Page 1

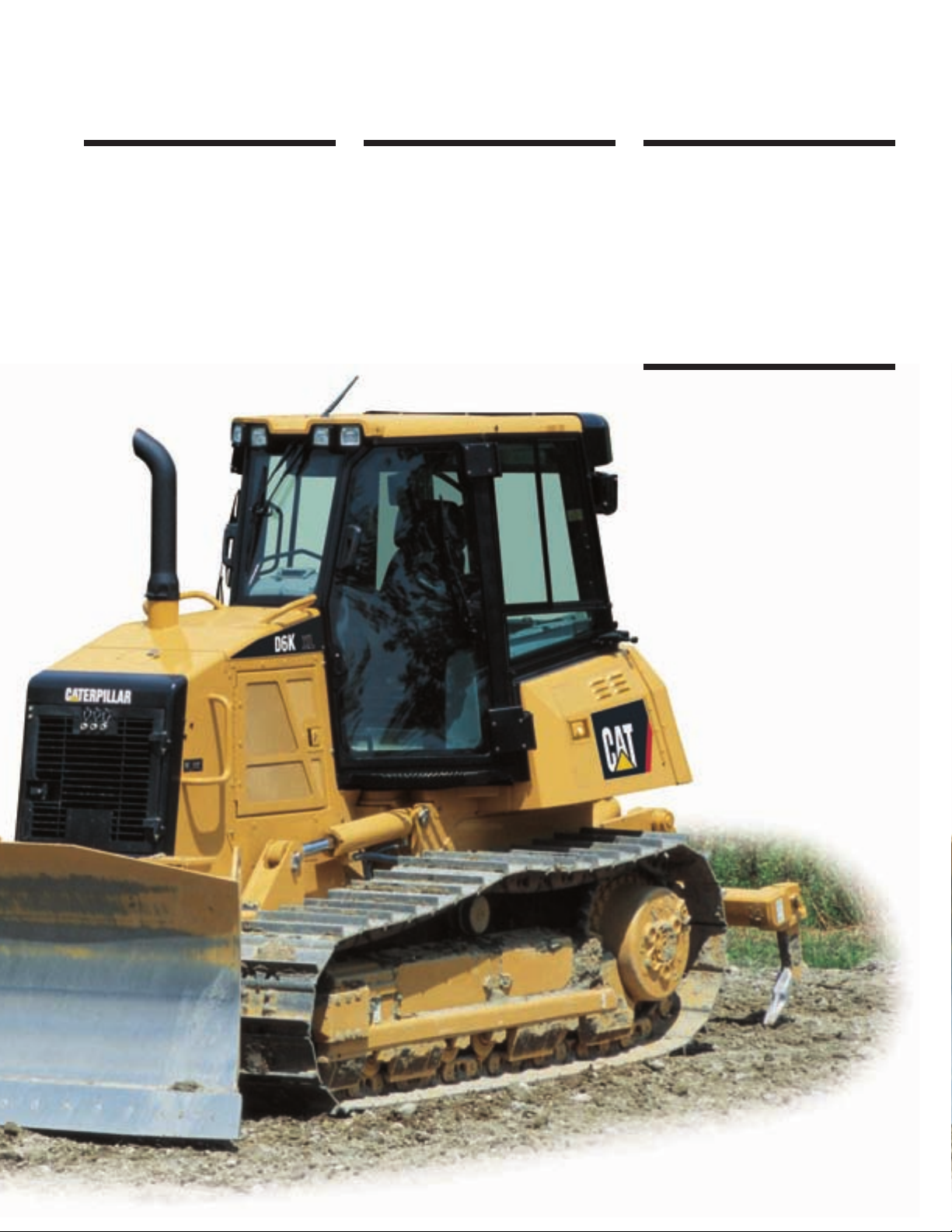

D6K

Track-Type Tractor

®

®

Engine

Engine Model Cat®C6.6 ACERT™

Flywheel Power 93.2 kW 125 hp

Weights

Operating Weight – XL 12 886 kg 28,409 lb

Operating Weight – LGP 13 467 kg 29,690 lb

Page 2

D6K Track-Type Tractor

Engine

The Cat®C6.6 engine meets stringent

✔

Tier 3/Stage IIIA emission standards

while providing outstanding engine

performance, fuel efficiency and

long-term durability. pg. 4

Serviceability and Accessibility

Grouped service points allow for

✔

efficient checks and maintenance,

from the ground level. The new design

of the cooling package facilitates

serviceability and cleaning of the

radiator and cooling fan. pg. 12

Structure

Steel castings and heavy steel plates are

✔

welded to insure a rigid one-piece frame

structure. Structures are designed to last

throughout the extended service life of

the D6K. pg. 5

Work Tools

Caterpillar offers a variety of work

tools, designed with the strength and

versatility needed to accomplish the

job quickly and effectively. pg. 13

Drive Train

The hydrostatic drive with electronic

✔

control provides precise modulation for

quick and smooth operation, superior

maneuverability and comfortable

operation, increasing productivity. pg. 6

2

Page 3

Operator Station

A new operator station offers excellent

✔

visibility and superior comfort.

