Page 1

OMNIS Sample Robot Pick&Place

2.101X.1010

Product manual

8.1012.8001EN / 2018-08-17

Page 2

Page 3

Metrohm AG

Ionenstrasse

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

OMNIS Sample Robot Pick&Place

2.101X.1010

8.1012.8001EN /

2018-08-17

Product manual

Page 4

Technical Communication

Metrohm AG

CH-9100 Herisau

techcom@metrohm.com

This documentation is protected by copyright. All rights reserved.

This documentation has been prepared with great care. However, errors

can never be entirely ruled out. Please send comments regarding possible

errors to the address above.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Overview 1

1.1 OMNIS Sample Robot Pick&Place – Product descrip-

1.2 OMNIS Sample Robot Pick&Place – Product versions ....... 1

1.3 Main module Pick&Place – Product versions ..................... 2

1.4 Pick&Place module – Product versions ............................... 3

1.5 Peristaltic pump module – Product versions ...................... 3

1.6 OMNIS Sample Robot Pick&Place – License versions ........ 4

1.7 About the documentation ................................................... 5

1.8 Additional information ......................................................... 5

1.8.1 Accessories .............................................................................. 5

Table of contents

tion ......................................................................................... 1

2 Safety 7

2.1 Product safety ....................................................................... 7

2.2 Hazard levels ......................................................................... 7

2.3 Warning symbols .................................................................. 8

2.4 Intended use ......................................................................... 9

2.5 Residual risks ........................................................................ 9

2.5.1 General dangers at the workplace ........................................... 9

2.5.2 Danger from electrical potential ............................................. 10

2.5.3 Danger from machine movements ......................................... 11

2.5.4 Danger from biological substances ........................................ 11

2.5.5 Danger from highly flammable substances ............................. 12

2.5.6 Danger from careless transport .............................................. 12

2.5.7 Danger from leakage ............................................................. 12

2.5.8 Danger from high temperatures ............................................. 13

2.6 Responsibility of the operator ........................................... 13

2.7 Personnel requirement ....................................................... 13

3 Functional description 14

3.1 System overview ................................................................. 14

3.1.1 System – Signals .................................................................... 14

3.1.2 System – Interfaces ................................................................ 15

OMNIS Sample Robot Pick&Place

3.2 Overview – OMNIS Sample Robot Pick&Place S .............. 16

3.3 Overview – OMNIS Sample Robot Pick&Place M ............ 17

3.4 Overview – OMNIS Sample Robot Pick&Place L .............. 18

3.4.1 Main module Pick&Place – Overview ...................................... 19

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

3.4.2 Pick&Place module – Overview .............................................. 21

3.4.3 Peristaltic pump module – Overview ...................................... 24

3.4.4 Rack base – Overview ............................................................ 28

3.5 Sample Robot Pick&Place – Functional description ........ 29

3.5.1 Main module Pick&Place – Functional description .................. 30

3.5.2 Pick&Place module – Functional description ........................... 30

3.5.3 OMNIS peristaltic pump module – Functional description ....... 30

3.5.4 Rack base – Functional description ......................................... 31

3.6 OMNIS Sample Robot – Indicators and controls ............. 32

3.7 Main module – Connectors ................................................ 33

4 Transport and storage 34

4.1 Checking the delivery ......................................................... 34

4.2 Storing the packaging ........................................................ 34

4.3 Lifting the sample robot .................................................... 34

5 Installation 35

5.1 Installation by Metrohm .................................................... 35

5.2 Sample robot setting up .................................................... 35

5.3 Replacing the seal of the sample beaker lid .................... 36

5.4 Inserting and equipping the titration head ...................... 38

5.5 Mounting the safety shield ................................................ 44

5.6 Connecting the tubing to the distributor of the

Pick&Place module ............................................................. 46

5.7 Connecting the drainage tubing ....................................... 48

5.8 Connecting the inlet and outlet tubing ............................ 49

5.9 Connecting/Disconnecting the power cord ...................... 50

6 Initial start-up 52

6.1 Initial start-up by Metrohm ............................................... 52

7 Operation and control 53

7.1 Operation ............................................................................ 53

7.2 Switching the OMNIS sample robot on and off ............... 53

7.3 Opening the gripper manually .......................................... 54

■■■■■■■■

IV

7.4 Attaching and removing the sample rack ........................ 55

8 Maintenance 58

8.1 General maintenance ......................................................... 58

8.2 Maintenance agreement .................................................... 59

OMNIS Sample Robot Pick&Place

Page 7

■■■■■■■■■■■■■■■■■■■■■■

9 Malfunctions and troubleshooting 83

10 Disposal 84

11 Technical specifications 85

Table of contents

8.3 Cleaning the product .......................................................... 60

8.3.1 Cleaning the Pick&Place module ............................................ 61

8.4 Checking and replacing product parts .............................. 67

8.4.1 Replacing the finger tip and PTFE sleeve ................................. 68

8.4.2 Replacing the beaker adapter ................................................ 70

8.4.3 Replacing the titration head ................................................... 73

8.4.4 Checking the pump tubing .................................................... 76

8.4.5 Replacing the pump tubing .................................................... 78

9.1 Troubleshooting .................................................................. 83

11.1 Ambient conditions ............................................................ 85

11.2 Main module – Energy supply ........................................... 85

11.3 Pick&Place module – Energy supply ................................. 85

11.4 Peristaltic pump module – Energy supply ........................ 86

11.5 OMNIS sample rack – Energy supply ................................ 86

11.6 OMNIS Sample Robot Pick&Place – Dimensions ............. 86

11.7 Main module Pick&Place – Dimensions ............................ 87

11.8 Pick&Place module – Dimensions ..................................... 88

11.9 Peristaltic pump module – Dimensions ............................ 88

11.10 OMNIS rack base / OMNIS module base – Dimensions .. 89

11.11 OMNIS sample rack – Dimensions .................................... 89

11.12 Main module Pick&Place – Housing ................................. 90

11.13 Pick&Place module – Housing ........................................... 90

11.14 Peristaltic pump module – Housing .................................. 91

11.15 OMNIS Sample Robot Pick&Place – Housing ................... 91

11.16 OMNIS module base – Housing ......................................... 91

11.17 OMNIS sample rack – Housing .......................................... 92

11.18 Main modules – Connectors specifications ...................... 92

11.19 OMNIS Sample Robot module – Connectors specifica-

tions ..................................................................................... 93

OMNIS Sample Robot Pick&Place

11.20 OMNIS rack base – Connectors specifications ................. 93

11.21 OMNIS sample rack – Connectors specifications ............. 93

11.22 OMNIS Sample Robot Pick&Place – Display specifica-

tions ..................................................................................... 93

■■■■■■■■

V

Page 8

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

11.23 Peristaltic pump module – Liquid Handling specifica-

tions ..................................................................................... 93

11.24 Magnetic stirrer – Stirrer specifications ............................ 94

11.25 OMNIS Sample Robot Pick&Place – Sample handling

specifications ...................................................................... 94

11.26 OMNIS sample rack – Sample handling specifications ... 95

■■■■■■■■

VI

OMNIS Sample Robot Pick&Place

Page 9

■■■■■■■■■■■■■■■■■■■■■■

Overview

1 Overview

1.1 OMNIS Sample Robot Pick&Place – Product description

The OMNIS Sample Robot Pick&Place system is suitable for use with titrations involving automatic sample changes.

The modular construction makes it possible to configure the system in

accordance with the area of application.

The OMNIS Software is used to control the system. The system is connected to the Ethernet network for that purpose.

1.2 OMNIS Sample Robot Pick&Place – Product versions

The OMNIS Sample Robot can be configured individually. The OMNIS

Sample Robot Pick&Place is available in the following versions as framework for the configuration:

Table 1

Art. no. Designation Version feature

2.1010.1010 OMNIS Sample Robot S Pick&Place S version

2.1011.1010 OMNIS Sample Robot M Pick&Place M version

2.1012.1010 OMNIS Sample Robot L Pick&Place L version

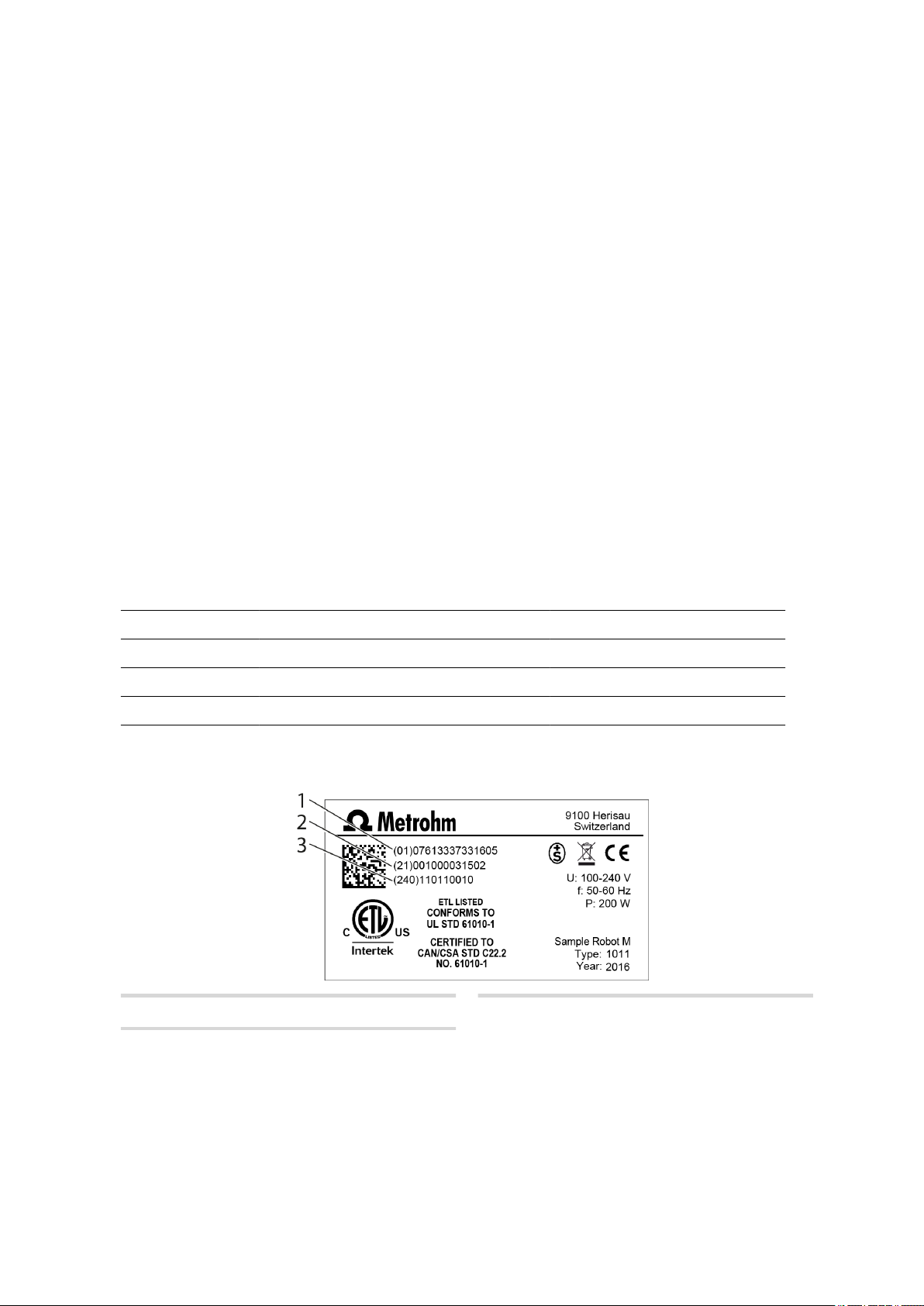

The required numbers for the customer service can be found on the type

plate (see example):

(01) = external article number

1

Product versions

(21) = Serial number

2

(240) = Metrohm article number

3

■■■■■■■■

1

Page 10

Main module Pick&Place – Product versions

■■■■■■■■■■■■■■■■■■■■■■

NOTICE

Information on the accessories for the respective product version can

be obtained either on the Internet at http://www.metrohm.com or

via your regional Metrohm representative.

1.3 Main module Pick&Place – Product versions

The product is available in the following versions:

Table 2

Art. no. Designation Version feature

2.1010.0010 Main module Pick&Place S Main module Pick&Place, S version

2.1011.0010 Main module Pick&Place M Main module Pick&Place, M version

2.1012.0010 Main module Pick&Place L Main module Pick&Place, L version

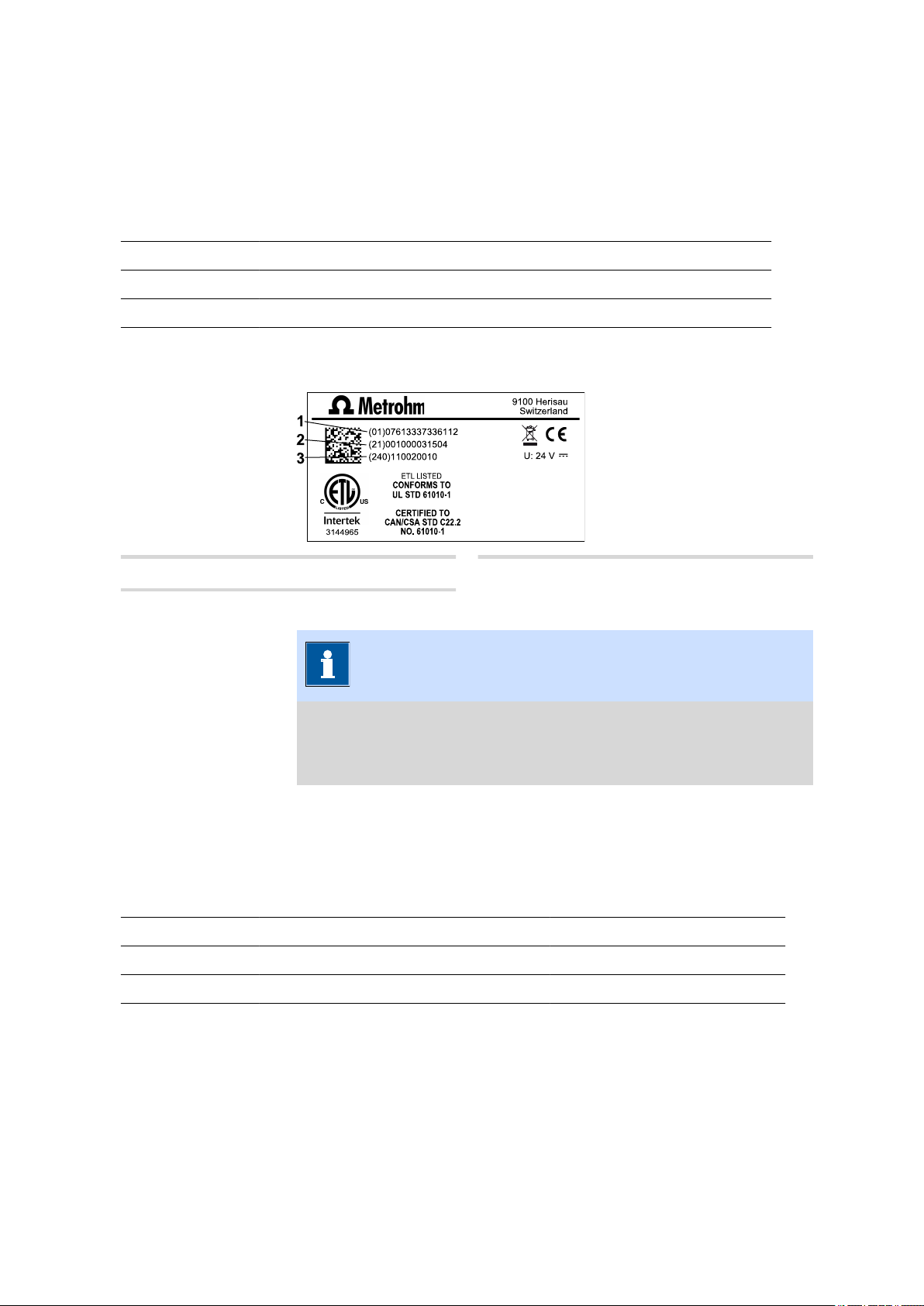

The required numbers for the customer service can be found on the type

plate (see example):

