Operating and Installation instructions

Wet Clean System

W 6071

To prevent accidents

and machine damage

read these instructions

before

installation or use.

en - US, CA

M.-Nr. 06 018 402

Contents

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Guide to the washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before using the washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Language selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting current time and date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Before the first wash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Prepare and sort the laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Load the laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Select a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Add detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Changing temperature and spin speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Program sequence display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Program end - opening the drum door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Special options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Prewash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Starch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Without final spin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Skipping program cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Interrupting a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cancelling a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Delay start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Washer care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning the washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning the drain pump and lint trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning the water inlet filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cleaning the detergent drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Frequently asked questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Technical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Guide to the data plate symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Help to protect the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Shipping struts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Level the washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Read all instructions before installation or

use to prevent injury and machine

damage.

This washer-extractor is only intended for

laundry which has not come in contact

with flammable substances.

Dry cleaning solvents must not be used

in this machine. Such solvents could

cause a fire or explosion.

This appliance conforms to all uniform

safety codes and regulations. The

manufacturer cannot be held responsible

for damage or injury caused by improper

use of this appliance.

All personnel working with this machine

must be fully trained in its use and safety.

SAVE THESE INSTRUCTIONS AND

REVIEW THEM PERIODICALLY

Correct usage of the washer

Do not wash articles that have been previously

~

cleaned, washed, soaked or spotted with gasoline,

dry-cleaning solvents, organic oils or other flammable

substances. These articles give off vapors that could

ignite or explode. Do not add these items to the wash

load.

CAUTION: Fire hazard!

~

Do not store or use gasoline, gasoline-based

substances or any easily flammable materials near

the machine. Do not use the top of the washer as a

storage area.

Do not store any chemicals (liquid detergents,

~

wash aids) on the top of the washer. The chemicals

could damage the surface. Spilled chemicals must

be immediately washed off with a wet sponge.

Under certain conditions, hydrogen gas may be

~

produced in a hot water system that has not been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, turn on all hot water faucets

and let the water flow from each for several minutes

before using the washing machine. This will release

any built-up hydrogen gas. Do not smoke or use an

open flame during this time, the gas is flammable.

Check the wash results when the laundry was

~

soiled with biological oils or grease. If the laundry is

not sufficiently cleaned, a spontaneous combustion

might occur when the laundry is dried in a dryer.

Use special detergents or wash programs.

3

IMPORTANT SAFETY INSTRUCTIONS

Electrical Safety

Be certain your appliance is properly installed and

~

grounded by a qualified technician.

To guarantee the electrical safety of this appliance,

continuity must exist between the appliance and an

effective grounding system. It is imperative that this

basic safety requirement be met. If there is any

doubt, have the electrical system of the house

checked by a qualified electrician. The manufacturer

cannot be held responsible for damages caused by

the lack, or inadequacy of, an effective grounding

system.

Before installation make sure that the voltage and

~

frequency listed on the data plate correspond with

the site electrical supply. This data must correspond

to prevent injury and machine damage. Consult a

qualified electrician if in doubt.

Installation, repair and maintenance work should

~

only be carried out by a Miele authorized technician

in accordance with local and national safety

regulations. Unauthorized repairs could cause injury

or machine damage. The manufacturer cannot be

held responsible for unauthorized work.

Do not repair of replace any part of the appliance

~

or attempt any servicing unless specifically

recommended in these operating instructions.

Contact Miele’s Technical Service Department for

assistance.

Do not damage, remove or bypass the safety

~

features and controls of the machine.

Do not operate a machine with an electrical fault

~

until repaired.

Only use the washer if all panels are properly in

~

place.

The appliance is only completely isolated from the

~

electrical supply when the fuse is withdrawn, the

circuit breaker has been tripped, or the unit has been

unplugged.

Check the packaging, the washer and

~

accessories for any signs of damage. Do not use a

damaged appliance.

Any removable outer panels must be in place, and

~

all moving or electrical parts shielded before the

machine is operated.

Use

Do not let children play in, on or near the washer.

~

Do not let them play with the controls or operate the

unit. Close supervision of children is necessary when

the appliance is used near children.

The drum door glass will be hot when washing at

~

very high temperatures. Do not touch the glass.

Persons who lack physical, sensory or mental

~

abilities, or experience with the machine should not

use it without supervision or instruction by a

responsible person.

Do not reach into the appliance if the drum is

~

moving.

Do not drink washer water! Harmful residues could

~

be present.

The machine should only be operated

~

unsupervised if there is a floor drain (gully) in the

direct vicinity of the machine.

Always follow the instructions of the chemical

~

manufacturer when using cleaning agents and

special application chemicals. Only use such

chemicals for the purpose and in the situation

specified by the manufacturer. This will prevent the

danger of adverse chemical reactions and material

damage.

If in doubt, check with the manufacturer to be sure

that the product is suitable for use in this machine.

Dyes, dye removers and descaling agents may

~

only be used in this machine if the manufacturer

states they are suitable for use in a washing machine.

Always observe the manufacturer’s instructions

carefully.

Fabric softeners may be used with this machine.

~

Follow the manufacturers instructions.

Do not use high pressure cleaners to hose down

~

the machine.

Check the hoses regularly for leaks to prevent

~

water damage.

Do not tamper with

~

the controls.

Do not use force to open the washer drum door.

~

The door handle is equipped with an extra safety

mechanism to guarantee that the door remains

locked.

Faulty components must only be replaced with

~

genuine Miele spare parts to guarantee the safe

operation of this machine.

4

IMPORTANT SAFETY INSTRUCTIONS

Additional information

Disinfecting and cleaning agents often contain

~

chlorides (salts) which can cause steel surfaces to

rust. To protect the machine from rust damage, only

use chloride free disinfecting and cleaning agents for

washing/disinfecting and for cleaning the machine. If

you are not sure about an agent contact Miele’s

Professional Department. If you accidentally spill an

agent containing chloride on the machine it should be

rinsed off with water and dried with a soft cloth.

The manufacturer of the washer does not take

~

responsibility for the effect of the chemical on the

laundry or the machine when a chemical cleaning

agent is recommended on technical application

grounds. Please be aware that changes in formula

tion, storage conditions etc., which may not be

published by the chemical producer, can have a

negative effect on the cleaning result.

Keep the area around the machine clean and free

~

of debris.

Before the appliance is removed for service or

~

discarded, remove the door.

The interior of the machine should be cleaned

~

periodically by a qualified service agent.

-

Chlorine damage to components

How to handle chlorine bleach and

perchloroethylene (PCE)

Heavy use of chlorine products increases

the risk of damage to appliance

components.

Depending on the chlorine concentration,

the exposure time, and the temperature, the

use of liquid and powdered chlorine-based

bleaches can erode the stainless steel

protective layer and lead to corrosion of the

appliance components. Therefore, it is

recommended that these products not be

used. Instead you can use oxygen-based

bleaches.

If you still need to use chlorine-based

bleaches in special cases, you will need to

perform a neutralizing step each time.

Failure to do so can result in permanent and

irreversible damage to the washing machine

and the laundered items.

Using accessories

Only use genuine Miele accessories. If other parts

~

are used, guarantee, performance and product

liability claims may become void.

Ensure that any one operating this machine is

~

familiar with these important safety instructions.

Chlorine neutralization

Chlorine neutralization must be done

immediately following the use of a

chlorine-based bleach. For best results, use

hydrogen peroxide or an oxygen-based laundry

soap or bleach, without draining the tub.

