Page 1

Operating instructions for

G 7781 DENTAL

Thermal Disinfector

To prevent accidents and

reduce the risk of damaging

the machine, read these

instructions before installing

or using the machine. M.-Nr. 04 701 092

ö]

Page 2

Contents

Contents

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Help to protect our environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

IMPORTANT SAFETY INSTRUCTIONS (detachable) . . . . . . . . . . . . Centre pages

Indications for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setting the water softener. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Opening and closing the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Loading and unloading the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adding rinsing agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Setting the dosage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adding neutralizing agent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adding detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Program Chart G7781 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Turning the machine on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Selecting a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Selecting an additional program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Program sequence indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Interrupting a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Programming special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Reactivating the water softener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning an care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Correcting minor problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2

Page 3

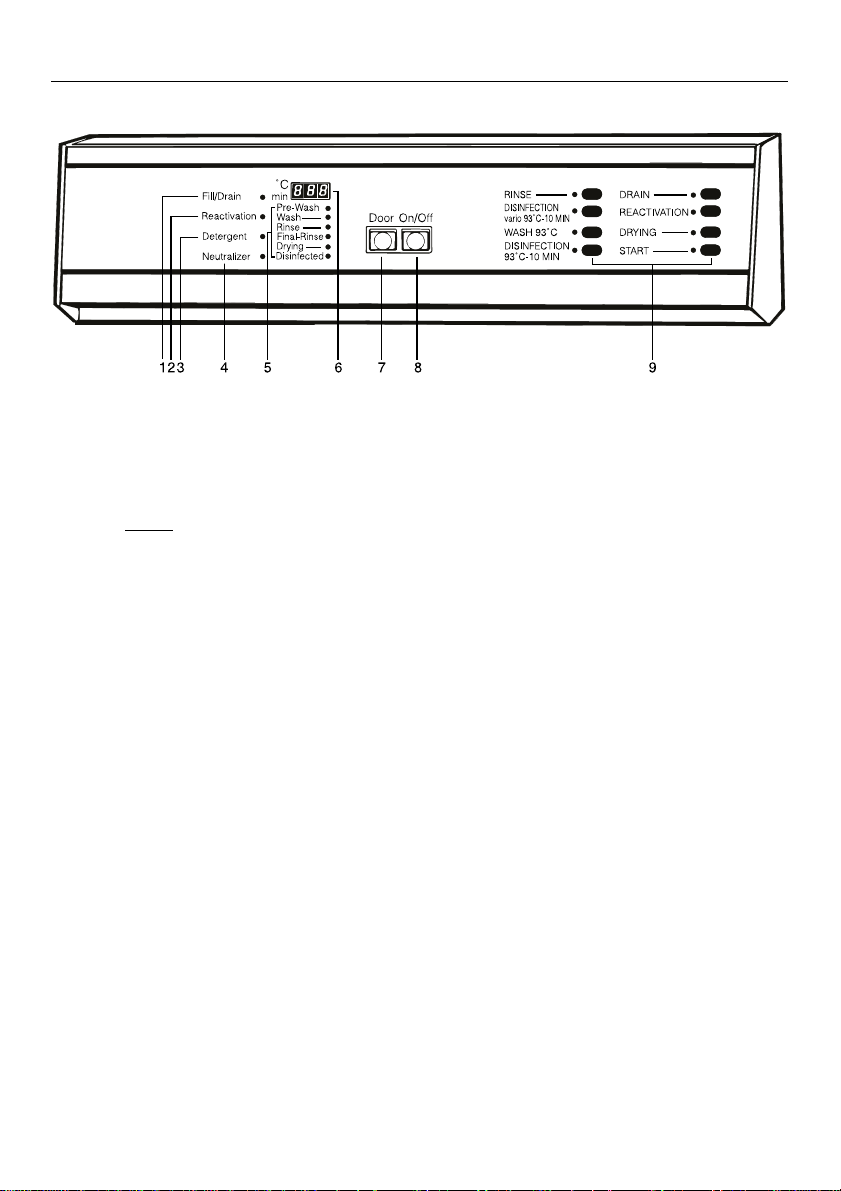

Guide to the machine

Guide to the machine

1 ”Check water inlet/drain”

indicator light

2 ”Reactivate water softener”

indicator light

3 ”Add

liquid detergent”

indicator light

(only where special DOS module is

connected externally)

4 ”Add neutralizing agent”