(01) = External article number

1

(240) = Metrohm article number

3

Product versions

(21) = Serial number

2

■■■■■■■■

2

NOTICE

Information on the accessories for the respective product version can

be obtained either on the Internet at http://www.metrohm.com or

via your regional Metrohm representative.

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.4 Pick&Place module – Product versions

The product is available in the following versions:

Table 3 Product versions

Art. no. Designation Version feature

2.1014.0010 Pick&Place module Without magnetic stirrer

2.1014.0110 Pick&Place module With integrated magnetic stirrer

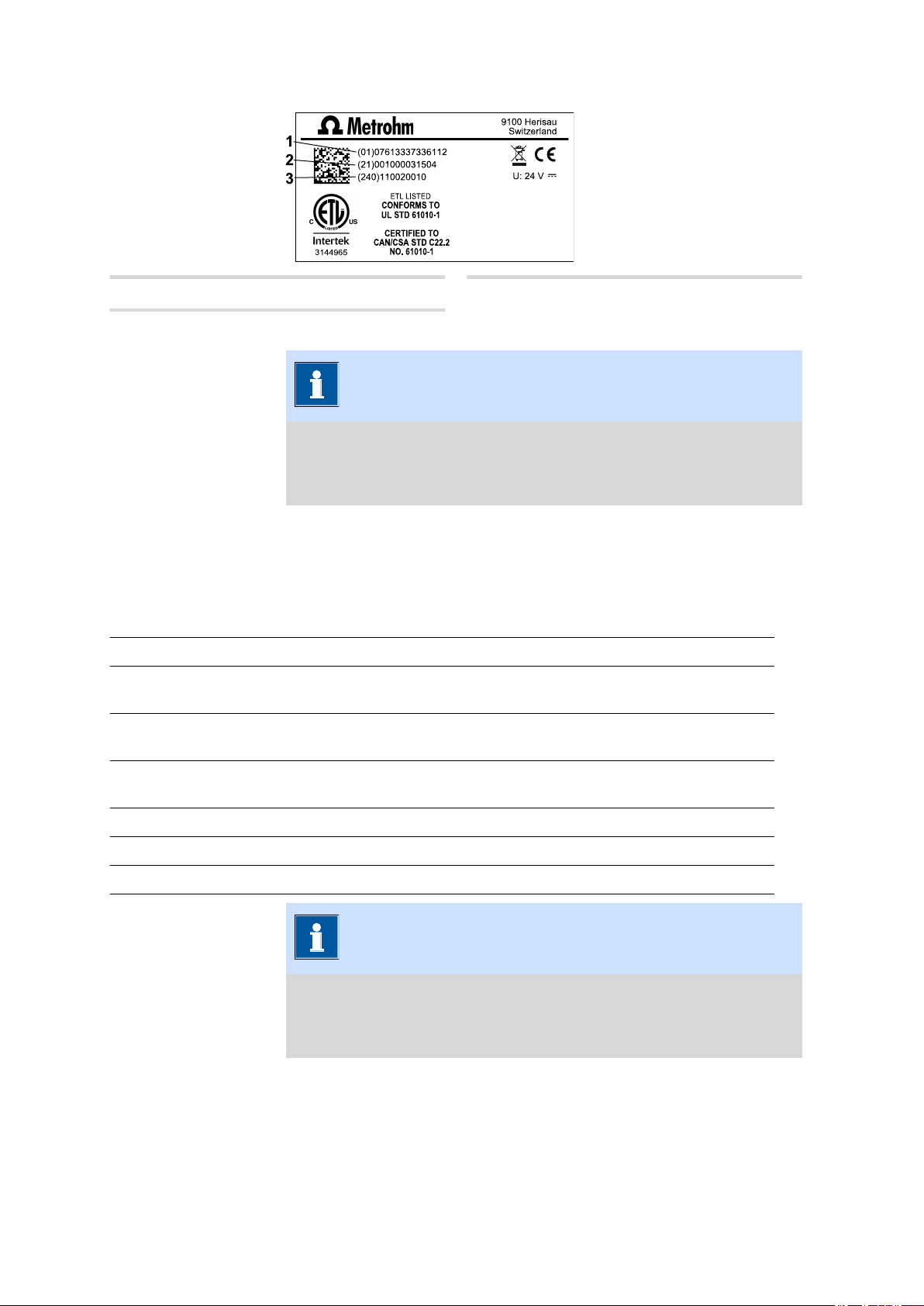

The required numbers for the customer service can be found on the type

plate (see example):

Overview

(01) = External article number

1

(240) = Metrohm article number

3

(21) = Serial number

2

NOTICE

Information on the accessories for the respective product version can

be obtained either on the Internet at http://www.metrohm.com or

via your regional Metrohm representative.

1.5 Peristaltic pump module – Product versions

The product is available in the following versions:

Table 4

Art. no. Designation Version feature

2.1016.0010 Peristaltic pump module (2-channel) 2 installed peristaltic pumps

2.1016.0110 Peristaltic pump module (4-channel) 4 installed peristaltic pumps

Product versions

The required numbers for the customer service can be found on the type

plate (see example):

■■■■■■■■

3

Page 12

OMNIS Sample Robot Pick&Place – License versions

■■■■■■■■■■■■■■■■■■■■■■

(01) = External article number

1

(240) = Metrohm article number

3

(21) = Serial number

2

NOTICE

Information on the accessories for the respective product version can

be obtained either on the Internet at http://www.metrohm.com or

via your regional Metrohm representative.

1.6 OMNIS Sample Robot Pick&Place – License versions

The licenses are available in the following versions:

Table 5

Art. no. Designation Version feature

6.06005.010 Function license S Included in the scope of delivery

6.06005.020 Function license M Included in the scope of delivery

License versions

of the main module Pick&Place

of the main module Pick&Place

6.06005.030 Function license L Included in the scope of delivery

of the main module Pick&Place

6.06005.910 Function license update S – M Update

6.06005.920 Function license update S – L Update

6.06005.930 Function license update M – L Update

NOTICE

Further information on the respective license version can be obtained

either on the Internet at http://www.metrohm.com or via your

regional Metrohm representative.

■■■■■■■■

4

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1.7 About the documentation

NOTICE

Please read through this documentation carefully before putting the

product into operation.

The documentation contains important information and warnings

which you must follow in order to ensure safe operation of the product.

Symbols and conventions

The following icons and formatting may appear in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the product part in the figure.

Overview

Instruction step

Carry out these steps in the sequence shown.

Method Designations for names of parameters, menu items,

tabs and dialog windows in the software.

File ▶ New Menu or menu item

Work area /

Properties

[Next] Button or key

Menu paths in order to arrive at a particular position

in the software.

1.8 Additional information

Additional information concerning the topic can be found:

■ in the Software Help

■ in the Metrohm information portal on the Internet https://

guide.metrohm.com

1.8.1 Accessories

Up-to-date information on the scope of delivery and optional accessories

for your product can be found on the Internet. You can download this

information using the article number as follows:

■■■■■■■■

5

Page 14

Additional information

■■■■■■■■■■■■■■■■■■■■■■

Downloading the accessories list

Enter https://www.metrohm.com/ into your Internet browser.

1

Enter the article number of the product (e.g. 2.1001.0010) into the

2

search field.

The search result is displayed.

Click on the product.

3

Detailed information regarding the product is shown on various tabs.

On the Included parts tab, click Download the PDF.

4

The PDF file with the accessories data is created.

NOTICE

When you receive your new product, we recommend downloading

the accessories list from the Internet, printing it out and keeping it for

reference purposes.

■■■■■■■■

6

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2 Safety

2.1 Product safety

This product exhibited no flaws in terms of technical safety at the time it

left the factory. To preserve this status and ensure non-hazardous operation of the product, the following instructions must be observed carefully.

2.2 Hazard levels

The following warning messages indicate the severity of the danger and

its possible effects.

Safety

DANGER

Immediate danger of life

Irreversible injuries that will result in death.

Warns of dangerous situations or unsafe actions that will most certainly cause severe injuries or death.

Lists measures to avoid hazard.

WARNING

Severe health hazards

Serious injuries that could result in death.

Warns of dangerous situations or unsafe actions that could result in

serious injuries or death.

Lists measures to avoid hazard.

■■■■■■■■

7

Page 16

Warning symbols

CAUTION

Health hazards or severe property damage

Warns of dangerous situations or unsafe actions that could result in

moderate injuries or considerable property damage.

Lists measures to avoid hazard.

2.3 Warning symbols

Make sure that any additional hazard symbols are marked on the product

for your operation of the product.

The following warning symbols in the documentation and at hazard areas

of the product point out hazard potentials:

– Warning of a hazard area

■■■■■■■■■■■■■■■■■■■■■■

NOTICE

Warning symbol on the product

If this warning symbol is on the product, read the respective documentation prior to installation and initial start-up.

– Warning of electric shock from electrical potential

– Warning of danger of fire and explosion from highly flammable

substances and gases

– Warning of danger of poisoning and chemical burns from chemi-

cal hazardous substances

– Warning of danger of infection and poisoning from biological

hazardous substances

■■■■■■■■

8

– Warning of risk of injury from high temperatures

Page 17

■■■■■■■■■■■■■■■■■■■■■■

– Warning of cut injuries from pieces of broken glass and/or sharp

edges

– Warning of risk of injury by laser radiation

– Warning of dangerous optical radiation

2.4 Intended use

Metrohm products are used for the analysis and handling of chemicals.

Usage therefore requires the user to have basic knowledge and experience

in handling chemicals. Knowledge regarding the application of fire prevention measures prescribed for laboratories is also mandatory.

Adherence to this technical documentation and compliance with the

maintenance specifications make up an important part of intended use.

Safety

Any utilization in excess of or deviating from the intended use is regarded

as misuse.

Specifications regarding the operating values and limit values of individual

products are contained in the "Technical specifications" section, if relevant.

Exceeding and/or not observing the mentioned limit values during operation puts people and components at risk. The manufacturer assumes no

liability for damage due to non-observance of these limit values.

The EU declaration of conformity loses its validity if modifications are carried out on the products and/or the components.

2.5 Residual risks

2.5.1 General dangers at the workplace

Generally, the regulations and provisions of the regulatory institutions and

authorities in the field of work apply.

The instructions regarding the following areas have to be followed when

using the products:

■ Work safety

■ Handling mechanical installations

■ Handling electricity

■ Handling hazardous and environmentally damaging substances

■ Handling hazardous and environmentally damaging liquids

■ Disposing hazardous and environmentally damaging substances

If they are not followed, this may result in:

■■■■■■■■

9

Page 18

Residual risks

■■■■■■■■■■■■■■■■■■■■■■

■ Disturbing, injuring and/or killing of people

■ Malfunction and/or damage to instruments and infrastructure

■ Damage and/or contamination of the environment

WARNING

General dangers at workplace

If the safety measures are not followed, working in a laboratory bears

a high risk of injury, which can endanger your life and health.

■ Only professionally trained and qualified specialist personnel may

operate the products.

■ Follow the applicable provisions concerning work safety and all

regulations on wearing protective clothing.

■ Use suitable tools to perform your work.

■ Check the fill level of waste bottles or waste canisters and analysis

vessels, and make sure they do not overflow.

■ Use protective grounding when working with highly flammable

substances and gases.

2.5.2 Danger from electrical potential

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the instrument.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the instrument, dis-

connect the instrument from the energy supply. Then notify Metrohm Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

10

■■■■■■■■

Page 19

■■■■■■■■■■■■■■■■■■■■■■

2.5.3 Danger from machine movements

WARNING

Risk of squashing and pinching from machine movements

Injuries from movable instrument parts.

■ Do not reach into the working area of the instruments during the

work process.

■ Install and use the protective devices enclosed with the product

during the work process.

■ Do not bypass the installed protective devices.

2.5.4 Danger from biological substances

If the product is used for biological hazardous substances, it must be

marked in accordance with regulations.

In case of a return shipment to Metrohm or a Metrohm Service partner,

the product or product component has to be decontaminated and the

hazard symbol for biological hazardous substances must be removed. A

declaration of decontamination must be enclosed.

Safety

WARNING

Danger of infection and poisoning from biological hazardous

substances

Poisoning from toxins and/or infections from samples contaminated

with microorganisms.

■ Clean and disinfect contaminated surfaces.

■ Wear protective equipment.

■ Use exhaust equipment when working with vaporizing hazardous

substances.