If thiosulfate is used (especially with hard

water), lime deposits can form, leading to

residue on the laundered items or a build-up

in the washing machine. The preferable

alternative is to use hydrogen peroxide,

because it helps promote the neutralization

of chlorine.

The exact amounts to be used, and at what

temperature(s), should be selected based

on the recommendations of the neutralizer

manufacturer, then checked for efficacy. The

laundry will need to be tested to ensure that

no active chlorine remains behind after

neutralization.

SAVE THESE

INSTRUCTIONS

5

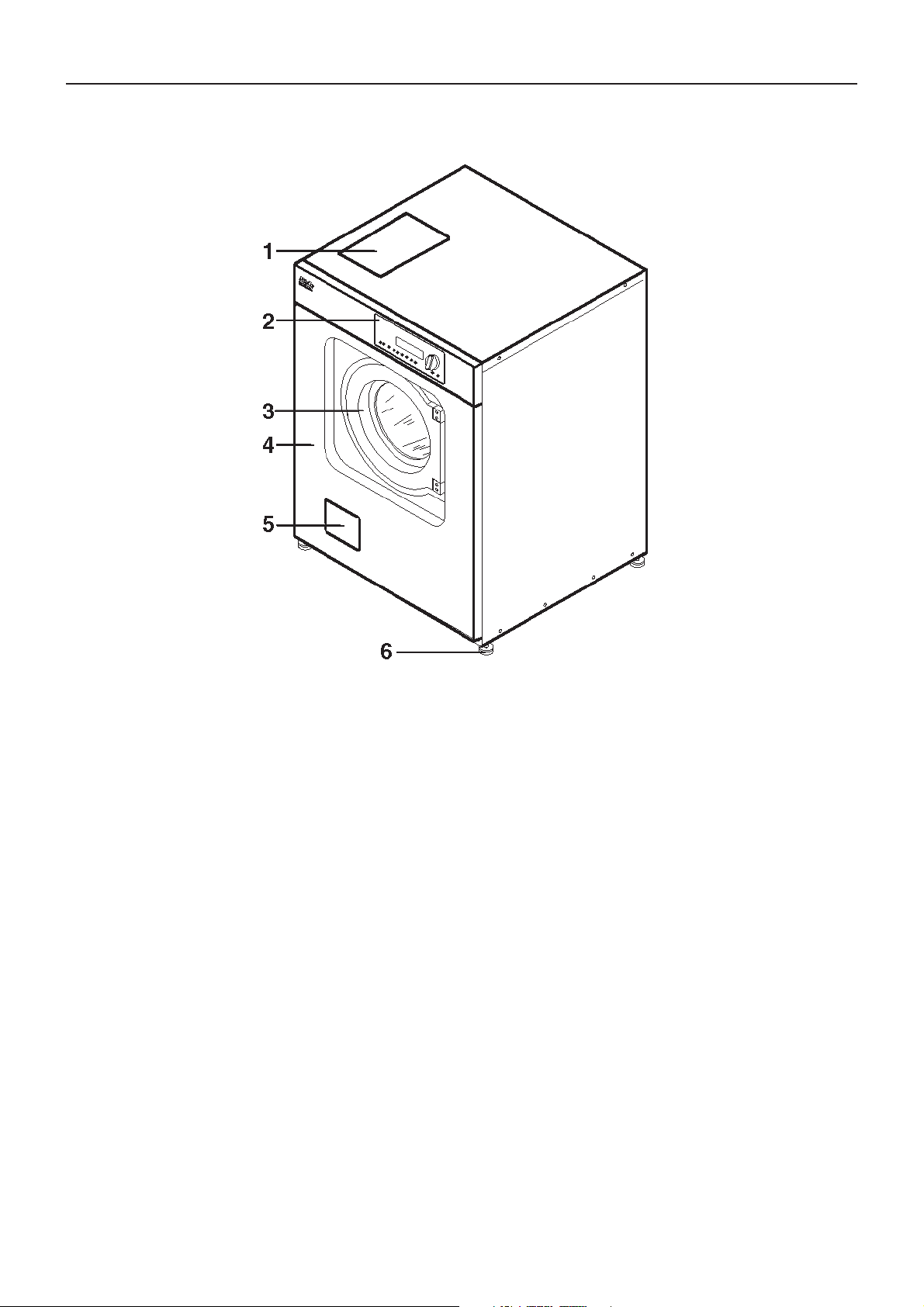

Guide to the washer

Front view

1 Detergent dispenser

2 Control panel

3 Drum door

4 Outer casing

5 Drain pump door

6 4 Height adjustable feet

6

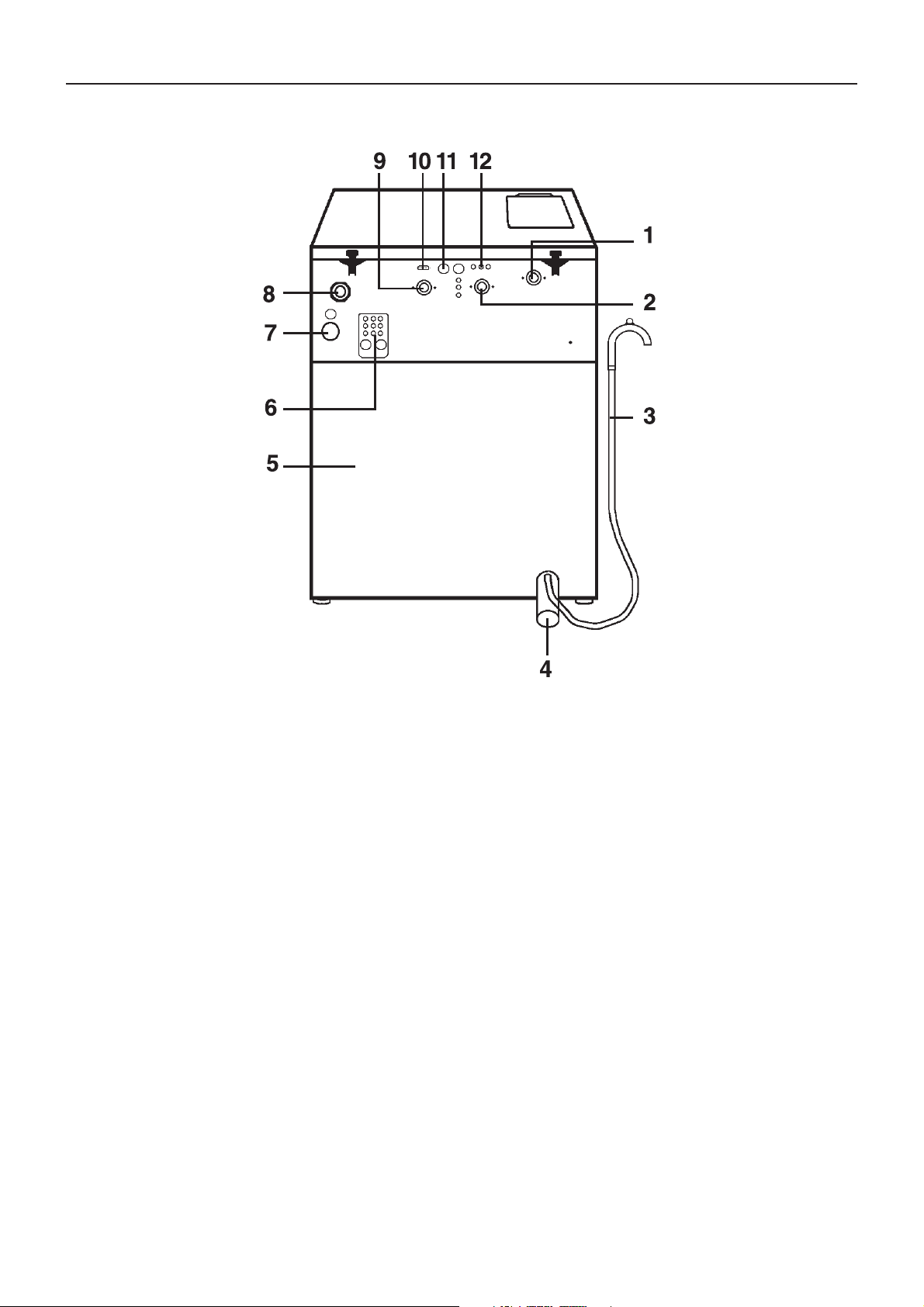

Rear view

Guide to the washer

1 Cold water connection

2 Warm water connection

3 Drain hose (for drain pump)

4 Drain (for drain valve)*

5 Back panel

6 Liquid dispenser drawer

Liquid dispensing system

* not available in W 6071

7 Air vent

8 Cable entry for electrical connection

9 Cold water connection for the

liquid dispensing system

10 Printer Interface

11 Cable connection for

3 dispenser pumps

