Page 1

NIRS

XDS MultiVial Analyzer

Manual

8.921.8002EN / 2013-12-19

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

NIRS

XDS MultiVial Analyzer

Manual

8.921.8002EN / 2013-12-19 fpe

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please send us your comments using the

address given above.

Page 5

▪▪▪▪▪▪▪

Table of contents

1 Introduction ................................................................................................................... 5

2 Site Readiness ................................................................................................................ 8

2.1 Temperature and Humidity ........................................................................... 8

2.2 General Environment .................................................................................... 8

2.3 Vibration ....................................................................................................... 8

2.4 Electrical Power ............................................................................................ 8

2.5 Instrument Communication .......................................................................... 8

2.6 Instrument Dimensions and Weight .............................................................. 9

3 XDS Instrument Connection ......................................................................................... 10

3.1 Network Connection, connected to an active network port as shown ........ 10

3.2 Direct Connection, in a free-standing manner with no network connection

11

3.3 Overview of XDS Instrument Communication ............................................. 11

3.4 Flowchart Diagram of XDS communication protocol .................................. 12

3.4.1 Microsoft Windows Firewalls ................................................................................ 13

3.4.2 Network Evolution Issues ...................................................................................... 13

3.4.3 Quick Glossary of Terms: ....................................................................................... 13

3.5 Connection in Vision ................................................................................... 14

3.6 Troubleshooting Connection Problems ....................................................... 15

3.6.1 Network Troubleshooting Overview ...................................................................... 16

3.6.2 Direct Connection Troubleshooting Overview ........................................................ 20

4 Assembly of the Instrument ......................................................................................... 22

5 XDS MultiVial Module .................................................................................................. 27

5.1 Introduction to Vial Analysis ....................................................................... 27

5.2 Creation of a Custom Vial Size .................................................................... 28

5.3 Spot Size Adjustment .................................................................................. 30

5.4 Iris Adapter ................................................................................................. 33

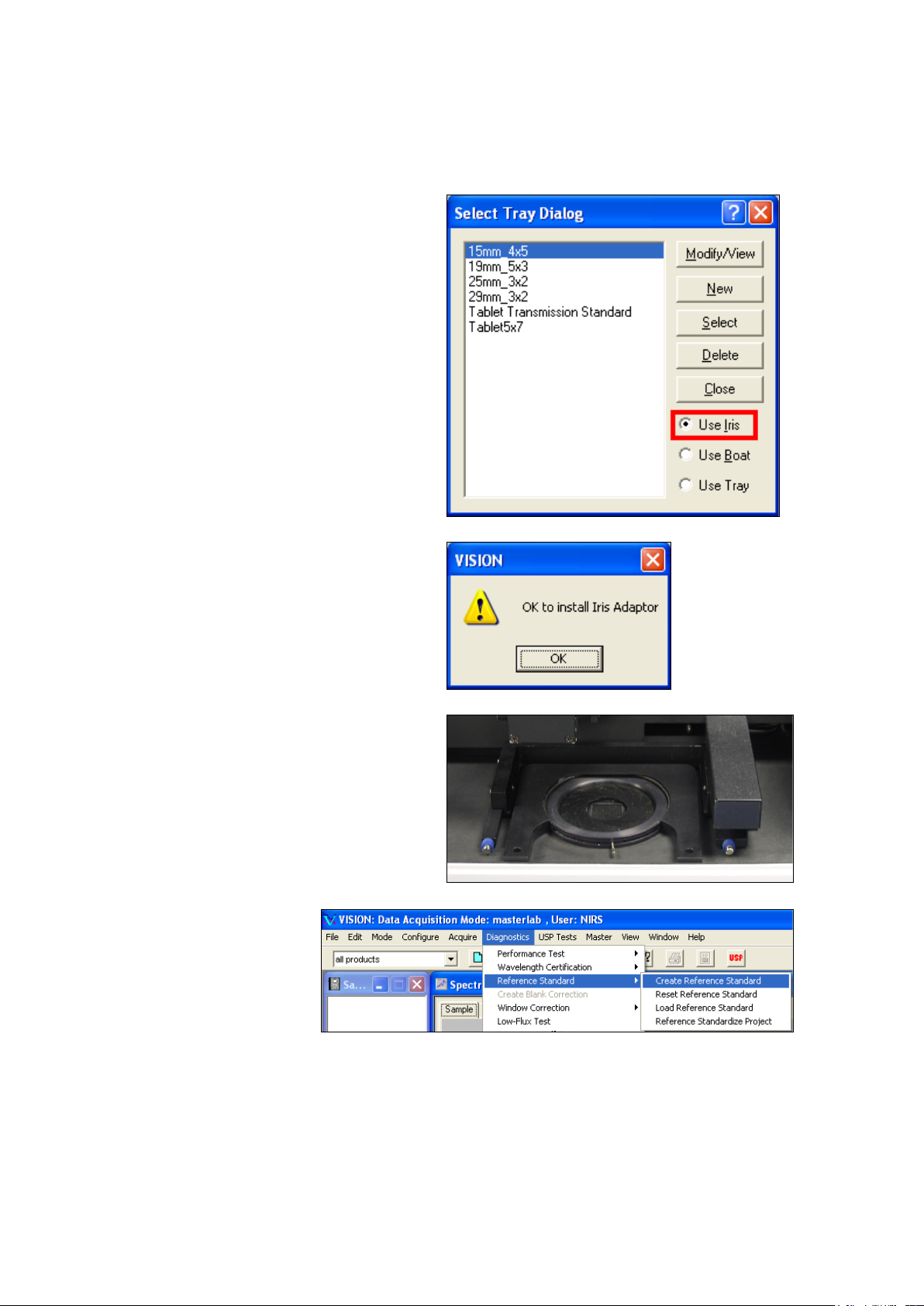

5.4.1 Installation of Iris Adapter: .................................................................................... 33

5.5 Use of the Sample Transport Mechanism .................................................... 35

5.5.1 Use of the Iris Adapter: ......................................................................................... 36

6 Vision Software: Connection to the Instrument ............................................................ 37

6.1 Entry into Vision ......................................................................................... 37

6.2 Use of Vial Dialog Selection Menu .............................................................. 43

6.2.1 Sample ID Entry .................................................................................................... 45

6.2.2 Order of Sampling ................................................................................................ 51

6.2.3 Additional Vial Dialog Functions ............................................................................ 53

7 Instrument Diagnostics................................................................................................. 57

7.1 Setup Diagnostics ....................................................................................... 57

7.1.1 Wavelength Linearization ...................................................................................... 58

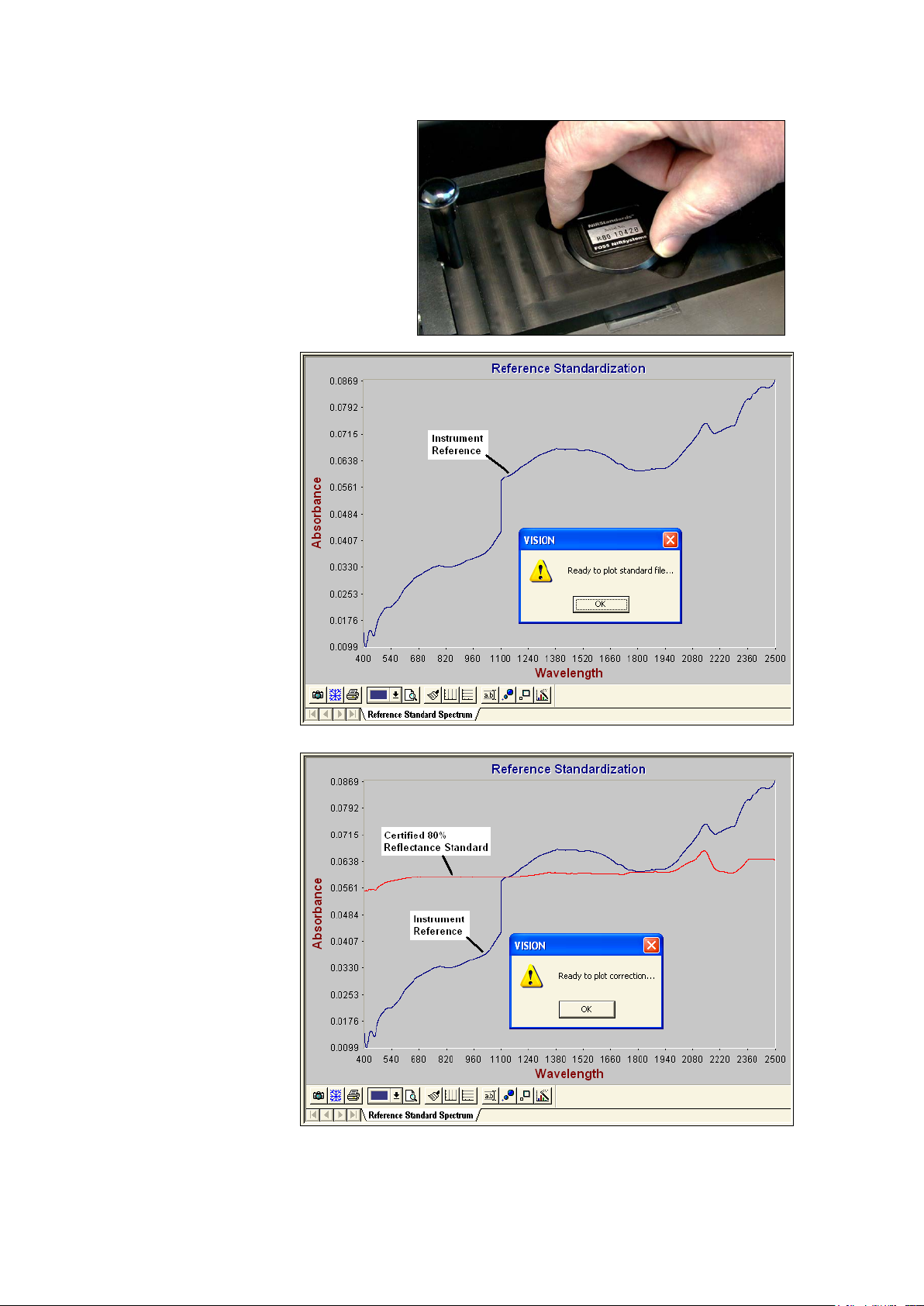

7.1.2 Reference Standardization, “Use Tray” Position ..................................................... 60

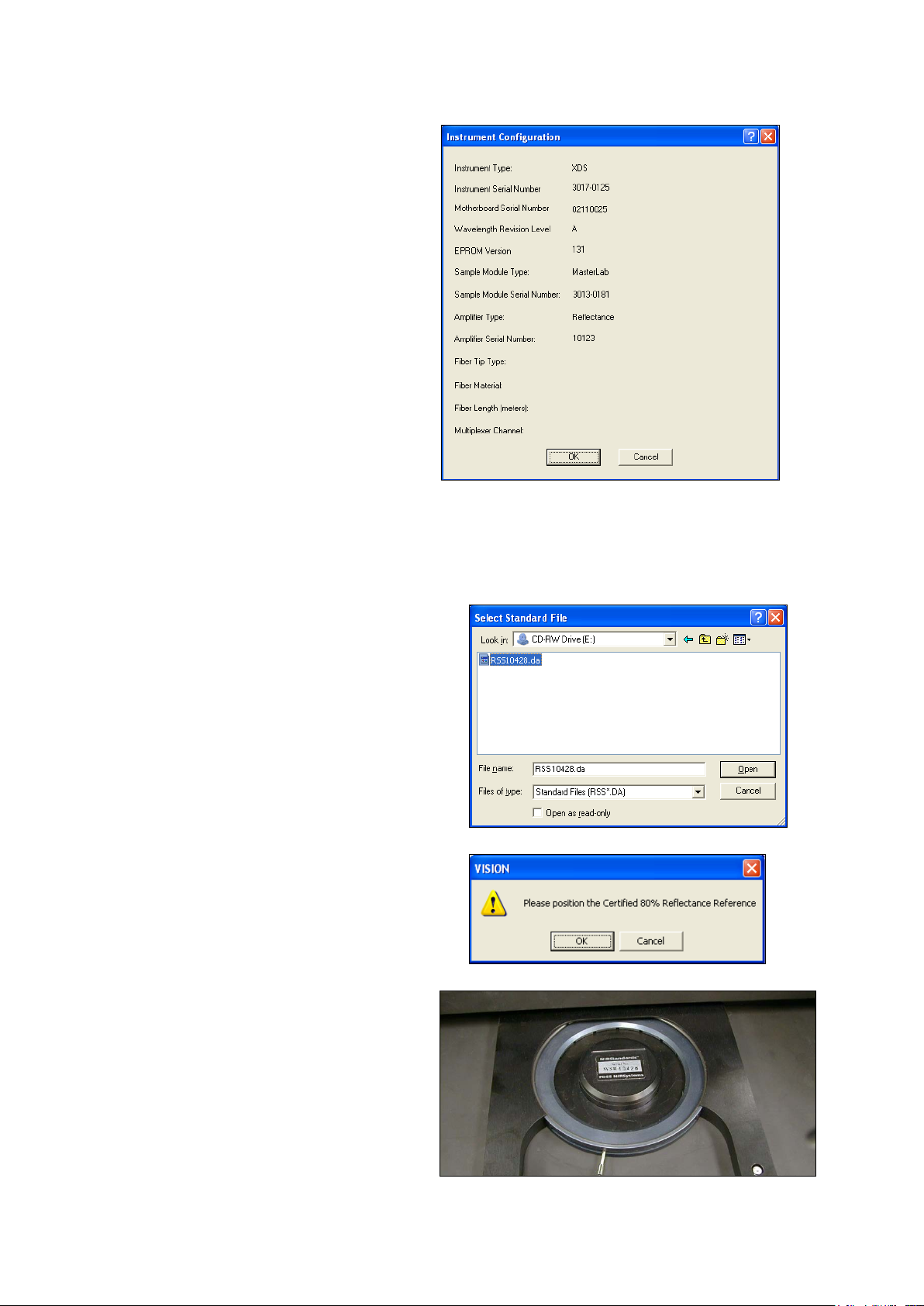

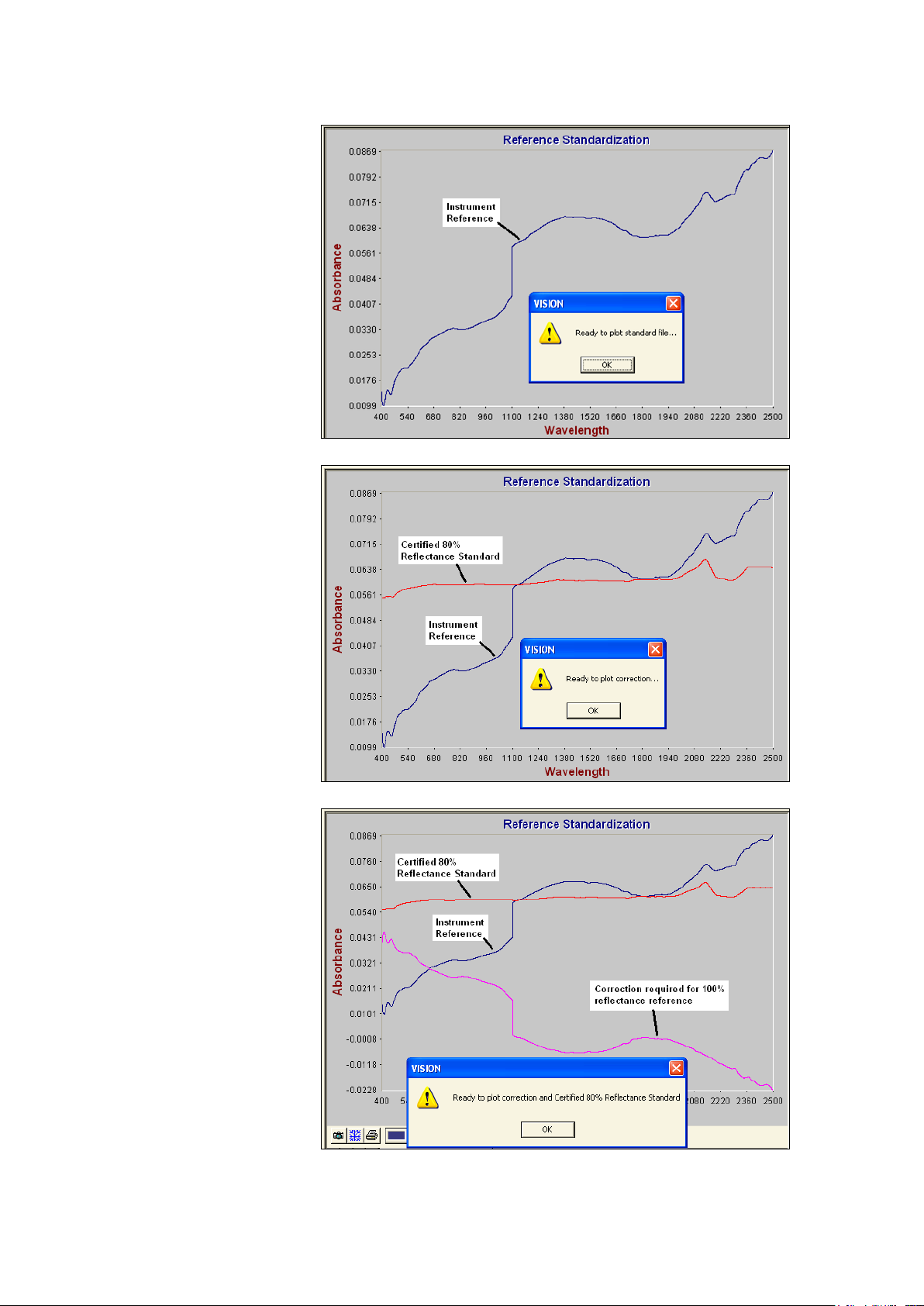

7.1.3 Reference Standardization, “Use Iris” Position ....................................................... 64

3

Page 6

▪▪▪▪▪▪▪

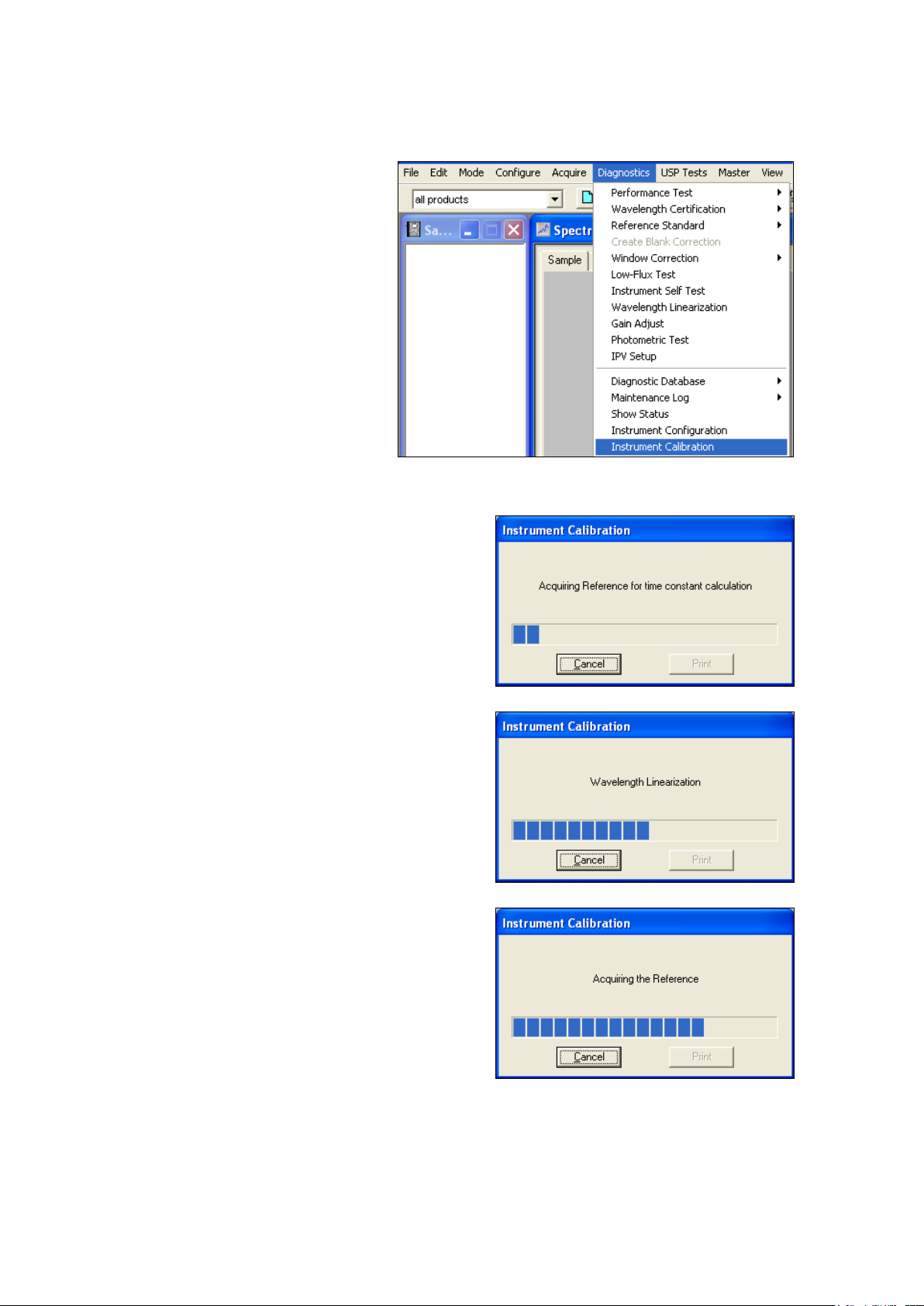

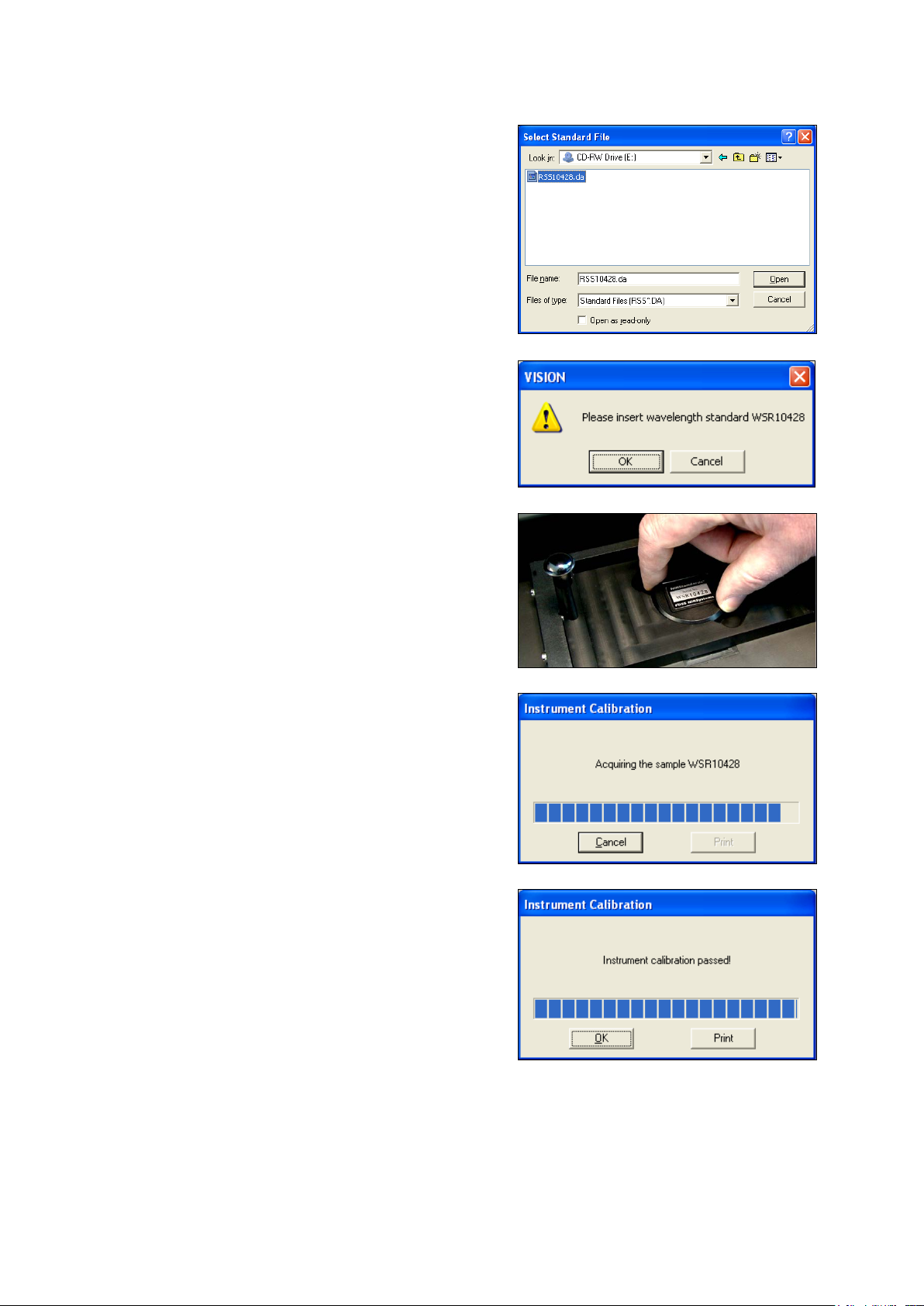

7.1.4 Instrument Calibration .......................................................................................... 68

