Page 1

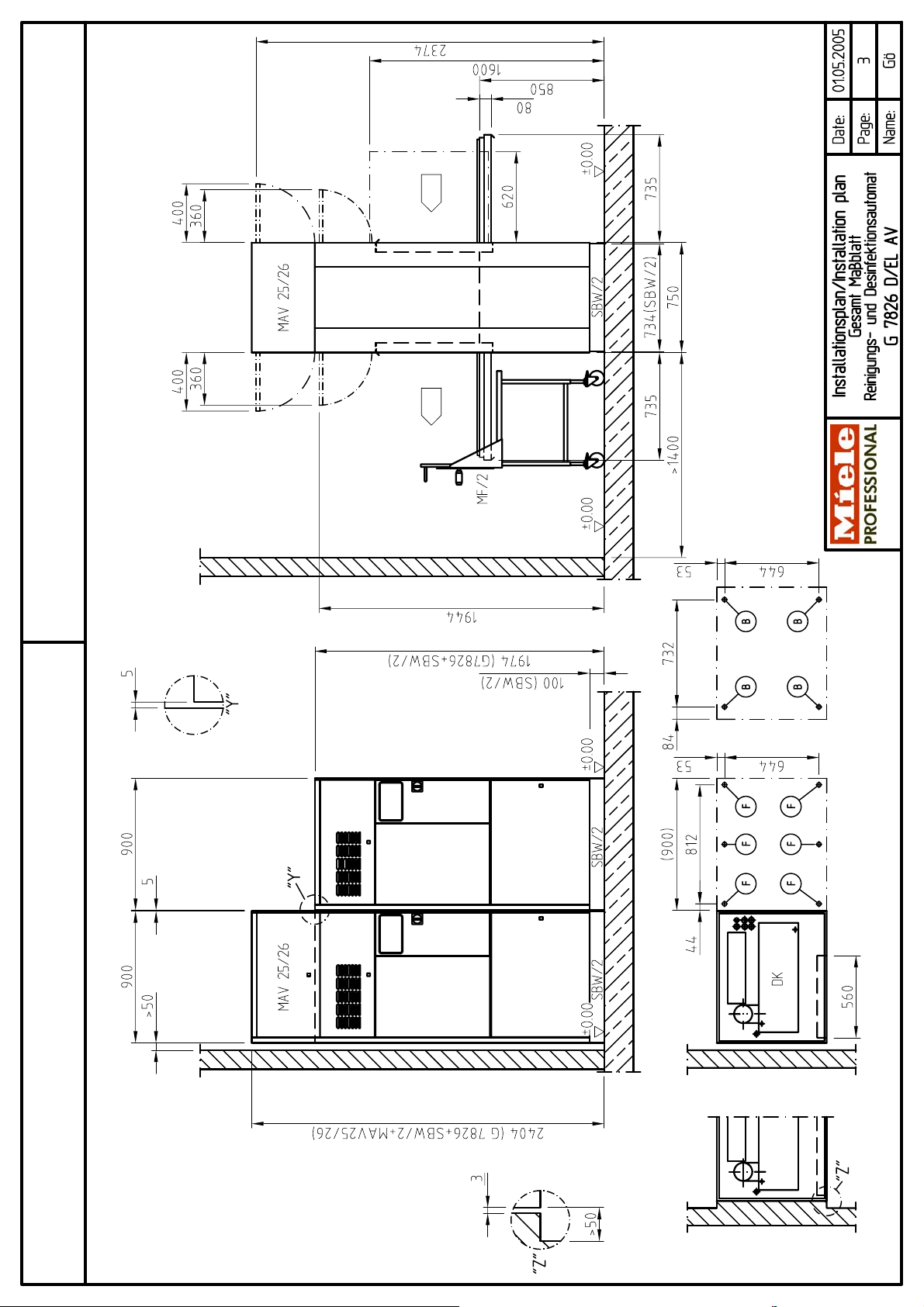

Installationsplan / Installation plan

Installatietekening Plano de instalación Asennusohje

Plan d`installation Plano de instalação Installasjonsplan

Pianta di installazione Σχέδιο εγκατάστασης Installationsplan

G 7826 D/EL AV (dump valve)

Materialnummer / Mat.-no.: 6573990

Änderungsstand / Version: 00

Datum Zeichnung / Drawing date: 01.05.2005

Datum Legende / Legend date: 01.05.2005

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Technical Datasheet

Washer-disinfector

Heating:

Legend:

Circled, bold-type abbreviations:

Connection required

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

G 7826 AV

Steam/Electric (D/EL)

Notes on supply connections:

Cold, hot and demineralised water, high-pressure steam, condensate and compressed air

supplies can be routed through the ceiling or, alternatively, through the floor. A combination of

the two is not possible.

