Page 1

511/521/522/532

®

Track Feller Bunchers &

Track Harvesters - ZTS (Zero Tail Swing)

511/521/522/532

Engine Model Cat

Gross Power @ 1800 rpm:

511 247 hp / 184.2 kW

521/522 284 hp / 211.8 kW

532 284 hp / 211.8 kW

®

C9 ACERT™ Tier II

Operating weights (w/o head):

511 24362 kg/53710 lb* 23790 kg/52440 lb**

521 27084 kg/59710 lb* 26050 kg/57440 lb**

522 30410 kg/67040 lb* 29806 kg/65710 lb**

532 31620 kg/69710 lb* 31450 kg/69340 lb**

* Track Feller Bunchers ** Track Harvesters

Page 2

Cat® 511/521/522/532 Track Feller

Buncher/Track Harvester

Power Train

The Cat® C9 ACERT™ Tier II high torque engine

provides excellent power, fuel economy,

serviceability and durability. With 5% greater

fuel efficiency than its predecessor, and

meeting the Tier II emission standards, the Cat

C9 ACERT is a dependable performer.

Hydraulics

Closed Center hydraulic system with electronic

programmable controls that produces excellent

multi-function capability; dedicated pilot,

travel, implement and saw pumps.

Operator Comfort

The Cat 500 Series has a purpose built forestry

cab with heavy-duty guarding, meeting FOPS/

ROPS/OPS requirements. Designed with

operator friendly controls and ergonomics,

the cab gives excellent front, side and rear

visibility. Isolation mounted cab and engine

reduce sound levels and vibration for quiet and

comfortable operation.

Leveling System

The most reliable tilt mechanism in the

industry provides stability and productivity

even in the steepest applications for the 522

and 532 models.

Undercarriage

Cat track machines feature a rugged

undercarriage custom designed for reliable

operation in tough harvesting conditions, from

wet bottomlands to steep rocky slopes.

Contents

Powertrain 3

Hydraulic Packages 4

Operator Comfort 5

Leveling System 6

Undercarriage 7

Boom and Stick 8

Owning and Operating Costs 9

Serviceability 10

Customer Focus 11

Cat 511/521/522/532 Specifications 12

Standard and Optional Equipment 16

2

2

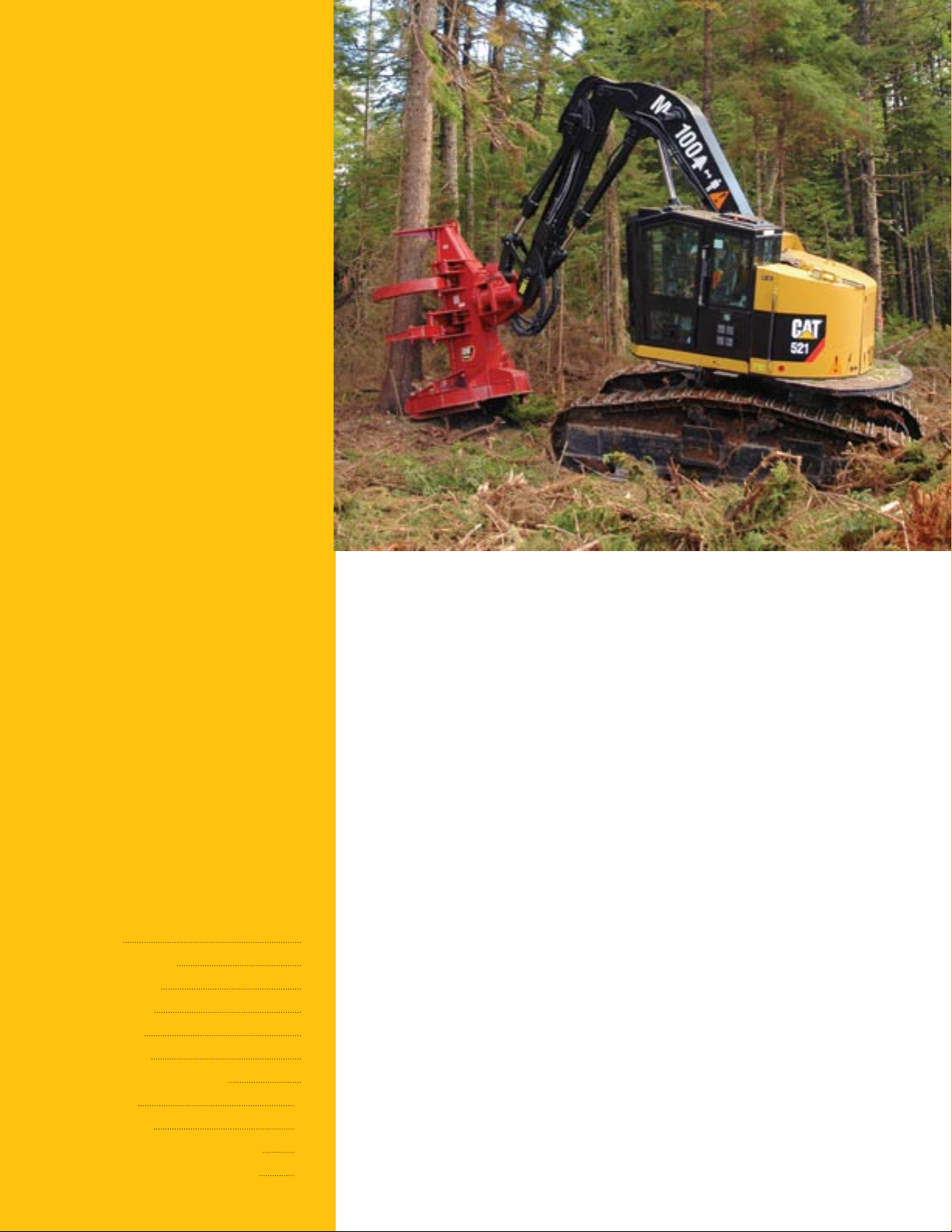

Versatility

Cat machines are available with factoryinstalled felling heads to meet your application

needs. Cat 500 series machines utilize high

pressure hydraulics and proven components.