■ Dispose of biologically contaminated substances properly.

■■■■■■■■

11

Page 20

Residual risks

2.5.5 Danger from highly flammable substances

WARNING

Danger of fire and explosion from highly flammable substances

and gases

Burns from fire and/or injuries from explosions.

■ Avoid ignition sources.

■ Use protective grounding.

■ Use exhaust equipment.

2.5.6 Danger from careless transport

WARNING

■■■■■■■■■■■■■■■■■■■■■■

Risk of injury from careless transport

Injuries from spilled chemical and/or biological substances, falling

parts and pieces of broken glass.

■ Remove loose parts (e.g. sample racks, sample beaker, bottles)

before transport.

■ Remove liquids.

■ Lift and transport the instrument with both hands on the base

plate.

■ Lift and transport heavy instruments only according to instruc-

tions.

2.5.7 Danger from leakage

WARNING

Risk of injury by leakage

A risk of injury exists in connection with escaping liquids of leaking

parts and/or connection elements.

12

■ Replace leaking parts and connection elements without delay.

■ Tighten loose connecting elements.

■ Use environmentally-friendly methods to dispose of escaping liq-

uids.

■■■■■■■■

Page 21

■■■■■■■■■■■■■■■■■■■■■■

2.5.8 Danger from high temperatures

WARNING

Risk of injury from high temperatures

Burns from hot surfaces and/or hot liquids.

■ Install and use the protective devices enclosed with the product.

■ Wear protective gloves while working in hot areas.

■ Clean up spilled liquids and solids immediately.

2.6 Responsibility of the operator

■ Eliminate defects or damage which impair operating safety without

delay.

■ Eliminate malfunctions which could impair safety without delay.

■ The rules, regulations and instructions listed in the present document

are not the only valid ones. Comply with the applicable statutory rules,

government agency directives and regulations.

■ Unauthorized modification of the products excludes any and all liability

on the part of the manufacturer for any damage resulting from this as

well as for any consequential damage. No modifications, attachments

or conversions which could impair safety may be carried out on the

products without the approval of the manufacturer.

■ Spare parts must meet the technical requirements established by the

manufacturer. Original spare parts always meet these requirements.

■ Personnel must be familiar with this safety-relevant information and it

must be available for consultation at all times.

Safety

2.7 Personnel requirement

Only qualified personnel may operate the present product.

Qualified personnel are people authorized by the safety responsible to

carry out the necessary operations. They are capable of recognizing and

avoiding possible dangers. These people are qualified due to their professional training, experience and/or instruction. They know the relevant

standards, laws, provisions, accident prevention regulations and the company conditions.

■■■■■■■■

13

Page 22

System overview

3 Functional description

3.1 System overview

3.1.1 System – Signals

Visual signals

All products and components of the system that are equipped with multicolor status displays indicate their respective status using colors and flashing patterns.

The meaning of the colors and flashing patterns is explained in the following table.

NOTICE

■■■■■■■■■■■■■■■■■■■■■■

Use of the flashing patterns

Not all products and components use all of the flashing patterns illustrated below.

However, the meaning of the flashing patterns is the same for all

products and components.

Signal Meaning

LED lights up yellow System start or initialization

LED flashes yellow (slowly) Ready for connection setup or

locking

LED flashes yellow (fast) Connection setup started or

locking underway

LED lights up green Ready for operation

LED flashes green (slowly) In operation

LED flashes red (fast) Malfunction or error

14

■■■■■■■■

Page 23

■■■■■■■■■■■■■■■■■■■■■■

3.1.2 System – Interfaces

The system provides the following interfaces:

Functional description

Designation Abbrevia-

Symbol Use

tion

Metrohm Device Link MDL For connecting additional mod-

ules or products to a basic product.

Human Interactive Device HID For connecting an external con-

trol product.

Metrohm Solution Identification MSI For connecting the OMNIS Liq-

uid Adapter.

Local Area Network LAN For connecting the product to a

local network.

USB connector USB For connecting USB devices.

