Page 1

Supplement

ScanMaker i800 features, scenarios, and information

Getting to Know Your ScanMaker i800

The ScanMaker i800 is a high-resolution, high-performance scanner for reflective and

transparency scanning. It features 9600 x 4800 dpi, 48-bit color, legal-size scan bed

(8.5" x 14"), dual FireWire and Hi-Speed USB interfaces, and eight Smart-T ouch

buttons (including a convenient Power button) on the front panel to automate

scanner functions. The built-in Transparent Media Adapter, together with Microtek's

EZ-Lock™ Film Holders, let you scan film and transparencies up to 8" x 12" in size.

The ScanMaker i800 also offers the exclusive PictuRescue™ system, with built-in

DIGIT AL ICE and ColoRescue™ for reconstruction and color restoration of photos

and film.

Contents

Getting to Know Your ScanMaker i80 0 ........................................................... 1

Features of the ScanMaker i800 ...................................................................... 2

Taking a Closer Look ........................................................................................ 3

Unlocking the Scanner .................................................................................... 4

Connecting to the FireWire Port .....................................................................6

How the Smart-Touch Scanner Buttons Work ..............................................7

DIGITAL ICE Technology .................................................................................. 8

Positioning Your Originals .............................................................................. 9

Positioning Reflective Originals ............................................................. 9

Positioning Transparent Film ............................................................... 10

A. Using the EZ-Lock 35mm Slide Holder ................................... 11

B. Using the EZ-Lock 35mm Filmstrip Holder ............................ 12

Copyright © 2005 Microtek International, Inc. http://www.microtek.com

I49-003912 A, March 2005

C. Using the EZ-Lock 6 x 22 cm (120) Film Holder ....................... 13

D. Using the EZ-Lock 4" x 5" Film Holder ..................................... 14

E. Using the Film Alignment Ruler .............................................. 15

Scanning Scenarios ....................................................................................... 16

Scanning Regular, Non-Damaged Photos (1) ..................................... 17

Scanning Regular, Non-Damaged Photos (2) ..................................... 18

Scanning Damaged Photos ................................................................. 20

A. Using the DIGITAL ICE button ................................................. 20

B. Scanning with Automatic Reconstruction ............................. 22

C. Scanning with Manual Reconstruction .................................. 24

Scanning Regular, Non-Damaged Film ............................................... 26

Scanning Damaged Film ...................................................................... 28

Specifications / System Requirements ........................................................ 30

Page 2

Features of the ScanMaker i800

The ScanMaker i800 comes with several important features, including the following:

• 9600 x 4800-dpi resolution: The exceptionally high resolution of the ScanMaker

i800 lets you scan even postage-size images and enlarge them with amazing

clarity , with little loss of detail. The scanner’s 4.0 maximum optical density allows it

to capture a wide range of tones approximating real-life color and hues.

• Transparent Media Adapter (TMA): With the TMA, the ScanMaker i800 lets you

scan a wide variety of slides, negatives, and transparencies, improving your

productivity and saving you money in having to acquire additional film-scanning

accessories.

• Microtek's PictuRescue system: This combined photo and film reconstruction and

restoration solution incorporates DIGIT AL ICE Technology and ColoRescue.

– With DIGITAL ICE Technology , the ScanMaker i800 can automatically map,

identify , and eliminate surface defects on both photos and film. Built into the

hardware and software, DIGIT AL ICE removes dust, scratches, rips, and tears,

reconstructing your damaged photos and film and restoring them to pristine,

near-original quality .

– With ColoRescue, the ScanMaker i800 restores faded colors in photos and film,

bringing hues back to their original luster and brilliance for more vibrant

images. ColoRescue's one-click, automatic color recovery process is simple

and straightforward, involving no learning curve or hassle.

• Seven Smart-Touch buttons: These buttons on the front panel of the scanner

provide you with a quick and easy way to launch frequently used scanner

functions. All it takes is one touch of a button — and you can launch the scanner

button's corresponding function. The seven Smart-Touch buttons include

DIGIT AL ICE, Scan, Copy , E-mail, OCR, PDF , and Custom.

• Microtek ScanWizard 5 scanning software: ScanW izard 5 features full scanning

tools that both novice and experienced scanner users will find productive and

easy to use. The Standard Control Panel offers a simple and straightforward way

to complete a scanning session, and the Advanced Control Panel provides you

with additional controls to fine-tune your scans.

