Page 1

MTS TestSuite

TW Elite Test Design Guide

100-234-122 G be certain.

Page 2

©

2014 MTS Systems Corporation. All rights reserved.

Trademark Information

MTS is a registered trademark of MTS Systems Corporation within the United States. This trademark

may be protected in other countries.All other trademarks or service marks are property of their respective

owners.

Proprietary Software

Software use and license is governed by MTS’s End User License Agreement which defines all rights

retained by MTS and granted to the End User. All Software is proprietary, confidential, and owned by

MTS Systems Corporation and cannot be copied, reproduced, disassembled, decompiled, reverse

engineered, or distributed without express written consent of MTS.

Software Verification and Validation

MTS software is developed using established quality practices in accordance with the requirements

detailed in the ISO 9001 standards. Because MTS-authored software is delivered in binary format, it

is not user accessible. This software will not change over time. Many releases are written to be

backwards compatible, creating another form of verification.The status and validity of MTS’s operating

software is also checked during system verification and routine calibration of MTS hardware. These

controlled calibration processes compare the final test results after statistical analysis against the

predicted response of the calibration standards. With these established methods, MTS assures its

customers that MTS products meet MTS’s exacting quality standards when initially installed and will

continue to perform as intended over time.

Manual Part Number—Publication Date—Release

100-234-122 G—February 2014—MTS TestSuite TW 2.3.4 or later

100-234-122 F—September 2013—MTS TestSuite TW 2.3.1

100-234-122 E—August 2013—MTS TestSuite TW 2.3

100-234-122 D—January 2013—MTS TestSuite TW 2.2

100-234-122 C—December 2012—MTS TestSuite TW 2.1

Page 3

Table of Contents

Preface

Before You Begin.............................................................................................................................................7

Documentation Conventions............................................................................................................................7

Technical Support

How to Get Technical Support.......................................................................................................................11

Before You Contact MTS...............................................................................................................................11

If You Contact MTS by Phone.......................................................................................................................13

Problem Submittal Form in MTS Manuals....................................................................................................14

Introduction

About This Guide...........................................................................................................................................16

Start TWE and Open the Example Test..........................................................................................................17

TWE Main Window.......................................................................................................................................17

Main Window Toolbar.......................................................................................................................20

About the Multi-Head Run Section....................................................................................................21

Multi-Head Run Section Properties...................................................................................................22

Table of Contents

Examine the Example Test

About this Chapter.........................................................................................................................................26

Design Flow...................................................................................................................................................26

Dene Tab......................................................................................................................................................27

Outline View in the Procedure Subtab...............................................................................................27

Workow in the Procedure Subtab....................................................................................................28

Set Up Section........................................................................................................................29

Run Section............................................................................................................................30

Examining the Logic in the Run Section................................................................................32

Program Command in the Example Test................................................................................33

Branches in the Parallel Paths Activity..................................................................................34

Go To + DAQ + Detection Activity.......................................................................................35

Finish Section.........................................................................................................................39

Test-Run Display Subtab....................................................................................................................40

Variables Subtab.................................................................................................................................40

Variable Denition.................................................................................................................41

Variable Use in the Example Test...........................................................................................41

Variable Availability Attributes..............................................................................................42

Report Templates Subtab....................................................................................................................43

Functions Subtab................................................................................................................................44

3

Page 4

Table of Contents

Resources Subtab...............................................................................................................................45

Test Denition Subtab........................................................................................................................47

Monitor Tab....................................................................................................................................................49

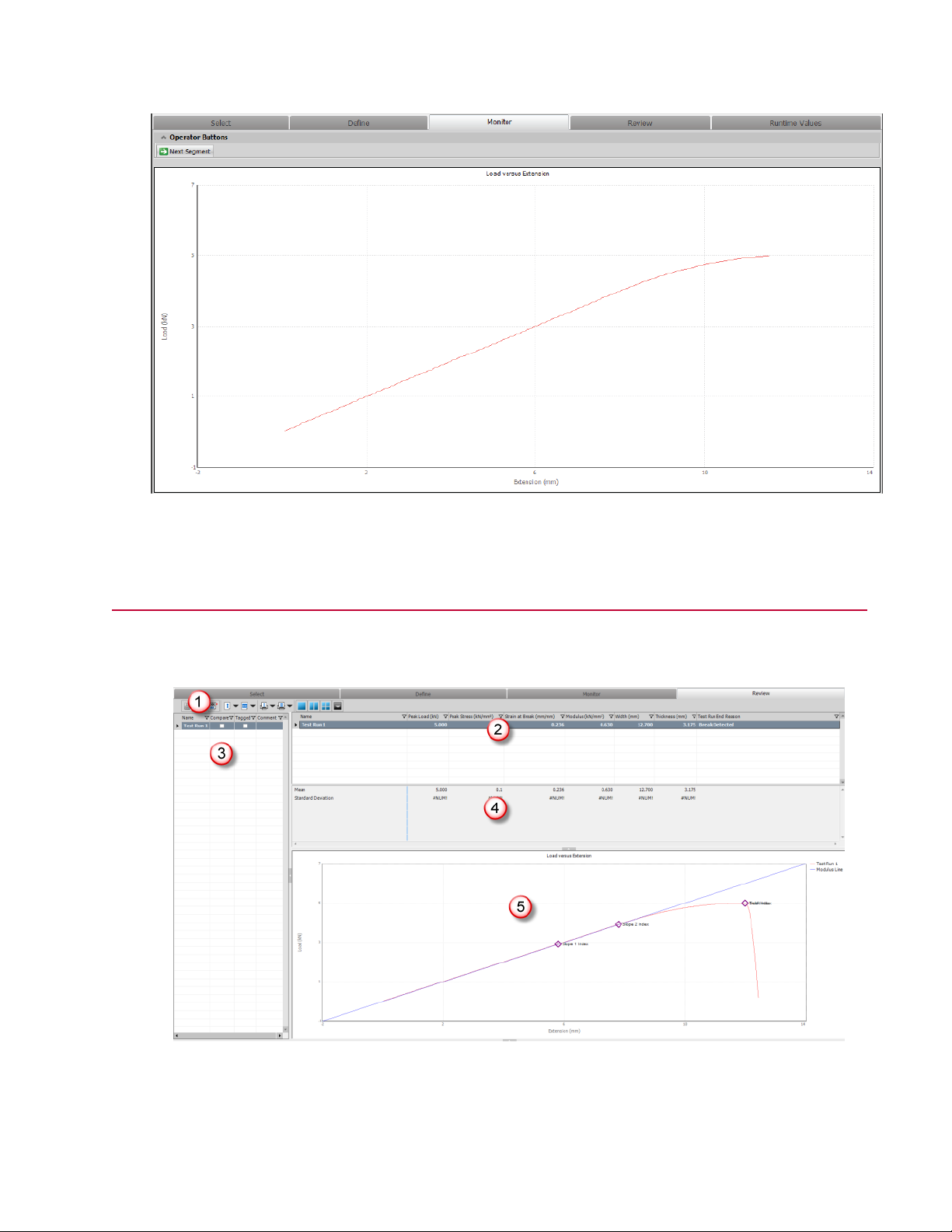

Review Tab Layout........................................................................................................................................51

Review Tab Toolbar...........................................................................................................................52

Test Run Results Table.......................................................................................................................53

Statistics Table....................................................................................................................................54

Panel of Charts and Tables.................................................................................................................54

Four-Panel View.................................................................................................................................56

Runtime Values Tab........................................................................................................................................57

Design Guidelines

About this Chapter.........................................................................................................................................60

Designing Tests..............................................................................................................................................60

Test Design Checklist.........................................................................................................................60

Tests and Templates............................................................................................................................61

Modifying Tests..................................................................................................................................63

Working With Variables.....................................................................................................................69

Conguring Data Acquisition............................................................................................................74

Choosing a Template to Run or Modify.................................................................................61

File Icons................................................................................................................................61

Working with Templates and Tests.........................................................................................62

Adding and Conguring Test Activities................................................................................63

Considerations for Test Sections ...........................................................................................65

Conguring What is Displayed After Test Runs....................................................................67

Interacting with the Operator During Tests............................................................................67

Run-Time Markers.................................................................................................................67

Batch Mode Tests...................................................................................................................67

Pre-Allocating Multiple Test Runs.........................................................................................68

Variable Concepts ..................................................................................................................69

Benets of Using Variables....................................................................................................69

Using Variables in Activities..................................................................................................70

Toggling Between Static Values and Variables......................................................................70

Variable Example...................................................................................................................70

Manipulating Variables in the Workow ..............................................................................71

Assigning Variable Availability..............................................................................................72

Adding Calculations to Variables ..........................................................................................72

Managing Variables................................................................................................................73

Used By Table Column..........................................................................................................74

Data Acquisition Properties Page...........................................................................................74

Mapping Variables to Acquired Data.....................................................................................74

Acquiring Data in a Continuous Stream.................................................................................75

4

Page 5

Acquiring Data in Blocks Without Mode Switching.............................................................75

Acquiring Data in Blocks With Mode Switching...................................................................75

Setting Buffer Size.................................................................................................................75

Data Acquisition for Test-Run Displays................................................................................76

Polarity Considerations for MTS Criterion Series 40 Systems .........................................................76

Debugging..........................................................................................................................................78

Automatic Saves and Experimentation..................................................................................79

Rapid Design Iterations..........................................................................................................79

Activity State in Outline View...............................................................................................79

Test Procedure Test-Run Display...........................................................................................79

Runtime Values Tab................................................................................................................79

Modify the Example Test

About this Chapter.........................................................................................................................................82

Modifying Tests..............................................................................................................................................82

Design Scenario..............................................................................................................................................83

Modifying the Set Up Section............................................................................................................83

Formula Assistant File...........................................................................................................84

Changing the Specimen Geometry.........................................................................................84

Adding an Input Variables Activity .......................................................................................86

Moving and Enabling Run External Application Activity.....................................................88

Modifying the Run Section................................................................................................................88

Enable and Congure the Custom Message Window Activity..............................................89

Editing the Go To + DAQ + Detection Activity ...................................................................90

Modifying the Finish Section.............................................................................................................92

Changing the Maximum Test Runs Variable..........................................................................92

Enabling and Conguring the Run Report Activity...............................................................93

