Page 1

Operating and installation instructions

Pressure steam oven

To prevent the risk of accidents or damage to the appliance, it is essen‐

tial to read these instructions before it is installed and used for the first

time.

en-AU, NZ M.-Nr. 10 260 910

Page 2

Contents

Warning and Safety instructions .......................................................................... 5

Caring for the environment................................................................................. 14

Overview ............................................................................................................... 15

Steam oven front view ........................................................................................... 15

Accessories supplied............................................................................................. 16

Control panel........................................................................................................ 17

Description of the functions ............................................................................... 18

Temperature........................................................................................................... 18

Duration.................................................................................................................. 18

Noises .................................................................................................................... 18

Heating-up phase .................................................................................................. 18

Cooking phase....................................................................................................... 18

Cooling down phase.............................................................................................. 18

Pull-out shelf.......................................................................................................... 18

Using for the first time......................................................................................... 19

Setting the water hardness level............................................................................ 19

Setting the correct boiling point for water ............................................................. 19

Opening the door................................................................................................... 19

Closing the door .................................................................................................... 20

Cleaning for the first time....................................................................................... 21

Oven functions ..................................................................................................... 22

Operation .............................................................................................................. 23

Operating principles............................................................................................... 23

Changing the function............................................................................................ 25

Changing the temperature or cooking duration..................................................... 25

Interrupting a process............................................................................................ 26

Continuing cooking................................................................................................ 26

Safety features ..................................................................................................... 27

Pressure release / Safety valve.............................................................................. 27

Overheating protection .......................................................................................... 29

Safety lock / System lock ...................................................................................... 30

General notes ....................................................................................................... 31

The advantages of cooking with steam................................................................. 31

Suitable containers ................................................................................................ 31

Cooking containers........................................................................................... 31

Your own containers ......................................................................................... 31

2

Page 3

Contents

Shelf level............................................................................................................... 31

Frozen..................................................................................................................... 31

Temperature........................................................................................................... 32

Duration.................................................................................................................. 32

Cooking with liquid ................................................................................................ 32

Your own recipes ................................................................................................... 32

Steam cooking ..................................................................................................... 33

Vegetables ............................................................................................................. 33

Meat....................................................................................................................... 36

Sausages ............................................................................................................... 38

Fish ........................................................................................................................ 38

Shelf level.......................................................................................................... 38

Shellfish.................................................................................................................. 41

Mussels.................................................................................................................. 42

Rice........................................................................................................................ 43

Pasta / Noodles...................................................................................................... 44

European dumplings.............................................................................................. 45

Grains..................................................................................................................... 46

Dried pulses ........................................................................................................... 47

Hen's eggs ............................................................................................................ 49

Fruit........................................................................................................................ 50

Menu cooking ........................................................................................................ 51

Special applications............................................................................................. 53

Reheat.................................................................................................................... 53

Defrost ................................................................................................................... 55

Bottling................................................................................................................... 58

Extracting juice ...................................................................................................... 61

Making yoghurt ...................................................................................................... 63

Proving yeast dough.............................................................................................. 64

Dissolving gelatine ................................................................................................. 65

Melting chocolate................................................................................................... 65

Skinning fruit and vegetables................................................................................. 66

Preserving apples ................................................................................................. 66

Blanching ............................................................................................................... 67

Sweating onions .................................................................................................... 67

Rendering fat ......................................................................................................... 68

Disinfecting items .................................................................................................. 68

Heating damp towels............................................................................................. 69

Decrystallising honey............................................................................................. 69

Preparing custard royale........................................................................................ 69

Settings................................................................................................................. 70

3

Page 4

Contents

Cleaning and care................................................................................................ 72

Notes on cleaning and care................................................................................... 72

Appliance front....................................................................................................... 73

Oven interior and pull-out shelf.............................................................................. 74

Accessories ........................................................................................................... 74

Cooking containers and drain filter................................................................... 74

Shelf runners.......................................................................................................... 74

Door seal / Safety valve ......................................................................................... 76

Water nozzle........................................................................................................... 77

Descaling ............................................................................................................... 78

Problem solving guide......................................................................................... 81

Optional accessories........................................................................................... 86

Cooking containers................................................................................................ 86

Cleaning and care products................................................................................... 88

Other accessories.................................................................................................. 88

Safety instructions for installation ..................................................................... 89

Installation notes.................................................................................................. 91

Building-in dimensions........................................................................................ 92

DGD 4635 in 380 mm high niche........................................................................... 92

DGD 4635 in a 450 mm high niche........................................................................ 93

DGD 6635 in a 380 mm high niche........................................................................ 94

DGD 6605 / DGD 6635 in a 450 mm high niche.................................................... 95

Installation and connection................................................................................. 96

Plumbing in the appliance................................................................................... 97

Connection to the water supply............................................................................. 97

Connection to the mains water supply .................................................................. 98

Connection to the drainage system....................................................................... 99

Connecting the drain hose .................................................................................... 99

Electrical connection......................................................................................... 100

Mains connection cable....................................................................................... 101

Wiring diagram..................................................................................................... 101

After sales service, data plate, warranty ......................................................... 102

4

Page 5

Warning and Safety instructions

This appliance conforms to current safety requirements. Inappro‐

priate use can, however, lead to personal injury and damage to

property.

To avoid the risk of accidents and damage to the appliance,

please read these instructions carefully before using it for the first

time. They contain important notes on installation, safety, use and

maintenance. Miele cannot be held liable for damage caused by

non-compliance with these instructions.

Keep these instructions in a safe place and ensure that new users

are familiar with the contents. Pass them on to any future owner.

5

Page 6

Warning and Safety instructions

Correct application

This steam oven is designed for domestic use and for use in simi‐

lar environments by guests in hotel or motel rooms, bed & break‐

fasts and other typical living quarters. This does not include com‐

mon/shared facilities or commercial facilities within hotels, motels or

bed & breakfasts.

The steam oven is not suitable for outdoor use.

This steam oven must only be used as described in these instruc‐

tions.

Any other usage is at the owner's risk and could be dangerous.

This appliance is not intended for use by persons (including chil‐

dren) with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervi‐

sion or instruction concerning its use by a person responsible for

their safety, and are able to recognise the dangers of misuse.

6

Page 7

Warning and Safety instructions

Safety with children

Activate the system lock to ensure that children cannot turn on

the appliance inadvertently. Use the safety lock when the appliance

is in use to prevent children from altering the settings selected.

Young children must not be allowed to use this appliance.

Older children may only use the steam oven when its operation

has been clearly explained to them and they are able to use it safely,

recognising the dangers of misuse.

Cleaning may only be carried out by older children under the su‐

pervision of an adult.

Please supervise children in the vicinity of the steam oven and do

not let them play with it.

Danger of suffocation! Children may be able to wrap themselves

in packing material or pull it over their heads with the risk of suffoca‐

tion. Keep children away from any packing material.

Danger of burning! Children's skin is far more sensitive to high

temperatures than that of adults. The steam oven must be installed

at such a height that young children cannot come into contact with

the door when it is hot.

The area around the door hinges can cause injury. Keep children

well away at all times.

7

Page 8

Warning and Safety instructions

Technical safety

Repairs and other work by unqualified persons could be danger‐

ous. Installation, maintenance work and repairs to electrical applian‐

ces must only be carried out by a Miele approved service technician.

A damaged appliance is dangerous. Check the appliance for any

visible damage. Never install or attempt to use a damaged appli‐

ance.

Reliable and safe operation of this oven can only be assured if it

has been connected to the mains electricity supply.

The electrical safety of this appliance can only be guaranteed

when continuity is complete between it and an effective earthing

system. It is most important that this basic safety requirement is

present and tested regularly and, where there is any doubt, the

household wiring system should be inspected by a qualified electri‐

cian.

Before connecting the appliance to the mains supply, ensure that

the connection data on the data plate (voltage and frequency)

matches the mains electricity supply. This data must correspond in

order to avoid the risk of damage to the appliance. Consult a quali‐

fied electrician if in any doubt.

Do not connect the appliance to the mains electricity supply by a

multi-socket adapter or an extension lead. These do not guarantee

the required safety of the appliance (e.g. danger of overheating).

For safety reasons, this appliance may only be used after it has

been built in.

This appliance must not be installed and operated in mobile in‐

stallations (e.g. on a ship).

Tampering with electrical connections or components and me‐

chanical parts is highly dangerous to the user and can cause opera‐

tional faults. Do not open the outer casing of the appliance.

8

Page 9

Warning and Safety instructions

The manufacturer's warranty will be invalidated if the appliance is

not repaired by a Miele approved service technician.

Faulty components must only be replaced by genuine Miele spare

parts. The manufacturer can only guarantee the safety of the appli‐

ance when Miele replacement parts are used.

If the connection cable is damaged, it must be replaced with a

special connection cable type H 05 VV-F (PVC insulated). See "Elec‐

trical connection".

During installation, maintenance and repair work, the appliance

must be disconnected from the mains electricity supply. It is only

completely isolated from the electricity supply when:

– it is switched off at the mains circuit breaker, or

– it is switched off at the wall socket and the plug is withdrawn

from the socket. Do not pull the mains connection cable but the

mains plug to disconnect your appliance from the mains electrici‐

ty supply.

This steam oven must be plumbed in by a suitably qualified per‐

son.

Miele cannot be held liable for damage caused by incorrect installa‐

tion or connection.

The appliance must be connected to the cold water supply only.

The tap must be easily accessible after the appliance has been in‐

stalled.

Before connection, check the inlet and drain hoses for visible

signs of damage.

The built-in water protection system will only protect the appli‐

ance from water damage if the following conditions have been met:

– The inlet and drain hoses are correctly fitted and connected.

– The steam oven is properly maintained and parts are replaced

where it can be seen that this is necessary.

9

Page 10

Warning and Safety instructions

– The tap has been turned off when the appliance is not used for a

longer period of time (e.g. during holidays).

In areas which may be subject to infestation by cockroaches or

other vermin, pay particular attention to keeping the appliance and

its surroundings clean at all times. Any damage caused by cock‐

roaches or other vermin will not be covered by the warranty.

10

Page 11

Warning and Safety instructions

Correct use

Danger of burning! The steam oven becomes hot when in use. Ex‐

ercise care when handling food and trays so as not to burn yourself

on the walls of the steam oven, shelf runners, trays, steam and hot

food itself. Use oven gloves when placing food in the steam oven,

removing it and when adjusting shelves etc. in a hot steam oven.

When putting cooking containers into the steam oven or taking them

out, take care not to spill the contents.

The appliance door gets hot when in use and remains hot for

quite a while after the steam oven has been switched off. The door

should only be touched using the door button and handle whilst it is

hot.

Do not use the steam oven to heat up or bottle food in sealed

tins.

Pressure will build up inside them and they can explode causing

damage to the appliance, as well as the risk of injury and scalding.

Food which is left in the steam oven can dry out and the escaping

moisture can lead to corrosion in the appliance. Do not leave

cooked food in the oven compartment and do not use any cooking

containers which are susceptible to corrosion as this could lead to

corrosion in the appliance.

11

Page 12

Warning and Safety instructions

Never open the door whilst the appliance is in use. The door must

only be opened

– after the cooling down phase has finished,

– the audible tone has stopped,

– the symbol is flashing in the time display.

If you try to open the door too early, a warning tone will sound and

the word will appear in the time display.

Danger of injury! Do not use temperatures above 95 °C when bot‐

tling food (at altitudes above 1000 m do not exceed 90 °C) as this

will cause the jars to explode.

The descaling process (see "Cleaning and care - Descaling") must

only be carried out in a cold steam oven. Otherwise aggressive va‐

pours can build up.

Never use the steam oven without a floor filter as large food resi‐

dues may block the water outlet and the pump.

This steam oven can recognise and put right certain faults. These

are indicated by the codes to in the display. The appliance

door can only be opened if the code is flashing in the display. If the

display is not flashing, the appliance is still trying to rectify the prob‐

lem. See "Problem solving guide" for more information.

Steam oven with lift-up door: The lift-up door must be left open

whilst the appliance is in use.

12

Page 13

Warning and Safety instructions

Cleaning and care

Do not use a steam cleaning appliance to clean this steam oven.

Pressurised steam could reach the electrical components and cause

a short circuit.

The shelf runners can be removed for cleaning purposes (see

"Cleaning and care - Accessories").

