Page 1

GROUP 11D

ENGINE OVERHAUL

<4G63-Turbo>

CONTENTS

11D-1

HOW TO USE THIS MANUAL. . . . . . 11D-2

GENERAL INFORMATION . . . . . . . . 11D-4

GENERAL SPECIFICATIONS . . . . . . 11D-4

SERVICE SPECIFICATIONS. . . . . . . 11D-5

REWOK DIMENSIONS . . . . . . . . . . . 11D-6

TORQUE SPECIFICATIONS . . . . . . . 11D-7

SEALANTS . . . . . . . . . . . . . . . . . . . . 11D-10

SPECIAL TOOLS. . . . . . . . . . . . . . . . 11D-11

ALTERNATOR AND IGNITION

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . 11D-14

REMOVAL AND INSTALLATION . . . . . . . . 11D-14

SOLENOID AND VACUUM HOSE . . 11D-15

REMOVAL AND INSTALLATION . . . . . . . . 11D-15

INLET MANIFOLD . . . . . . . . . . . . . . . 11D-30

REMOVAL AND INSTALLATION . . . . . . . . 11D-30

EXHAUST MANIFOLD . . . . . . . . . . . . 11D-31

REMOVAL AND INSTALLATION . . . . . . . . 11D-31

WATER PUMP AND WATER

HOSE . . . . . . . . . . . . . . . . . . . . . . . . . 11D-33

REMOVAL AND INSTALLATION . . . . . . . . 11D-33

ROCKER ARMS AND CAMSHAFT . . 11D-35

REMOVAL AND INSTALLATION . . . . . . . . 11D-35

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 11D-37

CYLINDER HEAD AND VALVES. . . . 11D-40

REMOVAL AND INSTALLATION . . . . . . . . 11D-40

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 11D-43

OIL PAN AND OIL PUMP. . . . . . . . . . 11D-46

REMOVAL AND INSTALLATION . . . . . . . . 11D-46

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 11D-53

TIMING BELT. . . . . . . . . . . . . . . . . . . 11D-16

REMOVAL AND INSTALLATION . . . . . . . . 11D-16

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . 11D-26

FUEL AND EMISSION PARTS . . . . . 11D-28

REMOVAL AND INSTALLATION . . . . . . . . 11D-28

PISTON AND CONNECTING ROD . . 11D-55

REMOVAL AND INSTALLATION . . . . . . . . 11D-55

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 11D-60

CRANKSHAFT AND CYLINDER

BLOCK . . . . . . . . . . . . . . . . . . . . . . . . 11D-62

REMOVAL AND INSTALLATION . . . . . . . . 11D-62

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 11D-66

Page 2

11D-2

ENGINE OVERHAUL <4G63-Turbo>

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

Scope of Service Explanations

This manual describes service procedures performed after removal of the engine from the vehicle.

For removal of the engine from the vehicle, installation of the engine in the vehicle, and on-vehicle inspection and service of

the engine, please use the separate Workshop Manuals prepared for the vehicle.

How to Read Explanations

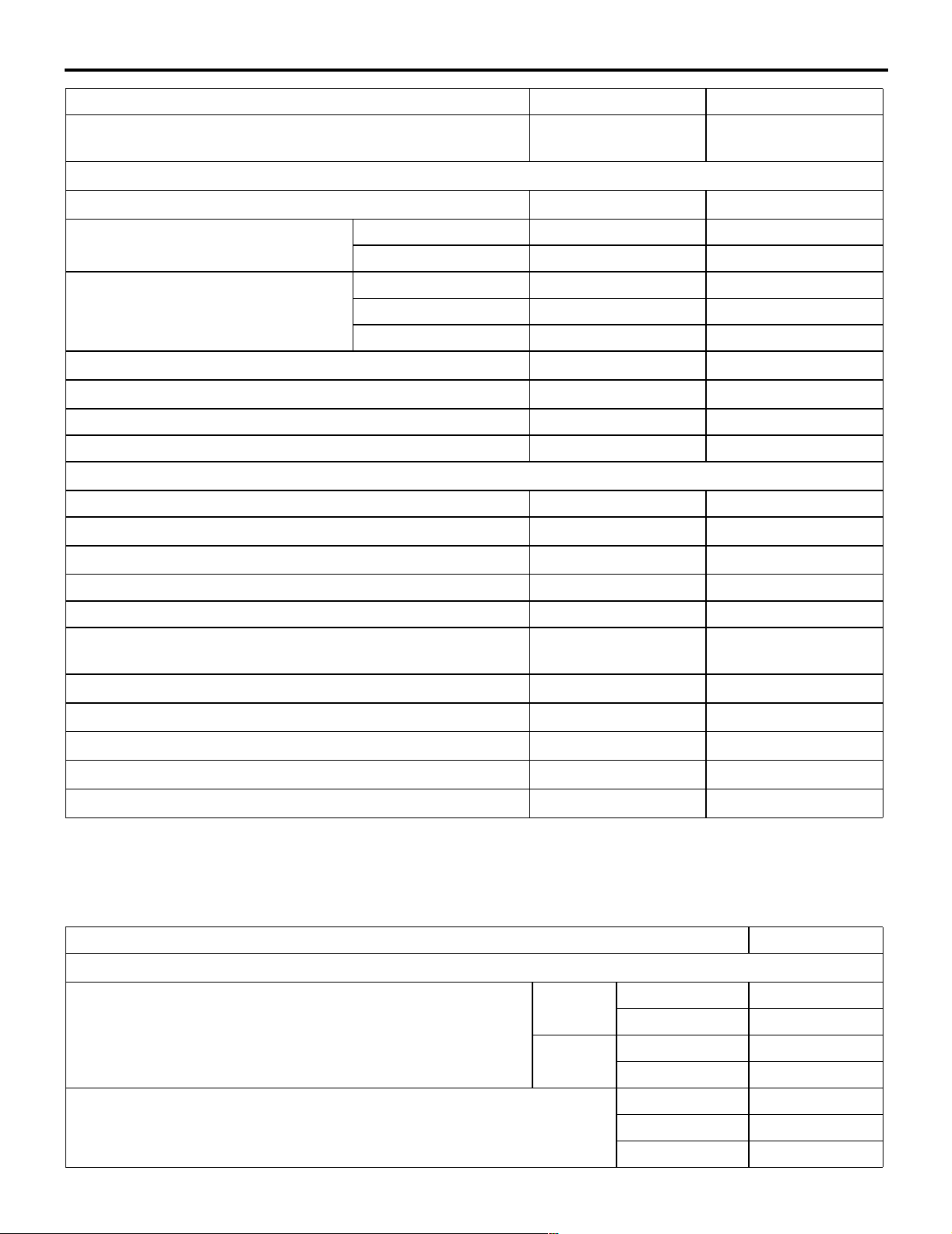

Service steps

(1) A component part drawing is shown at the beginning of each section to enable the technician to ascertain the installed con dition of the component parts.

(2) Service steps are indicated by means of numbers in the component part drawing. Non-reusable parts are indicated as such,

and tightening torques are shown.

·Removal steps

The numbers of the part names match the numbers in the component part drawing and indicate the removal sequence.

·Installation steps

Installation steps are omitted wherever installation can be achieved simply by performing the removal steps in reverse.

·Disassembly steps

The numbers of the part names match the numbers in the component part drawing and indicate the disassembly sequence.

·Reassembly steps

Reassembly steps are omitted wherever reassembly can be achieved simply by performing the disassembly steps in reverse.

M1113025100296

Classification of Service Points

Key service points, service standards, and instructions for

using special tools are collated as service points and explained in detail.

<<A>>: Outward-pointing brackets denote removal service points

or disassembly service points.

>>A<<: Inward-pointing brackets denote installation service points

or reassembly service points.

Lubricant and Sealant Symbols

Every location where a lubricant or sealant must be applied

or added is indicated using a relevant symbol in the component part drawing and/or on the page after the component

part drawing.

. . . . . . . . . . Grease

. . . . . . . . . . Sealant or form-in-place gasket (FIPG)

. . . . . . . . . . Brake fluid

. . . . . . . . . . Engine oil or gear oil

Inspection

Only those inspection procedures which use special tools or measuring appliances are described. You must perform general visual inspection and part cleaning whenever necessary although their procedures are not described in this manual.

AK202851

Page 3

ENGINE OVERHAUL <4G63-Turbo>

HOW TO USE THIS MANUAL

11D-3

11-54

CRANKSHAFT AND CYLINDER BLOCK

CRANKSHAFT AND CYLINDER BLOCK

REMOVAL AND INSTALLATION

ENGINE OVERHAUL

Apply engine oil

to all moving

parts before

installation.

Denotes non-reusable part.

16

15

Group title

9

8

11 ± 1 N·m

14

Section titlePage number

3

11 ± 1 N·m

6

4

5

9.0 ± 1.0 N·m

7

Tightening torque

2

1

132 ± 5 N·m

A

Removal steps

1. Drive plate bolt

2. Adapter plate

3. Drive plate

4. Crankshaft bushing

5. Rear plate

6. Bellhousing cover

>>E<< 7. Oil seal case

>>D<< 8. Oil seal

>>C<< 9. Bearing cap bolt

10. Bearing cap

>>B<< 11. Crankshaft bearing, lower

>>A<< 12. Crankshaft

The alphabetical character in this category of

heading matches that of the relevant removal

steps, installation steps, disassembly steps, or

reassembly steps.

13

12

11

10

25 ± 2 N·m + 90º to 100º

INSTALLATION SERVICE POINTS

>>A<< THRUST BEARING INSTALLATION

Grooves

AK204351

AB

Procedures and cautions for removal, installation, disassembly, and reassembly are explained under this category of heading.

AK100786

AB

AK300250

Page 4

11D-4

ENGINE OVERHAUL <4G63-Turbo>

GENERAL INFORMATION

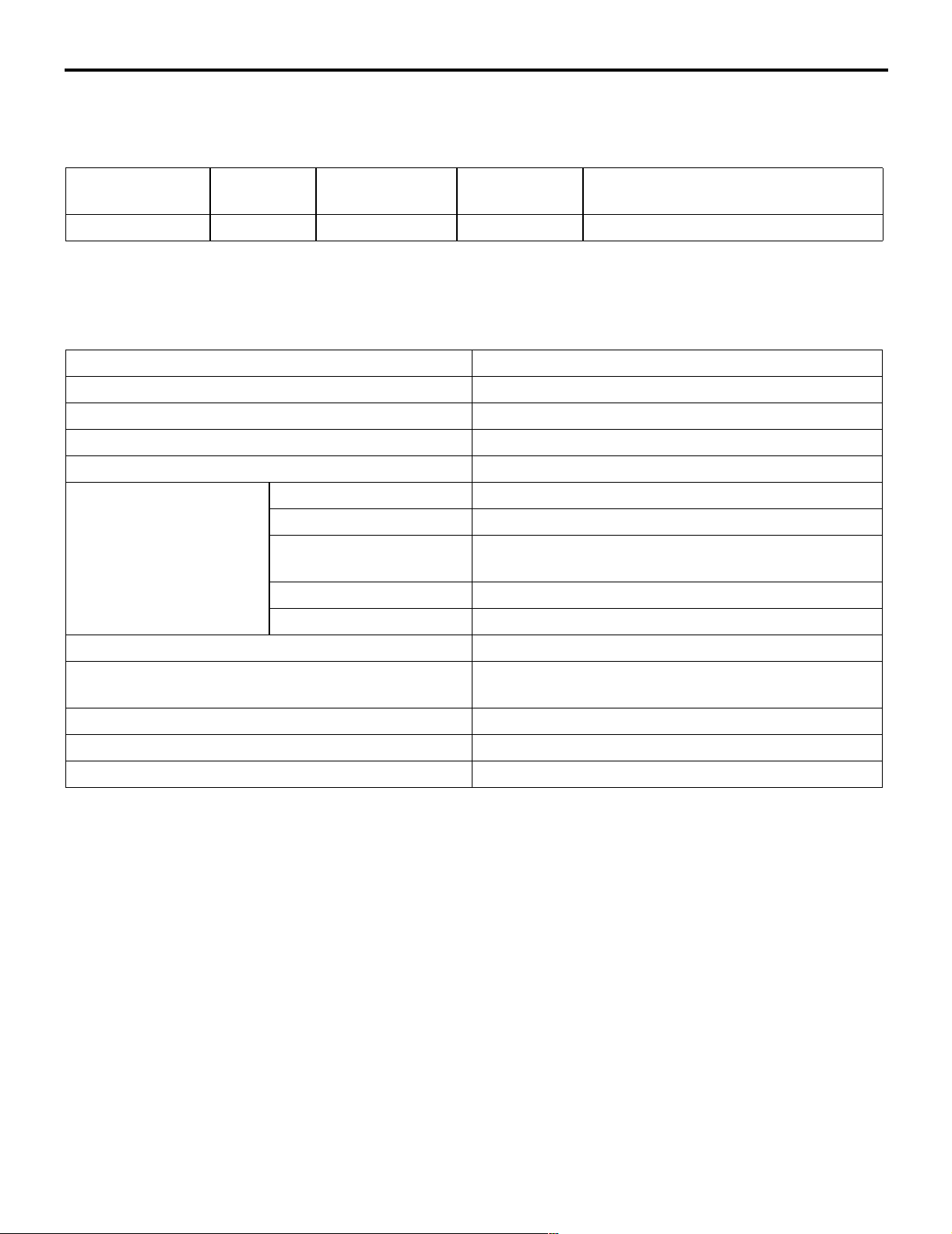

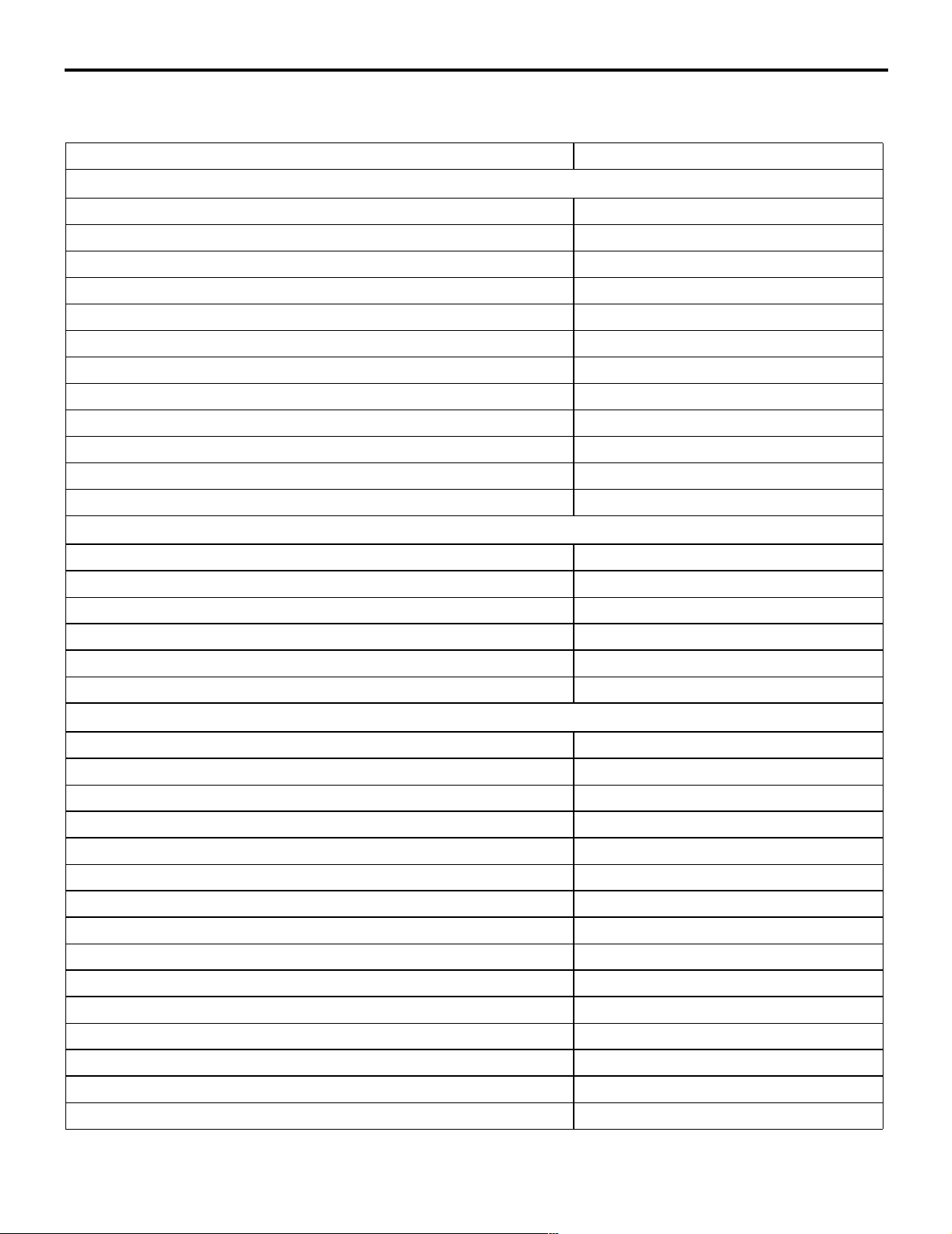

VEHICLE AND ENGINE MODELS

GENERAL INFORMATION

M1113000100523

Vehicle name Vehicle

model

OUTLANDER CU2W 4G63-7 1,997 Double overhead camshaft, 16-valve

Engine model Displacement mLSpecification

GENERAL SPECIFICATIONS

M1113000200779

Item Specification

Bore × stroke mm 85 × 88

Displacement mL 1,997

Combustion chamber Pentroof type

Number of cylinders 4

Valve mechanism Type Double overhead camshaft

Number of intake valves 2

Number of exhaust

valves

Lash adjusters Hydraulic

Rocker arms Roller cam followers

2

Compresssion ratio 9.0

Fuel injection system Electronically controlled multi-point injection (MPI)

system

Ignition system Electronically controlled two-coil system

Generator Alternator (with built-in IC regulator)

