Page 1

Operating Instructions

Tumble Dryers

T 6201

T 6251 / T 6351

T 6551 / T 6751

T 6551 TR

It is essential to read these

operating instructions before installing

or using the machine to avoid the risk

of accident, or damage to the

machine.

Q

M.-Nr.04 989 221/03

Page 2

- These instructions consist of 26 pages. -

- Diese Gebrauchsanweisung besteht aus 26 Seiten.-

2 «M.-Nr.04 989 221/03 - GB - »

Page 3

Contents

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Description of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

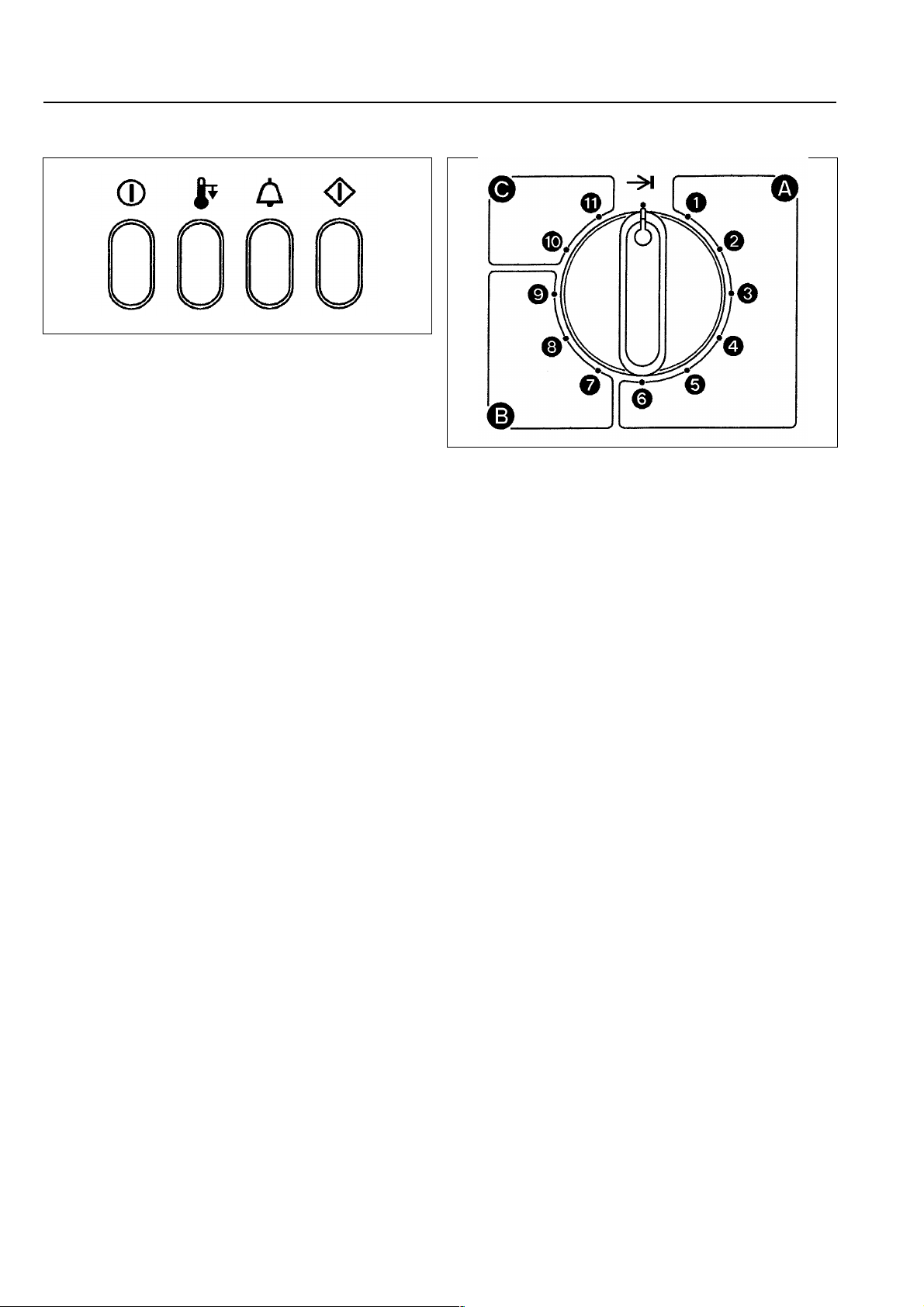

- Machine control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

- Pushbutton switches / programme selector . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

- Additional display with selector button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

- Programme sequence and check lights / fault messages . . . . . . . . . . . . . . . . . . . . 10

- “Reset” button / Emergency Stop switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

- Preparation of washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

- Weights of load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programme selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Coin operation unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Anti-crease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Interrupting a programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Emergency Stop switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

- Altering a drying programme - examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

- Reprogramming possibilities / Programmable residual moisture . . . . . . . . . . . . . . . . . 19

Page

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Meaning of the symbols on the data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Notes for the installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adjustable feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Steam connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

The tumble dryer must be installed by an approved

Service Engineer or authorized Service Dealer.

3 «M.-Nr.04 989 221/03 - GB - »

Page 4

Warning and

Safety instructions

Read the operating instructions through before

using this machine for the first time. This way

you will avoid the risk of accidents and damage to the machine.

The tumble dryer is only intended for dry-

ing fabrics, which have been washed in a

water solution, marked on the manufacturer’s

wash care label as being suitable for tumble

drying.

There is a danger of fire with the follow-

ing, and on no account should they be

dried in this machine:

– Articles containing foam rubber, rubber or

rubber like materials.

– Articles which have been treated with in-

flammable cleaning agents.