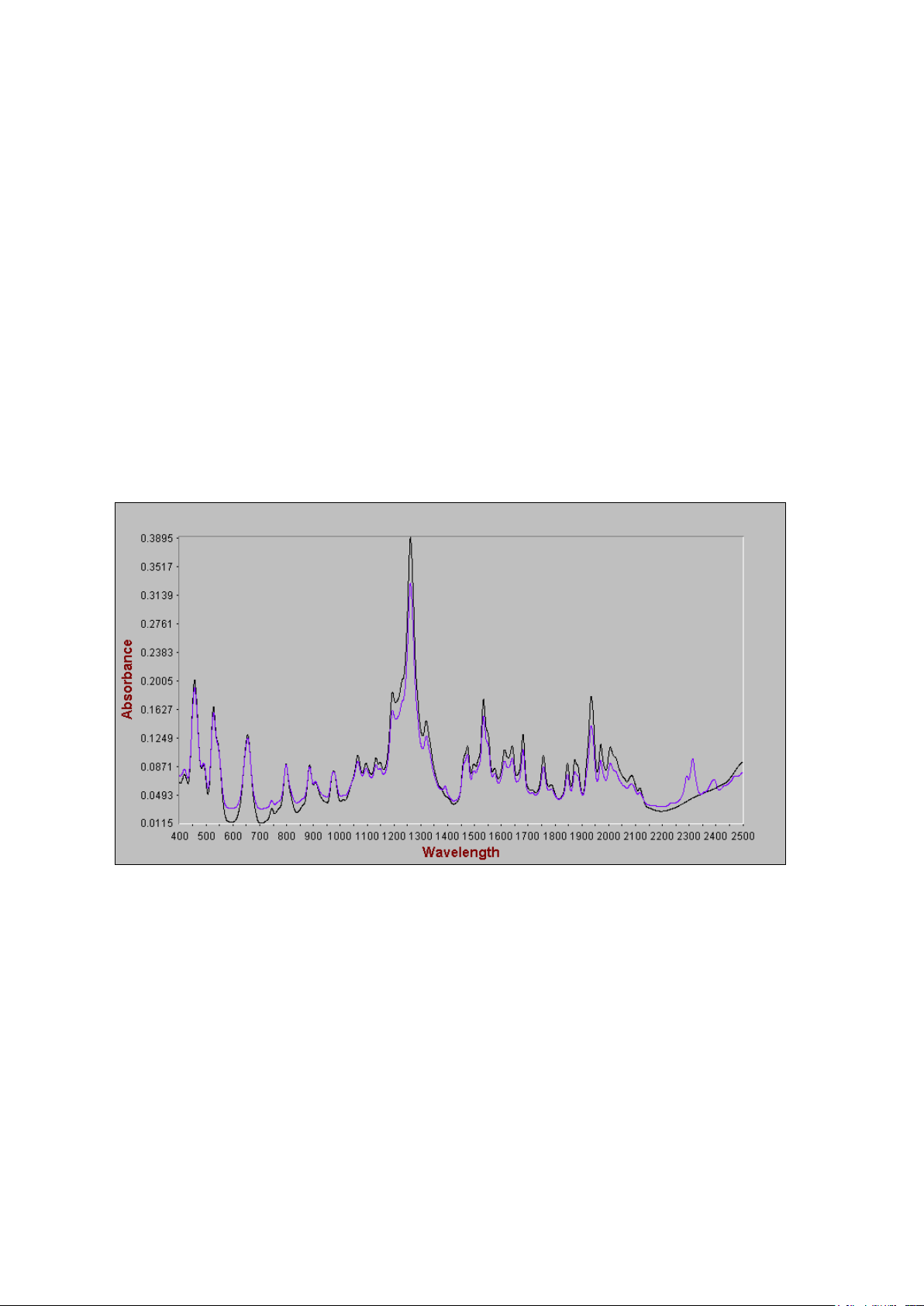

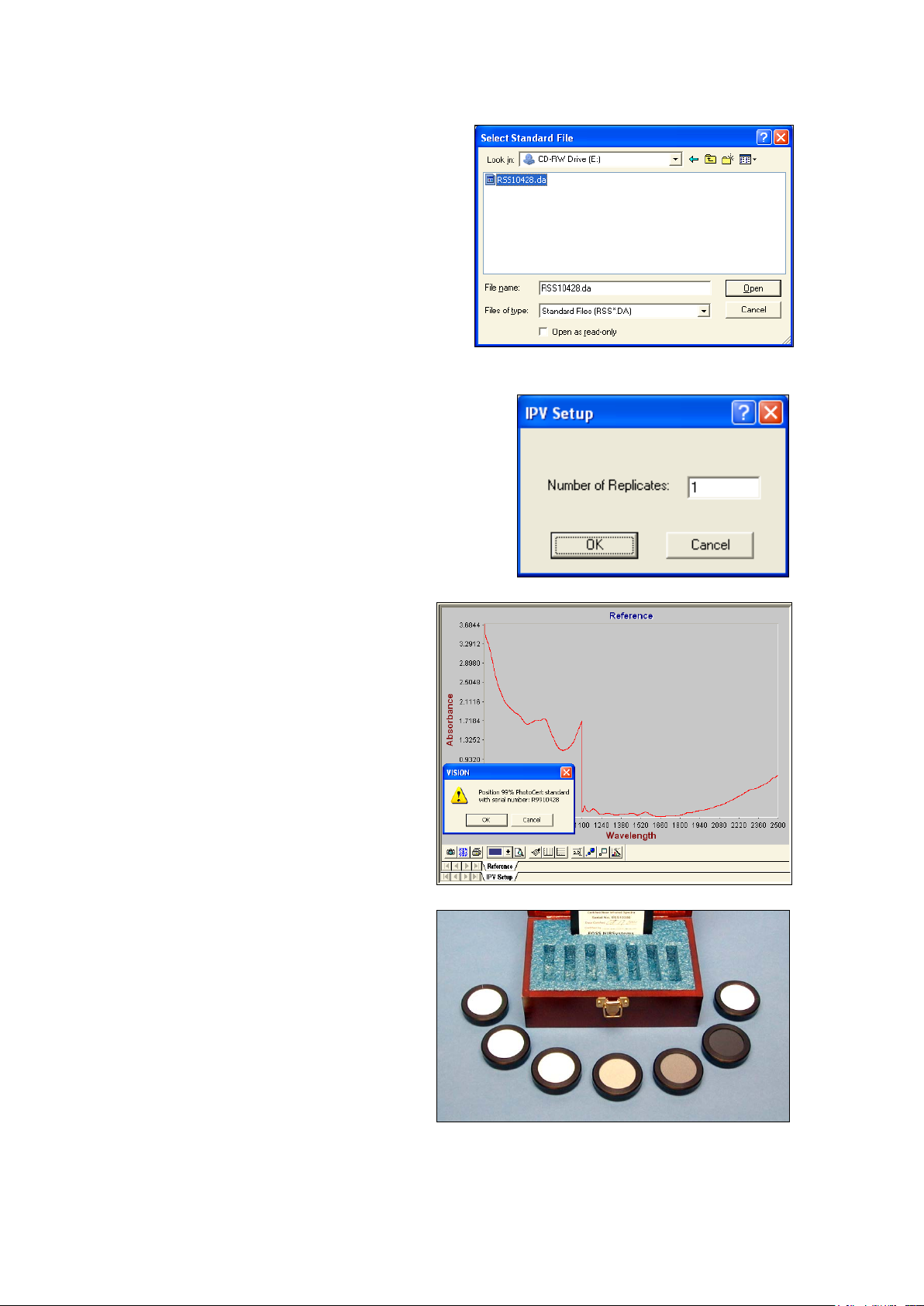

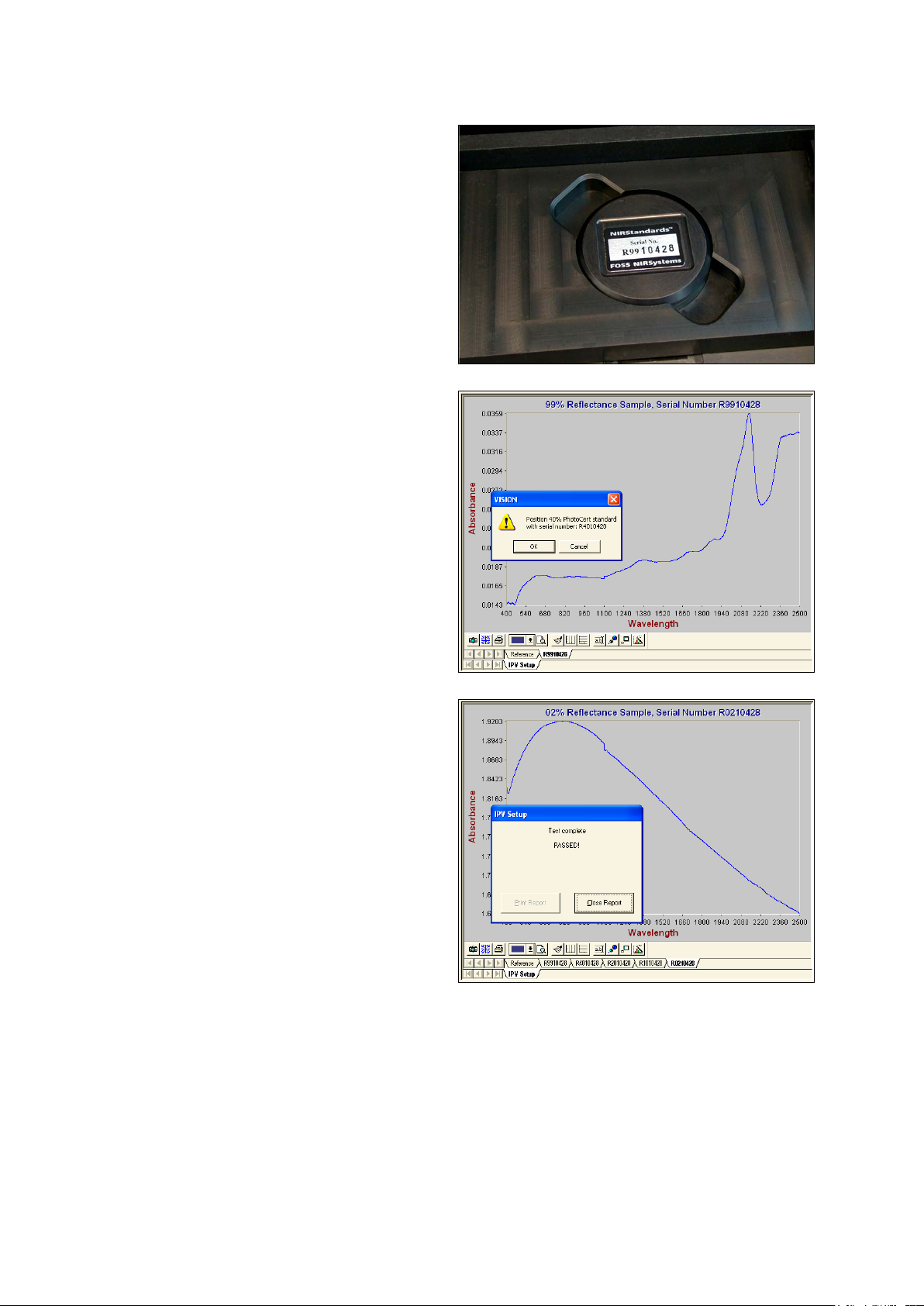

7.1.5 IPV Setup (Instrument Performance Verification) ................................................... 71

7.2 Evaluation Diagnostics ............................................................................... 73

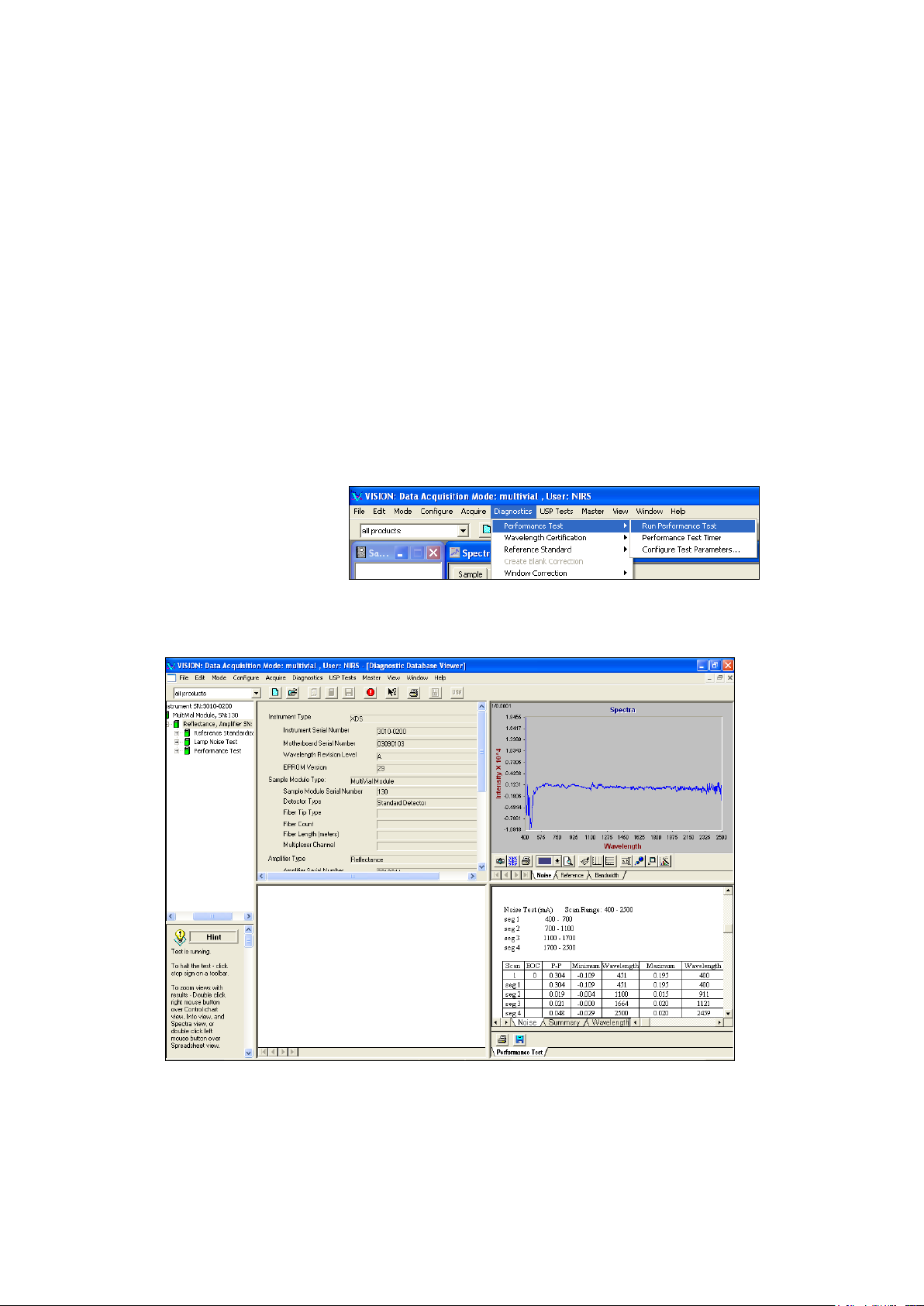

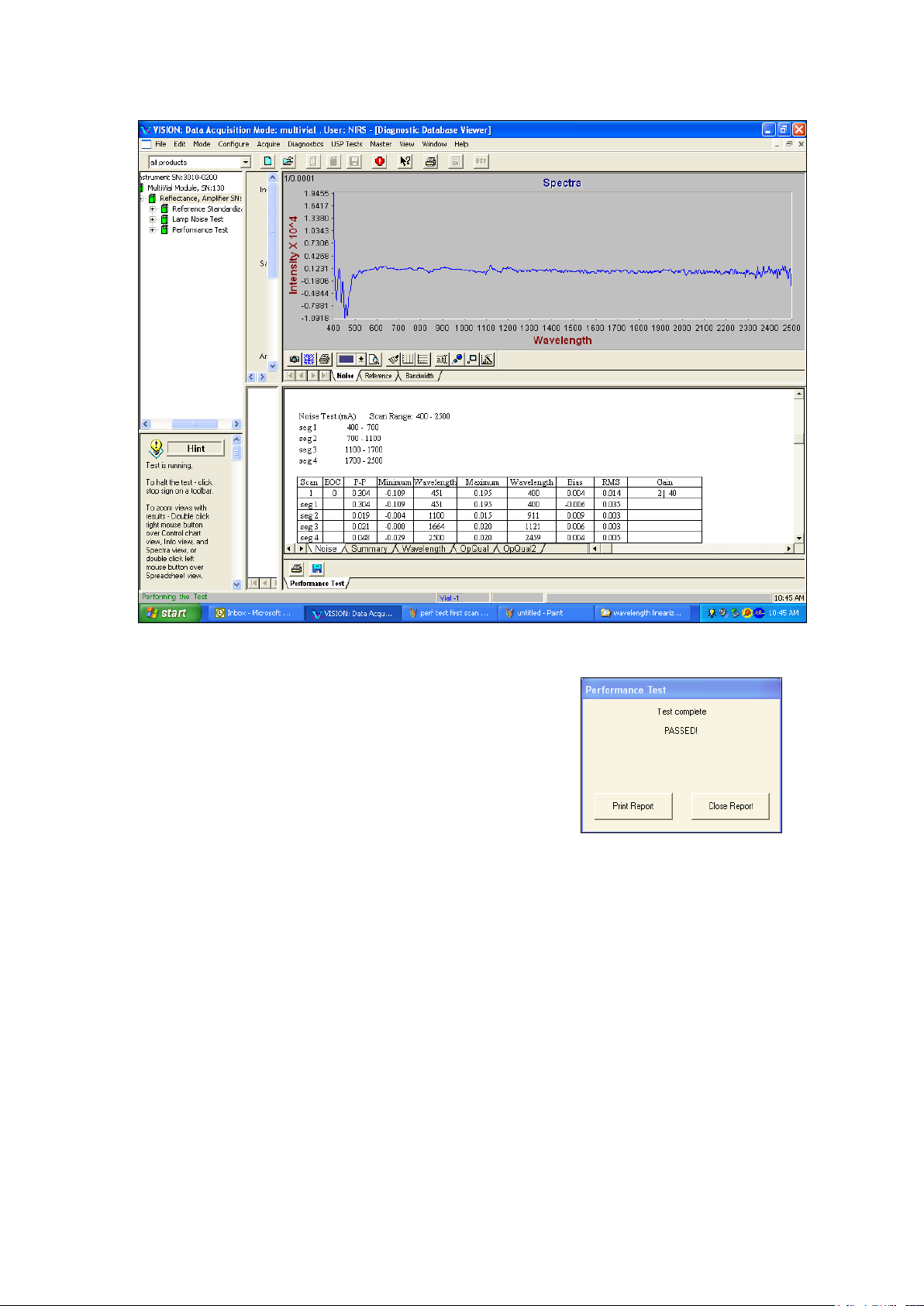

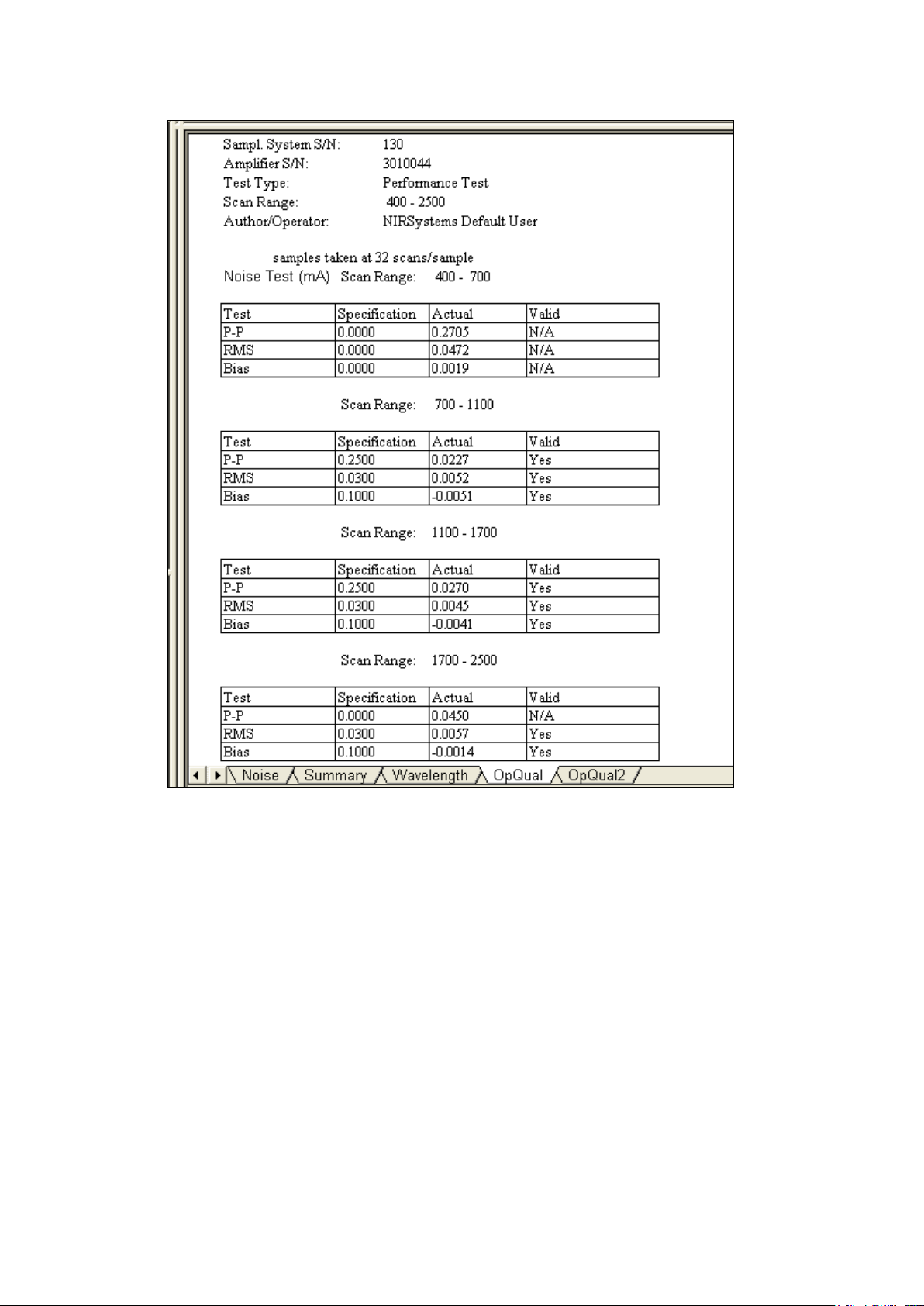

7.2.1 Performance Test ................................................................................................. 74

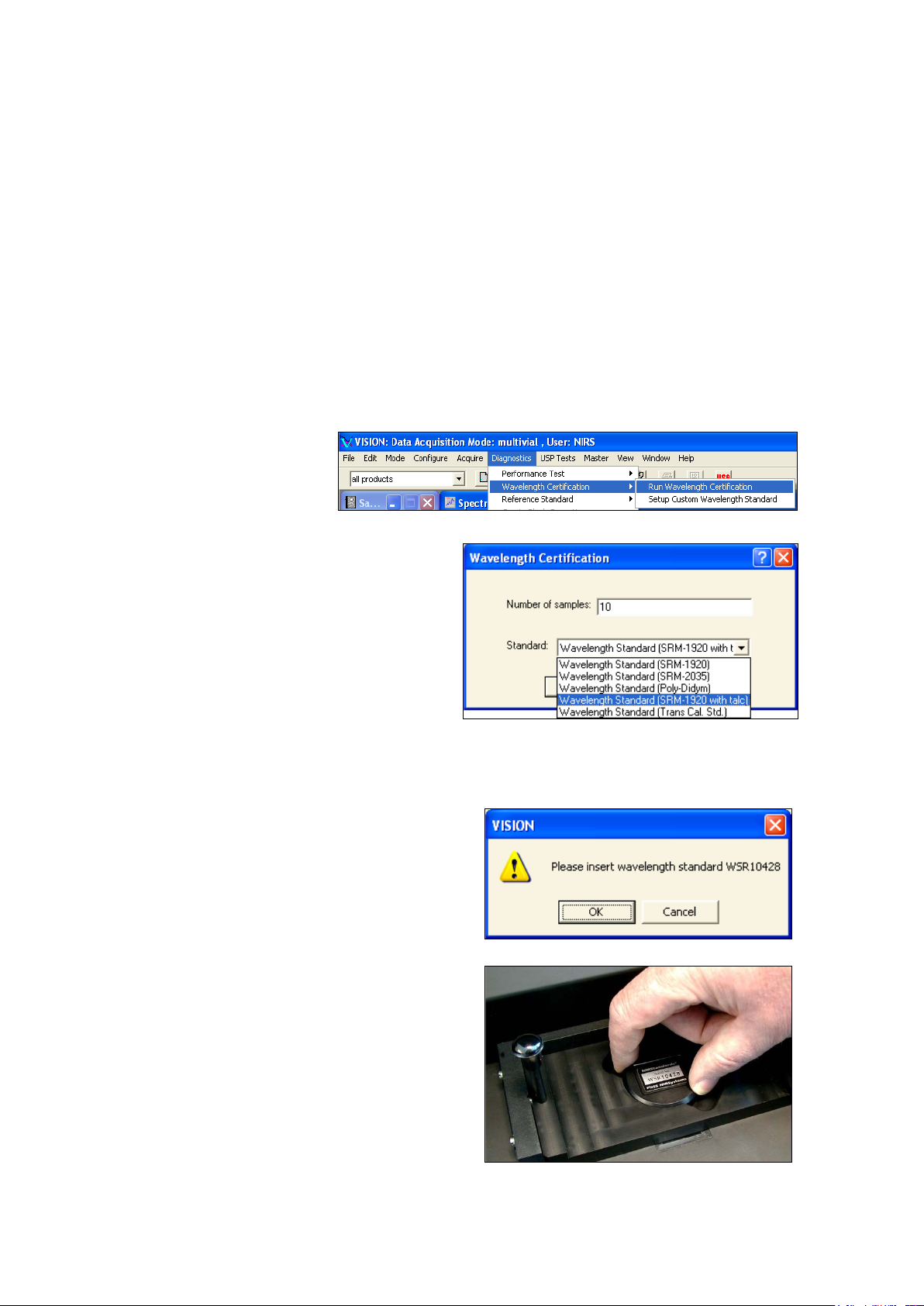

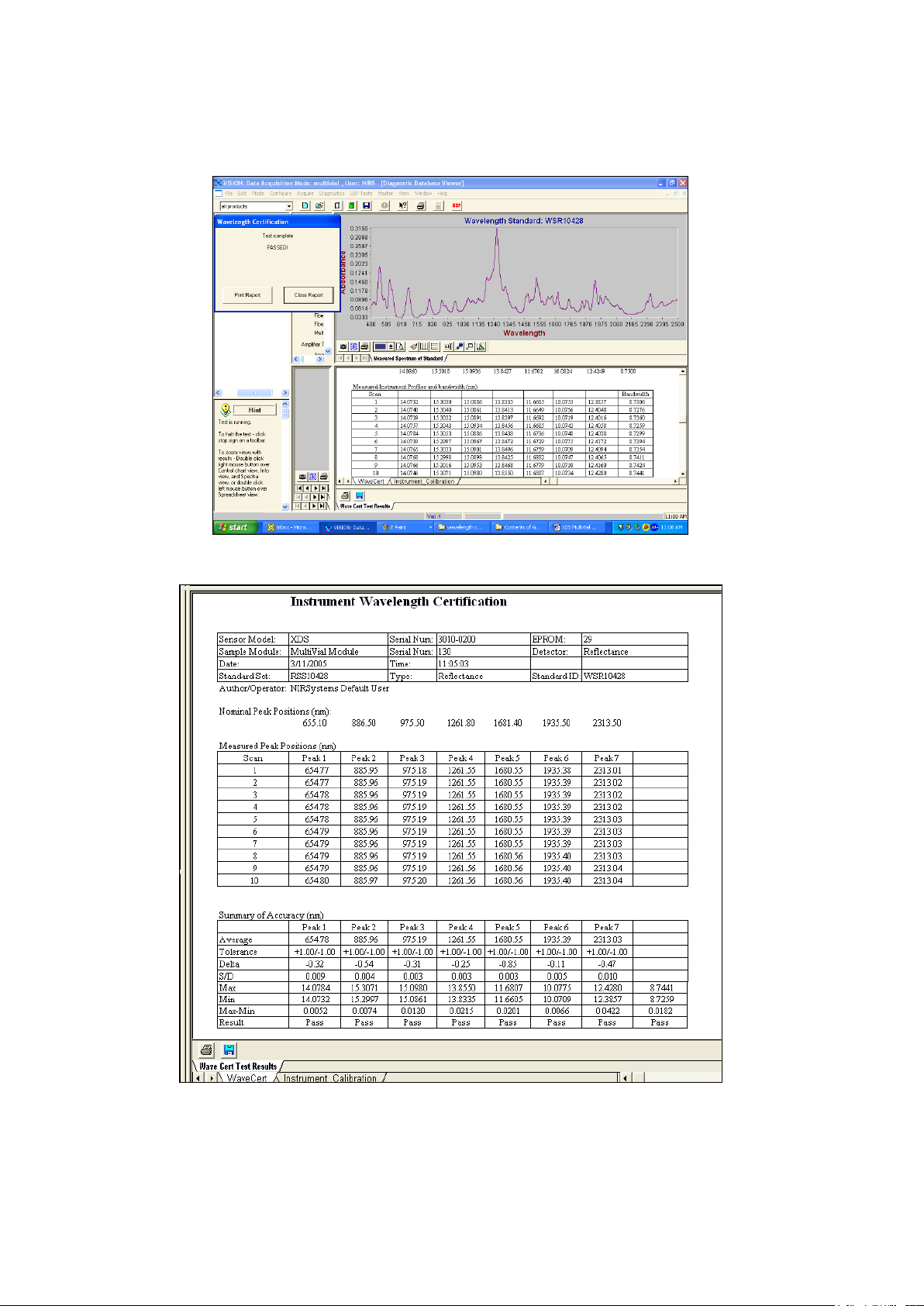

7.2.2 Wavelength Certification ...................................................................................... 77

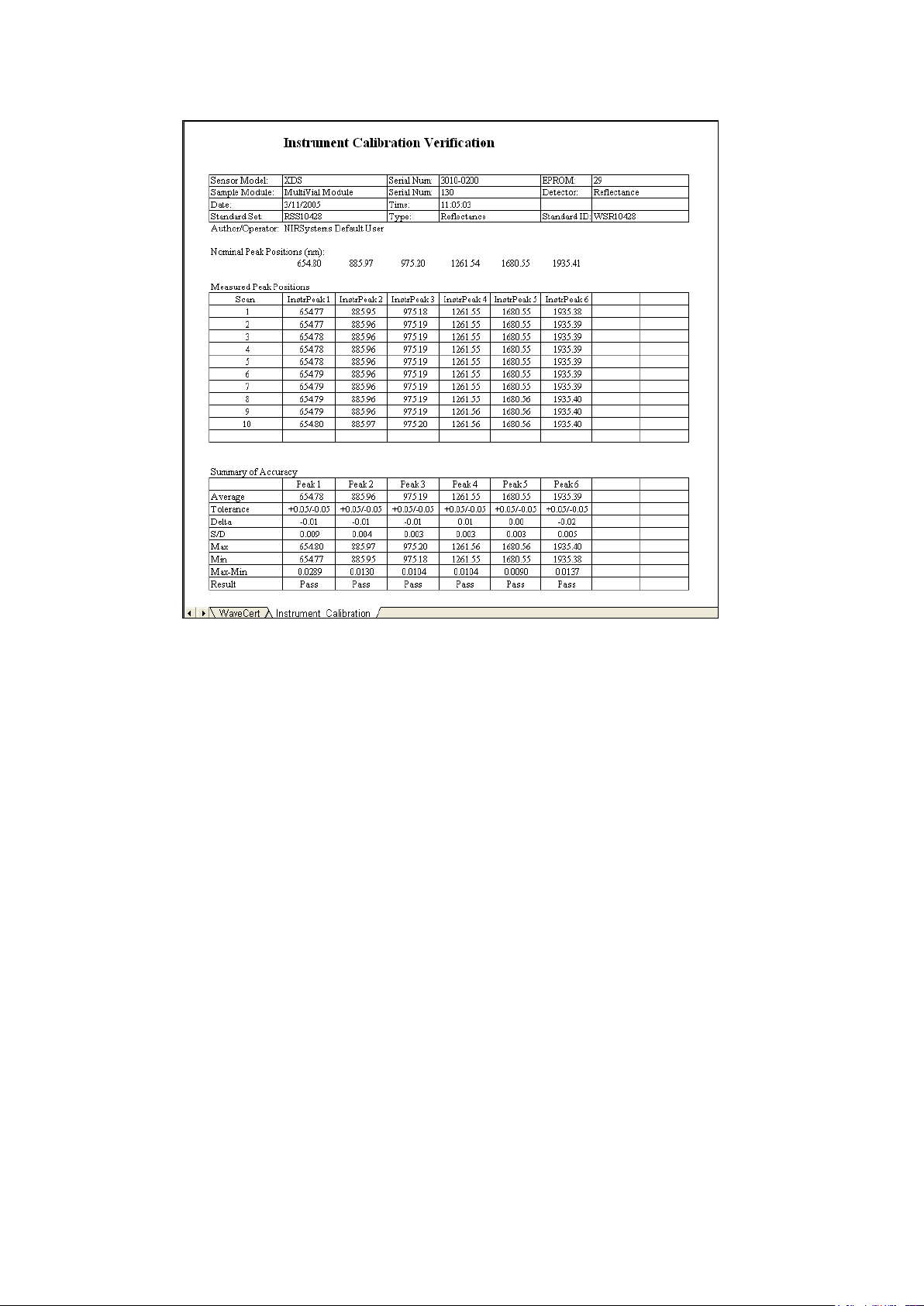

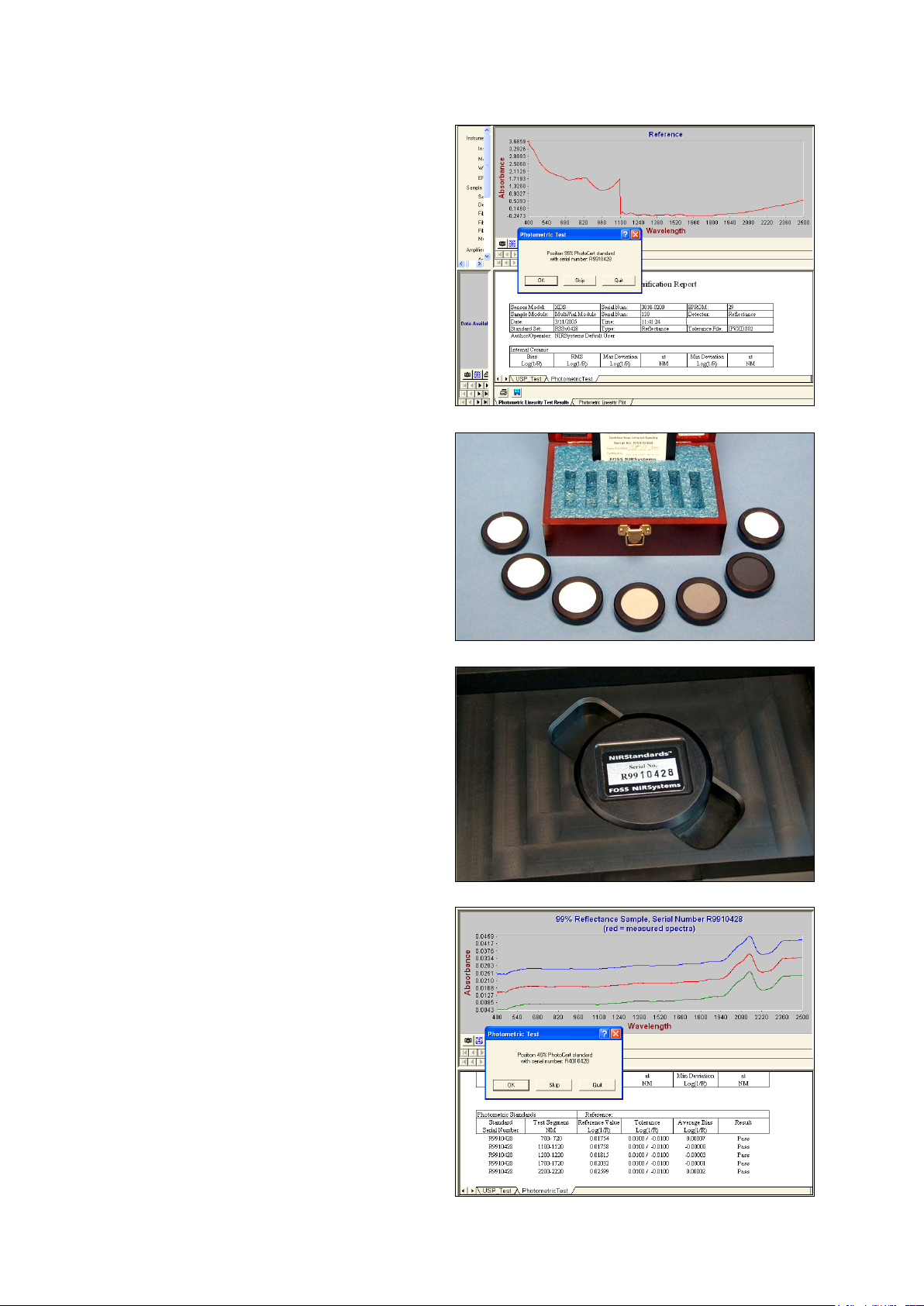

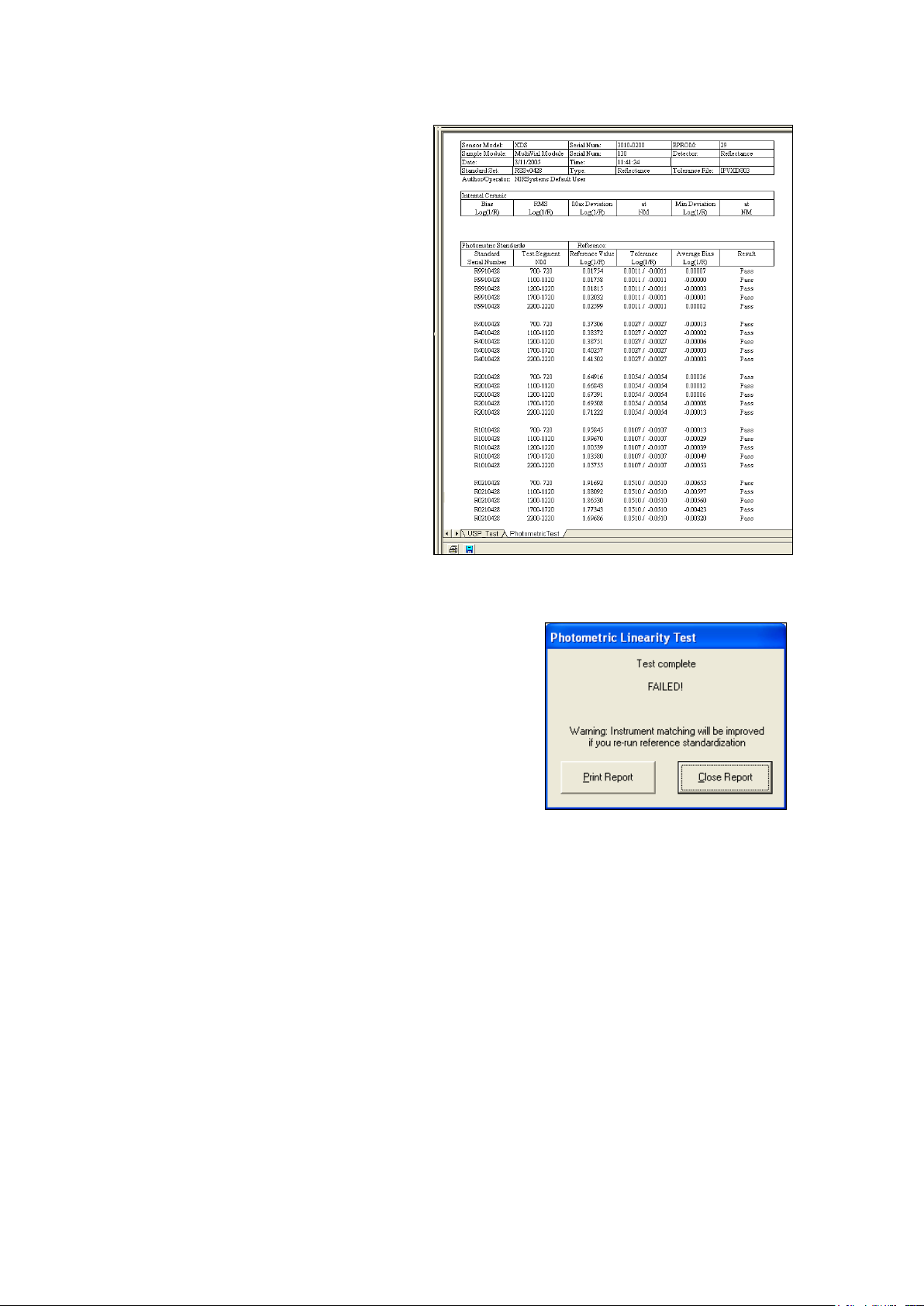

7.2.3 Photometric Test .................................................................................................. 81

7.2.4 Gain Test .............................................................................................................. 85