Ensure they are correctly fitted after cleaning and never operate the

steam oven without the shelf runners fitted.

13

Page 14

Caring for the environment

Disposal of the packing mate‐

rial

The transport and protective packaging

has been selected from materials which

are environmentally friendly for dispos‐

al, and can normally be recycled.

Recycling the packaging reduces the

use of raw materials in the manufactur‐

ing process and also reduces the

amount of waste in landfill sites. Ensure

that any plastic wrappings, bags etc.

are disposed of safely and kept out of

the reach of babies and young children.

Danger of suffocation.

Disposing of your old appli‐

ance

Electrical and electronic appliances of‐

ten contain materials which, if handled

or disposed of incorrectly, could be po‐

tentially hazardous to human health and

to the environment. They are, however,

essential for the correct functioning of

your appliance. Therefore, please do

not dispose of your old appliance with

your household waste.

Please dispose of it at your local com‐

munity waste collection / recycling cen‐

tre.

Ensure that your old appliance presents

no danger to children while being stor‐

ed for disposal.

14

Page 15

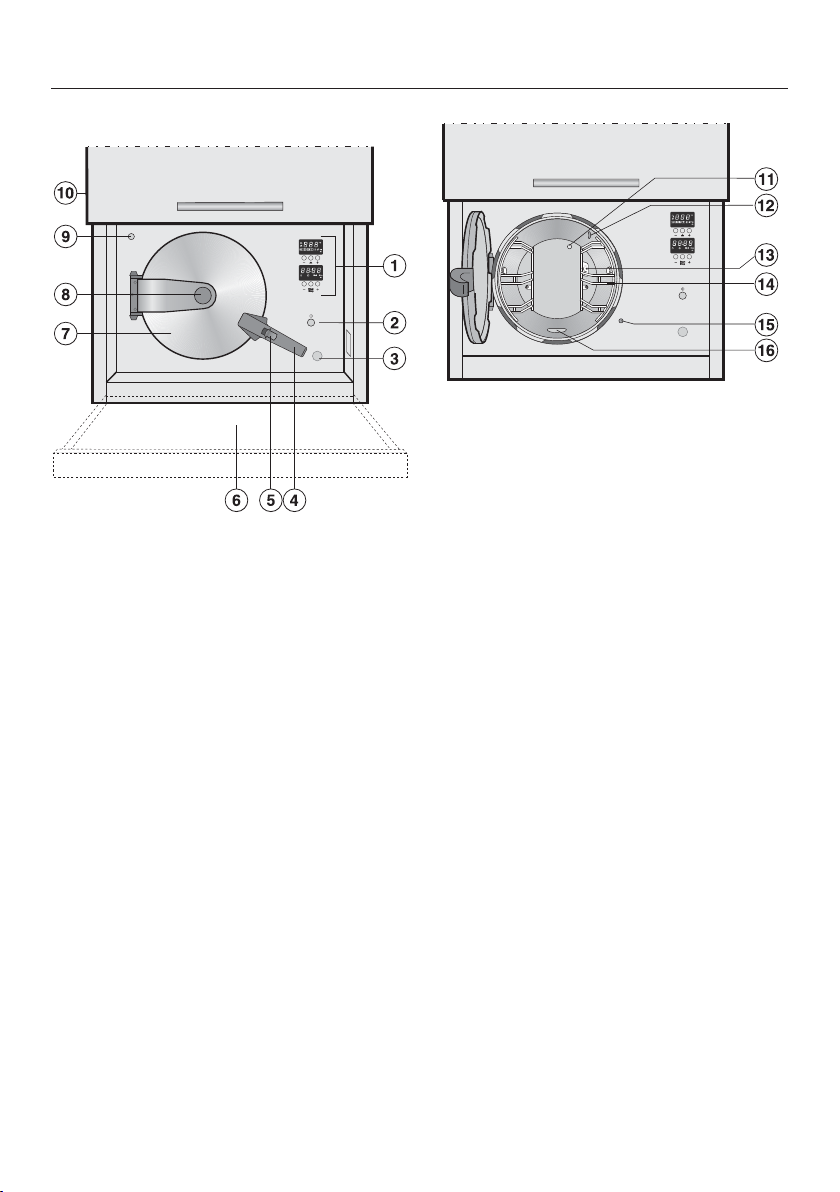

Steam oven front view

a

Control panel

b

On/Off button

c

Overheating protection device cover

d

Door handle

e

Door release

f

Pull-out shelf

g

Appliance door

h

Door button

i

Filling point for descaling agent

j

Lift-up door (depending on model)

k

Temperature sensor

l

Steam inlet

m

Deflector for water jet

n

Shelf runners

o

Door contact switch

p

Floor filter

Overview

15

Page 16

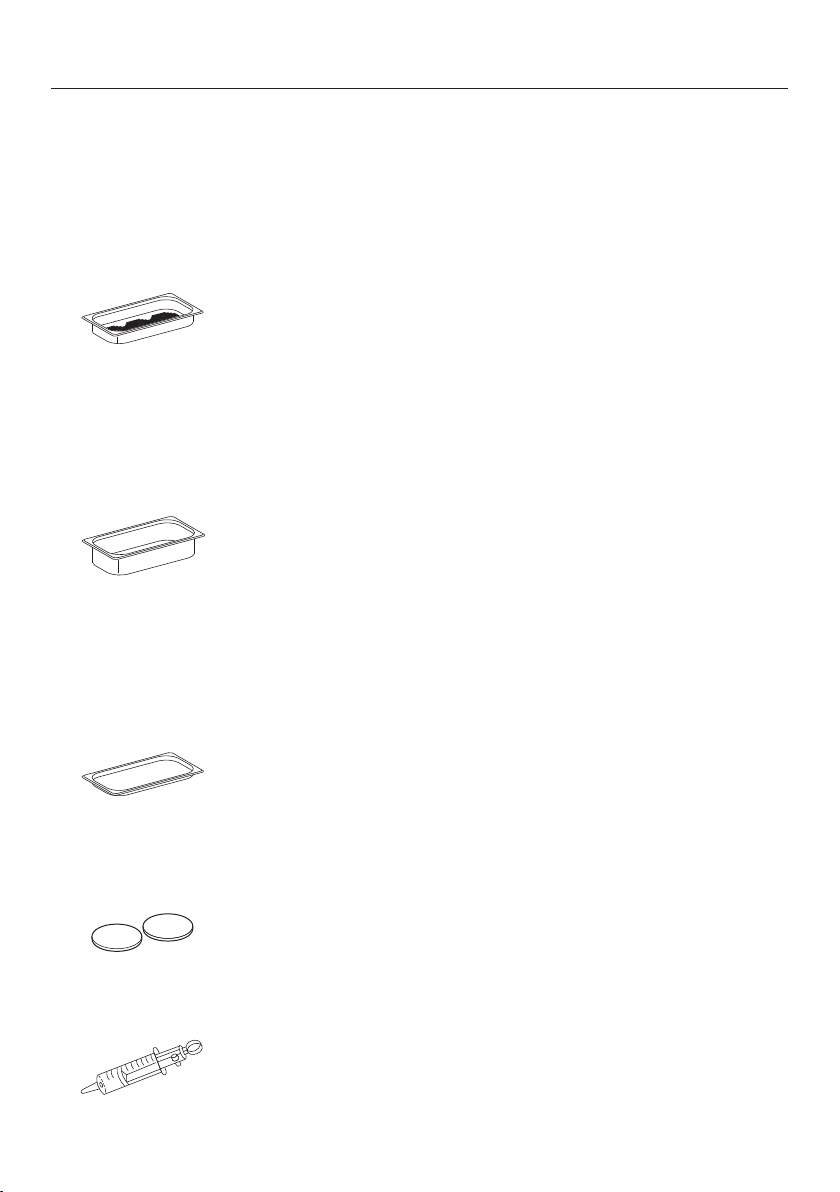

Overview

Accessories supplied

The accessories supplied with your ap‐

pliance, as well as a range of optional

ones, are available to order from Miele

(see "Optional accessories").

DGGL 1

2 perforated cooking containers

Gross capacity 1.5 litres / Useable ca‐

pacity 0.9 litre

325 x 175 x 40 mm (W x D x H)

DGG 2

1 solid cooking container

Gross capacity 2.5 litres / Useable ca‐

pacity 2.0 litres

325 x 175 x 65 mm (W x D x H)

Miele steam oven cookbook

Cooking for pleasure with Miele

A selection of the best recipes from the

Miele test kitchen.

Tray

For placing your own cooking contain‐

ers on.

Silicone washers

For pressure release valve.