– Articles which have been splashed with

hair lacquer, hair spray, nail varnish remover, etc.

– Kitchen overalls which may be greasy,

fatty or impregnated with other residues.

Do not dry mops, floor cloths etc in this ma-

chine if they contain substances such as

wax or chemical cleaning agents.

Padded or filled fabrics (eg. jackets or

cushions) should not be dried. If the filling

falls out it could cause a fire.

Some textiles get very hot during drying

and there may be a risk of high temperatures causing them to ignite in exceptional circumstances. They should therefore be taken

out of the machine as soon as the programme

has finished and as soon as possible if there

has been a power cut. It is advisable to keep a

fire extinguisher near the machine at all times.

The washing must not be taken from the

dryer before the drying programme has

finished, ie, the cooling down phase must

be completed.

If hot laundry items are stacked or packed

they can be liable to auto-combustion.

Do not let children play in or near the ma-

chine and do not let them play with the

controls or operate it.

Make sure that the drum is stationary be-

fore removing laundry. Never put you hand

into a drum that is still moving.

Repairs to machines operated by gas,

steam or electricity must only be carried

out by fully trained and qualified service engineers. Unauthorized repairs could be dangerous.

The electrical safety of this appliance can

only be guaranteed when continuity is complete between the appliance and an effective

earthing system which complies with local and

national regulations.

It is most important that this basic safety requirement is regularly tested by a qualified

electrician.

The manufacturer can not be held responsible

for the consequences of an inadequate earthing system.

The machine is only completely isolated

from the electricity supply either when it is

switched off at the wall switch or when the

mains fuses are withdrawn from the distribution board.

Do not damage, remove or bypass the

safety components, fixtures and control

elements of this machine.

Where there is any damage to the controls

or to the cable insulation the machine

must not be used until it has been repaired.

Faulty components must only be ex-

changed for Miele original spare parts.

Only when these parts are fitted can the safety

standards of the machine be guaranteed.

Do not touch the steam pipework and com-

ponents, there is a danger of being burnt.

When disposing of an old machine, make

the door lock inoperative and remove the

fluff filter access panel. This should prevent

children at play from being accidentally locked

in and endangering their lives.

Only use the machine if all of the remov-

able outer housing parts are in place. This

way any moving parts or electrical components cannot be accessed.

Fire and Explosion risk

Never use or store petrol or petroleum

based substances or any easily inflammable

substances near the machine.

Fire risk

Do not use the machine without the built-in

fluff filter in place. If the fluff filter is damaged

it must be replaced immediately.

A build up of fluff could block the air flow heating and ventilation, and impair the efficiency of

the machine.

4 «M.-Nr.04 989 221/03 - GB - »

Page 5

Warning and

Safety instructions

Disinfecting and cleaning agents often con-

tain chlorides (salts). If these substances

dry onto the steel surfaces the residual chlorides attack the steel and can cause rusting.

To protect your machine from rust damage we

recommend only using chloride free disinfecting and cleaning agents for washing and disinfecting and for cleaning the machine. If you

are not sure about a particular agent contact

the manufacturer for advice.

If you accidentally spill an agent containing

chloride on the machine it should be rinsed off

with water and dried with a soft cloth.

Do not use a high pressure cleaner or

water jet to clean the machine.

In the event of a fault or for cleaning and

maintenance the gas control valve must

be shut and the gas emergency control at the

meter shut off.

Caution If the tumble dryer switches off

prematurely during the drying cycle, without the fault indication light showing, this could

be due to high temperatures in the area of the

motor.

Heater limiters stop the tumble dryer.

In this case please check the seals and locks

on the machine door and the fluff filter.

Check the condition of the air inlet and air outlet vents. If no damage is evident to any of

the parts checked, the dryer can be re-started.

If the fault occurs again, call the approved

Service engineer.

Open all doors and windows.

Close any shut off valves at the gas con-

nection meter or mains supply immediately.

Shut off the gas-valve next to the machine.

If all gas valves are closed but there is still the

smell of gas in the room you should call you

local gas board immediately.

Important! Before signing off any commis-

sioning, maintenance, conversion or repair

work as finished, all gas pipework from the

manual isolating valve to the burner nozzles

must be checked for soundness.

Pay special attention to the test points on the

multifunction control, the connection pressure

monitor and the burner setting pressure.

The tests must be carried out with the burner

switched on and switched off.

Accessories

Accessory parts may only be fitted when

expressly approved by Miele. If other parts

are used, guarantee, performance and product liability claims may be invalidated.

All personnel working with this machine must

be fully trained in all aspects of its use and

safety.

Safety precautions to take if you smell

gas

-For gas heated dryers only-

(Natural gas usually has no smell of its own. In

the U.K. a smell is added by British Gas for

safey reasons).

If you smell gas you must act immediately.

Extinguish any flames.

Do not create any electrical sparks:

e.g. do not insert or withdraw any electrical

plugs or operate electrical switches such

as lights and door bells.

Do not enter a room with an open light

where there is the smell of gas.

Do not light cigarette lighters or matches.

Do not smoke.

Keep these operating instructions in a safe

place.

5 «M.-Nr.04 989 221/03 - GB - »

Page 6

Caring for the environment

Disposal of the packing material

The transport and protective packing has

been selected from materials which are environmentally friendly for disposal and can normally be recycled. Packaging e.g. cling film,

polystyrene and plastic wrappings must be

kept out of the reach of babies and young

children. Danger of suffocation. Rather than

just throwing these materials away, please ensure that they are recycled.

Disposal of your old machine

Electrical and electronic machines often contain materials which, if handled or disposed of

incorrectly, could be potentially hazardous to

human health and to the environment. They

are, however, essential for the correct functioning of your machine. Please do not therefore

dispose of it with your household waste.

