Page 1

Resona 7/Resona 7CV/Resona 7EXP/Resona 7S/Resona 7OB

Diagnostic Ultrasound System

Service Manual

Revision 11.0

Page 2

Page 3

i

Table of Content

Table of Content .....................................................................................................................i

Revision History .....................................................................................................................I

Intellectual Property Statement ............................................................................................II

Applicable for .........................................................................................................................II

Statement ...............................................................................................................................II

Responsibility on the Manufacturer Party .........................................................................III

Customer Service Department ............................................................................................III

1 Safety Precautions ..................................................................................................... 1-1

1.1 Meaning of Signal Words ..................................................................................................... 1-1

1.2 Symbols ................................................................................................................................ 1-1

1.2.1 Meaning of Safety Symbols .......................................................................................... 1-1

1.2.2 Warning Labels ............................................................................................................. 1-2

1.2.3 General Symbols .......................................................................................................... 1-2

1.3 Safety Precautions ............................................................................................................... 1-4

1.3.1 Electric safety ............................................................................................................... 1-4

1.3.2 Mechanical safety ......................................................................................................... 1-5

1.3.3 Personnel Safety .......................................................................................................... 1-5

1.3.4 Other ............................................................................................................................. 1-5

2 Specifications ............................................................................................................. 2-1

2.1 Overview .............................................................................................................................. 2-1

2.1.1 Intended Use ................................................................................................................ 2-1

2.1.2 Introduction of Each Unit .............................................................................................. 2-1

2.1.3 Peripherals Supported .................................................................................................. 2-9

2.2 Specifications ....................................................................................................................... 2-9

2.2.1 Dimensions & Weight ................................................................................................... 2-9

2.2.2 Electrical Specifications ................................................................................................ 2-9

2.2.3 Environmental Conditions ........................................................................................... 2-10

2.2.4 Monitor Specification .................................................................................................. 2-10

3 System Installation ..................................................................................................... 3-1

3.1 Preparations for Installation.................................................................................................. 3-1

3.1.1 Electrical Requirements ................................................................................................ 3-1

3.1.2 Installation Conditions ..................................................................................................... 3-2

3.1.3 Confirmation before Installation .................................................................................... 3-3

3.2 Unpacking ............................................................................................................................ 3-3

3.2.1 Unpacking Process ....................................................................................................... 3-3

3.2.2 Checking ....................................................................................................................... 3-6

3.3 Bare Machine Transport ....................................................................................................... 3-7

3.3.1 Tool ............................................................................................................................... 3-7

3.3.2 Device Transport ........................................................................................................... 3-8

3.3.3 Fixing Methods ............................................................................................................. 3-8

3.4 Installing Main Unit ............................................................................................................. 3-11

3.4.1 Opening up the Monitor .............................................................................................. 3-11

3.4.2 Connecting the Power Cord ....................................................................................... 3-11

3.4.3 Connecting ECG ......................................................................................................... 3-12

Page 4

ii

3.4.4 Installing Probe Holder ............................................................................................... 3-12

3.4.5 Installing Gel Holder ................................................................................................... 3-12

3.4.6 Connecting the Transducer ........................................................................................ 3-14

3.5 Installing Peripherals .......................................................................................................... 3-15

3.5.1 Connecting a Footswitch ............................................................................................ 3-15

3.5.2 Installing a Graph / Laser Printer ................................................................................ 3-16

3.5.3 Installing Video Printer ................................................................................................ 3-18

3.5.4 Installing a Wireless Printer ........................................................................................ 3-19

3.5.5 Installing a Barcode Scanner ...................................................................................... 3-20

3.6 Ascending/descending the Main Control Panel Manually .................................................. 3-21

3.7 System Configuration ......................................................................................................... 3-24

3.7.1 Running the System ................................................................................................... 3-24

3.7.2 Entering Doppler ......................................................................................................... 3-24

3.7.3 System Preset ............................................................................................................ 3-25

3.7.4 Printer Preset .............................................................................................................. 3-26

3.7.5 Network Preset ........................................................................................................... 3-27

3.7.6 DICOM/HL7 Preset ..................................................................................................... 3-28

3.7.7 Check System Information ......................................................................................... 3-29

4 Product Principle ........................................................................................................ 4-1

4.1 General Structure of Hardware System ............................................................................... 4-1

4.2 Ultrasound Front Unit ........................................................................................................... 4-2

4.2.1 Probe Board .................................................................................................................. 4-3

4.2.2 TR Board ...................................................................................................................... 4-4

4.2.3 Engine Board ................................................................................................................ 4-5

4.2.4 ECG Module ................................................................................................................. 4-6

4.2.5 4D-TEE Board .............................................................................................................. 4-7

4.3 Ultrasound Back-end Unit .................................................................................................... 4-7

4.3.1 COME (CPU) module ................................................................................................... 4-8

4.3.2 Independent GPU (GPU) .............................................................................................. 4-8

4.3.3 Memory device (SSD&SATA hard disk) ........................................................................ 4-8

4.3.4 PC carrier board ........................................................................................................... 4-8

4.3.5 User I/O Interface Board ............................................................................................. 4-16

4.3.6 WiFi Module ................................................................................................................ 4-17

4.4 Power Supply Unit .............................................................................................................. 4-17

4.4.1 AC Interface Module ................................................................................................... 4-17

4.4.2 Auxiliary Output Power Isolation Transformer ............................................................ 4-18

4.4.3 AC-DC module ............................................................................................................ 4-18

4.4.4 DC-DC board .............................................................................................................. 4-18

4.4.5 PHV module ................................................................................................................ 4-18

4.5 New Power Supply Unit ..................................................................................................... 4-19

4.5.1 AC-DC module ............................................................................................................ 4-20

4.5.2 12V to 24V Control Board ........................................................................................... 4-20

4.5.3 DC-DC board .............................................................................................................. 4-20

4.5.4 PHV module ................................................................................................................ 4-20

4.6 User Interaction Unit........................................................................................................... 4-21

4.6.1 Control Panel .............................................................................................................. 4-21

4.6.2 Primary Display Assembly .......................................................................................... 4-22

4.6.3 Secondary Display Assembly ..................................................................................... 4-22

4.6.4 Electrical Ascending/Descending and Electromagnet ................................................ 4-23

5 Function and Performance Checking Method ......................................................... 5-1

Page 5

iii

5.1 NOTE ................................................................................................................................... 5-1

5.2 Device Status Checking ....................................................................................................... 5-1

5.2.1 Running Status ............................................................................................................. 5-1

5.2.2 Working Condition ........................................................................................................ 5-1

5.3 General Exam ...................................................................................................................... 5-2

5.3.1 Check Flow ................................................................................................................... 5-2

5.3.2 Checking Content ......................................................................................................... 5-2

5.4 Function Checking ................................................................................................................. 5-4

5.4.1 Check Flow ................................................................................................................... 5-5

5.4.2 Content ......................................................................................................................... 5-5

5.5 Performance Test ............................................................................................................... 5-11

5.5.1 Test Process ............................................................................................................... 5-11

5.5.2 Test Content ................................................................................................................ 5-11

6 Software Installation &Maintenance ......................................................................... 6-1

6.1 Entering Maintenance .......................................................................................................... 6-1

6.2 Set Installment ...................................................................................................................... 6-1

6.3 Software Installation/Restoration ......................................................................................... 6-4

6.4 Enter Windows ..................................................................................................................... 6-4

6.5 Software Maintenance .......................................................................................................... 6-5

6.5.1 Export Log .................................................................................................................... 6-5

6.6 Data Backup and Storage .................................................................................................... 6-5

6.6.1 Preset Data Management ............................................................................................. 6-5

6.6.2 Patient Data Backup and Restoration .......................................................................... 6-6

6.7 Introduction on Hard Disk's Partitions .................................................................................. 6-7

7 Adjustments ................................................................................................................ 7-1

7.1 Adjusting Monitor .................................................................................................................. 7-1

7.1.1 Adjusting Position ......................................................................................................... 7-1

7.1.2 Adjusting Brightness and Contrast ............................................................................... 7-3

7.1.3 Monitor Test .................................................................................................................. 7-3

7.2 Touch Screen Adjustment .................................................................................................... 7-6

7.2.1 Touch Screen Brightness and Contrast Adjustment ..................................................... 7-6

7.2.2 Touch Screen Test ........................................................................................................ 7-6

7.3 Control Panel Adjustment ..................................................................................................... 7-7

7.4 Adjusting Caster ................................................................................................................... 7-7

8 Field Replaceable Unit ............................................................................................... 8-1

9 Structure and Assembly/Disassembly ...................................................................... 9-1

9.1 Structure of the Complete System ....................................................................................... 9-1

9.2 Preparation ........................................................................................................................... 9-2

9.2.1 Tools Required .............................................................................................................. 9-2

9.2.2 Engineers Required ...................................................................................................... 9-2

9.2.3 Requirements ............................................................................................................... 9-2

9.3 Assembly/Disassembly ........................................................................................................ 9-3

9.3.1 Large/Small Probe Holders, Left Bracket of Coupling Gel Heating cup, Intracavitary Probe

Holder 9-4

9.3.2 Cup Rack Assembly...................................................................................................... 9-5

9.3.3 Wire Pothook Assembly ................................................................................................ 9-6

9.3.4 Mesh of the Base .......................................................................................................... 9-6

9.3.5 Display (monitor) Assembly .......................................................................................... 9-7

9.3.6 Control Panel Assembly ............................................................................................... 9-9

Page 6

iv

9.3.7 Handle Panel Assembly ............................................................................................. 9-20

9.3.8 Touch Screen Assembly ............................................................................................. 9-20

9.3.9 Speaker Cover Assembly ........................................................................................... 9-22

9.3.10 Left/Right Speaker Assembly ...................................................................................... 9-23

9.3.11 Upper/Lower Support Arm Cover ............................................................................... 9-23

9.3.12 Support Arm Assembly ............................................................................................... 9-24

9.3.13 LCD Signal Connector PCBA assembly ..................................................................... 9-25

9.3.14 Support Arm Spanner/Bale of Wire for the Monitor/Side Control Panel Base/Base

Assembly ................................................................................................................................. 9-26

9.3.15 Control Panel Moving Mechanism Assembly ............................................................. 9-29

9.3.16 Main Unit Rear Cover Assembly ................................................................................. 9-34

9.3.17 Main Unit Left Cover Assembly .................................................................................. 9-34

9.3.18 Main Unit Right Cover Assembly ................................................................................ 9-35

9.3.19 Main Unit Front-top Cover Assembly .......................................................................... 9-36

9.3.20 Turbine Cover ............................................................................................................. 9-37

9.3.21 Turbine Protective Shell Assembly ............................................................................. 9-37