Syringe for descaling agent

16

Page 17

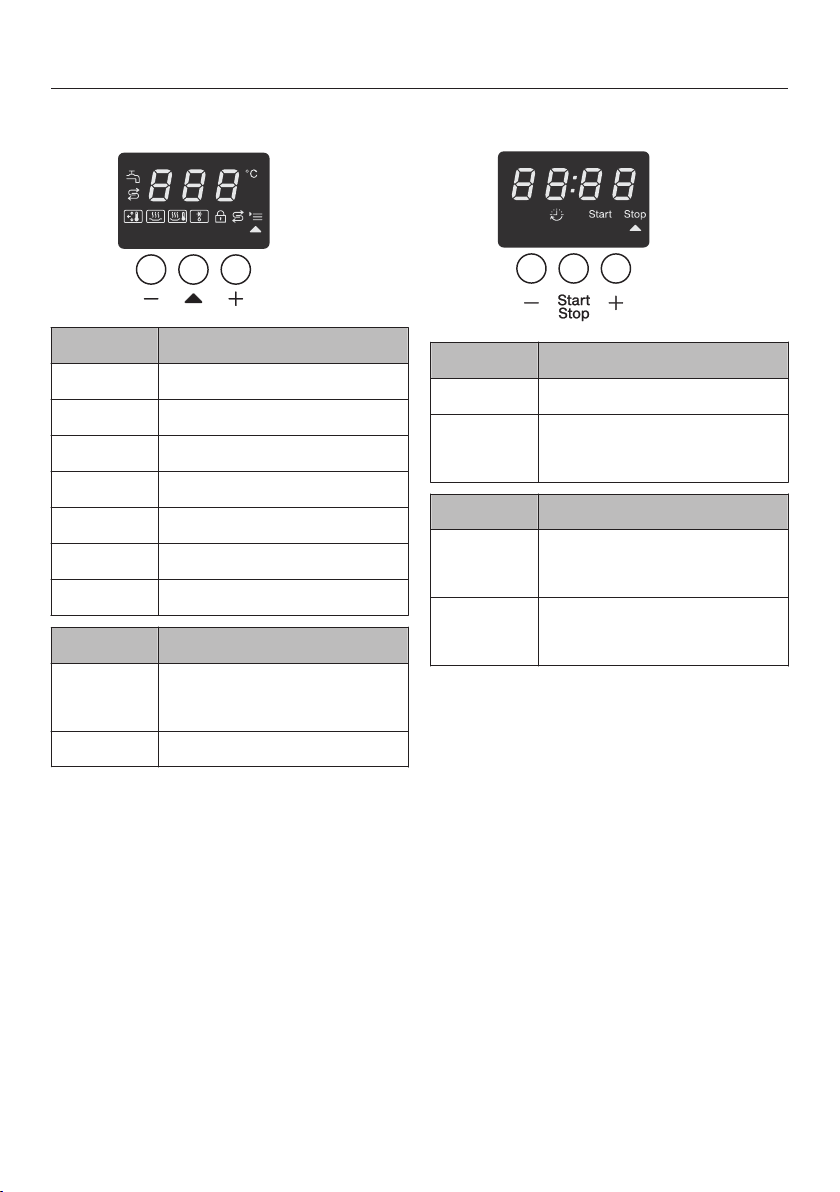

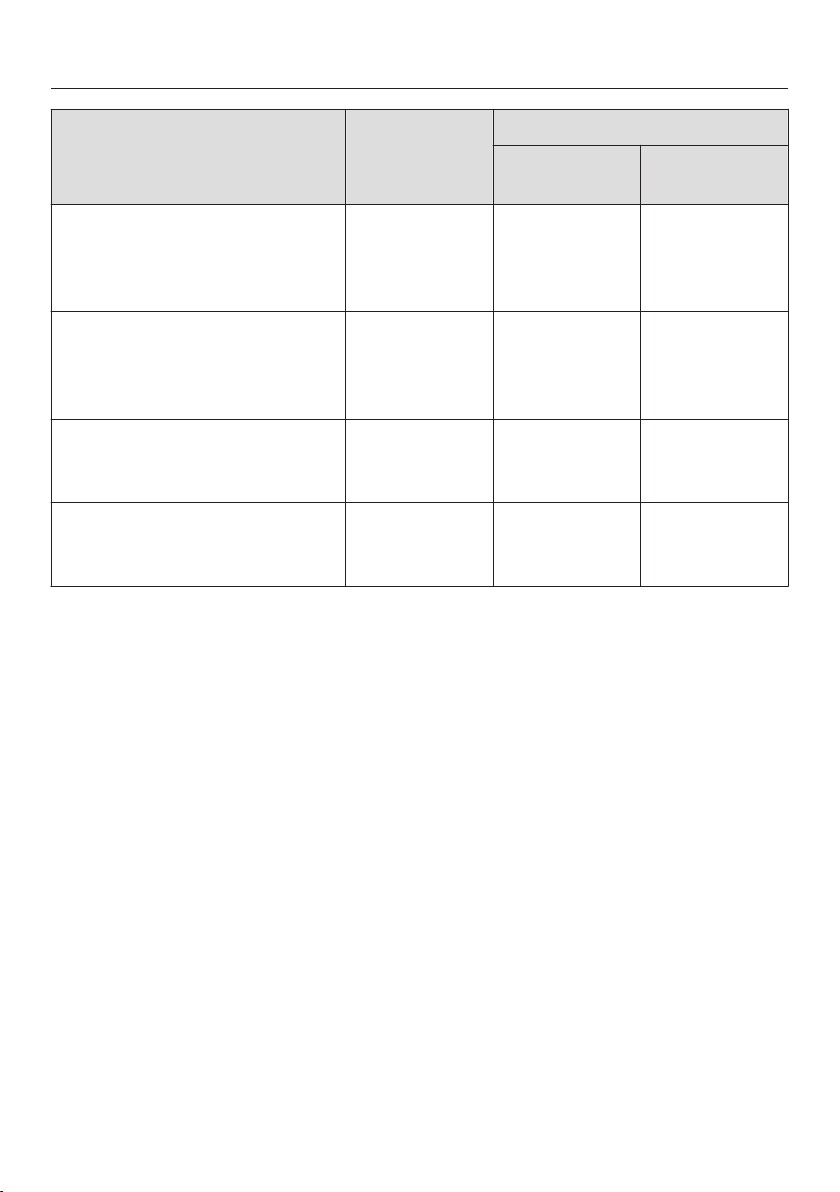

Control panel

Function / Temperature display

Symbol Meaning

Button(s) Function

-

+

Steam with pressure

Steam cooking

Reheat

Defrost

Safety lock

Descaling

Settings

Setting the temperature

Time display

Symbol Meaning

Start

Stop

Button(s) Function

-

+

Start

Stop

Duration

Starting a process

Interrupting a process

Setting a cooking dura‐

tion

Starting a process

Interrupting a process

Selecting a function

17

Page 18

Description of the functions

Temperature

All functions have a default recommen‐

ded temperature. The recommended

temperature can be altered for the pro‐

gramme in use, or for every time that

programme is used (see "Settings").

The recommended temperature can be

altered in 5 °C or 1 °C increments. If

you want to change the temperature in

1 °C increments you will have to

change the factory default setting (see

"Settings").

Duration

You can set a duration between 1 mi‐

nute (:) and 9 hours 59 minutes

(:). If the duration exceeds 59 mi‐

nutes you have to enter it in hours and

minutes. Example: Duration 80 minutes

= 1:20.

Noises

A buzzing sound can be heard after

switching on the appliance, during op‐

eration and after switching off the appli‐

ance.

This is not a fault. It is made by water

being pumped through the system.

Heating-up phase

During the heating-up phase the oven

compartment is heated to the set tem‐

perature. The display will show the tem‐

perature of the oven compartment as it

rises.

The duration of the heating-up phase

will depend on the quantity and the

temperature of the food. In general the

heating-up phase will last for approx. 5

minutes. The duration will be longer if

you are preparing refrigerated or frozen

food.

Cooking phase

The cooking phase begins when the set

temperature is reached. During the

cooking phase, the duration remaining

will be shown in the display.

Cooling down phase

The cooking process finishes with a

cooling down phase.

During the cooling down phase a scroll‐

ing bar graph will appear in the func‐

tion / temperature display. The cooling

down phase lasts about 1 minute. With

large amounts of food it could take lon‐

ger.

18

Pull-out shelf

Before opening the appliance door, pull

the shelf out. It can then be used for

resting dishes on. It will also catch any

droplets of hot water from containers.

Page 19

Using for the first time

Setting the water hardness lev‐

el

The water hardness level of the steam

oven is set to "Very hard" at the factory.

For trouble-free operation of the steam

oven, and to ensure that it is descaled

at the appropriate time, it is important

to set the water hardness level for your

area. The harder the water, the more of‐

ten the steam oven must be descaled.

Check which water hardness level

has been set and, if necessary, set

the correct water hardness (see "Set‐

tings - Water hardness").

Setting the correct boiling point for water

The boiling point for water depends on

the altitude above sea level.

The steam oven is set ex-works for an

installation location of under 1000 m. If

it is located at more than 1000 m above

sea level, the factory default setting will

have to be changed (see "Settings").

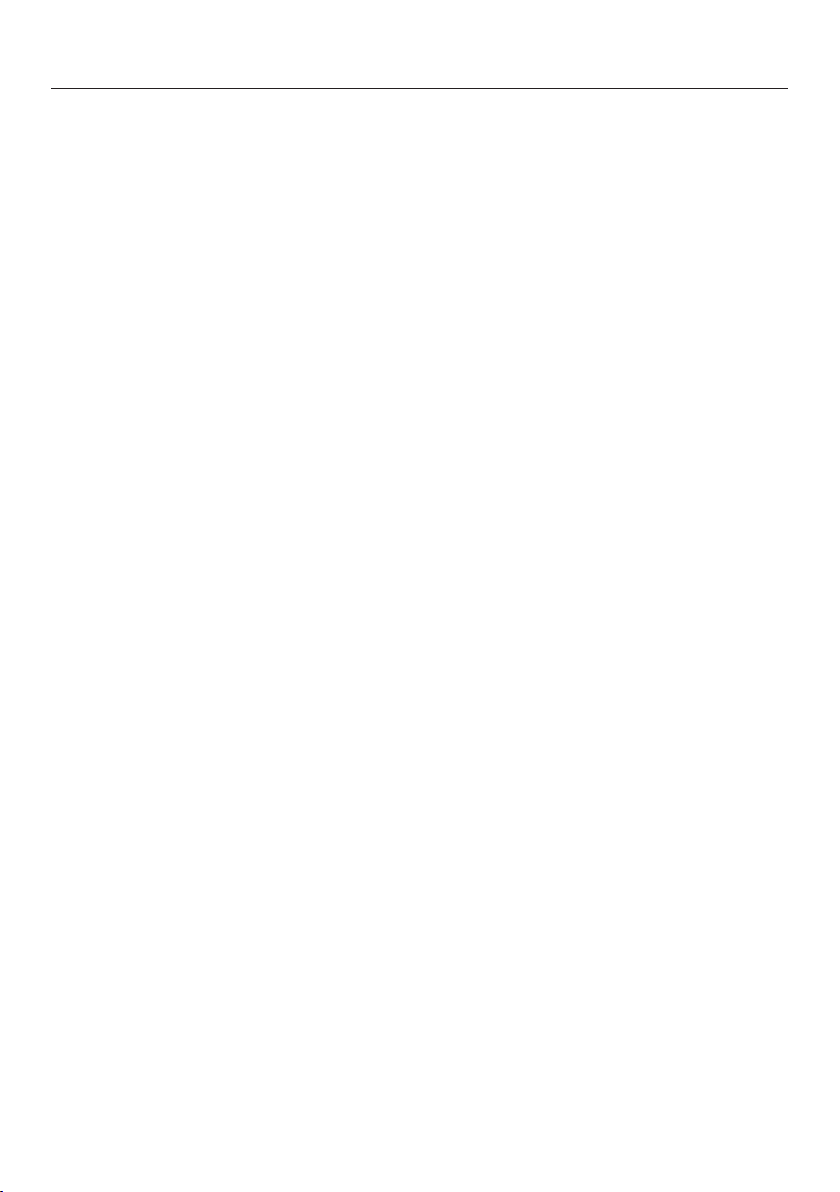

Opening the door

Using the thumb of your right hand,

push the door release forwards and

turn the handle upwards.

When it is in a horizontal position, the

door is unlocked and can be opened.

19

Page 20

Using for the first time

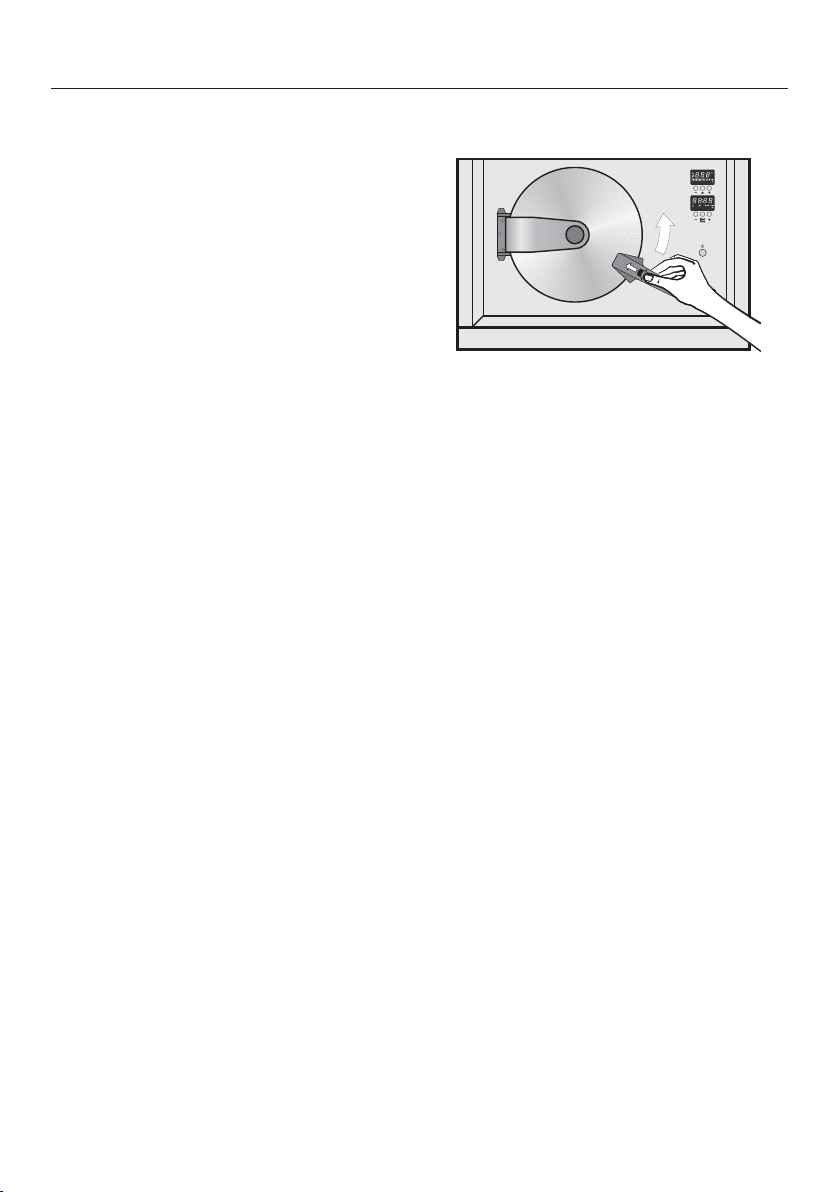

Closing the door

Turn the handle to the horizontal po‐

sition. In this position the lugs on the

door line up with those on the oven

compartment (see arrows).

