Page 1

Installation instructions

Gas hob

KM 416

IMPORTANT NOTICE

THIS APPLIANCE MUST ONLY BE INSTALLED OR SERVICED

BY AUTHORISED PERSONNEL

Note: The installation of this appliance must comply with the requirements

of the National Standard or AS 5601 (AG 601) Gas Installations.

To avoid the risk of accidents or

damage to the appliance it is

essential to read these instructions

before it is installed or used for the

first time.

M.-Nr. 05 668 520

en-SG

Page 2

r This appliance can be used in countries other than those specified on the

appliance. It is, however, set up for connection to the gas and electricity

supplies in the countries specified. For use in other countries please contact

the Miele spare parts or customer service department in your country.

D Das Gerät ist auch für den Gebrauch in anderen als auf dem Gerät

angegebenen Bestimmungsländer zugelassen. Die landesspezifische

Ausführung und die Anschlussart des Gerätes haben wesentlichen Einfluss auf

den einwandfreien und sicheren Betrieb. Für den Betrieb in einem anderen als

auf dem Gerät angegebenen Bestimmungsland wenden Sie sich bitte an den

für das Land zuständigen Kundendienst.

E El aparato está autorizado para el uso en países diferentes a los países de

destino indicados. La ejecución específica para cada país y el tipo de

conexión del aparato influyen de forma decisiva en el funcionamiento correcto

y seguro. Para el funcionamiento en un país diferente al país de destino

indicado en el aparato, consulte al Servicio Post-venta autorizado para el país.

F Cet appareil est également homologué dans des pays différents de ceux

mentionnés sur l'appareil. Pour que l'appareil fonctionne parfaitement et en

toute sécurité, il est important de disposer de l'exécution spécifique au pays et

du type de raccordement approprié. Pour le fonctionnement dans un pays

autre que celui spécifié sur l'appareil, veuillez vous adresser au service

après-vente du pays où sera installé l'appareil.

I L'apparecchio può essere usato anche in paesi diversi da quello indicato

sull'apparecchio stesso. Tuttavia, le varianti specifiche di un determinato paese

e il tipo di allacciamento alla rete hanno un'importanza fondamentale per il suo

sicuro e corretto funzionamento. Per questo se si vuole usare l'apparecchio in

un paese diverso rivolgersi al servizio di assistenza tecnica Miele del paese in

cui si intende usarlo.

M Het apparaat is ook toegelaten voor gebruik in andere landen dan de landen

die op het apparaat vermeld staan. De specifieke uitvoering en de aansluitwijze

zijn van groot belang voor het goed en veilig functioneren. Neem daarom

contact op met de Technische Dienst van de fabrikant in uw land als u het

apparaat in een land wilt gebruiken dat niet op het apparaat vermeld staat.

2

Page 3

Contents

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Building in ........................................................4

Safety distance above appliances ...................................5

Appliance dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

KM416...........................................................6

Worktop cut-out KM 416 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation KM 416 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fitting the spacer bars and support brackets .............................8

Fixing the spacer bars ...............................................9

Fixing the support brackets ..........................................10

Granite worktops................................................10

Building in the gas hob .............................................10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Conversion to another type of gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

