Page 1

GAS

GENERATOR SET

STANDBY 350 ekW

CONTINUOUS

350 ekW

60 Hz

Caterpillar is leading the power generation

marketplace with Power Solutions engineered

to deliver unmatched flexibility, expandability,

reliability, and cost-effectiveness.

FEATURES

FULL RANGE OF ATTACHMENTS

●

Wide range of bolt-on system expansion

attachments, factory designed and tested

SINGLE-SOURCE SUPPLIER

●

Fully Prototype Tested with certified torsional

vibration analysis available

WORLDWIDE PRODUCT SUPPORT

●

Worldwide parts availability through the

Caterpillar dealer network

●

With over 1,200 dealer outlets operating

in 166 countries, you’re never far from

the Caterpillar part you need.

●

99.5% of parts orders filled within 48 hours.

The best product support record in the

industry.

●

Caterpillar dealer service technicians are

trained to service every aspect of your electric

power generation system.

●

Preventive maintenance agreements

●

The Cat Scheduled Oil Sampling (S•O•SSM)

program cost effectively detects internal engine

component condition, even the presence of

unwanted fluids and combustion by-products

CAT®G3412 TA GAS ENGINE

●

Reliable, rugged, durable design

●

Field-proven in thousands of applications

worldwide

●

Low pressure gas

CAT SR4B GENERATOR

●

Designed to match performance and output

characteristics of Caterpillar engines

●

Optimum winding pitch for minimum total

harmonic distortion and maximum efficiency

●

Segregated AC/DC, low voltage accessory

box provides single point access to

accessory connections

CAT CONTROL PANELS

●

Two levels of controls, designed to meet

individual customer needs:

EMCP II provides digital monitoring, metering,

and protection

EMCP II+ provides EMCP II features along

with full-featured power metering and

protective relaying

WHERE THE WORLD TURNS FOR POWER

Page 2

CAT SR4B GENERATOR

Frame.................................................592

Type ................Self excited, static regulated, brushless

Construction ..................Single bearing, close coupled

Three phase .........................12 lead reconnectable

Insulation ......Class H with tropicalization and antiabrasion

IP rating .....................................Drip proof 22

Alignment.......................................Pilot shaft

Overspeed capability

Prototype tested ...................................150%

Production tested ..................................125%

Wave form..........................Less than 5% deviation

Paralleling capability..............................Standard

Voltage regulator .....3-phasing sensing with Volts-per-Hertz

Voltage regulation ...........Less than ± 1/2% (steady state)

Less than ± 1% (no load to full load)

Voltage gain ....................................Automatic

Telephone Influence Factor (TIF)................Less than 50

Harmonic Distortion (THD) ....................Less than 5%

CAT ENGINE

G3412 TA, 4-stroke-cycle, SCAC

Bore – mm (in)....................................137 (5.4)

Stroke – mm (in) ..................................152 (6.0)

Displacement – L (cu in) .........................27.0 (1649)

Compression ratio ....................................9.7:1

Aspiration .......................Turbocharged-Aftercooled

Ignition system .............................Digital ignition

Governor type ...........................Woodward 2301A

CAT CONTROL PANEL

24 Volt DC Control

NEMA 1, IP22 enclosure

Electrically dead front

Lockable hinged door

Generator instruments meet ANSI C-39-1

Terminal box mounted

Single location customer connector point

Consult your Caterpillar dealer for available voltages.

