Page 1

Operating Instructions

Tumble Dryers

T 6351

T 6551

T 6751

To prevent accidents

and machine damage read these

instructions before installation or

use.

ö]

M.-Nr. 05 640 910

Page 2

2 M.-Nr. 05640910

Page 3

Contents

WARNING AND SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Guide to the tumble dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Pushbuttons / program selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

- Additional display with selector button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

- Program sequence and fault indicators / fault messages . . . . . . . . . . . . . . . . . . . . 10

- ”Reset” button / Emergency Stop button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

- Preparation of laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

- Weight of loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Program selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

- Anti-crease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Interrupting a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Emergency Stop button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reprogramming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Changing the preset options of a drying program - examples . . . . . . . . . . . . . . . . . . 16

- Reprogramming possibilities / Programmable residual moisture . . . . . . . . . . . . . . . . . 19

Page

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Guide to the data plate symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Leveling the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Steam connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

M.-Nr. 05640910 3

Page 4

WARNING AND SAFETY INSTRUCTIONS

Installation, repair and maintenance work

should be by a Miele authorized service

technician. Work by unqualified persons

could be dangerous and may void the warranty.

Read all instructions before installation or use

of the tumble dryer to prevent injury and machine damage.

The tumble dryer is only intended for dry-

ing fabrics washed in a water solution.

Check fabric care labels to verify materials

can be machine dried.

To prevent fires, do not use this tumble

dryer to dry the following:

– Articles containing foam rubber, rubber or

rubber like materials.

– Articles which have been treated with

flammable cleaning agents.

– Articles which have been splashed with

hair lacquer, hair spray, nail varnish remover, etc.

– Clothing which may be greasy,

fatty or impregnated with other residues.

Do not dry mops, floor cloths etc in this ma-

chine if they contain substances such as

wax or chemical cleaning agents.

Padded or filled fabrics (e.g. jackets or

cushions) should not be dried. Loose filling could cause a fire.

Some textiles get very hot during drying

and there may be a risk of high temperatures causing them to ignite in exceptional circumstances. They should therefore be taken

out of the machine as soon as the program

has finished and as soon as possible if there

has been a power failure. It is advisable to

keep a fire extinguisher near the machine at

all times.

Laundry must not be removed from the

dryer before the drying program has

finished, i.e., the cooling down phase must

be completed.

If hot laundry items are stacked or packed

they can be liable to auto-combustion.

Do not let children play in or near the ma-

chine. Do not let them play with the controls or operate the unit.

Make sure the drum is stationary be-

fore removing laundry. Never put you

hand into a drum that is still moving.

Installation, repair and maintenance work

should be by a Miele authorized service

technician. Work by unqualified persons

could be dangerous.

Be certain your appliance is properly in-

stalled and grounded by a qualified technician.

To guarantee the electrical safety of this appliance, continuity must exist between the appliance and an effective grounding system. It

is imperative that this basic safety requirement

be met. If there is any doubt, have the electrical system of the house checked by a qualified electrician. The manufacturer cannot be

held responsible for damages caused by the

lack, or inadequacy of, an effective grounding

system.

Before installation or service, disconnect

the power supply to the work area by removing the fuse, ”tripping” the circuit breaker,

or unplugging the unit.

Do not damage, remove or bypass the

safety components, fixtures and control

elements of this machine.

Where there is any damage to the controls

or to the cable insulation the machine

must not be used until it has been repaired.

Faulty components must only be ex-

changed for Miele original spare parts.

Only when these parts are fitted can the

safety standards of the machine be guaranteed.

Do not touch the steam pipes and compo-

nents, there is a danger of burns.

When disposing of an old machine, pre-

vent hazards to children by removing the

drum door and the lint filter access panel.

Only use the dryer if all panels are

properly in place.

Fire and Explosion hazard

Never use or store gas or gasoline based

substances or any easily flammable substances near the machine.

Fire hazard

Do not use the machine without the built-in

lint filter in place. If the lint filter is damaged it

must be replaced immediately.

A build up of lint could block the airflow heating and ventilation, and impair the efficiency of

the machine.

4 M.-Nr. 05640910

Page 5

WARNING AND SAFETY INSTRUCTIONS

Disinfecting and cleaning agents often con-

tain chlorides (salts) that can cause steel

surfaces to rust. To protect your machine from

rust damage, only use chloride free disinfecting and cleaning agents for laundry and disinfecting and for cleaning the machine. If you

are not sure about a particular agent contact

Miele’s Professional Division.

If you accidentally spill an agent containing

chloride on the machine it should be rinsed off

with water and dried with a soft cloth.

Do not use a high-pressure cleaner or

water jet to clean the machine.

Caution If the tumble dryer shuts off dur-

ing the drying cycle, without the fault indication light showing, a temperature limiter has

activated.

Check the seals and locks on the machine

door and the lint filter.

Check the condition of the air inlet and air outlet vents. If no damage is evident to any of

the parts checked, the dryer can be restarted.

If the fault occurs again, call the Miele Technical Service Department.

Accessories

Only use genuine Miele accessories. If

other parts are used, guarantee, performance

and product liability claims may become void.

Disposal of an old appliance

When discarding an old appliance, disconnect the power supply, remove the power cord

and any doors.

All personnel working with this machine must

be fully trained in all aspects of its use and

safety.

KEEP THESE OPERATING INSTRUCTIONS

IN A SAFE PLACE

M.-Nr. 05640910 5

Page 6

Caring for the environment

Disposal of the packing material

The transport and protective packing

are environmentally friendly for

disposal and can be recycled.

Please recycle.

Disposal of an old machine

Old machines contain materials which can be

recycled. Please contact your local recycling

authority about the possibility of recycling

these materials.