12 Cable connection for the liquid

dispensing system

7

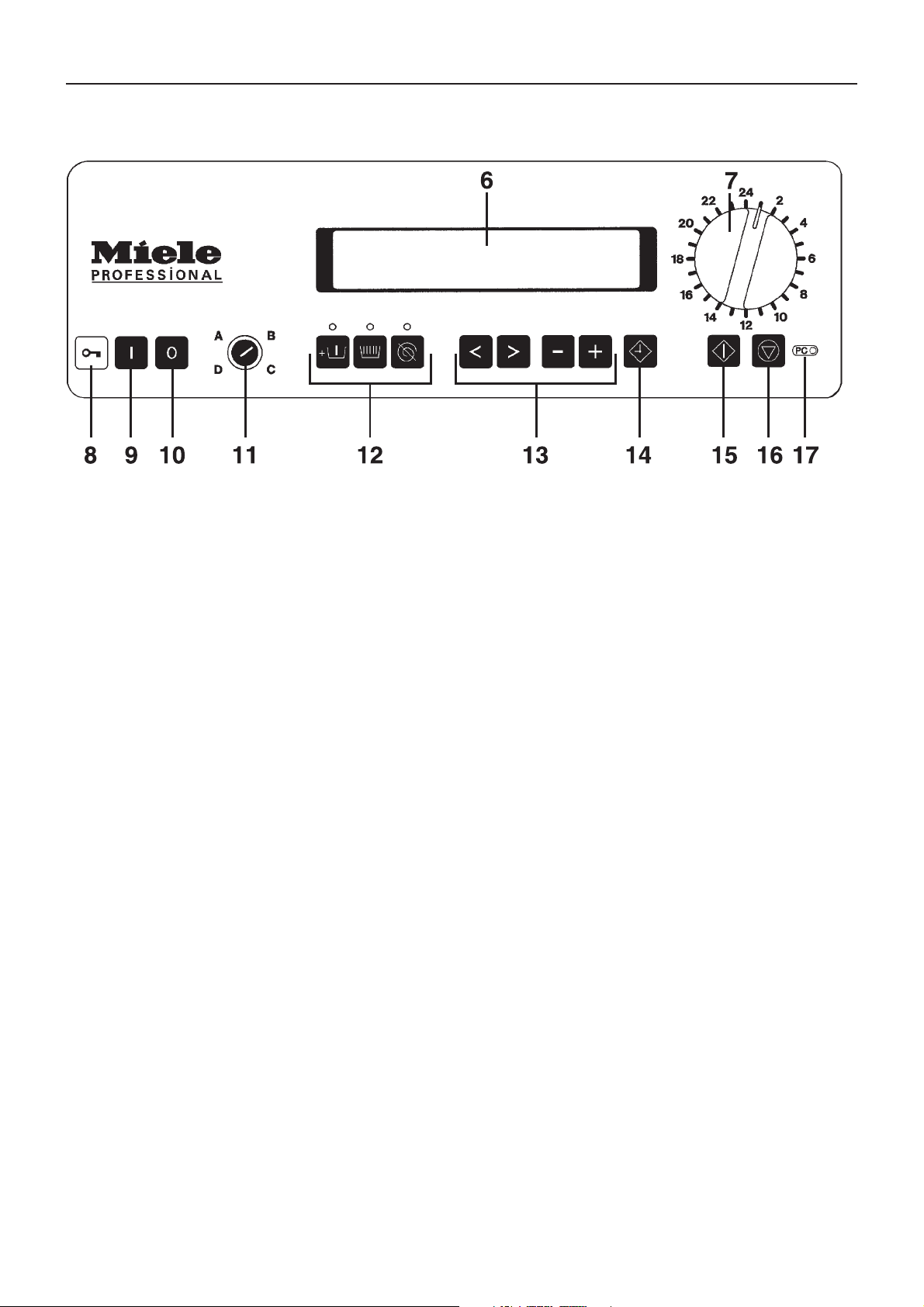

Guide to the washer

Facia panel

6 Display

7 Program selector

8 Door open

9 Y Power on button

10 Z Power off button

11 Access lock

12 Special options buttons

13 Cursor and input buttons

14 Delay Start button

15 X Start

16 7 End

17 Optic interface

8

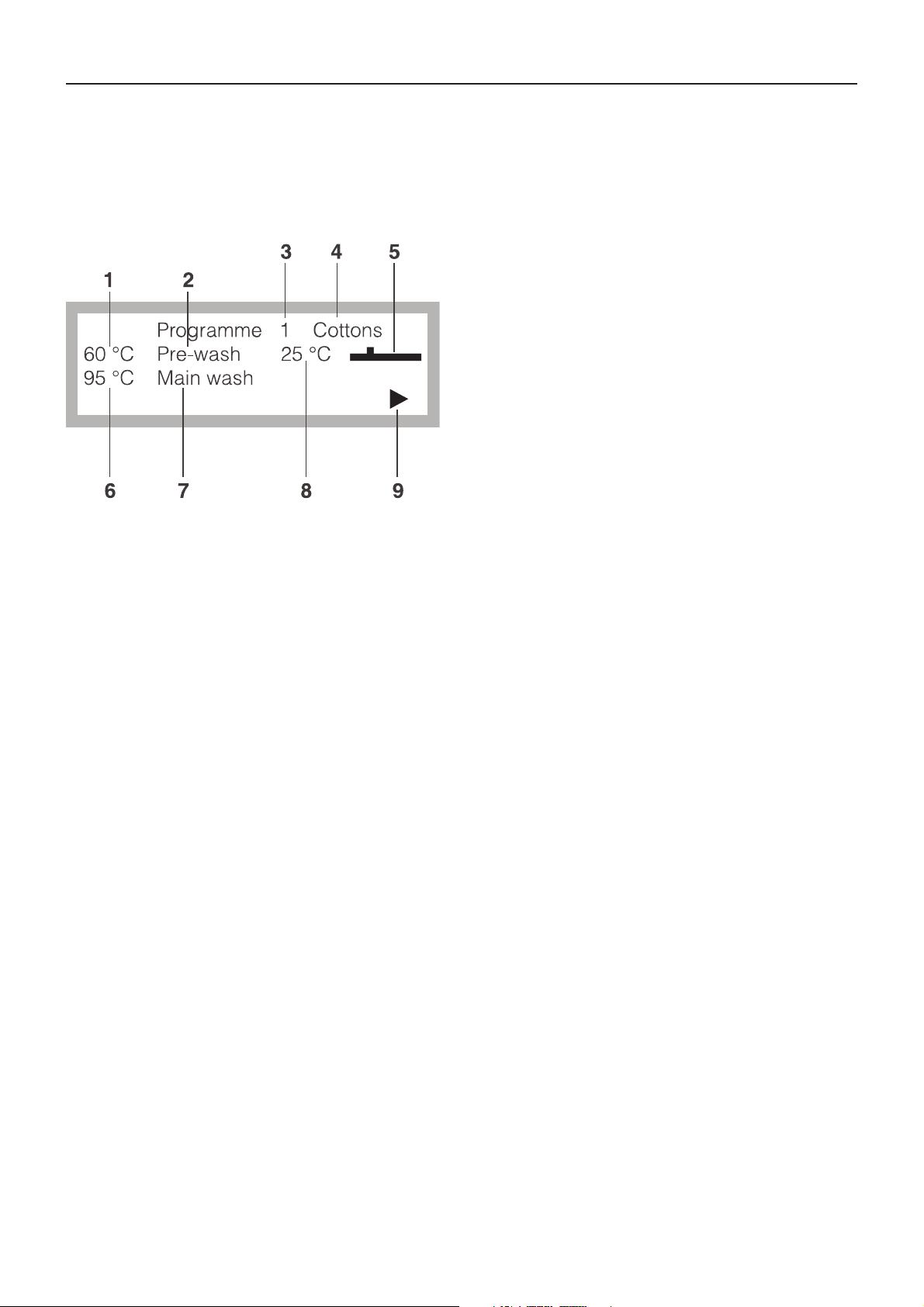

Display

The display content will appear once the

machine is turned on. It is up to four lines

and 40 digits long, showing which program

has been selected.

Guide to the washer

Display during a program

1 Planned temperature for the current cycle

2 Name of the current cycle

3 Program number

4 Program name

5 Time line for the current cycle

6 Planned temperature of the next cycle

7 Name of the next cycle

8 Actual temperature

9 Points to a further display line Access

lock

9

Guide to the washer

Program selector

Program numbers 1 - 24 can be selected

directly. Program numbers 25 - 99 can be

selected using selector position 24 and the

4 "Plus" button.

The name of the selected program and its

corresponding number appear in the

display. Program positions 1 - 21 are

standard programs.

