Page 1

Operating and Installation

Instructions

Laboratory Glassware

Washer

G 7804

To prevent accidents

and machine damage

read these instructions

before

installation or use.

en-US

M.-Nr. 09 234 570

Page 2

2

Page 3

Contents

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Function of the glassware washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Guide to the glassware washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the water softener ...........................................13

Filling the salt reservoir .............................................15

Salt indicator .....................................................16

Areas of application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Spring adapter for the water connection ................................19

Adjusting the upper basket ..........................................19

Effects of Processing Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Dispensing chemical agents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Turning on the lab washer ...........................................31

Starting a program.................................................31

Select the Drying 3 function if desired ................................31

Changing a program ...............................................31

Starting the program ...............................................32

Program sequence display ..........................................32

End of a program..................................................32

Turning off .......................................................32

Canceling a program...............................................33

Program guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Programming functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

The following instructions apply to all programming functions:...............36

To access the programming mode .................................36

Saving to memory and exiting the programming mode ..................36

Exiting the programming mode without saving ........................36

Buzzer ..........................................................37

Changing program parameters .......................................38

Changing the temperature ........................................38

Changing the holding time ........................................38

Activating Rinse 2 .................................................39

Delay start .......................................................40

Restoring the factory settings ........................................41

3

Page 4

Contents

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Routine checks ...................................................42

Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Frequently asked questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Thermo switch ....................................................58

After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Water inlet .......................................................64

Drainage ........................................................66

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Caring for the environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

This machine conforms to current

safety requirements. However,

inappropriate use can lead to

personal injury and property

damage.

To avoid the risk of accidents and

machine damage read the operating

instructions carefully before using

this machine.

Keep these instructions in a safe

place and pass them on to any

future user.

Please pay attention to the following

notes to maintain safe procedures.

Installation and repair work should

~

be performed by a Miele authorized

service technician. Work by unqualified

persons could be dangerous and may

void the warranty.

Do not use the labwasher until

~

properly installed.

Do not install the machine in an area

~

where a danger of explosion or of

freezing temperatures may be present.

WARNING - To reduce the risk of fire,

electric shock or injury:

Use

This lab washer is not intended for

~

any purpose that is not indicated in the

operating instructions. Conversions,

modifications, and other unintended

uses are considered to be dangerous.

The cleaning processes described here

apply only to those medical products

that are specifically designed by the

manufacturer to be re-used. Follow the

product manufacturer's instructions.

This lab washer in intended for

~

indoor stationary use only.

Before installation, make sure that

~

the voltage and frequency listed on the

data plate correspond with the

household electrical supply. This data

must correspond to prevent injury and

machine damage. Consult a qualified

electrician if in doubt.

Be certain this machine is properly

~

installed and grounded by an

authorized technician. To guarantee

the electrical safety of this machine,

continuity must exist between the

machine and an effective grounding

system. It is imperative that this basic

safety requirement be met. If there is

any doubt, have the electrical system

checked by a qualified technician.

Do not install or use a damaged

~

machine. A damaged machine is

dangerous. Unplug the machine and

call your Miele dealer or the Miele

Technical Service Department.

If the power cord is damaged it

~

must only be replaced by a Miele Ser

vice technician with a genuine Miele

power cord.

-

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

Do not use an extension cord to

~

connect this machine to electricity.

Extension cords do not guarantee the

required safety of the machine (e.g.

danger of overheating).

Defective components should be

~

replaced by Miele original parts only.

Before installation or service,

~

disconnect the power supply to the

work area by unplugging the unit,

"tripping" the circuit breaker or

removing the fuse.

When work has been performed on

~

the supply plumbing, air must be bled

from the supply line to the labwasher.

Otherwise, the water softening system

may be damaged.

Use

Please follow the advice on

~

installation in this manual and in the

separate Installation Instructions.

Personnel operating the lab washer

~

should be trained regularly. Children

and untrained personnel must not be

allowed access to the machine or its

controls.

Persons who lack physical, sensory

~

or mental abilities, or experience with

the machine should not use it without

supervision or instruction by a

responsible person.

Do not allow children to play in or

~

around the machine, or to operate it.

BURN AND SCALD HAZARD

~

This machine reaches very high

temperatures. Take care when

unloading the unit. Let baskets and

inserts cool before touching them. Any

water which may remain in containers

will be very hot and should be emptied

into the wash cabinet.

BURN HAZARD

~

The heating elements become

extremely hot during use. Do not touch

the heating elements during or directly

after the end of a program.

Take care when handling

~

processing chemicals (detergents,

softeners, neutralizers, etc.). These may

contain irritant or corrosive ingredients.

Wear protective gloves and goggles.

With all chemical agents the

manufacturer’s safety conditions must

be observed.

6

Page 7

IMPORTANT SAFETY INSTRUCTIONS

The lab washer is only designed to

~

operate with water and the

recommended processing chemicals.

The machine must NOT be operated

with organic solvents or flammable

liquids. This may cause an explosion or

damage to rubber and plastic

components, which in turn allows liquid

substances to leak out.

Avoid inhaling detergent. If

~

swallowed, it can cause burning in the

mouth and throat or inhibit breathing.

Be careful when sorting and loading

~

items to be washed: locate sharp items

so that they are not likely to damage the

door seal; and load sharp knives with

the handles up to reduce the risk of

injuries.

The water in the machine must not

~

be used as drinking water.

Do not sit or lean on the open door.

~

This could cause the machine to tip or

be damaged.

Never clean the machine or near its

~

vicinity with a water or high pressure

hose.

Only use cleaning agents

~

formulated for special processes and

approved by Miele for use with this

labwasher. Use of unsuitable cleaning

agents could adversely affect the

components of the machine.

Pre-treatments with detergents can

~

create suds, as can certain rinsing

agents. For pre-treatment and / or

cleaning only, use low-sudsing

detergents which have been approved

by Miele. Suds can have an adverse

effect on the cleaning process.

When a chemical additive is

~

recommended on technical application

grounds (e.g. with a detergent), this

does not imply that the manufacturer of

the labwasher takes responsibility for

the affect of the chemical on the

material of the items being cleaned.

Please be aware that changes in

formulation, storage conditions, etc.,

which may not be publicized by the

chemical producer, can have a

negative effect on the cleaning result.

Always follow the instructions of the

~

chemical manufacturer when using

detergents and special application

chemicals. Only use such chemicals for

the purpose and in the situation

specified to avoid such dangers as

chemical reactions and material

damage.

The labwasher is designed only for

~

operation with water and additive

cleaning agents. Organic solvents must

not be used in the machine. An

explosion or machine corrosion could

occur with the use of organic solvents.

In critical applications where very

~

stringent requirements must be met, it

is highly recommended that all relevant

factors for the process, such as

cleaning agent, quality of water, etc.,

be discussed with a Miele Application

Specialist.

For applications that demand

~

especially stringent cleaning and

rinsing results, the operator must

ensure that quality control occurs on a

regular basis.

7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

The mobile units and special inserts

~

should only be used for their specific

application.

Empty any containers or utensils

~

before arranging them in the machine.

Do not allow any remains of acids or

~

solvents, particularly hydrochloric acid

or chloride solutions, to get into the

wash cabinet. The presence of any

solvents should be minimized

(especially those in hazard class A1).

To avoid corrosion damage ensure

~

that solutions or steam containing

hydrochloric acid do not come into

contact with the steel outer casing of

the labwasher.

Please note the following symbols on

the machine:

Caution : See Operating

Instructions!

Caution : Danger of electric

shock!

Accessories

Only genuine, Miele parts and

~

accessories should be used with this

lab washer, including Miele mobile

units, baskets and inserts.

Adequate cleaning results cannot

~

be guaranteed when non-Miele

accessories are used, or when Miele

accessories are altered. Damages

resulting from the use of unsuitable

accessories are not covered by the

warranty.

Disposal of an old appliance

Obsolete appliances should be made

unusable. To do this, first disconnect

the appliance from the power supply,

then cut off the power cord. It is

important to note that the old appliance

may be contaminated from exposure to

pathogens, genetically modified

material, blood, etc., and therefore

must be decontaminated before

disposal.

For safety and environmental

protection, be sure to remove all

chemical residue, in compliance with

safety regulations (wear protective

eyewear and gloves!).

Remove or destroy the door latch, to

prevent children from locking

themselves inside. The appliance can

now be sent for disposal through the

proper resource recovery facilities.

SAVE THESE

INSTRUCTIONS

8

Page 9

Function of the glassware washer

This Miele dishwasher is designed for

cleaning and rinsing laboratory

glassware which is suitable for machine

reprocessing. Always follow the

labware manufacturer's instructions.

Examples of application areas:

laboratory glassware used in

–

research and development,

laboratory glassware used in areas

–

of analysis and specimen taking,

laboratory glassware used in

–

micro-biology and biotechnology.

The type of laboratory glassware which

can be reprocessed ranges from Petri

dishes to centrifugal test tubes.

Reprocessing glassware by machine

achieves reproducible results and

should be used in preference to

processing them by hand.

The cleaning program as well as the

agents used must be chosen according

to the type of soiling and load being

processed.

The agents used in the machine for

reprocessing should be selected

according to the level of cleaning

required as well as the method the

product will be used.

The use of a suitable carrier (mobile

unit, module, insert etc.) is important to

ensure adequate cleaning. Examples

are given in the section "Areas of

application".

The dishwasher is programmed to carry

out the final rinse with mains water or

with processed water of a quality to suit

the application (e.g. distilled, purified,

de-ionized or demineralized water). The

water quality is important for

applications requiring analytically clean

laboratory glassware.