Electrical

connection

Connection cable, min. cross-section mm² 5 × 2.5

Connection cable, min. length

From top edge of MAV panelling if supply lines

Above finished floor if supply lines pass through

Country variations:

Rated load kW 10,0

Fuse rating A 3 × 16

1. Voltage

pass through ceiling

floor

2. Voltage

Rated load kW 10.0

Fuse rating A 3 × 16

Connection cable, min. cross-section mm² 5 × 2.5

Voltage V/Hz 3 AC 230/50

Rated load kW 10.0

Fuse rating A 3 × 30

Connection cable, min. cross-section

3. Voltage

Rated load kW 10.0

Fuse rating A 3 × 30

Connection cable, min. cross-section mm² 4 × 4

V/Hz 3N AC 400-415/50

m 4.0

m 1.5

V/Hz 3N AC 400/50

mm² 4 × 4

convertible

V/Hz 3 AC 230/50

Voltage V/Hz 3N AC 400/50

Rated load kW 10.0

Fuse rating A 3 × 16

Connection cable, min. cross-section

4. Voltage

Rated load kW 10.0

Fuse rating A 3 × 30

Connection cable, min. cross-section mm² 4 × 4

Voltage V/Hz 3N AC 380/60

Rated load kW 10.0

Fuse rating A 3 × 16

Connection cable, min. cross-section

Installationsplan G 7826 D/EL AV

Stand: 01.05.2005

Seite 7

mm² 5 × 2.5

convertible

V/Hz 3 AC 220/60

mm² 5 × 2.5

convertible

Page 8

V/Hz 3N AC 380/60

5. Voltage

Rated load kW 10.0

Fuse rating A 3 × 16

Connection cable, min. cross-section mm² 5 × 2.5

Plug and socket connection recommended to facilitate

Connection

module

output signals

Voltage V/Hz 3 AC 220/60

Rated load kW 10.0

Fuse rating A 3 × 30

Connection cable, min. cross-section

6. Voltage V/Hz 3 AC 208/60

Rated load kW 10.0

Fuse rating A 3 × 30

Connection cable, min. cross-section mm² 4 x 10

7. Voltage V/Hz 3 AC 200/50

Rated load kW 10.0

Fuse rating A 3 × 30

Connection cable, min. cross-section mm² 4 × 4

8. Voltage V/Hz 3 AC 200/60

Rated load kW 10.0

Fuse rating A 3 × 30

Connection cable, min. cross-section mm² 4 × 4

accessibility for electrical safety tests.

Socket must be accessible after installation. Connection to

electrical supply should be in accordance with valid

regulations and safety standards. Observe correct phase

sequence (clockwise). Supply lead should not be in direct

contact with any source of heat.

The use of a current-operated ELCB is recommended!

Potential-free contacts (NO contacts):

A maximum of 9 contacts are available, possible assignment:

mm² 4 × 4

convertible

Max. contact load:

TA OPERATION Contact closed during drying block V/A/Hz 200-240/1/50-60

PRG RUNNING Contact closed during washing, drying and cool-down V/A/Hz 200-240/1/50-60

OPERATION Contact closed while machine is running V/A/Hz 200-240/1/50-60

FAULT Contact closed when fault occurs V/A/Hz 200-240/1/50-60

PRG END Contact closed between end of programme and door opening V/A/Hz 200-240/1/50-60

PAUSE w. WASH Contact closed during 'Pause with wash action' stage V/A/Hz 200-240/1/50-60

DRAIN STD Contact closed during drainage V/A/Hz 200-240/1/50-60

DRAIN RECY. Contact closed during drainage (water recycling drain pump) V/A/Hz 200-240/1/50-60

COLD Contact closed during cold water intake V/A/Hz 200-240/1/50-60

HOT Contact closed during hot water intake V/A/Hz 200-240/1/50-60

DEMIN. COLD Contact closed during cold demineralised water intake V/A/Hz 200-240/1/50-60

DEMIN. HOT Contact closed during hot demineralised water intake V/A/Hz 200-240/1/50-60

DOS1-EXT Control signal for external dispenser pump 1 V/A/Hz 200-240/1/50-60

DOS2-EXT Control signal for external dispenser pump 2 V/A/Hz 200-240/1/50-60

DOS3-EXT Control signal for external dispenser pump 3 V/A/Hz 200-240/1/50-60

DOS4-EXT Control signal for external dispenser pump 4 V/A/Hz 200-240/1/50-60

Module input

signals

SLA HZG Peak-load negotiation - Heating V/Hz 200-240/50-60

DOS-EXT Fill level of external dispenser canister V/Hz 200-240/50-60

MEDIUM Medium dispensing active, signal for flow and volume control V/Hz 200-240/50-60

Control voltage

Installationsplan G 7826 D/EL AV

Stand: 01.05.2005

Seite 8

Page 9

Cold water Max. temperature °C 20

Max. water hardness °dH 4

Min. flow pressure kPa 200

Max. pressure kPa 1000

Throughput l/min 15

On-site connection thread according to DIN 44 991 Inch 3/4" external thread

Water connection Australia:

To prevent back-syphonage, the water connection must be

via an approved Dual-Check-Valve supplied with the

machine.

