Operating instructions

Commercial dishwasher

PG 8067

To avoid the risk of accidents or

damage to the machine it is

essential to read these instructions

before it is installed, commissioned and used

for the first time.

en-GB

M.-Nr. 07 122 771

Contents

Description of the machine..........................................4

Guide to the machine ..............................................5

Control panel ......................................................5

Machine overview ..................................................6

Warning and safety instructions .....................................8

Caring for the environment.........................................14

Before using for the first time.......................................15

Opening and closing the door ......................................16

Adding rinsing agent ..............................................17

Rinsing agent level indicator ......................................17

External rinsing agent container (optional extra)..........................18

Add rinsing agent indicator .......................................18

Adding rinsing agent and venting the dispensing system ................19

Areas of application...............................................20

Loading the machine ...............................................20

Items that are not suitable for dishwashers ..............................21

Adding cleaning agent ............................................24

Adding liquid cleaning agent: ........................................24

Add cleaning agent indicator ......................................24

External cleaning agent container (optional extra) ........................25

Add cleaning agent indicator ......................................25

Maintenance of the dispensing system .................................26

Operation .......................................................27

Preparing the machine .............................................27

Selecting a programme .............................................28

Starting a programme ..............................................28

At the end of a programme ..........................................28

Changing a programme ..............................................28

Cancelling a programme ..............................................28

Switching off.......................................................28

Programmable functions...........................................29

Calling up programming levels .......................................29

Saving changes to memory ..........................................29

To come out of a programming level...................................29

Programming the cleaning agent dosage (DOS 1) ........................30

Setting the cleaning agent dispensing method ........................30

Setting the cleaning agent concentration level ........................30

2

Contents

Venting the cleaning agent dispensing system ........................31

Programming the rinsing agent dosage (DOS 2) .........................31

Setting the rinsing agent dispensing method..........................31

Setting the rinsing agent concentration level .........................32

Venting the rinsing agent dispensing system..........................32

Programming the temperatures and duration ............................33

Altering the wash temperature .....................................33

Altering the offset final rinse temperature.............................33

Setting the final rinse duration .....................................34

Programming the buzzer ............................................35

Setting the buzzer...............................................35

Deactivating the buzzer ..........................................35

Altering the programme duration......................................36

Altering the programme duration for the INTENSIVE programme ..........36

Altering the programme duration for the STANDARD programme .........37

Altering the programme duration for the SHORT programme .............37

Resetting the factory default settings ..................................38

Cleaning and care ................................................39

Cleaning the wash cabinet, tank and filter ..............................39

Cleaning the optional filter combination set .............................40

Cleaning the control panel...........................................41

Cleaning the front of the machine .....................................41

Cleaning the rinse arm and the spray arms .............................41

Problem solving guide ............................................42

Other problems ..................................................47

Cleaning the drain pump and non-return valve...........................47

Cleaning the filters in the water inlet ...................................48

After sales service ................................................49

Installation ......................................................50

Electrical connection UK...........................................51

Plumbing........................................................52

Programme overview..............................................54

Technical data ...................................................56

3

Description of the machine

This Miele machine is a commercial

dishwasher with a tank system which is

specially designed for processing

glassware. With its short programme

times and large cleaning capacity, it is

ideally suited for restaurants, pubs,

cafés, guest houses and other

commercial catering establishments.

The dishwasher is fitted as standard

with two built-in dispensing pumps for

cleaning agent and rinsing agent. The

respective containers for the chemicals

are integrated into the machine behind

the service panel. A funnel is supplied

with the dishwasher to help fill the

containers.

Where the water hardness level is ü 0.7

mmol/l (4 °d - German scale) an

external water softener unit, e.g. the

G 7897 Aqua-soft system, will need to

be fitted.

Optional conversion kits

The following conversion kits are

available from the Miele Spare Parts

Dept.:

A conversion kit to connect an

–

external cleaning agent container to

the built-in cleaning agent

dispensing pump.

A conversion kit to connect an

–

external rinsing agent container to

the built-in rinsing agent dispensing

pump.

A conversion kit for connecting the

–

built-in cleaning agent tank to the

built-in rinsing agent pump if an

external cleaning agent container is

being used.

– A filter combination set is available

for use where soiling levels are very

high. See "Cleaning and care" for

further details.

All of the above conversion kits must be

fitted by a Miele service technician.

4

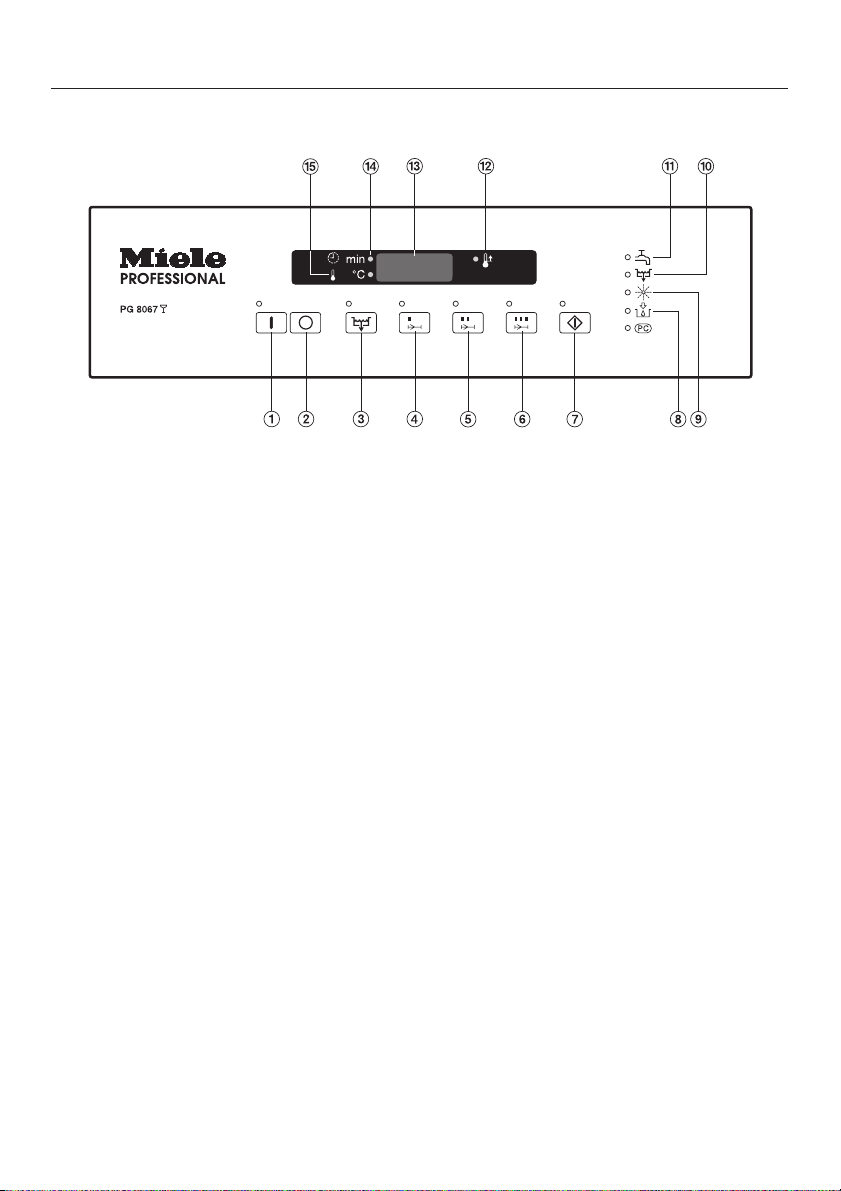

Control panel

Guide to the machine

a On button g

b Off button o

c DRAIN / SELF CLEANING button 6

d SHORT programme button \

e STANDARD programme button ]

f INTENSIVE programme button ^

g Start button h.