9.3.22 Main Unit Top Cover/Main Unit Top Cover Assembly ................................................. 9-38

9.3.23 Right/Left Brake Pedal ................................................................................................ 9-39

9.3.24 Machine Assembly...................................................................................................... 9-40

9.3.25 PC Main Board Assembly ........................................................................................... 9-47

9.3.26 Wireless Net Adapter .................................................................................................. 9-51

9.3.27 Antenna and Cable Assembly .................................................................................... 9-52

9.3.28 IO Assembly ................................................................................................................ 9-53

9.3.29 Probe Board Assembly ............................................................................................... 9-54

9.3.30 Electronics Assembly on the Base ............................................................................. 9-55

9.3.31 HDD Assembly ............................................................................................................ 9-63

9.3.32 DVD Assembly ............................................................................................................ 9-64

9.3.33 Front Output panel ...................................................................................................... 9-66

9.3.34 ECG Assembly ............................................................................................................ 9-68

9.3.35 Signal Cable of ECG Module ...................................................................................... 9-68

9.3.36 Mother Board Assembly ............................................................................................. 9-69

9.3.37 Housing Assembly of the Main Unit ............................................................................ 9-72

9.3.38 Magnetic Generator Trolley ........................................................................................ 9-88

9.3.39 Magnetic Navigator ..................................................................................................... 9-91

10 Installing Options ..................................................................................................... 10-1

10.1 Installing Optional Software ................................................................................................ 10-1

10.2 Installation of Hardware Optional Function ........................................................................ 10-3

10.2.1 Magnetic Transmitter Trolley Assembly ...................................................................... 10-4

10.2.2 Probe Adapter Installation .......................................................................................... 10-6

10.2.3 Pencil Probe Signal Cable Assembly ......................................................................... 10-7

11 System Diagnosis and Support ................................................................................11-1

11.1 General Status Indicator ..................................................................................................... 11-1

11.1.1 Indicators on Control Panel ........................................................................................ 11-1

11.1.2 The Status Indicator of the Batteries on IO Rear Board ............................................. 11-1

11.1.3 Display Status Indicator .............................................................................................. 11-2

11.1.4 Status of Entire Device ............................................................................................... 11-2

11.2 Starting Process of the Whole Machine ............................................................................. 11-3

11.3 Alarming and Errors ........................................................................................................... 11- 4

11.3.1 The voltage of system power is abnormal .................................................................. 11-4

11.3.2 Abnormal Temperature ............................................................................................... 11-4

Page 7

v

11.3.3 Fan Error ..................................................................................................................... 11 -5

11.3.4 PHV Error ................................................................................................................... 11-5

11.3.5 4D Board Error ............................................................................................................ 11-6

11.3.6 Other Errors ................................................................................................................ 11-6

11.3.7 Error Code List ............................................................................................................ 11-7

11.4 Self Test ............................................................................................................................ 11-12

11.4.1 Self Test Introduction ................................................................................................ 11-12

11.4.2 Operation Procedures of Maintenance Self Test ...................................................... 11-12

11.4.3 User Self Test ........................................................................................................... 11-17

11.4.4 Test Report ............................................................................................................... 11-19

12 Care and Maintenance .............................................................................................. 12-1

12.1 Overview ............................................................................................................................ 12-1

12.1.1 Tools, Measurement Devices and Consumables ....................................................... 12-1

12.1.2 Routine Maintenance Items ........................................................................................ 12-1

12.2 Cleaning ............................................................................................................................. 12-3

12.2.1 System Cleaning ......................................................................................................... 12-3

12.2.2 Peripherals Cleaning .................................................................................................. 12-7

12.3 Check ................................................................................................................................. 12-8

12.3.1 General Check ............................................................................................................ 12-8

12.3.2 System Performance Check ....................................................................................... 12-8

12.3.3 Check for Peripherals and Optional Functions ........................................................... 12-9

12.3.4 Mechanical Safety Inspection ................................................................................... 12-10

12.3.5 Electrical Safety Inspection ...................................................................................... 12-12

13 Troubleshooting of Regular Malfunctions .............................................................. 13-1

13.1 System Cannot Power On .................................................................................................. 13-1

13.1.1 Related Modules or Boards ........................................................................................ 13-1

13.1.2 Key Points Supporting Troubleshooting ..................................................................... 13-1

13.1.3 Troubleshooting---System Cannot Power up ............................................................. 13-2

13.2 System Cannot Start .......................................................................................................... 13-3

13.2.1 Related Modules or Boards ........................................................................................ 13-3

13.2.2 Key Points Supporting Troubleshooting ..................................................................... 13-3

13.2.3 Troubleshooting—The System Cannot Start .............................................................. 13-3

13.3 Image Problems ................................................................................................................. 13-4

13.3.1 Related Modules or Boards ........................................................................................ 13-4

13.3.2 Key Points Supporting Troubleshooting ..................................................................... 13-4

13.3.3 Troubleshooting-Imaging ............................................................................................ 13-5

13.4 Probe Socket System Malfunction ..................................................................................... 13-6

13.4.1 Related Modules or Boards ........................................................................................ 13-6

13.4.2 Key Points Supporting Troubleshooting ..................................................................... 13-6

13.4.3 Troubleshooting of Probe Socket System .................................................................. 13-6

13.5 IO Interface System Failure ............................................................................................... 13-6

13.5.1 Related Modules or Boards ........................................................................................ 13-6

13.5.2 Key Points Supporting Troubleshooting ..................................................................... 13-7

13.5.3 Troubleshooting of IO Interface System ..................................................................... 13-8

13.6 Control Panel Failure ......................................................................................................... 13-9

13.6.1 Related Modules or Boards ........................................................................................ 13-9

13.6.2 Key Points Supporting Troubleshooting ..................................................................... 13-9

13.6.3 Troubleshooting of Control Panel ............................................................................... 13-9

13.7 LCD Display Failure ......................................................................................................... 13-10

13.7.1 Related Modules or Boards ...................................................................................... 13-10

Page 8

vi

13.7.2 Key Points Supporting Troubleshooting ................................................................... 13-10

13.7.3 Troubleshooting of the Monitor ................................................................................. 13-11

13.8 ECG Module Failure ......................................................................................................... 13-11

13.8.1 Related Modules or Boards ...................................................................................... 13-11

13.8.2 Key Points Supporting Troubleshooting ................................................................... 13-12

13.8.3 Troubleshooting for ECG Module ............................................................................. 13-12

13.9 4D Troubleshooting .......................................................................................................... 13-12

13.9.1 Related Modules or Boards ...................................................................................... 13-12

13.9.2 Key Points Supporting Troubleshooting ................................................................... 13-12

13.9.3 4D Drive Troubleshooting ......................................................................................... 13-12

Appendix A Electrical Safety Inspection .................................................................. A-1

Appendix B Phantom Usage Illustration ................................................................... B-1

Appendix C Description of Self Test Items ............................................................... C-1

Page 9

I

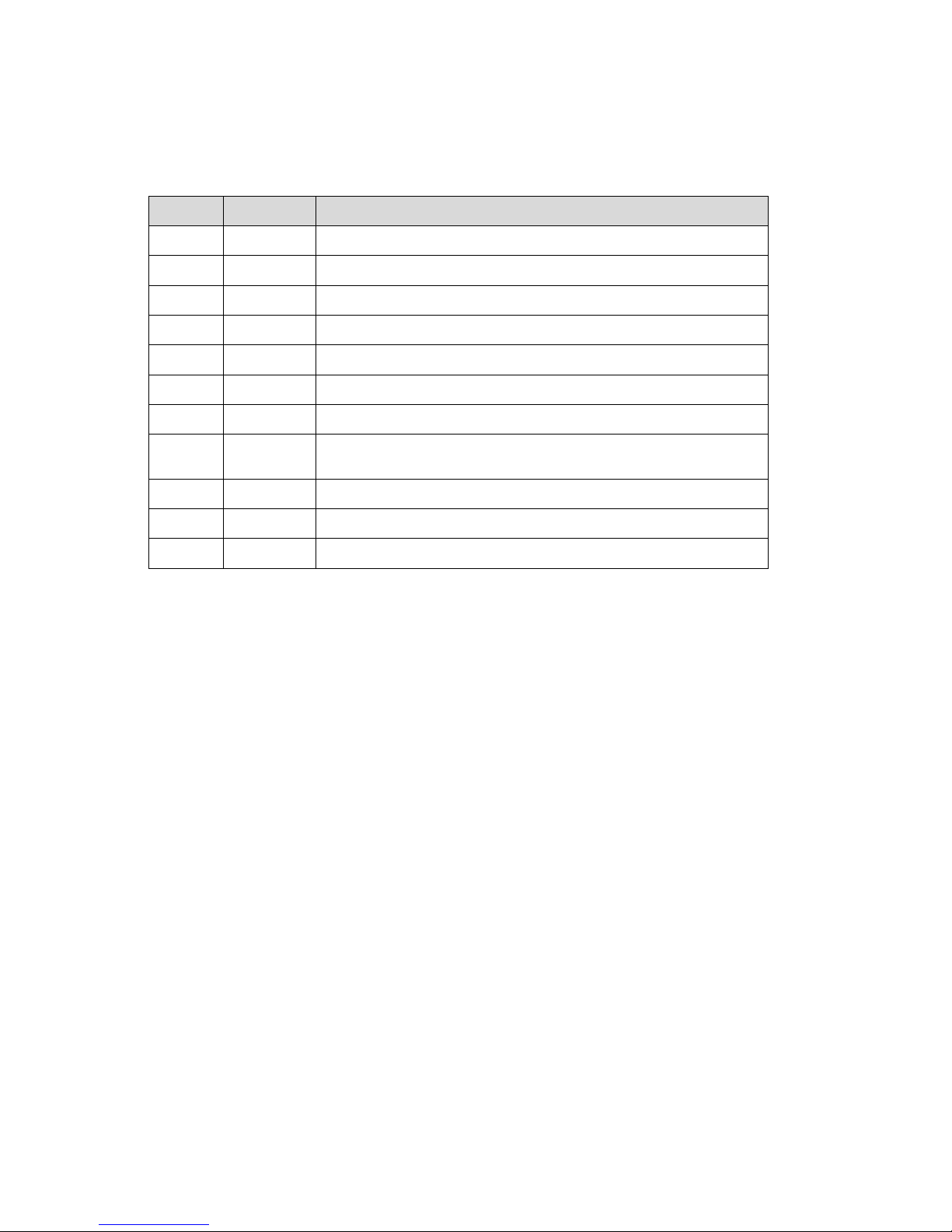

Revision History

Mindray may revise this publication from time to time without written notice.

Revision Date Reason for Change

1.0 2015.10

Initial release

2.0 2015.12

Change FRU order number.