Table of Contents

Working with MTS FlexTest Resources

Resource Basics..............................................................................................................................................96

Connecting to a Controller.............................................................................................................................96

Creating a Desktop Shortcut That Includes a Controller...............................................................................98

Station Congurations....................................................................................................................................98

Controller Resources......................................................................................................................................99

Resource Mapping..........................................................................................................................................99

Ofine Test Design......................................................................................................................................102

Resources That Allow Dimension Changes.................................................................................................103

Considerations for Servohydraulic Systems

Understand Software Concepts....................................................................................................................106

Using MTS TestSuite with Controller Software..........................................................................................106

5

Page 6

Table of Contents

Station Controls Panel......................................................................................................................107

Station Conguration Files..............................................................................................................108

TWE Startup.....................................................................................................................................109

Working with Limits........................................................................................................................109

Set Station Detector Limits..................................................................................................110

Access and Set Detector Settings.........................................................................................110

Reset Detectors.....................................................................................................................112

Using Manual Command to Install the Specimen............................................................................112

Manual Command Properties...............................................................................................112

Manually Position the Actuator............................................................................................114

Applying Offsets to the Input Signal (optional)...............................................................................115

Apply an Auto Offset to an Input Signal..............................................................................115

Apply a Manual Offset to an Input Signal...........................................................................115

TW Elite for TestWorks 4 Users

About this Chapter.......................................................................................................................................118

Basic Concepts.............................................................................................................................................118

Terminology Differences..............................................................................................................................119

Functional Differences.................................................................................................................................122

Converting TestWorks 4 Methods and Sample Files...................................................................................125

Conversion Issues for MTS FlexTest Controllers........................................................................................125

6

Page 7

Preface

Before You Begin

Safety first!

Before you use your MTS product or system, read and understand the safety information provided with

your system. Improper installation, operation, or maintenance can result in hazardous conditions that can

cause severe personal injury or death, or damage to your equipment and specimen. Again, read and

understand the safety information provided with your system before you continue. It is very important that

you remain aware of hazards that apply to your system.

Other MTS manuals

In addition to this manual, you may receive additional manuals in paper or electronic form.

You may also receive an MTS System Documentation CD. It contains an electronic copy of the manuals

that pertain to your test system.

Controller and application software manuals are typically included on the software CD distribution disc(s).

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your MTS manuals.

Hazard conventions

Hazard notices may be embedded in this manual. These notices contain safety information that is specific

to the activity to be performed. Hazard notices immediately precede the step or procedure that may lead

to an associated hazard. Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following are examples of all three

levels. (for general safety information, see the safety information provided with your system.)

Danger:

Danger notices indicate the presence of a hazard with a high level of risk which, if ignored,

will result in death, severe personal injury, or substantial property damage.

MTS TestSuite | 7

Page 8

Preface

Warning:

Warning notices indicate the presence of a hazard with a medium level of risk which, if ignored,

can result in death, severe personal injury, or substantial property damage.

Caution:

Caution notices indicate the presence of a hazard with a low level of risk which, if ignored,

could cause moderate or minor personal injury or equipment damage, or could endanger test

integrity.

Other special text conventions

Important:

Important notices provide information about your system that is essential to its proper

function. While not safety-related, if the important information is ignored, test results may

not be reliable, or your system may not operate properly.

Note:

Notes provide additional information about operating your system or highlight easily

overlooked information.

Recommended:

Recommended notes provide a suggested way to accomplish a task based on what MTS

has found to be most effective.

Tip:

Tips provide helpful information or a hint about how to most efficiently accomplish a task.

Access:

Access provides the route you should follow to a referenced item in the software.

Examples show specific scenarios relating to your product and appear with a shaded

background.

Special terms

The first occurrence of special terms is shown in italics.

Illustrations

Illustrations appear in this manual to clarify text. They are examples only and do not necessarily represent

your actual system configuration, test application, or software.

8 | MTS TestSuite

Page 9

Preface

Electronic manual conventions

This manual is available as an electronic document in the Portable Document File (PDF) format. It can be

viewed on any computer that has Adobe Acrobat Reader installed.

Hypertext links

The electronic document has many hypertext links displayed in a blue font. All blue words in the body text,

along with all contents entries and index page numbers, are hypertext links. When you click a hypertext

link, the application jumps to the corresponding topic.

MTS TestSuite | 9

Page 10

Page 11

Technical Support

How to Get Technical Support

Start with your manuals

The manuals supplied by MTS provide most of the information you need to use and maintain your equipment.

If your equipment includes software, look for online help and README files that contain additional product

information.

Technical support methods

MTS provides a full range of support services after your system is installed. If you have any questions

about a system or product, contact Technical Support in one of the following ways.

Web site

Outside the U.S.

For technical support outside the United States, contact your local sales and service office. For a list of

worldwide sales and service locations and contact information, use the Global MTS link at the MTS web

site:

www.mts.com > Global Presence > Choose a Region

www.mts.com > Contact Us (upper-right corner) > In the Subject field, choose

To escalate a problem; Problem Submittal Form

Worldwide: tech.support@mts.comE-mail

Europe: techsupport.europe@mts.com

Worldwide: 1 800 328 2255 - toll free in U.S.; +1 952 937 4000 - outside U.S.Telephone

Europe: +800 81002 222, International toll free in Europe

Before You Contact MTS

MTS can help you more efficiently if you have the following information available when you contact us for

support.

Know your site number and system number

The site number contains your company number and identifies your equipment type (such as material

testing or simulation). The number is typically written on a label on your equipment before the system

leaves MTS. If you do not know your MTS site number, contact your sales engineer.

Example site number: 571167

MTS TestSuite | 11

Page 12

Technical Support

When you have more than one MTS system, the system job number identifies your system. You can find

your job number in your order paperwork.

Example system number: US1.42460

Know information from prior technical assistance

If you have contacted MTS about this problem before, we can recall your file based on the:

• MTS notification number

• Name of the person who helped you

Identify the problem

Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

Know relevant computer information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant software information

For software application problems, have the following information available:

• The software application’s name, version number, build number, and (if available) software patch

number. This information can typically be found in the About selection in the Help menu.

• The names of other applications on your computer, such as:

— Anti-virus software

— Screen savers

— Keyboard enhancers

— Print spoolers

12 | MTS TestSuite

Page 13

Technical Support

— Messaging applications

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical support specialist. The agent

asks you for your:

• Site number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue will be assigned a unique

notification number.

Identify system type

To enable the Call Center agent to connect you with the most qualified technical support specialist available,

identify your system as one of the following types:

• Electrodynamic material test system

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to troubleshoot

Prepare to perform troubleshooting while on the phone:

• Call from a telephone close to the system so that you can implement suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an experienced user nearby to

assist you.

Write down relevant information

In case Technical Support must call you:

• Verify the notification number.

• Record the name of the person who helped you.

MTS TestSuite | 13

Page 14

Technical Support

• Write down any specific instructions.

After you call

MTS logs and tracks all calls to ensure that you receive assistance for your problem or request. If you

have questions about the status of your problem or have additional information to report, please contact

Technical Support again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with your software, hardware, manuals, or

service that are not resolved to your satisfaction through the technical support process. The form includes

check boxes that allow you to indicate the urgency of your problem and your expectation of an acceptable

response time. We guarantee a timely response—your feedback is important to us.

You can access the Problem Submittal Form at www.mts.com > Contact Us (upper-right corner) > In the

Subject field, choose To escalate a problem; Problem Submittal Form

14 | MTS TestSuite

Page 15

Introduction

Topics:

•

About This Guide...............................................................................................................................16

•

Start TWE and Open the Example Test............................................................................................17

•

TWE Main Window............................................................................................................................17

MTS TestSuite | 15

Page 16

Introduction

About This Guide

The MTS TestSuite TW Elite Test Design Guide contains the information you need to begin customizing

templates with the TW Elite (TWE) application. It includes the fundamental concepts of using the TWE

application with MTS control software to create and run tests.

This guide does not explain every TWE application feature. Its goal is to introduce the most important

features of the application in the context of customizing tests.

Summary

Introduction: Provides an overview of the TWE interface. In this section, you will open the example test

included with the TWE application. The example test was created to run in simulation and includes test

run data. This section describes the basic parts of the interface with the example test loaded.

Examine the Example Test: Examines the example test supplied with the system in detail. Understanding

the example test reveals application capabilities and design principles you can apply to your own tests.

Design Guidelines: Provides design guidelines for TWE tests in general.

Modify the Example Test: Provides a tutorial for how to modify the example test with typical enhancements

using the design guidelines, tips, and best practices.

Working with MTS FlexTest Resources: Provides information for mapping test resources to MTS FlexTest

controller resources.

Considerations for Servohydraulic Systems: Provides information for using TWE with MTS FlexTest

controllers for use in servohydraulic test systems.

MTS TWE for TestWorks 4 Users: Provides information to help users of MTS TestWorks 4 transition to

TWE.

Information pertaining to MTS TW Express

MTS offers a companion application to TW Elite named TW Express (TWX). TWX cannot be used to create

or modify tests; it can only run existing tests. In cases where this manual refers to functionality shared by

both applications (such as running tests), the term "TW application" is used.

Information pertaining to MTS Insight and MTS FlexTest controllers

The TWE application can be used with MTS Insight controllers on electromechanical systems and with

MTS FlexTest controllers on servohydraulic systems. The information in Examine the Example Test (p.

25) and Modify the Example Test (p. 81) is based on the example test supplied with the system which

runs on the MTS Insight controller in simulation. Information pertaining to systems used with MTS FlexTest

controllers is provided in Working with MTS FlexTest Resources (p. 95).

For More Information

Examine the Example Test (p. 25)

Modify the Example Test (p. 81)

Working with MTS FlexTest Resources (p. 95)

16 | MTS TestSuite

Page 17

Start TWE and Open the Example Test

Install TWE in simulation

Installation of TWE consists of running a self-extracting executable file. When running the MTS TestSuite

InstallShield wizard, ensure you select “Insight/Criterion Simulation” when choosing the controller type.

Note:

The following startup procedure is for electromechanical systems. For servohydraulic systems, see

TWE Startup (p. 109).

Open the Example MTS EM Tension (Simplified) Test

1. Start the TWE application.

Introduction

TW Elite Icon

Double-click the TWE icon on your desktop, or click Start > Programs > MTS TestSuite > TW Elite.

