Page 1

MOTOTRBO

PROFESSIONAL DIGITAL TWO-WAY RADIO

™

PORTABLE

™

MOTOTRBO

PORTABLE

DP2000e Series BASIC

SERVICE MANUAL

JULY 2019

©

2019

Motorola Solutions, Inc. All rights reserved

*MN002211A01*

MN002211A01-AE

Page 2

MN002211A01-AE

Contents

Contents

List of Figures..............................................................................................................5

List of Tables............................................................................................................... 7

Foreword......................................................................................................................9

Product Safety and RF Exposure Compliance.............................................................................. 9

Computer Software Copyrights......................................................................................................9

Document Copyrights.................................................................................................................... 9

Disclaimer......................................................................................................................................9

Trademarks..................................................................................................................................10

Document History..................................................................................................... 11

Notations Used in This Manual................................................................................12

Chapter 1: Introduction.............................................................................................13

1.1 Radio Description.................................................................................................................. 13

1.1.1 Limited Keypad Model............................................................................................. 14

1.1.2 Non-Keypad Model.................................................................................................. 15

1.2 Portable Radio Model Numbering Scheme........................................................................... 16

1.3 Model Charts......................................................................................................................... 17

1.3.1 UHF Model Chart..................................................................................................... 18

1.3.2 VHF Model Chart..................................................................................................... 18

1.3.3 300 MHz Model Chart.............................................................................................. 19

1.3.4 350 MHz Model Chart.............................................................................................. 19

1.4 Specifications.........................................................................................................................19

Chapter 2: Test Equipment and Service Aids........................................................ 25

2.1 Recommended Test Equipment............................................................................................ 25

2.2 Service Aids...........................................................................................................................26

2.3 Programming, Testing, and Alignment Cable........................................................................ 27

Chapter 3: Transceiver Performance Testing........................................................ 30

3.1 Setup..................................................................................................................................... 30

3.1.1 Setting Up DMR Transmitter and Receiver Test......................................................30

3.2 Display Model Test Mode...................................................................................................... 31

3.2.1 Entering Display Radio Test Mode.......................................................................... 31

3.2.2 RF Test Mode.......................................................................................................... 32

3.2.2.1 Testing RF Channel Selections..................................................................32

3.2.3 Display Test Mode................................................................................................... 35

3.2.4 LED Test Mode........................................................................................................36

3.2.5 Backlight Test Mode................................................................................................ 36

2

Page 3

MN002211A01-AE

Contents

3.2.6 Speaker Tone Test Mode........................................................................................ 36

3.2.7 Earpiece Tone Test Mode........................................................................................37

3.2.8 Audio Loopback Earpiece Test Mode

3.2.9 Battery Check Test Mode........................................................................................ 37

3.2.10 Button/Knob/PTT Test Mode................................................................................. 38

3.3 Non-Display Model Test Mode.............................................................................................. 39

3.3.1 Entering Non-Display Radio Test Mode...................................................................39

3.3.2 RF Test Mode.......................................................................................................... 39

3.3.2.1 Testing RF Channel Selections..................................................................40

3.3.3 LED Test Mode........................................................................................................43

3.3.4 Speaker Tone Test Mode........................................................................................ 43

3.3.5 Earpiece Tone Test Mode........................................................................................44

3.3.6 Audio Loopback Earpiece Test Mode......................................................................44

3.3.7 Battery Check Test Mode........................................................................................ 44

3.3.8 Button/Knob/PTT Test Mode................................................................................... 44

......................................................................37

Chapter 4: Radio Programming and Tuning...........................................................46

4.1 Customer Programming Software Setup............................................................................... 46

4.2 AirTracer Application Tool..................................................................................................... 46

4.3 Radio Tuning Setup...............................................................................................................47

4.3.1 RF Plug Disassembly...............................................................................................47

Chapter 5: Disassembly/Reassembly Procedures.................................................50

5.1 Preventive Maintenance........................................................................................................ 50

5.2 Safe Handling of CMOS and LDMOS Devices......................................................................51

5.3 General Repair Procedures and Techniques........................................................................ 51

5.4 Disassembling and Reassembling the Radio........................................................................ 53

5.5 Detailed Radio Disassembly..................................................................................................53

5.5.1 Front Kit from Chassis Disassembly........................................................................ 53

5.5.2 Back Kit Disassembly.............................................................................................. 58

5.5.3 Keypad, Display, and Keypad Board Disassembly..................................................59

5.5.4 Side Button, Speaker, Microphone, and UC-Audio Flex Disassembly.................... 62

5.6 Detailed Radio Reassembly.................................................................................................. 65

5.6.1 Speaker Reassembly...............................................................................................65

5.6.2 Side Button, Keypad, Display, and Keypad Board Reassembly..............................67

5.6.3 Back Kit Reassembly...............................................................................................71

5.6.4 Front Kit Reassembly...............................................................................................74

5.6.5 RF Plug Reassembly............................................................................................... 76

5.7 Ensuring Radio Immersibility................................................................................................. 78

5.7.1 Servicing.................................................................................................................. 78

5.7.2 Accidental Immersion...............................................................................................78

3

Page 4

MN002211A01-AE

Contents

5.7.3 Specialized Test Equipment.................................................................................... 78

5.7.4 Vacuum Pump Kit.................................................................................................... 78

5.7.5 Pressure Pump Kit...................................................................................................79

5.7.6 Miscellaneous Hardware

5.7.7 Vacuum Test............................................................................................................79

5.7.8 Pressure Test...........................................................................................................80

5.7.9 Troubleshooting Leak Areas....................................................................................81

5.7.9.1 Front Housing Troubleshooting..................................................................81

5.7.9.2 Replacing Battery Contact Seal................................................................. 81

5.7.9.3 Replacing Chassis Assembly.....................................................................82

5.7.9.4 Replacing Ventilation Seal and Ventilation Label.......................................82

5.7.9.5 Battery Maintenance.................................................................................. 82

5.7.10 Troubleshooting Charts..........................................................................................84

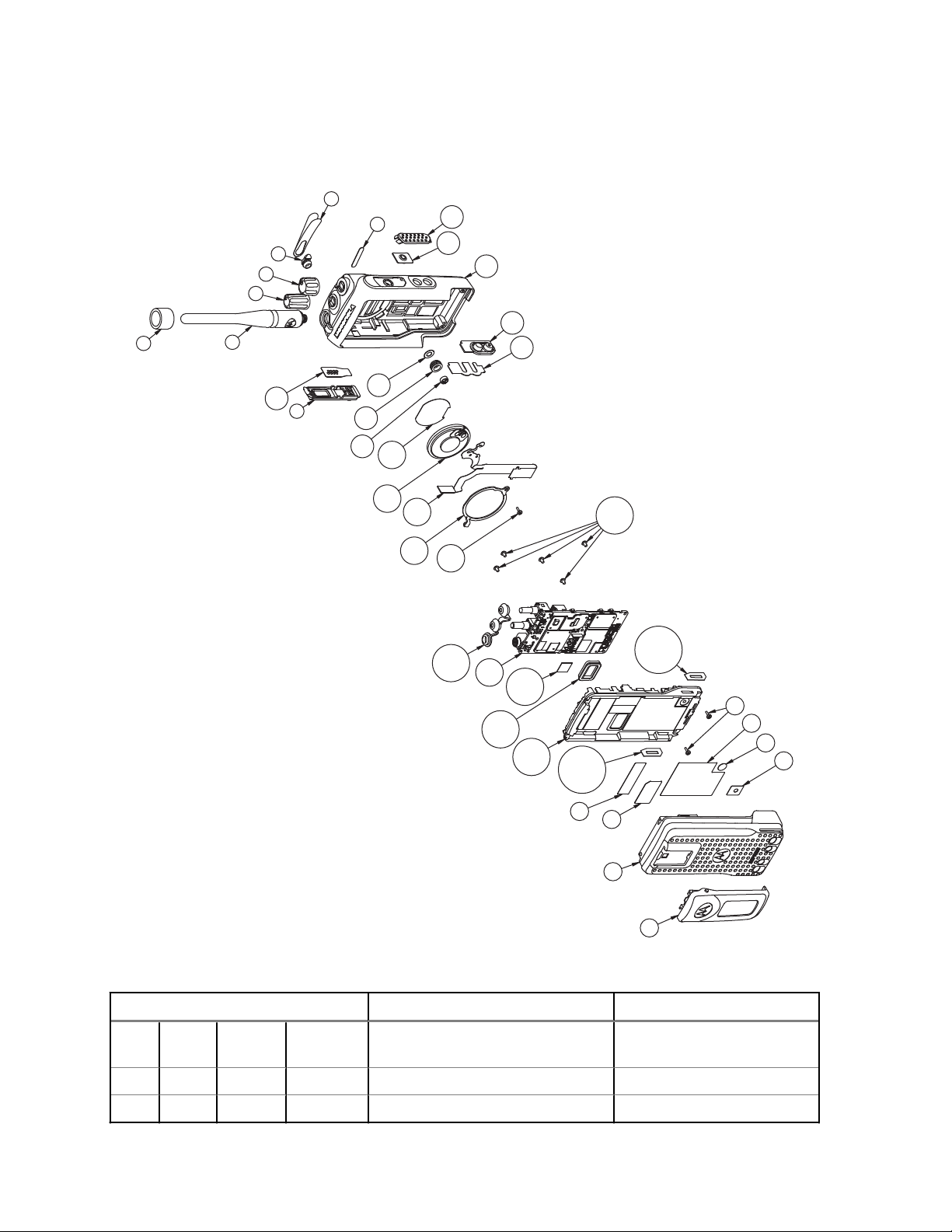

5.8 Radio Exploded Mechanical View and Parts List.................................................................. 87

5.8.1 Limited Keypad Model............................................................................................. 87

5.8.2 Non-Keypad Model.................................................................................................. 90

5.8.3 Additional Parts List................................................................................................. 92

5.9 Torque Chart..........................................................................................................................93

..........................................................................................79

Chapter 6: Basic Troubleshooting...........................................................................95

6.1 Replacement Back Cover Kit Procedures............................................................................. 95

6.2 Power-Up Error Codes.......................................................................................................... 95

6.3 Operational Error Codes........................................................................................................97

Appendix A: EMEA Regional Warranty, Service, and Technical Support........... 98

Appendix B: Service Information.............................................................................99

Appendix C: Limited Level 3 Servicing.................................................................101

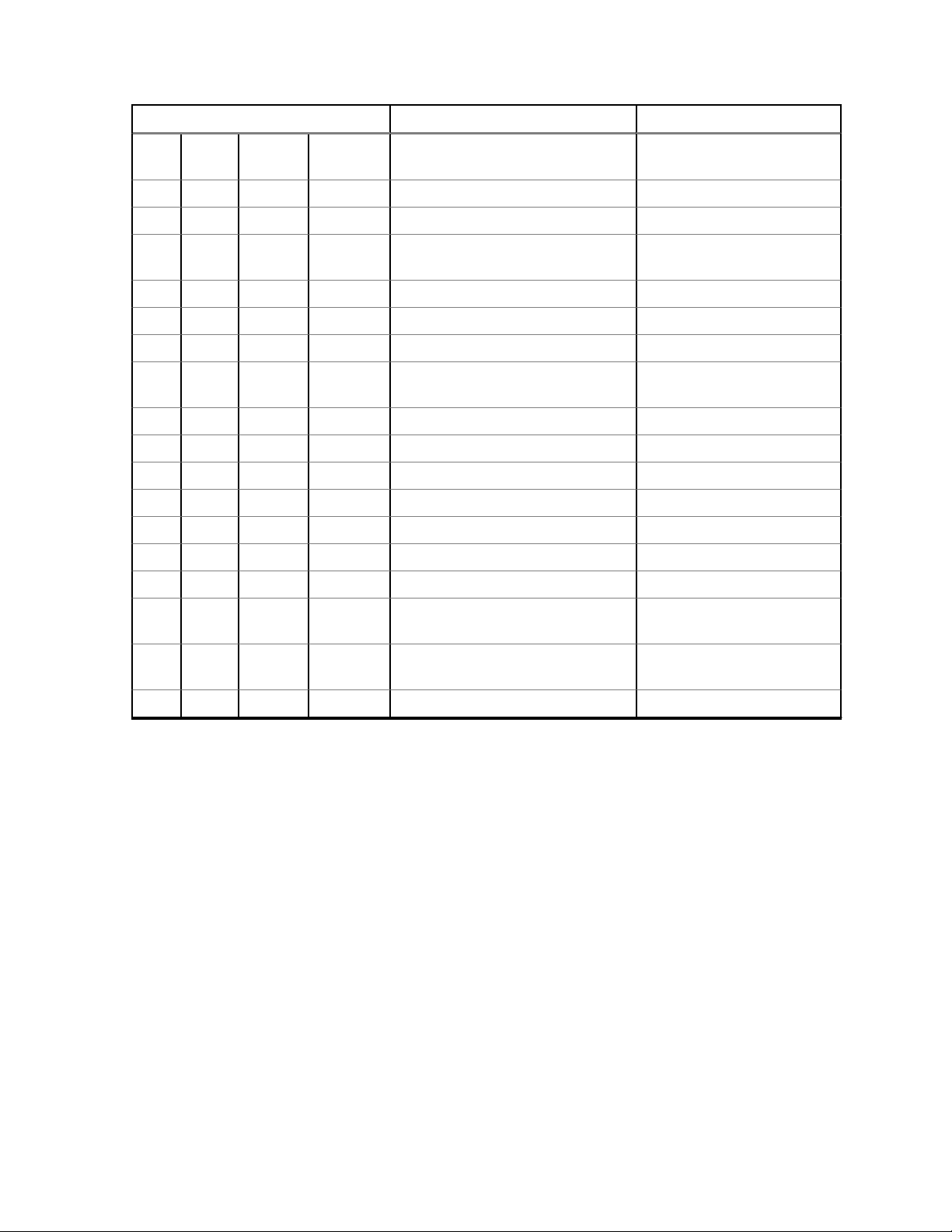

C.1 Component and Parts List...................................................................................................102

Glossary...................................................................................................................104

4

Page 5

MN002211A01-AE

List of Figures

List of Figures

Figure 1: Limited Keypad Model.............................................................................................................14

Figure 2: Non-Keypad Model..................................................................................................................15

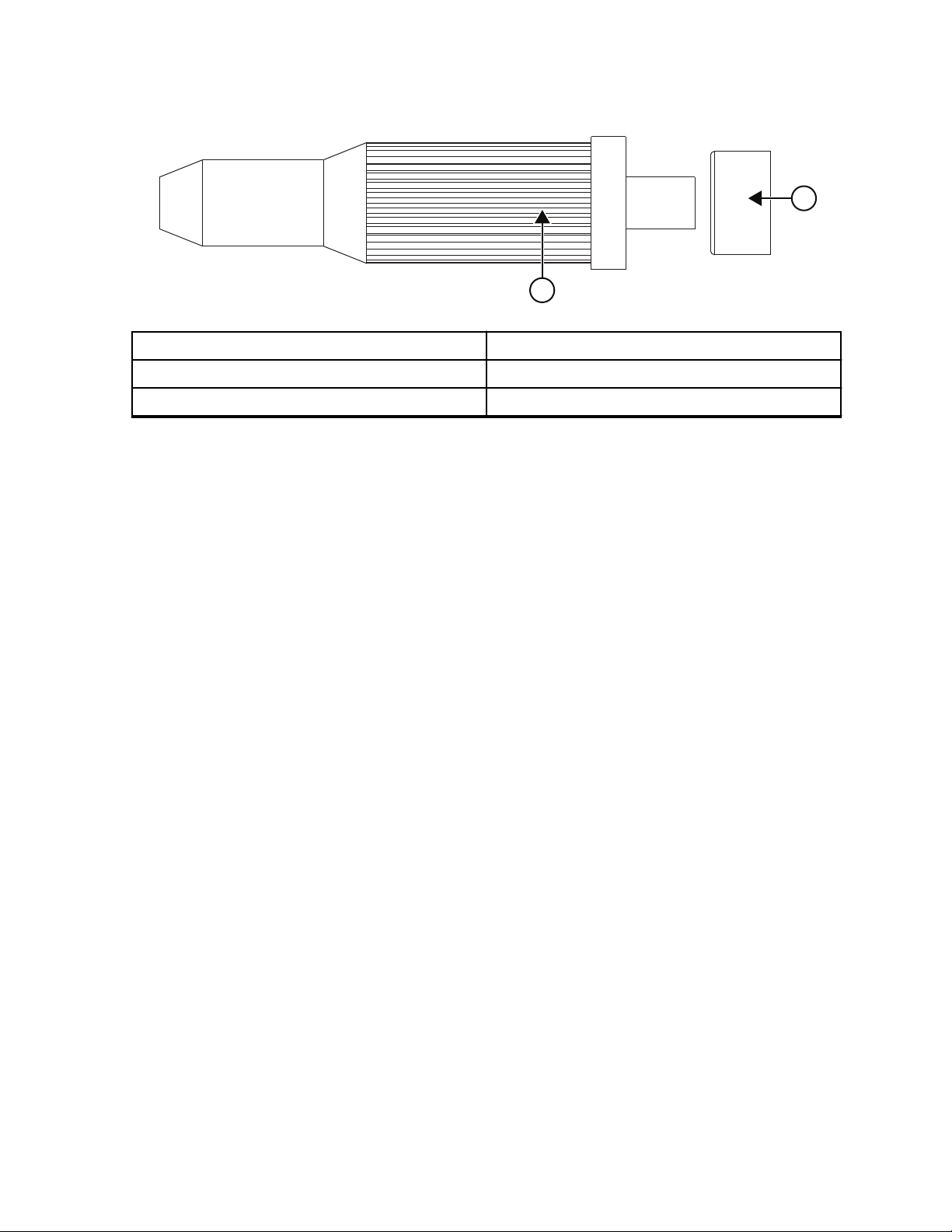

Figure 3: Programming, Testing, and Alignment Cable

Figure 4: Pin Layout of Side Connector..................................................................................................29