All models are available with hot saw

intermittent or harvesting linkage fronts.

Serviceability

The hydraulically actuated clam-shell service

door provides full service access to daily

service points simplifying maintenance.

Regularly scheduled maintenance extends

machine service life and lowers overall

operating costs.

ForestPro Consulting

Cat’s ForestPro Consulting Services provides

application consulting, training, market

development and leading forestry system

solutions to meet dealer and customer needs.

Boom and Stick

Harvester and Feller Buncher Linkage

Arrangements are available for all models.

All boom and stick structures are stress

relieved for extended service life.

Owning and Operating Costs

Proven fuel efficiency combined with

easier access and extended service

intervals maximize uptime, reduce

operating costs and maximize productivity.

Customer Focus

Your Cat dealer offers a wide range of

services that can be set up to meet your

equipment needs. The dealer will help you

choose a plan that can cover everything

from machine and attachment selection,

service and maintenance, to replacement.

A robust undercarriage utilizes proven components, customized

for demanding forestry conditions. The unique boom design

provides industry leading lift capacity throughout full reach

range, a benefit in large timber.

Four models are available with just the right horsepower, track

size and hydraulic configurations to fit your application needs.

Page 3

Powertrain

Built for power, reliability, low maintenance,

excellent fuel economy and low emissions.

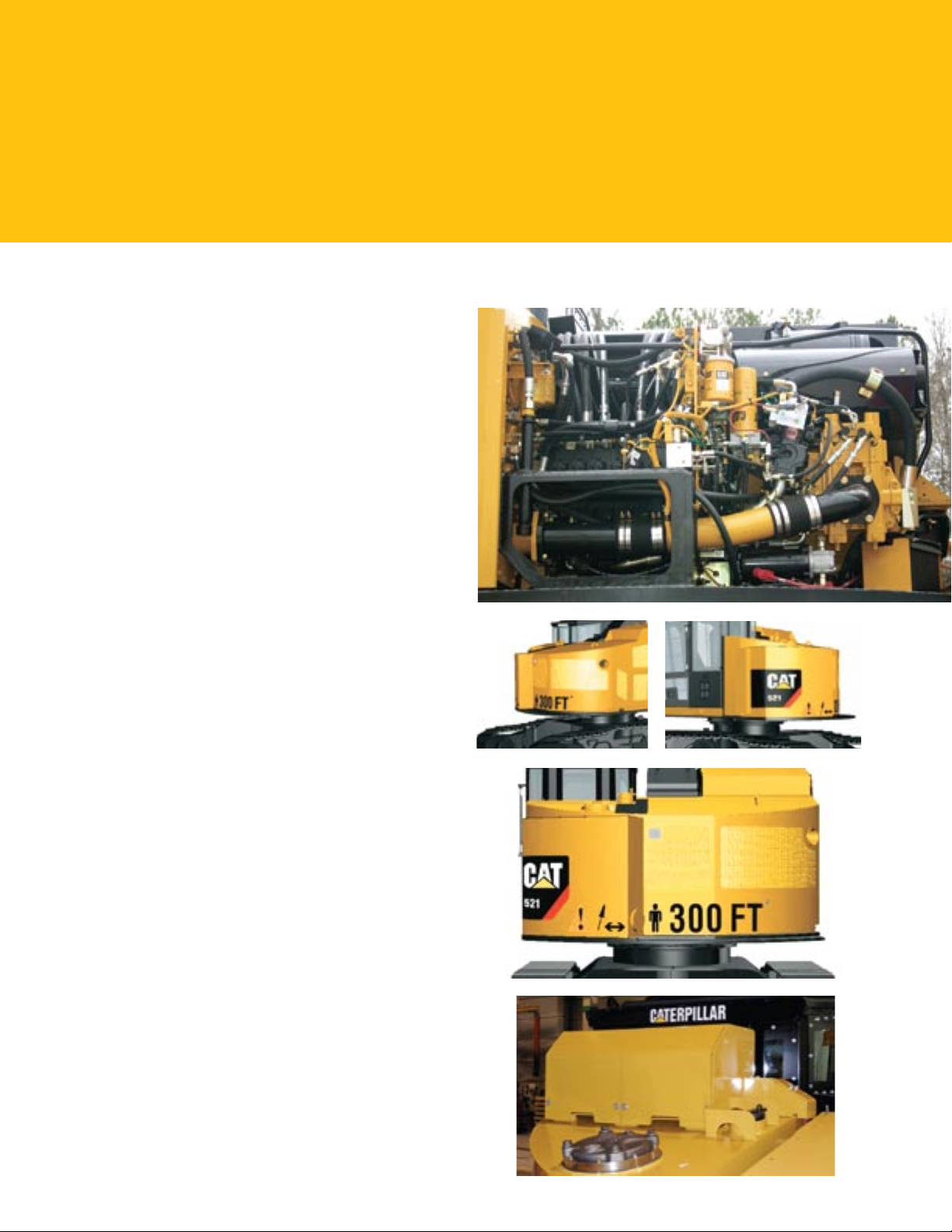

Powerful Performance

The Cat® C9 electronically controlled ACERT delivers power

while meeting all current Tier II emission standards. All

models contain a fuel/water separator, engine air intake heater

and a dual-stage combination air cleaner with pre-cleaner.