■■■■■■■■

15

Page 24

Overview – OMNIS Sample Robot Pick&Place S

■■■■■■■■■■■■■■■■■■■■■■

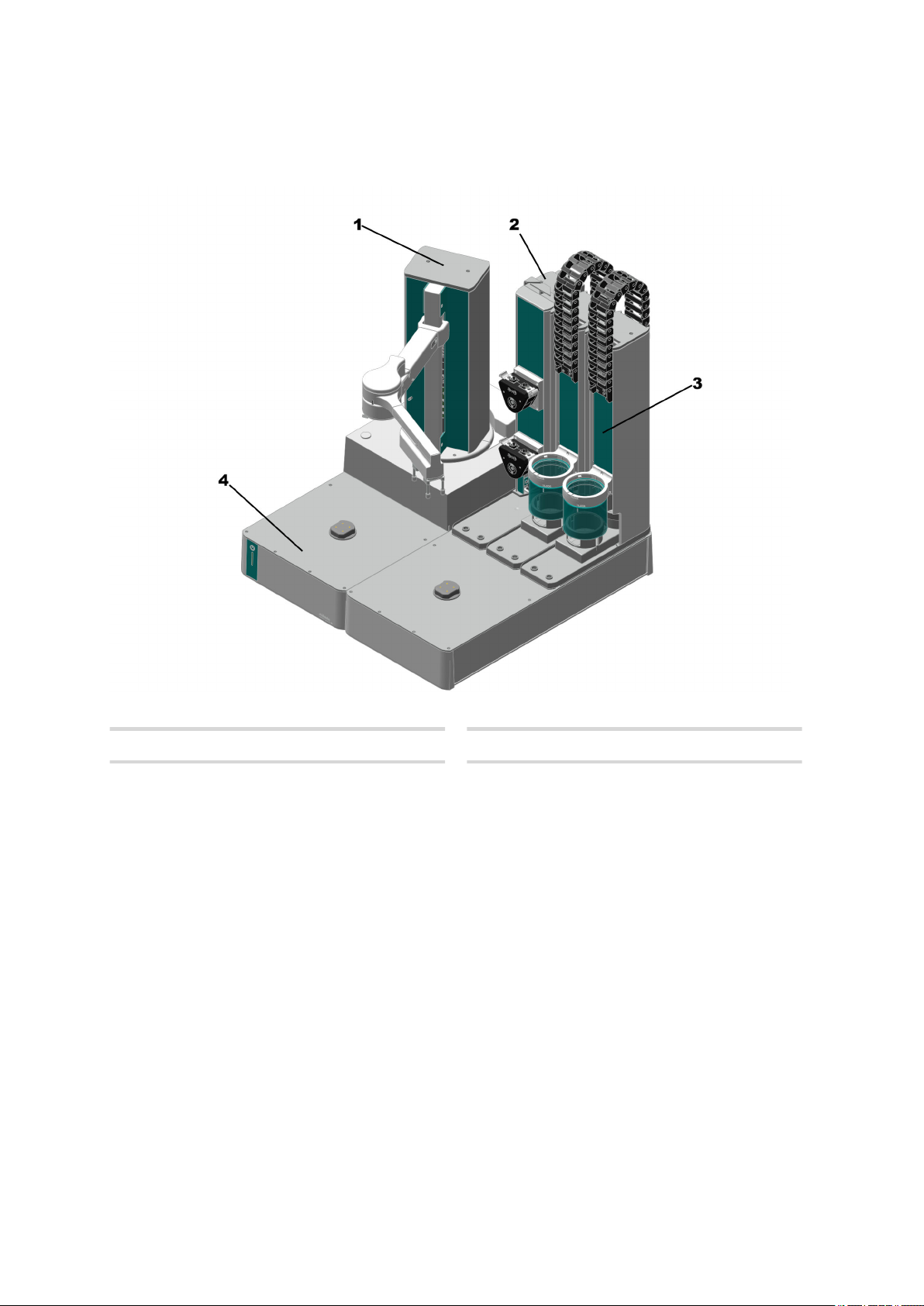

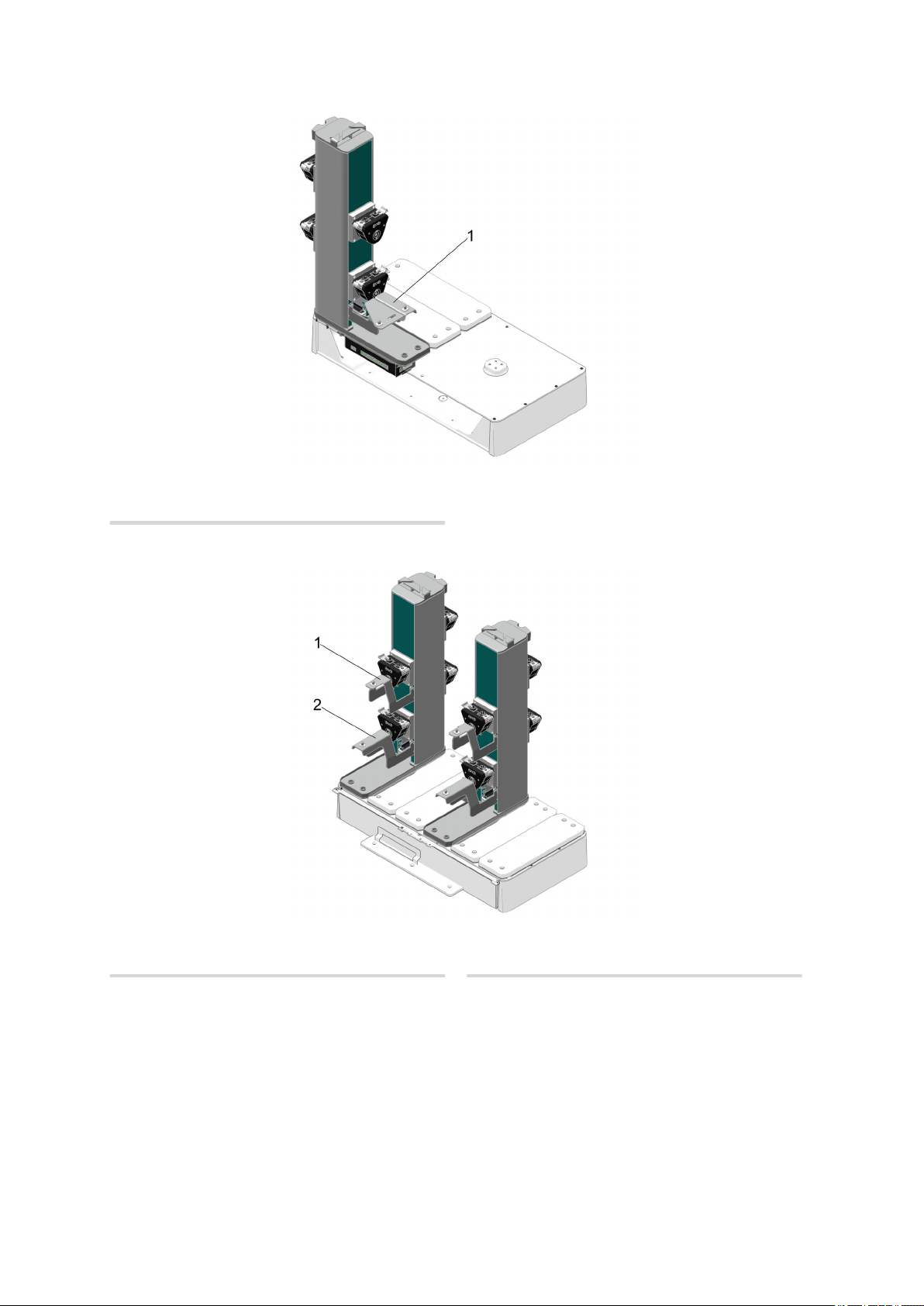

3.2 Overview – OMNIS Sample Robot Pick&Place S

Figure 1 OMNIS Sample Robot Pick&Place S

Main module

1

Pick&Place module

3

Pump module

2

Rack base

4

16

■■■■■■■■

Page 25

■■■■■■■■■■■■■■■■■■■■■■

Functional description

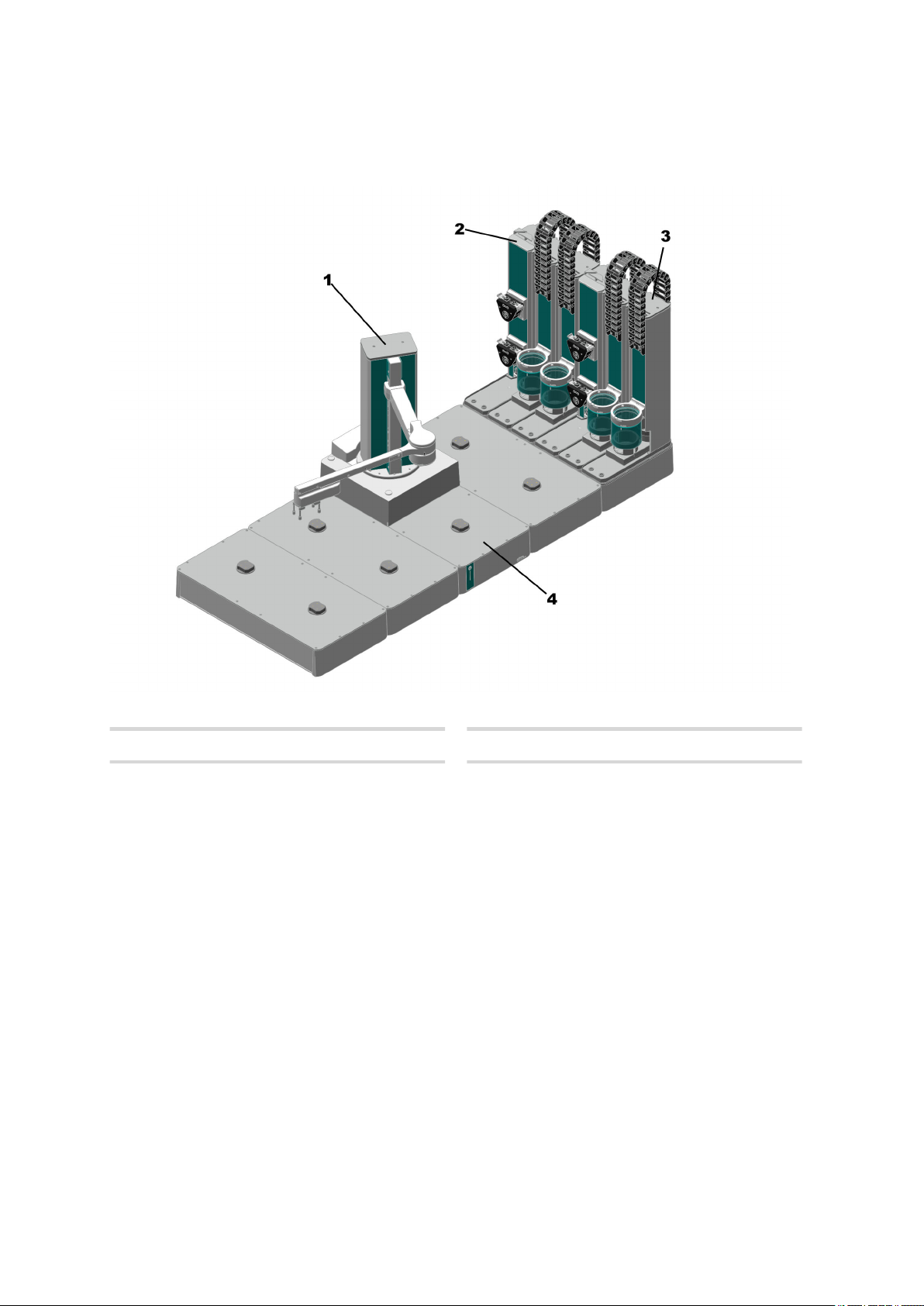

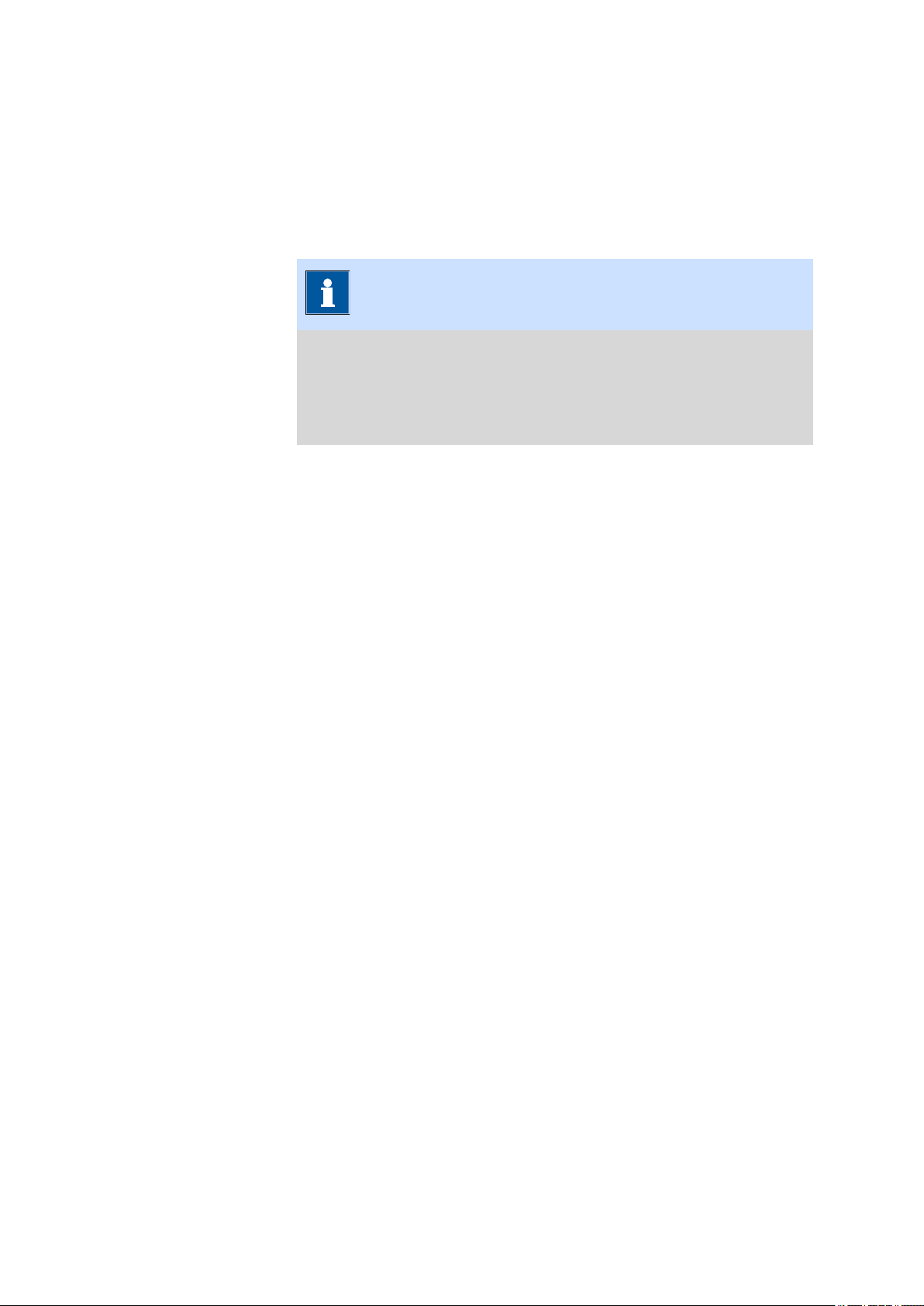

3.3 Overview – OMNIS Sample Robot Pick&Place M

Figure 2 OMNIS Sample Robot Pick&Place M

Main module

1

Pick&Place module

3

Pump module

2

Rack base

4

■■■■■■■■

17

Page 26

Overview – OMNIS Sample Robot Pick&Place L

■■■■■■■■■■■■■■■■■■■■■■

3.4 Overview – OMNIS Sample Robot Pick&Place L

Figure 3 OMNIS Sample Robot Pick&Place L

Main module

1

Pick&Place module

3

Pump module

2

Rack base

4

18

■■■■■■■■

Page 27

■■■■■■■■■■■■■■■■■■■■■■

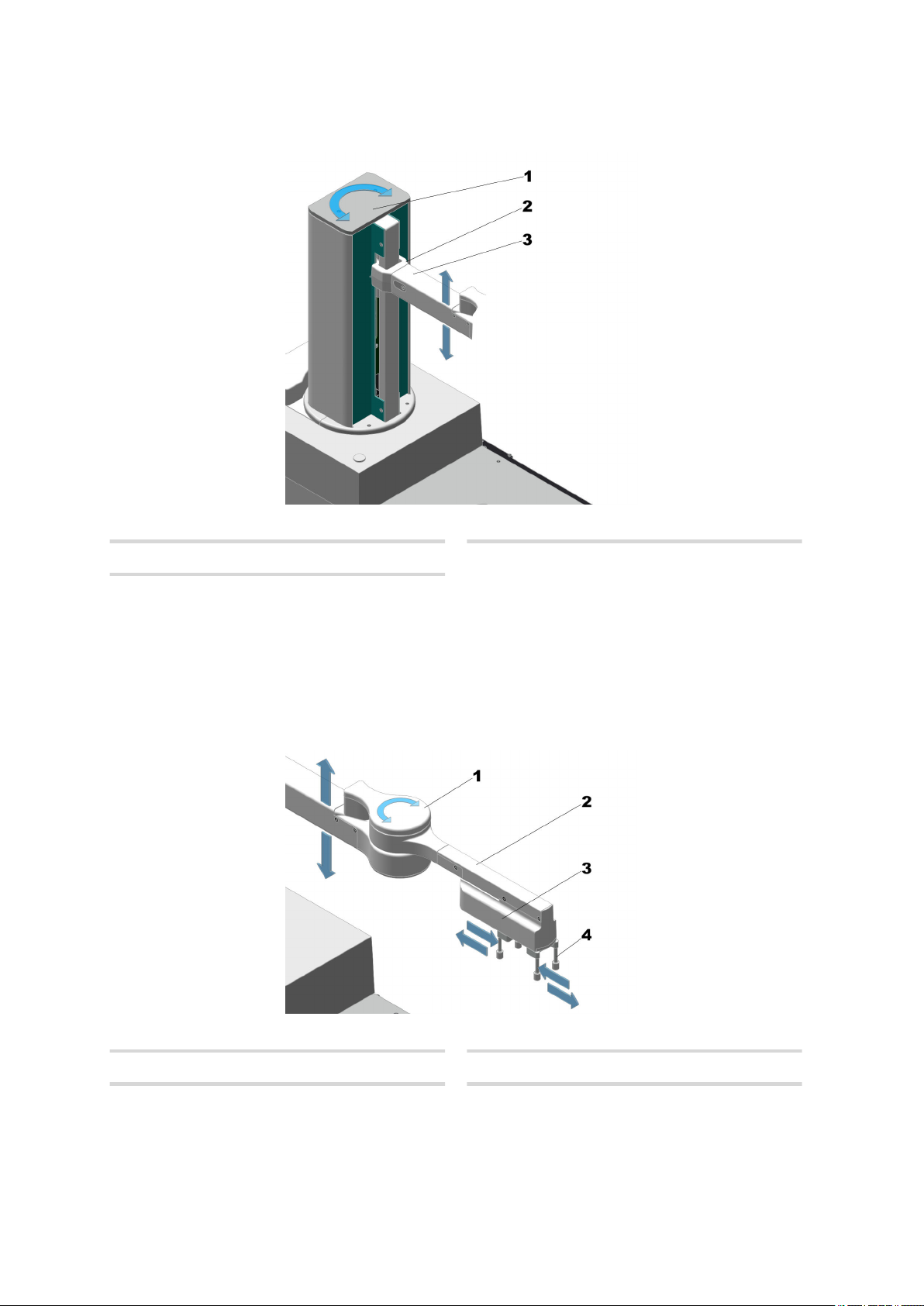

3.4.1 Main module Pick&Place – Overview

Functional description

Figure 4 Main module Pick&Place – General overview

Main lift

1

Lift arm

3

Gripper arm 3 - 5 Robot arm

5

Gripper

6

Arm holder

2

Arm joint

4

Gripper fingers

7

The main lift (4-1) is located on the main module Pick&Place.

The arm holder (4-2) connects the lift arm (4-3), the arm joint (4-4) and

the gripper arm (4-5) with the main lift. The gripper fingers (4-7) are

mounted on the gripper (4-6).

■■■■■■■■

19

Page 28

Overview – OMNIS Sample Robot Pick&Place L

3.4.1.1 Main lift – Overview

Figure 5 Main lift – Movement capacity

■■■■■■■■■■■■■■■■■■■■■■

Main lift

1

Lift arm

3

3.4.1.2

The lift arm (5-3) can be moved up and down along the main lift (5-1)

with the help of the arm holder (5-2).

The main lift (5-1) can be rotated to the left and right.

Gripper arm – Overview

2

Arm holder

20

Arm joint

1

Gripper

3

■■■■■■■■

Figure 6 Gripper arm – Movement capacity

Gripper arm

2

Gripper fingers

4

Page 29

■■■■■■■■■■■■■■■■■■■■■■

The gripper arm as a whole is moved up and down by the main lift.

With the arm joint (6-1), the gripper arm (6-2) can be turned to the left

and to the right. The gripper (6-3) can open and close the gripper fingers

(6-4), in order to pick up and hold beakers.

3.4.2 Pick&Place module – Overview

NOTICE

Extension versions

Up to 4 Pick&Place modules can be installed per OMNIS Sample

Robot.

In addition, if required, 1 holder for homogenizers (Polytron PT 1300

D) can be mounted on the front of the Pick&Place module.

Front

Functional description

Guide chain

1

Safety shield

3

Slide

5

Figure 7

Front – Pick&Place module

Lift tower

2

Collection tray

4

Titration head holder

6

On each Pick&Place module there is a slide (7-5) for positioning the sample beakers under the titration head.

■■■■■■■■

21

Page 30

Overview – OMNIS Sample Robot Pick&Place L

At both slide positions (7-5) (front and rear), the titration head holder

(7-6) can be moved downwards via the lift tower (7-2) so that the safety

shield (7-3) encases the sample beaker.

A titration head that fits the sample beaker to be used can be utilized in

the titration head holder (7-6). The titration head contains sensors, dosing

tips, cleaning accessories (and occasionally a rod stirrer or homogenizer)

that are required for the measurement.

Rear

■■■■■■■■■■■■■■■■■■■■■■

Drain nozzle

1

Figure 8 Rear – Pick&Place module

Distributor

2

At the rear of the Pick&Place module there is a drain nozzle (8-1) to which

a tubing is connected via a tubing adapter. Any liquid that may escape will

be routed through this tubing into the waste canister. In case of an error,

this protects the Pick&Place module from damage.

The distributor (8-2) that is used for connecting the rinsing tubing and

aspiration tubing is fitted on the back panel of the Pick&Place module.

Option for working with a homogenizer (Polytron PT 1300

D)

A homogenizer (Polytron PT 1300 D) (9-1) can be inserted in the titration

head (9-3) for applications which require homogenization of the sample.

A holder for homogenizers has to be mounted for guiding the homogenizer (9-2). For further information, see Inserting and equipping the

titration head.

22

■■■■■■■■

Page 31

■■■■■■■■■■■■■■■■■■■■■■

Functional description

Figure 9 Front – Pick&Place module with holder for homogenizer (Poly-

Holder for homogenizer (Polytron PT

1

1300 D)

Titration head

3

tron PT 1300 D)

Polytron PT 1300 D

2

■■■■■■■■

23

Page 32

Overview – OMNIS Sample Robot Pick&Place L

3.4.3 Peristaltic pump module – Overview

NOTICE

Extension versions

2 or 4 pumps can be mounted per pump module. In the case of the

two-way variant, the pumps are mounted on the front only and numbered 1 and 2. In the case of the four-way variant, 2 additional

pumps are mounted on the rear and numbered 3 and 4. Arrows indicating inlet and outlet are also to be found above each peristaltic

pump next to the numbering.

Optionally, 2 additional lid trays can be installed, e.g., for applications

with covered sample beakers such as volumetric Karl Fischer titration.

Front

■■■■■■■■■■■■■■■■■■■■■■

24

Tubing organizer

1

Peristaltic pumps

3

■■■■■■■■

Figure 10

Front – Peristaltic pump module

Housing

2

Page 33

■■■■■■■■■■■■■■■■■■■■■■

Functional description

Rear

Figure 11 Rear – Peristaltic pump module

Tubing organizer

1

Drain nozzle

3

Peristaltic pumps

2

2 or 4 peristaltic pumps (11-2) can be fitted on each peristaltic pump

module. 2 peristaltic pumps each can be used to rinse and clean the sensors in a Pick&Place module.