Standard features include a fully

adjustable air suspended seat, air

conditioning, electro-hydraulic controls,

advanced monitoring system and low

sound levels for comfortable operation

and maximum productivity. pg. 8

SystemOne™ Undercarriage

Designed exclusively by Caterpillar for

✔

Cat Machines, SystemOne Undercarriage

extends undercarriage system life,

improves reliability and reduces

Owning and Operating costs. pg. 10

AccuGrade®Laser and GPS Machine

Control and Guidance Systems

AccuGrade Laser and GPS systems can

✔

be easily installed on the AccuGrade

ARO (Attachment Ready Option)

equipped machine. pg. 11

Total Customer Support

Your Cat®Dealer offers a wide range

of services that can be set up under a

Customer Support Agreement when you

purchase your equipment. The dealer

will help you choose a plan that can

cover everything from machine and

attachment selection to replacementhelping get the best return on

investment. pg. 14

✔ New Feature

3

Page 4

Engine

The new Caterpillar®C6.6 Diesel Engine with ACERT™ Technology meets worldwide

emissions requirements for EPA Tier 3, EU Stage IIIA and Japan Moc Step 3 engine exhaust

emission regulations, while providing excellent performance.

lb x

N x

1000

1000

250

55

50

45

200

40

35

150

30

25

100

20

Drawbar Pull

15

50

10

5

0

0

01234567

0 2 4 6 8 10

D6K Drawbar Pull

Drawbar Pull

vs.

Ground Speed

Speed

Torque Rise. The direct injection

electronic fuel system provides a

controlled fuel delivery increase as

the engine lugs back from rated speed.

This results in increased horsepower

below rated power. A combination

of increased torque rise and maximum

horsepower improves response,

provides greater drawbar pull and

faster dozing cycles.

Cooling System. The cooling system is

a single coolant unit including hydraulic

oil cooler, radiator, ATAAC and fan

installation. Aluminum cores and

hydraulically driven demand fan provide

optimum cooling and fuel efficiency.

Electric Fuel Priming Pump. A standard

electric fuel priming pump is located in

the primary fuel filter base above the

combined water separator/primary fuel

filter. A switch enables to easily prime

the fuel system after a fuel filter service.

Cat®C6.6 Engine with ACERT™

Technology. The Cat®C6.6 is a

6.6 liters (403 in3) displacement,

six cylinder, inline configured engine

equipped with a Caterpillar Common

Rail fuel System. It uses ACERT

Technology, a series of Caterpillar

engineered innovations that provide

advanced electronic control, precision

fuel delivery and refined air management,

resulting in outstanding performance

and lower emissions. The Cat C6.6 with

ACERT Technology meets the U.S. EPA

Tier 3, European Union Stage IIIA and

Japan MOC Step 3 emissions standards.

Design. The C6.6 features a compact

design with heavy-duty engine features

for outstanding durability, reliability

and performance. The C6.6 incorporates

a new cross flow cylinder head design,

a 4 valve head and an ADEM A4

electronic controller.

Electronic Controls. The C6.6 engines

use advanced electronic controllers,

which have a proven track record for

performance and reliability. ADEM A4

Electronic Control Module (ECM)

receives data from engine-mounted

sensors and adjusts critical parameters

to maintain optimum performance.

These adjustments also optimize fuel

economy and emissions compliance.

Electronics also make engines easier

to troubleshoot and repair.

Fuel Delivery. Fuel is introduced in

the combustion chamber in a number

of precisely controlled microbursts.

Injecting fuel in this way allows for

precise shaping of the combustion

process. The ADEM™ A4 module

directs the injectors to deliver precise

quantities of fuel at exactly the right

times during combustion for optimum

efficiency and performance.

Air Management. The C6.6 uses a

turbocharger fitted with a smart waste

gate to give precise control of the boost

pressure. Over the entire engine operating

ranges the result is improved: Throttle

response, Lower fuel Consumption and

optimized engine performance. A new

cross-flow design in the cylinder head

facilitates air movement, while tighter

tolerances between the piston and

cylinder liner are reducing blow by gases.

mph

km/h

Turbocharged and Aftercooled. A wellmatched turbocharger and air-to-air

aftercooler results in higher power while

keeping rpm steady and exhaust

temperatures low.

4

Page 5

Structure

The frame is engineered to handle the most demanding applications, and is built to last

throughout the extended service life of the D6K.

Main Frame. The D6K one-piece main

frame is designed to absorb high

impact shock loads and twisting forces.

Robotic welding provides deep

penetration and consistency, ensuring

high quality, durability and reliability

throughout the structure.

Track Roller Frame. Track roller frames

feature an engineered box-section

design, which provides superior

strength and resistance to bending.

Equalizer bars are pinned in their

center to the machine main frame and

at the ends to each track roller frame.

This allows the forward ends of the track

roller frames to oscillate to keep more

track on the ground in uneven underfoot

conditions while providing maximum

traction and operator comfort.

Heavy Duty Components. Heavy duty

radiator grill, bottom guards and fuel

tank guard are available, for additional

protection in severe applications.

