Page 1

Engine

Engine Model Cat®C15 ACERT

Gross Power 259 kW 347 hp

Flywheel Power 231 kW 310 hp

Weights

Operating Weight 38 488 kg 84,850 lb

Shipping Weight 29 553 kg 65,152 lb

• Operating Weight: Includes hydraulic controls, blade tilt

cylinder, coolant, lubricants, 100% fuel, ROPS, FOPS cab,

SU-Blade, Single-Shank Ripper, 560 mm (22 in) MS shoes,

and operator.

• Shipping Weight: Includes coolant, lubricants, 20% fuel,

ROPS, FOPS cab, and 560 mm (22 in) MS shoes.

D8T

Track-Type Tractor

®

®

Page 2

2

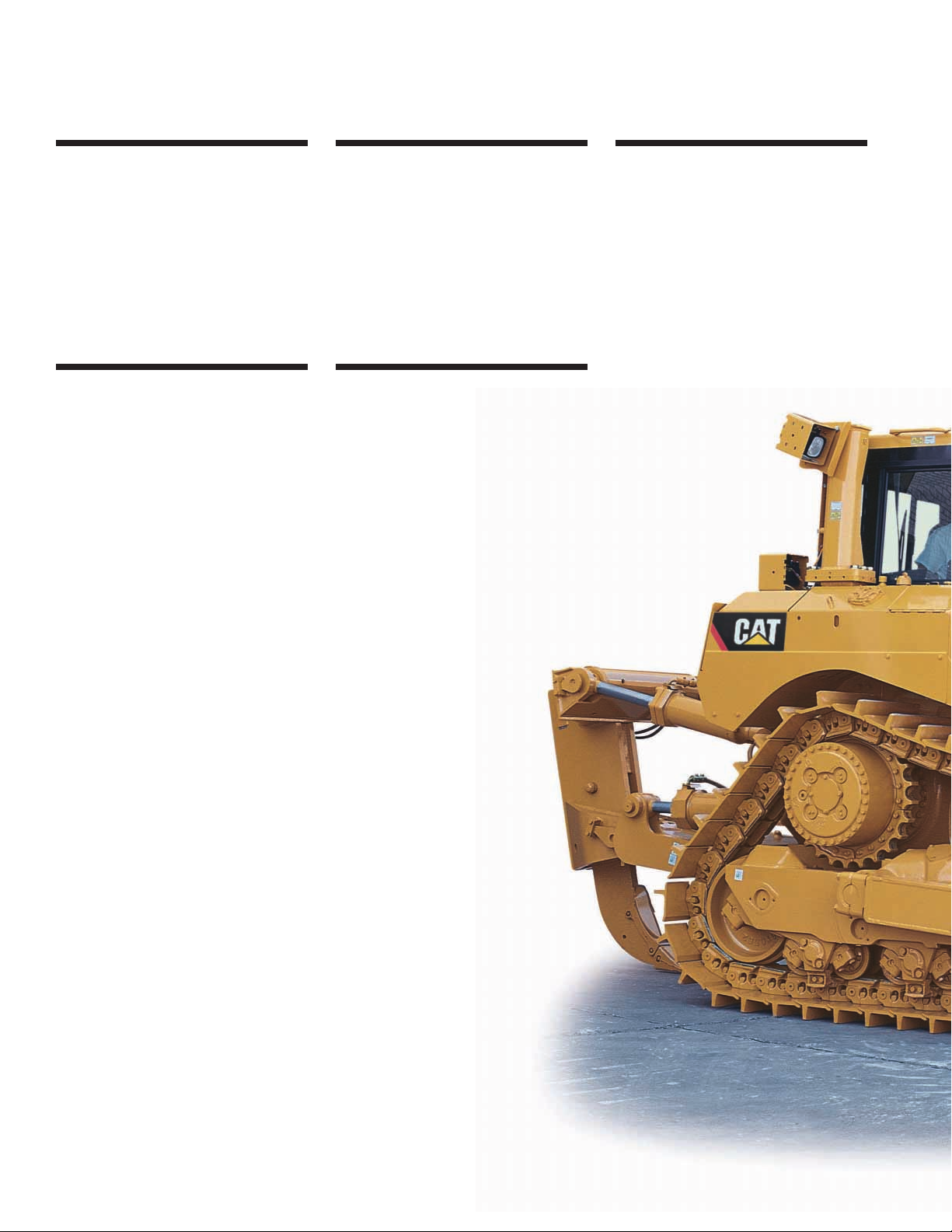

D8T Track-Type Tractor

Strength from the past. Power for the future.™ The D8T combines power and efficiency with

advanced technology for outstanding production at a lower cost-per-yard.

Engineered for demanding work.

The durable construction of the D8T is

well suited for tough working conditions.

Combined with the C15 engine for superior

performance, fuel economy and meeting

emission targets with the help of ACERT

Technology, it keeps material moving with

the reliability and low operating costs you

expect from Cat tractors.

Work Tools

Various bulldozer blades, rippers,

winches, and other options allow you

to adapt the D8T to match your specific

application, making you more productive.

pg. 14

Integrated Electronic Solutions

Caterpillar offers technology options

such as Product Link and AccuGrade

®

Grade Control System that provide

greater accuracy, higher productivity,

lower operating costs and more

profitability. pg. 12

Implement and Steering Controls

Electro-hydraulic implement controls

allow low operator effort for dozing and

ripping. Steering and gear selection in a

one-hand control system enhances

operator comfort. pg. 8

✔

Operator Station

Designed for operator comfort,

convenience, and productivity.

Machine control and vital information

is provided at the operator’s fingertips.