9

Page 10

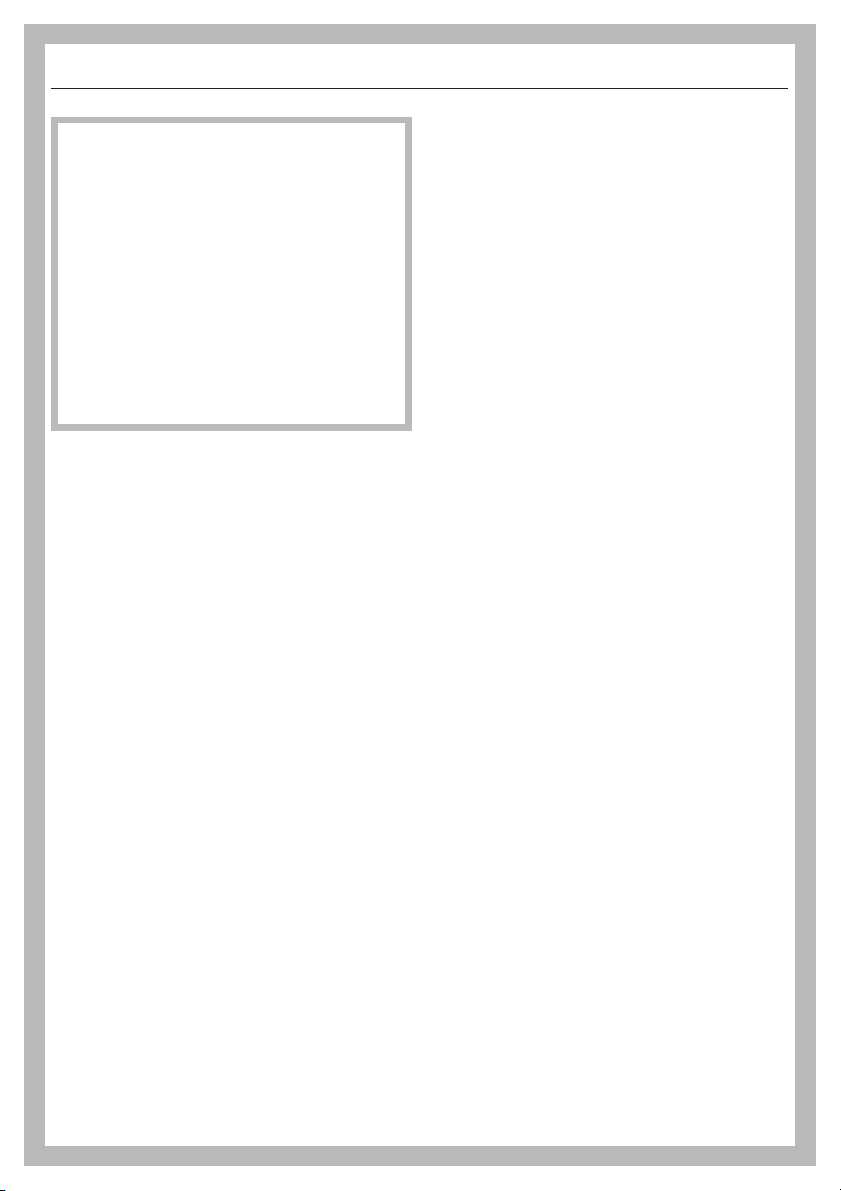

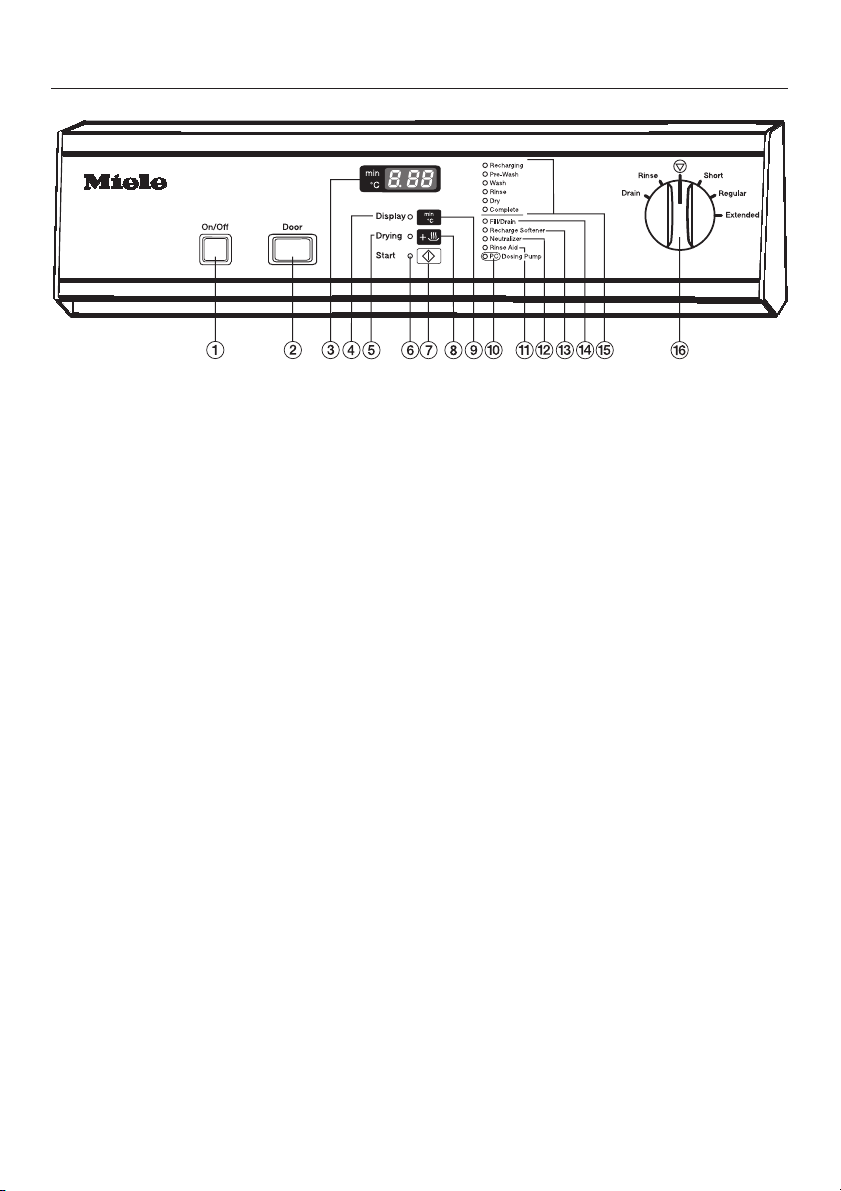

Guide to the glassware washer

a On/Off button

b Door button

c Display

d Display indicator

e Drying indicator

f Start indicator

g Start button 6

h Drying button 3

i Button 4 to switch between the

actual temperature and the elapsed

time.

Check / Refill indicators:

j 8 Optical interface for service

technician

k Rinse Aid

l Neutralizer

m Recharge softener

n Fill/Drain

o Program sequence indicators

p Program selector

10

Page 11

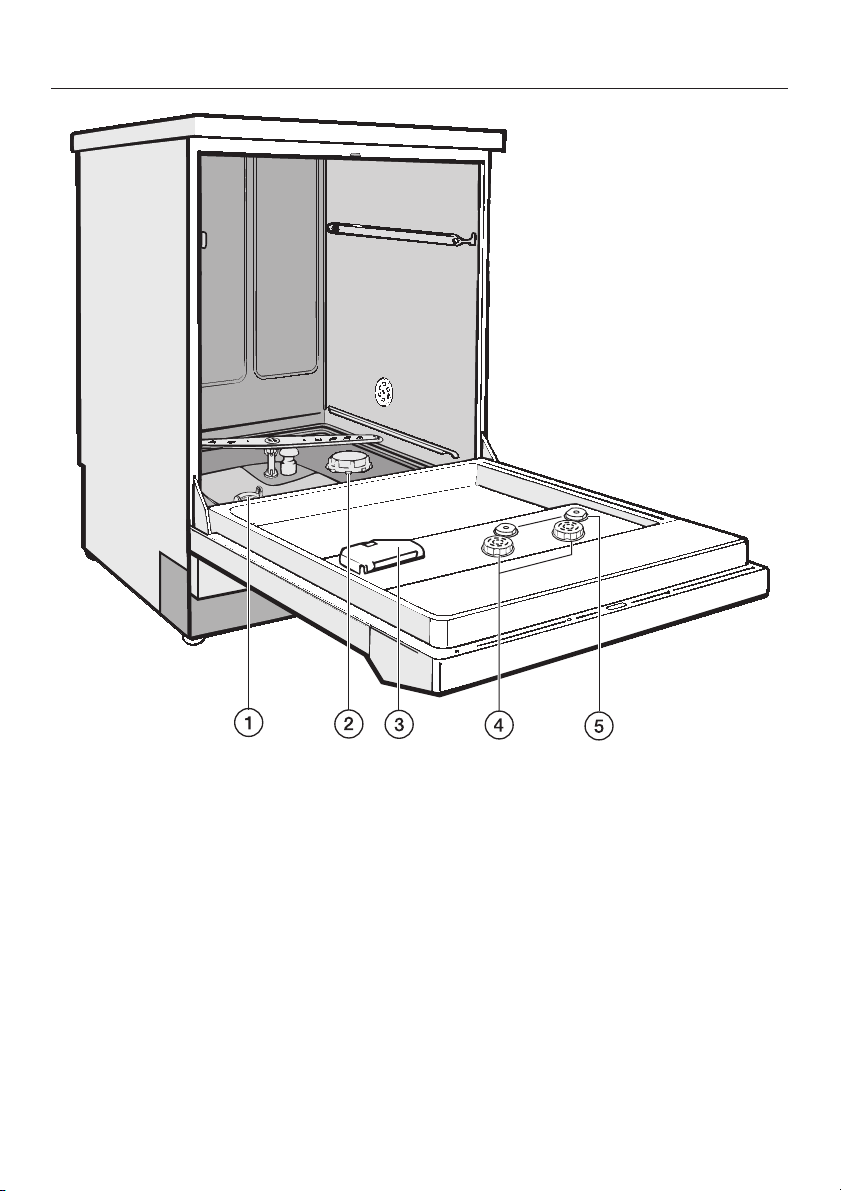

Guide to the glassware washer

a Filter combination

b Salt reservoir (water softener)

c Dispenser for powdered detergent

d Dispenser for rise aid or netralizing

agent (with dosage selector)

e Level indicator for rinse aid or

neutralizing agent

11

Page 12

Opening and closing the door

Electric door lock

The machine is equipped with an

electric door lock. The door can only be

opened when the electrical supply to

the machine is turned on, and the

"On/Off" button is pressed.