High Capacity Cooling System

The side-by-side radiator/oil cooler gives excellent cooling

capacity for high production bunching and harvesting. The

optional on-demand Flexxaire™ fan activates only when

required and allows the cooling fan to purge debris from the

radiator area, keeping a cleaner cooling system. The IQAN

control system infinitely controls blade pitch angle to reduce

horsepower demand from the cooling package, and lower

operating costs..

Engine Oil

Caterpillar® engine oil is formulated to optimize engine life and

performance and is recommended for use in Cat diesel engines.

The engine oil change interval has been increased to 500 hours.

Service

The clamshell engine compartment provides easy access to

oil filters, oil dipstick, hydraulic fill pump and hoses reducing

maintenance time.

Low Exhaust Emissions

The Cat C9 ACERT engine is a low emission engine designed

to meet US EPA off-road Tier II emission regulations.

Pony Tank

An optional add on fuel tank is available for all 500 ZTS track

feller buncher and track harvester models. The additional

90 gallon fuel capacity allows for increased work hours and

productivity by reducing work stoppages needed for refueling

machines.

Batteries

An optional starting aid for colder climates is available for all

500 ZTS track feller buncher and harvester models. This option

provides two (2) additional batteries, a HD starter, and HD

battery cables.

3

Page 4

Hydraulic Packages

Powerful hydraulic system combined with a powerful boom and

stick maximize productivity in any felling or harvesting job.

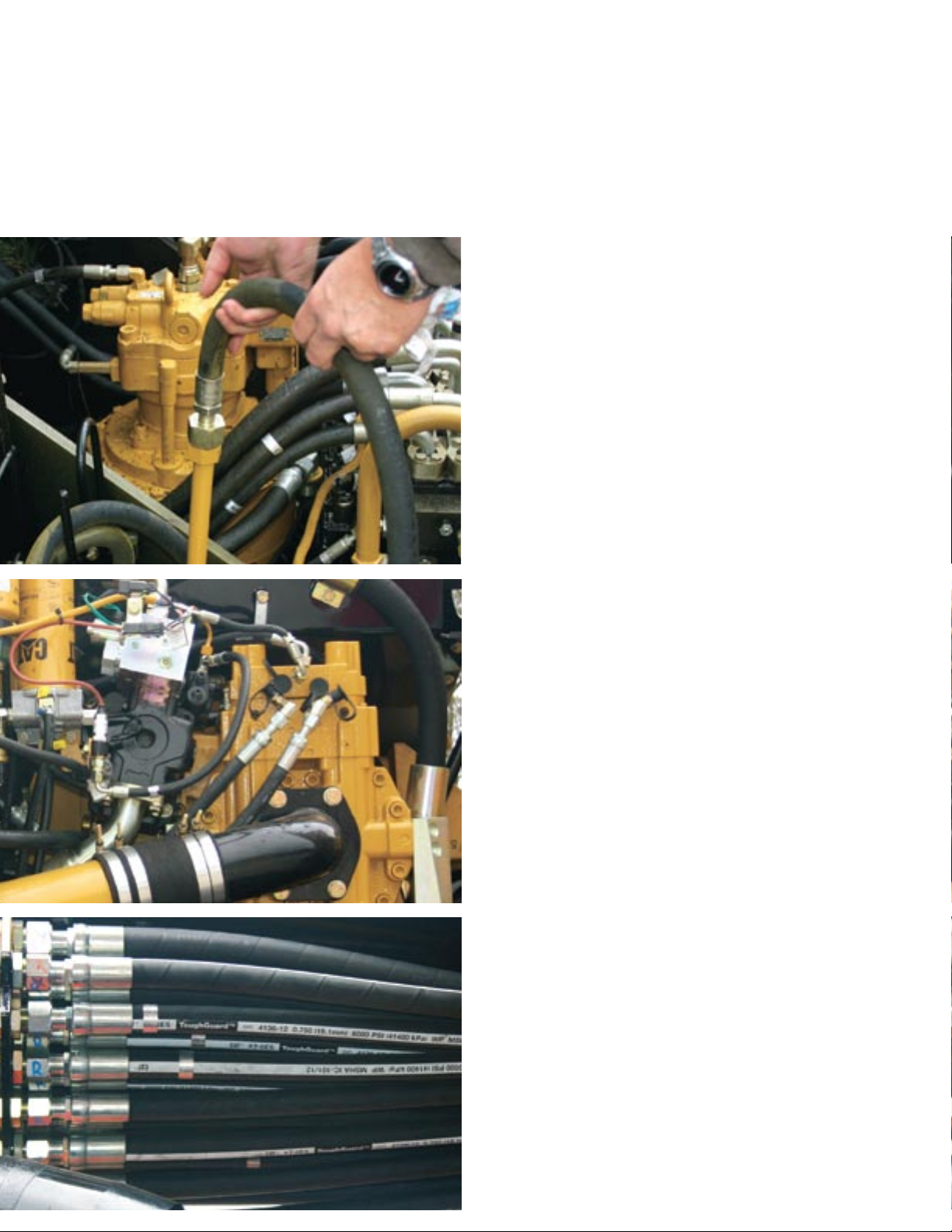

Electric Hydraulic Oil fill Pump

The hydraulic oil site gauge provides easy visibility to know

when hydraulic oil needs to be added. An easy accessible

service wand allows hydraulic oil to be pumped through the

hydraulic filtering system and into the tank. This reduces

maintenance time and helps to maintain oil cleanliness

requirements.

