Page 1

GAS

GENERATOR SET

CONTINUOUS 1300 ekW

1400 ekW

60 Hz

Caterpillar is leading the power generation

marketplace with Power Solutions engineered

to deliver unmatched flexibility, expandability,

reliability, and cost-effectiveness.

FEATURES

EMISSIONS

●

Meets most worldwide emissions requirements

down to 0.5 g/bhp-hr NOx level without after

treatment

FULL RANGE OF ATTACHMENTS

●

Wide range of bolt-on system expansion

attachments, factory designed and tested

SINGLE-SOURCE SUPPLIER

●

Fully Prototype Tested with certified torsional

vibration analysis available

WORLDWIDE PRODUCT SUPPORT

●

With over 1,800 dealer branch stores operating

in 166 countries, you’re never far from the

Caterpillar part you need.

●

99.5% of parts orders filled within 48 hours.

The best product support record in the industry.

●

Caterpillar dealer service technicians are

trained to service every aspect of your electric

power generation system.

●

Customer Support Agreements offer backto-back services from scheduled inspections

and preventive maintenance to before-failure

overhauls and Total Cost-Per-Hour Guarantees.

CAT®G3516B LE GAS ENGINE

●

Robust design provides prolonged life and

lower owning and operating costs

●

Designed for maximum performance on

low pressure pipeline natural gas

●

One electronic control module handles

all engine functions: ignition, governing,

air fuel ratio control, and engine protection

CAT SR4B GENERATOR

●

Designed to match performance and output

characteristics of Caterpillar engines

●

Optimum winding pitch for minimum total

harmonic distortion and maximum efficiency

●

Segregated low voltage (AC/DC) accessory

box provides single point access to accessory

connections

CAT CONTROL PANELS

●

Designed to meet individual customer needs:

EMCP II+ provides full-featured power metering,

purge cycle, staged shutdown logic, plus

programmable protective relaying functions

●

Remote control and monitor capability options

Shown with

Optional

Equipment

WHERE THE WORLD TURNS FOR POWER

LEHE2033-01

Page 2

CONTINUOUS 1300 ekW

1400 ekW

60 Hz

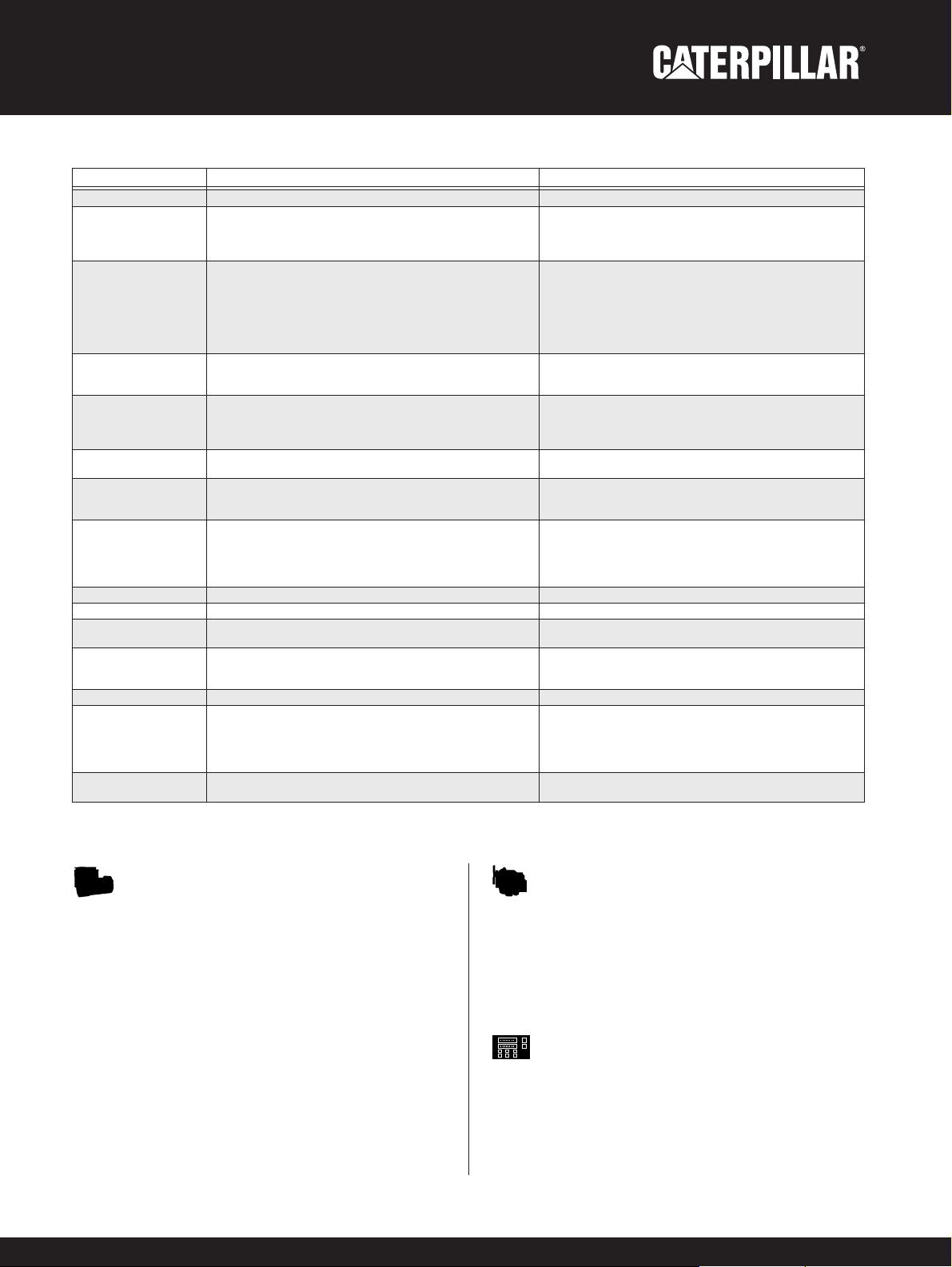

FACTORY INSTALLED STANDARD & OPTIONAL EQUIPMENT

System Standard Optional

Air Inlet Modular air cleaner, single element service indicator

Cooling Engine driven water pumps for jacket water

and aftercooler circuit, jacket water and

SCAC thermostats

Cat flange connections

Engine Control Fuel/air ratio control

Module Start/stop logic: gas purge cycle, stage shutdown

Engine Protection Systems: detonation sensitive

timing, high jacket water temperature, low oil

pressure, failure to start (overcrank), overspeed,

high oil temperature, emergency stop, transient

richening and turbo bypass control

Exhaust Dry exhaust manifolds 15 dBA muffler

CAT flanged outlet 18 dBA muffler

Spark arresting muffler without companion flanges

Fuel Electronic air fuel ratio control (Engine Control Fuel filter (non-coalescent)

Module; ADEM III based), electronic fuel Gas train with 24V double gas shutoff valve,

metering valve, gas shutoff valve, 24 volt isolation valve, regulator, gas leak detection

energized-to-run

Ignition Electronic ignition system, individual cylinder

timing and detonation control

Integrated Thermo 24 thermocouples to input individual exhaust port CCM transfers CAT DataLink information through

Sensing Module temperatures and turbo inlet and outlet RS232 to customer terminal

(ITSM) temperatures on both the turbine and compressor

Generator Permanent magnet excitation, 105° C rise, single Digital Voltage Regulator with KVAR/PF control

bearing, form wound, six lead, 3-phase sensing, Oversize and premium generators, bearing

platinum stator RTDs, class H Insulation, DVR with temperature detector

adjustable 1:1 or 2:1 Volts/Hz, bus bar termination, Low voltage cable extension box

segregated low voltage wiring panel

Circuit Breaker IEC compliant, 3-pole and 4-pole

Governor Electronic — Engine Control Module Electronic load sharing (ship loose module)

Control Panels EMCP II+ Local alarm and remote annunciator modules

Customer Interface Module, synchronizing module

Lube Lubricating oil and filter, oil drain valve Closed crankcase ventilation system

Crankcase breathers gear type lube oil pump,

integral lube oil cooler, filler/dipstick, prelube pump

Mounting Spring-type anti-vibration isolators

Starting/Charging 60 amp charging alternator Battery charger, air starting system, jacket water

Dual 24 volt starting motor heaters, 12 kW (dual 6 kW) 480 V/3 phase/60 Hz

Batteries with rack and cables heater element; 9 kW 480 V/3 phase 60 Hz with

Batteries disconnect switch 230 V/1 phase/60 Hz circulation pump.

Battery disconnects switch, oversize batteries

Other EEC declaration of Incorporation

CSA Certification (generator only)

LEHE2033-01

2

CAT SR4B GENERATOR

Frame size.........................................697/824

Excitation ..............................Permanent magnet

Pitch ...............................................0.6667

Number of poles .........................................4

Number of bearings......................................1

Number of leads .........................................6

Insulation ............UL 1446 Recognized Class H Insulation

IP rating....................................Drip proof IP22

Alignment.......................................Pilot shaft

Overspeed capability .................................125%

Wave form..........................Less than 5% deviation

Paralleling kit droop transformer ..................Standard

Voltage regulator ...........3-phase sensing with adjustable

1:1 or 2:1 Volts/Hz, UL 508A Listed

TIF ...........................................Less than 50

THD .........................................Less than 3%

Consult your Caterpillar dealer for available voltages.