Figure 5: DMR Radio Transmitter and Receiver Testing Setup............................................................. 31

Figure 6: Battery Check Test Mode Display...........................................................................................37

Figure 7: CPS Programming Setup........................................................................................................46

Figure 8: Radio Tuning Equipment Setup.............................................................................................. 47

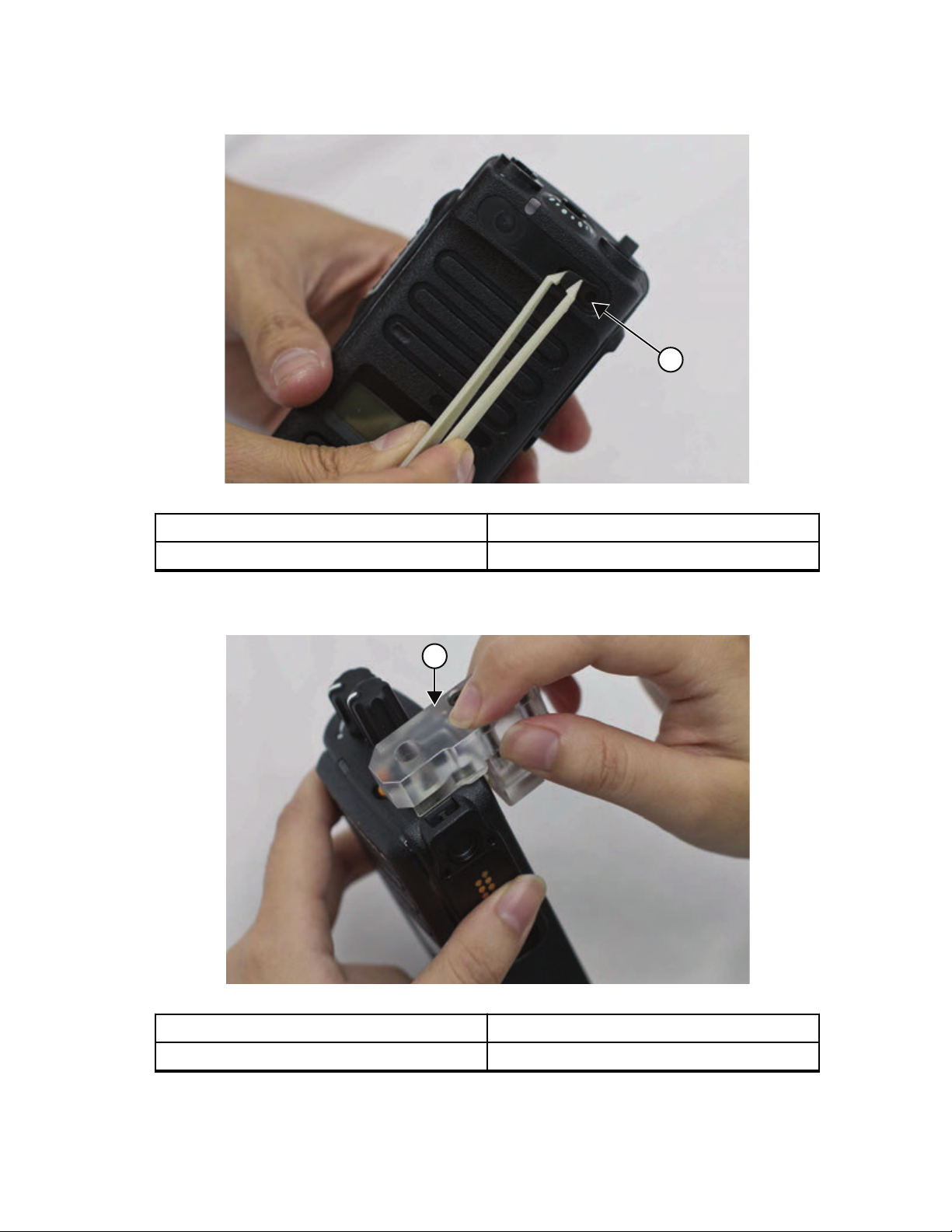

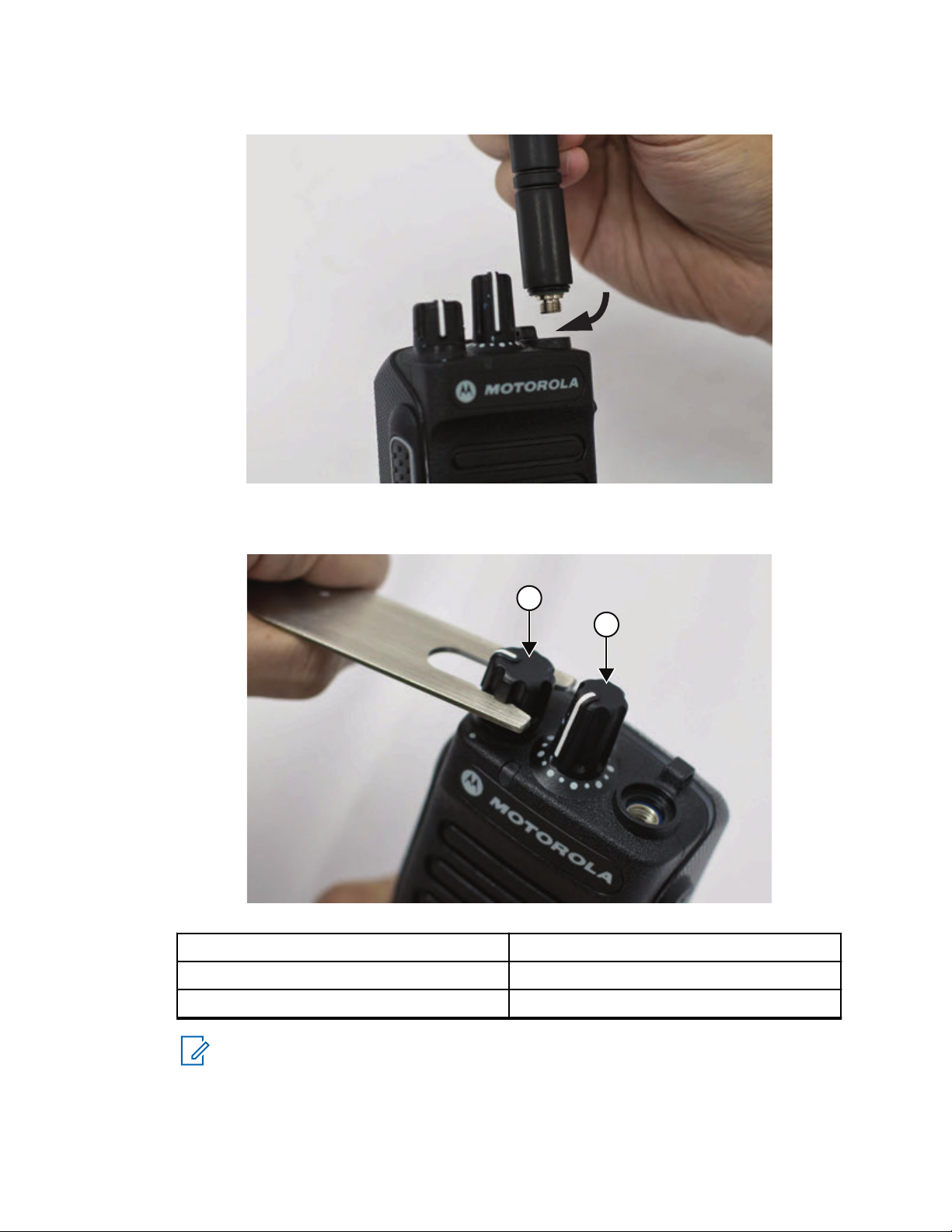

Figure 9: RF Plug disassembly...............................................................................................................48

Figure 10: RF Adaptor insertion............................................................................................................. 48

Figure 11: RF Adaptor screw..................................................................................................................49

Figure 12: RF Connector........................................................................................................................49

Figure 13: Battery removal..................................................................................................................... 54

Figure 14: Battery removal..................................................................................................................... 54

Figure 15: Antenna removal................................................................................................................... 55

Figure 16: Volume and Channel Knob removal......................................................................................55

Figure 17: Front Kit-Back Kit Screw removal..........................................................................................56

Figure 18: Back Kit disassembly............................................................................................................ 56

Figure 19: Back Kit removal................................................................................................................... 57

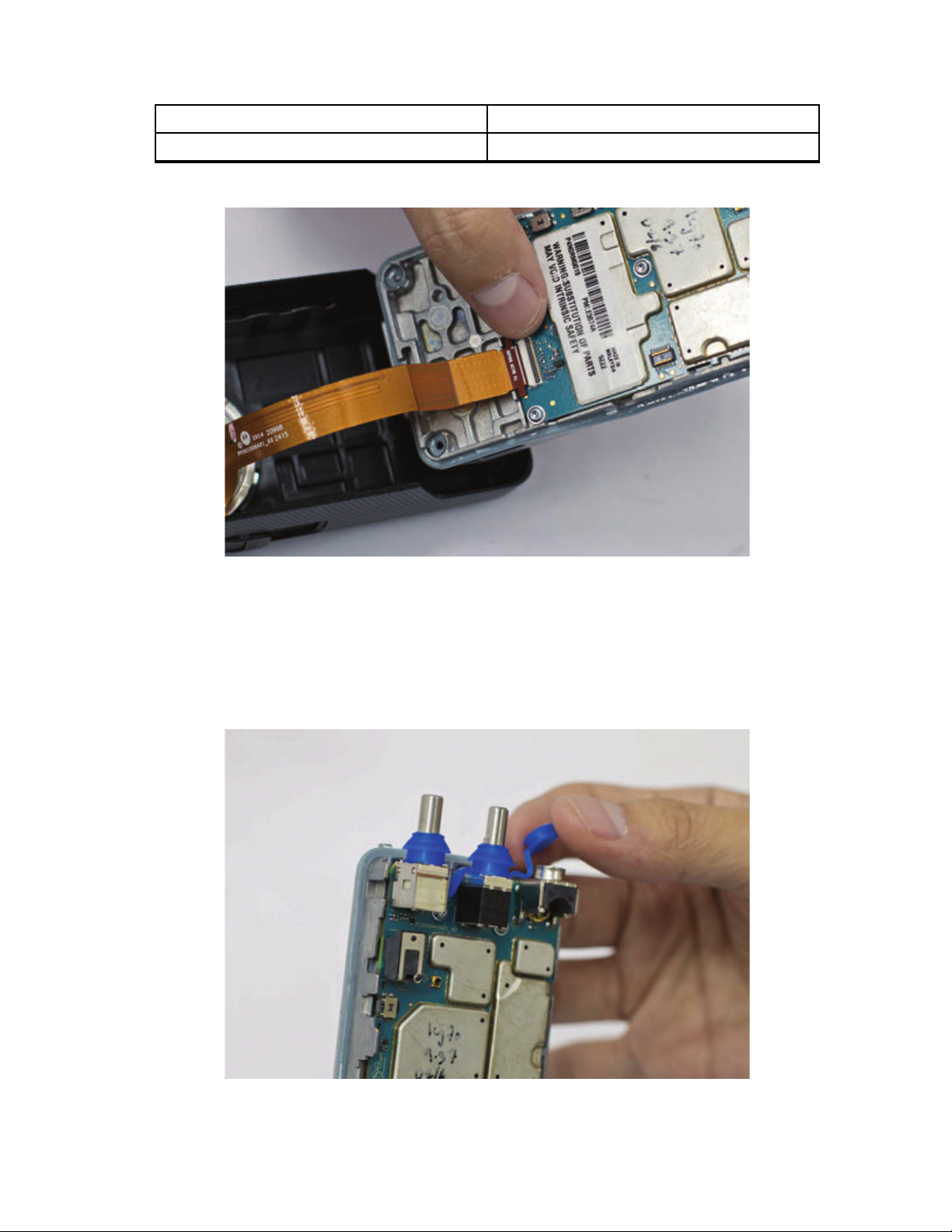

Figure 20: Disconnecting the interface UC-audio flex and keypad-display flex (Limited Keypad

Model)................................................................................................................................................57

Figure 21: Disconnecting the UC-audio flex (Non-Keypad Model).........................................................58

Figure 22: Top control seal removal.......................................................................................................58

Figure 23: Back Kit disassembly............................................................................................................ 59

Figure 24: Battery contact seal removal.................................................................................................59

Figure 25: UC-audio flex removal...........................................................................................................60

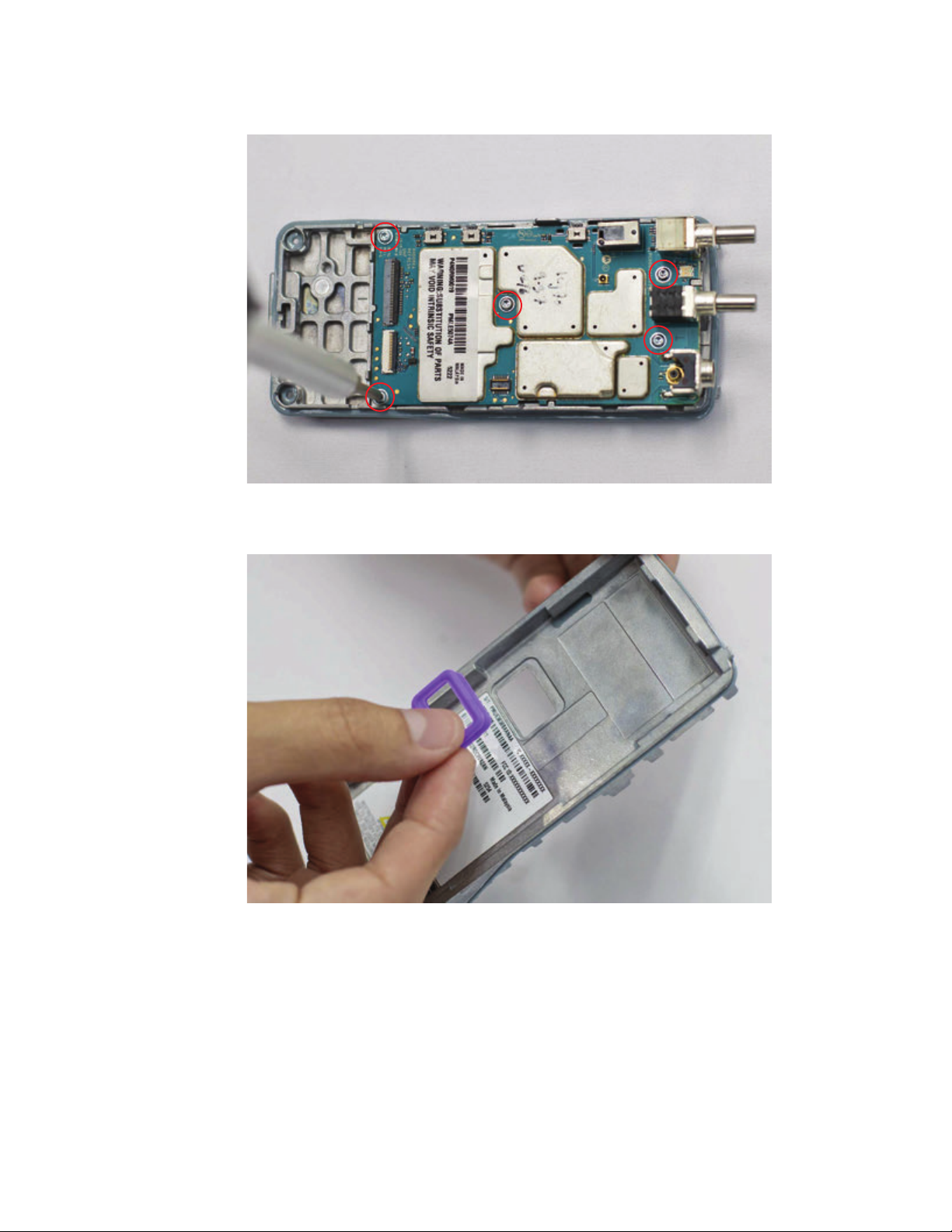

Figure 26: K18 screw removal................................................................................................................60

Figure 27: Display flex removal.............................................................................................................. 61

Figure 28: Keypad removal.................................................................................................................... 61

Figure 29: PTT retainer removal.............................................................................................................62

Figure 30: Side button removal.............................................................................................................. 62

Figure 31: UC escutcheon removal........................................................................................................63

Figure 32: UC-audio flex removal...........................................................................................................63