indicator light

5 Program sequence indicator light

6 Indicator display field

7 Door release

8 On-Off button

9 Program selectors

3

Page 4

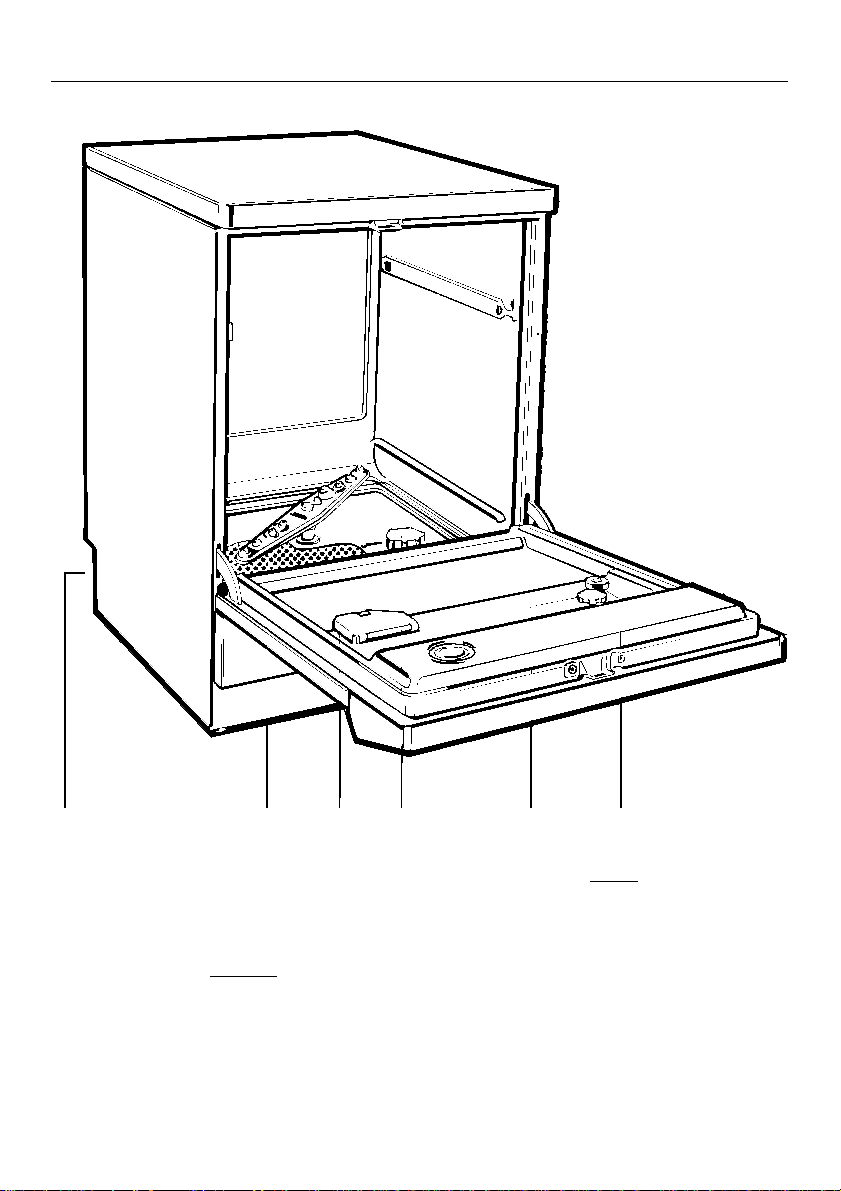

Guide to the machine

10 11 12 13 14 15

10 Connection for despenser pump

DOS C 60 (rear)

11 Filter combination

12 Dispenser for

13 Salt reservoir (water softener)

4

powder detergent

14 Dispenser for

with dosage selector

15 Rinsing agent level indicator

liquid rinsing agent

Page 5

Help to protect our environment

Help to protect our environment

Disposal of the packaging material

The transport and protective packaging is mostly manufactured from the

following reusable materials:

corrugated paper/cardboard

polystyrene (CFC-free)

polyethylene foil (transparent)

untreated wood

Rather than throwing these materials

away, please take them to the nearest

recyclables collection point.

Disposal of your old machine

Old machines contain materials which

can be recycled. Please contact your

local scrap merchant about potential recycling options before disposal.

When disposing of an old machine,

make sure the door catch is removed.

This will prevent children at play from

being accidentally locked in.

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed

including the following:

READ ALL INSTRUCTIONS BEFORE

USING THE APPLIANCE

WARNING –

The manufacturer cannot accept

responsibility for damage caused

when the appliance is not used

according to the instructions, or for

uses other than those for which it

was intended.

This special commercial machine

is suitable for the applications mentioned in the operating instructions. Do

not use for purposes other than those

for which it was designed, as these

may be dangerous. The manufacturer

cannot be held responsible for damage

caused by improper use.

Do not allow small children or un-

authorized personnel access to

the machine or its controls.

If thermal disinfection is required

(93ºC/200ºF/10min.), the process

needs to be checked and documented

regularly. This can be done by checking the disinfection control diode on the

machine. Alternatively, a chemical indicator may be used (e.g. the Disinfection Control Tubes by A. Browne Ltd.,

supplied by Miele). These disinfection

control tubes should be placed in the

filter combination. After the disinfection

cycle, they may be inspected by removing the coarse filter.

The disinfection program should

not be interrupted, as this would

affect the disinfection result. If interruption is necessary, the program should

be repeated.

Do not install the machine in areas

where there is a risk of explosion.

6

Page 7

IMPORTANT SAFETY INSTRUCTIONS

The machine is built in accordance

with current safety requirements.

Any repair work should only be carried

out by a suitably qualified and competent engineer. Repairs by unqualified

persons could be dangerous.

The electrical safety of this ma-

chine can only be guaranteed if

connected to an electrical system that

complies with all local and national

regulations. It should be checked by an

expert if necessary. The manufacturer

cannot be held responsible for damage

caused by incorrect wiring.

The machine should only be in-

stalled by a suitably qualified and

competent contractor. Before connecting the machine, the installer should

check that the voltage and frequency

of the electrical supply correspond with

the details on the data plate of the machine.

Only genuine Miele parts or acces-

sories should be used with the

G 7781 Dental Thermal Disinfector. The

performance and safety of non-genuine

parts or accessories cannot be guaranteed, and use of such parts or items

may void the machine warranty. If you

have specific questions about machine

options or accessories, please call

Miele.

The use of Neodisher cleaning,

neutralizing, and rinsing agents is

strongly recommended. The use of any

other products may invalidate the disinfection results and the manufacturer’s

warranty.

The machine is completely isolated

from the electricity supply only

when it is unplugged or the circuit

breaker is turned off. This must be

done before any repair work is carried

out.

The water in this machine must not

be used as drinking water.

Only use detergents which have

been approved of by Miele. Do not

use solvents in your machine as there

may be a danger of explosion.

7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

Take care when handling liquids

such as detergents, rinsing or neutralizing agents. These may contain

acids or alkalis. Follow the instructions

and safety procedures on the packaging carefully and wear protective

gloves and goggles. Read the Material

Safety Data Sheets.

Avoid inhalation of powder

cleaners.

Empty any containers or glassware

before placing it in the machine.

Do not allow any acids or solvents,

especially hydrochloric acid and

chlorides, to get into the wash cabinet.

Be careful when sorting instru-

ments with sharp pointed ends. If

possible, place the pointed end downwards.

Install special inserts in accord-

ance with the instructions provided.

When using the machine be care-

ful not to scald or burn yourself.

Baskets and inserts must first be

allowed to cool down. Any water which

may have collected in incorrectly

loaded items will be very hot and

should be emptied into the wash

cabinet.

Do not touch the heating elements

after the end of a program. You

could burn yourself.

Do not hose the machine down to

clean it.

Do not sit or lean on the open door.

This could cause the machine to

tip and be damaged.

When disposing of an old ma-

chine, make sure the door catch is

removed. This will prevent children at

play from being accidentally locked in.

8

Page 9

IMPORTANT SAFETY INSTRUCTIONS

All relevant safety procedures

should be obeyed. Relevant safety

procedures include, but are not limited

to, the Centers for Disease Control’s

Recommended Infection Control Practices for Dentistry and the OSHA Bloodborne Pathogens Standard.

The manufacturer cannot be held

responsible for damage caused by

failure to heed the warning and

safety instructions.

SAVE THESE

INSTRUCTIONS

9

Page 10

Indications for use

Indications for use

High-level disinfection

The G 7781 Dental Thermal Disinfector

is suitable for automatic treatment of

dental instruments and accessories. It

cleans and when using the disinfection

programs simultaneously thermally disinfects at 200ºF/93ºC instruments and

accessories.