6 M.-Nr. 05640910

Page 7

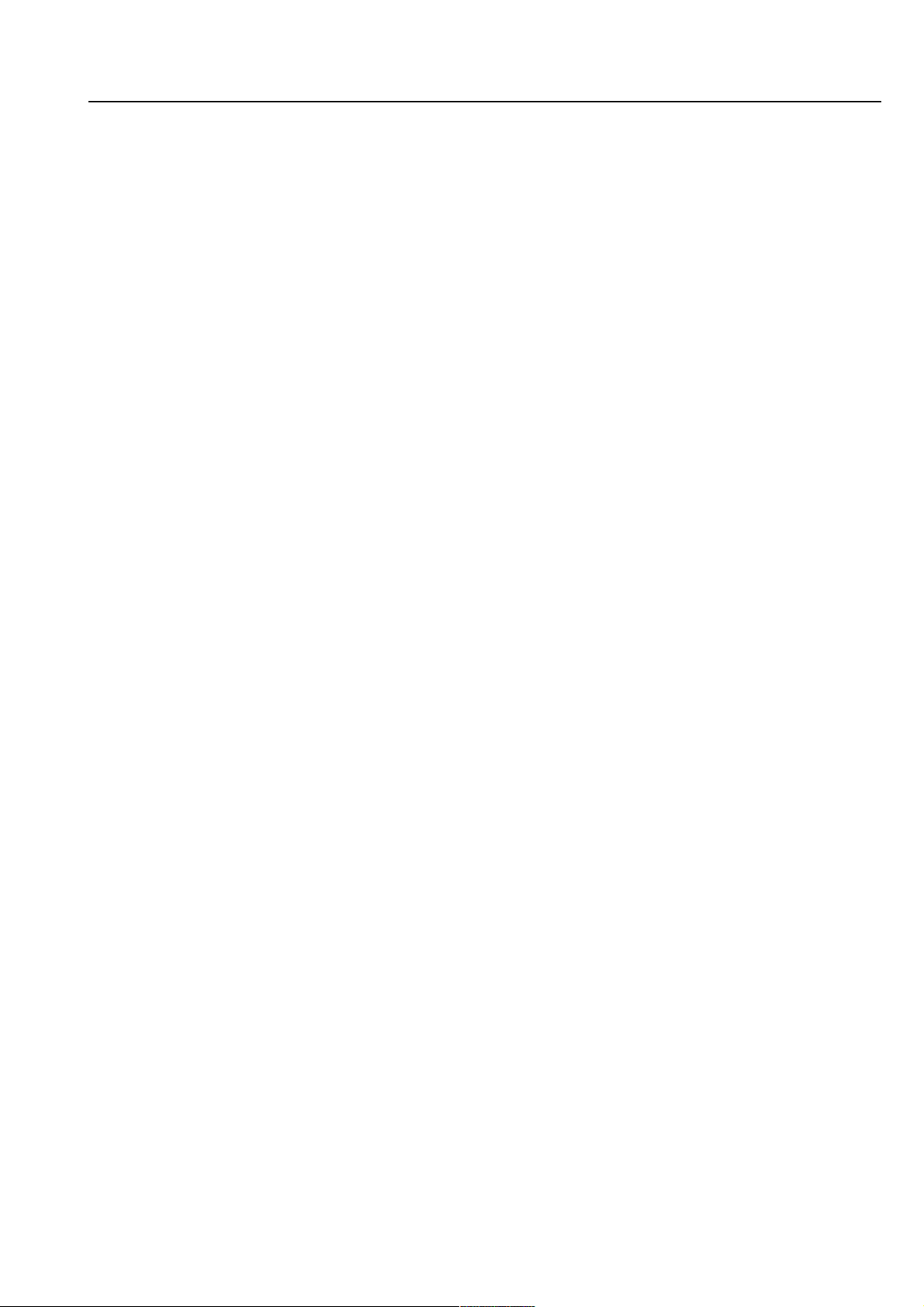

Guide to the tumble dryer

1

85

2

3

4

7

1 -Main power switch 5 -Lint filter

2 -Control panel 6 -Lint compartment flap

3 -Drum door 7 -Four adjustable screw feet

4 -Door handle 8 -Vent pipe / Vent socket

Control panel

6

9 10 11 12 13

9 --Program sequence/Fault indicators

10--Program selector with selector button

11--Push buttons

12--Additional display

13--"Emergency Stop" button

M.-Nr. 05640910 7

Page 8

Description of the machine

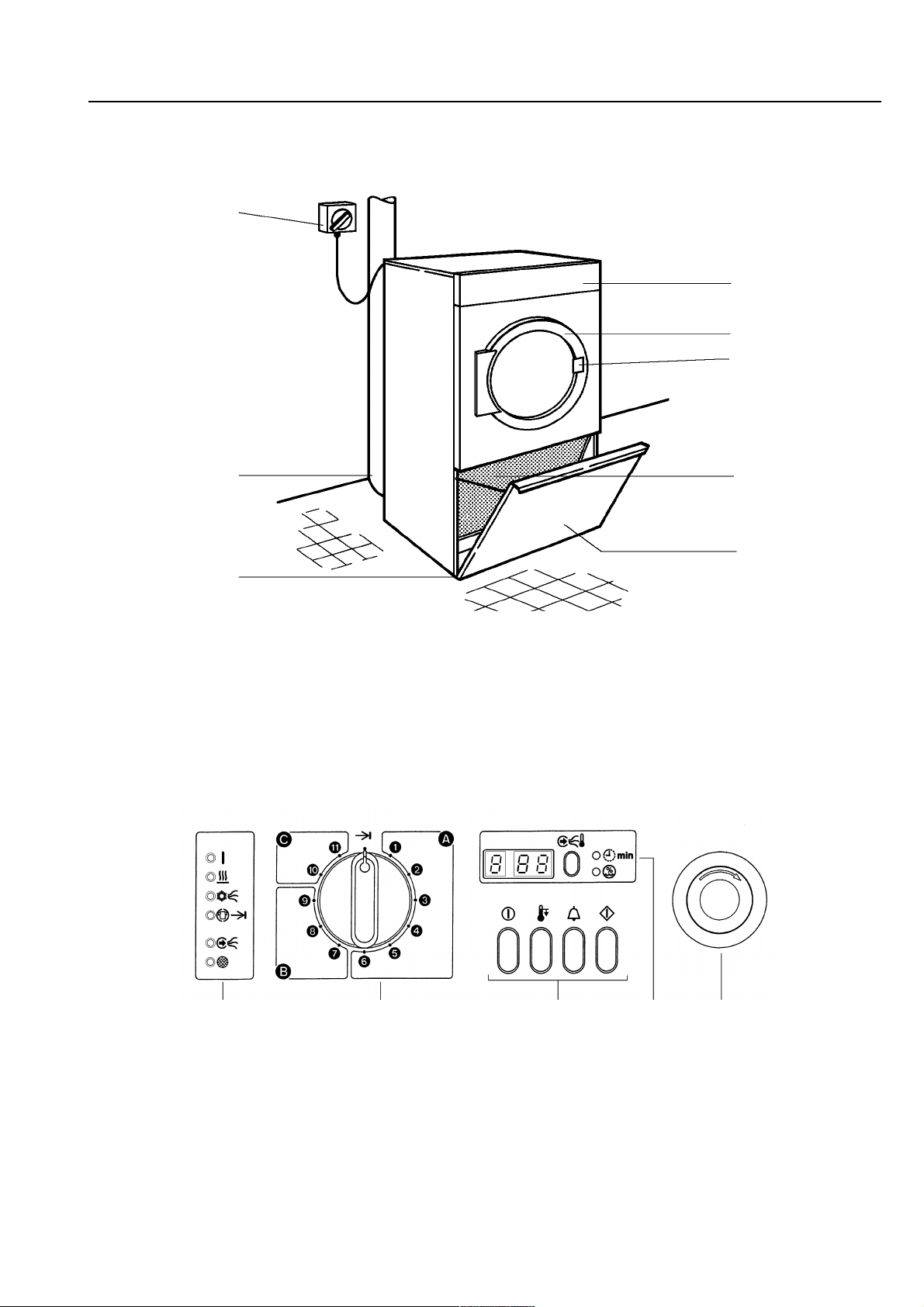

Push buttons

”On-Off s” button

”L Low temperature” button

Lowers the drying temperature for delicate fabrics (e.g. acrylics).

Press in the button to select this feature.

”l Buzzer” button

The end of a program can be indicated by a

buzzer.

Program selector

The program selector is used to select the program required.

COTTONS

A

Residual moisture value T6351 T6551/6751

Press in the button to select this feature.

”h ”Start" button

This button starts the program when pushed

in.

Extra dry (-4%) (-4%)

1

Normal + (-2%) (-2%)

2

Normal (3%) (3%)

3

Machine iron

4

Machine iron

5

Machine iron

6

MINIMUM IRON

B

Normal + (-2%) (-2%)

7

Normal (2%) (2%)

8

Machine iron

9

TIMED DRYING

C

without heating (15 min) (15 min)

0

with heating (20 min) (20 min)

!

End

r

- All the values given in brackets are preset standards.

And can be altered (see the following pages).

r

rr

rrr

r

(13%) (16%)

(20%) (22%)

(26%) (30%)

(8%) (8%)