Starter motor Gear reduction drive type

Page 5

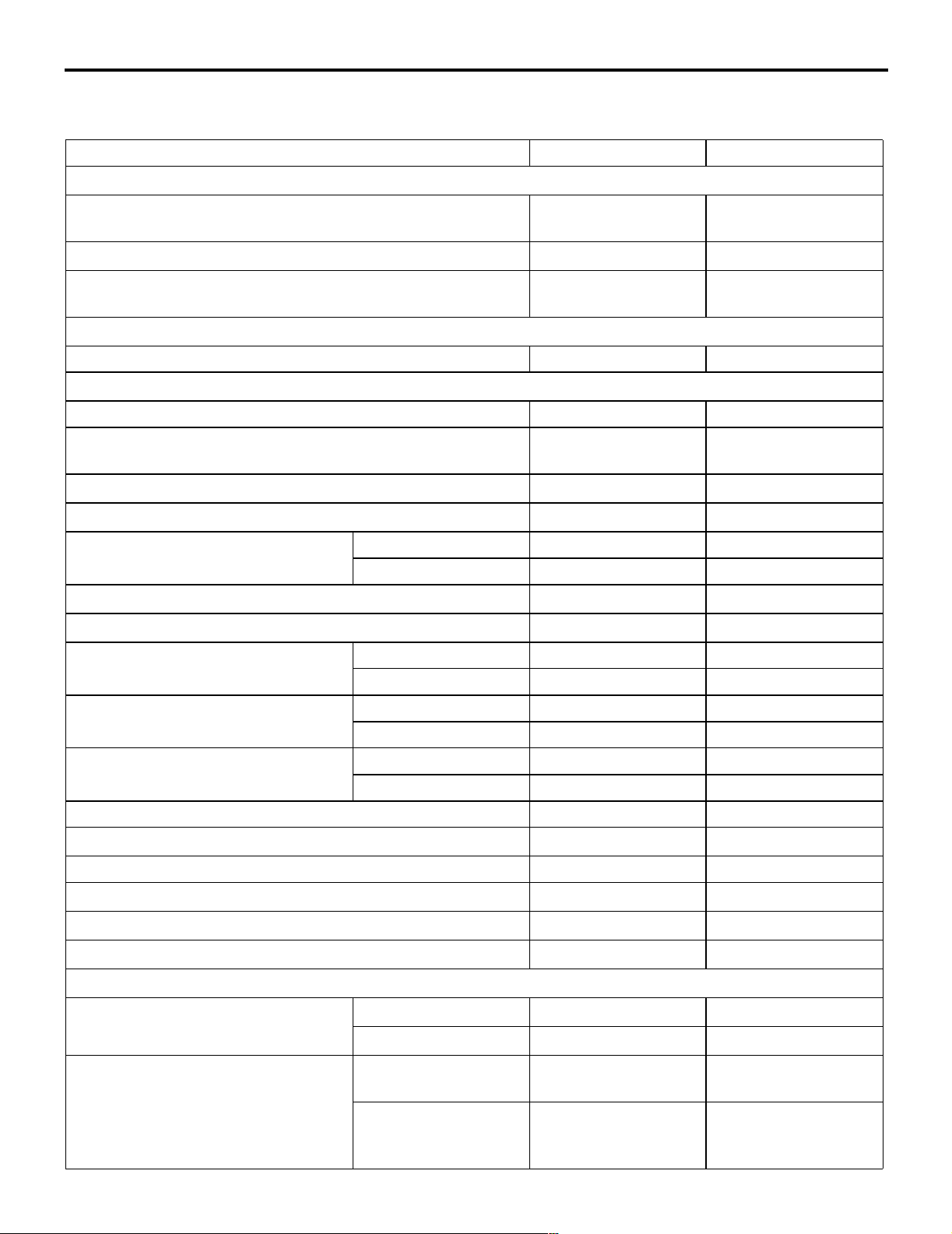

ENGINE OVERHAUL <4G63-Turbo>

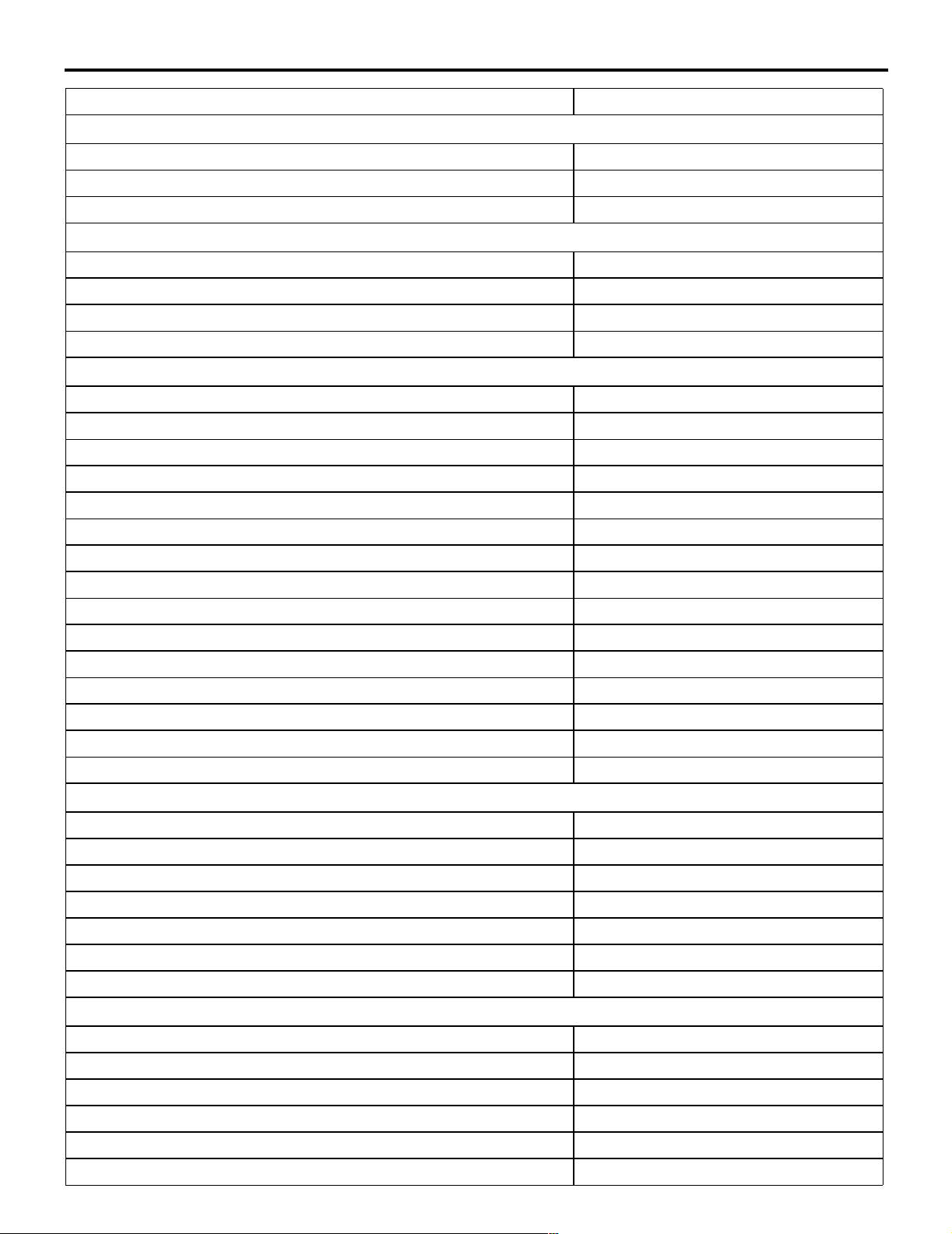

SERVICE SPECIFICATIONS

SERVICE SPECIFICATIONS

Item Standard value Limit

TIMING BELT

11D-5

M1113000300776

Auto-tensioner rod extension length

(with timing belt installed) mm

Auto-tensioner rod extension length (when free) mm 12.0

Auto-tensioner rod retraction length

(when pressed with force of 98 to 196 N) mm

ROCKER ARMS AND CAMSHAFTS

Cam height mm 34.91 34.41

CYLINDER HEAD AND VALVES

Cylinder head gasket surface warp mm Less than 0.05 0.2

Cylinder head gasket surface grinding limit

(including cylinder block grinding amount) mm

Cylinder head overall height mm 131.9 − 132.1

Cylinder head bolt nominal length mm

Valve margin mm Intake valves 1.0 0.5

Exhaust valves 1.5 1.0

Valve stem diameter mm 6.6

Valve face angle 43.5° − 44°

Valve stem-to-guide clearance mm Intake valves 0.02 − 0.05 0.10

Exhaust valves 0.05 − 0.09 0.15

3.8 − 4.5

Less than 1

−

−

−

−

−

0.2

−

99.4

−

−

Valve height mm Intake valves 109.5 109.0

Exhaust valves 109.7 109.2

Valve stem projection mm Intake valves 49.2 49.7

Exhaust valves 48.4 48.9

Valve spring free height mm 47.0 46.0

Valve spring load/height N/mm 240/40

Valve spring squareness 1.5° or smaller 4°

Valve face-to-seat contact width mm 0.9 − 1.3

Valve guide inside diameter mm 6.6

Valve guide press-in height mm 19.2 − 19.8

OIL PAN AND OIL PUMP

Oil pump gear side clearance mm Drive gear 0.08 − 0.14

Driven gear 0.06 − 0.12

Oil cooler by-pass valve mm Dimension (Normal

temperature)

By-pass hole closing

temperature 97 to

103°C

34.5

40.0

−

−

−

−

−

−

−

−

Page 6

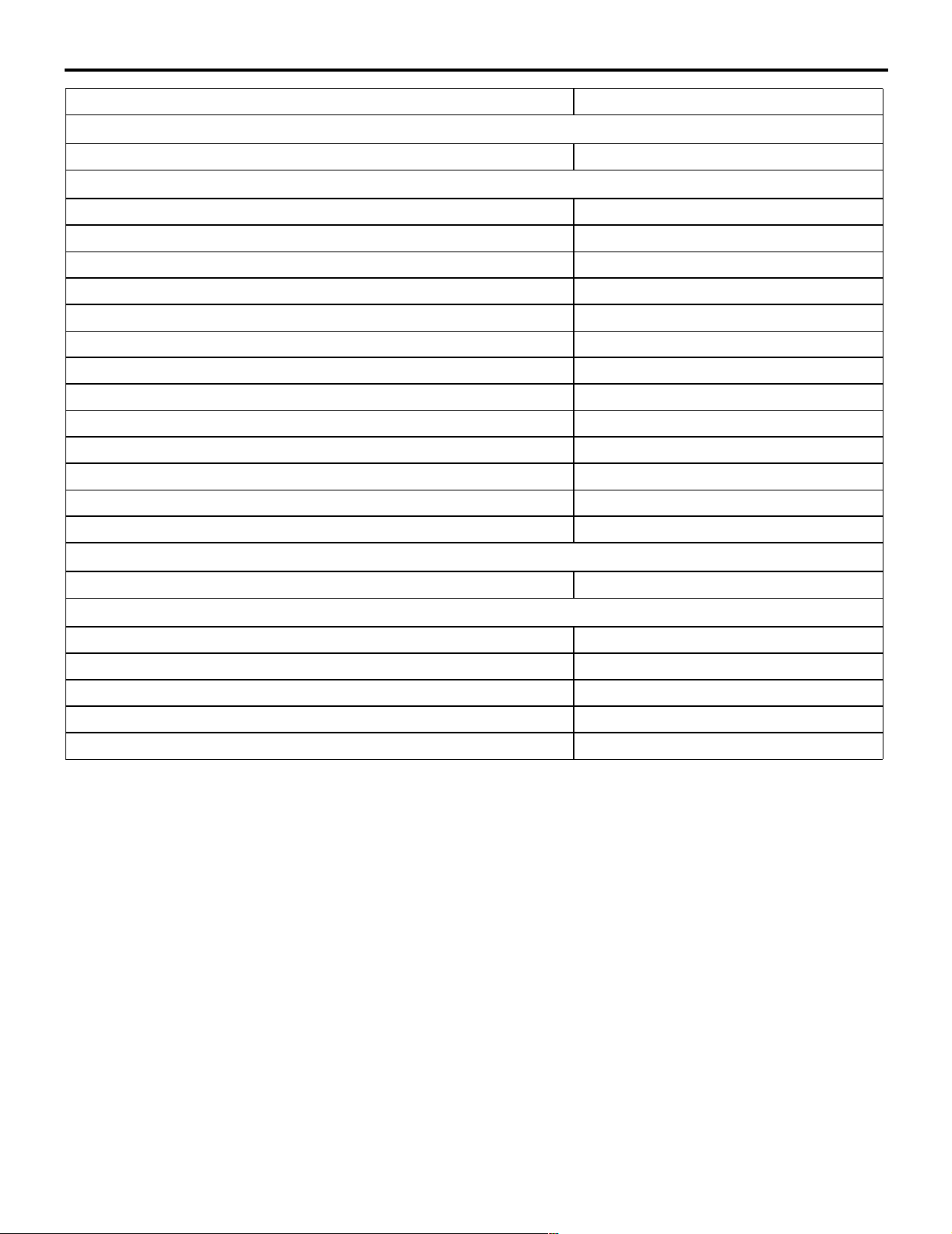

11D-6

Item Standard value Limit

ENGINE OVERHAUL <4G63-Turbo>

REWOK DIMENSIONS

Oil pressure at curb idle speed kPa

[oil temperature is 75 to 90°]

PISTONS AND CONNECTING RODS

Piston outside diameter mm 85.0

Piston ring side clearance in ring

groove mm

Piston ring end gap mm No. 1 0.20 − 0.30 0.8

Piston pin outside diameter mm 22.0

Piston pin press-in load (at ambient temperature) N 7,350 − 17,100

Oil clearance at crankshaft pins mm 0.03 − 0.05 0.1

Connecting rod big end thrust clearance mm 0.10 − 0.25 0.4

CRANKSHAFT AND CYLINDER BLOCK

Crankshaft end play mm 0.05 − 0.25 0.4

Crankshaft journal diameter mm 57.0

Crankshaft pin diameter mm 45.0

Oil clearance at crankshaft journals mm 0.03 − 0.04 0.1

No. 1 0.03 − 0.07 0.1

No. 2 0.02 − 0.06 0.1

No. 2 0.30 − 0.45 0.8

Oil ring 0.10 − 0.40 1.0

78 or more

−

−

−

−

−

−

Cylinder block gasket surface warp mm 0.05 0.1

Cylinder block gasket surface grinding limit

(including cylinder head grinding amount) mm

Cylinder block overall height mm 284

Cylinder bore diameter mm 85

Taper of cylinder mm 0.01 or less

Cylinder-to-piston clearance mm 0.02 − 0.04

Crankshaft bearing cap bolt nominal length mm

−

−

0.2

−

−

−

−

71.1

REWOK DIMENSIONS

M1113024300394

Item Standard value

CYLINDER HEAD AND VALVES

Diameter of oversize valve seat ring hole in cylinder head mmIntake 0.3 oversize 35.30 − 35.33

0.6 oversize 35.60 − 35.63

Exhaust 0.3 oversize 33.30 − 33.33

0.6 oversize 33.60 − 33.63

Diameter of oversize valve guide hole in cylinder head mm 0.05 oversize 12.05 − 12.07