Areas of effectiveness are physical

removal or thermal inactivation of vegetative bacteria including mycobacteria,

fungi, fungal spores, and viruses.

These categories include the Mycobacterium tuberculosis and the Enterococcus faecium.

Important: Only the programs labeled

‘DISINFECTION’ disinfect! Only use

these programs when handling contaminated items. All other programs are

designed to clean items without disinfecting them!

All relevant safety procedures should

be obeyed. Relevant safety procedures

include, but are not limited to, the

Centers for Disease Control’s Recommended Infection Control Practices for

Dentistry and the OSHA Bloodborne

Pathogens Standard.

The G 7781 Dental Thermal Disinfector

achieves high-level disinfection as

defined by the Spaulding categorization.

The Spaulding category high-level disinfection is the same type of means as

in the sterilant category except that the

use pattern is different. The sterilant is

used as a high-level disinfectant by

e.g. reducing the exposure time within

its effective range of tuberculocidal,

virucidal, and bactericidal action.

According to the Centers for Disease

Control’s Recommended Infection

Control Practices for Dentistry,

instruments should be classified in one

of the following categories and be

treated accordingly:

All critical instruments must be sterilized after treatment in the G 7781

Dental Thermal Disinfector. Critical instruments are used to penetrate soft

tissue or bone, e.g. forceps, scalpels,

bone chisels, scalers, or burs.

Semicritical instruments should be

sterilized after treatment in the G 7781

Dental Thermal Disinfector. If, however,

sterilization is not feasible because the

instrument will be damaged by higher

heat exposure, the instruments may be

treated terminally in the G 7781 Dental

Thermal Disinfector. Semicritical instruments do not penetrate soft tissues or

bone but contact oral tissues, e.g. mirrors and amalgam placement instruments.

Noncritical instruments may be

treated terminally in the G 7781 Dental

Thermal Disinfector. Noncritical instruments or devices come into contact

only with intact skin, e.g. external components of x-ray heads.

10

Page 11

Indications for use

Instruments suitable for

processing in the thermal

disinfector

All instruments, accessories, and other

items to be cleaned and disinfected in

the G 7781 Dental Thermal Disinfector

should have the following properties:

heat resistance to a temperature of

up to 95°C/203°F

corrosion resistance in the presence

of heat and alkalinity.

The high heat retention capacity of

stainless steel allows for fast drying.

Plastic has a lower heat retention capacity, thus needing a longer drying

time. In this case, a slightly extended

waiting period after the disinfection

cycle of 5 - 15 min. may be necessary.

Aluminum discolors using the program

DISINFECTION 93°C-10’. It may discolor using the program DISINFECTION VARIO 93°C-10’. Aluminum only

has a limited suitability for processing

in this system.

Do not clean fiberoptics or electrical

equipment or components in the thermal disinfector.

Rhodium coated specula must be arranged so that their surfaces do not suffer any mechanical damage. Not all

specula with glass are suitable for machine treatment.

In case you have any questions regarding the suitability of instruments for

being processed in the G 7781 Dental

Thermal Disinfector, please ask the instrument manufacturer’s advise.

Cleaning without disinfection

All other programs are designed to

clean goods without disinfecting them.

These programs are:

Rinse

Wash 93°C

Please refer to ”Program selection” for

detailed information.

Carbon steel may corrode in the process. Please try the corrosion resistance of carbon steel instruments with

initially one instrument, or do not process carbon steel items at all. If you do

process carbon steel items, the program DISINFECTION VARIO 93°C-10’

should be used.

Handpieces, drill bits, grinders, root

canal instruments or other rotating instruments only have a limited suitability

for the thermal disinfector. Please ask

the manufacturer’s advice on the suitability for processing in this system.

11

Page 12

Setting the water softener

Setting the water softener

To avoid the build-up of calcium deposits on items being cleaned and in

the machine, the water may need to be

softened (where the supply hardness

exceeds 107 ppm CaCO

To ensure a steady supply of soft water

the water softener must always be:

1. correctly set

2. regenerated with salt as soon as the

”Reactivation” indicator light comes on.

The water softener should be set to

correspond with the water hardness

upon installation of the machine.

Your local water authority can advise

you on the water hardness in your area.

Setting the water softener

The hardness range is divided into 18

units and a zero position. The machine

is set at the factory for a water hardness setting of 8, corresponding to 339

ppm CaCO

der or softer than this, the setting of the

controls should be changed. Find the

”Display Field” number corresponding

to your local water hardness in the

table.

. If your water supply is har-

3

).

3

Dis-

gr/gal mmol/l ° fH °eH ppm

play

Field

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

6

7

8

9

10

11

12

13

15

17

19

22

24

28

32

38

48

71

1.07

1.25

1.42

1.60

1.78

1.96

2.14

2.31

2.67

3.03

3.38

3.92

4.27

4.98

5.70

6.76

8.54

12.64

10.7

12.5

14.3

16.0

17.9

19.6

21.4

23.2

26.8

30.4

33.9

39.3

42.8

50.0

57.1

67.8

85.7

126.7

7.5

8.8

10.0

11.3

12.5

13.8

15.0

16.3

18.8

21.3

23.8

27.5

30.0

35.0

40.0

47.6

60.1

88.9

CaCO

107

125

143

160

179

196

214

232

268

304

339

393

428

500

571

678

857

1267

Press the ”Drain” and ”Drying” touch

pads simultaneously and, while depressed, turn the machine on, using

the main ”On/Off” switch.

”P…” will appear in the indicator

panel.

Press the ”Reactivation” touch pad.

The ”P…” will disappear and setting

”0” will appear in the display field.

This setting ”0” can now be changed

if necessary. To do this:

Press the ”DRYING” touch pad as

many times as necessary for the

desired value to appear in the display field.

Press the ”START” touch ad. ”SP” appears in the display field.

Press ”START” once more. The setting will now be stored. The display

field clears.

The machine is now ready for operation.

3

12

Page 13

If the water hardness in your area is

permanently below 107 ppm CaCO

you do not need to soften the water.

Please deactivate the water softener by:

Selecting the setting ”0” in the display field according to above instructions. The ”REACTIVATION” control

light will not come on and the water

softener will not need to be reactivated.

For instructions on reactivating the

water softener, see page 30.

,

3

Setting the water softener

13

Page 14

Opening and closing the door

Opening and closing the door

To open the door

press the ”DOOR” button on the control panel and open the door.

The door should only be opened during operation for emergencies, e.g. if

articles are knocking together. If this occurs in the disinfection program, restart

the complete program.