2 ScanMaker i800 Supplement

Page 3

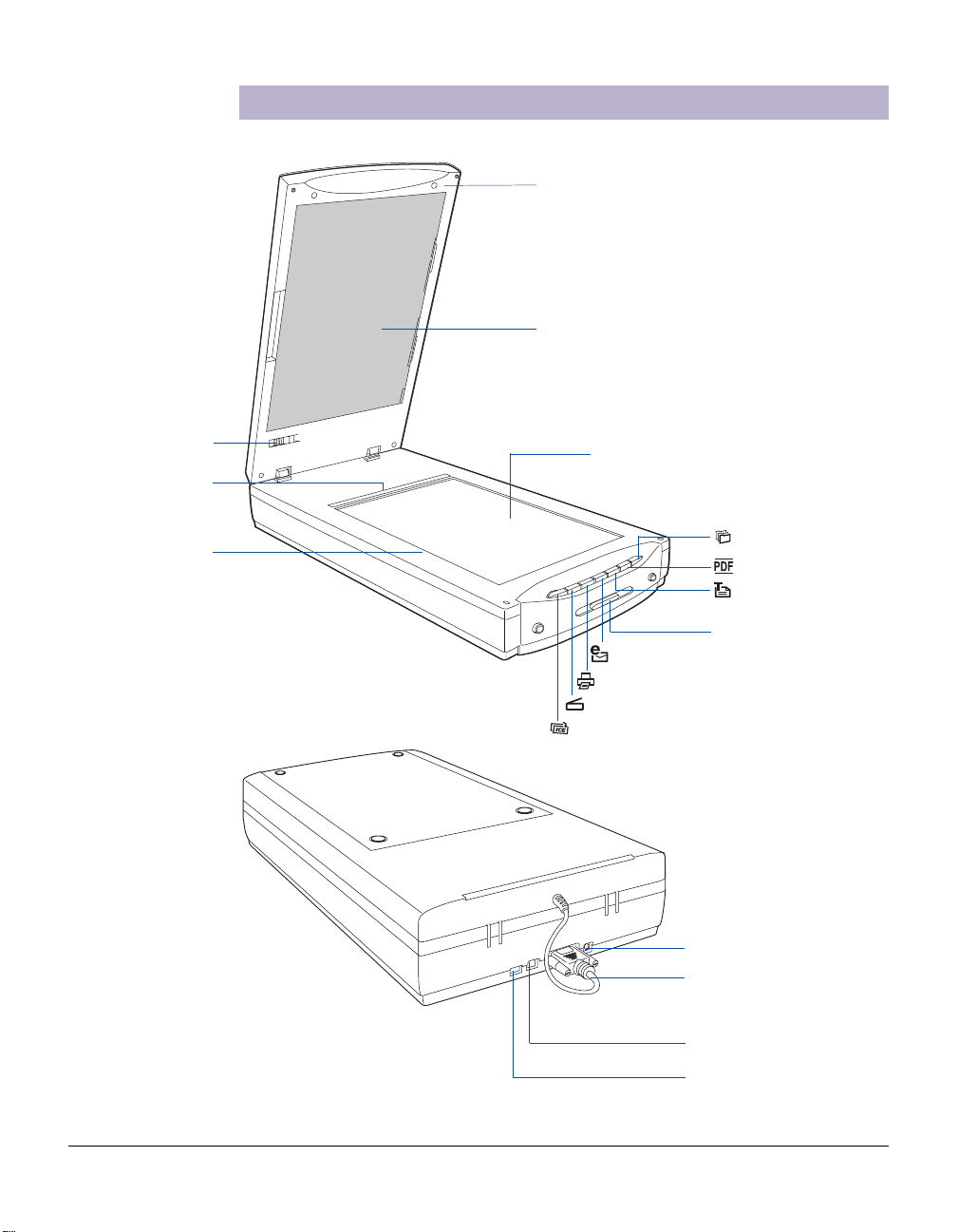

Locking switch

for TMA

Horizontal ruler

(top ruler)

Taking a Closer Look

Scanner lid (TMA)

Black mat

Glass surface

Vertical ruler

Custom button

PDF button

OCR button

Power button

E-mail button

Copy button

Scan button

DIGITAL ICE button

Power connector

Accessory port, with

connector of built-in

TMA securely connected

Hi-Speed USB port (1)

FireWire port (1)

ScanMaker i800 Supplement 3

Page 4

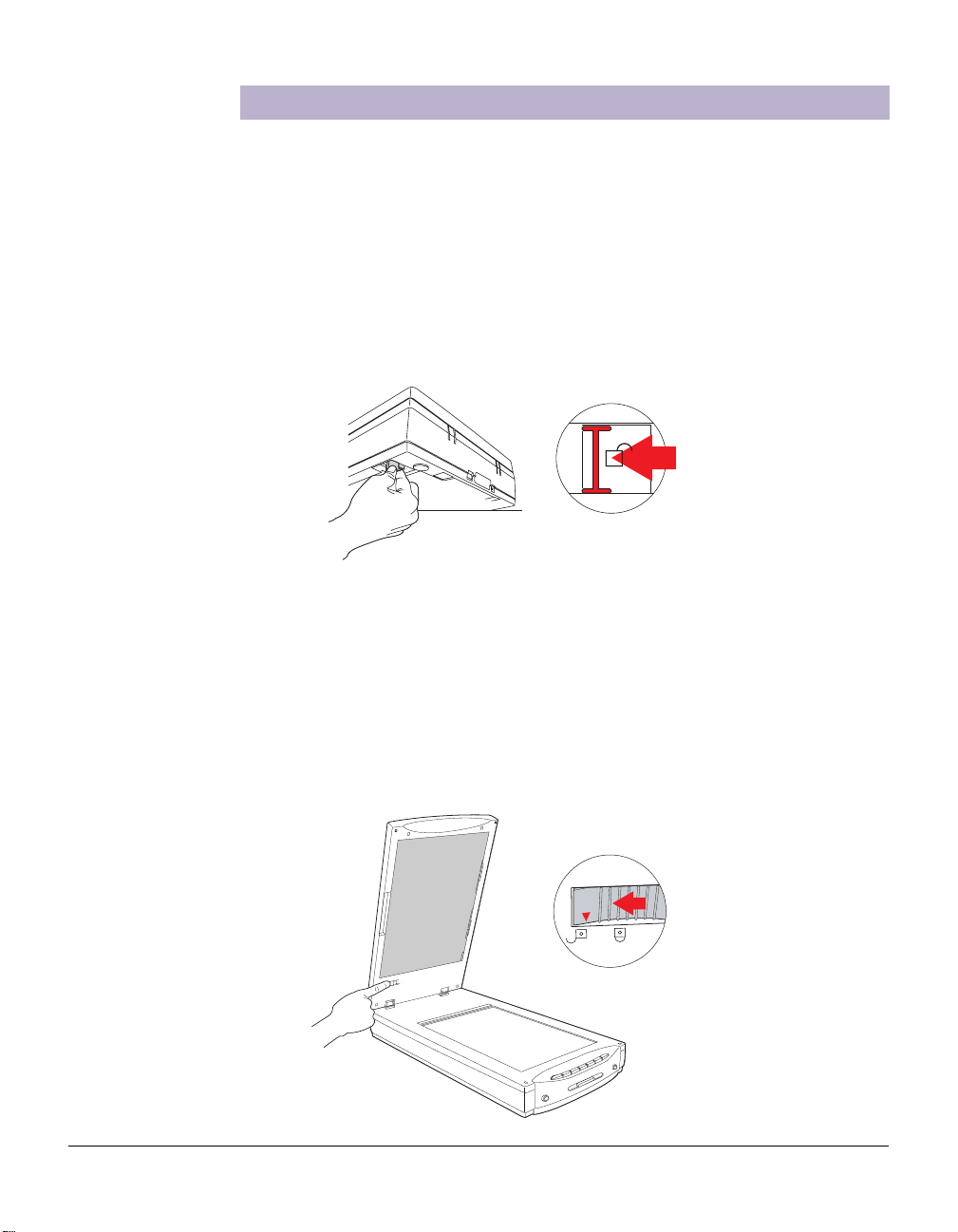

Unlocking the Scanner

Before you can operate the scanner, you will need to unlock the scanner and TMA.

T o unlock the scanner, follow the steps below:

1 . Remove the yellow “Step 3” sticker from your scanner .

2. With the scanner power off, tilt the back left corner of the scanner to see the

locking switch at the bottom.

3. Push the locking switch to the position as indicated in the graphic below, with the

icon on the lock showing as “unlocked”.

Unlocked

T o unlock the TMA, follow the steps below:

1 . Raise the scanner lid (TMA), then remove the yellow “Step 3” sticker from

the TMA.

2 . Look for the locking switch at the base of the TMA.

3. Push the locking switch to the position as indicated in the graphic below, with the

icon on the lock showing as “unlocked”.