The application opens and connects to the simulated MTS Insight controller (the MTS Insight icon

appears on the taskbar).

Note:

The example test is in Project 1, which is the default project. If Project 1 is not selected as the

default project, select Preferences > Configuration > Project > Project 1, right-click the mouse,

and then select Set as System Default Project.

2. The application automatically opens to the Select tab. In the Tests directory, open the Example MTS

EM Tension (Simplified) Test.

Note:

As a test designer, you typically log on to the TWE application as an Engineer or Administrator.

When you open a test, the main window displays the workflow. If you open a test while logged

on to TWE as an Operator, or when you open a test with the TW Express (TWX_ application,

the workflow is hidden, and the main window shows the test inputs on the Monitor tab.

For More Information

TWE Startup (p. 109)

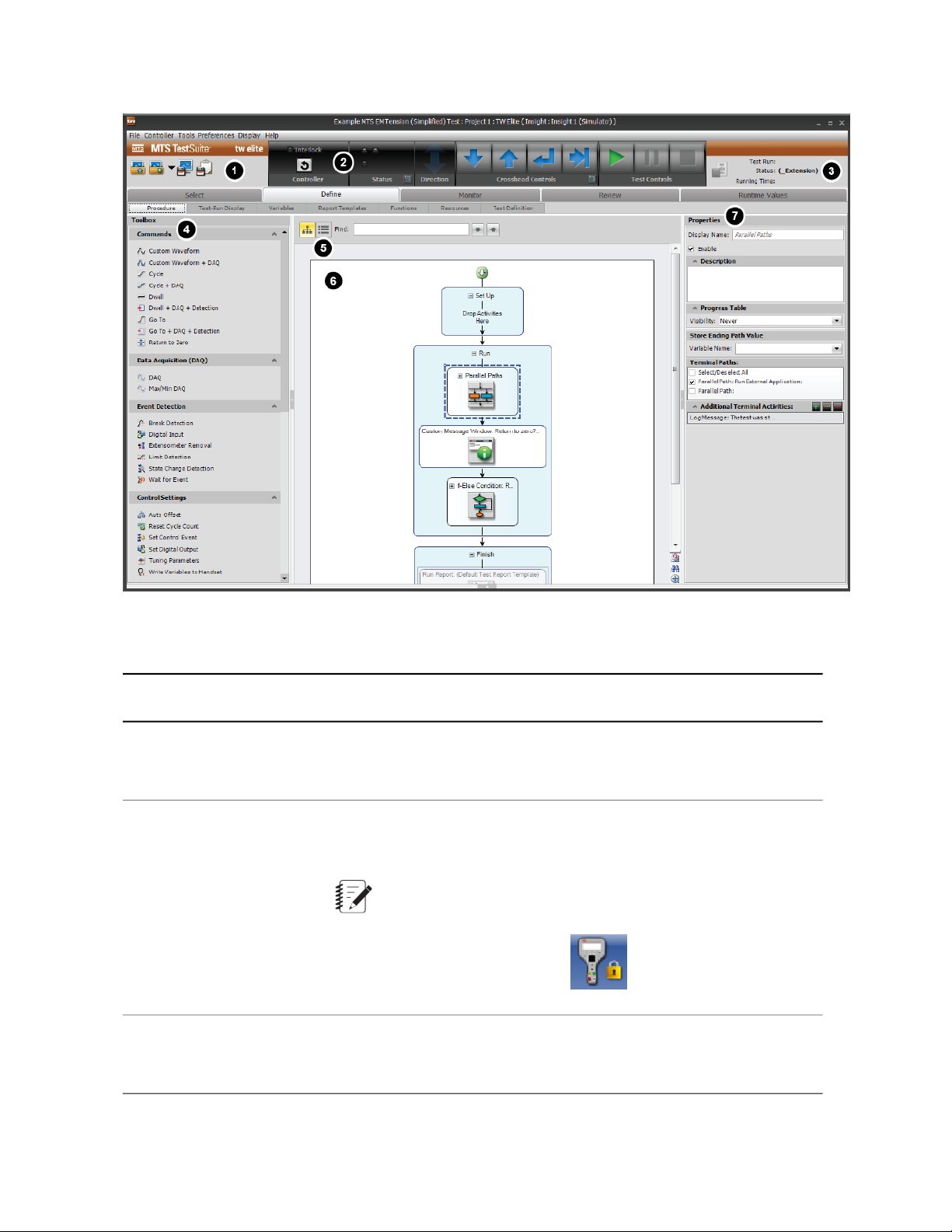

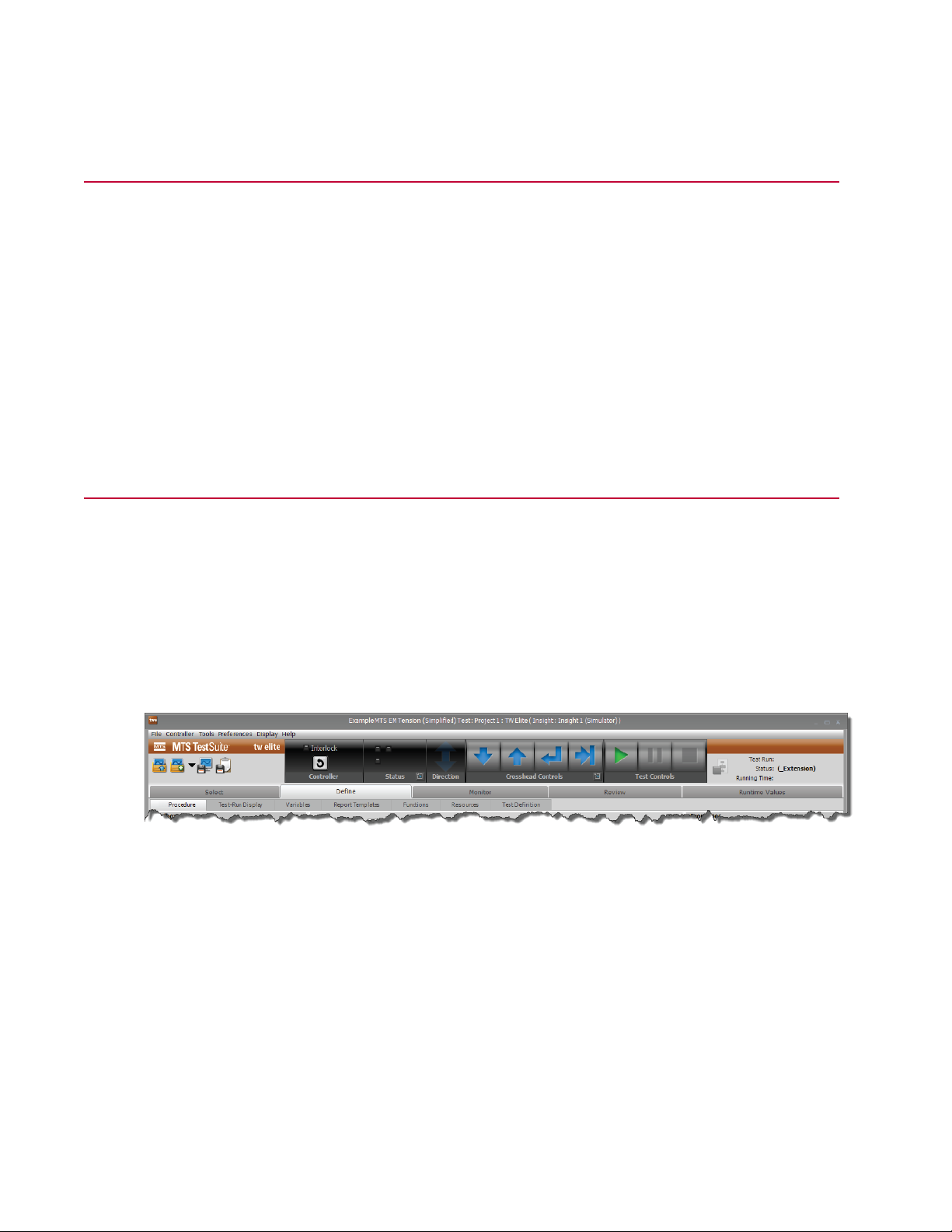

TWE Main Window

When you open a test, the application shows the workflow in the Define tab. Review the basic features in

the TWE application as shown in the following figures and tables.

MTS TestSuite | 17

Page 18

Introduction

TWE Application Main Window

TWE Main Window Description

DescriptionItemNumber

1

Menu bar and

Quick Access

panel

Control panel2

Status panel3

Provides menus and quick-access icons that allow you to perform tasks

such as opening tests, opening tests from templates, and saving tests

as templates.

Allows you to resolve interlocks; display fault status; view the direction

in which the crosshead is moving; position the crosshead; and start,

stop, and hold the test.

Note: When control is provided by a handset, the crosshead

controls will be locked and overlaid by the handset exclusive

control icon:

Shows test run information, including name, status, and running time.

This panel includes a control that allows you to terminate the current

test run.

18 | MTS TestSuite

Page 19

Introduction

DescriptionItemNumber

4

Toolbox panel (not

shown)

Outline button5

Workflow6

The contents of the Toolbox panel change depending on the subtab

selected in the Define tab:

• When you select the Procedure subtab, the Toolbox panel contains

components that pertain to test activities such as commands, data

acquisition, test flow control, and program actions.

• When you select the Test-Run Display subtab, the Toolbox panel

contains components that pertain to the display of test data, such as

cycle, variable, and signal views.

The Outline button displays a hierarchical view of the test in the center

panel when selected.

