Miele PG 8581, PG 8582, PG 8583 installation plan [es]

Installation plan / Plano de instalación

PG 8581 – PG 8583

Mat. no. / Número de material

Version / Estado de modificación

10 344 161

00

en, es – EX

Technical data sheet

Washer-disinfector PG 8581 - 8583

Legend: Circled, bold-type abbreviations:

Electrical

connection

(220 V)

Electrical

connection

Electrical

connection

(380 V)

Electrical

connection

Equipotential

bonding and

protective earth

conductor

Connection required

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

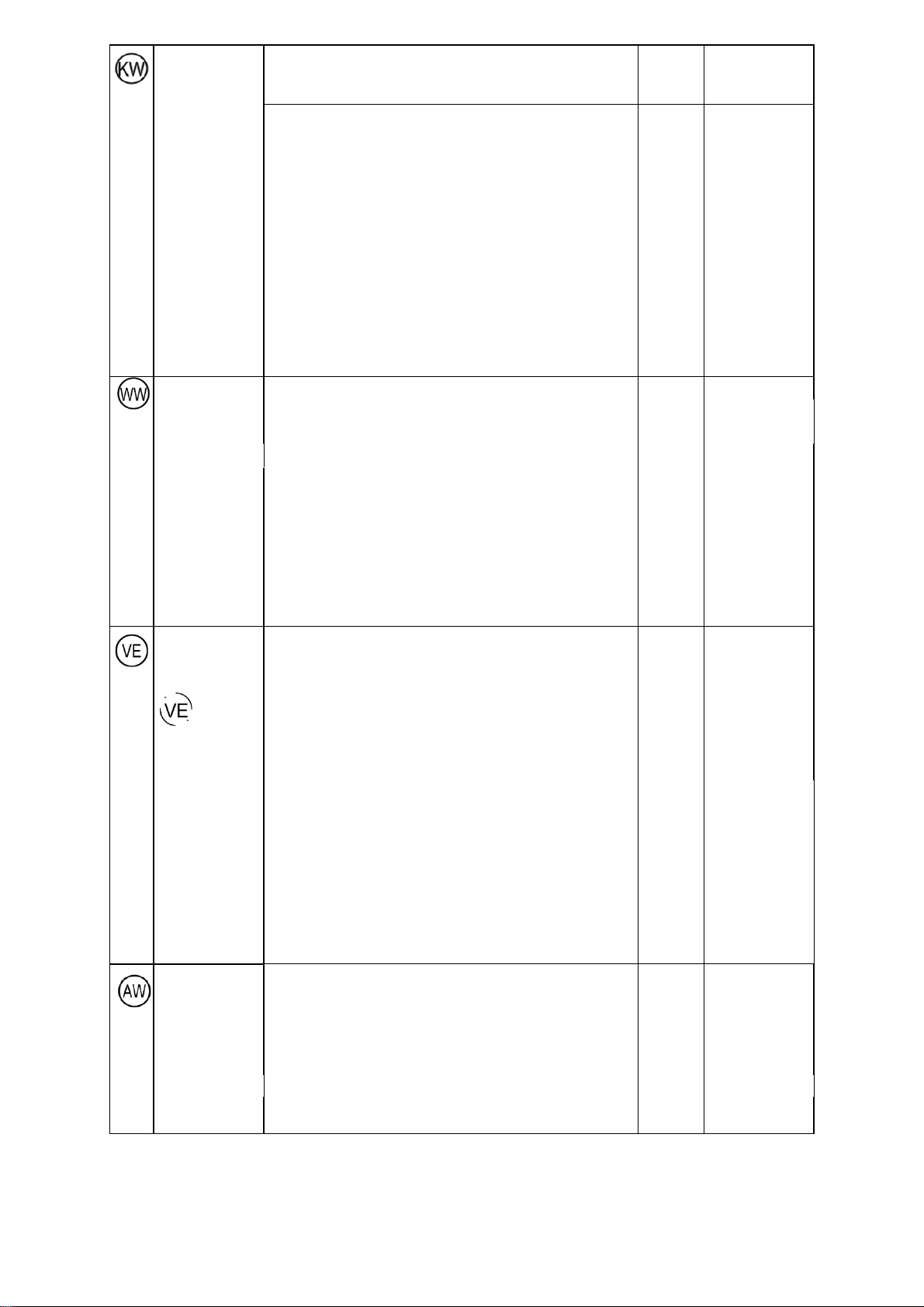

Voltage (standard version) V/Hz 3 AC 220 – 230 V/60

Connected load kW 6.9 – 7.5

Fuse rating A 3 x 20

Connection cable, min. cross-sectional area mm² 4 x 2.5

Length of mains connection cable (H05(07)RN-F) m 1.6

Voltage (convertible)

