Page 1

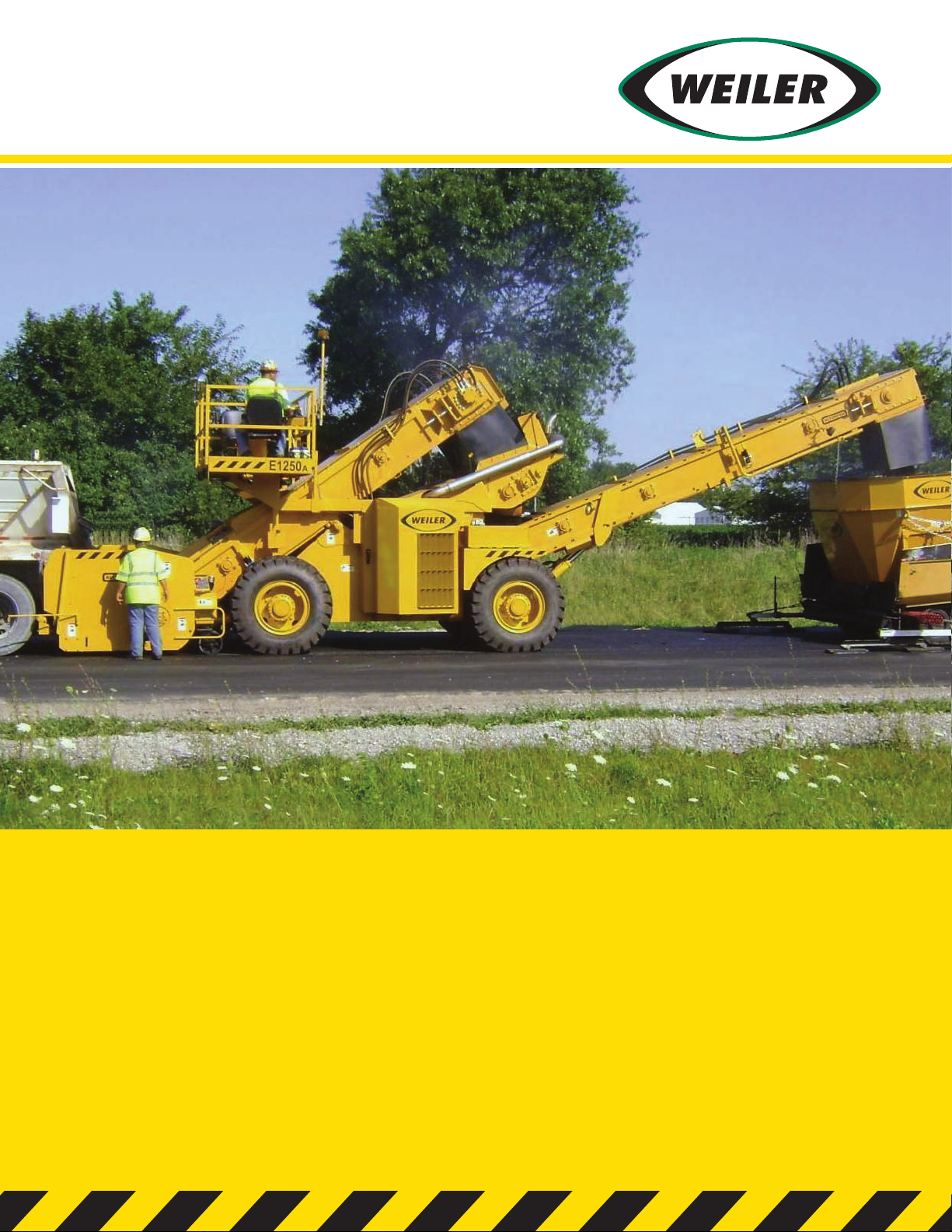

E1250

REMIXING TRANSFER VEHICLE

A

DESIGNED WITH THE OPERATOR IN MIND

Page 2

WEILER E1250 REMIXING TRANSFER VEHICLE

Ar1

98.9

167.4 °C

100

120

140

160

FLIR Systems

A

THE E1250A ALLOWS FOR NON-CONTACT,

NON-STOP PAVING.