3.0 2016.4

Change the order number of wireless net adapter.

4.0 2016.5

Add the installation of the Gel holder.

5.0 2016.7

Add the installation of Magnetic Generator Trolley.

6.0 2016.8

Change the warning labels.

7.0 2016.12

Change the description of the gel warmer.

8.0 2017.03

Add the installation of probe adapter, change the description of

the CW assembly.

9.0 2017.06

Add the installation of protective board.

10.0 2017.09

Change FRU number of PC board.

11.0 2018.5

Add the installation of AC Power Assembly (UR POWER).

© 2015-2018 Shenzhen Mindray Bio-medical Electronics Co., Ltd. All Rights Reserved.

Page 10

II

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray)

owns the intellectual property rights to this Mindray product and this manual. This manual may

referring to information protected by copyright or patents and does not convey any license under

the patent rights or copyright of Mindray, or of others.

Mindray intends to maintain the contents of this manual as confidential information. Disclosure of

the information in this manual in any manner whatsoever without the written permission of Mindray

is strictly forbidden.

Release, amendment, reproduction, distribution, rental, adaptation, translation or any other

derivative work of this manual in any manner whatsoever without the written permission of Mindray

is strictly forbidden.

,

, , , , BeneView, WATO,

BeneHeart, are the trademarks, registered or otherwise, of Mindray in China and other

countries. All other trademarks that appear in this manual are used only for informational or

editorial purposes. They are the property of their respective owners.

Applicable for

This service manual is applicable for the service engineers, authorized service personnel and

service representatives of this ultrasound system.

Statement

This service manual describes the product according to the most complete configuration; some of

the content may not apply to the product you are responsible for. If you have any questions, please

contact Mindray Customer Service Department.

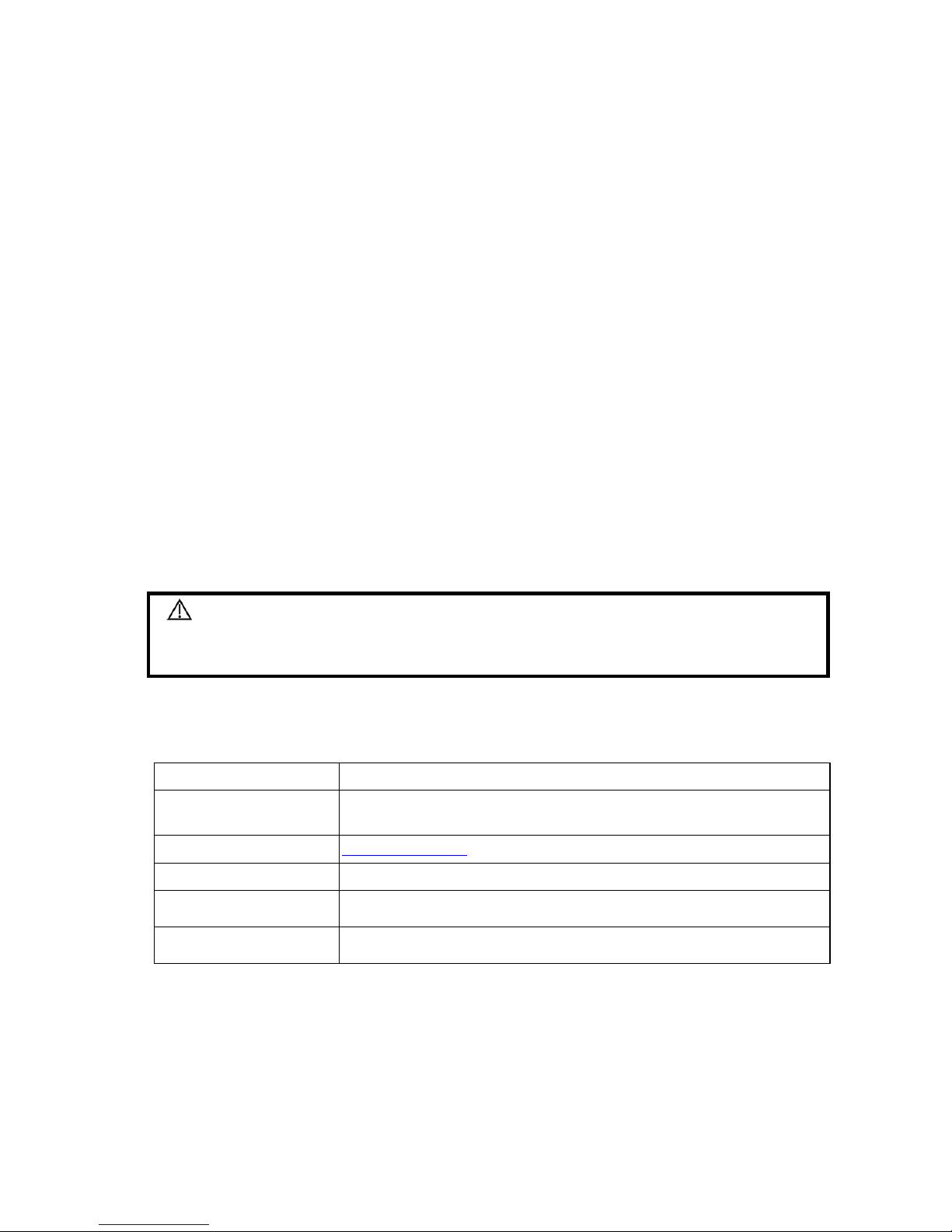

Do not attempt to service this equipment unless this service manual has been consulted and is

understood. Failure to do so may result in personnel injury or product damage.

Page 11

III

Responsibility on the Manufacturer

Party

Mindray is responsible for the effects on safety, reliability and performance of this product, only if:

z All installation operations, expansions, changes, modifications and repairs of this product are

conducted by Mindray authorized personnel;

z The electrical installation of the relevant room complies with the applicable national and local

requirements;

z The product is used in accordance with the instructions for use.

Mindray's obligation or liability under this warranty does not include any transportation or other

charges or liability for direct, indirect or consequential damages or delay resulting from the improper

use or application of the product or the use of parts or accessories not approved by Mindray or

repairs by people other than Mindray authorized personnel.

This warranty shall not extend to:

z Any Mindray product which has been subjected to misuse, negligence or accident;

z Any Mindray product from which Mindray's original serial number tag or product identification

markings have been altered or removed;

z Any products of any other manufacturers.

Customer Service Department

Manufacturer: Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address: Mindray Building, Keji 12th Road South, High-tech industrial park,

Nanshan, Shenzhen 518057,P.R.China

Website: www.mindray.com

E-mail Address: service@mindray.com

Tel:

+86 755 81888998

Fax:

+86 755 26582680

WARNING:

It is important for the hospital or organization that employs this

equipment to carry out a reasonable service/maintenance plan.

Neglect of this may result in machine breakdown or injury of human

health.

Page 12

Page 13

Safety precautions1-1

1 Safety Precautions

This chapter describes important issues related to safety precautions, as well as the labels and

icons on the ultrasound machine.

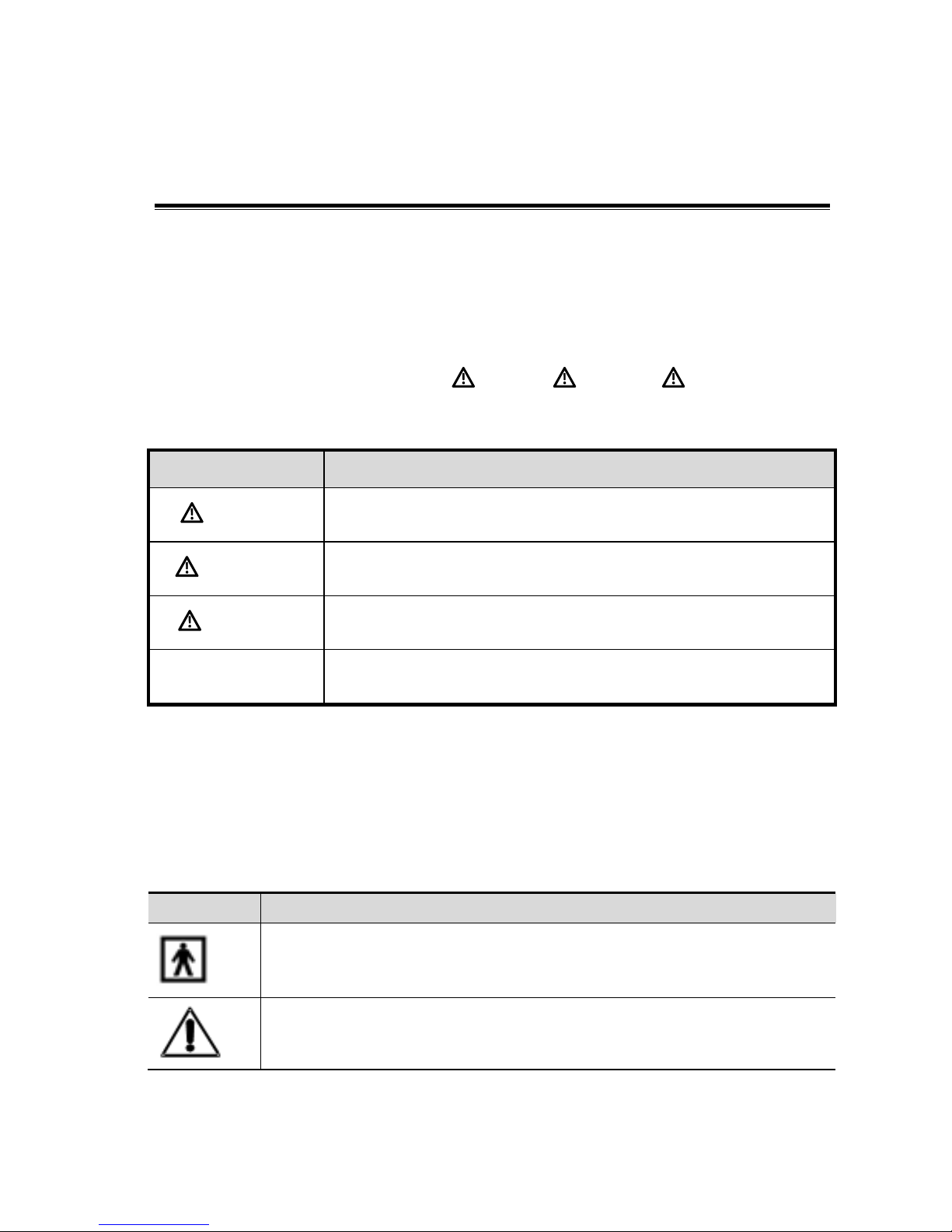

1.1 Meaning of Signal Words

In this operator’s manual, the signal words DANGER, WARNING, CAUTION and

NOTE are used regarding safety and other important instructions. The signal words and their

meanings are defined as follows.