h "Add liquid cleaning agent"

indicator light v *)

i "Add rinsing agent"

indicator light H *)

j "Drain fault" indicator light 6

k "Inlet fault" indicator light p

l "Boiler heating" indicator light Y

m Display

n "Time values" showing in the display

indicator light j

o "Temperature values" showing in the

display indicator light

*) Indicator light for retrospectively

fitted external DOS modules

5

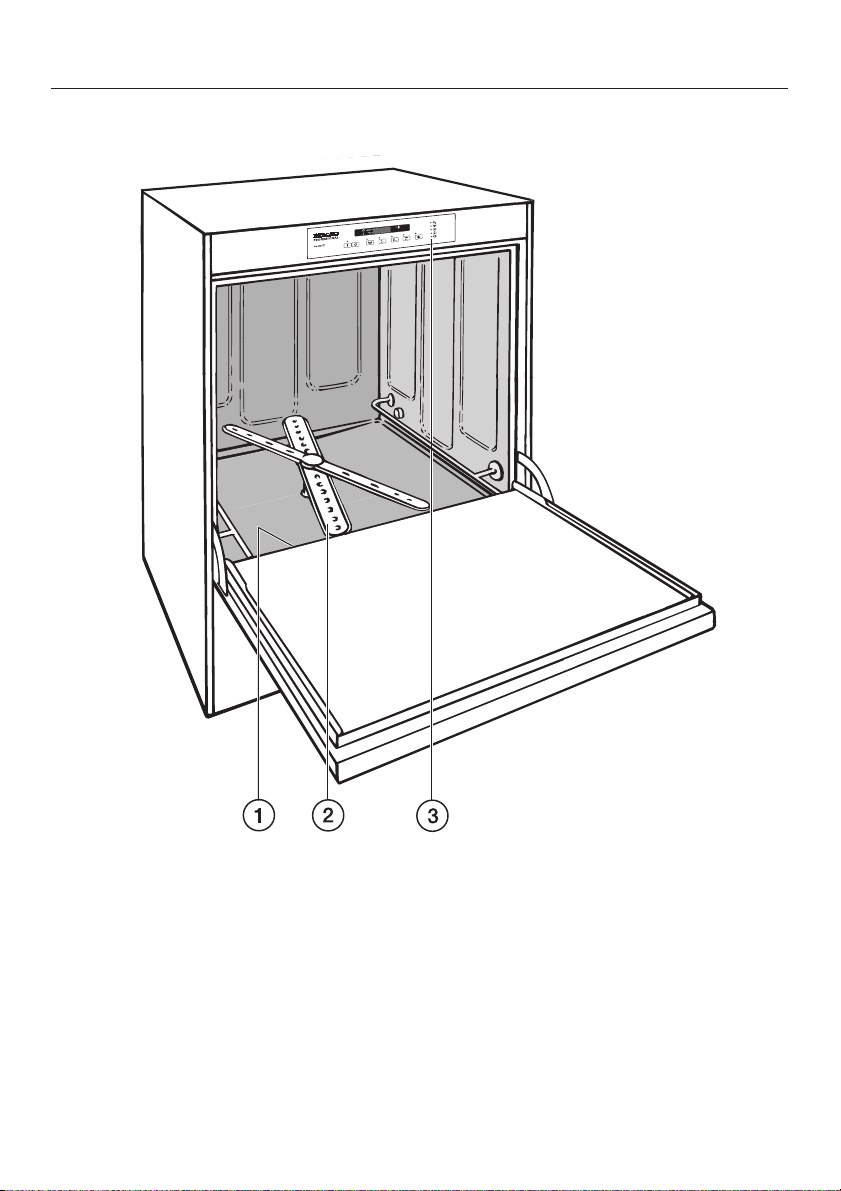

Guide to the machine

Machine overview

a Filter

b Cleaning arm combination (spray arm on top, and rinse arm underneath)

c Control panel

6

PG 8067

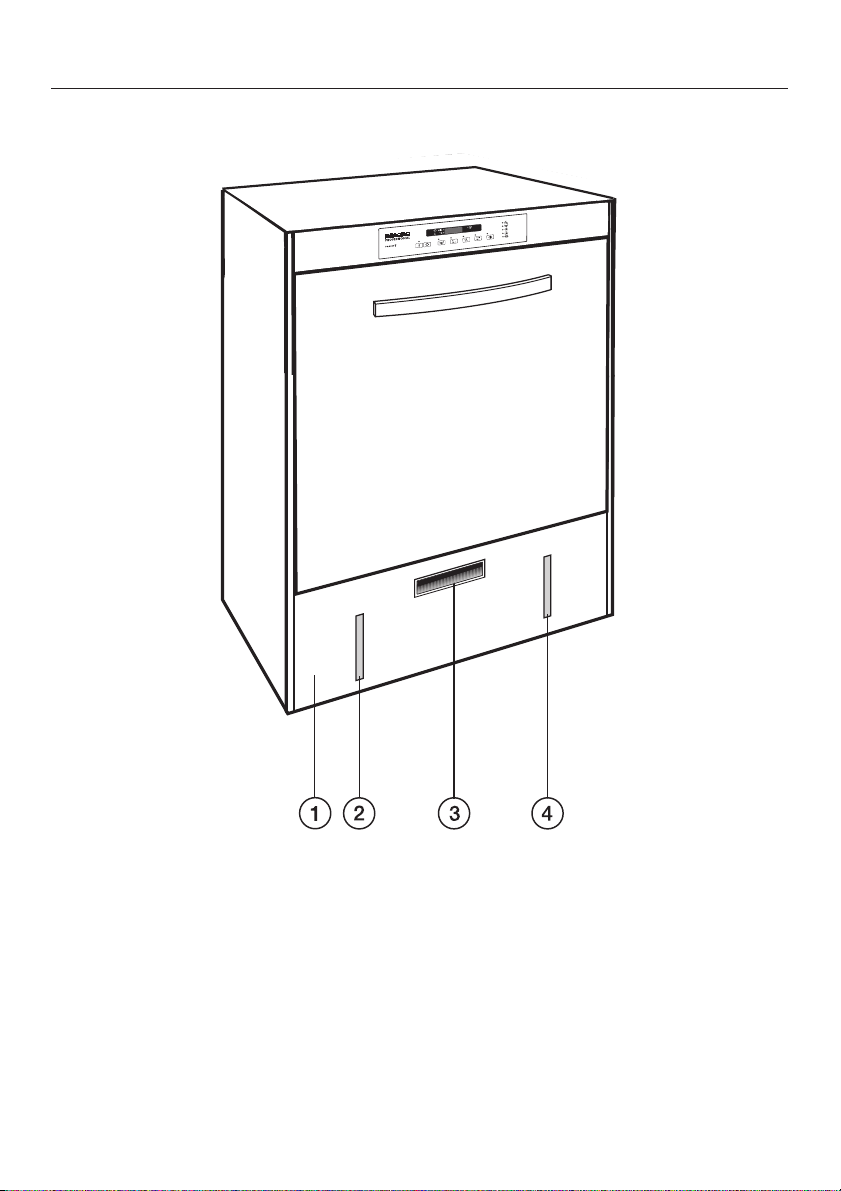

Guide to the machine

a Service panel

b Cleaning agent level indicator

c Handle for opening the service panel

d Rinsing agent level indicator

7

Warning and safety instructions

Personnel operating the machine

This machine complies with all

relevant legal safety requirements.

Incorrect use can, however, lead to

personal injury and damage to

property.

To avoid the risk of accidents and

damage to the machine please read

these instructions carefully before

starting to use it.

They contain important notes on the

installation, safety, operation and

care of the machine.

Keep these instructions in a safe

place and pass them on to any

future user.

Correct application

This machine is designed for

~

cleaning glassware only, as described

in these instructions. Alterations to the

machine, or using it for purposes other

than those for which it is designed, are

unauthorised and could be dangerous.

The manufacturer cannot be held liable

for damage caused by improper or

incorrect use of the machine.

~

should be trained regularly. Untrained

personnel should not be allowed

access to the machine or its controls.

The special inserts should only be

~

used for their specific application.

Technical safety

Before setting up the machine

~

check it for any externally visible

damage. Under no circumstances

should you use a damaged

dishwasher. A damaged dishwasher

may be dangerous.

The electrical safety of this machine

~

can only be guaranteed if connected to

a correctly installed earthing system on

site. It is most important that this basic

safety requirement is present and

regularly tested, and where there is any

doubt the on-site wiring system should

be inspected by a qualified electrician.

The manufacturer cannot be held liable

for damage or injury caused by the lack

of or inadequacy of an effective

earthing system (e.g. electric shock).

This machine is not intended for use

~

by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been

given supervision or instruction

concerning use of the machine by a

person responsible for their safety.

8

Warning and safety instructions

Please follow the advice on

~

installation in these instructions and the

separate Installation drawing.

Before connecting the machine to

~

the mains supply, make sure the rating

on the data plate corresponds to the

voltage and frequency of the on-site

supply. Consult a qualified electrician if

in any doubt.

A damaged machine is dangerous.

~

Switch off at the mains immediately and

call the Miele Service Department or an

authorised Miele Service Dealer.

Installation, maintenance and

~

repairs should only be carried out by a

suitably qualified and competent

person in accordance with local and

national safety regulations.

Repairs and other work by unqualified

persons could be dangerous and the

manufacturer will not be held liable.

Ensure current is not supplied to the

machine until after installation,

maintenance or repair work has been

carried out.

If the connection cable is damaged,

~

the new cable must be fitted by a Miele

approved service technician.

This machine should be

~

commissioned and then maintained by

a Miele authorised and trained service

technician or other suitably qualified

and competent approved person.

Repairs and other work by unqualified

persons could be dangerous.

The machine must be disconnected

~

from the mains electricity supply before

any maintenance or repair work is

carried out. Do not reconnect it until the

maintenance or repair work has been

successfully completed.