0.25 oversize 12.25 − 12.27

0.50 oversize 12.50 − 12.52

Page 7

ENGINE OVERHAUL <4G63-Turbo>

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

Item N⋅m

ALTERNATOR AND IGNITION COIL

Oil level gauge guide bolt 13 ± 1

Idler pulley bolt 79 ± 5

Auto-tensioner assembly bolt (M8) 24 ± 4

Auto-tensioner assembly bolt (M10) 44 ± 10

Water pump pulley bolts 8.8 ± 1.0

Alternator brace bolt (flange bolt) 23 ± 3

Alternator brace bolts (washer assembled bolt) 22 ± 4

Alternator nuts 44 ± 10

Crankshaft pulley bolts 25 ± 4

Center cover bolts 3.0 ± 0.5

Ignition coil bolts 10 ± 2

11D-7

M1113023400989

Spark plugs 25 ± 5

SOLENOID AND VACUUM HOSE

Vacuum pipe and hose assembly bolts 11 ± 1

EGR valve bolts 20 ± 2

Engine hanger bolt 19 ± 3

Solenoid valve assembly nut 36 ± 6

Solenoid valve assembly bolts(M6) 9.0 ± 1.0

Solenoid valve assembly bolts(M8) 23 ± 4

TIMING BELT

Timing belt cover bolts (flange bolt) 11 ± 1

Timing belt cover bolt (washer-assembled bolt) 9.0 ± 1.0

Power steering pump bracket bolts 49 ± 9

Tensioner pulley bolt 48 ± 5

Tensioner arm bolt 21 ± 4

Auto-tensioner bolts 23 ± 3

Idler pulley bolt 35 ± 6

Crankshaft angle sensor bolts 8.8 ± 1.0

Oil pump sprocket nut 54 ± 4

Crankshaft bolt 167

Tensioner "B" bolt 19 ± 3

Counterbalance shaft sprocket bolt 45 ± 3

Rocker cover bolts 3.5 ± 0.5

Engine support bracket bolts 49 ± 5

Camshaft sprocket bolts 88 ± 10

Page 8

11D-8

Item N⋅m

FUEL SYSTEM

Throttle body bolts 19 ± 3

Fuel pressure regulator bolts 9.0 ± 2.0

Delivery pipe and injector assembly bolts 11 ± 1

INLET MANIFOLD

Inlet manifold stay bolts 31 ± 3

Inlet manifold bolts (M8) 20 ± 2

Inlet manifold bolts and nuts (M10) 36 ± 6

Detonation sensor 23 ± 2

EXHAUST MANIFOLD

Engine hanger bolt 19 ± 3

Turbocharger heat protector bolts 23 ± 3

Oxygen sensor 44 ± 5

Exhaust fitting bracket bolts 36 ± 5

ENGINE OVERHAUL <4G63-Turbo>

TORQUE SPECIFICATIONS

Exhaust fitting bolts 59 ± 5

Air outlet fitting bolts 19 ± 1

Oil return pipe bolts 14 ± 1

Exhaust manifold heat protector bolts 23 ± 3

Turbocharger assembly and pipe assembly bolts, nuts 59 ± 5

Oil pipe bolt (flange bolt) 11 ± 1

Oil pipe bolt (eye bolt M10) 17 ± 2

Water pipe bolt (eye bolt M12) 28 ± 5

Water pipe bolt (flange bolt) 10 ± 1

Exhaust manifold nuts (M8) 33 ± 6

Exhaust manifold nuts (M10) 55 ± 10

WATER PUMP AND WATER HOSE

Engine coolant temperature sensor 29 ± 10

Engine coolant temperature gauge unit 10.8 ± 1.0

Water outlet fitting bolts 13 ± 2

Water inlet fitting bolts 13 ± 2

Thermostat housing bolts 23 ± 4

Water inlet pipe bolt (M8) 13 ± 2

Water pump bolts 14 ± 1

ROCKER ARMS AND CAMSHAFTS

Camshaft position sensor bolt 10 ± 1

Cover bolts 10 ± 2

Camshaft position sensing cylinder bolt 22 ± 4

Camshaft position sensor support bolts 14 ± 1

Bearing cap bolts 20 ± 1

Oil delivery body bolts 11 ± 1

Page 9

ENGINE OVERHAUL <4G63-Turbo>

TORQUE SPECIFICATIONS

Item N⋅m

CYLINDER HEAD AND VALVES

Cylinder head bolts 78 ± 2 → 0 → 20 ± 2 → + 90° + 90°

OIL PUMP CASE AND OIL PAN

Drain plug 39 ± 5

Oil filter 14 ± 2

Oil pan bolts 9.0 ± 3.0

Oil screen bolts 19 ± 3

Oil pressure switch 19 ± 3

Oil cooler by-pass valve 54 ± 5

Relief plug 44 ± 5

Oil filter bracket bolts 19 ± 3

Plug cap 23 ± 3

Flange bolt 36 ± 3

Oil pump case bolts 23 ± 3

11D-9

Oil pump cover bolts 17 ± 1

Oil pump cover screw 10 ± 2

PISTONS AND CONNECTING RODS

Connecting rod cap nuts 20 ± 2 → 90° to 94°

CRANKSHAFT AND CYLINDER BLOCK

Flywheel bolts 132 ± 5

Rear plate bolt 11 ± 1

Bell housing cover bolts 9.0 ± 1.0

Rear oil seal case bolts 11 ± 1

Beam bearing cap bolts 25 ± 2 → 90° to 100°

Page 10

11D-10

ENGINE OVERHAUL <4G63-Turbo>

SEALANTS

SEALANTS

M1113000500703

Item Specified sealant

Engine support bracket bolts Mitsubishi Genuine Part No.MD970389

or equivalent

Semicircular packing 3M ATD No.8660 or equivalent

Rocker cover Mitsubishi Genuine Part No. MD970389

or equivalent

Engine coolant temperature e gauge unit 3M Nut Locking Part No.4171 or

equivalent

Engine coolant temperature sensor 3M ATD No.8660 or equivalent

Water outlet fitting* Mitsubishi Genuine Part No. MD970389

Thermostat housing*

Cylinder head (camshaft bearing cap fitting section) 3M ATD No.8660 or equivalent

Camshaft position sensor support* Mitsubishi Genuine Part No. MD970389

Oil pressure switch 3M ATD No.8660 or equivalent

or equivalent

or equivalent

Oil pan* Mitsubishi Genuine Part No. MD970389

Rear oil seal case*

NOTE: *: Part to be sealed with a form-in-place

gasket (FIPG)

or equivalent

FORM-IN-PLACE GASKET (FIPG)

This engine has several areas where the

form-in-place gasket (FIPG) is used for sealing. To

ensure that the FIPG fully serves its purpose, it is

necessary to observe some precautions when

applying it.

Bead size, continuity and location are of paramount

importance. Too thin a bead could cause leaks. Too

thick a bead, on the other hand, could be squeezed

out of location, causing blocking or narrowing of fluid

passages. To prevent leaks or blocking of passages,

therefore, it is absolutely necessary to apply the

FIPG evenly without a break, while observing the

correct bead size.

FIPG hardens as it reacts with the moisture in the

atmospheric air, and it is usually used for sealing

metallic flange areas.

REMOVAL OF FIPG SEALED PARTS

Parts sealed with a FIPG can be easily removed

without need for the use of a special method. In

some cases, however, the FIPG in joints may have to

be broken by tapping parts with a mallet or similar

tool. You can also tap a flat, thin gasket scraper into

the joint to break the FIPG, taking extreme care not

to damage the mating surfaces.The oil pan cutter

(MD998727) is available as a special tool for

removing the oil pan. The tool, however, must not be.

CLEANING FIPG APPLICATION

SURFACE

Thoroughly remove all substances deposited on the

FIPG application surface, using a gasket scraper or

wire brush. Make sure that the FIPG application

surface is flat and smooth. Also make sure that the

surface is free from oils, greases and foreign

substances. Do not fail to remove old FIPG that may

remain in the fastener fitting holes.

APPLICATION OF FIPG

Applied FIPG bead should be of the specified size

and free of any break. FIPG can be wiped away

unless it has completely hardened. Install the mating

parts in position while the FIPG is still wet (in less

than 15 minutes after application). Do not allow FIPG

to spread beyond the sealing areas during

installation. Avoid operating the engine or letting oils

or water come in contact with the sealed area before

a time sufficient for FIPG to harden (approximately

one hour) has passed. FIPG application method may

vary from location to location. Follow the instruction

for each particular case described later in this

manual.

Page 11

ENGINE OVERHAUL <4G63-Turbo>

SPECIAL TOOLS

SPECIAL TOOLS

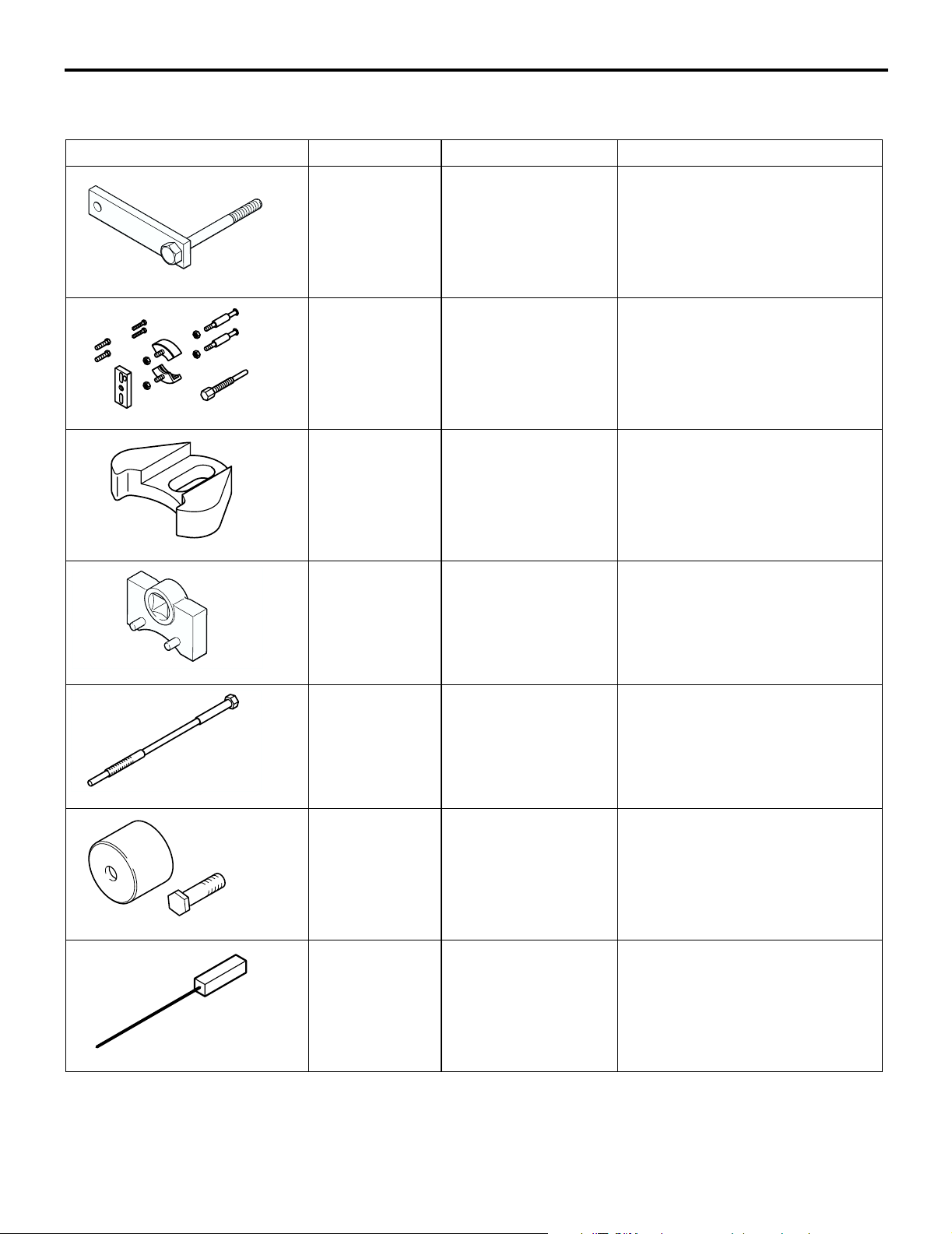

Tool Number Name Use

MD998781 Flywheel stopper Retention of flywheel

D998781

11D-11

M1113000600788

D998767

MD998778 Crankshaft sprocket

puller

Removal of crankshaft sprocket

and crankshaft sprocket B

MD998785 Sprocket stopper Retention of counterbalancer

shaft sprocket

MD998767 Tension pulley socket

wrench

Manipulation of tensioner pulley

during adjustment of timing belt

tension

MD998738 Set screw Retention of tensioner arm and

auto-tensioner during timing belt

installation

D998738

D998713

MD998713 Camshaft oil seal

Installation of camshaft oil seal

installer

MD998442 Air bleed wire Air bleeding of lash adjuster

Page 12

11D-12

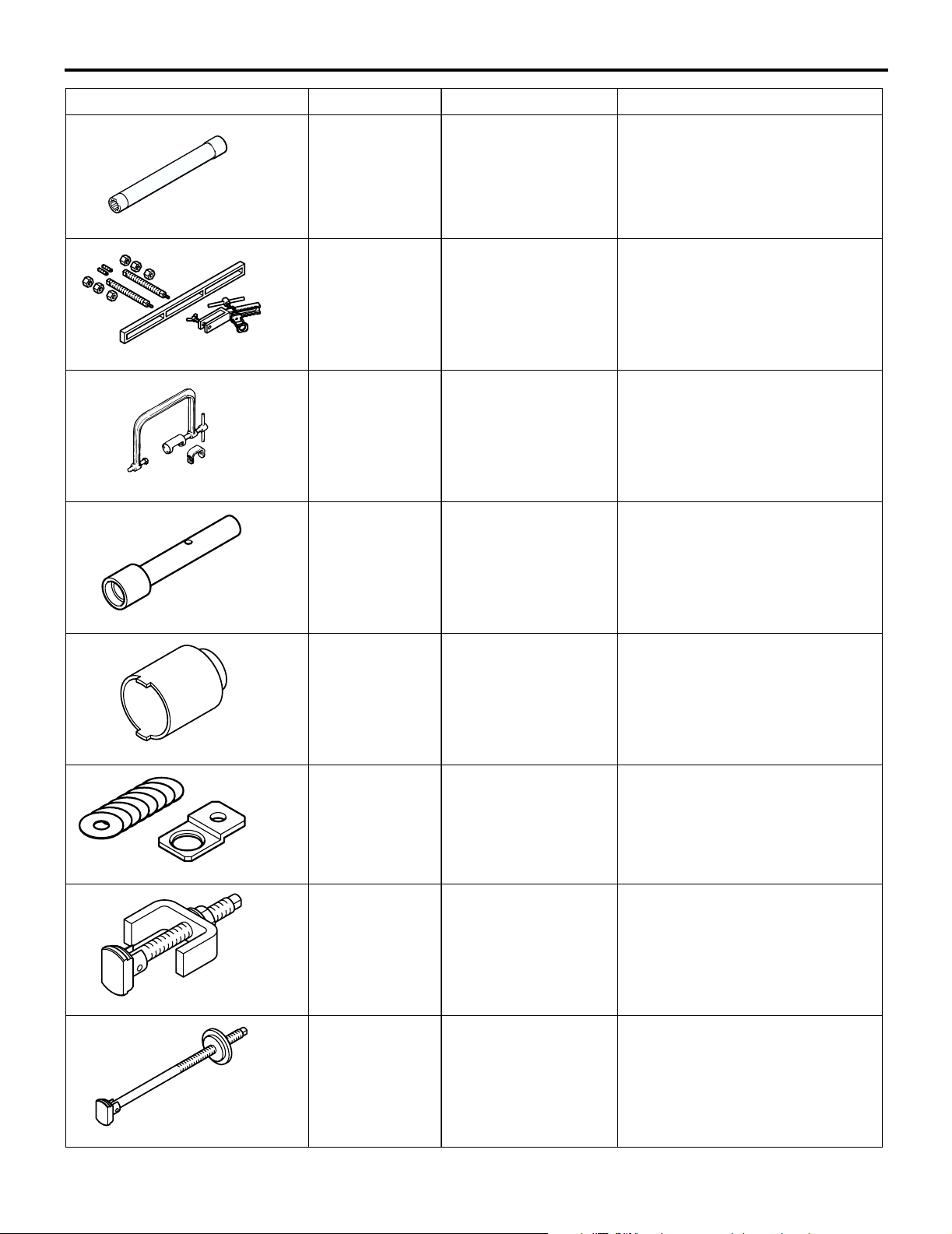

Tool Number Name Use

ENGINE OVERHAUL <4G63-Turbo>

SPECIAL TOOLS

B991654

MB991654 Cylinder head bolt

wrench

MD998772 Valve spring

compressor

MD998735 Valve spring

compressor

MD998737 Valve stem seal

installer

Removal and installation of

cylinder head bolts

Compression of valve spring

Compression of valve spring

Installation of valve stem seal

MD998162 Plug wrench Removal and installation of front

case plug cap

(Use with MD998783.)

MD998783 Plug wrench retainer Removal and installation of front

case plug cap

(Use with MD998162.)