A full day of work is no problem in this

efficient work place. pg. 6

✔

C15 Engine with ACERT®Technology

ACERT Technology works at the point

of combustion to optimize engine

performance and provide low exhaust

emissions. Matched with the torque

divider and power shift transmission,

it provides years of dependable and

efficient service. pg. 4

✔

Page 3

✔ New Feature

3

Serviceability and Customer Support

Combining easy to access, modular

components with your Caterpillar

®

Dealer’s advanced rebuild and repair

capabilities ensures rapid component

replacement and minimum downtime.

pg. 15

✔

Structure

Mainframe is heavy, strong and durable.

Full box sections, steel castings and

continuous rolled rails provide durable

support to the suspended undercarriage,

elevated final drives and other integral

frame components. pg. 11

✔

Undercarriage

The proven elevated sprocket

undercarriage isolates the drive train

components from ground-induced

impacts. The suspended undercarriage

puts more track on the ground for

higher traction and less track slip.

It absorbs shocks for a smoother ride

and longer machine life. pg. 10

Drive Train

The electronically controlled power

shift transmission, efficient differential

steering and durable planetary final

drives deliver outstanding power

transfer and long life to ensure

maximum productivity. pg. 9

Page 4

C15. Performing at full-rated net power

of 231 kW (310 hp) at 1,850 rpm, the

large displacement and high torque rise

allow the D8T to doze through tough

material. Matched to the high-efficiency

torque divider and electronically

controlled power shift transmission,

it will provide years of dependable service.

Constant Net Horsepower. Constant

net horsepower allows the operator to

maintain high standards of performance

and response, even when parasitic loads,

such as the on-demand cooling fan,

are applied. The engine automatically

adjusts to maintain power output and

conversely lowers output when demands

are low. This converts to a fuel savings

in cooler climates.

C15 Block. The one-piece, grey iron

block features generous ribbing for

stiffness and heavy bearing bulkheads

for rigidity and strength. Incorporation

of straight o-ring connection points

reduces the loss of engine oil and fluids.

ADEM™ A4 Engine Controller.

The ADEM A4 electronic control

module manages fuel delivery to get

the best performance per gallon (liter)

of fuel used. It provides flexible fuel

mapping, allowing the engine to respond

quickly to varying application needs.

It tracks engine and machine conditions

while keeping the engine operating at

peak efficiency.

Fuel Delivery. Multiple injection

fuel delivery involves a high degree

of precision. Precisely shaping the

combustion cycle lowers combustion

chamber temperatures generating

fewer emissions and optimizing fuel

combustion; translating into more work

output for your fuel cost.

4

A combination of innovations working at the point of combustion, ACERT Technology

optimizes engine performance while meeting EPA Tier 3 and EU Stage IIIa engine exhaust

emission regulations for off-road applications.

C15 Engine with ACERT®Technology

Page 5

MEUI Fuel System. A highly evolved

fuel system with a proven record of

reliability in the field. MEUI combines

the technical advancement of an electronic

control system with the simplicity of

direct mechanically controlled unit fuel

injection. The MEUI system excels in

its ability to control injection pressure

over the entire engine operating speed

range. These features allow the C15 to

have complete control over injection

timing, duration, and pressure.

ATAAC and Airflow. Air-to-air

aftercooling keeps air intake temperatures

down and, in concert with the tight

tolerance combustion chamber

components, maximizes fuel efficiency

and minimizes emissions. Significant

improvements in air flow are generated

by a water-cooled turbocharger, unique

cross-flow head and single overhead cam.

Turbocharging and Air-to-Air

Aftercooling. Provides high horsepower

with faster response time while keeping

intake temperatures low for long hours

of continuous operation.

Service. Easier maintenance and repair

through monitoring key functions and

logging critical indicators. Electronic

diagnostic access is possible with a

single tool, the Cat Electronic Technician.

5

Page 6

6

Designed for operator comfort, convenience, and productivity, the state-of-the-art cab sets

a new standard.

Operator Station

8

7

6

6

1

5

3

2

4

Page 7

1) Steering Control. Dual-twist tiller

control with standard differential steering

controls direction and degree of turns,

forward-reverse shifting, and gear

selection in a single control handle—

enhancing operator comfort.

2) Cat Comfort Series Seat.

Fully adjustable and designed for

comfort and support. Thick seat and

back cushions provide support for the

lower back and thighs, while allowing

unrestricted arm and leg movement.

Wide retractable seat belt provides

positive and comfortable restraint.

3) Adjustable Armrests. Standard

adjustable armrests provide additional

comfort for the operator.

4) Electronic Ripper Control. A rigidly

mounted handgrip, with low effort

thumb and finger controls, provides

firm support and positive control of

the ripper when operating in tough

conditions. Programmable features,

such as Auto Lift, Shank-Out and

Auto Stow, increase efficiency for

the operator.

5) Electronic, Programmable Dozer

Control. Features such as blade response,

blade float, auto blade pitch, and spread

rate can be set and adjusted using the

Advisor panel. Auto Blade Assist and

AutoCarry options make the tractor even

more efficient in specific applications.

6) Cat Monitoring Display System.

The combination dash mounted

instrument cluster and the Advisor

Monitoring System provide key machine

operating information and give the

operator and service technician insight

into the machine’s operation and

maintenance needs.

In-Dash Instrument Cluster.

The instrument panel, with easy to

read gauges and warning lamps, keeps

the operator aware of any potential

problems. All gauges and readouts

are easily visible in direct sunlight.

Advisor Monitoring System (AMS).

On-board diagnostic abilities minimize

downtime and maximize machine

performance.