(USA: 11.5 NH)

Hot water

Water connection Australia:

Final rinse water

Heating steam

Condensate On-site connection thread Inch 1/2" ext. thread

Compressed air

Max. temperature °C 60

Max. water hardness °dH 4

Min. flow pressure kPa 200

Max. pressure kPa 1000

Throughput l/min 15

On-site connection thread according to DIN 44 991 Inch 3/4" external thread

To prevent back-syphonage, the water connection must be

via an approved Dual-Check-Valve supplied with the

machine.

Water quality defined by cleaning requirements, e.g. reverse

osmosis, demineralised water, ultra-purified water, etc.

Max. conductivity (e.g. for surgical instruments) µS/cm 15

Min. flow pressure kPa 200

Max. pressure kPa 1000

Throughput l/min 15

On-site connection thread according to DIN 44 991 Inch 3/4" external thread

Steam pressure kPA 250-1000

Temperature °C 140-180

Rated capacity kg/h 50

On-site connection thread Inch 1/2" ext. thread

Capacity Qn m³/h 0.12

Supply pressure kPa 600-1.200

Connection thread (on site) Inch 1/2" ext. thread

(USA: 11.5 NH)

(USA: 11.5 NH)

Cooling circuit

feed line

(optional)

Cooling circuit

return pipe

(optional)

Waste water

Floor tray drain

Steam condenser (DK, optional) can be connected to a

cooling circuit. Connect to cold water if cooling circuit is not

available.

Max. cooling capacity kW 3.5

Max. pressure – Cooling circuit kPa 800

Pressure loss – Steam condenser kPa 30-50

Throughput "Wash", adjustable on site l/min 1.0-4.0

Throughput "Dry", adjustable on site l/min >4.0

Hose connector – Steam condenser (ext. dia. × l) mm 14 x 25

Stopcock and supply line filter to be provided on site!

Necessary to connect steam condenser to cooling circuit

Hose connector – Steam condenser (ext. dia. × l) mm 14 × 25

Stopcock to be provided on site!

Max. temperature °C 93

Connection DN 50

Max. peak delivery l/min 150

Fit odour trap on site

Max. temperature °C 70

Connection DN 50

Fit odour trap on site

Installationsplan G 7826 D/EL AV

Stand: 01.05.2005

Seite 9

Page 10

Vented

Machine-side connection (ext. dia. × wall thickness) mm 125 x 1.25

Air extracted from the 'unclean' side of the operation should

be replenished by ensuring sufficient air intake.

I. Vent to atmosphere. Vent multiple washer-disinfectors

individually (do not use manifold):

Vent air throughput m³/h 250

Temperature - Mean value / peak max. °C 70/95

Rel. humidity - Mean value / peak max. % 80/100

Max. permissible pressure loss in vent duct Pa 700

II. Connection without steam condenser to external fanassisted vent:

Min. throughput capacity of on-site vent in washing cycle m³/h 100

Min. throughput capacity of on-site vent in drying cycle m³/h 350

Temperature - Mean value / peak max. °C 70/95

Rel. humidity - Mean value / peak max. % 80/100

III. Connection with steam condenser to external fan-assisted

vent:

Min. throughput capacity of on-site vent in washing cycle m³/h 100

Min. throughput capacity of on-site vent in drying cycle m³/h 350

Temperature - Mean value / peak max. °C 28/32

Rel. humidity - Mean value / peak max. % <70/100

Prevent condensate backflow into washer-disinfector. Pitch

vent ducting and discharge condensate at lowest point.

Machine feet

Fasteners

Heat dissipation

to room

Machine data

Installation should only be carried out by authorised fitters in accordance with valid regulations!

Observe installation instructions when installing machine! All rights reserved! Measurements in mm

Height-adjustable mm 10

Foot diameter mm 25

Parts supplied with plinth/floor tray:

Adhesive anchors (4 off) mm M 8 × 150

Hole diameter mm 8

Unclean side kW 0.5

Clean side kW 0.5

Load on removal kW 0.8

Height incl. plinth/floor tray mm 1974

Height incl. plinth/floor tray and top-box panelling mm 2404

Width mm 900

Depth mm 750

Net weight incl. plinth/floor tray kg 417

Net weight incl. plinth/floor tray, top-box panelling and steam

condenser, etc.