8 M.-Nr. 05640910

Page 9

Description of the machine

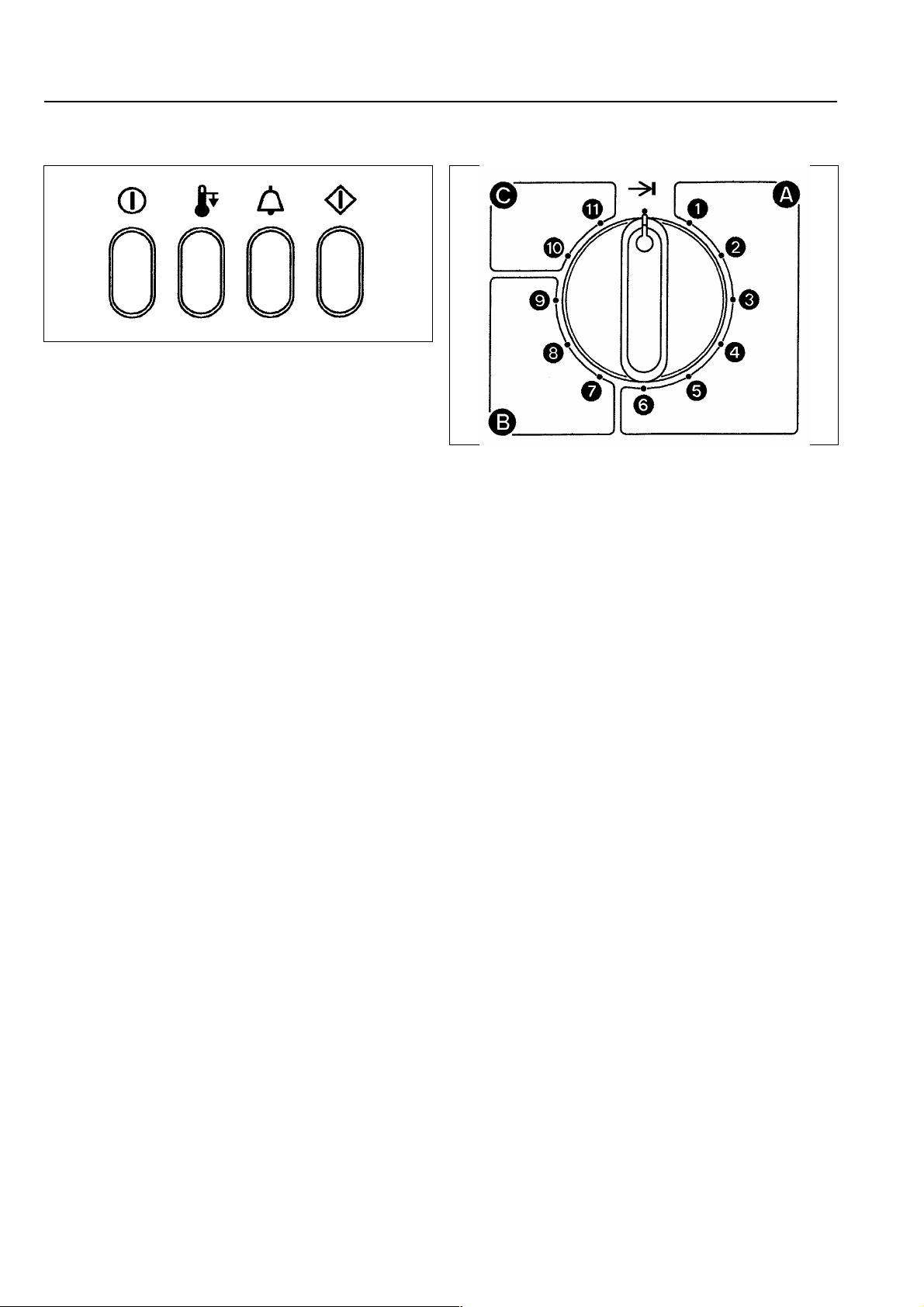

Additional display with selector button

Selector button

Display Indicator lights

Selector button "Residual moisture" /

"Time" / "Vented air"

"Residual moisture"

With this button the programmed residual

moisture values in programs 1 to 9 can be

changed.

Changes can only be made before the start of

the program. At the end of the cycle the program will revert to the preset standards.

"Time"

With this button the program duration can be

changed in program 0 (3 minutes to 1 hour)

and in program! (3 minutes to 3 hours).

recorded and displayed. The current residual

moisture value is shown during the program.

"Time"

Displays the time set for program 0 or ! .

The hours are shown in the left display field

and the minutes in the right fields. After the

program has started the remaining run time is

shown instead of the total time.

"Vented air"

Displays the current vented air temperature for

5 seconds while a program is running.

Indicator lights

"Residual moisture" / "Time"

"Residual moisture"

Lights up when the machine is turned on and

program 1 to 9 is chosen.

It goes out at the end of the program.

"Time"

Lights up when the machine is turned on and

a program between 0 and ! is chosen.

It goes out at the end of the program.

Changes can only be made before the start of

the program. At the end of the cycle the program will revert to the preset standards.

"Vented air"

If the button is pressed in while a program is

running and released immediately the current

vented air temperature will appear in the additional display for 5 seconds.

Display "Residual moisture" / "Time" /

"Vented air"

"Residual moisture"

Displays the residual moisture set for programs 1 to 9 .

A few minutes after the program has started

the residual moisture in the laundry is

M.-Nr. 05640910 9

Page 10

Description of the machine

Program sequence and fault indicators

On

Drying

Cool air

Anti-crease/End

Check venting

Check lint filter

Fault messages

Faults or interruptions are indicated by the sequence lights/fault indicators flashing.

”Venting”

The venting duct is obstructed.

Action: Check the vent ducting and clean if

necessary.

”Lint filter”

The lint filter is clogged.

Action: Clean the lint filter at the end of the program.

Note:

The "Drying", "Cool air" and "Anti-crease" indicators will flash if there is a power failure or if

a program has been interrupted (e.g. when a

door has been opened). They do not indicate

a fault. The indicators will stop

flashing once the "Start" button is pressed.

Heating

(flashes)

Safety period

(flashes

)

Gas/Venting

(lights up)

Lint filter

(lights up)

The messages are:

”Heating”

Fault in the heating system.

Action: Call Miele’s Technical Service

Department.

”Safety period”

The maximum running time of the drying program was exceeded because the residual

moisture at the start of the program was too

high.

Action: Restart the drying program.

If the fault message occurs again contact the

Miele Technical Service Department.

10 M.-Nr. 05640910

Page 11

Description of the machine

"Emergency Stop" button

Only use in an emergency.

Do not use this button to turn off the machine

during normal operation.

To reset the "Emergency Stop" button after it

has been used, turn the ribbed knob clockwise.

Conversion of °C to °F

°C °F °C

10 50 70 158

20 68 80 176

30 86 90 194

40 104 100 212

50 122 110 230

60 140 120 248

°F

M.-Nr. 05640910 11

Page 12

Before using for the first time

Before using for the first time, wipe the inside

of the drum with a soft dry cloth.

Preparing the laundry

Sort the laundry according to fabric type and

weave for even drying results.

Not all textiles are suitable for drying. Pay special attention to the manufacturer’s instructions

on the wash care label.

= Dry at normal temperature

q

= Dry at low temperature

r

= Do not tumble dry

s

Do not tumble dry articles made from pure

wool and wool mixtures as they tend to become matted and

shrink.