Variable Displacement Pump

Cat® 511 ZTS Track Feller Bunchers and Harvesters contain

a dedicated variable displacement pump for travel circuit and

implement functions, and a dedicated variable displacement

pump for felling attachments. Cat 521/522/532 ZTS Track

Feller Bunchers and Harvesters contain a dedicated 200 cc

variable displacement pump for travel circuit, a 190 cc variable

displacement pump for boom and implement functions, and

a dedicated 55 cc variable displacement pump for felling and

processing attachments. Optional hydraulic configurations

for dangle harvesting heads and intermittent saw heads are

available for all ZTS models.

Caterpillar® Hydraulic Oil

Provides maximum protection against mechanical and corrosive

wear in all hydraulic systems. It’s high zinc content reduces

wear, and extends pump life. Provided certain requirements are

met (e.g. S-O-SSM analysis every 500 hours), the hydraulic oil

change interval is extended from 2,000 hours to 4,000 hours.

Biodegradable Hydraulic Oil

The optional biodegradable hydraulic oil (HEES) is formulated

to provide excellent high-pressure and high-temperature

characteristics and is fully compatible with the all hydraulic

components. HEES is fully decomposed by soil or water

microorganisms, providing a more environmentally-sound

alternative to mineral-based oils.

ToughGuard Hoses

Abrasion resistant hoses along the boom and stick provide

strength and flexibility, increasing hydraulic hose service life.

The ToughGuard cover consists of a thin layer of UHMW

polyethylene bonded to the rubber cover, providing exceptional

abrasion resistance. In many applications, it eliminates the need

for external guarding.

4

™

Page 5

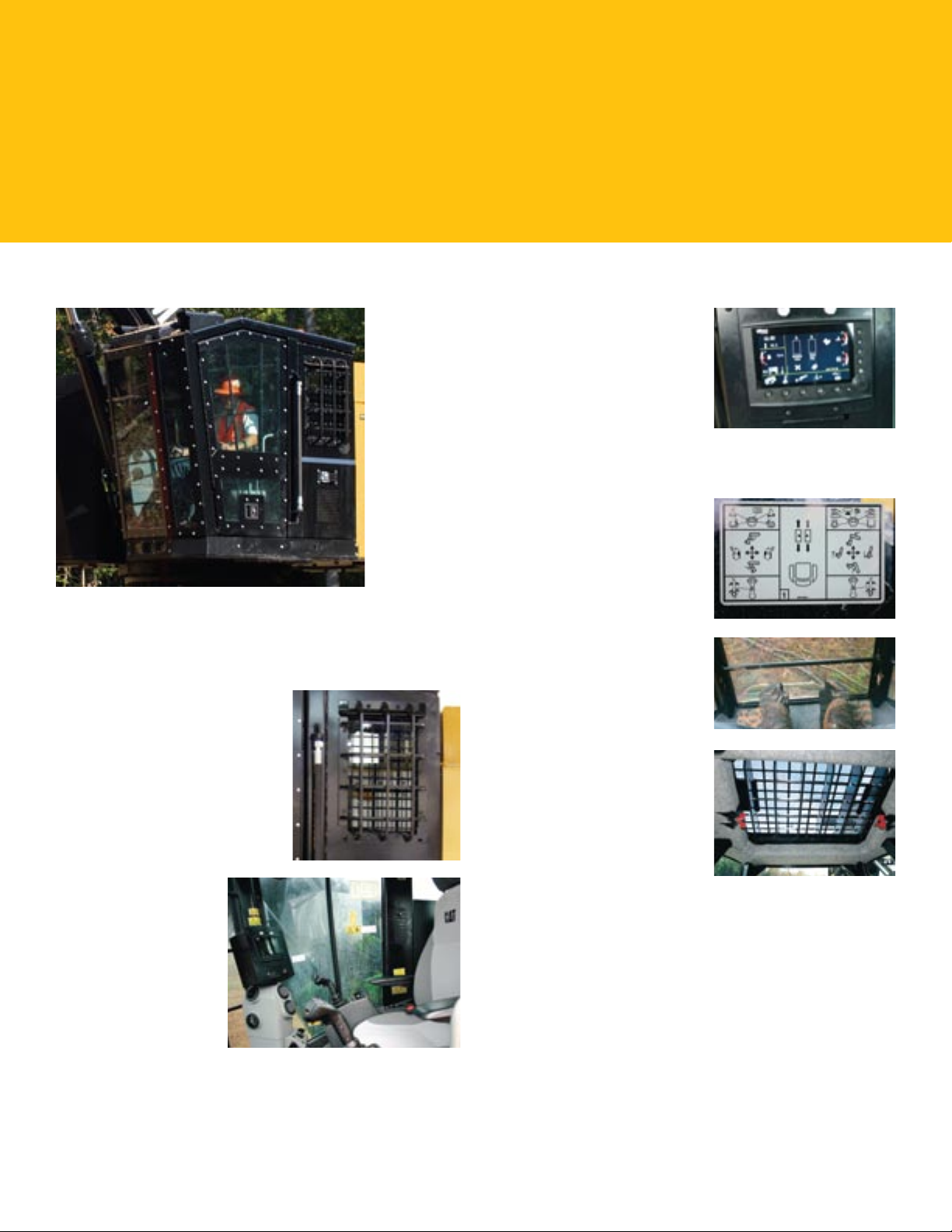

Operator Comfort

The interior layout maximizes operator space, provides

exceptional comfort and reduces operator fatigue.