For safety reasons, this machine

~

may only be used when it has been

fully installed.

Never open the housing of the

~

machine. Tampering with electrical

connections or components and

mechanical parts is highly dangerous

to the user and can cause operational

faults.

Faulty components must only be

~

replaced by genuine Miele original

parts. The manufacturer can only

guarantee the safety of the appliance

when Miele replacement parts are

used.

Do not connect the machine to the

~

mains electricity supply by a

multi-socket unit or an extension lead.

These do not guarantee the required

safety of the machine (e.g. danger of

overheating).

In countries where there are areas

~

which may be subject to infestation by

cockroaches or other vermin, pay

particular attention to keeping the

appliance and its surroundings in a

clean condition at all times. Any

damage which may be caused by

cockroaches or other vermin will not be

covered by the guarantee.

9

Warning and safety instructions

During installation, maintenance and

~

repair work, the machine must be

disconnected from the mains electricity

supply. It is only completely isolated

from the electricity supply when:

the mains fuse is disconnected,

–

the screw-out fuse is removed (in

–

countries where this is applicable),

or it is switched off at the isolator.

–

Ensure that current is not supplied to

the appliance until after maintenance

or repair work has been carried out.

Correct use

Take great care when handling

~

liquid agents and additives. These may

contain irritant or corrosive ingredients.

Do not use organic solvents as these

could cause an explosion.

Follow all relevant safety procedures

carefully. Wear protective gloves and

goggles. With all chemical agents, the

manufacturer's safety instructions must

be observed.

The water in the machine must not

~

be used as drinking water.

Only use detergents formulated for

~

commercial dishwashers. Do not use

washing up liquid. The use of

unsuitable cleaning agents could

adversely affect the components of the

machine, as well as items being

cleaned.

Only use low-foaming cleaning

~

agents. Incorrect cleaning agents, as

well as some types of soiling can cause

a build-up of foam in the machine.

Foam can have an adverse effect on

the cleaning process.

Please be aware that changes in

~

formulation, storage conditions etc,

which may not be publicised by the

chemical producer, can have a

negative effect on the cleaning result.

When using cleaning agents and

~

specialised products, it is essential that

the manufacturer's instructions are

followed. Only use such chemicals for

the purpose and in the situation

specifed, to the exclusion of other

chemicals, to avoid such dangers as

chemical reactions and material

damage.

10

Warning and safety instructions

The machine is designed for

~

operation with water and additive

cleaning agents only. Organic solvents

must not be used in this machine, as

there is the danger under certain

circumstances of explosion. (Although

this is not the case with all organic

solvents, other problems could arise

with their use, for example damage to

rubber and synthetic materials).

Do not allow any remains of acids or

~

solvents, and in particular hydrochloric

acid or chloride solutions, to get into

the wash cabinet. Similarly avoid any

materials with a corrosive effect.

The presence in compounds of any

solvents should be minimal (especially

those in hazard class A1).

Never clean the machine or near

~

vicinity with a water hose or pressure

washer.

To avoid any corrosion damage,

~

ensure that solutions or steam

containing hydrochloric acid do not

come into contact with the steel outer

casing of the machine.

After any plumbing work, the water

~

pipework to the machine will need to be

vented.

If this is not done, the softener system

could suffer damage.

While the appliance is under

~

guarantee, repairs should only be

undertaken by a service technician

authorised by the manufacturer.

Otherwise the guarantee will be

invalidated.

Do not sit or lean on the opened

~

door. This could cause the machine to

tip up and be damaged or cause an

injury.

Be careful when sorting items with

~

sharp pointed ends and positioning

them in the machine that you do not

hurt yourself or create a danger for

others. Sharp knives, forks etc. should

be placed in baskets with the pointed

ends facing downwards.

When using this machine in the

~

higher temperature ranges be

especially careful not to scald or burn

yourself when opening the door.

Baskets and inserts must be allowed to

cool down before they are unloaded.

Any water remaining in containers

could still be very hot. Empty them into

the wash cabinet before taking them

out.

Do not touch the heating elements

~

or the heated surfaces on the wash

cabinet floor during or directly after the

end of a programme. You could burn

yourself. They remain hot for some time

after the end of the programme.

Empty any containers or utensils

~

before arranging them in the machine.

11

Warning and safety instructions

Installation

This machine may only be used in

~

mobile installations such as ships,

caravans, aircraft etc. if a risk

assessment of the installation has been

carried out by a suitably qualified

engineer.

Do not install the machine in an area

~

where there is any danger of explosion

or of freezing conditions.

Safety with children

This machine is not a toy! Keep

~

children away from it at all times and

supervise them whilst you are using it.

They will not understand the potential

dangers posed by it. For instance,

whilst playing they could inadvertently

shut themselves inside it.

Older children should only be

~

allowed to use it unsupervised if its

operation has been clearly explained to

them and they are able to use it safely,

recognising the dangers of misuse.

Accessories

Only use genuine Miele spare parts

~

and accessories with this machine. If

spare parts or accessories from other

manufacturers are used, this will

invalidate the guarantee, and Miele

cannot accept liability.

They must be suitable for the

~

purpose they are being used for.

Consult Miele for advice.

12

Warning and safety instructions

Disposing of an old

dishwasher

For environmental and safety

~

reasons ensure the machine is

completely drained of any residual

water and cleaning agent. (Observe

safety regulations and wear safety

goggles and gloves).

Make the door lock inoperable, so that

children cannot accidentally shut

themselves in. Then make appropriate

arrangements for the safe disposal of

the machine.

For tank system machines ensure that

any water is emptied out of the tank.

The manufacturer cannot be held

liable for damage caused by

non-compliance with these Warning

and safety instructions.

13

Caring for the environment

Disposal of the packing

material

The transport and protective packing

has been selected from materials which

are environmentally friendly for

disposal, and can normally be

recycled.

Ensure that any plastic wrappings,

bags, etc. are disposed of safely and

kept out of the reach of babies and

young children. Danger of suffocation!

Rather than just throwing these

materials away, please ensure that they

are offered for recycling.

Disposal of your old machine

Electrical and electronic appliances /

machines often contain materials

which, if handled or disposed of

incorrectly, could be potentially

hazardous to human health and to the

environment. They are, however,

essential for the correct functioning of

your appliance or machine. Please do

not therefore dispose of your old

machine or appliance with your

household waste.

Please dispose of it at your local

community waste collection / recycling

centre and ensure that it presents no

danger to children while being stored

for disposal.

14

It should be unplugged or disconnected

from the mains electricity supply by a

competent person.

Before using the machine for the first

time, the following steps must be

carrried out.

Each step is described in more

detail in the appropriate section

further on in the booklet.

Before using for the first time

Only use detergents formulated for

commercial dishwashers

Do not use washing up liquid or

detergents formulated for domestic

dishwashers.

Adding cleaning agent

Load the machine carefully

Arrange the load so that water will

come into contact with all surfaces.

Concealed surfaces will not be

cleaned.

The rinse and spray arms must not be

blocked by any items.

Follow the cleaning agent

manufacturer's recommendations on

dosage.

The amount required will depend on the

type of cleaning agent used and the

programme selected.

Cleaning results may vary from brand

to brand. If you are not satisfied with

the results from one brand, try another

quality glass cleaner for commercial

dishwashers before contacting Miele

for advice.

The filter combination in the floor of

the wash cabinet and also the rinse

and spray arms must be kept clean.

It is therefore absolutely essential to

check and clean them regularly.

15

Opening and closing the door

To open the door

Grasp the handle and open the door.

^

The door should only be opened during

operation for emergencies, e.g. if

articles are knocking together or if a

programme fault is indicated in the

display (see "Cancelling a

programme").

Do not touch the inside of the

,

cabinet or the heated surfaces

during or directly after the end of a

programme. You could burn

yourself. They remain hot for some

time after the end of the programme.

To close the door

Lift the door upwards and push until

^

it clicks shut.

16

Adding rinsing agent

Rinsing agent is necessary to ensure

water does not cling and leave marks

on items during the drying phase, and

to help items dry faster after they have

been washed.

Rinsing agent is poured into the

storage container, and the amount set

is dispensed automatically in the final

rinse.

Preferably, use rinsing agent for

commercial dishwashers that is

specially formulated for glassware.

This dishwasher is fitted as standard

with a built-in dispensing pump and

rinsing agent container.

The container is located inside the right

hand side of the service panel. It holds

approx. 250 ml.

The rinsing agent level indicator is in

the right-hand viewing window on the

outside of the service panel.

Rinsing agent level indicator

Fill the rinsing agent container when the

indicator on the right of the service

panel shows there is insufficient rinsing

agent.

17

Adding rinsing agent

Grasp the service panel handle and

^

open the panel.

^ Take the red cap off the filler spout.

^ Fill the container with rinsing agent,

using the funnel supplied.

^ Replace the red cap and close the

service panel.

