Page 1

TECHNICAL REPORTS

GOT1000 Series

New Functions and New Products

Authors: Takahiro Kaneko* and Tsuguo Kawasaki**

1. Introduction

Aiming at a “true” display at factory automation

(FA) workstations, the GT15 model of the GOT1000

series (hereafter, “GOT”) and the GT11 standard model

were released in July 2004 wi th enhanced functions for

stand-alone use, to provide a rapid response,

high-definition display, enhanced troubleshooting,

greater work efficiency such as reduced downtime, high

value-added equipment, and lower total cost. The GT16

model, which is the successor to the GT15, was released in August 2008 to meet the user demand for

easy-to-understand solutions using moving images for

large-volume data processing, troubleshooting and

downtime reduction, and for network I/F standard features. As a lower-cost medium-size model, the GT14

was released in July 2011 featuring improved display

performance and added functionality for data acquisition (logging), to raise the position of th e medium-sized

model to compete with new products and improved

functions introduced by competitors.

Here, we introduce the new functions of the GOT

and the development of the recently-launched medium-sized display GT14 model, in order to meet user

demands such as for uniform manageme nt of information shared between personal comput ers connected to

a network.

2. Functional Enhancement of GOT1000

Series

2.1 GOT Solutions

When a failure occurs in production equipment,

rapid detection of the cause and measures to prevent

recurrence are essential for reducing downtime. Thus,

there is a high demand for various troubleshooting

functions on the display for monitoring and viewing the

condition of manufacturing equipment. Table 1 shows

the main GOT functions as indicators for efficiency and

visualization.

With regard to the GOT incorporated in manufacturing equipment, many functions have already been

developed not only to improve the equipment operation

and status check, but also to ensure a quick respo nse

to failures on site by identifying the locatio n and cause

of the failure, and to confirm the measures to be taken.

Table 1 GOT Solutions

Solution Efficiency and visualization GOT functions

Troubleshooting

Production/

management

cooperation

On-site

monitoring

and cooperation

Efficiency of troubleshooting

Early investigation and

analysis of the cause of

troubles on site, and reduction of down-time

Visualize manufacturing

information by linked personal computer

Monitor the entire system (on

site) and collectively manage

data by the personal computer in the office

Remotely visualize the

screen of the on-site GOT

Monitor and maintain the

remote system and equipment

Ladder monitor

function

Operation log function

Remote personal

computer operation

function

MES interface

FTP server function

SoftGOT-GOT link

function

FTP client function

VNC server function

As troubleshooting solutions, GOT has a ladder

monitor function that searches for the circuit causing

equipment failure in order to change the value of the faulty

device; a remote operation function for operating a remote

personal computer on which an operator is checking the

manual; and an operation log function for saving historical

data on operations performed on the GOT, to help identify

and analyze the cause of faults. These functions facilitate

troubleshooting at production sites.

The following functions can be used as production/management joint solutions with the GOT: an MES

interface function for promptly transmitting the device

values of connected equipment directly to an MES

database to save and manage the data; and an FTP

server function that allows a computer at an office to

read and write information files collected by the GOT

and files with the production control data such as m ixing conditions and processing conditions of materials.

In recent years, demand has increas ed for remote

monitoring and maintenance of overseas factories, in

particular, for viewing and operating GOT screens at

production sites. In response, we have provided a

SoftGOT-GOT link function as a joint solution for on-site

monitoring. With this function, it is possible to display

and operate the same screen as that of the on-site

GOT using SoftGOT on a personal computer with a

network connection to the GOT. The SoftGOT-GOT link

function enables monitoring of manufacturing equipment by collecting screen data from the target GOT and

using it as the screen data for the SoftGOT to display

*Nagoya Works **Himeji W orks 10

Page 2

TECHNICAL REPORTS

the same screen.

In remote monitoring and sharing, it is necessary to

periodically monitor the status of the manufacturing

equipment from an office using the FTP s erver functi on,

but we have now added the following two functions t o

quickly capture any change or abnormality at the production site, and for monitoring and operating the GOT

of on-site equipment without the SoftGOT.