KM416..........................................................16

Jet table ......................................................16

Changing the jets ...............................................17

Check the first intake of air ........................................19

3

Page 4

Warning and Safety instructions

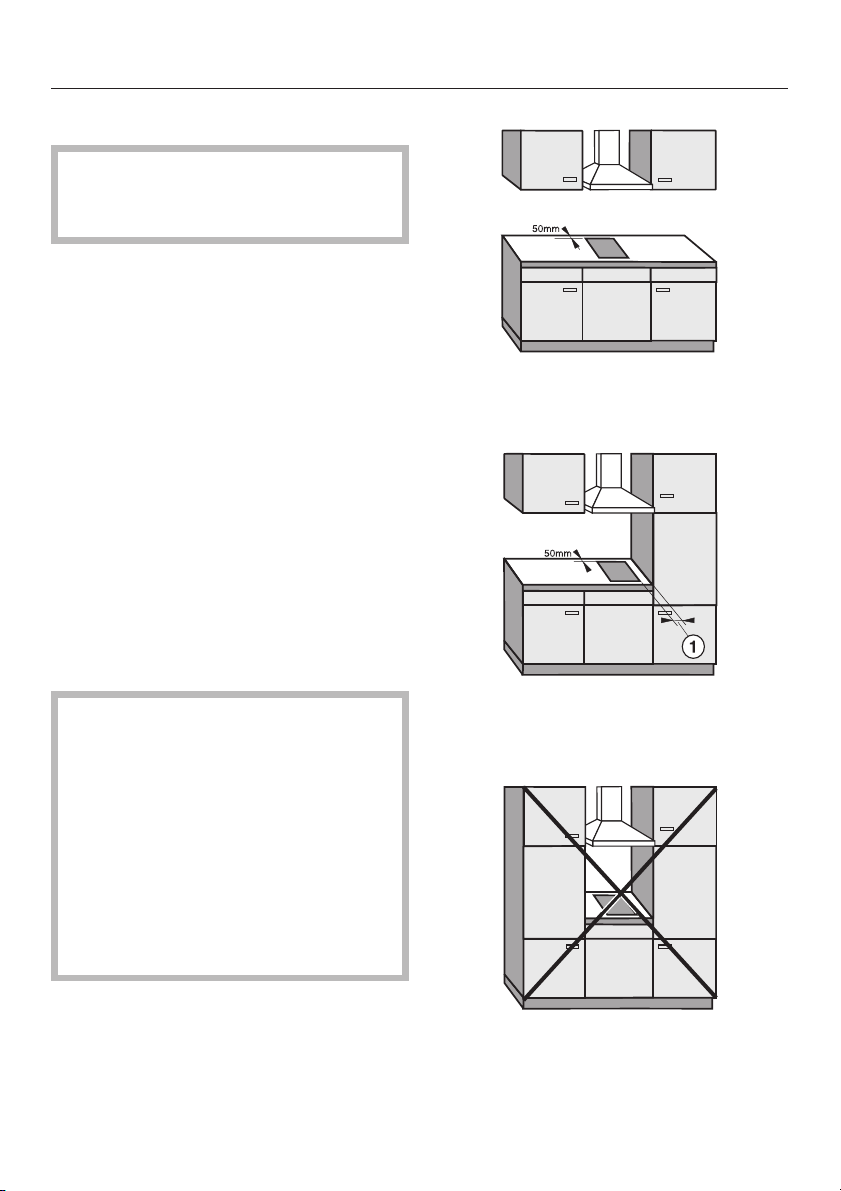

Building in

Fit wall units and cooker hood

before fitting the gas hob, to avoid

damaging the hob.

The room in which the gas hob is

~

installed must be at least 20 m

with a door or window in it which can

be opened to the outside air.

The veneer or laminate coatings of

~

worktops (or adjacent kitchen units)

must be treated with 100°C

heat-resistant adhesive which will not

dissolve or distort.

Any backmoulds must be of heat

resistant material.

Ideally the hobs should be installed

~

with plenty of space on either side.

There may be a wall at the rear and wall

or tall units at one side. On the other

side however, no unit or divider should

stand higher than the hob.

3

in size

recommended

Due to the heat radiated by the hob

and to allow cooking fumes to

dissipate it is essential that a

minimum safety distance a is

maintained between the worktop

cut-out and adjacent furniture, e.g. a

tall unit, as follows:

250 mm with KM 416

There must be a minimum safety

distance of 50 mm between the hob

and a back wall.

4

not recommended

not allowed

Page 5

Warning and Safety instructions

An electric fryer must not be

~

installed next to a gas hob, as the gas

flames could ignite the fat in the fryer.

It is essential to maintain a distance of

at least 288 mm between these two

appliances.

