Page 1

NAD

1

SERVICE MANUAL

C 325BEE

STEREO

C 325BEE

STEREO

AMPLIFIER

AMPLIFIER

Page 2

TABLE OF CONTENTS

2

DESCRIPTION PAGE

SERVICE CAUTION………………………………………………………… 3-4

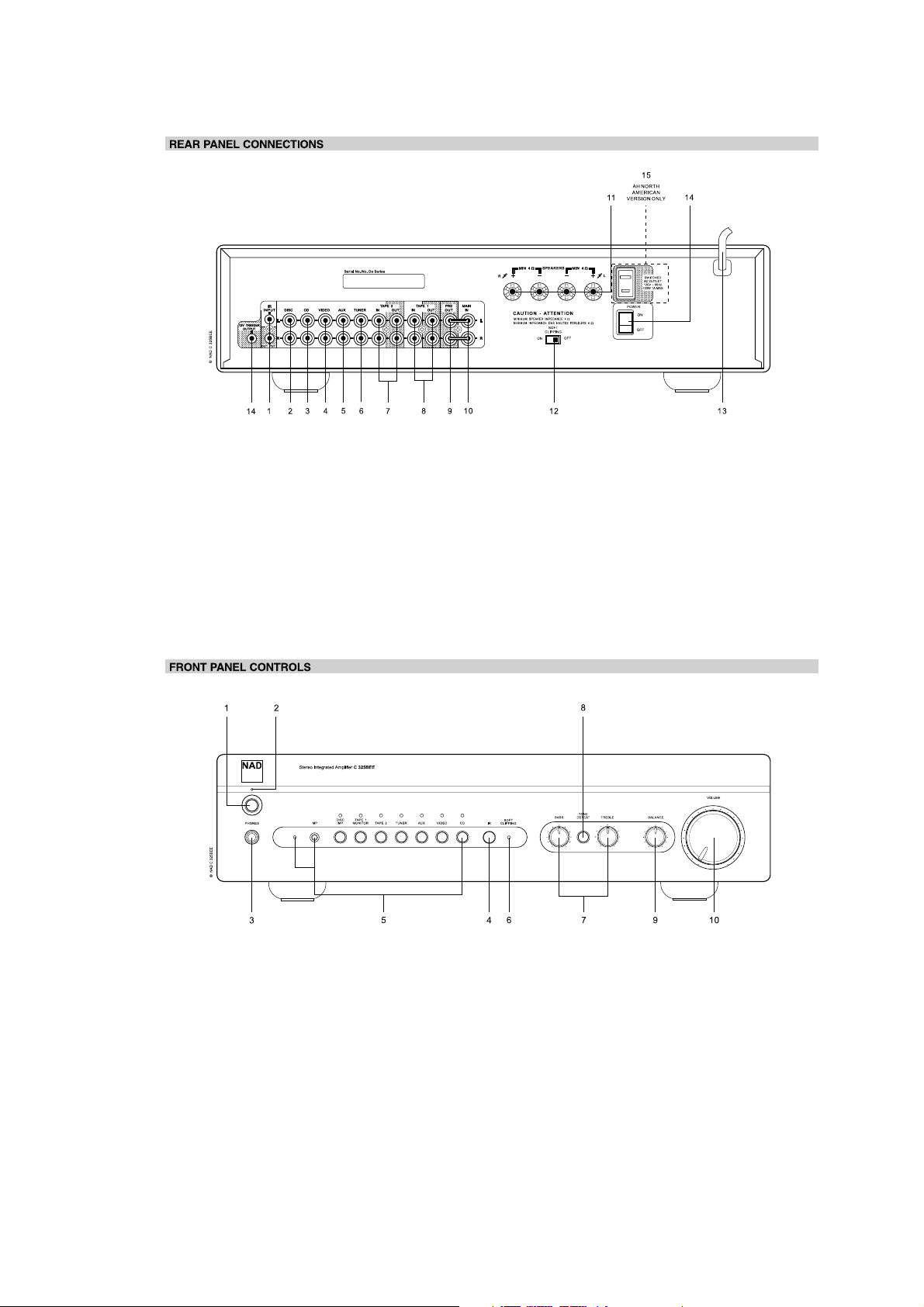

REAR PANEL/FRONT PANEL VIEW………………………………………...5

SPECIFICATIONS………………………………………………………….6-7

WIRING DIAGRAM………………………………………………………………8

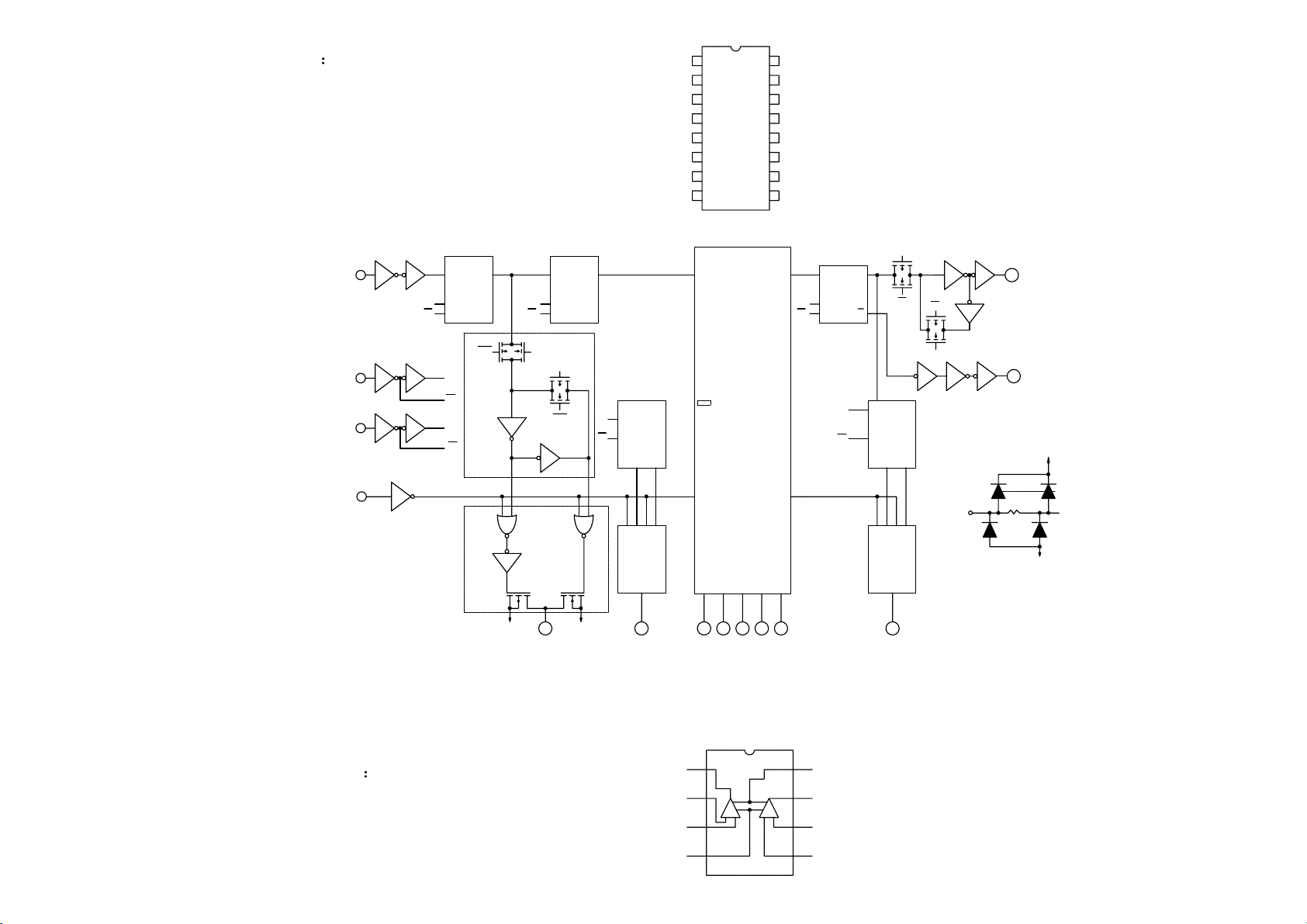

BLOCK DIAGRAM……………………………………………………. …….9-14

ALIGNMENT PROCEDURE……………………………………………..15

SCHEMATICS……………………………………………………………….16-19

PCB LAYOUT……………………………………………………………… 20-23

TROUBLE SHOOTING GUIDE…………………......................................24

ELECTRICAL PARTS LIST…………………………………………….25-34

EXPLODED VIEW……………………………………………………………..35

EXPLODED VIEW PARTS LIST……………………………………………...36

PROTECT IC CHANGE ..............……………………………………..……...37

Page 3

PRODUCT SAFETY SERVICING GUIDELINES

3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN

ANY WAY. NEVER PERFORM CUSTOMIZED INSTALLATIONS

WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED

MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT

MAY LEAD TO YOUR BEING LIABLE FOR ANY RESULTING

PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU

ARE THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING

SAFETY CHECKS AND SERVICING GUIDELINES. TO DO

OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS

AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR

PROTECTION FROM AC LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN

CORRECTED. A CHECK SHOULD BE MADE OF THE

FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN

SUCH A WAY AS TO AVOID POSSIBILITY OF ADJACENT

COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT

ON THOSE MODULES WHICH ARE TRANSPORTED TO AND

FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE

DEVICES SUCH AS INSULATORS, BARRIERS, COVERS,

SHIELDS, STRAIN RELIEFS, POWER SUPPLY CORDS, AND

OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE THAT THE SAFETY PURPOSE

OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE

COLD SOLDER JOINTS, SOLDER SPLASHES OR SHARP

SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE

FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR

DETERIORATION TO PARTS AND COMPONENTS. FOR

FRAYED LEADS, DAMAGED INSULATION (INCLUDING AC

CORD). AND REPLACE IF NECESSARY FOLLOW ORIGINAL

LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING

TUBE OR A RESISTOR RATED AT 1 WATT OR MORE. LEAD

TENSION AROUND PROTRUDING METAL SURFACES MUST

BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC. MUST BE

REPLACED WITH EXACT FACTORY TYPES, DO NOT USE

REPLACEMENT COMPONENTS OTHER THAN THOSE

SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT

MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN

AC LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF

THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA

TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET

IS SAFET TO OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER

DURING THIS TEST USE AN AC VOLTMETER, HAVING 5000

OHMS PER VOLT OR MORE SENSITIVITY, IN THE

FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT

RESISTOR, PARALLELED BY A .15 MFD, 150V AC TYPE

CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND

(WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED

METALLIC PARTS, ONE AT A TIME.

MEASURE THE AC VOLTAGE ACROSS THE COMBINATION

OF 1500 OHM RESISTOR AND .15 MFD CAPACITOR.