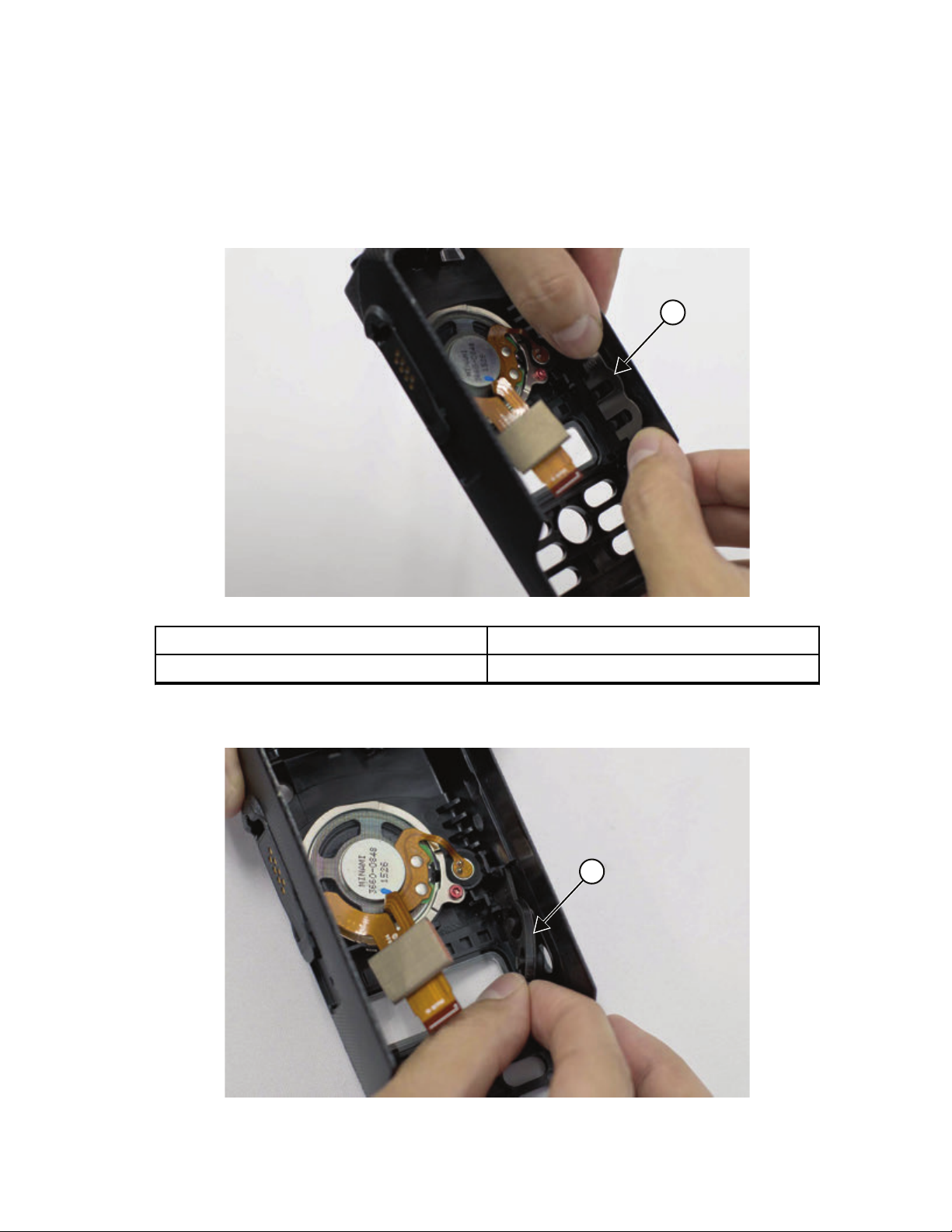

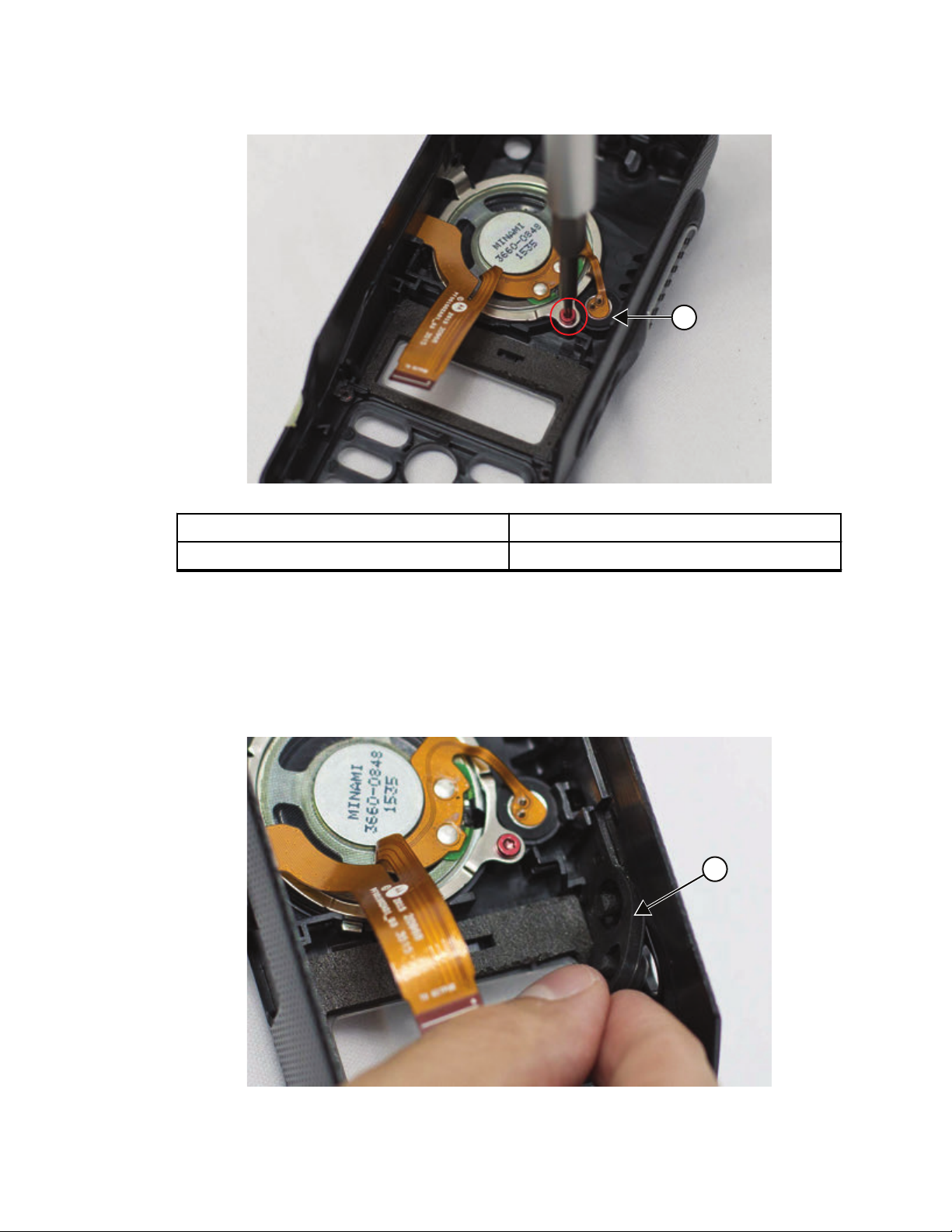

Figure 33: Speaker retainer screw removal............................................................................................64

Figure 34: Speaker retainer removal......................................................................................................64

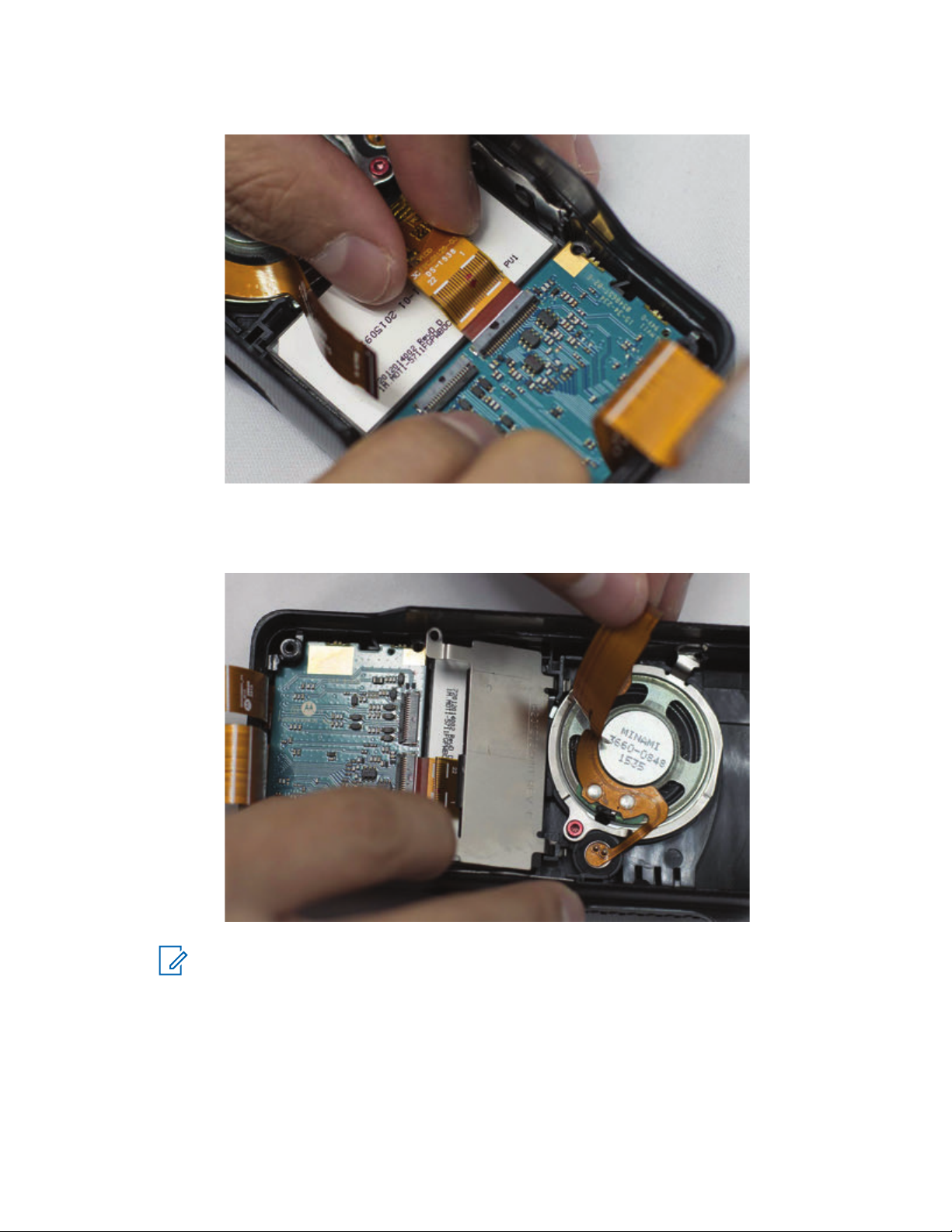

Figure 35: Speaker assembly.................................................................................................................65

..........................................................................28

5

Page 6

MN002211A01-AE

List of Figures

Figure 36: UC-audio flex.........................................................................................................................66

Figure 37: UC escutcheon......................................................................................................................66

Figure 38: Speaker retainer reassembly

................................................................................................ 67

Figure 39: Side button reassembly.........................................................................................................67

Figure 40: PTT retainer reassembly.......................................................................................................68

Figure 41: Display module reassembly.................................................................................................. 68

Figure 42: Keypad reassembly...............................................................................................................69

Figure 43: Keypad board reassembly.....................................................................................................69

Figure 44: Display flex reassembly.........................................................................................................70

Figure 45: Speaker retainer reassembly................................................................................................ 70

Figure 46: UC-audio flex pad reassembly.............................................................................................. 71

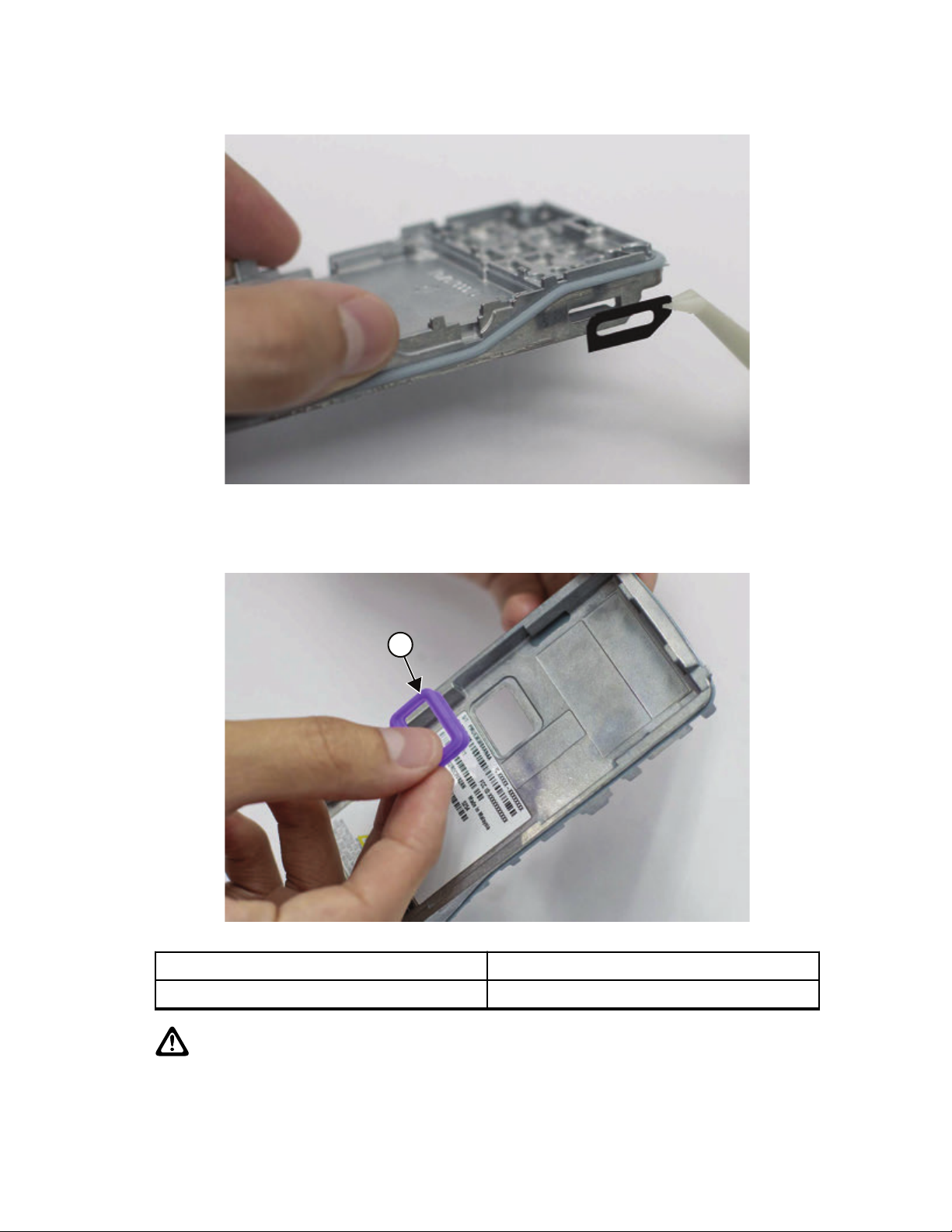

Figure 47: Replace thermal pad............................................................................................................. 71

Figure 48: Affix chassis label..................................................................................................................72

Figure 49: Battery contact seal reassembly........................................................................................... 72

Figure 50: Mainboard reassembly..........................................................................................................73

Figure 51: Top control seal reassembly................................................................................................. 73

Figure 52: Interface flexes reassembly (Limited Keypad Model)............................................................74

Figure 53: Interface flexes reassembly (Non-Keypad Model)................................................................ 74

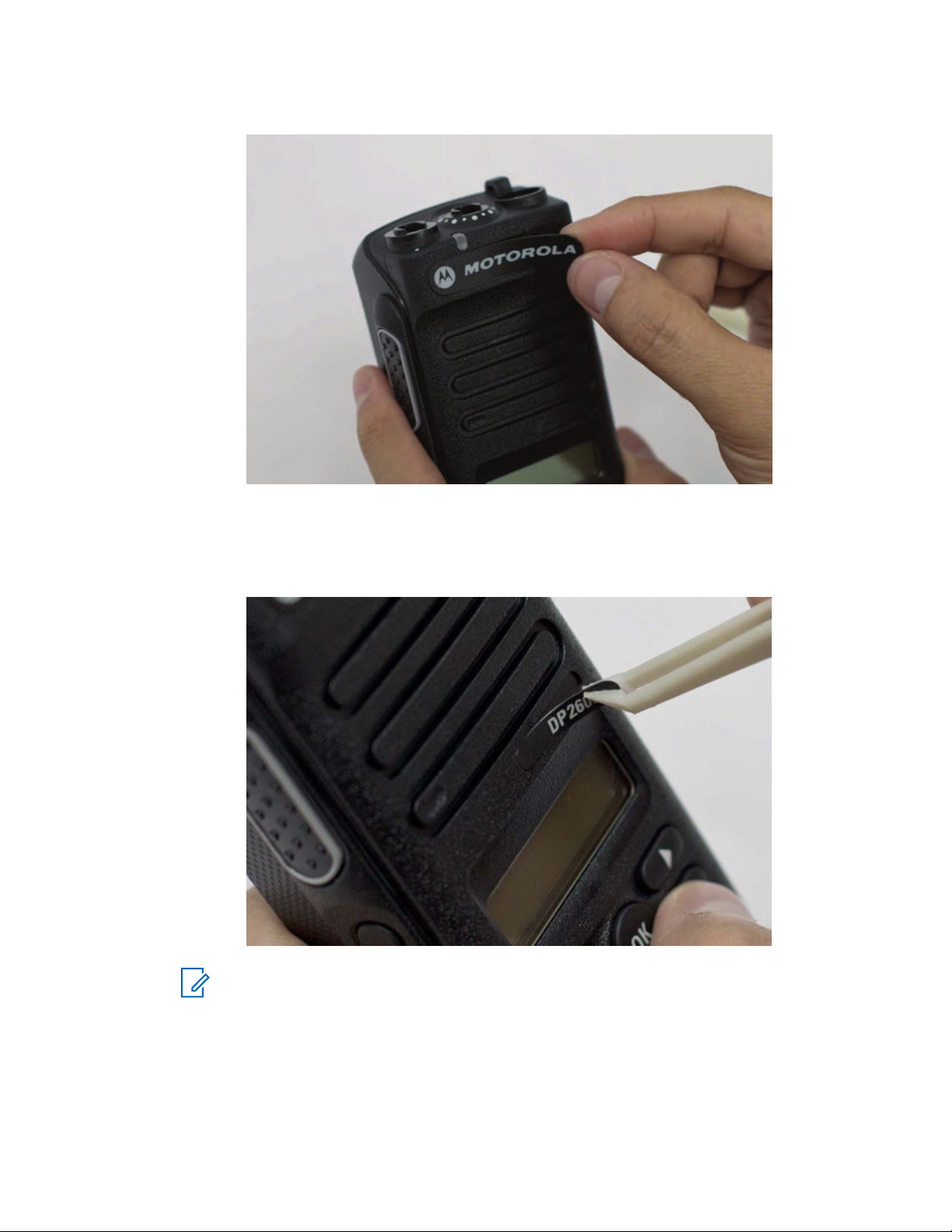

Figure 54: Front kit reassembly..............................................................................................................75