These appliances must not be

~

installed over a dishwasher, washing

machine, tumble dryer, refrigerator or

freezer. The high temperatures radiated

by hobs could damage the appliance

below.

This equipment is not designed for

~

maritime use or for use in mobile

installations such as caravans, aircraft

etc. However it may be suitable for

such usage subject to a risk

assessment of the installation being

carried out by a suitably qualified

engineer.

Safety distance above appliances

A minimum safety distance b must be

maintained between the hob and the

cooker hood above it. See the

manufacturer’s operating and

installation instructions for details. For

any flammable objects, e.g utensil rails,

wall units etc. a minimum safety

distance of at least 760 mm should be

maintained between it and the hob

below.

When two or more appliances are

installed together below a cooker

hood, e.g. a ceramic combiset and

a gas wok combiset, which have

different safety distances given in

their installation instructions you

should select the greater distance of

the two.

All dimensions in this instruction booklet

are given in mm.

Keep these instructions in a safe place

and pass them on to any future owner

of the appliance.

5

Page 6

Appliance dimensions

KM 416

a Support bracket

6

Page 7

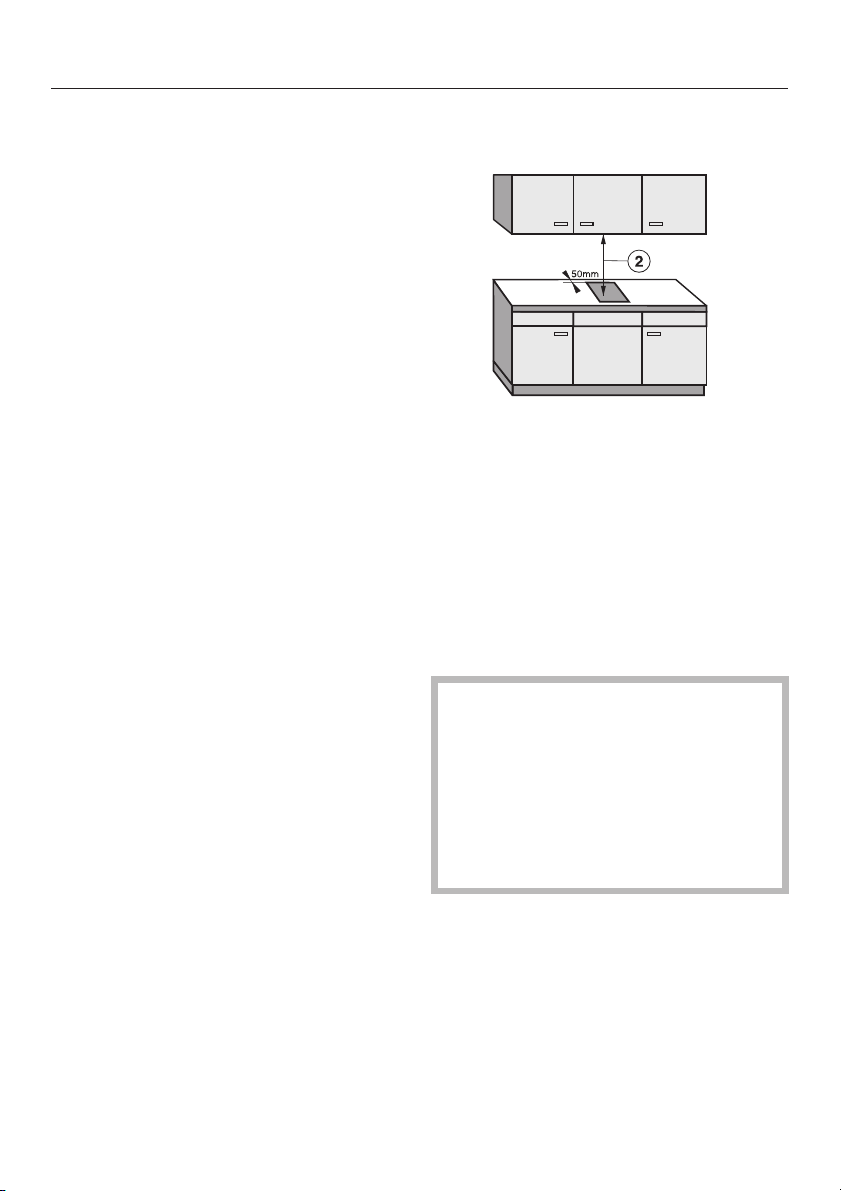

Worktop cut-out KM 416

Worktop cut-out

416

Number

of

appliances

Depth

in mm

±1mm

Width

(= Dim. B)

in mm

±1mm

Dimensions 7 mm and 11 mm are the

space taken up by the frame of the

appliance on the worktop.

^ Make a cut-out for the hob in the

worktop, paying attention to the

appliance height. See "Appliance

dimensions".

Dimension "B" applies to a combination

of appliances and is shown on the

chart.

^

There must be a minimum safety

distance of 50 mm between the hob

and the back wall and 250mm

distance from a side wall to the right

or left of the hob.

(See "Warning and Safety

instructions")

1

2

3

4

5

6

7

500

500

500

500

500

500

500

266

554

842

1130

1418

1706

1994

Important:

The maximum tolerance for the worktop

cut-out must not exceed ±1 mm.

When building in several combiset

appliances a spacer bar must be

fitted between each unit. See "Fitting

the spacer bars and support

brackets".

^

Seal the cut surfaces with a suitable

sealant to avoid swelling caused by

moisture.

The materials used must be heat

resistant.

7

Page 8

Installation KM 416

Fitting the spacer bars and

support brackets

a Support brackets