CAT ENGINE

G3516B SCAC, 4-stroke-cycle watercooled gas

Bore — mm (in)...................................170 (6.7)

Stroke — mm (in) .................................190 (7.5)

Displacement — L (cu in)..........................69 (4210)

Compression ratio ...................................11.1:1

Aspiration .......Turbocharged, Separate Circuit Aftercooled

Fuel system......................Electronic Ignition System

Governor type ............Electronic Engine Control Module

CAT CONTROL PANEL

24 Volt DC Control

NEMA 1, IP22 enclosure

Electrically dead front

Lockable hinged door

Generator instruments meet ANSI C-39-1

Terminal box mounted

Single location customer connector point

EC compliant — segregated AC/DC connections and wiring

SPECIFICATIONS

Page 3

CONTINUOUS 1300 ekW

1400 ekW

60 Hz

TECHNICAL DATA

**Assumes synchronous driver.

**Emissions data measurements are consistent with those described in EPA CFR 40 Part 89 Subpart D & E and ISO8178-1 for

measuring HC, CO, PM, NOx. Data shown is based on steady state engine operating conditions of 25° C (77° F), 96.28 kPa

(28.43 inches Hg) and fuel having a LHV of 35.6 mJ/N•m3(905 Btu/cu.ft) at 101.60 kPa (30.00 inches Hg) absolute and 0° C (32° F).

Not to exceed emission data shown is subject to instrumentation, measurement, facility and engine fuel system adjustments.

LEHE2033-01

3

Generator Set — 1800 rpm/60 Hz/480 Volts DM5498 DM5496

G3516B LE Gas Generator Set

Emission level (NOx) g/bhp-hr 0.5 0.5

Aftercooler — SCAC temperature Deg C Deg F 32 90 54 130

Package Performance

Power rating @ 1.0 pf (unity) ekW 1410 1310

Power rating @ 0.8 pf (3) ekW 1400 1300

kVA 1750 1625

Fuel Consumption (1)

100% load 60 without fan N•m3/hr scf/hr 407 15,190 380 14,174

75% load 60 without fan N•m3/hr scf/hr 319 11,912 298 11,134

50% load 60 without fan N•m3/hr scf/hr 229 8525 211 7879

Electrical Efficiency

% 35.3 34.8

Altitude Capability

(2)

At 25° C/77° F ambient M ft 553 1813 682 2237

Cooling System

Ambient air temperature Deg C Deg F 25 77 25 77

Jacket water temperature (maximum outlet) Deg C Deg F 92 198 92 198

Exhaust System

Combustion air inlet flow rate N•m3/min scfm 115 4290 110 4120

Exhaust stack gas temperature Deg C Deg F 529 985 523 974

Exhaust gas flow rate N•m3/min cfm 355 12,525 338 11,923

Exhaust flange size (internal diameter) mm in 203 8 203 8

Heat Balance

(2) (3)

Low Heat Value (LHV) fuel input kW Btu/min 4146 235,819 3868 220,033

Heat rejection to jacket water (total) kW Btu/min 826 46,996 798 45,398

Heat rejection to exhaust (LHV to 350° F) kW Btu/min 989 56,262 930 52,907

Heat rejection to A/C — Stage 2 kW Btu/min 193 10,956 133 7542

Heat rejection to atmosphere from engine kW Btu/min 138 7838 137 7794

Heat rejection to atmosphere from generator kW Btu/min 44 2513 43 2432

Alternator

Motor starting capability @ 30% voltage dip* KVA 3271 2661

Frame 824 697

Temperature rise Deg C 105 105

Lube System

Lube oil refill volume w/filter change for standard sump L Gal 401 106 401 106

Emissions**

NOx g/ghp-hr 0.5 0.5

CO g/ghp-hr 2.4 2.5

HC (total) g/ghp-hr 4.8 5.4

HC (non-methane) g/ghp-hr 0.72 0.81

Exhaust O2(dry) % 9.1 9.2

Continuous — Output available without varying load for an

unlimited time.

(1) Ratings and fuel consumption are based on ISO3046/1

standard reference conditions of 25° C (77° F) and 100 kPa

(29.61 inches Hg).

(2) Ratings and fuel consumption based on ISO3046/1

conditions with nominal 2.5 kPa inlet restriction and 5 kPa

exhaust restriction. All performance numbers listed on this

page are at these conditions except Fuel input (1) .

(3) Ratings are based on pipeline natural gas having a LHV

(low heat value) of 35.6 mJ/N•m3(905 Btu/cu.ft) and 80 MN.

For values in excess of the altitude, temperature, inlet/exhaust

restriction, or for natural gas compositions different from the

conditions listed, contact your local Caterpillar dealer.