The operator is given even more surge capacity by adding

the optional hopper insert for the paver. This unit is also

very versatile allowing for offset paving over barriers,

string lines or any obstacle making it difficult to get trucks

in front of the paver for inline paving.

▼

REMIX HOPPER

Twin interlaced augers remix both size and temperature segregated particles and narrow the material to enter

the conveyor. The cover over the drop through position forces all of the material to be mixed by the auger

flight. Other mixing systems cover and fill the augers rendering their mixing ability ineffective.

Page 3

OPERATOR’S STATION

The operator’s station can be positioned on either side of the

machine by simply lifting a spring-loaded pin and swiveling

the panel. The operator can adjust the steering wheel to a

desired position with the standard tilt wheel feature.

SHIFTING PLATFORM

The platform is capable of shifting 12 inches to either side

of the machine for better visibility to the truck driver as well

as the paver.

CONVEYOR & ELEVATOR DROP OUT FLOOR

Clean out of the conveyor and elevator is made easy.

Whether cleaning the machine or performing maintenance,

this feature is sure to make the crew and service personnel

jobs easier.

FOUR-WHEEL PLANETARY DRIVE SYSTEM

The four-wheel Caterpillar planetary drive system

maximizes pushing power while allowing for a tighter

turning radius and lower center of gravity.

DIRECT DRIVE MOTORS REDUCE NUMBER OF

WEAR PARTS AND INCREASE RELIABILITY

The elevator is direct drive with two high-torque hydraulic

Motors, the conveyor is driven with one. There are no

gearbox seals, bearings or fluids to worry about. The loop

flush valve keeps the motor cool.

MAIN CONTROLS AT YOUR FINGERTIPS

All of the commonly used functions are located based on real

operator input. A manual push-button override allows the

operator to run the elevator at max capacity without changing

the preset running speed. This provides for quick catch up if a

truck is delayed getting to the hopper.

Page 4

STANDARD EQUIPMENT:

E1250A ELEVATOR SPECIFICATIONS

Engine CAT C7-250 HP, Tier III Fuel Tank Capacity 150 gal

Weight 49,500 lbs Conveyor Drive

Hydrostatic with Direct Drive High

Tor

q

ue Motor

Height 138" Conveyor Slat Width 30"

Length 540" Elevator Drive

Hydrostatic with 2 Direct Drive High

Tor

q

ue Motors

Hydraulic Tank Capacity 100 gal Elevator Slat Width 58"

Transport Speed (MAX) 9.8 MPH Ground Drive

4 Wheel Hydrostatic with 2 Speed

Motors and Planetar

y

Drives

Working Speed (MAX) 2.3 MPH Truck Unloading Hopper Width 113"

Tires High Flotation 17.5 " x 25" 20 ply Unloading Hopper Auger Diameter 22"

ash down system w/50 ft

• W

hose reel and separate tank

• Dual operator seats

• Work lights

• Hydraulic extendable,

oscillating push roller

• Rear control panel

OPTIONS:

• Remixing hopper

indow attachment

• W

• Truck hitch

• Ground speed indicator

• Rotating beacon

• Work lights on conveyor

• Hydraulic 9 KW generator

• 13 Ton Hopper insert

• 8 Ton Insert extension

• 5 Ton Insert extension

Weiler reserves the right to make changes in engineering, design, and specifications, and to make improvements at any time without notice or obligation.

Weiler

815 Newbold Drive

P.O. Box 289

Knoxville, IA 50138

Phone: (641) 828-6622

Fax: (641) 828-6612

www.weilerproducts.com

Weiler is a premier whole product contract manufacturing provider and prototype development resource center.

Loading...

Loading...