4 ScanMaker i800 Supplement

Unlocked

Page 5

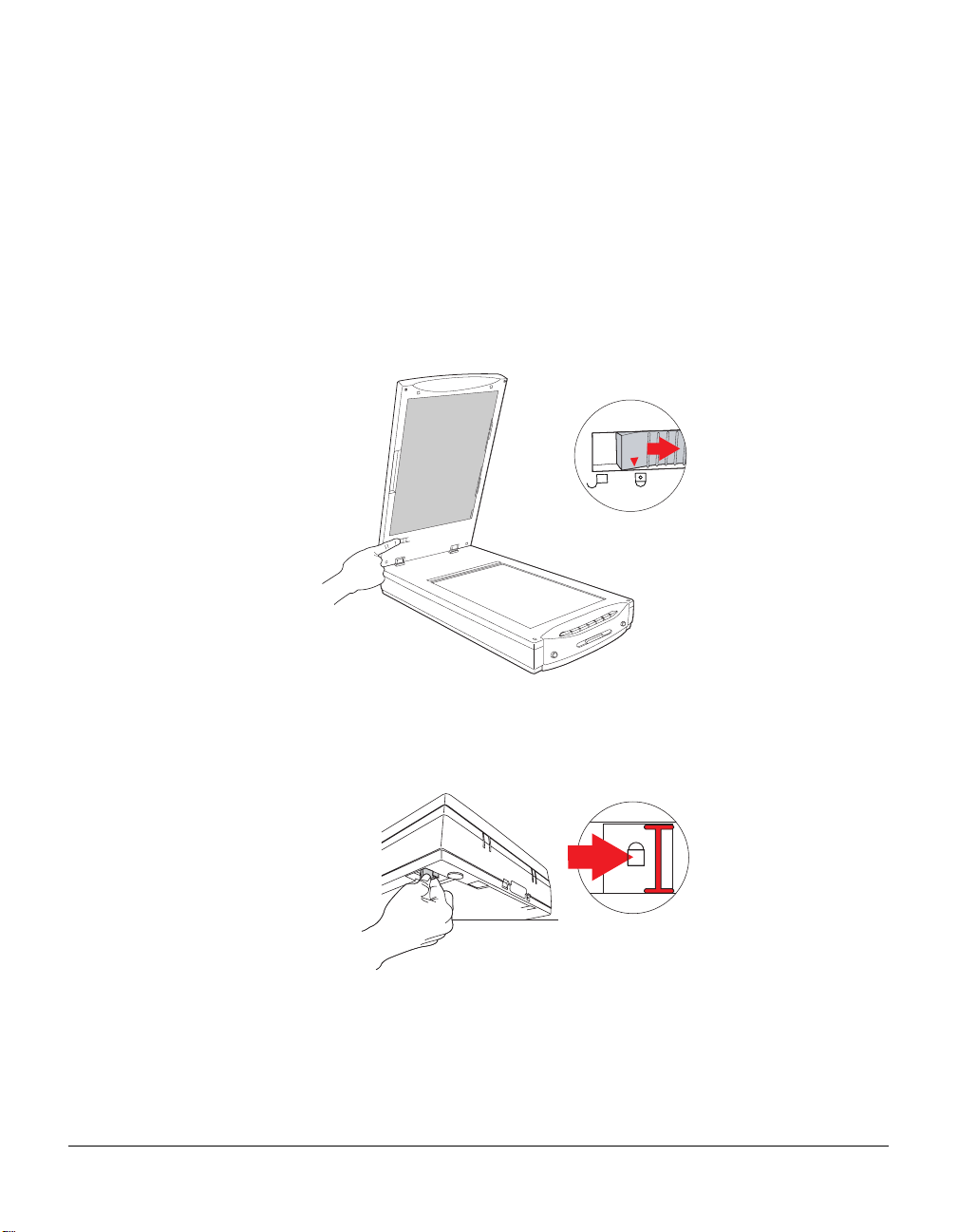

Shipping the Scanner

If you have to transport the scanner, you will need to lock the scanner and TMA

back. Follow the steps below:

1. Turn off the scanner if your scanner is on.

2 . Turn the scanner back on. The carriages of the scanner and TMA will move to the

standby position in a few moments.

3. When the lights on the front panel of your scanner stop blinking, push the

locking switch at the base of the TMA to the “Locked” position.

Locked

4. Push the locking switch at the bottom of the scanner to the “Locked” position.

Locked

5. Turn off your scanner. The scanner is now ready for transport.

ScanMaker i800 Supplement 5

Page 6

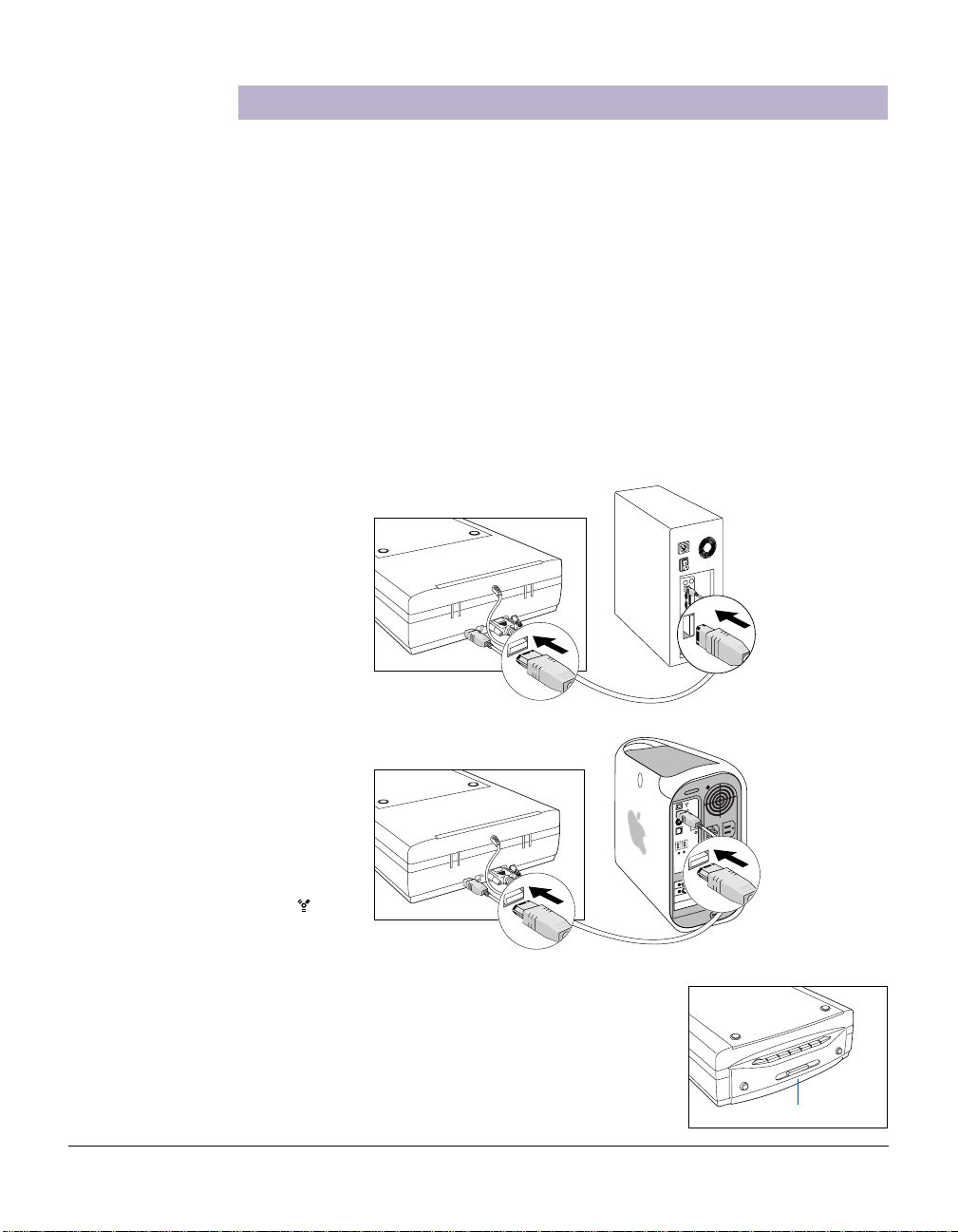

Connecting to the FireWire Port

The printed Start Here guide showed you how to connect your computer to the USB

port of the ScanMaker i800. Here, the Supplement shows you how to connect the

computer to the scanner's alternate FireWire port.