To close the door

lift the door upwards and push until it

clicks into position. Do not press the

”DOOR” button.

14

Page 15

Loading and unloading the machine

Loading and unloading the machine

The disinfector normally uses an upper

and a lower basket.

Depending on the type and shape of

the items being cleaned, inserts can be

supplied.

The diversity of the inserts is so great

that it is not possible to illustrate them

all or give detailed instructions on their

use here.

E.g. the thermal disinfector will allow

hollow instruments to be internally

cleaned and disinfected using the

upper basket O 177.

Removing excess soils

Empty all items to be cleaned before

loading into the machine.

Ensure that no acid or solvent

residues, especially hydrochloric

acid or chlorides, get into the wash

cabinet.

Notes

Load the items to be cleaned so the

water will come into contact with all

surfaces. This ensures that they will

be properly cleaned and disinfected.

Hand instruments should be processed in cassettes like the

E 146, E 363, or E 373.

Hinged instruments should be

placed into the universal mesh tray E

378 or E 379 with the hinge opened

at an angle of about 90° (right angle).

Hollow instruments should be

treated in the upper basket O 177,

and be positioned on jets or funnels.

Do not place items to be cleaned inside other pieces where they may be

concealed.

Vessels should be inverted and

placed in the correct inserts.

Deep based items should be placed

at enough of an angle for water to

run off them freely.

Tall and narrow pieces should be

placed in the center of the basket to

ensure good coverage with water.

Hollow instruments may only be processed correctly, i.e. cleaned and

disinfected inside and outside, in the

appropriate upper basket O 177.

The spray arms must not be blocked

by items which are too high for the

basket or which hang down in its

path. If necessary, manually rotate

the arm to test it.

The flap of the powder detergent dispenser on the door must not be obstructed and be prevented from

opening when the door is closed.

In order to avoid corrosion, it is recommended that only heat and corrosion resistant items be cleaned in

the machine. For the suitability of

instruments, please refer to ”Indications for use”.

Care should be taken that as little

dental cement or amalgam remains

on the instruments as possible. However, where necessary, the instruments can be cleaned manually after

thermal disinfection (following health

and safety regulations) with minimized danger of infection.

15

Page 16

Loading and unloading the machine

Use thermally stable plastic items

only.

Immediately after the program

finishes, partially open the door

(about 4 inches or 10 cm) for 10 to

15 minutes. This allows the goods to

cool down to avoid burning or scalding. Additionally, good drying results

are achieved using the residual heat,

which will help prevent the instruments from corroding. Aluminium

trays are usually not suitable for thermal disinfection.

Handpieces, drill bits, grinders, root

canal instruments or other rotating instruments only have a limited suitability for the thermal disinfector.

Please ask the manufacturer’s advice on the suitability for processing

in this system.

Do not clean fiberoptics or electrical

equipment or components in the

thermal disinfector.

Important

Make sure the spring loaded coupling

engages correctly when the upper basket is inserted into the machine. There

should be a tight fit between the coupling and the water inlet connector at the

top of the chamber. If there is not, adjust the adapter as follows:

Loosen the holding ring on the upper

basket.

Push up the adapter so it is 1/4’’

higher than the water inlet connector,

and tighten the holding ring.

Select baskets and inserts which are

appropriate for the application.

Disinfection monitors

Although the adhesion to the thermal

disinfection parameters (93°C/200°F/

10 min. +/-2°C) is monitored by the

electronic control, we advise to independently check the unit once a day

with the first run.

16

The Disinfection Control Tubes by A.

Browne Ltd., distributed by Miele, are

designed to monitor the time temperature combination of 93°C/200°F/ 9min.

They may be placed in the filter combination. These indicators change color

when the parameters are met. Although

this indicator does not indicate the

exact disinfection parameters, they will

alert the user to large discrepancies

from them.

Page 17

Loading and unloading the machine

Loading and unloading the machine

Loading examples

Upper basket O 177

The upper basket O 177 features 28

jets/funnels for direct injection of hollow

instruments like syringe tips or evacuation tips. The left side is free for alternative inserts.

Bottom basket U 165

Left hand side: insert E 131 for 5 mesh

trays (E146) and holders (E 328) for

double sided instruments. Right hand

side: E 130 insert for 10 trays.

Place hollow instruments directly onto

the jets. Where the inner diameter of

the hollow instruments does not allow

for positioning onto the jets, the jets

may be replace by funnels.

Bottom basket U 174 insert

Left hand side: E 130 for 10 trays.

Right hand side: E 379 universal mesh

tray for various instruments.

17

Page 18

Loading and unloading the machine

Unloading the machine

When the cycle is finished the indicator

light next to the ”START” touch pad will

go out.

If one of the ”DISINFECTION” programs was chosen, check the ”DISINFECTED” indicator light. If it is not

lighted, the load is not disinfected! In

this case please call technical assistance.

Check, if any warning lights (left

hand side of the control panel) are

on, or if the digital display shows two

dashes. If so, refer to the section

”Correcting minor faults”, or call technical assistance.

In case you used a disinfection monitor (disinfection control tubes),

check for the accuracy of the process. We advise to document the results.

Open the door partially (about 4’’ /

10 cm). Let the load cool down for

about 10-15 min. During this time the

load will usually dry out.

Adjusting the top basket

Adjustable top baskets can be used in

this machine. They can be raised or lowered by 3/4’’/2 cm from the initial setting.

In the middle position the basket will

accommodate:

instruments, utensils, accessories and

inserts up to 7 1/2’’ / 19 cm in height

while the lower basket can accommodate:

instruments, utensils, accessories

and inserts up to 9 3/4’’ / 19 cm in

height.

For further details regarding container height combinations, see table

below.

To p

basket

position

top 6 5/8" (17 cm) 10 5/8" (27 cm)

middle 7 1/2" /19 cm) 9 3/4" (25 cm)

Top basket

height cm

Bottom basket

height cm

In case you use powder detergent

check, if the dispenser lid has opened. If not, the instruments might

not be clean!

In case you use rinse aid check the

small bulls eye on the right hand

side of the inner side of the door. It

has to be black. If not, replenish the

liquid door dispenser with rinse aid.

Now you can safely unload the machine.

18

bottom 8 1/4" (21 cm) 9" (23 cm)

To adjust the top basket

Pull out the upper basket until a resistance is felt, lift from the runners

and remove.

Unscrew the knurled nuts on both

sides of the basket and reposition as

necessary.

