Page 1

TECHNICIAN’S HANDBOOK

Page 2

Table of Contents

Page 3

Table of Contents

PRODUCT INFORMATION ..............................................1

Disclaimer .................................................................................1

Contacting Technical Support...................................................2

Sending Us Feedback ..............................................................2

About The Document Set..........................................................2

INSTALL SYSTEM ...........................................................4

System Installation Overview....................................................4

Installation Planner ...................................................................5

Capacity....................................................................................8

Fiber Interface Module (FIM) ..................................................10

Controller ................................................................................13

Configurations .....................................................................13

Install the System ID Module ..............................................14

Install the 3300 Controller...................................................15

Configure the Controller......................................................17

Set the 3300 Controller IP Address ....................................18

Network Services Units...........................................................20

Install the 3300 Universal NSU...........................................20

Install the 3300 R2 NSU......................................................27

Install the 3300 BRI NSU ....................................................29

3300 NSU Pin Allocations...................................................30

NSU Chaining .........................................................................32

Analog Services Units.............................................................33

Install the 3300 Univers a l ASU ...........................................33

Install the 3300 ASU ...........................................................33

3300 ASU and Universal ASU Pin Allocations....................34

Peripheral Unit ........................................................................37

Overview of the Peripheral Unit Installation........................37

- iii -

Page 4

Table of Contents

Unpack, Position, and Ground the Peripheral Unit.............37

Peripheral Unit Card Layout ...............................................38

Connect Fiber Cable to the Peripheral Unit........................39

Peripheral Unit Grounding..................................................40

Power Converter.................................................................41

Install Peripheral Interface Cards .......................................43

Cable the Unit to the MDF ..................................................43

Peripheral Interface Cabling Tables ...................................45

USOC Connector Pin Designations....................................46

Card Connections to Cross-Connect Field.........................48

SUPERSET HUB....................................................................65

Overview of the SUPERSET Hub Installation ....................65

Install the Peripheral Slot FIM Carrier ................................66

Install the SUPERSET HUB ............................................... 66

Digital Service Unit .................................................................67

Overview of the Digital Service Unit Installation.................67

Unpack, Position, and Ground the DSU.............................68

DSU Card Layout................................................................68

Connect Fiber Cable to the DSU........................................69

Install DSU Cards ...............................................................70

Interface Assembly.............................................................70

DS1 Interface Assembly and Cabling.................................71

CEPT Interface Assembly and Cabling ..............................72

Install Wireless Devices .........................................................73

Install Symbol NetVision MiNET Phone Administrator

Tool.....................................................................................74

Install 3300 ICP as a Stand-alone IP Gateway......................74

Install 3300 ICP as a Stand-alone Voice Mail........................75

Software .................................................................................77

Install the 3300 Configuration Tool.....................................77

Install and Configure the Java Plug-In................................ 77

Install IMAT......................................................................... 78

- iv-

Page 5

Table of Contents

INSTALL UPGRADES AND FRUS................................. 79

Hardware.................................................................................79

Controller Upgrade Options ................................................79

250 User to 700 User System - No Compression...............80

250 User System - Add 32 Compression Channels ...........81

250 User System - Add 64 Compression Channels ...........83

700 User System - Add 32 Compression Channels ...........84

700 User System - Add 64 Compression Channels ...........86

SX-2000 LIGHT to 3300 ICP...............................................87

SX-2000 MICRO LIGHT to 3300 ICP..................................88

3200 ICP to 3300 ICP .........................................................89

Software..................................................................................89

Software Upgrade Procedure..............................................89

SX-2000 LIGHT to 3300 ICP...............................................93

SX-2000 MICRO LIGHT to 3300 ICP..................................94

3200 ICP to 3300 ICP .........................................................96

3800 Wireless Applications Gateway to 3300 ICP..............98

Field Replaceable Units........................................................100

Controller...........................................................................100

Peripheral Unit...................................................................105

Digital Service Unit............................................................112

PROGRAM SYSTEM ....................................................124

Overview of Programming ....................................................124

Use IMAT..............................................................................125

Register IP Telephones from the Station..............................126

TROUBLESHOOTING..................................................128

3300 Controller .....................................................................128

System Hardware Profile ..................................................130

3300 Universal NSU .............................................................131

- v-

Page 6

Table of Contents

3300 R2 NSU .......................................................................132

3300 BRI NSU......................................................................135

3300 Universal ASU ............................................................. 136

3300 ASU............................................................................. 137

Peripheral Unit......................................................................138

Troubleshoot Fiber Interface Module................................ 138

Troubleshoot the DID Loop/Tie Trunk Card .....................139

DNI Line Card...................................................................139

Troubleshoot the DTMF Receiver Card............................141

Troubleshoot E&M Trunk Card.........................................141

Troubleshoot LS/GS Trunk Card......................................142

Troubleshoot the ONS CLASS/CLIP Card .......................145

Troubleshoot the ONS Line Card .....................................146

Troubleshoot the OPS Line Card .....................................147

Digital Service Unit...............................................................147

BRI Troubleshooting.........................................................147

Troubleshoot the Conference Card .................................. 149

DS1 Formatter Card .........................................................149

Troubleshoot the PRI Card...............................................151

Troubleshoot the R2 Card ................................................ 153

Telephone.............................................................................154

No Dial Tone - Analog Telephones ..................................155

No Dial Tone - DNI Telephone ......................................... 157

No Dial Tone - IP Telephone............................................158

If the IP Telephone Fails to Boot ......................................159

Calls are Being Cut-off......................................................160

Calls Received in Error.....................................................160

Dial Tone at the Set but Unable to Make Calls................. 161

No Calls are Being Received............................................ 161

To PING from the 3300 ICP..............................................162

To PING from the IP Phone..............................................162

- vi-

Page 7

Table of Contents

Console.................................................................................162

SUPERCONSOLE 1000 Console.....................................162

Software................................................................................163

Restore Procedure............................................................ 163

Software Install Procedure................................................164

Management Tool Fails to Launch .......................................167

MAINTAIN.....................................................................168

Healthy System Checklist.....................................................168

Checking the System............................................................168

System Security Checklist ....................................................169

System Hardware Profile......................................................169

Backing Up System Information ...........................................169

Viewing Logs.........................................................................170

List of Maintenance Commands ...........................................172

- vii-

Page 8

Table of Contents

- viii- - 1 -

Page 9

Product Information

Disclaimer

The information contained in this document is believed to be

accurate in all respects but is not warranted by Mitel Networks

Corporation (MITEL®). The information is subject to change without

notice and should not be construed in any way as a commitment by

Mitel or any of its affiliates or subsidiaries. Mitel and its affiliates and

subsidiaries assume no responsibility for any errors or omissions in

this document. Revisions of this document or new editions of it may

be issued to incorporate such changes.

Trademarks

MiTAI, HOST COMMAND INTERFACE (HCI), TALK TO, ANSWER

PLUS, Speak@Ease are trademarks of Mitel Networks Corporation.

Mitel Networks is a trademark of Mitel Networks Corporation.

Windows and Microsoft are trademarks of Microsoft Corporation.

Java is a trademark of Sun Microsystems Incorporated.

Adobe Acrobat Reader is a registered trademark of Adobe Systems

Incorporated.

Other product names mentioned in this document may be

trademarks of their respective companies and are hereby

acknowledged.

Copyright

®, ™ Trademark of MITEL Networks Corporation

©Copyright 2002, MITEL Networks Corporation

All rights reserved

Page 10

3300 ICP Technician’s Handbook – Release 3.2

Contacting Technical Support

Please contact Mitel Technical Support if you require technical

assistance. Before you call, check this Help system for tips and

solutions. If you are unable to find a solution, please have the

following information ready when you call:

• The product serial number

• The nature of the problem

• What you were doing with the application when the problem

occurred

• Troubleshooting results.

Sending Us Feedback

If you have suggestions on how to improve this documentation,

please contact:

Mitel Networks Corporation

World Headquarters

350 Legget Drive, P.O. Box 13089

Kanata, Ontario, Canada K2K 2W7

Telephone: 613-592-2122

Fax: 613-592-4784

Internet: http://www.mitel.com

Email: techpubs@mitel.com

About The Document Set

The Mitel Networks 3300 ICP documentation set includes the

following components:

• General Information Guide (Web Site, CD-ROM, and system)

• Technician's Handbook (Web Site and paper with the system)

• Manual Maker (Web Site)

• Embedded User Information (Web Site and system)

• Hardware User Guide (Web Site, CD-ROM, and system)

• Configuration Tool Online Help (Web Site, CD-ROM)

- 2 -

Page 11

3300 ICP Technician’s Handbook – Release 3.2

• System Administration Tool Online Help (Web Site, CD-ROM,

and system)

• IMAT Online Help (CD-ROM).

- 3 -

Page 12

3300 ICP Technician’s Handbook – Release 3.2

Install System

System Installation Overview

The ground symbol within a circle identifies the terminal to be

connected to an external protective conductor. Connect this

terminal to earth ground before you make any other connections

to the equipment.

To install the 3300 ICP system:

1. Install the 3300 ICP Controller

2. Configure the Controller

3. Install the Universal NSU

4. Install the R2 NSU

5. Install the BRI NSU

6. Install the Universal ASU

7. Install the ASU

8. Install the Peripheral Unit

9. Install the SUPERSET HUB

10. Install the Digital Service Unit

11. Install Wireless Devices

12. Connect the Controller to the LAN

13. Launch the System Administration Tool to program the system.

(Refer to Overview of Programming).

Tip: You can complete all of the programming without having

physical connections to the Controller. After programming you

can connect units to the controller and then power-up the

system.

- 4 -

Page 13

3300 ICP Technician’s Handbook – Release 3.2

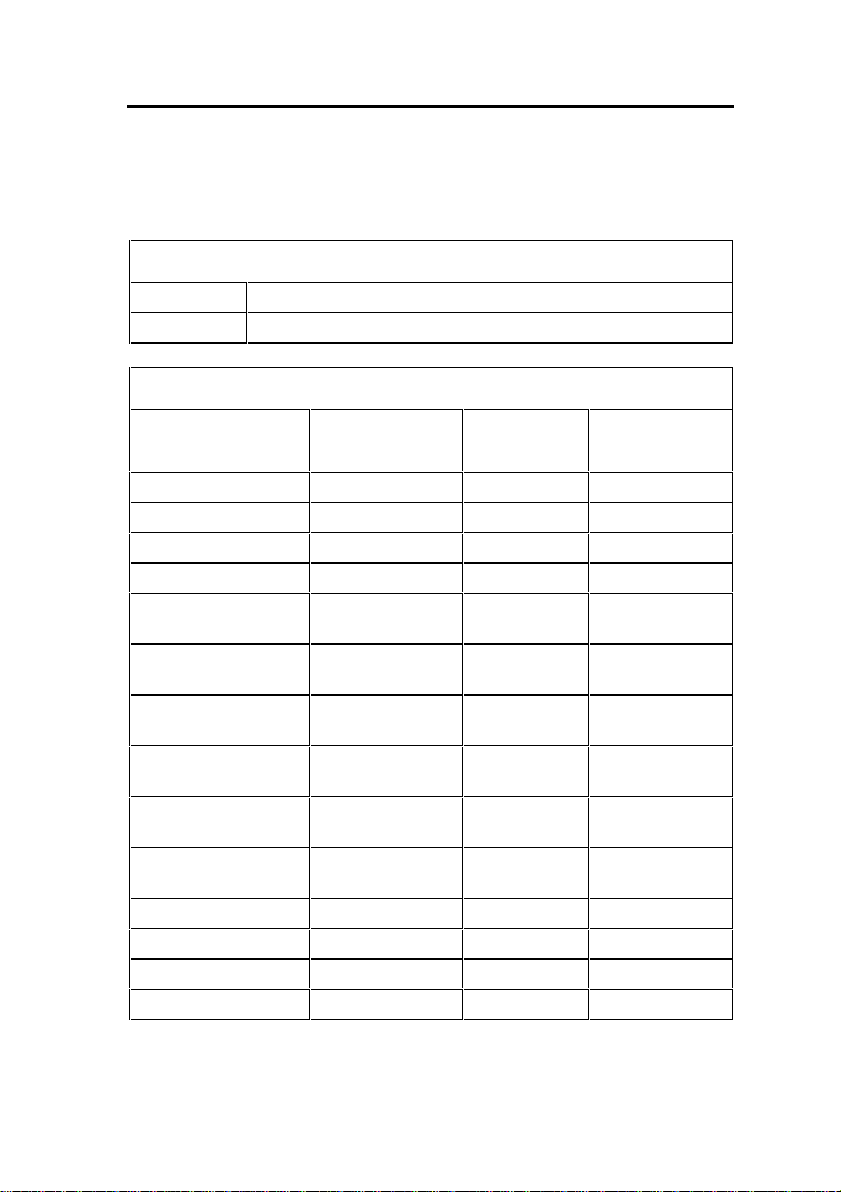

Installation Planner

The following required and default settings are necessary for an

installation:

System Administration Tool

username (Default = system)

password (Default = password)

Controller Configuration (RTC)

Default

Settings

boot device ata=0,0

processor number 0

host name

file name /sysro/RTC8260

inet on ethernet (e) 192.168.1.2

inet on backplane

(b)

host inet (h) IP address: ftp

gateway inet (g) Default

user (u) ftp FTP user

ftp password (pw) @ FTP password

flags (f) 0x0

target name (tn)

startup scripts (s)

other (o) motfcc

Settings to

Change

IP address:

subnet mask

server

Gateway

(installer’s PC)

(installer’s PC)

- 5 -

Page 14

3300 ICP Technician’s Handbook – Release 3.2

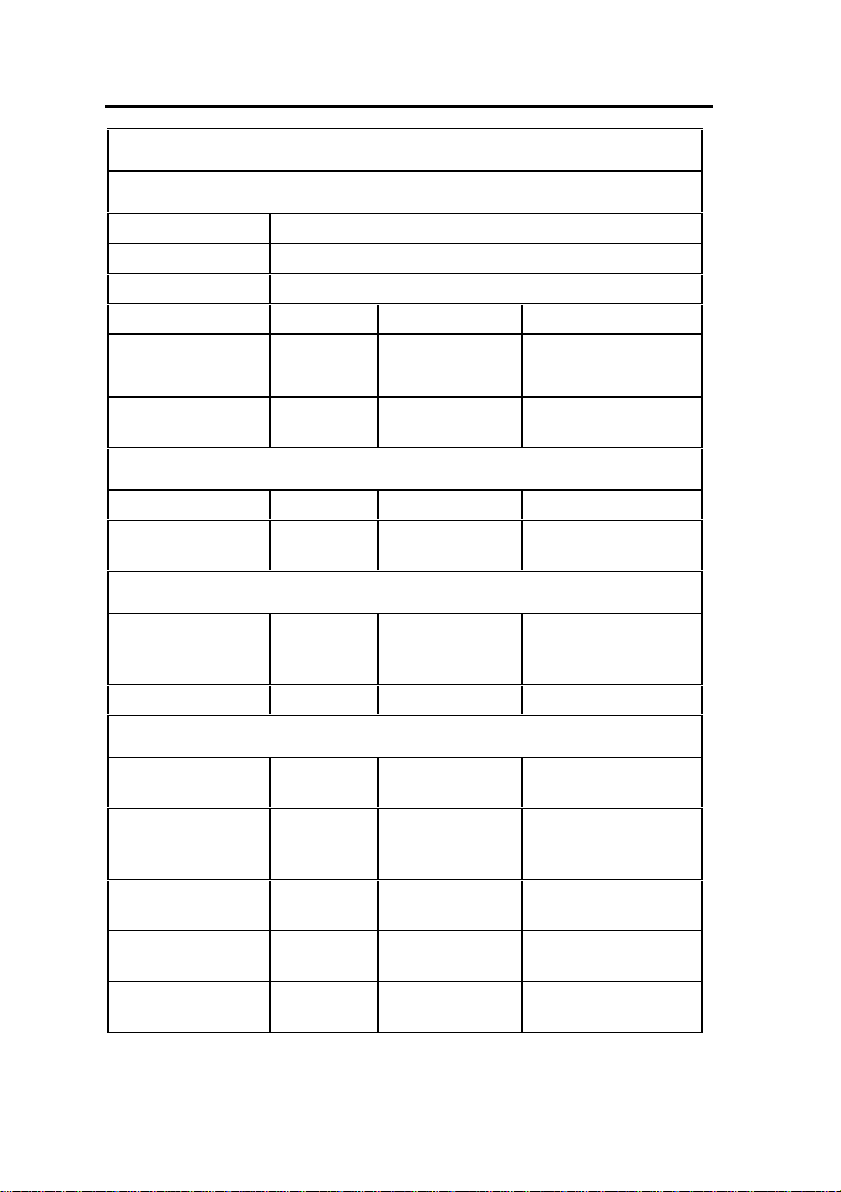

DHCP Configuration (for scope supporting IP Voice devices)

IP Address Scope

Start Address

End Address

Subnet Mask

Lease Duration Days: Hours: Minutes:

Options (for all

devices)

(Router) Default

Gateway

Options (for WEB devices)

DNS Server 006 IP Address

DNS Domain

Name

Options (for 3300 E2T)

TFTP Ser ver

(hostname or IP)

TFTP BootFile 067 ASCII String /sysro/E2T8260

Options (for IP Phones)

Mitel IP Phone

DHCP server

IP Phone TFTP

Server

MN3300 (RTC)

IP Address

VLAN ID 132 Hex Long (32

VLAN Priority 133 Hex Long (32

Identifier Data Type Value

003 IP Address

015 ASCII String

066 ASCII String (typically the IP

address of the

controller RTC)

130 ASCII String MITEL IP PHONE

128 IP Address (typically the IP

address of the

controller RTC)

129 IP Address

e.g. 0x2

bit word)

0x6

bit word)

- 6 -

Page 15

3300 ICP Technician’s Handbook – Release 3.2

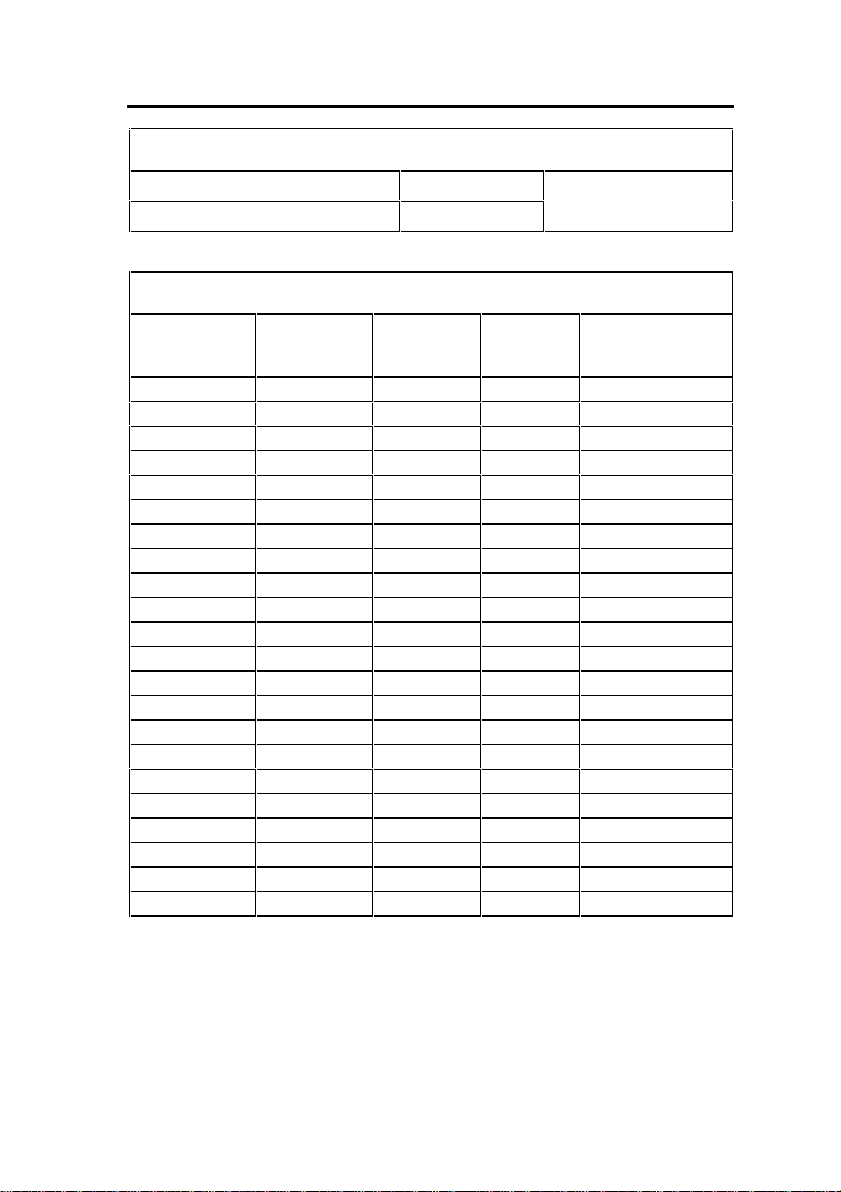

IP Phone MAC Information

IP Set Registration Code

IP Set Replacement Code

Set Programming Guide

User Name Location Set Type Number MAC Address

(See System Option

Assignment)

(optional)

- 7 -

Page 16

3300 ICP Technician’s Handbook – Release 3.2

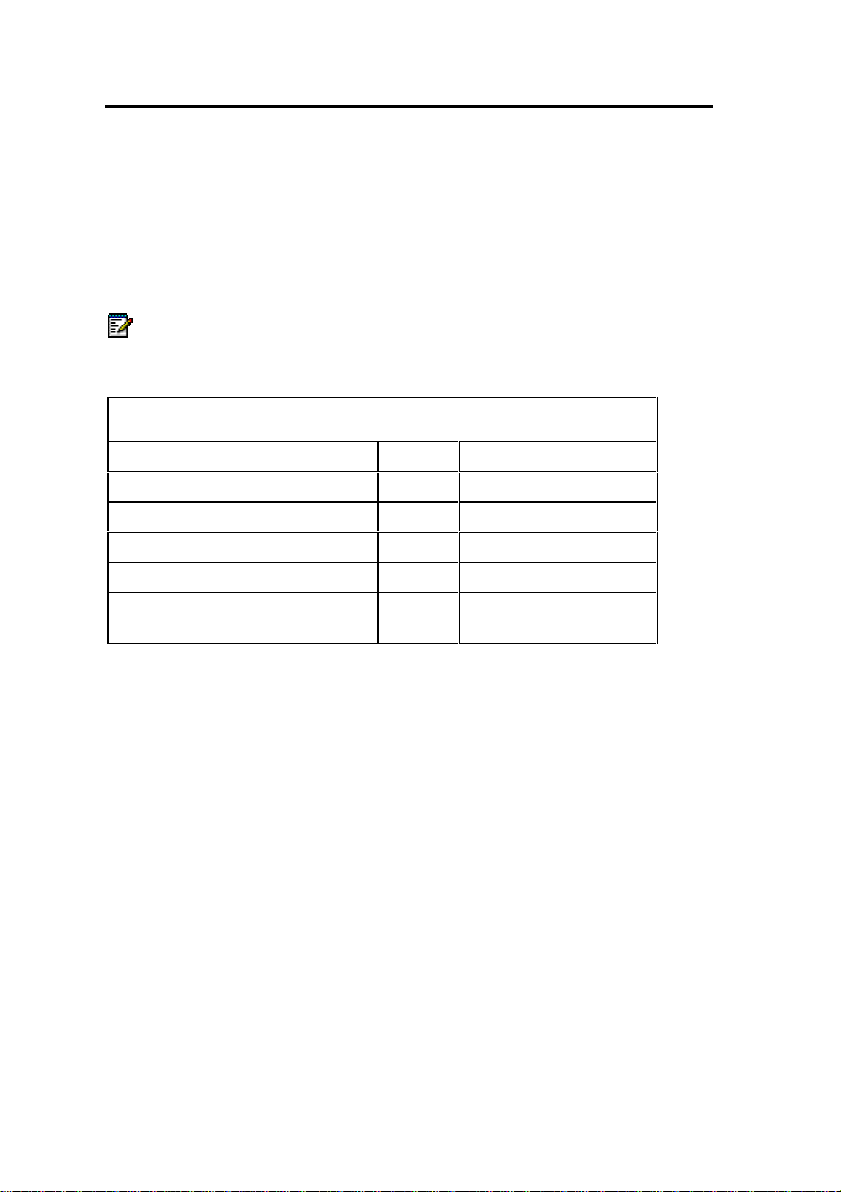

Capacity

The 250-user 3300 ICP will support one of the following maximum

configurations:

• 250 IP telephones and 96 ONS telephones with no

peripheral unit support.