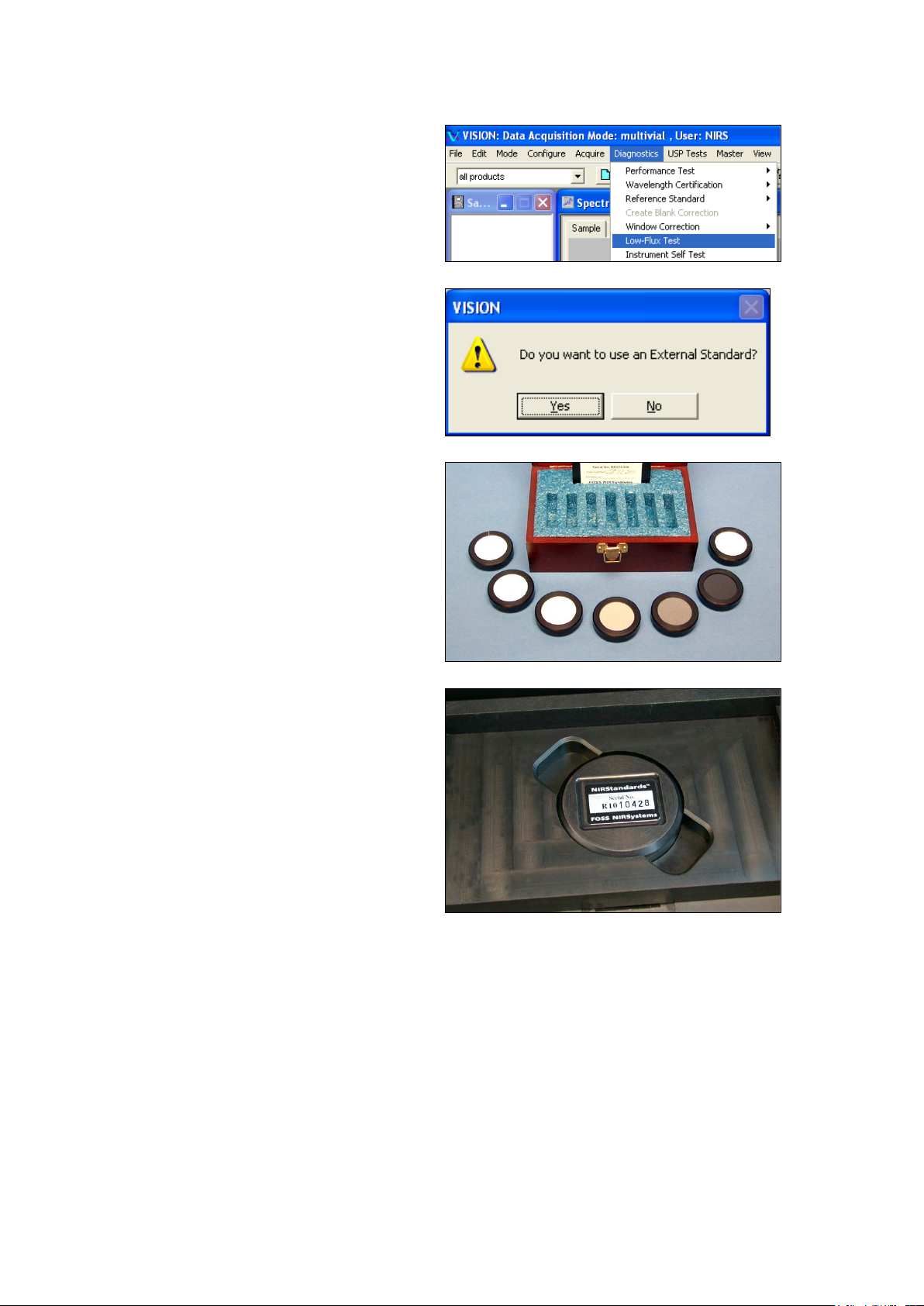

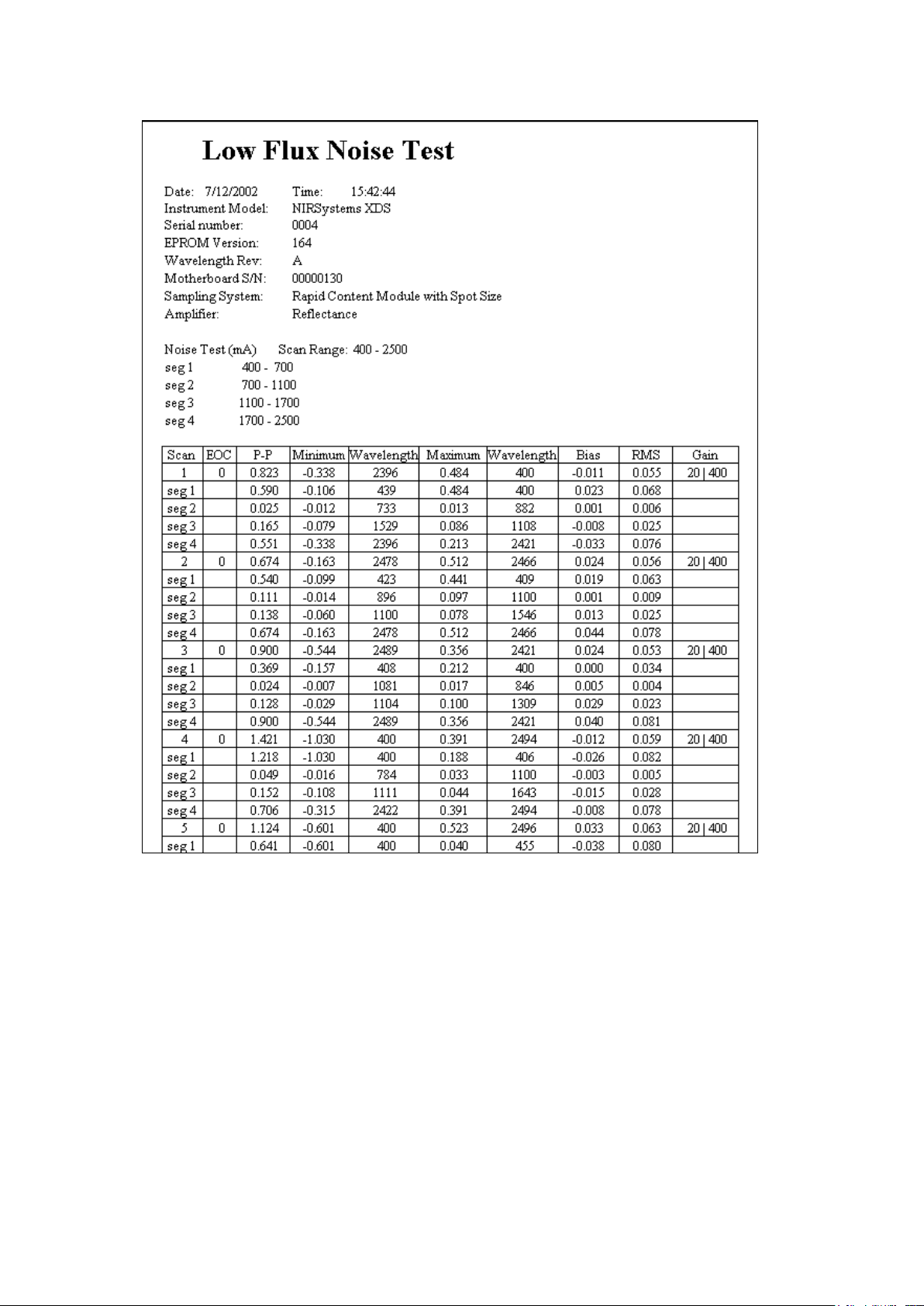

7.2.5 7.2.5 Low Flux Test .............................................................................................. 86

8 Instrument Maintenance .............................................................................................. 89

8.1 Overview .................................................................................................... 89

8.2 Fan Filter Replacement ............................................................................... 90

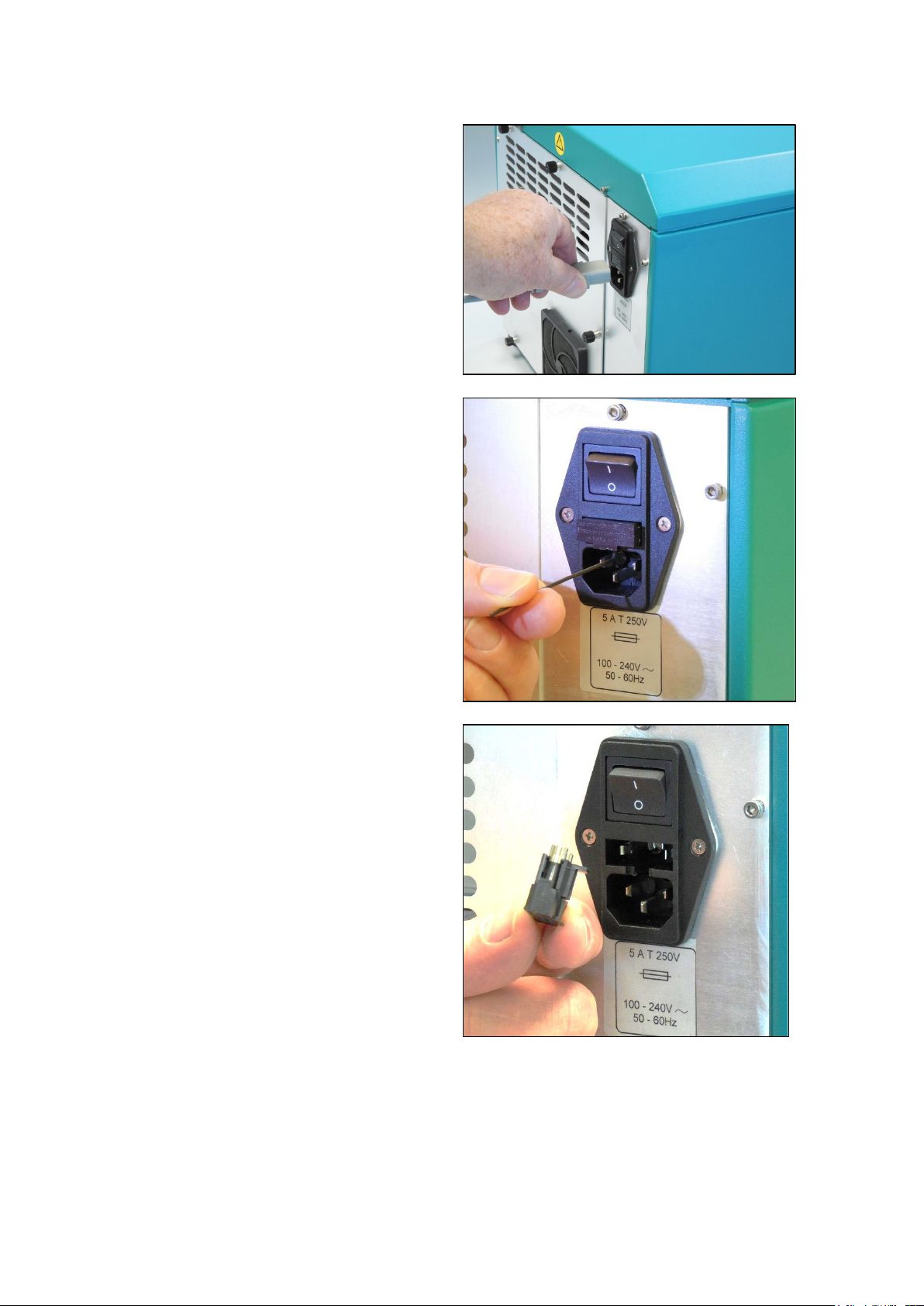

8.3 Lamp Replacement ..................................................................................... 91

8.4 Fuse Replacement ...................................................................................... 97

8.5 Maintenance Log ....................................................................................... 99

8.6 Window Cleaning ..................................................................................... 100

9 Validation Tools ......................................................................................................... 102

9.1 Hardware Validation Tools ....................................................................... 103

9.1.1 Factory Instrument Test Guide and Results .......................................................... 103

9.1.2 Installation and Operating Qualification Documents ............................................ 103

9.1.3 NIRStandards® for Instrument Performance Verification ..................................... 103

9.1.4 Instrument Performance Certification .................................................................. 103

9.1.5 Metrohm NIRSystems Master Instrument Program .............................................. 104

9.2 Software Validation Tools ........................................................................ 104

9.2.1 Installation and Operating Qualification Documents ............................................ 104

9.2.2 Vision Certificate of Validation ............................................................................ 104

9.2.3 21 CFR Part 11 Compliance ................................................................................ 105

10 Safety and Electrical Certification ............................................................. 107

11 Troubleshooting ....................................................................................... 108

12 Lifting and transporting the Metrohm instrument: .................................. 112

12.1 Instructions for MultiVial® Shipping Position........................................... 113

12.1.1 Instructions follow .............................................................................................. 113

13 Index ........................................................................................................ 115

4

Page 7

▪▪▪▪▪▪▪

1 Introduction

The versatile sampling mechanism of the MultiVial Analyzer

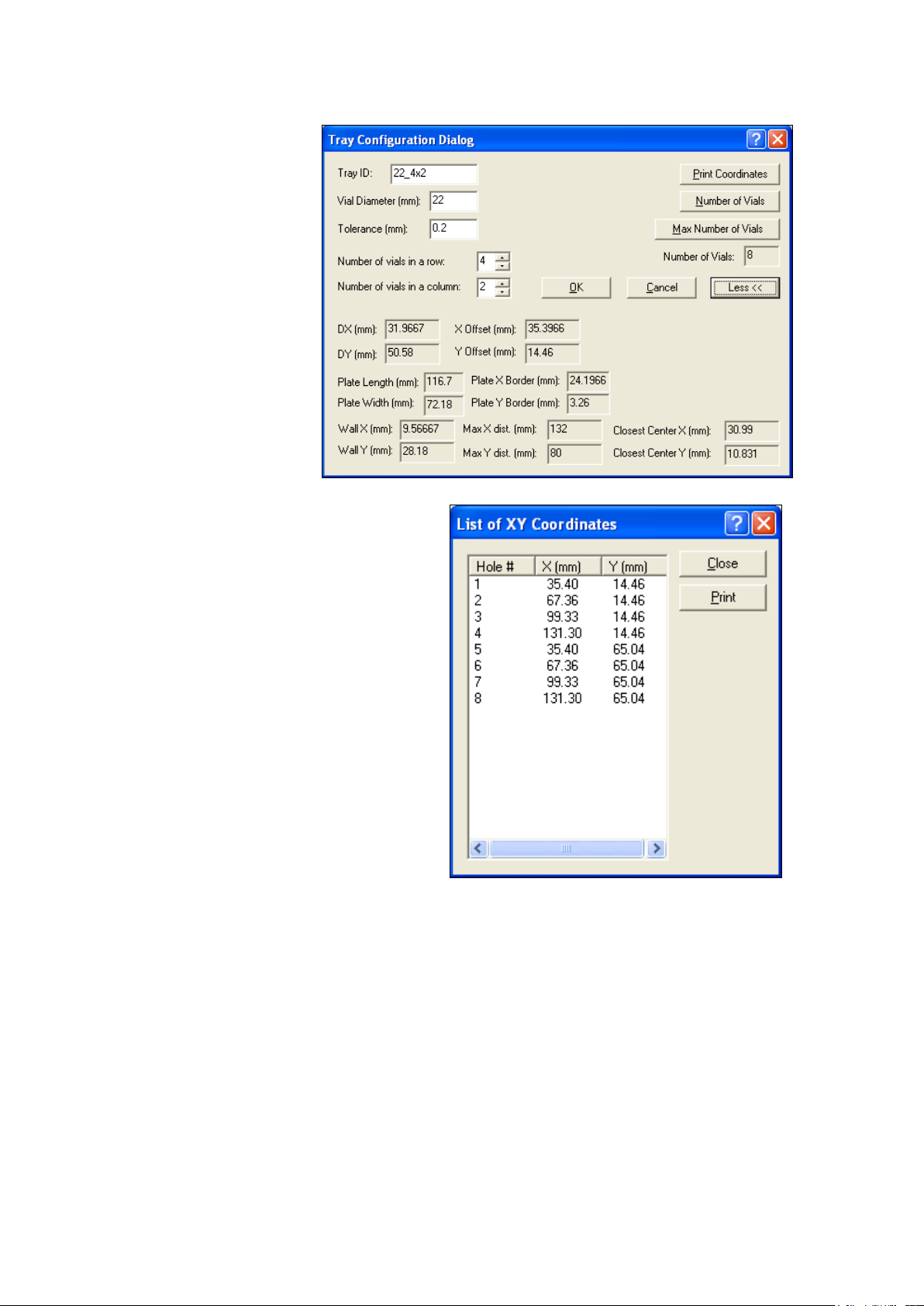

Thank you for selecting the XDS MultiVial Analyzer, manufactured by FOSS. This instrument is the

third generation in a series of instruments designed for precision NIR measurement, characterization

of organic materials, and qualification of known materials to allowable quality parameters.

The XDS MultiVial Analyzer is designed for stable operation in typical laboratory environments, while

providing the precision and accuracy users have come to expect of FOSS near-infrared (NIR)

instruments.

The MultiVial Analyzer comes with a choice of one vial tray. Others are optional.

The MultiVial Analyzer uses a proven monochromator design, employing a digitally-controlled

dispersive grating, sensitive detection devices, and state-of-the-art circuitry to enhance signal output

and minimize any extraneous noise that might influence performance. The XDS MultiVial Analyzer

uses various patented algorithms to provide superior accuracy and transferability between like

instruments. These software algorithms must be used to assure method transfer between

instruments. See section 7.1 for full details.

offers a movable sampling platform, suitable for handling

multiple vials or other samples. The software supports

acquisition of spectra in an unattended mode, freeing the

operator to prepare other samples, analyze data, or perform

unrelated tasks.

Vision supports four different default vial diameters, to

speed set-up. For custom vial diameters, set-up is

straightforward. The MultiVial Analyzer also offers variable

spot size, to focus energy on small vials.

Horizontal orientation of the sample transport mechanism facilitates loading, and prevents material

spills inside the sampling area of the instrument. The MultiVial Analyzer supports use of normal

sampling accessories for the XDS Rapid Solids Analyzer.

Sampling may be performed on two different physical levels, either directly on the sample window

(as with a normal XDS RCA) or on the vial tray, which is slightly raised from the glass. For this reason,

5

Page 8

▪▪▪▪▪▪▪

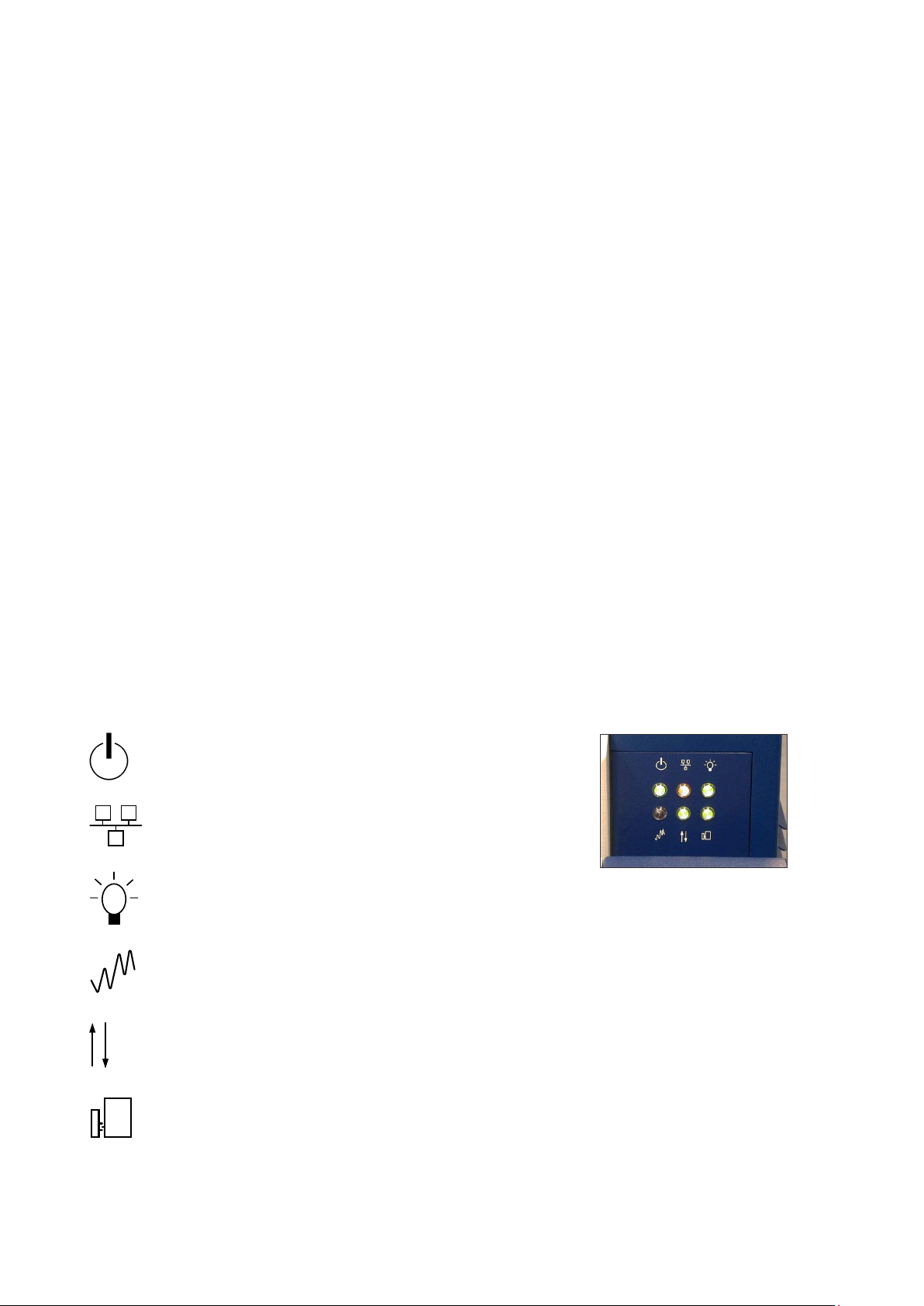

Icon

Status

Green when power is ON

Amber when connected to network or direct

Green when instrument lamp is ON

Red when scanning reference or sample

Green when module is properly attached

two sets of optical (“reference”) calibrations are stored in the instrument. It is important to Reference

Standardize on the correct level, as prompted by Vision Software. This aids in method transfer, and is

explained in the section on Reference Standardization.

This instrument uses near-infrared (NIR) spectral energy to illuminate the sample. By measuring the

energy reflected off (or passing through) the sample, chemical information and composition may be

determined. This information may be used for quantification of constituents, or for comparison to a

library of known materials, providing identification and qualification of materials.

Vision Software™ offers an easy user interface, using the familiar interface provided with previous

generations of NIR instrumentation. All functions required to perform identification, qualification, and

quantitation are provided, with easy tools for interpretation of results. Vision offers full instrument

diagnostics, with built-in acceptance specification tables for all tests. Vision stores all results in a

diagnostic database for later lookup, with control chart views of results tracked over time.

The menu-driven, validated Vision Software package meets all requirements of CFR 21 Part 11,

covering Electronic Records and Signatures. Vision comes with a full manual for operation and theory

of operation, with complete instructions for analytical development.

The XDS Analyzer provides 0.5nm data points, and uses several innovative methods to assure

wavelength accuracy and repeatability. Wavelength positions are traceable to NIST SRM-1920.

Because SRM-1920 does not have certified wavelengths above 2000 nm, an additional wavelength

absorber is included in the calibration standard, to provide stable wavelengths beyond 2000 nm.

These additional wavelengths have been independently measured on calibrated instrumentation to

ascertain the wavelength positions used.

A panel of 6 LED indicators provides information to the user on these functions:

connection

Green when stable operating temperature is reached

Instrument communication uses RJ-45 network connections, to eliminate issues involved with long

runs of RS-232 cable. An Internet Protocol (IP) address is dynamically requested upon connection.

6

Page 9

▪▪▪▪▪▪▪

This IP address may be permanently installed, if required for network purposes. RJ-45 connection also

permits remote interrogation and diagnostics checks of the instrument, if necessary and authorized.

The instrument enclosure is completely sealed to prevent contamination by dust or other substances.

The cooling fans operate outside the main enclosure, and are thermally linked to internal fans that

maintain a constant temperature inside the instrument enclosure. There is no airflow drawn into the

optics chamber instrument. An external fan-cooling loop is provided in the side chassis, with thermal

conduction from the inside of the optics chamber. This avoids contamination of the instrument in

dusty environments. An air filter is built into the door of this chamber. For cool environments, heaters

are embedded in the thermal transfer block to raise temperature when required.

Lamp changes are performed through a single panel on the rear surface of the instrument. The lamp

is easy to remove and replace, and requires no special tools or expertise.

7

Page 10

▪▪▪▪▪▪▪

2 Site Readiness

Like most precision instruments, the MultiVial Analyzer (RCA) is sensitive to environmental conditions

that can affect its performance and useful life. Observe the following guidelines when selecting a site

and installing the instrument:

2.1 Temperature and Humidity

The XDS Analyzer is designed to work in ambient air temperatures from 40-95°F (4.5-35°C).

Use the XDS Analyzer only in 10-90% relative humidity levels, non-condensing. Rapid changes in

humidity can cause interferences by adding trace moisture absorptions to the spectra. In general,

lower humidity levels are preferred.

The Performance Test (a comprehensive instrument diagnostic test in Vision software) is somewhat

sensitive to changes in ambient humidity, and the Performance Test may fail under conditions of

extreme humidity, or rapidly varying humidity.

2.2 General Environment

Minimize exposure of the monochromator to dust.

Inspect the fan filter at least monthly. If an accumulation of lint, dust, or other matter has

accumulated, pull open the right-hand panel from the instrument. Replace the filter. If dust has

accumulated on the fans, carefully wipe them clean with a moist soft cloth. Do not distort or damage

the fan blades or fins, as this will impede cooling.

Do not place the instrument directly near any HVAC duct. The direct flow of heating or cooling air

will cause the instrument to exhibit high noise during the Performance Test.

2.3 Vibration

Install the XDS Analyzer where it will not be affected by bench vibration from grinders, blenders,

stirrers, or mixers.

Never permit hammering or other physical impact on the bench top supporting the XDS Analyzer or

its computer.

2.4 Electrical Power

Power should be a single, separate, stable, transient-free filtered AC circuit. The circuit should have

surge protection.

Operating voltage for the instrument is 100-240VAC, 50/60Hz. The power supply is self-switching

and will provide the correct operating voltage to the instrument.

Maximum power consumption is 750W.

2.5 Instrument Communication

The XDS MultiVial Analyzer can communicate directly with the computer by use of a UTP Crossover

Cable (gray cable) supplied with unit.

Alternatively, the instrument may be accessed directly through a network connection. This uses a

standard RJ-45 type cable, such as CDW #074092, available from CDW Computer Centers, Inc. The

8

Page 11

▪▪▪▪▪▪▪

instrument detects network capability and optimizes communication speed.

The computer that operates the instrument must have clear access through the network, and be

configured to communicate properly. This communication is the responsibility of your on-site

network personnel.

Full instructions are given in section 3.0.

2.6 Instrument Dimensions and Weight

The XDS MultiVial Analyzer dimensions are:

• Width: 18.0” (457 mm)

• Height 15.25” (387 mm)

• Depth 22.5” (572 mm) front to back

Leave a minimum of 3” (76mm) around the instrument sides and back for airflow and access space.

Leave as much space as possible in front for sample handling.

• Weight 68.7 pounds (31.25 kg)

Follow lifting instructions (on last page) when moving the instrument. Avoid injury.

9

Page 12

▪▪▪▪▪▪▪

3 XDS Instrument Connection

The XDS instrument may be connected to the host computer in one of two ways: If the XDS

Instrument will be used as part of a network, use the Network Connection method shown

immediately below. If there are not enough active network ports near the XDS instrument, a hub or

router may be used.

This section assumes use of Windows® 2000, XP, or later versions of Windows Operating Systems.

For computers using Windows 95, 98, or NT 4.0, we recommend upgrade of the computer and

operating system to current specifications.

CAUTION: METROHM NIRSystems does not recommend the use of two network cards under any

circumstances. Do not use Direct Connection to the instrument along with a network connection to

the company network. The use of two network cards -- on one data bus in the computer – may

result in lost commands, lost data, and unsatisfactory software operation. Metrohm cannot be

responsible for software and instrument problems resulting from the use of two network cards in the

host computer.

This information is correct as of the time of original publication. Changes to computers, operating

systems, and network protocols may require revision of this information without notice.

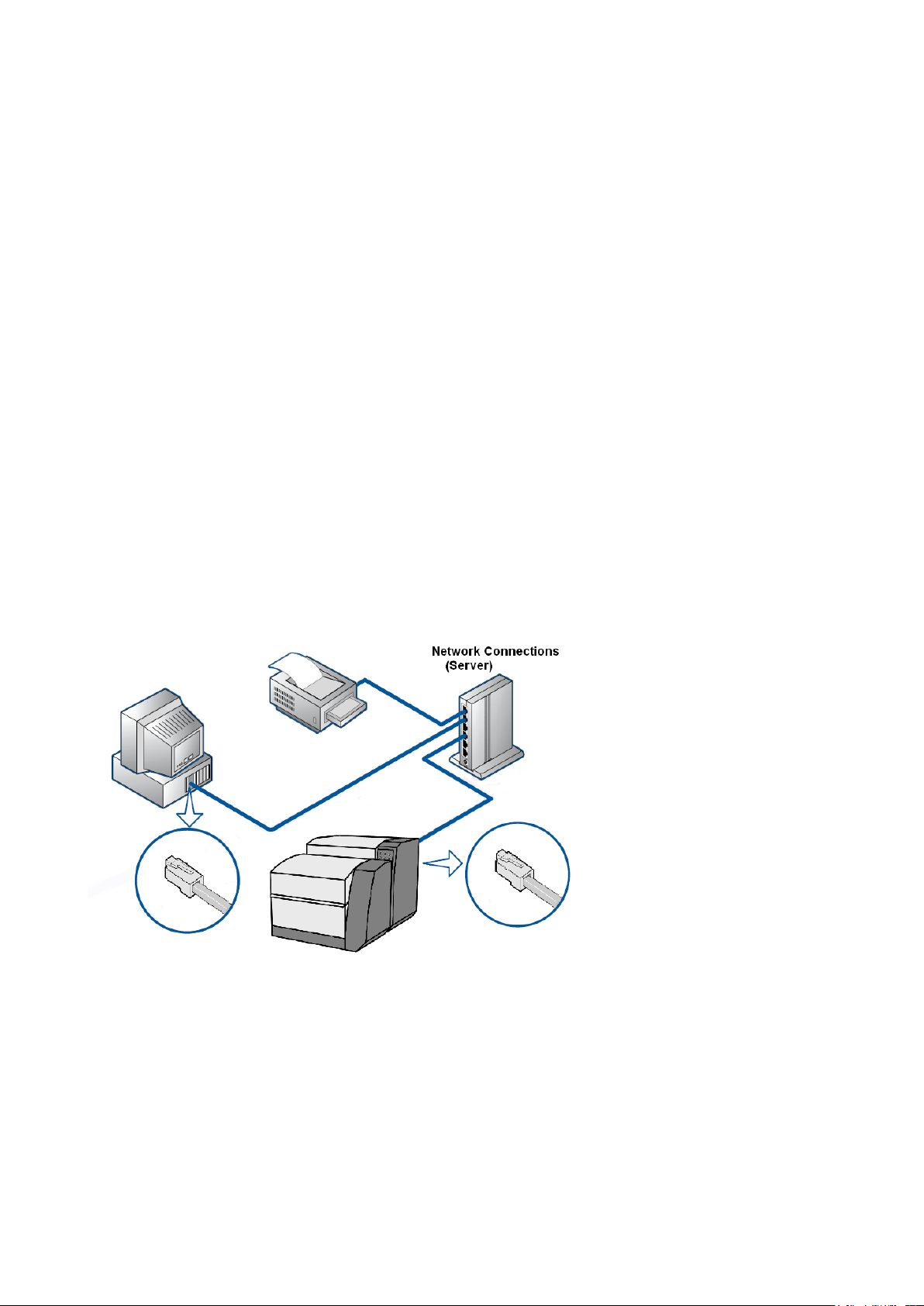

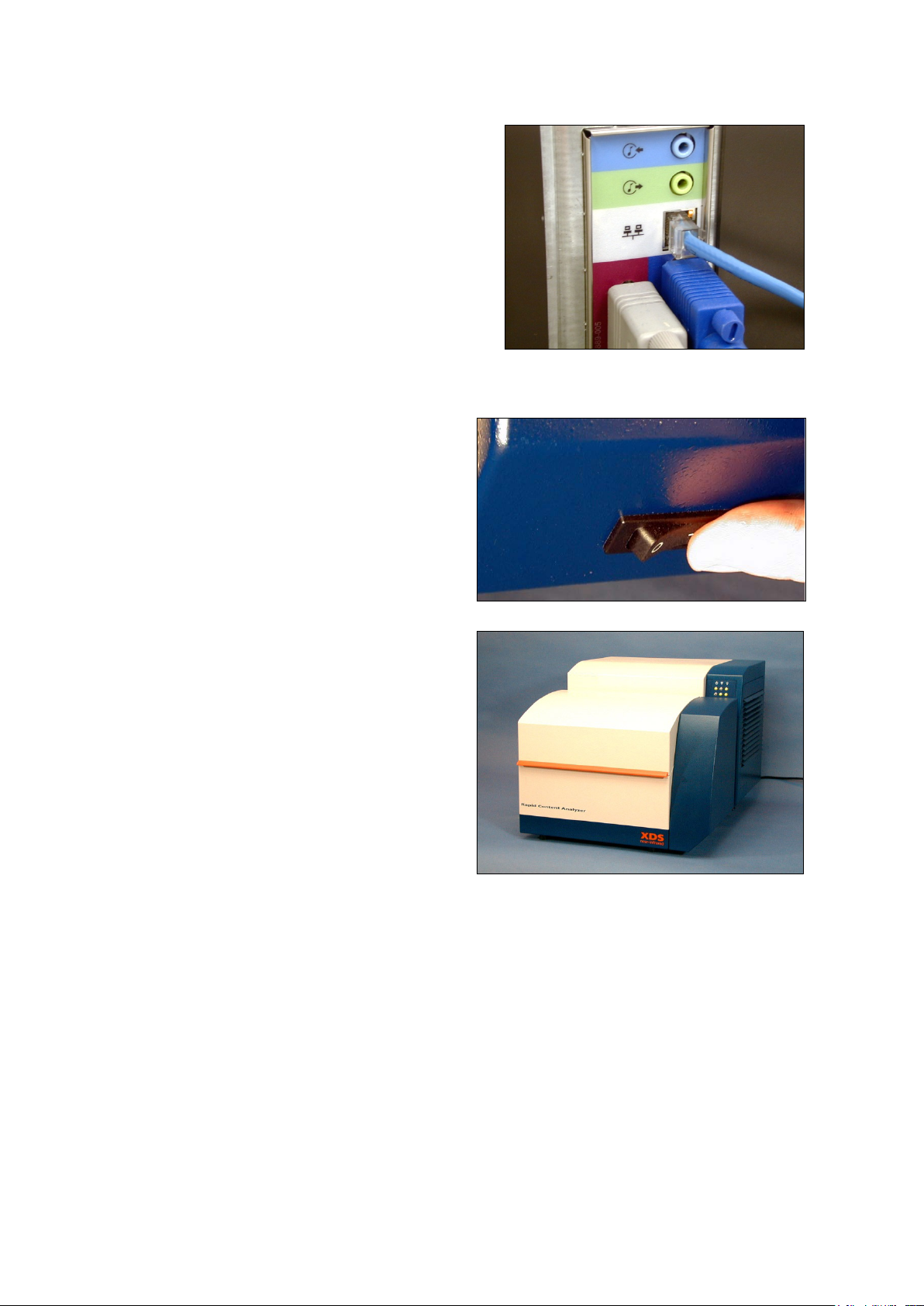

3.1 Network Connection, connected to an active network port as shown

This is the preferred method of instrument communication when a connection to the company Local

Area Network (LAN) is necessary. Specific information about this method follows:

• The XDS instrument should be connected -- with a “patch” cable – to the network port.