5

Page 6

Drive Train

The D6K features an electronically controlled hydrostatic drive system with independent

power and control of each track for fast acceleration, variable speed control, and on-the-go

direction changes.

Hydrostatic Drive. The electronically

controlled hydrostatic drive system

automatically maintains engine speed

to match the power requirements of

the application for peak performance.

The hydrostatic drive train also offers

independent power and control of each

track, for fast acceleration, infinitely

variable speed control and on-the-go,

direction changes. The operator can

command smooth “power turns” or

even counter-rotation of the tracks for

precise steering control in tight areas.

The Caterpillar hydrostatic drive system

manages itself, freeing the operator to

concentrate on using the Caterpillar

track-type tractor’s superb agility, speed,

and maneuverability to do more

productive work.

Infinitely Variable Speed Control.

Hydrostatic drive provides infinite

speed selection from 0 to 10 km/h

(0 to 6.2 mph) in forward and reverse.

This lets the operator select the optimum

speed for ground and job conditions.

It also eliminates power interruption

during shifting.

Ground Speed Balancing. Hydrostatic

drive provides a completely “step-less”

transmission of power and automatically

matches travel speed and implement

loads for increased efficiency and easier

operation.

High Power Utilization. The hydrostatic

drive system on the D6K is designed

to use full available engine power

throughout the machine working cycle.

If the implement hydraulic system is not

in use, this engine power can be

delivered to the drive train, providing

high drawbar pull and fast travel speeds.

If the implement hydraulics are being

worked hard, the machine control ECM

will automatically slow the tracks as

necessary to use the full remaining

engine power, without overloading

and stalling the engine. As soon as the

implement hydraulic load is decreased,

the machine control ECM will

automatically speed up the tracks until

the machine is traveling at the speed

the operator has commanded with the

Hystat Control (left).

Unsurpassed Maneuverability.

Power turn and counter-rotation capability

improve machine maneuverability and

productivity. On the D6K, power turns

are accomplished by slowing the speed

of one track versus the other, while

maintaining power to both tracks.

The Cat Hystat power turn feature also

enables the D6K to handle large loads

around corners or through hard spots

encountered when dozing. Power turn

capability improves machine mobility

in soft underfoot conditions and is

very effective for controlling machine

operation on side slopes. Counter-rotation

also provides easy, quick maneuvering

in tight areas or congested job sites.

6

Page 7

1

4

6

1. Machine Speed and Direction

Control. Electro-hydraulic, seat-mounted

joystick provides simultaneous onehanded steering and transmission control.

2. Engine. Caterpillar C6.6 diesel engine

with ACERT Technology meets current

exhaust emission regulations while

providing excellent performance.

2

5

3. Cooling System. Cooling package

features a hydraulically driven fan

providing optimum cooling and fuel

efficiency.

4. Hydrostatic Drive System.

Independent, electronically controlled

drive circuits provide superior

maneuverability and precise, smooth

power to each track.

3

5. Variable Displacement Drive Pumps

and Motors. Electronically controlled

and performance tuned to provide

precise speed control and maximum

drawbar pull for maximum productivity.

6. Final Drives. Large, robust planetary

drives for extended service life.

7

Page 8

Operator Station

The operator station is ergonomically designed to provide excellent visibility and superior

comfort for maximum productivity throughout the day.

Instrument Cluster. The compact

instrument cluster (shown with optional

AccuGrade GPS display) keeps the

operator aware of all vital machine

functions. The advanced monitoring

system tracks machine operating

conditions and informs the operator

of impending problems. The monitoring

system includes:

Operator Station. The operator station

features an ergonomic layout emphasizing

simplicity, ease of use and comfort.

Standard air conditioning, generous leg

room and superior visibility allow the

operator to focus on the job. With more

glass area, the operator station provides

a clear view to the blade and the

surrounding work site.

Air suspended seat. The Caterpillar

C500 Comfort air suspended seat is

available in cloth or vinyl and is fully

adjustable, for maximum operator

comfort. A standard lumbar adjustment

provides excellent lower back support.

For comfortable operation in cold

weather, a heated cloth seat is available.

Seat-mounted controls. For optimum

comfort and precise control, the D6K

features ergonomically designed

seat-mounted controls. Seat-mounted

controls isolate vibrations from the

operator, and provide independent seat

and controls adjustment. Individual

wrist pads and armrests can be adjusted

independently for optimum comfort.

Electro-hydraulic controls. New electrohydraulic controls provide quick

steering response, precise blade control,

and comfortable, low-effort operation.

• Alert indicators: action lamp

(3 warning categories), electrical

system

• Indicators: parking brake, engine oil

pressure, engine air filter, hydraulic

oil filter, electrical preheat, operator

presence, blade float, machine

security system, fuel system service,

implement lockout

• Gauges: hydraulic oil temperature,

engine coolant temperature, fuel level

• Digital display: service hours,

selected forward and reverse speeds

Messenger. Messenger is an electronic

monitoring system with real-time,

visual feedback on engine and machine

operating conditions. It provides

information on machine performance,

fuel consumption, diagnostics, and

allows the operator to set some

parameters, such as implement and

steering modulation.