^ Rinse out the funnel.

External rinsing agent

container (optional extra)

A Miele service technician can

retrospectively fit an external rinsing

agent container to this dishwasher by

means of a siphon tube.

The rinsing agent level indicator for the

external container is on the control

panel.

Place the rinsing agent container on

^

the floor next to the commercial

dishwasher, or in a nearby cupboard

or on a wall bracket.

The wall bracket is available from the

Miele Spare Parts Department.

Add rinsing agent indicator

On no account must cleaning agent

and rinsing agent be mixed.

18

The rinsing agent container must be

refilled when the Add rinsing agent

indicator light H on the control panel

comes on.

Adding rinsing agent

Fill the container with rinsing agent or

^

replace it with a new one.

^ Insert the siphon tube in the opening

at the top of the container and push it

down until it touches the bottom of

the container. Then screw it on

securely. Make sure you follow the

colour code.

Replenish the container in good

time. It should never be allowed to

get completely empty.

Adding rinsing agent and venting the

dispensing system

See "Programming functions" for setting

the dosage amount and venting the

dispensing system.

You should not start a programme

until after the dispensing system has

been vented.

19

Areas of application

Loading the machine

Preparing the load

Remove coarse residues and empty all

containers before loading into the

machine.

Please note:

Load items so that water will come

–

into contact with all surfaces. This

ensures that they will be properly

cleaned.

Do not place items to be cleaned

–

inside other pieces where they may

be concealed.

– Hollow vessels such as cups,

glasses, jugs etc. should be inverted

and placed in the correct inserts.

The water must be able to access

them unhindered.

– Deep-sided items should be placed

at an angle to make sure water runs

off them freely.

–

Tall, narrow, hollow items should be

placed in the centre of the baskets to

ensure better water coverage.

–

The rinse and spray arms must not

be blocked by items which are too

tall or which hang down in their path.

If in doubt, test for free movement by

manually rotating the arms.

Select baskets and inserts which are

appropriate for the application.

20

Items that are not suitable for

dishwashers

Cutlery with wooden or horn handles.

–

Wooden or plastic cutting boards.

–

Heat sensitive plastic items (see

–

"Programmes with reduced final rinse

temperature").

Items such as old knives with

–

handles which have been glued on.

Hand-made craft items.

–

Copper or tin items.

–

Please note:

– Silver and aluminium items can

become discoloured.

– Clouding may occur on glasses after

frequent washing.

Areas of application

21

Areas of application

Loading examples

The commercial dishwasher can be

loaded with one basket per cycle. The

basket used depends on the size and

shape of the glasses to be washed.

For information about the range of

baskets available, please contact your

supplier.

The following illustrations show the

most popular baskets with examples of

loading different types of glassware.

U 545 plastic basket divided 5x5 for

glasses

In this example, the plastic basket is

connected to the top frame with

extension pieces. It is designed to hold

25x 200 to 230 mm tall glasses. The

base dimensions for each section are

90x90mm.

U 525 mesh basket with five sections

The mesh basket is for glassware up to

80 mm in diameter.

22

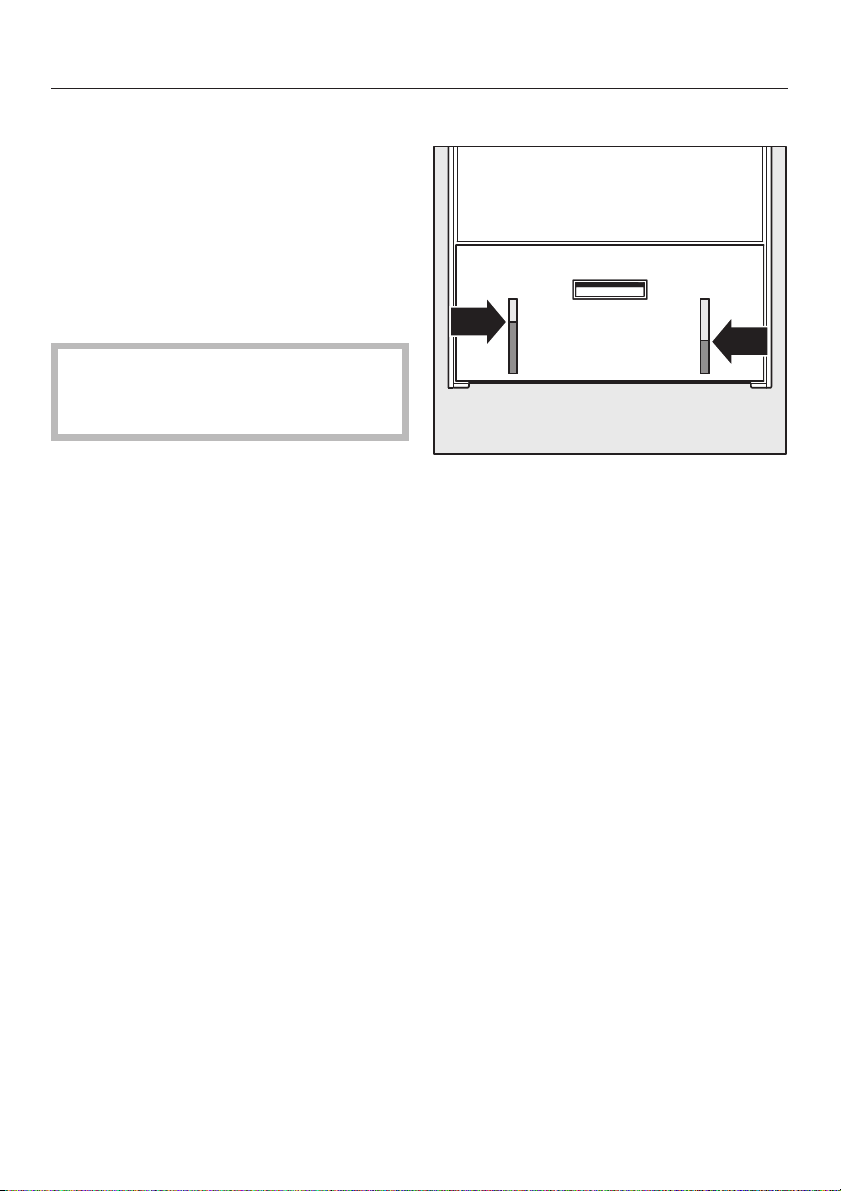

To assemble the plastic basket

The height of basket d can be

modified using frame a together with

either long extension pieces b or short

extension pieces c.

^ Insert all four extension pieces into

basket d.

Areas of application

^ Fit frame a securely onto the

extension pieces.

23

Adding cleaning agent

Only use a specialist glass

,

cleaning agent formulated for

commercial dishwashers. Do not

use washing up liquid or detergents

formulated for domestic

dishwashers.

Some types of soiling may require

different combinations of cleaning

agents and other additives. Please

contact Miele should you require advice.

Liquid cleaning agent can be

dispensed via the built-in container

inside the service panel.

Adding liquid cleaning agent:

The commercial dishwasher is fitted as

standard with a built-in dispensing

pump and cleaning agent container.

The container is located inside the left

hand side of the service panel. It holds

approx. 1300 ml.

Add cleaning agent indicator

Fill the cleaning agent container when

the indicator on the left of the service

panel shows there is insufficient

cleaning agent.

The cleaning agent level indicator is in

the left-hand viewing window on the

outside of the service panel.

24

Adding cleaning agent

Grasp the service panel handle and

^

open the panel.

^ Take the blue cap off the filler spout.

^ Fill the container with cleaning agent,

using the funnel supplied.

^ Replace the blue cap and close the

service panel.

^ Rinse out the funnel.

External cleaning agent

container (optional extra)

A Miele service technician can

retrospectively fit an external cleaning

agent container to this dishwasher by

means of a siphon tube.

The cleaning agent level indicator for

the external container is on the control

panel.

Place the cleaning agent container

^

on the floor next to the commercial

dishwasher, or in a nearby cupboard

or on a wall bracket.

The wall bracket is available from the

Miele Spare Parts Department.

Add cleaning agent indicator

On no account must cleaning agent

and rinsing agent be mixed.

The container must be refilled with

liquid cleaning agent when the Add

cleaning agent indicator light v on the

control panel comes on.

25

Adding cleaning agent

Fill the container with cleaning agent

^

or replace it with a new one.

^ Insert the siphon tube in the opening

at the top of the container and push it

down until it touches the bottom of

the container. Then screw it on

securely. Make sure you follow the

colour code.

Replenish the container in good

time. It should never be allowed to

get completely empty.

Maintenance of the dispensing

system

To ensure trouble-free operation,

regular maintenance should be carried

out at specified intervals by a Miele

approved service technician.

Every 1 to 1½ years

Replace the hoses on the commercial

dishwasher.

Take great care when handling

,

liquid agents and additives. These

may contain irritant or corrosive

ingredients.