Please dispose of it at your local community

waste collection/recycling centre, and ensure

that it presents no danger to children while

being stored for disposal.

It should be unplugged or disconnected from

the mains electricity supply by a competent

person. The plug must be rendered useless,

and the cable cut off directly behind it to prevent misuse. See the "Warning and Safety"

section of this booklet for further details.

6 «M.-Nr.04 989 221/03 - GB - »

Page 7

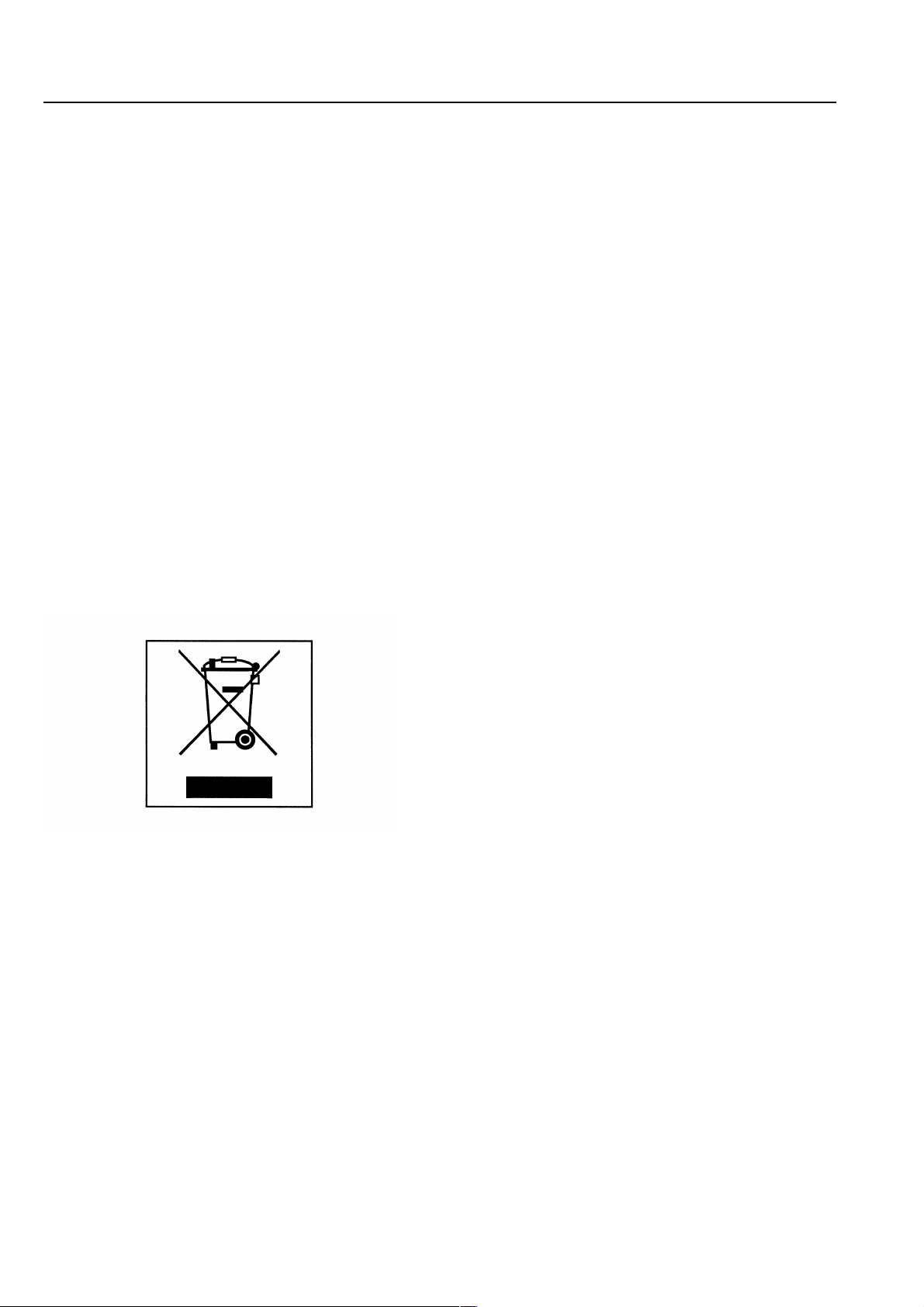

Description of the machine

Tumble dryer (T6201 / T6251 / T6351 / T6551 / T6751)

1

85

2

3

4

6

7

1 -Main switch 5 -Fluff filter

2 -Control panel 6 -Fluff compartment flap

3 -Drum door 7 -Four adjustable screw feet

4 -Door handle 8 -Venting pipework / Venting socket

Control panel

910 11 121314

9 -"Re-set" button 11 -Programme selector

(only for tumble dryers with gas heating)

10 -Indicator lights 13-Additional display with selector button

Programme sequence and check 14-"Emergency Stop" switch

lights

12-Push button switches

7 «M.-Nr.04 989 221/03 - GB - »

Page 8

Description of the machine

Push button switch

“On-Offs” switch

“L Low temperature” switch

Lowers the drying temperature for delicate fabrics (e.g. acrylics).

Press in the button switch to select this

function.

“l Buzzer” switch

The end of a programme can be indicated by

a buzzer.

Press in the button switch to select this function.

“h ”Start" button

This button switch starts the programme when

pushed in.

Programme selector

The programme selector switch is used to select the programme required.