MD998371 Silent shaft bearing

puller

MD998372 Silent shaft bearing

puller

Removal of counterbalancer shaft

front bearing

Removal of counterbalancer shaft

front and rear bearings

Page 13

ENGINE OVERHAUL <4G63-Turbo>

SPECIAL TOOLS

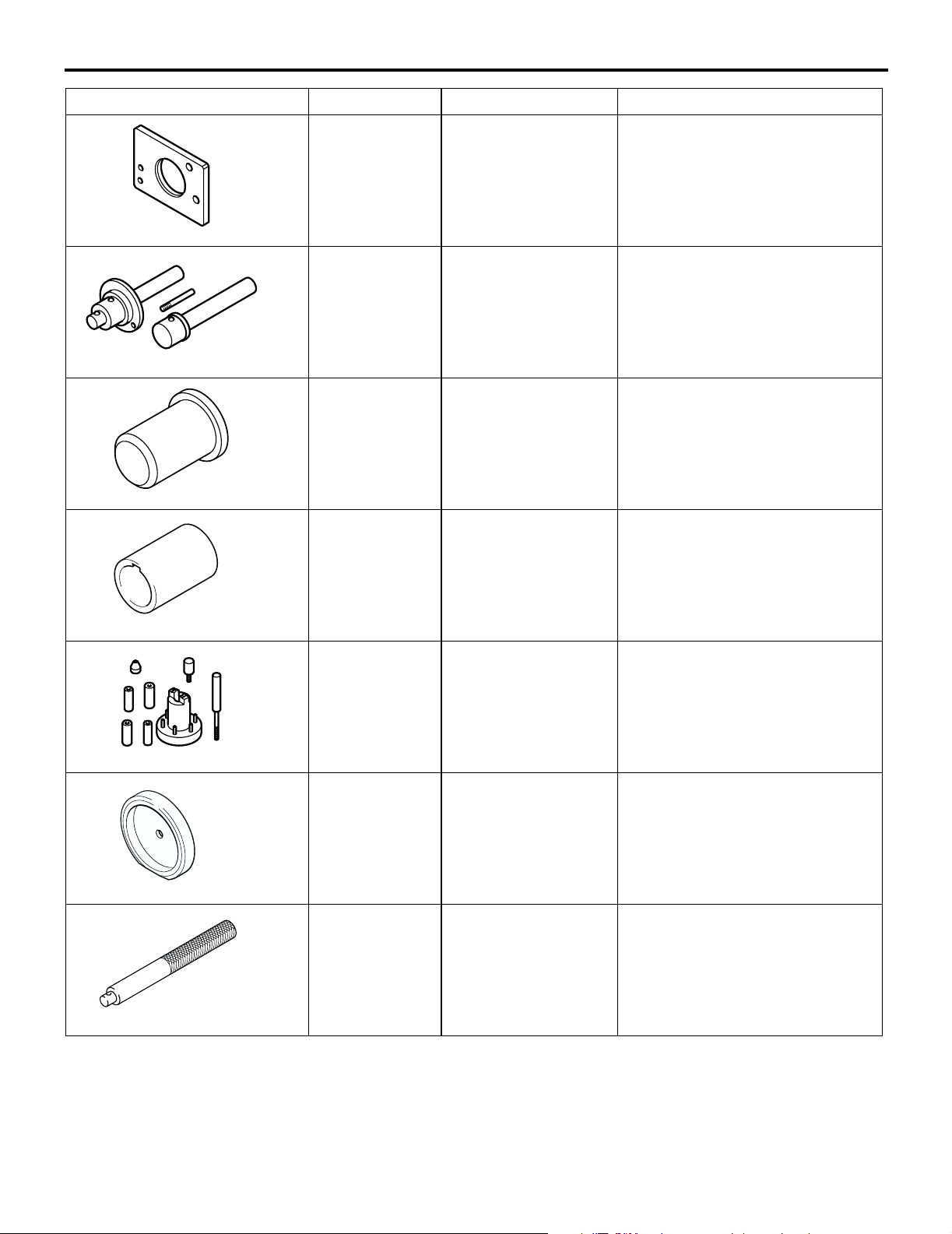

Tool Number Name Use

11D-13

MB991603 Silent shaft bearing

installer stopper

MD998705 Silent shaft bearing

installer

MD998375 Crankshaft front oil

seal installer

MD998285 Crankshaft front oil

seal guide

Guide and stopper for removal

and press-fitting of

counterbalancer shaft rear

bearing

Press-fitting of counterbalancer

shaft front and rear bearings

Installation of crankshaft front oil

seal

Guide for installation of

crankshaft front oil seal

D998285

D998776

MD998780 Piston pin setting tool Removal and press-fitting of

piston pin

MD998776 Crankshaft rear oil

seal installer

Installation of crankshaft rear oil

seal

MB990938 Handle Installation of crankshaft rear oil

seal

(Use with MD998776.)

Page 14

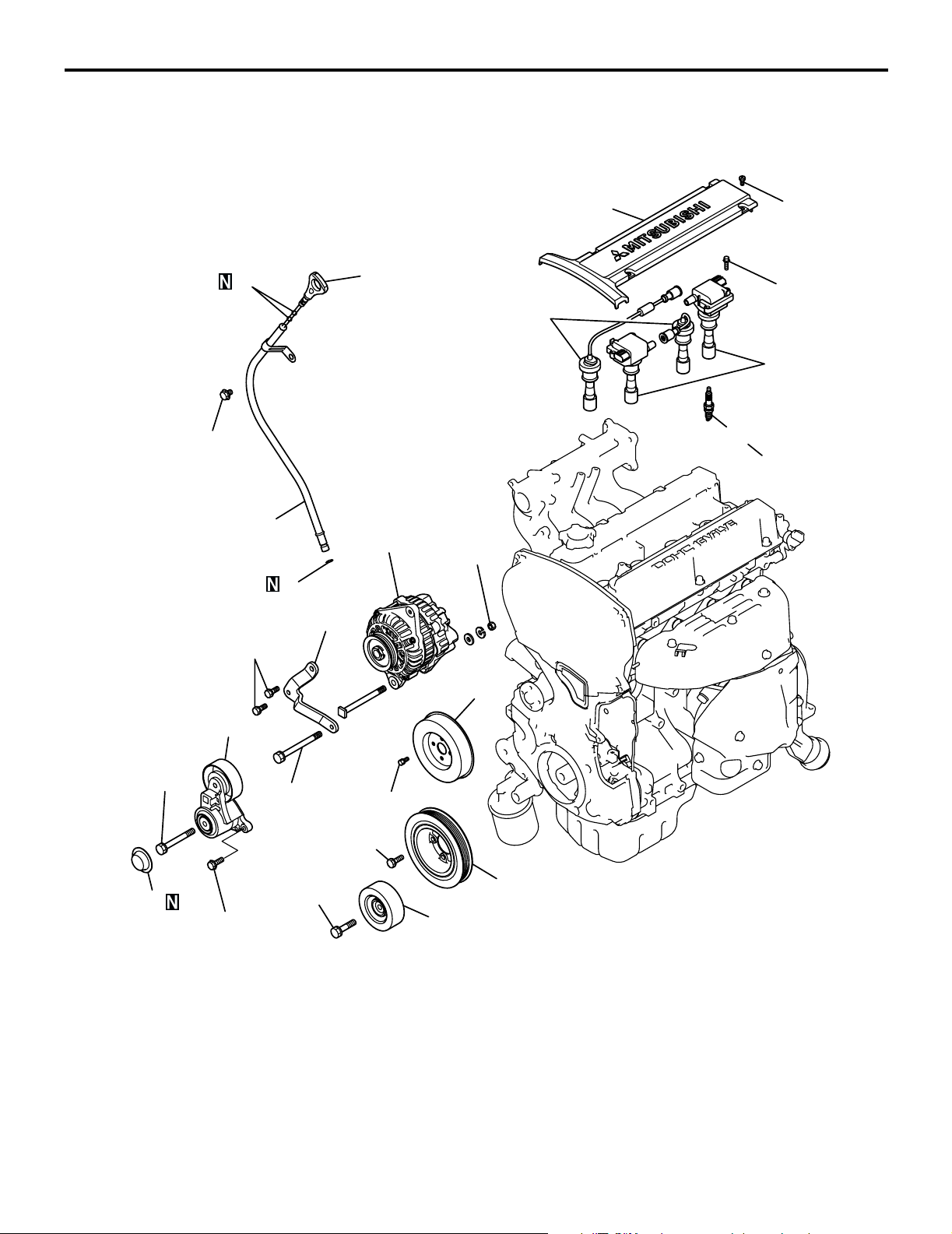

11D-14

ENGINE OVERHAUL <4G63-Turbo>

ALTERNATOR AND IGNITION SYSTEM

ALTERNATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

2

13 ± 1 N·m

3

M1113001000701

1

10

44 ± 10 N·m

13

12

3.0 ± 0.5 N·m

10 ± 2 N·m

14

15

25 ± 5 N·m

44 ± 10 N·m

6

4

9

22 ± 4 N·m

7

23 ± 3 N·m

79 ± 5 N·m

24 ± 4 N·m

Removal steps

1. Oil level gauge

2. O-ring

3. Oil level gauge guide

4. O-ring

5. Idler pulley

6. Cap

7. Auto-tensioner assembly

8. Water pump pulley

8.8 ± 1.0 N·m

25 ± 4 N·m

8

11

5

Removal steps (Continued)

9. Alternator brace

10. Alternator

11. Crankshaft pulley

12. Center cover

13. Spark plug cable

14. Ignition coil

15. Spark plug

AK305988

AC

Page 15

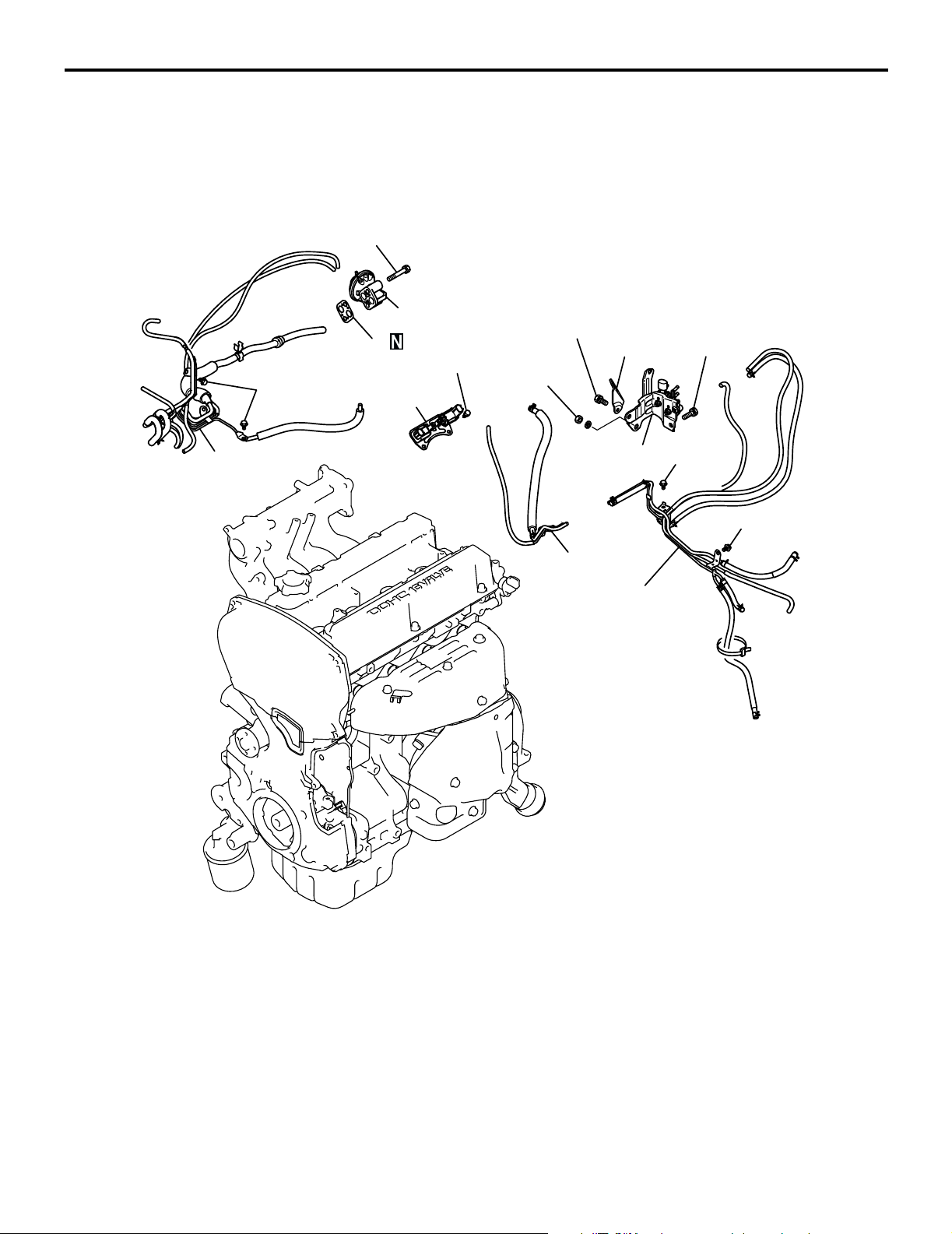

ENGINE OVERHAUL <4G63-Turbo>

SOLENOID AND VACUUM HOSE

SOLENOID AND VACUUM HOSE

11D-15

REMOVAL AND INSTALLATION

20 ± 2 N·m

11 ± 1 N·m

3

4

5

9.0 ± 1.0 N·m

7

19 ± 3 N·m

36 ± 6 N·m

M1113025300074

6

23 ± 4 N·m

11 ± 1 N·m

11 ± 1 N·m

8

2

Removal steps

1. Vacuum pipe and hose assembly

2. Vacuum pipe and hose assembly

3. Vacuum pipe and hose assembly

4. EGR valve

1

AK400296

Removal steps (Continued)

5. EGR valve gasket

6. Solenoid valve

7. Solenoid valve

8. Engine hanger

AB

Page 16

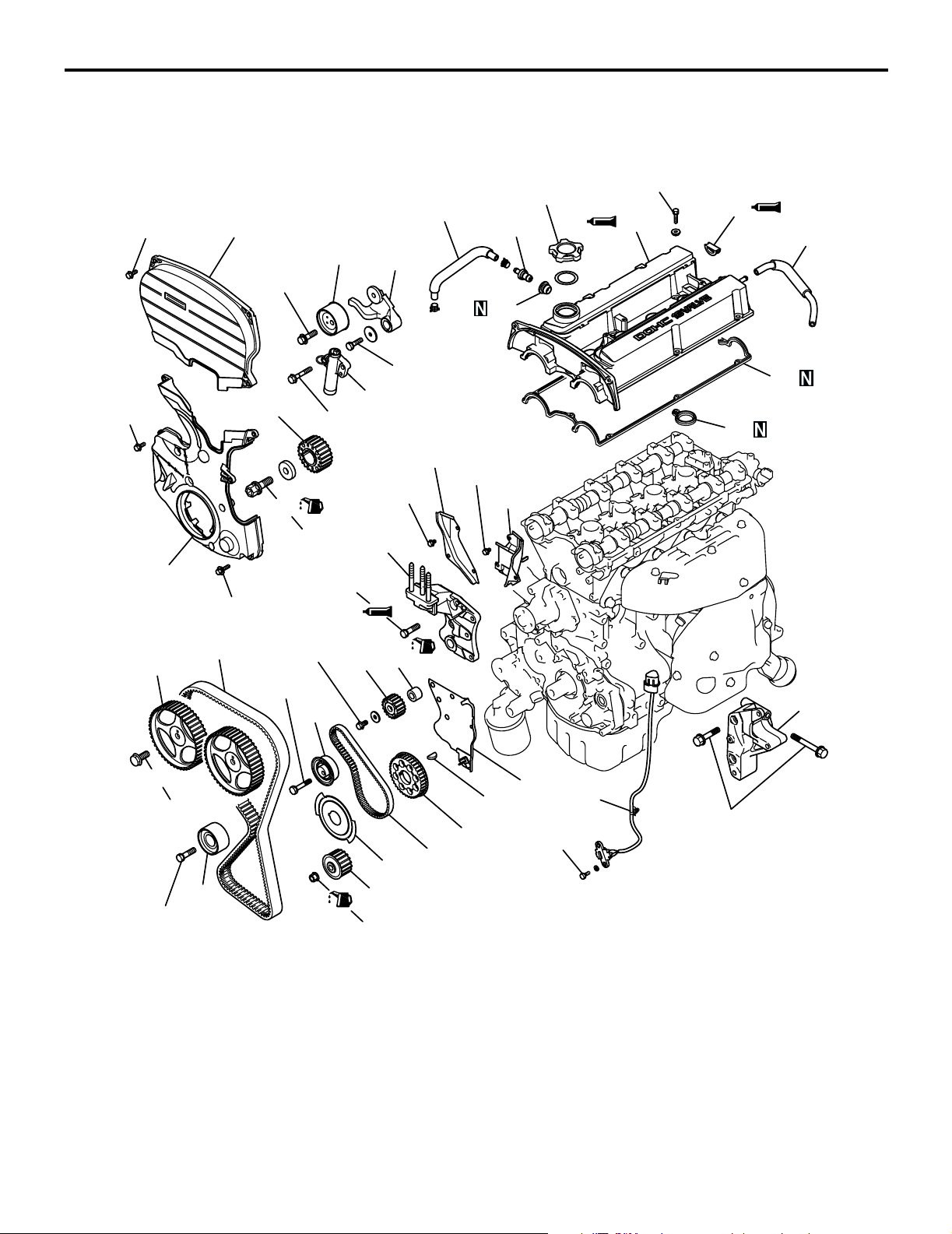

11D-16

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

TIMING BELT

REMOVAL AND INSTALLATION

11 ± 1 N·m

11 ± 1 N·m

2

1

48 ± 5 N·m

12

11

9.0 ± 1.0 N·m

5

23 ± 3 N·m

167 N·m

49 ± 5 N·m

M1113001900867

6

21 ± 4 N·m

7

11 ± 1 N·m

29

21

32

11 ± 1 N·m

23

33

22

24

3.5 ± 0.5 N·m

28

25

20

26

27

31

30

88 ± 10 N·m

35 ± 6 N·m

<<A>> >>M<<

>>L<<

>>K<<

<<B>> >>J<<

<<C>> >>I<<

4

45 ± 3 N·m

19 ± 3 N·m

16

17

14

13

8

Removal steps

1. Timing belt front upper cover

2. Timing belt front lower cover

3. Power steering pump bracket

4. Timing belt

5. Tensioner pulley

6. Tensioner arm

7. Auto-tensioner

8. Idler pulley

9. Crankshaft angle sensor

10. Oil pump sprocket

11. Crankshaft bolt

10

54 ± 5 N·m

15

34

19

18

8.8 ± 1.0 N·m

<<D>> >>I<<

<<E>> >>H<<

<<F>> >>G<<

<<G>> >>E<<

>>I<<

>>F<<

9

49 ± 9 N·m

AK305989

Removal steps (Continued)