• Upon power-up, the XDS instrument will request a dynamic IP address from the network

server. This is normally assigned in 5 to 10 seconds.

• The XDS instrument uses a proprietary, encrypted command language. It cannot be activated

by any program except Vision, or Metrohm programs designed to operate the instrument.

Therefore, the instrument maintains “Closed System” status under 21 CFR Part 11 rules. No

hacking or support of viruses is possible with XDS instruments.

10

Page 13

▪▪▪▪▪▪▪

• The XDS instrument appears just like a network printer (or other peripheral device) on the

LAN system. It generates no signals, and only responds when commanded by an authorized

user, logged into Vision software.

• This is the easiest connection method for XDS instruments.

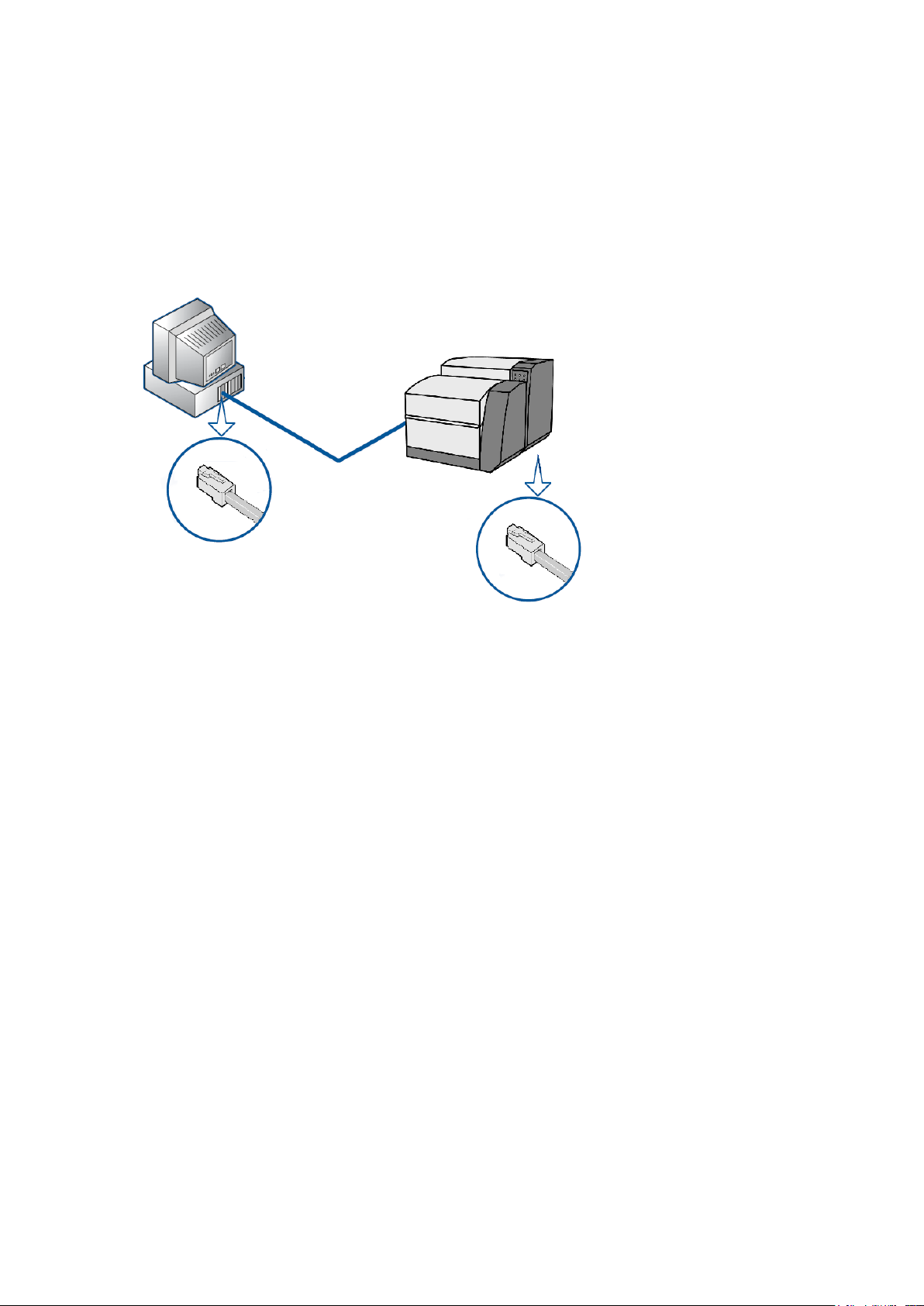

3.2 Direct Connection (without network)

This method allows users to connect to the instrument when there is no network present. In such

cases, a “crossover cable” (provided) is used. The XDS instrument, upon power-up, requests a

dynamic IP address. When none is supplied within 45 seconds, the XDS instrument concludes that no

DHCP server is available. It then defaults to an internal IP address which the computer may use for

“direct communication”.

This method of hookup should not be used when the computer is also connected to a network. Such

connection may result in lost commands, lost data, and unsatisfactory software operation. Metrohm

cannot be responsible for software and instrument problems resulting from the use of two network

cards in the host computer.

For IT personnel, it may be helpful to understand the sequence of events used by the XDS instrument

and Vision software when establishing an electronic connection. These are explained.

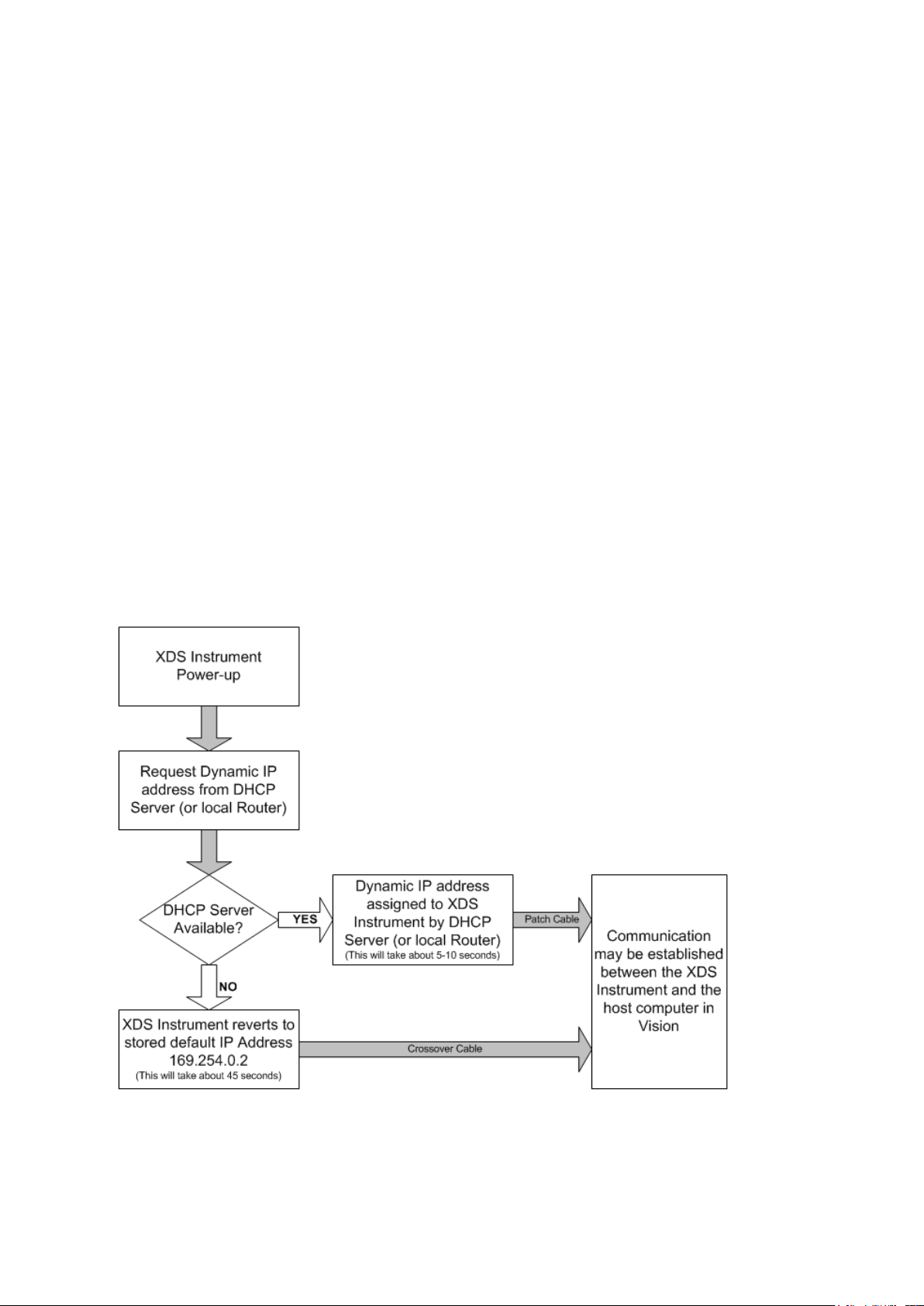

3.3 Overview of XDS Instrument Communication

The XDS instrument may be connected to LAN systems in the same manner as any printer or other

peripheral Ethernet-enabled device. These key items will help understand the communication

methods. See the flowchart diagram on next page.

1. The XDS instrument maintains “Closed System Status” under 21 CFR Part 11 guidelines. It

uses a proprietary, encrypted command language. It is not susceptible to hacking or virus

attacks.

2. The XDS system may only be addressed using proprietary software (usually “Vision”) which

can only be entered by an authorized user, using the “two-token” method of entry. (Unique

User ID and password)

3. Upon being powered up on a LAN, the XDS instrument requests a “dynamic” IP address from

11

Page 14

▪▪▪▪▪▪▪

the DHCP server which controls the LAN. This IP address is normally granted promptly

(typically in 5-10 seconds) so the instrument can function on the LAN. Most DHCP servers

track the XDS instrument by the “MAC” (Machine Access Code) to later re-assign that same IP

address whenever the XDS instrument is on the LAN.

4. If there is no DHCP server available to assign an IP address (a free-standing router may serve

the same DHCP function), the XDS instrument will “time out” in 45 seconds --and it will know

that it is not attached to an active LAN. It will then default to an internally-stored default IP

address. This address, 169.254.0.2, is used for local, free-standing communication only. In

such cases, a crossover cable, or a hub with two patch cables, should be used to connect the

computer and the XDS instrument.

5. Upon the next power-down and subsequent power-up of the XDS instrument, it will again

request an IP address of the DHCP server. It will go through the same cycle, eventually

reverting to the stored default IP address. This is intentional.

6. A dynamic IP address is the preferred method of XDS instrument connection. The default IP

address is only used when no DHCP server is available to assign a dynamic IP address.

A short glossary of terms follows. See the flowchart diagram for XDS instrument communication

which visually outlines the items explained above.

3.4 Flowchart Diagram of XDS communication protocol

12

Page 15

▪▪▪▪▪▪▪

3.4.1 Microsoft Windows Firewalls

The Microsoft Windows® Firewall on the PC may interfere with Vision communication. To assure

communication, follow these steps:

• Enter Control Panel, Security Center.

• On the “General” Tab, be sure that “exceptions” are allowed. (Un-click “Don’t allow

exceptions”.)

• On the “Exceptions” Tab, click “Add Program”.

• Select Vision from the list of programs – click on it. (Vision must be installed to appear on the

list.)

• Click on “OK” at each window to exit Control Panel.

3.4.2 Network Evolution Issues

This document is as correct as possible at the time or writing. However, network management is an

evolving discipline, and conditions will change. Some of the drivers for change include network

security, authentication, and data integrity. Technology changes factor into all of these issues.

Because the network communication environment is complex and ever-changing, we have tried to

provide the basic information needed for connection of the XDS instrument. 95% of users will have

no connection problems, if these instructions are followed.

In the rest of the cases, there may be network issues, corporate restrictions, or other issues which

inhibit easy connection. The troubleshooting section covers some of the most common problems.

In all cases, we recommend minimal tampering with computer settings. This can cause instability, and

may be prohibited by company policies.

At this time, we recommend Microsoft Windows® XP as the easiest operating system by which to

establish network communication. We strongly recommend that Windows 95, 98, and NT 4.0 be

avoided, as they require considerable expertise in network configuration.

3.4.3 Quick Glossary of Terms:

DHCP:

The Dynamic Host Configuration Protocol (DHCP) is an Internet protocol for automating the

configuration of computers that use TCP/IP.

DNS Server:

A Domain Name Server. DNS Servers run special-purpose software, as part of the Domain Name

System, for managing enterprise networks.

IP:

An Internet Protocol (IP) address is a numerical identification and logical address that is assigned to

devices participating in a computer network utilizing the Internet Protocol for communication

between its nodes.

IPv4:

IPv4 refers to “Internet Protocol version 4” which is the fourth revision in the development of the

13

Page 16

▪▪▪▪▪▪▪

1. Log into Vision with your User ID and

Internet Protocol (IP) and it is the first version of the protocol to be widely deployed. Together with

IPv6, it is at the core of standards-based internetworking methods of the Internet and is still by far

the most widely deployed Internet Layer protocol. XDS Instruments use IPv4.

LAN:

A local area network (LAN) is a computer network covering a small physical area, like a home, office,

or small group of buildings, such as a corporate site, a university, or an airport. These are often called

“enterprises”.

Subnet Mask:

“Subnetting” is used to break a large network into smaller sections. This can enhance efficiency, raise

speeds, and reduce “packet collisions” within the network. To accomplish subnetting, “Subnet

Masks” may be applied to separate one section of the network from another. A subnet mask typically

takes the form “255.255.255.0” or something similar. This scheme is becoming obsolete, as new

network management methods are being implemented.

TCP/IP:

(Transmission Control Protocol/Internet Protocol) is the basic communication language or protocol of

the Internet.

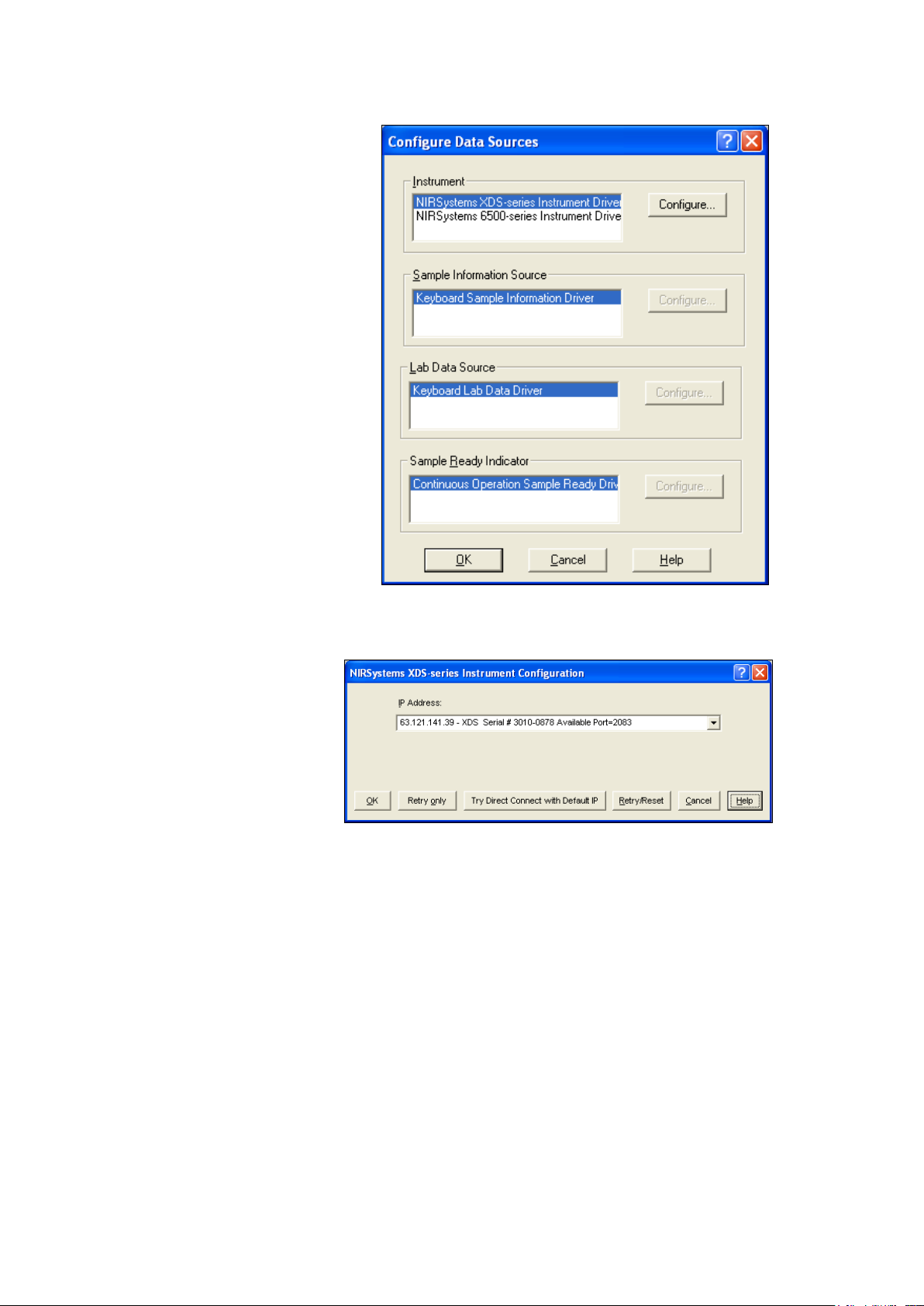

3.5 Connection in Vision

Password.

Click on Configure, Input as shown.

14

Page 17

▪▪▪▪▪▪▪

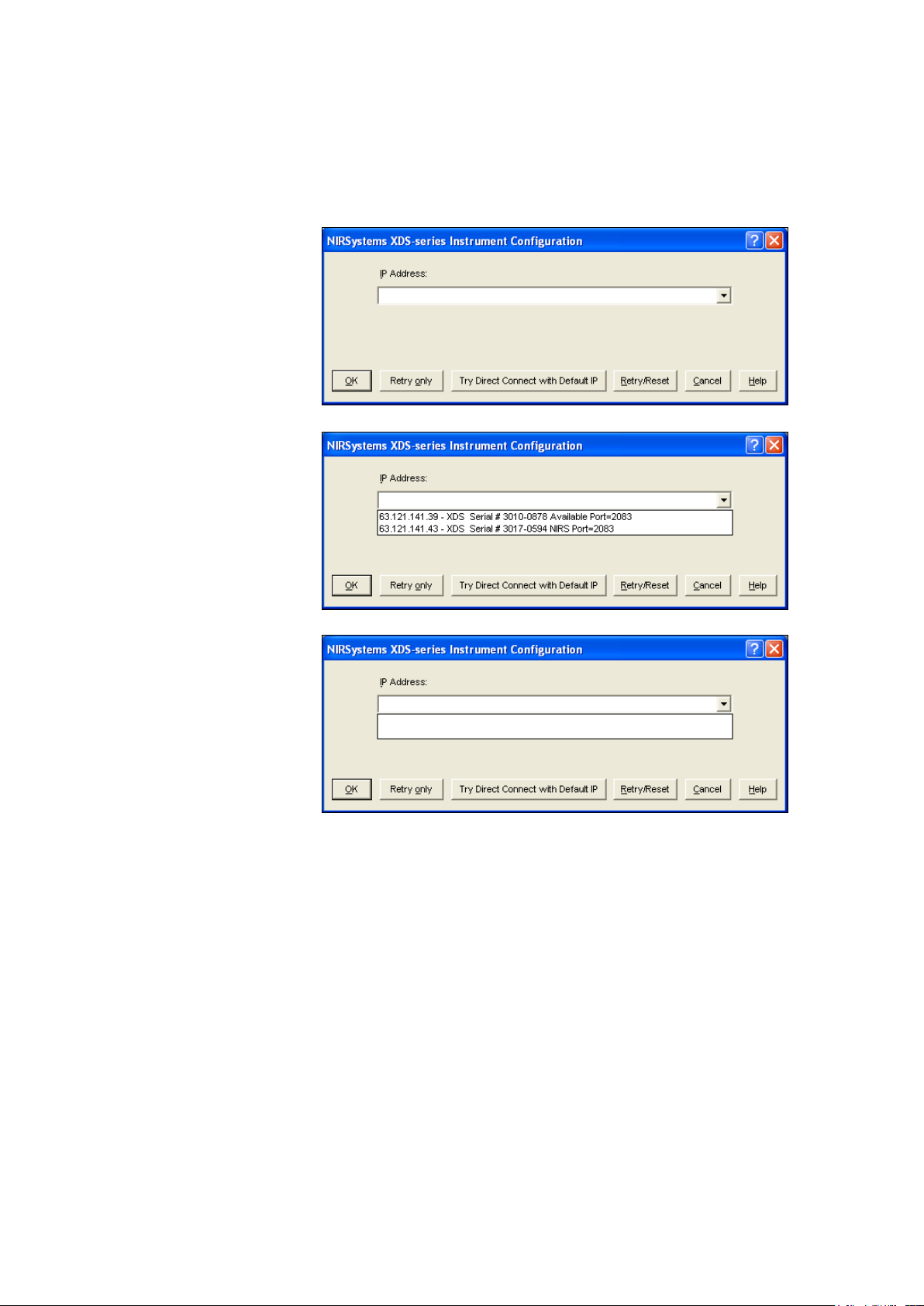

2. Highlight “NIRSystems XDS-

series Instrument Driver” as

3. When Vision “finds”

4. If the IP Address field is empty, the user should consult “Troubleshooting Connection

shown, then click on

“Configure”.

Information:

At this point, Vision requests any

XDS instrument on the local area

network (LAN) to report

connection status. This may take a

few moments.

If the instrument is not on a LAN,

and instead is connected with a

crossover cable, this will take a

minute or more. Vision first

requests a dynamic IP address, If

no server or router is available to

assign an IP address, Vision waits

45 seconds, then searches for the

default instrument IP address, in

the event of Direct Connection

using a crossover cable.

the instrument on the

LAN, it will be shown.

The dynamic IP

address (assigned by

Highlight the instrument and

click “OK”.

the server) is shown,

along with the XDS

Serial number. The

instrument is shown

as “Available” on port

2083.

Problems”.

3.6 Troubleshooting Connection Problems

Many connection problems are easily solved, especially with Windows® XP operating systems.

Windows XP is currently the preferred operating system, and has enhanced connectivity over other

operating systems. Vista is good also, but may impose user security restrictions. Windows 2000 is

almost as simple, but may require an extra step or two, as discussed.

15

Page 18

▪▪▪▪▪▪▪

1. Vision cannot see any

Solution: By expanding the

2. Vision still sees no

If your computer uses Windows 95, 98, or NT 4.0 for the operating system, we strongly recommend

upgrade to Windows XP for easiest connectivity. This may require a full computer upgrade, as older

computers may not have the processor speed, memory, or connectivity required to run Windows XP

with full Ethernet compatibility.

instrument on the

connection path.

Click on the “down

arrow” at the right

side of the empty field

to see if instrument(s)

are shown.

field, Vision can display the

instruments shown.

Note that only the top

instrument, Serial #30100878, is “Available”. Highlight

it and click “OK”.

instrument(s) after

expanding the field.

This indicates

connection or

network issues.

Verify Cable Type:

Verify correct cable type for hookup. Most networks use “patch” cables. Free-standing systems use a

“crossover cable”. Power down the XDS instrument, then power it back up. Wait 120 seconds for the

XDS instrument to fully reset its communication. If an instrument is shown, proceed to “Acquire”,

“Connect” in Vision.

If this does not resolve the problem, continue to the next section.

3.6.1 Network Troubleshooting Overview

If no XDS instrument shows as “available”, there may be a setting which should be changed. It may

be necessary to contact your IT department for assistance with these issues.

First, verify that the network has a DHCP Server. If no DHCP server is available, the instrument must

be connected by Direct connection, using a crossover cable. If this is the case, proceed to the section

entitled “Direct Connection Troubleshooting Overview”.

Network Solution 1:

16

Page 19

▪▪▪▪▪▪▪

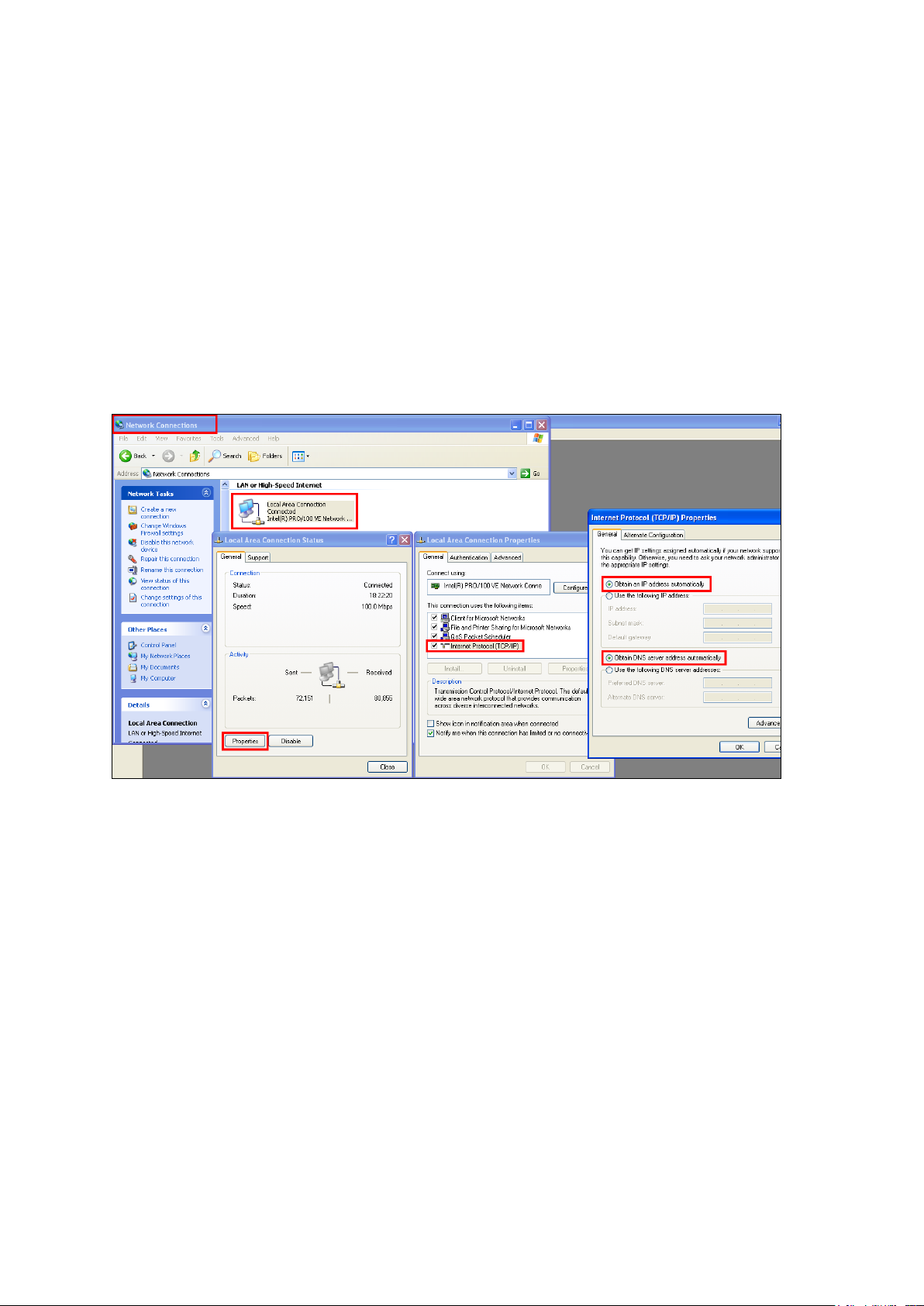

Check Internet Protocol (TCP/IP) Properties. (You may need to contact your IT department to follow

these steps.)

• Click on Start, then Control Panel

• Double-click on Network Connections

• Double-click on Local Area Connection

• Click on Local Area Connection Properties

• Click on Internet Protocol (TCP/IP)

• Click on Properties

The full path, from Network Properties forward to Internet Protocol (TCP/IP) Properties, is shown:

17

Page 20

▪▪▪▪▪▪▪

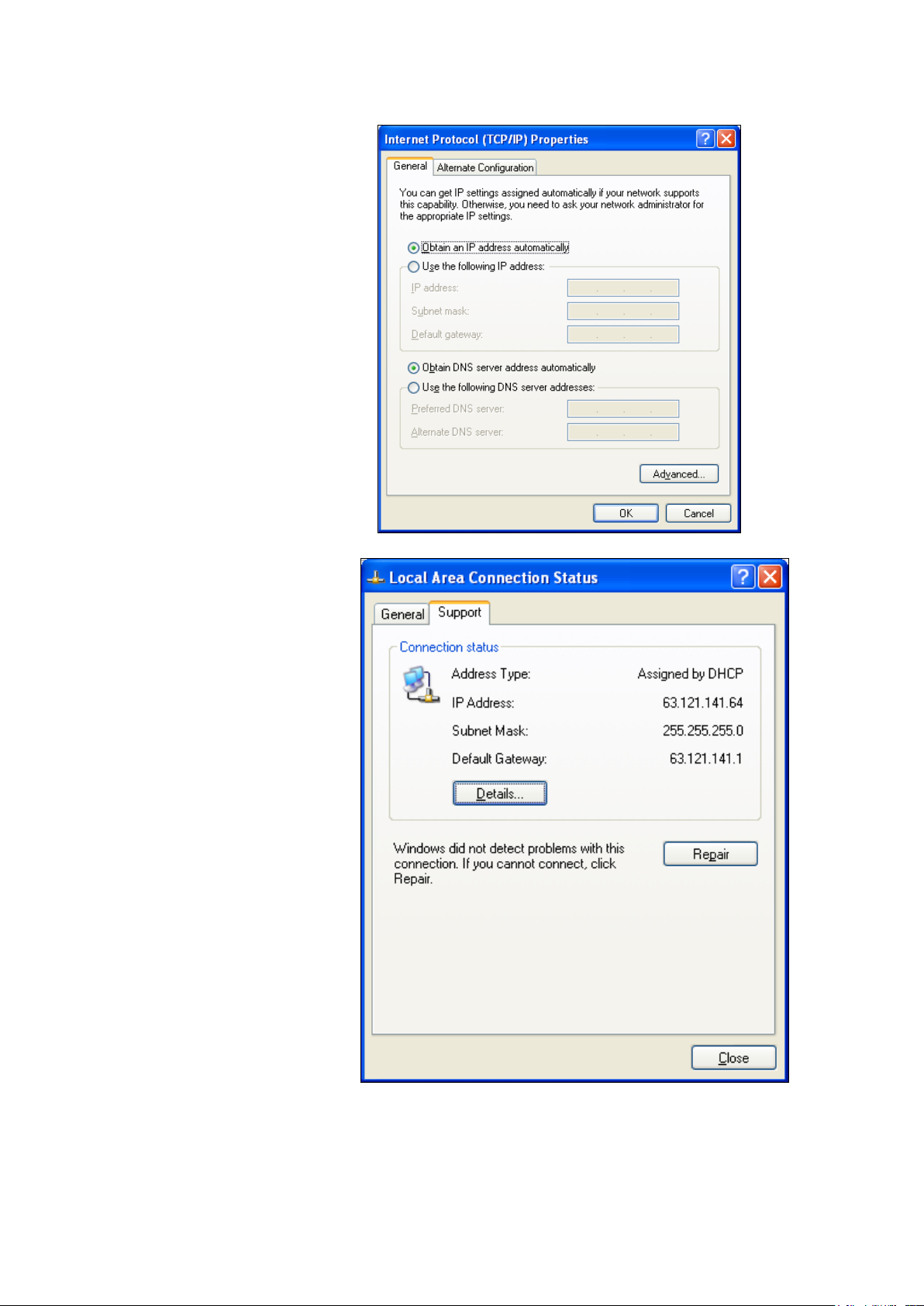

Verify these settings:

Network Solution 2:

• Obtain an IP address

automatically

• Obtain DNS server address

automatically

When finished, click “OK”. Close all

other boxes opened for this

verification.

If the settings were not set properly,

it may be necessary to exit Windows

XP, then re-enter XP, to have the

correct settings take effect. If in

doubt, do this and try XDS instrument

communications again after this takes

effect.

Returning to the Local Area

Connection Status dialog box, note

these items for the computer:

• Address Type:

(should be “assigned by

DHCP”)

• IP Address:

Write this address down for

the next step

• Subnet Mask:

Write this down for the

next step

If connection cannot be achieved,

it may be necessary to verify that

the XDS instrument is installed

“within the IP address range” of

the computer.

18

Page 21

▪▪▪▪▪▪▪

Network Solution 3:

The IT department at your company can verify if the network

Network Solution 4:

Network Retry, XP and

Verify network has full IPv4

compatibility.

Some networks have moved to

Ipv6 (Internet Protocol version 6)

which uses different address

formats.

Verify that the Firewall on the

computer has Vision loaded as an

“exception”.