7) Wide Panoramic View. The operator

station offers an exceptional viewing

area. A large view hole in the singleshank ripper frame provides a view of

the ripper tip. The tapered hood, notched

fuel tank and narrow single-shank ripper

carriage give the operator a clear line

of sight to the front and rear work areas.

The large single-pane door windows

provide an excellent view to the sides

and blade.

8) Heating and Air Conditioning.

Conveniently located air circulation

vents evenly distribute airflow within

the cab. Controls are easily accessible

from the operator seat.

Fuse Panel and Diagnostic Access.

The new compartment features a single

location fuse panel that includes a

diagnostic port for the Cat ET to connect

for rapid machine diagnostics.

Comfortable Operation. Standard

isolation-mounted cab reduces noise

and vibration. The cab is pre-wired

for a 12-volt or 24-volt radio, equipped

with two speakers, an antenna and a

radio mount recessed in the headliner.

7

Page 8

Dozer Control Lever. A low-effort,

electronic dozer control handle gives the

operator control of all dozer functions

with one hand. Fore/aft movement of

the lever lowers and raises the blade.

Left/right movement directionally tilts

the blade. When equipped with the

optional Dual Tilt feature, the thumb

lever at the top of the handle controls

blade pitch fore and aft. The trigger

switch toggles between single and

dual tilt.

The left and right side thumb buttons

provide control over the semi-automated

blade pitch functions, that the Dual Tilt

attachment provides. Blade pitch for

load, carry and spread segments can

be preset on Advisor and controlled by

the buttons. The left side button cycles

between the pitch settings for each

segment of the push cycle. The right

side button cancels out of the pitch

functions without loosing the preset

pitch angles. This Auto Blade Assist

(ABA) feature is turned on and off

using a switch on the right side console.

The two buttons also provide control

over the AccuGrade™ blade control

attachment when the machine is

so equipped. The buttons turn on

AccuGrade, provide manual increment

and decrement control, and turn off

AccuGrade.

Auto Pitch. Presetting blade pitch angles

for optimal performance during the

dozing cycle: one setting each for load,

carry, spread and return. Auto Pitch is

activated on the Advisor keypad; the

operator can select the dozing segment

by pushing the yellow button on the left

side of the dozer handle.

AccuGrade

®

Ready Option (ARO).

The AccuGrade Ready Option (ARO)

provides a factory installed on-board

platform for the AccuGrade GPS

installation. All of the changes required

to the electrical system, hydraulic

system, blade, and cab are incorporated

into the ARO. Mounting brackets added

on the blade allow easy installation of

the masts. Console mounting in the cab

secure the in-cab display. Plug-in points

inside the cab and on the front of the

machine make it easy to install

electronic components.

Computer Aided Earthmoving System

(CAES) (optional). This on-board

electronic site plan directs machine

operators, in real-time, where to cut and

fill. A graphical map of the design plan

and a view of the machine’s horizontal

and vertical position simplify operation

and enhance production. This advanced

information tool combines GPS

technology (centimeter-level) and in-cab

computing capabilities for precise grade

and slope control. It has proven to

provide measurable impact on work

quality and overall productivity.

Ripper Control Lever. A rigidly mounted

handgrip provides firm support for

the operator even when ripping in the

roughest terrain. The low effort thumb

lever controls raising and lowering.

The finger lever controls shank-in and

shank-out positioning. The thumb button

automatically raises the ripper.

Tiller Control System. A single lever,

dual-control tiller controls machine

speed, direction, and steering. The tiller

allows the operator to work precisely

in close areas, around structures, grade

stakes, other machines and during fine

grading work.

8

Implement and Steering Controls

Low effort control functions significantly reduce operator fatigue for increased performance.

Page 9

Torque Divider. A high efficiency torque

divider with fixed stator provides high

torque multiplication while shielding

the drive train from sudden torque

shocks and vibration.

Differential Steering System. A planetary

differential turns the machine by speeding

up one track and slowing the other,

while maintaining full power to both.

The system consists of:

• Three planetary gear sets:

• Two planetary gear sets

(steering and drive) make up

the “dual differential,” which

performs the traditional drive

function (forward or reverse).

Unlike competitive machines,

the differential also performs

a steering function with input

from the steering motor.

• A third planetary gear set, the

“equalizing planetary,” resides

inside the transmission case.

It is connected to the dual

differential, which provides

a maximum speed difference

between the right and left final

drives during a turn.

• A dedicated variable-displacement

hydraulic pump.

• A bi-directional, fixed-displacement

steering motor.

• Heavy-duty steering drive gears.

Planetary Power Shift Transmission.

Three speeds forward and three speeds

reverse, utilizing large diameter, high

capacity, oil-cooled clutches.

• Modulation system permits fast

speed and direction changes.

• Modular transmission and differential

slide into rear case for servicing

ease, even with ripper installed.

• Oil-to-water cooler for maximum

cooling capacity.

• Forced oil flow lubricates and cools

clutch packs to provide maximum

clutch life.

Drawbar Pull vs. Speed. As loads on

the tractor increase, the D8T offers

unmatched lugging capability and

smooth shifting as the need occurs

to change gears under varying loads.

The 3-speed forward, 3-speed reverse

transmission, backed by differential

steering, offers excellent runout speeds

and accurate steering capability

under load.

Elevated Final Drives. Isolated from

ground and equipment induced impact

loads for extended power train life.

• Crown-shaved drive gears provide

smooth, quiet, low maintenance

operation.

• Splash lubrication and Duo-Cone

®

Seals extend service life.

h

h

9

Drive Train

The drive train provides maximum efficiency in combination with the C15 engine with

ACERT Technology.

Power Shift with Differential Steer

lbs x

N x

1000

1000

140

600

120

1F

100

80

60

40

20

0

01234567

024 6810

2F

3F

Speed

500

400

300

Drawbar Pull

200

100

0

mp

km/

Page 10

Suspended Undercarriage Design.