12. Crankshaft sprocket

13. Crankshaft sensing blade

14. Tensioner "B"

15. Timing belt "B"

16. Counterbalancer shaft sprocket

17. Spacer

18. Crankshaft sprocket "B"

19. Crankshaft key

20. Breather hose

21. PCV hose

22. PCV valve

3

AB

Page 17

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

11D-17

Removal steps (Continued)

23. PCV valve gasket

24. Oil filler cap

>>D<<

>>D<<

>>C<<

>>B<<

<<H>> >>A<<

25. Rocker cover

26. Rocker cover gasket "A"

27. Rocker cover gasket "B"

28. Semicircular packing

29. Engine support bracket

30. Camshaft sprocket bolt

31. Camshaft sprocket

32. Timing belt rear cover, right

33. Timing belt rear upper cover, left

34 Timing belt rear lower cover, left

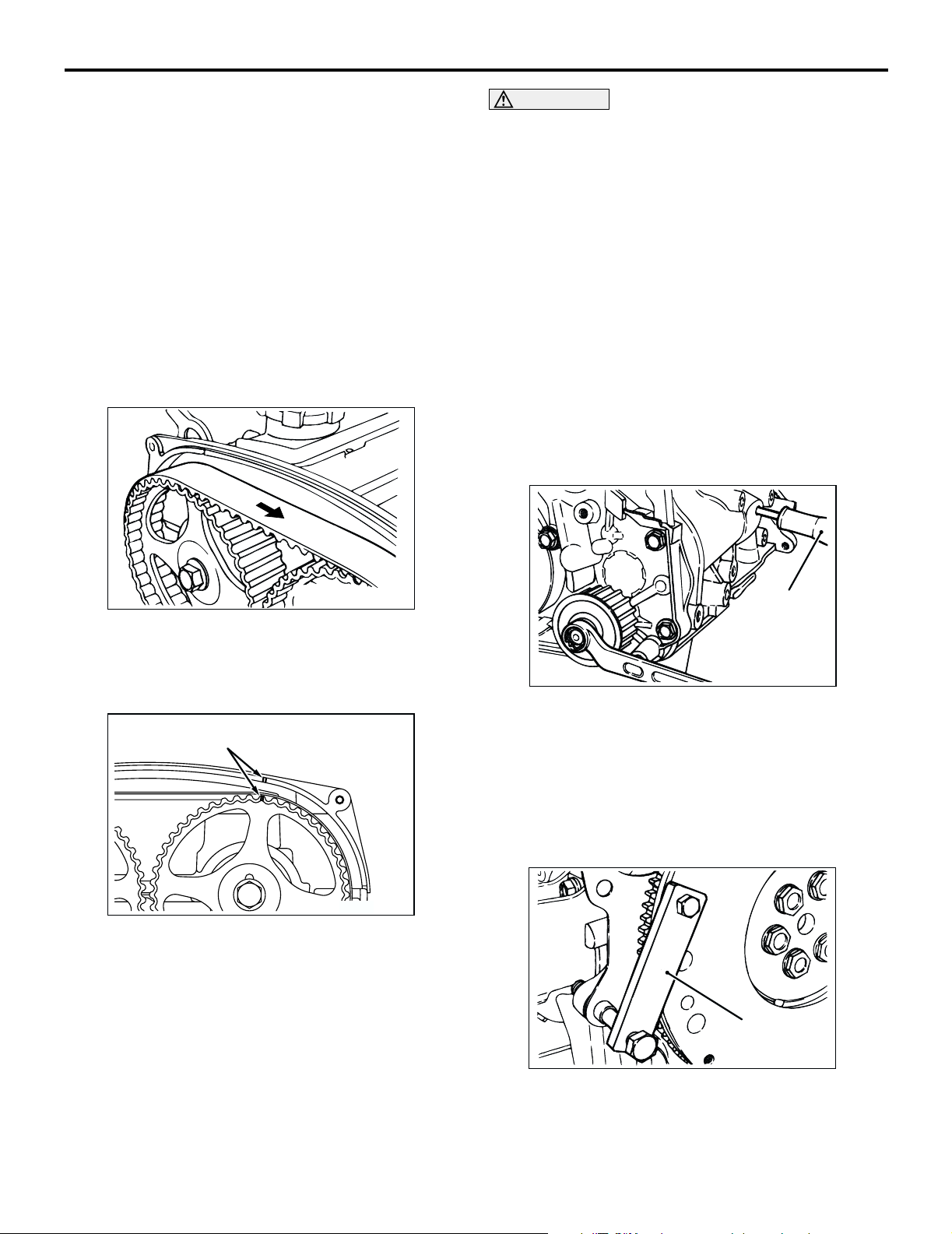

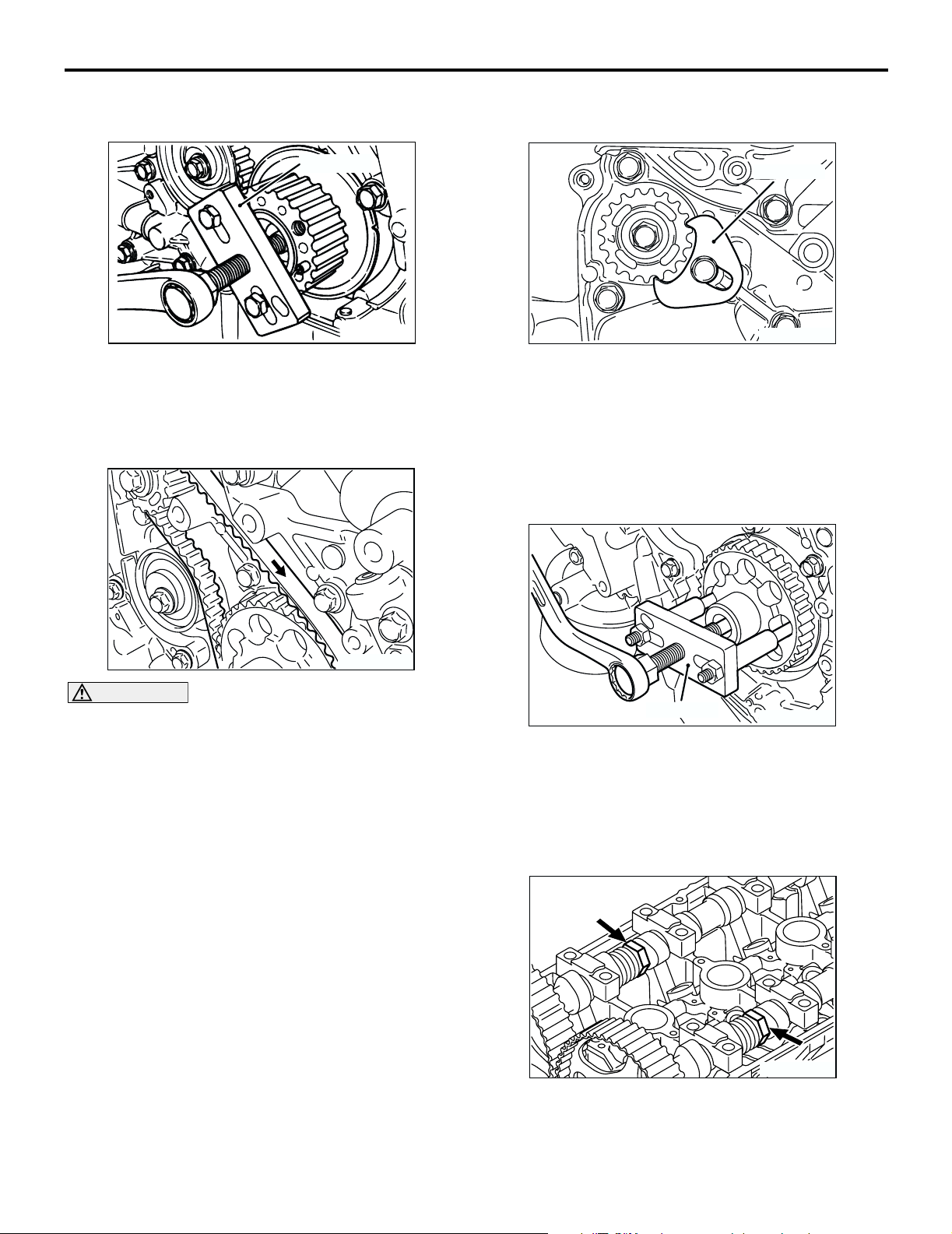

REMOVAL SERVICE POINTS

<<A>> TIMING BELT REMOVAL

CAUTION

Never remove the timing belt with any piston at

the top dead center (TDC). If a piston is at TDC,

the exhaust valves of the cylinder are pushed by

the exhaust cams, compressing the valve

springs. If the belt is removed under this condition, the sprocket will be turned in the reverse

direction by the force of the springs, incurring

risk of injury.

2. Set the timing mark of the exhaust camshaft

sprocket to a point about one tooth before the

TDC of the No.1 cylinder piston on compression

stroke.

3. Loosen the lock nut of the tensioner pulley, then

remove the timing belt.

<<B>> OIL PUMP SPROCKET REMOVAL

1. Remove the plug on the left side of cylinder block.

AK202756AB

1. If the timing belt is to be reused, make an arrow

mark with something like chalk on the back of the

belt indicating the direction of rotation so it may be

reinstalled in the same direction.

Timing marks

AK304440

AB

Crosspoint

screwdriver

AK202825

AD

2. Insert a crosspoint screwdriver (shank diameter 8

mm) to prevent the counterbalancer shaft from

rotating.

3. Remove the flange bolt.

4. Remove the oil pump sprocket.

<<C>> CRANKSHAFT BOLT REMOVAL

MD998781

AK202738

AC

1. Hold the drive plate with the special tool Fly wheel

stopper (MD998781).

2. Remove the crankshaft bolt.

Page 18

11D-18

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

<<D>> CRANKSHAFT SPROCKET

REMOVAL

MD998778

AK304176

AB

Use the special tool Crankshaft sprocket puller

(MD998778) if the sprocket is stuck and hard to

remove.

<<E>> TIMING BELT "B" REMOVAL

<<F>> COUNTERBALANCER SHAFT

SPROCKET REMOVAL

MD998785

AK300138

AD

1. Use the special tool Sprocket stopper

(MD998785) to prevent the counterbalancer shaft

sprocket from rotating.

2. Remove the counterbalancer shaft mounting bolt.

<<G>> CRANKSHAFT SPROCKET "B"

REMOVAL

AK300137

CAUTION

Water or oil on the belt shortens its life drastically, so the removed timing belt, sprocket, and

tensioner must be free from oil and water. These

parts should not be washed or immersed in solvent. Replace parts if contaminated. If there is oil

or water on each part, check the front case oil

seals, camshaft oil seal and water pump for

leaks.

1. Mark the belt running direction for reinstallation.

2. Loosen the tensioner "B" bolt, and then remove

the timing belt "B."

MD998778

AK300139

AD

Use the special tool Crankshaft sprocket puller

(MD998778) if the sprocket is stuck and hard to

remove.

<<H>> CAMSHAFT SPROCKET BOLT

REMOVAL

AK305990AC

Remove the camshaft sprocket bolt while preventing

the camshaft from rotation using a wrench fitted on

the hexagonal portion of the camshaft.

Page 19

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

11D-19

INSTALLATION SERVICE POINTS

>>A<< CAMSHAFT SPROCKET BOLT

INSTALLATION

AK305990AC

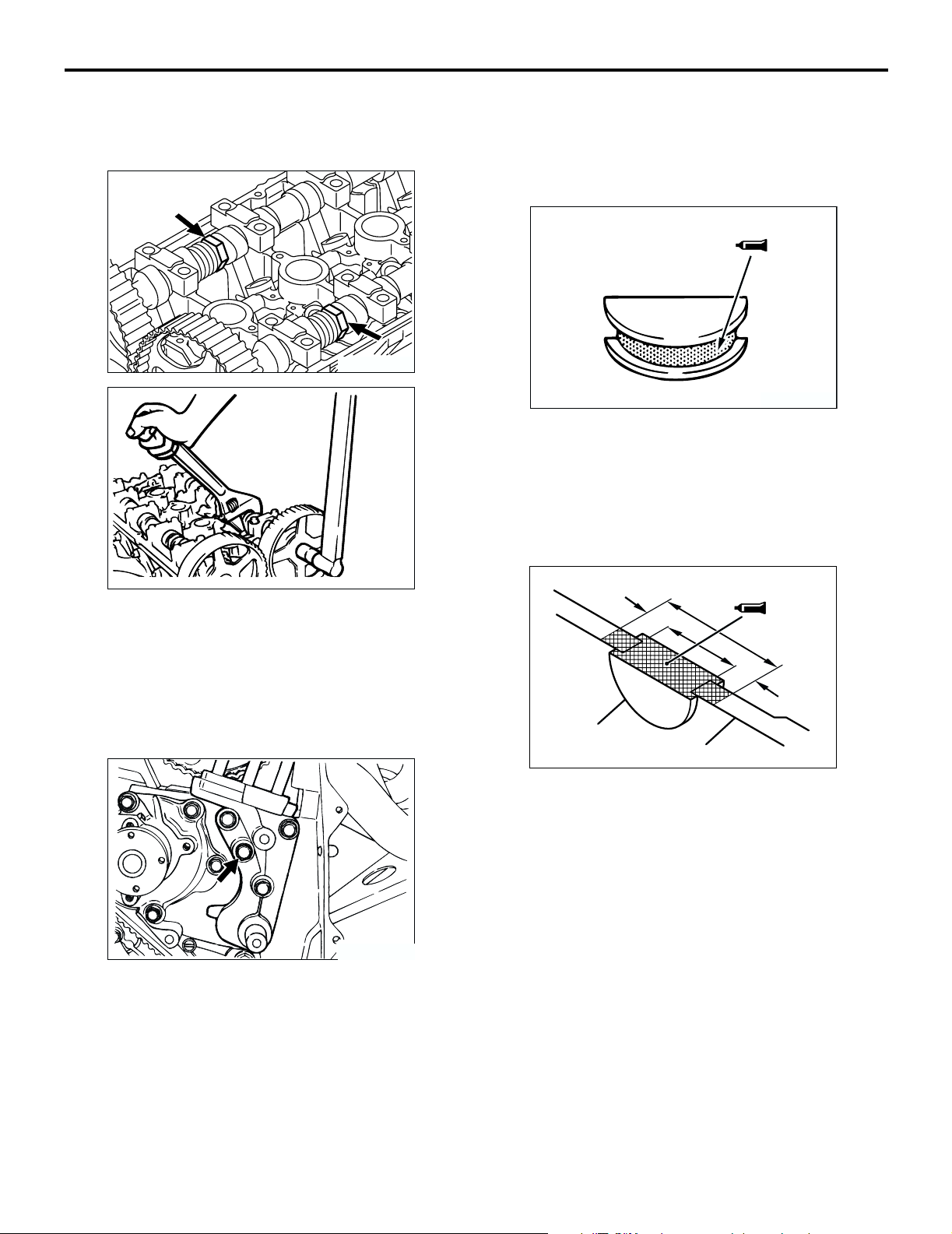

>>C<< SEMICIRCULAR PACKING

INSTALLATION

1. Remove thoroughly the old sealant and FIPG

remaining on the semicircular packing, cylinder

head, and rocker cover.

AK202860AB

2. Apply sealant to the surface indicated in the

drawing of the semicircular packing.

Specified sealant:

3M ATD No.8660 or equivalent

3. Install the semicircular packing on the cylinder

head.

AK304435

Tighten the camshaft sprocket bolt to 88 ± 10 N⋅m

while preventing the camshaft from rotation using a

wrench fitted on the hexagonal portion of the camshaft.

>>B<< ENGINE SUPPORT BRACKET

INSTALLATION

AK202743AB

1. Remove thoroughly the old sealant remaining on

the indicated bolt and in its hole.

2. Coat the bolt with sealant, then install and tighten

it.

Specified sealant:

Mitsubishi Genuine Part No.MD970389 or

equivalent

10 mm

10 mm

Semicircular

packing

Cylinder head

AK304411

AB

4. Apply sealant to the area indicated in the drawing

of the semicircular packing and cylinder head.