The subsequent program positions are listed

in the Programming Instructions. If the

program selector is turned to another

position after the start of the program, the

first line of the display flashes. The program

however does not change.

Standard programs:

Selector

Position

1

2

3

4

5

6

7

8

9

Program

WC

Sensitive

WC

Regular

WC Silks/

Rayons

Machine

Wash

High

Machine

Wash

Low

Outer

wear

Down

Outerwear

Comforter

Regular

Comforter

Down

-

Selector

Position

12

13

14

15

16

17

18

19

20

Program

Colored

Shirts

Starch

Only

Leather

Sensitive

Leather

Regular

Proofing

Soaking

30 mins

Soaking

60 mins

Separate

Drain

Separate

Spin

10

11

Table

cloths

White

Shirts

21

Separate

Rinse &

Spin

10

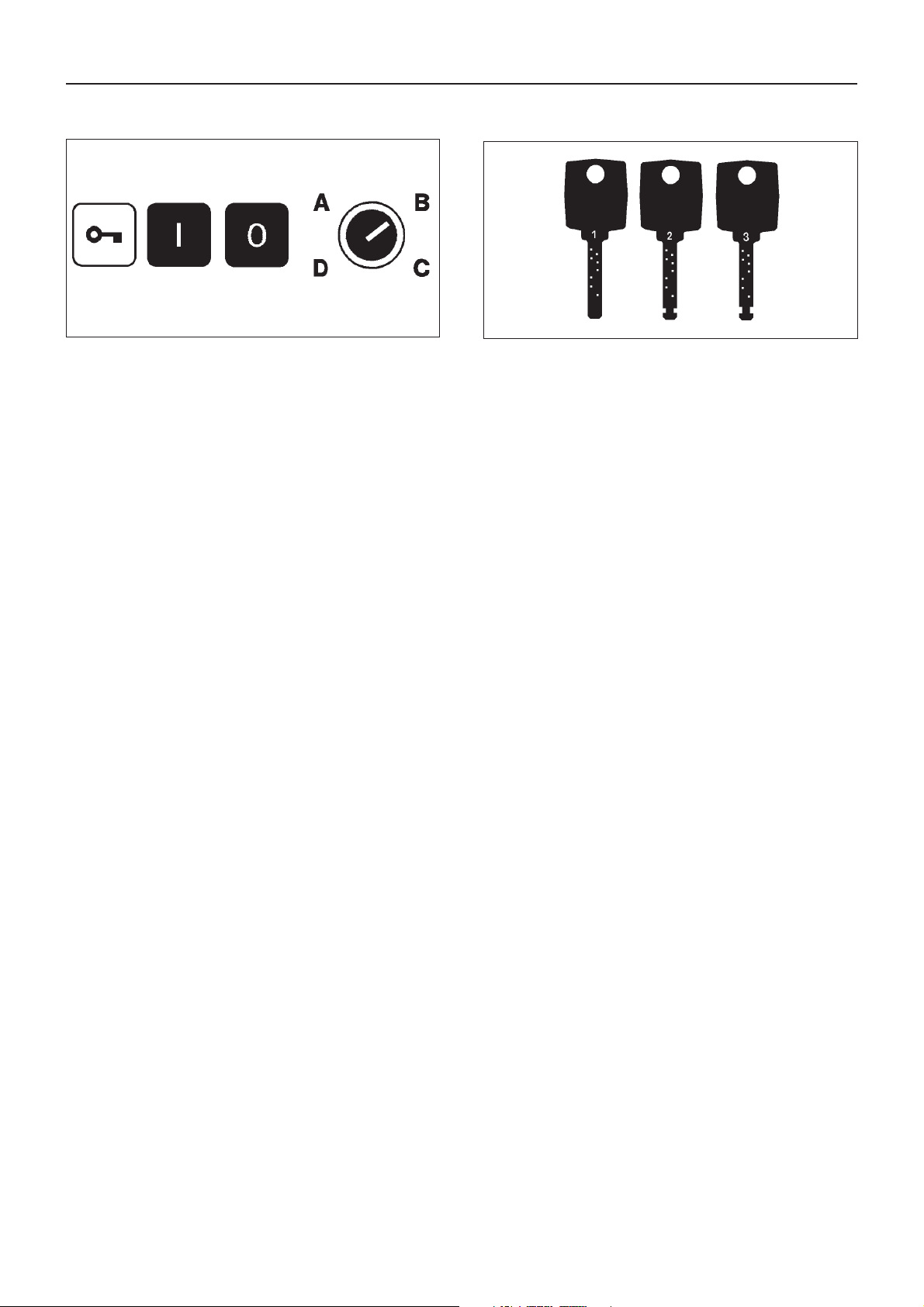

Guide to the washer

Access lock

Position A - Free access

Programs which have been allocated free

access can be run.

See Programming Instructions for allocation

of free access.

Position B - Operation

All programs can be started in this position.

The display will show the selected program

information.

Access keys

Key 1 (2 supplied) for operating levels

A and B.

Key 2 for operating levels A, B, C.

Key 3 for operating levels A, B, C, D.