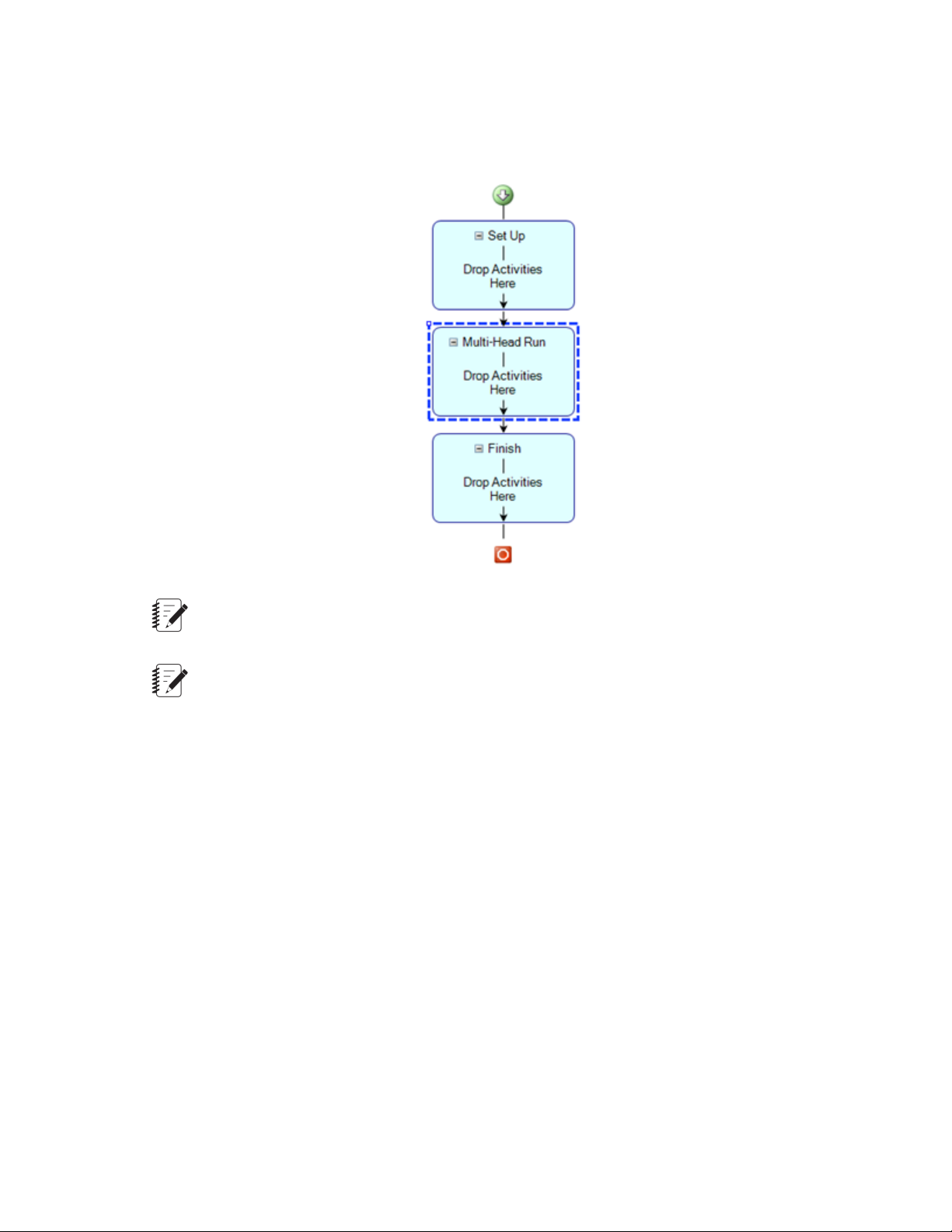

Provides a work area to edit tests. You drag test activities from the

toolbox to the workflow to edit tests. The workflow contains three

sections: Set Up, Run, and Finish.

• Use the Set Up section for activities that you want to perform before

you start test runs, such as configuring the load train (setting up

fixtures, etc.) and entering a test name. The Set Up section runs only

once when you start a test, that is, before the first test run in the test.

• Use the Run section for applying forces to the specimen while

performing test runs. The Run repeats for all test runs in the test,

and by default shows the Review tab after every test run.

If you are using a multi-head frame and template, your workarea will

show a Multi-Head Run section instead of a Run section. For more

information about the Multi-Head Run section, see About the

Multi-Head Run Section (p. 21).

• Use the Finish section for operations such as printing reports,

exporting files, saving test data, and archiving. The Finish section

runs when the number of test runs set for the test is complete, or

when the operator clicks the Run Finish Section button on the Review

tab.

Note:

The workflow includes Pan and Zoom features to help you

view complex test procedures.

Properties panel7

Allows you to define or change the information, characteristics, and

appearance of the selected procedure activities and runtime display

components. For example, you can use the Properties panel to change

the amplitude of a cycle command test activity in a procedure, or the

Y-axis signal selection on a signal scope in a test-run display.

MTS TestSuite | 19

Page 20

Introduction

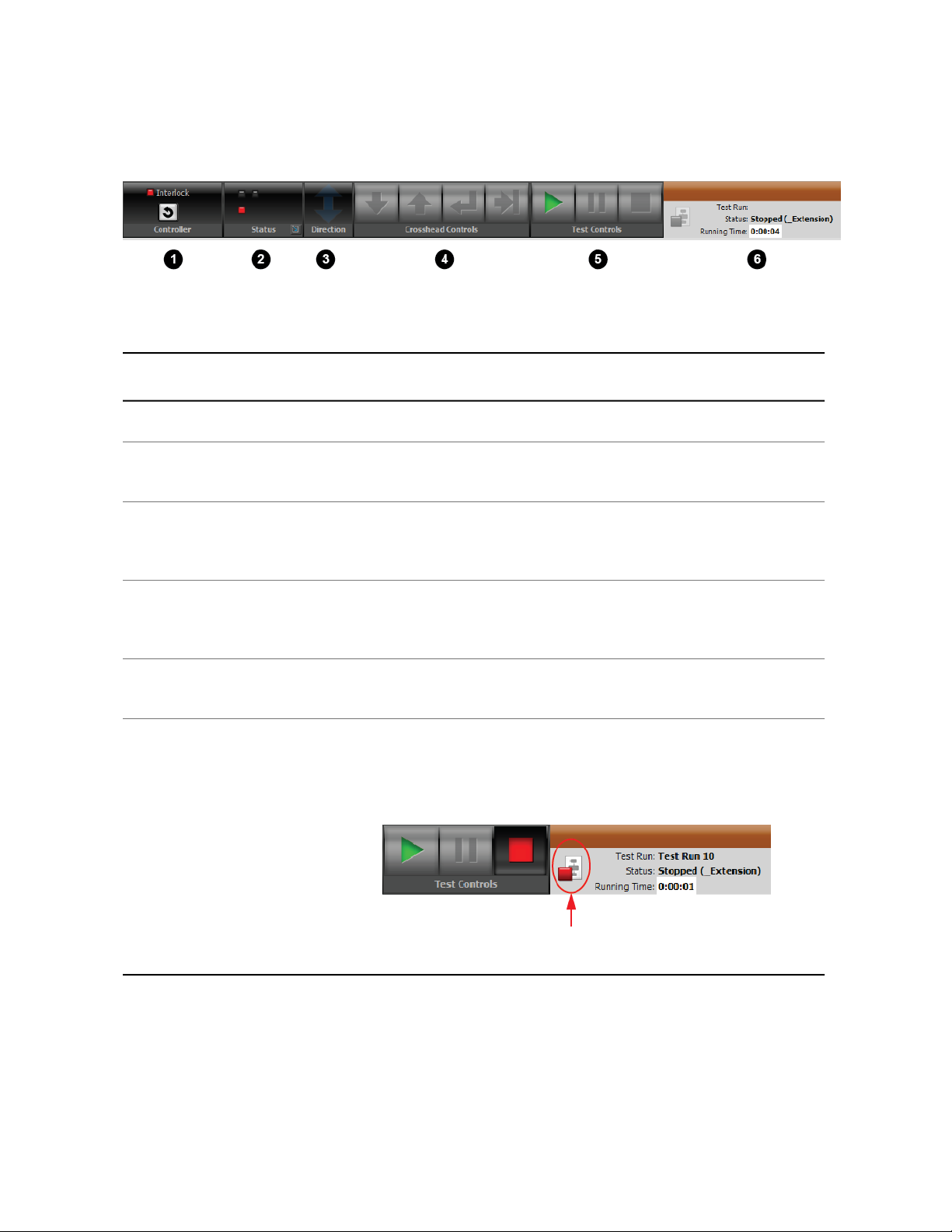

Main Window Toolbar

TWE Application Main Toolbar

Application Toolbar Description

DescriptionItemNumber

Allows you to reset interlocks.Controller panel1

Status panel2

Direction panel3

4

5

Crosshead

Controls panel

panel

Shows fault status information. This indicator is primarily for diagnosing

system errors with MTS service personnel.

Indicates when the crosshead/actuator is moving and in what physical

direction. This relates to physical motion, regardless of whether feedback

is increasing or decreasing.

Contains controls that allow you to move the crosshead up and down

for specimen installation, and for returning the crosshead to the zero or

a preset location.

Contains controls to run, hold, and stop the test run.Test Controls

Shows test run information, including name, status, and running time.Status panel6

It includes a Cancel Test Run button you can use to terminate the current

test run. When the test is stopped, pressing this button terminates the

current test run. Pressing the Run button starts a new test run.

20 | MTS TestSuite

Status Panel with Cancel Test Run Button

Page 21

About the Multi-Head Run Section

Introduction

Note:

The Multi-Head option is a separately licensed feature.

Note:

Prerequisite: Only analog data is collected from the multiple active load cells in a multi-head frame.

You must have National Instruments Data Acquisition (Ni-DAQ) hardware and software or an

extensometer installed which will convert the analog data to digital signals.

Multi-head frames can contain up to five active load cells which allow the simultaneous collection of test-runs

for multiple specimens. By default, the test run collects the results for all specimens within one file. You

can create a separate test-run file for each of the specimens by using the appropriate multi-head template

which contains the Multi-Head Run section in the test procedure work area. This section is similar to the

Run section found in templates for single head frames which contains activities for applying forces to the

specimen while performing test runs. Unlike the Run section, the Multi-Head Run section contains a

Properties Panel where you can input configuration data. The Multi-Head Run is only run once. Data is

collected simultaneously from the Ni-DAQ analog signals. After the test is completed, the data is split into

multiple tests runs. At the end of the test, a number of test runs will be created and populated with the

collected data. The new test runs appear post-test as if they were individually collected.

At the end of the multi-head test, the array data is split into multiple test-run files by moving the collected

data into the normal force, extension, and optional strain variables.