• 250 IP telephones and a 192 port peripheral unit with a

DTMF card installed.

• a combination of IP, ONS, and DNI telephones (for

example, 100 IP telephones, 96 ONS telephones, and 100

DNI telephones on a peripheral unit).

The 700-user 3300 ICP will support the quant iti es list ed in the

following hardware and feature capacity tables.

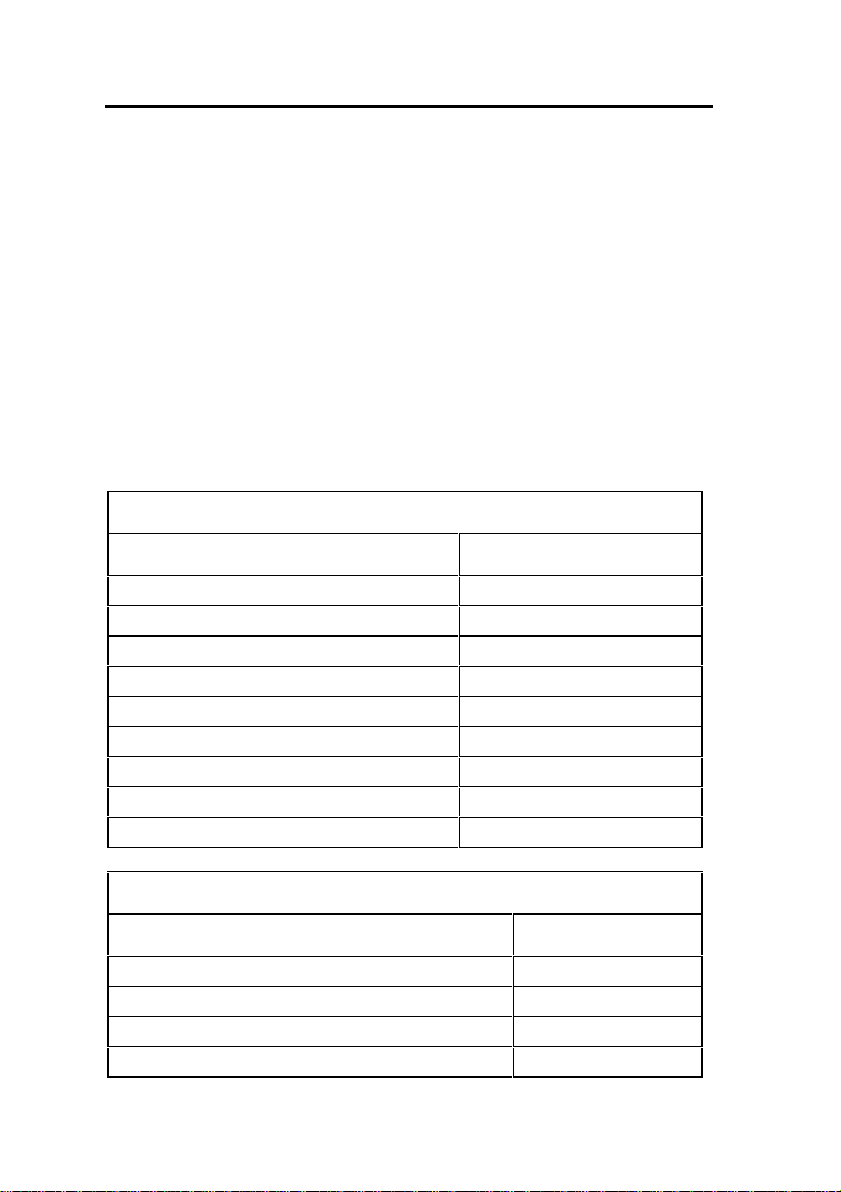

3300 ICP Hardware Capacity

Parameter Name Number

Attendant Consoles 24

DNI Channels 2368

Programmable Key Modules 75

System Ports

- DTMF Receivers 128

- Multiline Sets 756

- Single Line Sets (ONS/OPS Lines) 700

- Trunks 628

Tone Detector Circuits 32

3300 ICP Feature Capacity

Parameter Name Number

ACDII - Agent Groups 32

Agents per Group 500

ACDII - Agent IDs 1181

ACDII - Agent Paths 256

- 8 -

Page 17

3300 ICP Technician’s Handbook – Release 3.2

3300 ICP Feature Capacity

Parameter Name Number

Attendant Console Groups 48

Attendant Console Calls Waiting 72

Broadcast Groups 1875

- Members per Broadcast Group 32

Busy Lamp Groups (Monitored Devices) 439

- Members per Busy Lamp Group 16

Call Reroute Always 176

Call Reroute 1st Alternates 336

Call Reroute 2nd Alternates 32

Class of Restriction (COR) 96

Class of Service (COS) 96

Conferences; maximum 5

Conferees in a conference; maximum 5

Default Account Codes 225

Departments (in Tel Dir) 2000

Digit Modification Tables 256

Digit Blocks 4055

Digital Links 16

Group Page Groups 16

Hunt Groups 176

- Members per Hunt Group 64

Independent Account Codes 1000

Locations (in Tel Dir) 250

Modem Groups 15

Modems per Modem Group 10

MSDN/DPNSS Cluster Elements 30

MSDN/DPNSS Remote Directory Numbers 18500

Networked ACD - Remote Agent Subgroups 32

- 9 -

Page 18

3300 ICP Technician’s Handbook – Release 3.2

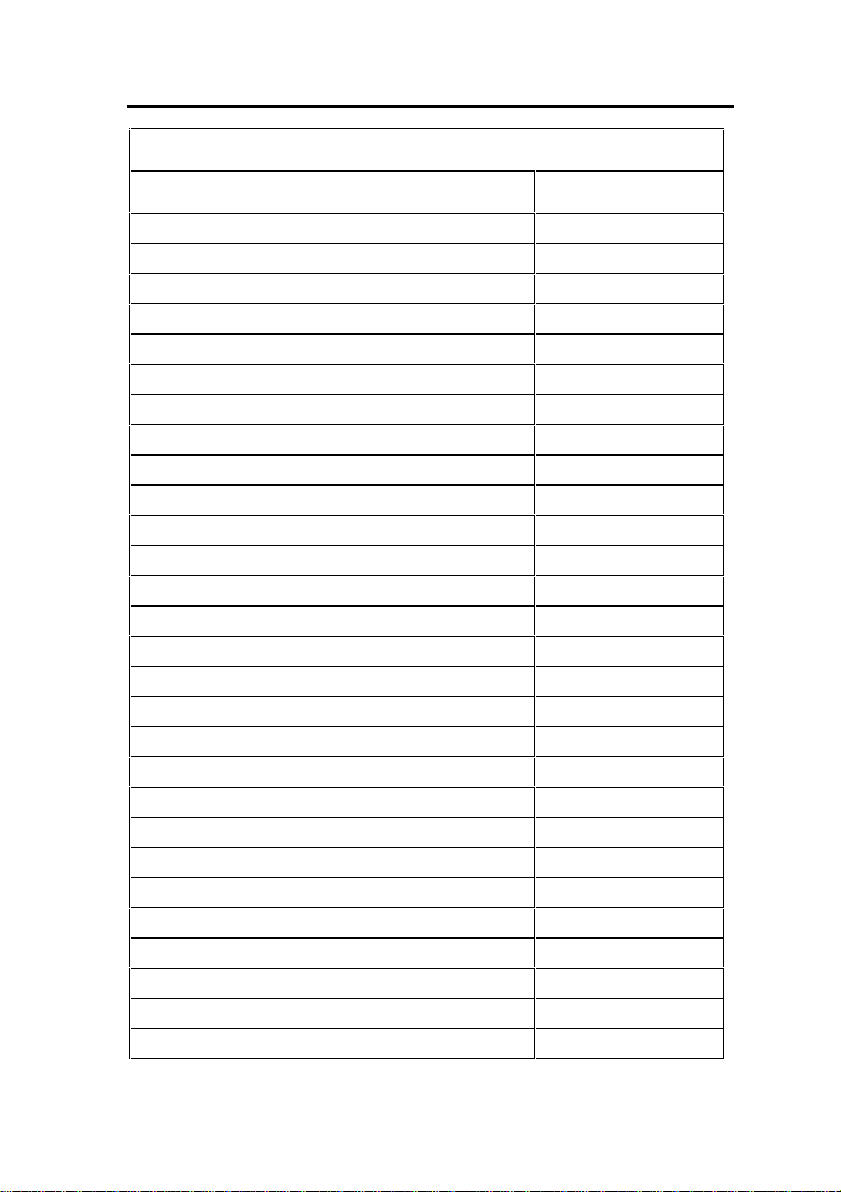

3300 ICP Feature Capacity

Parameter Name Number

Page Groups (Zones) 16

Personal Speed Call Users

(blocks of 10 speed calls per user)

Pickup Groups 200

- Members per Pickup Group 75

Routes 200

Route Lists 128

Speed Call Digit String (avg. 12 digits) 1500

SUPERSET Callback Messages per System 500

System Account Codes 24

System Digit Strings 6814

System Speed Call 600

Telephone Directory Entries 19995

Trunk Groups 112

Trunks per Trunk Group 175

Trunk Service Numbers 150

500

Fiber Interface Module (FIM)

Guidelines for Handling Fiber Optic Cable

• Never touch the tip of a fiber connector. Cleanliness of the

connector ferrule (tip) is important for error free transmission.

• Always place the dust caps onto the connectors immediately

after disconnecting.

• You can clean the ferrule tips on the connectors with ethyl

alcohol.

• Fiber optic cables are often more easily installed and pulled

than copper because of their lightweight and flexibility.

However, take care not to exceed the minimum bend radius or

maximum tensile strength.

- 10 -

Page 19

3300 ICP Technician’s Handbook – Release 3.2

• Procedures for the repairing, splicing, or assembling fiber optic

cables are available from fiber component manufacturers (many

offer training courses).

WARNING: Fiber optic sources emit infrared light that is

invisible to the human eye. Never look directly into a source or

into the end of a fiber energized by a source because it can

damage the retina.

When working with raw fiber optic cable, be careful of the fiber

ends or slivers that can puncture the skin or cause irritation.

Specifications

At each end of a fiber optic cable is a Fiber Interface Module (FIM).

At the transmitting end, the FIM converts electrical signals into

pulses of light to be transmitted over the cable. At the receiving end,

the FIM converts the pulses of light back into electrical signals

usable by the node.

The FIM connects the 3300 Controller to a peripheral unit or DSU.

These FIMs cannot be installed in the Appl ic ati ons Gate way. Each

FIM variant may be identified by its optical wavelength and fiber

type (indicated on the FIM faceplate). The same FIM variant must

be used at each end of a fiber optic cable. However, a node may be

equipped with different FIM variants to suit the length of each cable

run.