SPECIFICATIONS

STANDBY 350 ekW

CONTINUOUS 350 ekW

60 Hz

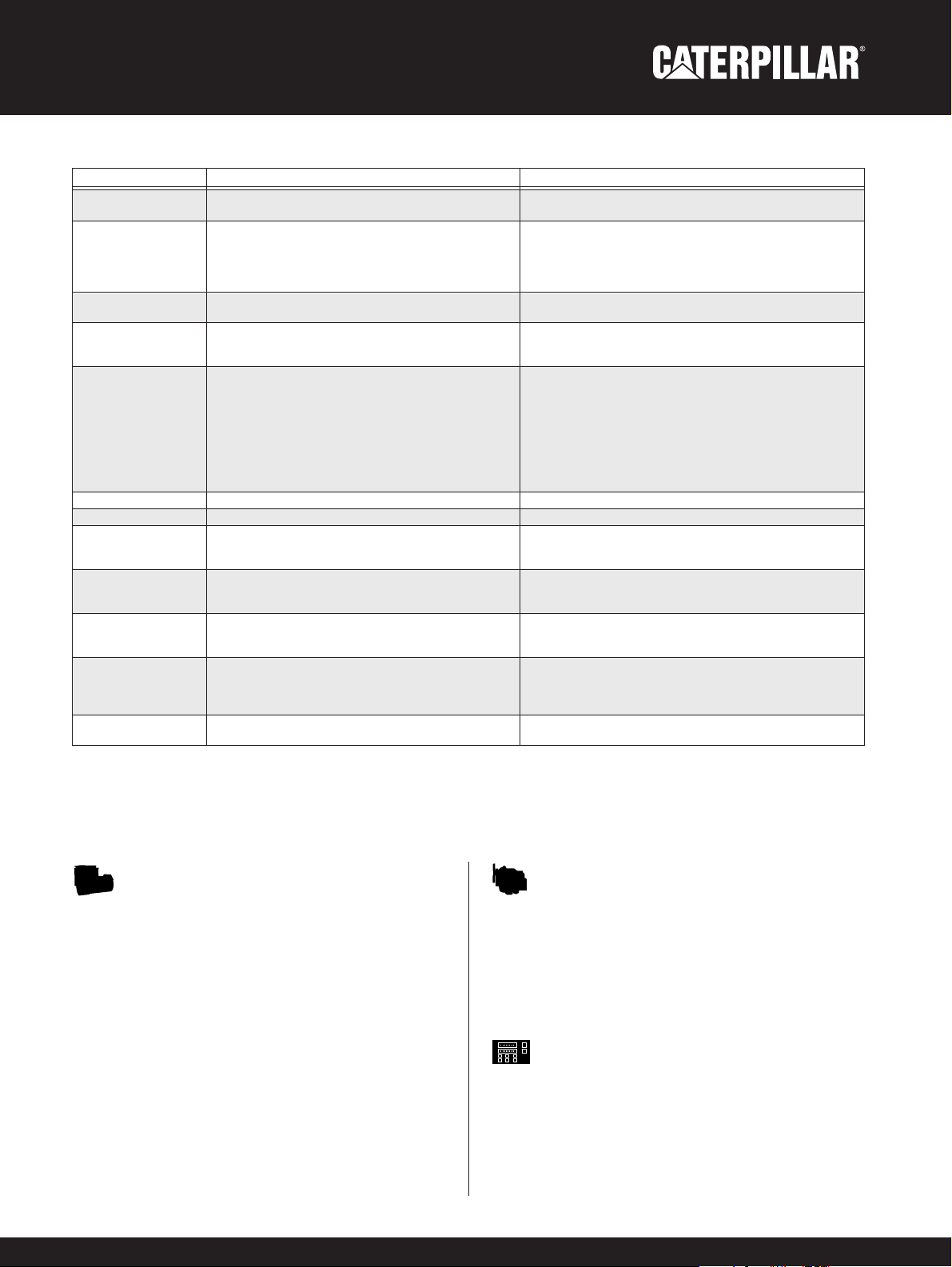

FACTORY INSTALLED STANDARD & OPTIONAL EQUIPMENT

System Standard Optional

Air Inlet Single element canister type air cleaner

Service indicator

Cooling Radiator with guard Jacket water coolant heater with shutoff valves

Coolant drain lines with valves Radiator removal

Fan and belt guards

Caterpillar Coolant

Low coolant level sensors

Exhaust Stainless steel exhaust flex with 15 dBA muffler

weld outlet flange

Fuel Gas pressure regulator

Low pressure fuel system

Energize To Run (ETR) gas shutoff valve

Generator Self excited Permanent magnet excited

Class H insulation Digital Voltage Regulator

Class F temperature rise Digital Voltage Regulator with KVAR/PF control

(105° C continuous/130° C standby) Anti-condensation space heater

VR6 Voltage Regulator, 3-phase sensing, Oversize & premium generators

with reactive droop Circuit breakers, UL, 3 pole with shunt trip

2:1 Volts/Hz or 1:1 Volts/Hz Multiple breaker capability

Bus bar termination

Extension box

Governor 2301A speed control with EG3P actuator Electronic load sharing

Ignition Digital ignition system

Control Panels EMCP II EMCP II+

Customer Communication Module

Local alarm & remote annunciator modules

Lube Lubricating oil and filter Manual sump pump

Oil drain line with valve

Fumes disposal

Mounting Wide base

Linear vibration isolators between base

and engine-generator

Starting/Charging 35 amp charging alternator Battery chargers, 5 & 10 amp

24 volt starting motor Oversize batteries

Batteries with rack and cables

Battery disconnect switch

General Automatic Transfer Switches (ATS)