To create a new multi-head template, you must start with an existing test or template that contains the

Multi-Head Run section. To save a test as a template, you must be assigned the Administrator or Engineer

privilege.

MTS TestSuite | 21

Page 22

Introduction

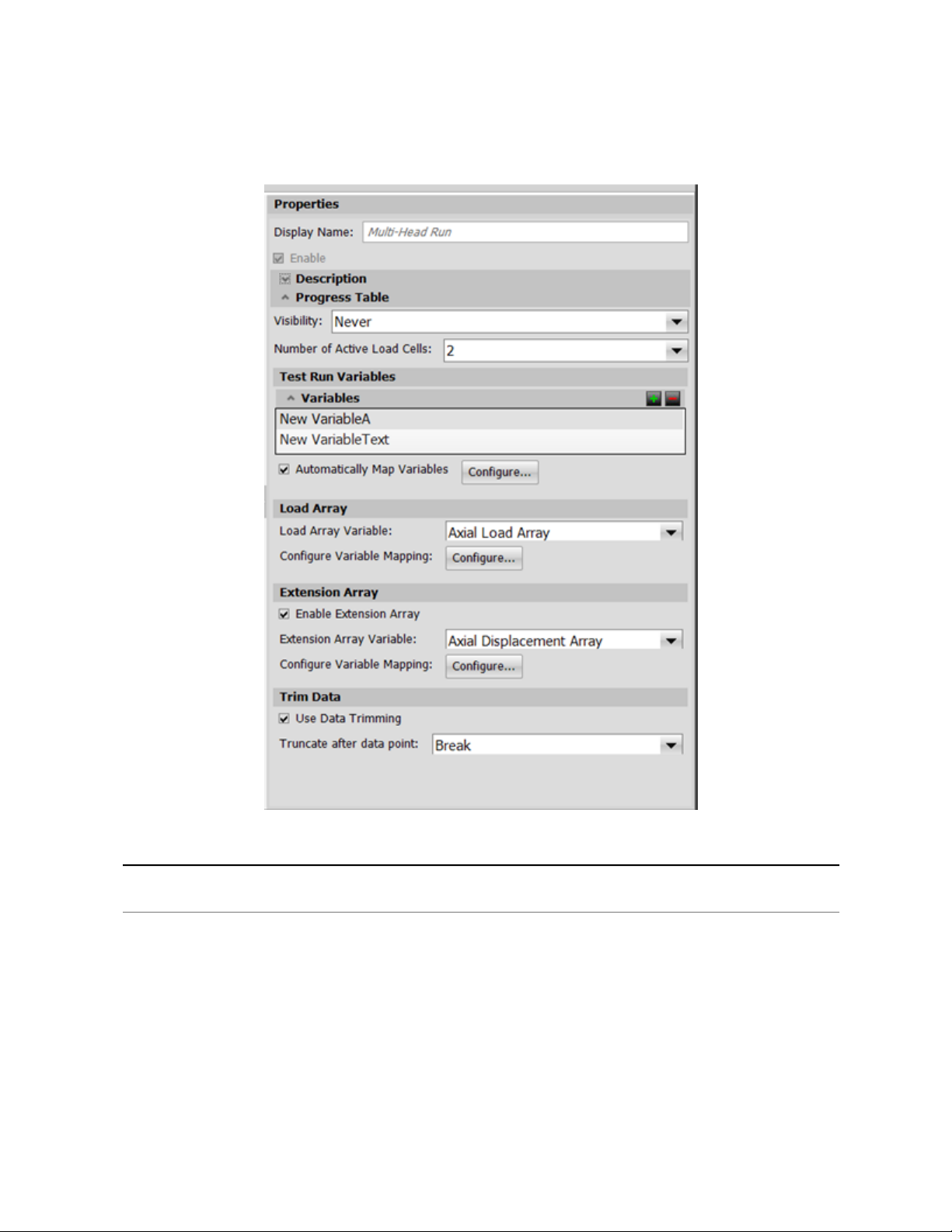

Multi-Head Run Section Properties

Number of Active Load Cells

22 | MTS TestSuite

Multi-Head Run Section Properties

DescriptionItem

Specify how many test-runs should be created. For example, if you are

testing four specimens, enter 4. When the test run has ended, four test

run files will be created. Default: 5

Click the Automatically Map Variables checkbox to have the system

map variables, or click the Configure button to open the Map Variables

window and manually map variables.

Page 23

DescriptionItem

Note:

If you select the Automatically Map option and then change the

Number of Active Load Cells value, some variables will be

created or removed.

If you map variables manually, and then select Auto Map

Variables, your manually created variables will be overwritten

by the automatically-generated variables.

Introduction

Test Run Variables

Load Array Variable

Enable Extension Channels

Trim Data

Specify variables that are not in the Common category. For example,

if Number of Active Load Cells is 5 and the Width variable is added

to this list, the other five variables should be mapped to the Width

variable (such as Width1, Width2… Width5). At the end of the test, the

variable values from Width1, Width2, and so on, must be moved to the

Width variable in the appropriate test runs. Click the green plus sign to

add a variable. To delete a variable, select a variable in the list and click

the red minus sign.

Click the Configure button to open the Map Variables window.

Specify the name of the array variable that is used to gather data from

the Force (Load) channel. Map it to the other array variables as

described above in the Test Run Variables description. At the end of

the test, the variable values from mapped arrays must be moved to the

selected Load Array variable in the appropriate test runs. Click the

Configure button to open the Map Variables window.

Select to map additional array variables to the other array variables.

You can also move data from mapped variables to the selected array

variable at the end of the test. Click the Configure button to open the

Map Variables window.

Select to have the trimming process performed after the data has been

split into test-run files. The trimming process will keep the point identified

by the variable. In other words, the data will be trimmed at the variable

index plus one. If the variable is invalid, no truncation will take place

and a message will be logged. Default for Truncate after data point:

Break

MTS TestSuite | 23

Page 24

Page 25

Examine the Example Test

Topics:

•

About this Chapter.............................................................................................................................26

•

Design Flow.......................................................................................................................................26

•

Define Tab.........................................................................................................................................27

•

Monitor Tab........................................................................................................................................49

•

Review Tab Layout............................................................................................................................51

•

Runtime Values Tab..........................................................................................................................57

MTS TestSuite | 25

Page 26

Examine the Example Test

About this Chapter

This chapter provides a detailed review of the example test provided with the TWE application.

You will examine the test’s workflow, test activities, use of variables, and so on. Understanding how the

example test was created with the TWE application and how the test appears in the interface will help you

understand how to create tests of your own.

Modify the Example Test (p. 81) provides a tutorial for modifying the example test for a different scenario.

For More Information

Start TWE and Open the Example Test (p. 17)

Modify the Example Test (p. 81)

Design Flow

The flow for designing tests with TWE is defined by the tabs shown on the main display after you open a

test:

• Select tab (or the initial open test/template window)

• Define tab

• Monitor tab

• Review tab

Main Tabs in TWE

Select tab

Use the initial open test/template window or the Select tab to choose an existing test or template to modify.

Define tab

Use the Define tab to modify the selected test by modifying the workflow, editing variables, applying

functions, and so on.

26 | MTS TestSuite

Page 27

Examine the Example Test

Note:

When operators use TWX, tests typically open to the Monitor tab so operators can review pretest

variables before performing test runs. However, if the selected test has validation errors, the test

opens to the Define tab so operators can use the Resource subtab to resolve resource conflicts.

Monitor tab

Use the Monitor tab to review pretest variables (inputs that typically apply to all of the test runs in the test)

shown to the operator. You may create additional pretest variables by editing variable properties in the

Variables subtab of the Define tab.

Review tab

Use the Review tab to view test results, customize table and chart content, define markers, and customize

report templates with the Reporter Add-In for Microsoft Excel.

Runtime Values tab

Use the Runtime Values tab to view current variable values and activity configuration values.

Define Tab

You perform most test design tasks on the Define tab, which includes the following subtabs:

• FitProcedure

• Test-Run Display

• Variables

• Report Templates

• Functions

• Resources

• Test Definition

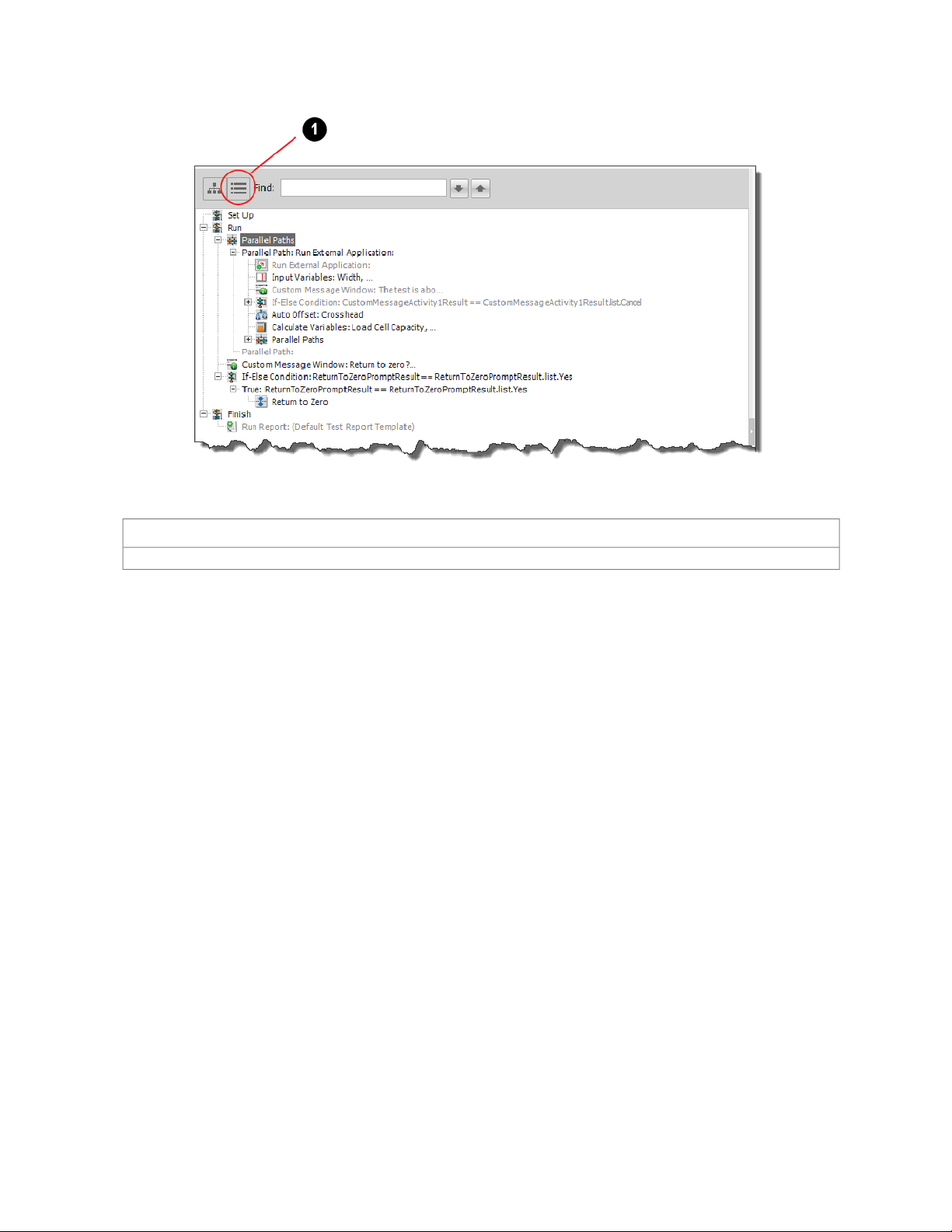

Outline View in the Procedure Subtab

When a test is opened in TWE, the Define tab and Procedure subtab are displayed by default. You can