To open the door

Press the "Door" button in as far as it

^

will go. At the same time, grip the

handle and open the door.

After the first intake of water, the door

remains locked and cannot be opened

until the end of the program (except

during the "Rinse" and "Drain"

programs). The machine can be

programmed to open during the

"Drying" program, if desired.

Do not touch the heating elements.

They remain hot for some time after

the end of the program and can

cause burns.

To open the door with the

emergency release

The emergency release should only be

used when the door cannot be opened

normally, e.g. in the event of a power

failure.

Turn the program selector to "Stop"

^

f.

Press the "On/Off" button to turn the

^

machine off.

Take precaution against pressure

wave release (rapid opening of the

door).

To close the door

^

Lift the door upwards and push it

until it clicks shut. Do not press the

release catch while shutting the door.

To cancel a program

If a program has to be canceled in an

emergency, e.g. the program has been

interrupted due to a fault, the door will

have to be opened manually.

^

Turn the program selector to the

"Stop" f position. The program is

canceled after approximately

2 seconds.

12

^

Pull the emergency release cable

(located at the bottom of the machine

behind the service panel) downwards

to open the door.

The door latch will reset after the

emergency cable has been activated.

Page 13

Water softener

Before using the lab washer for the first

time, the water softener should be

programmed. The water needs to be

softened to avoid calcium deposits on

the items being cleaned and in the

machine itself.

If the water supply is harder or softer

than the factory setting (including

below 4 gr/gal or 70 ppm), the setting

will need to be changed. See "Setting

the water softener".

In order to function properly, the

–

water softener requires a supply of

reactivation salt.

– The cleaner must be correctly

programmed to match the hardness

of the tap water supply.

– Your local water authority can

provide information about the

hardness of the tap water in your

area.

If the water hardness is known to

fluctuate, always program for the

highest value.

The built-in water softener can be

programmed at settings from

1 - 60 gr/gal or 20 - 1080 ppm.

It is useful to make a note of your water

hardness so that you can provide the

service technician with this information

in the event of any service calls.

Please note the water hardness in the

space provided here:

gr/gal or ppm

Setting the water softener

Use the On/Off button to switch off

^

the machine.

Turn the program selector to f.

^

Simultaneously press and hold the

^

"Display" ß and "Start" 6 buttons,

while turning the machine on with the

On/Off button.

The current program status P....

will appear in the display, and the

"Fill/Drain" indicator will come on.

Press the "Drying" 0 button once.

^

E01 will appear in the display.

^ Turn the program selector one switch

position clockwise (to 1 o'clock).

The number 19 will appear in the

display (this indicates the factory

setting in gr/gal).

^ Press and hold the "Display" ß

button until the required value

appears in the display.

Please refer to the "Settings" table for

detailed water hardness tables (water

hardness in gr/gal and ppm).

Once the 60 setting has been reached,

the counter begins again from 0.

^

Press "Start" 6.

SP will appear in the display.

^

Press "Start" 6 again.

The setting you selected will now be

stored in memory. The display light(s)

will turn off.

The machine is now ready for use.

13

Page 14

Water softener

Settings

Settings

1-30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

gr/gal

1-30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 **)

20

21

22

23

24

25

26

27

28

29

30

ppm

CaCO

0*)

20

40

50

70

90

110

130

140

160

180

200

220

230

250

270

290

310

320

340

360

380

400

410

430

450

470

490

500

520

540

Settings

3

31-60

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

gr/gal

31-60

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ppm

CaCO

560

580

590

610

630

650

670

680

700

720

740

760

770

790

810

830

850

860

880

900

920

940

950

970

990

1010

1030

1040

1060

1080

3

**) The "0" setting is only for machines that do not have a water softener

*) Factory setting

14

Page 15

Water softener

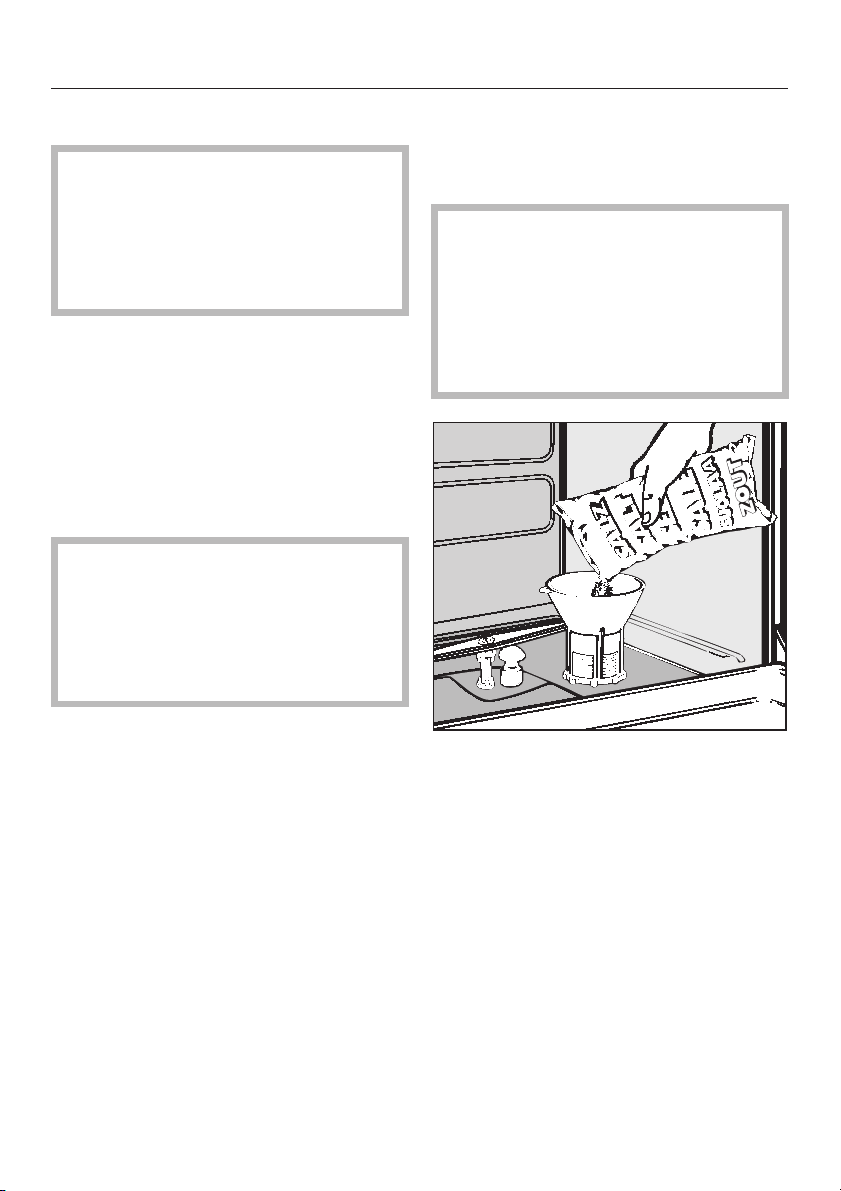

Filling the salt reservoir

Only special, coarse-grained

reactivation salt* should be used in

this lab washer.

*Available from Miele. Please see

back page for more information.

Do not use other types of salt, e.g. table

salt, agricultural or gritting salt. These

could contain components which are

insoluble in water and could damage

the water softener. If in doubt, consult

Miele Technical Service.

The salt reservoir holds approximately

2.5 kg salt.

Inadvertently filling the salt

,

reservoir with detergent will damage

the water softener.

Before filling the reservoir, make

sure that you are using reactivation

salt.

Remove the bottom basket from the

^

machine.

Unscrew the salt reservoir cap.

^

Before filling the salt reservoir for the

first time fill the reservoir with

approximately 2.5 liters of water, so

that the salt can dissolve properly.

Once the lab washer has been

operated, there will always be

enough water in the reservoir.

^

Place the funnel provided in place.

^

Carefully fill the reservoir with the

reactivation salt.

15

Page 16

Water softener

Wipe any residual salt off the screw

^

threads and seal of the reservoir.

^ Screw the cap on securely.

^ Immediately after this step, start the

"Rinse" program, to remove any

traces of salt from the inside of the

lab washer.

Note: There may be a delay of a few

minutes before the "Rinse" program

starts due to the reactivation of the

water softener.