Page 19

Adding rinsing agent

Adding rinsing agent

A storage container incorporated in the

door has a capacity of approximately

7.8 fl.oz. / 200 ml. The required amount

of appropriate liquid rinsing agent

(Neodisher MielClear) is dispensed

automatically from this container.

Adding rinsing agent

Pour rinsing agent into the storage container until the level indicator is dark

(see arrow in illustration). Use funnel if

necessary.

Firmly tighten the screw cap. Clean

up any spillage.

Refilling with rinsing agent

The level indicator shows how much

rinsing agent is left in the container.

When there is no dark coloring visible

in the level indicator, the container

needs to be refilled.

Setting the dosage

Unscrew the cap

The dosage adjustment in the opening

has settings from 1-6 (0.035-0.2 fl.oz. /

1-6 ml). It is set to ”3” (o.1 fl.oz. / 3 ml)

at the factory.

Use a higher setting if spots are left

on the cleaning goods after drying.

If smearing appears, use a lower setting.

19

Page 20

Adding neutralizing agent

Adding neutralizing agent

To reduce the pH level of the wash solution after the alkaline phase, special

neutralizing acids will be used in the

first interim rinse.

Place the container with neutralizing

agent on the floor close to the machine.

When the ”NEUTRALIZER” indicator

light on the control panel lights up

fill the container with neutralizing

agent, or change container, and then:

20

place the siphon tube firmly in the

opening of the free-standing container (pay attention to the color coding).

The container should never be allowed

to empty.

Page 21

Adding neutralizing agent

Venting the liquid dispensing system

Before using the machine for the first

time, or if the container has been

allowed to empty, the dispensing system must be vented. Please proceed

as follows:

Press the ”ON/OFF’ button.

Adding neutralizing agent

Use a sharp object to press in switch

”A” and/or ”B” at the left hand side

end of the control panel for three and

a half minutes.

Switch ”A” Dispensing system for

neutralizing agent.

Switch ”B” Dispensing system for

cleaning agent.

Each time the system is vented any

liquid which runs into the wash

cabinet must be washed out as follows:

Select the ”RINSE” program.

After this has run the dispensing system is filled and ready for use.

21

Page 22

Adding detergent

Adding detergent

Pour powder detergent into the powder

dispenser on the door before each program (see next page for ”DISINFECTION’ program).

Pull the opening catch on the container flap forward (see arrow). The

flap will spring open (the flap will remain open at the end of a program).

Fill the dispenser with the detergent

manufacturers recommended dosage. When calculating the dilution

ratio of the detergent, 10.5 liters is

the amount of water that is used the

main wash cycle (For example, if

3g/l dilution is required use about

30 grams of detergent).

Close the dispenser lid.

Use only specially formulated clean-

ing agents which are approved of by

Miele.

Under certain circumstances, different additives may be necessary.

Miele Customer Service will be

please to advise you.

Note

Take care when handling liquids such

as detergents, neutralizing agents or

rinse aids. These may contain acids or

alkalis. Follow the manufacturer’s safety

procedures and the instructions on the

packaging carefully. Wear protective

gloves and goggles if necessary.

22

Page 23

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

G 7781

To the person responsible for the machine:

Make this pull-out with the Warning and Safety Instructions available to any

operators of the machine. Place it near the machine, where it can be seen.

Ensure that operators know and understand these Warning and Safety Instructions, and observe them in use.

When using an electrical appliance, basic precautions should always be followed

including the following:

READ ALL INSTRUCTIONS BEFORE

USING THE APPLIANCE

WARNING –

The manufacturer cannot accept

responsibility for damage caused

when the appliance is not used

according to the instructions, or for

uses other than those for which it

was intended.

This special commercial machine

is suitable for the applications mentioned in the operating instructions. Do

not use for purposes other than those

for which it was designed, as these

may be dangerous. The manufacturer

cannot be held responsible for damage

caused by improper use.

Do not allow small children or un-

authorized personnel access to

the machine or its controls.

If thermal disinfection is required

(93°C/200°F/10min.), the process

needs to be checked and documented

regularly. This can be done by checking the disinfection control diode on the

machine. Alternatively, a chemical indicator may be used (e.g. the Disinfection Control Tubes by A. Browne Ltd.,

supplied by Miele). These disinfection

control tubes should be placed in the

filter combination. After the disinfection

cycle, they may be inspected by removing the coarse filter.

The disinfection program should

not be interrupted, as this would

affect the disinfection result. If interruption is necessary, the program should

be repeated.

Do not install the machine in areas

where there is a risk of explosion.

1

Page 24

IMPORTANT SAFETY INSTRUCTIONS

The machine is built in accordance

with current safety requirements.

Any repair work should only be carried

out by a suitably qualified and competent engineer. Repairs by unqualified

persons could be dangerous.

The electrical safety of this ma-

chine can only be guaranteed if

connected to an electrical system that

complies with all local and national

regulations. It should be checked by an

expert if necessary. The manufacturer

cannot be held responsible for damage

caused by incorrect wiring.

The machine should only be in-

stalled by a suitably qualified and

competent contractor. Before connecting the machine, the installer should

check that the voltage and frequency

of the electrical supply correspond with

the details on the data plate of the machine.

Only genuine Miele parts or acces-

sories should be used with the

G 7781 Dental Thermal Disinfector. The

performance and safety of non-genuine

parts or accessories cannot be guaranteed, and use of such parts or items

may void the machine warranty. If you

have specific questions about machine

options or accessories, please call

Miele.

The use of Neodisher cleaning,

neutralizing, and rinsing agents is

strongly recommended. The use of any

other products may invalidate the disinfection resus and the manufacturer’s

warranty.

The machine is completely isolated

from the electricity supply only

when it is unplugged or the circuit

breaker is turned off. This must be

done before any repair work is carried

out.

The water in this machine must not

be used as drinking water.

Only use detergents which have

been approved of by Miele. Do not

use solvents in your machine as there

may be a danger of explosion.

2

Page 25

IMPORTANT SAFETY INSTRUCTIONS

Take care when handling liquids

such as detergents, rinsing or neutralizing agents. These may contain

acids or alkalis. Follow the instructions

and safety procedures on the packaging carefully and wear protective

gloves and goggles. Read the Material

Safety Data Sheets.

Avoid inhalation of powder

cleaners.

Empty any containers or glassware

before placing it in the machine.

Do not allow any acids or solvents,

especially hydrochloric acid and

chlorides, to get into the wash cabinet.

Be careful when sorting instru-

ments with sharp pointed ends. If

possible, place the pointed end downwards.

Install special inserts in accord-

ance with the instructions provided.