select Outline view by clicking the Outline button. The Outline view shows the procedure as a hierarchy.

MTS TestSuite | 27

Page 28

Examine the Example Test

Outline View and the Find Feature

DescriptionItem

Outline button1

Tip

The Find feature is particularly useful for locating activities nested within other activities. For instance, to

locate the Go To + DAQ + Detection command activity in the example test, enter Go To and press return.

The outline hierarchy expands to show the Go To + DAQ + Detection activity, and the activity is highlighted

in the workflow.

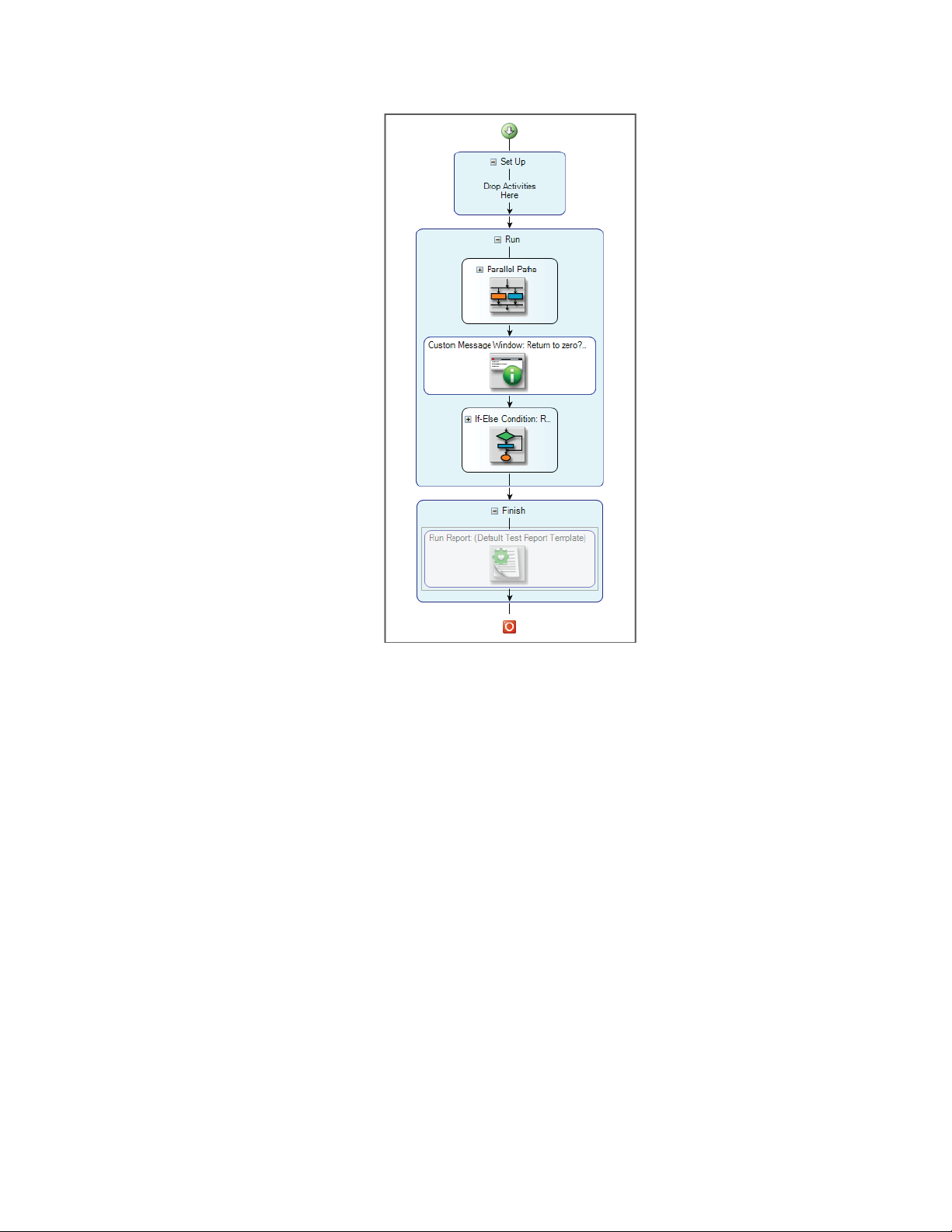

Workflow in the Procedure Subtab

The center of the main window shows the workflow. The workflow consists of a sequence of connected

activities divided into test sections; it is a graphical representation of the test.

Each section performs a specific function within the test.

28 | MTS TestSuite

Page 29

Examine the Example Test

Workflow of the Example Test

All TW tests include the following sections:

• Set Up

• Run

• Finish

Set Up Section

The Set Up section runs only once before the first test run. Since there are no activities in the Set Up

section of the example test, the Set Up section is skipped and the Run section begins immediately.

You typically use this section for activities that you want to perform before you start test runs, such as

configuring the load train (setting up fixtures, and so forth) and entering a test name.

For more information about activities, see Modify the Example Test (p. 81).

MTS TestSuite | 29

Page 30

Examine the Example Test

Set Up Section of the Example Test.

For More Information

Modify the Example Test (p. 81)

Run Section

The Run section performs a test run when the operator clicks the Run button. After each test run, the

Review tab appears, which shows test data in tables and charts.

The Run section of the example test has been performed three times, so the Review tab includes data

from three test runs.

30 | MTS TestSuite

Page 31

Examine the Example Test

Note:

The following figure shows the top Parallel Path activity in the Run section expanded.

Run Section of the Example Test

MTS TestSuite | 31

Page 32

Examine the Example Test

DescriptionNumber

Parallel Path activity: left branch.1

Parallel Path activity: right branch (disabled).2

If-Else activity (disabled).3

Custom Message activity (disabled): “The Test is About to Start”.4

Input Parameters activity.5

Parallel Path activity in left branch of (1).6

Custom Message activity: “Return to Zero”.7

For More Information

Review Tab

Run Section Description

Examining the Logic in the Run Section

The left branch of the parallel path (1) supports the normal test flow. The right branch (2) exists to support

the Cancel function associated with the If/Else activity (3) that follows the Custom Message (4) activity.

Default behavior

By default, the If/Else (3) and Custom Message (4) activities are disabled. So when you run the test, no

prompt appears to inform you that the test is about the begin, and that you can choose to cancel.

Because of this, when you run the test you are prompted for specimen dimensions per the Input Parameters

activity (5), and then the Test-Run Display tab shows a graph as the Go To + DAQ + Detection activity

performs a ramp. The Go To + DAQ + Detection activity is nested within the Parallel Paths activity (6).

(The Auto Offset and Calculate Variables activities run before the Parallel Paths activity, but do not

affect the interface.)

When a break is detected, the ramp stops and you are prompted to return to zero when the next Custom

Message activity (7) executes.

Behavior with the If/Else and Custom Message activities enabled

If the If/Else and Custom Message activities (3 and 4) are enabled, when you run the test, a prompt

appears to inform you that the test is about the begin, and that you can choose to cancel.

If you choose to cancel, the test logic uses the right side of the Parallel Path activity (2) to skip the ramp

command in the Go To + DAQ + Detection activity nested in the Parallel Paths activity (6). Next, the

Custom Message activity (7) prompts you to return to zero.

32 | MTS TestSuite

Page 33

Examine the Example Test

Program Command in the Example Test

In the example test, program command is issued from the Go To + DAQ + Detection activity nested within

the second Parallel Paths activity in the Run section. This is the only activity in the example test that

applies forces to the specimen.

Branches in the Parallel Activity

Description of Branches in the Parallel Activity

DescriptionItem

1

2

3

4

Auto Offset and Go To + DAQ + Detection activities. For more

information, see Path for the typical test flow .

State Change Detector activity. For more information, see Path

with the State Change Detector .

Limit Detection activity: Specimen. For more information, see

Path with the Limit Detector for the specimen .

Limit Detection activity: Load Cell. For more information, see Path

with the Limit Detector for the load cell. .

MTS TestSuite | 33

Page 34

Examine the Example Test

DescriptionItem

5

Digital Input Detector activity: Handset Connected. For more

information, see Path with the Digital Input Detector for the handset

.

Branches in the Parallel Paths Activity

The nested Parallel Paths activity in the example test contains five parallel branches. All of the branches

are terminal, meaning the completion of any of the paths ends all of the other paths.

Path for the typical test flow

In a typical test flow, the path that contains the Auto Offset and the Go To + DAQ + Detection activities

(1) ends the other paths when the specimen fails. The Auto Offset activity resets the running time of the

test run to zero, and the Go To + DAQ + Detection activity provides program command.

