Page 1

Installation plan

Series 120

To avoid the risk of accidents or damage to the

machine, it is essential to read these instructions

as well as the service documents before it is installed, commissioned and used for the first time.

en - GB, IE

M.-Nr. 11 275 810

Page 2

Installation notes

Installation requirements

Surrounding area

Electrical connection

This machine must be connected to the mains supply, and plumbed

in, in accordance with the installation instructions provided. Installation must only be carried out by authorised installers in accordance

with valid regulations, relevant standards and health and safety

codes.

The machine must be commissioned and operators trained in its use

by Miele Service or by an approved Miele Service Dealer only.

Condensate can build up in the area surrounding the machine. Any

cabinetry and fixtures in the room must be suitable. If the machine is

installed under a countertop (built-under model), the protective foil

supplied must be stuck to the underside of the worktop and a stainless steel panel must be installed above the door opening to provide

protection from the steam. The stainless steel panel can be ordered

from Miele.

Connection to the electrical supply must be carried out in accordance

with local and national safety regulations. The power cord must be

protected from the risk of thermal damage.

It is recommended to make electrical connection via a plug and

socket so that electrical safety checks can be carried out easily.

For hard-wired machines, connection must be via a main switch to

be provided on site, which must completely isolate the machine from

the power supply with a contact gap of at least 3mm.

The plug and socket as well as the main switch must be easily accessible after the machine has been installed.

Equipotential

bonding and

earthing

Plumbing

Liquid media: position of external

containers

For added safety the machine should be protected with a residual

current device with trip current of 30 mA.

Equipotential bonding should be carried out if required. A screw

connection for equipotential bonding is provided at the back of the

machine. Equipotential bonding and earthing must be completed before the machine is commissioned.

This machine can be connected directly to a cold water supply, a hot

water supply or a demineralised water supply and to the drainage

point without a non-return valve. If a hot water supply is not available, both inlet hoses (KW/WW) must be connected to the cold water

supply with a Y-connector. The stopcocks must be easily accessible.

The liquid agent container for external dispensing must be placed

next to or underneath the machine. Place the container next to the

machine on the floor or in an adjacent cabinet.

Do not position the container above the machine. The dispenser hose

must not be kinked or trapped.