Specified sealant:

3M ATD No.8660 or equivalent

Page 20

11D-20

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

>>D<< ROCKER COVER/ROCKER

COVER GASKET "A" INSTALLATION

Timing belt side

AK304203

1. Apply beads of FIPG on the surfaces of the rocker

cover indicated in the drawing.

Specified sealant:

Mitsubishi Genuine Part No.MD970389 or

equivalent

2. Install the rocker cover gasket "A" on the rocker

cover before the FIPG hardens.

Timing belt side

AB

>>E<< CRANKSHAFT SPROCKET "B"

INSTALLATION

Sprocket "B"

Degrease

Front case

Clean and then degrease the crankshaft sprocket "B"

and the sprocket fitting surface of the crankshaft.

NOTE: Degreasing is necessary to prevent lack of

frictional coefficient between the mating surfaces.

Crankshaft

AK301828

AD

>>F<< SPACER INSTALLATION

Counter

Oil seal

Spacer

balance

shaft

AK304204

AB

3. Apply beads of FIPG to the surfaces of the rocker

cover indicated in the drawing.

Specified sealant:

Mitsubishi Genuine Part No.MD970389 or

equivalent

4. Install the rocker cover on the cylinder head

before the FIPG hardens.

Chamfered

AK301298

AD

CAUTION

If the spacer is opposite in direction to that

shown in the drawing when installed, it will damage the oil seal lip.

1. Smear slightly oil on the outer surface of the

spacer that comes into contact with the oil seal.

2. Install the spacer with the chamfered end toward

the oil seal.

Page 21

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

11D-21

>>G<< COUNTERBALANCER SHAFT

SPROCKET INSTALLATION

MD998785

AK300138

AD

1. Use the special tool Sprocket stopper

(MD998785) as shown in the drawing to prevent

the counterbalancer shaft sprocket from rotating.

2. Tighten the sprocket mounting bolt to 45 ± 3 N⋅m.

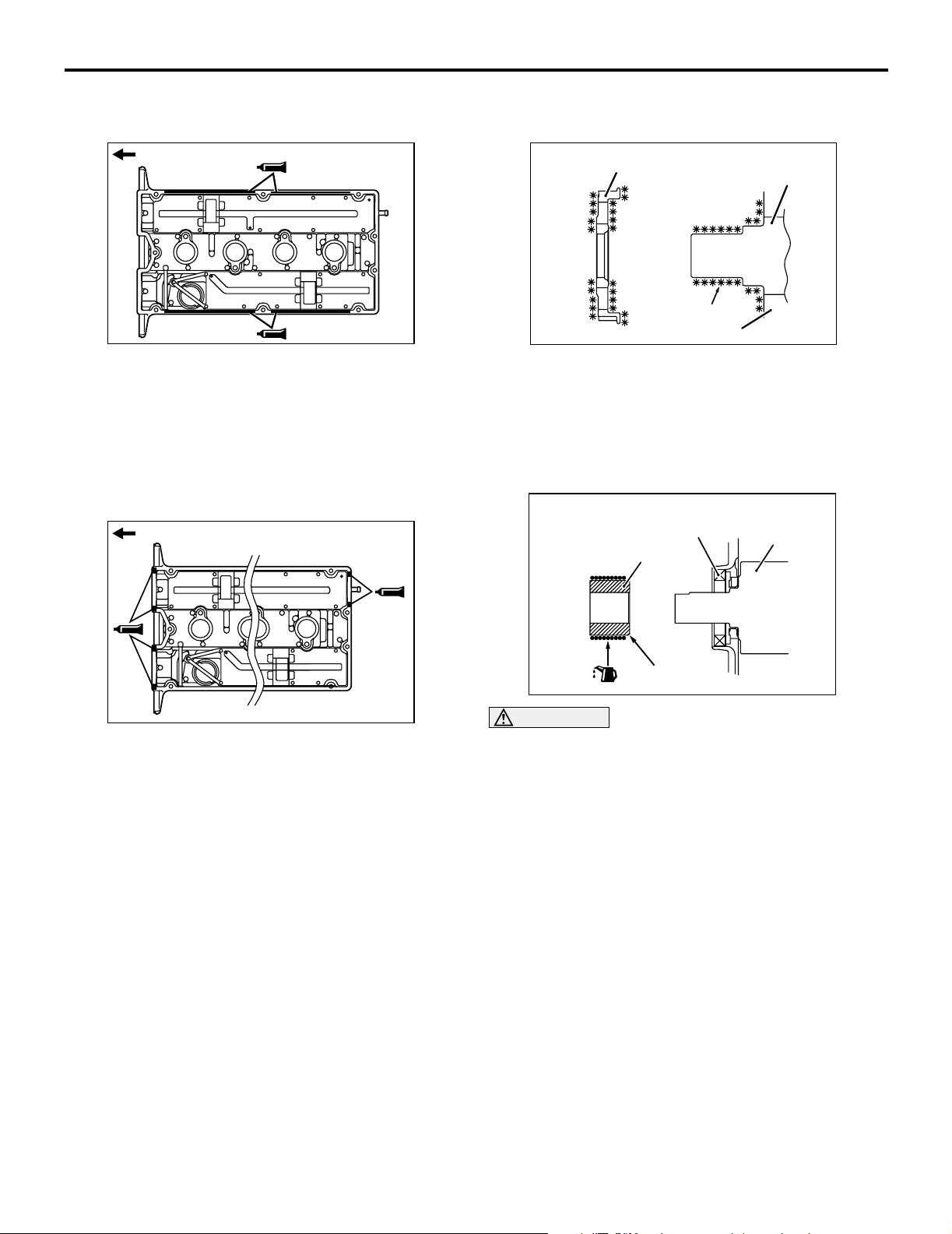

>>H<< TIMING BELT "B" INSTALLATION

Tensioner "B"

Tensioner "B"

centre

Tension section of belt

Mounting bolt centre

Timing

belt "B"

AK305992

AC

3. Make sure that the tensioner "B" center is

positioned as shown in the drawing relative to the

mounting bolt center.

Timing

marks

Timing

marks

AK305991

AC

1. Align the timing marks on the crankshaft sprocket

"B" and counterbalancer shaft sprocket with the

corresponding timing marks on the oil pump case.

2. Install the timing belt "B" on the crankshaft

sprocket "B" and counterbalancer shaft sprocket.

There should be no slack in the tension section of

the belt.

AK304436

AB

4. Lift the tensioner "B" with fingers to move it in the

direction of the arrow until the tension section of

the timing belt becomes taut. While keeping the

tensioner "B" in this position, tighten its bolt.

NOTE: When the bolt is tightened, prevent the

tensioner "B" shaft from turning. If the shaft turns,

the belt will be overtightened.

5. Make sure that the timing marks on the oil pump

case and those of the sprockets are all aligned

with each other.

5 – 7 mm

AK305993

AC

6. Push a central point of the timing belt "B" tension

section lightly with an index to see if it deflects 5 −

7 mm.

Page 22

11D-22

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

>>I<< CRANKSHAFT

BOLT/CRANKSHAFT

SPROCKET/CRANKSHAFT SENSING

BLADE INSTALLATION

Crankshaft

bolt

Big chamfered side

Sprocket

Washer

1. Clean and then degrease the crankshaft sprocket,

sprocket fitting surface of the crankshaft, and

crankshaft sensing blade. Install the crankshaft

sprocket and crankshaft sensing blade on the

crankshaft.

2. Clean the bolt hole in the crankshaft, and then

washer.

3. Apply a necessary minimum amount of oil to the

threads and seating surface of the crankshaft bolt.

Sensing blade

Clean

Degrease

Crankshaft

AK301075

AD

>>J<< OIL PUMP SPROCKET

INSTALLATION

AK300172

1. Prevent the counterbalancer shaft from rotating in

the same method as in the removal procedure.

2. Install the oil pump sprocket.

3. Apply a thin coat of engine oil to the seating

surface of the nut.

4. Tighten the flange nut to 54 ± 5 N⋅m.

>>K<< AUTO-TENSIONER INSTALLATION

A

B

MD998781

AK202738

AC

4. Hold the drive plate using the special tool Fly

wheel stopper (MD998781).

5. Tighten the crankshaft bolt to a torque of 167 N⋅m.

AK301074

AD

1. If the auto-tensioner rod remains in its fully

extended position, reset it to the retracted position

as follows:

(1) Clamp the auto-tensioner in a vise at right

angles to the jaws.

(2) Push in the rod little by little with the vise until

the set hole A in the rod is aligned with the set

hole "B" in the cylinder.

(3) Insert a piece of wire (1.4 mm diameter) into

the set holes.

(4) Remove the auto-tensioner from the vise.

Page 23

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

AK300154

2. Install the auto-tensioner in position. Leave the

wire installed until the auto-tensioner is

completely installed.

11D-23

NOTE: If the timing marks were aligned, the

exhaust camshaft would be turned

counterclockwise by one sprocket tooth and stay

there by the force of the valve springs.

Timing marks

AK304441

AB

>>L<< TENSIONER PULLEY

INSTALLATION

Tensioner

pulley hole

AK300147

AE

Install the tensioner pulley with its holes aligned as

shown in the drawing.

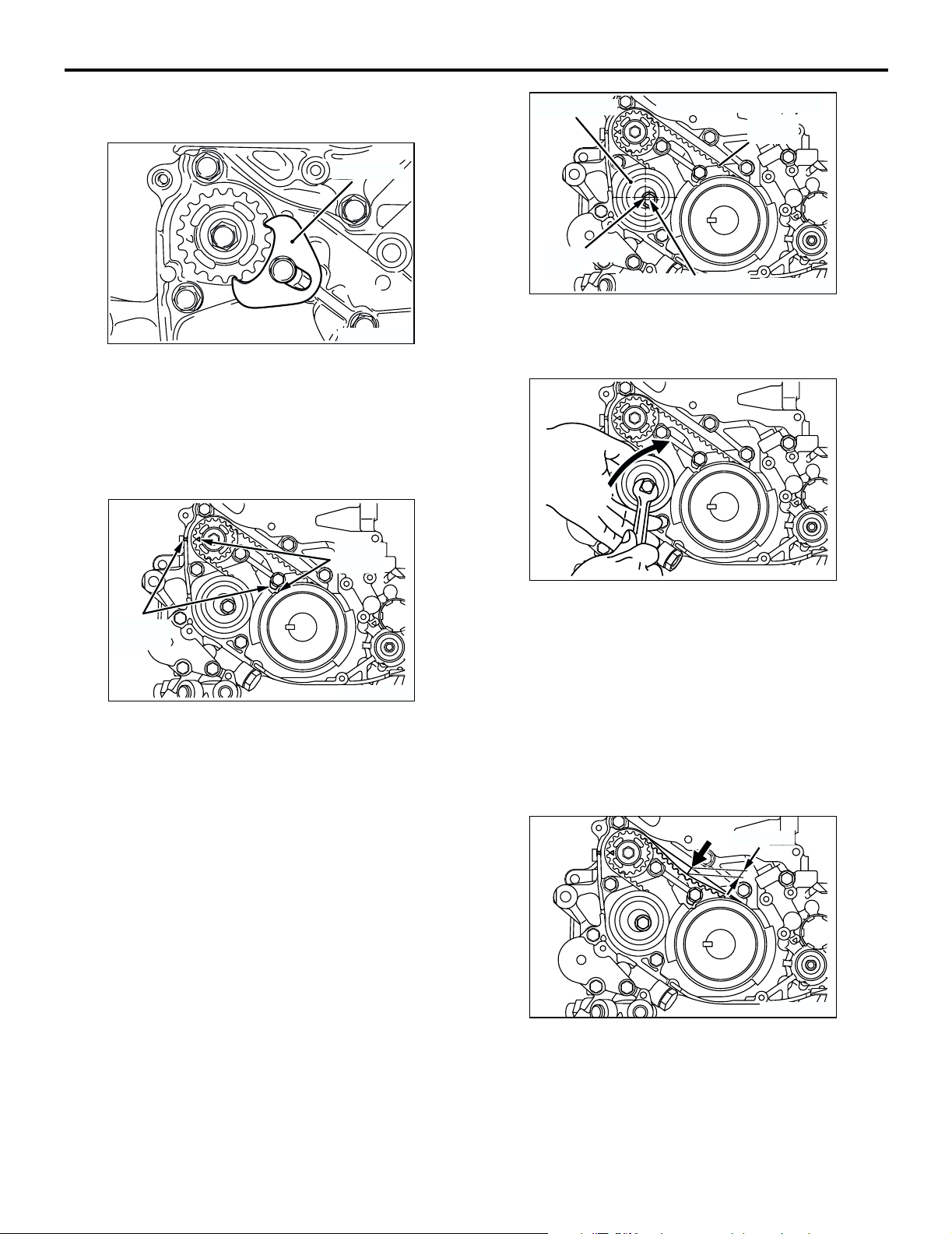

>>M<< TIMING BELT INSTALLATION

Timing marks

2. Align the timing mark on the intake camshaft

sprocket with that on the rocker cover.

NOTE: The intake camshaft will be turned slightly

clockwise from where the timing marks are

aligned by the force of the valve springs and stay

there.

Timing marks

AK304563

AB

3. Bring the timing mark on the crankshaft sprocket

to a point one sprocket tooth away from the

mating timing mark in the counterclockwise

direction like in the operation with the exhaust

camshaft sprocket.

AK304440

AB

1. Bring the timing mark on the exhaust camshaft

sprocket to a point one sprocket tooth away from

the timing mark on the rocker cover in the

counterclockwise direction.

60 mm or more

Counter

balance

shaft

AK301077

AD

4. Align the timing mark on the oil pump sprocket

with that on the cylinder block.

(1) Remove the plug from the cylinder block.

Page 24

11D-24

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

(2) Insert a crosspoint screwdriver with a shank

diameter of 8 mm through the plug hole. If it

can be inserted 60 mm or more, the sprocket

is in the correct phase. If the insertion depth is

up to 20 − 25 mm, the screwdriver is blocked

by the counterbalancer shaft. Then turn the oil

pump sprocket one turn and realign the timing

marks. Then check that the screwdriver can

be inserted 60 mm or more. Keep the

screwdriver inserted until installation of timing

belt is finished.

Timing marks

AK202761

AD

(3) Turn the oil pump sprocket counterclockwise

by one sprocket tooth.

6. Turn the intake camshaft sprocket

counterclockwise to bring the timing mark on it

one sprocket tooth away from the mating timing

mark in the counterclockwise direction. Then

install the timing belt on the sprocket and hold it in

place with a paper clip.

NOTE: The timing marks will be aligned when the

belt is installed since the intake camshaft is turned

slightly clockwise by the force of the valve

springs.

Timing marks

AK305994

AC

7. Turn the exhaust camshaft sprocket clockwise to

align the timing marks, and make sure that the

intake camshaft sprocket timing marks are also

aligned.

AK202771

5. Install the timing belt on the exhaust camshaft

sprocket, and hold it in place with a paper clip at

the point indicated in the drawing.

AK202772

Crankshaft

sprocket

Oil pump

sprocket

AK202762AE

8. Install the timing belt on the idler pulley, oil pump

sprocket, and crankshaft sprocket, in this order.

NOTE: There should be no slack in the installed

portion of the belt.

Camshaft

sprocket

Tensioner

pulley

AK202773

AD

9. Install the timing belt on the tensioner pulley.

Page 25

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

NOTE: Turning slightly the intake camshaft

sprocket counterclockwise will facilitate installation of the belt on the tensioner pulley.

Crankshaft

sprocket

11D-25

MD998738

AK202763AB

10.Turn slightly the crankshaft sprocket clockwise to

take up the slack in the idler pulley portion of the

timing belt.

11.Check that each of the timing marks on the

crankshaft, oil pump, and exhaust camshaft

sprockets is one sprocket tooth away from its

mating timing mark in the counterclockwise

direction.

MD998767

AK202764

AD

12.Turn the tensioner pulley counterclockwise using

the special tool Tension pulley socket wrench

(MD998767) to give tension to the belt and hold

the tensioner in position by temporarily tightening

the tensioner lock bolt.

NOTE: Take up the slack in the belt portion

between the intake and exhaust camshaft sprockets.

13.Turn the crankshaft clockwise to make the timing

mark align with the No.1 cylinder top dead center

mark.

AK202774

AD

14.Install the special tool Set screw (MD998738) and

turn down the tool until the wire (inserted in the

auto-tensioner when it was installed) can be

moved freely.

15.Loosen the tensioner pulley lock bolt.

MD998767

AK202775

AD

CAUTION

Prevent the timing belt from slipping as it

becomes loose following rotation of the intake

and exhaust camshafts.

16.Turn the torque wrench attached to the special

tool Tension pulley socket wrench (MD998767)

counterclockwise until the slack in the timing belt

is taken up.

17.Turn the torque wrench clockwise from the

position of step 16 until the torque wrench reading

becomes 3.5 N⋅m, then tighten the tensioner

pulley lock bolt.

18.Remove the special tool Set screw (MD998738)

that was installed in step 14.

19.Turn the crankshaft clockwise two turns, then let it

alone for approx. 15 minutes.