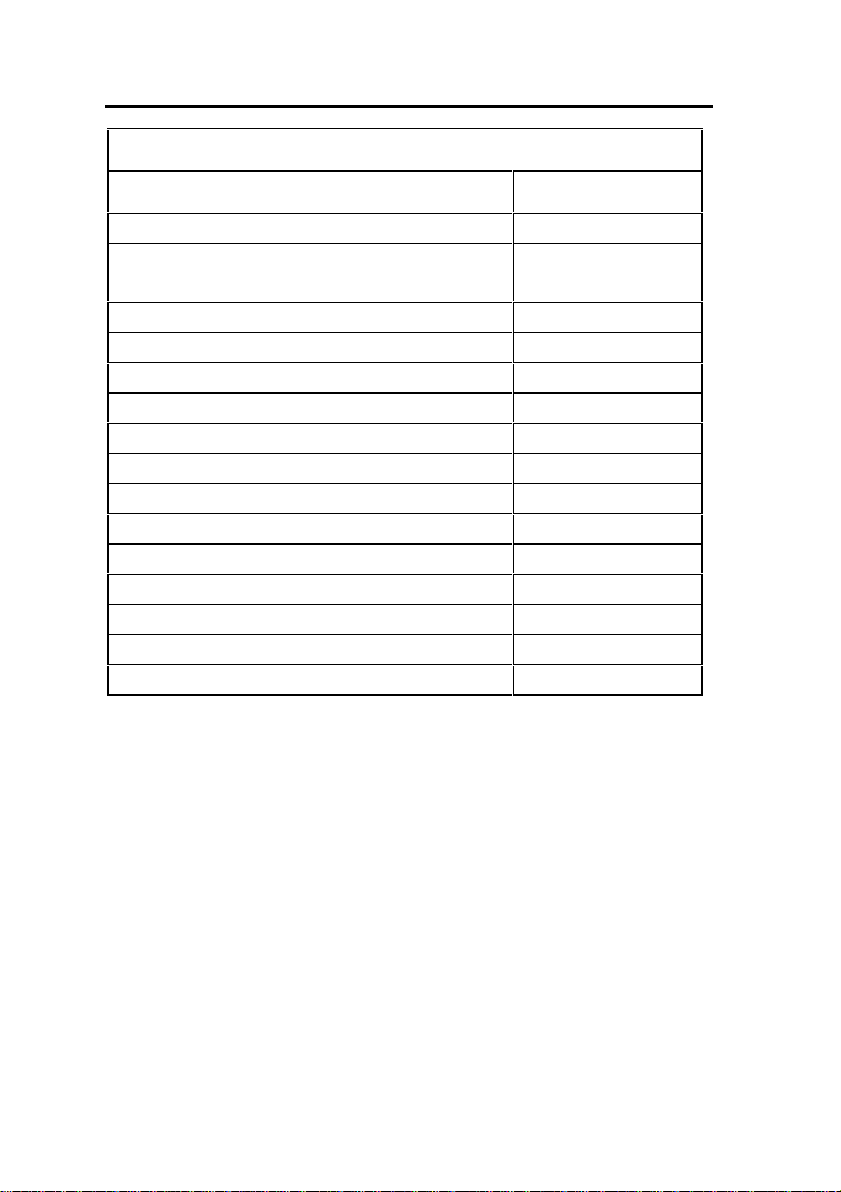

Fiber Interface Module Specifications (9400-300-301-NA)

Approximate maximum fiber cable run

length (See Note 1)

Power consumption (Watts) 2.5

Number of fiber links per FIM 1 Tx, 1 Rx

Fiber connector type ST (See Note 2)

Electrical interface (See Note 3) 8 serial ST links

Optical wavelength (nm) 820

Optical budget (See Note 4) 6 db

Date rate (Mbits/second) 16.384

Bit rate after encoding (Mbaud) 20.48

1km (0.62 miles)

- 11 -

Page 20

3300 ICP Technician’s Handbook – Release 3.2

Fiber Interface Module Specifications (9400-300-301-NA)

Fiber optic cable type 62.5/125 um Multimode

Notes:

1. The run length is the one-way length of fiber optic cable between

nodes.

2. ST is a registered trademark of AT&T.

3. Some channels of the electrical interface are not available.

4. The optical budget is the allowable loss through fiber optic cable,

splices, and connectors. The optical budget applies to the run length.

Operation

The FIM has three functional sections: a transmitter, a receiver, and

a control section.

The transmitter section accepts data from the node in which it is

installed. The data is converted to byte-interleaved format, and a

checksum is calculated. The checksum byte is combined wi th the

data and the frame synchronization information. The frame is

encoded as serial data and transmitted on the fiber.

The receiver section converts the incoming data to parallel format,

extracts the frame synchronization information, and decodes the

data. Control and status information is extracted and further

decoded. The checksum is verified and an error counter updated.

The status information and data are combined, frame-aligned, and

re-formatted for output.

The control section generates control signals and the transmit

clocks. This section also regenerates the telephony clocks for the

peripheral nodes, and provides status information for the Main

Controller.

Two LEDs indicate the detection of local and remote clocks.

- 12 -

Page 21

3300 ICP Technician’s Handbook – Release 3.2

Controller

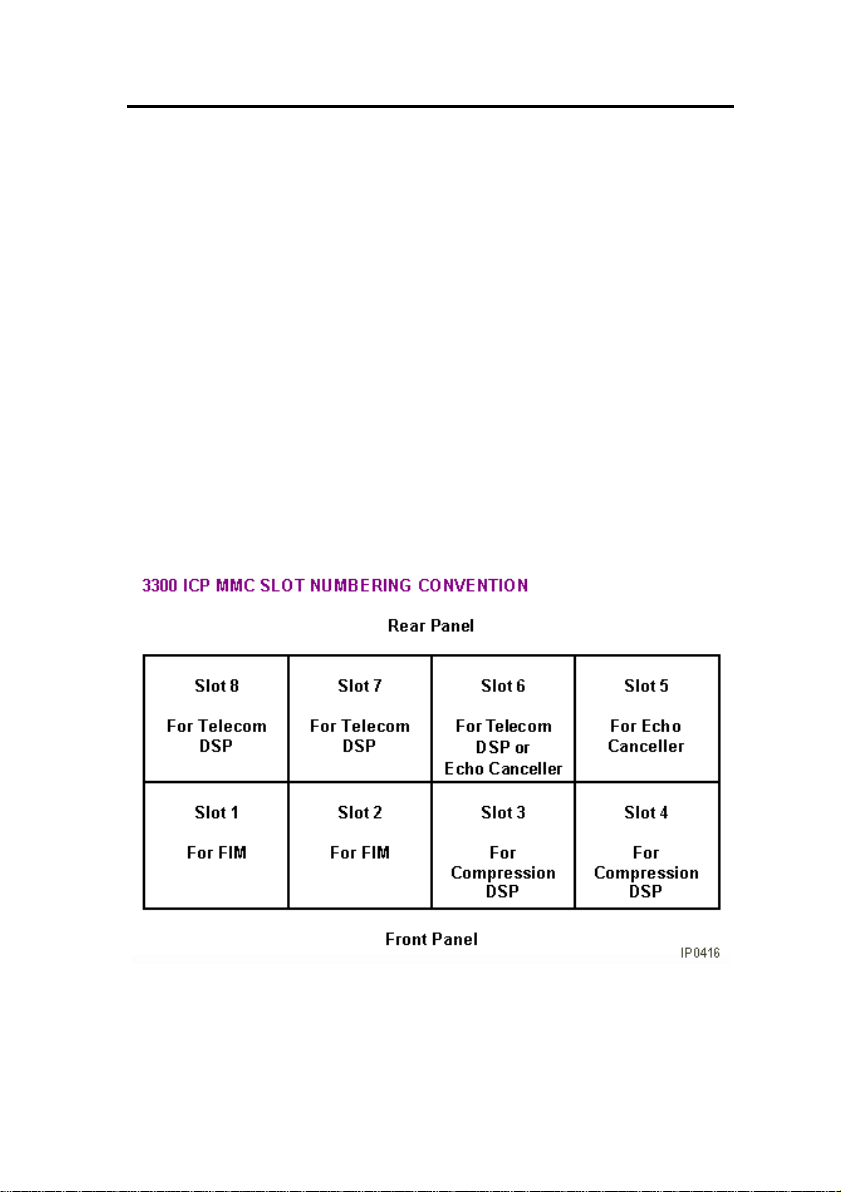

Configurations

There are several configuration options for the 3300 ICP:

• 250 user system without compression

• 250 user system with 32 compression channels

• 250 user system with 64 compression channels

• 700 user system without compression

• 700 user system with 32 compression channels

• 700 user system with 64 compression channels.

The following top view diagram shows the MMC/A slot numbering

convention. The diagram also indicates the type of MMC module

that will be used in a particular slot. Slots 1 through 4 allow

connectors to protrude through the front panel.

- 13 -

Page 22

3300 ICP Technician’s Handbook – Release 3.2

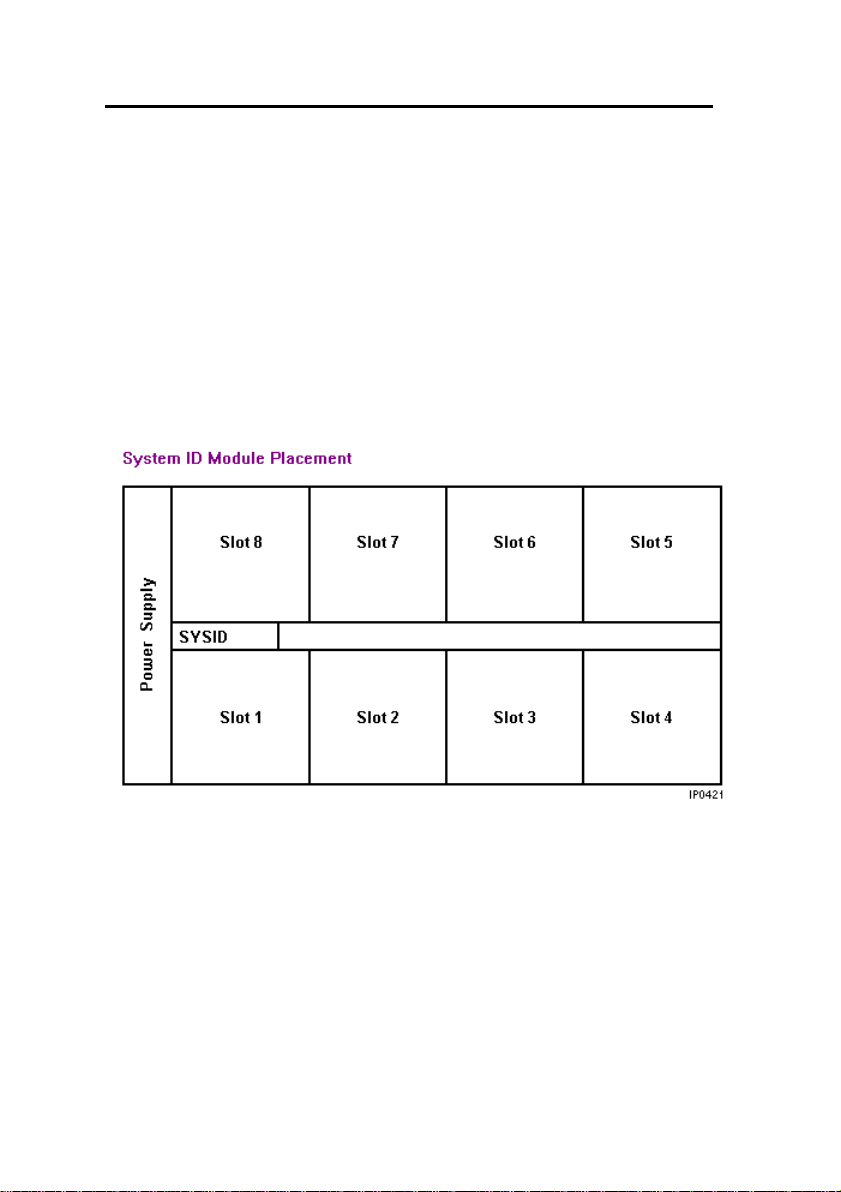

Install the System ID Module

The system ID module is shipped with the software. You must

install the system ID module in the 3300 ICP controller. The module

contains a unique identifier that the system reads on start-up.

To install the System ID Module:

1. Remove the cover.

2. Press firmly to seat the module on the board. Placement is

between MMC 1 (the Dual FIM) and MMC 8 (the DSP). The

module will cover the 'MMC 8' text printed on the board.