Prior to connection, check first to see if your computer system has a FireWire port. If

FireWire is present, connect the FireW ire cable to the FireW ire port. If your computer

does not have a FireWire port, install a FireW ire card to make use of the FireW ire port.

For details on how to install a FireWire card in your computer , refer to the

documentation that came with the FireWire card.

Note: Your ScanMaker i800 does not include a FireWire card in the package.

Follow the steps below to perform the FireWire connection:

1. Connect one end of the FireWire cable to your computer, and connect the other

end of the cable to the scanner’s FireW ire port.

(with a built-in FireWire port

or FireWire card installed)

(with a built-in FireWire port)

The latest Macintosh

computers (i.e., G3, G4, G5,

etc.) are equipped with a

built-in FireWire port, usually

labeled with the “ ” logo.

For PC users

For Mac users

2. Press the Power button on the front panel of the

scanner, and wait for the lights to stop blinking

and stay on steady.

The scanner will be detected by your system

automatically.

6 ScanMaker i800 Supplement

Power button

Page 7

How the Smart-Touch Scanner Buttons Work

Note: The Smart-Touch buttons on the front panel of your scanner automate frequently

performed tasks, such as Scan to File, Scan to Printer, etc. For each scanner button,

the parameters governing the use of that button are defined or set through the

Microtek Scanner Configuration (MSC) utility. For instance, you can use the MSC to

define how many copies are to be printed of your scan every time you hit the “Copy”

button. To launch the MSC, double-click the MSC icon on your desktop. Please note

that you need to exit ScanWizard 5 before accessing the MSC utility.

The ScanMaker i800 is equipped with 7 Smart-T ouch buttons for easy access to

frequently used scanner functions. To carry out a specific task, simply press the

corresponding button on the scanner. The Smart-Touch buttons are:

1. DIGIT AL ICE: Scans and removes dust, scratches, rips, and tears from damaged

photos. Take note that the DIGITAL ICE button works to reconstruct photos only.

T o reconstruct damaged film and transparencies, use the DIGIT AL ICE function in

the ScanWizard 5 software.

2. Scan: Captures an image that can be automatically saved as a file or sent to

another application for further processing.

3. Copy: Scans an image and sends it to your printer, transforming your scanner and

printer into a convenient copy station. Simply specify the number of copies you

want. To use the Copy button to print a stack of documents:

- Place the first page on the scanner glass surface.

- Press the Copy button to scan an image to a file, then automatically output to

your specified printer.

- Load the next page and press the Copy button again. The scanner works in

similar fashion to your printer, printing documents one after another with no

interruptions.

4. E-mail: Scans an image and delivers it directly to your e-mail editor.

5. OCR: Performs OCR (Optical Character Recognition) of a document and converts

it to a fully editable digital file. Saves time from retyping documents into your

word processor.

6. PDF: Captures an image and automatically saves it as an Adobe Portable Document

Format (PDF) file for immediate viewing with the Adobe Acrobat software.

7. Custom: Customizes the Custom button to perform four of the most commonly

used functions, including:

- Power Saving: Turns the scanner lamp ON or OFF to save power and lamp life.

- Scan: Defines another button to be a second “Scan” button. Use this if you need

a second “Scan” button with different parameters from the first Scan button.

- Fax: Launches a fax driver installed on your computer.

- Launch Application: Defines an application to be launched.

ScanMaker i800 Supplement 7

Page 8

DIGITAL ICE Technology

DIGITAL ICE is an advanced technology that reconstructs damaged photos and film

during the scanning process, transforming the traditional photo or film restoration

process into one that is automatic, fast, and economical. Unlike software-only

correction, DIGIT AL ICE is built into your ScanMaker i800 scanner hardware,

providing a seamless reconstruction process that brings damaged photos and film

back to near-original condition.

The Reconstruction Process

DIGIT AL ICE creates a defect map to identify the precise locations of physical

defects or visual “noise” on the print being scanned. The scanner's differential

shadowing technology and proprietary software algorithms then quickly and

automatically eliminate the unwanted defects.

In addition, Microtek has developed a unique Image Registration Technology that is

also built into your scanner to ensure precise color registration and superior image

quality. Because two scanning passes and two lamps are required in the use of

DIGIT AL ICE, precise registration is crucial in order to produce a perfectly aligned

image from the twin scanning passes. Microtek's Image Registration T echnology

ensures accurate movement of the scanner mechanism, so that the mechanical steps

during the scanning process are registered with the ultra-fine precision needed for

superior, accurate scans.

Using Applicable Scan Materials

DIGIT AL ICE is used in the ScanMaker i800 to reconstruct damaged photos and film.

It is not designed to be used for printed materials from newspapers and magazines, or

printouts from inkjet/laser printers.