Suspended undercarriage design absorbs

impact loads to reduce the shock loads

transferred to the undercarriage by up

to 50 percent in uneven terrain.

Bogie Suspension. Bogie suspension

conforms closely to the ground providing

up to 15 percent more ground contact,

especially in hard, uneven terrain.

Higher traction means less slippage,

better balance, and a smoother ride.

Integrated Carrier Roller Mount.

The carrier roller mount is cast into

the track roller frame making it easier

to add the optional carrier roller in the

field, if conditions require it.

Rollers and Idlers. Feature symmetric

Duo-Cone seals for long sealing life to

prevent oil loss and dirt entry. Toric rings

maintain performance over a wide range

of temperatures. Rollers and idlers are

serviceable and rebuildable to provide

value. Abutment-style caps securely

attach rollers and idlers to the bogies.

Roller Frames. Roller frames are tubular

to resist bending and twisting, with

added reinforcement where operating

loads are highest.

• Roller frames attach to tractor by a

pivot shaft and pinned equalizer bar.

• Large pivot shaft bushings operate

in an oil reservoir.

• A low friction, no maintenance

bushing is used in the saddle

connection.

• Aligned to use more of the available

wear material, running the track to

the outside of the rollers in forward

and to the inside in reverse.

Sprocket Segments. Made exclusively

of Caterpillar Tough Steel™ for longer

wear life and precision machined after

heat treat for proper fit. Segments can

be removed or replaced without

breaking the track.

Positive Pin Retention (PPR) Sealed

and Lubricated Track. Designed for

high-impact and high load applications.

The PPR exclusive Caterpillar design

locks the link to the pin.

Track Shoes. Track shoes come in a

variety of sizes and styles to best match

the working conditions.

10

Undercarriage

The Caterpillar elevated sprocket undercarriage is designed for optimized machine balance

and best possible performance and component life.

Page 11

Mainframe Strength. The D8T mainframe

is built to absorb high impact shock

loads and twisting forces.

Frame Rails. Full box section, designed

to keep components rigidly aligned.

Heavy Steel Castings. Adds strength

to the main case, equalizer bar saddle,

front cross member and tag-link trunnion.

Top and Bottom Rails. Continuous rolled

sections, with no machining or welding,

to provide superior mainframe durability.

Main Case. Elevates the final drives

well above the ground level work area

to protect them from impact loads,

abrasion and contaminants.

Pivot Shaft. The D8T pivot shaft runs

through the mainframe and connects to

the roller frames, allowing independent

oscillation. The full-length pivot shaft

distributes impact loads throughout

the case, reducing the bending stress

on the case.

Equalizer Bar. The equalizer bar features

limited slip seals and an oil-lubricated

joint for better oil flow. Large forged

pads reduce wear on the mainframe

and extend sealed joint life.

Tag-Link. The Tag-Link brings the blade

closer to the machine for more precise

dozing and load control.

The Tag-Link design provides solid

lateral stability and better cylinder

positions for constant break out force,

independent of blade height.

11

Structure

Engineered to provide durability and the solid support necessary for maximum production

and service life in the most demanding work.

Page 12

AccuGrade®System for Track-Type

Tractors. Caterpillar is helping customers

revolutionize the way they move

material with new technology solutions

for earthmoving machines – solutions

that provide greater accuracy, higher

productivity, lower operating costs and

more profitability.

The AccuGrade System is designed and

integrated into the machine and hydraulic

systems to create an automated blade

control system that allows operators

to grade with increased accuracy.

The system uses machine-mounted

sensors to calculate precise blade slope

and elevation information.

The integrated electrohydraulic valve

control module uses the information

received from the sensors to

automatically adjust the blade

to maintain grade.

Automated blade control allows

operators to improve efficiency and

productivity by achieving grade faster

and in fewer passes than ever before,

reducing the need for traditional survey

stakes or grade checkers.

AccuGrade Ready Option. The factory

ready option machine makes system

installation and setup quick and easy,

and optimizes performance and

reliability.

• Hydraulic control systems are

integrated into the machine

hydraulics for maximum

performance and dependability.

• AccuGrade controls are integrated

into the machine controls and

levers for reliable operation and

precise control.

• Wiring harnesses and cables

are routed during assembly for

improved wear protection and

better reliability.

• System is designed to withstand

vibration for long life in rugged

working environments.

• Safety interlock feature is built

in for added protection during

automated operation.

12

Caterpillar technology offers customers new opportunities for efficiency and profitability.

Integrated Electronic Solutions

Page 13

AccuGrade GPS. AccuGrade GPS

computes the positioning information

on the machine, compares the position

of the blade relative to the design plan

and delivers that information to the

operator via an in-cab display.

Information, such as blade elevation,

necessary cut/fill to achieve grade, visual

indication of the blade’s position on the

design surface and a graphical view of

the design plan with machine location.

AccuGrade GPS puts all the information

the operator needs to complete the job

in the cab, resulting in a greater level of

control. Vertical and horizontal guidance

tools visually guide the operator to the

desired grade.

Automated features allow the hydraulic

system to automatically control blade

adjustments to move the blade to grade.

The operator simply uses the light bars

to guide the machine for consistent,

accurate grades and slopes, resulting in

higher productivity with less fatigue.

Increases Productivity and Efficiency.

• Increases productivity by up to 50%

• Reduces guesswork and costly rework

by moving dirt right the first time

• Reduces survey costs up to 90%

• Improves material utilization

• Reduces operating costs

• Extends the work day

Enhances Worksite Safety.