Please understand their meanings clearly before reading this

manual.

Signal word Meaning

DANGER

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

NOTE

Indicates a potentially hazardous situation that, if not avoided, may result

in property damage.

1.2 Symbols

The following tables provide location and information of the safety symbols and warning labels,

please read carefully.

1.2.1 Meaning of Safety Symbols

Symbol Meaning

Type-BF applied part

The ultrasound transducers connected to this system are type-BF applied parts.

The ECG module connected to this system is Type-BF applied part.

"Attention"

indicates the points that you should pay attention to. Before using the

system, be sure to carefully read the relevant contents of this operator’s manual.

Page 14

1-2 Safety precautions

1.2.2 Warning Labels

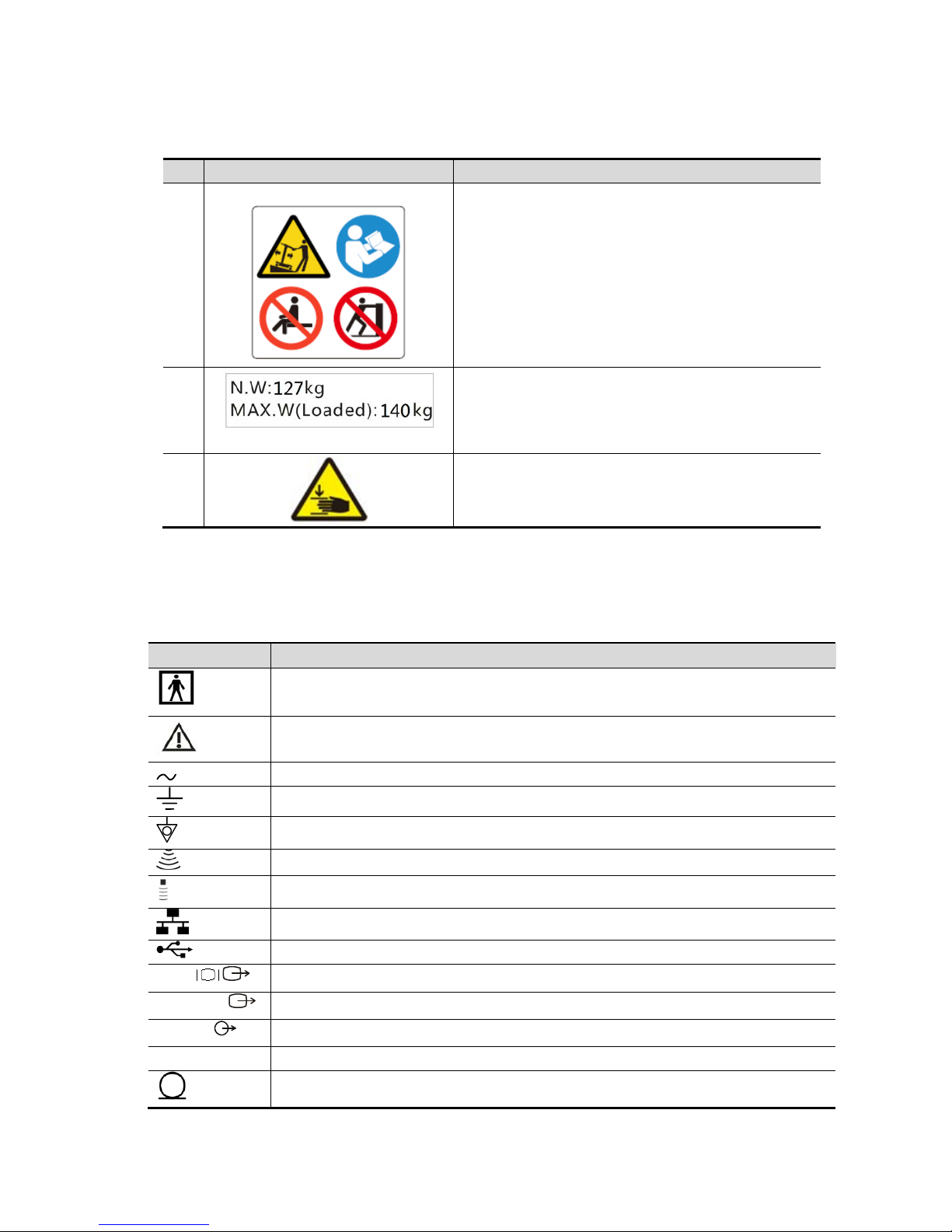

No. Warning Labels Meaning

1.

a. Do not place the device on a sloped surface.

Otherwise the device may slide, resulting in

personal injury or the device malfunction. Two

persons are required to move the device over a

sloped surface.

b. Do not sit on the device.

c. DO NOT push the device. When the casters are

locked.

2.

127kg:Main unit weight (not including the weight of

the probe)

140kg:The weight in total for main unit weight and

maximum load.

3.

Mind your hands.

1.2.3 General Symbols

This system uses the symbols listed in the following table, and their meanings are explained as

well.

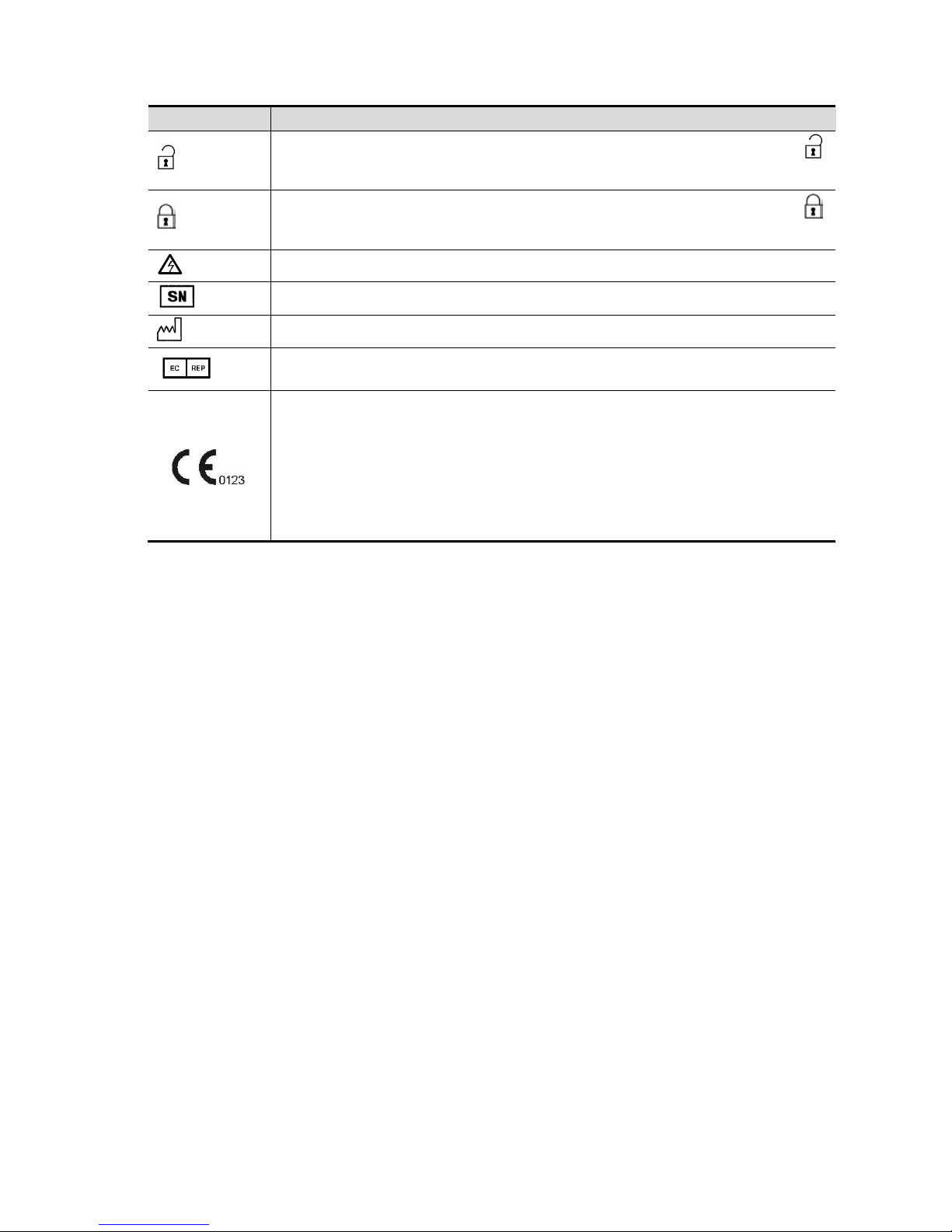

Symbol Description

Type-BF applied part

Refer to the relevant content in the Operator’s Manual, to avoid safety incidents

AC (Alternating current)

Functional grounding

Equipotentiality

Transducer sockets

Pencil probe port

Network port

USB port

VGA

Used for VGA output.

S-VIDEO

Reserved, used for separate video output

AUDIO

Used for stereo audio output.

HDMI High definition multimedia interface.

Microphone input jack

a

b c

Page 15

Safety precautions1-3

Symbol Description

When the lever located at the bottom of the monitor supporting arm points to ,

you can move the monitor to the right and left.

When the lever located at the bottom of the monitor supporting arm points to

,

the supporting arm is fixed in the middle position.

Dangerous voltage

Product serial number

Manufacture date

Authorized representative in the European Community

This product is provided with a CE marking in accordance with the regulations stated

in Council Directive 93/42/EEC concerning Medical Devices. The number adjacent to

the CE marking (0123) is the number of the EU-notified body certified for meeting the

requirements of the Directive.

The radio device used in this product complies with the essential requirements

and other relevant provisions of Directive 1999/5/EC (Radio Equipment and

Telecommunications Terminal Equipment Directive). The product is in compliance

with ETSI EN 300 328 and ETSI EN 301 489.

Page 16

1-4 Safety precautions

1.3 Safety Precautions

Please read the following precautions carefully to ensure the safety of the patient and the operator

when using the probes.

DANGER

Do not operate this system in an atmosphere containing flammable

or explosive gases such as anesthetic gases, oxygen, and

hydrogen or explosive fluid such as ethanol because an explosion

may occur.

1.3.1 Electric safety

WARNING:

1.

Connect the power plug of this system and power plugs of the

peripherals to wall receptacles that meet the ratings indicated

on the rating nameplate. Using a multifunctional receptacle

may affect the system grounding performance, and cause the

leakage current to exceed safety requirements. Use the power

cord accompanied with the system provided by Mindray.