3. Replace the cover.

- 14 -

Page 23

3300 ICP Technician’s Handbook – Release 3.2

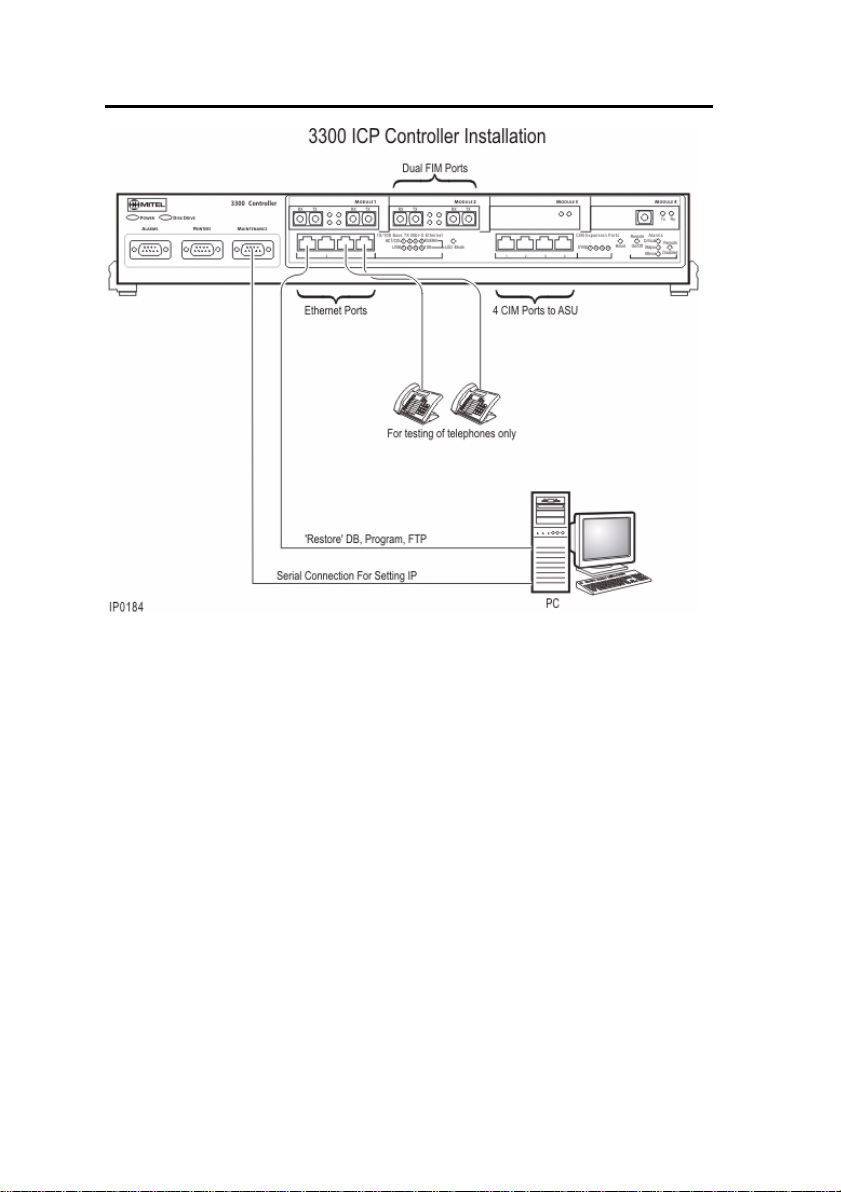

Install the 3300 Controller

To install the 3300 Controller:

1. Install the System ID Module.

2. Set up a serial connection between the 3300 Configuration Tool

PC and the Maintenance (RS-232) port on the 3300 Controller.

Baud rate - 9600, Data bits - 8, Parity - None Stop bits - 1, Flow

control - None.

3. Set up an Ethernet connection between the 3300 Controller and

the 3300 Configuration Tool PC (a standard LAN cable from an

RJ-45 connector on the 3300 Controller L2 switch to the PC

NIC).

Note: You can connect IP telephones to the 3300 Controller

through L2 switch external ports, for testing only, after

installation of the database and configuration. IP Phones

require a configured DHCP server.

- 15 -

Page 24

3300 ICP Technician’s Handbook – Release 3.2

- 16 -

Page 25

3300 ICP Technician’s Handbook – Release 3.2

Configure the Controller

Note: Before you begin, you should review the LAN and WAN

guidelines and plan the network . Complete the Ins ta lla tio n

Planner. You will need to know the IP addresses reserved by

the customer for the 3300 ICP Controller (one for the RTC and

one for the E2T) and for the IP Phones.

Time: The initial power-up and the reset in this procedure will

each take 15 to 20 minutes.

To complete the installation of the Mitel Networks 3300 ICP:

1. Connect power to the 3300 Controller. The controller will come

up, in 15 to 20 minutes, with factory-installed software.

2. To check connections between the 3300 Controller and the PC:

PING the 3300 Controller IP address

FTP to the 3300 Controller IP address

Go to the 3300 Controller URL address (http://192.168.1.2).

3. Launch browser to login to the System Administration Tool

(http://192.168.1.2 -- username is system, password is

password).

4. Optional. Install the Mitel Networks 3300 Configuration Tool on

your PC. Use the Configuration Tool to reset the default

database, import the .csv file, and make programming changes.

Refer to the 3300 Configuration Tool online help for detailed

instructions.

5. Enable the options in the License and Option Selection form

and reboot.

6. Program the system by using the System Administration Tool or

restore a database.

7. Configure the DHCP Server with IP addresses provided by the

customer. Refer to the Note and default settings table following

this procedure.

8. If you are using an external DHCP Server, disable the internal

DHCP Server.

9. Perform a Backup.

- 17 -

Page 26

3300 ICP Technician’s Handbook – Release 3.2

10. Reboot the system.

11. Set the 3300 Controller (RTC) IP address through a

communication program.

12. Install the other units as described in the System Installation

Overview.

13. As the final step, connect the 3300 Controller to the LAN.

Note: You may use the internal or an external DHCP Server.

The controller is shipped with the DHCP server Enabled. Use

DHCP reservations against the MAC address for the E2T.

Internal DHCP Server default settings - shipped enabled

TFTP Server 066 192.168.1.2

TFTP BootFile 067 /sysro/E2T8260

IP Phone TFTP Server 128 192.168.1.2

MN330 (RTC) IP Address 129 192.168.1.2

Mitel IP Phone DHCP Server 130 MITEL IP PHONE

Range Start

End

192.168.1.20

192.168.1.24

Set the 3300 Controller IP Address

To set the 3300 Controller IP address:

1. Establish a serial connection from the 3300 Configuration Tool

PC (or any PC equipped with a communications program) to

the Maintenance Port on the 3300 Controller.

2. Launch the communication program.

3. Set the RS-232 communication parameters:

Baud rate - 9600

Data bits - 8

Parity - None

Stop bits - 1

Flow control - None

4. Connect AC power to the 3300 Controller.

- 18 -

Page 27

3300 ICP Technician’s Handbook – Release 3.2

5. Press the Reset button on the 3300 Controller with a small

pointed object.

6. Wait for the "Press any key to stop auto-boot" message and

then press a key.

7. At VxWorks Boot type c and then press Enter.

Press Enter after you enter required text. For all other fields,

(displayed in grey text, for information only) accept the default

value or leave blank.

boot device: ata=0,0 (Boot device is Disk)

unit number: 0 (default, leave at 0, not used)

processor number: 0 (default, leave at 0, not used)

host name: (optional)

file name: /sysro/Rtc8260 (boot location and file name)

inet on ethernet (e): 134.199.63.11:ffffff00 (example RTC IP

and subnet mask)

Note: Type the IP address and subnet mask (in hexadecimal

format for the end user's site (i.e. ffffff represents

255.255.255.00).

inet on backplane (b):

host inet (h):

gateway inet (g): 134.199.63.251 (example Router (Gateway)

address)

Note: Enter the IP address of the end user's gateway for the

3300 Controller.

user (u): ftp (must be ftp for Release 3.1)

ftp password (ftp) (blank = @):

flags (f): 0x0 (a fixed IP address (0x40 is used on E2T for

DHCP)

target name (tn):

startup script (s):

other (o): motfcc (other device, E2T using Network to boot from)

8. Press the Reset button on the 3300 Controller.

9. Remove the Serial connection. The system will return to service

in about 10 to 15 minutes.

Note: It may be helpful to leave the serial connection in place to

capture any potential errors.

- 19 -

Page 28

3300 ICP Technician’s Handbook – Release 3.2

Network Services Units

Install the 3300 Universal NSU

To install the 3300 Universal NSU:

1. Set DIP switch #6 for Network or Line termination mode. The

default is network termination mode. Refer to Universal NSU

DIP Switch Settings.

2. Establish a fiber connection from the fiber port on the NSU to

the fiber port on the 3300 Controller.

3. Connect the NSU L0 and/or L1 port to the remote system (the

PSTN or another system) by using Category 5 cable.

4. Connect power to the NSU.

Note: The Ethernet port is used for FTP upgrades.

Note: The cable for the CIM ports must be an Ethernet

crossover cable.

Install for PRI/Q.SIG

To install and configure the 3300 Universal NSU as a PRI/QSIG

variant:

1. Install a Direct Connection Device Driver on a computer.

2. Create a Dial-up Network connection on your computer.

3. Connect the computer to the 3300 Universal NSU.

4. Use the IMAT Tool to complete required PRI configuration.

5. Connect the 3300 Universal NSU to the ISDN network.

Connecting a Laptop Computer to the NSU

To connect a computer to the NSU:

1. Install IMAT. From the 3300 Software CD-ROM, run

Tools/IMAT/Disk1/setup.exe.

2. Use a straight through serial cable for a direct connection.

- 20 -

Page 29

3300 ICP Technician’s Handbook – Release 3.2

3. Use a null modem adapter if connecting to the card through a

modem.

4. If you have not already done so on the laptop computer, install

a Direct Connect modem type. You may also wish to install a

modem for remote connection.

5. On the laptop, create a new Dial-up Networking entry.

Create a Modem Connection

1. Install the modem following the manufacturer's installation

instructions.

2. In the Modem Properties/Advanced Settings window - Turn off

error control - Turn on flow control and select Hardware.

Install Direct Connect Device Driver

By default, Windows does not support a direct cable connection.

You must add a device driver. Windows takes the information from

a Mitel file and creates the driver called NT Direct Connection.

Refer to detailed installation and configuration instructions for:

• Direct Connection Device Driver for Windows 95 and Windows

98

• Direct Connection Device Driver for Windows 2000 Professional

Driver for Windows 95 and Windows 98

To install and configure the Direct Connection Device Driver for

Windows 95 or Windows 98:

1. On the Start menu, point to Settings, and then click Control

Panel.

2. Double-click the Modems icon.

3. In the Modem Properties window, click Add.

4. In the Install New Modem screen, click Other.

5. Select Don’t detect my modem, I will select from a list. Click

Next.

6. Click Have Disk.

- 21 -

Page 30

3300 ICP Technician’s Handbook – Release 3.2

7. Type c:\Program Files\Mitel\Imat in the Copy manufacturer's

files from field and click OK.

8. On the Install from Disk window, click OK.

9. Click Next to select the NT Direct Connection.

10. Select COM 1 or COM 2, and then click Next.

11. Click Finish.

12. In the Modem Properties window, select NT Direct

Connection, and then click Properties.

13. Set the following parameters:

- Maximum speed: 38400

- Check: only connect at this speed

- Data bits: 8

- Parity: none

- Stop bits: 1

- Mode: auto answer In the Advanced Settings window, do the

following for a direct connect cable:

- Turn off: error control

- Turn off: flow control

14. Click OK and close the Control Panel window.

Driver for Windows 2000

To install and configure Direct Connection Device Driver for

Windows 2000 Professional:

1. On the Start menu, point to Settings, then click Control Panel.

2. Double-click Phone and Modem Options icon.

3. Select the Modem tab.

4. Click Add.

5. Click Other on the Install New Modem screen.

6. Select Don’t detect my modem, I will select it from a list and

click Next.

7. In the Modems field, select Communications cable between

two computers, then click Next.

8. Select COM 1 or COM 2, then click Next.

- 22 -

Page 31

3300 ICP Technician’s Handbook – Release 3.2

9. Click Finish.

10. T he COM Port will be displayed in the Phone and Modem

Options window, Modems tab. Select the COM Port and then

click Properties.

11. From the Maximum Port Speed drop-down menu, select

38400.

12. In the Communications cable between two computers, select

the Advanced tab, and then click Change Default

Preferences.

13. From the Port speed drop- d o wn list se lec t 38400, and then

from the Flow control drop-down list select None.

14. Select the Advanced tab. From the drop-down menus, set the

fields as follows: - Data bits: 8 - Parity: none - Stop bits: 1

15. Click OK and close the Control Panel window.

Create a Dial-up Network Connection

Typically, you will want to follow this procedure twice to create two

Dial-up Networking connections, one for on-site direct access, and

one for remote modem access.

Refer to detailed instructions for:

• Dial-up Networking Connection for Windows 95 or Windows 98

• Dial-up Network connection for Windows 2000 Professional

Dial-up Connection for Windows 95 or Windows 98

To create a dial-up networking connection for Windows 95 or

Windows 98:

1. On the Start menu, point to Programs, point to Accessories,

and then click Dial-Up Connections.