• Reduces the need for ground

personnel (survey stakers and

checkers) on the worksite, in the

vicinity of working equipment.

Assists with Labor Shortage.

• Reduces labor requirements and costs

• Customers can get the job done

more quickly and efficiently

• Reduces need for staking and grade

checkers

• Empowers operator, and improves

operator confidence by delivering

grading information to the cab

Improves Employee Satisfaction

and Retention.

• In-cab display brings elevation

control to the cab

• Empowers operator with real-time

results

• Real-time feedback on progress

increases job satisfaction, eliminates

guesswork and reduces operator stress

• Improves operator skills and takes

performance to the next level

• Investing in the latest technology

leads to a sense of value and trust

by the operator

Computer Aided Earthmoving System

(CAES) (optional). This on-board

electronic site plan directs machine

operators, in real-time, where to cut and

fill. A graphical map of the design plan

and a view of the machine’s horizontal

and vertical position simplify operation

and enhance production. This advanced

information tool combines GPS

technology (centimeter-level) and

in-cab computing capabilities for

precise grade and slope control. It has

proven to provide measurable impact on

work quality and overall productivity.

The D8T can be ordered with a CAESready option that provides necessary

wiring and mounts for the CAES system.

Cat®Product Link. When machines are

operating at several different job sites,

it becomes more difficult to keep current

and accurate records. That can lead to

missed maintenance, poor use of assets

and wasted time. Product Link provides

two-way information flow between

machine on-board systems and your

desktop computer through Dealer

Store Front and Equipment Manager.

Cat Product Link enables the use of

Equipment Manager to keep you in

touch with your machines.

Benefits.

• Provides machine location

• Provides machine health information

• Eliminates trips for service meter

hour readings

• Monitors fuel level and consumption

• Identifies unauthorized machine use

• Facilitates efficient maintenance

scheduling

• Can be retrofitted on Cat and other

brands of machines

13

Page 14

Bulldozers. All blades feature a strong

box-section design that resists twisting

and cracking. Blades are made of

Cat DH-2™ steel that has high tensile

strength and stands up to the most

severe applications. Heavy moldboard

construction and hardened bolt-on

cutting edges and end bits add strength

and durability.

• Semi-Universal Blade. The Semi-

Universal blade is built for tough

applications where penetration is more

important than capacity. The “SU” blade

is more aggressive in penetrating and

loading material than the “U” blade.

The blade wings are designed for superior

load retention and penetration in tightly

packed materials and for finishing

applications. Can also be configured with

a push plate for push loading scrapers.

• High-Capacity Universal Blade.

The high-capacity Universal blade offers

maximum capacity and is perfect for

moving big loads over long distances.

The “U” blade has large blade wings and

is ideal for stockpile work, reclamation,

charging hoppers or trapping for loaders.

Optional Dual Tilt. Improves load control

and allows the operator to optimize the

blade pitch angle for each portion of the

dozing cycle.

Single Lever. Controls all blade

movements, including the optional

dual tilt.

Cutting Edges and End Bits. Cutting edges

are DH-2 steel. End bits are DH-3™

steel to provide maximum service life

in tough materials.

Rippers. Single and multi-shank rippers

are made to penetrate tough material

fast and rip thoroughly for use in a

variety of materials.

Single-Shank Ripper. Operator can adjust

the shank depth from the seat using

an optional single shank pin puller.

Large upper frame view hole improves

ripper tip visibility. Heat-treated spacer

bars in the ripper carriage extend

pocket life and reduce shank notching.

Large one-piece shank is available in

deep rip configuration.

Multi-Shank Ripper. Tailors the tractor

to the material by using one, two or

three shanks.

Hydraulics. The D8T features field-proven

load-sensing hydraulics which respond to

operating requirements by automatically

and continually adjusting attachment

hydraulic power, increasing both

operator and machine efficiency.

Rear Counterweights. Provide proper

tractor balance to maximize dozing

production. Recommended if not

equipped with any other rear attachment.

Winches. Several options are available.

Contact your Caterpillar Dealer.

14

Work Tools

Work Tools and Ground Engaging Tools (G.E.T.) provide the flexibility to match the machine

to the job, maximizing performance.

Page 15

Serviceability. Minimizes maintenance

and repair downtime. New sight gauges,

filter locations, improved access to oil

and coolant sampling ports, and an

engine compartment mounted work

lamp, make daily and periodic service

faster and easier. Equipped with a dozer

and ripper, there are only 18 lube points.

Engine Oil Filter. Engine oil filter is

located on the engine for easy servicing

access and minimal downtime.

Save further time with the optional

quick oil change attachments.

Water Separator and Fuel Filter.

Easily located just inside the engine

access panel, the water separator

functions as the primary fuel filter,

just ahead of the secondary fuel filter.

Quick Disconnect Fittings. Allow for fast

diagnosis of the power train, hydraulics

and attachment oil systems.

S•O•SSMAnalysis. Scheduled Oil

Sampling made easier through live

sampling ports for the engine oil,

hydraulics and coolant.

Caterpillar Product Link PL300 (optional).

This option allows the customer or

dealer to obtain machine diagnostics

and location information from their

offices. Product Link PL300 provides

updates on service meter hours, machine

condition and machine location, as well

as integrated mapping/route planning.

Built-in flexibility allows for future

technology development.

Machine Selection. Make detailed

comparisons of the machines you are

considering before you buy. How long

do components last? What is the cost

of preventive maintenance? What is the

true cost of lost production? Your Cat

Dealer can give you answers to these

very important questions.

Purchase. Consider the financing options

available, as well as day-to-day operating

costs. This is also the time to look at

dealer services that can be included in

the cost of the machine to yield lower

equipment owning and operating costs

over the long run.