Figure 55: Knob reassembly...................................................................................................................75

Figure 56: Attaching the antenna........................................................................................................... 76

Figure 57: RF Plug reassembly..............................................................................................................76

Figure 58: Nameplate replacement........................................................................................................ 77

Figure 59: Product nameplate reassembly.............................................................................................77

Figure 60: Connector Fitting - Fitting Seal Pump Connector..................................................................79

Figure 61: Troubleshooting Flow Chart for Vacuum Test (Sheet 1 of 2)................................................ 84

Figure 62: Troubleshooting Flow Chart for Vacuum Test (Sheet 2 of 2)................................................ 85

Figure 63: Troubleshooting Flow Chart for Pressure Test and Leakage Areas..................................... 86

Figure 64: Limited Keypad Model Exploded View..................................................................................87

Figure 65: Non-Keypad Model Exploded View.......................................................................................90

Figure 66: PCB Top View.....................................................................................................................102

Figure 67: PCB Bottom View................................................................................................................103

6

Page 7

MN002211A01-AE

List of Tables

List of Tables

Table 1: Radio Frequency Ranges and Power Levels........................................................................... 13

Table 2: Portable Radio Model Numbering Scheme.............................................................................. 16

Table 3: Sales Models – Description of Symbols

Table 4: Table Legend for Model Charts................................................................................................17

Table 5: DP2000e Series, UHF, 403–527 MHz Model Chart................................................................. 18

Table 6: DP2000e Series, VHF, 136–174 MHz Model Chart................................................................. 18

Table 7: DP2000e Series, 300 MHz, 300–360 MHz Model Chart.......................................................... 19

Table 8: DP2000e Series, 350 MHz, 350–400 MHz Model Chart.......................................................... 19

Table 9: General Specifications..............................................................................................................19

Table 10: Receiver Specifications.......................................................................................................... 20

Table 11: Transmitter Specifications...................................................................................................... 21

Table 12: Self-Quieter Frequencies........................................................................................................22

Table 13: Military Standards...................................................................................................................23

Table 14: Environmental Specifications................................................................................................. 24

Table 15: Test Equipment...................................................................................................................... 25

Table 16: Service Aids............................................................................................................................26

Table 17: Pin Configuration of Side Connector...................................................................................... 28

Table 18: Initial Equipment Control Settings.......................................................................................... 30

Table 19: Front Panel Access Test Mode Displays................................................................................31

Table 20: Test Environments..................................................................................................................32

Table 21: Test Frequencies....................................................................................................................33

Table 22: Transmitter Performance Checks...........................................................................................33

Table 23: Receiver Performance Checks...............................................................................................34

Table 24: Button/Knob/PTT Checks.......................................................................................................38

Table 25: Keypad Checks...................................................................................................................... 38

Table 26: Test Environments..................................................................................................................40

Table 27: Test Frequencies....................................................................................................................40

Table 28: Transmitter Performance Checks...........................................................................................41

Table 29: Receiver Performance Checks...............................................................................................42

Table 30: Button/Knob/PTT Checks.......................................................................................................44

Table 31: Software Installation Kits Radio Tuning Setup....................................................................... 46

Table 32: Lead Free Solder Wire Part Number List............................................................................... 52

Table 33: Lead Free Solder Paste Part Number List..............................................................................52

Table 34: Limited Keypad Model Exploded View Parts List................................................................... 88

Table 35: Non-Keypad Model Exploded View Parts List........................................................................90

Table 36: Batteries................................................................................................................................. 92

................................................................................... 16

7

Page 8

MN002211A01-AE

List of Tables

Table 37: Nameplates............................................................................................................................ 92

Table 38: Back Kits.................................................................................................................................92

Table 39: Antenna ID Band (in pack of 10 pieces)

.................................................................................93

Table 40: Belt Clips................................................................................................................................ 93

Table 41: Torque Specifications for Screws...........................................................................................93

Table 42: Types of Error Code............................................................................................................... 96

Table 43: Types of Error Code............................................................................................................... 97

Table 44: List of Telephone Numbers.................................................................................................... 99

Table 45: Component Parts List...........................................................................................................103

8

Page 9

MN002211A01-AE

Foreword

Foreword

This manual includes all the information necessary to maintain peak product performance and

maximum working time, using levels 1 and 2 maintenance procedures.

This level of service goes down to the board replacement level and is typical of some local service

centers, Motorola Solutions authorized dealers, self-maintained customers, and distributors.

CAUTION: These servicing instructions are for the use of qualified personnel only. To reduce

the risk of electric shock, do not service parts other than those contained in the Operating

Instructions unless you are qualified to do so. Refer all servicing to qualified service personnel.

This manual includes radio specification of LEX L11, general description of LEX L11, recommended

test equipment, service aids, general maintenance recommendations, procedures for assembly and

disassembly, and exploded views and parts lists.

Product Safety and RF Exposure Compliance

CAUTION: This radio is restricted to occupational use only to satisfy FCC RF energy exposure

requirements. Before using this product, read the Product Safety and RF Exposure booklet

enclosed with your radio which contains important operating instructions for safe usage and RF

energy awareness and control for compliance with applicable standards and regulations.

For a list of Motorola Solutions-approved antennas, batteries, and other accessories, visit http://

www.motorolasolutions.com

Computer Software Copyrights

The Motorola Solutions products described in this manual may include copyrighted Motorola Solutions

computer programs stored in semiconductor memories or other media. Laws in the United States and

other countries preserve for Motorola Solutions certain exclusive rights for copyrighted computer

programs, including, but not limited to, the exclusive right to copy or reproduce in any form the

copyrighted computer program. Accordingly, any copyrighted Motorola Solutions computer programs

contained in the Motorola Solutions products described in this manual may not be copied, reproduced,

modified, reverse-engineered, or distributed in any manner without the express written permission of

Motorola Solutions. Furthermore, the purchase of Motorola Solutions products shall not be deemed to

grant either directly or by implication, estoppel, or otherwise, any license under the copyrights, patents

or patent applications of Motorola Solutions, except for the normal non-exclusive license to use that

arises by operation of law in the sale of a product.

Document Copyrights

No duplication or distribution of this document or any portion thereof shall take place without the

express written permission of Motorola Solutions. No part of this manual may be reproduced,

distributed, or transmitted in any form or by any means, electronic or mechanical, for any purpose

without the express written permission of Motorola Solutions.

Disclaimer

The information in this document is carefully examined, and is believed to be entirely reliable.

However, no responsibility is assumed for inaccuracies. Furthermore, Motorola Solutions reserves the

right to make changes to any products herein to improve readability, function, or design. Motorola

Solutions does not assume any liability arising out of the applications or use of any product or circuit

described herein; nor does it cover any license under its patent rights nor the rights of others.

9

Page 10

MN002211A01-AE

Foreword

Trademarks

MOTOROLA, MOTO, MOTOROLA SOLUTIONS and the Stylized M logo are trademarks or registered

trademarks of Motorola Trademark Holdings, LLC and are used under license. All other trademarks are

the property of their respective owners.

©

2019 Motorola Solutions, Inc. All rights reserved.

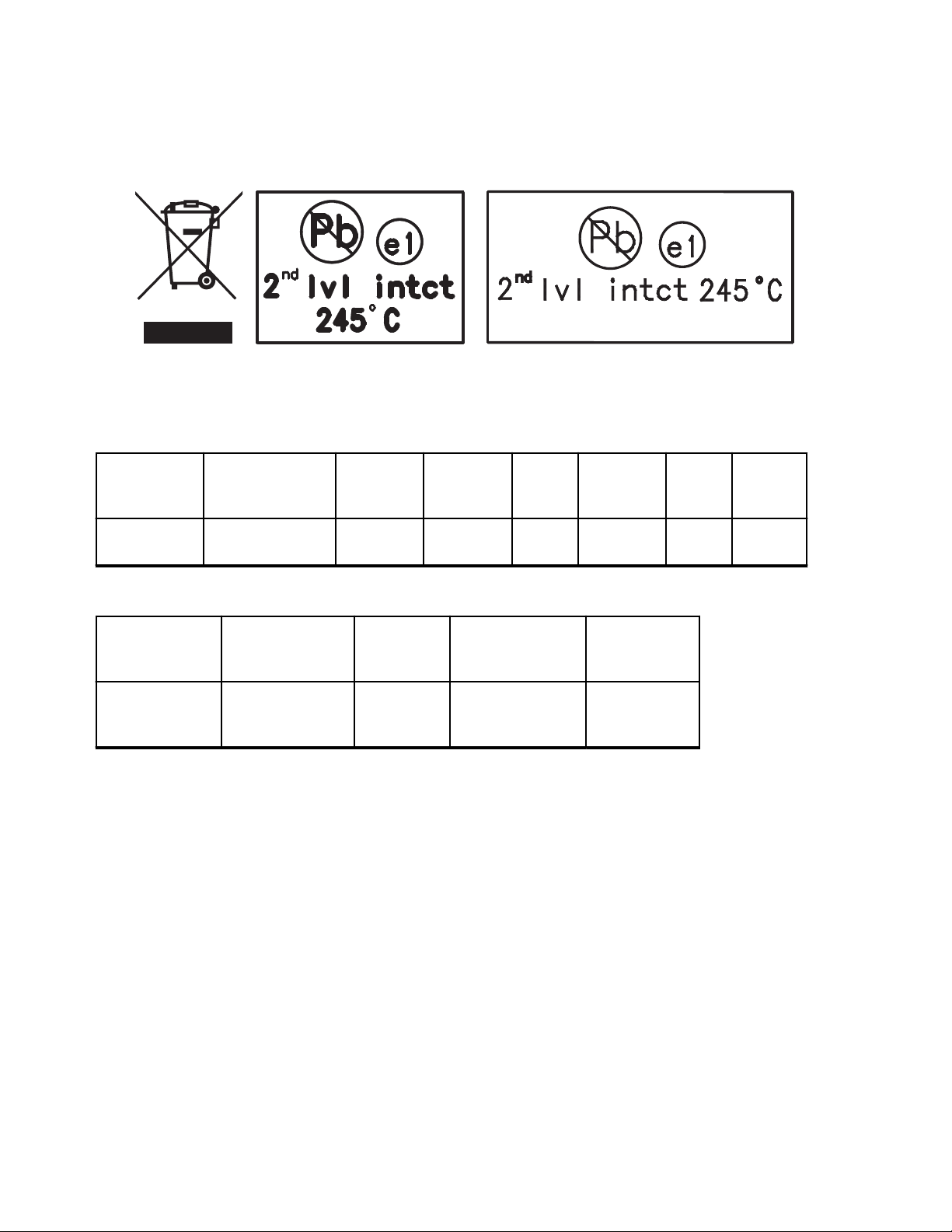

European Union (EU) Waste of Electrical and Electronic Equipment (WEEE)

directive

The European Union's WEEE directive requires that products sold into EU countries must have

the crossed out trash bin label on the product (or the package in some cases).

As defined by the WEEE directive, this cross-out trash bin label means that customers and end-users

in EU countries should not dispose of electronic and electrical equipment or accessories in household

waste.

Customers or end-users in EU countries should contact their local equipment supplier representative or

service centre for information about the waste collection system in their country.

10

Page 11

MN002211A01-AE

Document History

Document History

The following major changes have been implemented in this manual since the previous edition:

Edition Description Date

MN002211A01-AA Initial Release January 2016

MN002211A01-AB Updated Self Quieter Fre-

quencies in Specification section.

MN002211A01-AC Updated TIA Label to Non-

field replaceable in Exploded

View Parts Lists.

MN002211A01-AD Removed Footer. June 2019

MN002211A01-AE Added Limited Level 3 Servic-

ing section.

Updated Channel Capacity in

Specifications, General Specifications table.

December 2017

September 2018

July 2019

11

Page 12

MN002211A01-AE

Notations Used in This Manual

Notations Used in This Manual

Throughout the text in this publication, you will notice the use of warning, caution, and notice notations.

These notations are used to emphasize that safety hazards exist, and due care must be taken and

observed.

WARNING: WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or injury.

CAUTION: CAUTION indicates a potentially hazardous situation which, if not avoided, might

result in equipment damage.

NOTICE: NOTICE indicates an operational procedure, practice, or condition that is essential to

emphasize.

12

Page 13

Chapter 1

Introduction

1.1

Radio Description

These portable radios are available in the following frequency ranges and power levels.

Table 1: Radio Frequency Ranges and Power Levels

Frequency Band Bandwidth Power Level

VHF 136–174 MHz 1 W or 5 W

UHF 403–527 MHz 1 W or 4 W

300 Band 300–360 MHz 1 W or 4 W

350 Band 350–400 MHz 1 W or 4 W

MN002211A01-AE

Introduction

These digital radios are among the most sophisticated two-way radios available. They have a robust

design for radio users who need high performance, quality, and reliability in their daily communications.

This architecture provides the capability of supporting a multitude of legacy and advanced features

resulting in a more cost-effective two-way radio communications solution.

13

Page 14

1

2

3

4

5

6

7

8

9

10

11

12

MN002211A01-AE

Chapter 1: Introduction

1.1.1

Limited Keypad Model

This section explains the name and description of your radio buttons.

Figure 1: Limited Keypad Model

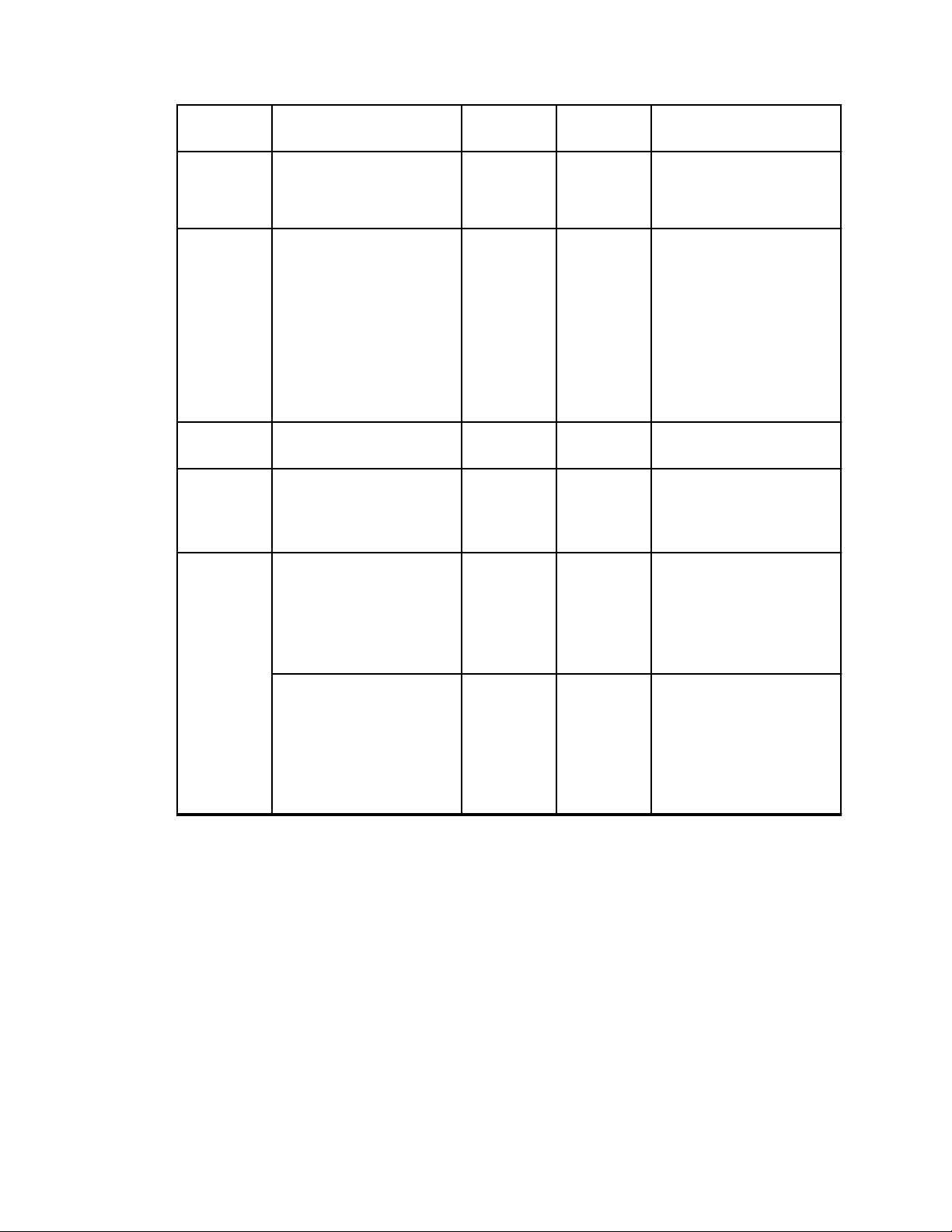

Label Item Description

1 Channel Selector Knob Rotate clockwise to increment channel and

counter-clockwise to decrement channel.