Path with the State Change Detector

The State Change Detector path (2) detects a stopped test state. If the operator clicks the Stop button

while the Go To + DAQ + Detection activity issues command, the Stop Change Detector activity detects

the stopped state and ends the Parallel Path activity. So if the operator clicks the Stop control while the

system is ramping, the ramp stops immediately and the “Return to Zero?” prompt appears. Because of

this, the operator cannot stop and then resume command in the example test.

Path with the Limit Detector for the specimen

The first Limit Detection activity (3) detects minimum and maximum load values applied to the specimen

while the Parallel Path activity is active. The minimum and maximum values are defined by Load Limit

Low and Load Limit High variables. The action for both limits is set to No Action. This means if either of

the specified values are detected, the detector trips and the Parallel Path activity ends.

This activity protects the specimen by allowing you to define the maximum compressive and tensile forces

applied to the specimen while the command is applied.

Path with the Limit Detector for the load cell

The second Limit Detection activity (4) detects the maximum load value you wish to apply to the load cell

while the Parallel Path activity is active. The maximum value is defined by Load Cell Capacity variable.

The Action is set to No Action, which means if the specified value is detected, the Parallel Path activity

ends.

This activity protects the load cell by allowing you to define the maximum compressive force applied to

the load cell while command is applied.

Path with the Digital Input Detector for the handset

The Digital Input Detector activity (5) detects a transition from low-to-high in the DI/O port associated

with the handset while the Parallel Path activity is active. The Action is set to No Action, which means if

the transition is detected, the Parallel Path activity ends. When the handset is connected, the DI/O port

is biased high.

This activity stops the command if the handset cable is disconnected while command is applied.

34 | MTS TestSuite

Page 35

Examine the Example Test

About detector action resources

Actions are test resources. By default, the only action available to the detectors in the example test is No

Action. The MTS Insight controller also supports Program Hold, Program Stop, and Interlock actions, but

these actions have been removed from the test because they are not used.

About restoring detector actions

You can restore unused controller resources to tests by importing them with the controls in the Resources

tab (Define tab > Resources subtab). In Modify the Example Test (p. 81), you will restore all controller

actions to the example test.

For More Information

Modify the Example Test (p. 81)

Go To + DAQ + Detection Activity

This composite activity performs multiple functions associated with the following tabs:

• Go To

• DAQ

• Limit Detection

• Break Detection

• Wait for Operator Action

For most tests, including the example test, the command content of the test is provided by one or more

Go To + DAQ + Detection activities in the Run section.

Go To tab

The Go To tab is configured to ramp the crosshead at a rate defined by the Test Rate variable. The

Termination Condition on this tab is not enabled, so the ramp is configured to continue until a specimen

failure is detected by the condition specified in the Break Detection tab. If that condition is not detected,

the ramp continues until one of the other branches of the Parallel Branch activity (such as a limit detection

branch) completes.

MTS TestSuite | 35

Page 36

Examine the Example Test

Go To Tab and Edit Variables Window

DAQ tab

The DAQ (data acquisition) tab is configured to continuously acquire timed load (force) and crosshead

(length) data at a sample rate defined by the Data Acquisition Rate variable. It is also configured to map

acquired data to array variables.

36 | MTS TestSuite

Page 37

Examine the Example Test

DAQ Tab, Trigger Properties Window, and Map Variables Window

About mapping data to variables

In all MTS templates created for TW, the Save data to variables? control is enabled by default. Mapping

data to arrays significantly extends the functionality of TW. Array variables provide the data in the charts

and tables in the Review tab, support the use of several types of test-run displays (for example, the

Array-Variable Chart, the Variable Data Table, and the Variable Meter), and support the use of the Reporter

Add-In for Microsoft Excel.

Limit Detection tab

Limit detection is not used in this tab in the example test. For more information about limit detection, see

Set Station Detector Limits (p. 110).

Break Detection tab

The Break Detection tab detects when the specimen breaks while the Parallel Path activity is active.

The break detector monitors the peak load applied to the specimen. When the current value exceeds the

value defined by the Break Threshold variable, the detector is armed.

MTS TestSuite | 37

Page 38

Examine the Example Test

When the detector is armed and the peak load value drops by the percentage defined by the Break

Sensitivity variable, a break is detected. The action is set to No Action. This means if a break is detected,

the detector trips and the Parallel Path activity ends.

For many types of tensile tests, the test run completes when the specimen fails and the break detector

trips.

Break Detection Tab

Wait for Operator Action tab

The Wait for Operator Action tab enables the operator to click a button shown on the Monitor tab while

the test run is being performed. Clicking this button prematurely ends the Parallel Path activity.

The button label shown on the Monitor tab is determined by the text entered in the Display Text box.

In the example test, the button is labeled Next Segment. When the operator clicks the Next Segment

button on the Monitor tab while the test is running, program command stops and the "Return to Zero?”

message is shown.

38 | MTS TestSuite

Page 39

Examine the Example Test

Wait for Operator Action Tab and the “Next Segment” Button Shown on the Monitor tab

Finish Section

The Finish section runs:

• Automatically, when the Maximum Test Runs variable equals the number of test runs performed, or

• Manually, when the operator clicks the Run the Finish Section button on the Review tab toolbar. The

Review tab appears automatically after each test run.

In the example test, the Maximum Test Runs variable is set to 9999 (default), so it is designed to be ended

manually.

The Finish section is typically used for operations such as printing reports, exporting files, saving test data,

and archiving.

The example test contains only a disabled Run Report activity, so no activities are performed when running

the Finish section.

Finish Section of the Example Test

MTS TestSuite | 39

Page 40

Examine the Example Test

Run the Finish Section Button on the Review Tab

Test-Run Display Subtab

When you click on the Test-Run Display subtab of the Define tab, the center of the main window shows

the designer view of the test-run displays used in the test. You can think of a test-run display as a readout

device—like a meter or scope—that shows test signals or other information on the Monitor tab during test

runs.

The only test-run display used in the example test is the Array-Variable chart. It uses the Load variable

for the Y-axis and the Extension variable for the X-axis, as shown on the Properties panel.

You can add any of the test-run displays in the Toolbox to the test to view test information during test runs.

Array-Variable Chart on the Test-Run Display Subtab

Variables Subtab

When you click on the Variables subtab of the Define tab, the main window shows the variables used in

the test.

40 | MTS TestSuite

Page 41

Examine the Example Test

Variables Subtab and Variable Availability Property

Variable Definition

A variable is a place with a name in which you can store one or more values. Variable types and examples

used in the test include:

• Simple variables (also referred to as scalar variables) store either a value or a string. In the example

test, the variable used to set the rate at which data is acquired is a simple variable. It has a display

name of Data Acquisition Rate, an internal name of DataAcqRate, and default value of 10 Hz.

• Array variables store an array, which is an ordered collection of numbers or strings. You can refer to

individual values in an array by specifying an index. In the example test, the variable used to store

acquired load data is an array variable. It has a display name of -Load, an internal name of _LoadArray,

and a default value of 0.000 kN (array variables resize automatically, so you can disregard the default

value).

• Calculated variables are variables (simple or array) that include a mathematical expression. In the

example test, the variable used to store stress data is a calculated variable. It has a display name of

Stress, an internal name of _StressArray, a default value of 0.000 kN/mm, and a calculation of

_LoadArray/Area.

Variable Use in the Example Test

Variables are used extensively in the example test. While using variables is not a requirement for test

design, using variables significantly extends the functionality of tests created with MTS TestSuite software.

If variables were not used in the example test:

• To change the properties of activities that are currently variables, you would have to navigate through

the layers in the workflow and locate specific property fields.

MTS TestSuite | 41

Page 42

Examine the Example Test

• You could not use the array-variable chart on the Test-Run Display subtab, or any of the other test-run

displays in the Variable Views category (or other test-run displays that use variables). You would only

be able to use test-run displays in the Signal Views category, such as signal meter and signal scope.

• The charts and tables in the Review tab, which are based on variables, would not contain useful

information.

• You would not be able to show test data in charts and graphs using the Reporter Add-in for Excel. In

this case, test data would be available only as tables of sampled signal data values.

Variable Availability Attributes

Variables have one or more of the following Availability attributes:

• Pretest

• During Test

• Editable Post Test

• Results

The Pretest, During Test, and Editable Post Test attributes specify when the operator can change the

variable during the test.

Pretest attribute

Variables with this attribute can be edited before the test is initialized and before each test run. In the

example test, the Data Acquisition Rate, Test Rate, and Grip Separation variables have this attribute. They

appear on the Monitor tab before the test is started and each time the operator clicks the Run button.

During Test attribute

Variables with this attribute can be edited in any of the test sections (Set Up, Run, or Finish) after the test

is started. In the example test, the Input Parameters activity in the Run section prompts the operator for

the width and thickness of the specimen, which apply to the Width and Thickness variables.

Editable Post Test attribute

Variables with this attribute can be edited in the Variables table on the Review tab after the test is complete

(1). The Variables table does not appear by default. To view the Variables table, you must change the

default panel view on the Review tab by clicking the Two or Four-Panel Views button (2). In the example

test, the Break Index variable has this attribute (3).

42 | MTS TestSuite

Page 43

Result attribute

Examine the Example Test

Access to the Variables Table and Editable Post-Test Variables

The Result attribute specifies the variables that appear in the Result table and Variables tables in the

Review tab. In the example test, the Peak Load variable has the Result attribute, and appears on the

Results table.

Peak Load Variable on the Result Table

Variables with both Results and Editable Post Test attributes

Some variables include both Editable Post Test and Result attributes. In the example test, this applies

to the Thickness variable. In this case, the variable appears in two locations on the Review tab:

• In a non-editable form in the Results table

• In an editable form in the Variables table (appears when you select a multi-panel view)

Report Templates Subtab

The Report Templates subtab shows the report templates available to the example test. Report templates

are Microsoft Excel files that specify what and how test information appears in generated reports. Report

templates are workbook files (.xltx); you can generate reports without Excel installed. Excel must be installed

to create or modify report templates.

MTS TestSuite | 43

Page 44

Examine the Example Test

Reports Templates Subtab

Default Test-Run Report template

Use the default Test-Run Report template for generating reports for individual test runs. The example test

does not include an activity in the workflow to generate a report for test runs. However, the operator could

generate a report for test runs using the toolbar controls on the Review tab.