8

Page 9

Work Tool Controls. The D6K can be

equipped with either a ripper or a

winch. For maximum flexibility, the

D6K can be configured for ripper

control, winch control, or a selectable

ripper or winch control.

Other cab features. For optimum

operator comfort, the D6K operator

station includes the following

amenities:

Brake and Decel pedal. The D6K features

a single, combined hystat brake and

decel pedal. Two braking configurations

are available through this pedal:

• Transmission braking only: As the

pedal is pressed, the machine will

slow by braking the transmission;

no engine decel will occur.

• Transmission braking and engine

decel: As the pedal is pressed, the

machine will slow by simultaneously

braking the transmission and reducing

the engine speed.

Bulldozer Control. The blade is

controlled with an ergonomically

designed joystick located to the right of

the operator. This joystick includes a

thumb wheel that controls blade angle.

AccuGrade buttons are conveniently

located on the joystick for quick,

efficient actuation. For non-AccuGrade

equipped machines, a blade shake

button provides aggressive blade

movement for effective removal of

sticky material.

• Foot rests for slope work

• Air filter

• Two 12-volt power points

• Storage compartment

• Cup holder

• Dome light

• Rearview mirror

• Coat hook

• Radio ready factory installed

components

• Rear attachment mirror

When the pedal is depressed beyond the

detent, the service brakes will be applied.

Speed and Direction Control.

The operator controls the speed of the

machine and the direction of travel with

a single joystick control located on the

left console. This joystick includes a

thumb wheel for precise speed control,

as well as a convenient button to store

and recall operator-defined, independent

operating speeds for forward and reverse.

9

Page 10

SystemOne™ Undercarriage

Exclusively for Caterpillar machines the SystemOne™ Undercarriage is a revolutionary new

undercarriage system – from the ground up.

SystemOne™ Undercarriage.

Exclusively for Caterpillar machines the

design extends system life and reduces

operating costs.

• Long-life Sprocket. Extended life

sprockets will outlast two or more

tracks. The rotating bushing

technology extends life.

• Guiding System. The guiding

system contacts link rails instead

of pin ends and helps keep the track

within the roller system. The result

is improved track guiding.

• Rollers. The increased flange

diameter on the rollers provide

optimum guiding and longer life.

• Carrier Rollers. Redesigned carrier

rollers are factory sealed and serviced

as a unit. The larger diameter provides

extended wear to better match

undercarriage system life.

• Idlers. The center tread idlers

contact only the bushing – not the

links – eliminating scalloping and

providing more guiding to the link

assembly. The idlers last longer

because they contact a rotating

bushing instead of a link rail.

• Cartridge Joints. Factory-sealed

cartridge joints are laser welded to

control end play. They offer improved

seal integrity through an innovative

new sealing system and do not

depend on the link interface to

remain sealed. As with all Cat

undercarriage products, they are

filled with special oils.

• May be used in any application.

• The track roller frames are welded

and have a box section design,

which provides strength and

resistance to bending without

adding extra weight.

• The track adjuster and mechanical

recoil spring and grease filled

adjustment cylinder which allows

the idler to move forward and back

to maintain proper track tension as

it absorbs undercarriage shock.

Undercarriage Arrangements.

XL (Extra Long) arrangement

• Forward idler position provides

more track on the ground and to

the front of the tractor. It provides

optimal balance, superior traction

and blade control for finish grading.

• Long roller frame provides good

flotation in soft underfoot conditions.

LGP (Low Ground Pressure)

arrangement

• Specially designed to work in soft

underfoot conditions.

• Wide track shoes, a longer track

frame and a wider gauge increase

track contact area and reduce ground

pressure for excellent flotation.

Complete Guarding. Caterpillar

undercarriages are designed with full

length guarding on top of the track

roller frame. This prevents abrasive

materials from being recirculated in

the track.

Roller Frames. Roller frames attach to

the tractor by a pivot shaft and pinned

equalizer bar.

Oscillating Undercarriage. The pinned

equalizer bar is saddle-mounted

beneath the mainframe, allowing the

roller frames and track to oscillate.

The oscillation provides a steady

working platform and smooth ride

for the operator.

10

Page 11

AccuGrade®Laser and GPS Machine Control and Guidance Systems

Advanced Laser and GPS technology improves operator accuracy, increases production

and lowers operating costs.

AccuGrade System for Track-Type

Tractors. Caterpillar is helping customers

revolutionize the way they move

material with new technology solutions

for earthmoving machines – solutions

that provide greater accuracy, higher

productivity, lower operating costs and

more profitability.

The AccuGrade System is designed and

integrated into the machine and hydraulic

systems to create an automated blade

control system that allows operators to

grade with increased accuracy.

The system uses machine-mounted

sensors to calculate precise blade slope

and elevation information.

The integrated electrohydraulic valve

control module uses the information

received from the sensors to automatically

adjust the blade to maintain grade.

Automated blade control allows

operators to improve efficiency and

productivity by achieving grade faster

and in fewer passes than ever before,

reducing the need for traditional survey

stakes or grade checkers.