REVERSE THE AC PLUG AND REPEAT AC VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART.

VOLTAGE MEASURE MUST NOT EXCEED 75 VOLTS R.M.S.

THIS CORRESPONDS TO 0.5 MILLIAMP AC ANY VALUE

EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT : GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE” WITHIN THE

PRODUCT’S ENCLOSURE THAT MAY BE OF SUFFICIENT MAGNITUDE TO

CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS

INTENDED TO ALERT THE USER TO THE PRESENCE OF IMPORTANT

OPERATING AND MAINTENANCE (SERVICING) INSTRUCTIONS IN THE

LITERATURE ACCOMPANYING THE APPLIANCE.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS,

CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER

OR CLOSE TO HEAT DUCT, OR IN THE PATH OF HEATED

AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS:

OUTDOOR PATIO INSTALLATIONS WHERE DEW IS A

FACTOR, NEAR STEAM RADIATORS WHERE STEAM

LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT

REAR VENTING. THE CUSTOMER SHOULD ALSO AVOID THE

USE OF DECORATIVE SCARVES OR OTHER COVERINGS

WHICH MIGHT OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A

COMMERCAL MOUNTING KIT MUST FOLLOW THE FACTORY

APPROVED MOUNTING INSTRUCTIONS A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS

ORIGINAL FEET (OR THE EQUIVALENT THICKNESS IN

SPACERS) TO PROVIDE ADEQUATE AIR FLOW ACROSS

THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM

LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A

PRODUCT ON SLOPING SHELF OR A TILTED POSITION,

UNLESS THE PRODUCT IS PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE

ON ITS MOUNTING TO THE CART. CAUTION THE

CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART

WITH SMALL CASTERS ACROSS THRESHOLDS OR DEEP

PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR

STAND WHICH HAS NOT BEEN LISTED BY UNDERWRITERS

LABORATORIES, INC. FOR USE WITH THEIR SPECIFIC

MODEL OF TELEVISION RECEIVER OR GENERICALLY

APPROVED FOR USE WITH T.V.’S OF THE SAME OR

LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION

CORDS, EXPLAIN THAT A FOREST OF EXTENSIONS

SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

Page 4

SERVICING PRECAUTIONS

4

CAUTION : Before servicing the A/V Receiver covered by this

service data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances

create conflict between the following servicing precautions and any

of the safety precautions in this publication, always follow the safety

precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the A/V Receiver AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical plug or

other electrical connection.

(3) Connecting a test substitute in parallel with an electrolytic

capacitor.

Caution : A wrong part substitution or incorrect polarity installation

of electrolytic capacitors may result in an explosion hazard.

2. Do not spray chemicals on or near this A/V Receiver or any of its

assemblies.

3. Unless specified otherwise in this service data, clean electrical

contacts by applying an appropriate contact cleaning solution to

the contacts with a pipe cleaner, cottontipped swab, or

comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with which

instruments covered by this service manual might be equipped.

5. Do not apply AC power to this A/V Receiver and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

6. Always connect test instrument ground lead to the appropriate

ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter(500V) to the

blades of the attachment plug. The insulation resistance between

each blade of the attachment plug and accessible conductive parts

(Note 1) should be more than 1M-ohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input

terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by

static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical Es

devices are integrated circuits and some field effect transistors and

semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed for

potential shock reasons prior to applying power to the unit under

test.

2. After removing an electrical assembly equipped with ES devices,

place the assembly on a conductive surface such as aluminum

foil, to prevent electrostatic charge buildup or exposure of the

assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically

shorted together by conductive foam, aluminum foil, or

comparable conductive material).

7. lmmediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to

the chassis or circuit assembly into which the device will be

installed.

Caution : Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handing unpackaged replacement

ES devices. (Normally harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a

carpeted floor can generate static electricity sufficient to damage

an ES device.)

Page 5

,5,1387287387

5

',6&,1387

&',1387

9,'(2,1387

$8;,1387

781(5 INPUT

7$3(,1287

7$3(,1287

35(287

0$,1,1

63($.(5287

62)7&/,33,1*

$&/,1(&25'

975,**(5287

6:,7&+('$&287/(721/<)25$+

32:(5

32:(567$1'%<3527(&7,21/('

+($3+21(

,55(&(,9(5

,13876(/(&725

62)7&/,33,1* LED

721(&21752/6

721('()($7

%$/$1&(

92/80(

Page 6

SPECIFICATIONS

6

POWER AMPLIFIER SECTION

STEREO MODE

CONTINUOUS AVERAGE POWER 50 W (17 dBW)

OUTPUT INTO 8 OHMS OR 4 OHMS

(Min. power per channel, 20 Hz – 20 kHz,

with no more than rated distortion)

Rated Distortion 0.03%

(THD 20 Hz – 20 kHz)

Clipping power 68 W

(maximum continuous power per channel 4 and 8).

IHF dynamic headroom: at 8 ohms + 3.4 dB

at 4 ohms + 5.0 dB

IHF dynamic power

(maximum short term power per channel)

8 ohms: 110 W (20.4 dBW)

4 ohms: 160 W (22.0 dBW)

2 ohms: 210 W (23.2 dBW)

Damping factor > 100

(ref. 8 ohms 1 kHz)

Input Impedance R = 20 kohms

C = 1 nF

Input sensitivity (for rated output into 8 ohms) 630 mV

Voltage gain 29 dB

Frequency response 20 Hz – 20 kHz

Signal / Noise ratio, A-weighted 100 dB ref. 1 W

THD + Noise < 0.03%

(Total Harmonic Distortion, 20 Hz – 20 kHz,

from 250 mW to rated output)

SMPTE I.M. < 0.01%

(Intermodulation Distortion, 60 Hz + 7 kHz, 4:1,

from 250 mW to rated output)

0.2 dB

117 dB ref. 50 W

IHF I.M. < 0.01%

(CCIF IM Distortion, 19 + 20 kHz at rated output)

Headphones Output Impedance 220 ohms

Page 7

PREAMPLIFIER SECTION

7

LINE LEVEL INPUTS

(Disk, CD, Video, Auxiliary, Tuner, Tape 1,Tape 2)

Input impedance (R and C) 200 kohms + 320 pF

Input sensitivity (ref. rated power) 220 mV

Maximum input signal 6 V

Signal / Noise ratio, A-weighted 93.0 dB ref. 1W

(from CD Input to Speakers Output, Volume Setting

for 500mV in , 8ohms 1W out)

Signal to noise ratio preamp out, IHF “A” weighted 106 dB re 500mV

Frequency response, 20 Hz – 20 kHz < +/-0.1 dB (tone defeat on)

< +/-0.5 dB (tone defeat off)

THD + Noise, SMPTE IM < 0.01% at 5 V out

LINE LEVEL OUTPUTS

Pre-amp output impedance 80 ohms

Tape output impedance Source Z + 1kohms

Maximum output level pre-amp out : > 12 V

Tape-out : > 10 V

CONTROLS

Treble +/- 5 dB at 10 kHz

Bass +/- 8 dB at 100 Hz

IR IN and OUT

Input Resistance > 10 kohms

Input Voltage Min 5 V

Output Resistance < 30 ohms

TRIGGER Out

Output Current 50 mA

Output Voltage 12 V

DIMENSIONS AND WEIGHTS

Net Weight 6.5 kg ( 14.3 Ib)

Shipping Weight 8 kg ( 17.6 Ib)

×

DIMENSION (W×H×D) 435

100 × 290MM

Page 8

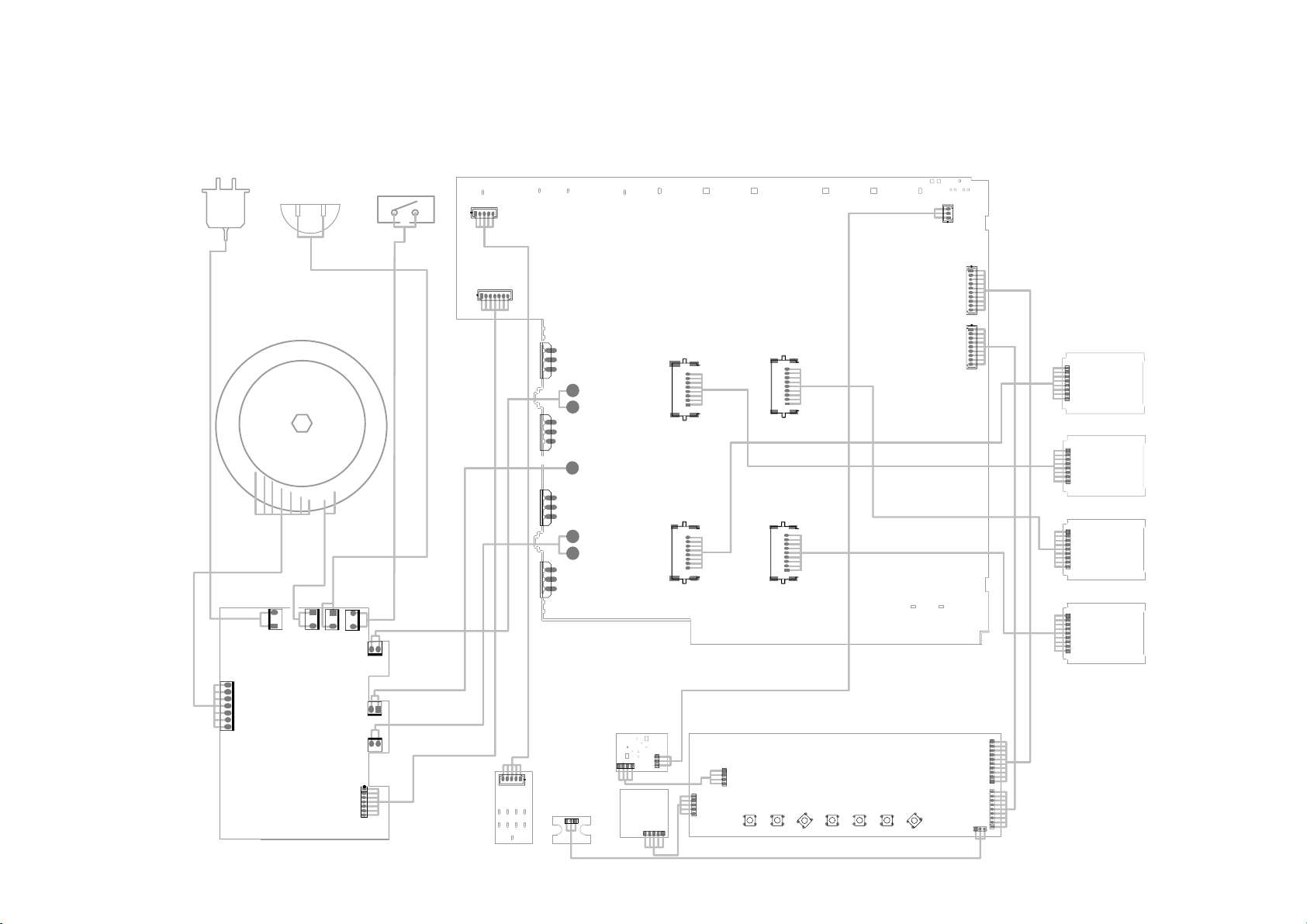

WIRING DIAGRAM

8

AC POWER PLUG

AC OUTLET

T401(TRANSFORMER)