COTTONS

A

Residual moisture value T6201/6251/6351 T6551/6751

Extra dry (-4%) (-4%)

1

Normal + (-2%) (-2%)

2

Normal (3%) (3%)

3

Machine iron

4

Machine iron

5

Machine iron

6

r

rr

rrr

(13%) (16%)

(20%) (22%)

(26%) (30%)

MINIMUM IRON

B

Normal + (-2%) (-2%)

7

Normal (2%) (2%)

8

Machine iron

9

TIMED DRYING

C

without heating (15 min) (15 min)

0

with heating (20 min) (20 min)

!

End

r

- All the values given in brackets are factory set standard values.

These values can be altered (see the following pages).

r

(8%) (8%)

8 «M.-Nr.04 989 221/03 - GB - »

Page 9

Description of the machine

Additional display with selector button

Selector button

Display Indicator lights

Selector button “Residual moisture” /

“Time” / “Vented air”

“Residual moisture” (%)

With this button the programmed residual

moisture values in programmes 1 to 9 can

be altered.

“Time” (h/mins)

With this button the programme duration can

The current residual moisture values are

shown continuously during the programme.

“Time” (h/mins)

Display of the time set for programmes

and !.

The hours are shown in the left hand display

field and the minutes in the other two fields.

After the programme has started the remaining time left to run is shown instead of the total

time.

“Vented air temperature” (oC)

Display of the current vented air temperature

while a programme is running. Display lasts

for approx 5 seconds. There is no display for

the "TR" models.

Note:

0

be changed in programme 0 (003 minutes

to 1.00 hour), and in programme ! (003 min-

utes to 3.00 hours).

- These changes can only be carried out before the start of the programme. Changes are

only valid each time for one selected programme. At the end of the programme the values set revert to the standard values. -

“Temperature of vented air” (oC)

If the button is pressed in while a programme

is running and released immediately, the current vented air temperature will show in the additional display for approx. 5 seconds. There

is no display for the "TR" models.

“Residual moisture” / “Time” / “Vented air”

display (Standard programming, see p. 19)

After the start button has been pressed a turning circle is shown for a short time in the display (meant to represent the turning drum of

the dryer).

Indicator lights “Residual moisture” /

“Time left”

“Residual moisture”

Lights up when the machine is switched on

and programme

or 9 is chosen.

It goes out at the end of the programme.

1

“Residual moisture” (%)

Display of the residual moisture set for programmes 1 to 9.

A few minutes after the programme has

started the residual moisture in the laundry is

recorded and displayed.

“Time left”

Lights up when the machine is switched on

and a programme between

and ! is chosen.

It goes out at the end of the programme.

9 «M.-Nr.04 989 221/03 - GB - »

0

Page 10

Description of the machine

Programme sequence and check lights

On

Drying

Cool air

Anti-crease/End

Check venting

Check fluff filter

Fault messages

Faults or interruptions are indicated by the sequence lights or the “check” lights flashing.

“Venting”

The venting duct is blocked or badly restricted.

Action: Check the vent ducting and if

necessary clean it.

“Fluff filter”

The fluff filter is clogged.

Action: Clean the fluff filter at the end of the

programme.

Note:

The "Drying", "Cool air" and "Anti-crease" indicator lights flash if there is a power cut or if a

programme has been interrupted (e.g. when a

door has been opened and shut). They are

not indicative of a fault. The lights will stop

flashing when the "Start" button is pressed.

This only applies to gas heated machines.

“Gas”

The gas check light comes on when:

Heating

(flashes)

Safety period

(flashes

)

Gas/Venting

(lights up)

Fluff filter

(lights up)

The messages are:

“Heating”

Fault in the heating system.

Action: Please inform the Service department.

“Safety period”

The maximum running time of the drying programme was exceeded because the residual

moisture at the start of the programme was

too high.

Action: Where the residual moisture was too

hight start the drying programme again.

If the fault message occurs again please call

the Service department.

– The site gas supply to the machine is inter-

rupted (e.g. gas stop valve has not been

opened).

Action: Open the gas stop valve.

– The gas connection pressure is too low

(there may be a drop in pressure in the gas

supply network).

Action: Inform your gas supplier.

The dryer cannot be switched on again

until the correct gas connection pressure

has been re-established.

– The venting duct is blocked or badly re-

stricted.

Action: Check the venting duct and clean if

necessary.

If the gas / venting check light remains on

after these measures have been taken the

Service department

must be called to deal

with the fault.

10 «M.-Nr.04 989 221/03 - GB - »

Page 11

Description of the machine

“ y & Re-set” push button

- Only for machines with gas heating.-

If the button lights up this indicates an ignition

fault. Wait for at least one minute before pushing the button to re-set.

“Emergency Stop” switch

Only use in an emergency.

Do not use this switch in normal operation to

switch the machine off.

To reset the “emergency stop” switch after it

has been used, turn the ribbed disk clockwise.

11 «M.-Nr.04 989 221/03 - GB - »

Page 12

Before using for the first time

Preparation of washing

Before using for the first time

Wipe the inside of the drum with a soft dry

cloth before loading the drum with laundry.

Preparing the laundry

Sort the laundry according to fabric type and

weave in order to achieve an even drying result.

Not all textiles are suitable for drying in a tumble dryer. Therefore pay special attention to

the manufacturer’s instructions in the wash

care label.

Significance of symbols:

= Dry at normal temperature

q

= Dry at low temperature

r

= Do not tumble dry

s

Articles made from pure wool and wool mixtures tend to become matted and shrink. They

should not be dried in a tumble dryer.

Sort the laundry according to the level of dryness required. It is not necessary to sort according to size.

Duvet covers and pillow cases should be

closed to prevent smaller items rolling up inside them.

For greater economy dry a full load, underloading is uneconomical. Do not overload as this

will impair the drying result and the laundry finish.

