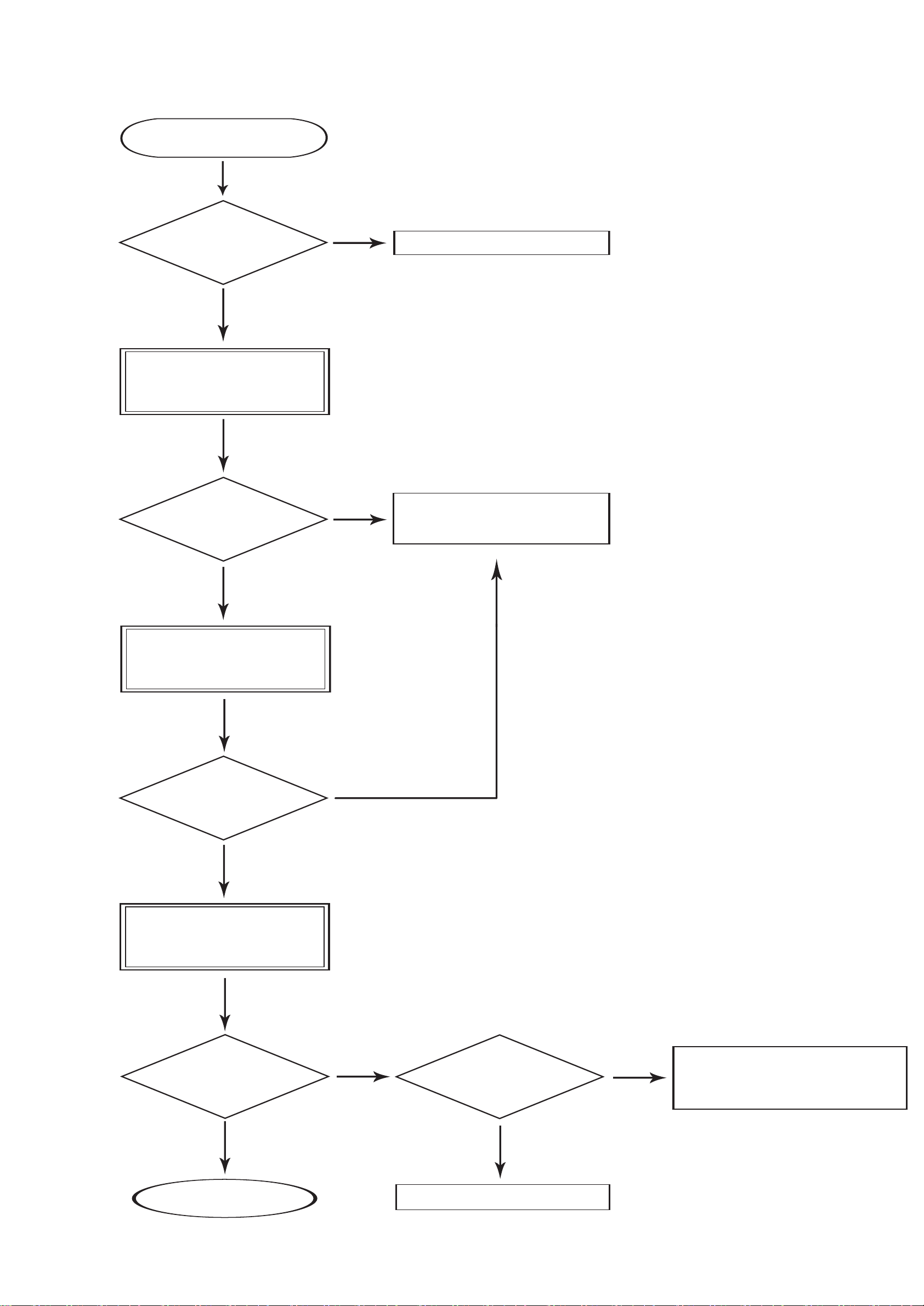

B

Press Tone Key to change

tone setting,measure preout

response

Response change properly?

YES

Press Z-2/record key to current

input channel then measure

output level and THD

Level=2V±0.1V

THD<0.03%?