A tubing organizer (10-1) is located on the top side of the peristaltic

pump module to ensure orderly placement and secure fastening of the

connected tubing.

A drain nozzle (11-3) to which a tubing is connected via a tubing adapter

can be found at the rear of the peristaltic pump module. Any liquid that

may escape will be routed through this tubing into the waste canister. In

case of an error, this protects the pump module against damage.

Option for working with covered sample beakers

For applications where the sample needs to be protected from environmental influences for example, the sample beakers can be closed with lids.

To store these lids during analysis, different lid trays can be installed that

offer space for 2 to 4 lids (depending on the product version of the

OMNIS Sample Robot Pick&Place).

■■■■■■■■

25

Page 34

Overview – OMNIS Sample Robot Pick&Place L

Figure 12 Front – Peristaltic pump module with lid tray for OMNIS

■■■■■■■■■■■■■■■■■■■■■■

Sample Robot S

1

Lid tray

Figure 13 Front – Peristaltic pump module with lid trays for OMNIS

Sample Robot M / L

26

Top lid tray

1

■■■■■■■■

Bottom lid tray

2

Page 35

■■■■■■■■■■■■■■■■■■■■■■

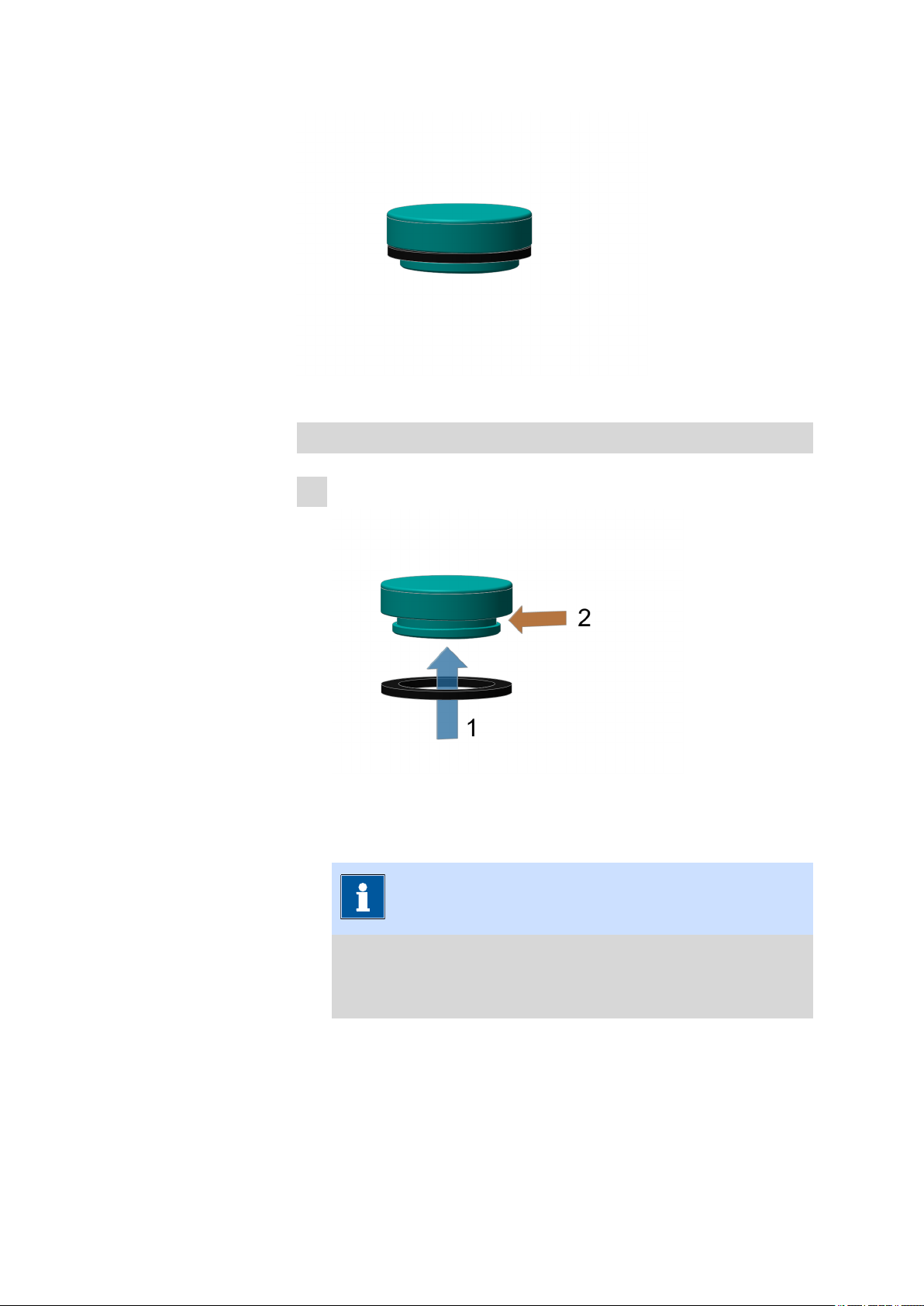

3.4.3.1 Overview – Peristaltic pump

Figure 14 Peristaltic pump

Functional description

Press clamp

1

Inlet

3

Outlet

2

LED

4

Supply and drainage tubing is connected at the inlet (14-3) and outlet

(14-2) of the peristaltic pump.

A pump tubing is located in the interior of the peristaltic pump between

the inlet and the outlet that is pinched off by four rollers. The conveyance

medium is pumped through the system by this volume displacement.

The press clamp (14-1) protects the pump tubing against external influences. The press clamp can be dismantled to check the pump tubing and to

replace it if necessary.

The LED (14-4) displays the status of the peristaltic pump.

■■■■■■■■

27

Page 36

Overview – OMNIS Sample Robot Pick&Place L

3.4.4 Rack base – Overview

Figure 15 Rack base of an OMNIS sample robot

■■■■■■■■■■■■■■■■■■■■■■

Rack base

1

3.4.4.1

On each rack base (15-1), up to 2 sample racks can be inserted on the

rack holders (15-2).

The system uses the sensors in the rack holder to detect which sample

rack type (if any) is present.

Sample rack – Overview

Rack holder

2

28

Sample beaker

1

Transport handles

3

■■■■■■■■

Figure 16 Sample rack

Sample position

2

Spout hole

4

Page 37

■■■■■■■■■■■■■■■■■■■■■■

The sample beakers (16-1) are stored in the sample positions (16-2) in the

sample rack.

The transport handles (16-3) allow for the sample rack to be transported

by hand so that it can be set down on and removed from the rack holder

of the rack base. Several empty sample racks can be stacked on top of one

another on the transport handles.

The sample rack contains rinsing holes for emptying liquids in case of

overflows and for cleaning.

NOTICE

Cleaning

The sample rack is not dishwasher-safe.

Table 6 Sample rack versions

Art. no. Beaker volume Number of beakers

Functional description

6.02041.010 250 mL 9

6.02041.020 200 mL 9

6.02041.030 120 mL 16

6.02041.040 75 mL 25

3.5 Sample Robot Pick&Place – Functional description

The Sample Robot Pick&Place is comprised of the following components:

■ Main module Pick&Place

■ Pick&Place module

■ Peristaltic pump module

■ Rack base

■ Module base

The OMNIS Sample Robot System is used for the automatic measurement

of different organic and inorganic samples.

The samples are stored, transported and processed through the components individually integrated in the system.

■■■■■■■■

29

Page 38

Sample Robot Pick&Place – Functional description

■■■■■■■■■■■■■■■■■■■■■■

3.5.1 Main module Pick&Place – Functional description

All of the attached modules in the OMNIS Sample Robot System are supplied with electricity through the main module Pick&Place.

The main lift with gripper and gripper arm is fastened to the main module

Pick&Place.

The gripper is used for transporting the sample beakers out of the sample

racks and into the processing stations intended for this purpose. Once the

processing of the samples has been completed, the gripper removes the

sample beakers out of the processing stations once again and transports

them back into the previously removed sample rack.

The control hardware is integrated in the interior of the main module

Pick&Place.

3.5.2 Pick&Place module – Functional description

The samples in the OMNIS sample robot system are analyzed on the

Pick&Place module.

The sample beakers are transported by the sample robot into the front

sample position of the Pick&Place module. After the sample beaker has

been put into place, the slide with the sample beaker moves under the

titration head and the lift moves downward.

The sensors installed in the titration head analyze the sample.

After completion of the measurement, the sensors are cleaned with one

of the pumps that are integrated in the pump module. The solution that is

generated during this process is aspirated by an additional pump of the

pump module and the lift with the sensors rises.

Afterwards the slide moves back out again and the sample beaker is

removed by the sample robot.

3.5.3 OMNIS peristaltic pump module – Functional description

2 or 4 peristaltic pumps are integrated on the peristaltic pump module.

2 peristaltic pumps are assigned to each workstation in the OMNIS sample

robot system.

The upper peristaltic pump (numbered with 1 or 3) rinses off the sensors

in the Pick&Place modules with solvent after the analysis of a sample. For

this purpose, the solvent is aspirated from the rinsing canister through the

peristaltic pump. If required, these pumps can also be used to dilute a

sample with solvent or to bring it into solution prior to an analysis.

30

The lower peristaltic pump (numbered with 2 or 4) aspirates the remaining

solution out of the sample beaker during and after the rinsing procedure

and routes it to the waste canister.

■■■■■■■■

Page 39

■■■■■■■■■■■■■■■■■■■■■■

Optionally, up to 2 lid trays can be installed on the pump module. The lid

that was removed from the sample beaker is parked on the lid tray until it

is needed again to seal the sample beaker.

If malfunctions occur at the peristaltic pump, this will be displayed via LED

at the peristaltic pump.

3.5.3.1 Functional description – Peristaltic pump

The peristaltic pump operates in accordance with the volume displacement principle.

The pump tubing in the interior connects the inlet and the outlet of the

peristaltic pump.

This pump tubing is pinched off by four internal rollers. Media are aspirated in and out by this squeezing of the pump tubing and the volume displacement that results from it.

3.5.4 Rack base – Functional description

The rack base is the skeletal structure for the sample robot.

The sample racks in which the sample beakers are located are stored on

the rack holders of the rack base. The rack holders contain sensors that

automatically detect which sample rack type is currently located on the

individual rack base.

Functional description

The OMNIS sample robot system uses the sample rack type to detect

which type of sample beakers are located in the sample rack. This information is passed along to the control which sets the gripper to the respective size of the sample beakers.

If a sample rack that is still to be approached by the sample robot is

removed, this is detected by the rack holders and passed along to the

OMNIS sample robot system. This sample rack will no longer be

approached by the sample robot and the absence of the sample rack will

be displayed in the control.

■■■■■■■■

31

Page 40

OMNIS Sample Robot – Indicators and controls

■■■■■■■■■■■■■■■■■■■■■■

3.6 OMNIS Sample Robot – Indicators and controls

Figure 17 OMNIS Sample Robot – Indicators and controls

On/off switch

1

Status display

2

Multi-colored

Indicators

The status of the instrument is displayed with the status display (17-2)

using different colors System – Signals (see chapter 3.1.1, page 14).

Controls

The on/off switch (17-1) is used for the hardware-side operation of the

OMNIS Sample Robot.

Table 7

Behavior of the on/off switch

Pressure duration Acoustic signal Functions on the sample

robot

Short pressing (1 to 5 s)

Beep after 1 s

Switching on the instrument

Shutting down the instrument

Long pressing (approx. 5 s) Double-beep Gripper opens (if available)

32

■■■■■■■■

Page 41

■■■■■■■■■■■■■■■■■■■■■■

3.7 Main module – Connectors

NOTICE

Symbol labeling

Observe the connector symbols when connecting the instruments.

Functional description

Figure 18 Connectors – Main module Pick&Place

Human Interactive Device (HID)

1

Metrohm Device Link (MDL)

3

Local Area Network (LAN)

2

Power socket

4

■■■■■■■■

33

Page 42

Checking the delivery

4 Transport and storage

4.1 Checking the delivery

Immediately upon arrival of the merchandise, check the shipment against

the delivery note to ensure completeness and absence of damage.

4.2 Storing the packaging

The product is supplied in extremely protective packaging together with

the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the product.

4.3 Lifting the sample robot

■■■■■■■■■■■■■■■■■■■■■■

Avoid lifting the sample robot after the initial installation whenever possible. The bigger M and L versions in particular need to be adjusted again

after transportation.

If it is necessary to lift the sample robot, try to avoid a sag by lifting the

system on all four sides. Take the total weight of the system into account.

Check the positioning accuracy of the sample robot after placing the sample robot down. If inaccuracies occur, Metrohm support will assist you.

34

■■■■■■■■

Page 43

■■■■■■■■■■■■■■■■■■■■■■

5 Installation

5.1 Installation by Metrohm

NOTICE

Installation of the products

As a basic rule, the installation of the system and of the new products

and modules is handled by trained and instructed specialists from the

Metrohm Company and/or its representative.

5.2 Sample robot setting up

Installation

The product has been developed for operation indoors and may not be

used in explosive environments.

Place the instrument in a location of the laboratory which is suitable for

operation and provides protection against corrosive atmosphere and contamination by chemicals.

The sample robot needs a horizontal and plane table that is stable and

free of vibrations for a precise mode of operation. The work surface may

not bend under a load of 60 kg.

Observe the dimensions and weights of the individual products and modules that are part of the complete system. You will find this information in

the "Technical specifications" section.

Protect the product against excessive temperature fluctuations and direct

sunlight.

The power cord has to be accessible while operating and must not be

replaced by an impermissible cable.

■■■■■■■■

35

Page 44

Replacing the seal of the sample beaker lid

■■■■■■■■■■■■■■■■■■■■■■

5.3 Replacing the seal of the sample beaker lid

The appropriate seals must be placed on sample beaker lids to tightly seal

sample beakers. These seals must not be damaged.

NOTICE

We recommend replacing the seal of the sample beaker lid approx.

every 6 months.