Product Support. Plan for effective

maintenance before buying equipment.

Choose from your dealer’s wide range

of maintenance services at the time you

purchase your machine. Programs such

as Custom Track Service (CTS),

S•O•S analysis, Technical Analysis

and guaranteed maintenance contracts

give peak life and performance to

your machine.

Parts Program. You will find nearly

all parts at your dealer parts counter.

Cat Dealers use a worldwide computer

network to find in-stock parts to minimize

machine downtime.

Ask about your Cat Dealer’s exchange

program for major components. This can

shorten repair time and lower costs.

Remanufactured Components.

Genuine Cat Remanufactured parts

save you money. You receive the same

warranty and reliability as new products

at cost savings of 40 to 70 percent.

Components available for the drive

train, engine, and hydraulics.

15

Serviceability and Customer Support

The most serviceable machines from the most committed dealers. World-class product

support. The Cat Dealer network trained experts keep your fleet up and running, maximizing

your equipment investments. Caterpillar. The difference counts.™

Page 16

16

D8T Track-Type Tractor specifications

Undercarriage

Shoe Type Moderate Service

Width of Shoe 560 mm 22 in

Shoes/Side 44

Grouser Height 78 mm 3 in

Pitch 216 mm 8.5 in

Ground Clearance 618 mm 24.3 in

Track Gauge 2082 mm 82 in

Length of Track on Ground 3207 mm 10.5 ft

Ground Contact Area 3.58 m

2

5,554 in

2

Track Rollers/Side 8

Number of Carrier Rollers 1 per side (optional)

• Positive Pin Retention Track.

Hydraulic Controls

Pump Type Piston-type, Variable

displacement

Pump Output (Steering) 276 L/min 73 gal/min

Pump Output (Implement) 226 L/min 60 gal/min

Tilt Cylinder Rod End Flow 130 L/min 34 gal/min

Tilt Cylinder Head End Flow 170 L/min 45 gal/min

Bulldozer Relief Valve Setting 24 100 kPa 3,500 psi

Tilt Cylinder Relief Valve Setting 24 100 kPa 3,500 psi

Ripper (Lift) Relief Valve Setting 24 100 kPa 3,500 psi

Ripper (Pitch) Relief Valve Setting 24 100 kPa 3,500 psi

Steering 39 200 kPa 5,700 psi

• Steering Pump output measured at 2,300 rpm and

30 000 kPa (4,351 psi).

• Implement Pump output measured at 1,850 rpm and

6895 kPa (1,000 psi).

• Electro-hydraulic pilot valve assists operations of ripper

and dozer controls. Standard hydraulic systems includes

four valves.

• Complete system consists of pump, tank with filter,

oil cooler, valves, lines, linkage and control levers.

Engine

Engine Model Cat C15 ACERT

Gross Power 259 kW 347 hp

Flywheel Power 231 kW 310 hp

Net Power – Caterpillar 231 kW 310 hp

Net Power – ISO 9249 231 kW 310 hp

Net Power – SAE J1349 229 kW 307 hp

Net Power – EU 80/1269 231 kW 310 hp

Net Power – DIN 70020 322 PS

Bore 137 mm 5.4 in

Stroke 172 mm 6.75 in

Displacement 15.2 L 928 in

3

• Engine ratings apply at 1,850 rpm.

• Net power advertised is the power available at the flywheel

when the engine is equipped with fan, air cleaner, muffler,

and alternator.

• No derating required up to 3658 m (12,000 ft) altitude,

beyond 3658 m (12,000 ft) automatic derating occurs.

Service Refill Capacities

Fuel Tank 643 L 170 gal

Cooling System 77 L 20.3 gal

Engine Crankcase* 38 L 10 gal

Power Train 155 L 41 gal

Final Drives (each) 12.5 L 3.3 gal

Roller Frames (each) 65 L 17.2 gal

Pivot Shaft Compartment 40 L 10.6 gal

Hydraulic Tank 75 L 19.8 gal

Variable Fan Hub 3.1 L 0.82 gal

* With oil filters.

Weights

Operating Weight 38 488 kg 84,850 lb

Shipping Weight 29 553 kg 65,152 lb

• Operating Weight: Includes hydraulic controls, blade tilt

cylinder, coolant, lubricants, 100% fuel, ROPS, FOPS cab,

SU-Blade, Single-Shank Ripper, 560 mm (22 in) MS shoes,

and operator.

• Shipping Weight: Includes coolant, lubricants, 20% fuel,

ROPS, FOPS cab, and 560 mm (22 in) MS shoes.

Page 17

17

D8T Track-Type Tractor specifications

Rippers

Type Single-Shank, Adjustable

Parallelogram

Number of Pockets 1

Maximum Clearance Raised 636 mm 25 in

(under tip, pinned in bottom hole)

Maximum Penetration 1130 mm 44.4 in

(standard tip)

Maximum Penetration Force 127.3 kN 28,620 lb

(shank vertical)

Pry out Force 222.7 kN 50,070 lb

Weight 4085 kg 9,005 lb

(without hydraulic controls)

Total Operating Weight* 38 488 kg 84,850 lb

(with SU-Blade and Ripper)

Type Multi-Shank, Adjustable

Parallelogram

Number of Pockets 3

Overall Beam Width 2464 mm 97 in

Maximum Clearance Raised 593 mm 23.35 in

(under tip, pinned in bottom hole)

Maximum Penetration 780 mm 30.7 in

(standard tip)

Maximum Penetration Force 124.2 kN 27,920 lb

(shank vertical)

Pry out Force 227.9 kN 51,230 lb

(Multi-Shank Ripper with one tooth)

Weight (one shank, without 4877 kg 10,752 lb

hydraulic controls)

Additional Shank 332 kg 732 lb

Total Operating Weight* 39 280 kg 86,597 lb

(with SU-Blade and Ripper)

* Total Operating Weight: Includes hydraulic controls, blade

tilt cylinder, coolant, lubricants, 100% fuel, ROPS, FOPS cab,

Blade, Ripper, 560 mm (22 in) MS shoes, and operator.