NO

NO

Check U112,±17V at tone board

Check TONE_STB,OPSEL_DATA

OPSEL_CLK signal

Check U109 U209 U111 U211

Check OPSEL_STB signal

YES

THE END

3-5

Page 20

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 11MHz CLOCK

FIG 1-1

2. AT89C51 reset is high active.

FIG 1-2

3-6

Page 21

4.REC(ZONE) select DATA and CLOCK

3-7

Page 22

5.Input select DATA and CLOCK

3-8

Page 23

BLOCK DIAGRAMS

1. POWER DISTRIBUTE DIAGRAM

L CHANNEL

MAIN

TRANSFORMER

±20V RECTIFY

B605

ON PSU

±72V RECTIFY

B606

ON PSU

HIGH CURRENT

POWER SUPPLY

RECTIFY

B603 B604

ON PSU

L CHANNEL

INPUT RELAYS

ON PREAMP

L CHANNEL

OUTPUT RELAYS

ON L AMP

±20V REGULATOR

B606

ON PSU

±72V REGULATOR

B606

ON PSU

ISC CIRCUIT

D602 D603

ON PSU

BALANCE AMP

ON BAL

PRE AMP

ON PRE AMP

L CHANNEL

AMPLIFIER

ON L AMP

AC INLET EMI FILTER

STANDBY RELAY

POWER SWITCH

FUSE F902

AH: 5A 250V

C: 3.15A 350V

FUSE F901

100mA 250V

FUSE F903

AH: 5A 250V

C: 3.15A 350V

R CHANNEL

MAIN

TRANSFORMER

R-CORE

STANDBY

TRANSFORMER

HIGH CURRENT

POWER SUPPLY

RECTIFY

B603 B604

ON PSU

±72V RECTIFY

B606

ON PSU

±20V RECTIFY

B605

ON PSU

5V REGULATOR

B901 IC1

12V RECTIFY

B902

ISC CIRCUIT

D602 D603

ON PSU

±72V REGULATOR

B606

ON PSU

±20V REGULATOR

B606

ON PSU

L CHANNEL

INPUT RELAYS

ON PREAMP

LOGIC CIRCUIT

ON PREAMP

MCU

LOGIC CIRCUIT

ON FPP

12V TRIGGER

ON BAL

STANDBY

RELAY

ON PSU

L CHANNEL

AMPLIFIER

ON L AMP

BALANCE AMP

ON BAL

PRE AMP

ON PRE AMP

3-9

L CHANNEL

OUTPUT RELAYS

ON L AMP

Page 24

2. PREAMP SIGNAL PATH

LEFT CHANNEL

DISC

CD

TUNER

INPUT4

INPUT5

INPUT6

BALANCE

DISC

CD

TUNER

INPUT4

INPUT5

INPUT6

BALANCE

BALANCE AMP

BALANCE AMP

INPUT SELECTOR

INPUT SELECTOR

STEREO/MONO

SWITCH

0/6.5dB SELECTABLE GAIN

AMP STAGE

0/6.5dB SELECTABLE GAIN

AMP STAGE

54dB ATTENUATOR

2dB/STEP

54dB ATTENUATOR

2dB/STEP

5dB TONE CONTROL

1dB/STEP

5dB TONE CONTROL

1dB/STEP

RIGHT CHANNEL

2,2.5,3,3.5dB SELECTABLE GAIN

AMP STAGE

2,2.5,3,3.5dB SELECTABLE GAIN

AMP STAGE

30dB ATTENUATOR

10dB/STEP

30dB ATTENUATOR

10dB/STEP

BIAMP HIGH PASS FILTER

BY PASS, 40, 60, 80, 100Hz

BIAMP HIGH PASS FILTER

BY PASS, 40, 60, 80, 100Hz

PRE OUT1

PRE OUT2

PRE OUT1

PRE OUT2

3-10

Page 25

3. SYSTEM CONTROL PATH

P0.0

P0.1

P0.2

P0.3

P0.4

P0.5

P0.6

P0.7

P1.0

P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

P2.0

P2.1

P2.2

P2.3

P2.4

P2.5

P2.6

P2.7

P3.0

P3.1

P3.2

MCU

AT89C51

P3.3

P3.4

P3.5

P3.6

P3.7

P4.0

P4.1

P4.2

P4.3

P4.4

P4.5

P4.6

P4.7

P5.0

P5.1

P5.2

P5.3

P5.4

P5.5

P5.6

P5.7

VFD

KEYS

U83 MAX3221 (FPP)

Q85 Q86 (FPP) IR IN/OUT SOCKET ( REAR PANEL)

Q89 inverter(FPP) Protect Circuit (High when Protect)

Q91 (PSU) OP91 OPTOISO (PSU) RL91 standby relay (PSU)

U84 U85 7400 (FPP) D81 Tri-color LED (FPP)

U108 U113 U208 U213

CD4094 (PRE)

U110 U210 (PRE)

CD4094

U105 (PRE) TC9274

U205 (PRE) TC9274

U109 U209 (PRE)

TC9274

U109 U209 (PRE)

TC9274

RL301 RL302 RL401 RL402

OUTPUT RELAYS (LAMP/RAMP)

ENCODE

EEPROM

RJ45 RS232 SOCKET (REAR PANEL)