2 Series 120

Page 3

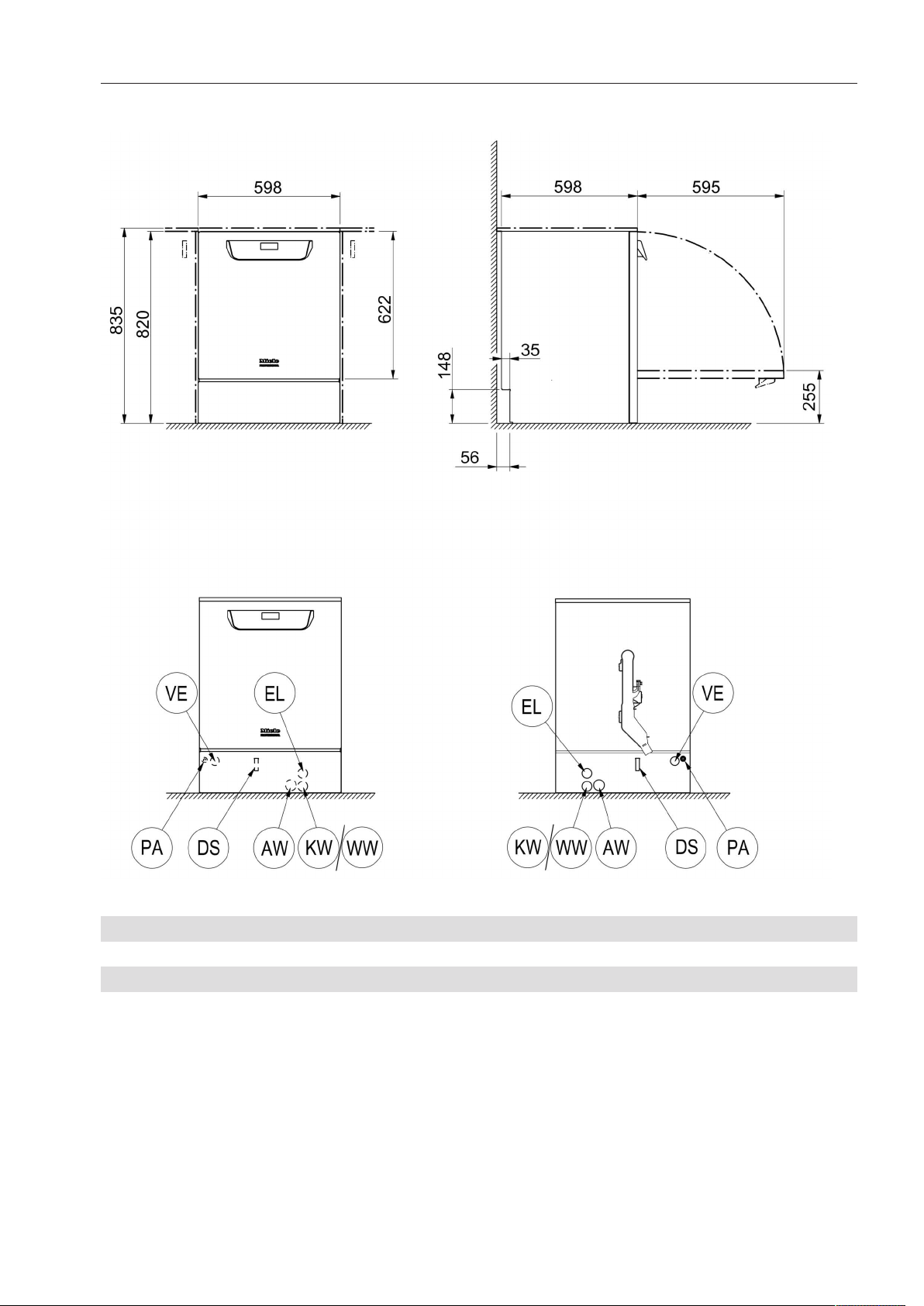

Illustrations

KW Cold water connection EL Electrical connection

WW Hot water connection DK Cold water connection, steam condenser

VE Demineralised water connection DS Dispensing systems

AW Drain connection PA Equipotential bonding

Series 120 3

Page 4

Illustrations

KW Cold water connection EL Electrical connection

WW Hot water connection DK Cold water connection, steam condenser

VE Demineralised water connection DS Dispensing systems

AW Drain connection PA Equipotential bonding

4 Series 120

Page 5

Technical data

Electrical connection

Voltage (standard version) AC 230/50

Total connected load 2.4kW

Fuse rating 1 x 13A

Connection cable, cross-section min. 3 x 1.5mm²

Length of mains connection cable (H05(07)RN-F) 1.8m

Cold water connection

Maximum incoming temperature 20°C

Max. permitted water hardness 12.6mmol/l

70°dH

Recommended flow pressure 200kPa

Minimum flow pressure with extended water intake 100kPa

Maximum pressure 1,000kPa

Flow rate 7.5l/min

On-site threaded union in accordance with DIN 44991 (flat sealing) 3/4Inch

Length of cold water inlet hose 1.7m

Hot water

Maximum incoming temperature 60°C

Max. permitted water hardness 12.6mmol/l

70°dH

Recommended flow pressure 200kPa

Minimum flow pressure with extended water intake 100kPa

Maximum pressure 1,000kPa

Flow rate 7.5l/min

On-site threaded union in accordance with DIN 44991 (flat sealing) 3/4Inch

Length of hot water inlet hose 1.7m

Series 120 5

Page 6

Technical data

Demin. water

Maximum incoming temperature 60°C

Recommended flow pressure (AD pressure-resistant) 200kPa

Minimum flow pressure with extended water intake 100kPa

Maximum pressure (AD pressure resistant) 1,000kPa

Flow rate 7.5l/min

On-site threaded union in accordance with DIN 44991 (flat sealing) 3/4Inch

Length of demin. water inlet hose 1.7m

Machines with a booster pump for demineralised water (ADP) are only suitable for connection/use with a nonpressurised system.