2. Double-click Make New Connection.

3. Enter an appropriate name for the connection (for example,

Direct for direct connections, Remote or a customer’s name for

remote connections) and click Next. Note: If you are creating a

direct connection, make sure NT Direct Connection is listed in

the drop-down list in the Make a New Connection window.

- 23 -

Page 32

3300 ICP Technician’s Handbook – Release 3.2

4. Enter an Area Code and Telephone Number and select a

Country Code from the drop-down list. Click Next. Note: Even

though it is not needed for a direct connection , Windows

requires that you enter this information.

5. Click Finish.

6. Right-click your new connection icon and click Properties.

7. Click Configure. Ensure the fields are set as follows:

- Data bits: 8

- Parity: none

For a direct connection:

- Maximum speed: 38400

- Check: only connect at this speed

- Select wait for dial tone before dialing

- Select cancel the call time at 60 sec.

- Click Advanced and turn off error control and flow control

For a remote connection:

- Stop bits: 1

- Click Advanced and turn on error control and select Compress

data.

- Turn on flow control and select Hardware.

8. Click OK.

9. Select Server Types tab and make sure that PPP: Windows,

WindowsNT3.5, Internet or PPP:Internet appears in the Type of

Dial-Up Server field.

10. In the Advanced Options field, sele ct Log onto Network and

Enable software compression .

11. Make sure that only TCP/IP is selected in the Allowed network

protocols field.

12. Select the Scripting tab and enter c:\program

files\mitel\Imat\pridun.scp for a 3300 Universal NSU c:\program

files\mitel\Imat\r2dun.scp for a 3300 R2 NSU.

13. Click OK.

Dial-up Connection for Windows 2000

To create a dial-up networking connection for Windows 2000

Professional:

- 24 -

Page 33

3300 ICP Technician’s Handbook – Release 3.2

1. On the Start menu, point to Programs, point to Accessories,

click Communications, and then click Dial-Up Connections.

2. Double click Make New Connection, and then click Next.

3. Select Dial-up to the Internet, and then click Next.

4. Select I want to set up my Internet connection manually, or I

want to connect through a local area network (LAN). Click

Next.

5. Select I connect through a phone line and a modem, and

then click Next.

6. Use the COM Port that has been configured as a NULL Modem

connection: 38400, 8, none, 1.

7. In the Choose Modem box, from the drop-down list select

Communications cable between 2 computers. Click Next.

8. Clear the box Use area code and dialing rules, and then click

Advanced.

9. For the Connection type, select PPP (Point to Point Protocol).

For the Logon procedure, select Use logon script, and then click

Browse. Select pridun.scp. Click OK, and then click Next.

10. In the Internet account logon information box, leave the

username and password fields blank and then click Next.

11. Dialog boxes appear that warn you that you will not be able to

connect to your Internet service provider without your user

name and your password. Disregard these warnings and click

Yes on these boxes to continue.

12. Enter the Connection name, and then click Next.

13. In the box to set up an Internet mail account, select No, and

then click Next.

14. De-select the option to connect to the Internet immediately,

then click Finish.

15. In the Network and Dial-up Connections window, right-click on

the new DUN connection, point to Properties, then click

Configure.

- 25 -

Page 34

3300 ICP Technician’s Handbook – Release 3.2

16. From the Maximum speed (bps) drop-down list, select 38400

for the baud rate.

17. Click OK until you exit the windows.

3300 Universal NSU DIP Switch Settings

Hybrid Port DIP Switch Settings

DIP

Switch

1 Tx Ground Ground when down; floating when up.

2 Rx Ground Ground when down; floating when up.

3 Impedance selector #1 120 ohm (enabled when down)

4 Impedance selector #2 100 ohm (enabled when down)

5 Impedance selector #3 75 ohm (enabled when down)

6 LT/NT selector Up for NT; down for LT.

PRI/T1 Mode Connector DIP Switch Settings

Impedance 1 Tx Gnd 2 Rx

100 Up Up Up Down Up Down

E1/MF-R2 Mode/Connector DIP Switch Settings

BNC

Adapt.

Req’d

No 120 Up Up Down Up Up Up

No 120 Up Up Down Up Up Down

Yes 75 Note Note Up Up Down Up

Yew 75 Note Note Up Up Down Down

Note: Site-dependant – normally Tx is grounded and Rx is not grounded, but

that depends on which remote connection is grounded.

Use Notes

3 I #1 4 I #2 5 I #3 6

Gnd

Imp. 1

Tx

Gnd

2

Rx

Gnd

3

120

ohm

4

100

ohm

5

75

ohm

LT/NT

6

LT/NT

- 26 -

Page 35

3300 ICP Technician’s Handbook – Release 3.2

Install the 3300 R2 NSU

To install and configure the 3300 R2 NSU:

1. Set the DIP switches for the protocol and site installation. The

default configuration of the DIP switches will support T1

protocols in network term inatio n m ode.

2. Establish a fiber connection from the fiber port on the NSU to

the fiber port on the 3300 Controller.

3. Connect the NSU L0 and/or L1 port to the remote system (the

PSTN or another system).

4. Install a Direct Connection Device Driver on a PC. Refer to

Install the 3300 Universal NSU for details.

5. Create a Dial-up Network connection on the PC. Refer to Install

the 3300 Universal NSU for details.

6. Connect the computer to the 3300 R2 NSU.

7. Use the IMAT Tool to complete the required configuration.

8. Connect the 3300 R2 NSU to the PSTN network.

9. Connect the 3300 R2 NSU to the 3300 Controller.

10. Connect power to the NSU.

Connections

Connect the computer to the 3300 R2 NSU

To connect the computer to the 3300 R2 NSU:

1. Connect the serial cable from the computer's COM port to the

3300 R2 NSU 9-pin serial port.

2. On the File menu, click Connect to Remote Site.

3. In the Dial-Up Entry box, select the <name> you entered for

the connection when creating the dial-up connection. (See DialUp Networking Connection.) Note: The 3300 R2 NSU does not

require a password.

4. Ensure that PRI CARD is selected under Remote ISDN

System.

- 27 -

Page 36

3300 ICP Technician’s Handbook – Release 3.2

5. Click Connect.

6. In the Connected to remote site window, click OK.

Note: A networked computer running Win95/98 has difficulties

communicating using Dial-up Networking. It is strongly

suggested that a non-networked computer be used.

Connect the 3300 R2 NSU to the 3300 Controller

A fiber connection originates from a fiber interface module (FIM)

port on the front of the 3300 Controller and is terminated on the FIM

port of the digital trunking 3300 R2 NSU.

The 3300 R2 NSU is connected to the Public Switched Telephone

Network (PSTN) termination point from the L0 port with CAT 5

cable.

MF-R2 Port DIP Switch Settings

Switch Use Default Notes

1 Tx Ground Up Tx shield ground when

down

2 Rx Ground Up Rx shield ground when

down

3 Impedance selector #1 Up 120 ohm

4 Impedance selector #2 Up 100 ohm

5 Impedance selector #3 Up 75 ohm

6 LT/NT selector Up Up for NT, down for LT

- 28 -

Page 37

3300 ICP Technician’s Handbook – Release 3.2

E1/MF-R2 Mode/Connector DIP Switch Setting

BNC

Adapt

Req’d

No 120 NT Up Up Down Up Up Up

No 120 LT Up Up Down Up Up Down

Yes 75 NT Note Note Up Up DownUp

Yes 75 LT Note Note Up Up DownDown

Note: Site dependent - normally Tx is grounded and Rx is not grounded,

but that depends on which remote connection is grounded.

Imp.

LT/NT

Mode1 Tx

Gnd

2

Rx

Gnd

3

120

ohm

4

100

ohm

5

75

ohm6LT/NT

Install the 3300 BRI NSU

To install the 3300 BRI NSU:

1. Configure the 3300 Controller E1 DPNSS on the 3300

Universal NSU that will be used to connect to the 3300 BRI

NSU.

2. Program the BRI-specific requirements for the E1 DPNSS

interface.

3. Set up the maintenance PC.

4. Complete the 3300 BRI NSU programming.

5. Connect power to the NSU.

Note: The 3300 BRI NSU is set for 75 ohms impedance when

connected to a digital trunking NSU running E1 DPNSS. The

3300 Universal NSU is also set for 75 ohms impedance.

Note: A Category 5 connection from the 3300 BRI NSU E1 port

to a 3300 Universal NSU that is running E1 DPNSS. E1

connections as TX and RX pairs in RJ-45. Option to ground one

side of TX and or RX (using DIP switch) to use with coax

adapter.

- 29 -

Page 38

3300 ICP Technician’s Handbook – Release 3.2

Note: The 3300 BRI NSU is connected to an appropriate device

(such as a PSTN or ISDN device) from a 25-pair Amphenol

connector.

Setting Up the Maintenance PC

To install, configure, and maintain the 3300 BRI NSU, you must

connect it to a maintenance computer. The computer must be

running DOS and have a communications program (such as

ProComm Plus ©) installed.

To connect a maintenance PC to the 3300 BRI NSU:

1. Using the RJ45 to 9-pin D-type MMI cable, connect the RS-232

port on the 3300 BRI NSU to COM port 1 or 2 on the PC.

2. Set up the communications program on COM port 1 or 2 with

the following parameters: 9600 baud, 8 data bits, no parity, 1

stop bit, ASCII character set, and XON/XOFF flow control.

3300 NSU Pin Allocations

T1 and E1 Connector Allocation

Signal Name RJ-45 Connector Pin

RXRING 1

RXTIP 2

Not used 3

TXRING 4

TXTIP 5

Not used 6

Not used 7

Not used 8

- 30 -

Page 39

3300 ICP Technician’s Handbook – Release 3.2

RS-232 Maintenance Connector Allocation

Signal Name RJ-45 Connector Pin

DTR (data terminal ready)

DCD (data carrier detector)

RXD (receive data) 2

TXD (transmit data) 3

DTR (data terminal ready) 4

GND 5

Not used 6

RTS (ready to send) 7

CTS (clear to send) 8

Not used 9

BRI Connector Allocation

T1 1

T2 2

T3 3

T4 4

T5 5

T6 6

T7 7

T8 8

T9 9

T10 10

T11 11

T12 12

T13 13

T14 14

T15 15

R1 26

R2 27

1

- 31 -

Page 40

3300 ICP Technician’s Handbook – Release 3.2

BRI Connector Allocation

R3 28

R4 29

R5 30

R6 31

R7 32

R8 33

R9 34

R10 35

R11 36

R12 37

R13 38

R14 39

R15 40

NSU Chaining

NSU chaining refers to the physical connection of two NSUs

together, on one fiber interface, from the Controller. BRI NSUs may

not be chained.

To connect two NSUs to the Controller:

1. Connect the first NSU to the controller through a fiber

connection from the fiber port on the NSU to the fiber port on

the 3300 Controller.

2. Using a CAT5 crossover cable make a connection from CIM2

on the first NSU to CIM1 on the second NSU.

3. Connect power to the NSU.

Note: The first NSU must have the Message Link dip switch set

to 1, up. The second NSU must have the Message Link dip

switch set to 2, down.

- 32 -

Page 41

3300 ICP Technician’s Handbook – Release 3.2

Analog Services Units

Install the 3300 Universal ASU

Before you begin, ensure that there is a free CIM port on the 3300

Controller.

To install the 3300 Universal ASU:

1. Mount the 3300 Universal ASU in the 19-inch rack (if

applicable).

2. Connect the supplied Cross-over Category 5 cable with RJ-45

connector to the CIM port on the 3300 Universal ASU and a

free CIM port on the 3300 Controller. Note that up to four ASUs

can be connected to the 3300 Controller.

3. Complete telephony cabling.

4. Complete programming.

5. Connect power to the 3300 Universal ASU. CIM LEDs will be

on once the CIM link synchronizes. The 3300 Controller will

detect the 3300 Universal ASU, and the application software

will download and start immediately.

Install the 3300 ASU

Before you begin, ensure there is a free CIM port on the 3300

Controller.

To install the 3300 ASU:

1. Mount the 3300 ASU in the 19-inch rack (if applicable).

2. Connect the supplied Cross-over Category 5 cable with RJ-45

connector to the CIM port on the 3300 ASU and a free CIM port

on the 3300 Controller. Up to four ASUs can be connected to a

3300 Controller.

3. Power up the 3300 ASU. CIM LEDs will be on once the CIM link

synchronizes. The 3300 Controller will detect the 3300 ASU,

and the application software will download and start

immediately.

