Moen 4350, 4200, 4220, 4340, 4330 User Manual

...

4200, |

4220, |

4330, |

4340, 4350, |

MT123A |

4400, |

4641, |

4643 |

SERIES |

|

â

®

INSTALLATION INSTRUCTIONS

THESE INSTRUCTIONS MUST BE

LEFT WITH HOMEOWNER

LAVATORY FAUCETS

Four-Inch Centerset

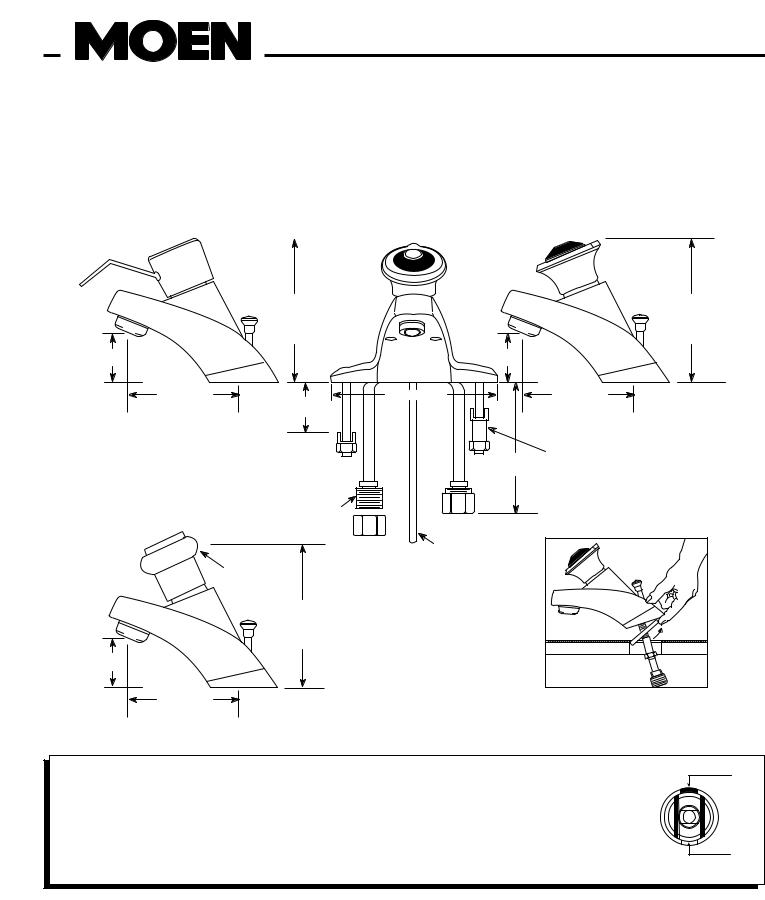

LEVER HANDLE |

KNOB HANDLE |

|

|

|

|

|

5" NOMINAL |

|

|

5" NOMINAL |

|

OPEN |

|

|

OPEN |

|

POSITION |

|

|

POSITION |

1-3/4" |

|

|

1-3/4" |

|

3-5/8" C.C. |

1-3/4" |

6" X 2" WIDE |

|

3-5/8" C.C. |

|

|

|

|

|

|

MAX. |

|

|

|

|

|

|

|

USE SPACER TO INSTALL |

|

|

|

|

ON THINNER LAVATORY |

|

|

|

4-3/4" |

BOWLS OR COUNTERS |

|

|

|

|

DISCARD SPACER WHEN |

|

|

|

|

INSTALLING ON THICKER |

|

|

|

LAVATORY BOWLS OR COUNTERS |

|

|

1/2" IPS |

|

|

|

CONCENTRIX HANDLE |

THREADED |

|

|

|

|

CONNECTIONS |

|

|

|

|

|

LIFT ROD |

|

|

|

|

POSITION |

|

|

|

HANDLE INSERT |

|

|

|

|

(NOT |

With clamp bar, spacer and |

|

|

|

INCLUDED) |

|

||

|

mounting |

nut installed, tilt |

|

|

|

|

|

||

|

|

clamp bar back as shown, |

|

|

|

5" NOMINAL |

then drop |

faucet supplies |

|

|

down through deck holes and |

|

||

|

OPEN |

|

||

|

tighten from below. On decks |

|

||

|

POSITION |

|

||

|

thicker than 3/4" you may |

|

||

|

|

|

||

|

|

have to remove spacer. |

|

|

1-3/4" |

|

|

|

TILT BACK |

|

|

|

CLAMP BAR |

|

3-5/8" C.C.

Fits 4" centers and through a 1" minimum diameter hole. All models equipped with a Moen Flow-Rator™.