Minimum flow pressure with extended water intake 8.5kPa

Maximum pressure (AD unpressurised) 60kPa

Machine connection (dia. x l) 6 x 30mm

Waste water

Drain hose length, standard 1.4m

Drain hose, max. drainage length 4.0m

Max. drain pump head height from bottom edge of machine 1.0m

Max. transient flow rate 16l/min

On-site sleeve for drain hose (dia. x length) 22 x 30mm

Machine feet

Height-adjustable machine feet 0 - 60mm

Diameter of machine feet 35mm

Insert for machine foot, size of thread M 8

Machine data

Building-under height 820mm

Height including lid 835mm

Width 598mm

Depth 598mm

Door height 622mm

Net weight 72kg

Floor load in operation 1,200N

Min. access width, incl. transport pallet 670mm

Min. access depth incl. transport pallet 740mm

Min. access height, incl. transport pallet 920mm

Noise level in dB (A),

sound pressure LpA during cleaning and drying phases

< 70dB

6 Series 120

Page 7

Technical data

Heat dissipation rate to installation site

From heat radiation during operation 0.35kWh

From load whilst unloading 0.40kWh

Installation requirements

Permissible ambient temperature 5 - 40°C

Max. relative humidity up to 31°C 80%

Rel. humidity, declining proportionally to 40°C 50%

Max. installation altitude above sea level 1,500

Series 120 7

Page 8

Carl-Miele-Straße 29, 33332 Gütersloh, Germany

Miele & Cie. KG

Manufacturer:

Malaysia

Miele Sdn Bhd

Suite 12-2, Level 12

Menara Sapura Kencana Petroleum

Solaris Dutamas No. 1, Jalan Dutamas 1

50480 Kuala Lumpur, Malaysia

Phone: +603-6209-0288

Fax: +603-6205-3768

Miele New Zealand Limited

IRD 98 463 631

Level 2, 10 College Hill

Freemans Bay, Auckland 1011, NZ

Tel: 0800 464 353

Internet: www.miele-professional.com.au

E-mail: info@miele-professional.com.au

New Zealand

Miele Pte. Ltd.

163 Penang Road

# 04 - 03 Winsland House II

Singapore 238463

Tel: +65 6735 1191, Fax: +65 6735 1161

E-Mail: info@miele.com.sg

Internet: www.miele.sg

Singapore

Miele (Pty) Ltd

63 Peter Place, Bryanston 2194

P.O. Box 69434, Bryanston 2021

Tel: (011) 875 9000, Fax: (011) 875 9035

E-mail: info@miele.co.za

Internet: www.miele.co.za

South Africa

Miele Appliances Ltd.

Gold & Diamond Park

Office No. 6-217, Sheikh Zayed Road

P.O. Box 11 47 82 - Dubai

Tel. +971 4 3044 999, Fax. +971 4 3418 852

800-MIELE (64353)

E-Mail: info@miele.ae, Website: www.miele.ae

United Arab Emirates

United Kingdom

Miele Co. Ltd.

Fairacres, Marcham Road

Abingdon, Oxon, OX14 1TW

Professional Sales, Tel: 0845 365 6608

E-mail: professional@miele.co.uk

Internet: www.miele.co.uk/professional

Miele Australia Pty. Ltd.

ACN 005 635 398

ABN 96 005 635 398

1 Gilbert Park Drive, Knoxfield, VIC 3180

Tel: 1300 731 411

Internet: www.miele-professional.com.au

E-mail: info@miele-professional.com.au

Australia

Miele (Shanghai) Trading Ltd.

1-3 Floor, No. 82 Shi Men Yi Road

Jing' an District, 200040 Shanghai, PRC

Tel: +86 21 6157 3500, Fax: +86 21 6157 3511

E-mail: info@miele.cn, Internet: www.miele.cn

China

41/F - 4101, Manhattan Place

23 Wang Tai Road

Kowloon Bay, Hong Kong

Tel: (852) 2610 1025, Fax: (852) 3579 1404

Email: customerservices@miele.com.hk

Website: www.miele.hk

Miele (Hong Kong) Limited

Miele India Pvt. Ltd.

Ground Floor, Copia Corporate Suites

Plot No. 9, Jasola

New Delhi - 110025

Tel: 011-46 900 000, Fax: 011-46 900 001

E-mail: customercare@miele.in, Internet: www.miele.in

India

Miele Ireland Ltd.

2024 Bianconi Avenue

Citywest Business Campus, Dublin 24

Tel: (01) 461 07 10, Fax: (01) 461 07 97

E-Mail: info@miele.ie, Internet: www.miele.ie

Ireland

Alteration rights reserved / Publication date: 2019-01-30 M.-Nr. 11 275 810 / 00

Series 120

Loading...

Loading...