The standard seals were designed for aqueous applications and Karl

Fischer titrations. If more aggressive solvents such as chlorobenzene

or glacial acetic acid are used, we recommend the more resistant

seals.

Table 8 List of sample beakers with seals for sample beaker lids

Art. no. Designation Beaker size

6.02710.000 Lid for sample beaker 75 mL (P&P) with

standard seals

6.02710.030 Lid for sample beaker 75 mL (P&P) with

resistant seals

6.02710.010 Lid for sample beaker 120 mL (P&P) with

standard seals

6.02710.040 Lid for sample beaker 120 mL (P&P) with

resistant seals

6.02710.020 Lid for sample beaker 250 mL (P&P) with

standard seals

6.02710.050 Lid for sample beaker 250 mL (P&P) with

resistant seals

75 mL

75 mL

120 mL

120 mL

250 mL

250 mL

NOTICE

The accessories for the respective product version can be obtained

either on the Internet at http://www.metrohm.com or via your

regional Metrohm representative.

36

■■■■■■■■

Page 45

■■■■■■■■■■■■■■■■■■■■■■

Installation

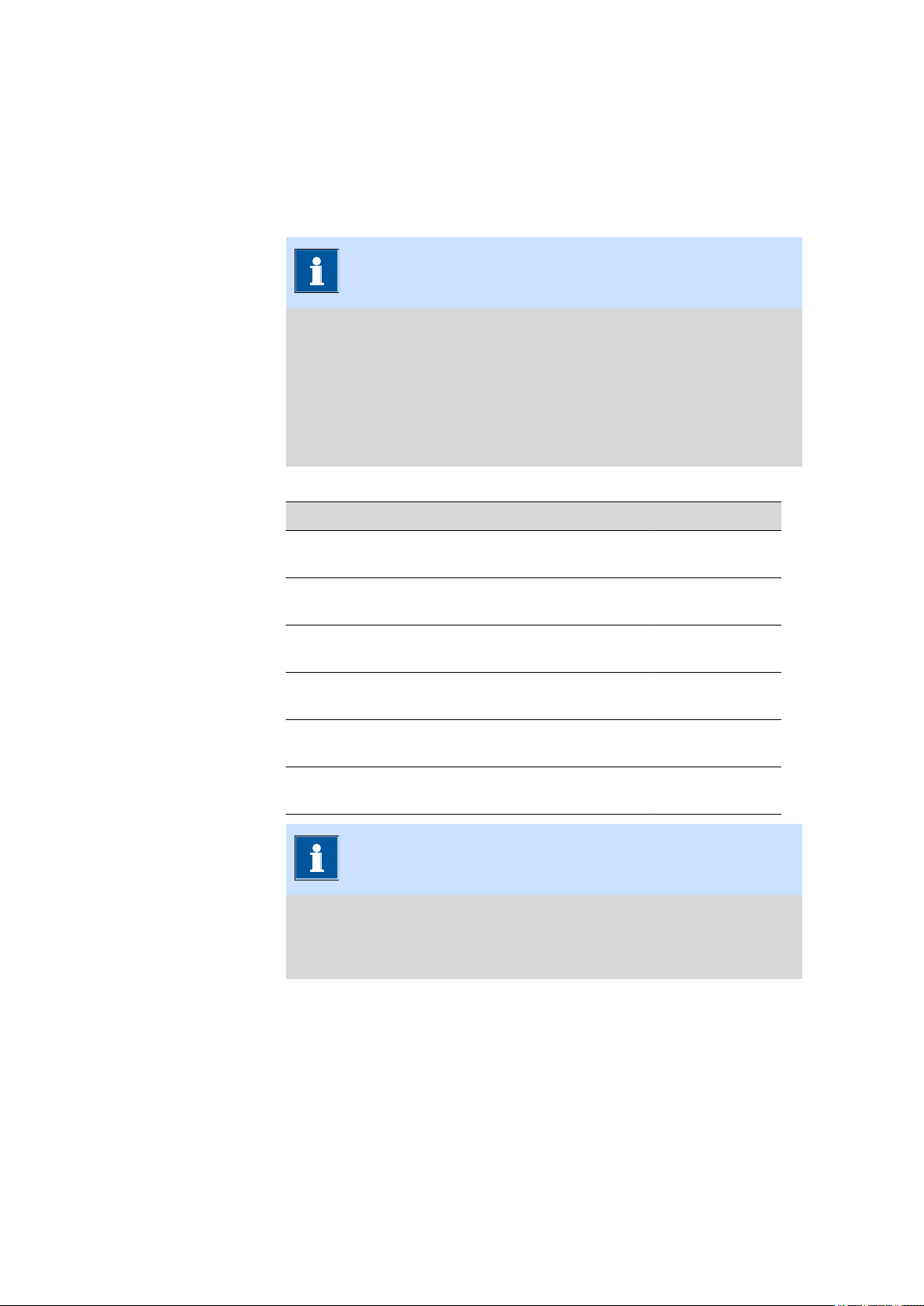

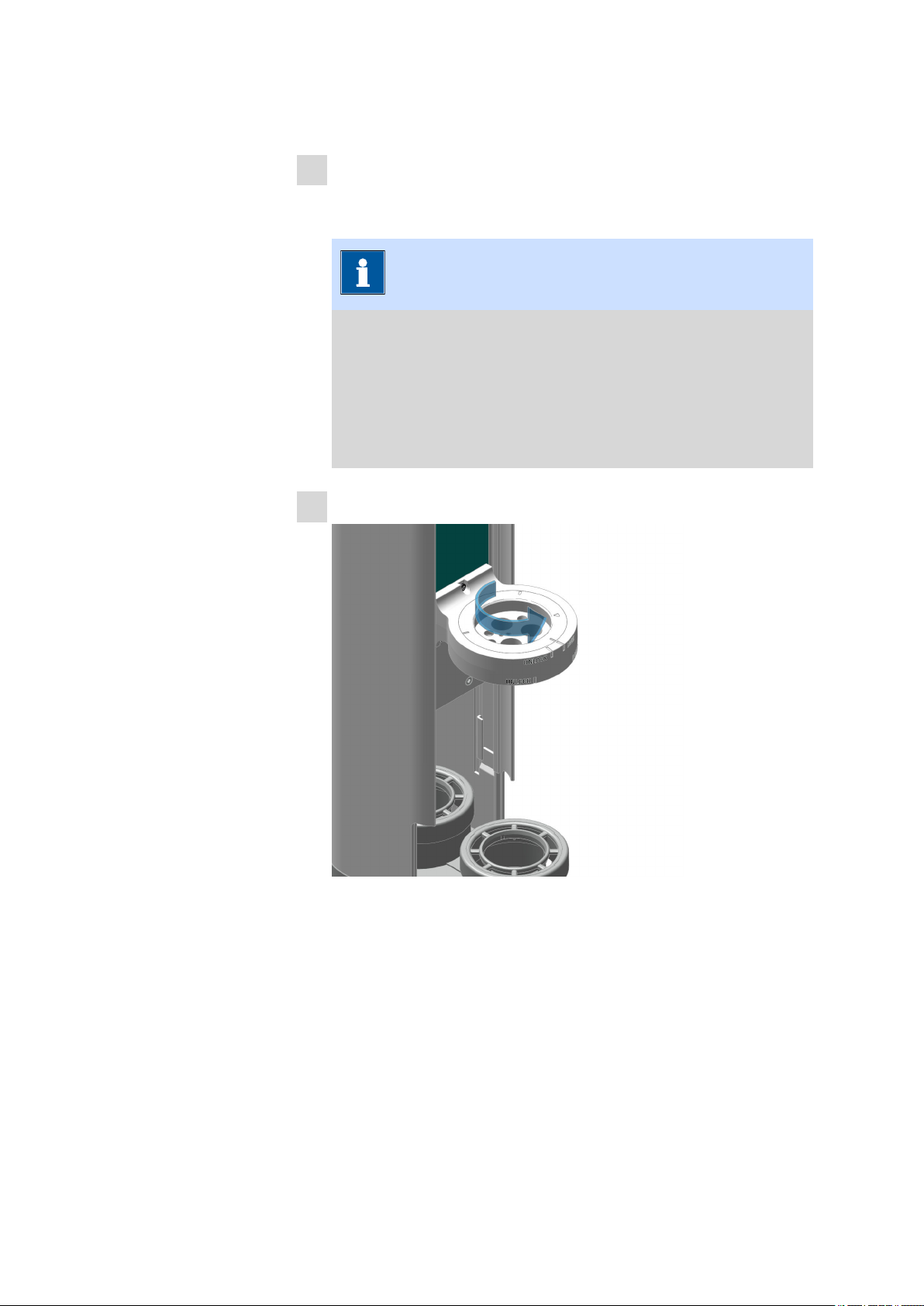

Figure 19 Sample beaker lid with seal for sample beaker lid (complete)

Placing the seal onto the sample beaker lid

1

Placing and fitting the lid seal

Figure 20 Placing the rubber seal onto the lid

Slide the rubber seal from below over the lid bottom so that it sits

neatly in the prefabricated groove.

NOTICE

Make sure that the rubber seal fits the groove perfectly. You

might need to stretch the rubber seal and press it into the

groove.

■■■■■■■■

37

Page 46

Inserting and equipping the titration head

■■■■■■■■■■■■■■■■■■■■■■

Removing the seal of the sample beaker lid

Pull the lid seal down over the lid bottom and remove it.

1

5.4 Inserting and equipping the titration head

NOTICE

The titration head has the markings "LOCK" for closed and "UNLOCK"

for open, also see Replacing the titration head (see chapter 8.4.3,

page 73).

38

Figure 21 Inserting the titration head (general)

Titration head

1

Markings "LOCK" and "UNLOCK"

3

Prerequisites:

■ The sample robot is switched off.

■ All of the sensors in the titration head are dismounted.

■■■■■■■■

2

Inserting the titration head

Titration head holder

Page 47

■■■■■■■■■■■■■■■■■■■■■■

■ The safety shield is dismounted.

1

Inserting the titration head

Insert the titration head (21-1) from below into the titration head

holder (21-2).

NOTICE

In case a rod stirrer is used:

The marked opening (triangle or arrow) for inserting the rod stirrer on the titration head should be located as close as possible to

the tower of the Pick&Place module. This ensures that the rod

stirrer is in a central position and takes up only a small amount

of space.

2

Fastening the titration head

Installation

Figure 22 Fastening the titration head

Rotate the titration head by hand until the marking points to "LOCK".

■■■■■■■■

39

Page 48

Inserting and equipping the titration head

Equipping the titration head for titration

Figure 23 Positions of the components in the titration head (titration

■■■■■■■■■■■■■■■■■■■■■■

with rod stirrer)

Position for the spray nozzles or rins-

1

ing nozzles

Position for the aspiration tip

3

Position for the rod stirrer

5

Equipping the titration head for titration

Prerequisites:

■ The sample robot is switched off.

■ The required titration head is mounted.

1

Position for the electrode

2

Position for the preinstalled dosing tips

4

for connecting dosing tubing

Mounting the rinsing tubing

Insert the spray nozzles from above into the positions intended for

this purpose and mount the rinsing tubing.

NOTICE

40

During insertion, take care to ensure that the spray nozzles do

not touch the rod stirrer because otherwise this could lead to

jamming of the stirrer.

■■■■■■■■

Page 49

■■■■■■■■■■■■■■■■■■■■■■

2

Inserting the electrode

Insert the electrode from above into the position intended for this

purpose.

3

Mounting the aspiration tubing

Insert the aspiration tip from above into the position intended for this

purpose and mount the aspiration tubing.

If necessary, shorten the aspiration tip to the desired length afterwards.

4

Mounting the dosing tubing

Mount the dosing tubing onto the preinstalled dosing tips.

5

Inserting the rod stirrer

Insert the rod stirrer from above into the position intended for this

purpose, place the corresponding stirring propeller from below onto

the rod stirrer coupling and connect the cable of the rod stirrer to the

MDL socket of the main module.

Installation

NOTICE

This step is not necessary if the Pick&Place module involved is

the version with the built-in magnetic stirrer (2.1014.0110).

■■■■■■■■

41

Page 50

Inserting and equipping the titration head

Equipping the titration head for Karl Fischer titration

Figure 24 Positions of the components in the KF titration head

■■■■■■■■■■■■■■■■■■■■■■

Buret tip for titrant

1

Preinstalled dosing tip with antidiffusion

valve

Stopper or aspiration tip

3

Screw nipples (4 pieces)

5

Screw nipple (6.2730.030)

Equipping the titration head for KF titration

Prerequisites:

■ The sample robot is switched off.

■ The required titration head is mounted.

1

Dosing tip for reagent (Solvent)

2

Preinstalled dosing tip with antidiffusion

valve

Double Pt wire electrode

4

Double Pt wire electrode, for KF sample

changers incl. electrode cable (6.0340.000)

Titration head for KF titration

6

(6.01403.020)

Inserting the stopper or aspiration tip

Insert the stopper (24-3) into the screw nipple at the back (close to

the Pick&Place module tower).

42

■■■■■■■■

Page 51

■■■■■■■■■■■■■■■■■■■■■■

NOTICE

Depending on the application, the stopper can also be replaced

by an aspiration tip to aspirate the solution after the titration.

The aspiration tip might need to be shortened to the desired

length and an aspiration tubing must be mounted.

2

Inserting the buret tip for the titrant

Insert the buret tip into the screw nipple on the left, mount the titration tubing and screw it tight.

NOTICE

The titration tip should be located just above the stirring bar, but

should not impede it.

Installation

3

Inserting the dosing tip for the reagent (Solvent)

Insert the dosing tip (24-2) into the screw nipple on the right, mount

the dosing tubing and screw it tight.

NOTICE

The dosing tip should be located just above the stirring bar, but

should not impede it.

4

Inserting the electrode

Insert the double Pt wire electrode (24-4) with the electrode cable

into the screw nipple at the front and screw it tight.

■■■■■■■■

43

Page 52

Mounting the safety shield

5.5 Mounting the safety shield

WARNING

Working without a safety shield

A risk of injury exists when working without a safety shield mounted.

■ Never operate the sample robot without a safety shield.

■ Before beginning work, make sure that all of the protective devi-

ces are mounted on the sample robot and operational.

■ Always wear personal protective equipment when working with

the sample robot.

NOTICE

■■■■■■■■■■■■■■■■■■■■■■

The safety shield has the designations "LOCK" for closed and

"UNLOCK" for open.