This is located under “Control

Panel”, “Windows Firewall”.

If this is not enabled, click “Add

Program” and select “Vision” from

the list.

When finished, click “OK”

offers full Ipv4 compatibility. If the network has migrated to

Ipv6 operation, a “compatibility pack” may need to be

loaded to support Ipv4-enabled devices.

Vista:

Windows XP and Vista users

should click on “Retry

Only”. This command resets

the communication port,

and allows Vision to “find”

the instrument, if connected

properly.

19

Page 22

▪▪▪▪▪▪▪

Network Retry, Windows

Direct Connection Solution 1:

2000:

Windows 2000 users should

click on “Retry/Reset”. This

command resets the

communication port, and

also resets Windows 2000

to the proper state to

connect using a dynamic IP

address in the XDS

instrument.

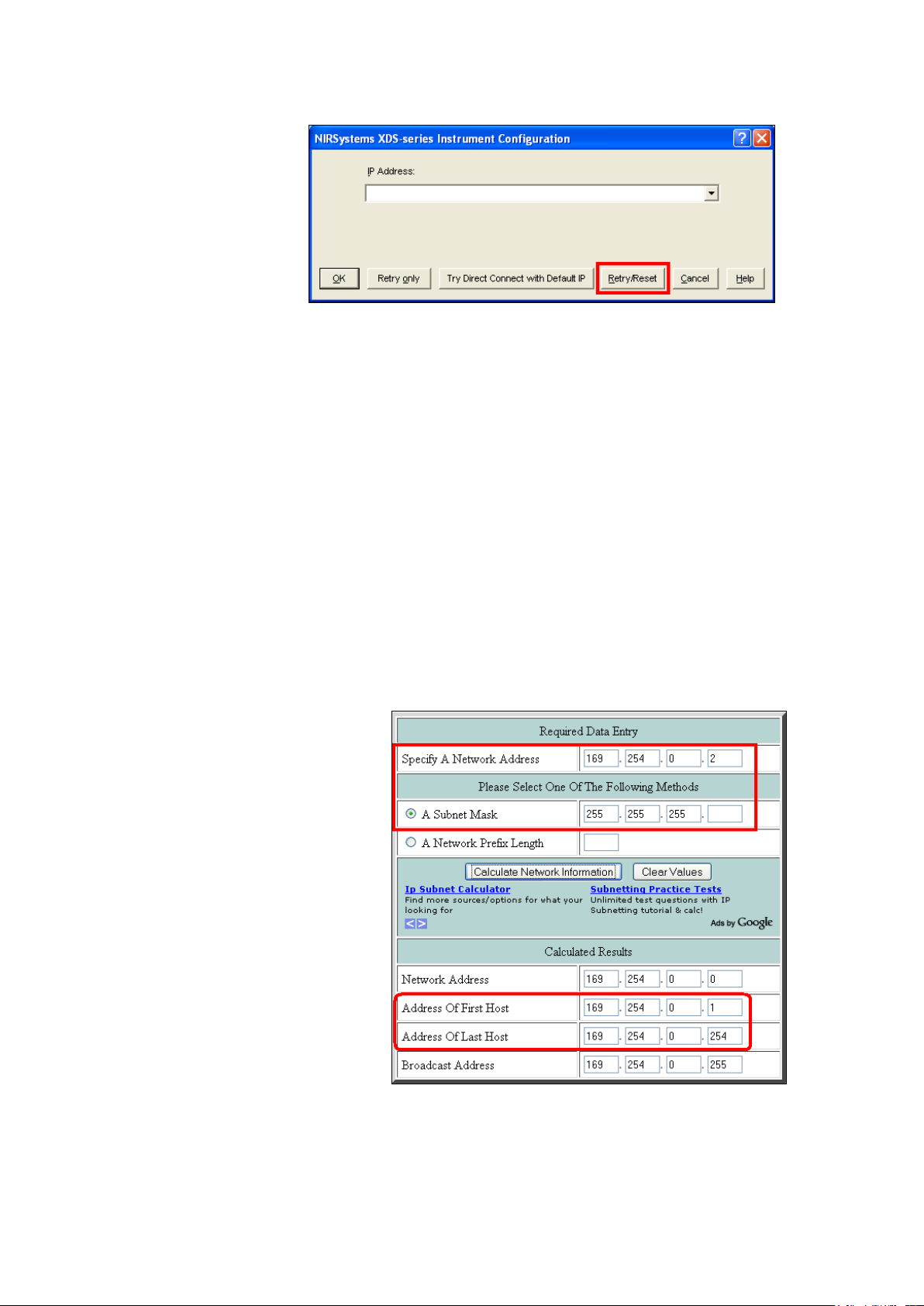

3.6.2 Direct Connection Troubleshooting Overview

If no XDS instrument shows as “available”, the computer may need to be configured for the IP

address range of the XDS instrument. It may be necessary to contact your IT department for

assistance with these issues.

First, verify the following:

• The instrument is free-standing not connected to a network with DHCP server

• There is only one network card in the computer

• A crossover cable is used between the XDS instrument and the computer

If these conditions are met, please proceed.

If using a crossover cable, verify that

the computer is communicating in the

same IP range as the XDS instrument.

The XDS instrument default IP address

is 169.254.0.2, as shown. This address

calculator gives the allowable computer

IP address range as 169.254.0.1

through 169.254.2.254.

DO NOT use 169.254.0.2 in the

computer!

Set the computer IP address to either:

• 169.254.0.1, or

• 169.254.0.3.

20

Page 23

▪▪▪▪▪▪▪

Direct Connection Solution 2:

Power down the XDS Instrument, then power it back

up. Wait 120 seconds, for the instrument to determine

Direct Connection

the correct method of Ethernet communication. Please

do not click anything for this amount of time, or

communication may be interrupted.

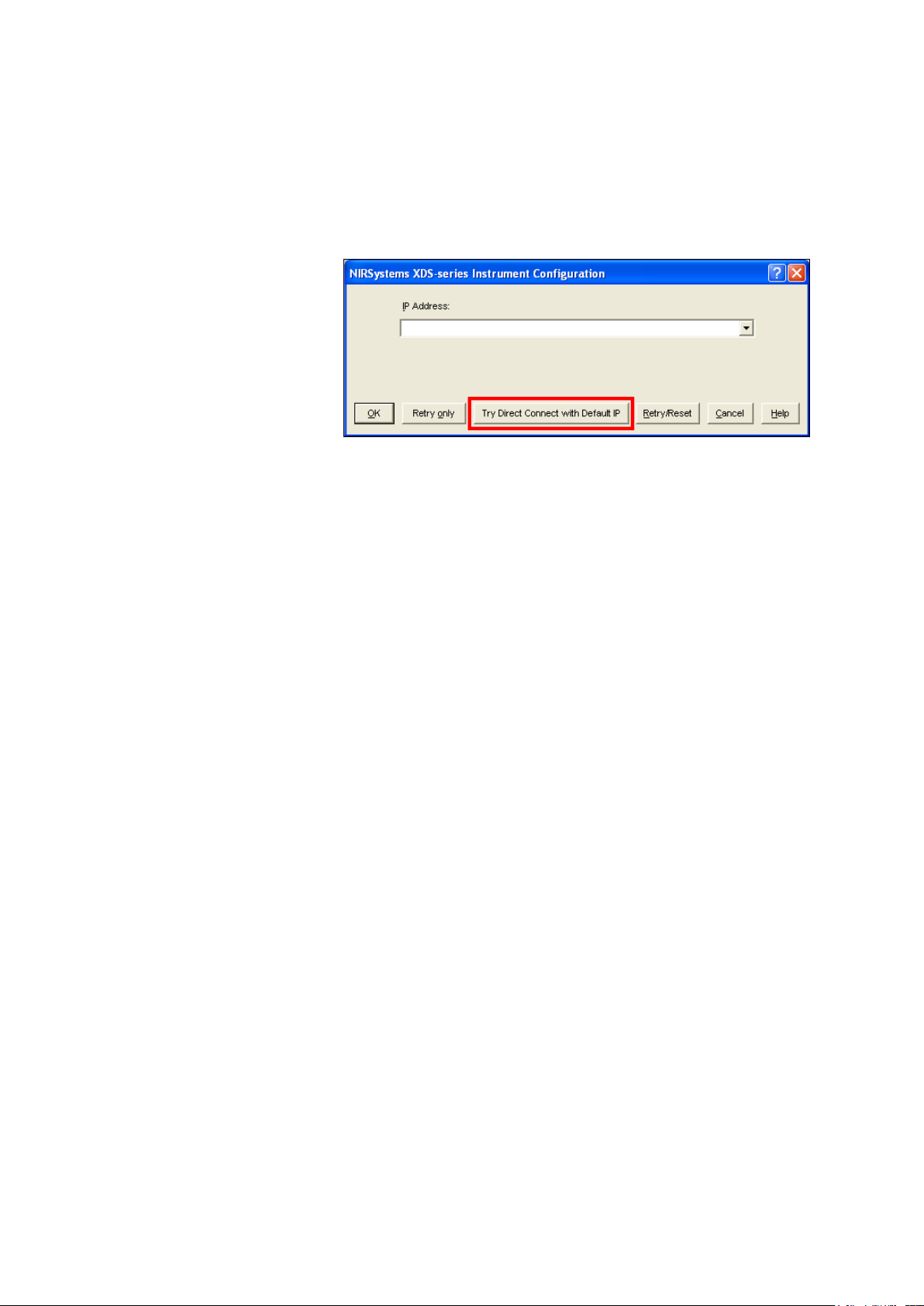

Solution 3:

Click on “Try Direct Connect

with Default IP”. This

searches for the default IP

address stored in the

instrument.

When the instrument is

found, click “OK”

This should resolve the connection issue. Proceed to “Acquire” and “Connect” in Vision.

21

Page 24

▪▪▪▪▪▪▪

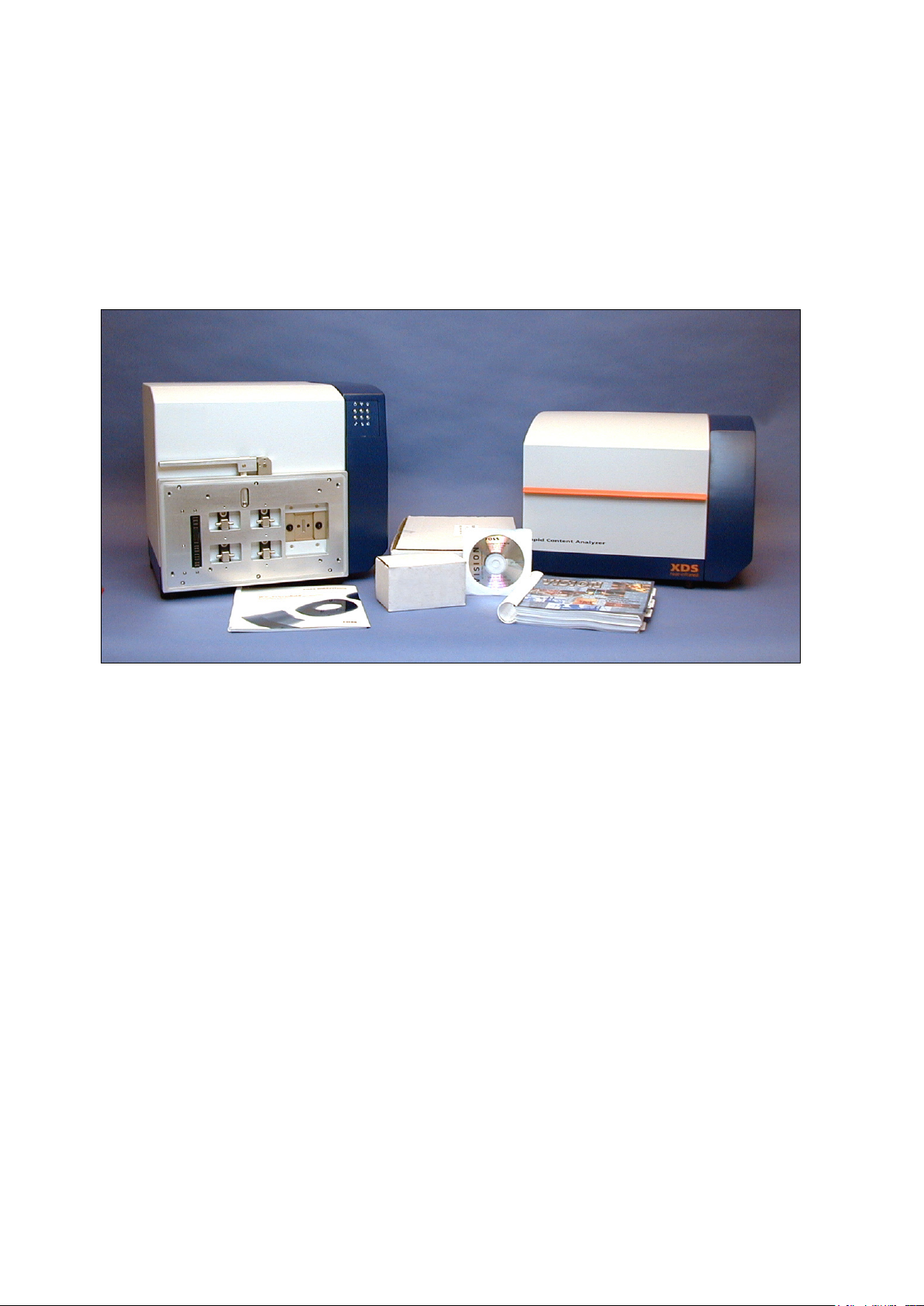

4 Assembly of the Instrument

The XDS Analyzer will be assembled and installed by a trained representative of Metrohm. This

person will perform a full suite of diagnostics to verify correct operation, and will explain basic

operating points. Assembly information is given as a guide for the user, should re-assembly ever be

required due to an instrument move or for other reasons.

Verify that the following items have been received in good condition:

• Metrohm XDS Monochromator

• MultiVial module

• Vision Spectral Analysis Software (Vision Manual is on CD)

• Spare Lamp

• Accessory Kit, containing cords, cables, standard tray, and other required items

• Safety Manual for CE certification

• Instrument Test Results Packet

(Packaging of items may vary from that shown.)

The serial number of the instrument and module are located on serial plates on the left side, when

facing the instrument. These serial numbers should match the serial numbers marked on the shipping

papers.

When using Vision software, the software will automatically read the monochromator serial number.

The module serial number must be entered manually, and is located on the module serial number

plate on the left side of the module, facing the instrument.

22

Page 25

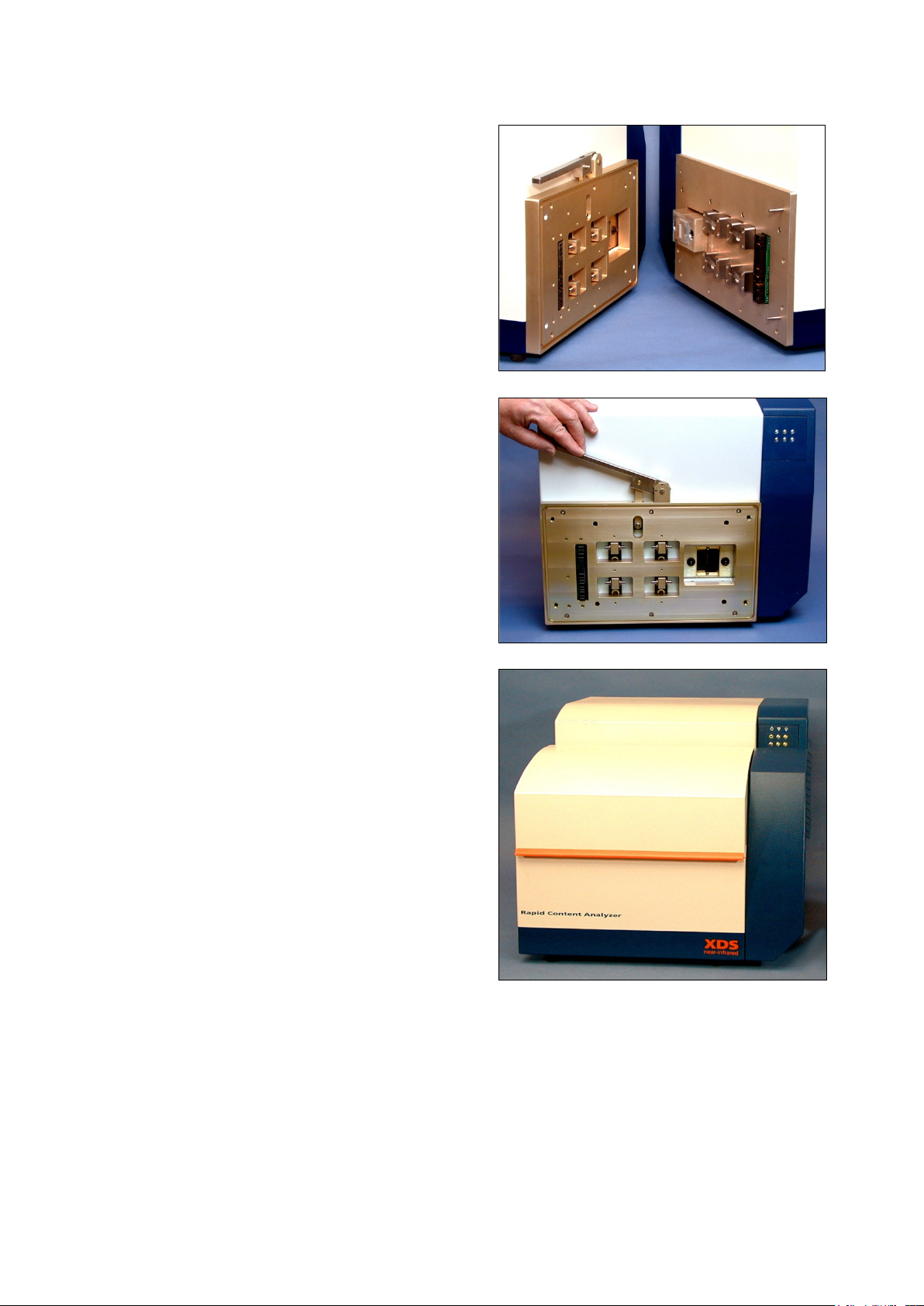

▪▪▪▪▪▪▪

DO NOT OPERATE OR TROUBLESHOOT WITH THE LID OPEN. SUNLIGHT MAY CONFUSE

1

2

Place the monochromator on the lab bench

3

Open the right-hand panel of the

THE OPTICAL INTERRUPTERS USED TO POSITION THE SAMPLE CARRIAGE. THIS MAY

CAUSE AN “X-Y POSITIONING ERROR” TO BE REPORTED.

Follow the assembly sequence that begins on the next page:

Load Vision Spectral Analysis Software onto

the computer designated to operate the

XDS instrument.

in the position shown.

instrument. Pull it gently by a fin, until the

catch releases. This panel opens to about a

45-degree angle for access to connectors,

and for filter inspection. Avoid scratches or

damage.

23

Page 26

▪▪▪▪▪▪▪

4

Gently thread the AC power cable and

5

Insert the AC power cable into the AC

6

Attach the RJ-45 cable to the network

network cable through the lower right

corner of the instrument access area as

shown.

The cables should snap into the black

holder. The innermost position is large, to fit

the power cord. If the power cord is in the

wrong location, the door may not close

fully.

The network cable may go into either of the

other two locations.

power block as shown.

connector on the instrument. If using Direct

Connection, use the gray cable from the

instrument accessory kit.

If using network connection, do not use the

gray cable, as it is a “UTP crossover” cable

and will not work with a network. Use a

network cable as described in section 3.0.

7 Close the outer cover of the instrument.

Push gently to the final closed position. It

should latch securely.

24

Page 27

▪▪▪▪▪▪▪

8

Position the sampling module directly in

front of the monochromator.

9

Lift the release handle on the

10

When the catches are fully engaged to the

11

Plug the AC power cord into a grounded AC outlet. A surge protector or Uninterruptible

This photo shows the mating connection

plates, prior to final alignment and

assembly. The locating pins help find the

final position.

The latches are used to lock the module in

position.

monochromator and engage the module

“catches” to the locking togs on the

monochromator. (Module not shown to

allow a good view of handle.)

Push monochromator and module together

firmly (with handle up) then lower the

release handle.

locking togs, push the release handle down

all the way.

This automatically engages the electrical

connector and fiber optic interface, and

maintains proper alignment of the module

to the instrument.

The final assembly is as shown.

Power Supply (UPS) is recommended for best operation.

25

Page 28

▪▪▪▪▪▪▪

12

If using a network, use a non-crossover type

13

When all the above assembly is finished,

14

Prepare to establish communication from

cable as listed in section 3.0. Plug the RJ-45

network connector into a functional network

port.

If this requires approval from a network

administrator, it should be properly approved

for hookup.

For “Direct Connection” the gray cable from the

instrument plugs directly to the computer

network jack. (Use the cable supplied with the

instrument.)

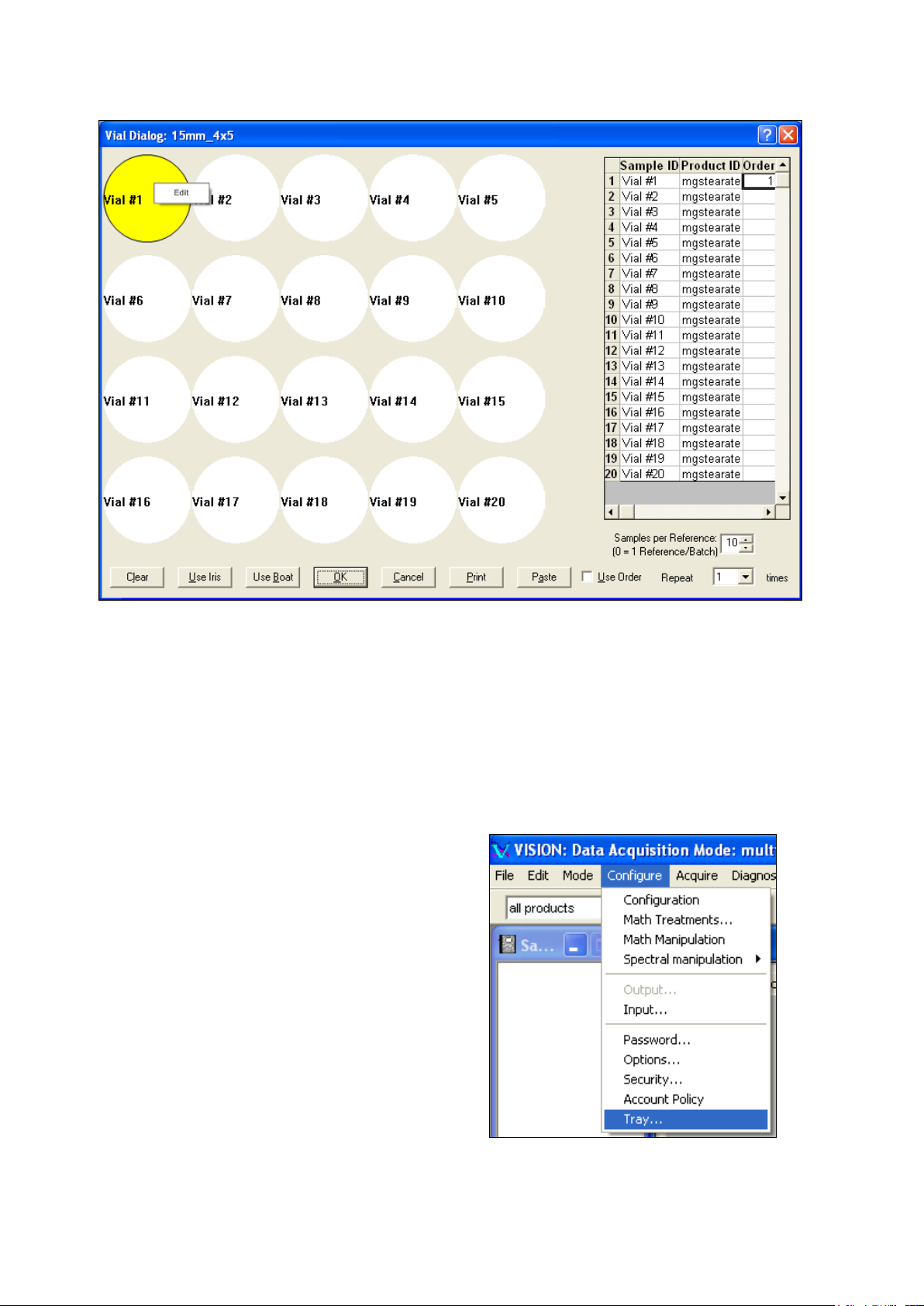

turn on the power switch on the

monochromator. It is located on the lower

surface, on the right-hand side as shown.

The monochromator performs some

initialization tests, which take a moment.

Some noises will be heard as items find their

initial positions. This is normal.

Vision to the XDS instrument. This is

detailed in Section 6.0, Vision Software.

This completes assembly of the MultiVial Analyzer.

26

Page 29

▪▪▪▪▪▪▪

5 XDS MultiVial Module

The MultiVial Analyzer is designed to provide

The XDS MultiVial Analyzer is primarily designed for vial sampling, which is the focus of this manual.

Optional sampling devices are available, and are also described following the vial information. For

optional sampling accessories, please contact your Metrohm NIRSystems distributor.

5.1 Introduction to Vial Analysis

sampling for trays of vials, like that shown at

right. This provides for a greater degree of

automation, and permits the operator to

perform sample loading and other duties while

one rack is being scanned by the instrument.

This extends the usefulness of the instrument

into a routine analytical tool, since no operator

input is required, once the sample information

is entered and the rack is in place. Spectral

information for each vial is acquired and

stored, and the calibration or library

identification is automatically applied.

Partial racks may be run, and the order of scanning determined by the user. Vision provides easy

graphical tools to make setup easy and accurate. No special software skill is required to set up the

instrument for routine analysis, once the calibration is in place.

Because the MultiVial may be used with different size vials, Vision accommodates setup by offering a

screen to help define the tray dimensions, including vial spacing. The number of columns and rows of

vials is entered, along with the manufacturer’s nominal diameter and tolerance. Vision takes this

information and provides centerline data for each bored hole in the tray, which can be used for

machining.

There are four default vial sizes set up in Vision, for commonly-used vials. The 15mm vial diameter is

shown as an example:

The setup screen for sampling is straightforward and easy to use. An example is shown:

27

Page 30

▪▪▪▪▪▪▪

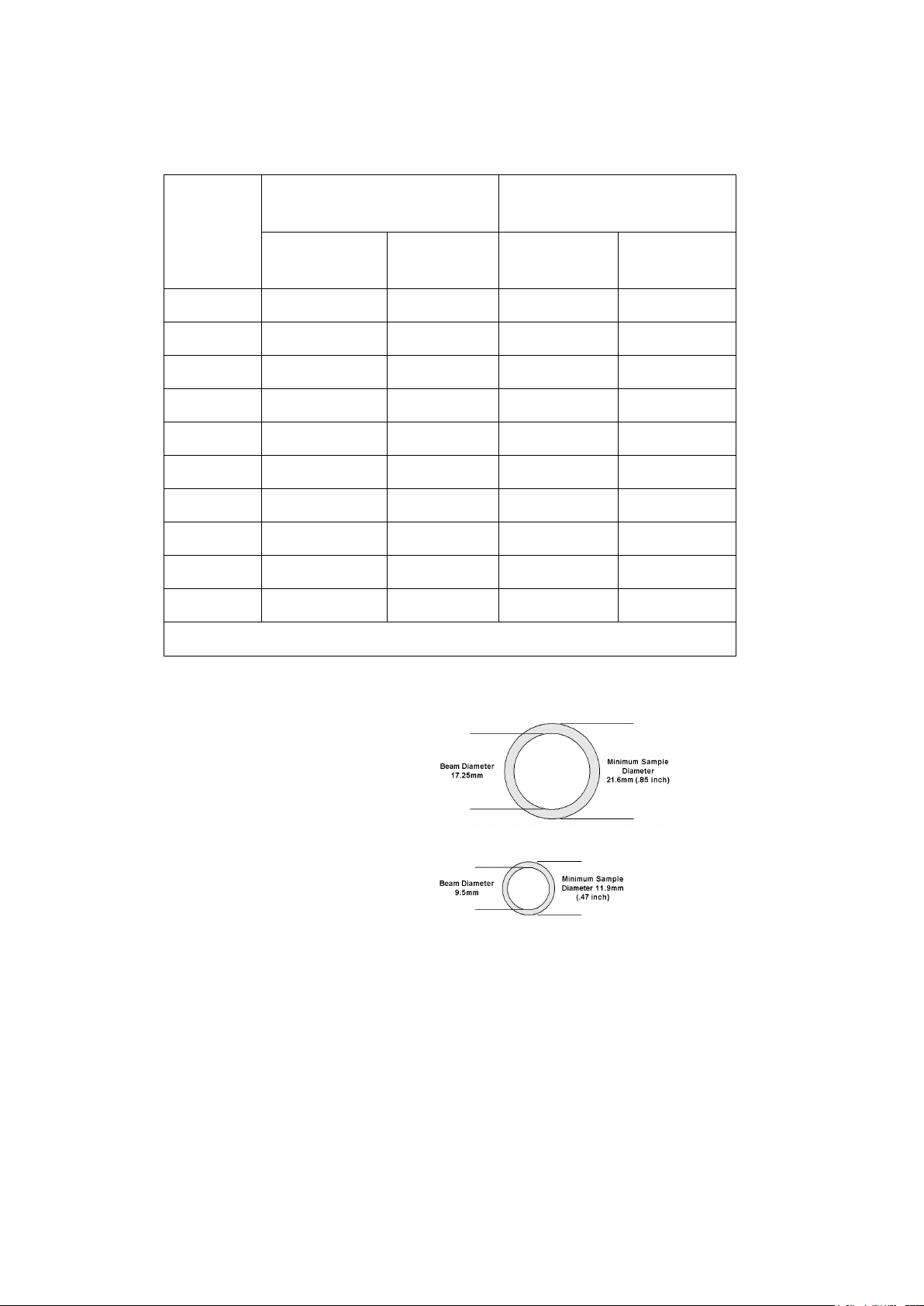

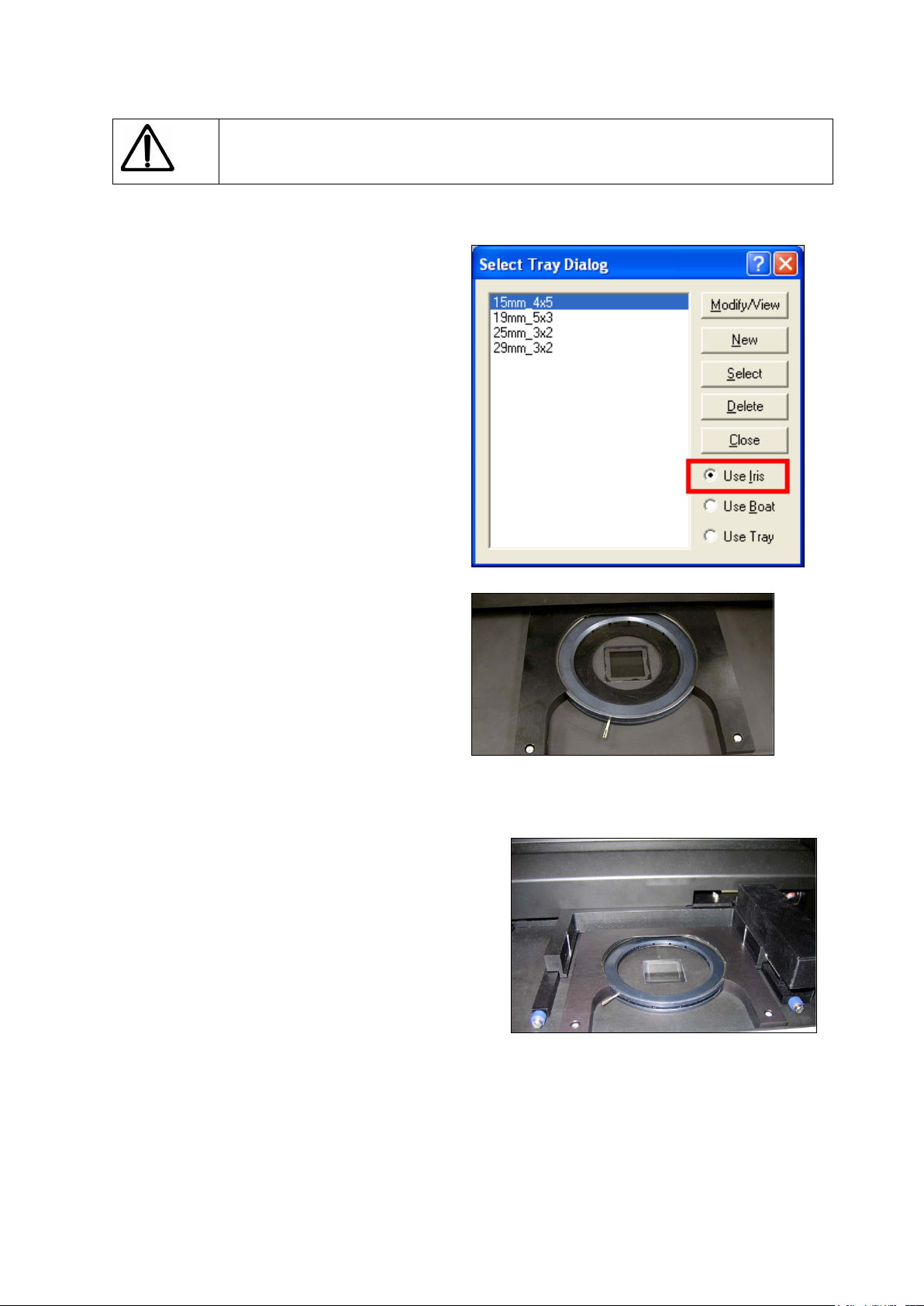

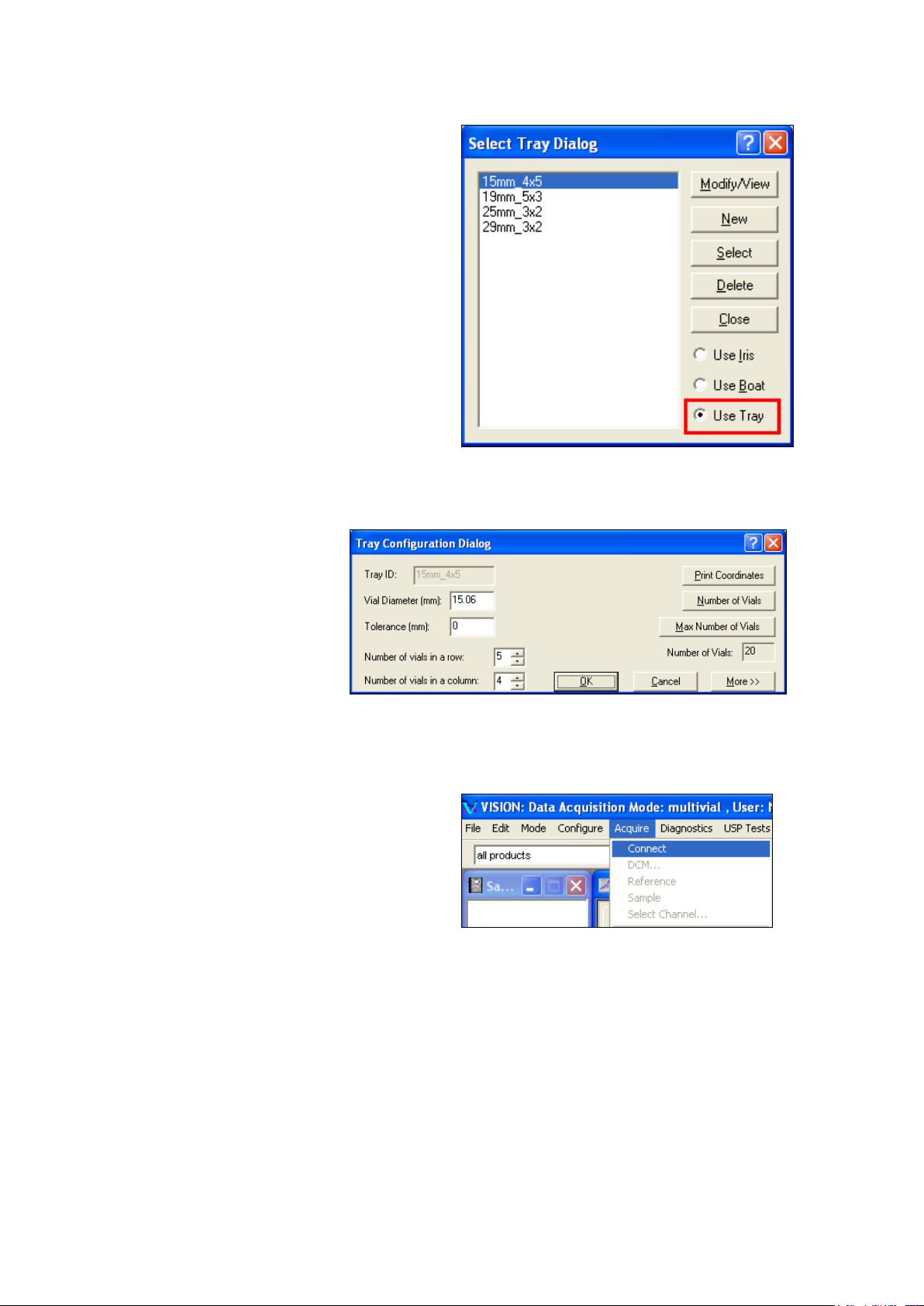

From the menu bar, select Configure, Tray.