IQAN

IQAN display allows the operator

to continuously monitor the

operating systems of the machine.

This provides early warning for

potential problems, and allows the

operator to adjust control parameters maximizing performance

and productivity.

Control Convenience

Each control is placed within easy

reach of the operator. Joysticks

control the implement and

attachment functions, providing

Viewing

Cab design optimizes post structures and window placement

to provide excellent operator visibility to front, sides and rear.

Standard 1.25" thick “Margard” front window maximizes

operator protection. All purpose

built forestry cabs are designed

with heavy-duty guarding, meeting

FOPS/ROPS/OPS requirements.

Fresh Air

Large sliding side window with

screen to allow fresh air into cab.

easy operation.

Foot Pedals

Ergonomically located pedals with

side-by-side foot rests provide for

maximum operator comfort while

operating machine travel.

Skylight

A unique large polycarbonate

skylight provides excellent

upward visibility, and acts as an

alternate escape hatch.

Interior Operator Station

The operator station is

quiet with conveniently

placed controls, joysticks

and an ergonomically

designed seat reducing

operator fatigue.

Quiet Operation

Isolation mounted cab and engine reduces sound levels and

vibration for quiet and comfortable operation.

Large Storage Compartment

A large storage space behind the seat, provides

sufficient room for a lunch box, hard hats and work tools.

Electrical System

24-volt electrical system with

in-cab 24-12 volt converter,

dual in-cab 12 volt power points and one 24 volt power point.

Power is provided by two 12 volt maintenance free batteries and

95 amp alternator. An optional cold weather starting attachment

may be selected to provide two additional batteries, a HD starter,

and HD cables.

5

Page 6

Leveling System

Tilting mechanism provides stability and

comfort in steep slope conditions.

Tilt Mechanism

With the most robust tilt mechanism in the industry, the ZTS

tilting models (522 and 532) have a patented 3-cylinder tilt

mechanism with simultaneous tilting forward and side-to-side.

Trunion cylinders are mounted on 2” (51 mm) steel plates and

transfer vertical loads down to the interface of the track frames

and carbody, putting the load into the track and ground.

Cylinders

Three-cylinder tilt mechanism with simultaneously

20 degree forward tilt and 11 degree side-to-side tilt.

Ground Clearance

ZTS machines have excellent ground clearance and

open carbody design. This provides increased mobility

by eliminating debris interference and other obstacles

encountered in rugged working conditions.

6

Page 7

Undercarriage

High quality custom engineered,

heavy duty forestry undercarriage.

Reliable

Precision welded, high-wide carbody has strong frames that

reduce flexing and increase reliability of rollers and track

links throughout the life of the machine. Nine bottom rollers

per side.

Travel Motor

Proven final drives and travel motors provide up to 85,000

lbs (38 555 kg) of tractive effort on the 532 giving excellent

traction and power to the ground.

Track Guards

Integrated welded track guards provided on the 511 and

521, with bolt-on track guards provided on the 522 and 532

leveling machines.

Carbody

Leveling 522 and 532 models feature a bolted track frame

to carbody design. This provides a standard gauge width,

or allows adjustment to a wide gauge width to improve

machine stability, and increase productivity on steep slope

applications.

7

Page 8

Boom and Stick

Designed for maximum reach and lift capacity.

With up to 15,600 lb (7100 kg) of bare pin lift capacity at

20' (6.1 m) on the 532 track feller buncher, the 500 series

machines are dominant over competitors in their size classes.

With market leading lift capacity, 26.6' (8.1 m) of maximum

reach, and tight stick tuck-in capabilities, these machines

deliver high performance felling in all applications. The 532

track harvester delivers the same high performance with

9,100 lbs (4100 kg) of bare pin lift capacity and 32' (9.8 m)

of maximum reach.

Versatility

Caterpillar® disc saw attachments

are available to meet felling needs.

Attachments

From plantation thinning to select cut of large diameter

wood, Cat® felling attachments provide reliable productive

felling solutions. These range in cut capacity from 22" to

24". Designed to allow maximum visibility of the cutting

area, all saws utilize high pressure hydraulics for fast saw

recovery and quick arm speed. This provides a positive

impact on production and better tree control.

Tilt

All models are available with a standard 40 degree partial

lateral tilt, or an optional 220 degree full lateral tilt.

8

Page 9

Owning and Operating Costs

Cat® 500 Series Track Feller Bunchers and Track Harvesters

provide the best value for your operation.

ACERT Technology Fuel Economy.