Figure 25 Inserting the safety shield

44

Safety shield

1

Markings "LOCK" and "UNLOCK"

3

■■■■■■■■

Titration head holder

2

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Mounting the safety shield

Prerequisites:

■ The sample robot is switched off

1

Inserting the safety shield

Insert the safety shield (25-1) from the bottom into the titration head

holder (25-2).

2

Fastening the safety shield

Installation

Figure 26 Fastening the safety shield

Rotate the safety shield clockwise until the marking points to

"LOCK".

■■■■■■■■

45

Page 54

Connecting the tubing to the distributor of the Pick&Place module

■■■■■■■■■■■■■■■■■■■■■■

5.6 Connecting the tubing to the distributor of the Pick&Place module

Rinsing tubing

1

Distributor

3

Outlet tubing

5

Figure 27 Connecting the tubing to the distributor

Aspiration tubing

2

Rinsing tubing

4

Connecting the tubing to the distributor

Prerequisites:

■ The sample robot is switched off

1

Connecting the rinsing tubing

Manually tighten or plug in the three rinsing tubings (27-1) in the M3

bore holes of the distributor (27-3).

NOTICE

The rinsing tubings lead to the spray nozzles of a titration head

in the Pick&Place module.

46

■■■■■■■■

Page 55

■■■■■■■■■■■■■■■■■■■■■■

2

Connecting the aspiration tubing

Manually tighten the aspiration tubing (27-2) in the M3 bore hole of

the distributor.

3

Connecting the rinsing tubing

Remove the union nut.

Pull the end of the tubing over the connection nipple of the distributor and fasten in place with the union nut.

NOTICE

The rinsing tubing (27-4) leads to the rinsing pump (Pump 1 or

Pump 3) and can be cut to the correct length.

4

Connecting the outlet tubing

Remove the union nut.

Installation

Pull the end of the tubing over the connection nipple of the distributor and fasten in place with the union nut.

NOTICE

The outlet tubing (27-5) leads to the aspiration pump (Pump 2

or Pump 4) and can be cut to the correct length.

■■■■■■■■

47

Page 56

Connecting the drainage tubing

5.7 Connecting the drainage tubing

Connecting and placing the drainage tubing

1

■■■■■■■■■■■■■■■■■■■■■■

Push the tubing adapter (1) in an angle of 30 degrees (see illustration) onto the drain nozzle.

2

3

48

■■■■■■■■

Page 57

■■■■■■■■■■■■■■■■■■■■■■

Plug the drainage tubing (2) in the tubing adapter and guide it

through the tubing duct (3) to the waste canister (red line). Take care

that the tubings are not bent upwards to prevent liquids from backing up.

5.8 Connecting the inlet and outlet tubing

Installation

Outlet tubing

1

Connecting element

3

Figure 28 Connecting the inlet and outlet tubing

Inlet tubing

2

Peristaltic pump

4

Connecting the inlet and outlet tubing of the peristaltic

pump

Prerequisites:

■ The sample robot is switched off

Plug the inlet tubing (28-2) into the connecting element (28-3) of

1

the peristaltic pump (28-4) by hand and rotate clockwise until it fits

closely.

■■■■■■■■

49

Page 58

Connecting/Disconnecting the power cord

■■■■■■■■■■■■■■■■■■■■■■

NOTICE

The tubing connections at the inlet and outlet of the peristaltic

pump correspond to the "Luer lock system".

The peristaltic pump rotates clockwise.

Connect the outlet tubing (28-1) following the same procedure.

2

Place the tubing without squeezing it onto the top side by using the

3

tubing organizer. Make sure that the tubing is positioned as close as

possible to the housing.

The pump operates the aspiration tubing and the three rinsing tubings

5.9 Connecting/Disconnecting the power cord

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the product.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the product, discon-

nect the product from the energy supply. Then notify Metrohm

Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

Connecting the power cord

Accessories

Use power cord according to specifications under "Technical specifications".

50

■■■■■■■■

Page 59

■■■■■■■■■■■■■■■■■■■■■■

Installation

Power cord with a maximum length of 2 m, three-core with IEC 60320

instrument plug type C13. Conductor cross-section 3x 0.75 mm2 / 18

AWG.

Power plug according to customer requirements (6.2122.XX0), designed

for a minimum of 10 A.

1

Plugging in the power cord

■ Plug the power cord into the product's power socket.

■ Connect the power cord to the energy supply.

NOTICE

To switch off the product, you must unplug the power cord from

the energy supply.

■■■■■■■■

51

Page 60

Initial start-up by Metrohm

6 Initial start-up

6.1 Initial start-up by Metrohm

NOTICE

Initial start-up of the product

As a basic rule, the initial start-up of the system and of the new products and modules is handled by trained and instructed specialists from

the Metrohm Company and/or its representative.

■■■■■■■■■■■■■■■■■■■■■■

52

■■■■■■■■

Page 61

■■■■■■■■■■■■■■■■■■■■■■

Operation and control

7 Operation and control

7.1 Operation

NOTICE

Operating via the control software

The product can be operated using the commands of the control

software.

Additional information can be found in the software help .

7.2 Switching the OMNIS sample robot on and off

Switching the OMNIS sample robot on and off

The on/off switch

robot.

1

Switching the OMNIS sample robot on

Press the on/off switch for one second until the single acoustic

signal is heard.

The status display (see "Indicators", page 32) is lit up yellow until it is

paired with the OMNIS Software.

As soon as the sample robot is paired with the OMNIS Software, the

color of the status display switches to green and the sample robot is

ready for operation.

2

Switching the OMNIS sample robot off

Press the on/off switch for one second until the single acoustic

signal is heard.

is located on the main module of the sample

The status display goes out and the sample robot is switched off.

■■■■■■■■

53

Page 62

Opening the gripper manually

NOTICE

Additional information on the controls, see OMNIS Sample Robot –

Indicators and controls (see chapter 3.6, page 32).

7.3 Opening the gripper manually

CAUTION

Unsecured sample beakers

If the gripper is opened, then unsecured sample beakers can cause

injuries and property damage to the instrument.

■ Wear personal protective equipment.

■ Always hold the sample beaker in one hand when the gripper is

being opened manually.

■■■■■■■■■■■■■■■■■■■■■■

54

On/off switch

1

■■■■■■■■

Figure 29 Main module Pick&Place, front

LED

2

Opening the gripper manually

Prerequisites:

■ The sample robot stands still.

Hold the sample beaker in one hand.

1

Page 63

■■■■■■■■■■■■■■■■■■■■■■

Hold the on/off switch (29-1) pressed down for five seconds until a

2

dual beep is heard.

The gripper opens and the sample beaker can be removed.

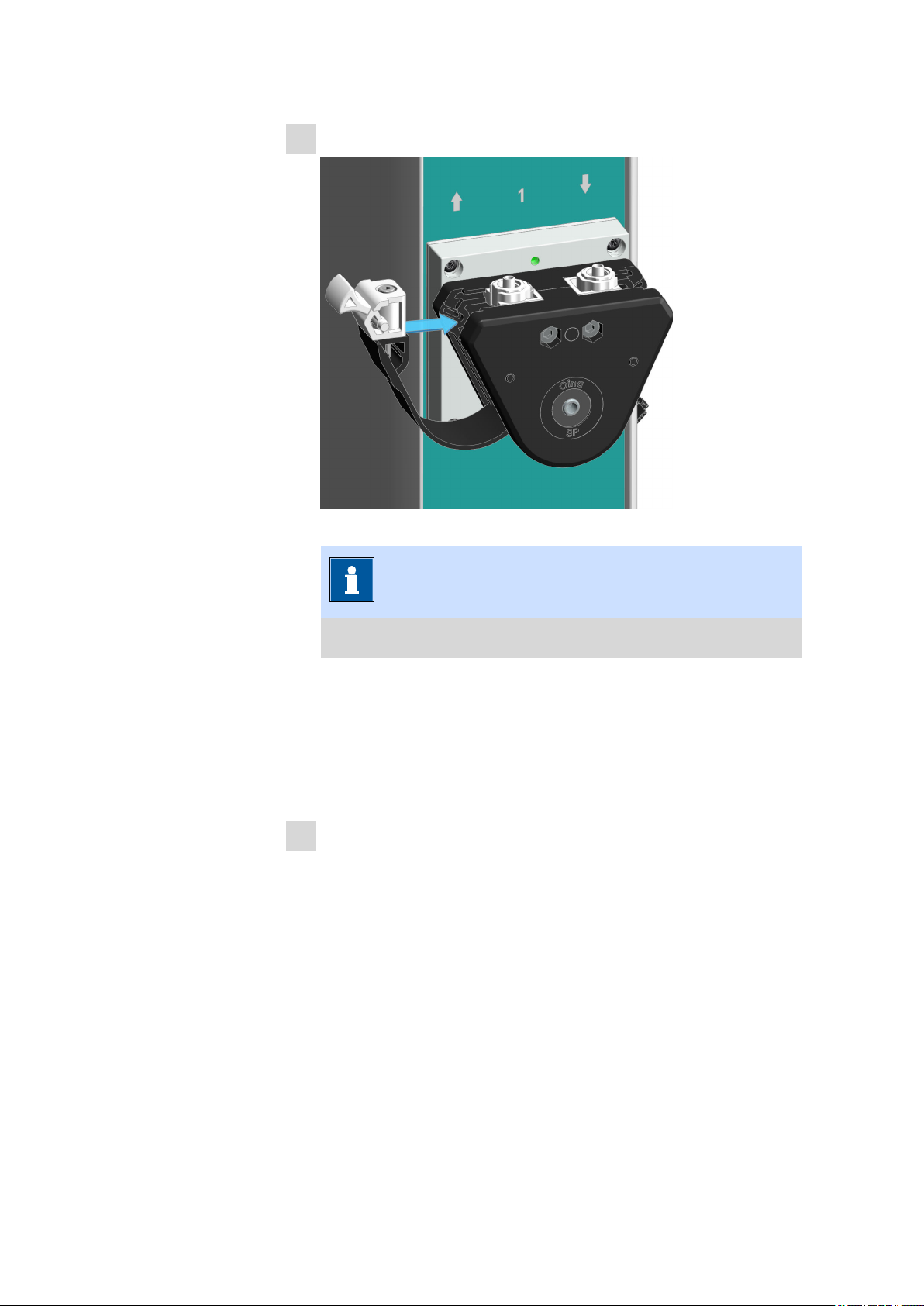

7.4 Attaching and removing the sample rack

CAUTION

Utilization of non-authorized sample beakers

The use of non-authorized sample beakers in the

OMNIS Sample Robot System can lead to injuries and considerable

property damage.

■ Use only sample beakers that are authorized by Metrohm.

Operation and control

NOTICE

Because of the shape of the rack holder and the counterpart on the

sample rack, only one position exists at which the sample rack can be

properly placed on the rack base.

■■■■■■■■

55

Page 64

Attaching and removing the sample rack

Figure 30 Overview image – Attaching and removing the sample rack

■■■■■■■■■■■■■■■■■■■■■■

1

3

Rack base

Sample rack

Rack holder

2

Transport handles

4

Attaching a sample rack

1

Attaching a sample rack

Figure 31 Attaching a sample rack

56

Grip the sample rack (30-3) on the transport handles (30-4) with

both hands and set it down on the rack base (30-1).

■■■■■■■■

Page 65

■■■■■■■■■■■■■■■■■■■■■■

2

Pushing in the sample rack

Figure 32 Pushing in the sample rack

Operation and control

Push the sample rack towards the front until it is firmly seated on the

rack holder (30-2).

NOTICE

A brief acoustic signal will sound as soon as the sample rack is

seated correctly on the rack base and the rack holder.

Removing the sample rack

Grip the sample rack on the transport handles with both hands and

1

remove it towards the top.

NOTICE

A brief acoustic signal will sound as soon as the sample rack has

been removed from the rack base and the rack holder.

■■■■■■■■

57

Page 66

General maintenance

8 Maintenance

8.1 General maintenance

The products require appropriate care. Excess contamination of the products may result in functional disruptions and a reduction in the service life

of the mechanics and electronics.

Only perform maintenance work that is described in this instruction. Contact the Metrohm service for further maintenance and repairing works.

Disconnect the product from the power grid prior to any maintenance and

cleaning.

Remove spilled chemicals and solvents immediately. Protect the plug connections in particular against contamination.

NOTICE

■■■■■■■■■■■■■■■■■■■■■■

The product is protected by design measures from being penetrated

by liquids.

CAUTION

Instrument damage due to removed covers

Damage of the instrument or malfunction by removing the housing

covers.

■ Never open the housing of the instrument when the power cord is

connected.

■ There are no parts inside the housing which may be serviced or

replaced by the user, unless this is explicitly described.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electric and electronic parts.

58

■■■■■■■■

Page 67

■■■■■■■■■■■■■■■■■■■■■■

Maintenance

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the product.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the product, discon-

nect the product from the energy supply. Then notify Metrohm

Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

WARNING

Risk of injury due to lack of safety shield

Risk of injury when working without mounted safety shields.

■ Never operate instruments without safety shields.

■ Before beginning work, make sure that all the safety shields are

mounted correctly and are operational.

8.2 Maintenance agreement

Maintenance of the product is best carried out as part of an annual service

performed by specialist personnel from Metrohm. Shorter maintenance

intervals may be necessary if you frequently work with caustic and corrosive chemicals.

Metrohm Service offers every form of technical advice for maintenance

and service of all Metrohm products.

■■■■■■■■

59

Page 68

Cleaning the product

8.3 Cleaning the product

WARNING

Danger of poisoning and chemical burns from chemical hazardous substances

Poisoning and/or chemical burns by contact with aggressive chemical

substances.

■ Use only detergents that do not cause any unwanted side reac-

tions with the materials to be cleaned.

■ Clean contaminated surfaces.

■ Wear protective equipment.

■ Use exhaust equipment when working with vaporizing hazardous

substances.

■ Dispose of chemically contaminated materials (e.g. cleaning mate-

rial) properly.

■■■■■■■■■■■■■■■■■■■■■■

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the product.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the product, discon-

nect the product from the energy supply. Then notify Metrohm

Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

Cleaning the surfaces of the product

Prerequisites

■ The product is disconnected from the power grid.

Clean the surfaces with a damp cloth.