Transmission

1 Forward 3.4 kph 2.1 mph

2 Forward 6.1 kph 3.8 mph

3 Forward 10.6 kph 6.6 mph

1 Reverse 4.5 kph 2.8 mph

2 Reverse 8 kph 5 mph

3 Reverse 14.2 kph 8.8 mph

1 Forward – Drawbar Pull (1000) 618.5 N 139 lbf

2 Forward – Drawbar Pull (1000) 338.2 N 76 lbf

3 Forward – Drawbar Pull (1000) 186.9 N 42 lbf

Blades

Type 8SU

Capacity (SAE J1265) 8.7 m

3

11.4 yd

3

Width (over end bits) 3940 mm 12.9 ft

Height 1690 mm 5.5 ft

Digging Depth 575 mm 22.6 in

Ground Clearance 1225 mm 48.2 in

Maximum Tilt 883 mm 34.8 in

Weight* 4789 kg 10,557 lb

(without hydraulic controls)

Total Operating Weight** 38 488 kg 84,850 lb

(with Blade and Single-Shank Ripper)

Type 8U

Capacity (SAE J1265) 11.7 m

3

15.3 yd

3

Width (over end bits) 4267 mm 14 ft

Height 1740 mm 5.71 ft

Digging Depth 575 mm 22.6 in

Ground Clearance 1225 mm 48.2 in

Maximum Tilt 954 mm 37.5 in

Weight* 5352 kg 11,800 lb

(without hydraulic controls)

Total Operating Weight** 39 051 kg 86,093 lb

(with Blade and Single-Shank Ripper)

Type 8A

Capacity (SAE J1265) 4.7 m

3

6.1 yd

3

Width (over end bits) 4990 mm 16.3 ft

Height 1174 mm 3.85 ft

Digging Depth 628 mm 24.7 in

Ground Clearance 1308 mm 51.5 in

Maximum Tilt 729 mm 28.7 in

Weight* 5459 kg 12,035 lb

(without hydraulic controls)

Total Operating Weight** 39 158 kg 86,328 lb

(with Blade and Single-Shank Ripper)

* Includes blade tilt cylinder.

**Operating Weight: Includes hydraulic controls, blade tilt

cylinder, coolant, lubricants, 100% fuel, ROPS, FOPS cab, Blade,

Single-Shank Ripper, 560 mm (22 in) MS shoes, and operator.

Page 18

18

D8T Track-Type Tractor specifications

Standards

• ROPS (Rollover Protective Structure) offered by Caterpillar

for the machine meets ROPS criteria SAE J1040 MAY94,

ISO 3471:1994.

• FOPS (Falling Object Protective Structure) meets

SAE J/ISO 3449 APR98 Level II, and ISO 3449:1992 Level II.

Winches

Winch Model PA140VS

Weight* 1790 kg 3,947 lb

Oil Capacity 15 L 4 gal

Increased Tractor Length 563 mm 22.2 in

Winch Length 1430 mm 56.3 in

Winch Case Width 1160 mm 45.6 in

Drum Width 320 mm 12.6 in

Flange Diameter 457 mm 18 in

Recommended Cable size 29 mm 1.13 in

Optional Cable size 32 mm 1.25 in

Drum Capacity – 84 m 276 ft

Recommended Cable

Drum Capacity – 59 m 193 ft

Optional Cable

Cable Ferrule Sizes – 60 mm 2.36 in

Outside Diameter

Cable Ferrule Sizes – 70 mm 2.76 in

Length

• Variable speed, hydraulically driven, dual braking system,

three roller fairlead.

* Weight: Includes pump and operator controls.

Page 19

19

D8T Track-Type Tractor specifications

Dimensions

All dimensions are approximate.

1 Ground Clearance 618 mm 24.3 in

2 Track Gauge 2.08 m 82 in

3 Width without Trunnions 2642 mm 8.7 ft

(Standard Shoe)

4 Width Over Trunnions 3057 mm 10 ft

5 Height (Top of Stack) 3448 mm 11.3 ft

6 Height (FOPS Cab) 3456 mm 11.34 ft

7 Height (ROPS/Canopy) 3461 mm 11.35 ft

8 Drawbar Height 708 mm 27.87 in

(Center of Clevis)

9 Length of Track on Ground 3207 mm 126.26 in

10 Overall Length Basic Tractor 4641 mm 15.2 ft

11 Length Basic Tractor 4998 mm 16.4 ft

with Drawbar

12 Length Basic Tractor 5275 mm 17.3 ft

with Winch

13 Length with SU-blade 6091 mm 20 ft

14 Length with U-blade 6434 mm 21.1 ft

15 Length with A-blade 6278 mm 20.6 ft

16 Length with 6422 mm 21 ft

Single-Shank Ripper

17 Length with 6344 mm 20.8 ft

Multi-Shank Ripper

18 Overall Length 7872 mm 25.8 ft

(SU-Blade/SS Ripper)

6, 7 5

1

2

3, 4

8

9

10, 11, 12

13, 14, 15

16, 17

18

Page 20

20

D8T Track-Type Tractor specifications

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

POWER TRAIN

C15 with ACERT Technology

24-volt electric start

Advanced Modular Cooling System (AMOCS)

Aftercooler, air-to-air (ATAAC)