When using the machine be care-

ful not to scald or burn yourself.

Baskets and inserts must first be

allowed to cool down. Any water which

may have collected in incorrectly

loaded items will be very hot and

should be emptied into the wash

cabinet.

Do not touch the heating elements

after the end of a program. You

could burn yourself.

Do not hose the machine down to

clean it.

Do not sit or lean on the open door.

This could cause the machine to

tip and be damaged.

When disposing of an old ma-

chine, make sure the door catch is

removed. This will prevent children at

play from being accidentally locked in.

3

Page 26

IMPORTANT SAFETY INSTRUCTIONS

All relevant safety procedures

should be obeyed. Relevant safety

procedures include, but are not limited

to, the Centers for Disease Control’s

Recommended Infection Control Practices for Dentistry and the OSHA Bloodborne Pathogens Standard.

The manufacturer cannot be held

responsible for damage caused by

failure to heed the warning and

safety instructions.

SAVE THESE

INSTRUCTIONS

4

Page 27

Adding detergent Program selection

The different programs and their applications are described in the following

program chart.

Powder detergent may be placed directly on the door in the ”WASH 93°C”

and ”DISINFECTION 93°C - 10’” programs.

As an optional extra, this machine can

be equipped with a

an automatic dosing pump for liquid

detergent. This is connected externally

by plugging into the rear of the machine.

DOS module C 60,

The DOS module is supplied with separate instructions for installation and

use.

23

Page 28

Program Chart G7781

Program Chart G7781

Program When to use

Detergent

(when not using liquid

detergent)

Please follow

manufacturer’s

instructions.

RINSE

(COLD)

DISINFECTION

VARIO

93°C-10’

WASH

93°C

DISINFECTION

93°C-10’

To rinse heavily soiled instruments, e.g. after

soaking them in a disinfecting agent. This

avoids the build-up of foam in the machine.

For protein soils (such as blood and secretions)

– for cleaning and thermal disinfection with

90-93°C and 10 minutes holding time for

instuments which are susceptible to chemicals

and changes in temperature.

Cleaning of instruments at 93°C with 3 mins

holding time.

For thermal disinfection and cleaning of

instruments at 93°C with 10 mins holding time.

Preferably a neutral liquid

detergent should be

dispensed

30 grammes on the righthand side

30 grammes on the righthand side

of the door interior

of the door interior

24

Page 29

Program Chart G7781

Program cycle Miscellaneous

1.

Pre-

wash

2.

Cleaning

and/or

thermal

disin.

X

XX

45°C**)

X

93°C

X

93°C

3.

Interim

rinse I

with neu-

tralization

*)

4.

Interim

rinse

II

5.

Final

rinse

and/or

disin.

XXX

93°C**)

XXX

80°C

XXX

80°C

6.

Drying

(extra

program)

(X)

(X)

(X)

see ”Programming

*)

special functions”

**)

To change temperature,

see ”Programming

special functions”

25

Page 30

Turning the machine on and off

Turning the machine on and off

1. Turning on

Press ”ON/OFF’ button.

2. Selecting a program

After turning on the machine, the indicators next to the available selections will

light up.

Press the selector for the required

program. The wash temperature of

the selected program will show in

the display.

Select the option ”DRYING” if

desired (see ”Selecting an additional

program”).

Press the ”START” touch pad. The

display panel will now show the running time in minutes for the selected

program.

During the heating stage in ”WASH”

and ”FINAL RINSE” the end temperature will be alternately displayed in the

panel. All other programs are blocked

and only the lights for the selected program stay on.

Program change

Provided the ”START” touch pad has

not yet been pushed, a mistakenly selected program may be changed as follows:

Press the appropriate touch pad to

select the correct program.

Press the ”START” touch pad.

Otherwise, see ”Interrupting a pro-

gram” on the next page.

3.Selecting an additional

program

The following additional programs are

available:

”DRYING”

This may be selected immediately

after choosing a wash program (exception: Rinse program). The heater

elements switches on intermittently

during the drying process for 10

minutes. The total running time of the

program will be lengthened accordingly.

The instrument will not be absolutely

dry. Please contact the sterilizer

manufacturer regarding the drying

stage required for your sterilization

device. Instead of selecting the

drying cycle you can also perform

the following steps:

26

Page 31

Turning the machine on and off

Immediately after the program

finishes, partially open the door

(about 4 inches or 10 cm) for 10 to

15 minutes. This allows the goods to

cool down to avoid burning or scalding. Additionally, good drying results

are achieved using the residual heat,

which will help prevent the instruments from corroding. Aluminium

trays are usually not suitable for thermal disinfection.

”REACTIVATION”

(see ”Reactivating the water softener”)

”DRAIN”

– Press the ”ON/OFF” button.

– Press the ”DRAIN” touch pad.

– Press the ”START” touch pad.

27

Page 32

Turning the machine on and off

Program sequence indicator

When a wash or disinfection program

has been selected, the indicator lights

in the display will show the program sequence.

PRE-WASH

WASH

RINSE

FINAL RINSE

DRYING (optional)

DISINFECTED (only valid with the ”DIS-

INFECTION 93°C - 10’” and the ”DISINFECTION VARIO 93°C-10’” programs)

When part of the program is completed, the corresponding indicator

light goes out. The wash cycle is completed when the ”START” light goes out.

The display panel will show the total

running time of the program.

Turning off

Press the ”ON/OFF” switch and let it

spring out. The machine can now be

opened and unloaded.

Interrupting a program

Once a program is running, it should

only be interrupted in extreme cases,

such as when articles in the machine

rattle or bump against each other and

have to be rearranged.

The machine must be turned off, the

water drained and the program restarted:

Turn the machine off by pressing the

”ON/OFF” switch and letting it spring

out.

Select the ”DRAIN” program.

On completion, open the door and

rearrange the articles securely and

correctly (wear protective wear if

necessary).

Replenish the powder detergent dispenser in the door if necessary.

Close the door. Reselect the program.

Important:

Make sure that the ”DISINFECTED”

light is lit at the end of a ”DISINFECTION” program, if the door was opened

before its completion.

the disinfection parameters were not

met and the entire program should be

repeated.

If the light is out,

28

Page 33

Programming special functions

Programming special functions

The following special functions can be

programmed where appropriate,

1. Extending the water inlet from 60’’

to 120’’ with level control

If the inlet water pressure is lower than

35 psi / 2.5 bar, too little water will flow

into the wash cabinet. By selecting the

extended water inlet, more water will

flow into the wash cabinet if there is low

water pressure (between 15 and 35 psi /

1.0 and 2.5 bar).