Please follow the manufacturer's

safety instructions.

Wear protective gloves and

goggles.

26

Operation

Preparing the machine

Close the door.

^

Open the stopcock.

^

Press the On button g to switch the

^

dishwasher on.

All the programme button indicator

lights will light up.

^ Press the programme button for the

programme you want.

(See "Programme chart").

The boiler and tank will now fill with

water, and the water will start to heat

up. This takes approx. 15-20 mins.

The time remaining will show in the

display.

The Boiler heating indicator { lights up

whilst the water is heating up.

If the door is opened during this

heating up phase, an audible tone

(buzzer) will sound after five

minutes. The tone will not stop until

the door is closed.

When the boiler and tank are full and

the operating temperature has been

reached, the indicator light next to the

Start button h will flash, and the

duration for the programme selected

will appear in the display in minutes.

The dishwasher is now ready to use.

^ Open the door.

Caution - the water or steam in

,

the wash cabinet will be hot. Danger

of burning or scalding.

^ Push the basket with the items to be

washed into the dishwasher.

^

Close the door.

27

Operation

Selecting a programme

Choose your programme according to

the type of load and the degree of

soiling.

The different programmes and their

uses are described in the programme

chart at the end of this booklet.

The programme selected will remain in

memory for the duration of the

operating session.

Starting a programme

^ Press the Start button h.

The indicator lights next to the Start

button and the relevant programme

button will light up.

During the programme, the time left

until the end of the programme is

displayed. The j indicator light will

come on.

At the end of a programme

0 will appear in the display when the

programme has finished.

See "Programmable functions" for

instructions on how to activate the

buzzer function so that the buzzer will

sound at the end of a programme.

^

Open the door and unload the

machine.

Changing a programme

Provided the Start button has not yet been

pressed, a wrongly selected programme

may be changed as described below (if it

has been pressed, see "Cancelling a

programme"):

Press the programme button for the

^

programme you want.

Press the Start button h.

^

Cancelling a programme

Once a programme is running it should only

be cancelled in extreme cases, e.g. when

articles in the machine rattle or jostle against

each other and have to be rearranged.

^ Press the Start button h for approx. 3

seconds.

The programme will be cancelled.

^ Open the door.

,

Caution. Water and items in the

machine may be hot. Danger of burning

or scalding.

^

Rearrange the load.

^

Close the door.

^

Press the Start button h again.

The programme will start again.

Switching off

28

^

Press the DRAIN 6 button.

^

Press the Start button h.

The water will drain away.

When the DRAIN programme has finished:

^

Press the Off button o.

For future servicing work, please

document any alterations to the stan

dard factory settings.

Enter any alterations in the relevant

Value set: box.

Programmable functions

Saving changes to memory

All changes carried out in a

programming level, need to be saved

to memory. To do so:

Press the Start button h.

^

Altering programmable function

settings or venting the dispensing

system causes the machine to drain

automatically. In order to save energy

and time, these tasks should be carried

out when the tank is empty.

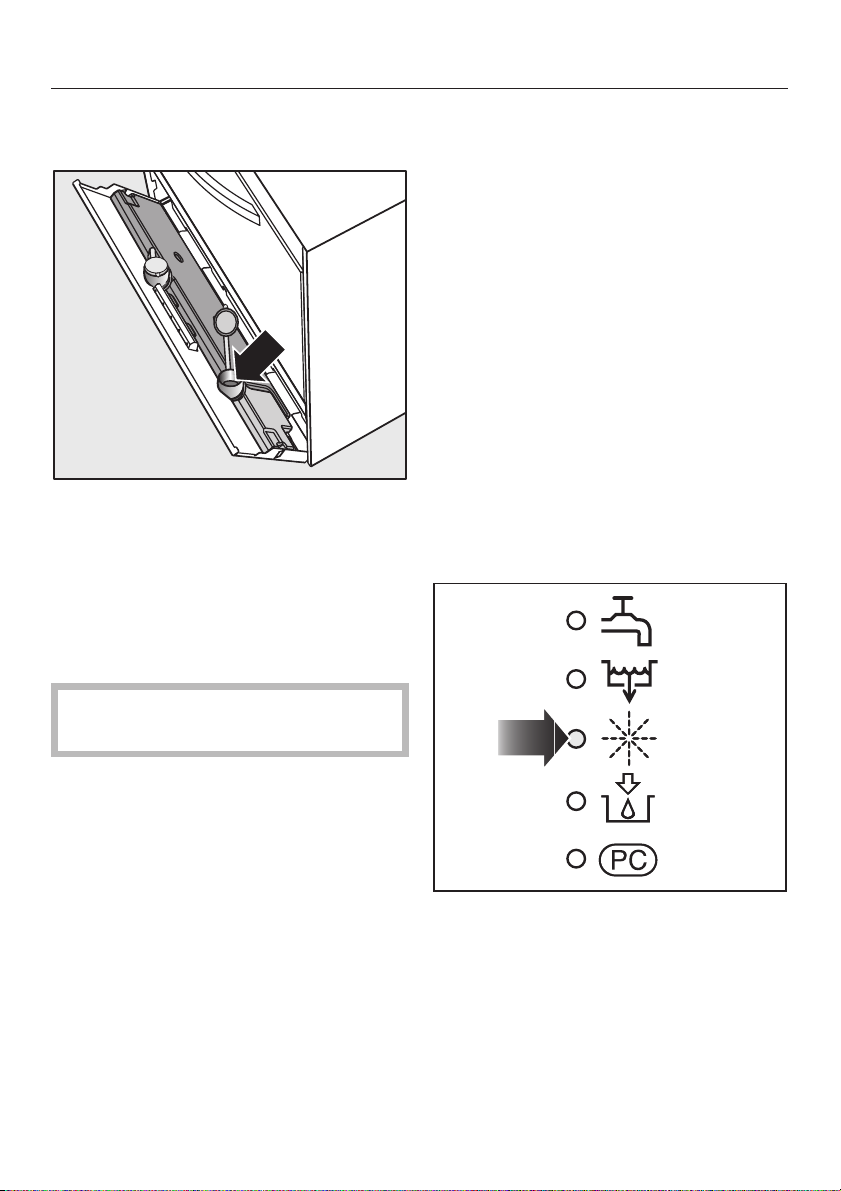

Calling up programming levels

The individual programmable functions

are called up via various programming

levels. Calling up a programming level

always happens in the following way:

^ Switch the dishwasher off by

pressing the Off button o.

^ Press and hold in the ^ and h

buttons, and at the same time switch

the dishwasher on using the On

button g.

The current programme status P... will

show up in the display.

The p indicator light will come on.

^

Press the programme button \

repeatedly until the programming

level you want appears.

SP will appear in the display.

Press the Start button h again.

^

The new values will then be saved to

memory.

Switch the dishwasher off by

^

pressing the Off button o.

To come out of a programming

level

To come out of a programming level

without saving changes to memory:

^ Press the Off button o.

The changes will be discarded.

2, 3, 4, 5, 6 or 7 will show up in the

display (representing programming

levels 2, 3, 4, 5, 6 or 7).

29

Programmable functions

Programming the cleaning

agent dosage (DOS 1)

The cleaning agent dosage is set using

Programming level 2.

Setting the cleaning agent

dispensing method

The cleaning agent dispensing method

is set via Options 0, 1, 2 or 3. The

Options are as follows:

0 = powder cleaning agent (not for

glasses), placed on the inside of the

door,

1 = liquid cleaning agent dispensed via

the built-in dispensing pump,

2 = this Option is not available on this

dishwasher,

3 = liquid cleaning agent dispensed via

the built-in dispensing pump from an

external container,

^ Press the SHORT programme button

\ twice.

2 will appear in the display

(Programming level 2).

^

Press the STANDARD programme

button ] once.

2.01 will appear in the display.

^

Press the INTENSIVE programme

button ^ once.

Setting the cleaning agent

concentration level

If the dispensing method in the

dishwasher has been programmed for

liquid cleaning agent, the concentration

can then be set.

Set the concentration level

according to the manufacturer's

recommendations.

Press the SHORT programme button

^

\ twice.

2 will appear in the display

(Programming level 2).

^ Press the STANDARD button ]

repeatedly until 2.02 appears in the

display.

^ Press the INTENSIVE button ^.

The liquid cleaning agent dosage

concentration will appear, displayed as

a%:

0.00 - 1.00 =0.0%-1%

Dosage concentration ex works is:

0.20 = 0.2 %).

^

Press the INTENSIVE button ^

repeatedly or hold pressed in until

the required value appears in the

display.

The dosage concentration level has

now been set.

Option 0, 1, 2, or 3 will appear in the

display

^

Press the INTENSIVE programme

button ^ repeatedly until the

cleaning agent dispensing method

you want appears.

30

Value set:

Example: If the cleaning agent

manufacturer recommends a cleaning

agent concentration of 0.5%, a value of

0.50 should be set.

