Page 1

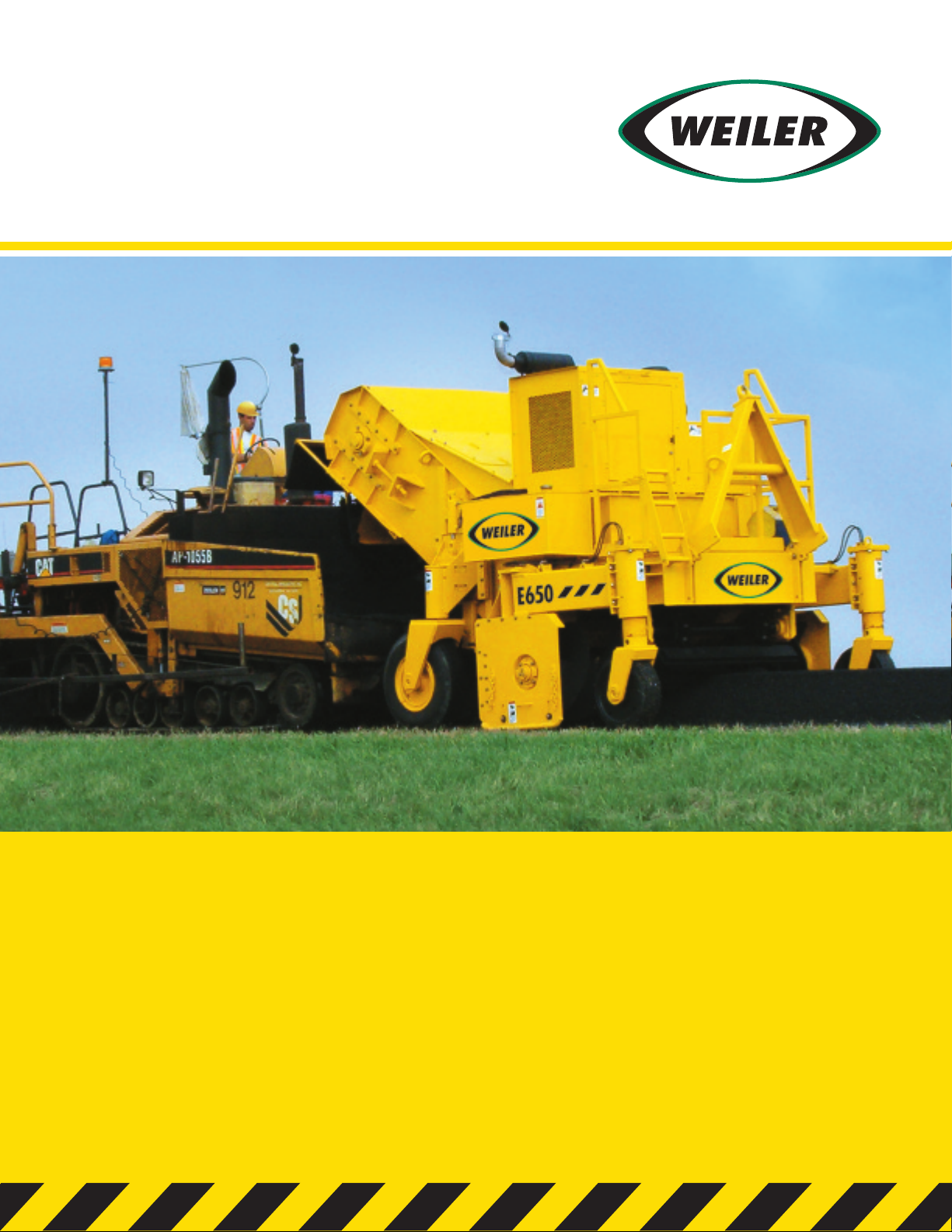

E650

WINDROW ELEVATOR

SIMPLE. PROVEN. POWERFUL.

Page 2

WEILER E650 WINDROW ELEVATOR

THE ROAD TO SUCCESS STARTS WITH

THE RIGHT WINDROW ELEVATOR.

THIS RUGGED, FEATURE-PACKED UNIT HELPS

PAVE THE WAY

When there’s a long road to pave, and you need to get

the job done quickly and without interruptions, turn to

the Weiler E650 windrow elevator. With a proven high-slat

entry position and operator-accessible chain speed and

direction control, this rugged, feature-packed machine

can help lead the way to high-production paving.

HIGH-SLAT ENTRY TACKLES TALL

WINDROWS

This feature enables the machine to tackle tall

windrows laid by belly dump trucks on high-

It also relieves

production or wide-width jobs

the load on the foot shaft to ensure longer life

of both the foot shaft and bearings.

.

MATERIAL-FEED SYSTEM IMPROVES MAT QUALITY

The material-feed system consists of two auger segments

and slat conveyors. The auger segments are positioned on

each side of the slat conveyors. The augers combine the

material and move it to the slat conveyors for distribution

into the hopper.