8 ScanMaker i800 Supplement

Page 9

Positioning Your Originals

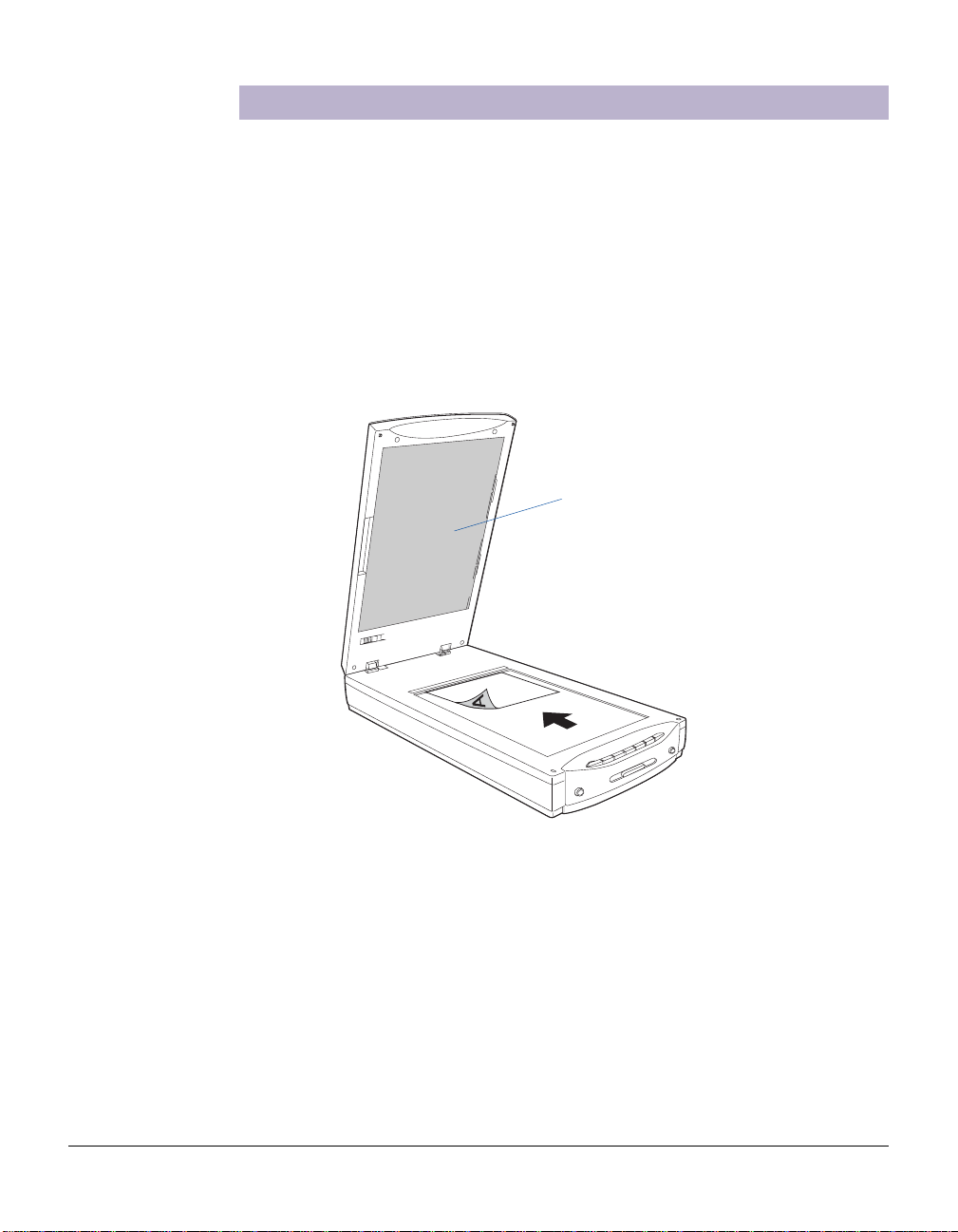

Positioning Reflective Originals

T o scan reflective originals such as photos and printed matter, use the Black Mat

which comes preattached to the scanner lid (TMA).

1 . Raise the scanner lid, and make sure the Black Mat is attached to the scanner lid.

2 . Place the reflective original face down on the scanner glass surface. Position the

top end of the photo towards the back of the scanner.

3 . Lower the scanner lid.

Black Mat

ScanMaker i800 Supplement 9

Page 10

Positioning Transparent Film

T o scan transparent film, use the EZ-Lock Film Holders or Film Alignment Ruler

included with your ScanMaker i800 package. Use the EZ-Lock Film Holders to scan

standard-size transparent film such as 35mm slides, 35mm filmstrips, 4" x 5" film,

6 x 4.5 cm, 6 x 6 cm, 6 x 7 cm, 6 x 9 cm, or 6 x 17 cm (120) film. Use the Film Alignment

Ruler to scan non-standard-size transparent film such as 8" x 10" film.

The EZ-Lock Film Holders not only ensure precise alignment of film and consistent

scans, but they perform automatic cropping during film scanning. T o scan film, use

the film holder that correctly matches the film type to be scanned.

Before proceeding with film scanning, take note of the information presented in the

two sections below.

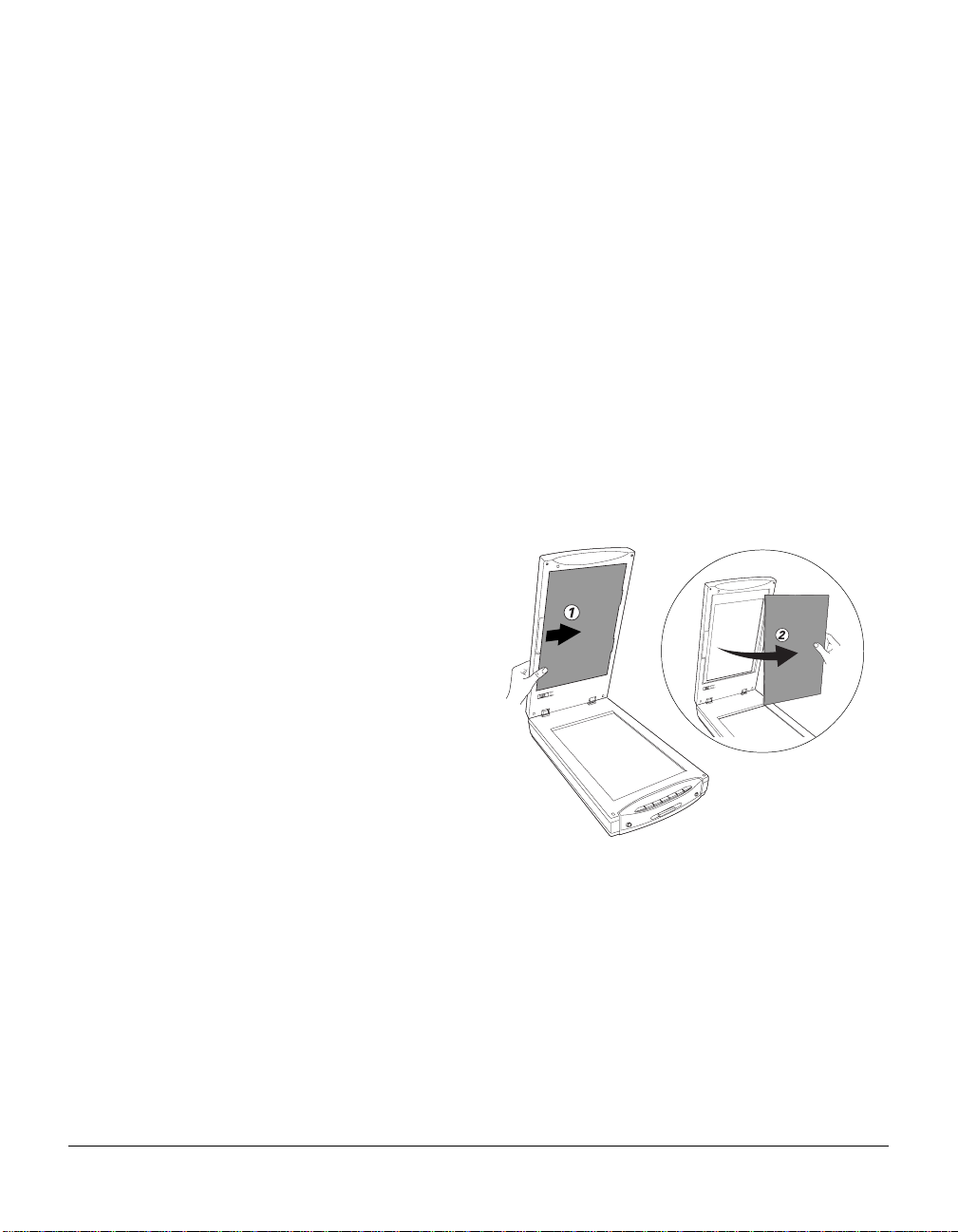

Removing the Black Mat

The Black Mat is designed to work with scanning of reflective materials such as

photos and printed matter. It is not designed to work with scanning of slides,

negatives, and transparencies. During film scanning, the Black Mat should be

removed to reveal the light source in the scanner for film.

T o remove the Black Mat:

Raise the scanner lid, push the

Black Mat to the side (1 in

diagram) to remove it from the

scanner lid (2 in diagram).