RL101 ... RL112, RL201 ... RL212

For Input Select and Biamp Filter Switch

Q130 Q131 Q230 Q231 for Mute

U104 U107 U204 U207 (PRE) MAX4621

30dB Attenuator, Q101...Q103, Q201...Q203,

6.5 Gain/ 0.5 Gain Switch

3-11

Page 26

CIRCUIT DIAGRAMS

N

N

1.POWER AMPLIFIER BOARD

R33

10

R34

10

GND

AGND

R3A7

17K3

R326

100K

D340

1N4148

R3A2

1K2

Q355

2SA970

R3A4

10K

Q356

2SC2240

3

R3A5 6K35

1

1K

R3A6

2

R328

C308

330P

300

R327

20K

R306

100

AGND

IC303A

TL082D

D316

LED

R307

82

R308

33

L301

100uH

R317

21/1/4W 1%

R320

33

R377

82

D319

LED

D317

1N4148

Q304

2SC2240

C305

33P/250V

Q303

2SC2240

Q306

2SA970

C307

33P/250V

Q307

2SA970

D320

1N4148

D301

18V

D302

18V

D318

1N4148

R318

100

2SC2240

D321

1N4148

Q330

C301

0.1uF

C306

0.1uF

R309

82 FP 1/2W

Q309

2SA1015

Q310

2SA1360

GND

Q311

2SC3423

Q312

2SC1815

R323

82 FP 1/2W

C310

0.1u/80V

AGND

C309

0.1uF

D303

1N4148

D304

1N4148

R324

100K

Q331

2SC3423

R31

1K

R32

1K2

Q332

2SA1360

D306

1N4148

AGND

C314

0.1U

D305

1N4148

Q308

2SC1815

R325

39K

C319

10uF/50V

R350

C303

10uF/50V

C302

1N

Q301

2SA970

AGND

R355

10K/0.6W

R358

10K/0.6W

C304

10uF/50V

R321

39K

180K

R305

27K

R304

100

Q302

2SC2240

R312

100

R313

27K

R314

100

R376

220K

Q305

2SA1015

R310

22K

R311

10K

AGND

R302

22K

AGND

R301

R37

200K

R303

470

100

Q329

2SC2878

AGND

AGND

R315

10K

R316

22K

C315

10uF/50V

+72V

-72V

CZ301

1

2

AGND

CON2

to HS4-M3-B007 PRE VC4.0.SCH J103

D311

1N4148

R36

4.7K

R3A1

1K

IC305

TL431

R3A3

1K

-74V

330/0.5W FP

R344

4K7/3W FP

+74V

R341

IC302

TL431

D308 BAV21

D307BAV21

Q313

2SA1360

Q314

2SC3423

R395

4K7/3W FP

+72V

R334

4K7/3W FP

IC301

TL431

2 3

R332

330/0.5W FP

R331

4R7/FS

R330

3R3/0.5W FP

R338

3R3/0.5W FP

R339

4R7/FS

2 3

R396

4K7/3W FP

-72V

R353

680

R348

15

R337

18

R3B1

R380

2.2

C325

470pF

22

Q322

2SC5200

R381

2.2

R3B5

0.1R 1W 5%

Q323

2SA1943

C328

0.1uF

Q324

2SC5200

0.1R 1W 5%

R352

1M

R382

2.2

R383

2.2

AGND

R3B2

R3B6

AGND

0.1R 1W 5%

Q327

2SA1943

D322

3.6V

D324

3.6V

Q328

2SC5200

0.1R 1W 5%

C329

1uF

R384

2.2

R385

2.2

Q317

Q337

2SC4793

2SC4793

R333

10K

C311

1

100UF/25V

R3881R389

R335

10K

R345

1K2 %1

Q315

KSC2690

R346

1K 1%

VR301

200

1

R342

R390

10K

1

C312

100u/25V

R343

10K C316

Q338

2SA1837

IC303B

TL082D

1

R347

220

1

2SA1015

C326

470pF R351

R391

1

Q318

2SA1837

R329

18

R349

15

R322

1K2 3W 1%

R319

1K2 3W 1%

C327

1uF

Q321

2SA1943

Q316

GND

R3B3

R3B7

0.1R 1W 5%

R386

2.2

Q319

2SA1943

D323

1N4148

D325

1N4148

Q320

2SC5200

R387

2.2

0.1R 1W 5%

R354

1M

R3B4

R3B8

C321

0.1R 1W 5%

4u7/50V

D309

BAV21

GND

R361

1K

R356

0.05/5W

R357

0.05/5W

0.1uF

0.1R 1W 5%

R362

56K

SPGND

+V74

R364

6K8

C320

22N

R359

10/2W FS

C318

0.1uF

GND

C323

10uF/80V

-V74

R363

22K

Q325

C2240

GNDADJ DC

C322

10uF/80V

Q326

2SA970

R365

10K

R371

56K

C317

0.1uF

PRGND

D326

1N4148

C334

2.2uF/50V

R368

2K2

C331

330u/16V

PRGND

GND

R35

200K

L CHANNEL AMP

R370

3K3

R369

C333

47u/50V

56K

8

IC304

7

1

2

2.2uF/50V

R399

3R3/1W FP

ote:

Cxl+Rxl network is between the chassis

and the de-coupling ground with the

minimum loop.

PRGND

D327

12V

C335

L302

1uH

uPC1237HA

4

3

5

C332

0.22u

GND

RL301A

RL302A

SPGND

6

D312

1N4148

C340

22N

THERMAL BREAKER

R375

200

Q350

2SA1015

D315

1N4148

R374

3K3

R373

100K

R392

0

R372

N.I.

R379

10K

PRGND

PRGND

Cxl

0.1uF/50V

RL301B

RL302B

R393

0

Q353

2SC1815

R378

10K

PRGND

+V24R

RT301

T0=80 degree C

-V74 +V74

Rxl

2R2

GND

to HS4-M3-B007 PSU VC4.0.SCH

P601 P602 P603

B301

R366

100K

PRGND

Q352

2SC1815

PROTECT

AC DET

SP A

SP B

PRGND

D314

1N4148

+72V-72V

SPGND

R398

10K

+V24R

PRGND

D313

1N4148

CZ302

1

2

3

4

5

6

7

8

9

10

CON10

CZ303

CON8

Q354

2SA1015

R397

100K

R394

N.I.