2.

Disconnect the AC power before you clean or uninstall the

ultrasound machine, otherwise, electric shock may result.

3.

When using peripherals not powered by the auxiliary output of

the ultrasound system, or using peripherals other than permitted

by Mindray, make sure the overall leakage current of peripherals

and the ultrasound system meets the requirement of the local

medical device electrical regulation (like enclosure leakage

current should be no more than 500uA of IEC 60601-1-1), and the

responsibility is held by the user.

4.

In maintenance or assembly/disassembly, make sure other

cables are connected well before the battery connecting cable

is connected, otherwise the system may be damaged due to

hot-plug.

5.

Do not use this system simultaneously with equipment such

as an electrosurgical unit, high-frequency therapy equipment,

or a defibrillator, etc.; otherwise electric shock may result.

6.

This system is not water-proof. If any water is sprayed on or

into the system, electric shock may result.

CAUTION:

1.

DO NOT connect or disconnect the system’s power cord or its

accessories (e.g., a printer or a recorder) without turning OFF

the power first. This may damage the system and its

accessories or cause electric shock.

2.

Avoid electromagnetic radiation when perform performance

test on the ultrasound system.

3.

In an electrostatic sensitive environment, don’t touch the

device directly. Please wear electrostatic protecting gloves if

necessary.

Page 17

Safety precautions1-5

4.

You should use the ECG leads provided with the ECG module.

Otherwise it may result in electric shock.

1.3.2 Mechanical safety

WARNING:

1.

Before moving the system, please hold the handle. If other parts

of the system are held, it may cause damage due to the

abnormal force. Do not push the system from the left/right side;

otherwise, it may be toppled over.

2.

Do not subject the transducers to knocks or drops. Use of a

defective probe may cause electric shock to the patient.

CAUTION:

1.

Fasten and fully secure any peripheral device before moving

the system, gently and carefully move the system to avoid

falling over.

2.

Do not expose the system to excessive vibration (during the

transportation) to avoid device dropping, collision, or

mechanical damage.

3.

Please install the system on a flat plane with the four casters

locked. Otherwise, damage may be resulted by accidental

moving.

4.

Pay extra attention when moving the system on a sloping

ground, do not move it on a more than 10°-sloped plane to avoid

system toppling.

5.

Move the system ONLY WHEN the system is shut down or in

standby status, otherwise the system hardware disk may be

damaged.

1.3.3 Personnel Safety

NOTE:

1.

The user is not allowed to open the covers and panel of the system, neither

device disassemble is allowed.

2.

To ensure the system performance and safety, only Mindray engineers or

engineers authorized by Mindray can perform maintenance.

3.

Only technical professionals from Mindray or engineers authorized by Mindray

after training can perform maintenance.

1.3.4 Other

NOTE:

For detailed operation and other information about the ultrasound system, please

refer to the operator’s manual.

Page 18

Page 19

Specifications 2-1

2 Specifications

2.1 Overview

2.1.1 Intended Use

The Resona 7/Resona 7CV/Resona 7EXP/Resona 7S/Resona 7OB series diagnostic ultrasound

system is intended for use in clinical ultrasonic diagnosis.

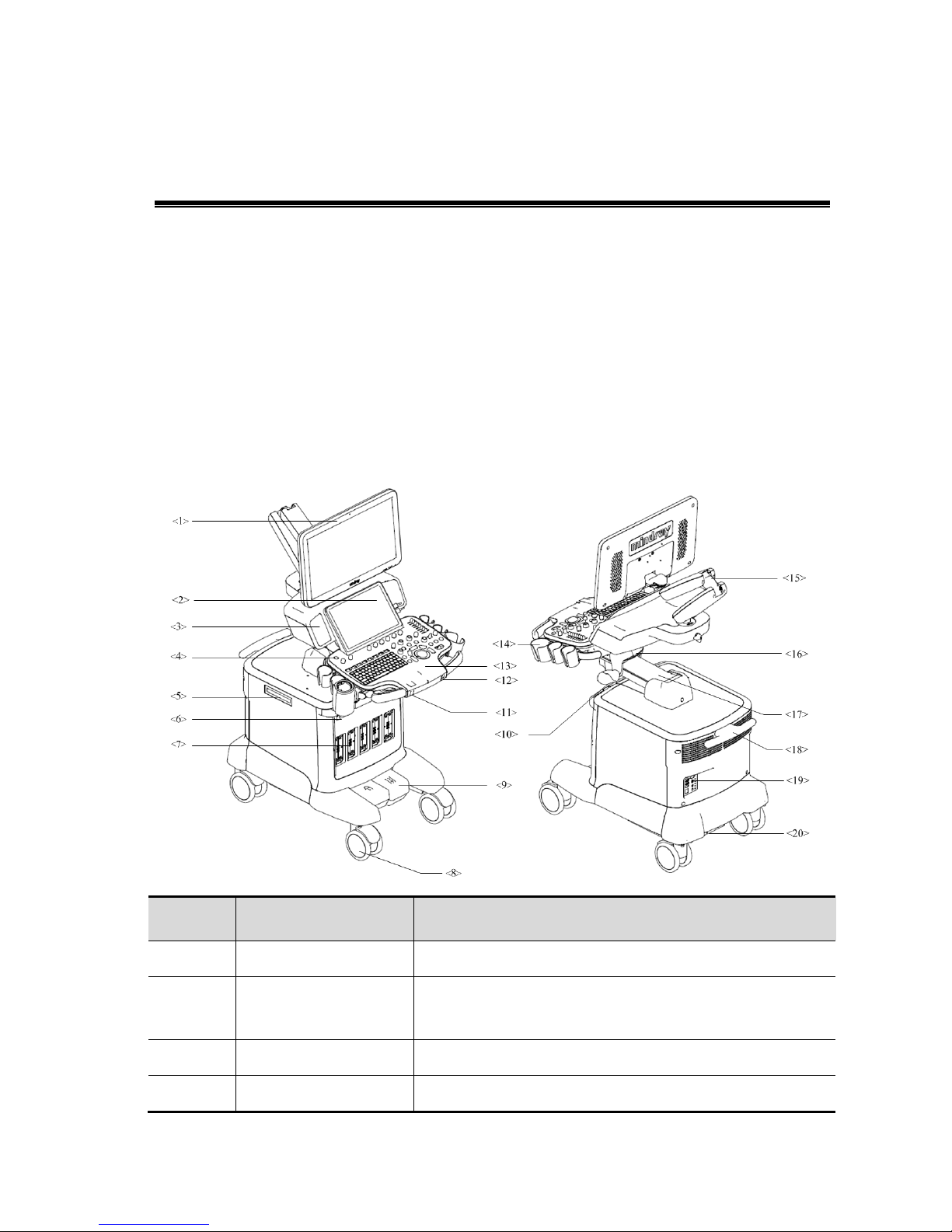

2.1.2 Introduction of Each Unit

No. Name Function

<1> Monitor

Displays the images and parameters during scanning.

<2> Touch Screen

Screen-touching operator-system interface or accessible to

control.

<3> Speaker Outputs the audio.

<4> Power button Used for powering on/ off the power supply.

Page 20

2-2 Specifications

No. Name Function

<5> DVD driver DVD reading and writing

<6> Front-in panel Connected to ECG leads and USB drive, etc.

<7> Probe port Sockets connecting transducers and the main unit.

<8> Caster Used for moving the system.

<9> Central brake

Used for securing the system or moving the system straight

forward.

Step on the left brake pedal to lock the device from being

moved.

Step on the right walking pedal to move the device straight.

<10>

Intracavitary probe

holder

Used for placing the probe.

<11>

Rotatable knob on the

control panel

Lock or unlock the movement of the control panel

<12>

Ascending/descending

button

The button to ascending or descending the system.

<13> Control panel

Key- pressing operator-system interface or accessible to

control

<14> Transducer (gel) holder Used for placing transducers and gel temporarily.

<15> Monitor support arm

Supports the monitor, for adjusting the angle of LCD

monitor.

<16>

The control panel

stretch mechanism

Used for stretching or rotating the control panel.

Note: subject to the Control Panel Moving Mechanism

Assembly when the user purchases the product.

<17>

Motor-driven lift

mechanical assembly

Used for adjusting the height of the control panel

<18>

The back handle of

main unit

Used for winding the cables up and assisting for moving the

system.

<19> I/O Panel Port panel for input and output signals.

<20>

Power supply assembly

for the system

Provides the power to the system.

Page 21

Specifications 2-3

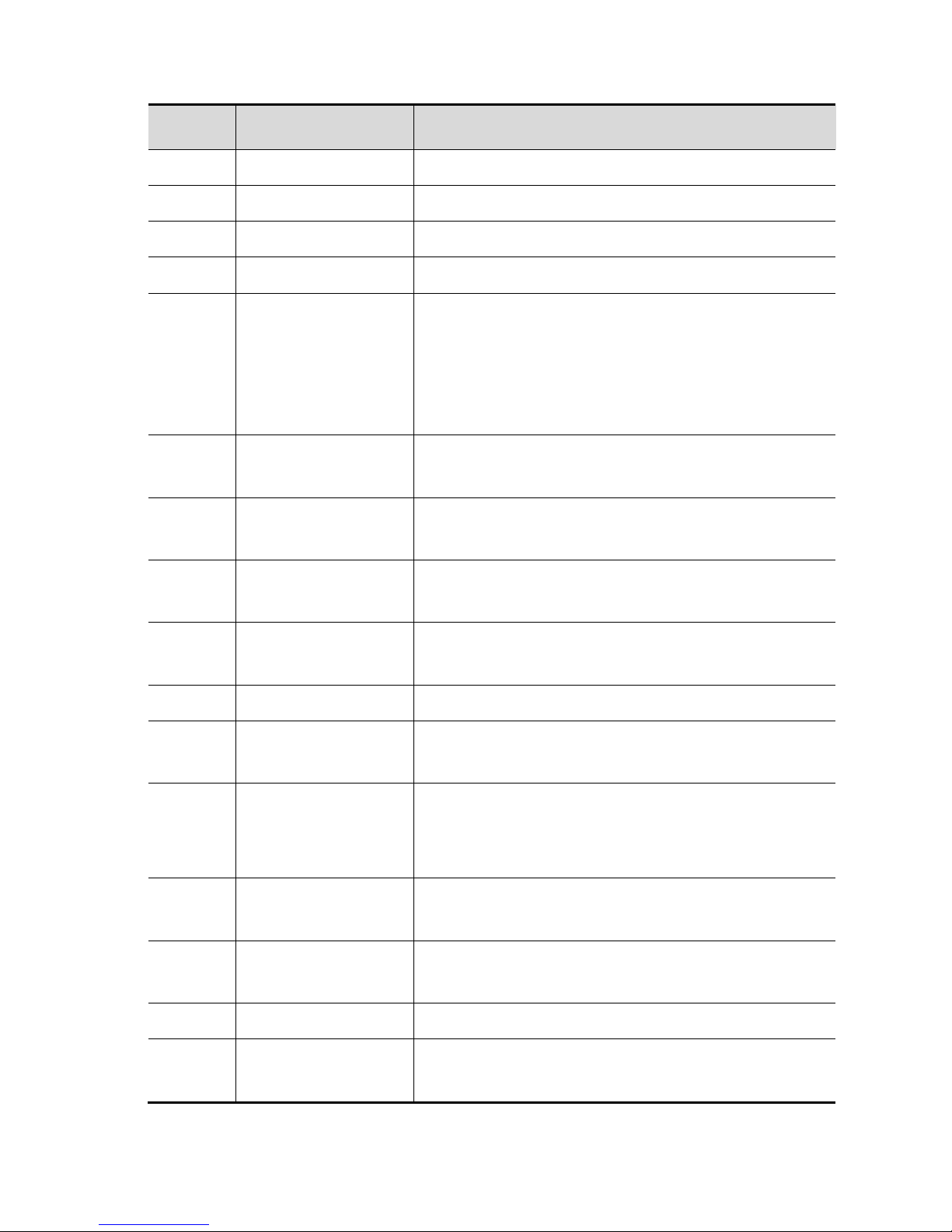

2.1.2.1 I/O panel

No. Symbol Function

<1>

USB ports.