Based on Caterpillar® testing, the fuel economy of Cat®

engines with ACERT technology is 3 to 5 percent better

than current competing technologies. This fuel economy

is directly related to the complete combustion of fuel

due to the integration between the electronic control that

monitors conditions, the air management system that

controls air volume and the fuel injection system that

delivers just the right amount of fuel as needed.

Clam-Shell Service Doors

The hydraulically actuated clam-shell service doors provide

easy and quick access reducing machine maintenance time.

Less service time means less down time, more work time

and greater productivity.

9

Page 10

Serviceability

Extended Service intervals and easy

access reduce operating costs.

Extended Service Intervals

Caterpillar® service and maintenance intervals have been

extended to reduce machine service time, increase machine

availability and reduce operating costs. Hydraulic oil change

intervals can be extended from 2,000 hours to 4,000 hours.

Engine coolant change intervals are 12,000 hour with Cat®

Extended Life Coolant/Anti-freeze. Regularly scheduled

maintenance extends machine service life and lowers overall

operating costs. 500-hour oil change interval reduces overall

maintenance costs.

Flexxaire™ Fan

Optional Flexxaire™ fan operates only when required

and allows the fan blades to reverse, purging debris from

the radiator area, reducing maintenance time, and fuel

consumption.

Clam-Shell Service Door

The hydraulically actuated clam-shell service door provides

easy and quick access reducing machine maintenance time.

10

Page 11

Customer Focus

Cat® dealer services help you operate

longer with lower costs.

Product Support

Your Cat® dealer will help provide you with parts quickly and

efficiently by utilizing the Cat worldwide dealer network parts

system, minimizing downtime.

Machine Selections

Make detailed comparisons of the machines you are

considering before you buy. What are job requirements,

machine attachments and operating hours? What production is

needed? Your Cat dealer can provide recommendations.

Purchase

Look past the initial price. Consider the financing options

available as well as day-to-day operating costs. This is also the

time to look at dealer services that can be included in the cost

of the machine to yield lower equipment owning and operating

costs over the long run.

Customer Support Agreements

Cat dealers offer a wide variety of product support agreements,

and work with customers to develop a plan that best meets

specific needs. These plans can help protect your investment.

Operation

Improving operating techniques can boost your profits. The

Cat Forest Products Consulting Services Group offers certified

operator training classes to help maximize the return on your

machine investment.

Maintenance Services

Repair option programs guarantee the cost of repairs up front.

Diagnostic programs such as S-O-S

Sampling and Technical Analysis help avoid unscheduled

repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you

evaluate the cost involved so you can make the right choice.

SM

Analysis and Coolant

11

Page 12

CAT® 511/521/522/532 Specifications

Powertrain - 511

Engine Model Cat® C9 ACERT

Gross Power @ 1800 RPM 184.2 kW / 247 hp

Rated Power @ 2100 RPM 170.0 kW / 228 hp

Displacement 537 in3 / 8.8 L

Powertrain – 521/522/532

Engine Model Cat C9 ACERT

Gross Power @ 1800 RPM 211.8 kW / 284 hp

Rated Power @ 2100 RPM 196.1 kW / 263 hp

Displacement 537 in3 / 8.8 L

Operating Weights (w/o heads)*

511 24362 kg / 53710 lb

521 27084 kg / 59710 lb

522 30410 kg / 67040 lb

532 31620 kg / 69710 lb

Operating Weights (w/o heads)**

511 23790 kg / 52440 lb

521 26050 kg / 57440 lb

522 29806 kg / 65710 lb

532 31450 kg / 69340 lb

Boom System

Max. Reach (w/ head)* 8.1 m / 26 ft 6 in

Max. Reach (w/ head)** 9.8 m / 32 ft

Bare Pin Lift @

Max Reach (w/o head)* 7100 kg / 15600 lb @ 20 ft / 6.1 m

Bare Pin Lift @

Max Reach (w/o head)** 4100 kg / 9100 lb @ 29.5 ft / 9.0 m

* Track Feller Buncher – Lift over front of tracks

** Track Harvester Configuration – Lift over front of tracks

Hydraulic System

Electric hydraulic oil fill pump

Dedicated variable displacement pump for travel circuit

511 - 180 cc

521, 522, 532 - 200 cc

Dedicated variable displacement pump for boom and implement functions

511 - 180 cc

521, 522, 532 - 190 cc

Dedicated 55 cc variable displacement pump for saw motor

Undercarriage (size/pitch)

511 325 HEX / 8 in (203.2 mm)

521/522 D6H HD / 8 in (203.2 mm)

532 330 HEX / 8.5 in (215.9 mm)

Track Gauge

511 / 521 102 in / 2591 mm

522 / 532 102 in – 113 in / 2591 mm – 2870 mm

Track Length

511 180 in / 4572 mm

521 / 522 189 in / 4801 mm

532 192.6 in / 4893 mm

Ground Clearance

511 30 in / 762 mm

521/522 33 in / 838 mm

532 35 in / 889 mm

Tractive Effort

511 30391 kg / 67,000 lb

521 31978 kg / 70,500 lb

522 34246 kg / 75,500 lb

532 38555 kg / 85,000 lb

Service Refill Capacities

Fuel Capacity 140 US gal / 530 L

Pony Fuel Tank (optional) 90 US gal / 341 L

Cooling System 16.1 US gal / 61 L

Engine Oil 10.3 US gal / 39 L

Hydraulic Tank 69.2 US gal / 262 L

Hydraulic System 79.3 US gal / 300 L

Swing Drive 2.6 US gal / 10 L

12

Nine bottom rollers per side

Integrated welded track guards – 511 / 521

Bolt-on track guards – 522 / 532

Leveling System

Non-leveling carbody – 511 / 521

Three-cylinder tilt mechanism w/ simultaneous 20 degree

forward tilt and 11 degree side-to-side tilt – 522 / 532

Standards

Cab meets FOPS/OPS/ROPS requirements

Page 13

L2

H

L1

H

W1

W2

Caterpillar® ZTS Track Harvesters Shipping Dimensions

MODEL Length 1 Length 2 Height* Width 1+ Width 2++ Weight

511 446 in (11328 mm) X 133 in (3378 mm) 126 in (3200 mm) X 52,800 lb (23950 kg)