Complies with ASME A112.18.1M and CSA B125

CAUTION: |

Always turn water off before disassembling the valve. Open valve handle to alleviate water |

pressure to insure that complete water shut-off has been accomplished. |

Before turning water on during either rough-in or trim-out, make sure that the cartridge retainer clip is in place. The cartridge and retainer clip were properly installed and tested before leaving the factory. Although it is unlikely, it is nevertheless possible that through the handling of the valve by any number of persons the retainer clip may not be properly installed. This should be carefully checked at time of rough-in and trim-out. If the retainer clip is not properly installed, water pressure could force the cartridge out of the casting. Personal injury or water damage to the premises could result.

Clip

Ear

Installation

Be sure lavatory or mounting surface is clean and dry. Place a bead of plumber's putty around the inside lip of the gasket. Lay gasket on deck and place faucet supplies and studs down through deck holes. Position faucet. Fasten faucet to deck, using clamp bars, spacers (if necessary), and mounting nuts on studs. Tighten. Engage tailpiece nuts on supplies to faucet nipples. Tighten nuts.

HOLD WITH

WRENCH

WARNING: Hold the faucet connection nipples with a wrench when tightening to prevent twisting and collapse of the tubing.

Flushing |

TIGHTEN |

|

IMPORTANT:

FAUCET

CONNECTION

NIPPLE

NUT

Pipe chips, sand, stones and other solids found in new and renovated plumbing can damage the sealing surface of the faucet cartridge and cause a leak. To avoid damage, DO NOT OPERATE VALVE until you have followed these instructions:

a.Make sure all water supplies are OFF.

b.Remove handle parts, stop tube, retainer clip and cartridge (see "Disassembly" for detailed instructions).

c.At the supplies, slowly turn both hot and cold water on and thoroughly flush out the body and lines.

Lift Rod & Waste Assembly

(For model with grid strainer assembly follow steps 1-3 only)

1.Thoroughly clean around drain opening in lavatory basin. Apply 1/4 inch bead of plumber's putty (not furnished) around the underside of seat (as shown).

2.Apply pipe joint compound or Teflon tape (not furnished) to top threaded end of the drain body. Slip drain body up through the drain opening and screw seat on the drain body.

3.Position the drain body (with pivot rod opening extending rearward) and tighten mounting nut until the drain body is snug. Wipe excess plumber's putty from the seat area. Apply pipe joint compound (not furnished) to top threaded end of tailpipe and screw into the drain body. Tighten firmly by hand.

4.Position the drain plug in either of the following ways:

A.VANDALPROOF - This design is to prevent unauthorized removal of the drain plug. Unscrew the pivot nut and remove the pivot rod. Inside the drain body position the pivot rod through the drain plug hole as shown in the illustration below. Screw the pivot nut back on the drain body. DO NOT OVERTIGHTEN.

B.EASY REMOVAL - This design is for quick removal of drain plug for cleaning. Just drop in the drain plug as shown in the illustration below.

|

A. VANDALPROOF |

B. EASY REMOVAL |

|

|

|

POSITION FOR |

|

|

|

EASY REMOVAL |

|

PIVOT |

VANDALPROOF |

PIVOT |

|

ROD |

ROD |

||

POSITION |

|||

|

|

LIFT ROD

AND KNOB

AND KNOB

DRAIN |

|

|

BASIN |

|

PLUG |

|

|

|

|

VANDALPROOF |

|

|

LIFT ROD |

|

HOLE |

|

|

||

|

|

|

STRAP |

|

|

|

|

SCREW |

|

SEAT |

2-1/8" |

PIPE |

|

|

|

|

|||

|

|

JOINT |

|

|

|

|

COMPOUND |

|

|

|

1-1/2" |

OR TEFLON |

|

|

PLUMBERS |

TAPE |

LIFT ROD |

||

|

||||

|

(NOT |

STRAP |

||

PUTTY |

|

|||

|

FURNISHED) |

|

||

MAX 2-1/2" |

|

|

||

|

|

|

||

MIN 1-1/2" |

|

|

|

BOTTOM GASKET

FLAT WASHER

FLAT WASHER

MOUNTING

NUT SPRING

CLIP

DRAIN

BODY

8" |

PIPE |

|

|

|

|

|

JOINT |

PIVOT NUT |

|

COMPOUND |

|

|

|

|

|

(NOT |

PIVOT ROD |

|

FURNISHED) |

SEAT |

|

TAILPIPE |

PIVOT |

|

ROD |

|

|

|

|

|

|

1-1/4" |

5.Hook up lift rod and knob, lift rod strap and spring clamp as shown.

6.With the drain plug in full open position, adjust lift rod and knob to clear faucet and tighten lift rod strap screw.

MT123A

Loading...

Loading...