4. Complete telephony cabling.

- 33 -

Page 42

3300 ICP Technician’s Handbook – Release 3.2

5. Complete programming.

3300 ASU and Universal ASU Pin Allocations

CIM Connector Pin Allocations

Pin Signal Pin Signal

1 RX+ 5 Not Used

2 RX- 6 TX3 TX+ 7 Not Used

4 Not Used 8 Not Used

Note: The 3300 Universal ASU connects to the 3300 Controller over a

Category 5 Universal Twisted Pair (UTP) cross-over cable through a CIM

interface. The Category 5 cable is of the same type used for Ethernet

connections and within the cable twisted pairs are arranged as: 1,2: 3,6;

4,5; 7,8. Each tied pair is connected to a 75 ohm resistor. The 3300

Universal ASU can be located up to 30 meters (98.4 feet) away from the

3300 Controller. The interface employs a single standard 8-pin modular

jack consisting of 2 balanced signal pairs and is located on the front of

the unit.

25 pair Connector Pin Allocations

Note: Connection of the Tip and Ring (A and B) leads of the ONS lines

and LS trunk circuits are through a 25 pair female D-type connector.

Pin Signal Pin Signal

1 ONS Tip 1 26 ONS Ring 1

2 ONS Tip 2 27 ONS Ring 2

3 ONS Tip 3 28 ONS Ring 3

4 ONS Tip 4 29 ONS Ring 4

5 ONS Tip 5 30 ONS Ring 5

6 ONS Tip 6 31 ONS Ring 6

7 ONS Tip 7 32 ONS Ring 7

8 ONS Tip 8 33 ONS Ring 8

9 ONS Tip 9 34 ONS Ring 9

- 34 -

Page 43

3300 ICP Technician’s Handbook – Release 3.2

25 pair Connector Pin Allocations

Note: Connection of the Tip and Ring (A and B) leads of the ONS lines

and LS trunk circuits are through a 25 pair female D-type connector.

Pin Signal Pin Signal

10 ONS Tip 10 35 ONS Ring 10

11 ONS Tip 11 36 ONS Ring 11

12 ONS Tip 12 37 ONS Ring 12

13 ONS Tip 13 38 ONS Ring 13

14 ONS Tip 14 39 ONS Ring 14

15 ONS Tip 15 40 ONS Ring 15

16 ONS Tip 16 41 ONS Ring 16

17 LS Tip 1 42 LS Ring 1

18 LS Tip 1-1 43 LS Ring 1-1

19 LS Tip 2 44 LS Ring 2

20 LS Tip 1-2 45 LS Ring 1-2

21 LS Tip 3 46 LS Ring 3

22 LS Tip 1-3 47 LS Ring 1-3

23 LS Tip 4 48 LS Ring 4

24 LS Tip 1-4 49 LS Ring 1-4

25 N/C 50 N/C

- 35 -

Page 44

3300 ICP Technician’s Handbook – Release 3.2

Music on Hold Connector Pin Allocations (Universal ASU only)

Pin Signal Pin Signal

1 Tip 1 5 Ring 3

2 Ring 1 6 Ring 2

3Tip 27Tip 4

4 Tip 3 8 Ring 4

Note: The four MOH tips & rings occupy an 8 pin female modular jack

located on the rear panel.

Note: Only one port is supported through software on the system.

Paging Connector Pin Assignments (Universal ASU only)

Pin Signal Pin Signal

1 Tip 1 5 Ring 2

2 Ring 1 6 Ring 1-1

3 Tip 1-1 7 Tip 1-2

4 Tip 2 8 Ring 1-2

Note: The paging port employs a single standard 8-pin modular RJ-45

jack located on the rear panel.

Each paging port has a tip/ring pair for audio and a second tip/ring pair

designated tip1/ring1 contact closures for zone control.

- 36 -

Page 45

3300 ICP Technician’s Handbook – Release 3.2

Peripheral Unit

Overview of the Peripheral Unit Installation

To install a Peripheral Unit:

1. Unpack, position, and ground the Peripheral Unit.

2. Check the card layout.

3. Connect the fiber cable to the node.

4. Check the grounding.

5. Install the power converter.

6. Install the Peripheral Interface cards.

7. Cable the node to the MDF.

8. Power up the Peripheral Unit.

Note: For information about removing and replacing the front

panel of the cabinet, see Front Panels in Install Upgrades and

FRUs.

Proceed to Installing a DSU Node, Installing a SUPERSET HUB, or

return to System Installation Overview.

Unpack, Position, and Ground the Peripheral Unit

To unpack, position, and ground the node:

CAUTION: Power must not be applied to the Peripheral Unit

until you have installed the ground cable.

1. Unpack the peripheral node.

2. Check the contents against the packing list.

3. Visually inspect the node and attached equipment for damage.

Repack and return any damaged equipment.

4. Position the node.

5. Connect an external ground to the ground terminal on the rear

panel of the peripheral cabinet. Refer to the Safety Instructions

- 37 -

Page 46

3300 ICP Technician’s Handbook – Release 3.2

for detailed grounding requirements. These instructions are

packaged with each system.

Peripheral Unit Card Layout

Typically, a peripheral cabinet is shipped with the peripheral switch

controller (PSC) card and Fiber Interface Module (FIM) installed. If

these cards were not shipped in the cabinet, install them as Field

Replaceable Units (FRUs). You must install and cable the FIM

before you install the peripheral switch controller card and power

converter (see Peripheral Unit FRUs section).

The cards in the peripheral unit should be installed in the following

configuration:

Slot Number Card Type

1 to 12 Peripheral Interface card

13, 14, 15 (combined) Power Converter

16 Peripheral Switch Controller (PSC)

17 Fiber Interface Module (FIM)

Note: If you are installing an expanded Peripheral Unit, or

expanding an existing one, the card layout will be different

depending on if the cabinet is used as the master or slave of

the peripheral pair.

- 38 -

Page 47

3300 ICP Technician’s Handbook – Release 3.2

Connect Fiber Cable to the Peripheral Unit

The fiber optic cable connects the FIM in the 3300 Controller to the

FIM in the Peripheral Unit.

To connect the fiber optic cable to the FIM in the peripheral node:

1. Review the guidelines for handling fiber optic cable.

2. Route the fiber optic cable through the cable port at the rear of

the peripheral cabinet into the cabinet. Extend the fiber cable

approximately 30 cm (1 ft) beyond the front of the cabinet.

3. Install a short piece of nylon spiral wrap over the cable at the

point where the cable exits the rear of the cabinet.

4. Close the sliding cable port door. Ensure that the door closes

on the nylon spiral-wrapped section of fiber cable.

- 39 -

Page 48

3300 ICP Technician’s Handbook – Release 3.2

5. Remove the plastic dust caps from the fiber optic cable and the

connector ferrules on the FIM faceplate.

6. Plug the fiber connectors into the connectors on the FIM

faceplate. The fiber connectors have a small key that must be

aligned with a slot on the FIM connectors. Lock each connector

into position by pushing the metal collar forward and clipping it

onto the FIM connector.

Peripheral Unit Grounding

CAUTION: Ensure that the grounding meets the requirements

specified in the Safety Instructions. These instructions are

packaged with each system.

WARNING: Danger to personnel and/or equipment damage

could result if the cabinet is not powered off.

To check the grounding:

1. Ensure that the power switch (S1) on the power distribution unit

(PDU) is set to the off (0) position and that the switch on the

power converter faceplate is set to the off (0) position.

2. Attach the anti-static wrist strap to your wris t.

3. Slide the installed circuit cards forward slightly so that the card

connectors are not in contact with the cabinet backplane. Leave

the power converter installed.

4. Remove the anti-static wrist strap.

5. Plug the external power cable from the AC commercial power

supply into the power-input plug on the power distribution unit

(PDU).

6. Disconnect the protective earth wire from the protective earth

ground stud on the rear of the cabinet.

7. Using a digital multimeter, measure the AC potential between

the protective earth wire (build in g ground) and the pr otective

earth ground stud. A voltage reading of less than 1 VAC is

acceptable. To prevent damage to the multimeter, set it to the

maximum AC scale, then reduce the setting gradually to the 10

VAC range.

- 40 -

Page 49

3300 ICP Technician’s Handbook – Release 3.2

8. If the potential is greater than 1 VAC, recheck the ground

connections and repeat the measure.

9. If the reading still exceeds 1 VAC, the building ground is

unacceptable. Connect the protective earth wire to a new

building ground and repeat the steps 7 through 9 until you have

an acceptable AC potential. WARNING: Do not continue until

you have a potential of 1 VAC or less between the building

ground and the protective earth ground stud. Otherwise,

personal injury and/or equipment damage may result.

10. Reconnect the protective earth wire to the protective earth

ground stud and attach the anti-static wrist strap to your wrist.

11. Slide the installed circuit cards back into contact with the

cabinet backplane. Ensure that each card is fully inserted in its

slot.

Power Converter

To install an AC power converter:

WARNING: Danger to personnel and/or equipment damage

could result if the cabinet is not powered off during installation

of the AC power converter.

1. At the rear of the cabinet, remove the two screws that fasten

the internal AC power cord access cover plate to the backplane,

and remove the cover plate (see figure).

2. Ensure that the switch on the power converter faceplate is set

to off (0).

3. Install the power converter in slots 13 through 15.

4. Plug the internal AC power cord from the power distribution unit

(PDU) into the power converter through the access cutout in the

backplane.

5. Replace the internal AC power cord access cover plate over the

access cutout in the backplane, and replace the two screws.

- 41 -

Page 50

3300 ICP Technician’s Handbook – Release 3.2

- 42 -

Page 51

3300 ICP Technician’s Handbook – Release 3.2

Install Peripheral Interface Cards

To install the Peripheral Interface cards:

CAUTION: To prevent static damage to electrical components,

ensure that the system is grounded before you install the

cards. Whenever you handle circuit cards, wear an anti-static

strap.

1. Install the peripheral switch controller card in slot 16.

2. Set the E&M Trunk Card settings and the OPS Line Card

Message Waiting Switches in the Peripheral Unit Specifications

section.

3. Install the Peripheral Interface cards. Refer to Install a Circuit

Card in "Install Upgrades and FRUs" for circuit card installation

procedures.

Cable the Unit to the MDF

Cable the lines and trunks from the Peripheral Unit to the Main

Distribution Frame (MDF) by using the Peripheral Interface Cabling

Tables.

About Peripheral Interface Cabling

Peripheral equipment (e.g., stations, SUPERSET telephones,

trunks) is connected to the relevant interface circuits of the system

via a cross-connect field. Peripheral Interface cards, situated in

slots 1 through 12, are connected to the cross-connect field by a

maximum of eight 25-pair cables (customer-supplied) per

Peripheral Unit. Cables terminate at the node on 50-pin plugs, J1

through J8, with the number of cables being dependent on the

quantity and type of interface cards installed in the node.

Plugs J1 through J8 are hardwired to backplane connectors in slots

1 through 12 to form four slot groups, each comprising three

adjacent cards and each associated with a pair of plugs. T wo

adjacent slot groups are shown in Backplane Connector

Arrangements. The circuits of interface cards contained in a slot

group are evenly distributed to the relevant pair of plugs, such that,

half the circuits of each card in a group are connected to the odd-

- 43 -

Page 52

3300 ICP Technician’s Handbook – Release 3.2

numbered plug and half to the even-numbered plug. Peripheral

Wiring (Backplane) details the hardwire connections between one

slot group and the associated plugs. The wiring sequence is

identical for the remaining three slot groups.

Cable jacks (P1 through P8), are customer-supplied and should be

labeled at time of installation. P1 through P8 are secured to J1

through J8 with hook and loop type fasteners. Equipment that is

external to the system (i.e., system to cross-connect field cables

and cross-connect field hardware) is not supplied by MITEL.

Therefore, the type of equipment used and the layout of the crossconnect field cables is at the discretion of the installation company.

Installation information for such equipment must be obtained from

the equipment manufacturer.

Backplane Connector Arr ang ements

- 44 -

Page 53

3300 ICP Technician’s Handbook – Release 3.2

Peripheral Wiring (Backplane)

Peripheral Interface Cabling Tables

Use the tables to cable the Peripheral Unit card connectors to the

main distribution frame.