AccuGrade Ready Option. The factory

ready option machine makes system

installation and setup quick and easy,

and optimizes performance and reliability.

• Hydraulic control systems are

integrated into the machine

hydraulics for maximum

performance and dependability.

• AccuGrade controls are integrated

into the machine controls and levers

for reliable operation and precise

control.

• Wiring harnesses and cables are

routed during assembly for improved

wear protection and better reliability.

• System is designed to withstand

vibration for long life in rugged

working environments.

• Safety interlock feature is built in for

added protection during automated

operation.

AccuGrade Laser. AccuGrade Laser

designed for precise grade control using

a laser transmitter and receiver.

A laser transmitter is set up on the

work site and creates a constant grade

reference over the work area. A digital

laser receiver is mounted on the machine

and captures the laser signal as the

machine moves across the work site.

The system captures information and

calculates the blade adjustments

necessary to achieve grade. The system

makes automatic elevation adjustments

typically performed by the operator

and provides automatic blade control.

The operator simply steers the machine.

The system also calculates cut/fill

requirements for manual blade control.

AccuGrade GPS. AccuGrade GPS

computes the positioning information

on the machine, compares the position

of the blade relative to the design plan

and delivers that information to the

operator via an in-cab display.

Information, such as blade elevation,

necessary cut/fill to achieve grade,

visual indication of the blade’s position

on the design surface and a graphical

view of the design plan with machine

location.

AccuGrade GPS puts all the information

the operator needs to complete the job

in the cab, resulting in a greater level of

control. Vertical and horizontal guidance

tools visually guide the operator to the

desired grade.

Automated features allow the hydraulic

system to automatically control blade

adjustments to move the blade to grade.

The operator simply uses the light bars

to guide the machine for consistent,

accurate grades and slopes, resulting

in higher productivity with less fatigue.

11

Page 12

Serviceability and Accessibility

Grouped service points and easy maintenance result in increased machine up-time.

Easy diagnostics. The Compact

Instrument Cluster allows for quick

identification of problems and its cause,

utilizing a three level warning system.

This monitoring system can easily be

upgraded by flashing software.

Engine compartment. All the regular

engine maintenance is made through

a large, hinged door located on the left

side of the machine. This compartment

gives access to the engine fuel filters

and water separator, the engine oil

filter, the engine oil dipstick and filler,

the electric fuel priming pump, and the

engine air pre-cleaner and filters.

Cooling package. Cores and fan are

accessible from ground level, for easy

cleaning and maintenance. Opening the

radiator front grid will allow full access

to the engine fan. The fan is mounted

on a swing-out door that will provide

access to the cores. The other side of the

cores is accessible through the engine

compartment.

Grouped pressure taps. Pressure taps

allow for quick measure and

troubleshooting of the hydraulic system.

These pressure taps are all located in

the left service access door, and are

accessible from ground level.

Ecology Drains. Ecology drains provide

an environmentally safer method to

drain fluids. They are included on the

radiator (coolant) and the hydraulic

tank, and for the engine oil change.

Product Link. This system streamlines

diagnostic efforts, downtime and

maintenance scheduling and costs by

providing communication flow of vital

machine data and location information

between the dealer and the customer.

Product Link provides updates on

service meter hours, machine condition

and machine location.

Cat Machine Security System (MSS).

MSS uses electronically coded keys

selected by the customer to limit usage

by individuals or time parameters.

MSS deters theft, vandalism and

unauthorized usage. Each machine

system can store up to 255 keys and

each key can be used on as many

machines as desired. MSS can be

controlled by a Personal Data Assistant.

Field installation is available.

12

Page 13

Work Tools

Cat®Work Tools and Ground Engaging Tools (G.E.T.) are designed to provide strength and

flexibility to match the machine to the job, maximizing performance.

Variable Pitch Power Angle and Tilt

Blade (VPAT). The VPAT blade is

specifically designed for finish grading,

backfilling ditches, cutting V ditches,

windrowing, fill spreading, medium

land clearing and heavy dozing.

The VPAT blade gives the operator

the ability to hydraulically adjust the

blade lift, angle and tilt from the

operator station.

VPAT Positions. For optimum

performance, pitch is manually

adjustable:

• 55° – maximum blade loads and best

finish grading

• 57° and 59.5° – good blade loads

and general dozing

• 61° – maximum blade penetration and

reduced material retention on blade

Foldable Blade. In order to comply with

transportation regulations, a foldable

blade is offered on the XL configuration.

Without blade removal, the machine

will be within the 2.55 meter (8.5 ft)

width requirement.

C-Frame.

• C-Frame is solidly pinned to the

mainframe for good blade control

and eliminates blade motion due

to track oscillation or side forces.

• C-Frame to tractor joint is sealed

and lubricated with remote lines

for extended service life and quiet

operation.

• Large C-Frame tower bearings

improve durability.

• Lubrication points are located at

all pin joints to reduce wear.

Parallelogram Ripper. The multi-shank

parallelogram ripper lets you choose

one, two or three shanks depending on

job conditions. Curved or straight shanks

are available. High strength mainframe

allows having stiffer ripper mounting

blocks for severe drawbar applications.