Connected load kW 3.0 -3.3

Fuse rating A 2 x 16

Connection cable, min. cross-sectional area mm² 3 x 1.5

Length of mains connection cable (H05(07)RN-F) m 1.8

Voltage (Standa

Connected load kW 8.5 – 9.3

Fuse rating A 3 × 16

Connection cable, min. cross-sectional area mm² 5 × 2.5

Length of mains connection cable (H05(07)RN-F) m 1.6

Voltage (convertible)

Connected load kW 3.0 – 3.3

Fuse rating A 1 x 16

Connection cable, min. cross-sectional area mm² 3 x 1.5

Length of mains connection cable (H05(07)RN-F) m 1.8

We recommended connecting the washer-disinfector to the

electrical supply via a plug and socket so that electrical safety

checks can be carried out easily. The plug and socket must

be easily accessible after installation. A hard-wired

connection is possible. It must be made in accordance with

IEE (IET) Wiring regulations BS 7671: 2008.

Splash protection class IP 21

There is a scre

washer-disinfector, to which equipotential bonding

can be connected if required.

Connect equipotential bonding and protective earth

conductor!

rd version) V/Hz 3N AC 380 – 400

w connection point at the back of the

V/Hz AC 220 – 230 V/60

V/60

V/Hz AC 220 – 230 V/60

Network/

printer connection

(optional)

Optional machine interface for transmission or process data

output

Communication module (not supplied)

Ethernet module or RS232 module (install electrical sockets

near machine if required)

Connections/installation must co

mply with IEC 60950.