Step by step instructions are given later in this manual. Please see Section 6.2 for full information.

It is important that the “spot size” adjustment be set up properly for a given vial size. This is also

covered in the section on Vision. Normally spot size should be no larger than 80% of vial size.

However, this is not pre-set, as users may wish to scan a smaller area.

5.2 Creation of a Custom Vial Size

Most users will work with one of the standard vial sizes offered. However, for setup of custom sizes,

this information is provided. To create a custom vial diameter, follow these steps:

28

Page 31

▪▪▪▪▪▪▪

At the Select Tray Dialog box, note that four

sizes (vial diameters) are already loaded in

A “Tray ID” must be assigned.

In this case, the vial diameter

Vision. (Other sizes may be added over time.)

NOTE: The spot size (set in the Data Collection

Method) should be no larger than 80% of the

vial diameter. For each default vial size, set spot

size as follows:

• 15mm vial: 12mm spot size

• 19mm vial: 15mm spot size

• 25mm vial: 17.5mm spot size

• 29mm vial: 17.5mm spot size

If your vial diameter is not shown, ignore the

default sizes. Click “New”.

This brings up the Tray Configuration Dialog

box shown below.

The normal convention is to

use the diameter, then the

number of vials in a row, and

a column.

You may use your own

naming method, of course.

The shortcut to this screen is

shown below.

is 22mm.

Enter “22” for Vial Diameter.

Click on “Number of Vials”.

Vision calculates the

maximum number of vials per

tray. IN this case, 8 may fit on

the tray. Vision fills in the

number of vials per row and

column.

Click “More”.

29

Page 32

▪▪▪▪▪▪▪

Upon selection of “More”,

These dimensions are the center of each vial

Vision shows key dimensions

of the tray, needed for

fabrication.

Click on “Print Coordinates”

to see additional dimensions.

opening in the tray. Vision uses these

coordinates to position each vial during

sampling.

Note that there are other important

dimensions, including the vial “support ledge”,

and the flatness of the final tray. Because the

fabrication is critical to repeatability, Metrohm

NIRSystems does not recommend local

machining.

Please contact your Metrohm NIRSystems

Distributor for ordering information.

You will need to supply both screens shown, as

the final tray will be machined to these

specifications.

A charge applies for each custom tray supplied.

5.3 Spot Size Adjustment

The MultiVial Analyzer offers spot size adjustment, which permits the user to set the relative size of

the illumination beam that strikes the sample. This is useful for small objects such as 15mm vials

(about 5ml volume), tablets, and other small-diameter materials. The instrument energy is focused

into a smaller area, providing better intensity within the area of interest. This generally provides

improved signal-to-noise on small samples. In the Data Collection Method (DCM) shown below, the

spot size is entered as 12mm, for a 15mm vial.

NOTE: The spot size (set in the Data Collection Method) should be no larger than 80% of the vial

diameter. For each default vial size in the Select Tray Dialog box, set spot size as follows:

• 15mm vial: 12mm spot size

30

Page 33

▪▪▪▪▪▪▪

• 19mm vial: 15mm spot size

• 25mm vial: 17.5mm spot size

• 29mm vial: 17.5mm spot size

As a rule, a large spot size is preferable for large samples. This provides as much sample viewing area

as possible for a good cross-sectional area of the sample. The default spot size is 17.25mm.

31

Page 34

▪▪▪▪▪▪▪

Spot Size

Minimum Sample

Scanned Sample Area

Diameter

Diameter

Square mm

Sq. Inches

9.5 mm

11.9 mm

0.47 in.

70.9 sq. mm

0.11 sq. in.

10 mm

12.5 mm

0.49 in.

78.5 sq. mm

0.13 sq. in.

11 mm

13.8 mm

0.54 in.

95.0 sq. mm

0.15 sq. in.

12 mm

15.0 mm

0.59 in.

113.1 sq. mm

0.18 sq. in.

13 mm

16.3 mm

0.64 in.

132.7 sq. mm

0.21 sq. in.

14 mm

17.5 mm

0.69 in.

153.9 sq. mm

0.25 sq. in.

15 mm

18.8 mm

0.74 in.

176.7 sq. mm

0.28 sq. in.

16 mm

20.0 mm

0.79 in.

201.1 sq. mm

0.32 sq. in.

17 mm

21.3 mm

0.84 in.

227.0 sq. mm

0.36 sq. in.

17.25 mm

21.6 mm

0.85 in.

233.7 sq. mm

0.37 sq. in.

When using the default spot size of

Diagrams may not be “actual size”—check dimension to verify sample size.

The adjustment ranges from 9.5mm to 17.25mm, in adjustment steps of 0.25mm. The effective

scanned sample areas at various spot sizes are as follows:

Diameter.*

(mm)

(in.)

*Based upon 125% of beam diameter

Interpolate for spot sizes in between those listed. Areas are rounded to the digits shown.

17.25mm, the sample diameter should be at

least 21.6mm (0.85 inch) as represented by

the gray circle in this diagram.

At the minimum spot size of 9.5mm, the

sample diameter should be at least 11.9mm

(.47 inch) as represented by the gray circle in

this diagram.

Set spot size in the Data Collection Method (DCM) under “Spot Size” as shown. The spot size should

generally be set to about 80% of the sample diameter for optimum illumination. (Looking at it the

other way, minimum sample size is recommended to be at least 125% of beam diameter.) Measure

the sample, and enter “Spot Size” into the DCM accordingly. Units are mm.

Once set in the DCM, and spectra are saved using this DCM, the spot size cannot be changed. This is

a safeguard to assure that all sample spectra are acquired using the same parameters.

32

Page 35

▪▪▪▪▪▪▪

NOTE: Perform Reference Standardization immediately after changing the spot

When scanning stationary objects, the “Use

Use the Iris Adapter for centering. Close the

The Iris Adapter is used for round sample cups,

size, to have the proper reference correction loaded in the instrument.

5.4 Iris Adapter

Iris” selection must be clicked. (Stationary

objects need not be moved across the sample

window for averaging.)

aperture around the object to center it, then

open the aperture to avoid reflecting light back

from the aperture itself.

5.4.1 Installation of Iris Adapter:

beakers, vials, and other stationary samples.

NOTE: Set the Select Tray dialog box to “Use Iris”.

Align the holes in the Iris Adapter with the pins on

the sample platform, and carefully lower into place.

The pins hold the Iris Adapter securely in position

over the sample window.

Use the adjustment lever to open the iris as needed.

33

Page 36

▪▪▪▪▪▪▪

Use the iris to center samples in the window area.

The MultiVial Analyzer may also be used for liquid

When using vial trays in the normal mode, the vials

Removal of the Iris Adapter is quite straightforward. Simply remove the Iris Adapter Assembly by

Push the handle to the right to center the sample,

then to the left to move the iris from the sample

window area.

Close the door of the sample chamber to exclude

ambient light.

Take a reference scan, the take a sample scan of the

material.

NOTE: If acquiring vial spectra that will later be used

with a vial tray, be sure to perform the Reference

Standardizations as described for both “Use Iris” and

“Use Tray” positions. This assures consistent spectra.

analysis using the Reflectance Cell and Immersion

Diffusers.

These cells are often used for clear to semi-clear

liquids such as alcohols and suitable fluids.

are slightly elevated from the sampling window. A

separate Reference Standardization is performed in

the “Use Tray” mode to account for the slight

photometric difference between the “Use Iris” mode

and the “Use Tray” mode.

Vision applies the proper Reference Standardization

based upon selection of “Use Iris” or “Use Tray”.

lifting straight upward, off the pins. Be sure to set the Select Tray dialog box to the correct setting

for the type of cell being used.

34

Page 37

▪▪▪▪▪▪▪

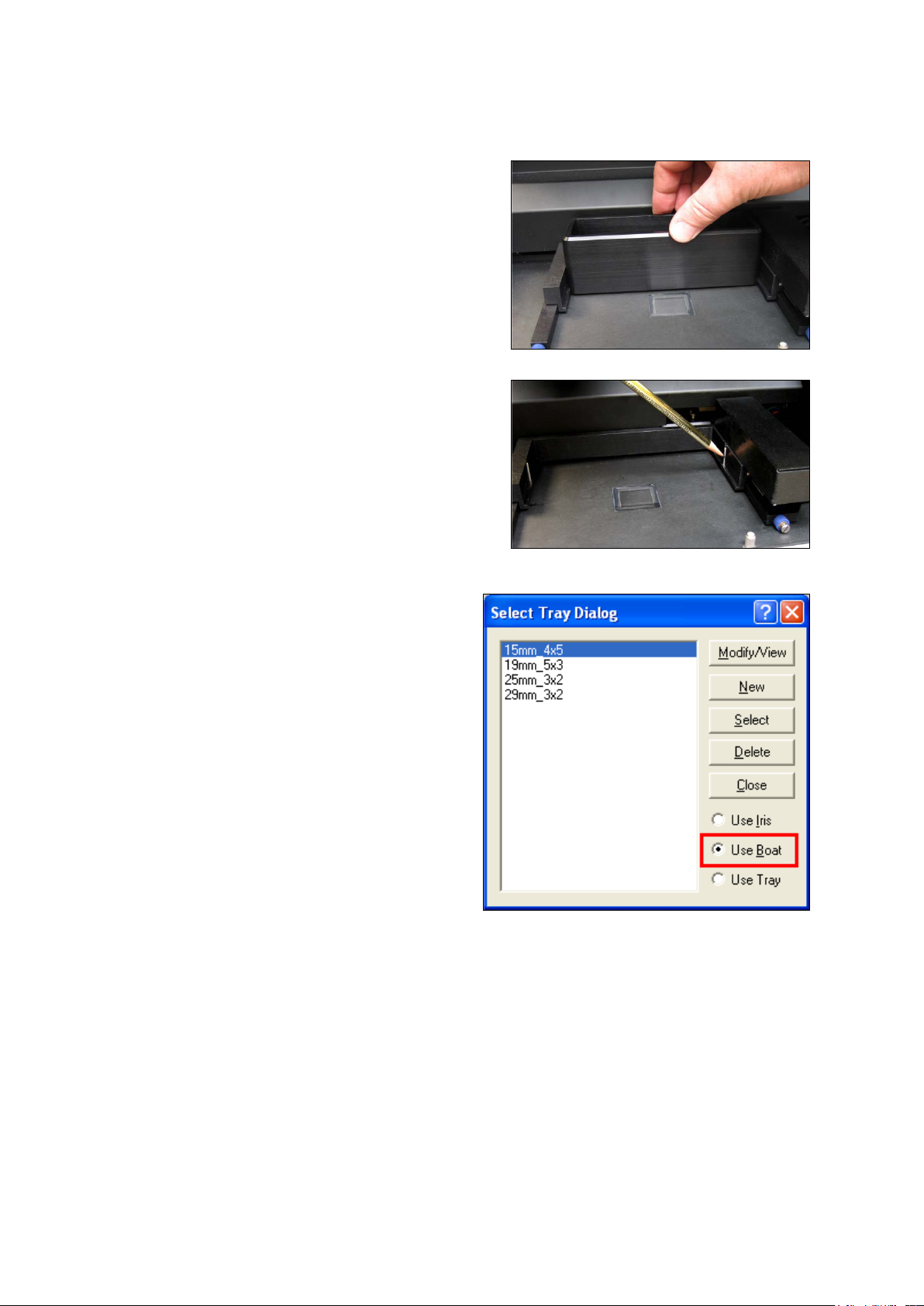

5.5 Use of the Sample Transport Mechanism

The sample transport uses a small motor and lead

To insert the sample cell “boat” into the MultiVial,

The Select Tray Dialog box must have the correct

screw to position the cell over the sampling window

of the module, as shown in the photo at right.

In normal operation, the mechanism will move the

cell to one of 8 sample positions, for maximum

sampling area exposure. This is completely under

control of the instrument, and requires no input from

the user.

note the round guides on the sample carrier. They

are shown in this photo – the pencil points to the

one on the right.

The sample cell must be positioned over these pins

and gently pressed down to the stops. If crooked, the

cell cannot be positioned correctly. Care must be

used in placing the cell on the pins.

selection made. Click on “Use Boat” as shown.

This selection de-activates the “y-axis” motion,

and allows the correct range of “x-axis” motion.

DO NOT OPERATE OR TROUBLESHOOT

WITH THE LID OPEN. SUNLIGHT MAY

CONFUSE THE OPTICAL INTERRUPTERS

USED TO POSITION THE SAMPLE CARRIAGE.

THIS MAY CAUSE AN “X-Y POSITIONING

ERROR” TO BE REPORTED.

35

Page 38

▪▪▪▪▪▪▪

The sample transport mechanism is quite rugged, and requires no service by the user. Please

When using the Iris Adapter, select the “Use Iris”

Gently position the Iris Adapter over the locating

DO NOT OPERATE OR TROUBLESHOOT WITH THE LID OPEN. SUNLIGHT MAY CONFUSE

observe these cautions:

• Never attempt to move the mechanism manually. This will cause a “Limit Switch Error” in

Vision. The user must then disconnect, cycle power, and re-connect to the instrument to

reset the mechanism.

• DO NOT operate with the lid open. This can induce X-Y Positioning Errors.

• Do not attempt to clean or lubricate the mechanism. The traversing nut is self-lubricating

and self-cleaning, and requires no service of any kind. The lead screw is stainless steel, and

needs no service.

There are no user-serviceable parts in the mechanism. It has been aligned and set for quiet, stable

operation. Please be gentle, and do not attempt to make any adjustments.

5.5.1 Use of the Iris Adapter:

setting in the Select Tray dialog Box. This

positions the sample carrier to a central position,

and permits the user to install the Iris Adapter.

(The Iris Adapter is shown in the next photo.)

NOTE: Failure to set the “Use Iris” setting may

result in damage to the instrument, which is not

covered by instrument warranty.

When set to “Use Iris” Vision ignores the tray

sizes shown on the left side of this dialog box,

and proceeds only for use of the Iris Adapter.

pins and press downward.

This photo shows the Iris Adapter in the correct

position for use. Note the silver positioning lever

at the left side of the iris – move this lever right

to close the iris to centering vials or other cells.

THE OPTICAL INTERRUPTERS USED TO POSITION THE SAMPLE CARRIAGE. THIS MAY

CAUSE AN “X-Y POSITIONING ERROR” TO BE REPORTED.

36

Page 39

▪▪▪▪▪▪▪

6 Vision Software: Connection to the Instrument

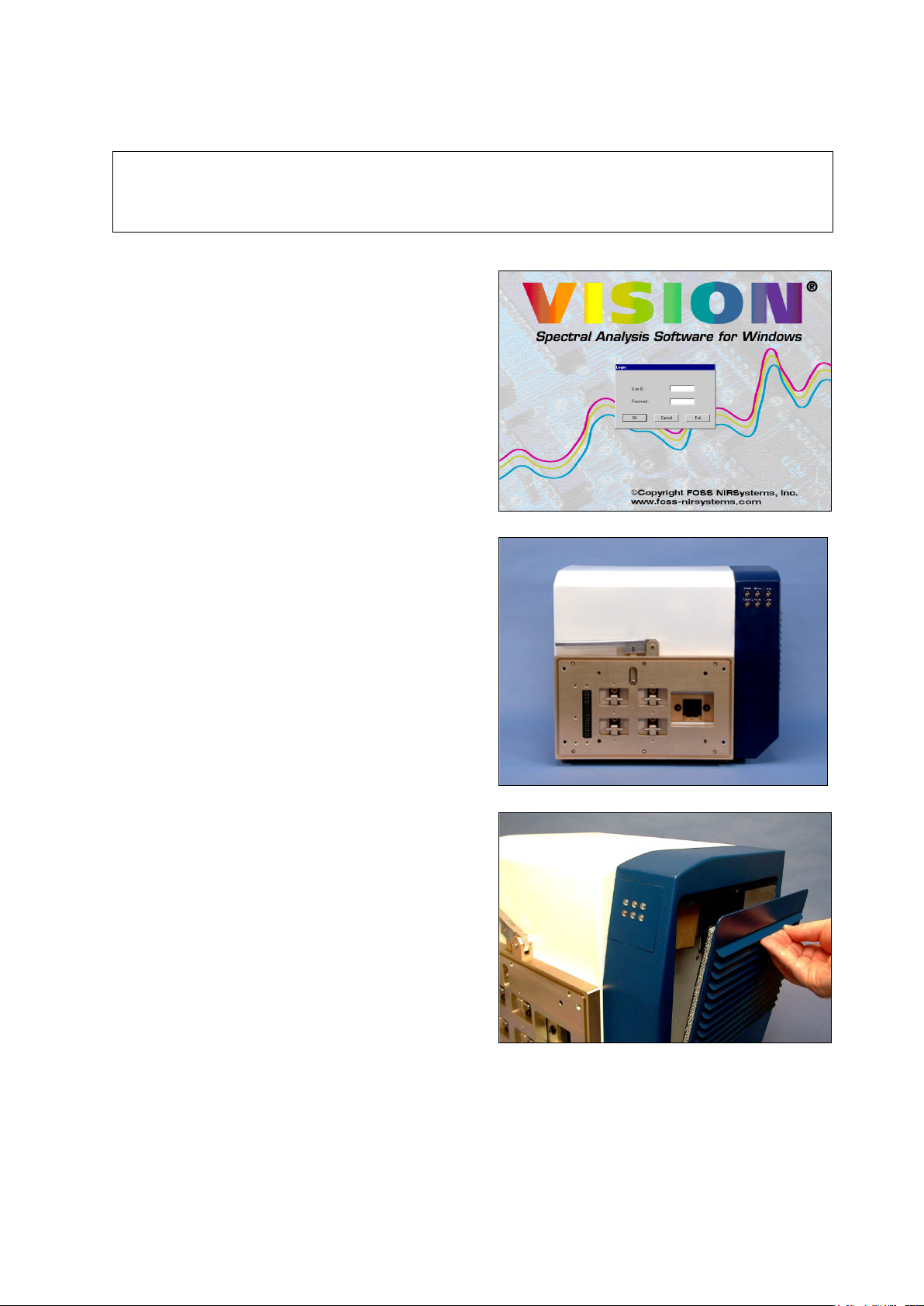

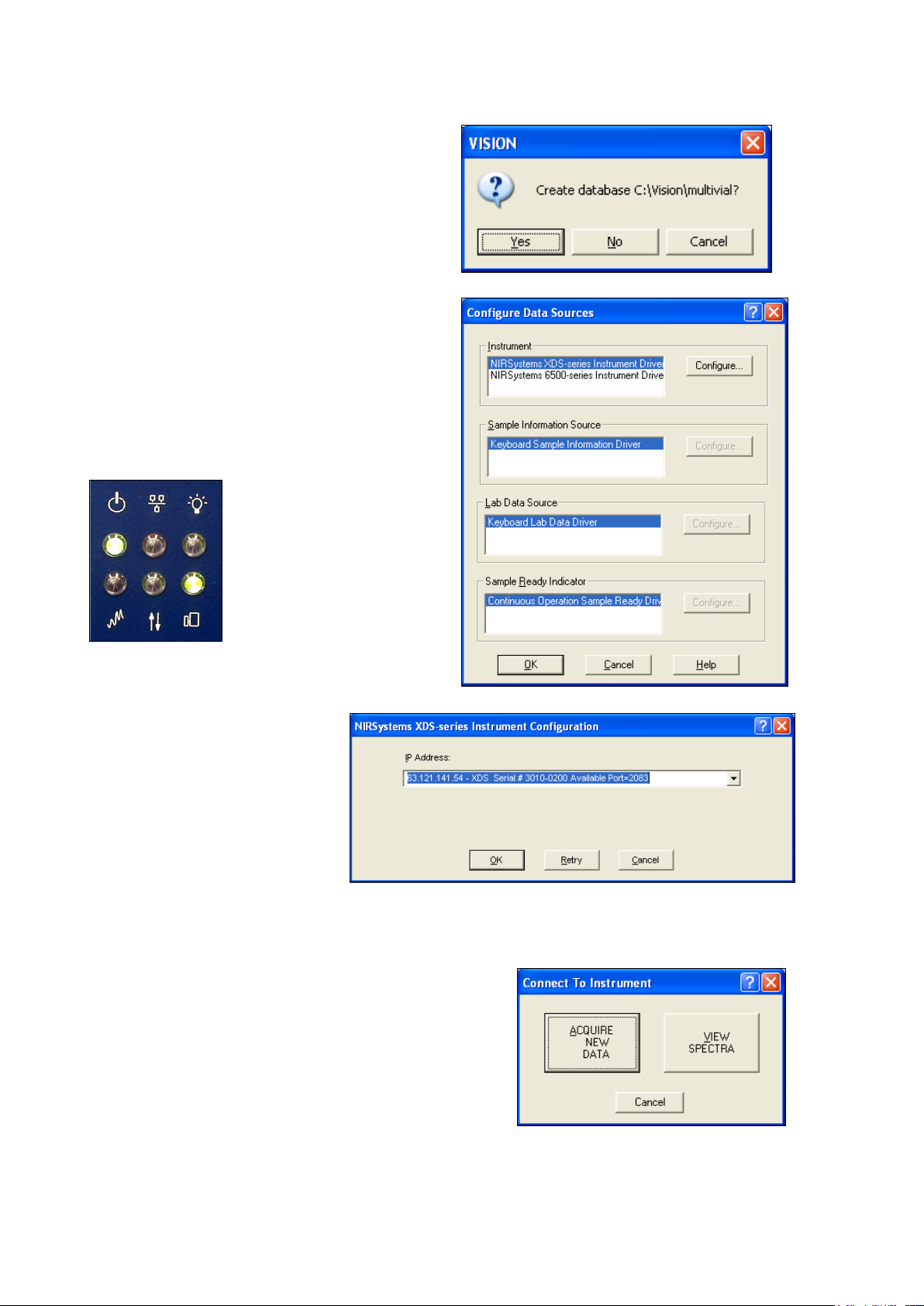

Install Vision on the computer to be used for

Enter the default User ID, “NIRS”. It is not case-

A new project must be created. The “project” is

This section describes communication between the computer (with Vision Software loaded) and the

XDS instrument. Please follow these steps to establish communication. The instrument may be “direct

connected” as explained in section 3.0 of this manual. Alternatively, the instrument and computer

must both be plugged into a live RJ-45 communication jack, on an active network.

6.1 Entry into Vision

instrument operations.

Once installed, click on the Vision icon on the

desktop. The log-in box appears on the opening

screen.

sensitive.

Tab (or mouse) to the Password box, and enter

the default password, “NIRS”.

Note that you should set up specific User ID and

passwords for each authorized user. Do not

operate on the default User ID, or you will be in

violation of CFR 21, Part 11.

used to store data and calibrations for a given

type of analysis.

Multiple projects may be used, to keep spectra,

calibrations and other data separate and wellorganized.

Assign the project some meaningful name, to

make it easy to remember. For our purposes, we

simply called this “multivial”. No spaces are

allowed – use the “underscore” instead.

Vision will assign a Location. Leave this blank,

unless you intend to place the spectra in a

specific folder of your choosing.

37

Page 40

▪▪▪▪▪▪▪

Vision asks if the default directory location is

This screen sets up communication parameters

Click “OK” to exit the dialog box, then “OK” again to exit Configure Data Sources.

Vision prompts the user to connect to the instrument.

acceptable.

Click on “Yes”. Vision creates a directory for the

project as shown.

for the instrument. The XDS instrument has a

unique driver. Highlight this box and click on

“Configure”.

Be sure the instrument is turned on and is ready.

The “power” LED (top left) and the “module” LED

(lower right) should be illuminated as shown.

This box directs the user to select

the instrument IP (Internet

Protocol) address.

Use the drop-down arrow of the

IP Address box, and select the

correct instrument. The

instrument must show “Available”

to be selected.

Before connection, we wish to figure the “Project

Options”.

Click on “View Spectra”. The user is returned to the main

screen of Vision.

38

Page 41

▪▪▪▪▪▪▪

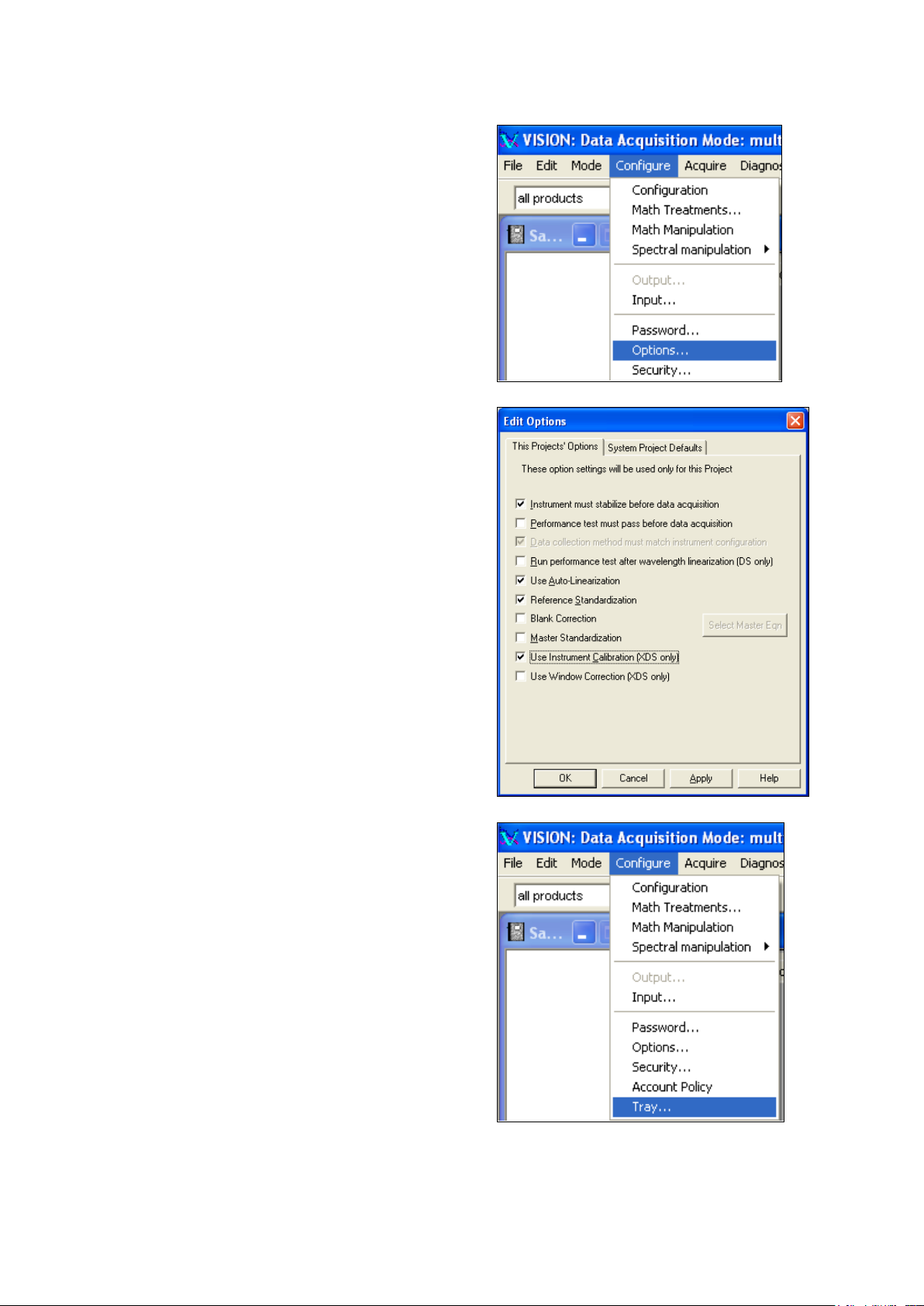

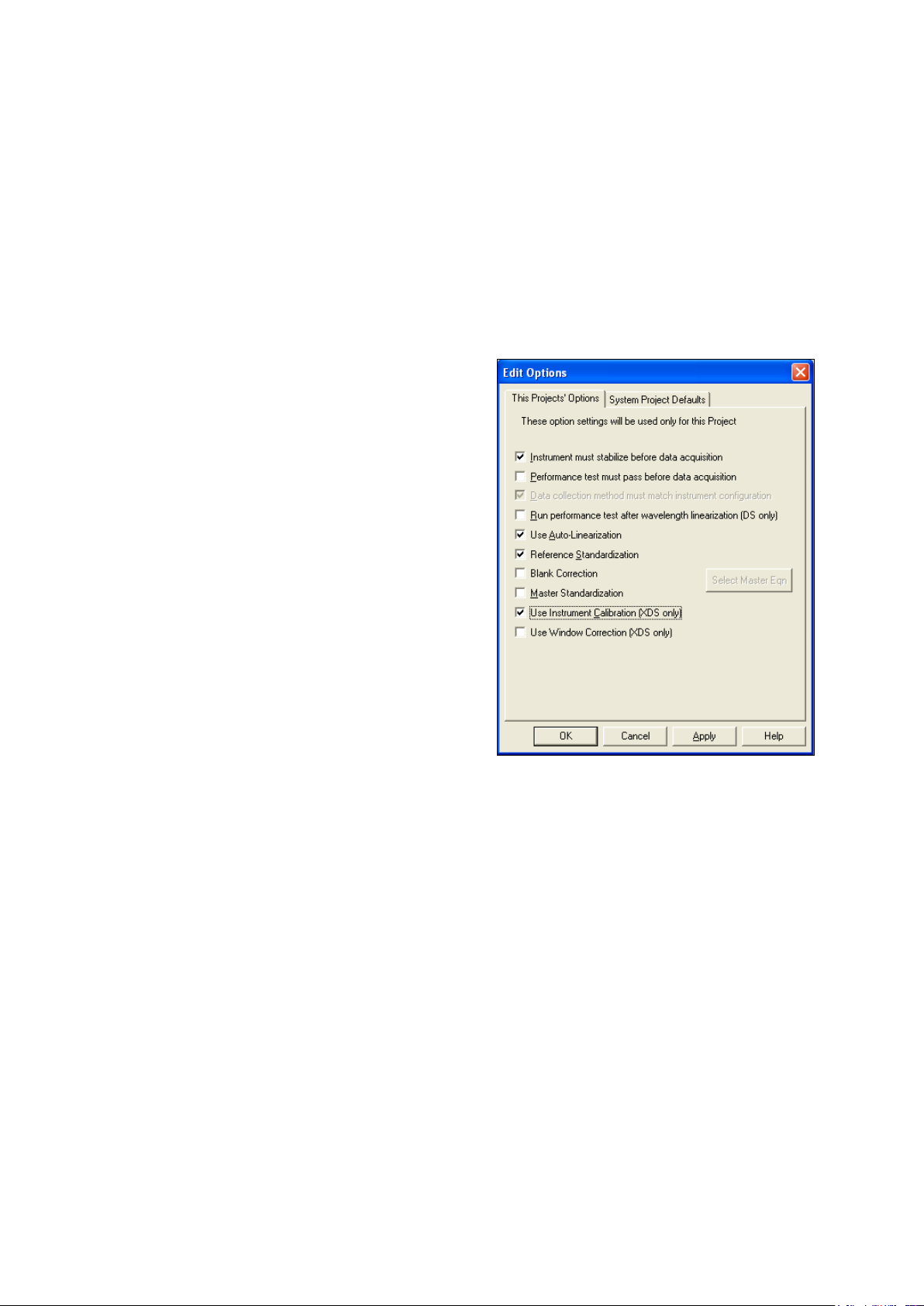

Select Configure, Options from the menu bar.