1

2

3

4

5

6

7

8

1

1

1

1

to HS4-M3-B007 PSU VC4.0.SCH CZ603to the binding post

P301

PCBNUT

P302

PCBNUT

P303

PCBNUT

P304

PCBNUT

R495

4K7/3W FP

Q408

2SC1815

R425

39K

C419

10uF/50V Q437

100

C402

1N

C403

10uF/50V

Q401

2SA970

AGND

C404

10uF/50V

C415

10uF/50V

39K

+72V

-72V

R405

27K

R450

220K

R404

100

Q402

2SC2240

R412

100

R413

27K

R414

100

R476

220K

Q405

2SA1015

R455

10K/0.6W

R458

10K/0.6W

R410

22K

R411

10K

AGND

R402

22K

AGND

R401

Q429

2SC2878

AGND

R47

200K

R403

470

AGND

R415

10K

R416

22K

CZ401

1

2

AGND

CON2

to HS4-M3-B007 PRE VC4.0.SCH J203

D411

1N4148

R46

4.7K

R406

100

R407

82

AGND

R477

82

L401

100uH

D419

LED

D417

1N4148

D416

LED

Q404

2SC2240

C405

33P/250V

Q403

2SC2240

R408

33

R417

21/1/4W 1%

R420

33

Q406

2SA970

C407

33P/250V

Q407

2SA970

D420

1N4148

IC403A

TL082D

D418

1N4148

R418

100

Q430

2SC2240

D421

1N4148

D401

18V

D402

18V

R409

82 FP 1/2W

Q409

2SA1015

Q410

2SA1360

GND

Q411

2SA3423

Q412

2SC1815

R423

82 FP 1/2WR421

C410

0.1u/80V

C401

0.1uF

C406

0.1uF

C409

0.1uF

2SC3423

R41

1K

R42

1K2

AGND

AGND

D403

1N4148

D404

1N4148

R424

100K

Q431

C414

0.1uF

Q432

2SA1360

D405

1N4148

R426 100K

GND

D406

1N4148

AGND

D440

R4A1

1N4148

1K

R4A2

1K2

Q455

2SA970

R4A7

17K3

R4A4

10K

Q456

2SC2240

3

TL431

IC405

R4A5 6K35

R4A3

1

1K

R427

20K

R428

300

2

C408

330P

1K

-74V

330/0.5W FP

4K7/3W FP

R4A6

R43

10

R44

10

+74V

R444

R441

IC402

TL431

D408 BAV21

D407BAV21

Q413

2SA1837

Q414

2SC4793

R438

3R3/0.5W FP

+72V

R434

4K7/3W FP

3

IC401

TL431

2

R432

330/0.5W FP

R431

4R7/FS

R430

3R3/0.5W FP

R439

4R7/FS

3

2

R496

4K7/3W FP

-72V

R448

R437

15

18

2SC4793

R433

10K

1

C411

100UF/25V

R4881R489

R435

10K

R447

220

R445

1K2 1%

Q415

KSC2690

R446

1K 1%

VR401

200

1

R442

10K

C412

100u/25V

R443

10K

R453

680

1

Q438

2SA1837

IC403B

TL082D

Q418

2SA1837

1

1

2SA1015

C426

470pF R451

R491

1R490

R429

18

Q417

2SC4793

R480

2.2

Q421

2SA1943

Q416

C425

470pF

22

GND

Q422

2SC5200

R481

2.2

R449

15

R422

1K2 3W 1%

R419

1K2 3W 1%

C427

1uF

R4B1

R4B5

0.1R 1W 5%

R482

2.2

Q423

2SA1943

C428

0.1uF

Q424

2SC5200

R483

2.2

0.1R 1W 5%

R452

1M

R4B2

R4B6

AGND

0.1R 1W 5%

R484

2.2

Q427

2SA1943

D422

3.6V

D424

3.6V

Q428

2SC5200

R485

2.2

0.1R 1W 5%

C429

1uF

AGND

R4B3

R4B7

0.1R 1W 5%

R486

2.2

Q419

2SA1943

D423

1N4148

D425

1N4148

Q420

2SC5200

R487

2.2

0.1R 1W 5%

R454

1M

R4B4

R4B8

C421

0.1R 1W 5%

4u7/50V

D409

BV21

GND

R461

1K

R456

0.05/5W

R457

0.05/5W

C416

0.1uF

0.1R 1W 5%

R462

56K

SPGND

GND

C420

22N

R459

10/2W FS

C418

0.1uF

C423

10uF/80V

-74V

R464

6K8

R463

22K

Q425

C2240

C417

C422

0.1uF

10uF/80V

Q426

2SA970

R471

56K

GND

PRGND

R467

10K

R468

2K2

C431

330u/16V

D426

1N4148

C434

2.2uF/50V

+74V

C433

GND

47u/50V

1

2

PRGND

D427

12V

C435

2.2uF/50V

Cxr+Rxr network is between the

chassis and the de-coupling ground

with the minimum loop.

PRGND

GND

ote:

5

R45

200K

R470

3K3

R469

56K

8

IC404

7

uPC1237HA

6

4

3

D412

1N4148

C432

0.22u

L402

1uH

R499

3R3/1W FP

SPGND

R CHANNEL AMP

THERMAL BREAKER

R475

200

Q450

2SA1015

R474

3K3

R473

100K

RL401B

R472

N.I.

PRGND

R478

10K

PRGND

RL401A

RL402A

C440

22N

Cxr

0.1uF/50V

B401

R466

100K

D414

D415

1N4148

1N4148

R4930R492

R479

10K

PRGND

PRGND

Q452

Q453

2SC1815

2SC1815

PROTECT

AC DET

SPK A

SPK B

+V24R

RT401

T0=80 degree C

-74V+74V

Rxr

2R2

GND

to HS4-M3-B007 PSU VC4.0.SCH

P701 P702 P703

0

+72V-72V

PRGND

SPGND

RL402B

R498

10K

+V24R

PRGND

D413

1N4148

CZ402

1

2

3

4

5

6

7

8

9

10

CON10

CZ403

CON8

Q454

2SA1015

R497

100K

R494

N.I.

1

2

3

4

5

6

7

8

1

1

1

1

to HS4-M3-B007 PSU VC4.0.SCH CZ703

to the binding post

P401

PCBNUT

P402

PCBNUT

P403

PCBNUT

P304

PCBNUT

3-12

Page 27

2. PREAMP BOARD

HDATA2

VOLA2

HDATA

HCLK

VOLA

RRCA1

INPUT1

RRCA2

INPUT2

RRCA3

INPUT3

RRCA4

INPUT4

RRCA5

INPUT5

RRCA6

INPUT6

LRCA1

INPUT1

LRCA2

INPUT2

LRCA3

INPUT3

LRCA4

INPUT4

LRCA5

INPUT5

INPUT6

OPSEL_CLK

OPSEL_DATA

5

6

44

S51S62S73S84S9

S141S242S343S4

37

Rin5

Rin6

Rin7

R201

220R

R202

C220

1M

100pF

R203

220R

C221

R204

100pF

1M

R205

220R

C222

R206

100pF

1M

R207

220R

C223

R208

100pF

1M

R209

220R

C224

R210

100pF

1M

R211

220R

C225

R22

100pF

1M

R213

220R

CZ101

8

7

6

5

4

3

2

1

FROM BAL_SCH CZ504

R113

220R

R101

220R

R102

C120

1M

100pF

R103

220R

R104

C121

1M

100pF

R105

220R

R106

C122

1M

100pF

R107

220R

R108

C123

1M

100pF

R109

220R

R110

C124

1M

100pF

R111

220R

R12

C125

1M

100pF

LRCA6

37

S141S242S343S4

44

Lin6

Lin7

LIN7

LIN

10

10

LIN7

LIN

Rin4

C202

100p

S51S62S73S84S95S10

Lin4

Lin5

MAIN IN L

MAIN IN L

S10

S117S128S139S1410S1511S1612S1713S18

S10'28S9'29S8'30S7'31S6'32S5'33S4'34S3'35S2'36S1'

27

Rin2

Rin3

C201

100p

100p

C203

C204

100p

C205

100p

C206

100p

C101

100p

C102

100p

C103

100p

C104

100p

C105

100p

C106

100p

28

27

S9'29S8'30S7'31S6'32S5'33S4'34S3'35S2'36S1'

S10'

S117S128S139S1410S1511S1612S1713S18

6

Lin2

Lin3

LOUT

-18VL

+18VL

123456789

CZ108LCON5

CZ108 CON5

123456789

+18VL

LOUT

-18VL

14

S18'20S17'21S16'22S15'23S14'24S13'25S12'26S11'

Rin1

Rin1

Rin2

Rin3

Rin4

Rin5

Rin6

Rin7

Lin7

Lin1

Lin2

Lin3

Lin4

Lin5

Lin6

-18VL

+18VL

Lin1

OPSEL_STB

16

18

19

U209

CK

TC9274N

STB

DATA

Vdd38GND15Vss

40

-18VR

+18VR

C230

C231

0.1uF

0.1uF

3

RL201A

1

2

6

RL201B

4

5

3

RL202A

1

2

6

RL202B

4

5

3

RL203A

1

2

6

RL203B

4

5

RIN

3

RL204A

1

2

6

RL204B

4

5

3

RL205A

1

2

6

RL205B

4

5

3

RL206A

1

2

6

RL206B

4

5

2

RL207A

1

3

5

RL207B

4

6

6

RL212B

4

5

RL212A

2

1

3

3

RL107A

1

2

6

RL107B

4

5

3

RL101A

1

2

6

RL101B

4

5

LIN

3

RL102A

1

2

6

RL102B

4

5

3

RL103A

1

2

6

RL103B

4

5

3

RL104A

1

2

6

RL104B

4

5

3

RL105A

1

2

6

4

RL105B

5

3

1

RL106A

2

6

4

RL106B

5

38

15

40

Vss

Vdd

S18'20S17'21S16'22S15'23S14'24S13'25S12'26S11'