Loading the machine

Weights of load (Dry weight)

T 6201 T 6251 T 6351 T 6551 T 6751

Drum volume

200

Litres

250

Litres

350

Litres

550

Litres

750

Litres

The surface of pure linen is liable to be roughened by tumble drying. Consult the manufacturer’s instructions.

Important: Any laundry item with metal buckles, hooks, eyes, zip tags etc. should be put

into the dryer in a cloth bag (eg. pillowcase) to

protect the drum from scratches and dents.

Closed zips in garments may bridge the sensor electrodes in the drum ribs causing the drying process not to end or to end too late. Items

with zips should be dried with the zips open.

Padded or filled fabrics (eg. jackets or cushions) should not be dried. If the filling falls out

it could cause a fire

Some woven and loopknit materials tend to

shrink to varying extents depending on their

quality. This tendency is exaggerated by overdrying. Avoid the Extra dry programme for

such fabrics.

Starched washing can be dried in the tumble

dryer. Select the most suitable programme for

ironing by hand or machine.

Cottons

max.

8 kg

max.

2,5 kg

Poplin without wool lining, Padded jackets

__max.

Wool, Wool/Cotton, Wool/Synthetic,

Angora, Cashmere, Lambswool, Silk,

__max.

__max.

max.

10 kg

Minimum Iron and Delicates

max.

3.5 kg

Cotton, Jeans/Cord trousers,

max.

14 kg

max.

5 kg

Wet Care (TR)

10 kg

Viscose

5 kg

Bedding

7 kg

max.

22 kg

max.

7.5 kg

max.

15 kg

max.

7.5 kg

max.

11 kg

max.

30 kg

max.

10 kg

max.

20kg

max.

10 kg

max.

15 kg

12 «M.-Nr.04 989 221/03 - GB - »

Page 13

Selecting a programme

Close the drum door.

Switch on the mains switch

(on site).

Press in the “s On/Off” switch.

Select a programme:

The dryer has an electronic sensor system

which monitors the residual moisture in the

laundry.

Note: The drying programmes are not only

monitored electronically but are also timed

for extra safety. The heating time is limited

as standard to 60 minutes. Customer Service are able where necessary to programme in other safety times.

Once the required level of dryness has

been reached the laundry is cooled down

and the drying programme finishes automatically.

-The programme selector can be turned in

a clockwise or anti-clockwise direction.Different drying programmes can be selected with the programme selector depending on the dryness level required for

further handling.:

without heating (15 mins)

0

For airing laundry

with heating (20 mins)

!

To dry small loads or

to finish off drying

individual items.

If required also select the “L Low temperature” and/or “l Buzzer” functions.

Special programmes

1. Wet Care (TR)

For drying washable outer clothing which is

also stated on the laundry care label to be

suitable for machine drying *:

A/2

Poplin without wool lining *, padded

garments *

A/2

Jeans, Cord trousers

A/3

+ “L Low temperature” button switch

Cotton

COTTONS

A

For drying cotton/linen textiles

Residual moisture T6201/6251/6351 T6551/6751

Extra dry (-4%) (-4%)

1

Normal + (-2%) (-2%)

2

Normal (3%) (3%)

3

Machine Iron

4

Machine Iron

5

Machine Iron

6

MINIMUM IRON

B

For drying polyester cotton mixtures,

delicates and synthetics

Normal + (-2%) (-2%)

7

Normal (2%) (2%)

8

Hand Iron

9

r

rr

rrr

r

(13%) (16%)

(20%) (22%)

(26%) (30%)

(8%) (8%)

A/3

Cotton/Synthetic

A/4

Wool /Cotton, Wool/Synthetic

+ “L Low temperature” button switch

+ “L Low temperature” button switch

C/!

Wool, Angora, Cashmere, Lambswool, Silk,

Viscose etc.

2. Bedding

To dry bedding, which has a laundry care

label stating that it is machine-washable:

C/!

Bedding (e.g. non-seamed duvets, seamed/

pocketed feather duvets, synthetic duvets,

pillows, etc.)

- Continued on the next page -

TIMED DRYING

C

Airing and timed drying

13 «M.-Nr.04 989 221/03 - GB - »

Page 14

Selecting a programme

Important: Before drying bedding a re-programming of the standard options must be

carried out with A / 1, A / 2 and A / 4

(see table at the top of page 19).

- See pages 16 - 18 for conditions and

examples for reprogramming. Note: The duration of the C / ! programme

is set ex-works to 20 minutes, (the standard

option) (see table at the top of page 19).

A change to the duration of the programme

can be made by reprogramming for B / 9

"with heating (followed by Cooling down) Programme 11 ", (see table at the top of page 19).

If required also select the “l Buzzer”

functions.

Press in the “h Start” button.

- The drying programme selected now

starts.-

The end of the drying programme is indicated by the “ ~ r Anti-crease / End” light

lighting up and the buzzer sounding if selected.

Turn the programme selector to “r End”.

Open the drum door.

Remove the washing.

If the dryer is not going to be used again in

the near future:

Press the “s On/Off” button to switch off

the machine.

Switch off at the site main switch.

Clean the fluff filter.

Note

The “l Check fluff filter” light comes on if the

fluff filter needs to be cleaned. Clean the filter

as soon as the programme has finished. (see

page 20 for more details).

On gas heated dryers the “

comes on if there is an ignition fault. The ignition fault can be resolved by waiting for at

least one minute, then pressing the “

set” button. If ignition problems become more

frequent contact the Service department.

The washing must not be taken from the dryer

before the drying programme has finished, ie,

the cooling down phase must be completed.

If hot laundry items are stacked or packed

they can be liable to auto-combustion.