Turn off the machine.

Press ”DRAIN” and ”DRYING” at the

same time, while turning on the machine. ”P3” appears in the display.

Press ”DISINFECTION 93°C-10’”.

”10” or ”11” will appear in the display.

10 = 60’’ water intake

11 = 120’’ water intake with level

control

Press ”DRYING” to change the display to ”11”.

Press ”START”. ”SP” appears in the

display.

Press ”START” again. The change

has been stored and the display

field clears.

2. Deactivating of neutralizer dispensing

The G 7781 is programmed from the

factory to dispense neutralizer during

the first interim rinse. It is strongly

recommended to use this option to

avoid discoloration or corrosion. However, dispensing of neutralizer might

not be necessary if a pH neutral detergent is being used.

To deactivate the neutralizer setting perform the following.

Turn off the machine.

Press ”DRAIN” and ”DRYING” at the

same time, while turning on the machine. ”P3” appears in the display.

Press "WASH 93°C-3’": ”20” or ”21”

will appear in the display.

20 = without interim rinse I

21 = with neutralizing agent

dispensed in interim rinse I

Press ”DRYING” to change from 21

to 20 or vice versa.

Press ”START”. ”SP” appears in the

display.

Press ”START” again. The change

has been stored and the display

field clears.

29

Page 34

Programming special functions

3. Altering temperatures T1 (wash

temperature) and T2 (rinse temperature) in the ”DISINFECTION VARIO

93°C-10’” program

The wash and final rinse temperatures

are set as standard at 45°C/113°F and

93°C/200°F. If a wash temperature of

60°C/140°F is required, this can be set

in the following manner:

Turn off the machine.

Press ”DRAIN” and ”DRYING” at the

same time, while turning on the machine. ”P3” appears in the display.

When DISINFECTION VARIO

93°C-10’ is pressed, ”30” appears in

the display. Press ”DRYING” to

change ”30” to ”31” or vice versa.

When ”RINSE” is pressed, ”40” appears in the display. Do not change

this setting as it would be insufficient

for disinfection!

The following options are possible:

Main

Wash

30 – 40 45°C

113°F

30 – 41 45°C

113°F

31 – 40 60°C

140°F

31 – 41 60°C

140°F

To store the setting, press ”START”

twice.

30

Rinse

93°C

200°F

80°C

176°F

93°C

200°C

80°C

176°F

Page 35

Reactivating the water softener

Reactivating the water softener

When the ”REACTIVATION” indicator

light on the left hand side of the control

panel comes on during a program, the

built-in water softener is depleted and

cannot supply any more soft water.

Filling the salt container

It should be reactivated with salt

soon as the wash program has finished. If this cannot be done, and further loads have been washed, then the

reactivation process should be carried

twice in succession.

out

Each reactivation cycle requires:

2 kg / 4.4 lb. of water softener salt.

A granule size of 1 to 4 mm is recommended by Miele. Do not use any

other type of salt, it may damage the

water softener.

The plastic salt container which is

supplied with the machine.

Important

If the only reactivation salt available is

fine grain, please consult Miele Customer Service.

Water softener salt with granules larger

than 4 mm cannot be used.

as

Unscrew the filter insert from the salt

container and remove.

WARNING: PERSONAL INJURY/

EQUIPMENT DAMAGE HAZARD

Do not fill container with cleaning

detergent! Fill with reactivation salt

only! Detergents can be corrosive,

causing potential personal injury

and damage to the water softener.

Fill the salt container with approx.

4.4 lbs (2 kg) of granular salt and

screw the filter insert back in place.

31

Page 36

Reactivating the water softener

Position the salt container as follows:

Remove the lower basket from the

machine.

Unscrew the plastic cap in the base

of the wash cabinet.

Close the door.

Turn on the machine.

Press the ”REACTIVATION” touch

pad.

Press the ”START” touch pad.

The reactivation program proceeds

automatically and finishes when the

”Reactivation” light at the left hand side

of the control panel and the ”Start” indicator light have gone out.

Then:

Turn off the machine.

Remove salt container slowly,

allowing pressure to be released.

Do not open by force, If you cannot

unscrew it by hand, contact the

Miele Service Department.

Screw the plastic lid back on the

socket.

Reposition the lower basket.

Place the salt container on the reactivation socket and screw firmly into

place.

32

Rinse the salt container and filter insert thoroughly.

Important

If the water pressure is below 35 psi /

2.5 bar of if it fluctuates, the water softener cannot be reactivated in the normal way. After reactivation, salt may still

be found in the salt container.

To use up the salt and to wash out the

water softener, the ”Reactivation” program must be run again.

Page 37

Cleaning an care

Cleaning the filters in the

wash cabinet

The filter combination in the base of the

cabinet should be inspected regularly

and cleaned if necessary.

Cleaning the coarse filter

Cleaning an care

To unscrew the micro-fine filter, take

hold of the two tabs and turn twice in

a counter clockwise direction.

Press the 2 tabs together, remove

and clean the filter.

Put the clean filter back in position

and press until it clicks in place.

Cleaning the fine, flat and micro-fine

filters

Remove the coarse filter.

Remove the fine filter from between

the flat and the micro-fine filters.

Pull up and remove the two filters.

Clean the filters.

The filter combination is then re-

placed in the reverse order in which

it was removed.

The machine must not be used without

all filters in place.

33

Page 38

Cleaning an care

Cleaning the water inlet filters

Filters are incorporated into the stainless steel housing located between the

valve and the hose.

The filters must be cleaned when dirty,

otherwise insufficient water will flow into

the wash cabinet,

Turn off the valves.

Unscrew the water inlet hoses.

1

2

Clean the large area filter (1) and the

fine filter (2) or replace if necessary.

After reconnection, turn on the

valves and test for leaks.

34

Page 39

Correcting minor problems

With the aid of the following explanatory notes, minor problems can be corrected without contacting the Miele Service Dept.

Any work on the electrical components

of the machine should only be carried

out by a suitably qualified and trained

person.

Warning lights

Correcting minor problems

The ”REACTIVATION” light is on

The water softener needs to be replenished. Please refer to ”Reactivating the water softener”.

The ”DETERGENT” light is on

You are using the optional DOS module C 60. The liquid detergent container has to be refilled.

The ”DRAIN/FILL” warning light

flashes

Check that both water intake hoses

are connected to the water supply

and that the faucets are turned on.

Check the drain hoses. They should

not be higher than 3 feet / 1 m from

the base level of the machine. The

inner diameter of the hoses should in

no point be less then 3/4’’ / 2 cm.