Installation plan / Plano de instalación PG 8581 – PG 8583

Date created / Fecha de creación 2020-08-14

M.-Nr. 10 344 161 / 00

Page / Página 2 / 7

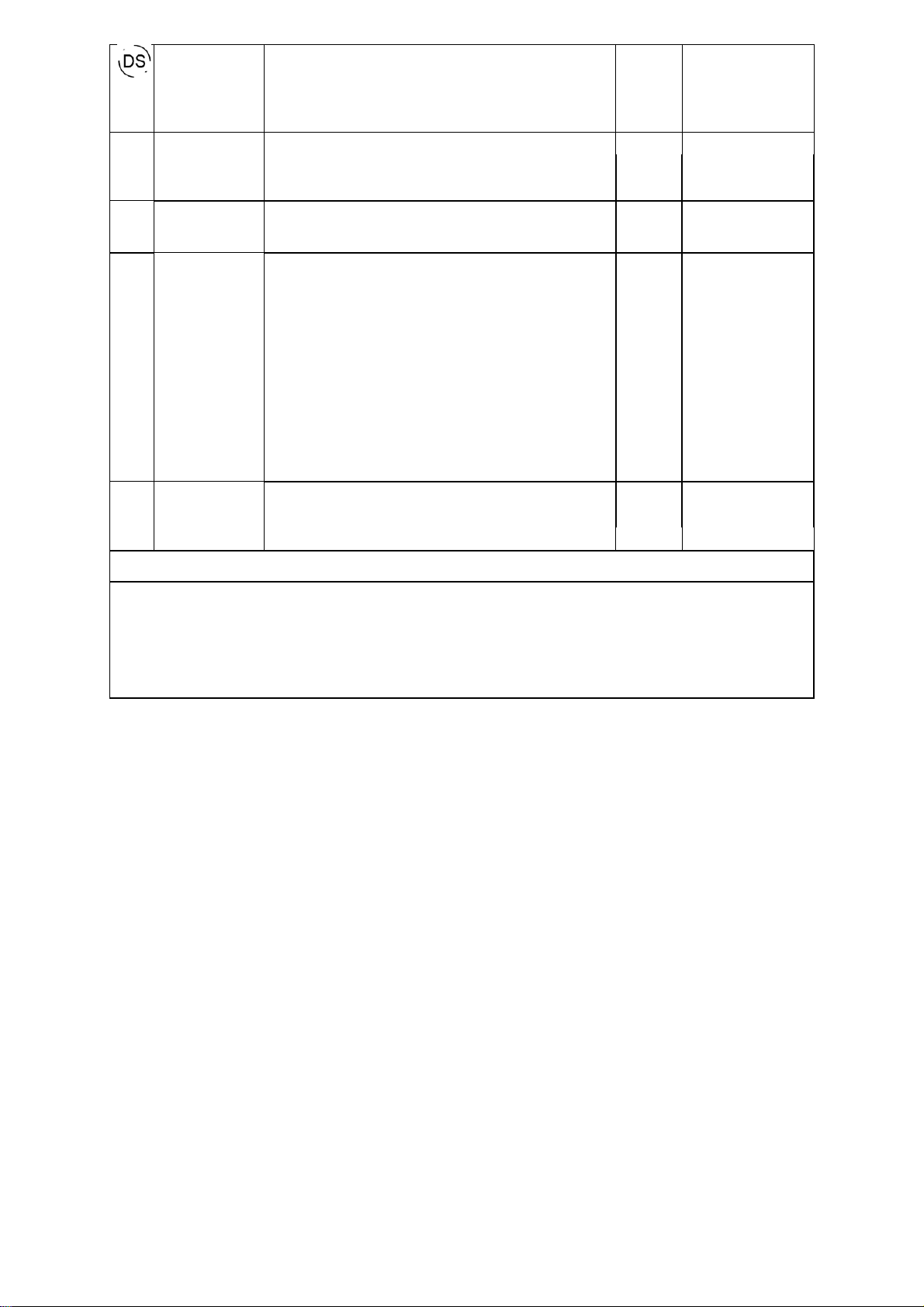

Cold water Two cold water connections are required for models with a steam

Hot w

ater

(not available for

PG 8581)

condenser (DK). The second cold water hose can be connected

using the Y-piece provided.

Maximum temperature °C 20

Max. water hardness mmol/l

Minimum flow pressure kPa 200

Minimum flow pressure with extended water intake kPa 100

Maximum pressure kPa 1,000

Flow rate l/min 7.5

On-site threaded union in accordance with DIN 44991 (flat seal) Inch 3/4" male thread

Length of cold water inlet hose m Approx. 1.7

Length of steam condenser hose m Approx. 1.7

Connection to a drinking water supply in the UK requires the

installation of an additional WRAS approved non-return device.

Maximum temperature °C 65

Max. water hardness mmol/l

Minimum flow pressure kPa 200

Minimum flow pressure with extended water intake kPa 40

Maximum pressure kPa 1,000

Flow rate l/min 7.5

On-site threaded union in accordance with DIN 44991 (flat seal) Inch 3/4" male thread

Length of hot water inlet hose m Approx. 1.7

Connection to a drinking water supply in the UK requires the

installation of an additional WRAS approved non-return device.

°dH

°dH

12.6

70

12.6

70

Demineralised

wa

ter

(PG 8581

note machine

version)

PG 8583 o

Waste w

nly: Model with feed pump for unpressurised demineralised water

ater Drainage temperature °C 93

Maximum temperature °C 65

Minimum flow pressure (AD pressure resistant) kPa 200

Minimum flow pressure with extended water intake kPa 30

Maximum pressure (AD pressure resistant) kPa 1,000

Flow rate l/min 7.5

On-site threaded union in accordance with DIN 44991 (flat seal) Inch 3/4" male thread

Length of demin. water inlet hose m Approx. 1.7

Connection to a drinking water supply in the UK requires the

installation of an additional WRAS approved non-return device.

(ADP)

Minimum flow pressure (AD unpressurised) kPa 8.5

Maximum pressure (AD unpressurised) kPa 60

Machine connection nipple (outer dia. x l) mm 6 x 30

Hose from supply container to machine to be fitted on site

Length of drain hose m Approx. 1.4

Max. drain hose extension m Approx. 4.0

Max. drain pump head height from base of machine m 1.0

Max. transient flow rate l/min 16

On-site sleeve for drain hose (dia. x length) mm 22 x 30

It is advisable to lay the drain hose in a curve min. 600 mm above

floor level to the drainage point.

Installation plan / Plano de instalación PG 8581 – PG 8583

Date created / Fecha de creación 2020-08-14

M.-Nr. 10 344 161 / 00

Page / Página 3 / 7

External

dispensing

(optional)

(note machine

model)

Machine feet Height-adjustable mm -0/+60

Heat dissipation

rate to installation

site

Machine data Undercounte

Installation

conditions

Connection for up to two dispensing units for liquid agents on

the back panel.

Machine foot diameter mm 35

Machine foot socket M 8

Heat dissipation through heat radiation kWh/h 0.35

Load heat dissipation on removal kWh/h 0.40

r height mm 820

Height incl. lid mm 835

Width mm 598

Depth mm 598

Door height mm 622

Net weight kg 74

Floor load in operation N 1,200

Min. access width, incl. transport pallet mm 670

Min. access depth incl. transport pallet mm 740

Min. access height, incl. transport pallet mm 920

Permissible ambient temperature °C 5-40

Maximum relative humidity % 80

Max. installation above sea level m 1,500

It is essential to observe the installation instructions when installing the washer-disinfector.

In order to reduce the risk of steam damage, the area around the washer-disinfector should be limited to furniture and fittings

that are designed for use in commercial environments.

Installation should only be performed by qualified fitters in accordance with valid regulations, relevant standards and health

and safety codes!

All rights reserved! Measurements in mm

Installation plan / Plano de instalación PG 8581 – PG 8583

Date created / Fecha de creación 2020-08-14

M.-Nr. 10 344 161 / 00

Page / Página 4 / 7

Loading...

Loading...