2 On/Off/Volume Knob To turn on the radio, rotate clockwise until the

knob clicks; To turn off the radio, rotate counterclockwise until the knob clicks. Rotate clockwise

to increase volume level; rotate counter-clockwise to decrease volume level.

3 LED Indicator Red, green, and amber light-emitting diodes indi-

cate operating status.

4 Push-To-Talk (PTT) Press to execute voice operations (for example,

Group Call and Private Call).

5 Microphone Allows the voice to be sent when PTT or voice

6 Side Buttons These buttons are field programmable using the

operations are activated.

Customer Programming Software (CPS).

14

Page 15

1

2

3

4

5

6

7

8

9

MN002211A01-AE

Chapter 1: Introduction

Label Item Description

7 Menu Navigation Buttons Five buttons to provide menu navigation and se-

lection interface.

8 Front Buttons These buttons are field programmable using the

CPS.

9 Liquid Crystal Display (LCD) 65 x132 full dotk-matrix grayscale display pro-

vides visual information about many radio features.

10 Speaker Outputs all tones and audio that are generated

by the radio (for example, keypad tones and

voice audio).

11 Universal Connector Interface point for all accessories to be used with

the radio. It has eight points to which specific accessories connect and be activated.

12 Antenna Provides the needed RF amplification when

transmitting or receiving.

1.1.2

Non-Keypad Model

This section explains the name and description of your radio buttons.

Figure 2: Non-Keypad Model

15

Page 16

MN002211A01-AE

Chapter 1: Introduction

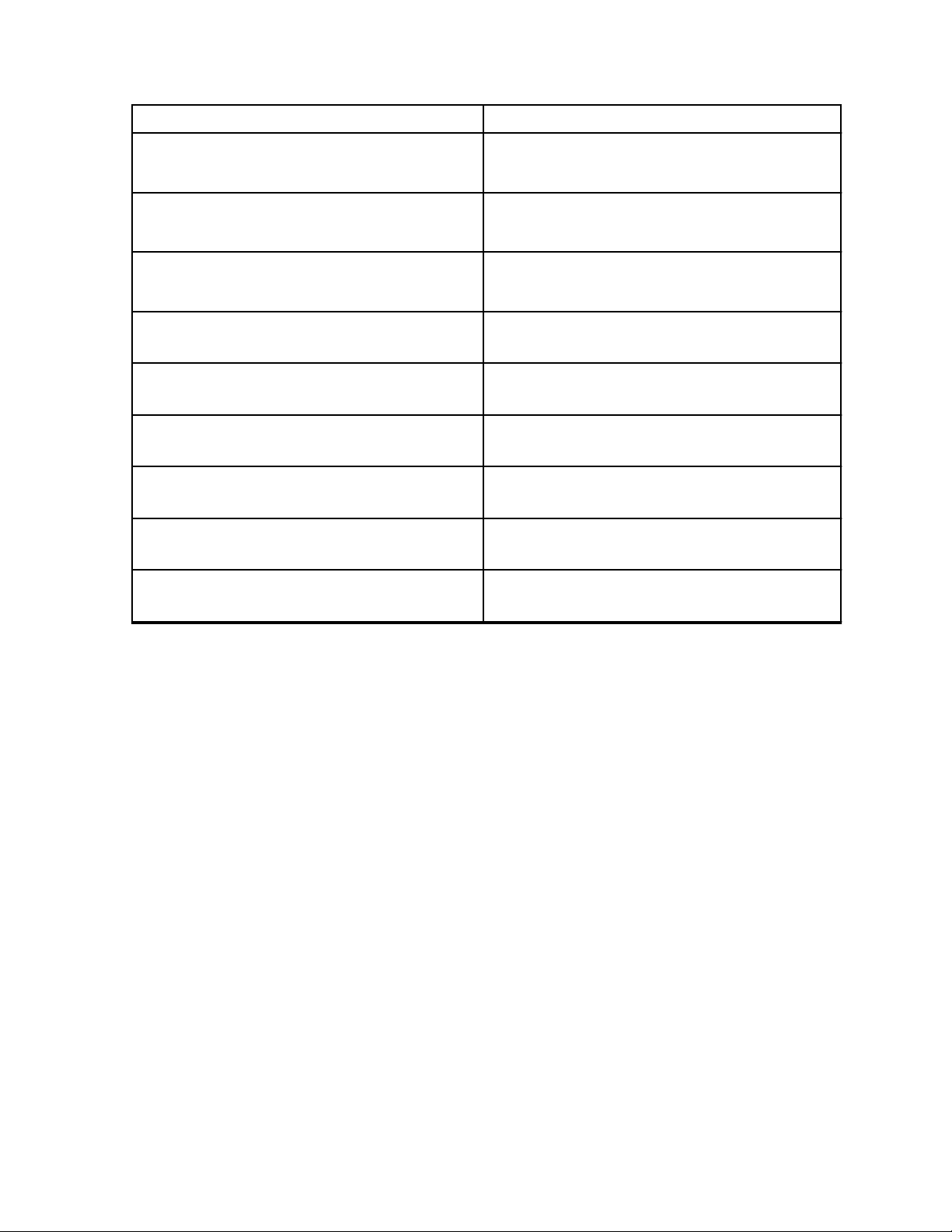

Label Item Description

1 Channel Selector Knob Rotate clockwise to increment and counter-

clockwise to decrement the channel.

2 On/Off/Volume Knob To turn on the radio, rotate clockwise until the

knob clicks; To turn off the radio, rotate counterclockwise until the knob clicks. Rotate clockwise

to increase volume level; rotate counter-clockwise to decrease volume level.

3 LED Indicator Red, green, and amber light-emitting diodes indi-

cate operating status.

4 Push-To-Talk (PTT) Press to execute voice operations (for example,

Group Call and Private Call).

5 Microphone Allows the voice to be sent when PTT or voice

operations are activated.

6 Side Buttons These buttons are field programmable using the

Customer Programming Software (CPS).

7 Speaker Outputs all tones and audio that are generated

by the radio (for example, keypad tones and

voice audio).

8 Universal Connector Interface point for all accessories to be used with

the radio. It has eight points to which specific accessories connect and be activated.

9 Antenna Provides the needed RF amplification when

transmitting or receiving.

1.2

Portable Radio Model Numbering Scheme

Table 2: Portable Radio Model Numbering Scheme

Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Typical Model

Number

Table 3: Sales Models – Description of Symbols

Position Description Value

1 Region AA = North America

MD H 0 2 J D C 9 U A 2 A N xy

AZ = Asia

LA = Latin America

MD = Europe/Middle East/Africa

2 Type of Unit H = Portable

3 Model Series 23 = DP2000 Model Series: 02

4

5 Band J = 136–174 MHz

16

Page 17

MN002211A01-AE

Chapter 1:

Position Description Value

K = 300–360 MHz

N = 350–400 MHz

R = 403–527 MHz

6 Power Level C = 1.0, 2.0, 2.5, or 3.5 W

D = 4.0–5.0 W

7 Physical Packages C = Plain Model (Low Tier)

H = Monochrome Display Limited Keypad (Mid Tier)

T = Non-Keypad (Limited Tier)

8 Channel Information 8 = Variable/Programmable Channel Spacing with unique

number of channels

9 = Variable/Programmable Channel Spacing

9 Primary Operation U = WiFi Only

W = Basic (No embedded GOB, Bluetooth, and WiFi)

Introduction

10 Primary System

Type

11 Feature Level 1 = Standard with FM

12 Version Letter N/A

13 Unique Variation N = Standard Package

14 Custom Housing 03 = GP328D

1.3

A = Conventional

B = Trunking

C = Analog Only

2 = Non-FM

3 = CSA IE CEx ATEX

4 = CQST

04 = GP338D

Model Charts

Table 4: Table Legend for Model Charts

Legend Description

X The part is compatible with checked model.

_ The latest version kit. When ordering a kit, refer to your specific kit for the

suffix number.

17

Page 18

MN002211A01-AE

Chapter 1: Introduction

1.3.1

UHF Model Chart

Table 5: DP2000e Series, UHF, 403–527 MHz Model Chart

Model/Item Description

MDH02RDH9VA1AN DP2600e, 403–527 MHz, 4 W, MO-

TOTRBO Limited Keypad Portable

MDH02RDC9VA1AN DP2400e, 403–527 MHz, 4 W, MO-

TOTRBO Non-Keypad Portable

X PMLE5076_ Back Cover Kit, MOTOTRBO Limited

Keypad Portable

X PMLE5075_ Back Cover Kit, MOTOTRBO Non-Key-

pad Portable

X PMLN7271_ Front Cover Kit Limited Keypad

X PMLN7272_ Front Cover Kit Non-Keypad

X X PMAE4068_ UHF Whip Antenna (403–527 MHz)

X X PMAE4069_ UHF Stubby Antenna (403–450 MHz)

X X PMAE4070_ UHF Stubby Antenna (440–490 MHz)

X X PMAE4071_ UHF Stubby Antenna (470–527 MHz)

X X PMAE4079_ Slim UHF Whip Antena (403–527 MHz)

1.3.2

VHF Model Chart

Table 6: DP2000e Series, VHF, 136–174 MHz Model Chart

Model/Item Description

MDH02JDH9VA1AN DP2600e, 136–174 MHz, 5 W, MO-

TOTRBO Limited Keypad Portable

MDH02JDC9VA1AN DP2400e, 136–174 MHz, 5 W, MO-

TOTRBO Non-Keypad Portable

X PMLD4734_ BC Kit, 136–174 MHz, 5 W, Limited Key-

pad Portable

X PMLD4737_ BC Kit, 136–174 MHz, 5 W, Non-Keypad

Portable

X PMLN7271_ Front Cover Kit Limited Keypad

18

X PMLN7272_ Front Cover Kit Non-Keypad

X X PMAD4117_ VHF Helical Antenna (136–155 MHz)

X X PMAD4116_ VHF HelicalAntenna (144–165 MHz)

X X PMAD4118_ VHF Helical Antenna (152–174 MHz)

X X PMAD4119_ VHF Stubby Antenna (136–148 MHz)

X X PMAD4120_ VHF Stubby Antenna (146–160 MHz)

Page 19

MN002211A01-AE

Chapter 1:

Model/Item Description

MDH02JDH9VA1AN DP2600e, 136–174 MHz, 5 W, MO-

TOTRBO Limited Keypad Portable

MDH02JDC9VA1AN DP2400e, 136–174 MHz, 5 W, MO-

TOTRBO Non-Keypad Portable

X X PMAD4121_ VHF Stubby Antenna (160–174MHz)

1.3.3

Introduction

300 MHz Model Chart

Table 7: DP2000e Series, 300 MHz, 300–360 MHz Model Chart

Model/Item Description

MDH02KDC9VA1AN DP2400e, 350–400 MHz, 4 W, MOTOTRBO Non-Keypad Portable

PMLD4799_ Back Cover Kit, MOTOTRBO Limited Keypad Portable

PMLN7272_ Front Cover Kit, MOTOTRBO Non-Keypad Portable

PMAD4135_ Stubby Antenna (320–360 MHz)

PMAD4137_ Stubby Antenna (300–337 MHz)

1.3.4

350 MHz Model Chart

Table 8: DP2000e Series, 350 MHz, 350–400 MHz Model Chart

Model/Item Description

MDH02NDC9VA1AN DP2400e, 350–400 MHz, 4 W, MOTOTRBO Non-Keypad Portable

PMLD4799_ Back Cover Kit, MOTOTRBO Limited Keypad Portable

PMLN7272_ Front Cover Kit, MOTOTRBO Non-Keypad Portable

PMAD4136_ Stubby Antenna (350–380 MHz)

PMAD4133_ Stubby Antenna (360–400 MHz)

PMAD4139_ VHF Whip Antenna (350–400 MHz)

1.4

Specifications

Table 9: General Specifications

Parameter Limited Keypad Non-Keypad

Channel Capacity 128 32

Frequency VHF: 136–174 MHz

UHF: 403–527 MHz

300 Band: 300–360 MHz

350 Band: 350–400 MHz

19

Page 20

MN002211A01-AE

Chapter 1: Introduction

Parameter Limited Keypad Non-Keypad

Dimensions (H × W × T) with

122.0 x 56.0 x 39.4 mm 122.0 x 56.0 x 39.4 mm

NiMH battery

Weight with Core Slim Li-Ion

281 g 264 g

battery

Weight with IMPRES Li-Ion

281 g 264 g

battery

Weight with Li-Ion IP57 bat-

299 g 282 g

tery

Power Supply 7.5 V nominal

Average battery life at 5/5/90 duty cycle with battery saver enabled in carrier squelch and transmitter in high power.

Core NiMH IP56 Battery (1400

mAh)

Core Li-Mn Low Temp Submersible Battery (1400 mAh)

IMPRES IP56 Li-Ion Battery

(1600 mAh)

Core Slim Li-Ion Battery (1650

mAh)

Analog: 9.5 hr

Digital: 12.0 hr

Analog: 9.5 hr

Digital: 12.0 hr

Analog: 11.0 hr

Digital: 14.5 hr

Analog: 11.5 hr

Digital: 15.0 hr

Slim IMPRES Li-Ion Battery

(2050 mAh)

IMPRES Li-Ion Battery (2250

mAh)

IMPRES TIA4950 Hi-Cap LiIon Battery (2900 mAh)

IMPRES Ultra Hi-Cap Li-Ion

Battery (3000 mAh)

Analog: 14.0 hr

Digital: 18.5 hr

Analog: 16.0 hr

Digital: 20.5 hr

Analog: 20.0 hr

Digital: 26.5 hr

Analog: 21.0 hr

Digital: 27.5 hr

NOTICE:

Weight can have 5% margin of error.

Limited Keypad Model is not applicable to 300 Band.

Table 10: Receiver Specifications

Parameter Limited Keypad and Non-Keypad

Frequency VHF: 136–174 MHz

UHF: 403–527 MHz

300 Band: 300–360 MHz

350 Band: 350–400 MHz

Channel Spacing 12.5 kHz/20 kHz/25 kHz

20

1

Page 21

Parameter Limited Keypad and Non-Keypad

MN002211A01-AE

Chapter 1:

Introduction

Frequency Stability (-30 °C to

±0.5 ppm

+60 °C)

Analog Sensitivity (12 dB SI-

0.26 µV (0.15 µV typical)

NAD)

Digital Sensitivity (5% BER) 0.22 µV (0.13 µV typical)

Intermodulation (TIA603D) 70 dB

Adjacent Channel Selectivity TIA603A: 60 dB @ 12.5 kHz, 70 dB @ 20/25 kHz

TIA603D: 45 dB @ 12.5 kHz, 70 dB @ 20/25 kHz

Spurious Rejection (TIA603D) 70 dB

Rated Audio 500 mW

Audio Distortion @ Rated Au-

5% (3% typical)

dio

Hum and Noise -40 dB @ 12.5 kHz

-45 dB @ 20/25 kHz

1

Audio Response TIA603D

Conducted Spurious Emission

-57 dBm

(TIA603C/D)

1

1

Table 11: Transmitter Specifications

Parameter Limited Keypad and Non-Keypad

Frequency VHF: 136–174 MHz

UHF: 403–527 MHz

300 Band: 300–360 MHz

350 Band: 350–400 MHz

Channel Spacing 12.5/20/25 kHz

Frequency Stability (-30 °C to

±0.5 ppm

2

+60 °C)

Power Output (Low Power) VHF/UHF: 0.5 W

300/350 Band: 1 W

Power Output (High Power) VHF: 5 W

UHF/300 Band/350 Band

: 4 W

Modulation Limiting ±2.5 kHz @ 12.5 kHz

±5.0 kHz @ 25 kHz

±4.0kHz @ 20 kHz

2

FM Hum and Noise -40 dB @ 12.5 kHz

1

350 Band does not support 20 kHz.

2

350 Band does not support 20 kHz.

21

Page 22

MN002211A01-AE

Chapter 1: Introduction

Parameter Limited Keypad and Non-Keypad

-45 dB @ 20/25 kHz

2

Conducted/Radiated Emission -36 dBm < 1 GHz

-30 dBm > 1 GHz

Adjacent Channel Power 60 dB @ 12.5 kHz

70 dB @ 20/25 kHz

2

Audio Response TIA603D

Audio Distortion 3%

FM Modulation 12.5 kHz: 11K0F3E

25 kHz: 16K0F3E

4FSK Digital Modulation 12.5kHz Data: 7K60F1D and 7K60FXD

12.5kHz Voice: 7K60F1E and 7K60FXE

Digital Vocoder Type AMBE+2

™

Digital Protocol ETSI-TS102361-1

ETSI-TS102361-2

ETSI-TS102361-3

NOTICE: Limited Keypad Model is not applicable to 300 Band.

Conforms to:

• ETSI TS 102 361 (Parts 1, 2, and 3) - ETSI DMR Standard

•

ETSI EN 300 086 - ETSI RF Specifications (Analog)

• ETSI EN 300 113 - ETSI RF Specifications (Digital)

• 1999/5/EC (R&TTE - Radio and Telecommunications Terminal Equipment)

• 2011/65/EU (RoHS 2 - Banned Substances)

• 2012/19/EU (WEEE - Waste Electrical and Electronic Equipment)

• 94/62/EC (Packaging and Packaging Waste)

• Radio meets applicable regulatory requirements.