Drawbar. The D6K is equipped with a

drawbar for pulling work tools such as:

• Disks

• Compactors

• Chopper wheels

• Retrieval of other equipment

Hydrostatic Winch. PA50 winch

is driven by its own closed-loop

hydrostatic system consisting of a

variable displacement hydraulic piston

pump and motor. This winch offers

outstanding control of the load with

infinitely variable modulation of speed

and pull, and lowers operator effort.

Check with your Caterpillar Dealer

for details.

Sweeps and Screens. Optional sweeps

and screens are available. Sweeps help

to shield critical components on the

tractor such as hydraulic lines, exhaust

stacks, cab windows and lights from

damage. Screens provide protection to

the cab windows. This equipment is

recommended for land clearing, forestry

or other severe applications.

13

Page 14

Total Customer Support

Your Cat Dealer offers a wide range of services that can be set up with a Customer Support

Agreement. The dealer can customize a plan for you, from PM service to total machine

maintenance, allowing you to optimize your return on investment.

Selection. Make detailed comparisons

of the machines you are considering

before you buy. How long do components

last? What is the cost of preventive

maintenance? What is the true cost of

lost production? Your Cat Dealer can

give you answers to these questions.

Purchase. Consider the financing

options available as well as day-to-day

operating costs. This is also the time

to look at dealer services that can be

included in the cost of the machine to

yield lower equipment owning and

operating costs over the long run.

Operation. Improving operating

techniques can boost your profits.

Your Cat Dealer has training videotapes,

literature and other ideas to help you

increase productivity.

Product Support. Your Cat Dealer

offers a wide range of services that can

be set up under a Customer Support

Agreement (CSA) when you purchase

your equipment. The dealer will help

you choose a plan that can cover

everything from the machine and

attachment selection to replacement.

This will help you get the best return

on your investment.

Remanufactured Components.

Save money with remanufactured parts.

You receive the same warranty and

reliability as new products at a cost

savings of 40 to 70 percent.

Service Capability. Whether in the

dealer’s fully equipped shop or in

the field, you will get trained service

technicians using the latest technology

and tools.

Replacement. Repair, rebuild or

replace? Your Cat Dealer can help

evaluate the cost involved so you can

make the right choice.

Maintenance. More and more equipment

buyers are planning for effective

maintenance before buying equipment.

Choose from your dealer’s wide range

of maintenance services at the time of

your purchase. Repair option programs

guarantee the cost of repairs up front.

Diagnostic programs such as Scheduled

Oil Sampling and Technical Analysis

help avoid unscheduled repairs.

SAFETY.CAT.COM™.

14

Page 15

Engine

Undercarriage

Engine Model Cat®C6.6 ACERT™

Flywheel Power 93.2 kW 125 hp

Net Power – Caterpillar 93.2 kW 125 hp

Net Power – ISO 9249 93.2 kW 125 hp

Net Power – SAE J1349 92.1 kW 123.4 hp

Net Power – EU 80/1269 93.2 kW 125 hp

Bore 105 mm 4.13 in

Stroke 127 mm 4.99 in

Displacement 6.6 L 403 in

3

• Engine Ratings at 2,100 rpm.

• Net power advertised is the power available at the flywheel

when the engine is equipped with fan, air cleaner, muffler

and alternator.

• No derating required up to 3000 m (9,842 ft) altitude, beyond

3000 m (9,842 ft) automatic derating occurs.

Service Refill Capacities

Fuel Tank 295 L 77.9 gal

Cooling System 24.4 L 6.4 gal

Engine Crankcase 16.5 L 4.35 gal

Final Drive (XL each) 15 L 4 gal

Final Drive (LGP each) 23 L 6 gal

Hydraulic Tank 58 L 15.3 gal

Width of Shoe – XL 560 mm 22 in

Width of Shoe – LGP 760 mm 30 in

Shoes/Side – XL 40

Shoes/Side – LGP 40

Grouser Height 48 mm 1.9 in

Track Gauge – XL 1770 mm 70 in

Track Gauge – LGP 2000 mm 79 in

Track on Ground – XL 2645 mm 104 in

Track on Ground – LGP 2645 mm 104 in

Ground Contact Area – XL 3 m

Ground Contact Area – LGP 4 m

2

2

4,650 in

6,200 in

Ground Pressure – XL 42.5 kPa 6.16 psi

Ground Pressure – LPG 32.7 kPa 4.74 psi

Track Rollers/Side – XL 7

Track Rollers/Side – LGP 7

Blades

Blade Type VPAT

XL VPAT – Blade Capacity 2.7 m

XL VPAT – Blade Width 3077 mm 10 ft

LGP VPAT – Blade Capacity 2.9 m

LGP VPAT – Blade Width 3360 mm 11 ft

3

3

3.5 yd

3.8 yd

2

2

3

3

Weights

Operating Weight – XL 12 886 kg 28,409 lb

Operating Weight – LGP 13 467 kg 29,690 lb

Shipping Weight – XL 12 611 kg 27,802 lb

Shipping Weight – LGP 13 192 kg 29,083 lb

• Operating Weight: Includes cab, air suspended seat,

VPAT dozer, drawbar, transmission, 3-valve hydraulics,

engine enclosures, operator and 95% fuel.