Programmable functions

Venting the cleaning agent

dispensing system

The cleaning agent dispensing system

is vented as follows:

Press the SHORT programme button

^

\ twice.

2 will appear in the display

(Programming level 2).

Press the STANDARD button ] until

^

2.03 appears in the display.

Press the INTENSIVE button ^.

^

do1 will appear in the display.

^ Press the INTENSIVE button ^

again.

The dispensing system will be vented

automatically. 0 will appear in the

display when the venting process has

finished.

Programming the rinsing agent

dosage (DOS 2)

The rinsing agent dosage is set using

Programming level 3.

Setting the rinsing agent dispensing

method

The rinsing agent dispensing method is

set via Options 0 or 1. The Options are

as follows:

0 = Built-in pump with external

container,

1 = Built-in pump and container.

^ Press the SHORT programme button

\ 3 times.

3 will appear in the display

(Programming level 3).

^ Press the STANDARD programme

button ] once.

3.01 will appear in the display.

^ Press the INTENSIVE button ^.

Either 0 or 1 will appear in the display.

^

Press the INTENSIVE programme

button ^ repeatedly until the rinsing

agent dispensing method you want

appears.

31

Programmable functions

Setting the rinsing agent

concentration level

Set the concentration level

according to the manufacturer's

recommendations.

Press the SHORT programme button

^

\ 3 times.

3 will appear in the display

(Programming level 3).

Press the STANDARD button ] until

^

3.02 appears in the display.

^ Press the INTENSIVE button ^.

The liquid cleaning agent dosage

concentration will appear, displayed as

a%:

000 - 100 = 0.0 % - 0.1 %

Dosage concentration ex works is:

030 = 0.03 %.

^ Press the INTENSIVE button ^

repeatedly or hold pressed in until

the required value appears in the

display.

Venting the rinsing agent dispensing

system

Press the SHORT programme button

^

\ 3 times.

3 will appear in the display

(Programming level 3).

Venting the rinsing agent dispensing

system:

Press the STANDARD button ] until

^

3.03 appears in the display.

Press the INTENSIVE button ^.

^

do2 will appear in the display.

^ Press the INTENSIVE button ^

again.

The dispensing system will be vented

automatically. 0 will appear in the

display when the venting process has

finished.

The dosage concentration has now

been set.

Value set:

Example: If the manufacturer

recommends a concentration level of

0.03 %, a value of 030 should be set.

32

Programmable functions

Programming the

temperatures and duration

The main wash temperature, final rinse

temperature and final rinse duration are

set in Programming level 4.

Please make a note of any changes

to the main wash and final rinse

temperatures and/or the final rinse

duration in the appropriate column of

the programme chart.

The factory default settings for the main

wash and final rinse temperatures and

for the final rinse duration are given in

the programme chart.

Altering the wash temperature

A main wash temperature of

20 °C - 65 °C can be set in

Programming level 4.

^ Press the SHORT programme button

\ 4 times.

4 will appear in the display

(Programming level 4).

^

Press the STANDARD programme

button ] until 4.01 appears in the

display.

^

Press the INTENSIVE programme

button ^ once.

Altering the offset final rinse

temperature

The final rinse temperature is linked to

the main wash temperature. It is set as

standard at 5°C above the main wash

temperature (offset). The offset range

for the final rinse temperature is from

5°C to 25°C.

Press the SHORT programme button

^

\ 4 times.

4 will appear in the display

(Programming level 4).

Press the STANDARD programme

^

button ] until 4.02 appears in the

display.

^ Press the INTENSIVE button ^.

The current offset final rinse

temperature will show in the display,

e. g. 5 The factory default setting for

the offset final rinse temperature is

5 °C.

^ Press the INTENSIVE programme

button ^ repeatedly until the

temperature you want appears.

Example:

Main wash temperature = 60°C

Offset final rinse temperature = 5°C

Final rinse temperature = 65°C.

The current wash temperature will show

in the display, e. g. 60. The factory

default setting is 60 °C.

^

Press the INTENSIVE programme

button ^ repeatedly or hold pressed

in until the required temperature

appears in the display.

33

Programmable functions

Setting the final rinse duration

The final rinse duration for all wash

programmes can be set between 3 and

10 seconds.

Press the SHORT programme button

^

\ 4 times.

4 will appear in the display

(Programming level 4).

Press the STANDARD programme

^

button ] until 4.03 appears in the

display.

Press the INTENSIVE programme

^

button ^.

The current final rinse temperature will

show in the display, e. g. 6.0. The

setting will appear in tenths of a second

steps. The factory default setting is 6

seconds (6.0).

^ Press the INTENSIVE programme

button ^ repeatedly or hold pressed

in until the required final rinse

duration appears in the display.

34

Programming the buzzer

Programming level 5 allows you to

activate a buzzer to sound when:

a programme has finished = a

–

reminder tone

a fault has occurred = an alarm tone

–

the door is opened = an alarm tone

–

It is not possible to deactivate the

buzzer when the door is open.

Programmable functions

Press the STANDARD programme

^

button ] until 5.01 appears in the

display.

Press the INTENSIVE programme

^

button ^ once.

The current function will show in the

display, e. g. 0 (the factory default

setting).

Press INTENSIVE programme button

^

^ repeatedly until opton 0, 1, 2,or3

appears in the display.

Setting the buzzer

The buzzer is set in Programming level

5 using Options 0, 1, 2 or 3. The

Options are as follows:

0 = Buzzer is switched off

(factory default setting)

1 = Buzzer will sound at the end of a

programme

2 = Buzzer will sound when a fault

has occurred

3 = Buzzer will sound when a fault

has occurred and at the end of a

programme

^

Press the SHORT programme button

\ 5 times.

5 will appear in the display

(Programming level 5).

Value set:

Deactivating the buzzer

The buzzer at the end of a programme

can be switched off as follows:

^ Press the Off button o (disconnect

power supply), or

^ Open door at the end of the

programme.

The alarm tone denoting that there is a

fault can be switched off as follows:

^

Press the Start button h (Fault

confirmation for F0E, F2E), or

^

Press the Off button o (disconnect

the power supply).

If the fault has not been rectified, the

buzzer will start again after power

has been restored.

35

Programmable functions

Altering the programme

duration

The duration of the main wash can be

altered in Programming level 6.

You can set the programme duration in

a range from 60 seconds to 480

seconds.

The SHORT programme will always be

shorter than the STANDARD

programme, and the INTENSIVE

programme longer than the STANDARD

programme.

If you wish to lengthen the programme

duration of every programme, then start

with the INTENSIVE programme.

Altering the programme duration for

the INTENSIVE programme

Press the SHORT programme button

^

\ 6 times.

6 will appear in the display

(Programming level 6).

Press the STANDARD programme

^

button ] until 6.03 appears in the

display.

Press the INTENSIVE programme

^

button ^ once.

The current programme duration will

show in the display, e. g. 120. The

factory default setting is 120 seconds.

^ Press the INTENSIVE programme

button ^ repeatedly or hold pressed

in until the required programme

duration appears in the display. The

duration is set in 5 second stages.

36

Programmable functions

Altering the programme duration for

the STANDARD programme

Press the SHORT programme button

^

\ 6 times.

6 will appear in the display

(Programming level 6).

Press the STANDARD programme

^

button ] until 6.02 appears in the

display.

Press the INTENSIVE programme

^

button ^ once.

The current programme duration will

show in the display, e. g. 90. The

factory default setting is 90 seconds.

^ Press the INTENSIVE programme

button ^ repeatedly or hold pressed

in until the required programme

duration appears in the display. The

duration is set in 5 second stages.

Altering the programme duration for

the SHORT programme

Press the SHORT programme button

^

\ 6 times.

6 will appear in the display

(Programming level 6).

Press the STANDARD programme

^

button ] until 6.01 appears in the

display.

Press the INTENSIVE programme

^

button ^ once.

The current programme duration will

show in the display, e. g. 60. The

factory default setting is 60 seconds.

^ Press the INTENSIVE programme

button ^ repeatedly or hold pressed

in until the required programme

duration appears in the display. The

duration is set in 5 second stages.

37

Programmable functions

Resetting the factory default

settings

You can reset all parameters back to

the factory default settings in

Programming level 7 as follows:

call up the factory default setting,

–

then confirm the factory default

–

setting.

Press the SHORT programme button

^

\ 7 times.

7 will appear in the display

(Programming level 7).

To call up the factory default setting:

^ Press the STANDARD programme

button ] until 7.01 appears in the

display.

^ Press the INTENSIVE programme

button ^.

If you select the 00 setting by

mistake, you can still call up your

own customised settings again by

selecting the PP setting.

Press the INTENSIVE programme

^

button ^ to switch between the 00

and pp settings.

To confirm the factory default

setting:

Press the Start button 6. SP will

^

appear in the display.

^ Press the Start button h again.