Position C - Programming

At this position, programming, copying,

deleting, printing, altering, giving or barring

free access, and creating new program

sequences can be done. See Programming

Instructions.

Position D - Unlocking

At this position barred programs can be

unlocked. Locked Programs can not be

cancelled once they have started. If the key

switch is turned to position D in such a

program, the program running is unlocked

and can be cancelled. See "Programming

Instructions".

11

Guide to the washer

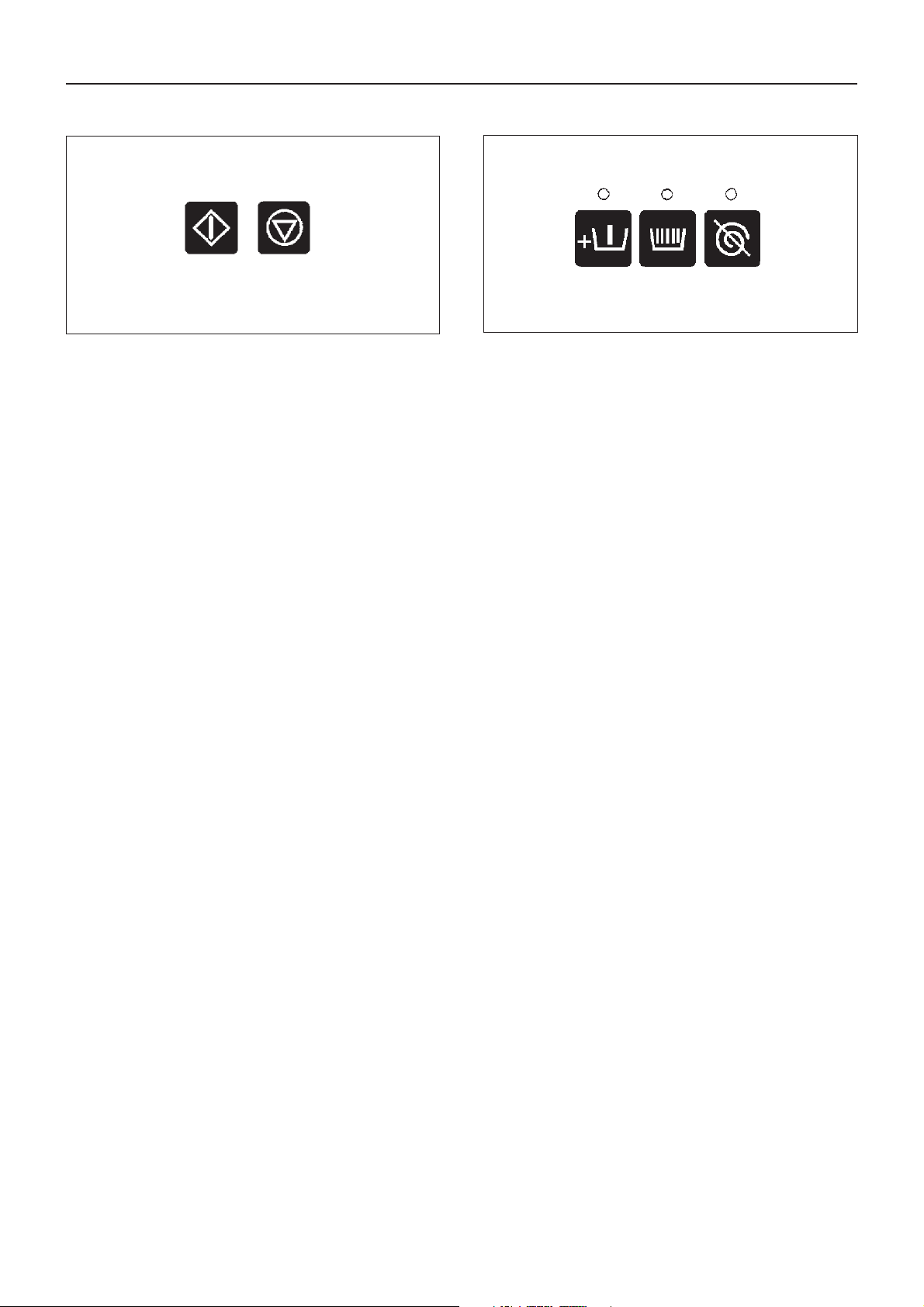

Buttons

X Start

Press this button to start the selected

program.

7 End

Press this button to stop a program. Press

once more to terminate a program. A

stopped program can be restarted by

pressing the Start button.

Special options

T Prewash with indicator

A Prewash cycle is added to the program.

U Starch with indicator

Press this button for starched laundry.

V Without spin with indicator

Press this button if a final spin is not required

after the final rinse.

12

Guide to the washer

Cursor, input and Delay Start buttons

1 2 Cursor

The cursor buttons are used to pass

backwards or forwards into the input fields

or into the next display, (this appears as > <

flashing in the display).

Once the program begins, you can move

forward or backward in the display to view

the cycles. Press and hold on the button to

run quickly through the display screens.

Optical interface

Data transfer to and from the machine’s

controls and a PC can take place using the

proper software. The optic interface 9 on

the machine’s control panel provides the

connection point.

Conversion of °C to °F

°C °F °C °F

10 50 70 158

20 68 80 176

30 86 90 194

40 104 100 212

50 122 110 230

60 140 120 248

3 4 Minus / Plus

The "Minus / Plus" buttons allow you to

modify an input field. Press continuously on

the button runs quickly through the display

screens.

W Delay start

The display indicates that a start time should

be selected. If the button is pressed again

the "Delay start" option is cancelled.

If the button is pressed after the start of a

program the current time of day and date

are shown.

13

Before using the washer

If pauses between programming steps

lasts longer than 25 seconds, the display

will return to the basic stage and the

changes will be lost.

Language selection

(if necessary)

Turn on the main power to the washer.

^

Turn the key to position B "Operation".

^

Press the Z "Off" button to turn off the

machine.

Press the X "Start" button and the Y "ON"

^

button at the same time and hold pressed

in, until the display shows the following:

SETTING LOCAL LANGUAGE

DEUTSCH >ENGLISH<

After selection press Start button.

Setting current time and date

Turn off the machine with the Z "Power off"

^

button.

Turn the key to position B "Operation".

^

Press the W "Delay start" button and the Y

^

"ON " button at the same time and hold

pressed in, until the display shows the

following:

SETTING TIME AND DATE

Time of the day >14< : 30 hrs

Date 23. 03. 1995

After selection press Start.

Use the 2 "Cursor" to position the cursor

^

on the input field to be changed and set

the change with the 3 4 "Minus or Plus"

buttons.

^ Position the cursor on the hours and set

the hours.

^ Select the desired language with the 1 2

"Cursor" buttons.

The display content is automatically

converted to the local language.

^ Confirm the selected local language by

pressing the X "Start" button.

^ Position the cursor on the minutes and set

the minutes.

^ Position the cursor on Day and set the day.

^ Position the cursor on Month and set the

month.

^ Position the cursor on Year and set the

year.

^

Store the changes by pressing the X

"Start" button.

14

Operation

Before the first wash

Important: This machine must be properly

installed before using. The first run of the

washer must be performed by a Miele

authorized service technician.

Open the water valves to the washer.

^

Turn the main power on at the wall switch.

^

Turn the key to position B "Operation".

^

Run a wash program without laundry to

^

flush out any water from the factory testing.

Add detergent to compartment j of the

^

detergent dispenser.

Turn the program selector to “11

^

COTTONS 60°C”

^ Press the X "Start" button.

Prepare and sort the laundry

Empty all pockets.