521 453 in (11506 mm) X 140 in (3556 mm) 126 in (3200 mm) X 57,800 lb (26217 kg)

522 X 318 in (8077 mm) 152 in (3861 mm) 126 in (3200 mm) 137 in (3480 mm) 68,160 lb (30917 kg)

(boom tucked)

532 X 318 in (8077 mm) 156 in (3962 mm) 126 in (3200 mm) 137 in (3480 mm) 70,400 lb (31933 kg)

(boom tucked)

Length, Height and Width 1 assume 24 in ( 610 mm) SG shoes

* Height to top of cab w/ standard skylight

+ Width 1 is minimum width w/ 24” SG shoes

++ Width 2 is maximum width when undercarriage is set wide

All 522 and 532 TFB models are shipped in the maximum width configuration using Width 2++ dimension.

These illustrations and values are ESTIMATED for TRUCK SHIPMENT ONLY FROM THE FACTORY.

These are subject to change based on attachments, configurations, add-ons, etc.

CAT 522/532 (Tilter) Track Harvesters CAT 511/521 (Non-Tilter) Track Harvesters

13

Page 14

L

H

L

H

L

H

W1

W2

CAT® 511/521/522/532 Specifications

Caterpillar® ZTS Track Feller Bunchers Shipping Dimensions

MODEL Length Height ** Width 1+ Width 2++ Weight

511 333 in (8458 mm) 133 in (3378 mm) 126 in (3200 mm) X 53,360 lb (24204 kg)

511* 423 in (10744 mm) 133 in (3378 mm) 126 in (3200 mm) X 60,160 lb (27288 kg)

521 340 in (8636 mm) 140 in (3556 mm) 126 in (3200 mm) X 57,660 lb (26154 kg)

521* 431 in (10947 mm) 140 in (3556 mm) 126 in (3200 mm) X 64,460 lb (29239 kg)

522 340 in (8636 mm) 152 in (3861 mm) 126 in (3200 mm) 137 in (3480 mm) 66,540 lb (30182 kg)

522* 431 in (10947 mm) 152 in (3861 mm) 126 in (3200 mm) 137 in (3480 mm) 73,340 lb (33266 kg)

532 339 in (8611 mm) 156 in (3962 mm) 126 in (3200 mm) 137 in (3480 mm) 70,720 lb (32078 kg)

532* 430 in (10922 mm) 156 in (3962 mm) 126 in (3200 mm) 137 in (3480 mm) 77,520 lb (35162 kg)

Length, Height and Width assume 24 in (mm) SG shoes

* w/ HF 201 Partial Tilt Felling Head, tilted back and lifted (assumes an estimated

additional head weight of 7,069 lb (3213 kg)

** Height is to top of cab w/ standard skylight

+ Width 1 is minimum width

++ Width 2 is maximum width when undercarriage is set wide

All 522 and 532 TFB models are shipped in the maximum width configuration using Width 2++ dimension.

These illustrations and values are ESTIMATED for TRUCK SHIPMENT ONLY FROM THE FACTORY.

These are subject to change based on attachments, configurations, add-ons, etc.

CAT 511/521/522/532 Track Feller Bunchers

14

Page 15

Caterpillar® ZTS Track Feller Bunchers & Track Harvesters - Range Diagrams

Lift Range Information - Felling Linkage

511/521/522/532 - ZTS

Non-tilter — 511/521

Tilter — 522/532

Height (ft)Height (ft)

Lift Range Information Harvesting Linkage

511/521/522/532 - ZTS

Reach (ft)

Lift Over Front of Tracks

MODEL 511 521 522 532

Reach Lift Capacity Lift Capacity Lift Capacity Lift Capacity

2.4 m / 8 ft 16900 kg / 37200 lb 17300 kg / 38200 lb 17800 kg / 39300 lb 17900 kg / 39400 lb

4.5 m / 15 ft 9500 kg / 21000 lb 9600 kg / 21200 lb 9700 kg / 21500 lb 9800 kg / 21500 lb

6.1 m / 20 ft 7100 kg / 15600 lb 7100 kg / 15600 lb 7100 kg / 15600 lb 7100 kg / 15600 lb

Lift Over Side of Tracks

MODEL 511 521 522 532

Reach Lift Capacity Lift Capacity Lift Capacity Lift Capacity

2.4 m / 8 ft 16900 kg / 37200 lb 17300 kg / 38200 lb 17800 kg / 39300 lb 17900 kg / 39400 lb

4.5 m / 15 ft 8600 kg / 18900 lb 9500 kg / 21000 lb 9700 kg / 21500 lb 9800 kg / 21500 lb

6.1 m / 20 ft 5400 kg / 11900 lb 6100 kg / 13300 lb 7100 kg / 15600 lb 7100 kg / 15600 lb

Note: Lift Capacity shown without attachment.