POWER SWITCH

CB45

CB47

Q215

P1-L

-46V WHITE

+46V RED

P2-L

Q214

P5-GND

Q114

P4-R

+46V RED

-46V WHITE

P3-R

Q115

MAIN BOARD

CB21

CB11

CB32

CB33

CB35

CB31

CB34

AMP-SMD-R BOARD

CZ11

AMP-SMD-L BOARD

CZ21

IN MODULE BOARD

01-32560-01

CB61

OUT MODULE BOARD

01-32560-02

CB61

CB51

CB55

POWER BOARD

CB58

CB52

CB53

CB54

CZ45

HEADPHONE BOARD

Ipod SOCKET BOARD

CZ75

CZ74

CZ72

IR BOARD

CZ73

STANDBY BOARD

CB73

CB74

S75

S74

KEY BOARD

S76

S71

S72

S73

S77

CZ72_1

CZ71

CB72

CB56

CB59

CB57

Page 9

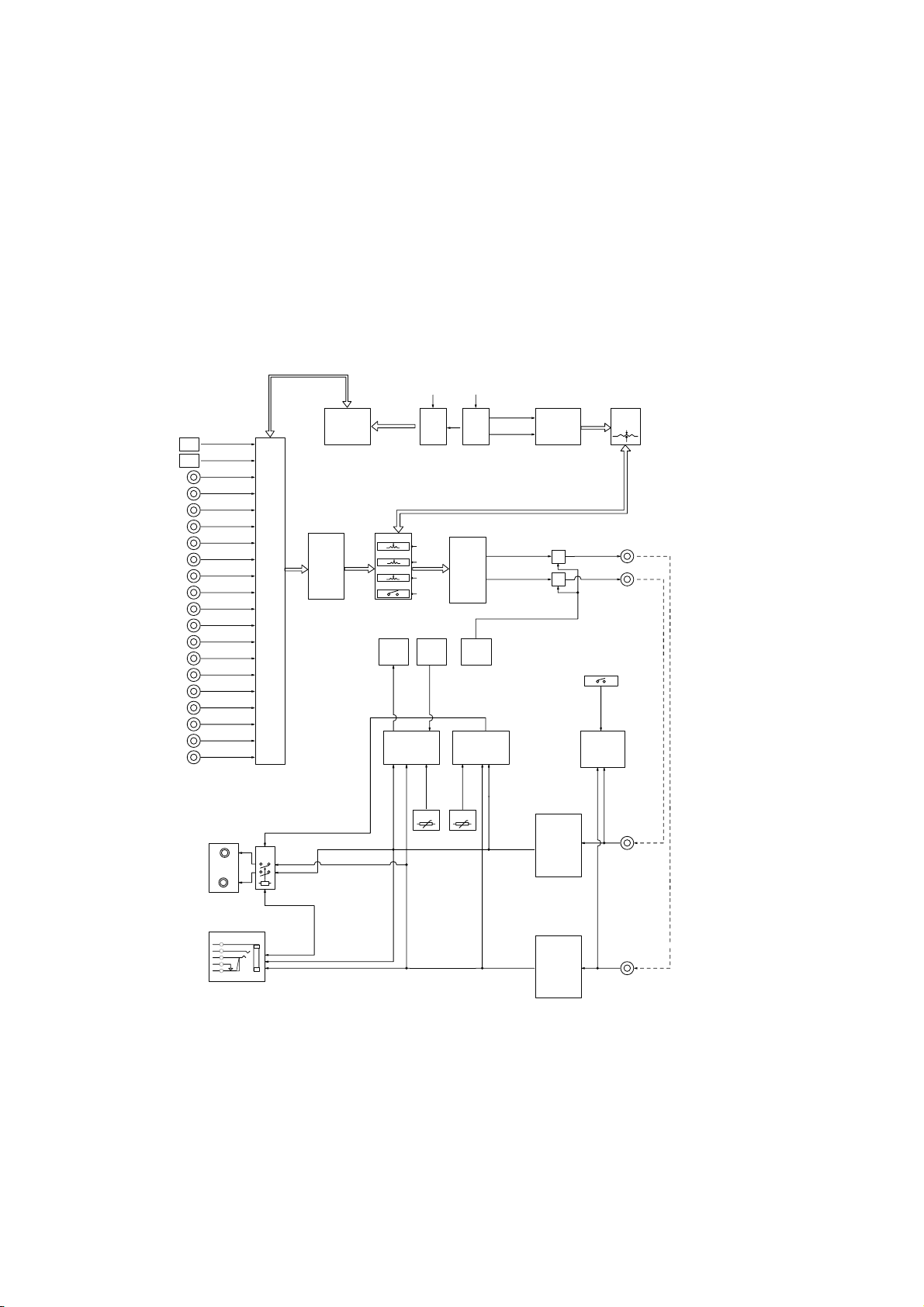

DISC L

9

DISC R

VIDEO L

VIDEO R

AUX L

AUX R

TUNER L

TUNER R

TAPE1 IN L

TAPE1 IN R

TAPE1 OUT L

TAPE1 OUT R

TAPE2 IN L

TAPE2 IN R

TAPE2 OUT L

TAPE2 OUT R

11,12,13,14)

RT31

RT32

RT34

SW31

SCR

CONTROL

CIRCUIT

TRIG I-V

ISC CIRCUIT

(IC43,TL082D)

(4,5,6,7

IC74

CD4094

BASS

TREBLE

BALANCE

TONE DEFEAT

MIRROR

CURRENT

SOURCE

CIRCUIT

R467

POSISTOR

(80 DEGREE C)

01-32560-02

(IC44,UPC1237HA)

R439

POSISTOR

(90 DEGREE C)

INPUT SELECTION

CIRCUIT (BY RELAY)

MP L

MP R

CD L

CD R

01-32560-01

IN

˄˅

AMP CIRCUIT

PREAPM MODULE

Relay Switchs

RL12/2

Speaker R

Speaker L

F1AA012V

92

IC 75

CD4094

OUT

˄˅

AMP CIRCUIT

PREAPM MODULE

MUTE

CONTROL

CIRUIT

PROTECTION

CIRCUIT

VOL+

5

4

VOL-

VOLUME CONTROL

CIRCUIT (REMOTE)

Q31

MUTE

Q32

MUTE

POWER AMP

CIRCUIT L

PRE-OUT L

PRE-OUT R

S41

SOFT CLIPPING

CONTROL CIRCUIT

RT33

VOLUME

CONTROL

BLOCK DIAGRAM

MAIN IN R

MCU

MCU

(1,2,3)

(1,3)

HEADPHONE

JK41

POWER AMP

CIRCUIT R

MAIN IN L

Page 10

4

10

3

Vss

SDA5SCL6NC7Vcc

CIRCUIT

IR OUT

+5V

3

2

27pF

IC72

1

IS1U60L

C79

C710

27pF

IC71

24C01

NC1NC2NC

8

+5V

Y71

11.0592M

IR Flash

Mute Flash

Remote Mute Flash

IP

C

TA1

DI

TU

TA2

AU

VI

TO RELAY CONTROL CIRCUITTO VOL CONTROL CIRCUIT

CIRCUIT

IR IN

IC75

10

9

11

12

13

14

7

6

5

4

10

9

11

12

13

14

7

6

5

4

4094

IC74

4094

8

QS

VEE

QS

Q8

Q7

Q6

16

Q5

VCC

15

Q4

OE

+5V

3

Q3

CLK

2

Q2

D

1

Q1

STR

10

5

6

7

9

P3.48P3.5

GND

P3.3(INT1)

P3.2(INTO)

8

QS

VEE

QS

Q8

Q7

Q6

16

Q5

VCC

15

Q4

OE

+5V

3

Q3

CLK

2

Q2

D

1

Q1

STR

P3.711(AIN0)P1.012(AIN1)P1.113P1.214P1.215P1.416P1.517P1.618P1.719VCC

3

XTAL24XTAL1

Input selection

Keys

P3.0(RXD)2P3.1(TXD)

1

RST/VPP

20

IC73

AT89C4051

+5V

2

MICROPROCESSOR CONNECTION DIAGRAM

13

IC76

TCM810MEND

+5V

PHONE71

Ipod IN

Circuit

18V Power Supply

Sandby control line

10k

10k

10K

2K2

Q717

+5V

Page 11

CD4094

11

KEY BOARD IC74&IC75

PIN CONFIGURATION

1

STROBE

2

DATA

3

CLK

4

Q1

5

Q2

6

Q3

7

Q4

89

VSS

16

15

14

13

12

11

10

VDD

OUTPUT ENABLE

Q5

Q6

Q7

Q8

Q'S

QS

2

CLOCK

*

3

STROBE

*

1

OUTPUT ENABLE

*

15

CL

p

Q

D

1

CL

CL

TR

CL

CL

TR

LATCH

TR

1

VDD

CL

CL

TR

3 - STSTE

1

p

4

Q1

Q

D

2

TR

DQ

CL

CL

n

8

CL

Q

CL

CL

STAGES

TR

VSS

3- 7

TR

LATCH

2

TR

3-

STATE

2

n

n

5

Q2

6

7121314

Q3 Q4 Q5 Q6 Q7

TR

LATCH

TR

8

3

STATE

8

11

Q8

p

n

SERIAL

OUT

10

Q'S

SERIAL

OUT

10

QS

*VDD

* ALLINPUTS

PROTECTED BY

CMOS PROTECTION

NETWORK

VSS

TL082D

MAIN BOARD IC41&IC42&IC43

OUTPUT A

INVERTING INPUT A

NON-INVERTING INPUT A

1

2

A

-

3

++

45

V-

8

V+

7

B

OUTPUT B

-

6

INVERTING INPUT B

NON-INVERTING INPUT B

Page 12

uPC1237HA

12

MAIN BOARD: IC44

8PIN PLASTIC SLIM SIP

1

8

ICS BLOCK DIAGRAM

VCC

78

1

2

Overload Detector

Output Offset Detector

Flip--Flop

VCC ON

MUTE

AC---OFF detector

Relay driver

6

5

GND

Switch for latch/automatic --reset

43

Page 13

24C01

13

KEY BOARD IC71

3,1&21),*85$7,21

)81&7,21$/%/2&.',$*5$0

9FF

6'$

6&/

:3

6/$9($''5(66

5(*,67(5

&203$5$725

1

NC

2

NC

3

NC

4 5

VSS

&21752/

/2*,&

8

VCC

7

NC

6

SCL

SDA

+,*+92/7$*(

*(1(5$725

7,0,1*&21752/

;

'(&2'(5

((3520

$55$<

*1'

:25'$''5(66

&2817(5

<

'(&2'(5

$&.