• Shipping Weight: Includes cab, air suspended seat,

VPAT dozer, drawbar, transmission, 3-valve hydraulics

and engine enclosures.

Ripper

Type Parallelogram

Number of Pockets 3

Overall Beam Width 1951 mm 76.8 in

Beam Cross Section 165 6.5

211 mm 8.3 in

Maximum Penetration – XL 360 mm 14.2 in

Maximum Penetration – LGP 360 mm 14.2 in

Weight – With One Shank 845 kg 1,863 lb

Each Additional Shank 34 kg 75 lb

D6K Track-Type Tractor specifications

15

Page 16

Winch

Standards

Winch Model PA50

Weight* 907 kg 2,000 lb

Winch and Bracket Length 842 mm 33.1 in

Winch Case Width 905 mm 35.6 in

Drum Diameter 203 mm 8 in

Drum Width 274 mm 11 in

Flange Diameter 457 mm 18 in

Recommended Cable Size 19 mm 0.75 in

Optional Cable Size 22 mm 0.87 in

Drum capacity – 91 m 300 ft

Recommended cable

Drum capacity – Optional cable 66 m 216 ft 6 in

* Weight: Includes pump, operator controls, oil, mounting

brackets and spacers.

• ROPS (Rollover Protective Structure) offered by Caterpillar

for the machine meets ROPS criteria SAE J1040 MAY94,

ISO 3471:1994 and DLV criteria SAE J397B, ISO 3164:1995.

• FOPS (Falling Object Protective Structure) meets

SAE J/ISO 3449 APR98 Level II, ISO 3449:1992 Level II

and DLV criteria SAE J397B, ISO 3164:1995.

• Brakes meet the standard SAE J/ISO 10265 MARCH99,

ISO 10265:1998.

• The operator sound exposure Leq (equivalent sound

pressure level) measured according to the work cycle

procedures specified in ANSI/SAE J1166 OCT 98 is 81 dB(A),

for cab offered by Caterpillar, when properly installed and

maintained and tested with the doors and windows closed.

• The operator sound pressure level measured according to

the procedures specified in ISO 6394:1998 is 72 dB(A) for

the cab offered by Caterpillar, when properly installed and

maintained and tested with the doors and windows closed.

• Hearing protection is recommended when operating with an

open operator station and cab (when not properly maintained

or doors/windows open) for extended periods or in noisy

environment.

• The exterior sound pressure level for the standard machine

measured at a distance of 15 meters according to the test

procedures specified in SAE J88 APR 95, mid-gear-moving

operation, is 79.5 dB(A).

• The labeled sound power level is 109 dB(A) measured

according to the test procedure and conditions specified

in 2000/14/EC.

16

D6K Track-Type Tractor specifications

Page 17

Dimensions (approximate)

3

9

1

2

4

5

6

8

7

Tractor Dimensions

XL LGP

1 Track gauge 1770 mm 70 in 2000 mm 79 in

2 Width of tractor

With the following attachments:

Standard shoes without blade 2330 mm 92 in 2760 mm 109 in

Standard shoes with VPAT blade angled 25° 2817 mm 111 in 3118 mm 123 in

Standard shoes with foldable blade in transport position 2336 mm 92 in 2760 mm 109 in

3 Machine height from tip of grouser:

With the following equipment: ——

ROPS canopy 2958 mm 116 in 2958 mm 116 in

ROPS cab 2958 mm 116 in 2958 mm 116 in

4 Drawbar height (center of clevis)

From ground face of shoes 483 mm 19 in 483 mm 19 in

5 Length of track on ground 2645 mm 104 in 2645 mm 104 in

6 Length of basic tractor (with C-Frame) 4220 mm 166 in 4220 mm 166 in

With the following attachments,

add to basic tractor length: ——

With the following attachments, add to basic tractor length:

Drawbar 320 mm 13 in 320 mm 13 in

Ripper 1133 mm 45 in 1133 mm 45 in

PA50 winch 640 mm 25 in 640 mm 25 in

VPAT blades, straight 468 mm 18 in 468 mm 18 in

VPAT blade, angled 25° 1116 mm 44 in 1179 mm 46 in

7 Height over stack from tip of grouser 2914 mm 115 in 2914 mm 115 in

8 Height of grouser 48 mm 2 in 48 mm 2 in

9 Ground clearance from ground face of shoe (per SAE J1234) 360 mm 14 in 360 mm 14 in

D6K Track-Type Tractor specifications

17

Page 18

Standard Equipment

Standard equipment may vary. Consult your Caterpillar dealer for details.