Notes on auto-cropping for film scanning

For the scanner to perform automatic cropping during scanning, the following

conditions below should all be met:

• Your computer's operating system is either Windows or Mac OS X

• The EZ-Lock Film Holder is correctly aligned on the scan bed

• The scan material is positive or negative film, with the slide or filmstrip to be

scanned is correctly loaded on the EZ-Lock Film Holder

• In the Scan Job Queue window of ScanWizard 5, the “Multiple Auto-crop for EZLock Film Holder” option is checked.

10 ScanMaker i800 Supplement

Page 11

A. Using the EZ-Lock 35mm Slide Holder

To scan 35mm slides, use the EZ-Lock 35mm

Slide Holder, which can hold up to 12

mounted 35mm slides at a time.

1 . Place the 35mm slides to be scanned inside the individual frames of the EZ-Lock

35mm Slide Holder. The shiny base of the 35mm slide should be facing down, and

the emulsion side of the slide should be facing up.

Orient the holder with

the “Microtek” logo

facing up

2 . Raise the scanner lid, then place the EZ-Lock 35mm Slide Holder towards the back

Keep calibration strip

on the glass surface clear

and free of any obstruction

“Microtek” logo

of the scanner, with the loaded film on the scanner glass surface.

To make sure the auto multiframe

cropping feature performs correctly,

place the holder on the scan bed,

correctly oriented and showing the

side with the Microtek logo face up.

Align the red arrows so that the

holder’s front edge is flush against

the top ruler of the scanner.

ScanMaker i800 Supplement 11

Page 12

B. Using the EZ-Lock 35mm Filmstrip Holder

To scan 35mm filmstrips, use the EZ-Lock

35mm Filmstrip Holder, which can

simultaneously hold four strips of 6 frames

each, or a total of 24 frames.

1 . Place the 35mm filmstrip to be scanned inside the frame of the EZ-Lock 35mm

Filmstrip Holder. The shiny base of the 35mm filmstrip should be facing down, and

the emulsion side of the filmstrip should be facing up.

Orient the holder with the

“Microtek” logo facing up

2 . Raise the scanner lid, then place the EZ-Lock 35mm Filmstrip Holder towards the

back of the scanner, with the loaded film on the scanner glass surface.

Keep calibration strip

on the glass surface clear

and free of any obstruction

12 ScanMaker i800 Supplement

To make sure the auto multiframe

cropping feature performs correctly,

place the holder on the scan bed,

correctly oriented and showing the

side with the Microtek logo face up.

Align the red arrows so that the

holder’s front edge is flush against

the top ruler of the scanner.

“Microtek” logo

Page 13

C. Using the EZ-Lock 6 x 22 cm (120) Film Holder

T o scan 6 x 4.5 cm, 6 x 6 cm, 6 x 7 cm, 6 x 9

cm, and 6 x 17 cm film, use the EZ-Lock 6 x

22 cm (120) Film Holder, which can hold up

to 4 pieces of 6 x 4.5 cm film, 2 pieces of 6 x

9 cm film, or a single piece of 6 x 17 cm film.

1 . Place the 120 film to be scanned inside the EZ-Lock 6 x 22 cm (120) Film Holder , as

indicated in the graphics below . The shiny base of the 120 film should be facing

down, and the emulsion side of the filmstrip should be facing up.

a) Push on the side to

2 . Raise the scanner lid, then place the EZ-Lock 6 x 22 cm (120) Film Holder towards

Keep calibration strip

on the glass surface clear

and free of any obstruction

open the lid.

b) Place the film face

down into the holder.

c) Pull down the side

to close the lid.

the back of the scanner, with the loaded film on the scanner glass surface.

To make sure the auto multiframe

cropping feature performs correctly,

place the holder on the scan bed,

correctly oriented and showing the

side with the Microtek logo face up.

Align the red arrows so that the

holder’s front edge is flush against

the top ruler of the scanner.

“Microtek” logo

ScanMaker i800 Supplement 13

Page 14

D. Using the EZ-Lock 4" x 5" Film Holder

T o scan 4" x 5" film, use the EZ-Lock 4" x 5"

Film Holder, which can hold up to 2 pieces of

4" x 5" film at a time.

1 . Place the 4" x 5" film to be scanned inside the EZ-Lock 4" x 5" Film Holder, as

indicated in the graphics below. The shiny base of the 4" x 5" film should be

facing down, and the emulsion side of the filmstrip should be facing up.

a) Push on the side to

2 . Raise the scanner lid, then place the EZ-Lock 4" x 5" Film Holder towards the back

Keep calibration strip

on the glass surface clear

and free of any obstruction

open the lid.

b) Place the film face

down into the holder.

c) Pull down the side

to close the lid.

of the scanner, with the loaded film on the scanner glass surface.

To make sure the auto multiframe

cropping feature performs correctly,

place the holder on the scan bed,

correctly oriented and showing the

side with the Microtek logo face up.

Align the red arrows so that the

holder’s front edge is flush against

the top ruler of the scanner.

“Microtek” logo

14 ScanMaker i800 Supplement

Page 15

Calibration strip

E. Using the Film Alignment Ruler

To scan non-standard-size film such as

8" x 10" film, use the Film Alignment Ruler ,

which allows you to scan film up to

8" x 12" in size.

1 . Place the Film Alignment Ruler towards the back of the scanner on the scanner

glass surface.

Important: Align the Film Alignment

Ruler firmly against the top ruler of the

scanner, with the ruler oriented

correctly and with the correct side up.

During placement of the Ruler, make

sure that the calibration strip on the

Ruler is kept clear and free of

obstruction at all times.

2 . Place the film (non-standard size film) to be scanned on the scanner glass surface,

and center the film along the Film Alignment Ruler on the scanner .

ScanMaker i800 Supplement 15

Page 16

Scanning Scenarios

The following pages provide various scenarios for scanning with the ScanMaker

i800, including the following:

• Scanning regular, non-damaged photos (1): This scenario can also be your first

scan in order to familiarize yourself with scanning basics. It makes use of the

Standard Control Panel in ScanWizard 5.

• Scanning regular, non-damaged photos (2): This scenario is similar to above but

uses the Advanced Control Panel in ScanWizard 5.

• Scanning damaged photos: This scenario utilizes DIGIT AL ICE for reconstructing

damaged photos. Three methods are available for launching this function:

through the DIGITAL ICE button on the front panel of the scanner; through the

Automatic Reconstruction option; and through the Manual Reconstruction

option. The last two methods are accessed through the Advanced Control Panel

in ScanWizard 5.

• Scanning regular, non-damaged film: This scenario details the steps for scanning

film. It makes use of the Advanced Control Panel in ScanW izard 5.

• Scanning damaged film: This scenario utilizes DIGIT AL ICE for correcting flaws

that may be present in your slides, negatives, and transparencies. It makes use of

the Advanced Control Panel in ScanW izard 5

16 ScanMaker i800 Supplement

Page 17

Scanning Regular, Non-Damaged Photos (1)

This scenario uses the Standard Control Panel.

1. Raise the scanner lid, and place the photo to be

scanned face down on the scanner glass surface.

Position the top end of the photo towards the

The Black Mat

comes

preattached to

the scanner lid.

back of the scanner.

Note: For the automatic cropping feature to

work correctly during the preview scan of your

photo, make sure the Black Mat is attached on

the scanner lid before you launch ScanWizard 5.