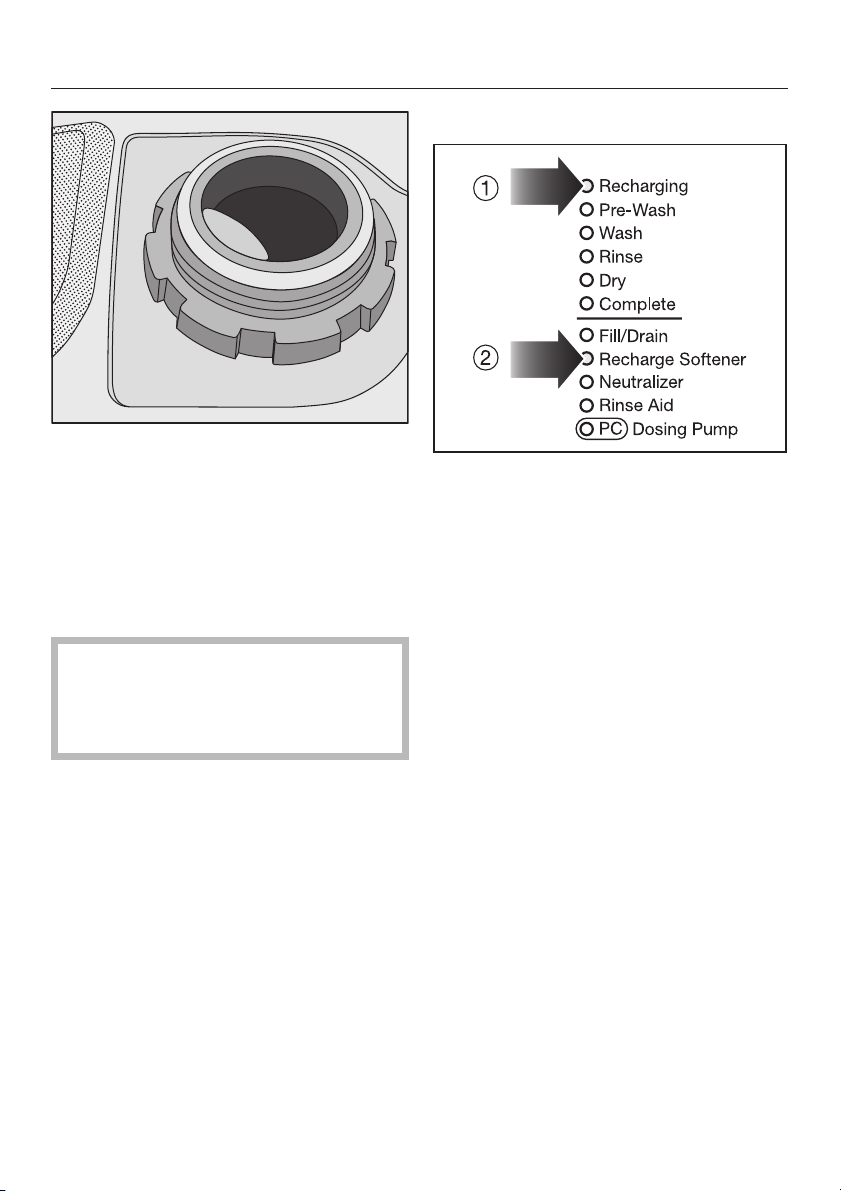

Salt indicator

When the salt reservoir is empty, the

"Recharge Softener" indicator b lights

to remind you to fill the reservoir.

Reactivation takes place automatically

as needed during a program. The

"Recharging" indicator a lights while

this is occurring.

16

Page 17

Areas of application

Depending on the type of labware you

wish to clean, the lab washer can be

used with an upper basket, lower

basket, or injector wagon, as well as an

assortment of inserts and special

baskets to suit your needs.

Baskets and inserts should be

properly selected to match the

application desired.

Before every program start, conduct

the following visual inspection:

– Is the labware properly loaded and

secured in the lab washer?

– Are the hollow vessels properly

loaded so that all cavities and

channels will be flushed clean?

– Are the spray arms clean, and can

they rotate freely?

– Is the filter combination free of

coarse debris (clean if necessary)?

After every program completion,

conduct the following visual

inspection:

Inspect the labware for cleanliness.

–

Has any hollowware been dislodged

–

from its proper position on the

nozzles?

Any items that were dislodged

,

from the adapters during a program

cycle must be washed again.

Are the cavities and channels in any

–

hollow vessels cleaned through?

– Are the nozzles and connections

firmly attached to the

baskets/inserts?

–

Is the basket adapter properly

connected to the water supply for the

spray arms and nozzles?

–

Are the chemical dispensers filled?

17

Page 18

Areas of application

Loading the machine

Disposable items must not be

processed in the machine.

Always load items in a way that all

–

surfaces are exposed. This ensures

that the items will be properly

cleaned.

Do not nest any items inside other

–

items. Keep each item separate.

Hollow vessels must be arranged for

–

complete inside exposure to the

cleaning water.

– Prior to loading the machine or

connecting to the machine ensure

that vessels with long, narrow

cavities they can be completely

flushed.

– Hollow vessels should be inverted

and placed in suitable baskets and

inserts so that water will have

unrestricted access and exit.

–

Deep-based items should be

arranged at an angle, so that water

can run off easily.

–

Tall, narrow pieces should be placed

in the center of the basket for best

water coverage.

–

Secure light loads with netting and

place small items in a mesh

tray/basket so that they do not

obstruct the spray arms.

–

Baskets and inserts with an adapter

must be properly connected.

–

The spray arms must not be blocked

by items that are too tall or hang

through the baskets.

To avoid corrosion, only load

–

stainless steel instruments in good

condition.

Do not use this machine to wash

–

nickel-plated items or discolored

(oxidized) aluminum items.

Do not load plastics unless they are

–

heat-resistant.

Prepare items before loading

Empty all glassware before loading

^

into the machine. Comply with all

applicable infection-control

regulations.

^ Remove all agar residue from petri

dishes.

^ Remove all stoppers, corks, labels,

sealing wax residue, etc.

,

Ensure that no acid or solvent

residues, especially hydrochloric

acid or chlorides, get inside the

machine.

Special preparations before

operating the machine

Items effected by heavy contamination

that resists removal, such as vacuum

grease, paper labels, etc., can affect

the cleaning and rinsing of the whole

load. Pre-treat these items before

loading.

Lab equipment that is contaminated by

microbiological material, pathogens,

propathogens, genetically altered

material, etc., should be sterilized

before being washed in the lab washer

18

Page 19

Areas of application

Spring adapter for the water

connection

The spring adapter for the water

connection must be properly engaged

when a basket or the injector wagon is

inserted into the machine. It must be

4-5mmhigher than the water inlet in

the machine.

If this is not the case, the adapter

needs to be adjusted as follows:

Adjusting the upper basket

The upper basket can be adjusted

above and below the middle position,

by 2 cm.

Depending on the height selected and

which inserts are used, labware of

various heights can be arranged in the

baskets.

To adjust the upper basket:

Pull the upper basket out as far as it

^

will go, lift it up off the runners and

remove.

Use a wrench to unscrew the roller

bearings on either side of the basket,

then reposition as required.

^

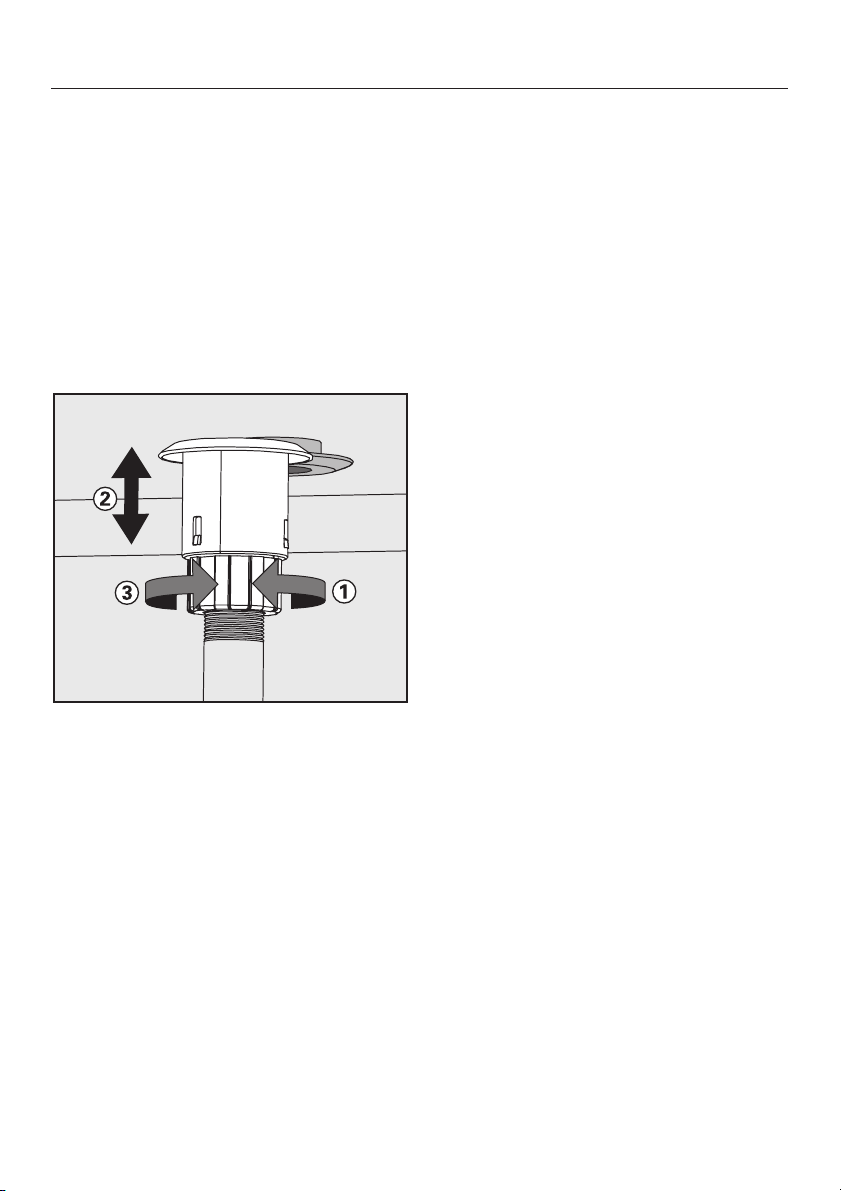

Loosen the locking ring a.