(1) File transfer function (FTP client)

(2) *VNC Server function

*VNC: Virtual Network Comp uting

2.2 New functions of GOT1000 Series

2.2.1 File transfer function (FTP client)

With the conventional GOT, files for abnormality

analysis obtained by the GOT (operation logs, i.e., files

created by a logging function described later) can be

acquired using the FTP server function by a personal

computer with a network connection at the office when

an abnormality occurs at the production site, without

actually going to get the files. However, if such information could be obtained at the same time as the abnormality occurs, the cause could be analyzed immediately.

As shown in Table 2, the new FTP client function

can transmit the files for abnormality analysis to the file

server managed at an office from the on-site equipm ent

side, based on the information being monito red by the

GOT. These files can then be used to analyze the

status of the manufacturing equipment and the caus es,

and quickly restore the system (Fig. 1).

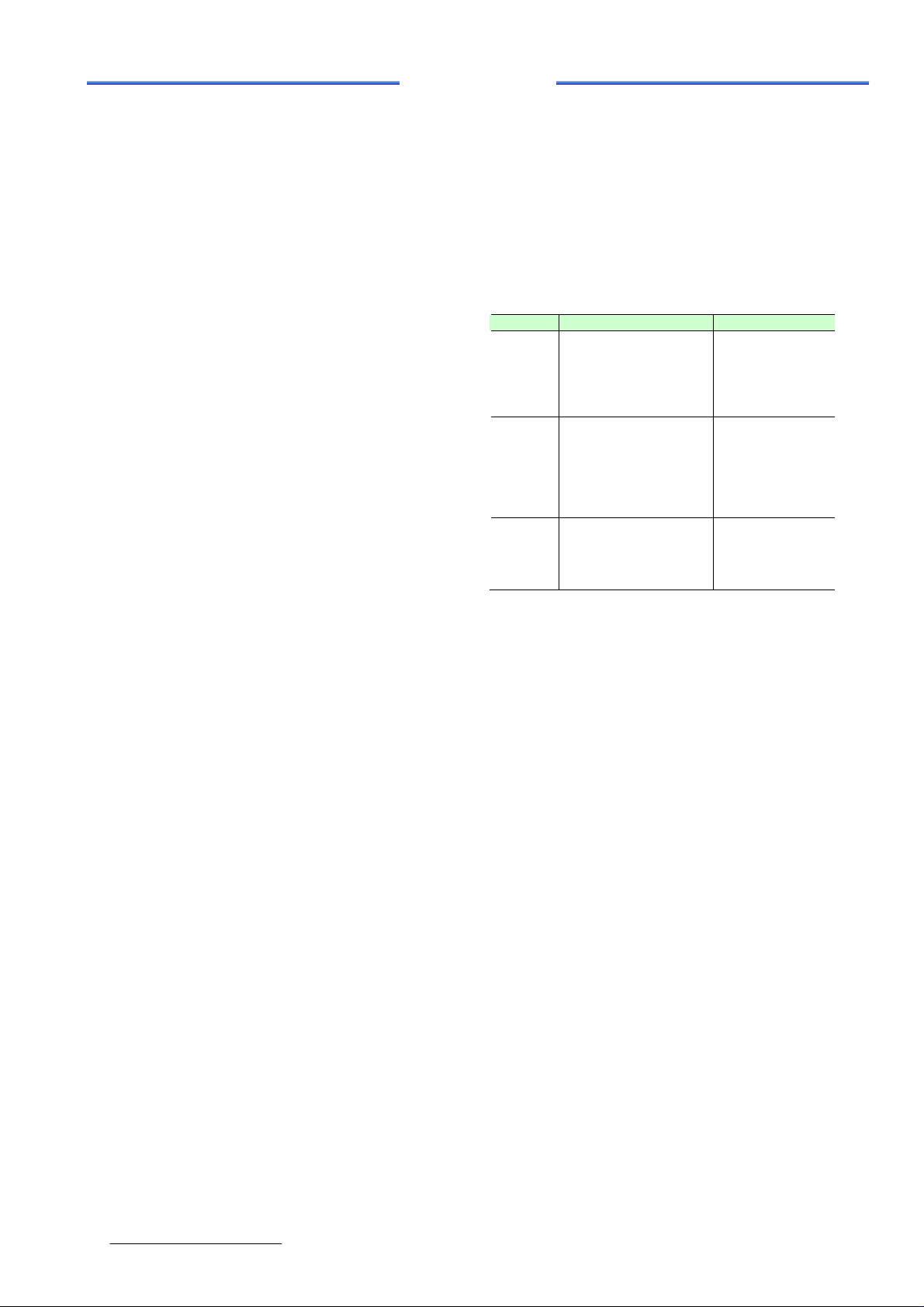

Table 2 File transfer function and conventional functions

Item FTP client FTP server MES interface

Transmission

trigger

Transmission

details

Transmission

Timing

Personal computer

Personal computer

Office

Office

On-site GOT Office personal

File File Device value

Equipment

event,

Time period

(FTP server)

(FTP server)

computer

Polling monitoring from the

office

On site

On site

On-site GOT

Equipment event,

Time period

Abnormality!

Abnormality!