If the laundry is rinsed with hot water in the

final rinse, the residual heat in the laundry,

together with the reduced residual moisture

content, will lead to shorter processing times

and save energy.

y &

Re-set” light

y &

Re-

Coin operation unit

Drying with coin operation unit

C 4031 / C 4051 / C 5002

C 4060 / C 4065 / C 4070

It is important to follow the sequence below as

otherwise coins or tokens could be lost and

not credited.

1. Load the laundry and close the door.

2. Press in the “s On-Off” button.

3. Select a programme.

4. If required select the “L Low tempera-

ture” and/or “l Buzzer” functions.

5. Insert coins or tokens.

6. Press in the “h Start” button.

Note

Empty the coin box daily. This avoids a build

up of coins or tokens in the box which could interfere with operation.

14 «M.-Nr.04 989 221/03 - GB - »

Page 15

Note

Anti-crease

If the laundry is not removed from the machine

at the end of the programme an anti-crease

phase switches in automatically. There is

drum movement at intervals to minimise creasing in the laundry.

The anti-crease phase lasts about 59 minutes.

Interrupting the programme

The door can be opened during operation to

add articles of laundry or to remove articles

early. Do not reach into a moving drum.

To continue the drying process:

Close the drum door.

(The fan automatically switches on as a

safety measure when the temperature in

the interior of the dryer is too high.

The display lights “drying” “cold air” “anticrease/end” and the data in the additional

display flash).

selected or is turned to “End” to finish the programme.-

“Emergency stop” switch

Operate this switch only in a moment of dan-

ger. The dryer is then immediately put out of

operation. Do not use this switch in normal operation to switch the machine off.

To reset the “Emergency stop” switch after it

has been used, turn the ribbed disc clockwise.

Press the “h Start” button."

If the drying programme is interrupted, either

by opening the door, opening the fluff filter

panel (6), or operating the “Emergency stop”

switch, to start the machine again the “Start”

button has to be pressed.

If a new programme is to be selected, first turn

the programme selector to “End” and then to

the desired programme. Press the “Start”

button to start the new programme.

-The “On” indicator light flashes if the programme selector is turned to a different

position after the start of a programme. It stops

flashing when the programme selector is

turned back to the programme originally

15 «M.-Nr.04 989 221/03 - GB - »

Page 16

Note

Changing individual drying programmes

by reprogramming.

(Changing the standard options)

Individual drying programmes can be changed

and adapted to special requirements, usage

and processes.

Note

When a coin operation unit is fitted the standard options cannot be reprogrammed.

Example of reprogramming

Basic position:

➧

Press in the “s On-Off” switch.

- The “On” indicator light comes on.

The dryer must be switched off and the drum

door closed.

All of the switches must also be in the “Off” position, i.e. released not pressed in.

➧

Press the “L low temperature” button twice in

and twice out within 4 seconds:

After a few seconds the letter “P” lights up in

the left hand field of the additional display.

The programme sequence indicator lights “Drying” and “Cold air” flash.

- A reprogramming can now be carried out;

see examples 1 and 2 on the following pages.

The programme selector must be at the

“r End” position.

16 «M.-Nr.04 989 221/03 - GB - »

Page 17

Notes

Example 1:

Altering the drum reversing action period

(standard = 1 minute and 27 seconds) in the

cotton programmes.

A drum reversing action period can be selected between 20 seconds and 2 minutes.

Here a reversing time of 1 minute and 5 seconds is chosen.

Turn the programme selector to the"r End"

position.

- The change to the drum reversing action period in the cottons programmes is stored in

memory. The programming process is ended.

Turn the programme selector to programme

/ 1.

A

In the additional display the following are

shown alternately:

or

To leave the programming level:

➧

Press the “s On/Off”button.

Please enter the programming in the list on

the next but one page.

Example 2:

Changing the residual moisture value in programme 5 to 5 Machine iron rr (20%).

Press and release the “Start” button until “I 05"

appears in the additional display.

Residual moisture values can be selected between 18 and 22%.

Here a residual moisture value of 18% is selected.

- Create the basic position for reprogramming

(see example 1). -

17 «M.-Nr.04 989 221/03 - GB - »

Page 18

Note

Turn the programme selector to A / 3 .

- “P3" and ”3" are shown alternatively in the

additional display. -

➧

Use the selector switch to choose the programme to be changed.

Programme 5 Machine iron rr (20%).

Press the selector as often as necessary until

a residual moisture of 20% is shown in the additional display.

To leave the programming level:

➧

Release the “s On/Off” switch.

Please enter the programming in the list on

the following page.

See the next page for further reprogramming

examples.

Press the “h Start” button repeatedly to select

the required residual moisture of 18%.

Turn the programme selector to the"r End"

position.

- The change to the residual moisture value is

stored in memory and the programming process is ended.

18 «M.-Nr.04 989 221/03 - GB - »

Page 19

Notes

Reprogramming possibilities

Programme

Q

Cottons

Minimum iron

Timed drying

alterations

Reversing time*

in the Cottons

Programmes 1 to 6

and Timed drying

programmes 10 & 11

Reversing off /

Pause interval

in Cottons

programmes 1 to 6

and Timed drying

programmes 10 & 11

Residual moisture/

Prog. selection with the

Selector switch

Fan and heating

in pause times

Cooling down temperature

Vented air to

Reversing time*

in the Minimum iron

programmes 7 to 9

Reversing off/

Pause interval

in Minimum iron

programmes 7 to 9

without heating

Programme 10

with heating

followed by Cooling down

Programme 11

Additional display

during operation

Position of the

Programme

selector switch

1

2

A

3

4

5

6

7

B

8

9

0

C

!