Additional reach and attachment weight will reduce lift capacity.

Non-tilter — 511/521

Tilter — 522/532

Lift Over Front of Tracks

MODEL 511 521 522 532

Reach Lift Capacity Lift Capacity Lift Capacity Lift Capacity

3 m / 10 ft 4500 kg / 10000 lb 4500 kg / 10000 lb 4500 kg / 10000 lb 4500 kg / 10000 lb

6.1 m / 20 ft 6900 lg / 15200 lb 6900 kg / 15200 lb 6900 kg / 15200 lb 6900 kg / 15200 lb

9.0 m / 29.5 ft 4100 kg / 9100 lb 4100 kg / 9100 lb 4100 kg / 9100 lb 4100 kg / 9100 lb

Lift Over Side of Tracks

MODEL 511 521 522 532

Reach Lift Capacity Lift Capacity Lift Capacity Lift Capacity

3 m / 10 ft 4500 kg / 10000 lb 4500 kg / 10000 lb 4500 kg / 10000 lb 4500 kg / 10000 lb

6.1 m / 20 ft 5300 kg / 11600 lb 5900 kg / 13000 lb 6900 kg / 15200 lb 6900 kg / 15200 lb

9 m / 29.5 ft 2900 kg / 6300 lb 3300 kg / 7200 lb 4100 kg / 9100 lb 4100 kg / 9100 lb

Note: Lift Capacity shown without attachment.

Additional reach and attachment weight will reduce lift capacity.

Reach (ft)

15

Page 16

CAT® 511/521/522/532 Standard Equipment

Standard equipment may vary. Consult your Caterpillar® dealer for details.

ELECTRICAL

24-volt electrical system

2-12 volt maintenance free batteries with 950 CCA

95 Amp alternator

IQAN programmable controls

MDL large display screen

GUARDS

Hydraulically actuated hinged engine enclosure

with warning alarm

Engine fan guard

Bottom guards

Isolation mounted cab and engine

Heavy duty radiator guard door

OPERATOR ENVIRONMENT

OPS/FOPS/ROPS cab

Dual joystick control

Reverse slope windshield

Air ride seat

Skylight - alternate escape hatch

Top escape hatch

3 inch retractable seat belt

Heater/air conditioner w/climate control

DIN mount radio ready

Operator sound suppression to standards

Travel alarm

Cup holders (2)

2-l2volt and 1-24 volt power outlets

Front Window, 1.25 in Thick Margard

POWERTRAIN

C9 ACERT engine meets Tier II emissions requirements

Infinitely variable travel speed

Under hood centrifugal precleaner and primary air filter

43C degree ambient temperature cooling package

- Aluminum core ATAAC and side-by-side radiator

and oil cooler

- Removable debris screen

- Swing out A/C condenser

Electric fuel priming pump

Fuel water separator

UNDERCARRIAGE

Track roller guards with access holes

Hydraulic track adjusters

Double flange track rollers

GFT110 Lohmann final drives (532)

GFT80 Lohmann final drives (521/522)

GFT60 Lohmann final drives (511)

Caterpillar® 330 undercarriage components (532)

Caterpillar D6H HD grease lubricated and swaged

undercarriage components (521/522)

Caterpillar 325 undercarriage and components (511)

Bolted, variable gage leveling carbody with

3-cylinder tilt mechanism (522/532)

Welded, non-leveling carbody (521/511)

OTHER STANDARD EQUIPMENT

Vandalism protection

Spare hose storage area

Grease gun bracket and storage area

140 US gallon fuel tank

HYDRAULICS

Dedicated pilot pump

Two dedicated variable displacement track pump

and implement pump

30 gpm dedicated saw pump

Cat® 325C swing drive and swing motor

Electric hydraulic oil fill pump

70 US gal hydraulic tank

ANTIFREEZE

50% concentration extended life coolant

16

Page 17

CAT® 511/521/522/532 Optional Equipment

Optional equipment may vary. Consult your Caterpillar® dealer for details.

TRACK SYSTEMS

24" SG pads, clipped corners, with mud/snow reliefs

24" DG pads, clipped corners, with mud/snow reliefs (511/521)

28" SG pads, clipped corners, with mud/snow reliefs (521/522/532)

28" DG pads, clipped corners, with mud/snow reliefs (511/521)

36" Tri-track, clipped corners, with mud/snow reliefs (511/521/522)

Star Carrier Rollers

OTHER EQUIPMENT

Starting Aid, Cold Weather

Starting Aid, Arctic

Pony Tank, additional 90 US gal (341 L) fuel capacity

Flexxaire™ Fan

FIELD INSTALLED ATTACHMENTS

CD Player with AM/FM Stereo – remote capable

Skylight, peaked, removable

Loose Linkage Arrangements

17

Page 18

Notes

Page 19

Notes

Page 20

CAT 511/521/522/532 Track Feller Bunchers &

Track Harvesters - ZTS (Zero Tail Swing)

For more complete information on Cat® products, dealer services, and industry solutions,

visit us on the web at www.cat.com/forestry

© 2009 Caterpillar Inc.

All rights reserved

Materials and specifications are subject to change without notice. Featured machines

may include additional equipment. See your Caterpillar® dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow” and

the POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

CATZTS(01-09)

Loading...

Loading...