Q026

&ORFN

',2

!

5(*,67(5

'$7$

Page 14

A

T89C4051

14

KEY BOARD IC73

Pin Configuration

PDIP/SOIC

RST/VPP

(RXD) P3.0

(TXD) P3.1

XTAL2

XTAL1

( INT0 ) P3.2

( INT1 ) P3.3

(TO) P3.4

(T1) P3.5

GND

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

VCC

P1.7

P1.6

P1.5

P1.4

P1.3

P1.2

P1.1 (AIN1)

P1.0 (AIN0)

P3.7

Block Diagram

Vcc

GND

REGISTER

RAM ADDR.

REGISTER

B

ACC

TMP2

RMA

PSW

ALU

TMP1

INTERRUPT SERIAL PORT

AND TIMER BLOCKS

STACK

POINTER

FLASH

PROGRAM

ADDRESS

REGISTER

BUFFER

PC

INCREMENTER

PROGRAM

COUNTER

RST

TIMING

AND

CONTROL

OSC

INSTRUCTION

REGISTER

ANALOG

COMPARATOR

+

-

PORT 1

LATCH

PORT 1 DRIVERS

PORT 3

LATCH

PORT 3 DRIVERS

P 1.0 - P 1.7 P 3.0 - P 3.5 P 3.7

DPTR

Page 15

ALIGNMENT PROCEDURES

15

I. INITIAL

A. LOWEST VOLUME ADJUSTMENT

1. Tune the volume pot to lowest state.

2. Input a high voltage signal such as 5V from CD input.

3. Connect a oscilloscope to L channel binding posts.

4. Observing the oscilloscope,adjust VR301,make the output of speakers become to the

lowest level.

5. Adjusting VR302,make R channel output become to the lowest level by same way.

B. IDLING CURRENT

1. Level power on for a minimum of 5 minutes

2. Connect a DC voltmeter toTP1 and TP2 ,adjust VR22 for 4mV reading on voltmeter.

3. Connect a DC voltmeter toTP3 and TP4 ,adjust VR12 for 4mV reading on voltmeter.

C.ISC CIRCUIT ORIGINAL ADJUSTING

Adjust the pot VR3 to make the DC voltage of the point of TP10 to the same as TP11

II. FINAL ADJUSTMENT

Repeat procedure A,B and C for the lowest volume level, idling current alignment

and ISC original level respectively.

C325BEE

TP1

VR22

TP2

TP3

MAIN BOARD

TP10 TP11

VR3

VR12

TP4

VR302

VR301

Page 16

SCHEMATICS DIAGRAM

16

PREAMP CIRCUIT Vm1.2

PCB-1:MAIN BOARD Vm2.0

RCA31A

RCA31C

CD

RCA32A

RCA32C

RCA33A

RCA33C

RCA33E

RCA34A

RCA34C

RCA31B

RCA31D

CD

RCA32B

RCA32D

RCA33B

RCA33D

RCA33F

RCA34B

RCA34D

CB35

CON3

R31

470

R349

1M

R33

470

R351

1M

R35

470

R353

1M

R37

470

R355

1M

R39

470

R357

1M

R311

470

R337

1M

R313

470

R338

1M

R315

470

R339

1M

R317

470

R393

470

R394

1M

3

2

1

R396

470

R395

1M

R32

470

R350

1M

R34

470

R352

1M

R36

470

R354

1M

R38

470

R356

1M

R310

470

R358

1M

R312

470

R341

1M

R314

470

R342

1M

R316

470

R343

1M

R318

470

DISC

VIDEO

AUX

TUNER

TAPE2

REC2

TAPE1

REC1

Ipod-L

Ipod-R

DISC

VIDEO

AUX

TUNER

TAPE2

REC2

TAPE1

REC1

C314

100p

C31

100p

C33

100p

C35

100p

C37

100p

C39

100p

C311

100p

C313

100p

C315

100p

C317

100p

C304

100P

C305

100P

C32

100p

C34

100p

C36

100p

C38

100p

C310

100p

C312

100p

C316

100p

C318

100p

RL31B

RL32B

RL33B

RL34B

RL35B

RL36B

RL37B

RL38B

RL39B

RL39A

RL31A

RL32A

RL33A

RL34A

RL35A

RL36A

RL37A

RL38A

R345

220K

MF

LOW NOISE AMP

IN MODULE

R346

220K

MF

L-CH INPUTS

C319

0.1u 10%

1

2

3

CB32

4

5

6

7

8

9

R-CH INPUTS

C320

0.1u 10%

C324

47u/25

+18V

-18V

C323

47u/25

C325BEE RELAY CONTROL CIR.

D37

D38

D39

D310

D311

R407

1K

R361

30K

R362

30K

1N4148

N.I.

N.I.

Q403

A1015

Q404

C1815

TUNER

C335

N.I.

C336

N.I.

1N4148

5%,63V

C331 0.22u C333

1u,63V,5%

63V

C332

0.22u 5%

C334

1u,63V,5%

D312

R329

1K5 MF

RT32A

R331

390 MF

R330

1K5 MF

RT32B

BASS POT

10KA

R332

390 MF

R404

10K

R405

1K

BASS POT

10KA

LOW NOISE AMP

OUT MODULE

1N4148

1N4148

1N4148

1N4148

RL31C RL32C RL33C RL34C RL35C RL36C RL37C RL38C

DISC

CD

VIDEO

AUX

R391 560 1%

R392 560 1%

TONE DEFEAT SW

C301

10uF/50V

C325

47u/25

C321

0.1U

R319

N.I.

TONE DEFEAT SW

C326

47u/25

C322

0.1U

R320

N.I.

C325BEE TONE CONTROL CIR.

R325

390 MF

R321

3K3 MF

C327

63V

22n 5%

R363

51K

RT31A

TREBLE POTTREBLE POT

10KA

R323

750 MF

3K3 MF

R322

R324

750 MF

R402

10K

Q401

A1015

R403

1K

Q402

C1815

C329

0.1u 5%

63V

R327

180 MF

C328

22n 5%

C330

0.1u 5%

63V

R328

180 MF

OFF

ON

4u7/25V

SW31A

1

OFF

2

3

ON

R326

390 MF

R364

51K

RT31B

10KA

SW31B

4

5

6

+5V

VOLUME CONROL

RT33C

20KB

- +

M

C417

R406

1K

C303

220p

VR303

VR304

C418

4u7/25V

C302

220p

D313

1N4148

TAP2

RT33A

RT34A

CB33

RT34B

RT33B

20KB

VOLUME POT

VOLUME POT

20KB

20K MN

BALANCE POT BALANCE POT

20K MN

R448

100K

C434

22n/63V

D316

1N4148

TAP1

BY MOTOR

+18V

1

2

3

4

5

6

7

8

9

BY MOTOR

+18V

Q411

-18V

R451

330K

C337

0.1U

C339

1u/16

C338

0.1u

C340

1u/16

+12V

R489

100K

A1015

R435

390k

RL39C

-46V

CB31

TAP1

10

DISC

9

TAP2

8

TUNER

7

AUX

6

VIDEO

5

CD

4

+12V

IROUT

IRIN

220p

12V TRIG

Q31

K363

R389

10M

D315

1N4148

D314

N.I.

R390

10M

Q32

K363

+12V+12V

-46V-46V

+5V

+18V

-18V

Protection

Standby

Soft Cliping

Ipod

3

2

1

TO CZ72

PHONE1B

IR IN

PHONE1A

IR OUT

PHONE2

+12V Trigger

R347

C363

100K

100pF

R348

C364

100K

100pF

CB34

1

2

3

4

5

6

7

8

9

TO CZ71

RCA35A

L PRE-OUT

RCA35B

R PRE-OUT

+12V

+5V

RI510K

RI1 10K

RI6

VR301

100

R385

1.8

R386

1.8

VR302

100

D423

1N4148

10K

RI7

C362

330,5%

10n

RI3

33

R2

10

C3 0.1uF

R335

68

C343

220p

R333

4.7K

C344

R336

68

R334

4.7K

+5V

+18V

-18V

Soft Cliping

REMOTE MUTE

Standby

Protection

+5V

VOLVOL+

QI1

2SC1815

Ipod

+5V

RI2

RI4

1K

4.7K

QI2

2SA1015

C345

0.1uF

C341

47u/25

C349 N.I.

R387

20K

R383

560 1%

R384

560 1%

R388

20k

C350 N.I.

C346 0.1uF

C342

47u/25

R436

56K

R457

220K

PREAMP IN/OUT MODULE BOARD Vm1.2

PCB-6/7:OUT/IN MODULE BOARD Vm1.0

CZ61

+18V

1

LOUT

2

LIN-

3

LIN+

4

GND

5

RIN+

6

RIN-

7

ROUT

8

-18V

9

CON9

C68

0.1u 20%

R621 30K

C611

Note:C611 is 43pF ON "IN MODULE"

75pF ON "OUT MODULE"

R62

220

R64

1M

C62

220p

C610

100p

R68

1K

Q62

2SK170

C67

0.1u 20%

R610

430 2%

C64

22p

D63

1N4148

D64

1N4148

R614

10K

Q65

A970

R612

1K

R617

C63

22p

D61

1N4148

D62

1N4148

R613

10K

Q63

A970

R611

1K

Q67

D667

R615

33

R61810R619

Q64

B647

10

C66

Q68

0.1u 20%

D667

R616

R620

33

10

10

Q66

B647

R61

220

R63

1M

C61

220p

C69

100p

R67

1K

Q61

2SK170

C65

0.1u 20%

R69

430 2%

Page 17

SCHEMATICS DIAGRAM(1/4)

17

AMP CIRCUIT Vm1.4

PCB-1:MAIN BAORD Vm2.0

+46V

-46V

RCA35D

1

2

3

S41A

RCA35C

MAIN-IN R-CH

D410

20V

OFF

S41B

ON

D411

20V

MAIN-IN L-CH

22n 10% 63V

C219

47uF/25V

C119

R158

2.2k

R258

2.2k

C12/1

+46V

+37V

Q12/1

A1015

+12V

ISC Circuit:

It switch the power

supply to lower voltage

when the load

impedance is low, or the

temperature on the

heatsink is over 80C

degree

Over Heat Protection:

It shuts down the unit

when the temperature on

the heatsink is over 90C

degrees.

It also shuts down the unit

when the unit enters the

standby mode.