b Spacer bars

Installation of several appliances

The illustration above shows an

example of a worktop cut-out with

spacer bars b and support brackets a

for 3 appliances.

For more than 3 appliances, repeat

dimension 288 mm.

The worktop cut-out dimensions for

several appliances are shown in the

table on the previous page.

8

c Gap between spacer bar and

worktop.

d Drilling for a granite worktop.

^

Fix the spacer bars b and the

support brackets a supplied to the

positions indicated. See "Fixing the

spacer bars" and "Fixing the support

brackets".

Page 9

Installation KM 416

Fixing the spacer bars

d

c

The spacer bar is only required when

combined with another appliance.

^ Position the spacer bars b in the

positions shown in "Fitting the spacer

bars and support brackets" so they

are flush with the top edge of the

cut-out and secure using the

3.5 x 25 mm screws supplied.

Granite worktops

With granite worktops the spacer bars

b must be positioned and secured with

strong double-sided adhesive tape. In

addition, coat the edges with silicone

and fill in the gap c.

The screws are not required for granite

tops.

^

Then fill in the gap c between the

bars and the worktop with silicone

from the tube supplied.

9

Page 10

Installation KM 416

Fixing the support brackets

^ Position the two support brackets

supplied a in the positions shown in

"Fitting the spacer bars and support

brackets" so they are flush with the

top edge of the cut-out and secure

using the 3.5 x 25 mm screws

supplied. 2 screws are needed to

secure each support bracket.

The thickness of the worktop will

determine which drill hole is used.

Granite worktops

On a granite worktop a hole must be

drilled d at the position indicated to

secure each support bracket.

Using a piece of strong, double-

^

sided adhesive tape position the

support brackets supplied a at the

positions indicated flush with the top

edge of the worktop and secure each

bracket with one screw in hole d as

shown.

Building in the gas hob

^ Place the gas hob in the prepared

cut-out.

^ Feed the electricity connection cable

through the cut-out and connect.

^ Make the gas connection.

(see relevant section).

^

Secure the gas hob from below

through the middle elongated hole b

in each support bracket using the

two screws supplied. Carefully adjust

the hob if necessary.

10

Page 11

Important

General

Under no circumstances should

sealant find its way between the

frame of the top part of the hob and

the worktop.