Dynamic floor load N ~6524

Min. transport width incl. pallet mm 820

Min. transport height incl. pallet mm 2070

kg 496

Notes on supply connections:

Cold, hot and demineralised water, high-pressure steam, condensate and compressed air supplies

can be routed through the ceiling or, alternatively, through the floor. A combination of the two is not

possible. Connection of waste water and floor tray on dump valve (AV) models is only possible

through floor. Cooling circuit feed and return pipes for steam condenser (optional) through ceiling only.

Easily accessible central stopcock and main switch recommended.

Installationsplan G 7826 D/EL AV

Stand: 01.05.2005

Seite 10

Page 11

Preparatory work

Core-drilled access hole in floor according to drawings or template, Mat. no. 5488570, available from

Spares. Further access holes required for tubing and cabling if chemical product supply line access is

through the floor.

Recommended core-drilling diameters: Waste water connections 100 mm Ø

Chemical supply connections 230 x 170 mm (W x D)

Use directly abutting templates for run of machines. Template size corresponds to diaphragm wall cutout which is slightly larger than machines to allow for 5 mm gap between machines and 3 mm gap

between machine and diaphragm wall. These gaps are sealed on site using a suitable sealant.

Waste water connection:

Drain manifold (minimum diameter DN 100) to be installed under floor and fitted with odour trap on

site. Connections to manifold (DN 50) to be fitted vertically to extend to specified height above floor at

predetermined points. Hose sleeve of drain pipe for drip tray drain should end 35 mm above finished

floor level; hose sleeve of drain pipe for machine drainage should end at finished floor level. Additional

removable stub-out with slip joint to 200 mm above finished floor required for machine drainage. Stubout extensions to be cut to size and removed to facilitate machine handling. Stub-out extension fitted

after washer-disinfector has been positioned in the plinth/floor tray. If plinth/floor tray is planned later,

use pipe caps to close pipes.

Electrical connection:

Electrical supply lines can be routed through floor or ceiling. Min. cable length of 1500 mm above

finished floor surface required with access through floor. Min. cable length of 4000 mm from top edge

of top-box panelling required with access through ceiling.

Standard installation, chemical supply connections:

Install supply lines vertically from ceiling, adjust and locate. All pipework, including insulation, fittings

and valves with taps should be located within the designated area (520 mm × 130 mm). No part of the

installation should extend beyond this area.

Hot, cold and demineralised water lines, high-pressure steam and condensate lines end with a ¾" ext.

thread and compressed air lines with a ½" int. thread 2,224 mm above finished floor.

Miele recommends the installation of a check valve directly below the condensate trap in order to

prevent water hammer.

If washer-disinfector is installed with a steam condenser, install cooling circuit feed and return pipes

vertically from ceiling and secure. Both are connected to the steam condenser with a flexible hose (int.

diameter 14 mm) which is to be provided on site. In the absence of cooling circuit, connect steam

condenser to cold water.

Installationsplan G 7826 D/EL AV

Stand: 01.05.2005

Seite 11

Page 12

Alternative installation, chemical supply connections:

Route supply lines through floor to approx. 200 mm above finished floor and secure. Supply lines are

shortened after installation of plinth/floor tray. If plinth/floor tray is planned later, use pipe caps to close

pipes. Install floor tray horizontally using spirit level. Stopcocks in the chemical supply lines are

installed after the floor tray has been fitted. Install stopcocks for cold, hot and demineralised water,

high-pressure steam, condensate and compressed air according to drawings. Pipework and

stopcocks should rise by no more than 90 mm above finished floor and should on no account rise

above plinth/floor tray.

If washer-disinfector is installed with a steam condenser, install cooling circuit feed and return pipes

vertically from ceiling and secure. Both are connected to the steam condenser with a flexible hose (int.

diameter 14 mm) which is to be provided on site. In the absence of cooling circuit, connect steam

condenser to cold water.

Waste air installation:

In order to expel vapours, air throughput of 350 m³/h for each machine is required on the unclean side

of the operation.

Connection to external vent system with or without steam condenser:

Connection of the washer-disinfector to an external vent system is via an extractor canopy. An air gap

of at least 80 mm should be provided. A suitable vent canopy is provided with the washer-disinfector.

The use of a two-stage fan is recommended (cf. Technical Data Sheet 'Electrical connection' on fan

control). Laying a flexible duct to directly above the machine facilitates installation.

Venting to atmosphere:

The canopy provided should not be fitted if the washer-disinfector is vented directly to atmosphere.

Never merge vent ducts from multiple washer-disinfectors! Vent each machine separately!

Installationsplan G 7826 D/EL AV

Stand: 01.05.2005

Seite 12

Loading...

Loading...