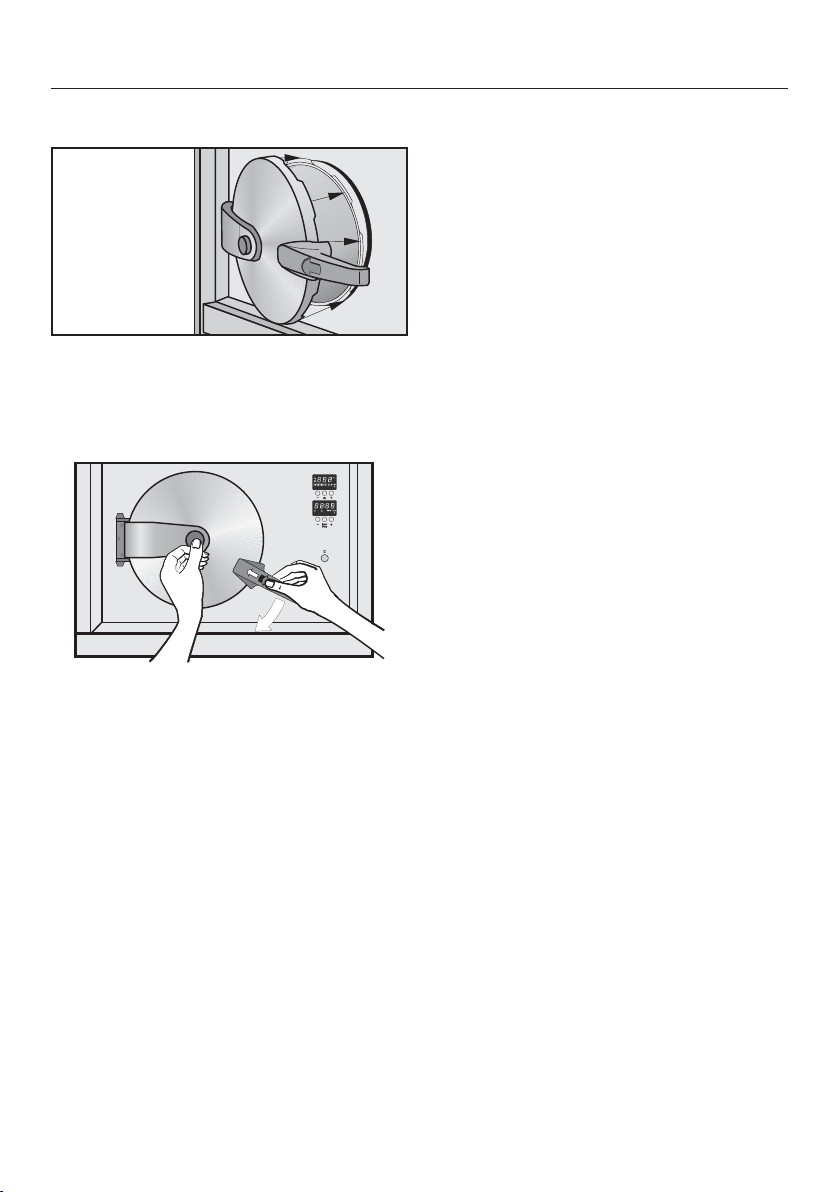

Using your left hand, press firmly on

the door button.

Using your right hand, turn the han‐

dle downwards until you hear it en‐

gage. While doing so, also push the

door release forwards with your

thumb. This vents the oven compart‐

ment and makes it easier to close the

door.

The steam oven cannot be used until

the door has been closed properly.

20

Page 21

Using for the first time

Please stick the extra data plate for

the appliance supplied with this doc‐

umentation in the space provided in

the "After sales service, data plate,

warranty" section of this booklet. Al‐

ternatively, the additional label can

be stuck near the appliance if the ap‐

pliance markings are not visible after

installation.

Remove any protective wrapping and

stickers (but not the data plate).

Cleaning for the first time

Accessories / Oven interior

Remove all accessories from the

steam oven.

Wash them by hand using warm wa‐

ter with a little amount of washing-up

liquid and a soft sponge or in the

dishwasher.

The interior of the steam oven has been

treated at the factory with a condition‐

ing agent.

To remove this, clean the oven interi‐

or with a mild solution of washing-up

liquid and warm water applied with a

soft sponge, and then dry thoroughly

with a soft cloth.

You should then run the Steam with

pressure programme at 120 °C

for 10 minutes to flush out the water‐

ways. Proceed as described in "Op‐

eration".

Danger of burning!

Do not open the appliance door dur‐

ing use. Danger of burning and

scalding.

If you try to open the door during use

or before the cooling down phase

has finished, a warning tone will

sound and the word will appear

in the time display.

21

Page 22

Oven functions

Oven function Recommen‐

ded tempera‐

ture

Steam with pressure

For cooking foods able to with‐

stand pressure, extracting

juice, special applications

Steam cooking

For cooking all types of food,

bottling, extracting juice, spe‐

cial applications

Reheat

For gentle reheating of cooked

food

Defrost

For gentle defrosting of frozen

food

* The recommended temperatures can be altered in 5 °C increments within the range quo‐

ted. If you wish to adjust the temperature in 1 °C increments, you will need to alter the fac‐

tory default setting (see "Settings").

120 °C 105–120 °C 101–120 °C

100 °C 40–100 °C 40–100 °C

95 °C 95 °C –

60 °C 50–60 °C 50–60 °C

Temperature range*

Factory set‐

ting

Modified set‐

ting

22

Page 23

Operation

Check that the floor filter is correctly

in place before each programme as

large food residues may block the

water outlet.

Danger of injury!

Do not open the appliance door dur‐

ing use. Danger of burning and

scalding. Be particularly vigilant with

children.

The door must not be opened until

- the cooling down phase has finish‐

ed,

- the buzzer has stopped,

- the symbol is flashing in the

time display.

If you try to open the door before

this, a warning tone will sound and

the word will appear in the dis‐

play. When removing containers from

the oven, be careful not to spill the

contents.

Operating principles

Selecting a function

Close the appliance door.

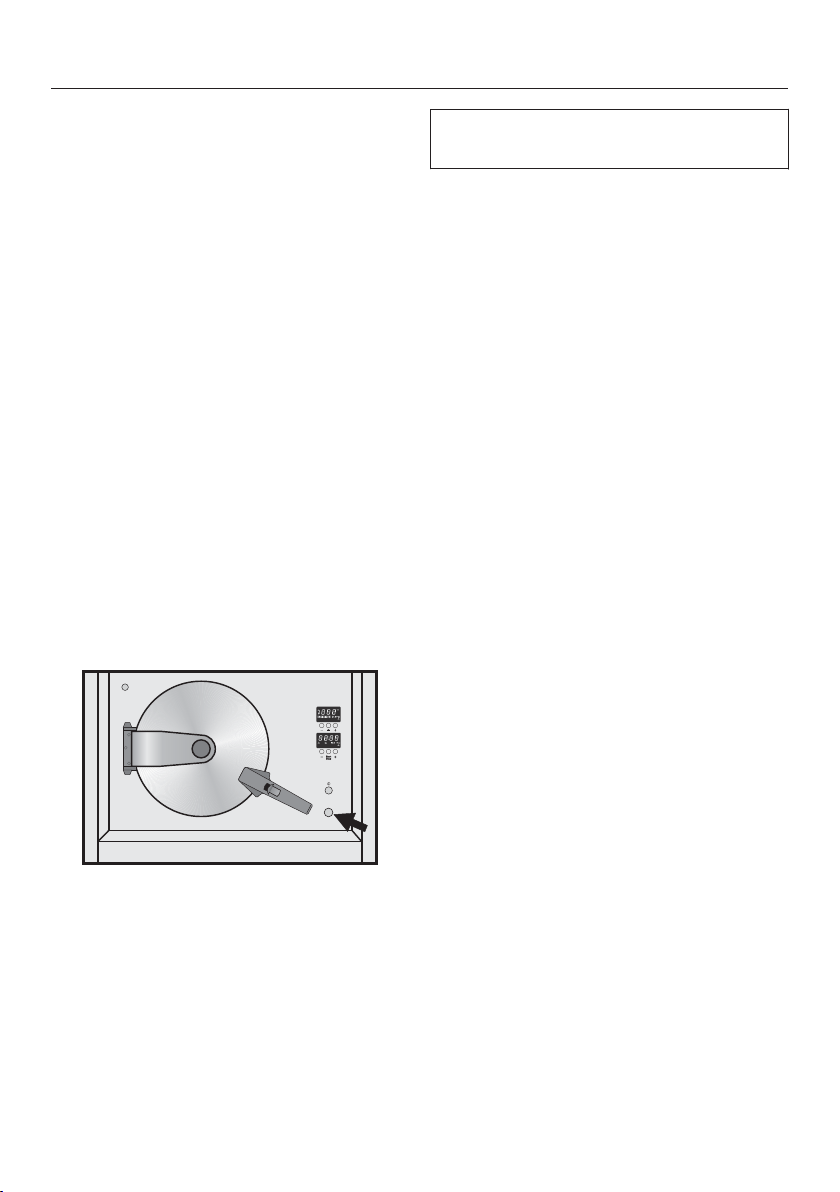

Switch the steam oven on with the

On/Off button.

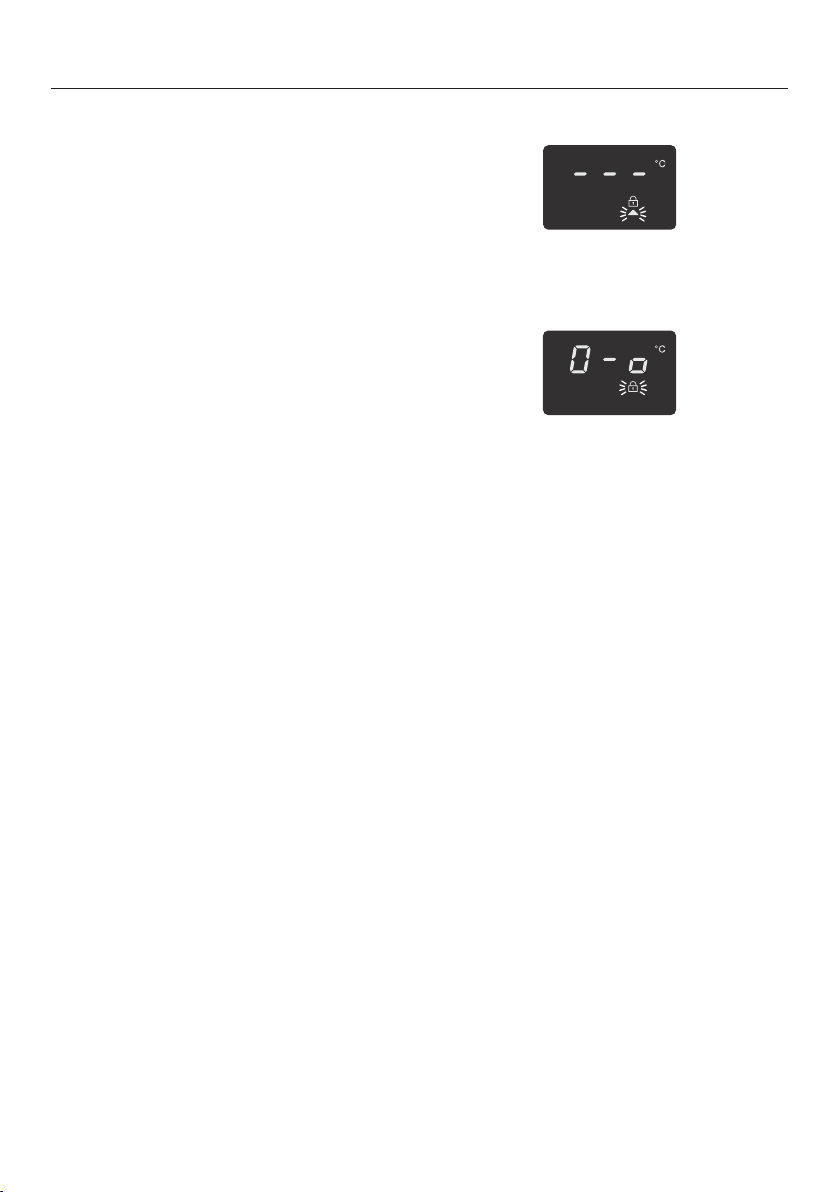

The following will appear in the func‐

tion / temperature display:

After a few seconds the display will au‐

tomatically display the Steam with pres‐

sure function .