R427

22/1W FP

Q413

KSC2690

C419

10uF

R495

510

12V TRIG

+18V

Q414

C1815

Q423

C2240

+18V

STANDBY

R438

22K

R439

T0=90 degree C

POSISTOR

R483

270K

RL12/1

F1AA012V

O/P RELAY

5 6

3 4

1 2

D412

1N4148

R437

47K

D43

1N4148

D42

1N4148

+18V

C443

0.1uF

Q422

D667

R494

12

C446

10uF

C429

10u/25V

R477

47K

R473

43K

C426

10u/25V

D431

3.6V

R428

2K2

C49

47u/25V

C411

0.1uF

R429

5K1

C410

47u/25V

C412

0.1u

-18V

+18V

R474 1K

C430

10u/25V

R472

470K

8

6

5

IC43B

TL082D

4

R476

1K

-18V

ISC CIRCUIT

R446

R445

56K

56K

R12/2

22K

1

Q412

0V

C1815

2

0V

0V

0V

C422

330u/16V

PROTECTION CIR.

SUPPLY CIR.

D49

18V

R414

2K2

MF

STANDBY

R413

680

R412

2K

MF

7

D418

1N4148

C431

10u/25V

R490

100K

R491

100K

1N4148

+3.25V

+2.16V

8

345

R471

10K

D420

+46V

C432

0.22u

R411

680

C41

0.1uF

R410

680

C48

10u/25V

R441

4.7K

R442

56K

7

IC44

UPC1237HA

R401

4K7

D417

1N4148

C420

100u/16V

+2.0V

Q41

R45

2SC2690

C46

22p

C428

10u/25V

+18V

C45

22p

Q43

C1815

Q44

A1015

Q42

2SA1220

C425

10u/25V

2

3

220/2W FPR452

220/2W FP

R440

2K2

R443

150 1/2W FS

33/0.5W FS

C413

220u/35V

R47

680

R48

680

C414

220u/35V

R46

33 / 0.5W FS

R482

4K7

R478

100K

R479

100K

R480

3K9

R OUT

L OUT

C47

47u/25V

R49

680

D403

1N4148

R470

TP10

10K

1

IC43A

TL082D

TP11

R487

18K

R488

18K

D419

1N4148

R453

6

C421

4u7/50V

+37V

R41

680

R43

680

C43

220u/63V

C44

220u/63V

R44

680

R42

680

R493

180k

VR3

10K

+18V

CB45

CZ45

1

1

2

2

3

3

4

4

5

5

R454

100,2W

+18V

C445

100uF

C444

4700uF/16V

D430

-37V

I-V

AC DET.

ISC TRIG

+18V

D428

R469

R468

1N4148

10K

22K

Q421

C1815

R467

T0=80 degree C

BINDING POSTS

4

3

2

1

N8C320D03

JK41

PHONES SOCKET

R455

100,2W

C325BEE HEADPHONE BOARD Vm1.2

PCB-10:HEADPHONE Vm1.0

STANDBY

Protection

Soft Cliping

+5V

+18V

-18V+5V

+12V

-18V

-46V

+12V

-46V

Standby

DB104

SPKOUT

+5V

2

IC45

1

AMS1117-5.0

3

*

CB47

1

2

3

4

5

6

7

7PIN

R130

82/1W FS

R169

1M2

+18V

R154

10

C13

10u/35V

C12

1nF

R149

68,1/4 1% MF

C22

1nF

R249

68,1/4 1% MF

C14

10u/35V

R155

10

R254

10

C23

10u/35V

C24

10u/35V

R255

10

39k,MF,5%

39k,MF,5%

-18V

+18V

39k,MF,5%

39k,MF,5%

-18V

R110

R210

C11

R11

470

R12

220K

A1015

R420

36K

4

5

6

R421

36K

C1815

R21

470

R22

220K

10u/16V

C17

0.1uF/63V

Q47

Q48

C1815

10u/25V

10u/25V

R419

100

C415

C416

R417

100

Q45

A1015

C27

0.1uF/63V

C21

10u/16V

R25

22K

R418

100

R422

1.3K

R424

1.3K

R425

1.3K

R423

1.3K

R416

100

Q46

+18V

R14

100

-18V

R15

22K

SOFT CLIPING CIR.

+18V

R24

100

-18V

CZ11

CZ11

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

CON8

CON9

CZ21

CZ21

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

CON8

CON9

39K,MF,5%

R101

Q103

C3324-GR

R119

220k,MF,5%

220k,MF,5%

220k,MF,5%

220k,MF,5%

R103

R106

Q104

A1312-GR

Q203

C3324-GR

R203

R206

Q204

A1312-GR

82,MF,5%

82,MF,5%

82,MF,5%

82,MF,5%

82,MF,5%

Q16

A1015

C18

39p

Q18

2SB647

Q19

C19

2SD667

39p

Q17

C1815

R120

82,MF,5%

P/N: 01-32520-02

AMP-SMD MODULE R CHANNEL Vm1.4

PCB-5:AMP-SMD-R Vm1.0

R219

82,MF,5%

Q26

A1015

C28

39p

Q28

2SB647

Q29

C29

2SD667

39p

Q27

C1815

R220

82,MF,5%

P/N: 01-32520-01

AMP-SMD MODULE L CHANNEL Vm1.4

PCB-4:AMP-SMD-L Vm1.0

R121

100K,MF

R123

D14

1N4148

C124

R169

R221

100K,MF

R223

D24

1N4148

C224

R269 330

D13

1N4148

47K

D23

1N4148

47K

D15

1N4148

D16

1N4148

R122

100K,MF,5%

1nF

330

D25

1N4148

D26

1N4148

R222

100K,MF,5%

1nF

C103

22uF/16V

R111

100,MF,5%

Q12

A1312-GR

Q13

C3324-GR

R112

100,MF,5%

22uF/16V

22uF/16V

R211

100,MF,5%

Q22

A1312-GR

Q23

C3324-GR

R212

100,MF,5%

22uF/16V

C104

R159 100,5%

L12 100uF

C203

C204

R259 100,5%

L22 100uF

Q101

Q14

C3324-GR

R115

15

R116

15

Q15

A1312-GR

Q102

A1312-GR

R105

39k,MF,5%

39K,MF,5%

R201

Q201

Q24

C3324-GR

R215

15

R216

15

Q25

A1312-GR

Q202

A1312-GR

R205

39k,MF,5%

R102

C3324-GR

R104

R202

C3324-GR

R204

R19

R29

C15

220uF/63V

D102

1N4148

D103

1N4148

C16

220uF/63V

R131

82/1W FS

R230

82/1W FS

R269

1M2

C25

220uF/63V

D202

1N4148

D203

1N4148

C26

220uF/63V

R231

82/1W FS

R162

1K

R262

1K

D101

1N4148

R163

1K

Q117

2SA970

Q118

2SC2240

C123

0.1uF

R168

1K

D201

1N4148

R263

1K

Q217

2SA970

Q218

2SC2240

C223

0.1uF

R268

1K

POWER AMP CIR. L

3K3/2W FP

330/0.5W FP

R164

R165

10K

10K

R166

5K6

IC11

AZ431

R167

1K

POWER AMP CIR. R

R264

R265

10K

10K

R266

5K6

IC21

AZ431

R267

1K

KSA1220

Q110

Q111

KSC2690

330/0.5W

R126

R132

3K3/2W FP

R128

R124

3.3/0.5W FP

D11

4.7V

C110

47u/25V

D12

4.7V

C111

47u/25V

R125

R137

3.3/0.5W

R129

R127

R133

3K3/2W FP

3K3/2W

R226

R232

3K3/2W

3K3/2W FP

R228

330/0.5W FP

R224

3.3/0.5W FP

Q210

KSA1220

C210

47u/25V

C211

47u/25V

Q211

KSC2690

R225

R229

R233

3K3/2W FP

R237

3.3/0.5W

10

FP

330/0.5W

R227

3K3/2W

470p,100V,20%

R138

430

FS

10

470p,100V,20%

470p,100V,20%

D21

4.7V

R238

430

D22

4.7V

FS

470p,100V,20%

R142

22,MF,5%

R107

39,MF,5%

C112

R136

Q112

10

FS

KSC2690

TP3

VR12

R144

200

0.068/3W CE

C127

N.I.

R145

0.068/3W CE

Q116

KSC2690

TP4

R139

412

Q113

KSA1220

C113

R108

39,MF,5%

R143

22,MF,5%

R242

22,MF,5%

R207

39,MF,5%

C212

R236

Q212

KSC2690

FS

10

TP1

VR22

R244

200

0.068/3W CE

C227

N.I.

R245

0.068/3W CE

Q216

KSC2690

TP2

R239

412

Q213

KSA1220

C213

R208

39,MF,5%

R243

22,MF,5%

Q115

Q114

2SA1943

2SC5200

Q214

2SA1943

R147

1K

R247

1K

Q215

R148

15K

R146

1K8,1W,1%,MF

D27

1N4148

R248

15K

C220

22n 10%

63V

R246

1K8,1W,1%,MF

2SC5200

D17

1N4148

C120

22n 10%

-46V

+46V

-46V

0.1u

C215

0.1u

C114

0.1u

C115

C214

0.1u 10% 63V

R12/1

6K8

R152

22K

Q11

C1815

R156

470K

3

2

IC41A

TL082D

R157

470K

R252

22K

Q21

C1815

R256

470K

5

6

IC42B

TL082D

R257

470K

R151

10/1W FS

L11

0.5uH

R251

10/1W FS

0.5uH

R250

1/1W FP

R150

1/1W FP

L21

C118

0.1u 10% 63V

R160

48

1K,5%

R161

1K,5%

1uF,63V,5%

R260

48

1K,5%

R261

1K,5%

1uF,63V,5%

C121

1uF,63V,5%

1

C122

C218

0.1u 10% 63v

22n 10% 63V

C221

1uF,63V,5%

7

C222

-18V

+18V

-18V

+18V

P5-GND

-46V+46V

P3-RP4-R

-46V+46V

P1-LP2-L

Page 18

SCHEMATICS DIAGRAM(4/4)

18

C325BEE IR BOARD Vm1.0

PCB-11:IR BOARD Vm1.0

P9

IC72

IS1U60L

SHIELDING

S78 STANDBY

RED GREEN

CZ73

1

2

12345

CB73

R71

330

+5V

+12V

R701

2K2

R766

4.7K

3 4

VCC

3

2

R72

470

C1815

Q73

C1815

1

SIGNAL

5

Q74

GND

IR RECEIVER

C325BEE STANDBY BOARD Vm1.0

PCB-8:STANDBY BOARD Vm1.0

POWER/PROTECTION IND.