This could cause difficulties if the

hob ever needs to be taken out for

servicing, (possibly leading to

damage to the frame and worktop).

The sealing strip under the edge of the

top part of the hob provides a sufficient

seal for the worktop.

11

Page 12

Electrical connection

All electrical work should be carried

out by a suitably qualified and

competent person, in strict

accordance with national and local

safety regulations.

Installation, repairs and other work

by unqualified persons could be

dangerous. The manufacturer

cannot be held responsible for

unauthorised work.

Ensure power is not supplied to the

appliance until after installation or

repair work is being carried out.

Connectionshould be made via a

suitable isolator (rated load above

3 kW) or a double pole fused spur

connection unit or fused plug and

switched socket (rated load up to 3 kW)

which complies with national and local

safety regulations and the on/off switch

should be easily accessible after the

appliance has been built in.

When switched off there must be an

all-pole contact gap of 3 mm in the

isolator switch. For extra safety it is

advisable to install a residual current

device (RCD) with a trip current of

30 mA.

The appliance must only be

operated when built-in. This is to

ensure that all electrical parts are

shielded. Live parts must not be

exposed.

Do not connect the appliance to the

mains electricity supply by an

extension lead. These do not

guarantee the required safety of the

appliance.

After the appliance has been built in,

a check must be made that all

electrical parts are shielded.

The voltage and connected load are

given on the data plate. Ensure that

these match the household mains

supply.

Important

The wires in the mains lead are

coloured in accordance with the

following code:

Green/yellow = earth

Blue = neutral

Brown = live

Warning!

This Appliance must be

earthed.

12

Page 13

Electrical connection

Disconnection from the power supply

will depend on the isolator, according

to country e.g.:

Safety fuse:

–

Completely remove the fuse links

from the fuse carrier.

or

Safety cut-outs (screw type):

–

Press the (red) test button until the

black centre button pops out.

or:

Built-in safety cut-outs

–

(MCBs at least type B or C):

Set rocker from 1 (On) to 0 (Off)

or:

– FI-Safety-switch (RCD):

Set main switch from 1 (On) to 0 (Off)

or press the test button.

Non-rewireable plugs (BS 1363)

If this appliance is fitted with a

non-rewireable plug, the following

information applies:

If the socket outlets are not suitable for

the plug supplied with this product, it

must be cut off and an appropriate plug

fitted.

The fuse carrier and the fuse should be

removed from the old plug and

disposed of. The plug cut from the

flexible cord should then be disposed

of and on no account be inserted into

any socket elsewhere in the house

(electric shock hazard).

The fuse cover must be re-fitted when

changing the fuse, and if the fuse cover

is lost, the plug must not be used until a

suitable replacement is obtained. The

colour of the correct replacement cover

is that of the coloured insert in the base

of the plug, or the colour that is

embossed in words in the base of the

plug (as applicable to the design of the

plug fitted).

The correct fuse rating of the

replacement fuses that are ASTA

approved to BS 1362 should be fitted.

Replacement fuse covers may be

purchased from your local electrical

supplier, or Miele Service agent.

Technical Data

Fusing:

See data plate

For appliances up to 3 kW 13 amps

For appliance above 3 kW 20 amps

If the cable needs to be changed select

either

type H 05 RR-F (rubber insulated) or

type H 05 W-F (PVC-insulated)

See data plate for connection data.

The manufacturer cannot be held

responsible for the consequences of

an inadequate earthing system.

The manufacturer can assume no

responsibility for damage which is

the direct or indirect result of

incorrect installation or connection.

13

Page 14

Gas connection

Connection to the gas supply, or

conversion from one type of gas to

another should only be undertaken

by an approved and registered gas

fitter in strict accordance with local

and national safety and building

regulations. Every appliance should

have its own isolating valve and test

point.

Check with your local gas supplier

about the type of gas and its

calorific value, and compare this

information with the type of gas

quoted on the hob data plate.

The installer is responsible for

ensuring that the appliance

functions correctly when installed.