If you want to use a different function,

press the button repeatedly until

the function you want appears in the

display, e.g. Steam cooking .

Setting the temperature

Use the + or - buttons to set the tem‐

perature you want.

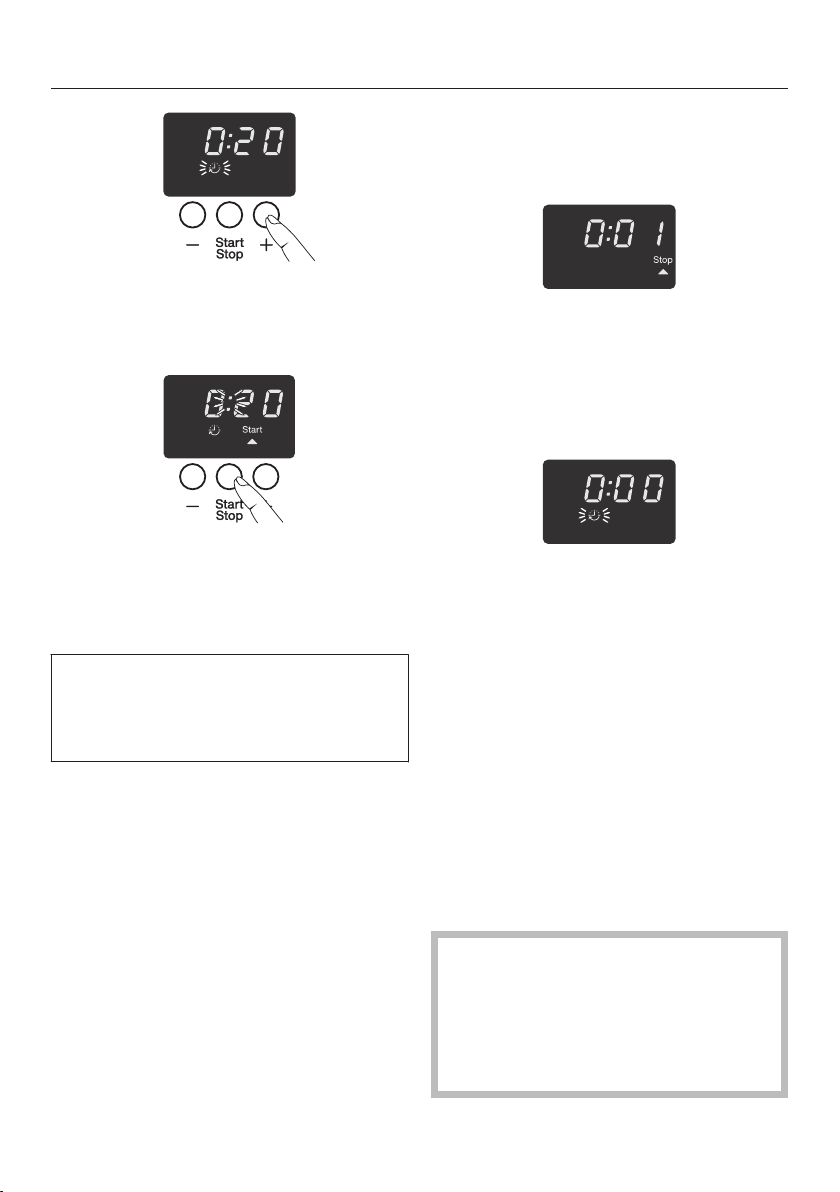

Setting a cooking duration

You will see 3 zeros and a flashing

symbol in the time display.

23

Page 24

Operation

Use the + or - buttons to select the

required duration, e.g. 20 minutes.

Starting a process

Press the Start/Stop button.

"Start" will appear in the time display,

the symbol will stop flashing and the

colon will begin to flash.

If the door is not properly shut, a

warning tone will sound when you

start the programme and will ap‐

pear in the time display.

At the end of the cooking duration

The cooking process finishes with a

cooling down phase.

"Stop" will appear in the time display,

the symbol and "Start" will go out,

and the colon will stop flashing.

During the cooling down phase a scroll‐

ing bar graph will appear in the func‐

tion / temperature display.

Wait until you have heard several

tones, 3 zeros appear in the time dis‐

play and the symbol is flashing

before you open the door to take

food out.

Switch the steam oven off.

The appliance will now drain. Three hor‐

izontal bars - - - will light up in the func‐

tion / temperature display.

24

°C will then appear in the display as

long as the temperature inside the oven

is still above 45 °C. Please note that the

appliance does not switch off until the

°C has gone out.

Danger of burning!

You could burn yourself on the oven

interior, spilled food, accessories

and hot steam. Use oven gloves

when removing hot food from the

appliance.

Page 25

Operation

After use

Once °C has gone out in the func‐

tion / temperature display, wipe the

oven interior out with a solution of

warm water and washing-up liquid or

vinegar. Then dry with a soft cloth.

Turn off the tap after use to prevent

the risk of water damage.

Leave the appliance door open until

the oven interior is completely dry.

Changing the function

Press the Start/Stop button.

Wait for the cooling down phase to

finish.

Select the function you want and

then proceed as before.

Changing the temperature or cooking duration

You can alter the temperature and

cooking duration at any time during op‐

eration.

Use the + or - button to enter the val‐

ue required.

25

Page 26

Operation

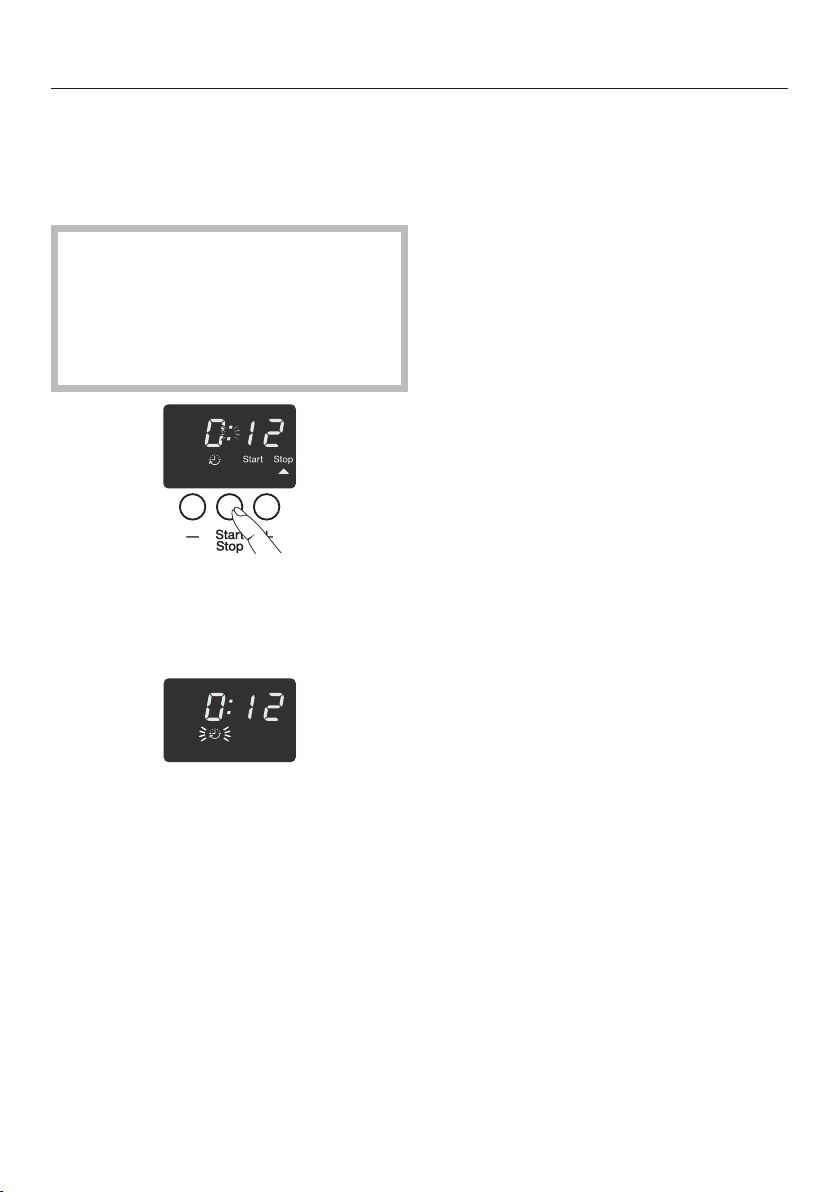

Interrupting a process

You can interrupt operation at any time,

for example, to place another container

of food in the oven.

Danger of burning!

You could burn yourself on the oven

interior, spilled food and accesso‐

ries. Use oven gloves when placing

food in the oven and when removing

hot food from the oven.

Press the Start/Stop button.

"Stop" will appear in the time display.

The cooling down phase will start.

Continuing cooking

Close the door.

Push the shelf back in.

Press the Start/Stop button.

The steam oven will heat up again and

the display will show the temperature in

the cooking compartment as it rises.

Pull the shelf out.

Wait until you have heard several

beeps and the symbol is flashing

in the time display before you open

the door.

26

Page 27

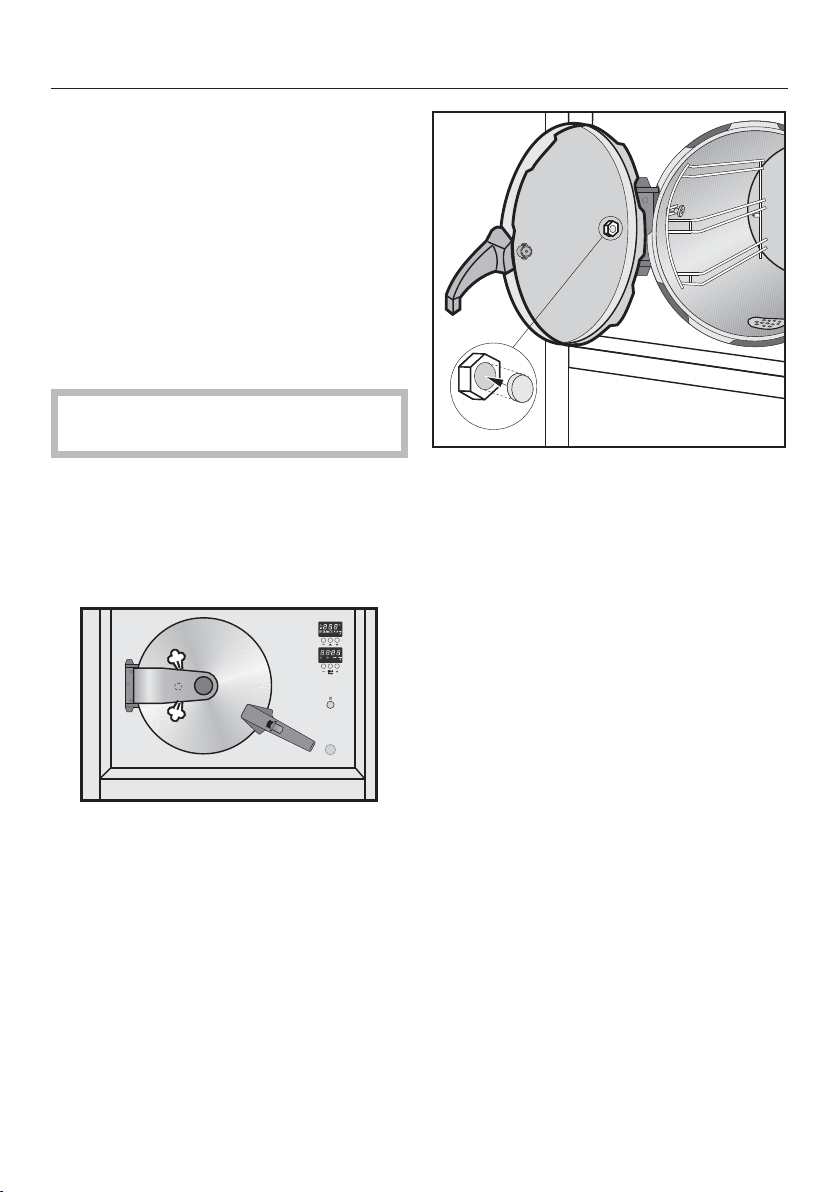

Under normal circumstances, the appli‐

ance controls pressure and temperature

automatically. However, should a fault

occur, the appliance has a pressure re‐

lease and a safety valve to prevent high

pressure developing, as well as a safety

device to prevent overheating.