Table 12: Self-Quieter Frequencies

UHF (MHz) VHF (MHz) 300 Band (MHz) 350 Band (MHz)

403.2 +/-10KHz 136.8 +/-10KHz 307.2 +/-10KHz 360 +/-10KHz

408 +/-10KHz 139.2 +/-10KHz 312 +/-10KHz 364.8 +/-10KHz

410.4 +/-10KHz 144 +/-10KHz 319.2 +/-10Khz 369.6 +/-10KHz

422.4 +/-10KHz 148.8 +/-10KHz 324 +/-10Khz 384 +/-10KHz

427.2 +/-10KHz 153.6 +/-10KHz 336 +/-10KHz 396 +/-10KHz

432 +/-10KHz 158.4 +/-10KHz 340.8 +/-10KHz -

446.4 +/-10KHz 160 +/-10KHz 345.6 +/-10KHz -

22

Page 23

Chapter 1:

UHF (MHz) VHF (MHz) 300 Band (MHz) 350 Band (MHz)

456 +/-10KHz 163.2 +/-10KHz 360 +/-10KHz -

460.8 +/-10KHz 168 +/-10KHz - -

465.6 +/-10KHz 172.03 +/-10KHz - -

468 +/-10KHz 172.8 +/-10KHz - -

480 +/-10KHz - - -

499.2 +/-10KHz - - -

501.6 +/-10KHz - - -

504 +/-10KHz - - -

508.8 +/-10KHz - - -

519.25 +/-10KHz - - -

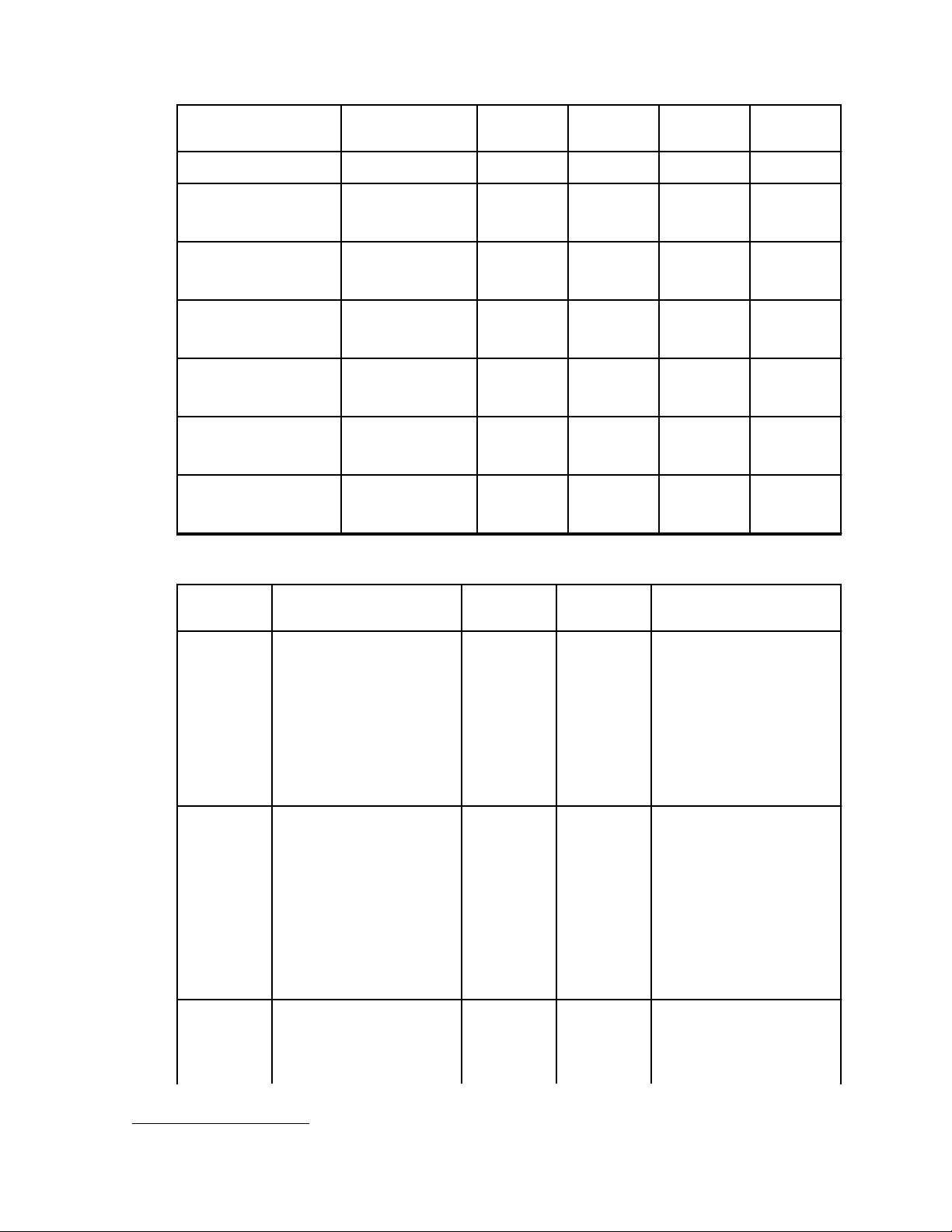

Table 13: Military Standards

MN002211A01-AE

Introduction

Applicable

MILSTD

Low

Pressure

High

Temperature

Low

Temperature

Temperature

Shoc

k

810C 810D 810E 810F 810G

Meth

ods

Procedures

Meth

ods

Procedures

Meth

ods

Procedures

Meth

ods

Procedures

Meth

ods

Procedures

500.1 Ⅰ 500.2 Ⅱ 500.3 Ⅱ 500.4 Ⅱ 500.5 Ⅱ

501.1 Ⅰ,

Ⅱ

501.2 Ⅰ/A1

,

Ⅱ/A1

501.3 Ⅰ/A1

,

Ⅱ/A1

501.4 Ⅰ/

Hot,

Ⅱ/H

501.5 Ⅰ/A1

,

Ⅱ/A1

ot

502.1 Ⅰ 502.2 Ⅰ/C

3,

Ⅱ/C

1

502.3 Ⅰ/C

3,

Ⅱ/C

1

502.4 Ⅰ/C

3,

Ⅱ/C

1

502.5 Ⅰ/C

3,

Ⅱ/C

1

503.1 Ⅰ 503.2 A1/C3503.3 A1/C3503.4 Ⅰ 503.5 Ⅰ-C

Solar

505.1 Ⅱ 505.2 Ⅰ/

Radiation

Rain 506.1 Ⅰ,

Ⅱ

Hu-

507.1 Ⅱ 507.2 Ⅱ/

midity

Hot-

Dry

506.2 Ⅰ,

Ⅱ

Hot-

Humid

505.3 Ⅰ/

Hot-

Dry

506.3 Ⅰ,

Ⅱ

507.3 Ⅱ/

Hot-

Humid

505.4 Ⅰ/

505.5 Ⅰ/A1

Hot-

Dry

506.4 Ⅰ,

Ⅲ

506.5 Ⅰ,

Ⅲ

507.4 – 507.5 Ⅰ/

Hot-

Humid

23

Page 24

MN002211A01-AE

Chapter 1:

Introduction

Applicable

MILSTD

Salt

810C 810D 810E 810F 810G

Meth

ods

Procedures

Meth

ods

Procedures

Meth

ods

Procedures

509.1 Ⅰ 509.2 Ⅰ 509.3 Ⅰ 509.4 – 509.5 –

fog

Dust 510.1 Ⅰ,

Ⅱ

Vibration

514.2 Ⅷ/F,

Curv

e-W,

Ⅺ

Shock516.2 Ⅰ,

Ⅱ

510.2 Ⅰ,

Ⅱ

514.3 Ⅰ/

Cat1

0, Ⅱ/

Cat3

516.3 Ⅰ,

Ⅳ

510.3 Ⅰ,

Ⅱ

514.4 Ⅰ/

Cat1

0, Ⅱ/

Cat3

516.4 Ⅰ,

Ⅳ

Table 14: Environmental Specifications

Parameter Specifications

Operating Temperature -30 °C to +60 °C

Meth

ods

Procedures

510.4 Ⅰ,

Ⅱ

514.5 Ⅰ/

Cat2

4, Ⅱ/

Cat5

516.5 Ⅰ,

Ⅳ

Meth

ods

Procedures

510.5 Ⅰ,

Ⅱ

514.6 Ⅰ/

Cat2

4, Ⅱ/

Cat5

516.6 Ⅰ,

Ⅳ

Storage Temperature -40 °C to +85 °C

Thermal Shock Per MIL-STD

Humidity Per MIL-STD

ESD IEC 61000-4-2 Level 4

Water Intrusion IEC 60529 -IP67

Packaging Test MIL-STD 810D and E

3

Operating temperature specification with Li-Ion battery is -10 °C to +60 °C. Operating temperature specification with NiMH battery is -20 °C to +60 °C.

24

Page 25

MN002211A01-AE

Test Equipment and Service Aids

Chapter 2

Test Equipment and Service Aids

This chapter lists the recommended test equipment and service aids, as well as information on field

programming equipment that can be used in servicing and programming Motorola Solutions radios.

2.1

Recommended Test Equipment

The list of equipment contained in the following table includes most of the standard test equipment

required.

Table 15: Test Equipment

Equipment Characteristics Example Application

Service

Monitor

Digital RMS

Multimeter

RF Signal

Generator

Oscilloscope

Power Meter

and Sensor

4

4

4

Can be used as a substitute.

100 µV to 300 V Fluke 179 (www.fluke.com) or

5 Hz to 1 MHz

10 ㏁ Impedance

100 MHz to 1 GHz Agilent N5181A (www.agi-

-130 dBm to +10 dBm

FM Modulation: 0 kHz

to 10 kHz

Audio Frequency: 100

Hz to 10 kHz

2 Channel Tektronix TDS1001b

50 MHz Bandwidth

5 mV/div to 20 V/div

5% Accuracy Bird 43 Thruline Watt Meter

4

100 MHz to 500 MHz

50 W

Aeroflex 3920 (www.aero-

flex.com) or equivalent

equivalent

lent.com), Ramsey

RSG1000B (www.ramseye-

lectronics.com), or equivalent

(www.tektronix.com)

or equivalent

(www.bird-electronic.com) or

equivalent

Frequency/deviation meter

and signal generator for

wide-range troubleshooting

and alignment.

AC/DC voltage and

current measurements. Audio voltage measurements.

Receiver measurements

Waveform measurements

Transmitter power output

measurements

RF Millivoltmeter

Power Supply

4

Can use Service Monitor as substitute.

100 mV to 3 V RF Boonton 92EA

10 kHz to 1 GHz

0 V to 32 V B&K Precision 1790

0 A to 20 A

RF level measurements

(www.boonton.com) or equivalent

Voltage supply

(www.bkprecision.com)

or equivalent

25

Page 26

MN002211A01-AE

Chapter 2: Test Equipment and Service Aids

2.2

Service Aids

The following table lists the service aids recommended for working on the radio. While all of these

items are available from Motorola Solutions, most are standard workshop equipment items, and any

equivalent item capable of the same performance may be substituted for the item listed.

Table 16: Service Aids

Motorola

Solutions

Part No.

RLN4460_ Portable Test Set Enables connection to the audio/accessory jack.

GMVN5141_ CPS on CD-ROM Allows servicer to program radio parameters, tune

PMKN4115_ Portable Programming Cable This cable connects the radio to a USB port for ra-

PMKN4117_ Portable Programming, Testing,

Description Application

Allows switching for radio testing.

and troubleshoot radios.

dio programming and data applications.

This cable connects the radio to a USB port for ra-

and Alignment Cable

dio programming, testing, and alignment.

NOTICE:

• This cable does not support external

PTT using Testbox.

This cable does not auto route to ex-

•

ternal Audio path once the cable is attached.

• All test instructions will require

through software tool (for example,

CPS, Tuner, and more.)

PMNN4428_ 7.5 V Universal Battery Elimina-

tor

PMLN6154_ RF Adaptor Adapts radio antenna port to BC cabling of test

PMLN6201_ RF Adaptor Holder Holds RF adaptor in place.

PMLN6422_ SMA RF Cable RF cable with SMA and N-type connector.

1185937A01 Grease Acts to lubricate parts.

TL000013A01Chassis and Knob Opener Removes chassis from the front housing.

NLN9839_ Vacuum Pump Kit Allows servicer to test for leakages.

NTN4265_ Pressure Pump Kit Allows servicer to locate leakages.

5871134M01 Connector Fitting This connector allows the vacuum hose to be con-

3271133M01 Fitting Seal This seal secures the connector fitting to the radio

26

Connects to radio by using battery eliminator cable.

equipment.

nected to the radio chassis.

chassis.

Page 27

MN002211A01-AE

Chapter 2: Test Equipment and Service Aids

2.3

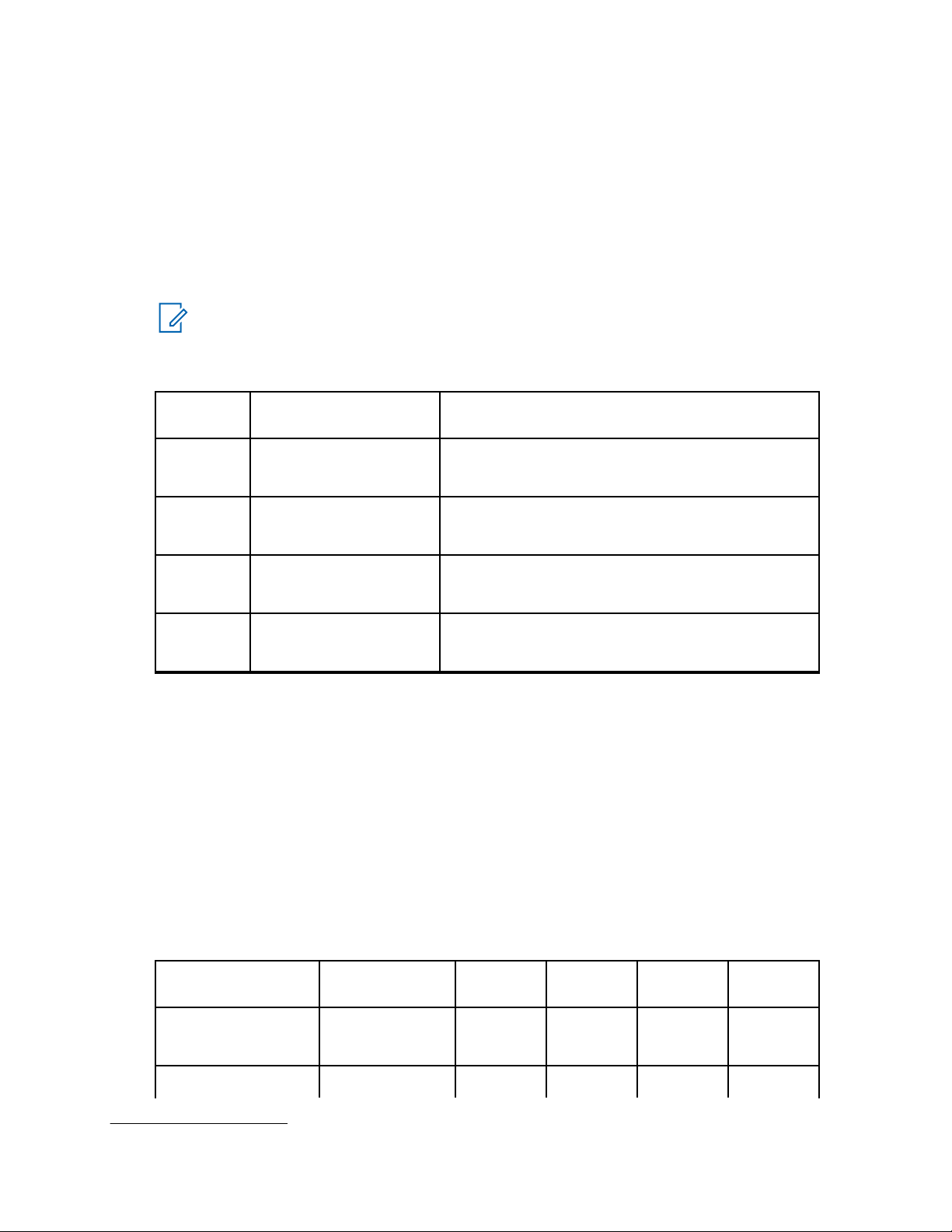

Programming, Testing, and Alignment Cable

Programming, Testing, and Alignment Cable and Side Connector are required in servicing and

programming radios.

27

Page 28

#13

#25 #14

#1

P1

P4

#2

#4

#6

#8

#1

#3

#5

#7

P3

#1#4

P2

MN002211A01-AE

Chapter 2: Test Equipment and Service Aids

Figure 3: Programming, Testing, and Alignment Cable

Table 17: Pin Configuration of Side Connector

CONNECTION

P1 P2 P3

Pin Pin Pin Function

- 1 1 VCC (5 V)

28

Page 29

P1 P2 P3

1

3

5

7

4

2

6

8

Pin Pin Pin Function

- 3 5 Data+

- 2 4 Data-

16 4 8 Ground

1 and 5 - 2 External Speaker+

2 and 7 - 3 External Speaker-

17 - 6 External Mic+

16 - 7 External Mic-

Figure 4: Pin Layout of Side Connector

MN002211A01-AE

Chapter 2: Test Equipment and Service Aids

CONNECTION

29

Page 30

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

Chapter 3

Transceiver Performance Testing

These radios meet published specifications through their manufacturing process by utilizing highaccuracy laboratory-quality test equipment.