Page 26

11D-26

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

Extension

amount

AK202829

AB

20.Check that the wire (inserted in the auto-tensioner

when it was installed) can be moved freely. If the

wire can be pulled freely, the belt tensioner is

adjusted properly. Remove the wire. At that time,

check that the auto-tensioner rod extends by the

specified amount.

Standard value: 3.8 − 4.5 mm

CAUTION

Be sure to check the tightening torque of the

crankshaft bolt anytime the crankshaft has been

turned counterclockwise. If the torque lower than

specification, tighten the bolt to the specified

torque.

21.If the wire cannot be pulled out freely, perform the

steps 14 through 18 again to make the belt

tension proper.

INSPECTION

M1113002000685

TIMING BELT

Check closely the entire timing belt.

Replace it if any of the following conditions is found.

Cracks

Peeling of canvas

Cracks in tooth roots

Cracks in sides

AK202793

2. Cracks in back rubber surface.

3. Cracks in canvas.

4. Cracks in tooth roots.

5. Cracks in belt sides.

Rounded edge

Abnormal wear

(Fluffy strand)

AK202795

6. Abnormally worn belt sides;

NOTE: belt sides are normal if they have

“knife-cut” surfaces.

Canvas lost and

rubber exposed

Cracks

AB

AB

AK202794

1. Hardened back side rubber.

Back side surface is glossy, lacking in elasticity,

and so hard that no impression is left when

pressed with fingernail.

Missing

Tooth

AK202796

AB

7. Badly worn teeth.

Initial stage: Canvas is worn (canvas fiber is fluffy;

teeth look whitish due to worn-out rubber; canvas

texture is unclear)

Second stage: Canvas is lost and rubber is exposed

(tooth width narrows down)

8. Missing tooth.

Page 27

ENGINE OVERHAUL <4G63-Turbo>

TIMING BELT

11D-27

AUTO-TENSIONER

12 mm

AK301307

1. Check the auto-tensioner for leaks from the

sealed sections.

Replace it if leaky.

2. Check the rod end for wear and other damage.

Replace the auto-tensioner if the rod is badly

worn or damaged.

AD

3. Measure the extension length of the rod.

If it is not within the standard value range, replace

the auto-tensioner.

Standard value: 12 mm

98 to 196 N

Movement

AK301308

AE

4. Press the rod with a force of 98 to 196 N and

measure the amount of retraction. If the

measurement exceeds the standard value,

replace the auto-tensioner.

Standard value: 1 mm maximum

Page 28

11D-28

ENGINE OVERHAUL <4G63-Turbo>

FUEL AND EMISSION PARTS

FUEL AND EMISSION PARTS

REMOVAL AND INSTALLATION

9.0 ± 2.0 N·m

11 ± 1 N·m

3

8

5

6

M1113002200708

4

11

9

10

7

19 ± 3 N·m

1

2

>>C<<

>>B<<

Removal steps

1. Throttle body

2. Throttle body gasket

3. Fuel pressure regulator

4. O-ring

5. Injector and delivery pipe

6. Insulator

>>A<<

AK400297

Removal steps (Continued)

7. O-ring

8. Injector

9. O-ring

10. Grommet

11. Delivery pipe

AB

Page 29

ENGINE OVERHAUL <4G63-Turbo>

FUEL AND EMISSION PARTS

11D-29

INSTALLATION SERVICE POINTS

>>A<< INJECTOR INSTALLATION

1. Apply a thin coat of engine oil to a new O-ring.

CAUTION

Prevent engine oil from getting into the delivery

pipe.

2. Insert the injector into the delivery pipe while

turning it in both directions carefully not to

damage the O-ring.

3. Check that the injector turns smoothly. If it does

not, the O-ring may be jamming, so remove the

injector and check the O-ring for damage. If the

O-ring is intact, insert the injector into the delivery

pipe and check it for smooth rotation again.

>>B<< FUEL PRESSURE REGULATOR

INSTALLATION

1. Apply a thin coat of engine oil to a new O-ring.

CAUTION

Prevent engine oil from getting into the delivery

pipe.

3. Check that the fuel pressure regulator turns

smoothly. If it does not, the O-ring may be

jamming, so remove the fuel pressure regulator

and check the O-ring for damage. If the O-ring is

intact, insert it into the delivery pipe and check it

for smooth rotation again.

>>C<< THROTTLE BODY GASKET

INSTALLATION

Ta b

AK305995

Install the throttle body gasket with its tab located as

shown in the drawing.

AC

2. Insert the fuel pressure regulator into the delivery

pipe while turning it in both directions carefully not

to damage the O-ring.

Page 30

11D-30

ENGINE OVERHAUL <4G63-Turbo>

INLET MANIFOLD

INLET MANIFOLD

REMOVAL AND INSTALLATION

36 ± 6 N·m

20 ± 2 N·m

2

5

M1113026100062

36 ± 6 N·m

3

4

23 ± 2 N·m

>>A<<

31 ± 3 N·m

Removal steps

1. Inlet manifold stay

2. Alternator brace stay

3. Inlet manifold

4. Inlet manifold gasket

5. Detonatoin sensor

1

INSTALLATION SERVICE POINTS

>>A<< INLET MANIFOLD STAY

INSTALLATION

Intake manifold

stay

AK400302

AK400845

AB

AB

Tighten the bolts to the specified torque 31 ± 3 N⋅m

on both ends after making sure that the stay is in

close contact with the bosses on the inlet manifold

and cylinder block.

Page 31

ENGINE OVERHAUL <4G63-Turbo>

EXHAUST MANIFOLD

EXHAUST MANIFOLD

11D-31

REMOVAL AND INSTALLATION

19 ± 3 N·m

1

55 ± 10 N·m

M1113004900725

12

21

20

23 ± 3 N·m

59 ± 5 N·m

33 ± 6 N·m

11 ± 1 N·m

14

15

17 ± 2 N·m

17 ± 2 N·m

19 ± 1 N·m

16

7

8

59 ± 5 N·m

44 ± 5 N·m

>>C<<

>>B<<

28 ± 5 N·m

10 ± 1 N·m

5

6

2

4

36 ± 5 N·m

11

Removal steps

1. Engine hanger

2. Oxygen sensor

3. Turbocharge heat protector

4. Exhaust fitting bracket

5. Exhaust fitting

6. Exhaust fitting gasket

7. Air outlet fitting

8. Air outlet fitting gasket

9. Oil return pipe

10. Oil return pipe gasket

11. Oil return pipe gasket

17

10 ± 1 N·m

18

28 ± 5 N·m

13

19

23 ± 3 N·m

10

9

23 ± 3 N·m

14 ± 1 N·m

>>A<<

3

AK400396

Removal steps (Continued)

12. Exhaust manifold heat protector

13. Turbocharge assembly and pipe

assembly

14. Turbocharge gasket

15. Ring

16. Oil pipe

17. Water pipe "B"

18. Water pipe "A"

19. Turbocharge assembly

20. Exhaust manifold

21. Exhaust manifold gasket

AC

Page 32

11D-32

ENGINE OVERHAUL <4G63-Turbo>

EXHAUST MANIFOLD

INSTALLATION SERVICE POINT

>>A<< EXHAUST MANIFOLD

INSTALLATION

1. Hand tighten all the exhaust manifold mounting

nuts.

2. Tighten the M8 nuts to 29 ± 3 N⋅m in the indicated

sequence.

3. Tighten the M10 nuts to 49 ± 5 N⋅m in the

indicated sequence.

4. Tighten the M8 nuts again to 29 ± 3 N⋅m in the

indicated sequence.

543

1

7

98

5. Finally tighten the M10 nuts and the M8 nuts to

the specified torque, both in the indicated

sequence.

Tightening torque:

33 ± 6 N⋅m <M8>

55 ± 10 N⋅m <M10>

6

AK305997

2

AC

>>B<< OIL RETURN PIPE GASKET

INSTALLATION

Ta b

AK305998

AC

Install the oil return pipe gasket with its tab located

as shown in the drawing.

NOTE: The gasket on the turbocharger end of the

pipe does not require special alignment for

installation.

>>C<< OUTLET FITTING GASKET

INSTALLATION

Ta b

AK400303

AB

Install the air outlet fitting gasket with its tab located

as shown in the drawing.

Page 33

ENGINE OVERHAUL <4G63-Turbo>

WATER PUMP AND WATER HOSE

WATER PUMP AND WATER HOSE

11D-33

REMOVAL AND INSTALLATION

13 ± 2 N·m

13

12

M1113017900372

4

11

13 ± 2 N·m

9

13 ± 2 N·m

8

1

23 ± 4 N·m

7

2

6

10

10.8 ± 1.0 N·m

5

3

29 ± 10 N·m

14 ± 1 N·m

>>E<<

>>D<<

>>C<<

>>B<<

>>A<<

>>A<<

>>A<<

15

14

Removal sequence

1. Water hose

2. Water hose

3. Water hose

4. Water hose

5. Engine coolant temperature sensor

6. Engine coolant temperature gauge

unit

7. Water inlet fitting

8. Thermostat

9. Water outlet fitting

10. Thermostat housing

11. O-ring

12. Water inlet pipe

13. O-ring

14. Water pump

15. Water pump gasket

AK304981

AC

INSTALLATION SERVICE POINTS

>>A<< O-RING/WATER INLET PIPE

INSTALLATION

CAUTION

• Never allow any oil or grease to touch the

O-rings.

• Clamp the water inlet pipe only after

installation of the thermostat case.

Replace the O-rings at both ends of the water inlet

pipe with new ones. Insert the O-rings into the water

pump and thermostat housing after wetting their

peripheries with water.

Page 34

11D-34

ENGINE OVERHAUL <4G63-Turbo>

WATER PUMP AND WATER HOSE

>>B<< THERMOSTAT HOUSING

INSTALLATION

AK305999

1. Remove all old FIPG remaining on the thermostat

housing and cylinder head.

2. Apply a 2.7 ± 0.3 mm diameter bead of FIPG on

the indicated surface of the thermostat housing.

Specified sealant:

Mitsubishi Genuine Part No.MD970389 or

equivalent

AC

>>C<< WATER OUTLET FITTING

INSTALLATION

>>D<< ENGINE COOLANT

TEMPERATURE GAUGE UNIT

INSTALLATION

AK300711

1. Remove all old sealant remaining on the threaded

hole in the engine coolant temperature gauge unit

and the thermostat housing.

NOTE: A new engine coolant temperature gauge

unit is coated with sealant. It does not require

coating with sealant before installation.

2. Apply sealant to the indicated threads of the

engine coolant temperature gauge unit.

Specified sealant:

3M Nut Locking Part No.4171 or equivalent

AB

AK202755AB

1. Remove all old FIPG remaining on the water

outlet fitting and thermostat housing.

2. Apply a 2.7 ± 0.3 mm diameter bead of FIPG to

the indicated surface of the water outlet fitting.

Specified sealant:

Mitsubishi Genuine Part No.MD970389 or

equivalent

>>E<< ENGINE COOLANT

TEMPERATURE SENSOR INSTALLATION

AK300712

CAUTION

When using a tool, avoid letting it touch the

connector portion which is made of plastic.

1. Remove all old sealant remaining on the threads

of the engine coolant temperature sensor and in

the threaded hole in the thermostat housing.

2. Apply sealant to the engine coolant temperature

sensor's threads indicated in the drawing.

Specified sealant:

3M ATD Part No.8660 or equivalent

AB

Page 35

ENGINE OVERHAUL <4G63-Turbo>

ROCKER ARMS AND CAMSHAFT

ROCKER ARMS AND CAMSHAFT

11D-35

REMOVAL AND INSTALLATION

14

13

20 ± 1 N·m

10

15

7

16

12

17

M1113005400853

8

11

9

6

11 ± 1 N·m

18

3

4

22 ± 4 N·m

5

10 ± 2 N·m

14 ± 1 N·m

2

1

10.8 ± 1.0 N·m

>>F<<

>>E<<

>>D<<

>>C<<

>>C<<

>>C<<

>>C<<

>>C<<

>>C<<

>>C<<

>>B<<

Removal steps

1. Camshaft position sensor

2. O-ring

3. Cover

4. Gasket

5. Camshaft position sensing cylinder

6. Camshaft position sensor support

7. Camshaft oil seal

8. Bearing cap, rear right

9. Bearing cap, rear left

10. Bearing cap, front

11. Bearing cap No.5

12. Bearing cap No.2

13. Bearing cap No.3

14. Bearing cap No.4

15. Camshaft

Apply engine oil to

all moving parts

before installation.

AC

<<A>> >>A<<

AK306000

Removal steps (Continued)

16. Rocker arm

17. Lash adjuster

18. Oil delivery body

SERVICE POINTS FOR REMOVAL

<<A>> LASH ADJUSTER REMOVAL

CAUTION

When reusing a lash adjuster, it must be washed

and inspected before installation. (Refer to

P.11D-37, the instruction under LASH ADJUSTER

in the INSPECTION section.)

Page 36

11D-36

ENGINE OVERHAUL <4G63-Turbo>

ROCKER ARMS AND CAMSHAFT

INSTALLATION SERVICE POINTS

>>A<< LASH ADJUSTER INSTALLATION

CAUTION

When reusing a lash adjuster, it must be washed

and inspected before installation. (Refer to

P.11D-37, the instruction under LASH ADJUSTER

in the INSPECTION section.)

Install the lash adjuster into the rocker arm, being

careful not to spill the diesel fuel it contains.

>>B<< CAMSHAFT INSTALLATION

Timing belt side

Slit

Exhaust camshaft

AK202869

AD

CAUTION

• Do not confuse the intake camshaft with the

exhaust camshaft.

• The exhaust camshaft has a 4 mm wide slit at

the rear end.

>>C<< BEARING CAP INSTALLATION

Dowel pin

2. The bearing caps No. 2 to 5 are identical in shape

for both intake and exhaust camshafts. Check the

identification mark on each cap before installation.

Identification mark (stamped on front and

Nos. 2 − 5 bearing caps)

I: intake camshaft

E: exhaust camshaft

3. Remove completely sealant remaining on the

bearing caps and cylinder head.

AK202871AB

4. Apply sealant to the surfaces indicated in the

drawing.

Specified sealant:

3M ATD No.8660 or equivalent

5. Install each bearing cap and tighten its bolts in two

or three passes.

6. Finally tighten the bolts to 20 ± 1 N⋅m.

7. Check that the rocker arms are correctly installed.

NOTE: Wipe off any squeezed out sealant

completely.

AK203979

AC

1. Set each camshaft with its dowel pin at the top.

Cap number

Intake/exhaust

identification

letter

AK202870

AB

>>D<< CAMSHAFT OIL SEAL

INSTALLATION

MD998713

AK304515

Use the special tool Camshaft oil seal installer

(MD998713) to drive each oil seal into position in the

cylinder head.

AB

Page 37

ENGINE OVERHAUL <4G63-Turbo>

ROCKER ARMS AND CAMSHAFT

11D-37

>>E<< CAMSHAFT POSITION SENSOR

SUPPORT INSTALLATION

AK202754AB

1. Remove completely the FIPG remaining on the

camshaft position sensor support and cylinder

head.

2. Apply a 3 ± 1 mm diameter bead of FIPG to the

indicated surface of the camshaft position sensor

support.

Specified sealant:

Mitsubishi Genuine Part No.MD970389 or

equivalent

INSPECTION

M1113005500708

CAMSHAFT

AK202797AB

Measure the cam height (nose-to-heel diameter).

If any cam is worn beyond the limit, replace the camshaft.

Standard value:

Intake: 35.79 mm

Exhaust: 35.49 mm

Limit:

Intake: 35.29 mm

Exhaust: 34.99 mm

>>F<< CAMSHAFT POSITION SENSING

CYLINDER INSTALLATION

Smaller vane

Camshaft

posittion sensor

AK306001

1. Turn the exhaust camshaft to the No.1 cylinder

top dead center position.

NOTE: The camshaft will slightly turn

counterclockwise by the force of the exhaust

valve spring.

2. Install the camshaft position sensing cylinder with

the smaller vane located as shown in the drawing.

AC

LASH ADJUSTERS

CAUTION

• The lash adjuster is a precision-engineered

component. Do not allow dust or other foreign matter to enter it.

• Do not disassemble lash adjusters.

• Use only non-contaminated diesel fuel to

clean the lash adjuster.

For rough

cleaning

ABC

1. Prepare three containers and approximately five

liters of diesel fuel. Pour into each container the

diesel fuel in an amount enough for a lash

adjuster placed in the container in its upright

position to completely submerge.

For finish

cleaning

For diesel

fuel filling

AK202836

AB

Page 38

11D-38

ENGINE OVERHAUL <4G63-Turbo>

ROCKER ARMS AND CAMSHAFT

CAUTION

The hole in the side of the lash adjuster must be

directed toward the inside of container A. Never

direct it against any person.

4. Take the lash adjuster out of the container, then

move the plunger by pushing the steel ball gently

to discharge the diesel fuel from the pressure

Diesel fuel

chamber.

AK300587

AB

2. Place the lash adjuster in container A and wash

its outside surface.

NOTE: Use a nylon brush if there are

hard-to-remove deposits.

Diesel fuel

MD998442

AK202839

AB

CAUTION

The steel ball spring of the lash adjuster is

extremely weak. The lash adjuster's functionality

may be badly affected if the special tool is

inserted too strongly.