^

Foreign objects left in pockets (e.g.

,

nails, coins, paper clips, etc.) can cause

damage to clothes and the machine.

^ Sort the laundry by color and fabric.

Only wash items that are labeled machine

washable by the manufacturer. Most

garments have a fabric care label in the

collar or side seam. Sort the laundry by care

label and color.

Wool and wool blends can be cleaned in the

Woolens program if they have a care label

stating they are machine washable.

15

Operation

Load the laundry

Maximum load size (dry) 17 lbs (7,5 kg).

Additional load size information for each

program are available in the "Programming

Instructions".

^ Load the laundry into the drum.

For best results, wash mixed loads of small

and large items. This will improve washing

effectiveness and help distribute the load

evenly.

Note: Overloading the washer will affect

wash results and cause wrinkling.

Close the drum door with a firm swing.

^

To prevent damage to the door seal and

clothing, make sure that there are no

clothes caught between the drum door

and the seal.

16

Select a program

Turn the access key to position B

^

"Operation".

Operation

?

?

Press the Y "Power on" button.

^

Select a program (e.g. Program 11

^

Cottons).

Use the T "Prewash" button to select a

^

"Prewash" if required. The indicator above

the T button will light.

When "Prewash" is selected the following

appears in the display:

PROGRAMME 11 COTTONS

40° C Prewash 1

90 °C Main wash1

Rinse 3 1200 RPM

The following will appear in the display:

PROGRAMME 11 COTTONS

>95 °C< Main wash 1

Rinses 3 1000 RPM

17

Operation

Add detergent

Detergent for:

– Main wash in compartment j

– Prewash in compartment i

– Fabric softener in compartment p

– Bleach in compartment x

Water hardness

Water

hardness

levels

I soft 0 - 130 0 - 7

II middle 130 - 250 7 - 14

III hard 250 - 380 14 - 21

IV very

If you do not know the local water level

hardness contact the local water authority.

Water

quality

hard

ppm grains per

gallon

over 380 over 21

Bleaching agents

Only use bleaching agents on textiles with

the symbol x on the wash care label. Liquid

bleaching agents must only be added to the

compartment without a symbol. The agent

will then be dispensed automatically during

the 2nd rinse (cold bleaching). Liquid

bleaching agents should only be used with

colored fabrics if the textile manufacturer’s

wash care label states that the material is

color fast and suitable for bleaching.

Amount of detergent to be dispensed

– Only use low sudsing detergent.

–

Follow the recommendations of the

chemical manufacturer when using

cleaning agents and special application

chemicals.

The amount of detergent used depends on:

–

the load size,

–

the water hardness,

–

the level of soiling on the laundry.

For cold bleaching the 4th rinse must be

programmed, (see "Programming

Instructions").

^

Do not fill fabric softener or bleaching

agent higher than the level marker in the

relevant dispenser compartment. Other

wise they will be siphoned into the suds

container.

-

18

Operation

Changing temperature and spin

speed

The following parameters can be changed

before the start of a program:

the temperature in 1 °C steps from cold,

–

15 °C to maximum 95 °C .

the spin speed in 100 rpm steps from 0,

–

300 - 1200 rpm maximum.

PROGRAMME 11 COTTONS

>60°< Prewash 1

95 °C Main wash 1

Rinse 3 1200 RPM

Use the 2 "Cursor" to position the cursor

^

on the input field for the Prewash temp

erature, and set the temperature required

(here 60 °C) with the 3 4 "Minus or Plus".

^ Position the cursor on the input field for the

Main wash temperature, and set the

temperature required with 3 4 "Minus or

Plus".

^ Position the cursor on the input field for the

spin speed, and set the spin speed with

the 3 4 "Minus or Plus".

^ Press the X "Start" button to begin the

program.

-

Program sequence display

The program sequence is shown in the

display after the start of the program.

PROGRAMME 11 COTTONS

60° C Prewash 20 °C ^^^^^^^^

90° C Main wash

~

In the second display line, here Prewash, the

actual suds temperature is shown, and the

time line extending off to the right, underneath the next cycle of the program is

shown, here Main wash.

PROGRAMME 11 COTTONS

90 °C Main wash 20 °C

^^^^^^^^

Rinse 1PROGRAMME STOP

~

When the Prewash cycle has finished, the

Main wash appears in the display, with the

actual suds temperature, and the time line

extending off to the right. Underneath the

next cycle of the program is shown, here

Rinse 1.

When an arrow appears at the right of the

last line (~), this indicates that there is a

following display line.

Press the 2 "Cursor", and further information

on the program appears in the lower lines.

Program end display

After water from the last heating phase has

drained away, or after the last "Cool Down"

the program end time is shown in hours and

minutes.

PROGRAMME 11 COTTONS

Rinse 1

Rinse 2

Programme end 11:25 hrs ~

^^^^^^^^^

19

Operation

Program end - opening the drum

door

At the end of the program, with a stationary

drum and no more water in the machine the

following display is shown (for example):

PROGRAMME 11 COTTONS

PROGRAMME END

DOOR IS UNLOCKED

Press the 5 "Door open" button to open

^

the door.

Remove the laundry.

^

If the program is interrupted during a cycle,

the following display messages will appear:

PROGRAMME 11 COTTONS

PROGRAMME END

DOOR IS LOCKED

THERE IS WATER IN THE MACHINE

If this was the last load of wash for the day,

or longer:

Leave the drum door open.

^

Turn off the machine.

^

Turn the unit off at the main power switch.

^

Close the water valves to the washer.

^

or:

PROGRAMME 11 COTTONS

PROGRAMME END

DOOR IS LOCKED

DRUM NOT YET STATIONARY

^

Run the separate drain or separate spin

program. At the end of the program open

the door.

20

Special options

Prewash

Select a Prewash for heavily soiled laundry.

?

The prewash can selected by pressing the

T "Prewash" button. The Prewash indicator

above the button will light.

Press the button a second time to deselect

the feature.

Starch

Starch can be added before the program

?

begins by pressing the U "Starch" button.

The indicator above the button will light.

PROGRAMME 11 COTTONS

Rinse 3

STARCH HOLD

Press the Starch and the Starch Hold button.

"Starch hold" flashes in the display when it is

time to add starch to the laundry.

^ Add starch prepared according to

manufacturer’s instructions to

compartment i. The wash time is

automatically extended by 4 minutes.

Press U "Starch" to continue the program

21

Special options

Without final spin

?

Without spin can selected before the

program starts by pressing the V "Without

spin" button. The indicator above the button

will light.

PROGRAMME 11 COTTONS

Rinse 3

WITHOUT SPIN

Press Without spin or End button.

Rinsing with hot water

Standard programs

10 Cottons 200 °F (95°C) and

11 Cottons 140 °F (60°C)

are programmed to rinse with hot water.

If a hot water supply is available it is

advantageous to run the final rinse with hot

water. This reduces the residual moisture

content of the laundry after spinning.

If the laundry is dried or ironed immediately

after washing, drying times will be shortened

and ironing easier.

"Without spin" flashes in the display when the

spin cycle is reached. Press the V "Without

spin" button again to continue the program

with a spin. Press the 7 "End" button for the

program to finish with water in the machine.

Select the drain program and press the X

"Start" button. The door can be opened once

the water is drained.

22

Special options

Skipping program cycles

Cycles of a program in progress can be

skipped or repeated.

Press the 7 "End" button to stop the

program.

PROGRAMME 11 COTTONS

Main wash

PROGRAMME STOP

PROGRAMME STOP blinks in the display.