^

Move the adapter up to the proper

height b.

^

Tighten the locking ring c.

19

Page 20

Areas of application

Laboratory equipment

Wide-necked labware, e.g., beakers,

wide-necked Erlenmeyer flasks and

Petri dishes, or cylindrical items,

e.g., test tubes, can be cleaned inside

and out by the rotating spray arms.

For proper cleaning, load these items in

whole, half or quarter inserts, and place

them in an empty lower basket or upper

basket with spray arm.

Narrow-necked items, e.g., narrow

necked Erlenmeyer flasks, round flasks,

volumetric flasks and pipettes, require

the use of injector wagons or injector

baskets.

Separate instructions are included

for the use of injector baskets and

inserts for narrow-necked labware.

This section only covers basic

information on how to prepare and load

labware.

Petri dishes and similar items should

–

be loaded in a suitable insert with the

soiled side facing center.

Pipettes should be placed with the

–

narrow end facing down.

Protective netting can be used to

–

avoid glass breakage.

Quarter baskets should be loaded at

–

least 3 cm away from the edge of the

wagon.

20

Page 21

Areas of application

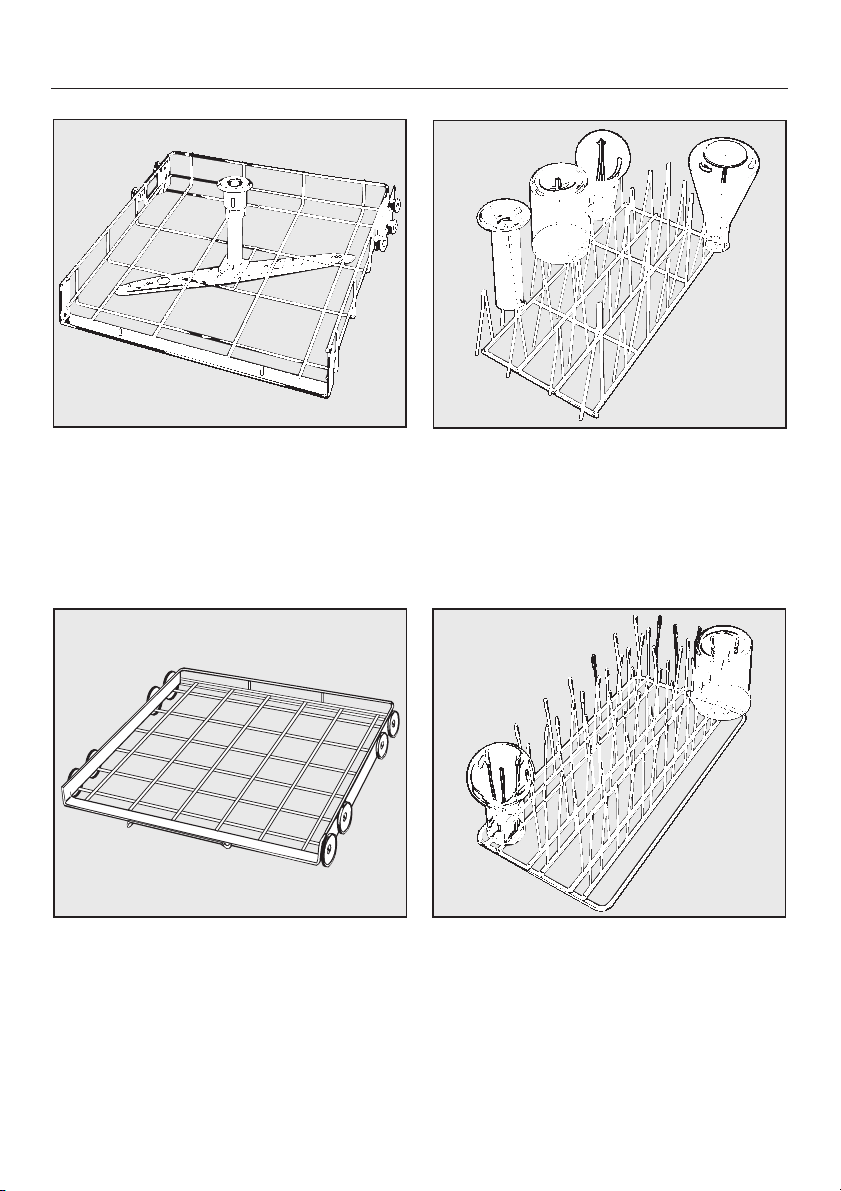

Upper basket O 188/1

For various inserts.

Lower basket U 874/1

For various inserts.

E 106/2

Stainless steel half insert with 26 spring

hooks in 2 different heights for various

glassware, e.g. narrow necked flasks,

graduated cylinders, medicine bottles,

etc.

E 109

Stainless steel half insert to

accommodate 21 beakers up to 250 ml,

Erlenmeyer flasks, round flasks, etc.

21

Page 22

Effects of Processing Chemicals

General information

Effects Action

Damage to elastomer (seals and hoses)

or plastic components of the lab

washer may cause the materials to

swell, shrink, harden or become brittle,

possibly causing cracks to form in the

materials. This will impair their function,

which will generally lead to leaks.

Strong foaming during the program

prevents proper cleaning and rinsing of

the load. Foam escaping from the wash

compartment can result in damage to

the lab washer.

If foaming occurs, the cleaning process

is not standardized and not validated.

Stainless steel corrosion in the wash

compartment and/or accessories may

appear in various ways:

– rust formation (red spots / stains),

–

black spots / stains,

–

white spots / stains (smooth surface

is slightly corroded).

Corrosion that forms holes can result in

leaks in the lab washer. Depending on

the application, the corrosion may

impair the cleaning and rinsing results

(laboratory analysis) or cause corrosion

of the load (stainless steel).

Find and correct the causes of the

–

damage.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

Find and correct the cause of the

–

foaming.

The process must be checked

–

regularly in order to detect any

foaming.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

– Find and correct the cause of the

corrosion.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

22

Page 23

Effects of Processing Chemicals

Connected processing chemicals

Effects Action

The ingredients of the processing

chemicals have a considerable effect

on the durability and functionality (feed

performance) of the metering systems.

The metering systems (feed hoses and

pump) are designed for a specific type

of processing chemicals.

General categories:

alkaline to neutral pH products,

–

acid to neutral pH products,

–

The processing chemicals can damage

the elastomer and plastic components

of the lab washer and its accessories.

The following processing chemicals

can result in excessive foaming:

– tenside cleaners containing

detergent and rinse aid.

The foaming can occur:

–

in the program block in which the

processing chemical is added,

–

in the subsequent program block

due to carry-over,

–

in the case of rinsing agents, in the

subsequent program due to

carry-over.

Use only those processing chemicals

–

recommended by Miele.

Consult a Miele Applications

Specialist.

Perform regular visual inspections of

–

the metering system.

Regularly check the feed

–

performance of the metering system.

– Use only those processing chemicals

recommended by Miele.

Consult a Miele Applications

Specialist.

– Perform regular visual inspections of

all visible elastomer and plastic

components.

– The process parameters of the wash

program, e.g. metering temperature,

metering concentration, etc. must be

set so that the overall process

creates little or no foam.

–

Observe the instructions of the

manufacturer of the processing

chemicals.

23

Page 24

Effects of Processing Chemicals

Connected processing chemicals

Effects Action

Antifoaming agents, particularly

silicone-based antifoaming agents, can

cause the following:

deposits in the wash compartment,

–

deposits on the wash load,

–

damage to the elastomer and plastic

–

components of the lab washer,

attack certain plastics (e.g.

–

polycarbonates, plexiglass, etc.) in

the wash load.

Use antifoaming agents only in

–

exceptional cases or when they are

absolutely necessary for the process.

Periodic cleaning of the wash

–

compartment and accessories

without a load and without an

antifoaming agent using the

"Regular" or "Extended" program.

Consult a Miele Applications Specialist.

24

Page 25

Effects of Processing Chemicals

Soiling

Effects Action

The following substances can damage

the elastomer components (hoses and

seals) and, in some cases, the plastic

components of the lab washer:

oils, waxes, aromatic and

–

unsaturated hydrocarbons,

softeners,

–

cosmetics, hygiene and skin care

–

products such as creams (analysis

and filling sections).

The following substances can cause

excessive foaming during washing and

rinsing:

– agents such as disinfection agents,

dish detergents, etc.

– reagents for analysis, e.g. for

microtitration plates,

– cosmetics, hygiene and skin care

products such as creams (analysis

and filling sections).

–

foaming substances in general, for

instance tensides.

Retrofit the lab washer with more

–

grease-resistant elastomers.

Depending on usage, periodically

–

wipe the lower door seal with a

lint-free cloth or sponge.