GND

U109

TC9274N

CK16DATA18STB

19

14

OPSEL_STB_L

OPSEL_DATA_L

OPSEL_CLK_L

1C57

10n

1R66

1R65

4.7K

4.7K

1C56

100p

Z2 MUTE

24VR

78

RL207C

2C13

10n

2R13

2R14

4.7K

4.7K

2Q07

2SC1815

2C14

100p

RIP7

1R700R1R71

FUNC

HDATA

HCLK

+5V

2C52

HCLK

15

2

3

16

100N

U213

OE

4094

24VL

CLK

VCC

GND

8

10

RIP7

RMUTE1

MONO

FILTER1

FILTER2

FILTER3

0.22uF

C238

R277

220K

+20VR

2C31

+17VR

100N

2C32

100N

-20VR

-18VR +18VR

2Q21

KSA1220

2C40

2C39

0.1uF

0.1uF

VOLR_CLK

VOLR_DATA

VOLR_STB

OPSEL_CLK

OPSEL_DATA

TONE_STB

-18VL -20VL

1Q21

KSA1220

1C40

1C39

0.1uF

0.1uF

C138

0.22uF

LIN

R177

220K

C139

1U

+17VL

+20VL

1C31

100N

R13 100k

1R85 220K

R14

1C32

100N

10

-20VL

VOLL_CLK

VOLL_DATA

VOLL_STB

HCLK

HDATA2

VOLA2

OPSEL_CLK

OPSEL_DATA

OPSEL_STB

FUNC

DATA

HCLK

+5V

123456789

10

0R

HDATE L

1R73

FUNC L

HCLK L

+5V

1R72

10K

1R74

10K

24VL

78

RL112C

1D16

1N4148

1C13

10n

1R13

1R14

4.7K

4.7K

1Q25

2SC1815

1C14

100p

LIP7

2D07

1N4148

2C15

10n

2R16

2R15

4.7K

4.7K

2C16

100p

RMUTE1

+5V

1R69

10K

1Q27

2SC3326

10K

2C51

1

D

STR

GND

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

8

10

RIP3

RMUTE2

R282

1M

C239

1U

2R85

220K

R23

100k

R24

10

-20VR

+20VR

2R43

430

2R42

2C38

5K6

0.1uF

+20VL

2R39

430

2R38

1C38

5K6 1C36

0.1uF

R182

1M

C136

220U

1R86

442

Q103

2SC3326

1D12

1N4148

10

CZ208

CON10

CON10

CZ208L

123456789

24VL

+5V

1Q26

2SC3326

78

RL107C

1D07

1N4148

1Q07

2SC1815

C226

100uF/16V

R275

6K65 1%

Q202

2SC3326

Not assemble

R183

1M

R145

10K

VOLA

HDATA

+5V

+5V

2C48

1D2

3OE15

16

100N

1R101

10K

1R102

0

STR

CLK

VCC

1Q28

2SC3326

1R60

5K

1R103

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

C208

22P

R296

10K

R299

10K

V+

V-

1R92

180

123456789

+20VR

-20VR

R279

499 1%

U202B

AD8512ARZ

11

2C55

1U

12

13

+20VR

+5V

-20VR

-1dBR

-0.5dBR

5dB R

PREAMP MODULE

6

V+

V-

1

5

2R92

180

C228

1U

2C55

1U

47K

2R97

U101B

PREAMP MODULE

6

5

-18VL

1R99

100K

R197

82

1R49

82

R198

100K

+18VL

U212B

4

5

74F00

U212D

74F00

GND

8

-10dB RR

-20dB RR

0dB R

-30dB RR

U201A

R285

2

33

L2

0R

2R93

1M

VR+VR-

6

VR202

10K(NC)

5

-18VR

2R99

100K

R297

82

1R50

82

R298

100K

+18VR

33

R185

8

L3

0R

1R93

1M

VL+VL-

VR102

10K(NC)