RATING DEFINITIONS AND CONDITIONS

Page 4

CONTINUOUS 1300 ekW

1400 ekW

60 Hz

LEHE2033-01

4

TECHNICAL DATA

**Assumes synchronous driver.

**Emissions data measurements are consistent with those described in EPA CFR 40 Part 89 Subpart D & E and ISO8178-1 for

measuring HC, CO, PM, NOx. Data shown is based on steady state engine operating conditions of 25° C (77° F), 96.28 kPa

(28.43 inches Hg) and fuel having a LHV of 35.6 mJ/N•m3(905 Btu/cu.ft) at 101.60 kPa (30.00 inches Hg) absolute and 0° C (32° F).

Not to exceed emission data shown is subject to instrumentation, measurement, facility and engine fuel system adjustments.

Generator Set — 1800 rpm/60 Hz/480 Volts DM5497 DM5495

G3516B LE Gas Generator Set

Emission level (NOx) g/bhp-hr 1.0 1.0

Aftercooler — SCAC temperature Deg C Deg F 32 90 54 130

Package Performance

Power rating @ 1.0 pf (unity) ekW 1410 1310

Power rating @ 0.8 pf (3) ekW 1400 1300

kVA 1750 1625

Fuel Consumption (1)

100% load 60 without fan N•m3/hr scf/hr 396 14,770 369 13,789

75% load 60 without fan N•m3/hr scf/hr 312 11,650 288 10,737

50% load 60 without fan N•m3/hr scf/hr 223 8321 208 7777

Electrical Efficiency

% 36.3 35.7

Altitude Capability

(2)

At 25° C/77° F ambient M ft 872 2862 903 2961

Cooling System

Ambient air temperature Deg C Deg F 25 77 25 77

Jacket water temperature (maximum outlet) Deg C Deg F 92 198 92 198

Exhaust System

Combustion air inlet flow rate N•m3/min scfm 110 4117 105 3926

Exhaust stack gas temperature Deg C Deg F 532 990 530 986

Exhaust gas flow rate N•m3/min cfm 342 12,064 325 11,469

Exhaust flange size (internal diameter) mm in 203 8 203 8

Heat Balance

(2) (3)

Low Heat Value (LHV) fuel input kW Btu/min 4032 229,357 3764 214,100

Heat rejection to jacket water (total) kW Btu/min 783 45,511 764 43,448

Heat rejection to exhaust (LHV to 350° F) kW Btu/min 958 54,471 906 51,547

Heat rejection to A/C — Stage 2 kW Btu/min 180 10,211 118 6717

Heat rejection to atmosphere from engine kW Btu/min 137 7793 136 7762

Heat rejection to atmosphere from generator kW Btu/min 44 2523 43 2432

Alternator

Motor starting capability @ 30% voltage dip* KVA 3271 2661

Frame 824 697

Temperature rise Deg C 105 105

Lube System

Lube oil refill volume w/filter change for standard sump L Gal 401 106 401 106

Emissions**

NOx g/ghp-hr 1.0 1.0

CO g/ghp-hr 2.5 2.6

HC (total) g/ghp-hr 4.1 4.4

HC (non-methane) g/ghp-hr 0.62 0.66

Exhaust O2(dry) % 8.9 9.2

Page 5

CONTINUOUS 1300 ekW

1400 ekW

60 Hz

697 GENERATOR FRAME

CONTINUOUS POWER GENERATOR SET PACKAGE — TOP VIEW

Note: Do not use for installation design.

See general dimension drawings

for detail (Drawing # 212-9995).

Package Dimensions with 697 Frame Generator

Length

4879.3 mm 192.10 in

Width

2160.0 mm 85.04 in

Height

2415.4 mm 95.09 in

Shipping Weight

12 283.0 kg 27,080.0 lbs

LEHE2033-01

5

697 GENERATOR FRAME

CONTINUOUS POWER GENERATOR SET PACKAGE — SIDE VIEW

2160.0 (85.04)

2415.4 (95.09)

4879.3 (192.10)

Page 6

www.CAT-ElectricPower.com

TMI Reference No.: DM5495, DM5496, DM5497, DM5498 © 2002 Caterpillar

All rights reserved.

U.S. sourced Printed in U.S.A.

LEHE2033-01 (02-02) Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

CONTINUOUS 1300 ekW

1400 ekW

60 Hz

824 GENERATOR FRAME

CONTINUOUS POWER GENERATOR SET PACKAGE — TOP VIEW

824 GENERATOR FRAME

CONTINUOUS POWER GENERATOR SET PACKAGE — SIDE VIEW

Note: Do not use for installation design.

See general dimension drawings

for detail (Drawing # 212-9995).

Package Dimensions with 824 Frame Generator

Length

4848.3 mm 190.88 in

Width

2160.0 mm 85.04 in

Height

2415.4 mm 95.09 in

Shipping Weight

12 873.0 kg 28,380.0 lbs

2160.0 (85.04)

2415.4 (95.09)

4848.3 (190.88)

Loading...

Loading...