Use the 2 "Cursor" to skip ahead to a cycle

in the program.

Use the 1 "Cursor" to move back to a cycle

in the program.

At the position required press X "Start" to

continue the program again.

Cancelling a program

To cancel a program, press 7 "End" twice.

If the program is interrupted during a cycle,

the following display messages will appear:

PROGRAMME 11 COTTONS

PROGRAMME END

DOOR IS LOCKED

THERE IS WATER IN THE MACHINE

or

PROGRAMME 11 COTTONS

PROGRAMME END

DOOR IS LOCKED

DRUM NOT YET STATIONARY

Select the Drain or Spin program and

^

press the X "Start" button. The door can

be opened once the water is drained.

Interrupting a program

Press 7 "End" to stop the program.

Press X "Start" to restart the program.

23

Special options

Delay start

Use the W "Delay start" button to program

the unit to start automatically at a later time.

Turn the key to position B "Operation".

^

Turn on the machine and select a program

^

with the program selector.

The display shows the following (example):

PROGRAMME 11 COTTONS

>90°C> Main wash 1

Rinse 3 1200 RPM

Press W "Delay Start".

^

Here the display shows the following:

?

Press X "Start" to confirm the delayed

^

start. The following will appear in the

display:

PROGRAMME 11 COTTONS

90°C Main wash1

Start time 18 : 30 hrs

PROGRAMME 11 COTTONS

Start time >14< : 30 hrs

After the time has been set

press the Start button

The current time of day (military time) is

displayed first.

The cursor points to the input field for

‘hours’.

^ Select the start time with 34"Minus or

Plus" buttons.

^

Position the cursor on the input field for

minutes and select the minutes with 34

"Minus / Plus".

When the start time is reached the program

begins and the display shows the program

sequence. If W "Delay start" is pressed

during the program, the actual time of day

and date are shown.

?

If 7 "End" is pressed the delay start function

will be cancelled.

24

PC- Printer connection:

The machine can be connected to a PC or

printer using an SD kit.

PC-Operation:

Program changes can be made via a PC, or

a new program can be downloaded. This

requires a special Editor Program which is

available from the Miele Professional

Department.

Printer-Operation:

It is possible to print out whole programs or

parts of programs. See "Programming

Instructions".

Special options

25

Washer care

Before cleaning the appliance,

,

disconnect the power supply by

unplugging the unit or manually "tripping"

the circuit breaker.

Cleaning the washer

Clean the exterior of the washer with a mild

^

solution of non-abrasive detergent or soap

and water, and wipe dry with a soft cloth.

Wipe away any deposits from the drum

^

door seal with a damp cloth.

Clean the drum with a stainless steel

^

cleaner specially formulated for use in a

washer, available from Miele’s Technical

Service Department

Cleaning the drain pump and lint

trap

Occasionally small objects (buttons, coins,

etc.) may find their way into the lint trap. If

the machine does not drain completely, the

lint trap should be checked to ensure that it

is free of foreign objects.

To clean the lint trap, remove the tool from

^

behind the detergent dispenser drawer.

^ Open the lint trap door.

26

Place a 2 qt (2 l) capacity container under

^

the drain tube.

^ Turn the lint trap lid counterclockwise 2- 3

times.

About 2 quarts of water will drain out of the

hose.

If the main drain hose is clogged, more

water will be retained in the machine (max.

7.5 gal [30l]). In this case, tighten the lint

trap lid and empty the container before

repeating the procedure as often as

necessary.

Washer care

Check that the drain pump impeller (in the

^

back of the chamber) rotates freely by

spinning with your hand. If not: remove

foreign bodies.

^ Clean the inside of the lint trap housing.

Remove any detergent deposits or foreign

objects from the threads of the filter

housing and filter unit before replacing the

drain filter.

^

To interrupt the water drainage: Tighten the

drain filter lid.

,

Caution: If laundry has been washed

at a high temperature, the water draining

out of the machine will still be hot! Stop

and allow it to cool before proceeding.

^

If no more water drains: Remove the lint

trap and clean.

^

Remove any foreign objects (buttons,

coins, etc.) from the lint trap.

27

Washer care

Cleaning the water inlet filters

The washer has two water inlet filters to

protect each inlet valve. These filters should

be checked and cleaned if necessary every

6 months. This may have to be done more

frequently with some water supplies.

Cleaning the inlet hose filters

Cleaning the filter in the inlet valve

Using a wrench, carefully loosen and

^

remove the plastic hose connector on the

inlet valve.

Using needle nose pliers, withdraw the

^

plastic filter by pulling on the bar (see

illustration). Rinse under running water.

^ Turn off the water valve.

^ Unscrew the inlet hose from the water

valve.

^ Remove the rubber seal,1, from the

connector.

^

Using needle nose pliers, grasp the plastic

filter, 2, and pull it out of the hose

connector and clean.

^

Reassemble the filter and seal.

The inlet hose filters should be cleaned

every 6 months.

Inspect the hose regularly. The hose must

be in good condition to withstand high water

pressure. The hose must be replaced if there

are small cracks in the surface or if it has

been damaged or cut.

Only use hose that can withstand a minimum

pressure of 70 bar. Original Miele hoses fulfill

this requirement.

^ Reassemble the filter and seal.

Both filters must be put back in place

after cleaning.

28

Cleaning the detergent drawer

The detergent dispenser should be

^

cleaned after each use to remove any

detergent residue.

The siphon tubes in the § and x

^

compartments should also be cleaned.

Washer care

^ Unscrew the siphon tubes.

^ Clean the siphon tubes with warm water.

Return the siphon tubes checking that the

are hooked in correctly.

29

Frequently asked questions

Power failure

During a short power failure

The program remains in the last position.

When power is restored the following

message appears in the display:

PROGRAMME 11 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Press X "Start" to continue the program.

Press the “Start” X button to continue the

^

program.

Emergency door release during a

prolonged power failure

,Make sure the machine is off and the

drum has stopped turning. A moving

drum is dangerous.

Turn off the water to the washer.

^

Open the lint trap door as described in

^

"Cleaning the drain pump and lint trap".

Drain the water from the washer as

^

described in "Washer care / Cleaning the

drain pump and lint trap."

^

To open the door, pull down on the ring in

the upper right corner of the access area.

^

Remove the laundry.

30

Fault messages

,Repairs should only be carried out by a

qualified and trained person in accord

ance with local and national safety

regulations. Unauthorized repairs could

cause an injury or machine damage.

Frequently asked questions

PROGRAMME 11 COTTONS

PROGRAMME STOP

-

Contact Technical Service.

^

HEATING SYSTEM FAULT

Faults that occur before or after the start of a

program flash in the display.

PROGRAMME 11 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Press "Start" to continue the program.

Once power is restored, press X "Start".

^

This fault message can also indicate: The

overload cut-out of the drive motors has over

heated. Allow the motor to cool down.

PROGRAMME 11 COTTONS

PROGRAMME STOP

WATER INLET FAULT

Open water stopcock and press Start button.

^ Open the water valve (stopcock) and

press X "Start".

PROGRAMME 11 COTTONS

PROGRAMME STOP

DRAIN FAULT

Check drain system and press Start button.

PROGRAMME 11 COTTONS

PROGRAMME STOP

DRIVE SYSTEM FAULT

Multiplug drive variants failure.

Contact Technical Service.

^

PROGRAMME 11 COTTONS

90 °C Main wash 20 °C

Rinse 1

DRIVE SYSTEM FAULT

^ Contact Technical Service. if there is no

drum movement after this message.