The recommended field service equipment approaches the accuracy of the manufacturing equipment

with few exceptions. This accuracy must be maintained in compliance with the calibration schedule

recommended by the manufacturer.

Although these radios function in digital and analog modes, all testing is done in analog mode.

3.1

Setup

Supply voltage is provided using a 7.5 VDC power supply.

procedures is connected as shown in the Radio Tuning Setup chapter.

WARNING: Do NOT use any form of connector, for example wires, crocodile clips, and probes,

to supply voltage to the radio, other than the Motorola Solutions approved battery eliminator.

Initial equipment control settings must be as indicated in the following table:

Table 18: Initial Equipment Control Settings

Service Monitor Power Supply Test Set

Monitor Mode: Power Monitor Voltage: 7.5 Vdc Speaker set: A

RF Attn: -70 DC on/standby:

AM, CW, FM: FM Volt Range: 10 V PTT: OFF

Oscilloscope Source: Mod

Oscilloscope Horizontal: 10 ms/Div

Oscilloscope Vertical: 2.5 kHz/Div

Oscilloscope Trigger: Auto

Monitor Image: Hi

Monitor Bandwidth: Narrow

Monitor Squelch: Middle setting

Monitor Vol: 1/4 setting

The equipment required for alignment

Speaker/load:

Standby

Current: 2.5 A

Speaker

3.1.1

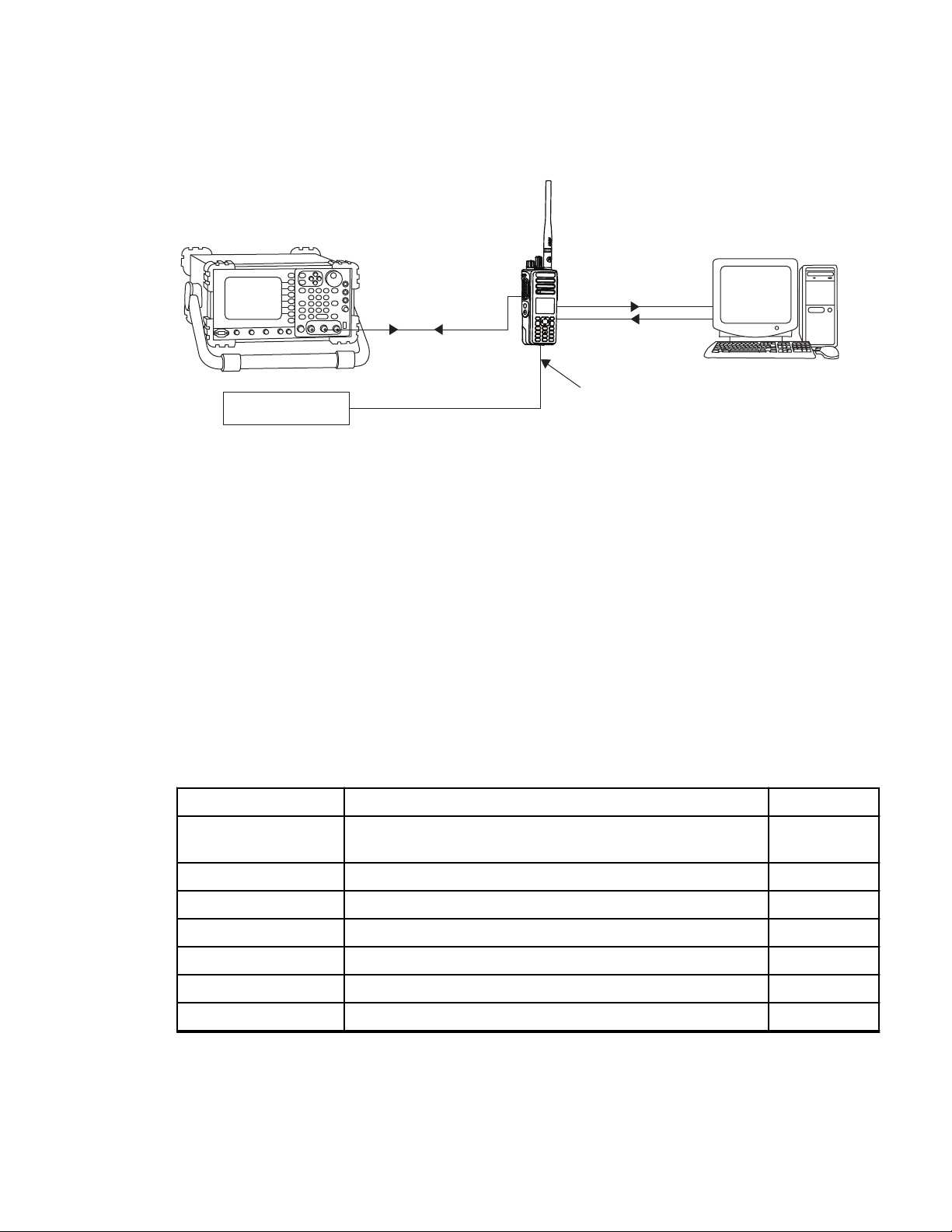

Setting Up DMR Transmitter and Receiver Test

Procedure:

1 Connect the Programming cable to the radio and computer.

2 Remove the RF plug.

3 Connect the RF antenna adaptor to the 50 Ω RF Input/Output port of the radio.

30

Page 31

T/R Port

Power Supply

Ant. Input / Output

Programming Cable

Modulated RF Test

Signal / Tx

modulated RF Signal

Battery Eliminator

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

4 Connect the other end of the RF antenna adaptor to the T/R port of the Radio Test Set 3920

using the RF cable shown in the following figure.

Figure 5: DMR Radio Transmitter and Receiver Testing Setup

See RF Plug Disassembly on page 47 for RF Plug Removal and RF Adaptor Insertion.

3.2

Display Model Test Mode

3.2.1

Entering Display Radio Test Mode

Procedure:

1 Turn the radio on.

2 Within 10 seconds after Self-Test is complete, press Side Button 2 five times in succession.

The radio beeps and shows a series of displays regarding various version numbers and

subscriber-specific information. The displays are described in the following table.

Table 19: Front Panel Access Test Mode Displays

Name of Display Description Appears

Service Mode The literal string indicates the radio has entered test

mode.

Host Version The version of host firmware. Always

DSP Version The version of DSP firmware. Always

Model Number The radio model number as programmed in the codeplug. Always

MSN The radio serial number as programmed in the codeplug. Always

FLASHCODE The FLASH codes as programmed in the codeplug. Always

RF Band The radio band. Always

Always

31

Page 32

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

NOTICE: The radio stops at each display for 2 seconds before moving to the next

information display. If the information cannot fit into one line, the radio display scrolls

automatically character by character after 1 second to view the whole information. If the

button is pressed before the last information is displayed, the radio suspends the

Left

information display until the user presses the Right button to resume the information

display. The last display shows RF Test Mode.

3.2.2

RF Test Mode

When the radio is operating in its normal environment, the radio microcontroller controls the RF

channel selection, transmitter key-up, and receiver muting, according to the customer codeplug

configuration.

However, when the unit is on the bench for testing, alignment, or repair, it must be removed from its

normal environment with a special routine, called Test Mode or air test.

3.2.2.1

Testing RF Channel Selections

Prerequisites: In RF Test Mode, the first line of your radio displays RF Test and power level icon.

And the second line of your radio displays the test environment, channel number, and channel spacing.

The default test environment is CSQ.

5

Procedure:

1 Each short press of Side Button 2 changes the test environment (CSQ->TPL->DIG->USQ

->CSQ).

NOTICE: DIG is digital mode and other test environments are analog mode as described

in the following table.

Table 20: Test Environments

No. of

Description Function

Beeps

1 Carrier Squelch (CSQ) RX: if carrier detected

TX: mic audio

2 Tone Private-Line

(TPL)

RX: unsquelch if carrier and tone detected

TX: mic audio + tone

3 Digital Mode (DIG) RX: if carrier detected

TX: mic audio

4 Unsquelch (USQ) RX: constant unsquelch

TX: mic audio

The radio beeps once when radio toggles to CSQ, beeps twice for TPL, beeps three times for

DIG, and beeps four times for USQ.

5

Only for radios with display.

32

Page 33

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

2 Each short press of Side Button 1 toggles the channel spacing between 25 kHz, 12.5 kHz, and

20 kHz.

The radio beeps once when radio toggles to 20 kHz, beeps twice for 25 kHz, and beeps three

times for 12.5 kHz.

3 Turn Channel Knob to change the test channel from 1 to 14.

See Table 21: Test Frequencies on page

33 for test channel descriptions.

The radio beeps in each position.

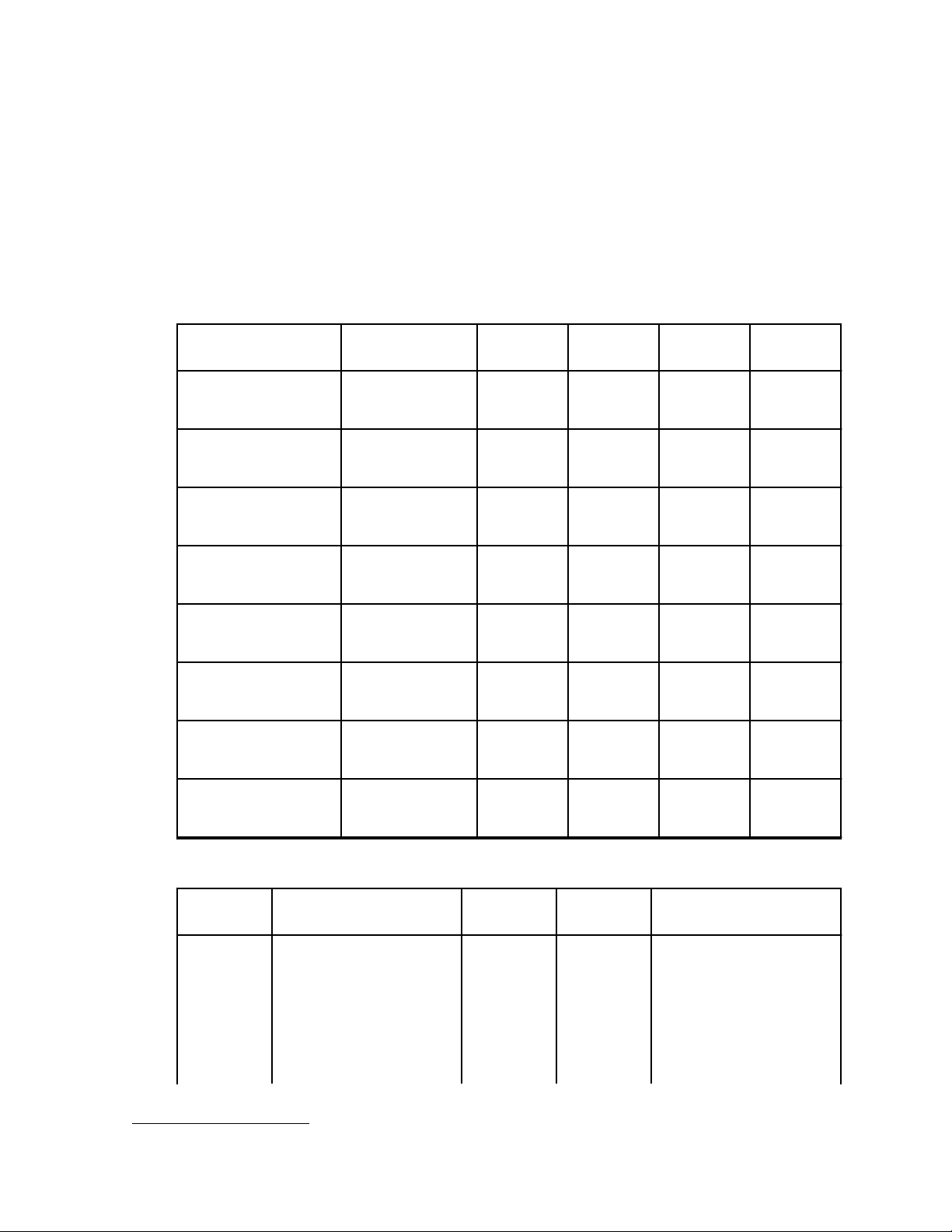

Table 21: Test Frequencies

Channel Selector

Switch Position

1 Low Power

9 High Power

2 Low Power

10 High Power

3 Low Power

11 High Power

4 Low Power

12 High Power

5 Low Power

13 High Power

6 Low Power

14 High Power

7 Low Power

15 High Power

Test Channel UHF VHF 300

Band

TX#1 or #9

RX#1 or #9

TX#2 or #10

RX#2 or #10

TX#3 or #11

RX#3 or #11

TX#4 or #12

RX#4 or #12

TX#5 or #13

RX#5 or #13

TX#6 or #14

RX#6 or #14

TX#7 or #15

RX#7 or #15

403.15

403.15

423.25

423.25

444.35

444.35

465.45

465.45

485.55

485.55

506.65

506.65

526.75

526.75

136.075

136.075

142.575

142.575

146.575

146.575

155.575

155.575

161.575

161.575

167.575

167.575

173.975

173.975

300.025

300.025

308.525

308.525

317.025

317.025

325.525

325.525

334.025

334.025

342.525

342.525

351.025

351.025

350

Band

350.025

350.025

357.525

357.525

364.525

364.525

371.525

371.525

378.525

378.525

385.525

385.525

392.525

392.525

8 Low Power

16 High Power

TX#8 or #16

RX#8 or #16

Table 22: Transmitter Performance Checks

Test

Name

Reference Frequency

Communications Analyzer

Mode: PWR MON

Fourth channel test

frequency

6

Monitor: Frequency error

Input at RF In/Out

6

See Table 21: Test Frequencies

on page 33

527.00

527.00

174.000

174.000

359.925

359.925

Radio Test Set Comments

Test

Mode,

Test

Channel

4 carrier

PTT to

continuously

transmit.

Frequency error to be:

±68 Hz for VHF

±150 Hz for 300 Band

squelch

±175 Hz for 350 Band

.

399.925

399.925

33

Page 34

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

Test

Name

Communications Analyzer

Radio Test Set Comments

±201 Hz for UHF

Power RF As above As above As above Low Power:

0.9–1.5 W

(UHF/VHF/300

Band/350 Band)

High Power:

4.0–4.8 W (UHF/300

Band/350 Band

5.0–6.0 W (VHF)

Voice

Modulation

Mode: PWR MON

Fourth channel test

frequency

6

As above As above,

meter selector to

mic

Deviation:

≥ 4.0 kHz but ≤ 5.0 kHz

(25 kHz Ch Sp).

atten to -70, input to RF

In/Out

Monitor: DVM: AC Volts

Set 1 kHz Mod Out lev-

el for 0.025 Vrms at

test set,

80 mVrms at AC/DC

test set jack

)

Internal

Voice

Modulation

Mode: PWR MON

Fourth channel test

frequency

6

atten to -70, input to RF

In/Out

TPL

Modulation

As above

Fourth channel test

frequency

6

BW to narrow

Table 23: Receiver Performance Checks

Test

Name

Reference Frequency

Communications Analyzer

Mode: PWR MON

Fourth channel test

frequency

6

Monitor: Frequency error

Test

Mode,

Test

Channel

4 carrier

squelch

output at

Remove

modulation input

Press PTT switch on

radio. Say "four" loudly

into the radio mic.

Measure

deviation:

≥ 4.0 kHz but ≤ 5.0 kHz

(25 kHz Ch Sp)

antenna

Test

Mode,

Test

As above Deviation:

≥500 Hz but ≤1000Hz

(25 kHz Ch Sp).

Channel

4

TPL

Radio Test Set Comments

Test

Mode,

Test

Channel

4 carrier

PTT to

continuously

transmit.

Frequency error to be:

±68 Hz for VHF

±150 Hz for 300 Band

squelch

34

Page 35

Chapter 3:

MN002211A01-AE

Transceiver Performance Testing

Test

Name

Communications Analyzer

Input at RF In/Out

Rated

Audio

Mode: GEN

Output level: 1.0 mV

RF

Sixth channel test

frequency

6

Mod: 1 kHz tone at

3 kHz deviation

Monitor: DVM: AC Volts

Distortion As above, except dis-

tortion

Sensitivity (SINAD)

As above, except SINAD, lower the RF level for

12 dB SINAD.

Noise

Squelch

RF level set to 1 mV

RF

Threshold

(only radios with

conventional

system

need to

be tested.)

As above, except

change frequency to a

conventional system.

Raise RF level from

zero until radio un-

squelches.

Radio Test Set Comments

output at

antenna. ±175 Hz for 350 Band

±201 Hz for UHF

Test

Mode

, Test

Meter selector to

Audio PA

Set volume

control to 2.83 Vrms

Channel

6 carrier

squelch

As above As above Distortion <3.0%

As above Nil RF input to be <0.35

μV

As above Meter se-

lection to

Set volume

control to 2.83 Vrms

Audio PA,

speaker/

load to

speaker

Out of

Test

Mode; select a

conven-

As above Unsquelch to occur at

<0.25 μV.

Preferred SINAD =

6–8 dB

tional

system.

3.2.3

Display Test Mode

Procedure:

1 Press and hold Side Button 1 to enter display test mode.

2 Upon any button or key press, the LCD displays the growing horizontal bars. Press any button

until the LCD display turns black and change to vertical bars. Press any button until LCD display

full screen black and change to icon display.