All values which had been changed

have now been reset to the factory

default settings.

^ Switch the dishwasher off by

pressing the Off button o.

The current setting will appear in the

display:

–

00 Factory default setting, or

–

PP Programmed value.

^

Press the INTENSIVE programme

button ^ repeatedly until 00 (factory

default setting) appears in the

display.

The factory default settings have now

been called up.

38

Cleaning and care

Cleaning the wash cabinet,

tank and filter

This dishwasher must not be

,

used without the filter in place.

The tank and the filter should be

inspected regularly and cleaned if

necessary. How often they need to be

cleaned will depend on the degree of

soiling and the number of times the

dishwasher is used. However, they

should be cleaned at the end of every

operating session.

Caution:

,

Watch out for glass splinters which

could cause injury.

Cleaning the tank and wash cabinet,

and draining the machine

^ Press the DRAIN/SELF CLEANING

programme button 6.

^

Press the Start button h.

Cleaning the filter

The water in the tank can be hot.

,

The tank must be drained before

removing the filter.

^ Lift the filter out.

^ Clean the filter thoroughly under

running water.

^ Replace the clean filter. Ensure that

the filter sits flat in the base of the

wash cabinet.

The DRAIN programme with integrated

SELF CLEANING will start.

If the cleaning result is not

satisfactory, you can start the

programme again. It will run again

but for a shorter duration.

^

Press the Start button h to start the

DRAIN/SELF CLEANING programme

again.

39

Cleaning and care

Cleaning the optional filter

combination set

Cleaning the flat filters

The water in the tank can be hot.

,

The tank must be drained before

removing the filters.

^ First remove the flat filter at the front.

To do this lift it up a little at the front.

^

Then remove the flat filter at the rear.

To do this lift it up a little at the back.

^

Clean the filters thoroughly under

running water.

^

Replace the filters by carrying out the

above steps in the reverse order.

Make sure that you place the filters

correctly in position. Ensure that the

filters sit flat in the base of the wash

cabinet.

Cleaning the fine filter

The water in the tank can be hot.

,

The tank must be drained before

removing the filters.

Remove the flat filters.

^

^ Turn the fine filter anti-clockwise to

remove it from the sump.

^ Clean the fine filter thoroughly under

running water.

^

Replace the fine filter in the sump

and turn it clockwise to secure it.

Replace the filters by carrying out the

above steps in the reverse order.

Ensure that the filters sit flat in the base

of the wash cabinet.

40

Cleaning and care

Cleaning the control panel

This should only be cleaned with a

^

damp cloth or a suitable cleaner for

use on plastic materials, or with a

disinfectant tested and recognised

as suitable for this use.

Do not use abrasive cleaners,

,

glass cleaners or all-purpose

cleaners.

Because of their chemical

composition they could cause

serious damage to plastic

components.

Cleaning the front of the

machine

^ Clean using a proprietary cleaning

agent designed for the type of front

the machine is fitted with.

,

Do not use cleaning agents

containing ammonia or thinners.

Cleaning the rinse arm and the

spray arms

Waste particles can lodge in the rinse

and spray arm jets.

It is therefore important to inspect the

rinse and spray arms regularly.

Use a sharp pointed object to push

^

particles into the rinse and spray arm

jets, and rinse well under running

water.

Remove the rinse and spray arms as

follows:

^ Unscrew the upper spray arm in the

top of the wash cabinet.

^ Remove the lower basket.

^ First unscrew the lower spray arm,

and then remove the lower rinse arm

from the bottom of the wash cabinet.

Food residues in the lower rinse arm

are easier to rinse out if the caps are

opened first of all.

^

Open the caps in the direction of the

arrow. After cleaning screw them in

again securely.

Important:

After replacing the rinse and spray

arms, check that they rotate freely.

41

Problem solving guide

With the aid of the following guide, minor problems can be easily corrected

without calling in a Miele service technician, saving you both time and money.

The following guide may help you to find the reason for a fault, and to correct it.

You should, however, note the following:

Repairs should only be carried out by a suitably qualified and trained

,

person in strict accordance with current local and national safety regulations.

Unauthorised or incorrect repairs could cause personal injury or damage to the

machine.

Fault Possible cause Remedy

The dishwasher does

not start.

The dishwasher stops

during a programme.

A few minutes after

starting the programme,

the p indicator light

flashes (fault code F..E

appears in the display).

The door is not properly

closed.

The machine is not

switched on at the mains.

The fuse is defective or

has tripped.

The fuse is defective or

has tripped.

The door is not properly

closed.

The stopcock is closed. Open the stopcock fully.

The water inlet filter is

blocked.

The Waterproof system

has reacted.

The water pressure at the

intake is lower than 100

kPa (0.5 bar).

Close the door firmly.

Switch on at the mains.

Reset the fuse.

(Minimum fuse rating see data plate).

Reset the fuse.

(Minimum fuse rating see data plate).

Close the door firmly.

Before rectifying the

problem you must:

–

Switch the dishwasher

off by pressing the Off

button o.

Then:

–

Clean the water inlet

filter. See "Cleaning the

water inlet filter".

Call the Miele Service

Department.

Seek professional advice.

42

Problem solving guide

Problem Possible cause Remedy

The wash cycle finishes

early and the 6

indicator light flashes

(fault code F..A appears

in the display).

Before rectifying the

problem you must:

Switch the dishwasher

–

off by pressing the Off

button o.

The filter in the wash

cabinet is blocked.

The drain pump or

non-return valve may be

blocked.

The drain hose is kinked. Remove any kink in the

Knocking noise in the

wash cabinet.

Rattling noise. Glasses are unstable

Knocking noise in water

pipe.

There are rust stains on

cutlery.

The rinse arm or spray

arm is knocking against a

glass.

inside the wash cabinet.

This may be caused by

the on-site installation or

the cross-section of the

piping.

The affected items are not

corrosion resistant.

Clean the filter. See

"Cleaning and Care".

Clean the drain pump and

the non-return valve. See

"Cleaning the drain pump

and non-return valve".

drain hose.

Interrupt the programme,

and rearrange glasses

that are obstructing the

rinse or spray arms.

Interrupt the programme

and rearrange the glasses

securely.

This has no influence on

dishwasher function. If in

doubt contact a suitably

qualified plumber.

There is no remedy.

Purchase cutlery which is

dishwasher-proof.

43

Problem solving guide

Fault Possible cause Remedy

The glasses are not

clean.

The glasses are not dry

or are flecked.

The glasses were not

loaded correctly. Glasses

were placed inside other

glasses, water could not

access all surfaces.

The programme selected

was not suitable.

Not enough detergent

was dispensed.

Tall glasses are blocking

the path of the rinse or

spray arms.

The jets on the rinse or

spray arms are blocked.

The filter in the wash

cabinet is not clean or is

not correctly fitted.

This may cause the spray

arm jets to get blocked.

The non-return valve is

open and blocked. Dirty

water has flowed back

into the wash cabinet.

The amount of rinsing

agent may be insufficient,

or the rinsing agent

container empty.

See "Loading the

machine".

Select a suitable

programme. See

"Programme chart".

Use more detergent, see

"Programming functions".

Check the rinse and spray

arms by turning them, and

rearrange the load as

required.

Clean the rinse or spray

arm jets. See "Cleaning

and Care".

Clean and/or replace the

filter correctly. Clean the

spray arm jets. See

"Cleaning and Care".

Clean the drain pump and

the non-return valve, see

"Cleaning the drain pump

and non-return valve".

Increase the dosage or

replenish the rinsing

agent container. See

"Programmable functions".

44

Problem solving guide

Fault Possible cause Remedy

The glasses are cloudy

or have a white residue

which can be wiped off.

The glasses are smeary.

Glasses have a blue

tinge. Residues can be

wiped off.

Glasses are dull and

discoloured. Residues

cannot be wiped off.

Tea or lipstick stains

have not been

completely removed.

Plastic items are

discoloured.

Not enough rinse aid was

used.

The rinsing agent dosage

is set too high.

The glasses are not

dishwasher-proof. The

surfaces are affected.

The wash temperature of

the programme selected

was too low.

The bleaching effect of

the detergent used is too

low.

Natural dyes e.g. from

carrots, tomatoes or

ketchup may be the

cause. The amount of

cleaning agent used or its

bleaching effect was not

sufficient to deal with

natural dyes.

Increase the rinsing agent

dosage. See

"Programmable functions".

Increase the rinsing agent

dosage. See

"Programmable functions".

There is no remedy.

Purchase glasses which

are dishwasher-proof.

Select a programme with

a higher wash

temperature.

Use a different type of

cleaning agent.

Use more cleaning agent.

See "Programming

functions".

Discolouration is irreversible.

45

Problem solving guide

Other fault codes

If a fault code, which is not referred to

in the previous pages, appears in the

display, proceed as follows:

Switch the dishwasher off by

^

pressing the Off button o.