<2> HDMI High definition multimedia interface.

<3>

Network port.

<4>

VGA

VGA signal output.

<5> S-Video Used for separate video output.

<6>

Audio signal output port, left channel.

Audio signal output port, right channel.

<7>

<8> / 12V power indicator

<9> / 5V power indicator

<10> / 3.3V power indicator

<11> / LVDS_OK indicator

<12> / PHV protection indicator (reserved)

NOTE: 1. The S-VIDEO port performs better with analog video printing.

2. When connecting an external video device (HDMI/VGA), make sure the display

resolution setting is 1920x1080, otherwise the image quality may be degraded.

Page 22

2-4 Specifications

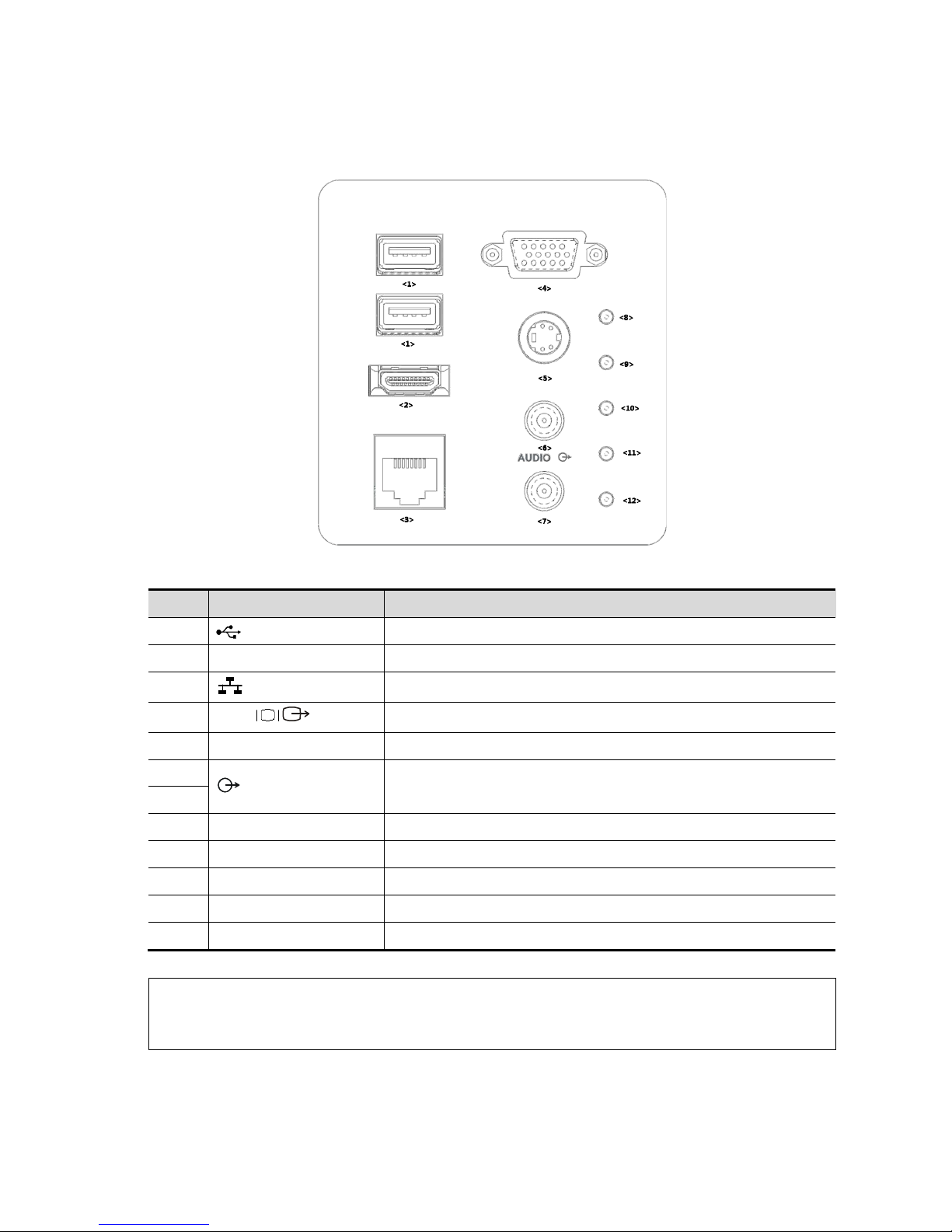

2.1.2.2 Power Supply Panel

No. Name Function

<1>

Alternative

current auxiliary

output

Supply power for optional peripheral devices.

<2> Circuit breaker Used for switching off/ on the power supply.

<3> Power inlet AC power inlet

<4>

Equipotential

terminal

Used for equipotential connection, that balances the protective earth

potentials between the system and other electrical equipment.

Page 23

Specifications 2-5

2.1.2.3 Physio Panel

2.1.2.4 Control Panel

No. Name Function

<1> USB port Connects USB devices.

<2> MIC interface Microphone input

<3> Pencil probe port Used for connecting a pencil probe.

<4>

ECG lead signal input

port / external ECG

signal input port

Connects to ECG leads, to directly obtain the ECG signals of

the patient.

Connects the signal output port of ECG monitoring device.

<5> Reserved port Reserved feature.

<6> PCG signal input port

Connects to PCG transducer, to directly obtain the PCG

signals of the patient.

<1>

<2>

<3>

<4>

<8>

<9>

<6>

<7>

<5>

<10>

<11>

<12>

<13>

<14>

<15>

<16>

<17>

<18>

<19>

<20>

<21>

<22>

<23>

<24>

<25>

<26>

<27>

<28>

<29>

<30>

<31>

<32>

<33>

Page 24

2-6 Specifications

No. Name Description

<1> /

Power button

Press the button to turn on the system, the system enters the

work status and the indicator becomes green.

AC (Alternating current). It turns on at AC supply.

Standby. It becomes orange in standby status.

Hard disk indicator. It blinks when reading/writing the disk.

<2> A.power Adjust the acoustic power.

<3> Volume /

<4> / Adjust the corresponding functions on the touch screen.

<5> P1-P4

Undefined Button, set by the user in the Preset. See the

operator’s manual [Basic Volume] for details.

<6> Fusion

Enter fusion. Or

Undefined Button, set by the user in the Preset. See the

operator’s manual [Basic Volume] for details.

<7> Elasto

Enter elastography. Or

Undefined Button, set by the user in the Preset. See the

operator’s manual [Basic Volume] for details.

<8> Contrast

Enter contrast imaging. Or

Undefined Button, set by the user in the Preset. See the

operator’s manual [Basic Volume] for details.

<9> iWorks

Enter iWorks. Or

Undefined Button, set by the user in the Preset. See the

operator’s manual [Basic Volume] for details

<10> /

Press: to set the Baseline

Rotate: to set the Scale

Slide: to set the Steer

<11> PW

Press to enter PW mode, and rotate to adjust PW gain (in PW

mode) or CW gain (in CW mode); while in 3D/4D mode, rotate

the knob to cycle the 3D image through Y axis.

<12> C

Press to enter Color mode, and rotate to adjust Color gain (in

color mode) or Power gain(in Power mode); while in 3D/4D

mode, rotate the knob to cycle the 3D image through Z axis.

<13> /

Press: to enter 3D

Slide right: to enter 4D

Slide upwards: to enter quad-split display

Slide downwards: to enter dual-split display

Rotate: to switch the view

<14> TGC Slide to adjust the depth gain.

<15> Cursor Display/hide the cursor.

<16> Clear Remove the comments or measurement caliper.

Page 25

Specifications 2-7

No. Name Description

<17> M

Enter M mode, and rotate to adjust M mode gain. While in

3D/4D mode, rotate the knob to cycle the 3D image rotate

through X-axis.

<18> CW Enter CW mode.

<19> Power Enter Power mode.

<20> Dual

Enter Dual mode in Non-Dual mode.

Press to switch between the two interfaces in the Dual mode.

<21> B Press: to enter B mode; Rotate: to adjust B mode gain.

<22> Depth Adjust the depth in real-time imaging.

<23> Zoom

Rotate to enter the pan-zoom mode, and press to enter the

spot-zoom mode.

<24> Measure Enter/exit the application measurement mode.

<25> Update

Switching key: Press to change the currently active window.

Start/stop image acquisition in iScape or 3D/4D mode.

<26> Caliper Enter/exit the general measurement mode.

<27> /

Confirm an operation. The function is same with the

left-button of the mouse.

<28> / Move the trackball to change the cursor position.

<29> /

Confirm an operation. The function is same with the

left-button of the mouse.

<30> iTouch Press to optimize the images.

<31> Save Save the image; user-defined key.

<32> Print Print: user-defined key.

<33> Freeze Freeze/defreeze the image.

NOTE: “/” means the key is undefined or has no silk print. For the undefined keys, you can

customize them.