Depending on frequency of use, the

safety valve and the pressure release

valve should be replaced every 1 to 2

years.

Safety devices must not be altered

or tampered with.

Safety features

Pressure release / Safety valve

The pressure release and the safety

valve may operate separately, together

or one after the other.

When either or both trip, steam will be

released above and below the door

hinge arm.

Press the Start/Stop button.

Wait until the cooling down phase

has been completed (see "Operation

- Interrupting a process").

Open the door.

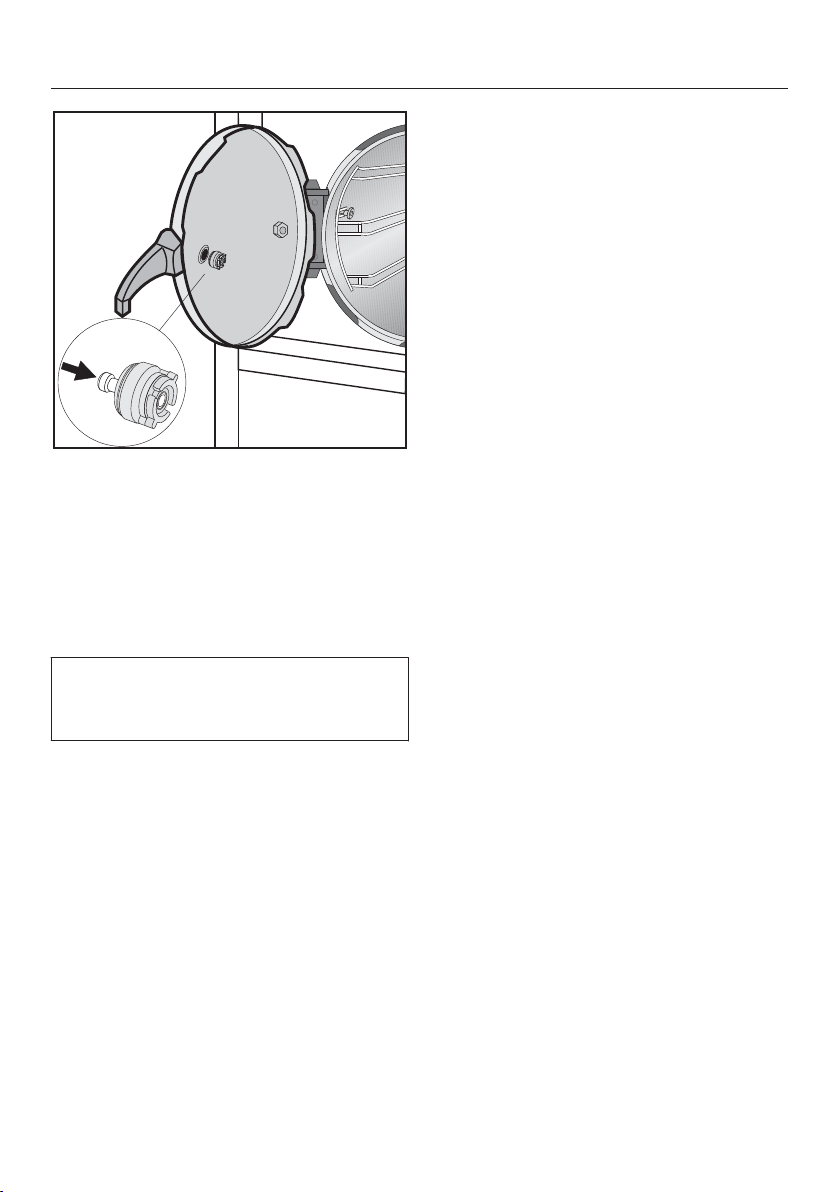

First check whether the silicone

washer has been forced out of the

pressure release mechanism. If it

has, fit a new one (see "Overview -

Accessories supplied") into the hold‐

er in the pressure release mechanism

inside the door.

The steam oven can now be used again

as normal.

If the pressure release mechanism

has not been activated (i.e. the sili‐

cone washer is still in its holder), re‐

move the safety valve from inside

the appliance door.

27

Page 28

Safety features

Press the metal pin on the safety

valve back in.

Insert the safety valve back in posi‐

tion. Make sure that the seal fits cor‐

rectly.

The steam oven can now be used again

as normal.

If the pressure release mechanism or

the safety valve trips again, please call

Miele.

28

Page 29

Safety features

Overheating protection

The overheating protection device is lo‐

cated underneath the On/Off switch.

This switches the heating off automati‐

cally if the temperature in the steam

generator gets too high. will appear

in the function / temperature display

and the cooling down phase will start.

The cooling down phase lasts for 1 mi‐

nute. There will be several beeps when

it is finished. will then flash in the

function / temperature display for a

short while and then three horizontal

bars - - - will appear. A short while later

will appear in the display.

Switch the appliance off and open

the door.

Allow the appliance to cool down for

approx. 30 minutes.

will disappear from the display

whilst the appliance is cooling down.

If the overheating protection device

trips again, contact Miele.

Remove the protective cap from the

overheating protection device (see

arrow). Use a screwdriver or similar

thin tool to press the device in again.

Replace the cap.

The steam oven can now be used again

as normal.

29

Page 30

Safety features

Safety lock / System lock

The appliance is fitted with a lock to

prevent it being switched on by acci‐

dent and also to prevent certain set‐

tings from being altered when the

steam oven is in use.

If you wish to use the lock, you will

need to alter the setting (see "Settings")

once.

The system lock can be activated as

long as the appliance is ready for

use. Once activated, the appliance can

be switched on or off. It cannot, howev‐

er, be used.

The safety lock is activated whilst the

appliance is in use. Once activated,

the appliance functions are restricted:

– The recommended temperature can

only be reduced. It cannot be in‐

creased.

– The cooking duration can only be re‐

duced.

– The appliance can be switched off

and back on again, but you will not

be able to select a function.

Activating the lock

Press the button repeatedly until 3

bars and the symbol appear in the

function / temperature display.

Press the + temperature button.

will appear in the function / temper‐

ature display and the symbol will

start to flash.

If you try to enter a setting while the

lock is active, will appear in the

function / temperature display.

Deactivating the lock

Press the button repeatedly until

and appear in the display.

Press the - button.

The lock is now deactivated.

30

Page 31

General notes

This section contains general informa‐

tion. You will find more detailed infor‐

mation about particular foods and how

to cook them in the other sections.

The advantages of cooking with steam

Almost all vitamins and minerals are re‐

tained as the food is not immersed in

water.

Cooking with steam also retains the

true taste of the food better than con‐

ventional cooking. We therefore recom‐

mend seasoning the food after it has

been cooked. Food also retains its

fresh, original colour.

Suitable containers

Cooking containers

This steam oven is supplied with stain‐

less steel cooking containers. Other

containers, in a variety of sizes, both

perforated and solid, are available as

optional extras (see "Optional accesso‐

ries"). This enables you to choose the

most suitable container for the food you

are preparing.

It is best to use perforated containers

for steam cooking. The steam can

reach the food from all sides and the

food is cooked evenly.

Your own containers

You can also use your own containers.

However, please note the following:

– Containers must be heat-resistant to

120 °C and able to withstand hot

steam. With plastic containers please

check with the manufacturer that

they are suitable for use in a steam

oven.

– Thick-sided containers made from

porcelain, china or stoneware, for ex‐

ample, are not very suitable for

steam cooking. They do not conduct

heat well and as a result cooking du‐

rations will be considerably longer

than those given in the charts.

– Place the cooking container on the

tray, not on the floor of the steam

oven.

– To ensure that steam can reach food

from all sides without hindrance,

make sure that cooking containers

do not touch the sides of the oven.

Shelf level

You can select any shelf level. You can

also cook on several levels at the same

time. This will not alter the cooking du‐

ration.

Frozen

The heating up phase for frozen food is

longer than for fresh food. The greater

the quantity of frozen food, the longer

the heating up phase.

31

Page 32

General notes

Temperature

A maximum temperature of 120 °C can

be achieved with the Steam with pres‐

sure cooking function. Robust

foods can be cooked at this tempera‐

ture, whereas more delicate types of

food should be cooked at 100 °C using

the Steam cooking function.

Some types of food, e.g. berries, need

to be cooked at less than 100 °C as

otherwise they would explode. See the

relevant sections in these operating in‐

structions for more detail about cooking

with steam.

Duration

In general, the cooking durations for

cooking in a steam oven 100 °C are the

same as for cooking food in a sauce‐

pan. More information about any fac‐

tors which may affect the cooking dura‐

tion is given in the relevant sections.

Using Steam with pressure can re‐

duce cooking durations by about half.

The quantity of food does not affect the

cooking duration. 1 kg of potatoes will

take the same time to cook as 500 g.

The durations given in the charts are

guidelines only. We recommend select‐

ing the shorter cooking duration quoted

to start with. If food is not cooked suffi‐

ciently after the shorter time, it can be

put back in the oven and cooked for

longer.

Cooking with liquid

When cooking with liquid, only fill the

cooking container ²/₃ full to prevent the

liquid spilling when the cooking con‐

tainer is removed from the oven.

When using Steam with pres‐

sure 120 °C to cook food air will cir‐

culate throughout the cabinet during

the cooling down phase. This circulat‐

ing air can cause food to be drawn out

of the container it is being cooked in

and soil the cabinet. This is more likely

to occur with food that is cooked in liq‐

uid (soup, casseroles etc.) and with

food with a mushy consistency such as

apple sauce.

Cover the container with a lid (see "Op‐

tional accessories") to prevent this hap‐

pening. Place the container together

with the lid in between the rails of a

shelf runner and not on top of it to hold

the lid in place.

Your own recipes

Food and recipes which are prepared in

a pot or a pan can also be cooked in

the steam oven. The cooking times in

the steam oven will be the same.

Please note that food will not be brown

or crisp when cooking with steam.

32

Page 33

Steam cooking

Vegetables

Fresh

Prepare fresh vegetables in the usual

way, i.e. wash, clean and cut them up.

Frozen

Frozen vegetables do not need to be

defrosted beforehand unless the vege‐

tables have been frozen together in a

block.

To cook frozen vegetables, programme

the same time as for fresh ones.

Break up the larger, frozen together

pieces. Please refer to the cooking

times on the packaging.

Cooking containers

Food such as peas or asparagus

spears, which have little or no space

between them, will take longer to cook

because the steam has less space to

work in. For an even result, it is best to

use a shallow container for these types

of food, and only fill it about 3 - 5 cm

deep. When cooking large quantities,

divide the food between 2 or 3 shallow

containers rather than using one deep

one.

Different types of vegetables which

take the same length of time to cook

can be cooked together in one cooking

container.

Shelf level

When cooking vegetables with a dis‐

tinctive colour (e.g. beetroot) in a perfo‐

rated container at the same time as

cooking other foods in other containers,

place the solid tray directly underneath

the perforated container to catch any

drips and therefore avoid any colour

transfer.

Duration

As with conventional methods, when

cooking vegetables with steam at

100 °C the cooking duration will de‐

pend on the size and also whether you

want the vegetables to be al dente or

soft/well-done. Example:

Firm potatoes, cut into quarters = ap‐

prox. 18 minutes

Firm potatoes, cut in half = approx. 22

minutes

Brussels sprouts, large, al dente = ap‐

prox. 12 minutes

Brussels sprouts, small, soft = approx.

12 minutes

Settings

Steam with pressure

Temperature: 120 °C

or

Steam cooking

Temperature: 100 °C

Duration: see chart

Use solid containers for vegetables

which are cooked in liquid, e.g. cab‐

bage.

33

Page 34

Steam cooking

The durations given in the charts for fresh vegetables are guidelines only. We rec‐

ommend selecting the shorter cooking duration quoted to start with. If vegetables

are not cooked sufficiently after the shorter time, they can be put back in the

steam oven and cooked for longer.