Clean the wash compartment and

accessories without a load using the

"Regular" or "Extended" program.

To process the load, use the

–

program "Regular" or "Extended" and

place additional powder cleaning

agent on the door.

– Thoroughly rinse the items in water

beforehand.

– Select the "Extended" program

(pre-wash with cold or hot water).

– Taking the specific application into

account, add an antifoaming agent,

one without silicone oils if possible.

The following substances can cause

corrosion to the stainless steel in the

wash compartment and accessories:

–

hydrochloric acid,

–

other substances that contain

chloride, e.g. sodium chloride, etc.

–

concentrated sulphuric acid,

–

chromic acid,

–

iron particles.

–

First rinse the load with a sufficient

quantity of water.

–

Let the load drip dry before putting it

on the carts, baskets and inserts and

placing in the lab washer.

25

Page 26

Effects of Processing Chemicals

Reactions between processing chemicals and soils

Effects Action

Natural oils and greases can be

saponified with alkaline processing

chemicals. This may cause a lot of

foaming.

In combination with alkaline processing

chemicals, loads with soiling that

contains proteins, e.g. blood, can

cause excessive foaming.

In combination with very acidic or

alkaline processing chemicals, base

metals such as aluminum, magnesium

and zinc can release hydrogen

(detonating gas).

Use the "Regular" or "Extended"

–

program.

Depending on the application add an

–

antifoaming agent that does not

contain silicone oils.

Select the "Extended" program

–

(pre-wash with cold water) where a

cold water connection is available.

Observe the instructions of the

–

manufacturer of the processing

chemicals.

26

Page 27

Only use cleaning agents

formulated for this machine. Do not

use detergents formulated for

domestic dishwashers.

Observe the instructions of the

manufacturer of the processing

chemicals.

Dispensing neutralizing or

rinsing agent

A duo-dispensing system for liquid

agents which can be used to dispense

either neutralizing agent or rinsing

agent, is located in the door.

A change of agent, e.g. from

neutralizer to rinsing aid, requires

re-programming by Miele Service.

The machine is set to dispense

neutralizer as factory default.

The duo-dispensing system consists of

two reservoirs and two dosage

selectors.

Dispensing chemical agents

Neutralizing agent

Neutralizing agent (pH-level: acidic)

neutralizes residues of alkaline cleaning

agents on the surface of instruments

and utensils.

The neutralizer is automatically

dispensed in the program stage Rinse

1 following the main wash of a program.

The dispensing system reservoir must

be filled and the dishwasher

programmed to dispense neutralizing

agent.

Rinsing agent

Rinse aid is necessary to ensure water

does not cling and leave marks on

items, and to help items dry faster after

they have been washed. The

dispensing system reservoir must be

filled and the dishwasher programmed

to dispense rinsing agent.

The components of the rinsing agent

remain on the surface of items after

they have dried. Depending on what

the utensils are being used for, it is

therefore important to check that rinsing

agent may be used.

The components of the rinsing agent

remain on the surface of items after

they have dried. Depending on what

the utensils are being used for, it is

therefore important to check that rinsing

agent may be used.

27

Page 28

Dispensing chemical agents

Filling the reservoirs

Important: Both reservoirs must

,

always be filled with the same liquid

agent.

Only fill the duo-dispensing

,

system with neutralizing agent or

rinsing agent formulated for

dishwashers. Do not fill with

cleaning agent. This would damage

the reservoirs.

Open the door fully.

^

Add liquid agent until the level

^

indicator is dark (see arrow on

illustration). Use a funnel if

necessary.

Each reservoir holds approx. 6 oz.

(180 ml).

^ Screw the caps back on.

^

Unscrew the caps.

28

^ Mop up any spilt liquid agent. This

prevents over-foaming occurring

during the next program.

Page 29

Dispensing chemical agents

Adjusting dosage

The dosage adjuster in the opening has

settings adjustable from 1 to 6 (1- 6 ml).

It is preset to "5" (10 ml) as the

recommended dosage for neutralizer.

^ Use a flat headed screw driver to turn

the dial to the correct setting.

If spots appear on items:

Add neutralizing agent indicator

^ The container for neutralizing agent

should be refilled when the indicator

lights up.

Add rinsing agent indicator

^

When using neutralizing agent select

a lower dosage.

^

When using rinsing agent select a

higher dosage.

If clouding or smearing appears on

items:

^

When using neutralizing agent select

a higher dosage.

^

When using rinsing agent select a

lower dosage.

^

Add rinsing agent to the rinsing

agent reservoirs when the indicator

lights up.

29

Page 30

Dispensing chemical agents

Adding detergent

Use only cleaning agents

,

formulated for this machine. Do not

use detergents formulated for

household dishwashers.

Avoid inhaling cleaning agents

,

in powder form. If processing

chemicals are ingested, they can

cause chemical burns in the mouth

and throat or suffocation.

Before starting the program, load the

powdered detergent into the

compartment (except for the programs

"Rinse" and "Drain").

Dosage: To achieve a detergent

concentration of approximately 3 g/l,

use 30 g of detergent.

Always follow the detergent

manufacturer's recommendations for

dosage concentration.

The flap is always open at the end of a

program.

^ Add powder cleaning agent to the

compartment.

^ Close the dispenser flap.

,

At the end of the program, check

that there are no cleaning agent

residues remaining in the dispenser.

If there are, you will need to repeat

the program.

^

Press the button on the powder

cleaning agent dispenser. The flap

will spring open.

30

Some types of soiling may require

different combinations of cleaning

agents and other additives. Contact

a Miele Applications Specialist if in

doubt.

Page 31

Operation

Turning on the lab washer

Make sure the spray arms are not

^

blocked.

Close the door.

^

^ Press the "On/Off" button to turn the

machine on.

Starting a program

Choose a program based on the type

of glassware being cleaned and the

degree of soiling.

Refer to the "Program Guide" for more

details.

^

Turn the program selector clockwise

or counterclockwise to the desired

program.

The wash temperature of the selected

program is shown in the display

(except for "Rinse" and "Drain").

The "Start" indicator will flash.

Select the Drying 3 function

if desired

"Drying" may be selected as an

additional feature once a program has

been selected (except in the "Rinse"

and "Drain" programs).

^ Select the "Drying" button.

Drying is phased over 10 minutes. The

total running time of the program

lengthens accordingly.

Changing a program

The program can only be changed if

the Start button has not been pressed.

^

Turn the program selector to the

desired program.

^

Select the "Drying" feature, if desired.

^

Press the "Start" button.

31

Page 32

Operation

Starting the program

Press the "Start" 6 button.

^

The display shows the current

temperature.

The "Start" indicator comes on.

Once the program has started, all other

programs are blocked. If the program

selector is turned to another program

during the running program, the values

shown in the display disappear. The

values appear again if the program

selector is turned back to the running

program.

During a program, the "Display" ß

button can be used to toggle between

the:

– actual temperature

– elapsed program time, and

Program sequence display

The current step of a wash program is

indicated by a program sequence

display.

End of a program

Once the "Start" indicator goes out, and

the "Complete" indicator comes on, the

program has ended. You will see a 0 in

the middle of the display, and all other

indicators will turn on then go out in

sequence.

A buzzer sounds for a maximum of

30 seconds by default.

To change the buzzer function, see

"Programming functions".

Use the "Display" ß button to view

^

the total running time or temperature

of the program.

Immediately after the program is

finished open the door (about 4 inches)

for 10 - 15 minutes, then unload the

dishwasher. This will help ensure a

good drying result and prevent

corroding.

Turning off

^

Press and release the On/Off button.

Because of the electric door lock,

the door can only be opened if the

On/Off button is pressed (see

"Opening and closing the door").

32

Page 33

Operation

Canceling a program

If a program is canceled it must

,

be run again to be complete.

Canceling a program because of an

interruption

The program is stopped prematurely

and a Fault message appears in the

display.

Depending on the cause the

appropriate measures must be taken to

correct the fault. See "Frequently asked

questions".

Manually canceling a program

Avoid canceling a running program

unless absolutely necessary, for

example if the glassware is moving

around excessively or the wrong

program has been selected.

Turn the program selector to f.

^

The program is canceled after

2 seconds.

Open the door.

^

Caution! Water and items in the

,

machine may be hot. There is a

danger of burning or scalding.

^ Rearrange the items securely. Wear

protective gloves as needed, and

comply with all applicable health and

safety regulations for infectious

disease control.

^ Replenish powder detergent if

necessary.

^

Close the door.

^

Start the "Drain" program.

The water will be drained away.

^

Select and start the program.

33

Page 34

Program guide

Program Application Powder cleaning agent

(follow manufacturers

instructions)

SHORT For laboratory glassware with light

water-soluble contamination, not

suitable for denaturing and acid-soluble

residues such as proteins, metallic salts

and amines, for low level soiling and low

rinse requirements.

REGULAR For laboratory glassware with light

water-soluble contamination, not

suitable for denaturing and acid-soluble

residues such as proteins, metallic

salts and amines, for low level soiling

and medium rinse requirements.

EXTENDED For removal of organic residues (e.g.

specific oils and fats) and specific

inorganic residues, for low to medium

level soiling and medium rinse

requirements.

DRAIN To drain water out of the machine,

e.g. after a program has been canceled,

see "Canceling a program".

RINSE For rinsing heavily soiled items (e.g. for

removing soiling or disinfectant residue,

or to prevent soiling drying on to dishes

when a complete program does not

need to be run yet).

Approx. 20 g in the

powder cleaning agent

dispenser.