Page 26

2-8 Specifications

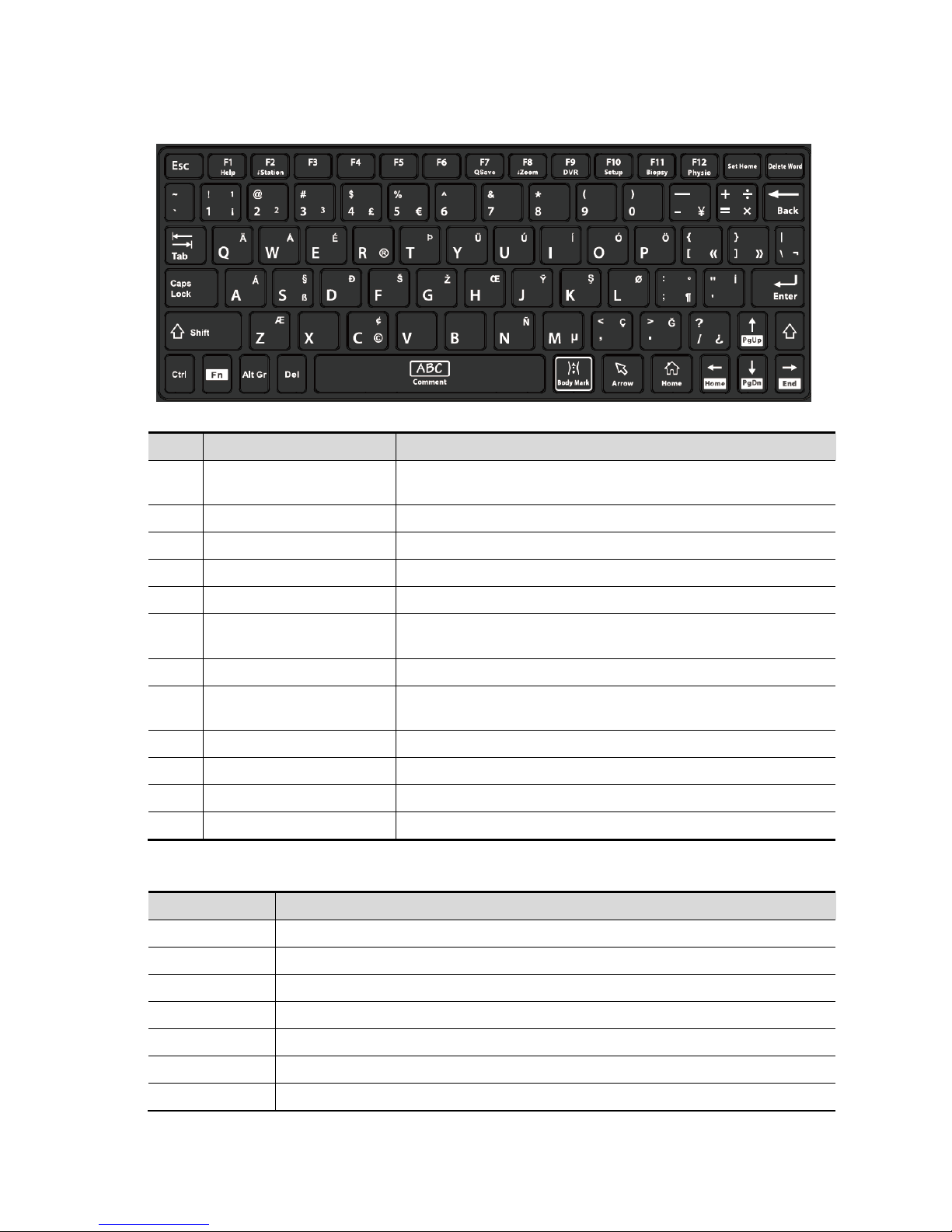

Keyboard

Common functional keys

No. Key Description

1. Enter

Confirms the input data; or moves the cursor to the head of

next row of the text or the input field.

2. Esc Cancel or quit the operation.

3. Tab Go to the next operation item.

4. Space or comment Insert a space or input the comment

5. Caps Lock Switch the upper/ lower case.

6. Home

Activate the Home function: return to the start position of

comment.

7. Delete Text Delete all comments on the screen.

8. Direction keys

Move the cursor one letter each time; or, select the ambient

one in a selectable area.

9. Arrow Press the key to turn to the symbol of arrow.

10. Body Mark Press the key to enter the body mark.

11. Back Space Delete the character before the cursor

12. Del Delete the character after the cursor

Functions of the F1 to F12 keys

Key Function

F1 Help Open or close the accompanying help documents.

F2 iStation Enter or exit the Patient Info system.

F3~F6 User-defined keys, the functions of which can be preset.

F7 QSave Save the current image parameters quickly.

F8 iZoom Enter/exit full-screen zoom status.

F9 DVR Enter VCR/DVR mode.

F10 Setup Enter/exit Setup.

Page 27

Specifications 2-9

Key Function

F11 Biopsy Display/hide the guide line.

F12 Physio Enter Physio mode.

For user-defined keys, please refer to the operator’s manual [Basic Volume].

2.1.3 Peripherals Supported

Type Model

Graph/text printer HP Officejet 7000 wide format, HP Officejet Pro 8100

Black/white video

printer (digital)

MITSUBISHI P95D

SONY UP-D897

SONY UP-D898MD

Digital color video

printer

SONY UP-D25MD

Black/white video

printer (analog)

SONY UP-X898MD

Photo printer Cannon SELPHY CP800

Barcode reader SYMBOL LS2208 (1D), SYMBOL DS6707-SR

Footswitch

Wired: 971-SWNOM (2-pedal, 3-pedal)

Wireless: Steute (2-pedal, 3-pedal)

Note: the printer driver is preinstalled in the system. Please install other printer drivers for other

types of the printers.

2.2 Specifications

2.2.1 Dimensions & Weight

External dimension: depth: 945±10mm; width: 545±10 mm (main unit)/510±10mm (control panel);

height: 1360±10 mm (with the display vertical).

Weight: less than 135 Kg (not including the weight of the probe).

2.2.2 Electrical Specifications

2.2.2.1 AC Input

Voltage

220-240~ 100-127V~

Frequency 50/60Hz

Power consumption 1000VA

Page 28

2-10 Specifications

2.2.3 Environmental Conditions

Operating conditions Storage and transportation conditions

Ambient temperature 0°C~40°C -20°C~55°C

Relative humidity 20%~85% (no condensation) 20%~95% (no condensation)

Atmospheric pressure 700hPa~1060hPa 700hPa~1060hPa

Warning:

Do not use this system in the conditions other than those

specified

2.2.4 Monitor Specification

2.2.4.1 Main Monitor

2.2.4.2 Touch Screen

Size 21.5 inches

Voltage 12 V

Resolution 1920×1080

Visible angle ≥170°

Size 12.1 inches

Voltage 12 V

Resolution 1280×800

Visible angle ≥140°

Page 29

System Installation 3-1

3 System Installation

3.1 Preparations for Installation

NOTE:

Do not install the machine in the following locations:

Locations near heat generators;

Locations of high humidity;

Locations with flammable gases.

3.1.1 Electrical Requirements

3.1.1.1 Requirement of Regulated Power Supply

Power specification is showing in chapter 2.2.2. Due to the difference of the power supply

stability of different districts, please advise the user to adopt a regulator of good quality

and performance such as an on-line UPS.

3.1.1.2 Grounding Requirements

The power cable of the system is a three-wire cable, the protective grounding terminal of

which is connected with the grounding phase of the power supply. Please ensure that the

grounding protection of the power supply works normally.

WARNING:

DO NOT connect this system to outlets with the same

fuses that control the current of devices such as

life-support systems. If this system malfunctions and

generates an over current, or when there is an

instantaneous current at power ON, fuses of the

building’s supply circuit may be tripped.

3.1.1.3 EMI Limitation

Ultrasound machines are susceptible to Electromagnetic Interference (EMI) by radio

frequencies, magnetic fields, and transient in the air wiring. They also generate a weak

electromagnetic radiation. Possible EMI sources should be identified before the unit is

installed. Electrical and electronic equipment may produce EMI unintentionally as the

result of defect.

These sources include: medical lasers, scanners, monitors, cauterizing guns and so on.

Besides, other devices that may result in high frequency electromagnetic interference

such as mobile phone, radio transceiver and wireless remote control toys are not allowed

to be presented or used in the room. Turn off those devices to make sure the ultrasound

system can work in a normal way.

Page 30

3-2 System Installation

3.1.2 Installation Conditions

3.1.2.1 Space Requirements

Place the system with necessary peripherals in a position that is convenient for operation:

1. Place the system in a room with good ventilation or an air conditioner.

2. The door is at least 0.8m wide. The ultrasound machines can move into the room

easily.

3. Leave at least 0.2m clearance around the system to ensure effective cooling.

4. An adjustable lighting system in the room (dim/bright) is recommended.

5. Except the receptacle dedicated for the ultrasound system, there should be at least

3-4 more receptacles on the wall for other medical devices and peripherals.

6. The distance between wall outlet and any peripherals should be less than 2m and

distance between ultrasound system and peripherals should be less than 1m, to

make it easy for cable connections.

3.1.2.2 Networking Pre-installation Requirements

Both wireless and wired LANs are supported by this ultrasound system.

Data transmission is allowed between different departments or areas without network

cable. Network can be automatically connected after disconnection in case that the device

is required to be moved, wireless transmission task can be recovered after the network

resumed to normal condition. Confirm the network devices and network conditions before

the installation.

1. General information: default gateway IP address, and the other routers relevant

information.

2. DICOM application information: DICOM server name, DICOM port, channels, and IP

address.

Page 31

System Installation 3-3

3.1.3 Confirmation before Installation

Perform the following confirmation before installing the system:

1. The video format used in the region or country where the system is installed.

2. The language used in the region or country where the system is installed.

3. The power voltage used in the region or country where the system is installed.

4. Obstetric formulae and other measurement formulae used in the region or country

where the system is installed.

5. Other settings to be used in the region or country where the system is installed but

different from the factory settings.

6. The doctor’s habits of using the system.

Perform the confirmation above before installing the system. And set up the system to

make it according with the usage of the region or country where the system is installed.

3.2 Unpacking

Unpacking tool: a pair of scissors

Installation duration: 1~2 people, 20 minutes.

3.2.1 Unpacking Process

1. Cut off 4 strips of the external package.

2. Remove the wooden cover and use it as the slope in the front of the device.

Page 32

3-4 System Installation

3. Remove the crate. Press the clasps down to release them.

4. Remove "front foam", "LCD protect foam", "back foam", "small accessory carton".

Page 33

System Installation 3-5

5. Remove "support arm foam", "big accessory carton", release the buckle, and remove

"front foam", "handle foam".

6. Pull the machine out along the slope.

Support arm

foam

Large accessory

carton

Front foam

Handle foam

Front foam

LCD protect foam

Small accessory carton

Back foam

Page 34

3-6 System Installation

Note: please follow up the procedures of reverse unpacking when transporting.