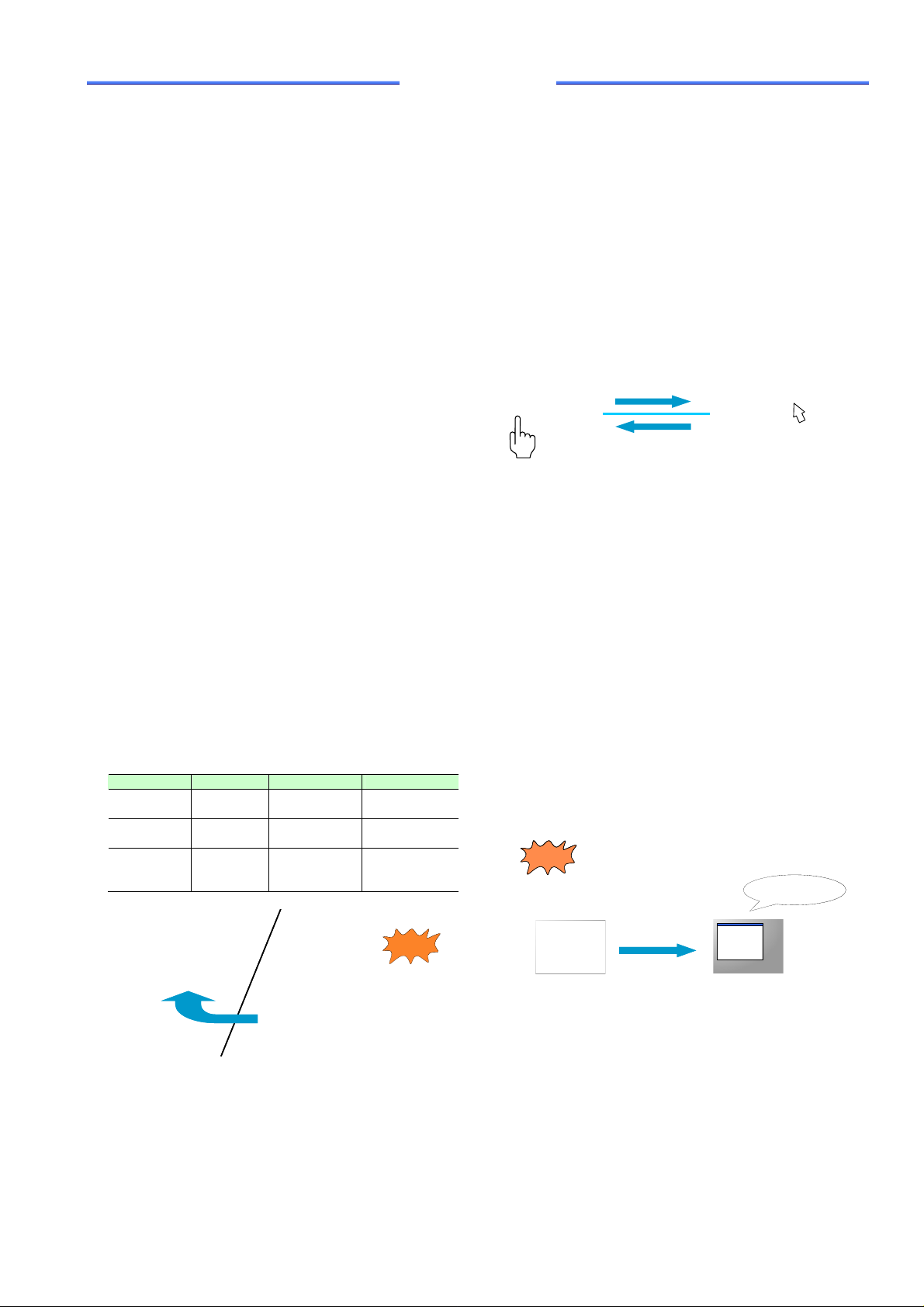

With this function, both the server and client can be

generally operated. However, if operations are simultaneously performed at both the remote and on-site locations, it may cause unintended operation for the manufacturing equipment. To avoid this, the VNC server function has an operation exclusion function: as shown in Fig.

2, the GOT acting as a server exclusively manages the

operations. When the client side has operational authorization, the GOT disables touch-panel operation and

enables operation only from the client side.

On site

GOT (VNC server)

When an on-site operator has operat ional authorization, only touch-panel

operation is available

When the office has operational authorization, only operation

information of the mouse is available.

Periodically transmits

screen image

Operation

information of mouse

Personal computer (VNC client)

Fig. 2 Authorization of VNC server function

Office

This new function enables the GOT and hence

manufacturing equipment to be operat ed and control led

remotely away from the production site, even from a

restricted-access area such as a clean room where

precision industrial products such as semiconductors

and display units are manufactured.

As shown in Fig. 3, manufacturing equipment in

different lines can be monitored and operated by one

GOT by connecting each GOT of the equipment in

multiple manufacturing systems via a network and

using the remote personal computer operati on function

(VNC client) of the GOT.

Manufacturing line BManufacturing line A

Manufacturing line BManufacturing line A

Stopped

Stopped

Displays the GOT screen

Displays the GOT screen

of manufacturing line A

of manufacturing line A

Transmits the

Transmits the

screen image

screen image