Pure linen is liable to be roughened by tumble drying. Consult the manufacturer’s instructions before drying.

Important: Items with metal buck-les, hooks,

eyes, zippers etc. should be put into the dryer

in a cloth bag (eg. pillowcase) to protect the

drum from scratches and dents.

Items with zippers should be dried with the zippers open.

Padded or filled fabrics (eg. jackets or cushions) should not be dried. Loose filling falls

could cause a fire.

Weights of load (Dry weight)

T 6351 T 6551 T 6751

Cottons

max.

6 lbs

Minimum Iron and Delicates

max.

2 lbs

Cotton, Jeans/Corduroy,

Poplin without wool lining,

max.

5 lbs

Wool, Wool/Cotton, Wool/Syn-

Angora, Cashmere, Lamb’s wool,

max.

2 lbs

max.

3 lbs

max.

10 lbs

max.

3 lbs

Wet Cleaning

Padded jackets

max.

7 lbs

thetic,

Silk,

Viscose

max.

3 lbs

Bedding

max.

5 lbs

max.

14 lbs

max.

5 lbs

max.

9 lbs

max.

5 lbs

max.

7 lbs

Some woven and loop knit materials shrink

with over-drying. Avoid the Extra dry program

for such fabrics.

If drying starched laundry, select the most suitable program for ironing by hand or machine.

Sort the laundry according to the level of dryness required. It is not necessary to sort according to size.

For cost efficiency, only dry full loads. Over

loading the dryer will impair the drying result

and the laundry finish.

Loading the machine

12 M.-Nr. 05640910

Page 13

Selecting a program

Close the drum door.

Turn on the power main

(on site).

Press in the “s On/Off” button.

Select a program by turning the program

selector clockwise or counterclockwise:

COTTONS

A

For drying cotton/linen textiles

Residual moisture T6351 T6551/6751

Extra dry (-4%) (-4%)

1

Normal + (-2%) (-2%)

2

Normal (3%) (3%)

3

Machine Iron

4

Machine Iron

5

Machine Iron

6

MINIMUM IRON

B

For drying polyester cotton mixtures,

delicates and synthetics

Normal + (-2%) (-2%)

7

r

rr

rrr

(13%) (16%)

(20%) (22%)

(26%) (30%)

Once the required level of dryness has

been reached the laundry is cooled and

the drying program ends.

Special programs

1. Wet Cleaning

For drying washable materials which are

also stated on the laundry care label to be

suitable for machine drying *:

A/2

Poplin without wool lining *, padded

garments *

A/2

Jeans, Corduroy trousers

A/3

A/3

Cotton/Synthetic

A/4

Wool /Cotton, Wool/Synthetic

C

Wool, Angora, Cashmere, Lambs wool, Silk,

Viscose etc.

+ “L Low temperature” button

Cotton

+ “L Low temperature” button

+ “L Low temperature” button

/

!

Normal (2%) (2%)

8

Hand Iron

9

TIMED DRYING

C

Airing and timed drying

without heating (15 mins)

0

For airing laundry

with heating (20 mins)

!

To dry small loads or

to dry individual items.

The “L Low temperature” and “l Buzzer”

features can be selected at this time.

Note: The dryer uses an electronic sensor

system which monitors the residual moisture in the laundry and a timer for extra

safety. The heating time is limited to 60

minutes.

r

(8%) (8%)

M.-Nr. 05640910 13

Page 14

Selecting a program

2. Bedding

To dry bedding, which has a laundry care

label stating that it is machine-washable:

C/!

Bedding (e.g. non-seamed duvets, seamed/

pocketed feather duvets, synthetic duvets,

pillows, etc.)

Important: Before drying bedding the standard

options must be

reprogrammed with A / 1, A / 2 and A / 4

(see, Table "Reprogramming possibilities").

- See, "Reprogramming" for conditions and

examples. Note: The duration of the C / ! program is

preset to 20 minutes. See, Table "Reprogramming possibilities").

A change to the duration of the program can

be made by reprogramming for B / 9 "with

heating (followed by Cooling down) Program 11 ", (see, Table "Reprogramming possibilities").

The end of the drying program is indicated by the “ ~ r Anti-crease / End” in-

dicator lighting up and the buzzer

sounding if selected.

Turn the program selector to “r End”.

Open the drum door.

Remove the laundry.

If the dryer is not going to be used again in

the near future:

Press the “s On/Off” button to turn off the

machine.

Turn off power at the site power main.

Clean the lint filter.

If required also select the “l Buzzer”

functions.

Press the “h Start” button.

- The selected drying program will now

start.

Note

The “l Check lint filter” light comes on if the

lint filter needs to be cleaned. Clean the filter

as soon as the program has finished. See,

"Cleaning and Care" for details.

The laundry must not be removed from the

dryer before the drying program has finished,

ie, the cooling down phase must be completed.

If hot laundry items are stacked or packed

they could auto-combust.

If the laundry is rinsed with hot water in the

final rinse, the residual heat in the laundry,

together with the reduced residual moisture

content, will lead to shorter processing times

and save energy.

14 M.-Nr. 05640910

Page 15

Selecting a program

Anti-crease

If the laundry is not removed from the machine

at the end of the program an anti-crease cycle

will automatically start. The drum turns at intervals to minimize creasing in the laundry.

The anti-crease cycle runs 59 minutes.

Interrupting the program

The program will stop if the door is opened

during operation to add or remove articles of

laundry. The program will also be interrupted if

the lint filter compartment flap is opened or the

"Emergency Stop" button pressed. Do not

reach into a moving drum.

To continue the drying process:

Close the drum door.

Press the “h Start” button".