6

11

10k

2D15

1N4148

4

R283

C214

1M

100p

3

C229

1uF

2R90

1M

R276

3K24 1%

7

Q201

2SC3326

2R91

10K

2D13

1N4148

C242

2.2N

U203C

TL084

2R98

47k

2C45

-18VR

0.1U

U203A

R245

10K

2C44

R280

TLO84

+18VR

10K

0.1U

U203B

TL084

+20VL

12

10

C114

100p

9

7

-20VL

R179

499 1%

C108

1R90

C129

1M

1uF

22p

C128

R176

3K24 1%

1U

Q101

2SC3326

7

1R91

10K

U102B

AD8512ARZ

C141

2.2N

C142

2.2N

U103B

TL084

1R97

47K

1R98

47k

U103D

R196

10K

TL084

U103C

R199

10K

TL084

1C45

+18VL

U103A

0.1U

1C44

TL084

0.1U

-18VL

U212A

1

3

2

74F00

U212C

9

8

10

74F00

+5V

1C54

100N

OPSEL_DATA

OPSEL_STB

VOLR_STB

VOLR_CLK

VOLR_DATA

OPSEL_CLK

ZERO R

ZERO L

1011121314151617181920212223242526

78

RL101C

1Q01

2SC1815

2D16

1N4148

-0dB R

-2dB R

-4dB R

-6dB R

-8dB R

-10dB R

-12dB R

-14dB R

-16dB R

-18dB R

-20dB R

-22dB R

-24dB R

-26dB R

-28dB R

-30dB R

-32dB R

-34dB R

-36dB R

-38dB R

-40dB R

-42dB R

-44dB R

-46dB R

-48dB R

-50dB R

-52dB R

-54dB R

-0dB L

-2dB L

-4dB L

-6dB L

-8dB L

-10dB L

-12dB L

-14dB L

-16dB L

-18dB L

-20dB L

-22dB L

-24dB L

-26dB L

-28dB L

-30dB L

-32dB L

-34dB L

-36dB L

-38dB L

-40dB L

-42dB L

-44dB L

-46dB L

-48dB L

-50dB L

-52dB L

-54dB L

24VL

24VR

78

RL201C

2C01

10n

2R02

2R01

4.7K

4.7K

2Q01

2SC1815

2C02

100p

RIP1

R216 453

R217 357

R218 294

R219 255

R220 191

R221 150

R222 121

R223 95.3

R224 75

R225 59

R226 46.4

R227 38.3

R228 28.7

R229 23.2

R230 18.7

R231 15

R232 11.8

R233 9.53

R234 6.81

R235 5.90

R236 4.75

R237 3.65

R238 2.8

R239 2.32

R240 1.87

R241 1.47

R242 1.15

R243 0.909

R244 3.57

1

2

3

4

-18VR

POWER+18VR

R116 453

R117 357

R118 294

R119 255

R120 191

R121 150

R122 121

R123

R124 75

R125 59

R126 46.4

R127 38.3

R128 28.7

R129 23.2

R130 18.7

R131 15

R132 11.8

R133 9.53

R134 6.81

R135 5.90

R136 4.75

R137 3.65

R138 2.8

R139 2.32

R140 1.87

R141 1.47

R142 1.15

R143 0.909

R144 3.57

1Q14

DTA114ESC

2

2

1R76

1Q13

DTC114ESC

1 3

5dB L

1D01

1N4148

1C03

10n

1R03

1R04

4.7K

4.7K

1C04

100p

LIP2

78

RL202C

2D01

1N4148

2C03

10n

2R03

2R04

4.7K

4.7K

2Q02

2SC1815

2C04

100p

RIP2

J204

J204T

4

4

3

3

2

2

1

1

R-SIGNAL

R-SIGNAL

J105

J105T

1

2

3

4

DATA

DATA

J205

J205T

-18VT

4

4

3

3

2

2

1

1

POWER

+18VT

95.3

J104T

J104

4

4

3

3

2

2

1

1

L-SIGNAL

L-SIGNAL

+20VL

1

3

1R77

1R75

1K

10K

1K

1C26

100p

-20VL

24VL 24VL

78

RL102C

1D02

1N4148

1R05

4.7K

1Q02

2SC1815

LIP3

24VR

+18VT

1C30

100N

2C30

100N

-18VT

16

19

18

STB

DATA

40

2

-1dBL

1C05

10n

1R06

4.7K

1C06

100p

2D02

1N4148

2R05

4.7K

RIP3

C209

82N

R246

309

R247

160

R248

274

R249

402

R250

887

R251

1K58

R252

698

R253

249

R254

121

R255

68.1

R256

48.7

R257

121

1C29

0.1U

+18VT

2C29

0.1U

14

CK

Vdd38GND15Vss

S18'20S17'21S16'22S15'23S14'24S13'25S12'26S11'

+18VT

TONE CONTROL BOARD

C109

82N

R146

309

R147

160

R148

274

R149

402

R150

887

R151

1K58

R152

698

R153

249

R154

121

R155

68.1

R156

48.7

R157

121

1Q16

DTA114ESC

2

1 3

1Q15

DTC114ESC

78

RL103C

1D03

1N4148

1Q03

2SC1815

78

2C05

10n

2R06

4.7K

2C06

100p

C211

0.22uF

1R52

10R

6

-3dB B

-4dB B

-5dB B

S117S128S139S1410S1511S1612S1713S18

27

-3dB T

-4dB T

-5dB T

1R51

10R

MMBFJ108

MMBFJ108

MMBFJ108

MMBFJ108

MMBFJ108

MMBFJ108

MMBFJ108

MMBFJ108

MMBFJ108

MMBFJ108

C111

MMBFJ108

0.22U

+20VL

1

3

1R78

10K

-20VL

1R07

4.7K

LIP4

24VR

RL203C

2Q03

2SC1815

5

-1dB B

-2dB B

S10

S10'28S9'29S8'30S7'31S6'32S5'33S4'34S3'35S2'36S1'

-1dB T

-2dB T

Q107

Q108

Q109

Q110

Q111

Q112

Q113

Q114

Q115

Q116

Q117

1R791K1R80

1C27

100p

1C07

10n

1R08

4.7K

1C08

100p

24VR

78

RL208C

2Q08

2SC1815

+5V

15

16

100N

OE

VCC

RIP1

RIP4

RIP5

RIP6

10

9

-20VR

2R88

180

C236

220U

2R86

442

Q203

2SC3326

2Q22

KSC2690

2R44

430

2C35

0.1uF

1Q22

KSC2690

2R40

430

1C35

0.1uF

4

3

1R84

1R88

180

C119

1U

1C33

0.1U

1

U102A

1R87

AD8512ARZ

10K

C140

2.2N

1C52

100N

GND

8

10

FILTER1L

FILTER2L

1C15

1R16

1R15

4.7K

4.7K

FILTER3L

78

RL209C

2D08

1N4148

2C17

10n

2R17

2R18

4.7K

4.7K

2Q09

2SC1815

2C18

100p

FILTER2

1

2

3

U208

D

4094

STR

CLK

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

RIP2

12

U201B

24VR

PREAMP MODULE

L4

V+

8

0R

V-

R212

7

33

11

2R89

2R84

499

1M

C207

22P

C219

1U

2C33

+18VR

84

2

0.1U

1

3

U202A

2R87

AD8512ARZ

10K

2C34

0.1U

-18VR

2D12

1N4148

1R47

5K1

2R45

2C36

2C37

5K6

0.1uF

0.1uF

+18VL

1R48

5K1

2R41

1C37

5K6

0.1uF

0.1uF

+20VL

6

U101A

PREAMP MODULE

L1

V+

2

0R

V-

R112

1

5

33

-20VL

499

C107

1R89

22P

1M

+18VL

84

2

3

1C34

-18VL

0.1U

1D2

3OE15

16

VCC

LIP5

LMUTE1L

FILTER3L

78

10n

1C16

100p

RL108C

1Q08

2SC1815

100N

U113

4094

STR

CLK

GND

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

8

10

LIP6

LIP7

Z2 MUTE

1D08

1N4148

1C17

10n

1R18

1R17

4.7K

4.7K

1C18

100p

FILTER1L

2C46

0.1U

2C47

0.1U

1C46

0.1U

1C47

0.1U

VR101

10K(NC)

24VR24VR

78

RL210C

2D09

1N4148

2C19

10n

2R20

2R19

4.7K

4.7K

2Q10

2SC1815

2C20

100p

FILTER1

+17VR

R27

100K

VR+

R28

22

VR201

10K(NC)