ELECTRICAL

Horn

Backup alarm

Converter 12V, 15-amp

Diagnostic connector

Heavy duty 950 CCA batteries

Integrated four front halogen lights, two rear halogen lights

Alternator, 24V, 95 Amp, heavy duty brushless

24V Starter

OPERATOR ENVIRONMENT

ROPS/FOPS cab with sliding side windows and air

conditioning

Cat C500 comfort cloth air suspended seat with adjustable

armrests

76 mm (3-inch) retractable seat belt

Adjustable seat-mounted, electro-hydraulic controls

Foot rests

Compact Instrument Cluster including:

Gauges for engine coolant temperature, hydraulic oil

temperature and fuel level

12 indicators

digital display (ground speed, engine RPM, hour meter)

Rotary throttle switch

Electronic travel speed limiter

Independent forward/reverse speed settings

Single pedal combining deceleration and braking functions

Messenger: electronic monitoring and display system

Rearview mirror

Auxiliary mirror for rear attachment

12V Radio Ready

Two 12V power ports

Coat hook

Storage compartment

Cup holder

Heavy duty rubber floor mat

Windshield washers and wipers, front and rear

POWER TRAIN

Caterpillar C6.6 ACERT diesel engine, turbocharged and

aftercooled with Common Rail fuel system

Aluminum bar plate cooling system (radiator, power train,

aftercooler)

Hydraulic demand fan

Air cleaner with precleaner, automatic dust ejection and

under-hood intake

Electric fuel priming pump with integrated fuel/water

separator

Dual path, electronic control, closed-loop hydrostatic

transmission

Under-hood muffler

Starting aid, ether injection

HYDRAULICS

Hydraulics, 3 valve

Implement load sensing pump

UNDERCARRIAGE

SystemOne™ Undercarriage

Sprocketed center tread idlers

Lifetime lubricated track rollers (7) and idlers

Carrier rollers

Tracks, 40 sections – XL configuration 560 mm (22")/

LGP configuration 760 mm (30")

Adjustable idler height position

Hydraulic track adjusters

OTHER STANDARD EQUIPMENT

C-Frame

Fuel tank and guard

Hinged crankcase guard

Lockable engine enclosures

Idler guards

Hinged radiator grill and swinging fan

Front pull device

Rigid drawbar

Ecology drains (engine oil, power train and implement oil,

and engine coolant)

Swing-out radiator fan

S•O•SSMports (engine, power train, hydraulics and

engine coolant)

ANTIFREEZE

Extended life coolant, –37° C (–35° F)

HYDRAULIC FLUID

Cat HYDO Advanced 10

18

D6K Track-Type Tractor specifications

Page 19

Optional Equipment

Optional equipment may vary. Consult your Caterpillar dealer for details.

POWER TRAIN

Oil change, high speed

Fan, demand, reversing

UNDERCARRIAGE

TRACK PAIRS, XL

Track, 510 mm (20") MS XL

Track, 510 mm (20") ES XL

Track, 560 mm (22") ES XL

Track, 510 mm (20") MS center hole, XL

TRACK PAIRS, LGP

Track, 610 mm (24") MS LGP

Track, 610 mm (24") ES LGP

Track, 760 mm (30") ES LGP

Track, 760 mm (30") Self cleaning, LGP

OPERATOR ENVIRONMENT

Canopy

Canopy, heated

Cab, polycarbonate windows

Seat, vinyl, air suspension

Seat, cloth, air suspension, heated

HYDRAULICS

Hydraulics, winch ready

Hydraulics, 4 valve

Hydraulic oil, biodegradable

GUARDS

Guard, fuel tank, heavy duty

Guard, fuel tank, heavy duty for winch

Grill, radiator, heavy duty

Guard, crankcase, heavy duty

Guard, track guiding, center

Guard, track guiding, long

Guard, track guiding, moderate service

Guard, lift cylinder

Guard, lights, rear

Screen, rear, cab

Screen, side, cab

Screen, rear, canopy

Screen, front and sides, canopy

Sweeps, cab

Sweeps, canopy

BLADES

VPAT XL blade

VPAT LGP blade

VPAT XL blade, foldable

REAR ATTACHMENTS

Winch preparation

Ripper, multi-shank

REAR ATTACHMENT CONTROL

Control, ripper

Control, winch

Control, ripper and winch

MACHINE CONTROL AND GUIDANCE

Installation, AccuGrade ready

STARTING AIDS

Heater, engine, coolant, 120V

Heater, engine, coolant, 240V

RIPPER ATTACHMENTS

Teeth, curved, set of 3

Teeth, straight, set of 3

OTHER ATTACHMENTS

Fuel tank, fast fill

Enclosure, sound suppression

Machine Security System

Rotating beacon

ANTIFREEZE

Coolant, ext. life, –50° C (–58° F)

FIELD INSTALLED ATTACHMENTS

PA50 winch

Radio

D6K Track-Type Tractor specifications

19

Page 20

D6K Track-Type Tractor

AEHQ5736-02 (9-08)

Replaces AEHQ5736-01

For more information on Cat products, dealer services,

and industry solutions, visit us on the web at www.cat.com

© 2008 Caterpillar

All Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.

Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, ACERT, SystemOne, AccuGrade, SAFETY.CAT.COM,

their respective logos, “Caterpillar Yellow” and the POWER EDGE trade dress,

as well as corporate and product identity used herein, are trademarks

of Caterpillar and may not be used without permission.

R

Loading...

Loading...