2. Double-click the ScanWizard 5 icon ( ) on your desktop to launch the

ScanWizard 5 S tandard Control Panel.

When ScanWizard 5 launches, it automatically performs a fast preview of the

material on your scanner glass surface and displays it in the preview area.

3 . In the preview window , you can resize the scan frame (floating dotted line) around

the image by dragging on the edge or corner of the scan frame to determine the

final size of the actual scan.

4. Click the Original button, then select Photo.

5. Click the Scan to button to scan the image.

• Allows you to switch to the

Advanced Control Panel

• Shows the scanner type,

model, and status

• Contains the built-in

ScanWizard 5 help

• Exits ScanWizard 5

• Minimizes ScanWizard 5

(Windows only)

Resize the scan

frame to adjust

the actual size of

your scan

Selections and options for

image settings

ScanMaker i800 Supplement 17

Page 18

Scanning Regular, Non-Damaged Photos (2)

This scenario makes use of the Advanced Control Panel.

1. Raise the scanner lid, and place the photo to be scanned face down on the

scanner glass surface. Position the top end of the photo towards the back of the

scanner. Make sure the Black Mat is attached on the scanner lid, then close the

scanner lid.

2. Double-click the ScanWizard 5 icon ( ) on your desktop to launch the

ScanWizard 5 S tandard Control Panel.

When ScanWizard 5 launches, it automatically performs a fast preview of the

material on your scanner glass surface and displays it in the preview area.

3 . Click the Switch icon ( ) on the right corner of the Standard Control Panel to

switch to the Advanced Control Panel.

4 . Click the Overview button to perform a preliminary scan of the image, which will

appear in the Preview window.

5 . In the preview window , you can resize the scan frame (floating dotted line) around

the image by dragging on the edge or corner of the scan frame to determine the

final size of the actual scan.

6. Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution.

c) Adjust the scan frame settings if necessary.

7. Adjust image quality if necessary , using the Advanced Image Correction (AIC) tools.

8. If the colors in your photo are faded and need restoring, check the “Automatic

Color Restoration” box in the Settings window.

9. Click the Scan to button to scan the image.

18 ScanMaker i800 Supplement

Page 19

ScanMaker i800 Supplement 19

Page 20

Scanning Damaged Photos

T o reconstruct damaged photos with DIGIT AL ICE, three methods are available:

through the DIGITAL ICE button on the front panel of the scanner; through the

Automatic Reconstruction option; and through the Manual Reconstruction option.

A. Using the DIGITAL ICE button

1. Raise the scanner lid, then place the damaged photo to be scanned face down on

the scanner glass surface. Center the top of the photo along the horizontal ruler

towards the back of the scanner.

Note: Make sure the Black Mat is

Black Mat

attached to the scanner lid. This will

ensure that uneven photos lay as flat as

possible, which will enhance the

accuracy of detecting surface damage on

photos.

2 . Press the DIGITAL ICE button on your

scanner. This will automatically scan,

detect and remove surface defects on

your photos. The saved image is stored

in your local disk and also appear as a

shortcut under the My Images folder on

your desktop.

20 ScanMaker i800 Supplement

Direction of

carriage motion

DIGITAL ICE

Note: If the creases in your photo lie

parallel to the direction of the carriage

motion, the creases may not be detected

by the scanner. To fix this problem,

position your photo slightly skewed

(min. 10°, max. 45°), so that none of the

creases are parallel to the direction of

the carriage movement.

Page 21

Customizing the DIGITAL ICE button

The DIGITAL ICE button can be customized to suit your preferences, so that you

can specify settings that, for instance, indicate the strength of your DIGIT AL ICE

setting, the location of files to be saved, etc. Pressing the DIGIT AL ICE button after

customizing will invoke these settings repeatedly until you change your

preferences.

To customize the DIGITAL ICE button:

1. Double-click the Microtek Scanner

Configuration icon ( ) on your desktop

to launch the MSC utility .

2 . When MSC is launched, click the “ICE” tab

on the top to view or customize the

DIGIT AL ICE button to your need.

3. Choose your settings, then click the “OK”

button to save the settings and to exit the

MSC utility .

ScanMaker i800 Supplement 21

Page 22

B. Scanning with Automatic Reconstruction

With the Automatic Reconstruction option, DIGIT AL ICE scans for defects and

applies an algorithm calculated automatically for optimal photo reconstruction and

correction.

1. Raise the scanner lid, then place the damaged photo to be scanned face down on

the scanner glass surface. Center the top of the photo along the horizontal ruler

towards the back of the scanner. Make sure the Black Mat is attached on the

scanner lid, then close the scanner lid.

2. Double-click the ScanWizard 5 icon ( ) on your desktop to launch the

ScanWizard 5 S tandard Control Panel.

3 . Click the Switch icon ( ) on the right corner of the Standard Control Panel to

switch to the Advanced Control Panel.

4 . Click the Overview button to perform a preliminary scan of the image, which will

appear in the Preview window .

5 . In the preview window , you can resize the scan frame (floating dotted line) around

the image by dragging on the edge or corner of the scan frame to determine the

final size of the actual scan.

6. Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution. Recommended resolution for DIGITA L ICE is 600

or 1200 dpi.

c) Adjust the scan frame settings if necessary.

7. Adjust image quality if necessary , using the Advanced Image Correction (AIC) tools.

Important: The Descreen setting in the Settings window should be “None.”

Otherwise the “DIGIT AL ICE” option in the next step will be dimmed and will not

be available for selection.

8. In the Settings window, choose “Automatic

Reconstruction” from the DIGIT AL ICE

options menu.

22 ScanMaker i800 Supplement

Page 23

Before After

9. If the colors in your photo are faded and need restoring, check the “Automatic

Color Restoration” box in the Settings window .

10. Click the Scan to button to scan the image. After the scan, defects such as dust,

scratches, cracks, creases, rips, folds and other artifacts on the photo are all

removed, resulting in an improved image.

ScanMaker i800 Supplement 23

Page 24

C. Scanning with Manual Reconstruction

With the Manual Reconstruction option, the damaged photo is restored through the

use of manual settings and procedures. This is a more complicated and involved

procedure, but Manual Reconstruction gives you greater control in fine-tuning the

degree of correction you would like. It also allows you to include areas of damage

that may not be “seen” through the automatic reconstruction process but which you

can detect with the naked eye or which you know are there.

1. Follow the procedures (steps 1 through 7) for scanning damaged photos in the

previous section “Scanning in Automatic Reconstruction” to carry out scanning.

2. In the Settings window, choose “Manual

Reconstruction” from the DIGIT AL ICE options menu.

A message appears, indicating that the correction of

defects will be implemented according to manual

settings after the image is scanned.

3 . In the Preview window , click the “Scan To” button to

perform scanning.

4. When the “Scan To” button is pressed, the Save As

dialog box appears. Specify the necessary settings for

the output image, then click “Save”.

At this point, scanning of the damaged photo begins

and a defect map is created in the process. This may

take a few minutes.

A “Manual Reconstruction with DIGITAL ICE”

window then appears, with a preview of the scanned

image and corresponding function tools.

24 ScanMaker i800 Supplement

Page 25

When the “Manual Reconstruction with DIGIT AL ICE” window is launched the

first time, the scanned image appears with defect markers. This option is checked

automatically. You can change the color of the defect marker to get a better view

of the defects by clicking the Marker Color icon.