Switch the dishwasher on again by

^

pressing the On button g.

Start the DRAIN/SELF CLEANING

^

programme 6.

Select a wash programme so that the

^

boiler and tank will fill with water.

If the DRAIN/SELF CLEANING

programme 6 will not start or the fault

code appears again, call the Miele

Service Department.

46

Other problems

Cleaning the drain pump and

non-return valve

If water has not been pumped away at

the end of a programme, the drain

pump or the non-return valve might be

blocked. They are easy to clean.

The water in the tank can be hot.

,

Allow the residual water to cool

down.

Take the filter out of the wash

^

cabinet.

The drain pump a is situated under the

non-return valve.

^ Before replacing the non-return

valve, check that the drain pump a

and the filter b are free of

obstructions.

^ Any foreign object causing an

obstruction must be removed.

^ Replace the non-return valve

carefully in the reverse order.

^

Tilt the non-return valve forwards and

then lift it upwards.

^

Rinse thoroughly under running

water.

^

The vent hole must not be blocked.

^

If it is blocked, use a pointed tool to

unblock it.

^

Replace the filter. Ensure that the

filter sits flat in the base of the wash

cabinet.

47

Other problems

Cleaning the filters in the water

inlet

Filters are incorporated in the screw

connection of the water inlet hose to

protect the water inlet valve. If these

filters get dirty they need to be cleaned,

otherwise insufficient water flows into

the wash cabinet.

The plastic housing of the water

,

connection contains an electrical

component. It must not be dipped in

water.

To clean the filter

^ Disconnect the machine from the

mains supply (switch off at the mains

and pull out the plug, switch off the

appropriate circuit in the fuse box or

withdraw the mains fuse).

^ Turn off the stopcock and unscrew

the water inlet hose.

Clean the large area filter (1) and fine

^

filter (2), and replace with new filters

if necessary.

^ Replace filters and the seal. Make

sure they are sitting correctly.

^ Reconnect the hose to the water inlet,

making sure that it goes back on

straight.

^ Open the stopcock carefully.

If there is a leak, screw the

connections on more tightly.

48

Should you still have any difficulties or if

a fault code "F..." appears in the display

again, please contact:

your authorised Miele Service Dealer,

–

or

the Miele Customer Contact Centre

–

(see back cover for contact details).

When contacting the your Dealer or

^

the Miele Customer Contact Centre,

please quote the model and serial

number of your machine both of

which are shown on the data plate.

Please note that telephone calls may

be monitored and recorded for

training purposes.

After sales service

49

Installation

Please refer to the installation

diagram supplied with the machine.

Furniture and fittings installed

,

near the machine must be of a

commercial standard (e.g. stainless

steel) able to withstand the effects of

steam and condensation.

The machine must be installed correctly

and levelled.

Any unevenness in the floor level can

be compensated for and the height of

the machine raised or lowered by

adjusting the four screw feet.

The machine can be installed in the

following ways:

– Built-under (standard):

The machine can be installed under a

continuous worktop or sink drainer.

The recess must be at least 60 cm

wide, 60 cm deep and 82 cm high.

– Free-standing (optional)

Cover plate (protects the worktop)

The underside of the worktop must be

protected against water damage by a

stainless steel plate.

(A "Lid" conversion kit is required)

–

Slot-in or at the end of a row

(optional):

The machine can be installed next to

other machines or furniture, or in a

suitable niche. The niche must be at

least 60 cm wide and 60 cm deep. (A

"Lid" conversion kit is required)

50

All electrical work must be

,

carried out by a suitably qualified

and competent person in

accordance with local and national

safety regulations.

Electrical connection UK

The machine must only be operated

with the voltage, frequency and fusing

shown on the data plate.

This machine can be converted in

accordance with the conversion

diagram and wiring diagram supplied.

Connection should be made via a

–

suitable isolator, with an on-off switch

which should easily accessible for

servicing work.

For extra safety it is advisable to

–

install a suitable residual current

device (RCD).

Please contact a qualified electrician for

advice.

WARNING

THIS MACHINE

MUST BE EARTHED

– Equipotential bonding should be

carried out.

– The mains connection cable may

only be replaced by an original Miele

spare part or an appropriate cable

with wire end ferrule.

–

For technical data see data plate

and wiring diagram supplied.

The data plate is located at the back of

the machine and at the bottom of the

wash cabinet behind the service panel

on the left hand side.

See also the installation diagram

supplied.

Bonding connection

There is a screw connection point

marked with the earth symbol (

the back of the machine, to which the

earth lead must be connected.

8)at

51

Plumbing

Connection to the water inlet

Water in the machine must not

,

be used as drinking water.

The machine must be connected to

–

the water supply in accordance with

local and national water authority

regulations.

If the iron content in the water is too

–

high, there is a risk of corrosion

damage to the machine and its load.

If the chloride content of the water

exceeds 100mg/l, the risk of

corrosion damage to the load will

increase considerably.

– This machine is constructed to

comply with German water

regulations (DVGW), and may be

connected to a suitable supply

without an extra non-return valve if

national regulations permit.

– The water pressure (flow rate) must

be a minimum of 1 bar (100 kPa).

If the water pressure (flow rate) is

below 1 bar (100 kPa), the filling time

is automatically extended.

The max. permitted static pressure is

10 bar (1000 kPa).

If the water pressure is not in the

range of 1 to 10 bar (100-1000 kPa)

the p / 6 indicator light may come

on and the fault code "F2E" show in

the display. Please contact the Miele

Service Department.

–

The machine is supplied as standard

for connection to a cold or a hot

water supply up to a max.

temperature of 65 °C.

A stopcock with 3/4 inch male thread

–

must be provided on site. It should

be easily accessible so that the

water supply can be turned off when

the machine is not in use.

The DN 10 inlet hose is approx. 1.7

–

m long terminating in a 3/4 inch

female thread. A 1.5 metre long

flexible metal extension hose,

pressure tested to 140 bar, is

available as an optional accessory if

required. On no account may the

inlet filter be removed.

A water inlet filter is enclosed in the

–

kit supplied with the machine for

installing between the stopcock and

the inlet hose (see the illustration in

"Cleaning the water inlet filter".

,

The inlet hose must not be

shortened or damaged in any way

(see illustration).

See also the installation diagram

supplied.

52

Drainage

The drainage system is fitted with a

–

non-return valve which prevents dirty

water from flowing back into the

machine via the drain hose.

The machine should preferably be

–

connected to a separate drainage

system on-site.

If separate drainage is not available

contact your Miele application

specialist for professional advice.

The on-site drain connection point

should be sited between 0.3 m and

1mabove the lower edge of the

machine.

If it is lower than 0.3 m, lay the hose

in a curve at a height of at least

0.3 m.

The drainage system must be able to

take a minimum drainage flow of

16 l/min.

Plumbing

– The drain hose is approx. 1.4 m long,

is flexible and has an internal

diameter of 22 mm. It must not be

shortened.

Hose clips are supplied for securing

it in position.

–

A longer drain hose (up to 4 m long)

is available to order from the Miele

Spare Parts Dept.

–

The drainage system must not

exceed 4 metres.

See also the installation diagram

supplied.

53

Programme overview

Programme

1)

^

For heavily soiled crockery with dried on soiling.

When to use

INTENSIVE

2 min

]

For normally soiled loads.

STANDARD

1.5 min

\

Quick programme for lightly soiled crockery.

SHORT

1 min

6

DRAIN/

To drain the dirty water and also for cleaning the inside of the

cabinet. (e.g. at the end of a programme).

SELF

CLEANING

1)

The short programme durations are only possible when the machine is

connected to a hot water supply and the heater rating is 9.25 kW.

54

Programme sequence

Programme overview

Main wash

2) 3)

Run-off Final rinse

2) 4)

60°C/100 sec 5 sec 65°C/15 sec

60°C/70 sec 5 sec 65°C/15 sec

60°C/40 sec 5 sec 65°C/15 sec

2 min 45 sec

2)

To alter the main wash and final rinse temperature and the final rinse duration,

see "Programmable functions".

3)

Durations may vary.

4)

Times will depend on drainage and final rinse durations.

55

Technical data

Height: 82 (85) cm

Width: 60 cm

Depth: 60 cm

Voltage: see data plate

Connected load: see data plate

Fuse rating: see data plate

Mains connection cable: approx. 1.5 m

Water pressure (flow rate): 1 - 10 bar (100 - 1000 kPa)

Cold or hot water connection: up to max. 65 °C

Delivery head: min. 0.55 m, max. 1 m

Drainage length: max. 4 m

Inlet hose: approx. 1.5 m

Drain hose: approx. 1.4 m

Noise level in dB (A):

Sound level LpA Free standing: <70

Built under: <70

Test marks: VDE, interference suppression, DVGW

565758

59

Alteration rights reserved/3008

M.-Nr. 07 122 771 / 01

Loading...

Loading...