1

60

■■■■■■■■

Page 69

■■■■■■■■■■■■■■■■■■■■■■

Maintenance

NOTICE

If the suspicion arises that liquids have found their way into the

product, disconnect the product from the power grid and contact your Metrohm Service.

NOTICE

Water or ethanol can be used as a cleaning medium.

NOTICE

The connectors at the rear of the product must only be cleaned

with a dry cloth.

8.3.1 Cleaning the Pick&Place module

WARNING

Harmful or irritant materials

There is an increased risk of injury through contact with chemical or

biological materials while cleaning the instrument.

■ Use detergents that do not cause any unwanted reactions with the

materials to be cleaned.

■ Always wear personal protective equipment when cleaning the

instrument.

Cleaning the surfaces of the Pick&Place module

Prerequisites

■ The instrument is disconnected from the power grid.

Remove dust and dirt from the Pick&Place module surface with a

1

damp cloth.

■■■■■■■■

61

Page 70

Cleaning the product

■■■■■■■■■■■■■■■■■■■■■■

NOTICE

The safety shield has the designations "LOCK" for closed and

"UNLOCK" for open.

Figure 33 Cleaning the safety shield

Safety shield

1

Markings "LOCK" and "UNLOCK"

3

Cleaning the safety shield

Prerequisites

Titration head holder

2

62

■■■■■■■■

Page 71

■■■■■■■■■■■■■■■■■■■■■■

■ The instrument is disconnected from the power grid.

1

Dismantling the safety shield

Maintenance

Figure 34 Dismantling the safety shield

■ Grip the safety shield (33-1) with one hand and rotate it counter-

clockwise until the marking points to "UNLOCK" (33-3).

■ Remove the safety shield downwards out of the titration head

holder (33-2).

2

Cleaning the safety shield

Remove dust and dirt from the safety shield with a damp cloth.

■■■■■■■■

63

Page 72

Cleaning the product

3

Inserting the safety shield

■■■■■■■■■■■■■■■■■■■■■■

Figure 35 Inserting the safety shield

Insert the safety shield from the bottom into the titration head

holder.

4

Fastening the safety shield

64

Figure 36 Fastening the safety shield

Rotate the safety shield clockwise until the marking points to

"LOCK".

■■■■■■■■

Page 73

■■■■■■■■■■■■■■■■■■■■■■

Maintenance

Figure 37 Cleaning the slide and collection tray

Slide

1

Collection tray

2

Cleaning the slide and collection tray

Prerequisites

■ The instrument is disconnected from the power grid.

1

Removing the slide

Figure 38 Removing the slide

Remove the slide (37-1) by hand upwards out of the collection tray

(37-2).

■■■■■■■■

65

Page 74

Cleaning the product

■■■■■■■■■■■■■■■■■■■■■■

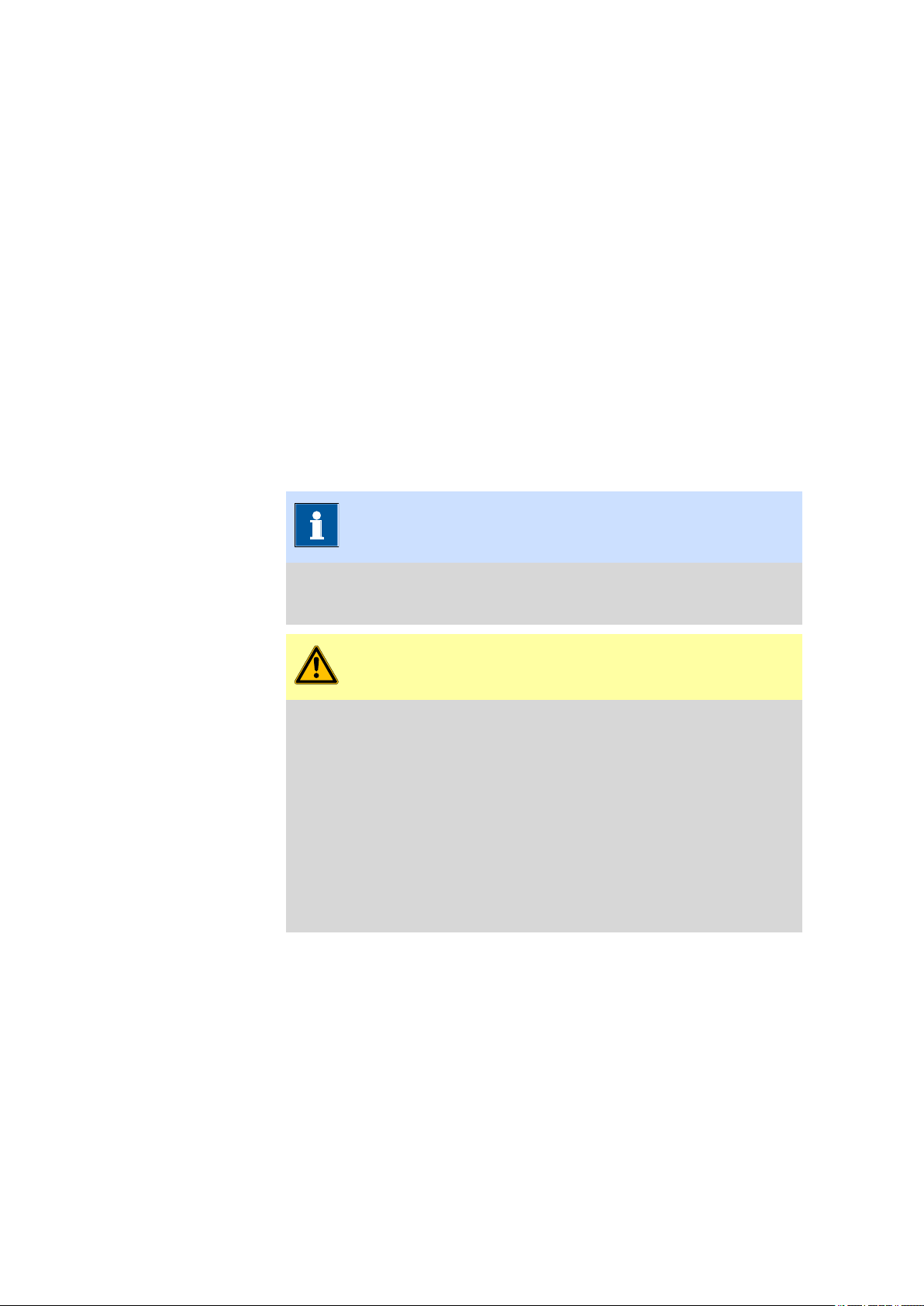

NOTICE

The slide is fastened to the guide rails of the Pick&Place module

with four magnets.

2

Cleaning the slide

NOTICE

Clean carefully as the electronic board is open.

Remove dust and dirt from the slide with a damp cloth.

3

Cleaning the base plate

Remove dust and dirt from the base plate with a damp cloth.

NOTICE

If a magnetic stirrer is integrated in the Pick&Place module, skip

it during cleaning.

4

Attaching the slide.

66

Figure 39 Attaching the slide

■■■■■■■■

Page 75

■■■■■■■■■■■■■■■■■■■■■■

Attach the slide from above onto the collection tray.

NOTICE

Water or ethanol can be used as a cleaning medium.

8.4 Checking and replacing product parts

To guarantee the flawless functioning and operation of the products as

well as of their functional units, all parts must be regularly checked and

replaced if needed.

NOTICE

The following points must always be observed:

Maintenance

■ The product is switched off.

■ The product is disconnected from the power grid.

In the following paragraphs you will find an explanation of how the product parts can be checked individually and what has to be taken into

account. The procedure for replacing the parts is then described step-bystep where necessary.

WARNING

Electric shock from electrical potential

Risk of injury by touching live components or through moisture on

live parts.

■ Never open the housing of the product.

■ Protect live parts (e.g. power supply unit, power cord, connection

sockets) against moisture.

■ If you suspect that moisture has gotten into the product, discon-

nect the product from the energy supply. Then notify Metrohm

Service.

■ Only personnel who have been issued Metrohm qualification may

perform service and repair work on electrical and electronic components.

■■■■■■■■

67

Page 76

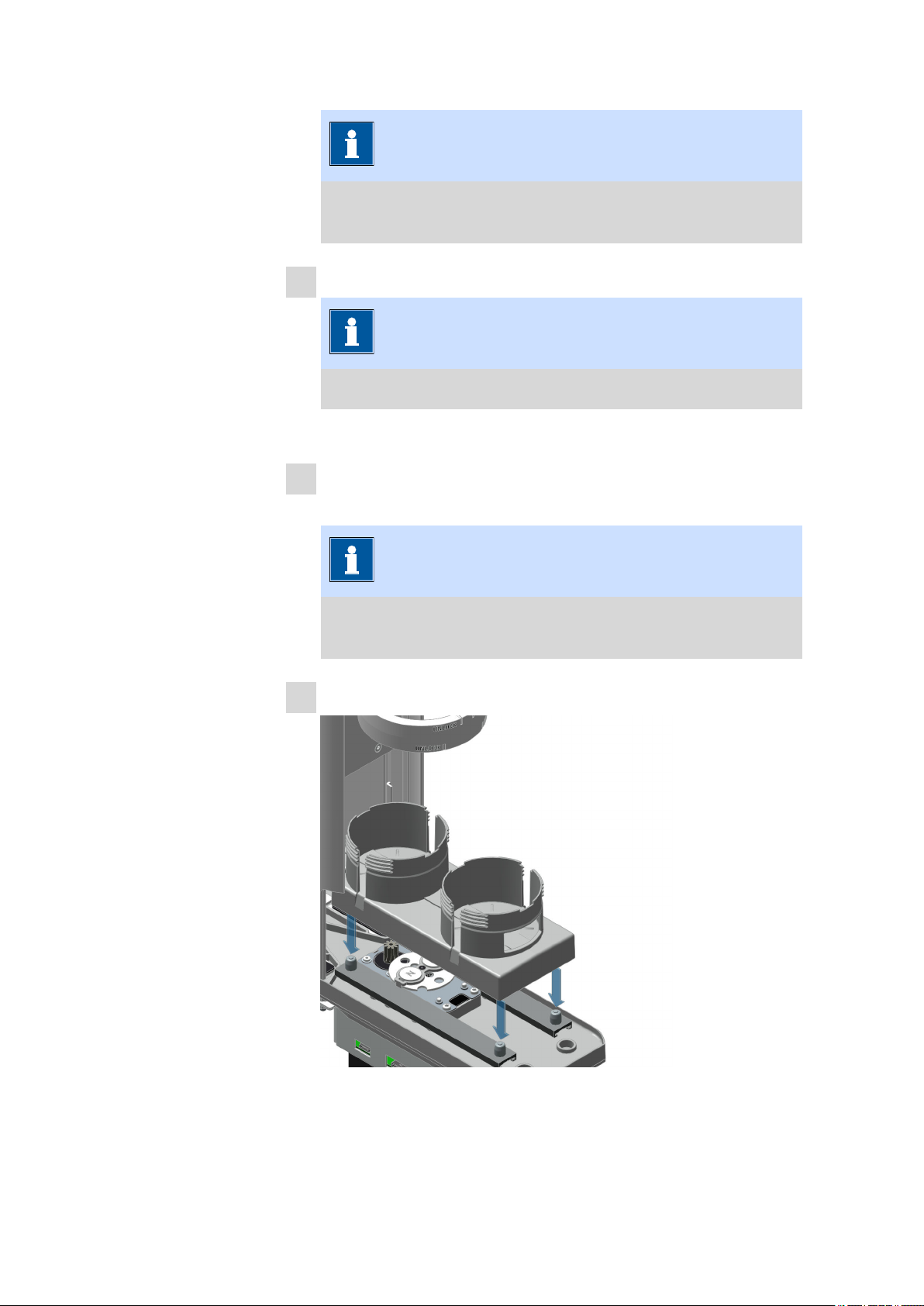

Checking and replacing product parts

8.4.1 Replacing the finger tip and PTFE sleeve

Figure 40 Replacing the finger tip and PTFE sleeve

■■■■■■■■■■■■■■■■■■■■■■

1

3

5

Gripper

PTFE sleeve

Retainer

Gripper finger

2

Finger tip

4

Dismantling the finger tip and PTFE sleeve

Prerequisites

■ The sample robot is switched off.

■ There is no beaker in the gripper.

NOTICE

If you are using a gripper with retainer (40-5), lift the retainer off the

gripper beforehand.

Clasp the gripper (40-1) from above with one hand and hold it firmly.

1

Use the other hand to pull the finger tip (40-4) downwards and off

2

the gripper finger (40-2) by applying gentle rotating movements.

Stretch the PTFE sleeve (40-3) and pull it off downwards.

3

68

■■■■■■■■

Page 77

■■■■■■■■■■■■■■■■■■■■■■

NOTICE

A slot to facilitate assembly and disassembly is located in the

PTFE sleeve. The PTFE sleeve can be stretched over this slot, e.g.,

with a small screwdriver or fingernail, and then subsequently

removed via the lower section on the gripper finger.

Mounting the finger tip and PTFE sleeve

Prerequisites

■ The sample robot is switched off.

■ The PTFE sleeve and the finger tip are dismounted.

Clasp the gripper from above with one hand and hold it firmly.

1

Stretch the PTFE sleeve and slide it onto the gripper finger from

2

below.

Maintenance

NOTICE

A slot to facilitate assembly and disassembly is located in the

PTFE sleeve. The PTFE sleeve can be stretched over this slot, e.g.,

with a small screwdriver or fingernail, and then subsequently

pushed over the lower section on the gripper finger.

Using gentle rotating movements, slide the finger tip onto the PTFE

3

sleeve from below.

Make sure that the finger tip is firmly seated on the gripper finger

4

and that it can still be rotated.

Place the retainer (40-5), if applicable, back onto the gripper with

5

retainer.

CAUTION

The gripper with retainer must always me operated with the retainer!

This ensures that the beakers are always gripped correctly.

■■■■■■■■

69

Page 78

Checking and replacing product parts

8.4.2 Replacing the beaker adapter

■■■■■■■■■■■■■■■■■■■■■■

Slide

1

Beaker adapter

3

Figure 41 Replacing the beaker adapter

Ring

2

Table 9 Available beaker adapters and settings

Beaker volume

Beaker diameter

Beaker height Article num-

ber

75 mL 35.5 mm 113 mm 6.01404.040