Default Test Report template

Use the default Test Report template for generating reports that apply to all the test runs in the test. The

example test includes a disabled Run Report activity in the Finish section of the workflow. To generate a

test report, the designer would have to enable this activity. Otherwise, the operator could generate a test

report using the toolbar controls on the Review tab, as shown

Generate Reports Buttons on the Review Tab

Functions Subtab

The Functions subtab shows the custom functions available to the example test. The MTS TestSuite TW

application uses functions to perform complex mathematical operations during tests.

Functions Subtab

The example test includes the SimulatedLoad function, which derives load data from extension data

provided by the MTS Insight Controller simulator. This function was created with Python. To view the

Python code for this function (as shown), select the function and click Edit, or double-click the function.

44 | MTS TestSuite

Page 45

Examine the Example Test

Using Python with MTS TestSuite

Python is an interpreted, general-purpose, high-level programming language with an extensive resource

library. You can use Python to create custom functions to extend the functionality of MTS TestSuite software.

You can use Python for reading and writing to files, dynamic mathematical calculations, and manipulating

variables.

Python Code for the SimulatedLoad Function in the Function Editor

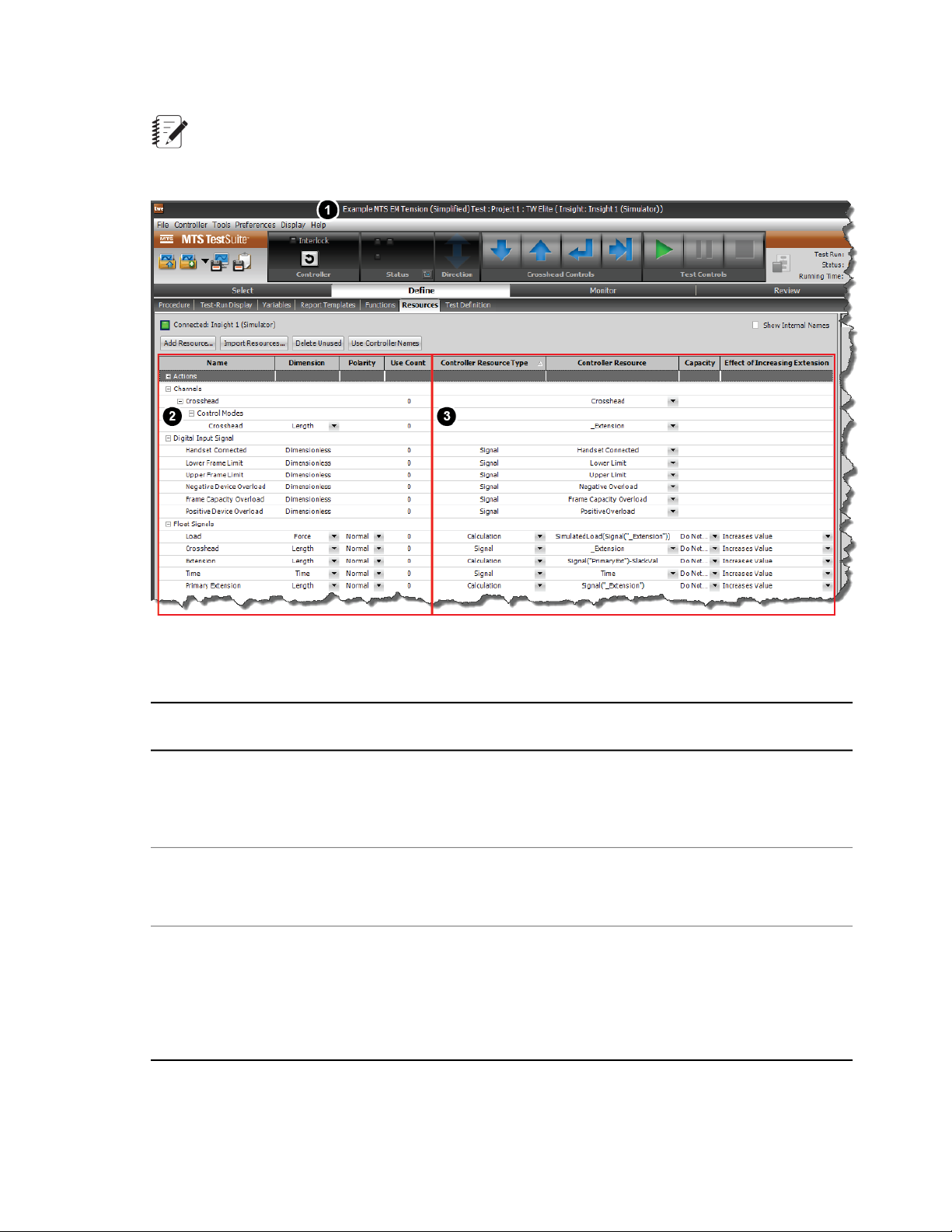

Resources Subtab

The Resources subtab of the Define tab shows the mapping of test resources to controller resources.

Note:

The information in this section applies to using the TWE application with MTS Criterion frames and

MTS Insight controllers.

Resources Subtab (Default)

MTS TestSuite | 45

Page 46

Examine the Example Test

Resources Tab Description

DescriptionNumber

Connection indicator1

Test resources2

Controller resources3

Resource management controls4

Controller identification

The connection indicator (1) shows the controller configuration associated with the current test when TW

is connected to a controller. In the example test, the controller configuration is labeled “C42.503 (Simulator)”.

The main window shows the test name, project, application name, controller name, and controller

configuration. In the example test, this is:

“Example MTS EM Tension (Simplified) Test: Project 1: TW Elite (Insight:C42.503 (Simulator))”.

Test resources

The resources in (2) are test resources. Test resources are required by the test and must map to equivalent

resources in the Controller Resources column when connected to a controller.

In the example test, the control mode labeled “Crosshead” is a test resource. You can use test resources

for various test elements, such as activities, runtime display devices, and variables.

Controller resources

The resources in (3) are controller resources. A controller resource refers to a hardware resource in the

controller as it appears in the controller configuration. In the example test, the control mode labeled

“_Extension” is a controller resource.

When connected to a station, controller resources reflect the resources in the controller configuration.

When not connected to a controller, controller resources are the resources TWE expects to find when

connected to a controller.

Managing resources

Resource management controls (4) allow you to add, import, delete, and rename test resources.

It is important to understand that only the controller resources required by the test are typically shown on

the Resources subtab. To view all of the resources available in the connected controller, click Import

Resources... > Import All Unused Controller Resources.

In the example test, the default Resources subtab shows just one control mode resource; when all unused

resources are imported, it shows multiple control modes, as shown.

46 | MTS TestSuite

Page 47

Examine the Example Test

Resources Subtab with Imported Resources

Resource mapping

A test resource is not required to have the same name as the equivalent controller resource. For instance,

in the example test, the control mode test resource is labeled “Crosshead”, and the equivalent controller

resource is labeled “_Extension”.

However, if the names are different when TWE connects to the controller, you must map the test resource

to the equivalent controller resource.

Suppose you disconnect the example test from the controller and reconnect to a different controller in

which the equivalent resource is labeled “_Displacement”. In this case, TWE would be unable to

automatically map the new controller resource “_Displacement” to the test resource “Crosshead”, and a

validation icon would appear in the window.

To resolve the error, you would have to manually map the controller resource to the test. To do this, you

would click the list icon next to the “_Displacement” test resource and select “Crosshead”.

Resource mapping is saved with the test.

Note:

When you create tests while the TWE application is connected to a controller, it is referred to as

“online” test design. You can also perform “offline” test design.

Test Definition Subtab

The Test Definition subtab of the Define tab shows general settings for the test, including:

• The Formula Assistant File

• The Log Type, which determines whether an audit trail is created for the test.

• Whether the test can be started remotely with a digital input.

• Whether the display automatically switches to the Review tab at the completion of a test run.

MTS TestSuite | 47

Page 48

Examine the Example Test

Note:

All fields are read-only until you click the Edit button.

Formula Assistant File

Test Definition Subtab

The Formula Assistant File provides a base set of system variables, calculations, and functions associated

with a specific type of test. The example test uses a formula assistant file labeled “Electro-Mechanical

Formula Assistant”.

If you need to change the Formula Assistant File associated with a template, contact your MTS Field

Service Engineer for assistance.

When a test variable is associated with the Formula Assistant File, an Option list becomes available in

the Calculation panel for the variable. The options available depend on the selected variable.

For example, when you select the Area variable on the Variables subtab of the Define tab, several

specimen geometry types are available in the Options list.

Log type

The log type selections include Basic or Audit Trail. The example test uses the Basic log type.

The Audit Trail feature is for tracking changes to the test. When selected, each time you run a test on an

MTS Criterion or MTS Insight system, the application writes the TEDS model and serial number to the test

run log. When the test is complete, you can right-click on a test run in the Review tab and validate the raw

data for that test run.

Remote start

This control is disabled by default, and is disabled for the example test.

This control works in tandem with the Digital Input control in the Preferences menu (Preferences >

Configuration > Test > Select additional methods to start the test > Digital Input).

If you enable both controls, you can select a digital input source and specify a transition type to start the

test remotely.

Switching to the Review tab

This control is enabled by default, and is enabled for the example test.

48 | MTS TestSuite

Page 49

Examine the Example Test

If you disable this control, the display remains on the Monitor tab after each test run instead of automatically

switching to the Review tab.

For More Information

Changing the Specimen Geometry (p. 84)

Monitor Tab

Monitor tab view before the test starts

Before the operator starts the test by clicking the Run button, the Monitor tab shows the pretest inputs

the operator can change.

In the example test, this includes the Data Acquisition Rate, Test Rate, and Grip Separation variables, as

shown.

Monitor Tab Before the Test Starts

Test opens to Monitor tab for operators

If you open a test while logged on to TWE as an Operator, or when you open a test with the TWX application,

the workflow is hidden, and the main window shows the test inputs on the Monitor tab. If the test contains

validation errors, it opens to the Resource subtab of the Define tab so the operator can resolve the errors.

Editing pretest inputs on the Variables subtab

You can edit the pretest inputs that are shown to the operator in the Variables subtab of the Define tab.

To view variables that have the pretest attribute, use the Column Chooser to add the Pretest column to

the table, then edit as desired in the Availability panel.

MTS TestSuite | 49

Page 50

Examine the Example Test

DescriptionNumber