GOT (VNC server)

GOT (VNC server)

Transmits alarm log

Transmits alarm log

file, logging file, and

file, logging file, and

operation log when

operation log when

an abnormality

an abnormality

occurs

occurs

GOT (FTP client)

GOT (FTP client)

Fig. 1 File transfer function (FTP client)

2.2.2 VNC server function

The VNC server function transmits screen images

of the on-site GOT to a remote personal computer

through the network for display by the V NC client of t he

personal computer to monitor and operate the GOT.

Mitsubishi Electric ADVANCE June 2013 11

Fig. 3 Combination of VNC server function and remote

personal computer operation function

3. Development of Medium-Sized Display

GT14 Model

3.1 Market demands and challe nges of me-

dium-sized display

For medium-sized displays, there is increasing

demand for high-value-added functions to en able clear

GOT (VNC client)

GOT (VNC client)

Page 3

TECHNICAL REPORTS

letters and figures and photos to be displayed, data

obtained on site to be brought back t o the office using

USB memory, and the data of a display to be operated

from an upper-level personal computer via a network.

However, there were concerns that our medium-sized

display GT11 model was inferior in function and appearance, and our higher-level model was functionally

sufficient but expensive compared with competitors’

products. Therefore, we developed the GT14 model to

meet the market demand for a medium-sized display

featuring the following at a low price:

(1) Enhanced functions

(2) Differentiation from competitors’ products

(3) Lower price

3.2 Development and challenges of GT14 Model

(1) Enhanced functions

The main specifications of the GT14 model are

compared with those of the convention al GT11 model in

Table 3.