Vegetables

Artichokes 12–14 32–38

Cauliflower, whole – 27–28

Cauliflower, florets 2 8

Green beans 2 6–8

Broccoli, florets – 2–4

Chantenay carrots, whole 3 7–8

Chantenay carrots, halved 3 5–6

Chantenay carrots, chopped 1 4

Chicory, halved – 4–5

Chinese cabbage, chopped 1 3

Peas – 2

Fennel, halved 4–5 10–12

Fennel, cut into strips 2 4–5

Curly kale, chopped 4–6 23–26

Firm potatoes, peeled

whole

halved

quartered

Fairly firm potatoes, peeled

whole

halved

quartered

Soft potatoes, peeled

whole

halved

quartered

Kohlrabi, cut into batons 2 6–7

Pumpkin, diced – 4–8

–

9

6

–

7

5

–

7

5

[min.]

20–25

15–20

10–15

23–28

18–23

14–18

25–30

20–25

15–20

34

Page 35

Steam cooking

Vegetables

Corn on the cob 15 10–15

Silverbeet, chopped – 2–3

Capsicum, diced/cut into strips – 2

New potatoes, firm – 20–25

Mushrooms – 2

Leek, chopped 1 2–4

Leek, stalks halved lengthways – 4–6

Romanesco, whole – 22–25

Romanesco, florets 2 5–7

Brussels sprouts 3–4 10–12

Beetroot, whole 24–26 50–60

Red cabbage, chopped 4 15–20

Black salsify, whole 3–4 9–10

Celeriac, cut into batons 2 6–7

Green asparagus – 2–4

White asparagus, whole – 5–10

Carrots, chopped 1 6

Spinach – 1–2

Spring cabbage, chopped 2–3 10–11

Celery sticks, chopped 1–2 2–5

Turnips, chopped 2–3 6–7

White cabbage, chopped 2 12

Savoy cabbage, chopped 2 10–11

Zucchini, sliced – 2–3

Sugar snap peas – 2–3

[min.]

Duration

35

Page 36

Steam cooking

Meat

Fresh

Prepare the meat in the usual way.

Frozen

Meat should be thoroughly defrosted

before cooking in the steam oven (see

"Special applicaitons - Defrost").

Preparation

Meat which needs to be seared before

being cooked, e.g. stewing steak,

should be seared in a pan on the cook‐

top.

Duration

The cooking duration depends on the

thickness and the texture of the meat,

and not on the weight. The thicker the

piece of meat, the longer the cooking

duration. A piece of meat weighing 500

g which is 10 cm thick will take longer

to cook than a piece of meat weighing

500 g which is 5 cm thick.

– When cooking meat with the addi‐

tion of liquid please follow recipe in‐

structions regarding the amount of

liquid to use. This is particularly im‐

portant when using Steam with pres‐

sure . Using too much can cause

the liquid to boil over. If you need to

add more liquid, e.g. add more stock,

it is best to do so after the food has

been cooked.

Settings

Steam with pressure

Temperature: 120 °C

or

Steam cooking

Temperature: 100 °C

Duration: see chart

Useful tips

– Use a perforated container to retain

the flavours when cooking meat.

Place a solid container underneath to

catch the juices. You can use these

to make a gravy or freeze them for

later use.

– Boiling chicken, pork rind, meat, ribs

and meat bones can be used to

make stock. Place the meat together

with some mixed vegetables in a sol‐

id cooking container and add cold

water. The longer the cooking dura‐

tion, the stronger the stock.

36

Page 37

Steam cooking

The durations given in the chart are guidelines only. We recommend selecting the

shorter cooking duration quoted to start with. If meat is not cooked sufficiently af‐

ter the shorter time, it can be put back in the steam oven and cooked for longer.

Meat

Beef shin, covered with water 45–50 110–120

Pork knuckle 75–80 135–140

Chicken breast fillet – 8–10

Knuckle 58–63 105–115

Beef soup bones, covered with water 38–43 110–120

Veal for stewing – 3–4

Gammon steaks 3–4 6–8

Lamb ragout 6–8 12–16

Poularde 30 60–70

Turkey roulade – 12–15

Turkey schnitzel – 4–6

Rib of beef, covered with water 50–55 130–140

Beef stew 30–35 105–115

Boiling chicken, covered with water 40 80–90

Silverside 45–50 110–120

[min.]

Duration

37

Page 38

Steam cooking

Sausages

Settings

Steam cooking

Temperature: 90 °C

Duration: see chart

Sausages

Frankfurters 6–8

Sausages 6–8

White sausages 6–8

Duration

[min.]

Fish

Fresh

Prepare fresh fish in the usual way, i.e.

clean, gut and fillet.

Frozen

Fish does not need to be fully defrosted

before cooking. Defrost so that the sur‐

face is sufficiently thawed to take herbs

and seasoning. Depending on the

thickness of the fish, 2–5 minutes

should be enough.

Preparation

Add some lemon or lime juice to fish

before cooking. The citric acid helps

the flesh stay firm.

It is not necessary to season fish when

cooking with steam as this method re‐

tains the minerals which give the fish its

unique flavour.

Cooking containers

If using a perforated container, grease it

first or line it with baking paper.

38

Shelf level

When cooking fish in a perforated con‐

tainer at the same time as cooking oth‐

er types of food in other containers,

place the container with the fish directly

above the tray to catch any liquid and

so avoid any transfer of tastes to other

food.

Page 39

Steam cooking

Temperature

85 °C – 90 °C

For gently cooking delicate types of

fish, such as flounder.

100 °C

For cooking firmer types of fish, e.g.

salmon.

Also for cooking fish in sauce or stock.

Duration

The cooking duration depends on the

thickness and the texture of the fish,

and not on the weight. The thicker the

fish, the longer the cooking duration. A

3 cm thick piece of fish weighing 500 g

will take longer to cook than a 2 cm

thick piece of fish weighing 500 g.

The longer fish cooks, the firmer its

flesh will become. Use the cooking du‐

rations given in the chart. If you find

that the fish is not cooked sufficiently,

only cook it for a few minutes more.

When cooking fish in sauce or stock,

we recommend that you increase the

cooking duration quoted by a few mi‐

nutes.

– You can use any fish scraps, e.g. fish

heads, bones, tails etc. to make a

fish stock. Place the fish scraps to‐

gether with some mixed vegetables

in a solid cooking container and add

cold water. Cook at 100 °C for 60 to

90 minutes. The longer the cooking

duration, the stronger the stock.

– Blue fish is fish which is cooked in

water and vinegar. It is important not

to damage the skin of the fish. This

method is suitable for cooking carp,

trout, tench, eel and salmon.

Settings

Steam cooking

Temperature: see chart

Duration: see chart

Useful tips

– Adding herbs and spices, such as

dill, will help bring out the full flavour

of the fish.

– Cook large fish in the swimming posi‐

tion. To help maintain the structure of

the fish, place a small cup or similar

upside down in the cooking contain‐

er, and arrange the fish bellyside

down over the cup.

39

Page 40

Steam cooking

The durations given in the chart are guidelines for fresh fish. We recommend se‐

lecting the shorter cooking duration quoted to start with. If the fish is not cooked

sufficiently after the shorter time, it can be put back in the steam oven and cooked

for longer.

Fish

Eel 100 5–7

Perch fillet 100 3–5

Bream/Snapper fillet 85 3–5

Trout, 250 g 90 8–12

Halibut/Trumpeter fillet 85 4–6

Blue eye trevalla/Ling fillet 100 6

Carp, 1.5 kg 100 18–25

Salmon fillet 100 4–8

Salmon steak 100 8–10

Ocean trout/Rainbow trout 90 8–10

Basa fillet 85 3

Rosefish fillet 100 6–8

Jackass morwong fillet/Terakihi fillet 100 4–6

Flounder fillet 85 4–5

Stargazer/Monkfish fillet 85 6–8

Sole fillet 85 3

[°C] [min.]

Turbot fillet 85 5–8

Tuna fillet 85 4–8

Pikeperch fillet 85 4

Temperature / Duration

40

Page 41

Steam cooking

Shellfish

Preparation

Defrost frozen shellfish before cooking with steam.

Peel, remove and discard the intestines, and then wash the shellfish.

Cooking containers

If using a perforated container, grease it first or line it with baking paper.

Duration

The longer shellfish are cooked, the tougher they become. Use the cooking dura‐

tions given in the chart.

When cooking shellfish in sauce or stock, we recommend that you increase the

cooking duration quoted by a few minutes.

Settings

Steam cooking

Temperature: see chart

Duration: see chart

[°C] [min.]

Crevettes 90 3

Prawns 90 3

King prawns 90 4

Small shrimps 90 3

Crayfish 95 10–15

Large shrimps 90 3

Temperature / Duration

41

Page 42

Steam cooking

Mussels

Fresh

Warning - danger of food poisoning!

Only cook mussels which are closed. Do not eat mussels which have not

opened after being cooked.

Steep fresh mussels in water for a few hours before cooking to rinse out any sand.

Then scrub the mussels thoroughly to clean them.

Frozen

Defrost frozen mussels before cooking.

Duration

The longer mussels are cooked, the harder they become. Use the cooking dura‐

tions given in the chart.

Settings

Steam cooking

Temperature: see chart

Duration: see chart

[°C] [min.]

Goose barnacles 100 2

Cockles 100 2

Blue mussels 90 12

Scallops 90 3

Razor clams 100 2–4

Vongole 90 2–4

Temperature / Duration

42

Page 43

Steam cooking

Rice

Rice swells when cooked and needs to be cooked in liquid. The proportion of rice

to liquid will vary depending on the type of rice.

The rice absorbs all the liquid. Therefore none of the nutrients are lost.

Settings

Steam with pressure

Temperature: 120 °C

or

Steam cooking

Temperature: 100 °C

Duration: see chart

Ratio

Rice : Liquid

Basmati rice 1 : 1.5 7 15

Parboiled rice 1 : 1.5 11 23–25

Arborio rice

Milk rice

Risotto rice

Brown rice 1 : 1.5 13 25–30

Wild rice 1 : 1.5 13 25–30

Duration

1 : 2.5

1 : 2.5

[min.]

11

18–19

30

43

Page 44

Steam cooking

Pasta / Noodles

Dry pasta and noodles

Dry pasta and noodles swell when they are cooked and need to be cooked in liq‐

uid. The liquid must cover the pasta or noodles. Using hot liquid gives better re‐

sults.

Increase the cooking time stated by the manufacturer by approx. 1/3.

Fresh pasta and noodles

Fresh pasta and noodles, such as you can buy from the supermarket chilled coun‐

ter, do not need to absorb water. Cook fresh pasta and noodles in a greased, per‐

forated container.

Separate any pieces of pasta or noodles which have stuck together and spread

them out in the cooking container.

Settings

Steam with pressure

Temperature: 120 °C

or

Steam cooking

Temperature: 100 °C

Duration: see chart

Fresh

Gnocchi – 2

Knöpfli – 1

Ravioli – 2

Spätzle – 1

Tortellini – 2

Dry pasta / noodles, covered with water

Flat noodles / Fettuccine 8 14

Vermicelli – 8

Duration

44

[min.]

Page 45

Steam cooking

European dumplings

Ready-made dumplings in wrappers need to be covered completely with water.

Otherwise they will not absorb enough water and will fall apart, even if steeped in

water prior to cooking.

Cook fresh dumplings in a greased, perforated container.

Settings

Steam cooking

Temperature: 100 °C

Duration: see chart

[min.]

Steamed dumplings 30

Yeast dumplings 20

Boil-in-the-bag potato dumplings 20

Boil-in-the-bag bread dumplings 18–20

Duration

45

Page 46

Steam cooking

Grains

Grain swells when cooked and needs to be cooked in liquid. The proportion of

grain to liquid will vary depending on the type of grain.

Grain can be cooked whole or cracked.

Settings

Steam with pressure

Temperature: 120 °C

or

Steam cooking

Temperature: 100 °C

Duration: see chart

Ratio

Grain : Liquid

Amaranth 1 : 1.5 8 15–17

Bulgur 1 : 1.5 4 9

Green spelt, whole 1 : 1 4 18–20

Green spelt, cracked 1 : 1 9 7

Oats, whole 1 : 1 9 18

Oats, cracked 1 : 1 4 7

Millet 1 : 1.5 – 10

Polenta 1 : 3 – 10

Quinoa 1 : 1.5 7 15

Rye, whole 1 : 1 18 35

Rye, cracked 1 : 1 5 10

Wheat, whole 1 : 1 15 30

Wheat, cracked 1 : 1 4 8

Duration

[min.]

46

Page 47

Steam cooking

Dried pulses

Soak pulses for at least 10 hours in cold water before cooking. Soaking makes the

pulses more digestible and shortens the cooking duration required. Soaked pulses

must be covered with liquid during cooking.