Approx. 30 g in the

powder cleaning agent

dispenser.

Approx. 30 g in the

powder cleaning agent

dispenser with an

additional 10 - 20 g

cleaning agent on the left

hand side of the door, if

necessary.

Organic residues such as oils and fats may require conversion to oil-resistant elastomers.

34

Page 35

Program cycle

Program guide

Pre-

wash

Main wash Interim

X

DOS 1

70°C/5’

X

DOS 1

70°C/5’

XX

DOS 1

70°C/5’

rinse 1

X

DOS 3

X

DOS 3

Interim

rinse 2

(X)

(DI)

DOS 3

(X)

(DI)

(X)

(DI)

Final rinse Drying

X

DI

(DOS 2)

70°C/3 min

X

DI

(DOS 2)

70°C/3’

DI

X

DI

(DOS 2)

70°C/3’

DI

(X)

(X)

(X)

X

X = Sections included in a program (with temperature/temperature holding time)

1

*

2

*

DI (Aqua destillata) = distilled water

DOS 1 = For dispensing cleaning agent

DOS 2 = For dispensing rinsing agent (must be activated by a Miele service technician)

DOS 3 = For dispensing neutralizing agent

To change a temperature or temperature holding time see"Programmable functions"

To activate "Rinse 2" see "Programmable functions". (To use AD water in the program

section "Rinse 2", the machine has to be programmed by a Miele service technician)

35

Page 36

Programming functions

For future servicing, be sure to document any changes made to the factory

settings in the fields provided.

General information:

Program selector positions that have no assigned function are represented by a

–

bar ( - ) in the middle of the display.

To call up the programming level, use the f position.

–

The status E.. will appear in the display.

For validated processes, any changes made to programs or dispensing

–

systems must be documented in a log book kept with the machine. The

machine's processes must be re-validated.

The following instructions apply to all programming functions:

To access the programming mode

^ Turn the program selector to f.

^ Turn off the machine.

^ Simultaneously press and hold the

"Display" ß and "Start" 6 buttons,

while turning on the machine by

pressing the On/Off button.

Saving to memory and exiting the programming mode

^

Press the "Start" 6 button.

^

Press the "Start" 6 button again.

Exiting the programming mode without saving

^

Press the On/Off button to turn off

the machine.

36

The current program status P..

appears in the display. The Fill/Drain

indicator lights.

SP appears in the display.

The change will now be stored in the

memory.

The change is canceled.

Page 37

Programming functions

Buzzer

The buzzer can be programmed for the following functions:

– a continuous tone at the end of a program, and/or

– an error signal that beeps in 1-second intervals.

The numbers shown in the display correspond to the following settings:

100 Buzzer off

101 End of program (factory setting)

102 Fault

103 End of program + Fault

Step Display / Result

Press the "Drying" 3 button until E01 appears in the

^

display.

E01

^ Turn the program selector to "Drain".

^ Press and hold the "Display" ß button until the

required value appears in the display, e.g., 103.

Value selected:

The buzzer will sound for 30 sec during the selected setting.

To switch it off earlier:

–

Turn the program selector to f.

–

Press the "Display" ß button.

–

Interrupt the power supply, e.g., open the door.

100 to 103

103

37

Page 38

Programming functions

Changing program parameters

The parameters for the Short, Regular and Extended programs can be changed to

suit particular requirements. To do this the temperature and the temperature

holding time in the Main wash and Final rinse program blocks can be changed.

Program parameters cannot be changed unless they are activated within a given

program (see "Program Guide").

It is important to document any changes e.g., by recording them in the

corresponding column in the program guide.

Changing the temperature

Values can be set from 86° - 158°F (30° - 70°C)

Step Display / Result

^ Press and hold the "Drying" 3 button until

the setting of the desired program block

appears in the display.

E03 for Main Wash

E05 for Final rinse

^ Set the program selector to the program

you wish to change, e. g., "Extended".

^ Press and hold the "Display" ß button until

the desired value appears in the display,

e.g., 70 °C.

Changing the holding time

Values can be set from1-10minutes

Step Display / Result

^

Press and hold the "Drying" 3 button until

the setting of the desired program block

appears in the display.

^

Set the program selector to the program

you wish to change, e. g., "Short".

^

Press and hold the "Display" ß button until

the desired value appears in the display,

e.g., 10.

38

°C ~65

°C ~70

E03 for Main Wash

E05 for Final rinse

min _ 1

min _ 10

Page 39

Programming functions

Activating Rinse 2

A second interim rinse can be programmed in to improve interim rinsing in all

programs except for Rinse.

Step Display / Result

Press and hold the "Drying" 3 button until

^

E01 appears in the display.

E01

Turn the program selector to the 5 o'clock

^

position.

Press and hold the "Display" ß button until

^

the required number appears in the display,

e.g. 51.

Value set:

To use DI water in the program section "Rinse 2" the machine has to be

programmed by a Miele Service Technician.

S0 Rinse 2 not activated

S1 Rinse 2 activated

S1

39

Page 40

Programming functions

Delay start

The start of a wash program can be delayed by up to 24 hours in 30 minute

stages.

Important: If a very long delay start is set there is a danger of items in the

machine drying out, impairing cleaning results.

Activating delay start

Step Display / Result

Press and hold the "Drying" 3 button until

^

E01 appears in the display.

E01

^ Turn the program selector to the 8 o'clock

position.

^ Press and hold the "Display" ß button until

the required number appears in the display,

e.g. 81.

Value set:

Setting the start time

The delay start time must be reset before the start of every program.

–

Values which can be set: 30 mins - 24 hours

^

After selecting the program press ß until the required value appears in the

display. The "Delay start" indicator light next to the ß button will light up.

When the 6 button is pressed, the delay time in the display starts counting down

to the automatic program start time.

80 Delay start not activated

81 Delay start activated

81

40

Page 41

Programming functions

Restoring the factory settings

Step Display / Result

Press and hold the "Drying" 3 button until

^

E07 appears in the display.

Turn the program selector to a program.

^

E07

Default factory setting(s):

Re-programmed setting(s):

When PP appears in the display, press the

^

"Display" ß button.

The water softener has been restored to the factory settings. Reprogramming is

required (see "Setting the water softener").

00

PP

00, the factory settings have

been restored.

41

Page 42

Maintenance

Periodic maintenance for the lab

washer is recommended annually.

Routine checks

The routine checks must be done daily

by the user before using the machine.

For the routine checks a checklist is

supplied with the machine.

Check the following points:

the filters in the base of the wash

–

cabinet must be empty,

the spray arms in the machine and at

–

the baskets should be clear,

– the wash cabinet and the door

gasket should be clear,

– the dispensing systems, and

– the baskets and inserts.

42

Page 43

Wear protective gloves and

,

goggles when cleaning this

machine.

Cleaning the filters in the wash

cabinet

The lab washer must not be

,

used without all filters in place. The

filters protect the circulation pump

from damage caused by foreign

objects.

The filter combination in the base of

the wash cabinet should be

inspected regularly and cleaned if

necessary.

Watch out for sharp objects which

could cause injury e.g. glass

splinters.

Cleaning and Care

Cleaning the coarse filter

^ Press the two tabs together, remove

and clean the coarse filter.

^ Put the clean filter back in position

and press until it clicks into place.

43

Page 44

Cleaning and Care

Cleaning the fine, flat and micro-fine

filters

Remove the coarse filter.

^

Remove the fine filter from between

^

the flat and micro-fine filters.

^ To unscrew the micro-fine filter,

grasp the two tabs and turn twice

counterclockwise.

Then remove together with the flat

^

filter.

^ Clean the filters.

^ Replace the filter combination in

reverse order. The flat filter must lie

flat in the base of the wash cabinet.

44

Page 45

Cleaning and Care

Cleaning the spray arms

The spray arms can get clogged.

Check daily and clean if necessary.

Removing the spray arms

Remove the baskets.

^

Spray arm at the upper basket or

mobile unit (if available):

Loosen the knurled nut and remove

^

the spray arm.

Metal knurled nuts have a left-hand

thread. Ceramic knurled nuts have a

right-hand thread.

Unscrew the upper spray arm.

^

Loosen the knurled nut of the lower

^

spray arm and remove.

Use a sharp pointed object to push

^

particles into the spray arm jets and

rinse thoroughly under running water.

Refit the spray arms in reverse order

^

after cleaning.

After replacing the spray arms

check that they can rotate freely.

45

Page 46

Cleaning and Care

Cleaning the drain pump and

non-return valve

If water has not been pumped away at

the end of a program the drain pump or

the non-return valve may be blocked.

Turn off the machine.

^

Remove the filter combination out of

^

the wash cabinet.

^ Tilt the locking clamp to the side.

^

Pull out the non-return valve and

rinse well under running water.

The drain pump is beneath the

non-return valve (see arrow).

^ Before refitting the non-return valve,

check that the drain pump is not

blocked. Spin the propeller several

times in both directions to check for

obstructions.

^ Carefully refit the non-return valve

and secure it with the locking clamp.

Refit and lock the filter in place.

For safety the load should be

washed again.

,

Use proper eye protection when

removing the non-return valve.

46

Page 47

Cleaning and Care

Cleaning the water inlet filters

To protect the water inlet faucet, filters

are incorporated in the intake hose

attached to the water supply. If the

filters are soiled they must be cleaned

to ensure sufficient water intake to the

wash cabinet.

The plastic housing of the water

,

connection contains electrical

components and should not be

submerged or run through water.

Cleaning the filters

Disconnect the lab washer from

^

electricity (unplug it or "trip" the

circuit breaker).