Verify that these selections are clicked:

• Instrument must stabilize before data

Select Configure, Tray from the menu bar.

acquisition

• Use Auto-Linearization

• Reference Standardization

• Use Instrument Calibration

These selections are explained in more detail,

further in this manual. Because some selections do

not apply to the MultiVial, they are not selected.

Reference Standardization and Instrument

Calibration must be selected for transferability

between similar instruments.

Click “OK” to exit the dialog box.

39

Page 42

▪▪▪▪▪▪▪

Vision has four “default” trays built in, for ease of

If the user clicks on “Modify/

(In this example, the 15mm vial will be used. See section 5.2, on Creation of a Custom Vial Size

Select Acquire, Connect to initiate

use. These are common trays, and should serve

many users.

Check the vial diameter you plan to use, and

highlight it on this list, if shown. (15mm_4x5 is

selected for this example.)

For a vial diameter not shown, click on “New”.

Vision provides a screen for creation of a new

size.

The default setting of “Use Tray” is clicked. Note

that the user may select “Use Iris” or Use Boat” if

another sampling method is planned. We plan to

use vials, so we keep the “Use Tray” setting.

Click on “Select” to save these settings and exit

this dialog box.

View” from the Select Tray Dialog

box, this screen is shown.

If “New” is clicked, all fields are

blank, for entry of vial

information.

Click “OK” to save and exit.

creation for details on setting up a custom vial size. Please continue to Acquire, Connect.)

communication with the instrument.

Upon successful connection, the amber LED (top

middle) will illuminate to indicate that

communication has been established.

40

Page 43

▪▪▪▪▪▪▪

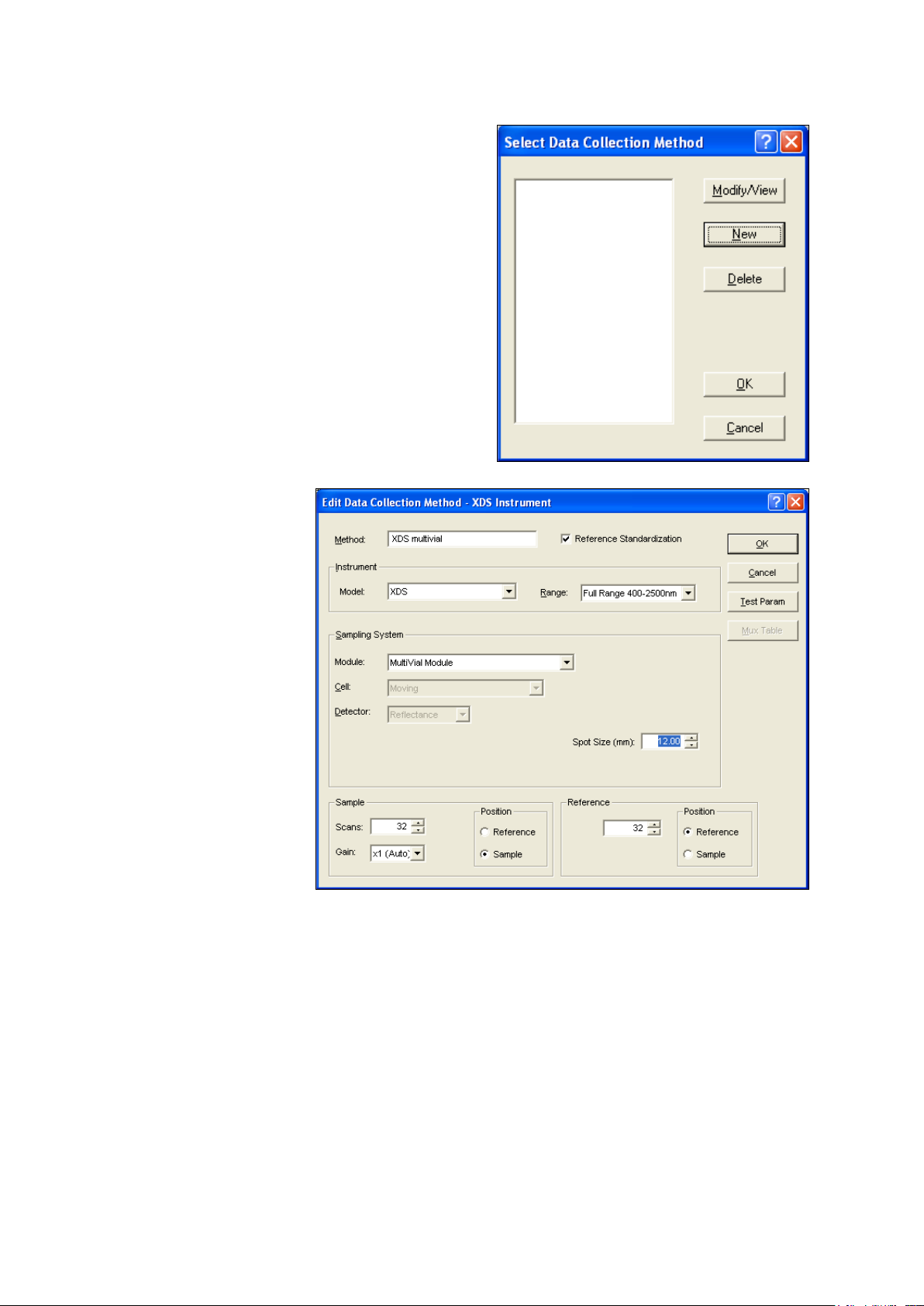

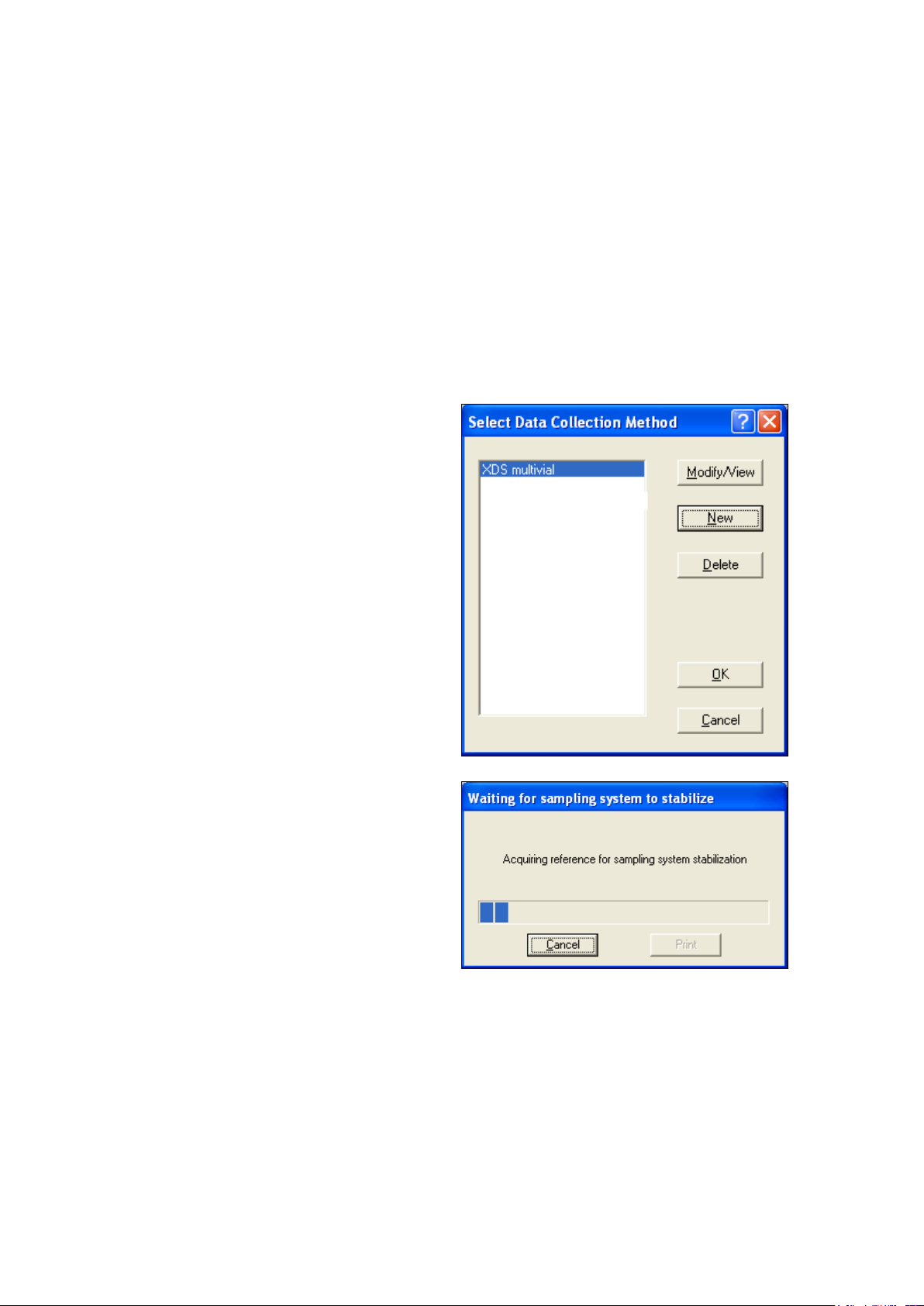

Vision requests that a Data Collection Method

(DCM) be selected for communication with the

The instrument “self-

instrument.

The DCM sets important parameters for how the

data is taken, and assures consistent methods.

There are no Data Collection Methods available

because this is a new project. Click “New” to

establish a new Data Collection Method.

identifies” as an XDS

system with the MultiVial

Module. The user should

enter a logical name for

the DCM. (Spaces are

OK.)

Note that the “Spot Size”

should be adjusted if the

vial used is smaller than

21.56mm diameter. The

default spot size is

17.25mm. Normally the

beam size should be set

for 80% of the vial

diameter.

For the 15mm vial, use a

12mm spot size.

41

Page 44

▪▪▪▪▪▪▪

Use 32 scans for “Sample” and 32 scans for “Reference.” The instrument scans on each forward

Next, select this DCM from the selection box.

Vision will connect with the instrument, and may

swing and each backward swing of the grating, unlike previous Metrohm instruments. Thus, 32

scans are accomplished on only 16 grating cycles, and are done rapidly. Click “OK” when finished.

The user will hear a slight ticking sound from the internal order sorter whenever the lamp is on.

This is normal, and has no effect on component life. The parts are kept in motion to reduce “wait

time” before instrument stabilization.

Verify that the box marked “Reference Standardization” is checked. If it is not, the user should

return to Configure, Options and select “Reference Standardization” on that menu before

establishing a DCM.

Click “OK” to exit the dialog box. The DCM information will be saved.

Click “OK” to connect to the instrument.

Once connected, verify that the amber

“Communication” LED is lit on the instrument

display a message that a reference is being

acquired to determine instrument stabilization.

If the instrument lamp has been on for some

time, this message will only be displayed for a

few scans. Otherwise, it may take some time for

the instrument to come to full internal operating

temperature.

42

Page 45

▪▪▪▪▪▪▪

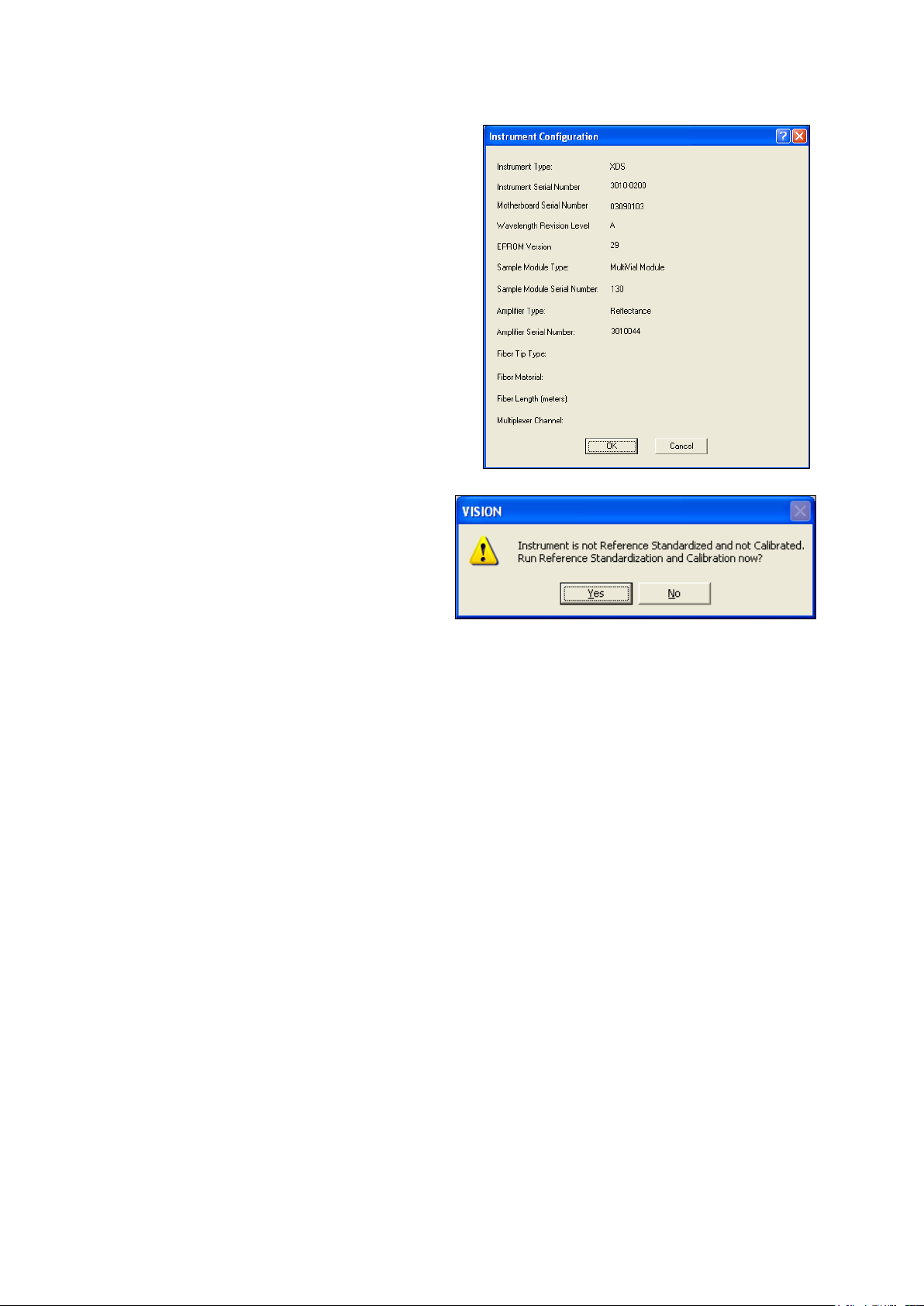

Upon connection, Vision may prompt for the

instrument configuration. This is used to establish

If a Reference Standardization does not exist

a Diagnostic Database. (Under some

circumstances this screen may not appear.)

It is important that the instrument be correctly

identified, to prevent corruption of the database.

If only one instrument is in use, accept the

information and click “OK”.

for the selected configuration, Vision will

display this message.

The user should perform both Reference

Standardization and Instrument Calibration,

to assure good method transfer.

As explained in the section on Reference Standardization, Vision stores two references, based upon

whether the sample is scanned directly on the sample window, or on the vial tray which is raised

from the sample window to allow free motion.

By storing two separate reference files, Vision can compensate for the optical difference between the

two methods. This allows use of one library or calibration, which is applied to either sampling

method.

If the user does not see this message, Vision has the required Reference Standardization in place to

perform this operation.

6.2 Use of Vial Dialog Selection Menu

The MultiVial Analyzer is designed for automated scanning of multiple vials. Vision Software supports

this feature, and permits the user to set up the system for each sample to be collected. While the

instrument is scanning, the user can prepare the next set of samples, or perform other necessary lab

work.

To set up the MultiVial Analyzer for automated sampling, follow these instructions:

43

Page 46

▪▪▪▪▪▪▪

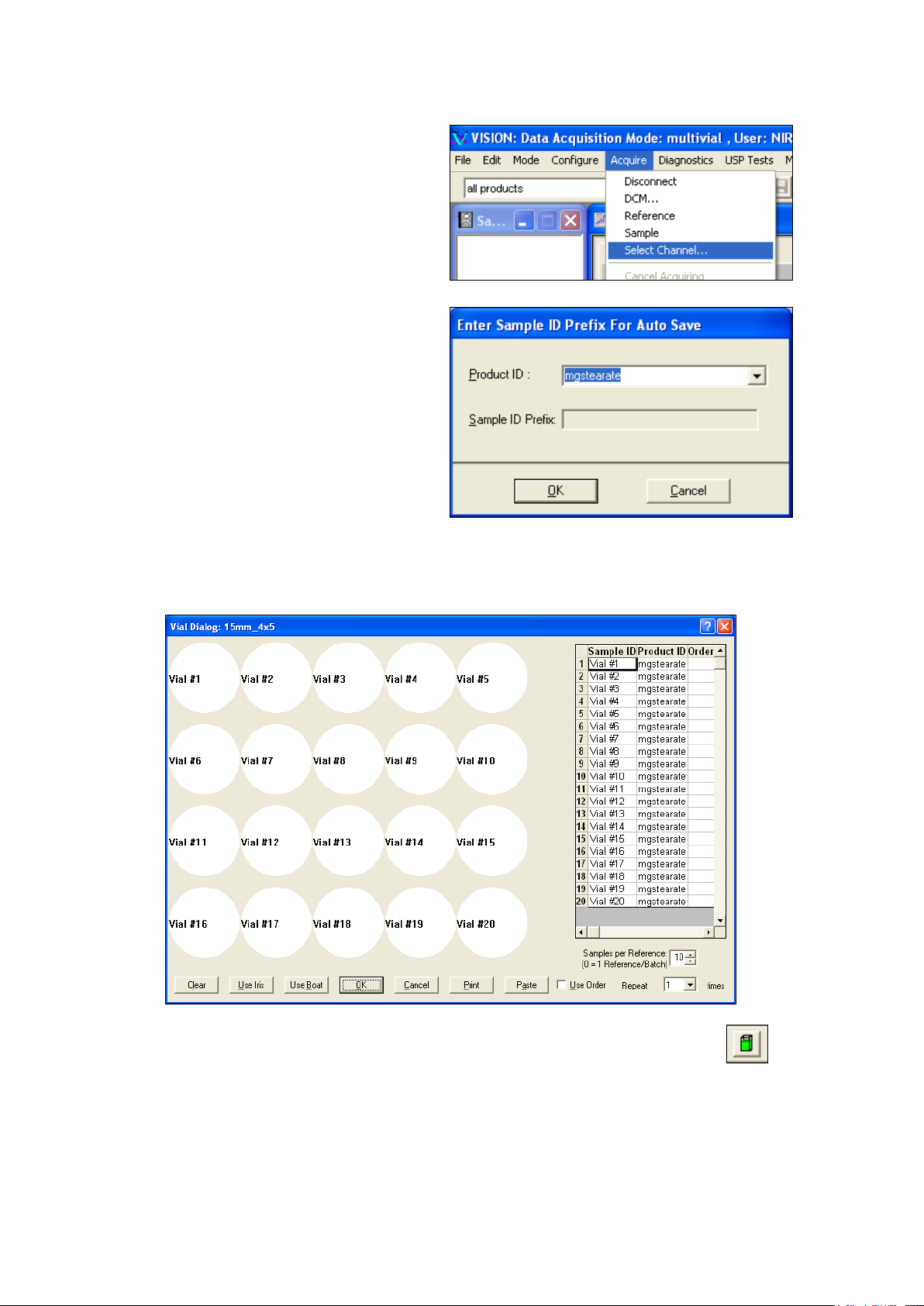

From the menu bar, go to Acquire, Select

Vision prompts for the Product ID using this

Note that the Vial Dialog box is also called when either of these actions is performed:

Channel.

dialog box. Enter the correct product name in

the Product ID field.

NOTE: If multiple products exist, click the

arrow to see all products, then highlight and

select the desired Product ID.

The Sample ID Prefix is not entered in this box –

that is done in the next screen.

Click “OK” when finished.

Vision displays this screen, which corresponds to the vial tray. Note that the Product ID is entered -this came from the previous dialog box.

1. The user clicks on the “Sample” Icon, or

44

Page 47

▪▪▪▪▪▪▪

2. The user selects Acquire, Sample from

the File menu bar.

To change the Product ID, right-click over the

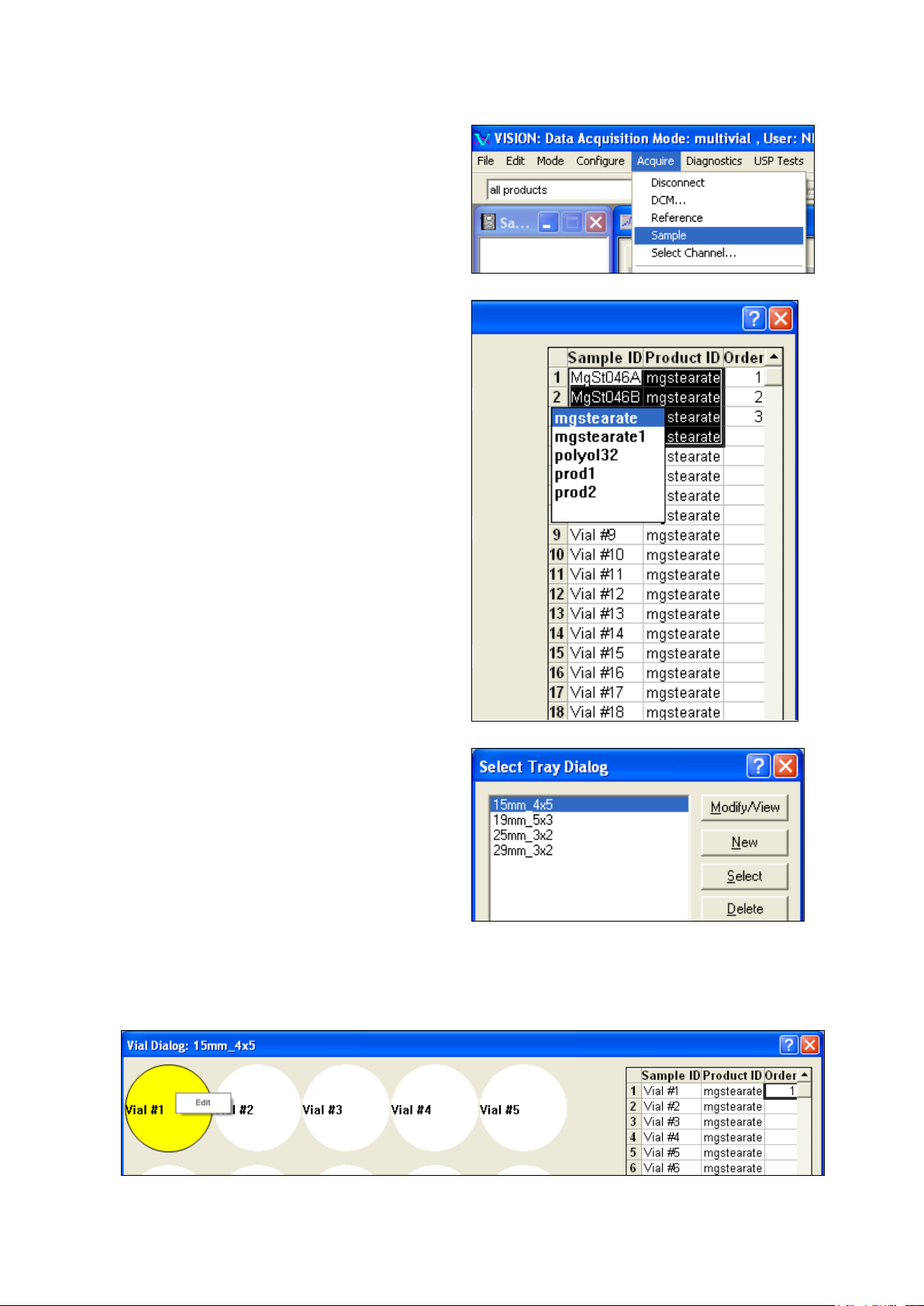

Also note that 20 vials are shown, in a 4 x 5

It is not necessary to acquire a reference first

with the MultiVial Analyzer, since it is

programmed to take a reference as part of the

scan sequence.

“Product ID” column. This brings up the

product selection menu.

Highlight the desired product, and press

“Enter”. This sets the product for the

highlighted rows.

configuration. This came from the Select Tray

Dialog box. (It is shown at right, as a reminder.)

6.2.1 Sample ID Entry

There are several ways to enter the Sample ID:

Entry Method 1: Right-click on the circle that represents the vial position. The circle turns yellow (It

45

Page 48

▪▪▪▪▪▪▪

is shown with a circle here, for clarity in “black and white”.)

The “Edit” box appears as shown. Click on “Edit”, then type the sample name into the vial position.

Press “Enter”. The Sample ID will also be shown in the table at right, as shown below:

Vision fills in the “Order” column, in the entry sequence of sample ID. Note the “1” in the Order

column. Another sample name is filled in as shown below:

Continue to enter sample names in this manner, until all 20 positions are filled. Note that the vial

positions become yellow when active, and the sampling order is incremented in the “Order” column.

Do not click on the vial position and turn it white – that removes it from the “Order” column, and deactivates sampling on that vial.

Entry Method 2: Double-click on the upper part of the vial position, which brings up the box

shown:

The Sample ID may be typed into this box. Press “Enter” when finished.

While entering Sample IDs, the user may verify or change the Product ID. To do this, double-click on

the vial position below the center of the circle.

This shows the available products, with the selected product highlighted. If the user wishes to save a

given sample to a different product, it may be set using this screen. The Product ID will be updated in

46

Page 49

▪▪▪▪▪▪▪

the column at the right. Note that the Product must exist (that is, it must have been created within

the Project) to be used in this manner.

In the example shown, there are two “mgstearate” products shown. One has a suffix “1” that is not

shown due to window size. In practice, the user may wish to keep the names shorter, or use a prefix

instead of a suffix to identify products.

The user may right-click on the Sample ID and Product ID column to see the product list, as shown

above. (A double-left-click also opens this list) The Product ID may be edited in this manner also.

Entry Method 3: Click on the cell in the Sample ID column, and type the sample name directly into

the cell. Be sure to click the vial position (to turn it yellow) to make the vial position active.

The cell entry method is shown above, highlighted by the red border. The user may type a Sample ID,

then press “Enter” to move down to the next row. This speeds entry of a column of sample names.

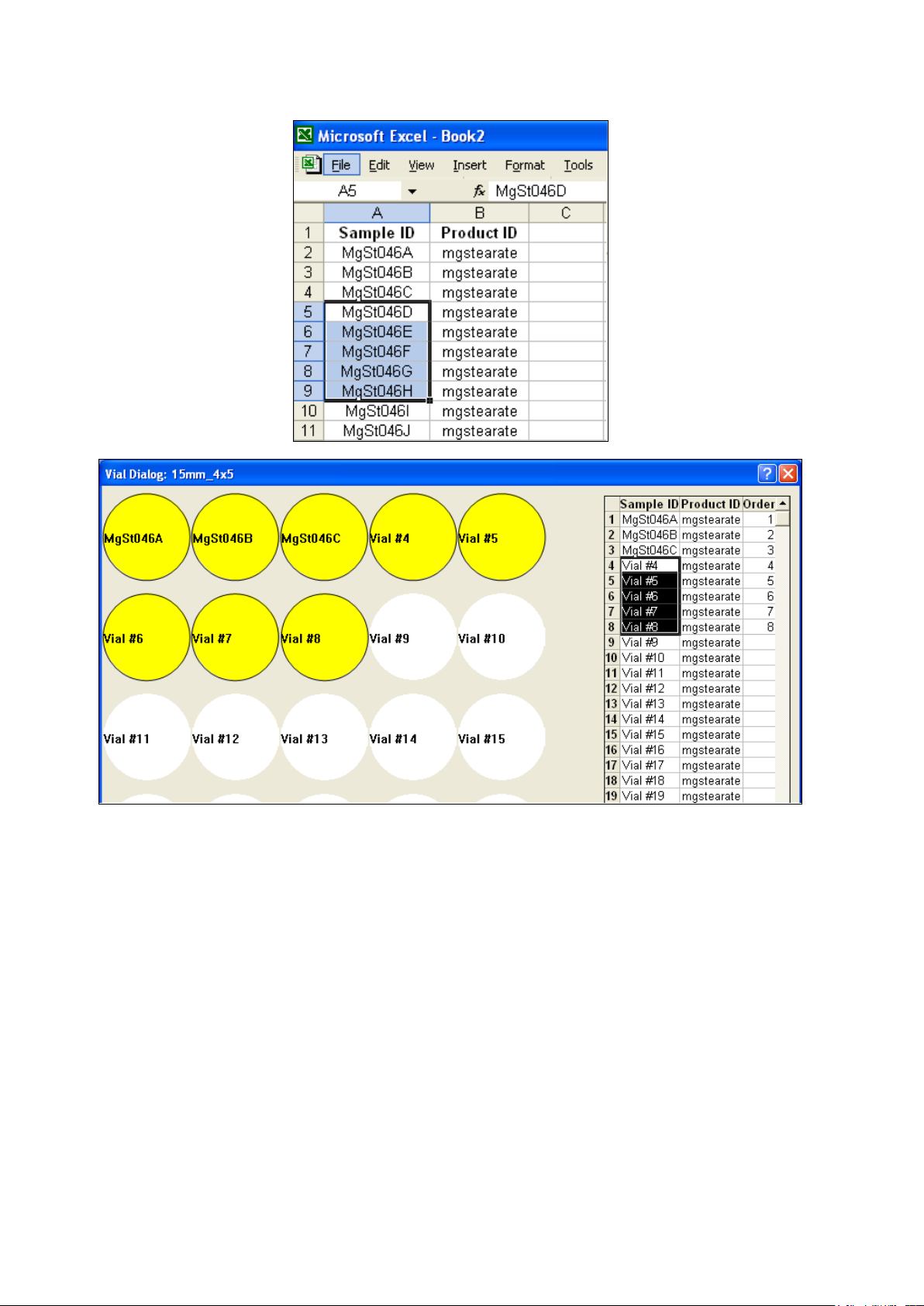

Entry Method 4: If the Sample ID names exist in an Excel spreadsheet, highlight those names in the

spreadsheet as shown at the right.

Hint: To select quickly, click on the first cell, hold the “Shift” key and click on the last cell. All cells in

between will also be highlighted.

Click “File, Copy”. Excel places the Sample ID names on the clipboard in Windows®.

Switch back to the Vision window.

47

Page 50

▪▪▪▪▪▪▪

Click on the vial positions to be entered, so they are yellow and active. (This may be done after

pasting Sample ID instead.)

Hint: To select quickly, click on the first cell, hold the “Shift” key and click on the last cell. All cells in

between will also be highlighted.

Highlight the Sample ID fields to be pasted as shown above. Click on the “Paste” button in the dialog

box. (It is outlined in red below.)

48

Page 51

▪▪▪▪▪▪▪

The Sample ID names are pasted into the column, as shown. In this case only five names were

pasted, for clarity. The entire column may be pasted, up to the limit of the vial positions.

Entry Method #5:

The user may use the right-click copy and paste method, as illustrated below:

This uses the Windows convention for pasting. Highlight the information to be copied, right-click,

and select “Copy”. Move the cursor to the destination field, right-click, and select “Paste”. The

information will be pasted into the field as desired.

49

Page 52

▪▪▪▪▪▪▪

There is a field for comments beside each sample.

To remove all entries from the Vial Dialog screen,

To delete only one entry, highlight that entry and

To see this field, click the small arrow at the

bottom right, and the field will be visible.

Alternatively, use the “Tab” key. Start on the

Sample ID, Product ID, or Order, and tab over to

the “Comments” field.

Enter comments, if applicable. No entry is

required; this field is optional. The field is shown

here.

click on the “Clear” button, at the lower left

corner of the screen. This will clear the entire

Sample ID column. Click “OK” to close.

If this button was clicked, and was a mistake,

click the “Cancel” button. The Vial Dialog screen

will close. Select Acquire, Select Channel, verify

the product, and the original screen will be

displayed.

use the “Delete” key on the PC keyboard.

50

Page 53

▪▪▪▪▪▪▪

To delete multiple Sample ID names, highlight

those fields, and use the “Delete” key on the PC

keyboard. Vision will ask for confirmation, as

shown.

If the fields are to be cleared, click “Yes”.

Otherwise click “No”.