3.2.2 Checking

1. After unpacking, check the objects in the container with the package list to see if

anything is missing or is wrong.

2. Ensure there is no damage, indentation or cracks occurring to the machine. If any

happen, please contact Mindray Customer Service Department.

Page 35

System Installation 3-7

3.3 Bare Machine Transport

Refer to chapter 3.2.1 for machine transport.

If the machine is not packaged, it is only allowed for short-distance trasnport. Refer to the

following procedures to protect the machine during the transport.

3.3.1 Tool

Tool Specifications

Vehicle

Vehicle door size: larger than 700 mm (width) X 1280 mm (height)

The space for the ultrasound device: larger than 1050mm (length) X 700

mm (width) X 1280 mm (height).

LCD protection

foam

LCD protection foam for bare machine transport (1)

Note: Do not dispose of red protection foam after completing the

unpacking.

Rope Several

Page 36

3-8 System Installation

3.3.2 Device Transport

3.3.3 Fixing Methods

1. Press the button to lower the control panel to the minimum position when the

ultrasound device is powered on. Press the button

to push the moving mechanism

straight forward.

Protect the monitor with the red

foam, and use the rope to fasten it

around the device. Protect the

monitor from moving.

Lower the support arm

to the minimum

Fasten the moving

mechanism (from

moving). Tie the rope

around the back

handle. Do not press

the external cover of

the device hard.

Unlock the brake pedal

Four ends of the

ropes should be

fastened to four

directions of the

car. Keep the

device from

moving in the car

Page 37

System Installation 3-9

2. Toggle the control switch along the red arrow’s direction and press the upper support

arm down following the blue arrow’s direction. The support arm stays at the lowest

position.

3. Protect the monitor with the red foam, and use the rope to fasten it around the device.

Protect the monitor from moving.

4. Push the ultrasound device into the car against the slope (other methods also work).

5. Warp the device tight around the front handle and the back handle. Keep the device from

moving in the car.

Page 38

3-10 System Installation

6. Rotate the two switches anticlockwise. Keep the two switches and the brake pedal loosed

(marked with the red circle).

Page 39

System Installation 3-11

3.4 Installing Main Unit

NOTE:

To prevent the machine from damage, when you perform the following

operations, please lock the casters.

3.4.1 Opening up the Monitor

Adjust the monitor from the horizontal position to the vertical position.

NOTE: Take care of your hands when adjust the monitor up and down.

3.4.2 Connecting the Power Cord

1. Push the retaining clamp upward, and insert the power plug into the receptacle. Take

off two screws and the fixing board of the power plug from the accessory kits. Fix the

power plug board on electronics assembly on the base to press the power cable with

2 M3X8 sunk head screws.

2. Plug the other end of power plug into an appropriate outlet. The grounding terminal

should be connected with a power grounding cable to ensure that protective

grounding works normally.

The power plug board

Grounding terminal

Page 40

3-12 System Installation

NOTE: Make sure to allow sufficient slack in the cable so that the plug won't be pulled

out when the system is moved slightly.

3.4.3 Connecting ECG

Connect the ECG cable to the corresponding interface on the physio panel under the

control panel. See “2.1.2.3 Physio Panel” for details.

3.4.4 Installing Probe Holder

Insert the coupling gel heating cup, left bracket, 4D probe holder, larger probe holder,

small probe holder and plug the coupling gel heating cup to the control panel.

3.4.5 Installing Gel Holder

1. Slide the left/right support beneath the control panel along the gliding track according

to the marks (“L” refers to the left bracket and “R” refers to the right support) on the

support of the gel warmer.

4D probe

holder

Large probe

holder

Small probe

holder

Small probe

holder

Large

probe

holder

Gel warmer and

left support

Page 41

System Installation 3-13

2. Put the gel warmer into the left/right support, and plug the cable of the gel warmer

into the port of the control panel bottom.

“L” refers to the left support of the gel warme

r

“R” refers to the right support of the gel warme

r

For example:

Slide the left

support

beneath the

control panel

along the left

gliding track

Page 42

3-14 System Installation

Placing the gel bottle:

Fasten the gel bottle, and then place the bottle in the gel warmer. See the figure

below:

3.4.6 Connecting the Transducer

Four sockets (A, B, C, D) are configured on the system; every socket can be connected

with all types of supported transducers.

1. Keep the cable end of the transducer to the up side of the system, and insert the

connector into the socket of the system, and then press in fully. (Shown as the left

figure)

2. Turn the lock handle 90° clockwise to lock it securely. (Shown as the right figure)

Fasten the gel

bottle, and then

place the bottle

in the gel

warmer.

The indicator of the gel

warmer facing outside

Lock

Page 43

System Installation 3-15

3. Place the probe properly to avoid being treaded or wrapping with other devices (use

hanger or hook). DO NOT allow the probe head to hang free.

4. Turn the lock handle 90° anticlockwise to unlock it, and then pull out the connector.

3.5 Installing Peripherals

For the models of the supported peripherals, please refer to “2.1.3 Supported

Peripherals”.

3.5.1 Connecting a Footswitch

WARNING:

Do not connect two or more footswitches to the main unit;

otherwise, it may lead to the malfunction to the system.

The system supports the wired footswitch (two-pedal, and three-pedal) and wireless

footswitch (two-pedal, and three-pedal).

The setting for the wireless footswitch:

1. Connect the wireless footswitch to the main unit.

2. Press <F10 Setup> to open the page. Select [Maintenance]->[Setup]->[Paring

Wireless Footswitch] to set the footswitch.

3. Click [OK]. The dialog box appears.

4. The warning dialog box appears.

Page 44

3-16 System Installation

5. Press two footswitches. Click [OK].

6. Select [Key Config]->[Footswitch] to set for the footswitch. After completing the

configuration, each of the footswitch can be used according to its function. Step the

footswitch to complete the operation.

The setting for the wired footswitch:

1. Connection: directly insert the USB port of the footswitch to the system applicable

USB ports.

2. Function setting: for details, please refer to chapter 3.8.3.

3.5.2 Installing a Graph / Laser Printer

NOTE: Please restart the ultrasound system after printer installation.

Connecting a local printer

NOTE: Printers listed in “2.1.3 Peripherals Supported” Chapter have drivers installed

already.

As shown in the figure below, a graph / text printer has a power cord and data cable.

The power cord should be directly plugged into a well-grounded outlet.

1. Connect the data cable to the USB port on the ultrasound system.

Page 45

System Installation 3-17

2. Power the system and the printer on.

3. Put the installation optical disk of the printer driver into the DVD R/W drive.

4. Install the printer driver: Select [Setup]→[Print Preset]→[Add Printer].

NOTE: all the operations are finished with right <Set> key.

5. Select [Add a local printer] and click [Next] to enter the screen used for browsing driver.

NOTE: see the printer’s operation manual to select the port, or try to use the default port

of the system.

6. Click [Have Disk…] to find the driver path (the installation type should be WIN7 64), and

then click [Next] to install the driver.

Page 46

3-18 System Installation

7. Complete the operation according to the tips on the screen. Click [Finish] to end the

installation.

NOTE: 1. Before adding the local printer, make sure the printer is powered on, and the

printer has been well connected with the ultrasound device (a sound

feedback will be heard when connecting)

2. In case of installation failure under Doppler, try to install the printer in

Windows (click [Enter Windows] on the Maintenance menu). If the

installation can’t be performed neither in Doppler nor Windows, then the

printer can’t be supported by the ultrasound machine.

3. Use the original driver disk to perform the driver installation.

Add network printer

1. As the system is connected into a LAN, open [Setup]-> [Printer Preset] screen.

2. Click [Add Printer], select [Add a network, wireless or Bluetooth printer].

3. The system starts to search all available printers within the network. Select the target

printer and click [Next], the system tries to connect to this printer.

4. When the connection is successful, the system prompts the dialogue box, click [Next]

according to the screen tips and then click [Finish].The printer is installed successfully.

Tips: the system has combined many types/brands of printer drivers, if targeted printer

drive is not included in the system, you may need to install the driver for the network

printer. Please use the optical disk or USB disk with the driver to install according to the

system prompts.

NOTE: When you install the printer’s driver, you must specify the specific path for

installation. A vague path may result in longer searching times.

The network printer functions depending on the configured network environment

in the hospital, please consult the network configuration manager in case of

failure.

Before connecting a network printer, connect the ultrasound machine into the

same network with the printer and make sure the network works normally.

Once a network printer is found, an identification dialogue box will appear if the

server needs identity confirmation. Enter the user name and pass code; select

“Auto Connecting” and then click [OK].

The printer name typed should be valid, \\server\printer for example. Otherwise,

a connection failure notice may appear.

Print

Both report and image can be printed on a graph / text printer.

To set the default report printer and its attribute:

In "[Setup]→[Print Preset]" screen, select the "Report Print" column in the service list.

You can select printer from the driver list next to “Printer” in the lower screen and set the

items in the "Property" box. Click [Save] after you have finished setting.

Please refer to the accompanying manuals of the printers for more details.

3.5.3 Installing Video Printer

The system support both black/white video printers (digital) and color video printers

(digital).

Page 47

System Installation 3-19

CAUTION:

The auxiliary power outlet in the system is used to supply

power for approved peripheral devices. Do not connect

other/unapproved devices to this outlet; otherwise the rated

output power may be exceeded and the system failure may

result. Maximum output power of the outlet is 240VA.

Local printer installation

1. Position the printer in the proper place.

2. Plug the printer power cord into an appropriate outlet.

3. Use a USB cable to connect between the system's USB port and the printer's USB port.

4. Load a paper roll, and turn on the system and printer.

See section “3.5.2 Installing a Graph / Laser Printer” for the driver installation procedure

(printer drivers listed in chapter “2.1.3 Peripherals Supported” are installed already).

5. Add a print service:

(1) Open the “[Setup] → [Print Preset]” screen.

(2) Click [Add Service] to enter the page.

(3) Select the service type and enter the service name manually.

(4) Click [OK] to return to the page.

(5) Select the target printer from the drop-down list in the “Property” box and set other

printing properties.

(6) Click [Save] to complete.

3.5.4 Installing a Wireless Printer

The system supports the Officejet Pro 8100 wireless printer for report printing.

1. Plug the printer power cord into an appropriate outlet.

2. Power the system and the printer on.

3. Make sure the ultrasound machine and the printer are connected to the same LAN,

and turn the printer's W-LAN function on.

4. Add a wireless adapter, following the steps described in “Add network printer.” See

chapter “3.5.2 Installing a Graph / Laser Printer.”

5. Open the [Setup] → [Printer Preset] page, select “Report Print” from the printer list,

select the printer to be Officejet Pro 8100, and set properties.

6. Click [Save] to exit the preset and make the settings effective.