Floor standing circuit breakers

2

Page 3

STANDBY 350 ekW

CONTINUOUS 350 ekW

60 Hz

3

TECHNICAL DATA

Open Generator Set — Standby Continuous

1800 rpm/60 Hz/480 Volts DM5441 DM5442

Package Performance

Power rating ekW 350 350

Power rating @ 0.8 PF kVA 438 438

Aftercooler temperature Deg C Deg F 54 130 54 130

Fuel Consumption

100% load with fan N•m3/hr scf/hr 119 4472 119 4472

75% load with fan N•m3/hr scf/hr 95 3575 95 3575

50% load with fan N•m3/hr scf/hr 72 2701 72 2701

Cooling System

Ambient air temperature*

Deg C Deg F 40 105 40 105

Air flow restriction (system) kPa

in water 0.12 0.5 0.12 0.5

Air flow (maximum @ rated speed for

standard radiator arrangement) m3/min

cfm 1257 47,480 1257 47,480

Engine coolant capacity with radiator L

Gal 106 28 106 28

Jacket water outlet temperature Deg C Deg F 99 210 99 210

Exhaust System

Combustion air inlet flow rate N•m3/min

scfm 24 872 24 872

Exhaust gas stack temperature

Deg C Deg F

478 892 478 892

Exhaust gas flow rate N•m3/min cfm 25 2476 25 2476

Exhaust flange size (internal diameter)

mm in 203 8 203 8

Exhaust system backpressure

(maximum allowable)

kPa in water 6.7 27 6.7 27

Heat Rejection

Low Heat Value (LHV) fuel input

kW Btu/min 1205 68,547 1205 68,547

Heat rejection to jacket water

(includes oil cooler)

kW Btu/min 437 24,869 437 24,869

Total heat rejection to exhaust (LHV to 25° C)

kW Btu/min 283 16,067 283 16,067

Heat rejection to exhaust (LHV to 120° C)

kW Btu/min 218 10,412 218 10,412

Heat rejection to A/C

kW Btu/min 15 866 15 866

Heat rejection to atmosphere from engine

kW Btu/min 48 2742 48 2742

Heat rejection to atmosphere from generator

kW Btu/min 29 1660 29 1660

Generator

Motor starting capability @ 30% voltage dip** kVA 928 928

Frame 592 592

Temperature rise Deg C 130 105

Emissions***

NOx g/bhp-hr 21.3 21.3

CO g/bhp-hr 1.5 1.5

HC (total) g/bhp-hr 1.9 1.9

HC (non-methane) g/bhp-hr 0.29 0.29

Exhaust O2 (dry) % 4.0 4.0

***Ambient capability at 200 m (660 ft) above sea level. For ambient capability at other altitudes, consult your Caterpillar dealer.

***Assumes synchronous driver

***Emissions data measurement is consistent with those described in EPA CFR 40 PART 89 SUBPART D and ISO 8178-1 for

measuring HC, CO, CO2and NOx. Data shown is based on steady state engine operating conditions of 77° F, 28.43 inches HG

and fuel having a LHV of 920 BTU per cubic foot at 30.00 inches HG absolute and 32° F. Not to exceed emission data shown is

subject to instrumentation, measurement, facility and engine fuel system adjustments.

Standby — Output available with varying load for the

duration of the interruption of the normal source power.

Continuous — Output available without varying load

for an unlimited time.

Ratings are based on ISO3046/1 standard reference

conditions of 25° C (77° F) and 100 kPa (29.61 in Hg).

Ratings are based on pipeline natural gas having a LHV

(low heat value) of 36.2 mJ/N•m3(920 Btu/cu ft). Variations

in altitude, temperature, and gas composition from standard

conditions or the use of a three way catalyst may require

a reduction in engine horsepower.

RATING DEFINITIONS AND CONDITIONS

Page 4

STANDBY 350 ekW

CONTINUOUS 350 ekW

60 Hz

Note: Do not use for installation design.

See general dimension drawings

for detail (Drawing #207-4502).

Package Dimensions

Length

4543.1 mm 178.86 in

Width

2235.8 mm 88.02 in

Height

2466.4 mm 97.10 in

Shipping Weight

6356 kg 14,000 lb

www.CAT-ElectricPower.com

TMI Reference No.: DM5441, DM5442 © 2001 Caterpillar

All rights reserved.

U.S. sourced Printed in U.S.A.

LEHE1431 (06-01) Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

STANDBY/CONTINUOUS POWER GENERATOR SET PACKAGE — TOP VIEW

STANDBY/CONTINUOUS POWER GENERATOR SET PACKAGE — SIDE VIEW

Loading...

Loading...