5 . Choose the “DIGITAL ICE Strength” option that works best for you for you to

repair surface defects. Select from Normal or Strong.

6. If necessary, use the Brush tool to add defects which cannot be detected by the

scanner after the scan, but are otherwise visible in the damaged print and which

you want to remove from the image.

7. If necessary, use the Eraser tool to remove any false or unwanted defect, which

can be detected by the scanner after the scan.

8. Check the “After Reconstruction” option. The defect correction applies to the

Defect Map area in real time.

Before

After

9 . Click the “OK” button to perform the defect fixing according to the settings

specified under this window. The scanned image is saved with the settings for

defect fixing.

ScanMaker i800 Supplement 25

Page 26

Scanning Regular, Non-Damaged Film

1 . Raise the scanner lid, then follow the

procedures in the “Positioning

Transparent Film” section to load the film

that you wish to scan and to place the

EZ-Lock Film Holder on the scanner

glass surface.

Gently lower the scanner lid down onto the

scanner glass bed.

Important: Do not use the Black Mat.

2. Double-click the ScanWizard 5 icon ( ) on your desktop to launch the

ScanWizard 5 Standard Control Panel, then click the Switch icon ( ) on the right

corner of the Standard Control Panel to switch to the Advanced Control Panel.

3 . In the Preview window of

ScanWizard 5, click the Scan

Material button or drop-down

menu. Choose Negative Film or

Negative for negatives; choose

Positive Film or Positive for

transparencies and slides,

depending on the film type you are using.

4 . In the Scan Job Queue window , check the “Multiple Auto-crop for EZ Lock Film

Holder” option.

5 . Click the Overview button to auto-crop and perform a preliminary scan of the film

loaded onto the scanner.

When done, you will see multiple scan frames that have been automatically

cropped in the Preview window. Multiple job titles will appear in the Scan Job

Queue window, numbered sequentially and all marked by a “Check” that indicates

the jobs are ready to be scanned. The scan area (framed in dotted lines) will

appear in the Preview window .

6. Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution.

c) Adjust the scan frame settings if necessary.

26 ScanMaker i800 Supplement

Page 27

7. Adjust image quality if necessary, using the Advanced Image Correction (AIC) tools.

8 . If the colors in your film sample are faded and need restoring, check the

“Automatic Color Restoration” box in the Settings window.

9 . Click the Scan to button in the Preview window to scan all the checked jobs.

Auto-cropped images are framed

in dotted line.

ScanMaker i800 Supplement 27

Page 28

Scanning Damaged Film

1. Raise the scanner lid, then follow the

procedures in the “Positioning

Transparent Film” section to load the film

that you wish to scan and to place the

EZ-Lock Film Holder on the scanner glass

surface.

Gently lower the scanner lid down onto

the scanner glass bed.

Important: Do not use the Black Mat.

2. Double-click the ScanWizard 5 icon ( ) on your desktop to launch the

ScanWizard 5 Standard Control Panel, then click the Switch icon ( )on the right

corner of the Standard Control Panel to switch to the Advanced Control Panel.

3 . In the Preview window of

ScanWizard 5, click the Scan

Material button or drop-down

menu. Choose Negative Film or

Negative for negatives; choose

Positive Film or Positive for

transparencies and slides,

depending on the film type you are using.

4 . In the Scan Job Queue window , check the “Multiple Auto-crop for EZ Lock Film

Holder” option.

5 . Click the Overview button to auto-crop and perform a preliminary scan of the film

loaded onto the scanner.

When done, you will see multiple scan frames that have been automatically

cropped in the Preview window. Multiple job titles will appear in the Scan Job

Queue window, numbered sequentially and all marked by a “Check” that indicates

the jobs are ready to be scanned. The scan area (framed in dotted lines) will

appear in the Preview window.

6. Specify your scanning requirements in the Settings window.

a) Select a desired image type.

b) Select a desired resolution. Recommended resolution for DIGITA L ICE is

1200 dpi.

c) Adjust the scan frame settings if necessary.

28 ScanMaker i800 Supplement

Page 29

7. Adjust image quality if necessary , using the Advanced Image Correction (AIC) tools.

8 . Choose the “DIGIT AL ICE” option that

works best for you. Select from None,

Normal, or Str ong . In Film mode, DIGITAL

ICE automatically removes surface defects

from your slides, negatives, and

transparencies.

9 . If the colors in your film sample are faded and need restoring, check the

“Automatic Color Restoration” box in the Settings window.

10. Click the Scan to button in the Preview window to scan all the checked jobs. After

the scan, defects such as dust, scratches, cracks, creases, rips, folds and other

artifacts on the original image are all removed, resulting in an improved image.

Before

After

ScanMaker i800 Supplement 29

Page 30

Specifications

Scanning Modes Color, grayscale, and black-and-white in a single scanning

pass

True 48-bit color (approx. 281 x 1012 colors)

16-bit grayscale (approx. 65,536 shades of gray)

Scanning Area Reflective: 8.5" x 14" (216 mm x 356 mm)

Transparent: 8" x 12" (203 mm x 305 mm)

Resolution Optical: 9600 dpi x 4800 dpi

Interpolated: 65,535 dpi (PC); 32,767 dpi (Mac)

Dynamic Range 4.0 Dmax

Interface Hi-Speed USB (USB 2.0) and FireWire (IEEE 1394)

Dimensions (L x W x H) 22.6" x 11.7" x 4.6" (576 mm x 297 mm x 118 mm)

Net Weight 14.1 lbs (6.4 kg)

Voltage AC 100V to 240V

1.2A Max; 47-63 Hz (Input)

15V/2.5A (Output)

Environment Operating T emperature: 50° F to 104° F (10° C to 40° C)

Relative Humidity: 20% to 85%

Power supply Manufacturer Model No. Voltage

(AC/DC adapter) F AI R WAY VE50-150A 100V to 240V

System Requirements

General Requirements

• CD-ROM drive (for installing software)

• Color display with 24-bit color output capability

• 128MB RAM (256MB or more to use DIGIT AL ICE T echnology)

PC and compatibles

• Pentium III PC or higher with USB, Hi-Speed USB (USB 2.0), or FireWire (IEEE

1394) port

• Microsoft Windows 98SE, Me, 2000 or XP

Macintosh

• iMac or Mac G3/G4/G5 with built-in USB port or FireWire port

• Mac OS 9.x, OS X 10.2 - 10.3

Important

Specifications, bundles, and accessories are subject to change without notice.

30 ScanMaker i800 Supplement

Page 31

FCC Compliance Statement

This equipment (Model: MRS-9600TFU2) has been tested and found to comply with

the limits for a Class B digital device, pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Note: A shielded Hi-Speed USB interface cable with ferrite core installed on the

scanner connector and must be used with this equipment.

Caution: Changes or modifications not expressly approved by the manufacturer

responsible for compliance could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Responsible Party: Loi Han

Microtek Lab, Inc.

16941 Keegan A venue

Carson, CA 90746

USA

Phone: 310-687-5800

Fax: 310-687-5950

ScanMaker i800 Supplement 31

Loading...

Loading...