If a new program is selected, first turn the program selector to “End” and then to the desired

program. Press “Start”.

The “On” indicator will flash if the program selector is turned to a different position after the

start of a program. It will stop

flashing when the program selector is turned

back to the originally

selected program or is turned to “End” to finish

the program.

"Emergency Stop" button

Use this button only in an emergency. The

dryer will shut off immediately. Do not use this

button in normal operation to turn the machine

off.

Turn the ribbed disc clockwise to reset the

"Emergency Stop" button.

M.-Nr. 05640910 15

Page 16

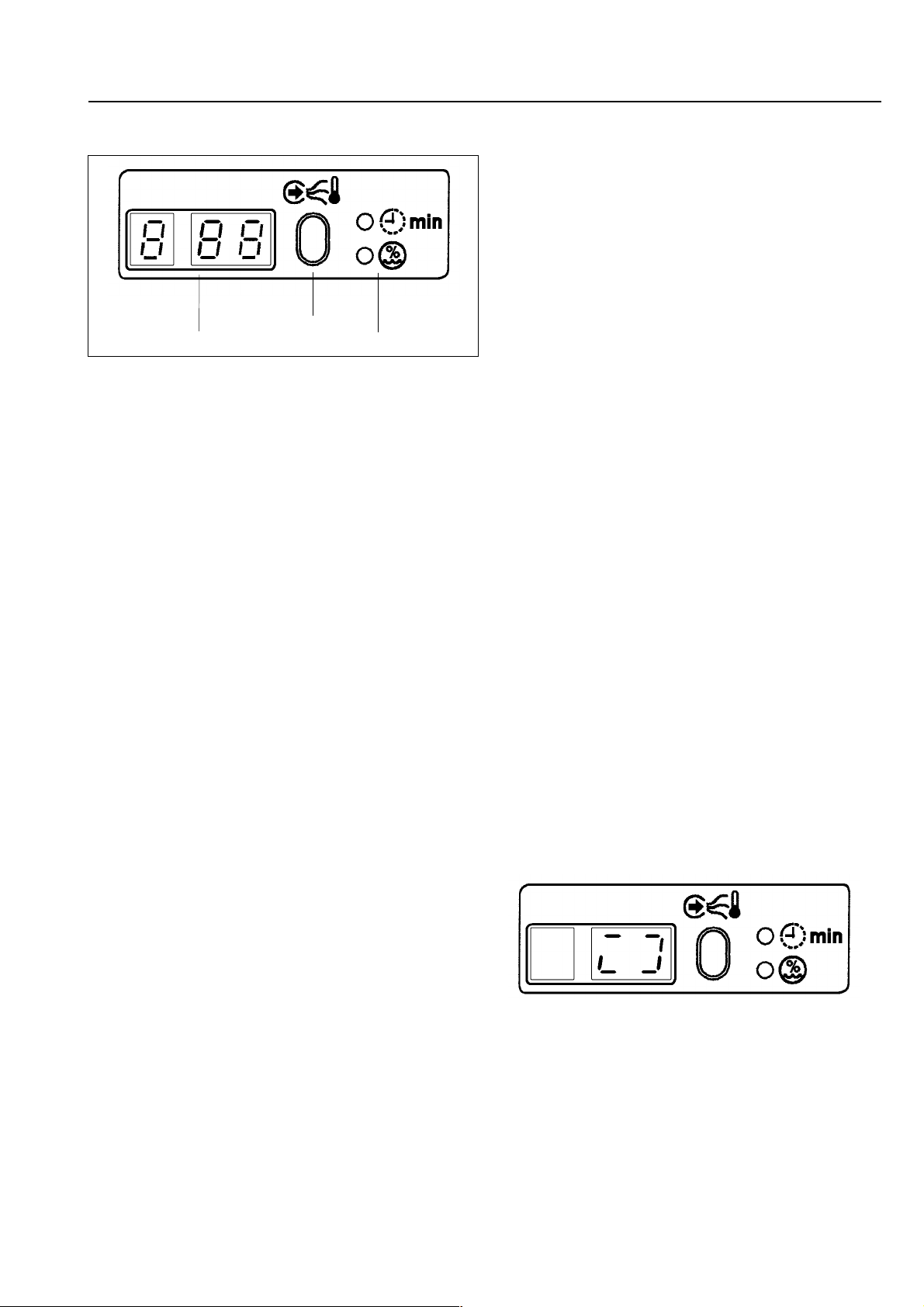

Reprogramming

Changing the preset options of a drying

program

Individual drying programs can be reprogrammed to meet special requirements,

usage and processes.

Example of reprogramming

Basic position:

➧

Press in the “s On-Off” switch.

The “On” indicator will light.

The dryer must be off and the drum door

closed.

All buttons must also be in the “Off” position,

i.e. released not pressed in.

The program selector must be at the

“r End” position.

➧

Press the “L low temperature” button twice in

and twice out within 4 seconds:

After a few seconds the letter “P” lights up in

the left field of the additional display.

The program sequence indicator “Drying” will

light and “Cold air” will flash.

The unit can now be reprogrammed, see

examples 1 and 2 on the following pages.

16 M.-Nr. 05640910

Page 17

Reprogramming

Example 1:

Reprogramming the drum reversing action

period (standard = 1 minute and 27 seconds)

in the cotton programs.

A drum reversing action period can be selected from 20 seconds to 2 minutes.

Here a reversing time of 1 minute and 5 seconds is chosen.

Turn the program selector to the"r End"

position.

- The changed drum reversing action period in the cottons programs is now stored in

memory.

Turn the program selector to program A / 1.

The following will alternate in the additional

display:

or

To exit programming:

➧

Press the “s On/Off”button.