Diesel fuel

MD998442

AK202839

AB

CAUTION

The steel ball spring of the lash adjuster is

extremely weak. The lash adjuster's functionality

may be badly affected if the special tool is

inserted too strongly.

5. Soak the lash adjuster in the diesel fuel in

container B. Move the plunger in and out 5 − 10

times by gently pushing the internal steel ball

using the special tool Air bleed wire (MD998442)

until the plunger moves smoothly to wash the lash

adjuster’s pressure chamber.

3. While gently pushing the internal steel ball using

the special tool Air bleed wire (MD998442), move

the plunger in and out 5 − 10 times to eliminate

stiffness in the plunger and expel contaminated

oil.

NOTE: The plunger must be free from jamming

and any other abnormalities. If a defect is found in

plunger operation, replace the lash adjuster.

MD998442

Diesel fuel

AK202840

AC

MD998442

Diesel fuel

AK202840

AC

CAUTION

The hole in the side of the lash adjuster must be

directed toward the inside of container B. Never

direct it against any person.

6. Take the lash adjuster out of the container, then

move the plunger by pushing the steel ball gently

to discharge the diesel fuel from the pressure

chamber.

Page 39

ENGINE OVERHAUL <4G63-Turbo>

ROCKER ARMS AND CAMSHAFT

8. Place the lash adjuster upright with the plunger at

the top. Push the plunger firmly until it makes a

full stroke, then return the plunger slowly and

release the hold of the steel ball to allow the

pressure chamber to be filled with diesel fuel.

11D-39

MD998442

Diesel fuel

AK202841

AB

CAUTION

Do not use container C for cleaning. If cleaning is

performed in container C, foreign matter could

enter the pressure chamber when the chamber is

filled with diesel fuel.

7. Soak the lash adjuster in the diesel fuel in

container C. Gently push the internal steel ball

using the special tool Air bleed wire (MD998442).

MD998442

Diesel fuel

AK202842

AB

AK202843

9. Take the lash adjuster out of the container, place it

upright with the plunger at the top, and push the

plunger firmly. The plunger must not move at all.

NOTE: If the lash adjuster contracts, perform the

operations 7 through 9 again. Replace the lash

adjuster if it still contracts even after the pressure

chamber has completely been filled with diesel

fuel (air has been bled).

10.Keep the serviced lash adjusters in their upright

positions to prevent diesel fuel from spilling out.

Protect them from dust or other foreign matter.

Install the lash adjusters onto the engine as soon

as possible.

Page 40

11D-40

ENGINE OVERHAUL <4G63-Turbo>

CYLINDER HEAD AND VALVES

CYLINDER HEAD AND VALVES

REMOVAL AND INSTALLATION

2

4

5

6

12

13

16

18

M1113006900787

1

20

78 ± 2 N·m → 0 N·m →

20 ± 2 N·m → +90˚ → +90˚

8

9

10

14

15

17

19

11

7

3

Apply engine oil to

all moving parts

before installation.

AK306002

AC

<<A>> >>D<<

<<B>> >>C<<

>>B<<

Removal steps

1. Cylinder head bolt

2. Cylinder head assembly

3. Cylinder head gasket

4. Retainer lock

5. Valve spring retainer

6. Valve spring

<<B>> >>C<<

>>B<<

<<C>> >>A<<

Removal steps (Continued)

7. Intake valve

8. Retainer lock

9. Valve spring retainer

10. Valve spring

11. Exhaust valve

12. Valve stem seal

13. Valve spring seat

Page 41

ENGINE OVERHAUL <4G63-Turbo>

CYLINDER HEAD AND VALVES

11D-41

Removal steps (Continued)

<<C>> >>A<<

14. Valve stem seal

15. Valve spring seat

16. Intake valve guide

17. Exhaust valve guide

18. Intake valve seat

19. Exhaust valve seat

20. Cylinder head

REMOVAL SERVICE POINTS

<<A>> CYLINDER HEAD BOLT REMOVAL

MB991654

AK202723

AE

Use the special tool Cylinder head bolt wrench

(MB991654) to loosen the cylinder head bolts.

<<B>> RETAINER LOCK REMOVAL

MD998735

NOTE: Store removed valves, springs and other

parts, after putting to each of them a tag that

identifies its cylinder No. or installation location.

<<C>> VALVE STEM SEAL REMOVAL

AK304633

Do not reuse removed valve stem seal.

INSTALLATION SERVICE POINTS

>>A<< VALVE STEM SEAL

INSTALLATION

CAUTION

The special tool must always be used when

installing the valve stem seal. Improper

installation could result in oil leaks past the valve

guide.

AK306003

MD998772

AK202742

AC

AD

Compress the valve spring using the special tool

Valve spring compressor (MD998735 or MD998772),

then remove the retainer lock.

1. Install the valve spring seat.

2. Install the valve.

3. Apply a thin coat of engine oil to a new valve stem

seal.

MD998737

AK304485

AC

4. Use the special tool Valve stem seal installer

(MD998737) to install the stem seal on the valve

guide. Use the stem of the valve to guide the stem

seal.

Page 42

11D-42

Intake valve stem seal

Colour: Gray

ENGINE OVERHAUL <4G63-Turbo>

CYLINDER HEAD AND VALVES

Exhaust valve stem seal

Colour: Grayish green

Compress the valve spring using the special tool

Valve spring compressor (MD998735 or MD998772),

then install the retainer lock.

>>D<< CYLINDER HEAD BOLT

INSTALLATION

AK304538

AB

NOTE: Do not confuse the stem seals for intake

valves with those for exhaust valves.

>>B<< VALVE SPRING INSTALLATION

Painted end

AK300717

AB

Install the valve spring whose small diameter is

shown from the rocker arm side.

>>C<< RETAINER LOCK INSTALLATION

MD998735

Shank length

AK300591AB

1. When reusing a cylinder head bolt, check that its

nominal length (shank length) is not greater than

the limit. If the limit is exceeded, replace the bolt.

Limit: 99.4 mm

2. Apply engine oil to the threads and washer of the

bolt.

MB991654

AK306003

MD998772

AK202742

AC

AD

Timing belt side

410

AK202723

13968

25

AK306004AC

AE

7

3. Tighten the bolts to 78 ± 2 N⋅m in the indicated

sequence.

NOTE: Use the special tool Cylinder head bolt

wrench (MB991654) to tighten the bolts.

4. Loosen all the bolts completely.

5. Tighten the bolts again to a torque of 20 ± 2 N⋅m

in the indicated sequence.

Page 43

ENGINE OVERHAUL <4G63-Turbo>

CYLINDER HEAD AND VALVES

90˚

90˚

Paint marks

AK202720

AB

CAUTION

• If the tightening angle is smaller than 90°,

proper fastening performance could not be

assured. Be sure to respect that angle.

• If the bolt is tightened to an angle greater than

the specified angle, loosen the bolt completely and then retighten it beginning with

the first step.

6. Make paint marks on each bolt’s head and on the

cylinder head.

7. Turn the bolts 90° in the tightening direction and in

the indicated sequence.

8. Give another 90° turn in the tightening direction to

each bolt, making sure that the paint mark on the

bolt head and that on the cylinder head are on the

same line.

11D-43

CAUTION

The thickness of the metal that can be removed

by grinding from both the cylinder head and the

mating cylinder block is limited to 0.2 mm in

total.

3. Check the cylinder head gasket surface for warp

using a straightedge and thickness gauge.

If the surface is warped beyond the limit, grind the

surface for rectification.

Gasket surface warp

Standard value: Less than 0.05 mm

Limit: 0.2 mm

Grinding limit: 0.2 mm

Cylinder head height (standard value for new

part): 131.9 − 132.1 mm

VALVES

1. Check the valve face for correct contact with the

seat. Reface the valve if the contact is partial or

one sided.

Contact

(Should be at

centre of face)

Margin

INSPECTION

M1113007000680

CYLINDER HEAD

1. Before cleaning the cylinder head, check it for

traces of water and gas leakage and for cracks

and any other damage.

2. Thoroughly remove oils, scale, sealants, carbon

and other contamination. Clean the oil passages,

then check using compressed air that they are not

blocked.

AK202724

AK300593

AB

2. Measure the margin.

Replace the valve if its margin is smaller than the

limit.

Standard values:

Intake 1.0 mm

Exhaust 1.5 mm

Limits:

Intake 0.5 mm

Exhaust 1.0 mm

Page 44

11D-44

ENGINE OVERHAUL <4G63-Turbo>

CYLINDER HEAD AND VALVES

VALVE GUIDE

Valve

guide

Total length

AK202876

3. Measure the total length of the valve.

Replace the valve if the length is less than the

limit.

Standard values:

Intake 109.5 mm

Exhaust 109.7 mm

Limits:

Intake 109.0 mm

Exhaust 109.2 mm

VALVE SPRINGS

Out of square

Free height

AB

Stem diameter

Guide inside diameter

AK300168

AE

Measure the valve guide inside diameter and valve

stem diameter to calculate the clearance between

the valve guide and valve stem.

If the limit is exceeded, replace the valve guide or

valve, or both.

Standard values:

Intake 0.02 − 0.05 mm

Exhaust 0.05 − 0.09 mm

Limits:

Intake 0.10 mm

Exhaust 0.15 mm

VALVE SEATS

Valve stem

end

Valve stem

projection

AK300594

AB

1. Measure the free height of the spring.

Replace the spring if its height is smaller than the

limit.

Standard value: 47.0 mm

Limit: 46.0 mm

2. Measure the squareness of the spring.

Replace the spring if it is out of square beyond the

limit.

Standard value: 1.5° or smaller

Limit: 4°

Spring

seating

surface

AK202814

AB

With the valve installed in position and its face

pressed against the valve seat, measure the valve

stem projection (distance between the valve stem

end and spring seating surface). If the measurement

exceeds the limit, replace the valve seat.

Standard values:

Intake 49.2 mm

Exhaust 48.4 mm

Limits:

Intake 49.7 mm

Exhaust 48.9 mm

Page 45

ENGINE OVERHAUL <4G63-Turbo>

CYLINDER HEAD AND VALVES

11D-45

VALVE SEAT RECONDITIONING

1. Before reconditioning the valve seat, check the

clearance between the valve guide and valve

stem and, if necessary, replace the valve guide.

0.9 ‘1.3 mm

44˚

10˚

AK304983

65˚

AC

65˚

0.9 ‘1.3 mm

44˚

10˚

2. Resurface the valve seat to the indicated width

and angles.

3. After resurfacing, lap the valve and valve seat

using lapping compound.

VALVE SEAT REPLACEMENT

0.5 - 1 mm

Intake valve seat hole diameters:

0.3 oversize: 35.30 − 35.33 mm

0.6 oversize: 35.60 − 35.63 mm

Exhaust valve seat hole diameters:

0.3 oversize: 33.30 − 33.33 mm

0.6 oversize: 33.60 − 33.63 mm

3. Before fitting the valve seat, cool it in liquid

nitrogen to prevent damage to its hole in the

cylinder head due to interference.

4. Resurface the valve seat. See the VALVE SEAT

RECONDITIONING section.

VALVE GUIDE REPLACEMENT

1. Force out the valve guide toward the cylinder

block using a press.

CAUTION

Do not use a replacement valve guide of the

same size as the removed one.

2. Machine the valve guide hole in the cylinder head

to the size matched to the selected oversize valve

guide.

Valve guide hole diameters

0.05 oversize: 12.05 − 12.07 mm

0.25 oversize: 12.25 − 12.27 mm

0.50 oversize: 12.50 − 12.52 mm

Cut

0.5 - 1 mm

AK300719

AB

1. Cut inside of the valve seat to be replaced until its

wall becomes thin enough for removal, then

remove the valve seat.

Valve seat

height

Oversize hole diameter

AK300720

AB

2. Rebore the valve seat hole in the cylinder head to

a diameter matched to the diameter of the

selected oversize valve seat.

19.2 – 19.8 mm

AK400848

AB

3. Press-fit the valve guide until it remains protruded

above the cylinder head by the amount indicated

in the drawing.

Standard value: 19.2 − 19.8 mm

NOTE: Press the valve guide from above the

cylinder head.

NOTE: The valve guides for the intake valves are

different in length from those for the exhaust

valves (45.5 mm for intake valves; 50.5 mm for

exhaust valves)

4. After installing the valve guide, insert a new valve

in it to check for smooth movement.

Page 46

11D-46

ENGINE OVERHAUL <4G63-Turbo>

OIL PAN AND OIL PUMP

OIL PAN AND OIL PUMP

REMOVAL AND INSTALLATION

Apply engine oil to

all moving parts

before installation.

23 ± 3 N·m

54 ± 5 N·m

19 ± 3 N·m

9

23 ± 3 N·m

16

26

25

20

M1113008100657

10 ± 2 N·m

22

23

24

17 ± 1 N·m

19 ± 3 N·m

10

21

19 ± 3 N·m

28

32

31

30

29

7

8

6

15

>>N<<

>>M<<

<<A>> >>L<<

<<B>> >>L<<

>>K<<

<<C>> >>J<<

14

13

17

11

18

36 ± 3 N·m

23 ± 3 N·m

12

3

44 ± 5 N·m

Removal steps

1. Drain plug

2. Drain plug gasket

3. Oil filter

4. Transmission stay

5. Oil pan lower

6. Oil pan upper

7. Oil screen

8. Gasket

9. Oil cooler by-pass valve

10.Oil pressure switch

11. Relief plug

12.Gasket

13.Relief spring

14.Relief plunger

15.Oil filter bracket

16.Gasket

17.Plug

19

27

23 ± 3 N·m

39 ± 5 N·m

9.0 ± 3.0 N·m

1

2

9.0 ± 3.0 N·m

<<D>> >>I<<

>>H<<

>>G<<

>>G<<

>>F<<

>>E<<

>>D<<

<<E>> >>C<<

<<F>> >>B<<

<<F>> >>A<<

4

5

9.0 ± 3.0 N·m

Removal steps (Continued)

18.O-ring

19.Flange bolt

20.Front case

21.Gasket

22.Oil pump cover

23.Oil pump driven gear

24.Oil pump drive gear

25.Crankshaft front oil seal

26.Counterbalancer shaft oil seal

27.Oil pump oil seal

28.Counterbalancer shaft, right

29.Counterbalancer shaft, left

30.Counterbalancer shaft front bearing

31.Counterbalancer shaft rear bearing,

right

32.Counterbalancer shaft rear bearing,

left

22 ± 4 N·m

AK400304

AB

Page 47

ENGINE OVERHAUL <4G63-Turbo>

OIL PAN AND OIL PUMP

11D-47

REMOVAL SERVICE POINTS

<<A>> OIL PAN LOWER REMOVAL

Remove the oil pan by tapping it through a piece of

wood applied to a side with a plastic hammer.

CAUTION

Do not use a scraper or the special tool to

remove the oil pan.

<<B>> OIL PAN UPPER REMOVAL

A

A

Screw bolts into the bolt holes A shown in the

drawing (holes at both ends) to remove the oil pan.

CAUTION

Do not use a scraper or the special tool to

remove the oil pan.

AK304400

AB

<<D>> FLANGE BOLT REMOVAL

Plug

1. Remove the plug on the left side of the cylinder

block. Insert a cross point screwdriver (shank

diameter 8 mm) into the plug hole more than 60

mm to prevent the left counterbalancer shaft from

rotating.

Crosspoint

screwdriver

AK202752

AK300173

AD

<<C>> PLUG REMOVAL

MD998162

MD998783

Fit the teeth of the special tools in notches of the plug

as shown in the drawing and support the tool with the

special tool to loosen the plug.

• Plug wrench (MD998162)

• Plug wrench retainer (MD998783)

AK300171

AD

2. Loosen and remove the flange bolt.

<<E>> COUNTERBALANCER SHAFT

FRONT BEARING REMOVAL

CAUTION

MD998371

AK300174

Remove the front bearing first. Otherwise, the

special tool cannot be used.

Use the special tool Silent shaft bearing puller

(MD998371) to remove the counterbalancer shaft

front bearing from the cylinder block.

AD

Page 48

11D-48

ENGINE OVERHAUL <4G63-Turbo>

<<F>> COUNTERBALANCER SHAFT

REAR BEARING REMOVAL

OIL PAN AND OIL PUMP

MB991603

MD998705

Rear bearing

MD998372

AK300175

AD

1. Use the special tool Silent shaft bearing puller

(MD998372) to remove the counterbalancer shaft

rear bearings from the cylinder block.

MB991603

MD998372

AK300176

AD

2. When removing the rear bearing of the left

counterbalancer shaft, install the special tool

Silent shaft bearing installer stopper (MB991603)

on the front of the cylinder block and use a special

tool Silent shaft bearing puller (MD998372) to pull

out the bearing.

INSTALLATION SERVICE POINTS

>>A<< LEFT COUNTERBALANCER

SHAFT REAR BEARING INSTALLATION

MB991603

AK300619

AG

1. Install special tool Silent shaft bearing installer

stopper (MB991603) to the cylinder block.

2. Apply engine oil to the rear bearing outer surface

and bearing hole in the cylinder block.

3. Using special tool Silent shaft bearing installer