R29

22

VR-

R21

100K

C240

2.2N

-17VR

+5V

2Q19

2SC1815

+5VMR

+5V

1Q19

2SC1815

+5VML

+17VL

R17

100K

VL+

R18

22

R19

22

VL-

R11

100K

-17VL

+5V+5V 1C51

1D2

3OE15

16

U108

4094

STR

CLK

VCC

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

LIP1

LIP2

LIP3

LIP4

LMUTE2L

78

RL109C

1D09

1N4148

1C19

1R20

1R19

4.7K

4.7K

1Q09

2SC1815

1C20

100p

LMUTE1L

10n

2D10

1N4148

2R21

4.7K

FILTER3

-0dB R

-2dB R

-4dB R

-6dB R

-8dB R

-10dB R

-12dB R

-14dB R

-16dB R

-18dB R

-20dB R

-22dB R

-24dB R

-26dB R

-0dB L

-2dB L

-4dB L

-6dB L

-8dB L

-10dB L

-12dB L

-14dB L

-16dB L

-18dB L

-20dB L

-22dB L

-24dB L

-26dB L

-18VL

+18VL

1D2

STR

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

-1dBL

5dB L

78

RL110C

1Q10

2SC1815

78

RL211C

2C21

10n

2R22

4.7K

2Q11

2SC1815

2C22

100p

U205

41

S1

42

S2

43

S3

44

S4

1

S5

2

S6

3

S7

4

S8

5

S9

6

S10

7

S11

8

S12

9

S13

10

S14

11

S15

12

S16

13

S17

14

S18

16

CK

18

DATA

19

STB

TC9274N

2D18

-18VR

20V 0.5W

2D17

+18VR

20V 0.5W

1D18

-18VL

20V 0.5W

1D17

+18VL

20V 0.5W

1D19

1V 0.5W

1D20

1V 0.5W

1D21

1V 0.5W

2D21

1V 0.5W

U105

41

S1

42

S2

43

S3

44

S4

1

S5

2

S6

3

S7

4

S8

5

S9

6

S10

7

S11

8

S12

9

S13

10

S14

11

S15

12

S16

13

S17

14

S18

16

CK

18

DATA

19

STB

TC9274N

1C24

0.1U

+5V

1C48

3OE15

16

100N

CLK

VCC

-0.5dBL

-10dB LL

-20dB LL

0dB L

-30dB LL

1D10

1N4148

1C21

10n

1R22

1R21

4.7K

4.7K

1C22

100p

FILTER2L

78

RL212C

2D11

1N4148

1C23

10n

1R23

2R23

4.7K

4.7K

2Q12

2SC1815

2C23

100p

MONO

-28dB R

37

S1'

36

-30dB R

S2'

35

-32dB R

S3'

34

-34dB R

S4'

33

-36dB R

S5'

32

-38dB R

S6'

31

-40dB R

S7'

-42dB R

30

S8'

29

S9'

28

-44dB R

S10'

27

-46dB R

S11'

26

-48dB R

S12'

25

-50dB R

S13'

24

S14'

23

-52dB R

S15'

22

S16'

21

-54dB R

S17'

20

S18'

+18VR

38

Vdd

40

Vss

-18VR

15

GND

2C24

0.1U

2C25

0.1U

2D20

2.2V

1R108

3R3

37

-28dB L

S1'

36

-30dB L

S2'

35

-32dB L

S3'

34

-34dB L

S4'

33

-36dB L

S5'

32

-38dB L

S6'

-40dB L

31

S7'

30

-42dB L

S8'

29

S9'

28

-44dB L

S10'

-46dB L

27

S11'

26

-48dB L

S12'

25

-50dB L

S13'

24

S14'

23

-52dB L

S15'

22

S16'

21

-54dB L

S17'

20

S18'