Please enter any program changes to the

"Reprogramming possibilities" chart.

Example 2:

Changing the residual moisture value in program 5 to 5 Machine iron rr (20%).

Press and release the “Start” button until “I 05"

appears in the additional display.

M.-Nr. 05640910 17

Residual moisture values can be selected between 18 and 22%.

Here a residual moisture value of 18% is selected.

- Go to the basic position for reprogramming

(see example 1).

Page 18

Reprogramming

Turn the program selector to A / 3 .

- “P3" and ”3" will alternate in the additional

display.

➧

Use the selector switch to choose the program to be changed.

Program 5 Machine iron rr (20%).

Press the selector until a residual moisture of

20% appears in the additional display.

To exit programming:

➧

Release the “s On/Off” button.

Please enter any program changes to the

"Reprogramming possibilities" chart.

Press the “h Start” button repeatedly to select

the residual moisture of 18%.

Turn the program selector to the"r End"

position.

- The change to the residual moisture value is

now stored in memory and the programming

process is complete.

18 M.-Nr. 05640910

Page 19

Reprogramming

Reprogramming possibilities

Program

ö

alterations

]

Reversing time*

in the Cottons

Programes 1 to 6

and Timed drying

programes 10 & 11

Cottons

Minimum iron

Timed drying

Reversing off /

Pause interval

in Cottons

programes 1 to 6

and Timed drying

programes 10 & 11

Residual moisture/

Prog. selection with the

Selector switch

Fan and heating

in pause times

Cooling down temperature

Vented air to

Reversing time*

in the Minimum iron

programes 7 to 9

Reversing off/

Pause interval

in Minimum iron

programes 7 to 9

without heating

Program 10

with heating

followed by Cooling down

Program 11

Additional display

during operation

Position of the

Program

selector

1

2

A

3

4

5

6

7

B

8

9

0

C

!

Options Notes Enter

Standard WC Bedd-

1 minute and

27 seconds25secs25secs

3

seconds

see chart

"Programmable

residual

moisture"

1 0 0 0 or 1 1 = On

50 oC 40 °C 30 to 60 oC

1 minute

27 seconds55secs

3

seconds

15

minutes

20

minutes3mins

0 2 0, 1 or 2 0 = Residual moisture

ing

10

secs

Adjustable

20 seconds

to

2 minutes

0 (Off)

or

2 to 10

seconds

20 seconds

to

2 minutes

0 (Off)

or

2 to 10

seconds

3 minutes

to

1 hour

3 minutes

to

3 hours

*)Drum reverses to the left

and to the right in programmed timed intervals

Call up the residual moisture

values to be changed with

the selector switch and alter

with the start button.

0 = Off

add to this cooling down

time to a cool temperature

o

of 50

(temperature display for

5 secs, after the selector

button is pressed)

1 = temperature only

2 = residual moisture only

Programme position is not

occupied.

program

changes

here

C (Standard value).

Programmable residual moisture values

Program T 6351

Standard Adjustable Standard Adjustable

- 4 % - 3 % or - 5 % - 4 % - 3 % or - 5 %

- 2 % - 1 or 0% - 2 % - 1 or 0%

13 % 8 % or 16 % 16 % 8 % or 13 %

20 % 18 % or 22 % 22 % 18 % or 20 %

26 % 24 % or 30 % 30 % 24 % or 26 %

- 2 % 0 % or - 3 % - 2 % 0 % or - 3 %

A

1

2

3

4

5

6

7

B

8

9

The stored residual moisture values for the individual programs are shown in the additional display after the selector is

pressed. The sequence of the displayed residual moisture values for the programs is as follows:

Options

3 % 1 % or 5 % 3 % 1 % or 5 %

2 % 1 % or 4 % 2 % 1 % or 4 %

8 % 5 % or 10 % 8 % 5 % or 10 %

B/8, B/7, A/6, A/5, A/4

T 6551 / T 6751

Options

Notes Enter

program

changes here

A/3, A/2, A/1, B/9

M.-Nr. 05640910 19

,

Page 20

Cleaning and care

Before cleaning disconnect the machine from

the power supply via the mains switch.

Do not use a high pressure cleaner or

water jet to clean the machine.

Cleaning:

The following should be checked and if necessary serviced once a year by an authorized

Miele Service technician:

Heater element and heater shaft.

The whole interior of the tumble dryer

Fins on the ventilation fan

If proper maintenance is not performed regularly the machine may be damaged and operational faults posing a fire hazard could occur.

If there is there is a problem, please contact:

Miele Technical Service

1-800-999-1360

techserv@mieleusa.com

When contacting the Customer Service Department please quote the model and serial

number of the machine.

These can be found on the data plate:

Clean the lint filter (5) at least once a day and

when the “Clean lint filter” indicator light

comes on. Do not remove the lint filter.

Scoop out the lint and be careful not to damage the filter.

After drying starched laundry the drum should

be wiped out with a soft, damp cloth.

The housing, control panel and plastic parts

can be cleaned using a mild non-abrasive

cleanser with a soft, damp cloth and then

dried.

Stainless steel surfaces should be cleaned

with a stainless steel cleaner.

Never use abrasive cleaning agents to

clean the machine.

with the door open, or:

at the rear of the machine next to the exhaust

connection.