Options Notes Enter

Standard TR Bedd-

1 minute and

27 seconds25secs25secs

3

seconds

see chart

"Programmable

residual

moisture"

1 0 0 0 or 1 1 = On

50 oC 40 °C 30 to 60 oC

1 minute

27 seconds55secs

3

seconds

15

minutes

20

minutes3mins

0 2 0, 1 or 2 0 = Residual moisture

ing

10

secs

Adjustable

20 seconds

to

2 minutes

0 (Off)

or

2 to 10

seconds

20 seconds

to

2 minutes

0 (Off)

or

2 to 10

seconds

3 minutes

to

1 hour

3 minutes

to

3 hours

*)Drum reverses to the left

and to the right in programmed timed intervals

Call up the residual moisture

values to be changed with

the selector switch and alter

with the start button.

0 = Off

add to this cooling down

time to a cool temperature

o

of 50

(temperature display for

5 secs, after the selector

button is pressed)

1 = temperature only

2 = residual moisture only

Programme position is not

occupied.

programmed

options here

C (Standard value).

Programmable residual moisture values

Programme T 6201 / T 6251 / T 6351

Standard Adjustable Standard Adjustable

- 4 % - 3 % or - 5 % - 4 % - 3 % or - 5 %

- 2 % - 1 or 0% - 2 % - 1 or 0%

13 % 8 % or 16 % 16 % 8 % or 13 %

20 % 18 % or 22 % 22 % 18 % or 20 %

26 % 24 % or 30 % 30 % 24 % or 26 %

- 2 % 0 % or - 3 % - 2 % 0 % or - 3 %

A

1

2

3

4

5

6

7

B

8

9

The stored residual moisture values for the individual programmes are shown in the additional display after the selector is

pressed. The sequence of the displayed residual moisture values for the programmes is as follows:

Options

3 % 1 % or 5 % 3 % 1 % or 5 %

2 % 1 % or 4 % 2 % 1 % or 4 %

8 % 5 % or 10 % 8 % 5 % or 10 %

B/9, B/8, B/7, A/6, A/5, A/4

T 6551 / T 6751

Options

Notes Enter

programmed

options here

A/3, A/2, A/1

19 «M.-Nr.04 989 221/03 - GB - »

,

Page 20

Cleaning and care

Before cleaning disconnect the machine from

the power supply via the mains switch.

For dryers with gas heating the gas manual

stop tap must be shut and the gas valve at the

entry meter shut off.

Do not use a high pressure cleaner or

water jet to clean the machine.

Cleaning:

nearest Miele Sales office. See back page for

address.

The following should be checked and if necessary cleaned once a year by a Customer

Service Engineer:

Burner and burner cavity (with gas heating),

heater element and heater shaft (with electric

heating).

The whole interior of the tumble dryer

Fins on the ventilation fan

If appropriate maintenance is not carried out

regularly the efficient running of the machine

may be impaired and operational faults representing a fire hazard can occur.

Should a fault occur please contact your nearest Customer Service Dept.

Clean the fluff filter (5) at least once a day depending on the amount of fluff that has

collected and when the “Clean fluff filter” indicator light comes on. Do not remove the fluff

filter and be very careful not to damage it.

After drying starched washing the drum should

be wiped out with a soft, damp cloth.

The housing, control panel and the plastic

parts may only be cleaned using a mild cleaning agent or with a soft, damp cloth and then

dried.

Stainless steel housing should be cleaned

with a proprietary stainless steel cleaning

agent.

Never use abrasive cleaning agents to

clean the machine.

If you are unsure about a particular product or

need further advice please contact your

When contacting the Customer Service Department please give both the model type and

the serial number (Fabr.-Nr.) of the machine.

These can be found on the data plate:

with the door open, or:

at the rear of the machine next to the exhaust

connection.

Guide to the data plate

Typ Model type

Fabr.-Nr. Serial number

Art.-Nr. Article number

M.-Nr. Part number

IBN Commissioning date

20 «M.-Nr.04 989 221/03 - GB - »

Page 21

Explanation of symbols

on the data plate

1 Machine type

2 Serial number of the machine

3 Voltage/Frequency

4 Mains fusing

5 Drive motor

6 Plate diameter/Plate qty *

7 Drum data

8 Drum diameter/Drum depth *

9 Spin speeds *

10 Drum volume/Laundry dry weight

11 Kinetic Energy *

12 Top running time *

13 Braking time *

14 Heating

15 Electric heating

16 Fusing (on site)

17 Steam heating indirect

18 Steam heating direct *

19 Gas heating

20 Commissioning date

21 Water-Registration*

22 Space for test certificate /

e.g. CE - 0085 (Gas)

or country certificate

Noise emission

Registered on the “A” scale.

T 6201 67,7 dB

T 6251 67,7 dB

T 6351 72.7 dB

T 6551 74.2 dB

T 6751 75.1 dB

measured in Germany in accordance with

DIN (IEC) 45 635, machine noise regulations

3. GSGV p 1 1.a

* not valid for Tumble Dryers

21 «M.-Nr.04 989 221/03 - GB - »

Page 22

Notes for the installer

The tumble dryer may only be installed and

commissioned by a Service Engineer or by an

authorized Service Dealer.

Pay careful attention to the enclosed installation instructions and the installation diagram.

Do not install the dryer in a room where there

is danger of frost.

Ensure that there is adequate ventilation for

operation in the room where it is installed.

Ensure that the air being drawn into the machine is fresh and that it does not contain chlorine, fluoride or solvent-vapours.

Machines heated by gas and electricity must

not be installed in the same room as dry cleaning machines which use solvents containing

CFCs. Escaping vapours break down into hydrochloric acid if ignited. This would damage

any laundry as well as the machine.

If installed in an adjacent room there must be

no exchange of air between them.