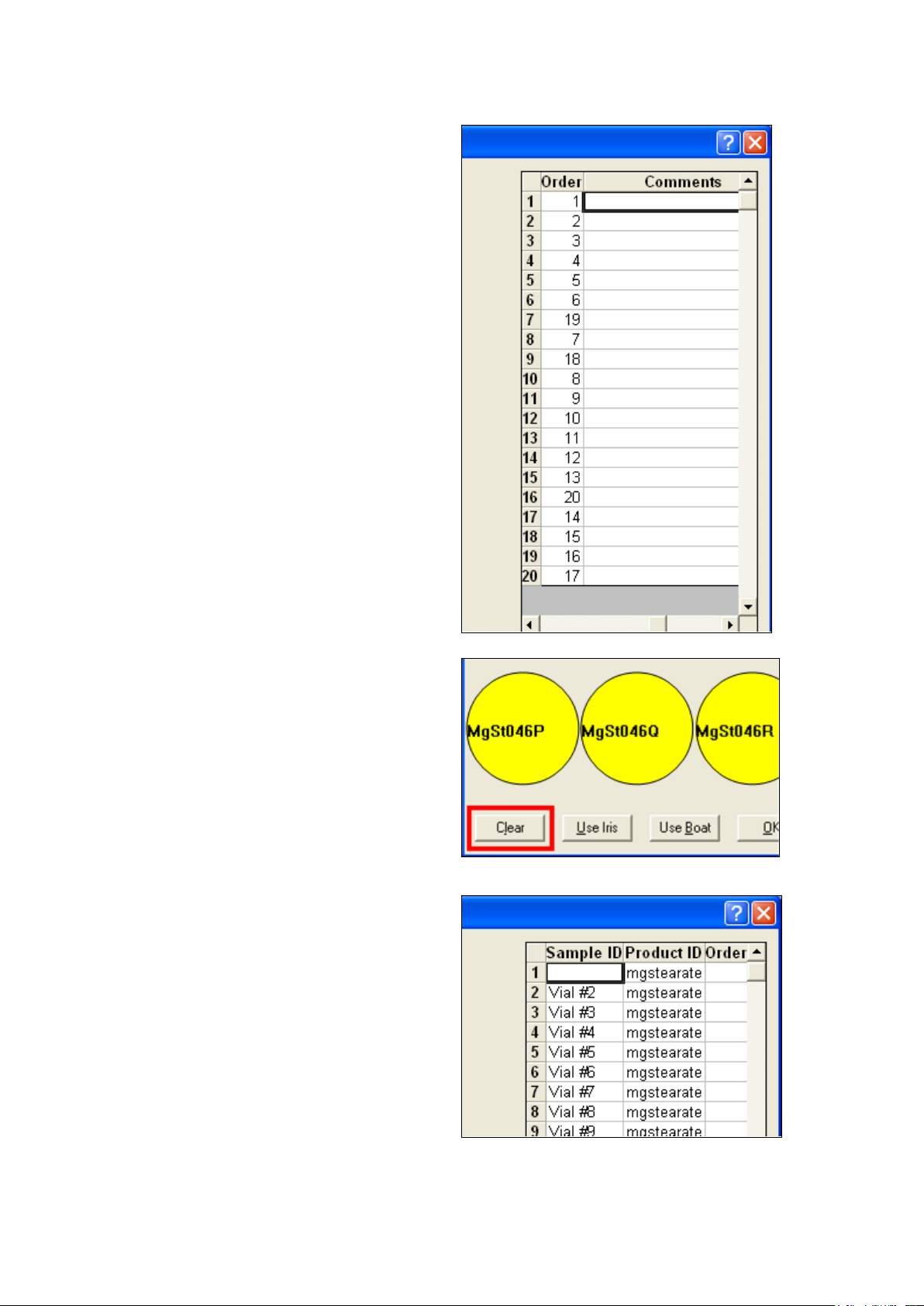

6.2.2 Order of Sampling

There are multiple ways to set the order of vial sampling. As a rule, it is faster to sample in the

sequence of the “Order” column, since this involves less movement of the MultiVial sampling

mechanism. This saves positioning time. If the Sample ID for each sample is entered in order, as

below, this is automatic.

51

Page 54

▪▪▪▪▪▪▪

At the bottom of the Vial Dialog screen is a

checkbox marked “Use Order”.

If this box is checked, the MultiVial Analyzer will

start with the sample marked “1” in the

“Order” column, and proceed numerically

upward through the order designated in the

“Order” column.

If this box is left unchecked, the MultiVial

Analyzer will proceed from vial position 1, to 2,

to 3, in numerical order of the physical vial

position in the tray. Vision will ignore the

“Order” column.

If the user plans to enable “Use Order” it is

important to set the order correctly.

Fortunately there is a method to set order easily, without losing Sample ID information.

In the example above, the order is out of sequence for samples, 7, 9, and 16. If “Use Order” is left

unchecked, Vision proceeds in order of Sample Number. No action is needed.

However, if the user wishes to set the sequence, the procedure is as follows:

1. Click on each vial position to be changed.

2. Re-click, and that vial’s “order” will be sent to the end of the sequence.

3. Because this may be difficult to achieve by setting one vial at a time, click on all vial positions,

to turn them white. Then click on each one, in the order desired. This will set the “Order”

52

Page 55

▪▪▪▪▪▪▪

column to the proper sequence.

4. Click on “Use Order” to have Vision follow the designated order.

6.2.3 Additional Vial Dialog Functions

There are several other important functions to be set or used in the Vial Dialog box. They are shown

below, and described in the text that follows.

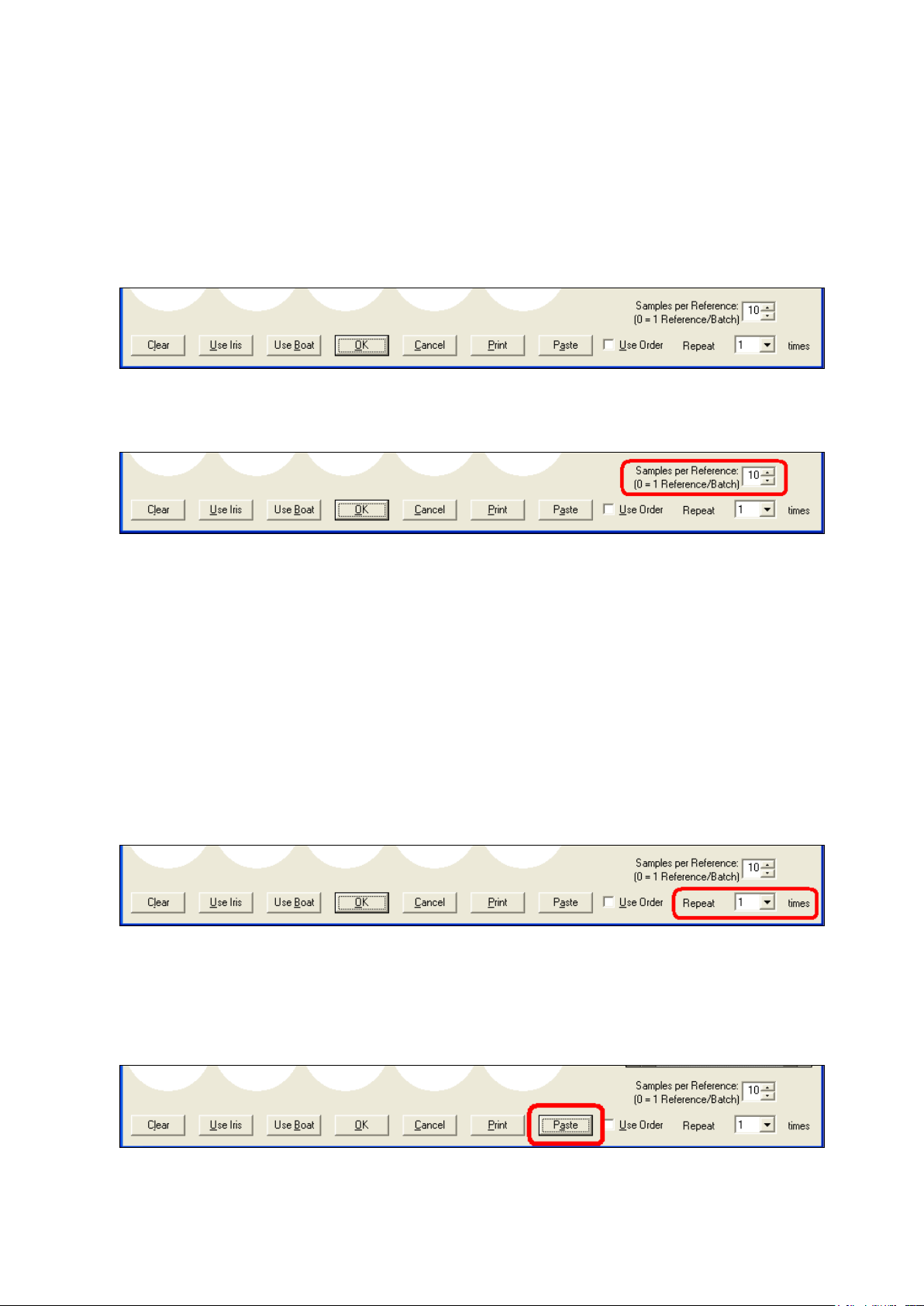

Starting at the right side:

Samples per Reference:

This setting defines the number of sample spectra to be taken per reference scan. With multiple

samples, it is cumbersome to take a reference scan for each sample spectrum, and very timeconsuming. Because it is not necessary to take a reference spectrum for every sample scan, Vision

may use the same reference scan for a number of sample spectra.

The default is “10”, as shown above. This means that on a tray of 20 vials, Vision will take an initial

reference scan, then scan the first ten vials. Then Vision will take another reference scan, and go on

to scan the last 20 vials. If the tray has fewer than 10 vials, Vision will scan up to ten vials, if the

setting is “10”. If the setting is another number (other than 10) Vision will use that setting as the

maximum number of vials to be scanned per reference.

A “0” may be entered in this field, and Vision will scan the whole tray with a single reference scan.

Repeat:

A given tray may be scanned multiple times, to acquire “replicate” data. This is not often done,

though some users may want two or more replicates of the data for statistical reasons.

As a rule, this should be left at “1” unless there is a specific reason that replicates are required.

Paste:

As explained in the previous section, if the Sample ID names exist in an Excel spreadsheet, they may

be pasted directly into the table. The “Paste” button is used to place the Sample ID names into the

53

Page 56

▪▪▪▪▪▪▪

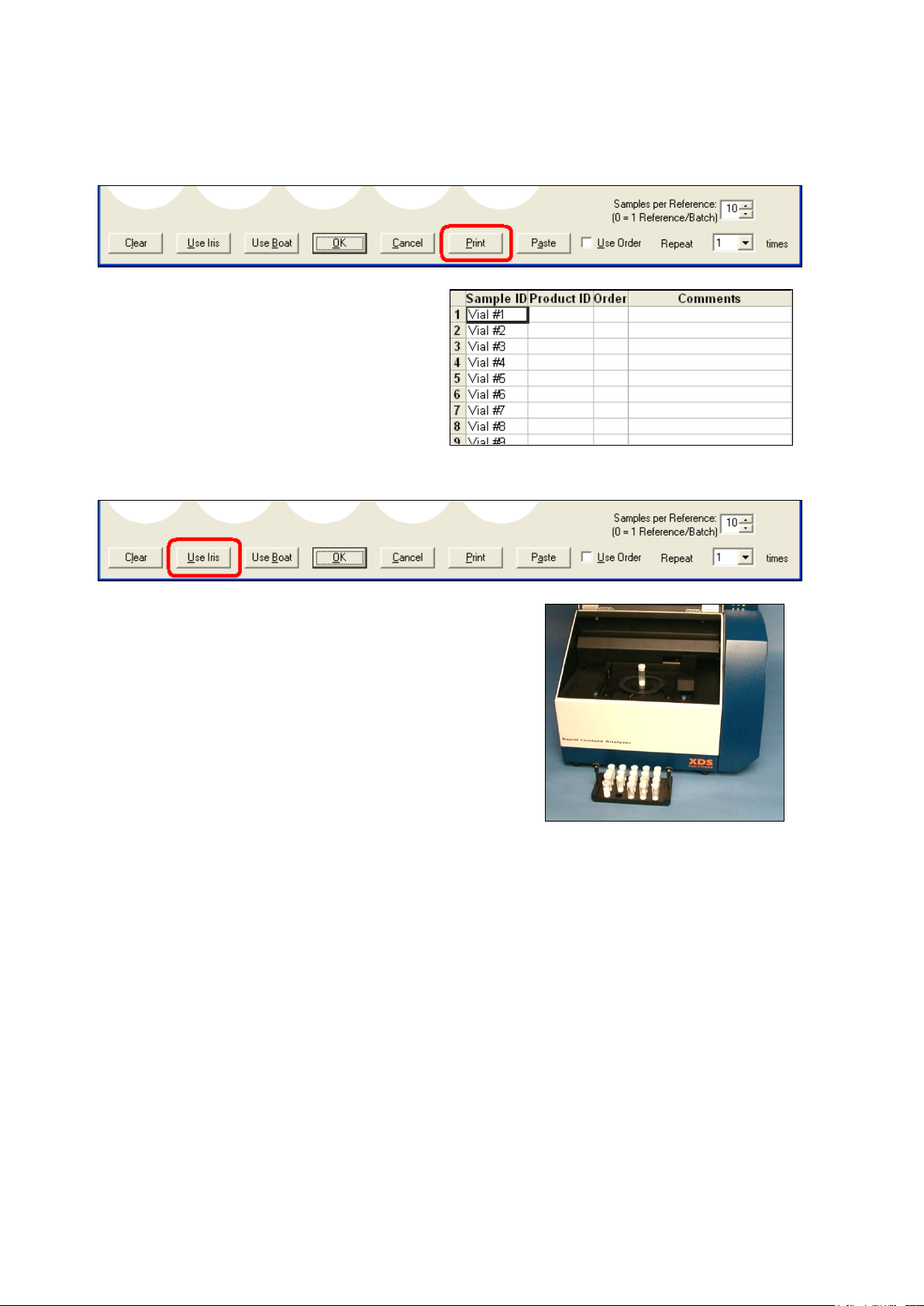

This prints the table containing the Sample ID,

If the user needs to scan a sample using the Iris Adapter, this

highlighted area of the table.

Print:

Product ID, Order, and Comments, as shown at

right.

The full length of the table will be printed – it is

cut off here for clarity. Print in “portrait” mode.

Use Iris:

box should be clicked. (This resets the choice made in the

“Select Tray” dialog box.)

The user should remove the tray. Vision will position the tray

mechanism out of the way, to allow the Iris Adapter to be

inserted.

When finished, the Iris Adapter should be removed, and the

tray re-inserted into the MultiVial mechanism.

Failure to remove the Vial Adapter will cause an error to be

reported in Vision.

54

Page 57

▪▪▪▪▪▪▪

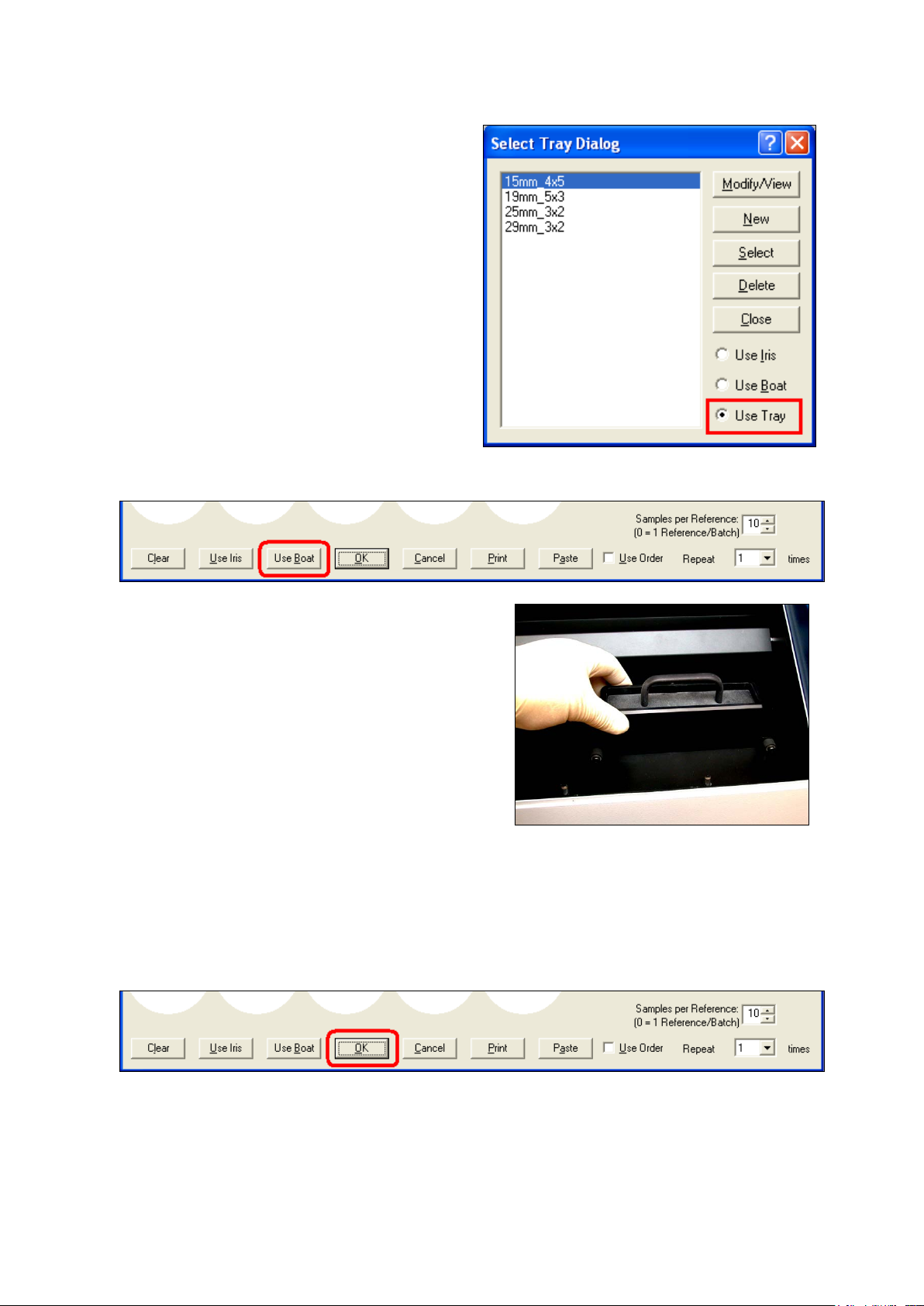

To reset the mechanism for MultiVial trays, select

Configure, Tray to return to the Select Tray dialog

If the user needs to scan a sample using the large

box, and re-select “Use Tray”.

Use Boat:

Sample Cell (boat), this box should be clicked. (This

resets the choice made in the “Select Tray” dialog

box.)

The user should remove the tray. Vision will position

the tray mechanism out of the way, to allow the

sample cell to be inserted.

When finished, the sample cell should be removed,

and the tray re-inserted into the MultiVial mechanism.

Failure to remove the Sample Cell may cause an error

to be reported in Vision.

To reset the mechanism for MultiVial trays, select Configure, Tray to return to the Select Tray dialog

box, and re-select “Use Tray”. (This was illustrated in the section immediately preceding this one.)

OK:

The “OK” button saves the settings made and closes the dialog box. When the user initiates a sample

scan, the information in the dial box will be applied.

Clear:

55

Page 58

▪▪▪▪▪▪▪

The “Clear” button removes all data from the dialog box. The user should clear the box before entry

of information on a new tray.

Note that this clears the Sample ID, Order, and Comments. It does not clear the Product ID column.

To edit the Product ID, double click on that row and the selection list is shown.

Cancel:

This cancels all actions performed while the dialog box has been open. The box is closed, and

remains as it was before it was opened.

56

Page 59

▪▪▪▪▪▪▪

7 Instrument Diagnostics

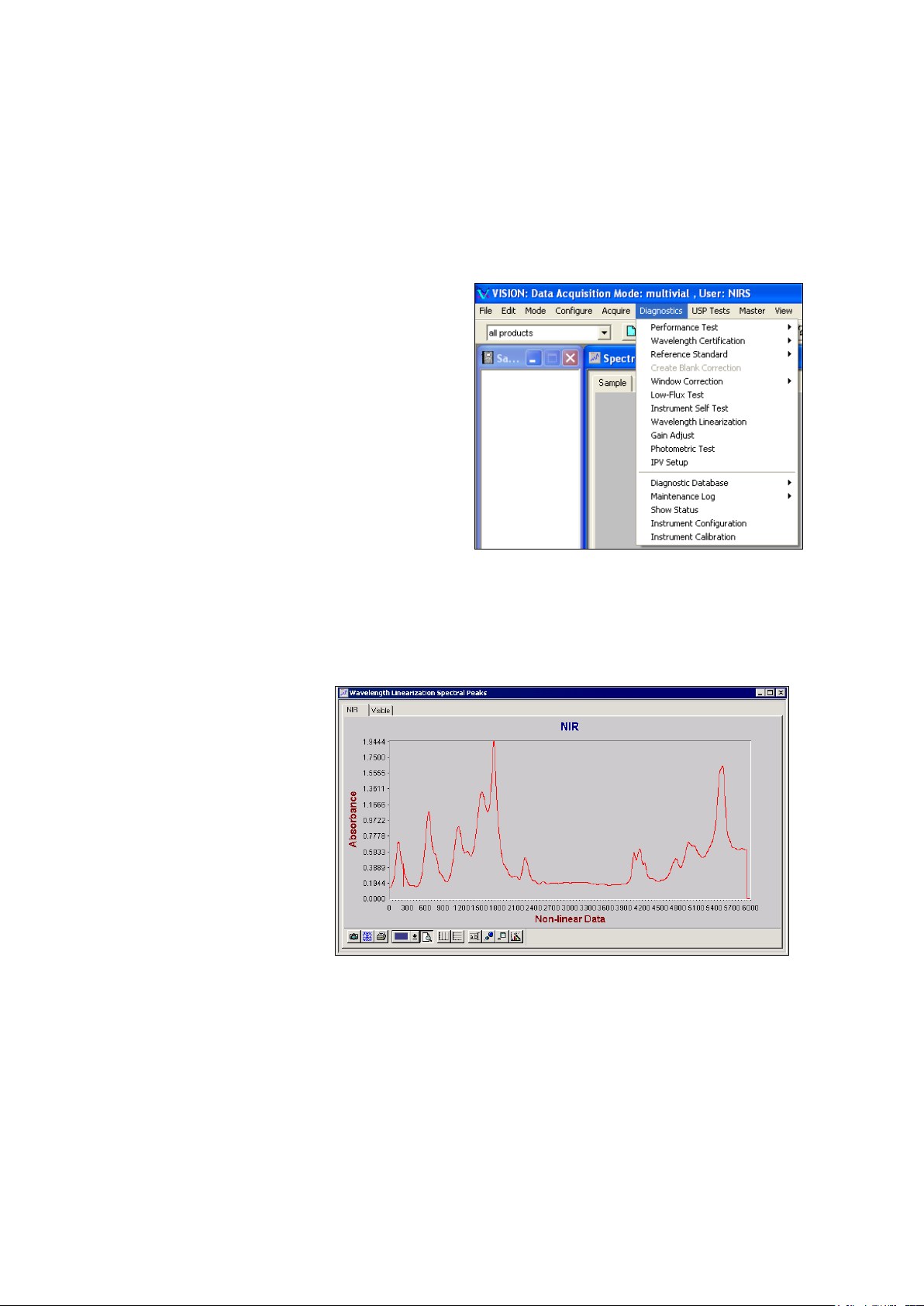

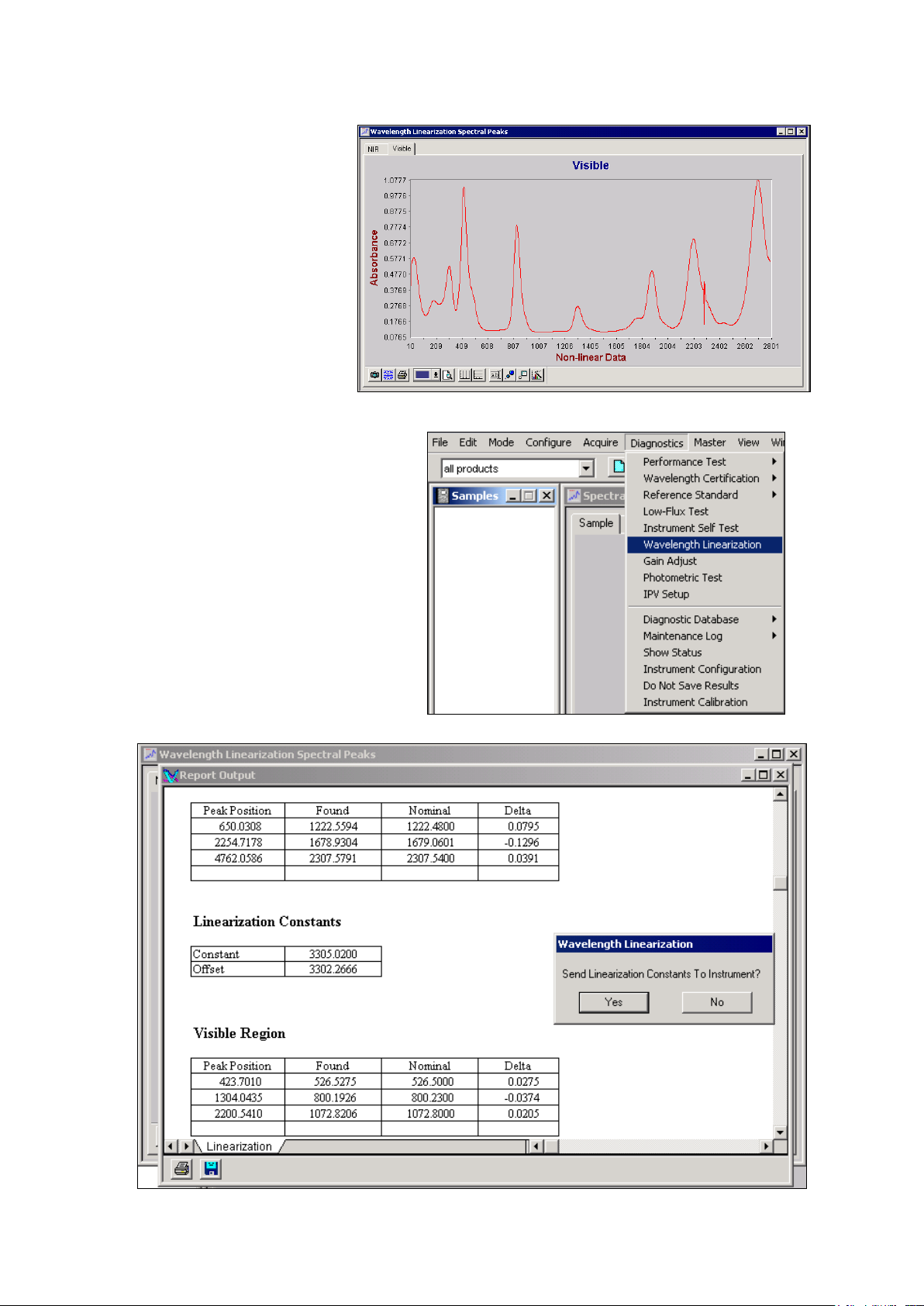

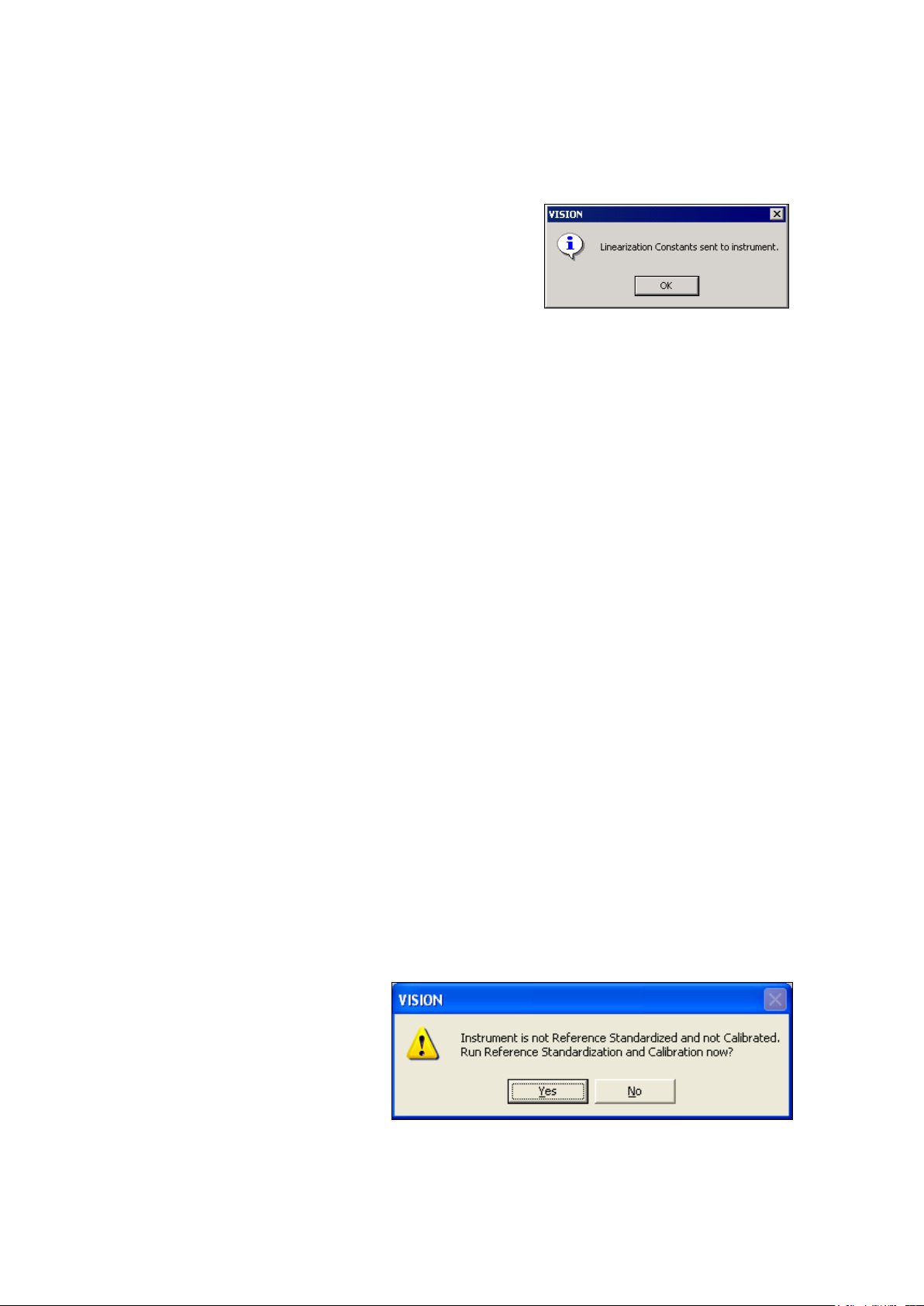

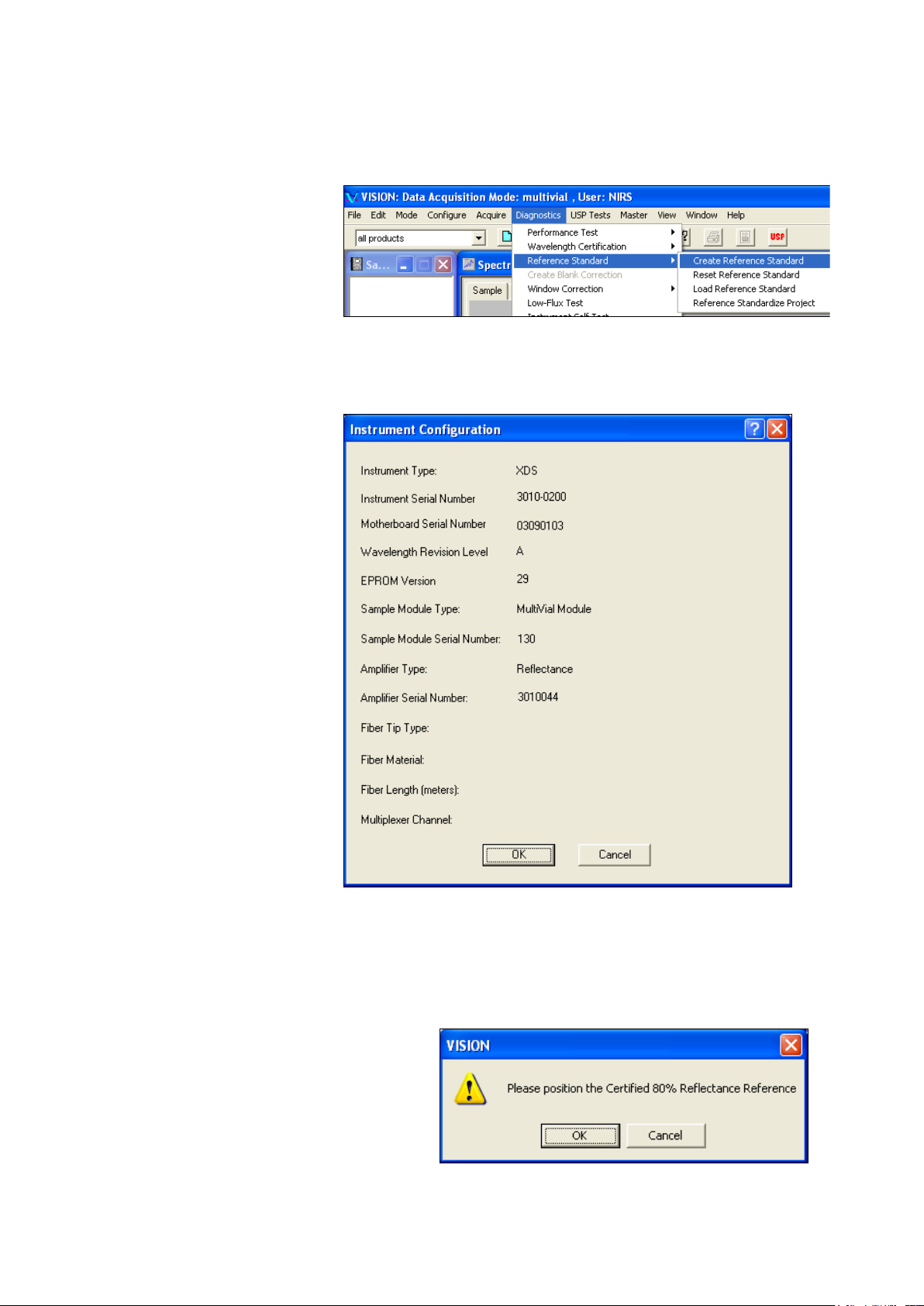

Before use of the XDS Analyzer, some steps must