D717

513AW

Q72

C1815

CZ76

R730

15K

3

1 2

D715

1N4148

D718

1N4148

CB72

CON3

PROTECTION

IPOD BAORD Vm1.0

PCB-9:IPOD BOARD Vm1.0

Ipod GREEN

R759

D719

TP701

C760

C758

PHONE71

Ipod IN

TO MAIN BOARD CB35

+5V

R703

2K2

Q717

2SC1815

R764

10K

R725

2K2

2k2

D716

GREEN

C721

Q718

10nF

C1815

R760

4k7

+5V

+12V

SOFT CLIPING

+12V

+5V

G

R

123

100p

L

CZ75

TAPE1

DISC

TAPE2

TUNER

AUX

VIDEO

CD

+12V

IR OUT

IR IN

SOFT CLIPING

REMOTE MUTE

PROTECTION

+5V

VOLVOL+

IPOD

C759

100p

0.1uF

CZ74

CB74

123

123

4

4

CZ76

TO CB31

CZ71

TO CB34

1

2

3

4

5

6

7

8

9

10

9

8

7

6

5

4

3

2

1

+5V

C78

0.1u

IC73

20

VCC

19

P1.7

18

P1.6

17

P1.5

16

P1.4

15

P1.2

14

P1.2

13

(AIN1)P1.1

12

(AIN0)P1.0

11

D73

VIDEO

VIDEO AUX TAPE2 TUNER DISC TAPE1CD

C714

Q79

10n

C1815

R741

4K7

R749

4K7

AU

C724

C725

N.I.

C716

10n

R757

10K

R743

4K7

N.I.

S76

TAPE2

C717

10n

R744

4K7

S75

DISC

S74

TAPE1

+12V

D714

1N4148

R727

2K2

D72

D74

TUNER

C718

10n

R745

4K7

TAPE1

GREEN

Q713

C1815

R753

4K7

C

GREENGREEN GREEN GREEN

Q712

C1815

R752

4K7

DI

S77

CD

R756

10K

D76

TAPE2

Q711

C1815

R751

4K7

TU

R763

10K

P22

P21

P20

P02

P01

P00

R758

10K

+5V

D71

AUX

C715

Q710

10n

C1815

R742

4K7

R750

4K7

TA2

C719

10n

R746

4K7

S73

VIDEO

S72

TUNER

S71

AUX

TA1

R754

4K7

Q714

C1815

D77

CD

GREEN

R726

2K2

C720

10n

R747

4K7

R761

4K7

IP

C723

100uF/16V

R762

10K

R702

10K

D75

DISC

AMBER

Q715

C1815

C71

100u/16V

+5V

+5V

0.1u 20%

8

IC75

4094

10

IR BLINK

MUTING BLINK

Q716

C1815

+5V

C77

10n

IC71

1

2

3

+5V

C711

VEE

R733

5K1

NC

NC

NC

Vss4SDA

24C01

16

15

VCC

8

Vcc

7

NC

6

SCL

5

C722

N.I.

C79

27p

3

2

1

D

OE

STR

CLK

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

VOL+

VOL-

3

2

1

R73 10K

D710

1N4148

D711

1N4148

D712

1N4148

D713

1N4148

REMOTE MUTE

IR IN

IR OUT

C72

0.1uF

+5V

R708

10K

Y71

11.0592MHz

C710

27p

8

VEE

10

CVITU

IP

2

IC76

R765

TCM810MENB

N.I.

1 3

1

RST/VPP

2

P3.0(RXD)

3

P3.1(TXD)

4

XTAL2

5

XTAL1

6

P3.2(INTO)

7

P3.3(INT1)

8

P3.4

9

P3.5

GND10P3.7

AT89C4051

C712

0.1u 20%

16

3

2

15

1

IC74

D

OE

4094

STR

CLK

VCC

Q14Q25Q36Q47Q514Q613Q712Q811QS9QS

R748

4K7

TA2

TA1

DI

VI

AU

KEY BOARD Vm1.2

PCB-3:KEY BOARD Vm1.0

Page 19

SCHEMATICS DIAGRAM (3/4)

19

POWER CIRCUIT Vm1.2

PCB-2:POWER BOARD Vm2.0

RED

WHITE

RED

WHITE

CB54

CB52

CB58

CB53

2

1

2

1

2

1

1

2

3

4

5

6

7

+46V

-46V

TRIG

AC DET.

I-V

+37V

-37V

~8V

0V

R531

0.05/3W 5% CE

A1015

Q510

R533

R567

1M

330K

+46V

-46V

R532

220

Q59

A1015

R534

2K2

R566

4K7

R562

1K

D531

TIC116D

15000uF/50V 10%

15000uF/50V 10%

Q519

A1015

C1815

Q520

R561

100

Q517

A1015

C517

C518

R565

100

R564

22K

D513

1N4004

Q518

C1815

R563

22K

R558

1K

D532

TIC116D

R544

22K

R560

1K

R559

1K

D55

KBU8D

NAD C325BEE POWER CIR.

!!

C52

D51

KBU8D

C523

3300u/50V

C524

2200u/50V

10n/250V

10%

C51

10n/250V

10%

+37v

D56

DB104

-37v

F51F52 F54 F53

F55

500mA/250V

6.3A/250V X4

C54

0.47uF

C53

4.7nF/400V

36.4V

36.4V

28.5V

28.5V

CB55

CZ55

3

3

2

2

1

1

CON3

CB56

1

2

3

CON3

CB59

1

2

3

CON3

CB57

3

1

CON3

CB51

1

2

0V

3

4

5

8V

6

0V

7

CON7

CZ56

1

2

3

CON3

CZ59

3

2

1

CON3

CZ57

1

2

3

CON3

CZ51

7

6

5

4

3

2

1

CON7

RED

VIO

BLK

ORG

GRY

AC POWER CORD

POWER SWIT CH

SW52

1

1

2

2

AC outlet

T401

!

(For AH version)

!

Transformer

Page 20

PCB-1: MAIN BOARD Vm2.0

SPKOUT

CB45

C445

IC45

C444

JDD

JDK

0VAC

GND

PL

R452

8VAC

-37

L-OUT

PR

C218

R251 L21

TRIG

AC DET

I-V

+37

D430

CB47

C219

S41

GND

RL12/1

J1

J2

R250

D412

R467

Q215

P1-L

(-46V)

WHITE

RED

(+46V)

Q214

P2-L

TP9

Q114

P4-R

(+46V)

RED

WHITE

(-46V)

Q115

P3-R

R439

J125

J193

J191

J164

(+46V)

J142

R453

TP5

J192

TP2

C215

C214

TP1

TP6

P5-GND

TP8

TP3

J143

C114

C115

TP4

TP7

J3

L-OUT

(DGND)

R245

R244

J166

J124

R150

J165

C119

(GND)

J144

J126

J123

R144

R145

J43

R478

RI2

RI5

C362

(+12V)

J34

MUTE

STANDBY

PROTECT

VOL-

R493

VOL+

J49

J50

Q413

H1

Q423

CB31

+5V

Ipod

PHONE2

R2

C3

RI3

RI4

QI2

RI6

RI7

RI1

J38

J37

QI1

(+5V)

J35

J36

IR IN

IR OUT

+12V

CD

VIDEO

AUX

TUNER

TAPE2

DISC

TAPE1

J203

CB34

R494

C446

R483

R-OUT

J7

C118

J6

L11

R-OUT

R151

J5

H7

C213

J199

Q211

Q213

(DGND)

Q216

C227

J195

J196

J197

J198

J190

J189

(GND)

(L-OUT)

J188

J171

R246

J167

(DGND)

(GND)

J169

J168

J146

J145

J147

J148

R146

C113

J122

J120

J121

J173

J172

C212

J170

Q212

Q210

H6

H4

Q112

Q110

C112

J141

J140

J134

(R-OUT)

J133

(GND)

VR12

J127

Q111

Q113

Q116

J119

C127

H5

J4

R487

R490

D419

R445

R446

D420

R491

R488

J10

J9

J8

(GND)

RCA35

C363

J13

R347

R348

Q31

Q32

C343

R389

D315

R334

R336

R335

J12

J11

R333

RCA34

C364

C344

C317

R390

D314

R339

R317

R318

C318

J25

R343

R315

C315

J26

RL38

RCA33

R338

R342

R316

R313

C313

C316

J28

J27

D313

R341

R337

R314

R311

C314

C311

J29

RL37

D312

R358

R357

R310

R39

R312

C39

C312

RL36

D311

COPYRIGHT C 2006

(MAIN IN L)

(GND)

(MAIN IN R)

(GND)

J31

J30

J200

R242

R225

R239

R237

R233

R230

R227

R238

R207

R229

D22

D21

R236

R228

J174

R224

R247

R208

R243

J162

J163

J149

R143

R147

R108

C25

C211

J187

J186

VR22

C210

C26

J175

R232

R231

R226

J161

J160

Q21

C220

Q11

C120

J150

R132

R126

R130

C416

J151

J14

R258

R257

R256

R261

R260

J201

J185

J184

J176

CB21

J177

J202

D27

R424

R422

R248

R252

J155

Q45

Q46

J205

J156

J158

J157

Q47

Q48

C415

R418

R420

D410

R148

R152

D17

CB11

C15

R136

R128

D11

R124

R142

C110

J130

J129

C111

D12

J152

R138

R107

R125

J128

R129

R139

R137

R127

R133

J132

J131

C16

R131

R160

R158

R157

R156

R161

C332

C334

(PRE OUT L)

J15

J16

J17

J18

IC42

C27

C21

R25

R24

R21

R22

J178

D202

R416

R425

R417

R423

Q217

R262

Q218

R263

J159

J154

Q118

R163

Q117

R162

D411

D102

D103

R421

R419

J138

J206

J137

R11

R12

C11 C17

R15

R14

IC41

VR304

VR303

J105

J109

R332

R330

R331

J107

J108

(PRE IN L)

(GND)

(PRE OUT R)

(GND)

J22

J19

J21

J20

BUS-BAR (PRE-GND)

C222

C221

J183

(GND)

(GND)

J180

J181

J179

D203

R268

C223

R267

R265

R264

IC21

R266

J207

D101 D201

R164

IC11

R166

J153

R165

R167

R168

C123

J139

(GND)

J136

J135

C122

J104

J106

C333

C331

R361

RT32

J23

J75

(+18V)

J182

J96

(MAIN IN R)

J97

J98

C121

SW31

R329

R362

J76

J77

J78

(PRE IN R)

J24

(+18V)

(-18V)

(-18V)

(+18V)

J79

(GND)

C323

C324

(GND)

J84

J85

J86

J94

J95

J99

(+18V)

PRE OUT L

R328

R327

R325

R321

R323

C330

R363

NAD C325BEE MAIN BOARD Vm2.0

CB32

J73

(-18V)

J80

CB33

(PRE OUT R)

(-18V)