The LCD displays the following icons:

• RSSI (with full bar)

Monitor

•

35

Page 36

MN002211A01-AE

Chapter

• Tone disabled

• Priority-two channel scan

Unread message

•

• Emergency

• Talkaround

• Battery strength indicator (with full bar)

The LCD display become clear and consequently display the rest of the icons, high-power level icon

(H), companding icon, option board icon, and secure operation icon upon any button/key press.

3.2.4

Transceiver Performance Testing

3:

LED Test Mode

Procedure:

1 Press and hold Side Button 1 after Display Test Mode.

The radio beeps once and displays LED Test Mode.

2 Press any button/key.

The red LED lights up and the radio displays Red LED On.

3 Press any button/key.

The red LED is turned off. The green LED lights up and the radio displays Green LED On.

4 Press any button/key.

The green LED is turned off. The radio lights up both LEDs up while displaying Both LEDs On.

The orange LED lights up.

3.2.5

Backlight Test Mode

Procedure:

Press and hold Side Button 1 after LED Test Mode.

The radio beeps once and displays Backlight Test Mode.

The radio turns on both LCD and keypad backlight.

3.2.6

Speaker Tone Test Mode

Procedure:

Press and hold Side Button 1 after Backlight Test Mode.

The radio beeps once and displays Speaker Tone Test Mode.

The radio generates a 1 kHz tone with the internal speaker.

36

Page 37

Rem. Capacity100%

Chapter 3: Transceiver Performance Testing

3.2.7

Earpiece Tone Test Mode

Procedure:

1 Connect the external accessory to the radio.

2 Press and hold Side Button 1 after Speaker Tone Test Mode.

The radio beeps once and displays Earpiece Tone Test Mode.

The radio generates a 1 kHz tone from the earpiece.

3.2.8

Audio Loopback Earpiece Test Mode

Procedure:

Press and hold Side Button 1 after the Earpiece Tone Test Mode.

The radio beeps once and displays Audio Loopback Earpiece Test Mode.

The radio routes any audio on the external mic to the earpiece.

MN002211A01-AE

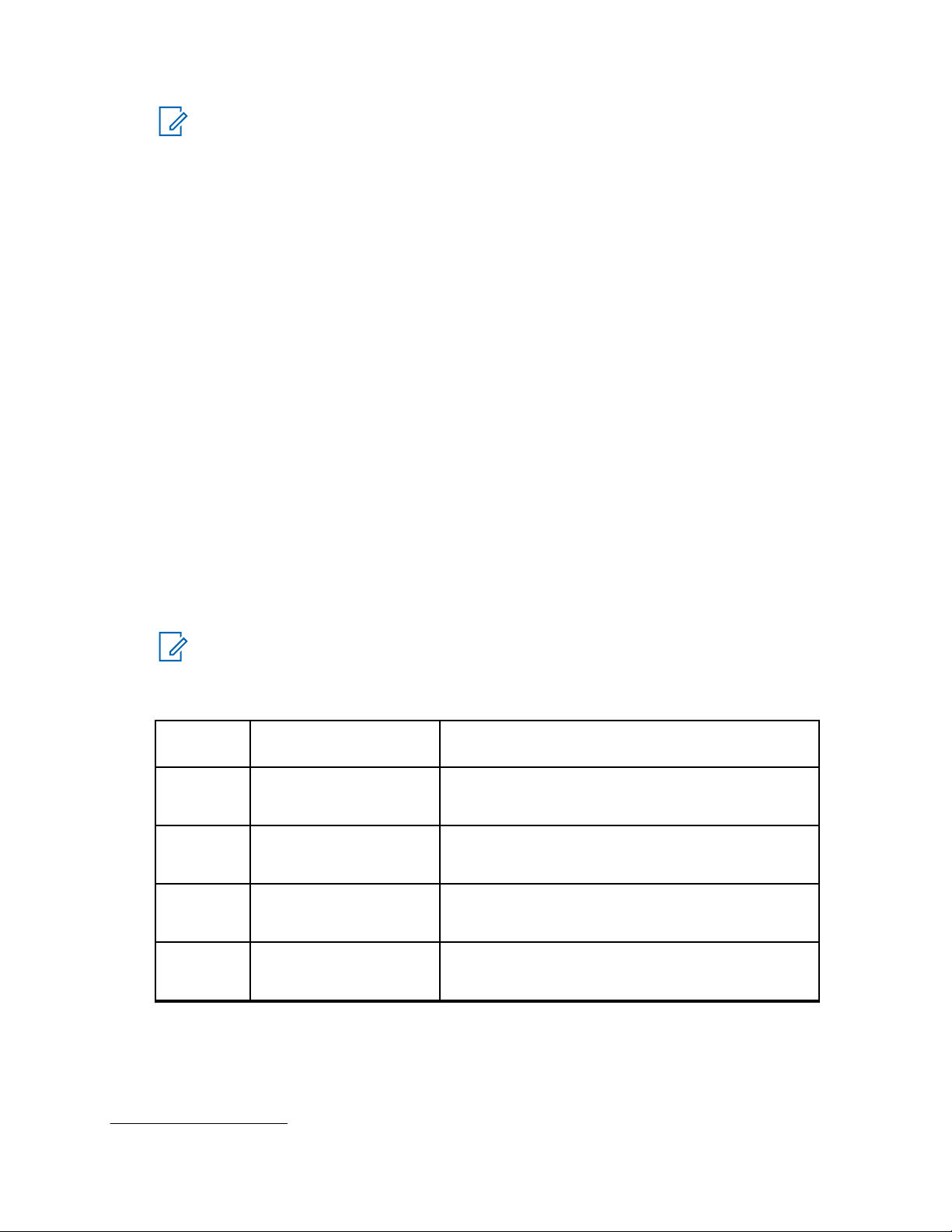

3.2.9

Battery Check Test Mode

Procedure:

Press and hold Side Button 1 after Audio Loopback Earpiece Test Mode.

The radio beeps once and momentarily displays Battery Check Test Mode.

The radio displays the following:

Figure 6: Battery Check Test Mode Display

37

Page 38

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

3.2.10

Button/Knob/PTT Test Mode

Any key press causes the test to advance from one step to the next.

Table 24: Button/Knob/PTT Checks

Action Result

Press and hold Side Button 1. The radio displays Button Test (line 1).

The radio beeps once.

Rotate the Volume Knob. 2/1 through 2/255 appears.

The radio beeps at each position.

Rotate the Channel Knob clockwise. 4/1 appears.

The radio beeps at each position.

Rotate the Channel Knob counterclockwise. 4/-1 appears.

The radio beeps at each position.

Press Side Button 1. 96/1 appears.

The radio beeps.

Release the button. 96/0 appears.

The radio beeps.

Press Side Button 2. 97/1 appears.

The radio beeps.

Release the button. 97/0 appears.

The radio beeps.

Press the PTT

Release the button. 1/0 appears.

Table 25: Keypad Checks

Action Result

Press the P1 button. 160/1 appears.

Release the button. 160/0 appears.

Press the P2 button. 161/1 appears.

button. 1/1

The radio beeps.

The radio beeps.

The radio beeps.

The radio beeps.

The radio beeps.

appears.

Release the button. 161/0 appears.

The radio beeps.

Press the MENU button. 85/1 appears.

The radio beeps.

38

Page 39

Chapter 3: Transceiver Performance Testing

Action Result

Release the button. 139/0 appears.

The radio beeps.

MN002211A01-AE

Press the BACK button. 129/1

The radio beeps.

Release the button. 129/0 appears.

The radio beeps.

Press the Left button. 128/1 appears.

The radio beeps.

Release the button. 128/0 appears.

The radio beeps.

Press the Right

Release the button. 130/0 appears.

Press the OK button. 85/1 appears.

Release the button. 85/0 appears.

3.3

button. 130/1

The radio beeps.

The radio beeps.

The radio beeps.

The radio beeps.

appears.

appears.

Non-Display Model Test Mode

3.3.1

Entering Non-Display Radio Test Mode

Procedure:

1 Turn the radio on.

2 Within 10 seconds after Self-Test is complete, press Side Button 2 five times in succession.

The radio beeps.

3.3.2

RF Test Mode

When the radio is operating in its normal environment, the radio microcontroller controls the RF

channel selection, transmitter key-up, and receiver muting, according to the customer codeplug

configuration.

However, when the unit is on the bench for testing, alignment, or repair, it must be removed from its

normal environment with a special routine, called Test Mode or air test.

39

Page 40

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

3.3.2.1

Testing RF Channel Selections

Prerequisites: In RF Test Mode, the first line of your radio displays RF Test and power level icon.

And the second line of your radio displays the test environment, channel number, and channel spacing.

The default test environment is CSQ.

Procedure:

1 Each short press of Side Button 2 changes the test environment (CSQ->TPL->DIG->USQ

->CSQ).

NOTICE: DIG is digital mode and other test environments are analog mode as described

in the following table.

Table 26: Test Environments

7

No. of

Description Function

Beeps

1 Carrier Squelch (CSQ) RX: if carrier detected

TX: mic audio

2 Tone Private-Line

(TPL)

RX: unsquelch if carrier and tone detected

TX: mic audio + tone

3 Digital Mode (DIG) RX: if carrier detected

TX: mic audio

4 Unsquelch (USQ) RX: constant unsquelch

TX: mic audio

The radio beeps once when radio toggles to CSQ, beeps twice for TPL, beeps three times for

DIG, and beeps four times for USQ.

2 Each short press of Side Button 1 toggles the channel spacing between 25 kHz, 12.5 kHz, and

20 kHz.

The radio beeps once when radio toggles to 20 kHz, beeps twice for 25 kHz, and beeps three

times for 12.5 kHz.

3 Turn Channel Knob to change the test channel from 1 to 14.

See Table 27: Test Frequencies on page

40 for test channel descriptions.

The radio beeps in each position.

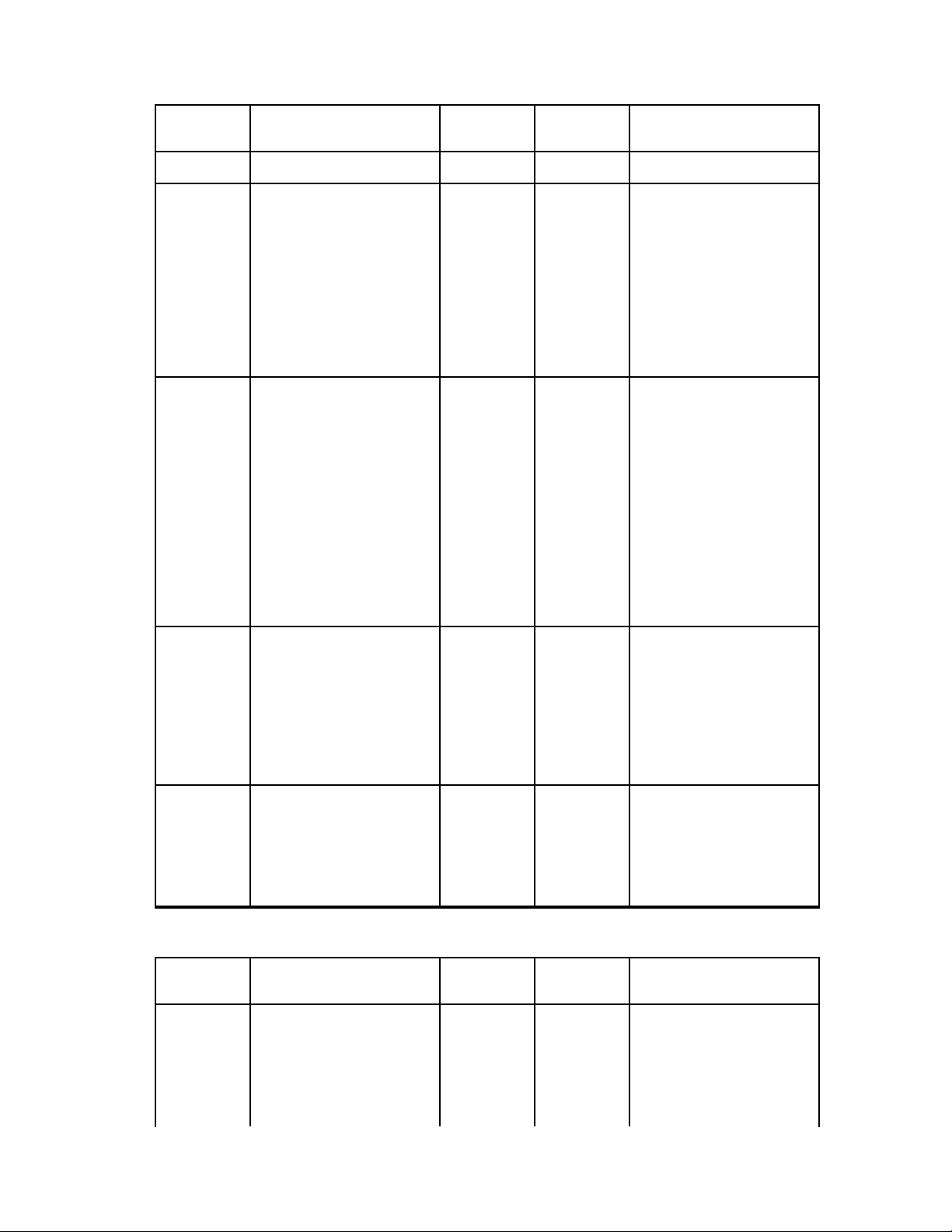

Table 27: Test Frequencies

Channel Selector

Switch Position

1 Low Power

9 High Power

2 Low Power TX#2 or #10 423.25 142.575 308.525 357.525

7

Only for radios with display.

40

Test Channel UHF VHF 300

Band

TX#1 or #9

RX#1 or #9

403.15

403.15

136.075

136.075

300.025

300.025

350

Band

350.025

350.025

Page 41

MN002211A01-AE

Chapter 3: Transceiver Performance Testing

Channel Selector

Test Channel UHF VHF 300

Switch Position

10 High Power

3 Low Power

11 High Power

4 Low Power

12 High Power

5 Low Power

13 High Power

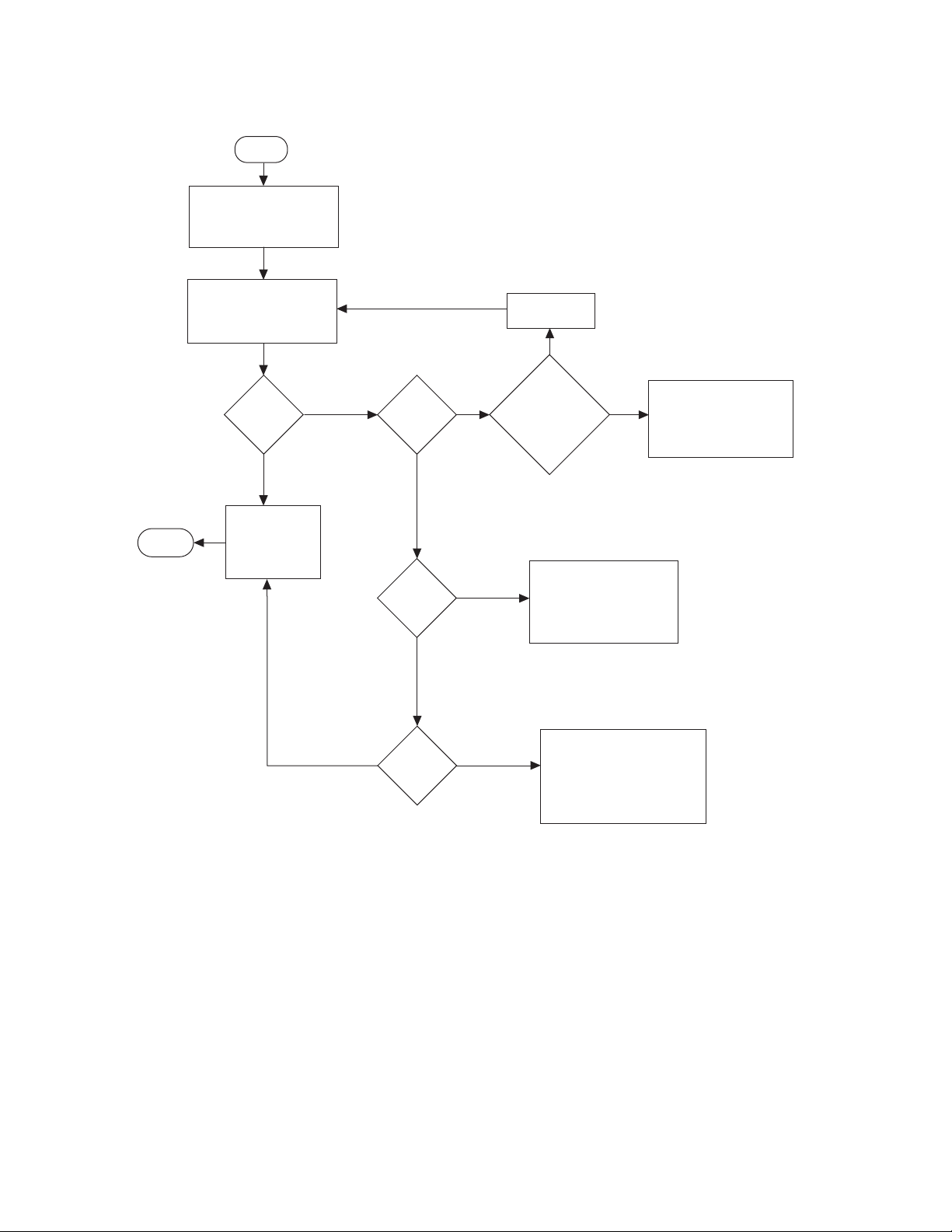

6 Low Power