PROGRAMME 11 COTTONS

PROGRAMME STOP

IMBALANCE SWITCH

Press the On-Off switch.

^ Press Z "Power off" and Y "Power on".

PROGRAMME 11 COTTONS

PROGRAMME STOP

PRESSURE MONITOR FAULT

^

Check and clean the drain system and

press X "Start".

PROGRAMME 11 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Short circuit on heat sensor 1.

^

Contact Technical Service.

PROGRAMME 11 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Cut-out on heat sensor 1.

^

Contact Technical Service.

^

Contact Technical Service.

PROGRAMME 11 COTTONS

PROGRAMME STOP

DISPENSING SYSTEM FAULT

Dispensing container 1 empty

^

Change the dispensing container.

31

Frequently asked questions

Why is the washer over sudsing?

Possible Cause Fix

Only use detergent formulated for use in

Detergent type

Too much detergent

commercial washers. Domestic detergents

are not suitable.

Follow the detergent manufacturer’s

instructions and adjust amount to the local

water hardness.

High sudsing detergent

Very soft water In areas with soft water, use less detergent.

Soiling level of laundry For lightly soiled laundry use less detergent.

Residues, (undissolved detergent spots)

Small loads

Drum speed too high during a wash Reduce the drum speed and wash rhythm.

Use a low sudsing detergent or contact

Miele’s application specialists.

Run a prewash without detergent and without

selecting a temperature.

Laundry soaked before washing must be

thoroughly rinsed before being washed.

Reduce the amount of detergent dispensed

accordingly.

32

In the event of any fault which you cannot fix

yourself, please contact:

The Miele Technical Service

–

Department

USA 1-800-999-1360

techserv@mieleusa.com

CDN 1-800-565-6435

service@miele.ca

When contacting Technical Service please

quote the model (M.-Nr.) and serial number

(Fabr.-Nr.) of the machine. These can be

found on the silver data plate:

by opening the drum door, or:

Technical Service

on the back panel of the machine.

Only use original Miele spare parts when

performing maintenance or repairs on this

machine.

33

Guide to the data plate symbols

1 Machine type

2 Serial number / Year of production *

3 Voltage / Frequency

4 Fuse rating

5 Drive motor

6 Plate diameter / Plate quantity *

7 Drum data

8 Drum diameter / Drum depth

9 Spin speed

10 Drum volume / Laundry dry weight

11 Kinetic Energy

* Not valid for this machine

12 Expected time to top speed

13 Breaking time

14 Heating

15 Electric heating

16 Fusing (on site)

17 Steam heating indirect *

18 Steam heating direct *

19 Gas heating*

20 Commissioning date

21 Water-registration test

DVGW-test cert (Water)

22 Field for CE test symbol/

(Product ID-No./Gas)

Noise level

Wash cycle Spin cycle

58.5 dB 74.3 dB

34

Installation Instructions

Help to protect the environment

Disposal of the packing materials

The packing materials protect the appliance

during shipping. They have been designed

to be biodegradable and recyclable.

To prevent suffocation, ensure that any

plastic wrappings, bags, etc. are disposed

of safely and kept out of the reach of

children.

Disposal of an old appliance

Old appliances may contain materials that

can be recycled. Please contact your local

recycling center about the possibility of

recycling these materials.

Ensure that the appliance presents no

danger to children while being stored for

disposal. Before discarding an old

appliance, unplug it from the outlet, cut off

its power cord and remove any doors to

prevent hazards.

36

The washer must only be installed a Miele

authorized service technician.

Refer to the enclosed installation diagram.

Installation Instructions

Shipping struts

Once the machine is in its final position the

red-marked shipping struts "A", "B" and "C"

must be removed.

Installation site

Horizontal access washers should be

installed on the ground floor or basement of

the construction for best results.

A concrete floor is the most suitable surface

for the washer. Concrete floors are less

prone to vibration during the spin cycle than

other floors.

The corner of a room where the stability of

the floor is at its greatest is the best place to

install the washer.

Note:

– The machine must be levelled and

securely positioned.

– To avoid vibration while spinning, the

machine should not be installed on soft

floor coverings.

Save the shipping struts for future use. They

must be refitted if the machine is moved.

Removing the front shipping strut

To remove the front shipping strut, unscrew

the 13 screws and the 2 lower torx screws

from the front panel.

“A”

– Do not install the washer on carpeting.

Carpeting will block the washer’s air vents.

– When installing the toe kick, the machine

must be secured with clamps.

–

To prevent damage, do not install this

machine in a room exposed to frost or

freezing temperatures.

37

Installation Instructions

Removing the rear shipping struts

To remove the rear shipping struts, unscrew

the 13 screws and loosen the 15 lower torx

screws from the back panel.

“B” “C”

Level the washer

The machine must be level to ensure proper

operation.

The machine can be leveled by turning the

legs clockwise or counterclockwise as

necessary.

Do not transport the washer without

,

these shipping struts in place.

^ the washer is levelled by adjusting the four

screw feet.

^ Use a multiple slip-joint gripping pliers to

hold the foot.

^ Unscrew each of the four feet as much as

necessary by turning both the foot and the

locking ring to the left using a screw driver.

,

The machine must not be moved

without all of the outer panels in place.

38

Please read the installation diagram and

instructions supplied. They are important

for the proper connection of supplies.

Water connection

The water hook up is by a water valve, which

conforms with local and national regulations.

This work must be carried out by a Miele

authorized service technician.

The inlet pressure hoses supplied with the

machine must be used for connection to the

water supply.

To ensure the hot water inlet hose (marked

194°F/90°C) lasts for many years, do not

hook the hose up to a hot water connection

supplying water hotter than 158°F (70°C).

Plumbing

Drainage system

Possible connections:

1. Directly into a sink: hook the hose over

the edge of the sink and secure it firmly

(e.g. by tying the hose to the water

faucet.)

2. To a stand pipe: place the drain hose into

½

" stand pipe and firmly secure it.

a 1

3. To a floor drain: The machine is

equipped with an air gap/anti-siphoning

system so that no minimum drain height

is required.

The machine drains using a pump with a

–

maximum delivery height of 3 ft.

The elbow on the end of the drain hose

–

can be turned or removed if necessary.

This hose should only be replaced with a

genuine Miele spare parts.

A water pressure flow rate of 30 psi - 145 psi

(2 -10 bar) is required.

Water taken into the machine must not

exceed a temperature of 158°F (70°C).

Connection to cold water only:

see, the supplied installation diagram.

– Make sure there are no kinks in the drain

hose.

– If desired, the drain hose may be

extended to run 16 ft maximum as long as

the 3 ft height is not exceeded. Hose

extensions are available from your dealer

or Miele’s Technical Service Department.

39

Electrical Connection

Electrical connection

All electrical work must be performed

,

by a qualified technician in accordance

with applicable codes and standards.

The machine must only be connected to the

voltage and frequency shown on the data

plate.

The machine is supplied as standard for

connection to a 208 V, 60 Hz, 3 x 20 A,

three-phase electrical supply. Each leg of

power must be 104 - 110 V.

There are further notes on electrical

connection in the installation diagram.

The electric heater rating is factory preset to

15 kW.

The minimum suds level required to activate

heating is 2" (50 mm) column of water.

The motor has an overload protection

switch.

Connection should be made via a suitable,

approved isolator, with an easily accessible

on-off switch to be as an emergency off

switch or for servicing.

WARNING

THIS APPLIANCE MUST BE

GROUNDED

!

404142

43

Alterations rights reserved / 2008 M.-Nr. 06 018 402 / 00

Loading...

Loading...