Guide to the data plate

Typ Model type

Fabr.-Nr. Serial number

Art.-Nr. Article number

M.-Nr. Part number

IBN Commissioning date

20 M.-Nr. 05640910

Page 21

Guide to the data plate symbols

1 Machine type

2 Serial number of the machine

3 Voltage/Frequency

4 Mains fusing

5 Drive motor

6 Plate diameter/Plate qty *

7 Drum data

8 Drum diameter/Drum depth *

9 Spin speeds *

10 Drum volume/Laundry dry weight

11 Kinetic Energy *

12 Top running time *

13 Braking time *

14 Heating

15 Electric heating

16 Fusing (on site)

17 Steam heating indirect

18 Steam heating direct *

19 Gas heating

20 Commissioning date

21 Water-Registration*

22 Space for test certificate /

or country certificate

Noise emission

T 6351 72.7 dB

T 6551 74.2 dB

T 6751 75.1 dB

* not valid for Tumble Dryers

M.-Nr. 05640910 21

Page 22

Installation

Installation, repair and maintenance work

should be by a Miele authorized service technician. Work by unqualified persons could be

dangerous and may void the warranty.

Pay careful attention to the enclosed installation instructions and the installation diagram.

Do not install the dryer in a room where there

is danger of frost.

Ensure that there is adequate ventilation for

operation in the room where it is installed.

Ensure that the air being drawn into the machine is fresh and that it does not contain chlorine, fluoride or solvent fumes.

Machines heated by electricity must not be installed in the same room as dry cleaning

machines using solvents containing CFCs.

Escaping fumes will break down into hydrochloric acid if ignited. This will damage the

machine.

If installed in an adjacent room there must be

no exchange of air between them.

To facilitate cleaning of the duct, cleaning

flaps or covers should be fitted on the bends

wherever possible.

With upward sloping exhaust ducting a condensate drain must be made at the lowest

point.

The dryer is fitted with an exhaust fan which

can be heard during operation. The noise

level of the fan can be reduced by fitting a

muffler to the dryer vent stub (available from

Miele’s Technical Service Department).

The minimum dimensions and distance required from the wall, as shown in the installation diagram, must be observed to allow

service to be performed.

The central air inlet and the area around the

dryer must be kept free from lint particles, to

prevent machine damage.

The exhaust must not be led into a chimney

used by another gas, coal or oil heated appliance. The warm humid air should be directed

by the shortest route into the open air or into a

suitable venting duct. The duct must be so designed and installed to accommodate the high

throughput of air (few bends, as short a duct

as possible, well shaped and leakproof joints).

No filters or louvres should be built into the exhaust duct.

The connection between the exhaust ducting

and the exhaust connection on the dryer must

be airtight.

Where the exhaust is ducted directly into the

open air, the end of the duct should be protected against the weather, ideally by a downward angle of 90o .

22 M.-Nr. 05640910

Page 23

Installation

Leveling the unit

The machine must be leveled for proper operation. The machine does not need to be installed on a base, however any unevenness in

the floor must be compensated for.

The machine can be leveled by adjusting the

screw feet.

Electrical connection

The electrical connections to the dryer must

be in accordance with instructions given on

the installation diagram and comply with local

regulations.

Once installed in position all detachable outer

casing parts must be attached again.

THIS APPLIANCE MUST BE GROUNDED.

Before installation, make sure that the voltage

and frequency listed on the data plate correspond with the site electrical supply. The

dryers are ready for connection to a 208V,

60Hz, 20A power supply.

Make the electrical connection (L1, L2, L3,

Ground) at the terminal block. Follow the instructions given on the enclosed wiring diagram (located on the terminal block).

Once leveled the discs must be turned with a

screwdriver against the machine’s base plate.

WARNING

Verify that the unit is in-phase:

the ventilation motor should turn clockwise

(open the

panel to the lint filter.)

the dryer door should suck in from the

under pressure.

All removable outer housing parts must be refitted after the electrical connection has been

made.

The electrical rating:

18.0 kW T6351

27.0 kW T6551

36.0 kW T6751

M.-Nr. 05640910 23

Page 24

Installation

Steam connection

Please pay attention to the installation diagram and instructions supplied with the machine. These are important for the connection

to steam.

All removable outer housing parts must be

refitted after the steam connection has been

made.

Important notes for the heat exchanger

To avoid damage to the heat exchanger the

following must be observed during installation:

1. To avoid unnecessary heat tension, ensure

that heating up is even (no sudden bursts of

steam).

2. To prevent corrosion the intake water must

be treated. It is particularly important during

idle periods to ensure that air (oxygen and

CO2) cannot get into the heat exchanger.

Empty the heat exchanger when not in use.

Make sure that any condensation has been

dried out.

3. The heat exchanger must be protected from

aggressive gases on the side exposed to

the air.

4. Ensure that the heat exchanger does not

operate at a higher operating pressure or

temperature than is stated on the data plate.

5. Pay heed to all current local and national

guidelines, standards and regulations relating to the installation, operation and maintenance of heating and ventilation systems,

with particular regard to the use of heat exchangers.

24 M.-Nr. 05640910

Page 25

Notes:

M.-Nr. 05640910 25

Page 26

Notes:

26 M.-Nr. 05640910

Page 27

M.-Nr. 05640910 27

Page 28

USA:

Miele, Inc.

9 Independence Way

Princeton, NJ, 08540

Phone: 800-843-7231

609-419-9898

Fax: 609-419-1435

Internet:

www.mieleusa.com

Technical Service 800-999-1360

E-Mail:

techserv@mieleusa.com

WEST COAST REGIONAL SERVICE 1-800-245-8215

Canada:

Miele Limited

55G East Beaver Creek Road

Richmond Hill, Ontario L4B 1E5

Phone: 905-707-1171

Toll-Free: 1-800-565-6435

Fax: 905-707-0177

Internet: www.miele.ca

E-Mail: info@miele.ca (general inquiries)

E-Mail: service@miele.ca (technical service)

Alteration rights reserved 3501

Loading...

Loading...