Note: When cabling the SX-2000 MICRO LIGHT node

connectors, use the cabling tables that correspond to the

Peripheral Interface card slot in the node.

Cable Connectors

Connectors for customer supplied 25-pair cables terminating on

peripheral backplane (to MDF) and SFT unit (to MDF) use AMP

Champ or equivalent cable connectors:

• 50-pin RS (receptacle - screw lock)

• female

• screw lock

- 45 -

Page 54

3300 ICP Technician’s Handbook – Release 3.2

• 90 tapered slide-on hood.

USOC Connector Pin Designations

The USOC connector numbers are:

• RJ2I X for CO Trunks

• RJ2EX for 2-wire E&M Trunks

• RJ2FX for 4-wire E&M Trunks

• RJ2GX for 4-wire E&M Trunks

• RJ2HX for 4-wire E&M Trunks.

USOC Connector Pin Designations

Pin Color Code RJ21X RJ2EX RJ2GX RJ2FX RJ2HX

26 W/BL T T T T T

1BL/W R R R R R

27 W/O T E T1 E T1

2 O/W R M R1 SG R1

28 W/G T T E M E

3G/W R R M SB SG

29 W/BR T E T T M

4BR/W R M R R SB

30 W/S T T T1 E T

5S/W R R R1 SG R

31 R/BL T E E M T1

6BL/R R M M SB R1

32 R/O T T T T E

7O/R R R R R SG

33 R/G T E T1 E M

8 G/R R M R1 SG SB

34 R/BR T T E M T

9BR/R R R M SB R

35 R/S T E T T T1

10 S/R R M R R R1

- 46 -

Page 55

3300 ICP Technician’s Handbook – Release 3.2

Pin Color Code RJ21X RJ2EX RJ2GX RJ2FX RJ2HX

36 BK/BL T T T1 E E

11 BL/BK R R R1 SG SG

37 BK/O T E E M M

12 O/BK R M M SB SB

38 BK/G T T T T T

13 G/BK R R R R R

39 BK/BR T E T1 E T1

14 BR/BK R M R1 SG R1

40 BK/S T T E M E

15 S/BK R R M SB SG

41 Y/BL T E T T M

16 BL/Y R M R R SB

42 Y/O T T T1 E T

17 O/Y R R R1 SG R

43 Y/G T E E M T1

18 G/Y R M M SB R1

44 Y/BR T T T T E

19 BR/Y R R R R SG

45 Y/S T E T1 E M

20 S/Y R M R1 SG SB

46 V/BL T T E M T

21 BL/V R R M SB R

47 V/O T E T T T1

22 O/V R M R R R1

48 V/G T T T1 E E

23 G/V R R R1 SG SG

49 V/BR T E E M M

24 BR/V R M M SB SB

50 V/S -- -- SPARE -- -25 S/V -- -- SPARE -- --

- 47 -

Page 56

3300 ICP Technician’s Handbook – Release 3.2

Card Connections to Cross-Connect Field

The following tables show the “pin-out” signals of the interface

cards as they appear on J1 through J8. The following abbreviations

are used in the tables:

ONS L C: ONS line card and ONS CLASS/CLIP line card

OPS L C: OPS line card

LS/GS Trunk: Loop Start/Ground Start Trunk card

E&M Trunk: E&M trunk card

DID/LT Trunk: direct inward dialing/loop tie trunk card

DID/2 Trunk: direct inward dialing

DNI L C: digital network interface line card.

Tables for Card Slots 1 through 12 follow.

Card Slot 1

Card Slot 1 Connections To Cross-Connect Field

Pin Color

Code

26

W/BL

1

BL/W

27

W/O

2

O/W

28

W/G

3

G/W

29

W/BR

4

BR/W

30

W/S

5

S/W

31

R/BL

6

BL/R

32

R/O

7

O/R

ONS

L C

1T

1R

2T

2R

3T

3R

4T

4R

5T

5R

6T

6R

7T

7R

OPS

L C

1T

1R

1MWB

1MWA

2T

2R

2MWB

2MWA

3T

3R

3MWB

3MWA

4T

4R

LS/GS

Trunk

1T

1R

1T(MR)

1R(MR)

2T

2R

2T(MR)

2R(MR)

3T

3R

3T(MR)

3R(MR)

4T

4R

- 48 -

E&M

Trunk

1T

1R

1T1

1R1

1E

1SG

1M

1SB

2T

2R

2T1

2R1

2E

2SG

DID/LT

Trunk

1T

1R

2T

2R

DID/2

Trunk

1T

1R

2T

2R

3T

3R

4T

4R

DNI

L C

1T

1R

2T

2R

3T

3R

4T

4R

5T

5R

6T

6R

7T

7R

Backplane

Plugs

P1

Page 57

3300 ICP Technician’s Handbook – Release 3.2

Card Slot 1 Connections To Cross-Connect Field

Pin Color

Code

338R/G

G/R8T8R

26

W/BL

1

BL/W

27

W/O

2

O/W

28

W/G

3

G/W

29

W/BR

4

BR/W

30

W/S

5

S/W

31

R/BL

6

BL/R

32

R/O

7

O/R

33

R/G

8

G/R

ONS

L C

9T

9R

10T

10R

11T

11R

12T

12R

13T

13R

14T

14R

15T

15R

16T

16R

OPS

L C

4MWB

4MWA

5T

5R

5MWB

5MWA

6T

6R

6MWB

6MWA

7T

7R

7MWB

7MWA

8T

8R

8MWB

8MWA

LS/GS

Trunk

4T(MR)

4R(MR)2M2SB

5T

5R

5T(MR)

5R(MR)

6T

6R

6T(MR)

6R(MR)

7T

7R

7T(MR)

7R(MR)

8T

8R

8T(MR)

8R(MR)

E&M

Trunk

3T

3R

3T1

3R1

3E

3SG

3M

3SB

4T

4R

4T1

4R1

4E

4SG

4M

4SB

DID/LT

Trunk

3T

3R

4T

4R

DID/2

Trunk

5T

5R

6T

6R

7T

7R

8T

8R

DNI

L C

8T

8R

9T

9R

10T

10R

11T

11R

12T

12R

13T

13R

14T

14R

15T

15R

16T

16R

Backplane

Plugs

P2

Card Slot 2

Card Slot 2 Connections To Cross-Connect Field

Pin Color

Code

34

R/BR

9

BR/R

35

R/S

10

S/R

36

BK/BL

11

BL/BK

ONS

L C

1T

1R

2T

2R

3T

3R

OPS

L C

1T

1R

1MWB

1MWA

2T

2R

LS/GS

Trunk

1T

1R

1T(MR)

1R(MR)

2T

2R

E&M

Trun

k

1T

1R

1T1

1R1

1E

1SG

- 49 -

DID/LT

Trunk

1T

1R

2T

2R

DID/2

Trunk

1T

1R

2T

2R

DNI

L C

1T

1R

2T

2R

3T

3R

Backplane

Plugs

Page 58

3300 ICP Technician’s Handbook – Release 3.2

Card Slot 2 Connections To Cross-Connect Field

Pin Color

Code

37

BK/O

12

O/BK

38

BK/G

13

G/BK

39

BK/B

R

14

BR/B

40

K

15

BK/S

41

S/BK

16

Y/BL

B/Y

34

R/BR

9

BR/R

35

R/S

10

S/R

36

BK/BL

11

BL/BK

37

BK/O

12

O/BK

38

BK/G

13

G/BK

39

BK/B

R

14

BR/B

40

K

15

BK/S

41

S/BK

16

Y/BL

BL/Y

ONS

L C

4T

4R

5T

5R

6T

6R

7T

7R

8T

8R

9T

9R

10T

10R

11T

11R

12T

12R

13T

13R

14T

14R

15T

15R

16T

16R

OPS

L C

2MWB

2MWA

3T

3R

3MWB

3MWA

4T

4R

4MWB

4MWA

5T

5R

5MWB

5MWA

6T

6R

6MWB

6MWA

7T

7R

7MWB

7MWA

8T

8R

8MWB

8MWA

LS/GS

Trunk

2T(MR)

2R(MR)

3T

3R

3T(MR)

3R(MR)

4T

4R

4T(MR)

4R(MR

5T

5R

5T(MR)

5R(MR)

6T

6R

6T(MR)

6R(MR)

7T

7R

7T(MR)

7R(MR)

8T

8R

8T(MR)

8R(MR)

E&M

Trun

k

1M

1SB

2T

2R

2T1

2R1

2E

2SG

2M

2SB

3T

3R

3T1

3R1

3E

3SG

3M

3SB

4T

4R

4T1

4R1

4E

4SG

4M

4SB

DID/LT

Trunk

3T

3R

4T

4R

DID/2

Trunk

3T

3R

4T

4R

5T

5R

6T

6R

7T

7R

8T

8R

DNI

L C

4T

4R

5T

5R

6T

6R

7T

7R

8T

8R

9T

9R

10T

10R

11T

11R

12T

12R

13T

13R

14T

14R

15T

15R

16T

16R

Backplane

Plugs

P1

P2

- 50 -

Page 59

3300 ICP Technician’s Handbook – Release 3.2

Card Slot 3

Card Slot 3 Connections To Cross-Connect Field

Pin

42

17

43

18

44

19

45

20

46

21

47

22

48

23

49

24

50

25

42

17

43

18

44

19

45

20

46

21

47

22

48

23

49

Color

Code

Y/O

0/Y

Y/G

G/Y

Y/BR

BR/Y

Y/S

S/Y

V/BL

BL/V

V/O

O/V

V/G

G/V

V/BR

BR/V

-----

----Y/O

O/Y

Y/G

G/Y

Y/BR

BR/Y

Y/S

S/Y

V/BL

BL/V

V/O

O/V

V/G

G/V

V/BR

ONS

L C

1T

1R

2T

2R

3T

3R

4T

4R

5T

5R

6T

6R

7T

7R

8T

8R

-----

----9T

9R

10T

10R

11T

11R

12T

12R

13T

13R

14T

14R

15T

15R

16T

OPS

L C

1T

1R

1MWB

1MWA

2T

2R

2MWB

2MWA

3T

3R

3MWB

3MWA

4T

4R

4MWB

4MWA

-----

----5T

5R

5MWB

5MWA

6T

6R

6MWB

6MWA

7T

7R

7MWB

7MWA

8T

8R

8MWB

LS/GS

Trunk

1T

1R

1T(MR)

1R(MR)

2T

2R

2T(MR)

2R(MR)

3T

3R

3T(MR)

3R(MR)

4T

4R

4T(MR)

4R(MR)

-----

----5T

5R

5T(MR)

5R(MR)

6T

6R

6T(MR)

6R(MR)

7T

7R

7T(MR)

7R(MR)

8T

8R

8T(MR)

E&M

Trunk

1T

1R

1T1

1R1

1E

1SG

1M

1SB

2T

2R

2T1

2R1

2E

2SG

2M

2SB

SPARE

SPARE

3T

3R

3T1

3R1

3E

3SG

3M

3SB

4T

4R

4T1

4R1

4E

4SG

4M

DID/LT

Trunk

1T

1R

2T

2R

-----

----3T

3R

4T

4R

DID/2

Trun

k

1T

1R

2T

2R

3T

3R

4T

4R

-----

----5T

5R

6T

6R

7T

7R

8T

8R

DNI

L C

1T

1R

2T

2R

3T

3R

4T

4R

5T

5R

6T

6R

7T

7R

8T

8R

-----

----9T

9R

10T

10R

11T

11R

12T

12R

13T

13R

14T

14R

15T

15R

16T

Backplane

Plugs

P1

P2

- 51 -

Page 60

3300 ICP Technician’s Handbook – Release 3.2

Card Slot 3 Connections To Cross-Connect Field

Pin Color

Code

24

BR/V

50

-----

25

-----

ONS

L C

16R

-----

-----

OPS

L C

8MWA

-----

-----

LS/GS

Trunk

8R(MR)

-----

-----

E&M

Trunk

4SB

SPARE

SPARE

Card Slot 4

Card Slot 4 Connections To Cross-Connect Field

Pin Color

Code

W/BL

26

BL/W

1

W/O

27

O/W

2

W/G

28

G/W

3

W/BR

29

BR/W

4

W/S

30

S/W

5

R/BL

31

BL/R

6

R/O

32

O/R

7

R/G

33

G/R

8

W/BL