Check if any hoses are kinked. If so,

please straighten them out.

The water in the machine must then

be pumped out by choosing the

”Drain” program. Then please restart

the program you would like to run.

The ”NEUTRALIZER” light is on

The neutralizer container has to be

refilled.

The display shows two dashes

Please call technical assistance. The

machine is stalled and cannot be

operated until it is reset by a trained

technician.

35

Page 40

Correcting minor problems

Unsatisfactory cleaning results

Unsatisfactory cleaning results may

occur as drying spots, or as spots that

look like corrosion. Presumably corrosive spots often are bio-debris. They

have the shape of drying spots, blurry

edges, and the color of rust. Bio-debris

may also appear on surfaces that were

not contaminated before processing.

Please observe:

Have the instruments been stored in

the machine for more than 6 hours?

If so, please run the machine, even

partially loaded, within 6 hours of

loading.

Was enough detergent used? Please

check the dosage of the detergent

and adjust, if necessary. Too little as

well as too much detergent may

deteriorate the cleaning results.

Can both spray arms rotate easily,

even with the machine loaded? If

not, please rearrange the goods to

be cleaned in a way so that the

spray arms can rotate freely.

The water in the wash cabinet is not

heated; the program sequence lasts

too long

This machine has a resettable temperature limiter which will shut off the heating elements in the case of over-heating. This could be caused if large

articles cover the heating elements or if

the filters in the wash cabinet are

blocked.

Remove the cause of overheating.

Take off the service panel (see next

page).

Press in the blue reset button on the

temperature limiter.

If this switch trips repeatedly, the Miele

Service Dept. must be contacted.

In the event any problems cannot be

corrected, please contact the Miele

Service Department.

Does the flap of the powder detergent dispenser open? If not, check if

anything obstructs the flap and prevents it from opening. Otherwise,

please call technical assistance.

36

Page 41

Installation

Installation

The machine should only be installed by a competent contractor.

The contractor should be experienced in installing machines that

require electrical hook-up as well as

plumbing.

The machine must be installed and

leveled correctly. Any unevenness in

the floor can be compensated for by

screwing the adjustable feet in or out

as necessary.

The machine can be installed in the following ways:

Free-standing

Under counter.

The recess should be at least 23

3/4’’ / 60 cm wide, 23 3/4’’ / 60 cm

deep, and 33 1/4’’ / 85 cm high.

If necessary the machine top can be

removed as follows:

Open the door.

Remove the screws on the left and

right, using a Philips screw driver.

Pull the top forward, lift and remove.

By removing the lid, the machine can

be built into a recess 32 1/4’’ / 83 cm

high.

37

Page 42

Installation

To remove the service panel and

plinth

b

b

a

a

b

b

Remove the two 8 mm bolts ”a” from

the service panel.

Take hold of the service panel at

both sides and pull forward.

Remove all four plinth screws ”b”.

Do not us silicone sealant to seal the

gaps between the machine and any

neighboring units as this will hinder

ventilation to the circulation pump.

Depending on the installation requirements, the following kits are available:

34 1/4’’ / 87 cm high recess

This kit consists of longer machine feet

and a base plate.

(Part # 1107961)

Steam deflector

for use where the machine will be installed under a wooden countertop.

The underside of the work surface is

protected from steam damage by a

plate of niro-steel.

(Part # 1156150)

Disconnect grounding lead if necessary.

Remove plastic protective cap.

To re-assemble:

Replace plastic protective cap,

plinth facing and service panel in the

reverse order in which they were

removed.

Make sure the grounding lead is reconnected.

38

Page 43

Electrical connection

All electrical work must be carried

out by a qualified electrician and in

compliance with all local and national electrical codes.

Before making any connections, check

that the voltage shown on the data

plate corresponds to your power supply.

The machine is supplied as standard

for connection to a 208 V 60 Hz single

phase power supply and is fitted with a

power supply cord 6 ft / 1.8 m long with

a cross-section of AWG 10-4. It should

be connected to the main power supply according to the opposite chart.

Voltage: 208 V, single phase

Frequency: 60 Hz

Rated load: 6.0 kW

Circuit breaker: 30 A per phase

The machine can be converted for connection to a 3 phase power supply.

Electrical connection

WARNING

THIS APPLIANCE MUST BE

CORRECTLY GROUNDED!

The manufacturer cannot be held

responsible for damage or injury

caused by incorrect or missing

grounding.

wiring diagram can be found be-

The

hind the plinth on the left hand side, attached to the floor of the machine.

data plate with serial and model

The

numbers is on the rear of the machine

and on the plinth behind the service

panel.

39

Page 44

Plumbing

Plumbing

Connection to the water inlet

The machine must be connected to

the water supply in accordance with

all local and national plumbing

codes.

Drainage

The drain system is equipped with a

non-return valve which prevents dirty

water from flowing back into the machine.

The machine is constructed with an

air gap/anti-siphoning device on

both the intake and the drain sides.

No such additional devices are

necessary or recommended, as they

will impede the water inflow into and

out of the washer.

The water pressure must be between 35 and 145 psi (2.5 - 10.0

bar). If the water pressure is not

within this range, the Miele Service

Dept. can advise you of the

measures to be taken (see also ”Programming special functions”).

This machine is designed for cold

water connection only, in view of its

technical application.

Both inlet hoses (water supply and

steam condenser) should be connected to the valves for cold water.

Valves with 3/4’’ male hose thread

should be provided on-site, and

should be easily accessible.

The machine is supplied with two

5 ft. / 1.5 m long flexible drain hoses

with an inner diameter of 3/4’’ / 2 cm.

They should not be shortened or attached to any fittings that would

cause a reduction in water flow.

Longer drain hoses up to a length of

13 ft / 3.3 m are available if required.

Both hoses can be attached to existing drain lines through the use of a 1

1/2’’ / 3.5 cm or larger stand pipe / Ptrap combination. Alternately, the

hoses can be connected directly to

existing drain lines, provided any fittings or adapters used do not reduce the water flow.

The drain hoses should not exceed

13 ft / 3.3 m in length, or be attached

to the main drain at a point higher

than 3 ft. / 1m above the floor.

A floor drain is permissible.

For additional protection of the

valves against impurities in the water

supply, large surface area filters are

enclosed in the kit supplied with the

machine (see diagram in ”Cleaning

and care, water inlet”).

The water in the machine in not suitable for drinking.

404142

Page 45

Page 46

Page 47

43

Page 48

Copyright by 1996 Miele Appliances, Inc. / 000 0999

All rights reserved

Loading...

Loading...