Close the water supply and unscrew

^

the water inlet faucet.

Carefully remove the rubber seal.

^

Take out the filters with needle nose

^

pliers.

^

Rinse the large area filter 1 and fine

filter 2 under running water, and

replace if necessary.

^

Return filters and seal. Make sure

they are seated correctly.

^

Reconnect the hose to the water

faucet, checking that it is not

cross-threaded.

^

Open the water supply.

^

Check for leaks.

47

Page 48

Cleaning and Care

Cleaning the control panel

The control panel should only be

^

cleaned with a damp cloth or a

suitable cleaner for use on plastic

materials.

Do not use abrasive cleaners,

,

glass cleaners or all-purpose

cleaners! They will damage the

control panel.

Never clean the lab washer or

,

near its vicinity with a water or high

pressure hose.

Cleaning the wash cabinet

The wash cabinet is mostly self

cleaning.

If deposits have built, contact Miele for

info.

Cleaning the exterior

Stainless steel surfaces can be

^

cleaned using a non-abrasive

stainless steel cleaner or

dishwashing detergent and warm

water.

^ To help prevent resoiling, a

conditioner for stainless steel can

also be used. Apply sparingly with

even pressure.

,

Do not use cleaners containing

thinner or ammonia. They will

damage the surface.

Cleaning the door seal

Clean the door seal regularly with a

damp cloth to remove soiling.

To replace damaged or leaking door

seals please contact Miele's Technical

Service Dept.

Dispensing systems

Check the consumption of the used

chemicals regularly to notice any

irregularities of the dispensing.

48

Page 49

Cleaning and Care

Baskets and inserts

To ensure the function of baskets and

inserts, they must be checked daily. A

checklist is supplied with the lab

washer.

Check the following points:

Are the rollers in the proper condition

–

and are they securely fixed in the

mobile unit/insert?

Is the basket connection set to the

–

correct height and tightened?

Are all spray jets, spray sleeves and

–

hose adapters tightly connected to

the basket/insert?

– Are all spray jets, spray sleeves and

hose adapters, unclogged so that

the wash water can flow through?

– Are covers and fasteners tightly

screwed on the spray sleeves?

If available:

do the spray arms rotate freely?

–

Are the spray jets clogged? See

–

"Cleaning and Care - Cleaning the

spray arms"?

49

Page 50

Frequently asked questions

The following guide can be used to help address minor problems without a ser

vice call.

Repairs should only be performed by Miele Technical Service. Work

,

performed by unqualified persons can place the user at considerable risk of

harm.

To help avoid unnecessary service calls, please be sure to check first whether an

error message is due to operator error.

To do so:

Turn the program selector to f. The error message is erased.

^

Press the On/Off button to switch off the machine.

^

^ Turn the machine back on and re-start the program.

^ If the error occurs again and cannot be corrected, contact Miele Technical Ser-

vice for assistance.

You will need to provide the error code ( "F...") .

What if... Possible fault Solution

The machine will not

start.

The program does not

work.

The door is not properly

closed.

The machine is not

plugged in.

The fuses are defective or

the circuit breaker has

tripped.

The machine is not turned

on.

Fault message: F04 - F10,

F24-F26,F--

Close the door firmly.

Plug in the power cord.

Make sure the breaker has

not tripped.

Press the On/Off button

and select a program.

Contact Miele Technical

Service.

-

50

Page 51

Frequently asked questions

What if... Possible fault Solution

The "Recharge"

indicator flashes.

The "Neutralizer"

indicator flashes.

The Rinse Aid indicator

flashes.

A few minutes after the

start of a program, the

"Fill/Drain" indicator

flashes, and the

program stops.

The water softener has run

out of salt.

The neutralizing agent

container is empty.

The rinsing agent container

is empty.

Error message: F..E:

There is a problem with the

water intake.

Refill the salt reservoir.

Fill the container with

–

neutralizing agent

Fill the reservoir with

–

rinse aid.

Before addressing the

error:

Turn the program

–

selector to f. The error

message is erased.

Press the On/Off button

–

to switch off the

machine.

– Open the water valve

completely.

– Clean the water inlet

filters.

– The flow pressure at the

water connection is too

low. Contact a qualified

plumber for advice.

Then:

–

Turn the machine on.

–

Restart the program.

51

Page 52

Frequently asked questions

What if... Possible fault Solution

The rinse program is

interrupted and the

"Fill/Drain" indicator

light is flashing.

The water in the wash

cabinet does not get

hot; the program

sequence lasts too

long.

Error message: F..A:

There is a problem with the

water out take.

Error message: F01 - F02

The machine is equipped

with a temperature sensor

that switches off the heater

when it begins to overheat.

Overheating can occur

when, e.g., large items

cover the heating elements,

or when the filters in the

wash cabinet are blocked.

Before addressing the

error:

Turn the program

–

selector to f. The error

message is erased.

Press the On/Off button

–

to switch off the

machine.

Clean the filter

–

combination in the wash

cabinet.

Clean the drain pump.

–

Clean the non-return

–

valve.

– Remove any kinks in the

drain hose.

Then:

– Turn the machine on.

– Drain the water.

– Restart the program.

– Clean the filter

combination in the wash

cabinet.

–

Rearrange the

glassware.

–

Reset the Thermo

switch. See "Frequently

asked questions - Ther

mo switch".

-

52

Page 53

Frequently asked questions

What if... Possible fault Solution

After a program, there is

powdered detergent

residue left behind in

the door dispenser.

The powdered detergent

dispenser cover will not

close.

A banging noise can be

heard in the wash

cabinet.

A rattling noise can be

heard in the wash

cabinet.

A banging noise is

coming from the water

pipes.

The dispenser was wet

when it was loaded.

The powdered detergent

dispenser cover was

blocked by glassware.

Detergent residue is

blocking the latch.

A spray arm is hitting the

glassware.

Glassware is moving

around in the wash

cabinet.

This may be caused by the

installation or the diameter

of the pipes.

Remove any detergent

–

residue.

Prepare items again.

–

Make sure the dispenser is

dry before loading it.

Always arrange glassware

so the dispenser cover can

open.

Wipe away any detergent

residue.

Interrupt the program and

re-arrange any glassware

that it blocking the wash

arm, (see "interrupting a

program").

Interrupt the program and

re-arrange any glassware

that is loose, (see

"interrupting a

program").

Consult a qualified

plumber for advice.

53

Page 54

Frequently asked questions

What if... Possible fault Solution

Items made of glass

show signs of

corrosion.

Items made of stainless

steel show signs of

corrosion.

The items are not lab

washer-safe.

No neutralization took

place in the program

sequence.

Excessively high

temperatures are causing

glass corrosion.

Too alkaline detergent is

causing glass corrosion.

The chloride content of the

water is too high.

The screw cap on the

reactivation salt reservoir is

not tightened.

No neutralization took

place in the program

sequence.

Rust articles or a rust film

appears in the wash

cabinet, due to:

–

excessive iron content in

the water, or

–

rusty items in the

machine.

The grade of stainless

steel is not lab

washer-safe.

Only use lab washer-safe

glassware.

Fill the neutralizer

container.

Select an appropriate

program or lower the wash

temperature.

Choose a milder

detergent.

Test your water

composition. If needed,

condition the water

externally and use DI

water.

Properly thread the cap

and screw it tightly.

Fill the neutralizer

container.

– Check the piping.

–

Remove all rusty items

from use.

Only use high grade

stainless steel.

54

Page 55

Frequently asked questions

What if... Possible fault Solution

There are white

deposits and/or spots

on the labware.

The water softener setting

is too low.

Too much powder

detergent is being used.

The neutralizer is not

dispensing properly.

There is no reactivation

salt in the reservoir.

The screw cap on the

reactivation salt reservoir is

not tightened.

The rinse aid dosage was

set too low.

The rinse water quality was

insufficient.

Test the tap water

hardness and program the

water softener according.

Be sure you are using the

correct amount of

detergent.

Check the neutralizer

dispenser.

Carefully fill the reservoir

with the reactivation salt.

Properly thread the cap

and screw it tightly.

Increase the rinse aid

dosage setting.

– Use water with a lower

conductivity.

– If the machine is

connected to a

demineralizing

cartridge, check the

status and change as

needed.

55

Page 56

Frequently asked questions

What if... Possible fault Solution

The wash result is

unacceptable.

The baskets and inserts

were incorrectly loaded or

overcrowded.

The program used was not

suited to the type/amount

of soiling.

The detergent used was

not suited to the

type/amount of soiling.

The labware was left soiled

for too long.

A spray arm is blocked. Arrange the items do not

Jets are blocked in the

spray arms or inserts.

The filters in the wash

cabinet are soiled.

The basket or insert is not

properly connected to the

water supply.

Properly arrange the

glassware.

Do not overload baskets

and inserts.

Select an appropriate

program or modify the

program.

Use a suitable detergent

for machine washing.

Do not leave soiled

labware unwashed for

more than 6 hours.

block the spray arms.

Check the spray jets and

clean as needed.

Check the filters and clean

them if necessary.

Use the adapter to

properly connect the water

supply to the basket or

insert.

56

Page 57

Opening the machine during a

power failure

The emergency release should only

be used when the door cannot be

opened normally, e.g. in the case of

a power failure.

Turn the program selector to "Stop"

^

f.

Press the "On/Off" button to turn the

^

machine off.

Frequently asked questions

^

Reach behind the service panel and

pull the ring of the emergency

release downwards.

57

Page 58

Frequently asked questions

Thermo switch

This lab washer has a resettable heater

limiter which will shut off the elements in

the event of over-heating. This could be