J100

C322

C326

R346

R392

C320

C319

R391

R345

C325

C321

J93

J110

J81

J83

C342

J92

J103

C341

R326

R319

R320

R324

R322

C328

R364

C335

(GND)

(-18V)

J82

C346

J101

J102

C345

C327

C329

RT31

C310

C339

C336

R37

RL35

(GND)

RCA32

R356

R353

R355

C37

D310

R354

R38

C38

RL34

R36

R35

C35

C36

D39

NAD ELECTRONICS

J39

C429

C426

C430

J74

J45

J48

J47

J44

R441

Q12/1

(-37V)

(+37V)

J55

J54

C49

C411

C43

C44

C338 C340

J114

D43

R438

R442

R437

C47

R41

C410

C48

C301

J90

(PRE IN R)

C417

Q401

J117

J115

J116

(GND)

RT34

J72

J71

J70

(+18V)

J69

J68

J67

C412

R384

R386

VR302

R388

C350

J91

(PRE IN L)

R383

VR301

R387

R385

C349

C337

J112

J111

(GND)

J113

RCA31

R351

R352

R34

R33

C33

C34

RL33

D38

R473

R472

R477

R469

R468

R474

Q421

(+18V)

D428

R443

C12/1

R12/2

R12/1

J53

IC44

J56

D42

Q412

C420

C413

R49

R43

R45

J66

C45

R42

R46

R44

R410

J87

C46

C414

Q402

C303

R406

R407

R402

R403

R405

R404

J118

R480

R412

C418

Q403

R350

R349

R31

C31

RL32

D37

J32

TP10

TP11

IC43

J42

D417

D418

J41

R440

D423

C432

J58

J57

H3

C421

R411

R413

D49

Q41

R47

Q43

D403

Q44

R48

J88

R414

Q42

Q404

C302

H2

J89

PHONE1

CB35

R394

R395

R32

R393

R396

C32

C304

C305

RL31

R479

J40

Q411

R436

R489

R435

J204

RT33

RL39

D316

(DGND)

J33

(GND)

C431

C428

SOFT CLIPPING

R476

C425

(DGND)

R471

R470

R482

VR3

C434

J46

R448

R457

R451

J51

J52

C422

J59

J60

J61

J62

J63

J64

C419

C41

J65

C443

Q414

R428

R429

R401

R427

R495

Q422

20

Page 21

PCB-7:IN MODULE Vm1.0

COPYRIGHT C 2006 NAD ELECTRONIC

NAD C325BEE

R614

Q66

R616

R618

Q68

Q65

Q62

R68

C610

R610

MODULE BOARD Vm1.0

OUT

J61

D64

C67

C65

C66

C68

D61

D63

R612

C63

C64

C62

C61Q61

R64

R62

R61

R63

D62

R615

R613

Q67

R69

R611

Q64

Q63

C69

R617

R67

PCB-2:POWER BOARD Vm1.0

R563

R566

R564

R559

R560

F54

Q518

J513

J510

C52

R565

To AC cord

F53

CB55

C54

D55

D532

R558

Q517

CB51

Q520

Q519

J52

J57

RED

CB57

To Thansformer

C53

CB59

To AC Outlet

J520

J51

C518

CB56

To Power Switch

RED

+46V

CB54

WHITE

-46V

R620

CB61

R621

C611

R619

PCB-6:OUT MODULE Vm1.0

COPYRIGHT C 2006 NAD ELECTRONIC

NAD C325BEE

R614

Q66

R616

R618

Q68

Q65

Q62

R68

C610

R610

R620

CB61

MODULE BOARD Vm1.0

IN

J61

C65

D63

C64

R62

R64

R621

C67

C68

R61

D62

R615

D61

C63

Q61C61

R63

C611

D64

C66

R612

C62

R613

Q67

R611

R69

R619

Q64

Q63

C69

R617

R67

R531

CB53

CB58

J519

WHITE

-46V

TRIG

AC DET

I-V

+37V

-37V

8VAC

0V

(GND)

RED

+46V

CB52

J56

J514

(-46V)

BLUE

(GND)

J512

D531

F51 C51

Q59

Vm2.0

NAD ELECTRONICS

COPYRIGHT C 2006

NAD C325BEE

Q510

F52

R532

R567

R534

R562

R561

R533

D51

J516

J518

J54

J58

T500MAL/250V

F55

J515

(GND)

D56

J517

C524

C517

R544

D513

C523

21

Page 22

PCB-3:KEY BOARD Vm1.0

C72

IC71

J78

J792

Q72

CB73

R708

D713

Q73

J714

J79

J710

R71

R701

J712

RED

D714

J716

J715

(GND)

J71

J72

J74

J73

D712

D711

D710

RED

Q74

CB74

R763

R72

J711

R759

R758

J717

R756

J713

J75

J719

J718

C710

Y71

IC73

C725

D74

S75

R757

C79

C711

(+5V)

R765

J734

(GND)

(+5V)

C78

J733

D75

(+5V)

J724

J727

R726

J725

S74

C724

J721

J722

J723

J720

(+5V)

J735

J793

J726

IC75

IC74

C712

J736

(GND)

J737

R733

D718

J732

D72

D71

J776

J730

J731

J728

D76

J729

COPYRIGHT C 2006

NAD ELECTRONICS

C325BEE KEY BOARD Vm1.0

76

S

S72

S71

R752

R754

J738

(GND)

R748

R761

R760

R749

C721

D73

S73

R751

R750

R747

Q718

J

7

39

J740

R745

C718

C720

R727

J741

S7

Q713

Q715

J745

D77

J742

Q716

7

R744

R743

C716

C717

Q712

Q711

J744

J743

R762

J752

(GND)

R703

R725

R764

J753

R753

R742

C715

Q710

J746

J747

R702

R730

R73

C722

CZ72

Q79

R741

C714

C723

Q717

(GND)

R746

C719

Q714

J748

J749

(GND)

J750(GND)

D716

J794

CZ71

RED

C77

C71

CB72

D715

J76

J77

PCB-8:STANDBY BOARD Vm1.0

C325BEE STANDBY

BOARD Vm1.0

S78

D717

CZ73

RED

PCB-9:IPOD BOARD Vm1.0

C325BEE IPOD BOARD Vm1.0

C760

TP701

D719

L

RED

PHONE71

CZ74

WHITE

C758

R

RED

CZ75

PCB-11:IR BOARD Vm1.0

CZ76

IC72

C759

RED

S

G

V

PCB-10:HEADPHONE BOARD Vm1.0

C325BEE HEADP Vm1.0

R455

R454

J41

CZ45

JK41

22

Page 23

PCB-5:AMP-SMD-R BOARD Vm1.0

(TOP VIEW)

C325BEE AMP-SMD-R Vm1.0

D16

C104

Q19

Q18

D13

C103

P/N: 01-32520-02

(BOTTOM VIEW)

D14

R104

R155

R122

R106

R110

R120

Q104

Q102

R112

C14

R105

Q17

R123

C19

Q15

Q13

C18

R116

L12

R169

C124

Q103

Q16

Q14

R115

Q12

R159

R111

R149

Q101

R19

C13

CZ11

D15

R103

R121

C12

R119

R101

R102

R154

D24

R204

R255

R222

R206

R210

R220

C325BEE AMP-SMD-L Vm1.0

D26

C204

Q204

Q202

R212

C24

R205

Q27

R223

Q29

C29

Q25

Q23

Q28

C28

Q203

Q26

Q24

R216R215

Q22

R259R249

L22

R269

C224

R211

Q201

R29

D23

C203

C23

D25

R203

R221

C22

R219

R201

R202

R254

CZ21

PCB-4:AMP-SMD-L BOARD Vm1.0

(TOP VIEW)

P/N: 01-32520-01

(BOTTOM VIEW)

23

Page 24

TROUBLESHOOTING GUIDE

24

PUSH THE POWER SUPPLY

SWITCH TO ON

IS THE AMBER LED AMBER

LIGHT?

YES

CAN PRESSING ANY KEY MAKE

THE UNIT WORK NORMALLY?

YES

IS THE SPK OUT NORMAL?

YES

NO

IS IT RED?

YES

NO

ARE ALL POWER SUPPLIES OK?

NO

IS THE ABMER LED GREEN?

YES

YES

NO

NO NO

IS THE OUTPUT DC LEVEL

NORMAL?

YES

IS THERE SIGNAL OUTPUT? NORMAL?

YES

CHECK THE AMBER LED CONTROL

CIRCUIT(Q72,Q73,Q74,LED717)

CHECK 12V SUPPLY

NO

YES

YES

NO YES

YES

IS IT GREEN?

IS THE STANDBY SINGAL LOW

LEVEL?

NO

YES

NO

NO

IS THE POWER AMP INPUT

NO

IS THE MUTE SIGNAL OFF?

NO

IS THE VOLUME CONTROL CIRCUIT

NORMAL?

YES

ARE THE TWO MODULES NORMAL?

YES

NO

YES

YES

NO

NO

CHECK THE 5V SUPPLY CIRCUIT

(ON POWER BOARD)

CHECK THE LED CONTROL

CIRCUIT(Q72,Q73,Q74,LED717)

AND PROTECET CIRCUIT

CHECK THE POWER SUPPLIES

CIRCUIT

CHECK THE PROTECT CIRUIT

CHECK THE STANDBY CONTROL

CIRCUIT

CHECK THE KEYS CONNECTIONSOME KEYS IS USELESS?

CHECK MCU AND RELAY

CONTROL CIRCUIT

CHECK THE SERVO CIRCUIT

CHECK THE POWER AMP CIRCUIT

SECTION

CHECK THE MUTE CONTROL

CIRCUIT

CHECK THE VOLUME CONTROL

CIRCUIT

CHECK THE MODULES CIRCUIT

CHECK THE TONE CIRCUIT

IS THE REMOTE CONTROL OK?

YES

IS THE 12V SUPPLY NORMAL?

YES

OK

IS THE THD HIGH?

YES

IS THE IDLE CURRENT NORMAL?

YES

NO

NO

IS THE IR IN/OUT NORMAL?

YES

IS THE REMOTE HANDSET ITSELF

NORMAL?

YES

IS THE 18V SUPPLY NORMAL?

NO

NO

NO

NO

IS THE S/N RATE BAD? TURN THE TRANSFORMER

NO

YES

ADJUST THE IDLE CURRENT OR

CHECK THE IDLE CURRENT

CIRCUIT

CHECK THE POWER AMP CIRCUIT

(IF SOME TRANSISTORS ARE

DEFEATED)

CHECK THE IR IN/OUT

CONNECTION OR CIRCUIT(PARTS)

REPLACE THE BTTERIES OR

ANOTHER REMOTE CONTROL

HANDSET

CHECK THE IR CONTROL CIRCUIT

(INCLUDE THE IR RECEIVER AND

MCU)

CHECK THE 18V SUPPLY

YES

DID THE 12V SUPPLY SHORT

GROUND?