38

Vdd

40

Vss

15

GND

1C25

0.1U

U110

4094

GND

8

10

24VL24VL24VL24VL24VL

78

RL111C

1D11

1N4148

1C01

10n

1R02

1R01

4.7K

4.7K

1Q11

2SC1815

1C02

100p

LIP1

0dB B

0dB T

78

2D03

1N4148

Q207

MMBFJ108

Q208

MMBFJ108

Q209

MMBFJ108

Q210

MMBFJ108

Q211

MMBFJ108

Q212

MMBFJ108

Q213

MMBFJ108

Q214

MMBFJ108

Q215

MMBFJ108

Q216

MMBFJ108

Q217

MMBFJ108

1dB B

1dB T

1K

24VL

RL104C

1Q04

2SC1815

24VR

78

RL204C

2C07

10n

2R08

2R07

4.7K

4.7K

2Q04

2SC1815

2C08

100p

RIP4

5dB T

2R37

10M

4dB T

2R36

10M

3dB T

2R35

10M

2dB T

2R34

10M

R263

1dB T

2R33

10M

0dB T

2R32

10M

-1dB T

2R31

10M

-2dB T

2R30

10M

-3dB T

2R29

10M

-4dB T

2R28

2R106

10M

15

-5dB T

R269

2R27

287

10M

5dB T

4dB T

3dB T

44

5dB B

4dB B

3dB B

2dB B

2dB T

U112

S51S62S73S84S9

S141S242S343S4

TC9274N

1dB T

0dB T

-1dB T

37

-2dB T

5dB T

4dB T

3dB T

2dB T

-3dB T

-4dB T

-5dB T

1R38

5dB T

10M

1R39

4dB T

10M

1R40

3dB T

10M

1R41

2dB T

10M

1R42

1dB T

10M

1R43

0dB T

10M

1R44

-1dB T

10M

1R45

-2dB T

10M

1R24

-3dB T

10M

1R25

-4dB T

10M

1R26

-5dB T

R169

10M

287

+20VL

1

1Q18

2

DTA114ESC

2

3

1 3

1Q17

DTC114ESC

-20VL

-0.5dBL

1D04

1N4148

1C09

10n

1R10

1R09

4.7K

4.7K

1C10

100p

LIP5

24VR 24VR24VR24VR

78

RL205C

2D04

1N4148

2C09

10n

2R09

2R10

4.7K

4.7K

2Q05

2SC1815

2C10

100p

RIP5

R258

C213

866

332N

Q218

MMBFJ108

R259

Q219

316

MMBFJ108

R260

Q220

432

MMBFJ108

R261

Q221

681

MMBFJ108

R262

Q222

866

MMBFJ108

845

Q223

MMBFJ108

R264

Q224

487

MMBFJ108

R265

Q225

249

MMBFJ108

R266

Q226

150

MMBFJ108

R267

Q227

100

MMBFJ108

R268

Q228

53.6

MMBFJ108

C212

1uF

20K

2R107

2R46

10K

2R47

10K

2R48

10K

2R49

10K

2R50

10K

2R51

10K

2R52

10K

2R53

10K

2R54

10K

2R55

10K

2R56

10K

-18VT

Q118

MMBFJ108

R158

866

C113

332N

Q119

R159

MMBFJ108

316

Q120

R160

MMBFJ108

432

Q121

R161

MMBFJ108

681

Q122

R162

MMBFJ108

866

Q123

R163

845

MMBFJ108

Q124

R164

MMBFJ108

487

Q125

R165

MMBFJ108

249

Q126

R166

MMBFJ108

150

Q127

R167

MMBFJ108

100

Q128

R168

MMBFJ108

53.6

1R106

15

C112

1uF

20K

1R107

1R81

1R83

1R82

10K

1K

1K

1C28

100p

24VL

78

RL105C

1D05

1N4148

1C11

10n

1R11

1R12

4.7K

4.7K

1Q05

2SC1815

1C12

100p

LIP6

78

RL206C

2D05

1N4148

2C11

10n

2R12

2R11

4.7K

4.7K

2Q06

2SC1815

2C12

100p

RIP6

5dB B

10M

2R26

4dB B

10M

2R25

3dB B

10M

2R24

2dB B

10M

2R71

1dB B

10M

2R70

0dB B

10M

2R69

-1dB B

10M

2R68

-2dB B

10M

1R46

-3dB B

10M

2R74

-4dB B

10M

2R73

-5dB B

10M

2R72

2R57

5dB B

10K

2R58

4dB B

10K

2R59

3dB B

10K

2R60

2dB B

10K

2R61

1dB B

10K

2R62

0dB B

10K

2R63

-1dB B

10K

2R64

-2dB B

10K

2R65

-3dB B

10K

2R66

-4dB B

10K

2R67

-5dB B

10K

1R27

5dB B

10M

1R28

4dB B

10M

1R29

3dB B

10M

1R30

2dB B

10M

1R31

1dB B

10M

1R32

0dB B

10M

1R33

-1dB B

10M

1R34

-2dB B

10M

1R35

-3dB B

10M

1R36

-4dB B

10M

1R37

-5dB B

10M

24VL

1Q23

78

DTC114ESC

RL106C

1D06

1N4148

2

1Q06

2SC1815

-20VL

LMUTE2L

+20VL

J201

CON26

+18VR

1

2Q23

DTC114ESC

2D06

2Q24

1N4148

2

DTA114ESC

2

3

1R59

10K

1 3

2C53

100p

-18VR

RMUTE2

C218

R284

0.22uF

33K

R281

+17VR

1K9 1%

R25

100k

R278

220K

R26

10

2D14

1N4148

C241

2.2N

+18VR

R215

1K

Q204

2SA1015

R294

1K

Q205

2SA1015

2R146

10k

ZERO RP

R214

5K

C118

R184

0.22uF

33K

R181

1K9 1%

1 3

R15

100k

24VR24VL

C126

100uF/16V

R178

220K

R175

R16

6K65 1%

10

Q102

2SC3326

1D13

1D14

1N4148

1N4148

+18VL

R115

1K

Q104

2SA1015

R194

1K

Q105

R180

2SA1015

10K

1R146

10k

ZERO LP

R114

5K1

Not assemble

+18VL

1

1Q24

DTA114ESC

1D15

1R58

3

5K

1R57

1C53

1N4148

10K

100p

-18VL

VOLL_DATA

VOLL_CLK

TONE_STB

HCLK

FUNC

VOLL_STB

+17VL

2

+20VR

2

5dB R

3

2Q13

DTC114ESC

R170

97.6

R171

600

R172

600

R173

191

R174

196

1R94

57.6

R186

60.4

R187

60.4

R1002

28.0

R1001

27.4

1

R270

97.6

R271

600

R272

600

R273

191

R274

196

2R94

57.6

R286

60.4

R287

60.4

R2002

28.0

R2001

27.4

5

2

RL108A

C115

100n 5%

C116

R191

37.4K 1%

R192

28K 1%

1

2Q14

2

DTA114ESC

3

2R76

2R77

10K

1K

1 3

2C26

100p

-20VR

+18VR

+5VMR

-18VR

2R105

1.5

+18VR

-18VR

2R95

84.5

ROUT

6

RL211B

5

RL210B

100n 5%

4

C215

6

C216

56n 5%

2

RL209A

R291

3

37.4K 1%

R292

28K 1%

3

5

RL209B

4

2

6

2C60

0.22U

-18VL

+5VML

+18VL

1C43

100N

1R105

1.5

-18VL

+5VML

+18VL

1C42

100N

1R95

84.5

5

RL109B

6

2

RL111A

56n 5%

3

6

RL111B

5

2

RL109A

3

+18VL

C130

0.1uF

1C60

0.22U

U210

4094

10

+5VMR

RL210A

4

1

C131

0.1uF

+20VR

1

2Q16

DTA114ESC

2

2

3

2R78

2R79

10K

1K

1 3

2R75

2Q15

1K

DTC114ESC

-1dBR

-30dB R

2C43

100N

2C42

2C41

100N

100N

4

1

1

R288

300K

1C41

100N

-20dB LL

-10dB LL

0dB LL

0.1uF

C117

3

2

+18VL

5

6

4

1

1C49

2

3

U111A

OPA2134

5

R188

6

300K

-20dB R

0.1uF

C217

2

3

5

6

-30dB LL

U106B

OPA2134

100N

-10dB R

3

2

+18VR

5

6

-18VL

+18VL

-18VL

OPA2134

0dB R

U206B

OPA2134

U211B

OPA2134

16

15

14

13

12

11

10

16

15

14

13

12

11

10

9

8 4

84

U111B

2C27

100p

-20VR

U204

9

NO2

10

IN2

11

V+

12

VL

13

GND

14

V-

15

IN1

16

NO1

MAX4621

U207

9

NO2

10

IN2

11

V+

12

VL

13

GND

14

V-

15

IN1

16

NO1

MAX4621

-18VR

U206A

R293

1

200

C233

8 4

OPA2134

0.1uF

1R63

7

200

+18VR

2C49

100N

84

U211A

OPA2134

R289

1

200

2C50

100N

-18VR

1R64

7

200

U104

NO1

IN1

V-

GND

VL

V+

IN2

NO2

MAX4621

U107

NO1

IN1

V-