Table 3 Comparison of GT14 model and conventional

model

Item GT14 model

Liquid

Display

crystal

Backlight LED Cold cathode tube

Operation part

(touch panel)

User memory

capacity

USB USB device (1ch)

Ethernet 1ch None

General-purpose

memory

Functions Added character font, and

TFT LCD, 65,536 colors STN liquid

Analog resistance film

type

9 Mbytes 3 Mbytes

USB host (1ch)

SD card supported CF card supported

enhanced functions to

improve convenience and

to connect with external

equipment

i) Functional advancement of display screen

The GT14 model offers higher power thanks to its

TFT liquid crystal with excellent visibility and 65,536

colors rather than the conventional 256 colors, as well

as new fonts. When increasing the color variation, we

were careful not to decrease the rendering speed. The

increased color variation requires additional color information which increases the load of the rendering

process, so we raised the rendering speed by using a

more powerful microcomputer and by optimizing the

synthesis method for rendering data according to the

display properties based on window rendering.

The new model also uses approximatel y 15% less

energy than the conventional model, by u sing LEDs for

the liquid crystal backlight and impr oving the efficiency

of the power circuit.

GT11 model

(Conventional

model)

crystal, 256 colors

Matrix resistance

film type

USB device (1ch)

-

ii) Efficiency of screen design

Users can freely design the display screen using

dedicated rendering tools. The GT14 model allows

parts to be arranged at the pixel level, which is not

possible with the conventional model, by adopting an

analog resistance film-type touch panel. Furthermore,

users can design screens without consideri ng memory

capacity, since user memory capacity has been tripled

to 9 Mbytes.

iii) Enhancement of external interface and logging

function

We have developed new functions by ad ding USB

hosts, Ethernet and SD card support. Here, we introduce the logging function as an example.

The logging function collects the values of devices

such as a sequencer (or programmable controller) at

any time or at a fixed cycle. The collected data can be

stored in an SD card in CSV file format beforehand, and

the data can be brought back to the office from the

production site using USB memory, etc. This allows

quality control and productivity to be im proved by analyzing the data and giving feedback to the site. It also

possible to efficiently obtain data collected from the

personal computer at the office via Ethernet (Fig. 4).

Programmable

controller

Temperature

controller

Data

acquisition

Fig. 4

Factory

USB memory, etc.

Logging function

Office

(2) Differentiation from competitors’ products

As a leading manufacturer of programmable controllers in Japan, we have developed several functions to

enhance compatibility with our programmable controllers.

Examples include an FA transparent function for debugging by connecting a personal computer to our programmable controller via the display, and a

backup/restoration f unctio n. The latt er functi on is used t o

store (back up) the configuration information (sequence

programs, parameters, setting values, etc.) of programmable controllers in an SD card mounted on the display,

and return (restore) the stored information to the equipment. This allows a system to be backed up and restored

without using a personal computer, and hence easily

replace a faulty programmable controller on site and

promptly restore the system after a fault (Fig. 5).

12

Page 4

TECHNICAL REPORTS

Factory

Programmable

controller

Fig. 5

Backup/restoration function

To ensure reliability, drainage grooves on the

housing ensure that condensation water inside the

control panel does not penetrate into the display

through the fixed metal fittings of the GT14 model.

(3) Lower price

The GT14 features a new hardware configuration

from the conventional model. We selected highly reliable microcomputers and memory devices in consideration of the market trend of electronic components,

and reduced the number of parts by simplifying the

circuit configuration to lower the price.

Restore

Backup

SD card, etc.

4. Conclusion

The FTP server function to manage the sending

and receiving of data at the office and the FTP client

function to send and receive data based on the GOT

monitoring information, the SoftGOT-GOT link function

serving as a SoftGOT, and the VNC server function t o

display the GOT screen to operate expanded and optional functions, are similar yet have their own characteristics and can be selected as required. The medium-sized highly functional GT14 model helps to meet

a wide range of user needs.

We will strengthen the linkage with FA eq uipment

such as programmable controllers, which is our

strength, as well as servos and inverters, and emph asize the benefits of our products to firmly establish our

position in the market.

Reference

(1) S. Hashimoto: Graphic Operation Terminal

GOT1000 Series “GT16 Model,” Mitsubishi Denki

Giho (March 2010).

Mitsubishi Electric ADVANCE June 2013 13

Loading...

Loading...