Air filter with electronic service indicator

Auto-kickdown (auto downshift)

Automatic shift

(2F/2R, 2F/1R, 1F/2R)

Coolant, extended life

Directional shift management

Ether starting aid, automatic

Fan, suction with hydraulic demand drive

Four planet, double-reduction planetary final drives

Fuel priming pump, electric

Muffler with rain cap

Parking brake, electronic

Pre-cleaner with dust ejector

Prescreener

Separator, water/fuel

Thermal shields

Torque divider

Transmission, electronic control, (3F/3R speeds)

Turbocharger, wastegate

Water separator

OTHER STANDARD EQUIPMENT

Air conditioner box, corrosive resistant

Auto-blade assist and AutoCarry ready

CD ROM Parts Book

Ecology drains: engine oil, coolant,

hydraulic oil, torque converter, fuel tank,

power train case and transmission

Engine enclosures and hood, perforated

Equalizer bar, pinned

Front pull device

Guards:

Bottom, hinged

Radiator, hinged fan blast deflector

Independent steering and attachment

hydraulic pumps

Oil cooler, hydraulic

Product Link ready

S•O•SSMsampling ports

Toolbox

Under-hood standard service lamp

Vandalism protection (8 caplocks)

ELECTRICAL

Alternator, 100-amp brushless

Back-up Alarm

Batteries (4) maintenance free 12-volt, 24-volt system

Converter, 12-volt, 10-amp, two power outlets

Diagnostic connector

Horn, forward warning

Starting receptacle

OPERATOR ENVIRONMENT

Advisor operator interface:

- Electronic monitoring system

- Diagnostic service information

- Operator preferences

Armrests, adjustable

Cab, ROPS, FOPS, sound suppressed

Controls, electronic implement with lockout

Decelerator pedal

Dual-twist tiller control

Engine speed control, electronic

Heater

Hydraulic system, electronically controlled

for bulldozer and ripper control

Mirror, rearview

Radio-ready cab

Seat, adjustable contour suspension

(gray fabric)

Seatbelt, retractable 76 mm (3 in)

Steering control, twist tiller with touch shift

Wipers, intermittent

UNDERCARRIAGE

560 mm (22 in) moderate service grouser

with sealed and lubricated track (44 section)

Rollers and idlers, lifetime lubricated

Sprocket rim segments, replaceable

Suspension-type undercarriage,

Eight-roller tubular track roller frame

Carrier roller ready

Track adjusters, hydraulic

Track guides

Two-piece master link

Page 21

21

D8T Track-Type Tractor specifications

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

OPERATOR ENVIRONMENT

Air conditioner

Air conditioner, fender mounted

Air conditioner, ROPS mounted

Canopy

Enhanced cab

Glass, Ultra-strength up to 40 psi

Operators Arrangement

(gives additional comfort for smaller operators)

Seat, air suspension

Seat, vinyl

SPECIAL ARRANGEMENTS

Hydraulic implement towing arrangement, Low Ground

Pressure arrangement, Waste Handling arrangement and

Woodchip arrangement, in addition to other optional

attachments are available from the factory. Contact your

Dealer for availability.

BULLDOZER ATTACHMENTS

AccuGrade GPS attachment ready installation

(provides hydraulics, electrical, and blade mount

for system)

AutoCarry system

Dual tilt cylinders

8SU Blade, with rock guard and wear plate

8SU Blade, with push plate

8U Blade, with rock guard

Trunnion cover, (replaces trunnions)

RIPPERS

Single-Shank* – Standard depth

Single-shank* – Deep ripping

Multi-Shank* (includes one tooth)

Ripper attachments:

Additional tooth (for multi-shank ripper)

Pin Puller, hydraulic

OTHER ATTACHMENTS

Counterweights*:

Front mounted

Rear mounted

Drawbar, rigid

Parts book, paper

Starting aids:

Batteries, heavy-duty

Heater, engine coolant, 120- or 240-volt

Striker bars, front and rear

Winch*

* A rear attachment and/or counterweight is recommended

for improved performance and balance.

ELECTRICAL

Alternator, 150-amp

Converter, 24 volt to 12 volt

Light, ripper

Lights, supplemental:

6 Halogen

6 HID

8 HID high-mount for waste application

10 Halogen

10 Halogen high-mount for waste application

10 Halogen, sweeps

Warning, strobe

Switch, disconnect, remote mounted

WAVS single rear vision camera

AccuGrade ARO

CAES ARO

GUARDS

Fan, debris

Final drive and seals

Fuel tank

Idler seals

Pivot shaft seal

Radiator, heavy-duty, hinged

Rear tractor

Screen, rear

Sweeps

Track roller

Transmission

Undercarriage

UNDERCARRIAGE

Non-suspended

Tracks, Pair, Sealed and Lubricated (Standard arrangement):

560 mm (22 in), Extreme service

560 mm (22 in), Extreme service PPR

610 mm (24 in), Extreme servce

660 mm (26 in), Moderate service

710 mm (28 in), Moderate service

Tracks, Pair, Sealed and Lubricated (LGP arrangement):

810 mm (32 in), Moderate service

965 mm (38 in), Extreme service

Roller options:

Carrier rollers (one per side)

Seals, symmetrical, idler/roller

POWER TRAIN

Fan, reversible

Fuel system, fast fill

Pre-cleaner, turbine

Prelube, engine, automatic

Quick oil change system

Radiator, high ambient

Page 22

22

Notes

Page 23

23

Notes

Page 24

For more complete information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2007 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, ACERT, ADEM, their respective logos, “Caterpillar Yellow” and the

POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

AEHQ5590-01 (4-07)

D8T Track-Type Tractor

R

Loading...

Loading...