RELIABLE, DURABLE ENGINE AND

VY-DUTY COMPONENTS

HEA

ENSURE LOW-MAINTENANCE OPERATION

A Cat turbocharged engine with 112 hp at

2,200 rpm delivers high performance and

clean, quiet power. Plus, convenient positioning

of service points ensures easy accessibility.

WIDE THROAT AND ADJUSTABLE HYDRAULIC

DRIVE SYSTEM ENHANCE PRODUCTION

A wide 118-inch throat with large augers

delivers high production abilities

ariable hydraulic drive system allows the speed of

v

the conveyor system to be matched with material

and production requirements. Remixing also takes

place when material is conveyed to the hopper.

he infinitely

T

.

Page 3

THREE-POINT SUSPENSION SYSTEM

HELPS ENSURE SECURE BOND BETWEEN

MAT AND TACK COAT

The three-point suspension system consists of a

hydraulic cylinder for each of the front wheels, and

pair of interconnected hydraulic cylinders for the

a

two rear wheels. Because the two rear wheels are

connected, they are always mirroring each other.

The cylinders adjust the height of the wheels,

hich in turn, changes the height of the machine.

w

Pivoting front-wheel arms enable the wheels to be positioned outside the width of the windrow, allowing the

machine to easily pick up off-center windrows.

ADJUSTABLE SCRAPERS CREATE A CLEAN

WHEEL PATH

Three independent, adjustable scrapers allow

you the flexibility to clean the surface of the

Scrapers are

road for the elev

located at the rear of the material-feed housing

and extend across the width of the machine.

Scrapers are attached with shear pins that

protect them from damage by obstructions in

the surface being paved.

ator and paver

.

NEW INSTRUMENT PANEL, DUAL-SIDE OPERATING CONTROLS ENHANCE PRODUCTIVITY

AND SAFETY

Instrument panel gauges, located on the left side of

the machine, include oil pressure, water temperature,

volt meter, fuel, start switch, and hour meter. An

engine w

down the engine and helps prevent major damage.

With operational controls on both sides of the

machine

offering a choice to work on either side of the

machine in order to avoid traffic.

arning light alerts the operator to shut

this feature helps protect the operator by

,

EASY-ACCESS CHAIN CONTROL LEVER

SAVES TIME

Operator control of chain speed and direction

saves time when the chain needs to be

reversed or speed adjusted.

Page 4

A FIRM AND UNWAVERING COMMITMENT TO CONTINUOUS IMPROVEMENT, COUPLED WITH EXPERT MANUFACTURING

EXPERIENCE, MAKES WEILER THE RIGHT PARTNER.

GREASELESS PADS REDUCE DAILY

MAINTENANCE TIME

Phenolic pads eliminate the time-consuming

and messy job of greasing slider pads.

HYDRAULIC VALVES PROVIDE INCREASED

RELIABILITY

Hydraulic valves and face-sealed hoses and

fittings, along with Deutsch sealed connectors

HINGED ACCESS PANELS ENSURE EASY

MAINTENANCE

No tools are required to access the engine and

other service-related components.

on the harness, provide increased reliability

and serviceability.

WEILER E650 WINDROW ELEVATOR SPECIFICATIONS

Weight 17,600 lb (7,985 kg)

Engine

Height 116" (2,946 mm)

Length 208" (5,283 mm)

Length w/ Raised Towing Frame 168" (4,267 mm)

Width w/ Wings In 122" (3,099 mm)

Width w/ Wings Out 184" (4,674 mm)

Conveyor Throat Width 118" (2,997 mm)

Conveyor Slat Width 58" (1,473 mm)

Conveyor Slat Depth 7" (179 mm)

Weiler reserves the right to make changes in engineering, design, and specifications, and to add improvements or discontinue manufacturing at any time without notice or obligation.

Cat turbocharged 3054ET

112 hp (84 bKw)

Combining Auger Diameter 29" (737 mm)

Discharge Height 75" (1,905 mm)

Front Wheel Cylinder Lift 8" (203 mm)

Rear Wheel Cylinder Lift 8" (203 mm)

Front Tire Size 22" x 7" (559 mm x 178 mm)

Rear Tire Size 8.25 x R15

Front Wheel Width Range 96" – 170" (2,438 mm – 4,318 mm)

Fuel Tank Capacity 50 gal (189 L)

Hydraulic Tank Capacity 22 gal (83 L)

Five Star Industries, Inc.

815 Newbold Drive

P.O. Box 289

Knoxville, IA 50138

Phone: (641) 828-6622 • Fax: (641) 828-6612

www.fivestarind.com

Five Star Industries, Inc., is a premier whole product contract manufacturing provider and prototype development resource center.

©2006 Five Star Industries, Inc.

Loading...

Loading...