Conversion to another type of gas is

described under the relevant Section.

The gas connection must be installed

so that connection can be made either

from inside or outside the kitchen unit,

and the isolating valve must be easily

accessible and visible (by opening one

of the kitchen unit doors, if necessary).

A test for possible leakages must be

carried out after installation.

The relevant building regulations must

also be observed.

The hob is supplied ready for

connection to town gas.

Depending on country a set of jets for

conversion to liquid gas may be

included with the hob.

14

Page 15

a Connection for pressure gauge

b Governor fitted for connection to

town gas.

Inlet pressure 10-20 mbar/1-2 kPa,

burner pressure 10 mbar/1 kPa.

Gas connection

An appropriate rigid or flexible

connection and isolating valve must be

installed for final connection.

The gas connection must be so sited

that it is not adversely heated when the

appliance is in operation.

After installing the appliance the gas

burners have to be set for local

conditions.

When the gas hob has been

installed it is essential to check that

neither the gas hose nor the

electricity cable is in contact with hot

parts of the appliance or hot gas

exhaust, otherwise heat damage to

the hose and cable could occur.

Note:

Where a flexible connection (Hose

Assembly) is used it must

(I) be of an adequate size

and;

(II) comply with the National

standard or AGA certification

and;

(III) be suitable for the intended

use.

15

Page 16

Conversion to another type of gas

KM 416

When converting to LP gas, the main

jets and the small jets of all burners

must be changed.

Nominal rating at high setting

Gas type KW MJ/h

Town gas

10-20 mbar / 1-2 kPa

LP gas

30 mbar / 3 kPa

Nominal rating at low setting

Gas type KW MJ/h

5.6

4.0

20.0

14.3

Jet table

Main

jet

Ø

Town gas 3.70 1.00

LP gas 1.05 0.58

The jet markings refer to 1/100 mm of

the jet diameter.

Low

setting jet

Ø

Town gas

10-20 mbar / 1-2 kPa

LP gas

30 mbar / 3 kPa

Screw in the new jets according to the

following table.

16

0.6

1.1

2.2

3.9

Page 17

Conversion to another type of gas

Changing the jets

Disconnect the gas hob from the

electricity supply by switching off at

the socket and withdrawing the plug

or by removing the mains fuse.

^ Pull the control knob for the gas

burner upwards and off.

^ Use a (T20) Torx screwdriver to

unscrew the 4 Torx screws g (M4) in

the lower part of the hob housing.

^ Lift off the top part of the hob keeping

it level.

^

Take off the pan support, small

burner cap b, large burner cap c,

burner collar ring d and the large

burner cap base e.

^

Use a (T20) Torx screwdriver to

unscrew the 3 Torx screws f (M4).

17

Page 18

Conversion to another type of gas

Changing the main jet

^ Use a SW 10 socket spanner to

loosen the main jet from its holder, by

turning anti-clockwise. At the same

time use an SW 13 spanner to

counterhold.

Changing the small jets

a Low setting jet

^ Using a small screwdriver, unscrew

both small jets in the gas fitting.

^ Pull the jets out with a pair of pointed

pliers.

^

Select the jets as shown in the table

and fit, reversing the procedure, and

secure.

^

Screw in the new main jets, once

again using the spanner to

counterhold.

18

Page 19

Conversion to another type of gas

Check the first intake of air

a Securing screw

b Air sleeve

Gap X must measure:

8,0 mmfor Towngas

6,5 mmfor LP gas

If this is not the case, loosen the

^

securing screw, re-position the air

sleeve and then tighten the securing

screw.

Finally secure the jets against

^

inadvertent loosening with sealing

wax.

Re-assemble the hob in the reverse

^

order.

The flame must not go out in the lowest

setting, or when the control is turned

quickly from a high to a low setting.

In the highest setting the flame must

have a distinctive and visible core.

19

Page 20

Alteration rights reserved / 3408

M.-Nr. 05 668 520 / 03

Loading...

Loading...