CHECK THE CONNECTION

AND CHECK IF THE RELATIONAL

TRANSISTORS ARE DEFEATED

Page 25

ELECTRIAL PARTS LIST

25

PCB-1: MAIN BOARD

CIRCUIT NO. PART NO. DESCRIPTION

ICS

IC41, IC42, IC43 03-00082-00 TL082CP/CN/D

IC44 03-01237-00 UPC1237HA

IC45 03-01117-01

IC11, IC21 03-00431-03 AZ431BZ-B

DIODES

D430 DB104

D17, D27, D101, D102,

D103, D201, D202, D203,

D37, D38, D39, D310,

D311, D312, D313, D315,

D316, D42, D43, D403,

D412, D417, D418

D419, D420, D423, D428 1N4148 (Pitch=10mm)

D11, D12, D21, D22 4.7V, 0.5W

D410, D411 20V, 0.5W

D49 18V, 0.5W

TRANSISTORS

Q31, Q32 31-00363-00 2SK363

AMS1117-5.0/

LM1117MPX-5.0

1N4148 (Pitch=7.5mm)

Q31, Q32 or 31-00369-00 2SK369

Q31, Q32 or 31-00170-00 2SK170

QI2, Q12/1, Q44, Q45, Q47,

Q401, Q403, Q411

QI1, Q11, Q21, Q43, Q46,

Q48, Q402, Q404, Q412,

Q414, Q421

Q117, Q217 31-00970-00 2SA970 GR

Q423, Q118, Q218 31-02240-00 2SC2240

Q422 31-00667-00 2SD667A

Q413, Q41, Q216, Q211,

Q212, Q112, Q116, Q111

Q42, Q213, Q210, Q110,

Q113

C45, C46 05-22012-00 22p, 100V, ±10%

C31, C32, C33, C34, C35,

C36, C37, C38, C39, C304,

C305, C310, C311, C312,

C313, C314, C315, C316,

C317, C318, C363, C364

C343, C344, C302, C303 05-22151-01 220p, 50V, ±10%

C112, C113, C212, C213 05-47112-00 470p, 100V, ±10%

31-01015-00 2SA1015 GR

31-01815-00 2SC1815

31-02690-00 KSC2690AYSTU

31-01220-00 KSA1220AYSTU

CAPACITORS

05-10151-01 100p, 50V, ±10%

C362 05-10312-00 10n, 100V, +50%-20%

C120, C220, C434 24-22312-04 22n, 100V, ±10%

C123, C223, C3, C41, C443 24-10461-00 0.1uF, 63V, ±20%

C432 24-22461-00 0.22uF, 63V, ±20%

Page 26

C327, C328, C119, C219 25-22361-01 22n, 63V, ±5%

26

C329, C330 25-10461-05 0.1uF, 63V, ±5%

C114, C115, C118, C214,

C215, C218, C411, C412

C17, C27, C322, C321,

C345, C346, C337, C338,

C319, C320

C331, C332 25-22461-02 0.22uF, 63V, ±5%

C121, C122, C221, C222,

C333, C334

C339, C340 06-10951-08 1uF, 50V, ±20%

C421, C417, C418 06-47951-00 4.7uF, 50V, ±20%

C301, C48, C415, C416,

C419, C425, C426, C428,

C429, C430, C431, C446

C11, C21 06-10051-08 10uF, 50V, ±20%

C12/1, C110, C111, C210,

C211, C323, C324, C47,

C49, C410

C12/1, C110, C111, C210,

C211, C323, C324, C47,

C49, C410

C325, C326, C341, C342 06-47021-06 47uF, 25V, ±20%

C325, C326, C341, C342 06-47021-09 47uF, 25V, ±20%

C420, C445 06-10111-00 100uF, 16V, ±20%

C125, C126, C225, C226 100uF, 63V, ±20%(N.I)

C413, C414 06-22131-00 220uF, 35V, ±20%

C15, C16, C25, C26, C43,

C44

C422 06-33111-01 330uF, 16V, ±20%

C444 06-47211-00 4700u, 16V, ±20%

R169, R269 07-91204-02

R385, R386 07-10189-50 1R8, 1/6W, ±5%

R2 07-10100-50 10R, 1/6W, ±5%

R494 07-10120-50 12R, 1/6W, ±5%

R142, R143, R242, R243, 07-10220-51 22R, 1/4W, ±5%

RI3 07-10330-50 33R, 1/6W, ±5%

R107, R108, R207, R208 07-10390-51 39R, 1/4W, ±5%

R335, R336 07-10680-51 68R, 1/4W, ±5%

R14, R24, R416, R417,

R418, R419

RI7 07-10331-50 330R, 1/6W, ±5%

R138, R238 07-10431-51 430R, 1/4W, ±5%

25-10461-01 0.1uF, 63V, ±10%

25-10461-06 0.1uF, 63V, ±10%

25-10561-02 1u, 63V ±5%

06-10051-00 10uF, 50V, ±20%

06-47021-00 47uF, 25V, ±20%

06-47021-08 47uF, 25V, ±20%

06-22161-00 220uF, 63V, ±20%

RESISTORS

1M2¡, ±1%

07-10101-50 100R, 1/6W, ±5%

R11, R21 07-10471-50 470R, 1/6W, ±5%

R31, R32, R33, R34, R35,

R36, R37, R38, R39, R310,

R311, R312, R313, R314,

R315, R316, R317, R318,

R393, R396

R495 07-10511-50 510R, 1/6W, ±5%

R41, R42, R43, R44, R47,

R48, R49, R410, R411,

R413,

RI2, R162, R163, R167,

R168, R262, R263, R267,

R268

R147, R160, R161, R247,

R260, R261, R403, R406,

R405, R407, R474, R476

07-10471-51 470R, 1/4W, ±5%

07-10681-51 680R, 1/4W, ±5%

07-10102-50 1K, 1/6W, ±5%

07-10102-51 1K, 1/4W, ±5%

Page 27

R422, R423, R424, R425 07-10132-50 1K3, 1/6W, ±5%

/

27

R428, R440, R158, R258 07-10222-51 2K2, 1/4W, ±5%

R480 07-10392-51 3K9, 1/4W, ±5%

R401, R482, , R333, R334, 07-10472-51 4K7, 1/4W, ±5%

RI4 07-10472-50 4K7, 1/6W, ±5%

R429 07-10512-51 5K1, 1/4W, ±5%

R166, R266 07-10562-50 5K6, 1/6W, ±5%

R12/1 07-10682-51 6K8, 1/4W, ±5%

RI1, RI5, RI6, R164, R264,

R165, R265

R470, R471, R469, R402,

R404

R148, R248 07-10153-50 15K, 1/6W, ±5%

R441 07-10153-51 15K, 1/4W, ±5%

R487, R488 07-10183-51 18K, 1/4W, ±5%

R387, R388 07-10203-50 20K, 1/6W, ±5%

R15, R25, R152, R252 07-10223-50 22K, 1/6W, ±5%

R12/2, R468 07-10223-51 22K, 1/4W, ±5%

R420, R421 07-10363-50 36K, 1/6W, ±5%

R473 07-10433-51 43K, 1/4W, ±5%

R477, R437 07-10473-51 47K, 1/4W, ±5%

R436, R442, R445, R446 07-10563-51 56K, 1/4W, ±5%

R347, R348, R448, R478,

R479, R489, R490, R491

R438, R493 07-10184-51 180K, 1/4W, ±5%

R12,R22 07-10224-50 220K, 1/6W, ±5%

R457, R345, R346 07-10224-51 220K, 1/4W, ±5%

R483 07-10274-51 270K, 1/4W, ±5%

R451 07-10334-51 330K, 1/4W, ±5%

R435 07-10394-51 390K, 1/4W, ±5%

R472, R156, R157, R256,

R257

R337, R338, R339, R341,

R342, R343, R349, R350,

R351, R352, R353, R354,

R355, R356, R357, R358,

R394, R395

R327, R328 07-20181-51 180R, 1/4W, ±5%

R325, R326 07-23900-51 390R, 1/4W, ±1%

R331, R332 07-23900-50 390R, 1/6W, ±1%

R139, R239 07-24120-51 412R, 1/4W, ±1%

R383, R384, R391, R392 07-25600-50 560R, 1/6W, ±1%

R323, R324 07-27500-51 750R, 1/4W, ±1%

R329, R330 07-21501-50 1K5, 1/6W, ±1%

R412 07-20202-51 2K, 1/4W, ±5%

R414 07-20222-51 2K2, 1/4W, ±5%

R321, R322 07-20332-51 3K3, 1/4W, ±5%

R363, R364 07-20513-50 51K, 1/6W, ±5%

R389, R390 07-20106-50 10M, 1/6W, ±5%

R150, R250 07-30109-01 1R, 1W, ±5%

R124, R125, R224, R225 07-30339-00 3R3, 1/2W, ±5%

R427 07-30220-01

R452, R453 07-30221-03

R128, R129, R228, R229 07-30331-00 330R, 1/2W, ±5%

R146, R246 07-30182-02 1K8, 2W, FP, ±5%

R126, R127, R132, R133

R226, R227, R232, R233

R136, R137, R236, R237 07-50100-10

R151, R251 07-50100-01 10R, 1W, FS, ±5%

R45, R46 07-50330-00 33R, 1/2W, ±5%, FS

R130, R131, R230, R231 07-50820-02 82R, 1W, FS, ±5%

R443 07-50151-00 150R, 1/2W, ±5%

R144, R145, R244, R245 07-40687-03 0.068R, 3W, CE, ±5%

L11, L21 08-01005-00 0.5uH

07-10103-50 10K, 1/6W, ±5%

07-10103-51 10K, 1/4W, ±5%

07-10104-51 100K, 1/4W, ±5%

07-10474-51 470K, 1/4W, ±5%

07-10105-51 1M, 1/4W, ±5%

22¡, 1W ±5%

220¡

2W 5%

07-30332-12 3K3, 2W, FP, ±5%

10¡, 1/4W, ±5%

INDUCTORS

POTS

Page 28

VR301, VR302 09-02101-00 100R

28

VR12, VR22 09-02201-02 200R

VR3 09-02103-00 10K

VR304, VR303 09-02303-00 30K

RT31, RT32 09-01103-01 RK163121A2CA 10KAx2

RT33 09-01203-01 RK16812MG 20KBx2

RT34 09-01203-03 RK163121A10D 20KMN

SWITCHS

S41 11-05202-02 SK-22F03G7

SW31 11-02202-02 SPUN190700

RELAYS

RL31, RL32, RL33, RL34,

RL35, RL36, RL37,

RL38,RL39

RL12/1 12-01101-02 F1AA012V

MAIN BOARD--CB58 14-32501-00