Lentils do not need to be soaked before cooking.

With unsoaked pulses a certain ratio of pulses to liquid is required.

Settings

Steam with pressure

Temperature: 120 °C

or

Steam cooking

Temperature: 100 °C

Duration: see chart

Soaked

[min.]

Beans

Kidney beans 7 55–65

Azuki beans 3 20–25

Black beans 7 55–60

Borlotti beans 7 55–65

Haricot beans 7 34–36

Peas

Yellow split peas 11 40–50

Green peas, shelled 9 27

Duration

47

Page 48

Steam cooking

Unsoaked

Ratio

Pulses : Liquid

Beans

Kidney beans 1 : 3 – 130–140

Azuki beans 1 : 3 – 95–105

Black beans 1 : 3 15–16 100–120

Borlotti beans 1 : 3 – 115–135

Haricot beans 1 : 3 – 80–90

Lentils

Brown lentils 1 : 2 – 13–14

Red lentils 1 : 2 – 7

Peas

Yellow split peas 1 : 3 – 110–130

Green peas, shelled 1 : 3 – 60–70

Duration

[min.]

48

Page 49

Steam cooking

Hen's eggs

Use a perforated container to prepare boiled eggs in the steam oven.

The eggs do not need to be pierced before cooking as they are gradually warmed

during the heating-up phase and so do not burst when they are cooked with

steam.

When using a solid container for preparing egg dishes, remember to grease it first.

Settings

Steam cooking

Temperature: 100 °C

Duration: see chart

[min.]

Small (S)

soft

medium

hard

Medium (M)

soft

medium

hard

3

5

9

4

6

10

Large (L)

soft

medium

hard

Extra large (XL)

soft

medium

hard

Duration

5

6–7

12

6

8

13

49

Page 50

Steam cooking

Fruit

Cook fruit in a solid container so that none of the juice is lost. If you wish to cook

fruit in a perforated container, place a solid container directly underneath it to col‐

lect the juice.

Useful tip: You can use the collected juice to prepare a glaze for a fruit flan.

Settings

Steam with pressure

Temperature: 120 °C

or

Steam cooking

Temperature: 100 °C

Duration: see chart

[min.]

Apples, cut into pieces – 1–3

Pears, cut into pieces – 1–3

Cherries – 2–4

Mirabelle plums – 1–2

Nectarines/Peaches, cut into pieces – 1–2

Plums – 1–3

Quinces, diced 3–4 6–8

Rhubarb, cut into pieces – 1–2

Gooseberries – 2–3

Duration

50

Page 51

Steam cooking

Menu cooking

Menu cooking involves cooking various

foods with different cooking times in or‐

der to serve them all together in one

meal, e.g. Perch with rice and broccoli.

Foods are placed in the steam oven at

different times so that they are all ready

at the same time.

Shelf level

When cooking fish or food with a dis‐

tinctive colour (e.g. beetroot) in a perfo‐

rated container, place the perforated

container directly above the tray to

avoid any transfer of flavour or colour to

other food and to prevent liquid drip‐

ping onto food below it.

Temperature

Whole meals should be cooked at a

temperature of 100 °C as this is the

temperature required to cook the major‐

ity of foods.

Do not cook a whole meal at the lowest

temperature when different tempera‐

tures are required for different types of

food, e.g. 85 °C for seabream and

100 °C for potatoes.

Example:

Rice 20 minutes

Rosefish fillet 6 minutes

Broccoli 4 minutes

20 minutes minus 6 minutes = 14 mi‐

nutes (1st duration: rice)

6 minutes minus 4 minutes = 2 minutes

(2nd duration: rosefish fillet)

Remaining time = 4 minutes (3rd dura‐

tion: broccoli

Cook‐

ing du‐

rations

Settings 14 min. 2 min. 4 min.

6 min. - rosefish

20 min. - rice

fillet

4 min. -

broccoli

If the recommended cooking tempera‐

ture for the food is 85 °C for example,

try cooking it at 100 °C and testing the

result. Some delicate types of fish with

a soft structure, e.g. flounder will be‐

come very firm when cooked at 100 °C.

Duration

If you increase the recommended tem‐

perature, shorten the cooking duration

by approx. ¹/₃.

51

Page 52

Steam cooking

Procedure

Switch on the steam oven and select

Steam cooking 100 °C.

Place the rice in the steam oven first.

Set the first cooking duration: 14 mi‐

nutes.

After 14 minutes, place the fish in the

steam oven.

Set the second cooking duration:

2 minutes.

After 2 minutes, place the broccoli in

the steam oven.

Set the third cooking duration: 4 mi‐

nutes.

52

Page 53

Special applications

Reheat

The steam oven is very effective at re‐

heating food gently, without drying it

out or cooking it further. The food re‐

heats evenly and does not need to be

stirred during the reheating process.

You can reheat individual dishes or

plated meals which have been prepared

previously (e.g. meat, vegetables and

potatoes).

Suitable containers

Small quantities can be reheated on a

plate, larger quantities should be

placed in a cooking container.

Useful tips

– Do not reheat large items, such as a

joint of roast meat, whole. Divide it

into portions and reheat these as

plated meals.

– Compact items, such as stuffed cap‐

sicum or roulades, should be cut in

half.

Procedure

Cover the food with a deep plate, a

lid, or with clingfilm that is resistant to

temperatures up to 100 °C and to

steam.

Place the plate on the tray and place

in the oven.

Settings

Reheat

Duration: see chart

– Please note that breaded items, such

as schnitzel, will not retain their crisp‐

ness when they are reheated.

– Reheat sauces separately. Excep‐

tions: Food that is prepared in sau‐

ces, e.g. goulash.

53

Page 54

Special applications

[min.]

Vegetables

Cauliflower / Beans 2

Kohlrabi / Carrots 2

Side dishes

European dumplings / Potatoes, halved lengthways 3–4

Pasta / Rice 2–3

Meat and poultry

Roast in slices, 1.5 cm thick 3–5

Stew 3–5

Chicken schnitzel 3–5

Meatballs 3–5

Roulade in slices 3–5

Fish

Fish fillet 2–3

Fish roulade, halved 2–3

Plated meals

Chicken fricassee with rice 3–5

Roast pork with potatoes and vegetables 3–4

Spaghetti Napoli 2–3

Soups / Casseroles

Casserole 4–5

Creamy vegetable / Clear soup 2–3

54

Page 55

Special applications

Defrost

It is much quicker to defrost items in

the steam oven than at room tempera‐

ture.

Temperature

60 °C is the best temperature for de‐

frosting.

Exceptions: 50 °C for minced meat

and game.

Before and after defrosting

Remove all packaging before defrost‐

ing.

Exceptions: Leave bread, biscuits and

cakes in their packaging as otherwise

they will absorb moisture and become

soft.

Allow defrosted food to stand at room

temperature after removing it from the

oven. The standing time is necessary to

allow the even distribution of heat.

Cooking containers

Useful tips

– Fish does not need to be fully defros‐

ted before cooking. Defrost so that

the surface is sufficiently thawed to

take herbs and seasoning. Depend‐

ing on the thickness of the fish, 2–5

minutes should be enough.

– When defrosting food which has fro‐

zen together, e.g. berries, chops, fish

fillets etc. separate it about half-way

through the defrosting time.

– Do not refreeze food once it has

thawed.

– Defrost frozen ready meals according

to the instructions on the packaging.

Settings

Defrost

Temperature: see chart

Duration: see chart

Danger of salmonella poisoning!

Do not use the liquid from defrosted

meat or poultry. Pour it away and

wash the container, the sink and

your hands.

Use a perforated container with the sol‐

id tray underneath it when defrosting

food which will drip, such as poultry.

This way food will not be lying in de‐

frosted liquid.

Foods which don't drip can be defros‐

ted in a solid cooking container.

55

Page 56

Special applications

Food to be defrosted Quantity

Dairy products

Sliced cheese 125 g 60 15 10

Quark 250 g 60 20–25 10–15

Cream 250 g 60 20–25 10–15

Soft cheese 100 g 60 15 10–15

Fruit

Apple sauce 250 g 60 20–25 10–15

Apple pieces 250 g 60 20–25 10–15

Apricots 500 g 60 25–28 15–20

Strawberries 300 g 60 8–10 10–12

Raspberries / Blackcurrants 300 g 60 8 10–12

Cherries 150 g 60 15 10–15

Peaches 500 g 60 25–28 15–20

Plums 250 g 60 20–25 10–15

Gooseberries 250 g 60 20–22 10–15

Vegetables

Frozen in a block 300 g 60 20–25 10–15

Fish

Fish fillets 400 g 60 15 10–15

Trout 500 g 60 15–18 10–15

Lobster 300 g 60 25–30 10–15

Small shrimps 300 g 60 4–6 5

Ready meals,

Meat, vegetables, sides / Cas‐

serole / Soup

Meat

Roast meat slices 125–150 g each 60 8–10 15–20

Mince 250 g 50 15–20 10–15

Mince 500 g 50 20–30 10–15

Stew 500 g 60 30–40 10–15

56

480 g 60 20–25 10–15

[°C] [min.] [min.]

Page 57

Special applications

Food to be defrosted Quantity

Stew 1000 g 60 50–60 10–15

Liver 250 g 60 20–25 10–15

Saddle of hare 500 g 50 30–40 10–15

Saddle of venison 1000 g 50 40–50 10–15

Schnitzel / Chops / Sausages 800 g 60 25–35 15–20

Poultry

Chicken 1000 g 60 40 15–20

Chicken thighs 150 g 60 20–25 10–15

Chicken schnitzel 500 g 60 25–30 10–15

Turkey drumsticks 500 g 60 40–45 10–15

Cookies/Muffins

Puff pastries /Yeast buns – 60 10–12 10–15

Creamed mixture cakes / bis‐

cuits

Bread / Rolls

Bread rolls – 60 30 2

Rye bread, sliced 250 g 60 40 15

Whole grain bread, sliced 250 g 60 65 15

White bread, sliced 150 g 60 30 20

400 g 60 15 10–15

[°C] [min.] [min.]

Temperature / Duration / Standing time

57

Page 58

Special applications

Bottling

Danger of injury!

Do not use temperatures above

95 °C for bottling (or above 90 °C at

altitudes above 1000 m). Otherwise

the jars will break.

Only use unblemished, fresh produce

which is in good condition.

Glass jars

Use clean glass jars and accessories

and check them for any defects. Glass

jars with twist off lids or glass lids with

a rubber seal are suitable.

Make sure that all the glass jars are the

same size so that bottling is carried out

evenly.

After you have filled the jars with the

bottled produce, clean the glass rims

with a clean cloth and hot water and

then seal the jars.

Fruit

Sort fruit carefully, rinse it briefly but

thoroughly and allow it to drain. Take

great care when cleaning soft fruit as it

is very delicate and squashes easily.

Remove any peel, stalks, cores or

stones. Cut up large fruit. For example,

cut apples into slices.

If you are bottling fruit with stones (e.g.

plums, apricots) without removing the

stones, pierce the fruit several times

with a fork or wooden skewer as other‐

wise it will burst.

Green vegetables should be blanched

before bottling to help them retain their

colour (see "Special applications Blanching").

Fill volume

Fill the glass jars with produce up to a

maximum of 3 cm below the rim. Do

not pack it down as this will damage

the cell walls of the produce. Tap the jar

gently onto a cloth to help distribute the

contents evenly. Fill the jars with liquid.

The produce must be completely cov‐

ered.

Use a sugar solution for fruit and a salt

or vinegar solution for vegetables.

Meat and sausages

Briefly fry or cook the meat before bot‐

tling. Use the juices with some added

water, or the broth in which the meat

was cooked, as the liquid content of the

jars. Make sure there is no grease on

the rim of the jars.

When bottling sausages, only fill the

jars to halfway as the meat will rise dur‐

ing the bottling process.

Useful tips

– Make use of residual heat by leaving

the jars in the oven for 30 minutes af‐

ter it has switched off.

– Then cover the jars with a cloth and

allow to cool for approx. 24 hours.

Vegetables

Rinse, clean and cut up vegetables.

58

Page 59

Special applications

Procedure

Place a perforated container on the lowest shelf level.

Place the jars (all the same size) in the perforated cooking container. Ensure that

they do not touch one another.