The area around the dryer - particularly

around the central air inlet must be kept free

from fluff particles, so that these do not get

taken into the machine. Any fluff trapped in the

machine could lead to operational damage.

Where the exhaust is ducted directly into the

open air, the end of the duct should be protected against the weather, ideally by a downward angle of 90

To facilitate subsequent cleaning of the duct,

cleaning flaps or covers should be fitted on the

bends wherever possible.

With upward sloping exhaust ducting a condensate drain must be made at the lowest

point.

The dryer is fitted with an exhaust fan which

can be heard during operation. The noise

level of the fan can be reduced by fitting a

muffle to the dryer vent stub (available from

your Miele Dealer or the Miele Spare Parts

Department).

The machine does not need to be installed on

a base, however any uneveness in the floor

must be compensated for.

The machine must be installed evenly for it to

function smoothly.

To facilitate any subsequent service or maintenance work, the minimum dimensions and distance required from the wall, as shown in the

installation diagram, must be observed.

o .

The exhaust must not be led into a chimney

used by another gas, coal or oil heated appliance. The warm humid air should be directed

by the shortest route into the open air or into a

suitable venting duct. The duct must be so designed and installed to accommodate the high

throughput of air (few bends, as short a duct

as possible, well shaped and leakproof joints).

No filters or louvres should be built into the exhaust duct.

The connection between the exhaust ducting

and the exhaust connection on the dryer must

be airtight.

Coin operation unit.

The dryer can be fitted with a coin operation

unit*. The appropriate adapter* is also required.

The re-programming of the dryer which is necessary for fitting a coin unit can only be carried

out by the Miele Service department or a

Miele authorised service dealer.

All parts marked with an * are available from

Miele Spare Parts department and some Miele

dealers.

22 «M.-Nr.04 989 221/03 - GB - »

Page 23

Notes for the installer

The machine can be levelled by adjusting the

screw feet.

Once levelled the discs must be turned with a

screwdriver against the machine’s base plate.

WARNING

THIS APPLIANCE MUST BE EARTHED.

Follow instructions given on the enclosed wiring diagram (with the machine on the terminal

block). These are important for the correct

electrical connection to be made.

WARNING

Ensure that the ventilation motor is turning in

the correct direction. To do this open the

panel to the fluff filter. The ventilation motor

must turn clockwise.

The dryer may only be connected to the same

voltage and rated load as shown on the data

plate.

The electrical rating is usually set ex works as

follows:

13,5 kW T6201

13.5 kW T6251

18.0 kW T6351

The electrical connections to the dryer must

be in accordance with instructions given on

the installation diagram and comply with local

regulations.

Once installed in position all detachable outer

casing parts must be attached again.

Electrical connection

This machine has been constructed in accordance with current safety standards and complies with the following standards:

T 6201, T 6251 and T 6351 with IEC 335-1

and IEC 335-2-11,

T 6551 and T 6751 with EN 60204-1

The electrical connection may only be carried

out by a fully competent person in accordance

with local and national safety regulations.

Connection must be made by a suitable isolator and the on-off switch should be easily

accessible for servicing work.

27.0 kW T6551

36.0 kW T6751

The gas heated version must be connected

via an isolator.

Ensure the leads for N and phase L are correctly connected. Do not transpose.

All removable outer housing parts must be refitted after the electrical connection has been

made.

23 «M.-Nr.04 989 221/03 - GB - »

Page 24

Notes for the installer

Steam connection

The steam connection must only be undertaken by an authorized installer.

Please pay attention to the installation diagram and instructions supplied with the machine. These are important for the connection

to steam.

All removable outer housing parts must be refitted after the steam connection has been

made.

Important notes for the heat exchanger

To avoid damage to the heat exchanger the

following must be observed during commissioning:

1. To avoid unecessary heat tension ensure

that heating up is even (no sudden bursts of

steam).

2. To prevent corrosion the intake water must

be treated. It is particularly important during

idle periods to ensure that air (oxygen and

CO 2) cannot get into the heat exchanger.

The condensate drain must be installed in

such a manner that the heat exchanger can

empty fully when it is not in use. There must

be no condensation at all left in it.

3. The heat exchanger must be protected from

aggressive gases on the side exposed to

the air.

4. Ensure that the heat exchanger does not

operate at a higher operating pressure or

temperature than is stated on the data plate.

Gas connection

The gas connection may only be carried out

by a suitably qualified (e.g. Corgi registered)

engineer, in accordance with local and national safety regulations. The enclosed installation diagram and the installation instructions

for gas must be followed to ensure correct gas

connection.

Please pay attention to the installation diagram and instructions supplied with the machine. These are important for the connection

to gas.

The gas group to which the machines have

been set at the factory is given on the Gas

Data sticker affixed to the rear of the machine.

When converting to another gas group, or to

liquid gas, a conversion kit is required, available from the Spare Parts department, (give

the model and serial number of the machine

as well as the gas type, group and connection

pressure in the country of installation when ordering). The installation instructions for gas

heated machines must be followed. Conversion may only be carried out by suitable competent persons.

All removable outer housing parts must be refitted after the gas connection has been made.

Do not attempt to undertake any repairs to gas

heated machines yourself. Repairs must only

be carried out by suitably competent persons

to ensure safety, e.g. gas engineers must be

registered. Please consult the Miele Customer Service department or an authorized

Service dealer.

5. Pay heed to all current local and national

guidelines, standards and regulations relating to the installation, operation and maintenance of heating and ventilation systems,

with particular regard to the use of heat exchangers.

24 «M.-Nr.04 989 221/03 - GB - »

Page 25

Notes:

25 «M.-Nr.04 989 221/03 - GB - »

Page 26

Alteration rights reserved 13.06

Loading...

Loading...